Study on Seepage Effect of Roadway Based on Polyformaldehyde (POM) Fiber Concrete

Abstract

1. Introduction

2. Experimental Overview

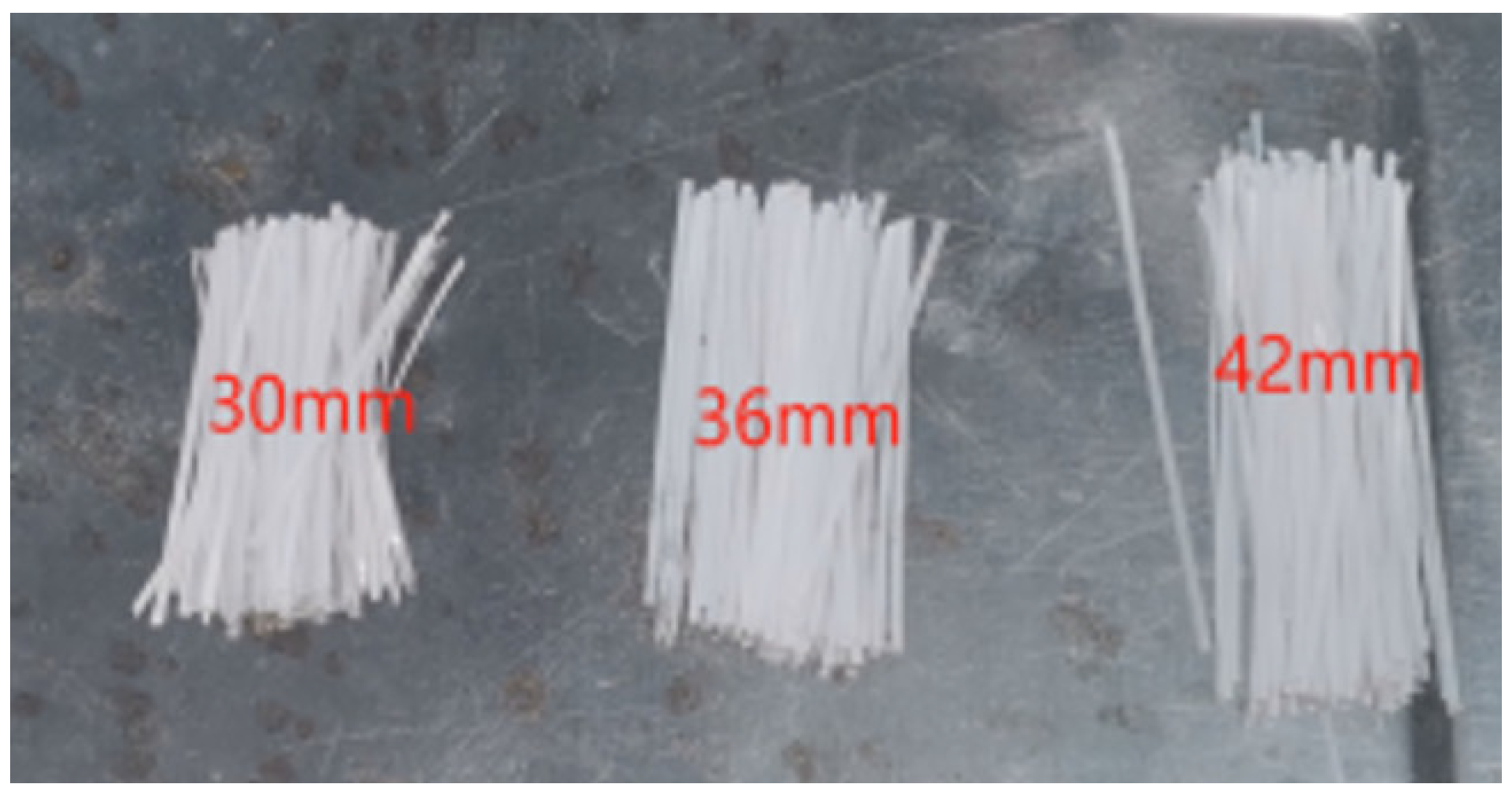

2.1. Materials

2.2. Test Scheme

2.3. FEM Details

2.4. Mixing Procedure

