Investigation of Tensile and Fatigue Behavior of Cr/CrN/TiCrN/TiCrCN Multilayer Films Coated on AA6063 and AZ91 Alloys by Closed-Field Unbalanced Magnetron Sputtering Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Coating Production

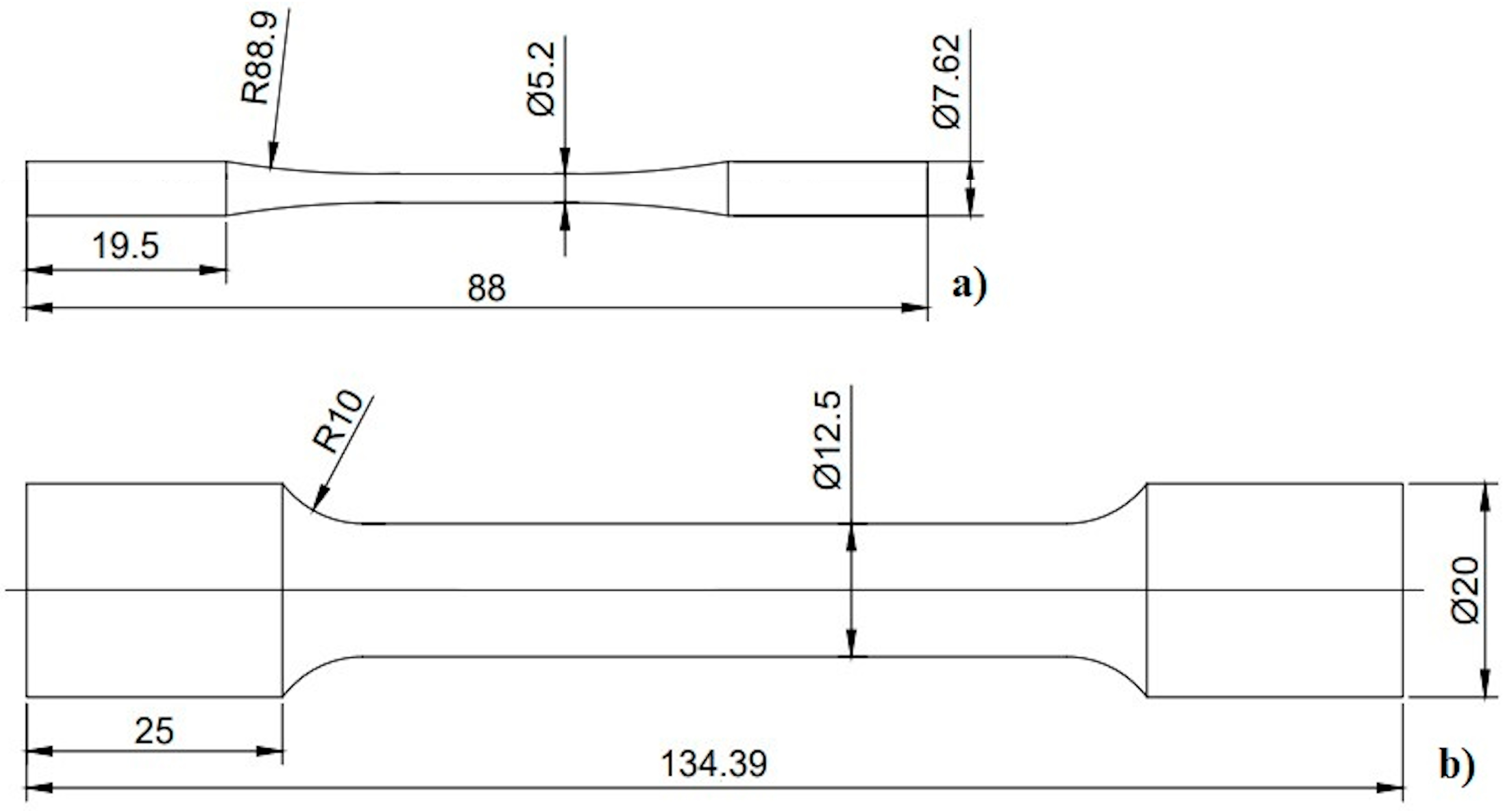

2.2. Fatigue and Tensile Tests of the Test Specimens

3. Research Results and Discussion

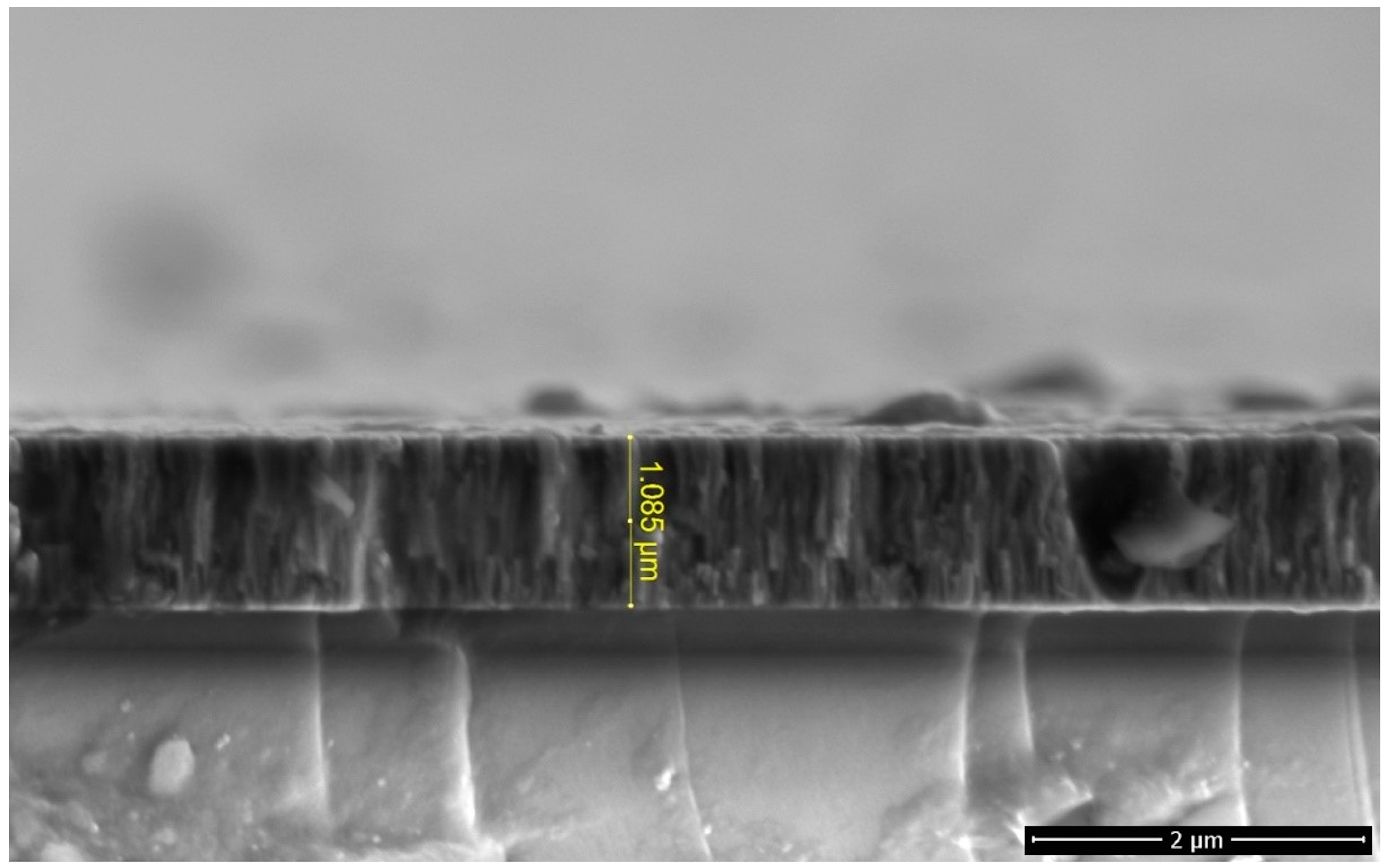