3. Results and Analysis

3.1. Test Results and Analysis of Stepwise Pressure Method

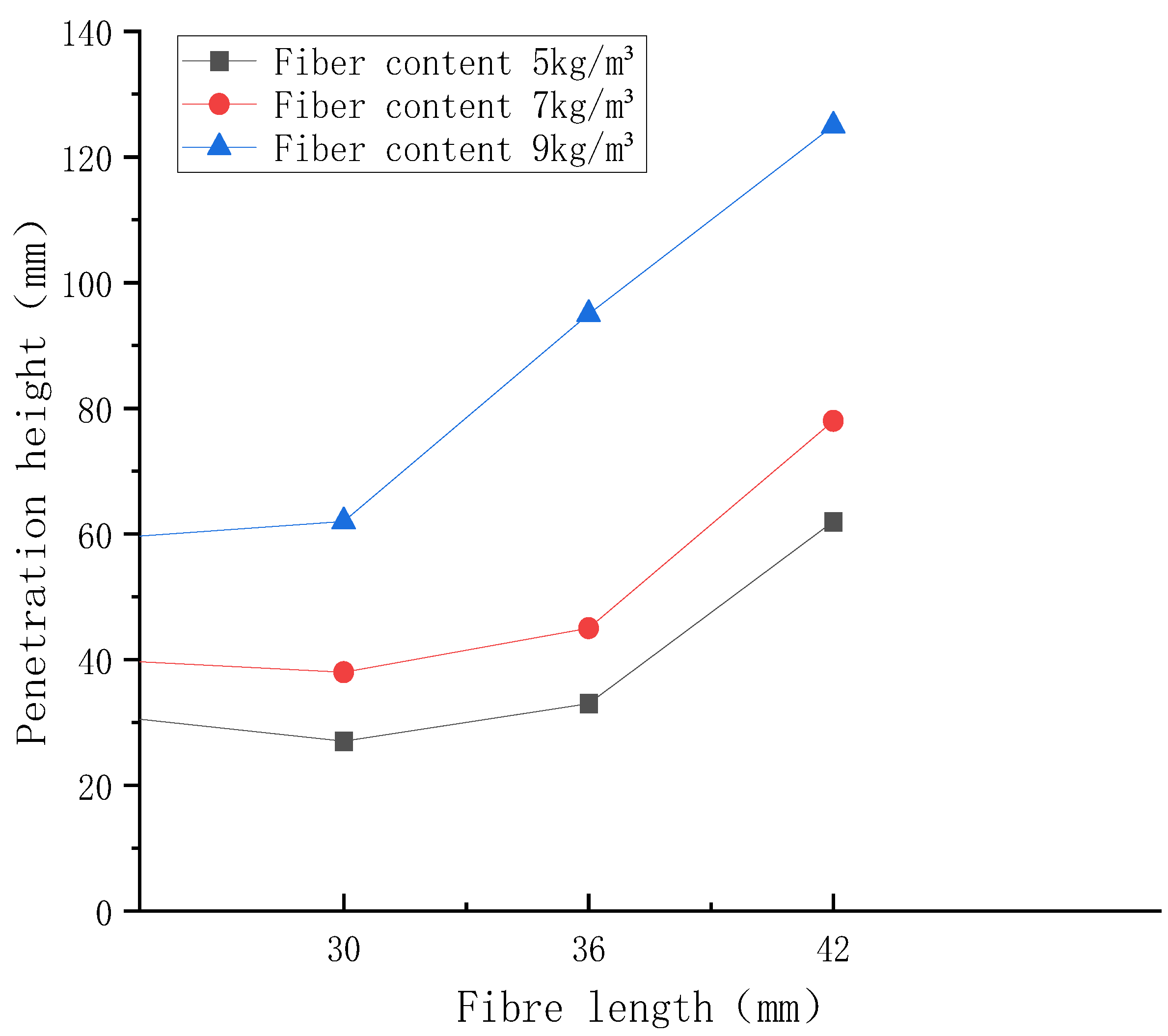

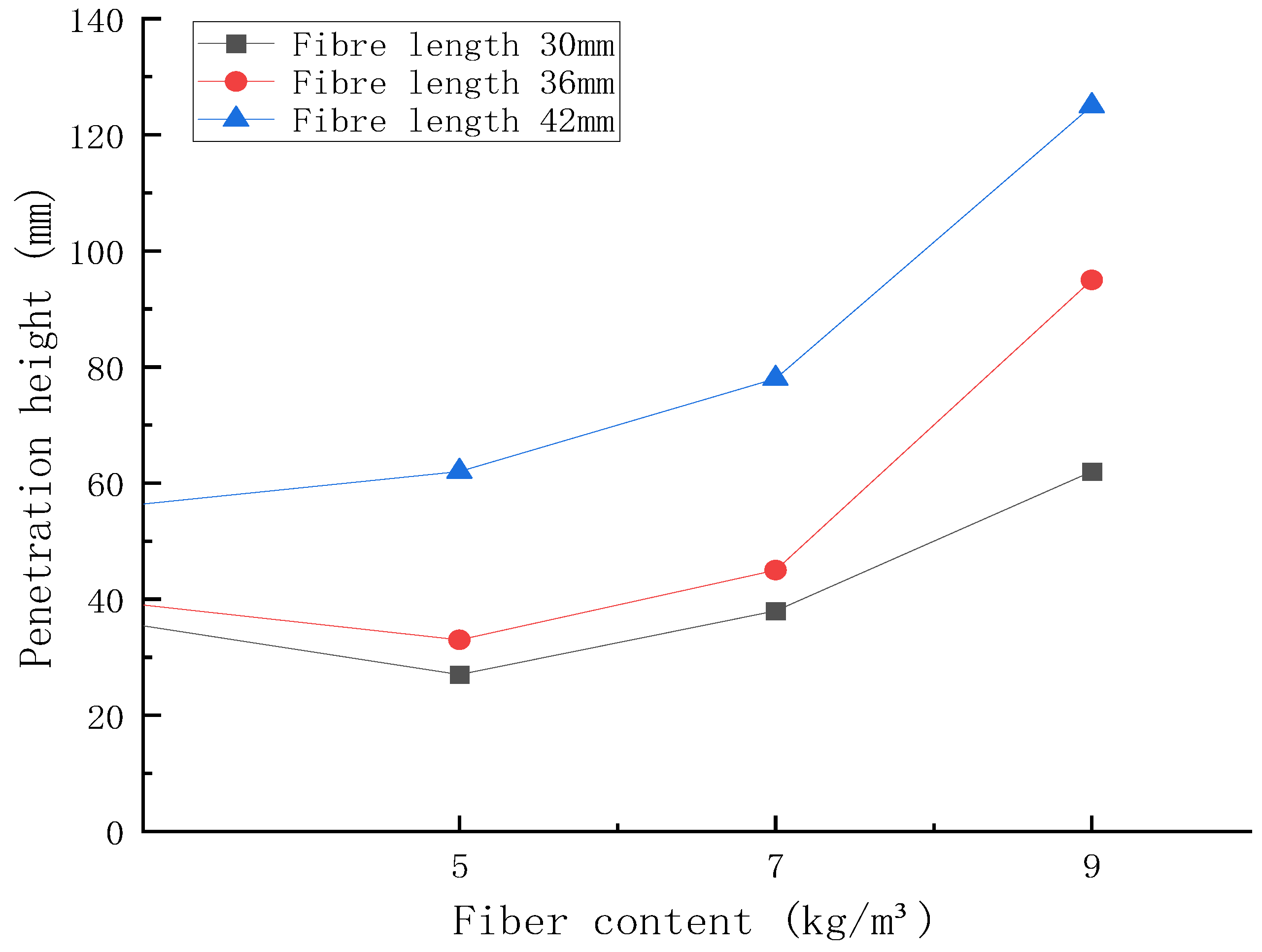

3.2. Test Results and Analysis of Seepage Height Method

3.2.1. Analysis of Influence of Fiber Length on Impermeability of Concrete

3.2.2. Analysis of Influence of Fiber Content on Impermeability of Concrete

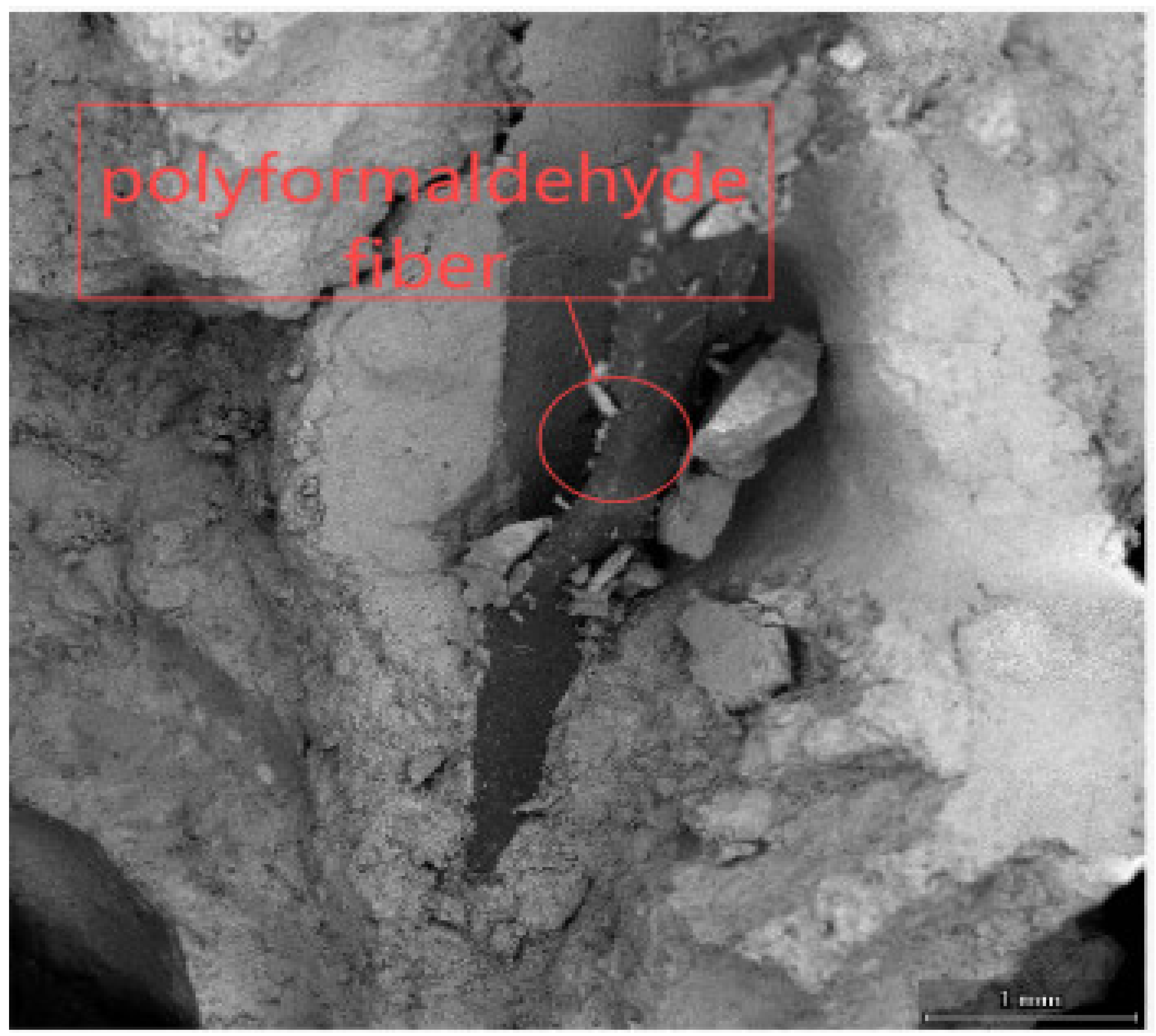

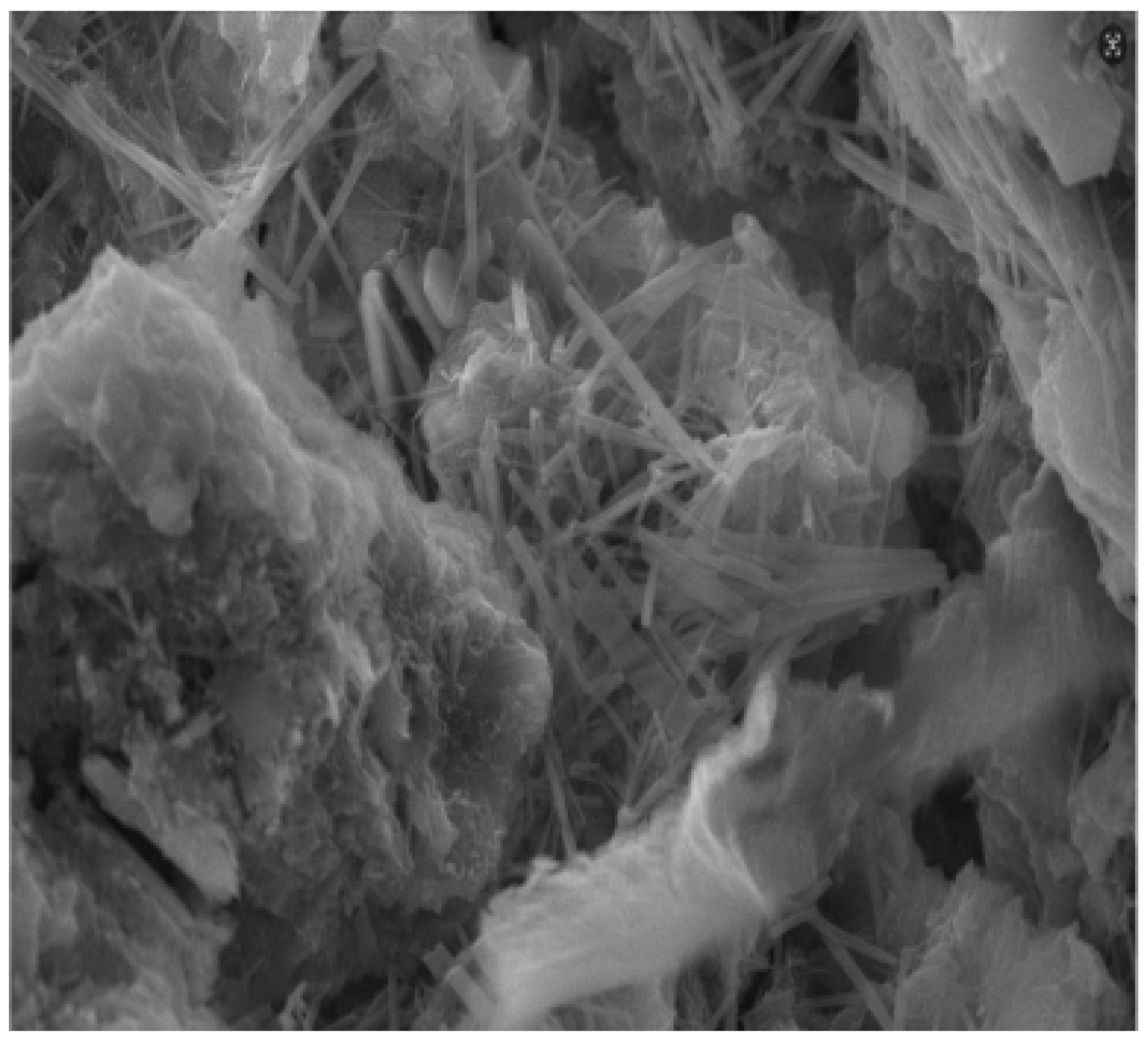

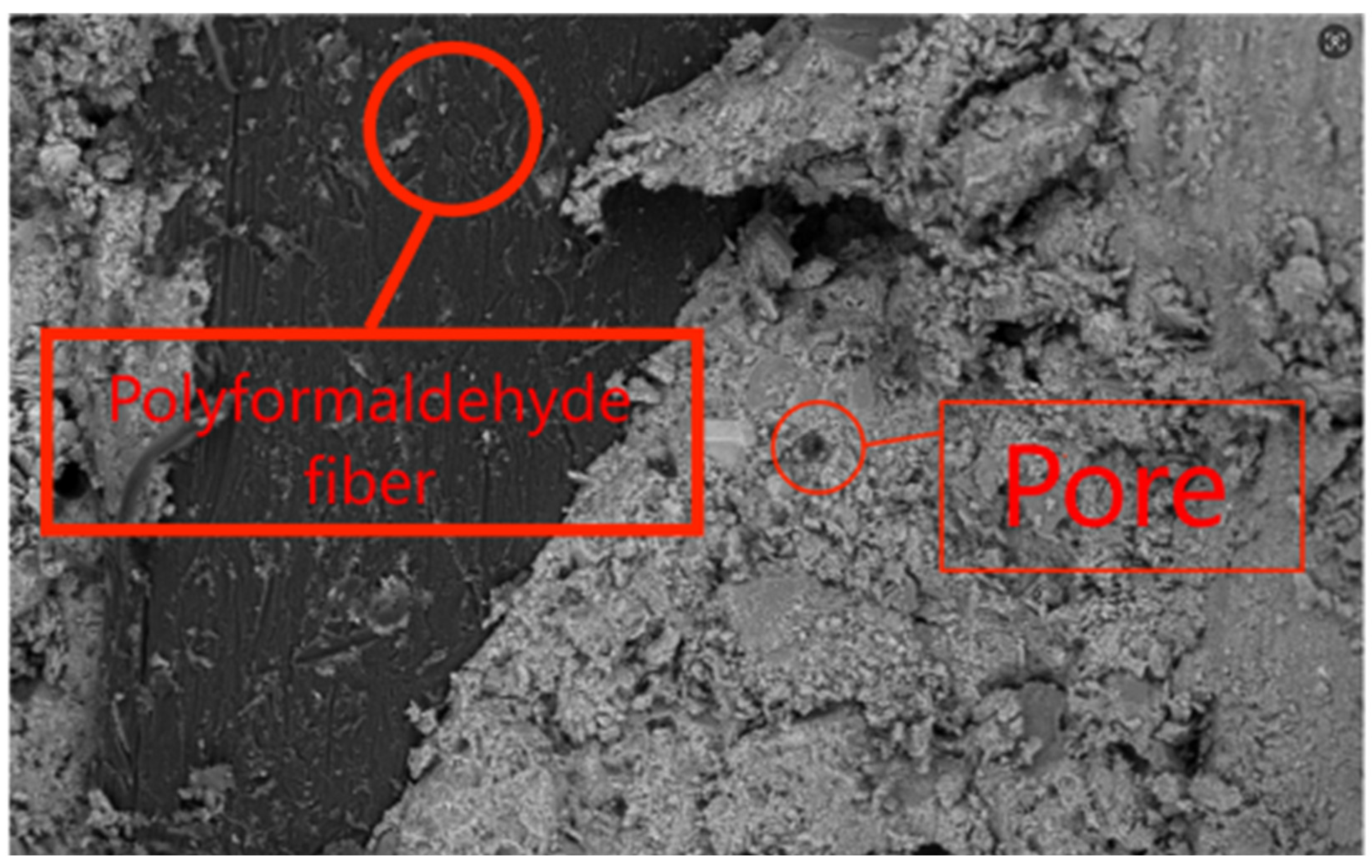

3.3. Analysis of Percolation Mechanism of Polyformaldehyde Fiber Concrete

3.3.1. Interaction Between Fiber Surface and Concrete

3.3.2. Analysis of Influence Mechanism of Percolation of Polyformaldehyde Fiber Concrete with Different Lengths and Dosages