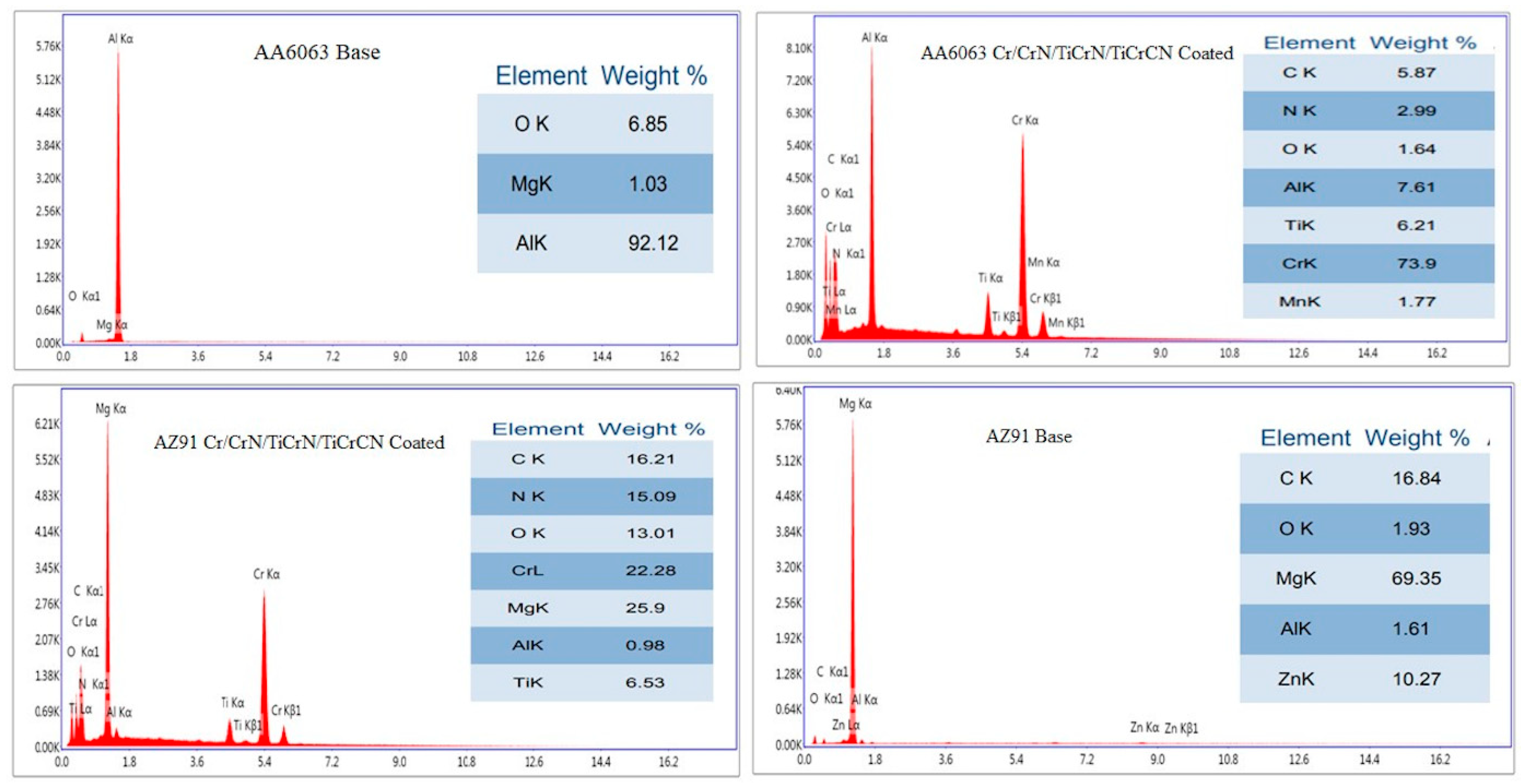

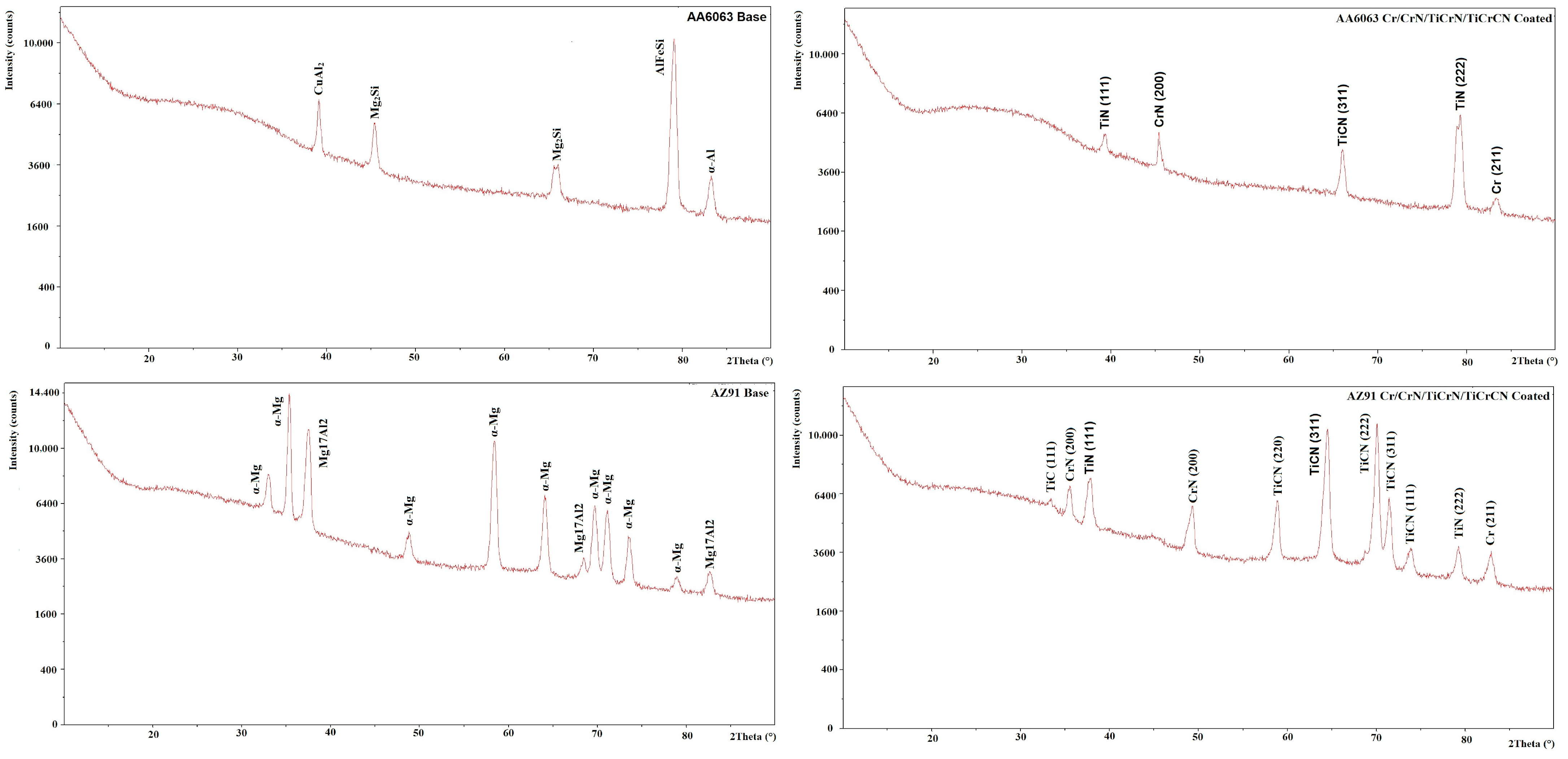

3.1. SEM and XRD Analyses

3.2. Fatigue Test

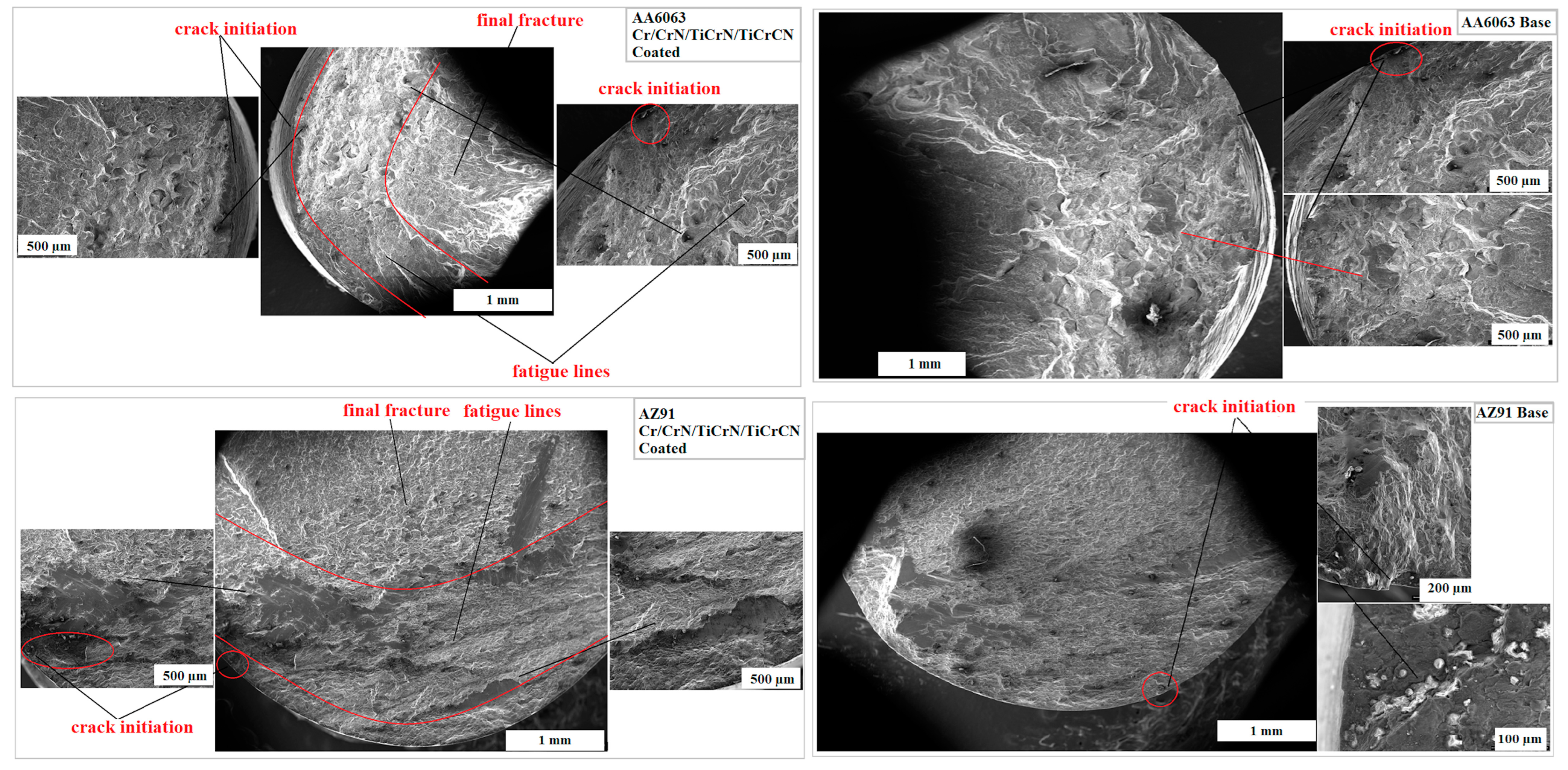

3.3. Fatigue Fracture Surfaces

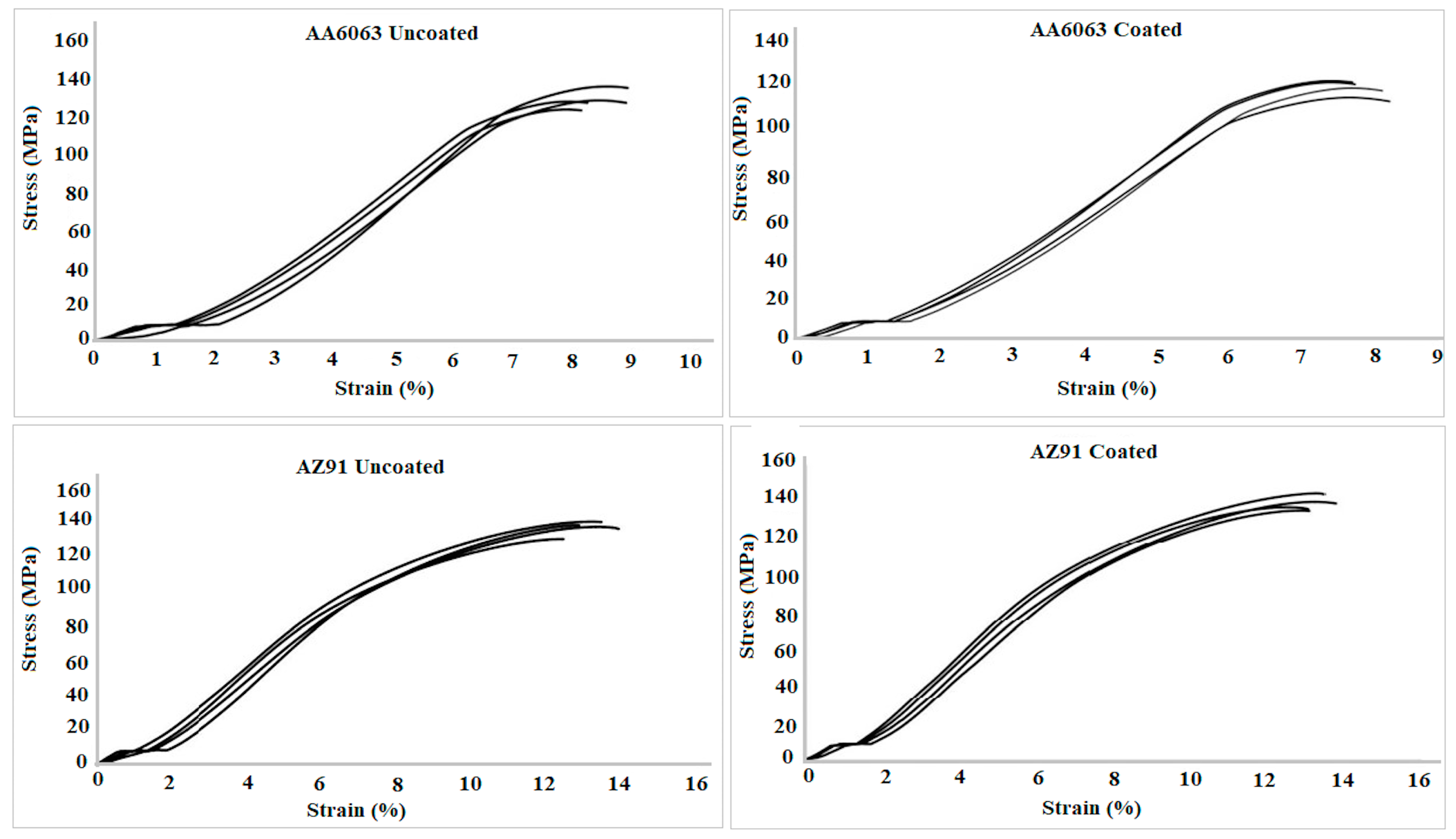

3.4. Tensile Test

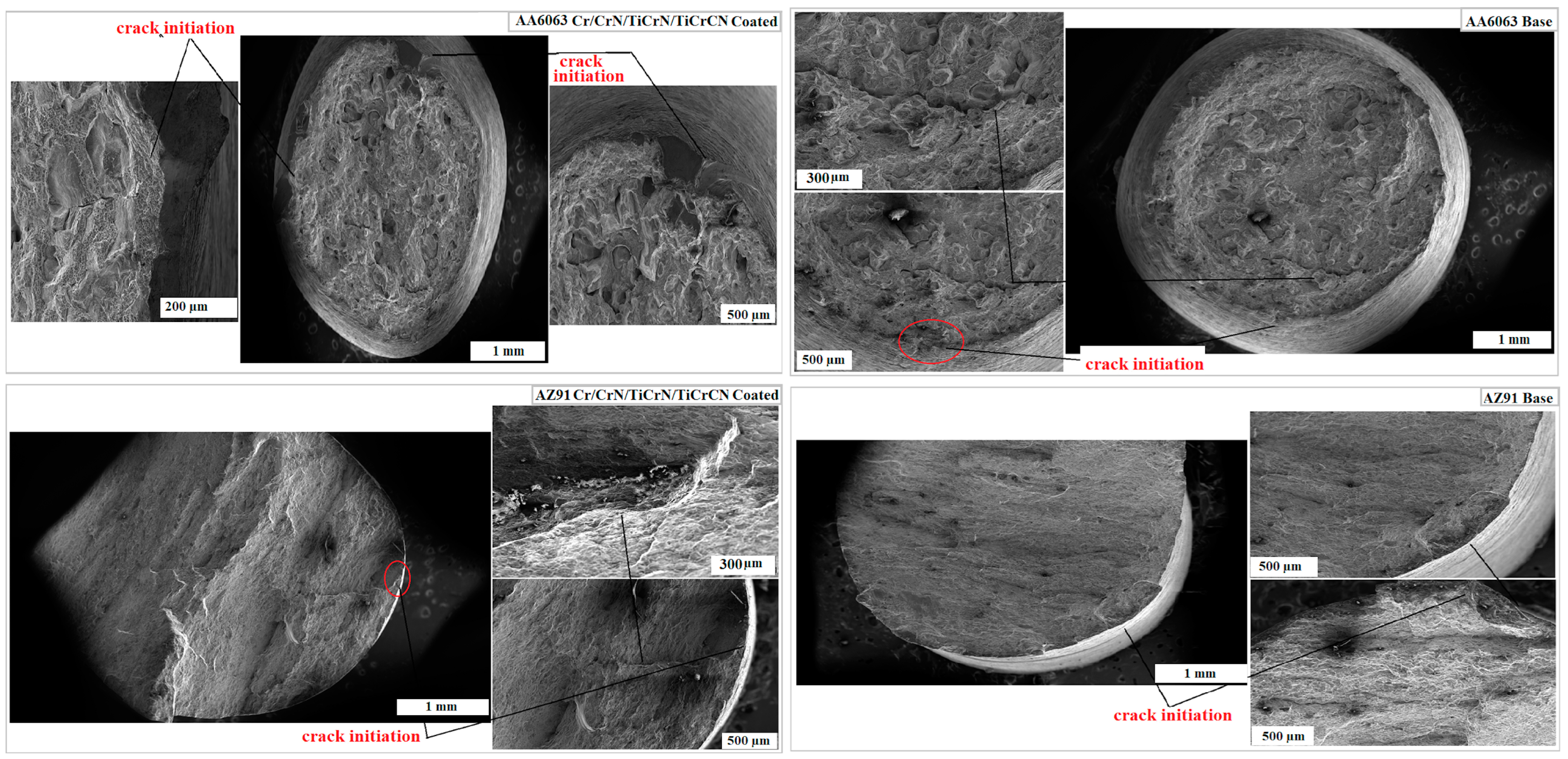

3.5. Tensile Fracture Surfaces