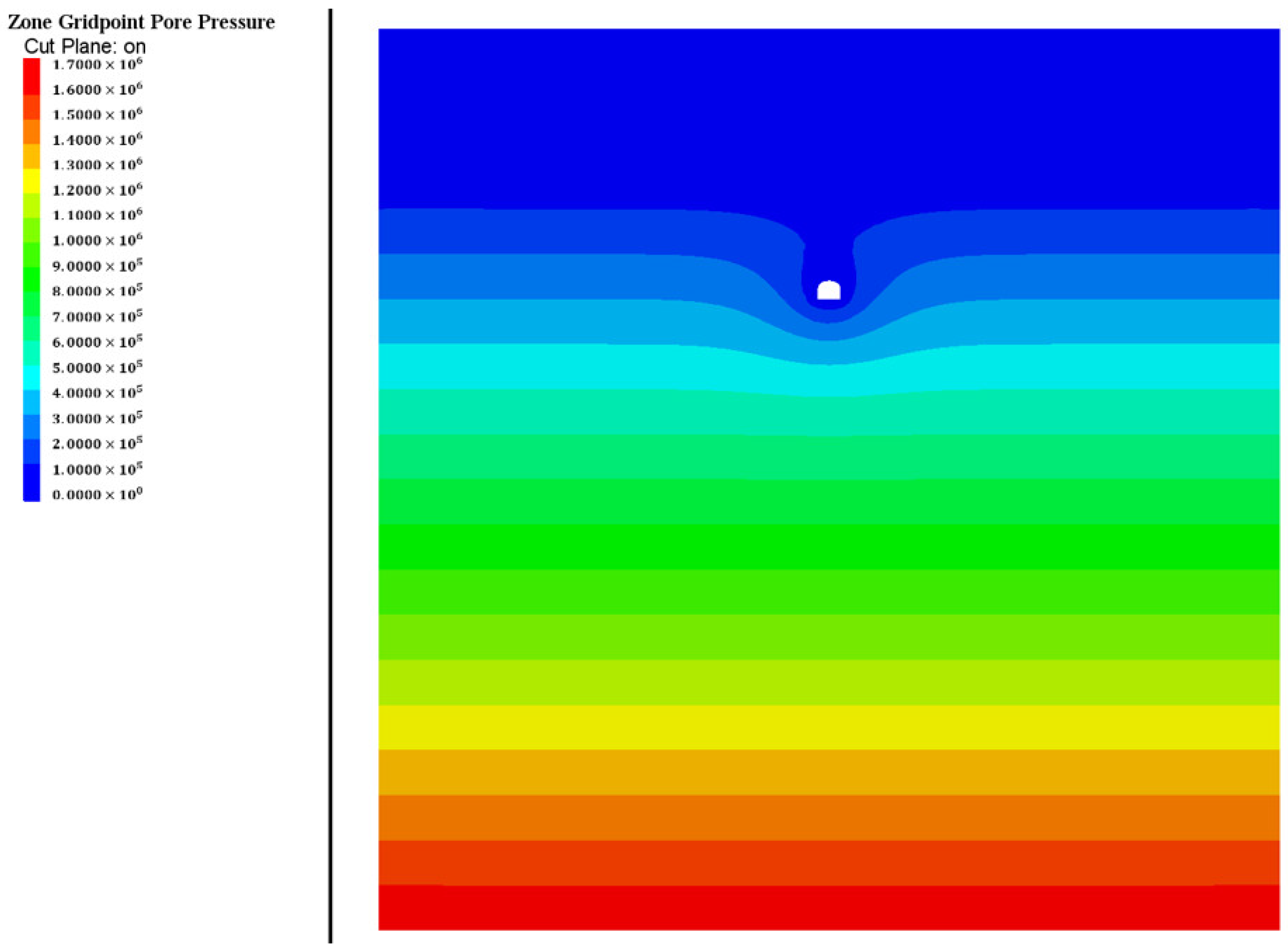

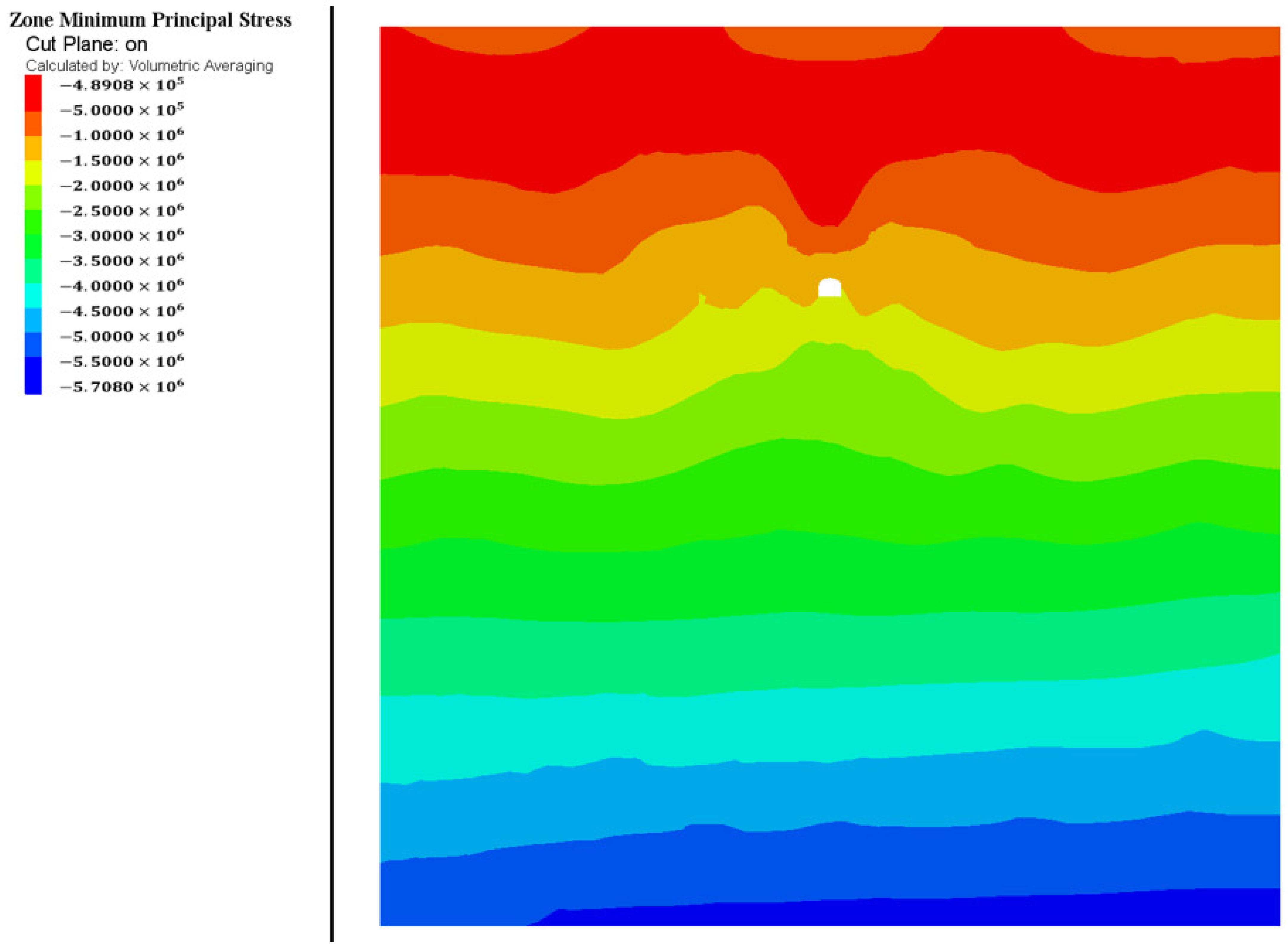

4. Numerical Simulation Analysis Based on FLAC3D

4.1. Stratigraphic Lithology

4.2. Hydrogeological Condition

4.3. Model Building

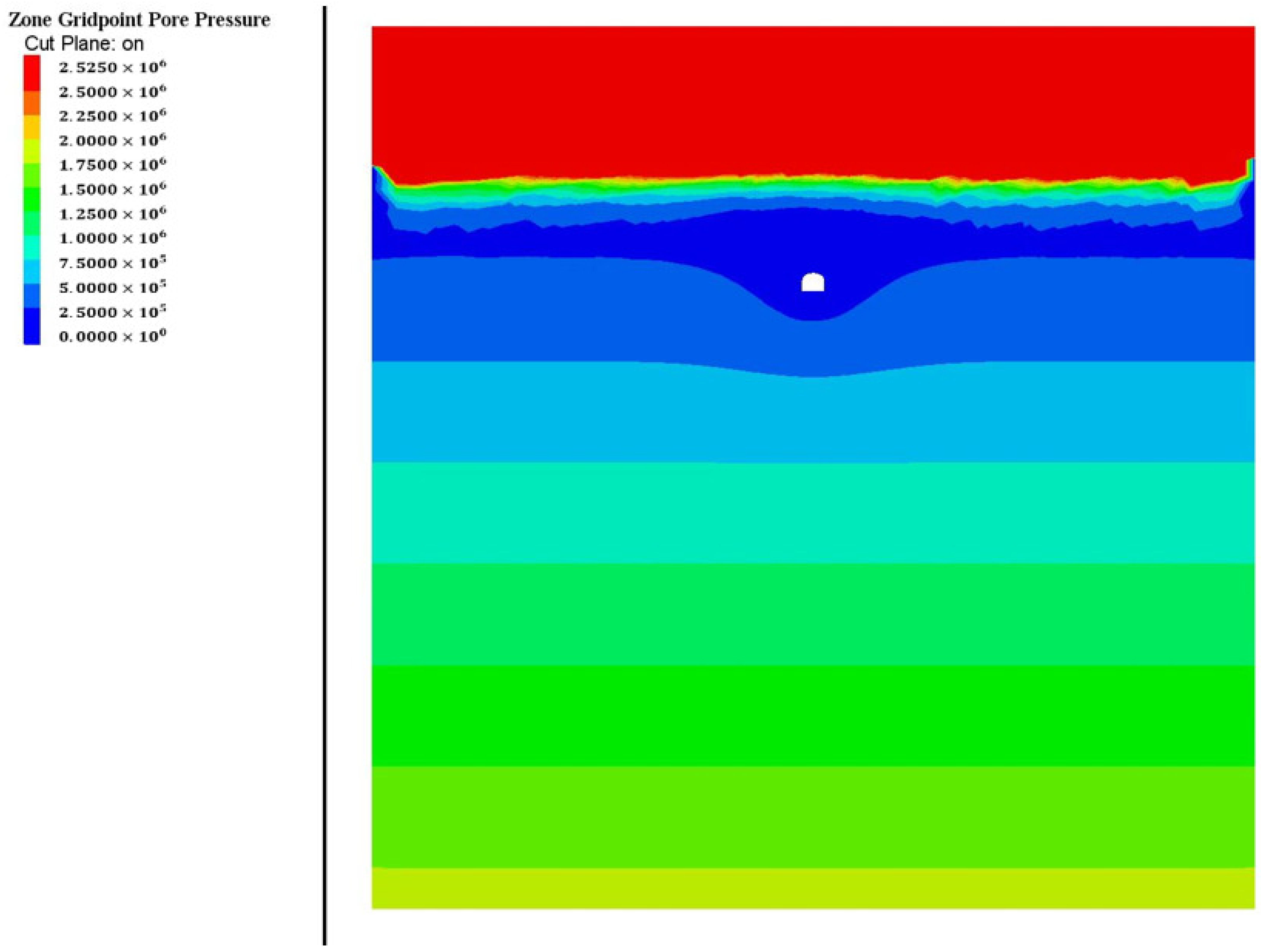

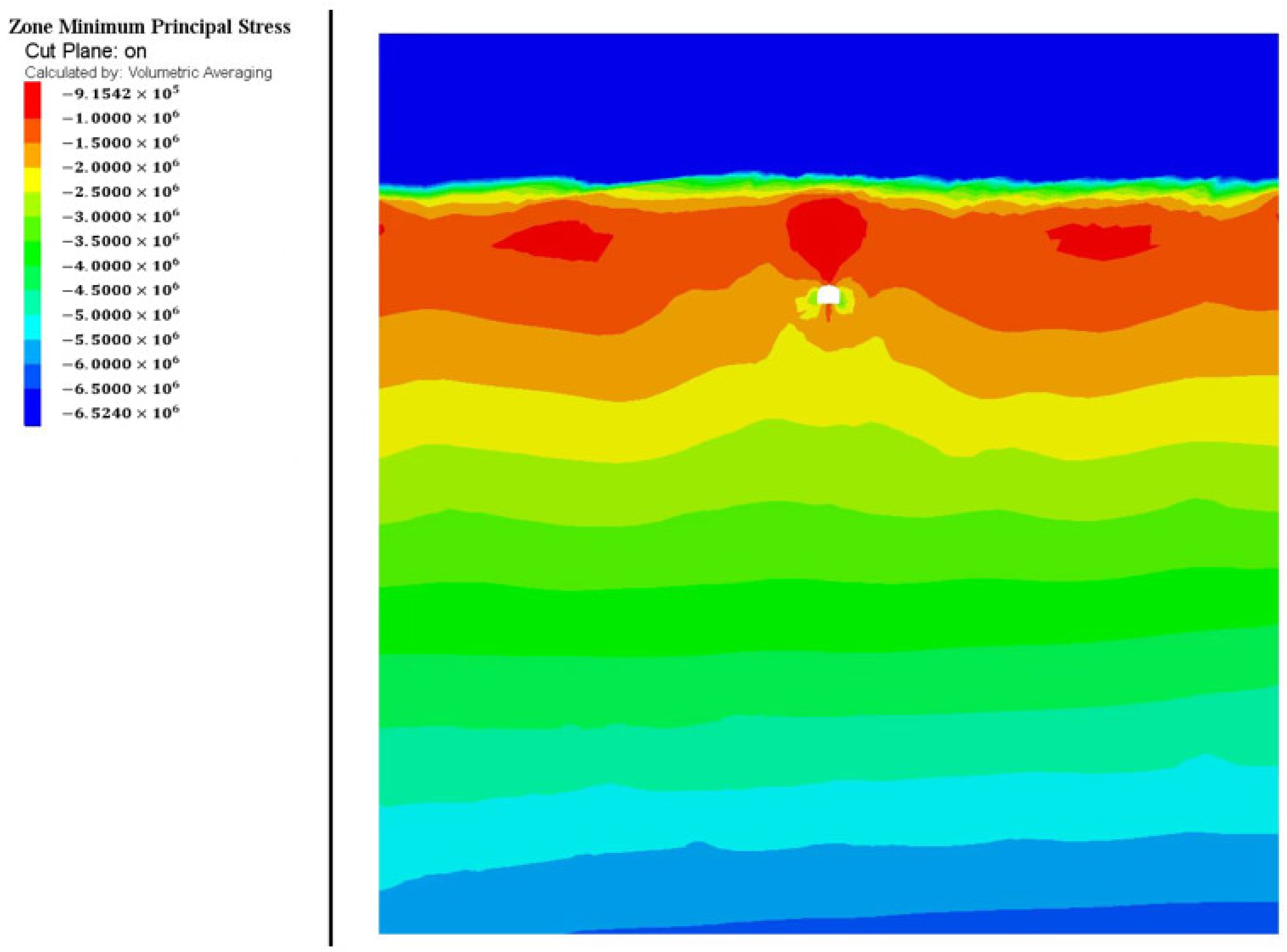

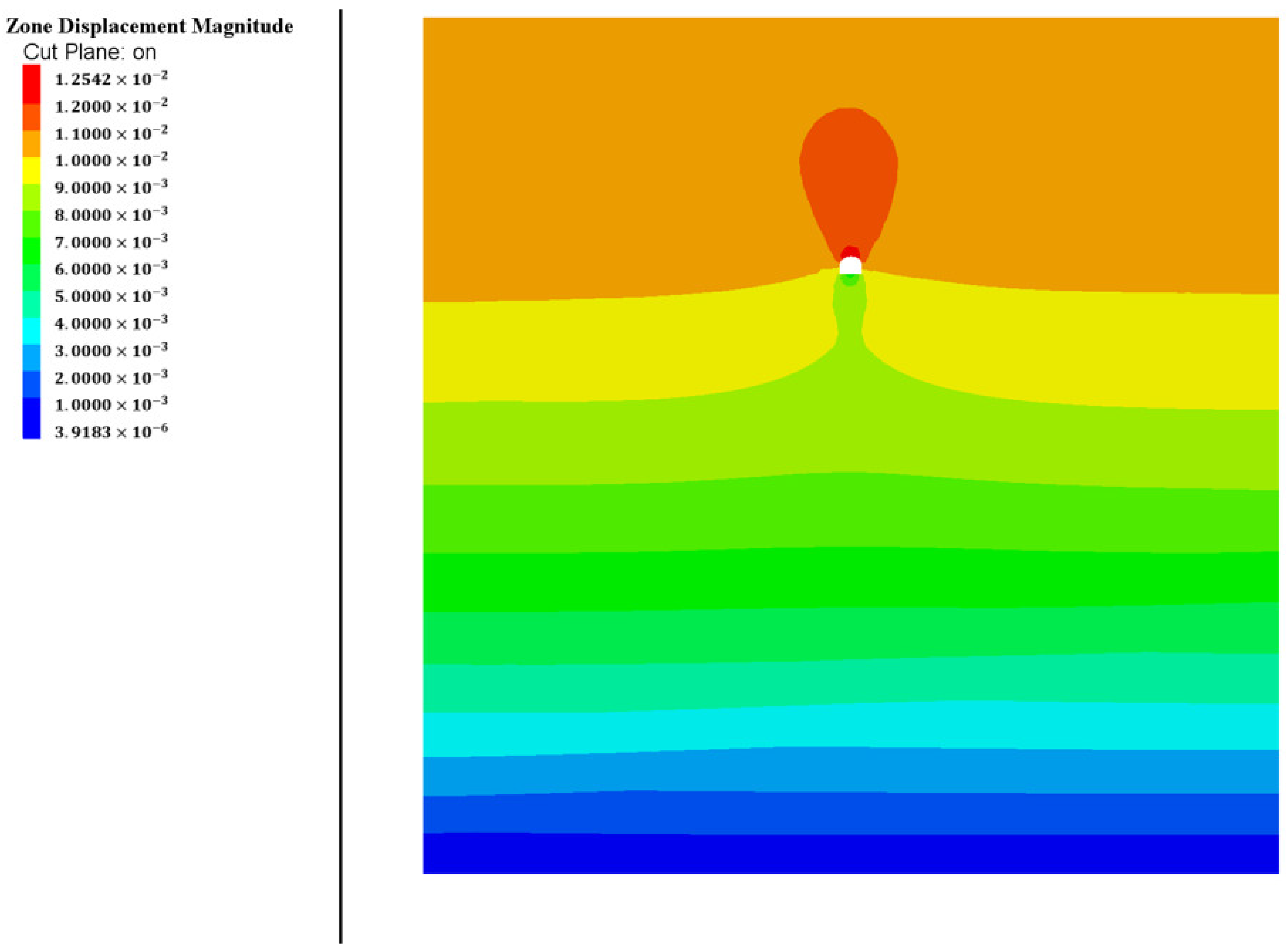

4.4. Analysis of Seepage Influence of Roadway Under Ordinary Support Conditions

4.5. Analysis of Seepage Effect of the Roadway Under the Condition of a Polyformaldehyde Fiber Concrete Support

5. Conclusions

- Polyformaldehyde Fiber Concrete Improves Impermeability: The results of the test showed that a small amount of POM fibers can significantly enhance concrete impermeability. The best result was achieved when using a content amount of 5 kg/m3 of fibers of a size of 30 mm, which reached a hydrostatic stress of 0.8 MPa, which was higher than that of the blank control group.

- Favorable Length and Fiber Content: The test results showed that the 30 mm fibers of a 5 kg/m3 content had the shortest seepage height, which yielded maximum impermeability. A fiber content amount of more than 7 kg/m3 showed a drop in impermeability due to a lack of fiber dispersion and an increase in porosity.

- Numerical Simulation Calibration: FLAC3D numerical simulation confirmed that polyformaldehyde fiber concrete improves road stability by reducing displacement under seepage. The polyformaldehyde fiber blend showed improved resistivity compared to normal concrete support systems.

- Effect on Roadway Stability due to Groundwater Seepage: In seepage, there was a minimal road displacement of polyformaldehyde fiber concrete, which was 30.5 mm lower, and improved pore water pressure resistance, which showed its potential in roadway stability in groundwater-saturated environments.

- The best content amount of polyformaldehyde fibers for concrete is 5 kg/m3. This content level is a balance between realizing improved impermeability and maintaining an effective dispersion of fibers in a concrete matrix. Adding a higher content of fibers results in lower performance due to the aggregation of fibers and increased porosity. In conclusion, the use of polyformaldehyde fibers in concrete presents a promising solution for improving the impermeability and stability of underground roadways, especially in mining environments where groundwater seepage is a significant concern. This research contributes to the advancement of concrete technology, offering valuable insights into the application of polyformaldehyde fibers for durable, water-resistant construction materials.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, J.; Liu, X.; Zhang, Z.; Liu, Y. Synergistic utilization, critical mechanisms, and environmental suitability of bauxite residue (red mud) based multi-solid wastes cementitious materials and special concrete. J. Environ. Manag. 2024, 361, 121255. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Wang, X.; Zhang, C. Three-dimensional high fidelity mesoscale rapid modelling algorithm for concrete. In Structures; Elsevier: Amsterdam, The Netherlands, 2024. [Google Scholar]

- Liu, X.; Liu, X.; Zhang, Z.; Ai, X. Effect of carbonation curing on the characterization and properties of steel slag-based cementitious materials. Cem. Concr. Compos. 2024, 154, 105769. [Google Scholar] [CrossRef]