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shaha, S.K.; Dayani, S.B.; Xue, Y.; Pang, X.; Jahed, H. Improving corrosion and corrosion-fatigue resistance of AZ31B Cast Mg alloy using combined cold spray and top coatings. Coatings 2018, 8, 443. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, P.V.; Amankeldina, Z.S.; Levashov, E.A. Effects of boron addition on the structure and properties of Cr–Al–Ti–Ncoatings obtained using the CFUBMS system. Phys. Met. Metallogr. 2020, 121, 575–581. [Google Scholar]

- Wuhrer, R.; Yeung, W.; Phillips, M.; McCredie, G. Study on d.c. magnetron sputter deposition of titanium aluminium nitride thin films: Effect of aluminium content on coating. Thin Solid Films 1996, 290–291, 339–342. [Google Scholar] [CrossRef]

- Ramadoss, R.; Kumar, N.; Pandian, R.; Dash, S.; Ravindran, T.; Arivuoli, D.; Tyagi, A. Tribological properties and deformation mechanism of TiAlN coating sliding with various counterbodies. Tribol. Int. 2013, 66, 143–149. [Google Scholar] [CrossRef]

- Keleş, A.; Çiçek, H.; Baran, Ö.; Totik, Y.; Efeoğlu, İ. Determining the critical loads of V and Nb doped ternary TiN-based coatings deposited using CFUBMS on steels. Surf. Coat. Technol. 2017, 332, 168–173. [Google Scholar] [CrossRef]

- Richman, R.; McNaughton, W. Correlation of cavitation erosion behavior with mechanical properties of metals. Wear 1990, 140, 63–82. [Google Scholar] [CrossRef]

- Monaghan, D.; Arnell, R. Novel PVD films by unbalanced magnetron sputtering. Vacuum 1992, 43, 77–81. [Google Scholar] [CrossRef]

- Altun, H.; Sen, S. The effect of DC magnetron sputtering AlN coatings on the corrosion behaviour of magnesium alloys. Surf. Coat. Technol. 2005, 197, 193–200. [Google Scholar] [CrossRef]

- Kalita, S.J. Microstructure and corrosion properties of diode laser melted friction stir weld of aluminum alloy 2024 T351. Appl. Surf. Sci. 2011, 257, 3985–3997. [Google Scholar] [CrossRef]

- Myung, H.S.; Park, Y.S.; Jung, M.J.; Hong, B.; Han, J.G. Synthesis and mechanical properties of amorphous carbon films by closed-field unbalanced magnetron sputtering. Mater. Lett. 2004, 58, 1513–1516. [Google Scholar] [CrossRef]

- Altun, H.; Sinici, H. Corrosion behaviour of magnesium alloys coated with TiN by cathodic arc deposition in NaCl and Na2SO4 solutions. Mater. Charact. 2008, 59, 266–270. [Google Scholar] [CrossRef]

- Liang, C.-L.; Cheng, G.-A.; Zheng, R.-T.; Liu, H.-P. Fabrication and performance of TiN/TiAlN nanometer modulated coatings. Thin Solid Films 2011, 520, 813–817. [Google Scholar] [CrossRef]

- Baran, Ö.; Keleş, A.; Çiçek, H.; Totik, Y.; Efeoğlu, İ. The mechanical and tribological properties of Ti [Nb, V] N films on the Al-2024 alloy. Surf. Coat. Technol. 2017, 332, 312–318. [Google Scholar]

- Hoche, H.; Groß, S.; Oechsner, M. Development of new PVD coatings for magnesium alloys with improved corrosion properties. Surf. Coat. Technol. 2014, 259, 102–108. [Google Scholar] [CrossRef]

- Kenzhegulov, A.; Mamaeva, A.; Panichkin, A.; Alibekov, Z.; Kshibekova, B.; Bakhytuly, N.; Wieleba, W. Comparative study of tribological and corrosion characteristics of TiCN, TiCrCN, and TiZrCN coatings. Coatings 2022, 12, 564. [Google Scholar] [CrossRef]

- Mattox, D.M. Handbook of Physical Vapor Deposition (PVD) Processing; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Park, M.; Leyland, A.; Matthews, A. Corrosion performance of layered coatings produced by physical vapour deposition. Surf. Coat. Technol. 1990, 43–44, 481–492. [Google Scholar] [CrossRef]

- Parameswaran, V.R.; Immarigeon, J.P.; Nagy, D. Tribological behaviour of ion deposited ZrN coatings on mild steel substrate. Surf. Coat. Technol. 1992, 13, 251. [Google Scholar]

- Jehn, H. Improvement of the corrosion resistance of PVD hard coating–substrate systems. Surf. Coat. Technol. 2000, 125, 212–217. [Google Scholar] [CrossRef]

- Kim, G.; Lee, S.; Hahn, J.; Lee, B.; Han, J.; Lee, J. Effects of the thickness of Ti buffer layer on the mechanical properties of TiN coatings. Surf. Coat. Technol. 2003, 171, 83–90. [Google Scholar] [CrossRef]

- Gorokhovsky, V.; Bowman, C.; Gannon, P.; VanVorous, D.; Voevodin, A.; Rutkowski, A.; Muratore, C.; Smith, R.; Kayani, A.; Gelles, D.; et al. Tribological performance of hybrid filtered arc-magnetron coatings: Part I: Coating deposition process and basic coating properties characterization. Surf. Coat. Technol. 2006, 201, 3732–3747. [Google Scholar] [CrossRef]

- Vetter, J.; Knaup, R.; Dweletzki, H.; Schneider, E.; Vogler, S. Hard coatings for lubrication reduction in metal forming. Surf. Coat. Technol. 1996, 86–87, 739–747. [Google Scholar] [CrossRef]

- Smith. Handbook of Thin-Film Deposition Processes and Techniques; Noyes Publications: Ridg, NJ, USA, 2001; p. 629. [Google Scholar]

- Ramana, J.V.; Kumar, S.; David, C.; Raju, V.S. Structure, composition and microhardness of (Ti, Zr) N and (Ti, Al) N coatings prepared by DC magnetron sputtering. Mater. Lett. 2004, 58, 2553–2558. [Google Scholar]

- Uchida, M.; Nihira, N.; Mitsuo, A.; Toyoda, K.; Kubota, K.; Aizawa, T. Friction and wear properties of CrAlN and CrVN films deposited by cathodic arc ion plating method. Surf. Coat. Technol. 2004, 177–178, 627–630. [Google Scholar] [CrossRef]

- Hones, P.; Diserens, M.; Sanjinés, R.; Lévy, F. Electronic structure and mechanical properties of hard coatings from the chromium–tungsten nitride system. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 2000, 18, 2851–2856. [Google Scholar] [CrossRef]

- Musil, J.; Vlček, J. Magnetron sputtering of hard nanocomposite coatings and their properties. Surf. Coat. Technol. 2001, 142–144, 557–566. [Google Scholar] [CrossRef]

- Barna, P.B.; Adamik, M. Growth mechanisms of polycrystalline thin films. In Science and Technology of Thin Films; World Scientific: Singapore, 1995; pp. 1–28. [Google Scholar]

- Guu, Y.; Hocheng, H. Improvement of fatigue life of electrical discharge machined AISI D2 tool steel by TiN coating. Mater. Sci. Eng. A 2001, 318, 155–162. [Google Scholar] [CrossRef]

- Puchi-Cabrera, E.S.; Matínez, F.; Herrera, I.; Berríos, J.A.; Dixit, S.; Bhat, D. On the fatigue behavior of an AISI 316L stainless steel coated with a PVD TiN deposit. Surf. Coat. Technol. 2004, 182, 276–286. [Google Scholar]

- Baldissera, P.; Cavalleri, S.; Marcassoli, P.; Tordini, F. Study of the effect of DCT and PVD treatments on the fatigue behaviour of AISI 302 stainless steel. Key Eng. Mater. 2010, 417–418, 49–52. [Google Scholar] [CrossRef]

- Baragetti, S.; Lavecchia, G.; Terranova, A. Variables affecting the fatigue resistance of PVD-coated components. Int. J. Fatigue 2005, 27, 1541–1550. [Google Scholar] [CrossRef]

- Oskouei, R.H.; Ibrahim, R.N. The effect of a heat treatment on improving the fatigue properties of aluminium alloy 7075-T6 coated with TiN by PVD. Procedia Eng. 2011, 10, 1936–1942. [Google Scholar] [CrossRef]

- Alibeyoğlu, F.; Karabudak, F.; Yeşildal, R.; Balcı, A.; Efeoğlu, İ.; Ateş, O.K. Fatigue and Tensile Behaviour of Ti + TiN + Ti + TiVN Multilayer Nitride Films Coated on AZ91 Magnesium Alloy by Closed Field Unbalanced Magnetron Sputtering. Mater. Res. Express 2024, 11, 066520. [Google Scholar] [CrossRef]

- ASTM STP 91; Handbook of Fatigue Testing. ASTM Committee E-9 on Fatigue. ASTM International: West Conshohocken, PA, USA, 1974; p. 566.

- ASTM E8/E8M-16a; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- Rettberg, L.H.; Jordon, J.B.; Horstemeyer, M.F.; Jones, J.W. Low-cycle fatigue behavior of die-cast mg alloys AZ91 and AM60. Met. Mater. Trans. A 2012, 43, 2260–2274. [Google Scholar] [CrossRef]

- Mokhtarishirazabad, M.; Boutorabi, S.; Azadi, M.; Nikravan, M. Effect of rare earth elements on high cycle fatigue behavior of AZ91 alloy. Mater. Sci. Eng. A 2013, 587, 179–184. [Google Scholar] [CrossRef]

- Pu, D.; Wu, S.; Yang, H.; Chen, X.; Li, J.; Feng, X.; Zheng, K.; Pan, F. Effect of Ti particles on microstructure and mechanical properties of TiP/AZ91 composites. J. Mater. Res. Technol. 2023, 22, 1362–1374. [Google Scholar] [CrossRef]

- Totik, Y.; Sadeler, R.; Kaymaz, I.; Gavgali, M. The effect of homogenisation treatment on cold deformations of AA 2014 and AA 6063 alloys. J. Mech. Work. Technol. 2004, 147, 60–64. [Google Scholar] [CrossRef]

- Leszczyńska-Madej, B.; Richert, M.; Wąsik, A.; Szafron, A. Analysis of the microstructure and selected properties of the aluminium alloys used in automotive air-conditioning systems. Metals 2017, 8, 10. [Google Scholar] [CrossRef]

- Thangapandian, N.; Prabu, S.B.; Padmanabhan, K.A. Effect of temperature on grain size in AA6063 aluminum alloy subjected to repetitive corrugation and straightening. Acta Metall. Sin. 2019, 32, 835–844. [Google Scholar] [CrossRef]

- Ali, L.F.; Kuppuswamy, N.; Soundararajan, R.; Ramkumar, K.; Sivasankaran, S. Microstructural evolutions and mechanical properties enhancement of AA 6063 alloy reinforced with Tungsten (W) nanoparticles processed by friction stir processing. Mater. Charact. 2021, 172, 110903. [Google Scholar] [CrossRef]

- Wang, D.S.; Wei, W.; Wei, K.X.; Alexandrov, I.V.; An, X.L.; Wang, D.D.; Liu, X.K. Grain Refinement and Mechanical Properties of Photovoltaic Frame 6063 Al Alloy with an Addition of ECAP-ed Al-5%Ti-1%B Master Alloy. JOM 2024, 76, 2027–2042. [Google Scholar] [CrossRef]

- Voevodin, A.; Rebholz, C.; Schneider, J.; Stevenson, P.; Matthews, A. Wear resistant composite coatings deposited by electron enhanced closed field unbalanced magnetron sputtering. Surf. Coat. Technol. 1995, 73, 185–197. [Google Scholar] [CrossRef]

- Aouadi, S.M.; Chladek, J.A.; Namavar, F.; Finnegan, N.; Rohde, S.L. Characterization of Ti-based nanocrystalline ternary nitride films. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 2002, 20, 1967–1973. [Google Scholar] [CrossRef]

- Leonov, A.A.; Denisova, Y.A.; Denisov, V.V.; Syrtanov, M.S.; Shmakov, A.N.; Savostikov, V.M.; Teresov, A.D. Structure and properties of CrN/TiN multi-layer coatings obtained by vacuum-arc plasma-assisted deposition method. Coatings 2023, 13, 351. [Google Scholar] [CrossRef]

- Lyu, Y.; Zhang, Q.; Liu, Y.; Deng, X.; Sun, H.; Mo, M. Effect of Microstructure of TiN/TiCN Layer on the Structural, Mechanical and Tribological Properties of the Ti/TiN/TiCN Films. Lubricants 2023, 11, 21. [Google Scholar] [CrossRef]

- Sala, N.; de Figueiredo, M.R.; Franz, R.; Kainz, C.; Sánchez-López, J.; Rojas, T.; Reyes, D.F.d.L.; Colominas, C.; Abad, M.D. Microstructural and mechanical properties of TiN/CrN and TiSiN/CrN multilayer coatings deposited in an industrial-scale HiPIMS system: Effect of the Si incorporation. Surf. Coat. Technol. 2024, 494, 131461. [Google Scholar] [CrossRef]

- Uslu, M.E.; Onel, A.C.; Ekinci, G.; Toydemir, B.; Durdu, S.; Usta, M.; Arslan, L.C. Investigation of (Ti, V) N and TiN/VN coatings on AZ91D Mg alloys. Surf. Coat. Technol. 2015, 284, 252–257. [Google Scholar]

- Fattah-Alhosseini, A.; Chaharmahali, R.; Babaei, K. Effect of particles addition to solution of plasma electrolytic oxidation (PEO) on the properties of PEO coatings formed on magnesium and its alloys: A review. J. Magnes. Alloys 2020, 8, 799–818. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Feng, H.-Q.; Chen, C.-C. Effect of CrMoN addition on the thermal stability and cyclic impact resistance of TiVN coatings. Surf. Coat. Technol. 2023, 473, 129963. [Google Scholar] [CrossRef]

- Xue, Y.; Horstemeyer, M.; McDowell, D.; Elkadiri, H.; Fan, J. Microstructure-based multistage fatigue modeling of a cast AE44 magnesium alloy. Int. J. Fatigue 2004, 29, 666–676. [Google Scholar] [CrossRef]

- Azadi, M.; Farrahi, G.H.; Winter, G.; Eichlseder, W. Fatigue lifetime of AZ91 magnesium alloy subjected to cyclic thermal and mechanical loadings. Mater. Des. 2014, 53, 639–644. [Google Scholar] [CrossRef]

- Mayer, H.; Papakyriacou, M.; Zettl, B.; Stanzl-Tschegg, S. Influence of porosity on the fatigue limit of die cast magnesium and aluminium alloys. Int. J. Fatigue 2003, 25, 245–256. [Google Scholar] [CrossRef]

- Stanzl-Tschegg, S.; Mayer, H.; Beste, A.; Kroll, S. Fatigue and fatigue crack propagation in AlSi7Mg cast alloys under in-service loading conditions. Int. J. Fatigue 1995, 17, 149–155. [Google Scholar] [CrossRef]

- Goodenberger, D.L.; Stephens, R.I. Fatigue of AZ91E-T6 cast magnesium alloy. J. Eng. Mater. Technol. 1993, 115, 391–397. [Google Scholar] [CrossRef]

- Shugurov, A.R.; Kuzminov, E.D. The effect of multilayer architecture and Ta alloying on the mechanical performance of Ti-Al-N coatings under scratching and uniaxial tension. Metals 2021, 11, 1307. [Google Scholar] [CrossRef]

| Alloys | Al | Zn | Mn | Si | Cu | Fe | Cr | Others | Ti | Mg |

|---|---|---|---|---|---|---|---|---|---|---|

| AZ91 | 8.84 | 0.61 | 0.18 | 0.02 | 0.005 | - | - | - | Balance | |

| AA6063 | Balance | 0.1 | 0.1 | 0.2–0.6 | 0.1 | 0.35 | 0.1 | 0.15 | 0.1 | 0.45–0.9 |

| Mechanical Characteristics/Alloys | AZ91 | AA6063 (T6) |

|---|---|---|

| Modulus of Elasticity (GPa) | 45 | 68 |

| Tensile Strength (MPa) | 230 | 205–245 |

| Yield Strength (MPa) | 150 | 170–210 |

| Hardness (Brinell) | 63 | 75 |

| Elongation (%) | 3–7 | 12 |

| Poisson ratio | 0.35 | 0.33 |

| AA6063 Base | AA6063 Coated | AZ91 Base | AZ91 Coated | |||||

|---|---|---|---|---|---|---|---|---|

| Stress (Mpa) | Strain (%) | Stress (Mpa) | Strain (%) | Stress (Mpa) | Strain (%) | Stress (Mpa) | Strain (%) | |

| Average | 129.35 | 8.18 | 118.16 | 7.50 | 137.89 | 12.83 | 139.65 | 12.74 |

| Deviation | 5.12 | 0.35 | 3.52 | 0.14 | 4.41 | 0.45 | 4.04 | 0.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yeşildal, R.; Sezer, S.; Karabudak, F. Investigation of Tensile and Fatigue Behavior of Cr/CrN/TiCrN/TiCrCN Multilayer Films Coated on AA6063 and AZ91 Alloys by Closed-Field Unbalanced Magnetron Sputtering Process. Appl. Sci. 2025, 15, 3525. https://doi.org/10.3390/app15073525

Yeşildal R, Sezer S, Karabudak F. Investigation of Tensile and Fatigue Behavior of Cr/CrN/TiCrN/TiCrCN Multilayer Films Coated on AA6063 and AZ91 Alloys by Closed-Field Unbalanced Magnetron Sputtering Process. Applied Sciences. 2025; 15(7):3525. https://doi.org/10.3390/app15073525

Chicago/Turabian StyleYeşildal, Ruhi, Sadberk Sezer, and Filiz Karabudak. 2025. "Investigation of Tensile and Fatigue Behavior of Cr/CrN/TiCrN/TiCrCN Multilayer Films Coated on AA6063 and AZ91 Alloys by Closed-Field Unbalanced Magnetron Sputtering Process" Applied Sciences 15, no. 7: 3525. https://doi.org/10.3390/app15073525

APA StyleYeşildal, R., Sezer, S., & Karabudak, F. (2025). Investigation of Tensile and Fatigue Behavior of Cr/CrN/TiCrN/TiCrCN Multilayer Films Coated on AA6063 and AZ91 Alloys by Closed-Field Unbalanced Magnetron Sputtering Process. Applied Sciences, 15(7), 3525. https://doi.org/10.3390/app15073525