- Su, Y.; Cui, Y.-J.; Dupla, J.-C.; Canou, J. Soil-water retention behaviour of fine/coarse soil mixture with varying coarse grain contents and fine soil dry densities. Can. Geotech. J. 2022, 59, 291–299. [Google Scholar] [CrossRef]

- He, L.; Pan, J.; Hee, Y.S.; Chen, H.; Li, L.G.; Panda, B.; Chow, W.T. Development of novel concave and convex trowels for higher interlayer strength of 3D printed cement paste. Case Stud. Constr. Mater. 2024, 21, e03745. [Google Scholar] [CrossRef]

- Yang, L.; Gao, Y.; Chen, H.; Jiao, H.; Dong, M.; Bier, T.A.; Kim, M. 3D printing concrete technology from a rheology perspective: A review. Adv. Cem. Res. 2024. [Google Scholar] [CrossRef]

- Huang, H.; Li, M.; Zhang, W.; Yuan, Y. Seismic behavior of a friction-type artificial plastic hinge for the precast beam–column connection. Arch. Civ. Mech. Eng. 2022, 22, 201. [Google Scholar] [CrossRef]

- Gong, B.; Li, H. A couple Voronoi-RBSM modeling strategy for RC structures. Struct. Eng. Mech. 2024, 91, 239. [Google Scholar]

- Niu, Y.; Wang, W.; Su, Y.; Jia, F.; Long, X. Plastic damage prediction of concrete under compression based on deep learning. Acta Mech. 2024, 235, 255–266. [Google Scholar] [CrossRef]

- Haynes, M.A.; Coleri, E.; Obaid, I. Performance of waterproofing membranes to protect concrete bridge decks. Transp. Res. Rec. 2021, 2675, 1693–1706. [Google Scholar] [CrossRef]

- Kim, D.-G. Drainage system for leakage treatment of cement concrete structure in underground. J. Korean Tunn. Undergr. Space Assoc. 2019, 21, 573–585. [Google Scholar]

- Solsky, S.; Legina, E.; Bykovskaya, S. Quality and Effectiveness of Waterproofing Geosynthetic Materials Under Natural Conditions. Power Technol. Eng. 2023, 57, 514–519. [Google Scholar]

- Ivanič, A.; Lubej, S. Durability and degradation of PVC-P roofing membrane—Example of dynamic fatigue testing. Polymers 2022, 14, 1312. [Google Scholar] [CrossRef] [PubMed]

- Shuaeb, M.A.M. Clogging Potential of Low-Flush Toilet Drain System. Ph.D. Thesis, Seoul National University, Seoul, Republic of Korea, 2017. [Google Scholar]

- Giroud, J.; Han, J.; Tutumluer, E.; Dobie, M. The use of geosynthetics in roads. Geosynth. Int. 2023, 30, 47–80. [Google Scholar]

- Salami, B.A.; Bahraq, A.A.; ul Haq, M.M.; Ojelade, O.A.; Taiwo, R.; Wahab, S.; Adewumi, A.A.; Ibrahim, M. Polymer-enhanced concrete: A comprehensive review of innovations and pathways for resilient and sustainable materials. Next Mater. 2024, 4, 100225. [Google Scholar]

- Huang, H.; Yuan, Y.; Zhang, W.; Zhu, L. Property assessment of high-performance concrete containing three types of fibers. Int. J. Concr. Struct. Mater. 2021, 15, 39. [Google Scholar]

- Dopko, M. Fiber reinforced concrete: Tailoring composite properties with discrete fibers. Master Thesis, Iowa State University, Ames, IA, USA, 2018. [Google Scholar]

- Babaie, R.; Abolfazli, M.; Fahimifar, A. Mechanical properties of steel and polymer fiber reinforced concrete. J. Mech. Behav. Mater. 2019, 28, 119–134. [Google Scholar]

- Mohod, M.V. Performance of steel fiber reinforced concrete. Int. J. Eng. Sci. 2012, 1, 1–4. [Google Scholar]

- Acosta-Calderon, S.; Gordillo-Silva, P.; García-Troncoso, N.; Bompa, D.V.; Flores-Rada, J. Comparative evaluation of sisal and polypropylene fiber reinforced concrete properties. Fibers 2022, 10, 31. [Google Scholar] [CrossRef]

- Li, X.; Wu, P.; Liu, M.; Wang, Y.; Wu, D.; Wang, Z.; Bi, X. Effect of Polyformaldehyde Fibers on Durability of Concrete. In Proceedings of the International Conference on Geosynthetics and Environmental Engineering, Jeju Island, Republic of Korea, 30–31 March 2023; Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar]

- Mydin, M.A.O.; Abdullah, M.M.A.B.; Mohd Nawi, M.N.; Yahya, Z.; Sofri, L.A.; Baltatu, M.S.; Sandu, A.V.; Vizureanu, P. Influence of polyformaldehyde monofilament fiber on the engineering properties of foamed concrete. Materials 2022, 15, 8984. [Google Scholar] [CrossRef]

- Xargay, H.; Ripani, M.; Folino, P.; Núñez, N.; Caggiano, A. Acoustic emission and damage evolution in steel fiber-reinforced concrete beams under cyclic loading. Constr. Build. Mater. 2021, 274, 121831. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. High-performance fiber-reinforced concrete: A review. J. Mater. Sci. 2016, 51, 6517–6551. [Google Scholar]

- Ashkezari, G.D.; Fotouhi, F.; Razmara, M. Experimental relationships between steel fiber volume fraction and mechanical properties of ultra-high performance fiber-reinforced concrete. J. Build. Eng. 2020, 32, 101613. [Google Scholar] [CrossRef]

- Dvorkin, L.; Dvorkin, O. Basics of Concrete Science; Stroi-Beton: St. Petersburg, Russia, 2006; Volume 200. [Google Scholar]

- Ngo, T.T.; Tran, N.T.; Kim, D.J.; Pham, T.C. Effects of corrosion level and inhibitor on pullout behavior of deformed steel fiber embedded in high performance concrete. Constr. Build. Mater. 2021, 280, 122449. [Google Scholar]

- Yoo, D.-Y.; Jang, Y.S.; Oh, T.; Banthia, N. Use of engineered steel fibers as reinforcements in ultra-high-performance concrete considering corrosion effect. Cem. Concr. Compos. 2022, 133, 104692. [Google Scholar]

- Shi, X.; Wang, X.; Wang, Q.; Zhang, T.; Yang, F.; Xu, Y.; Zhan, J. Experimental analysis and establishment of strength attenuation model of POM fiber reinforced geopolymeric recycled concrete under freeze-thaw cycles. Materials 2023, 16, 1699. [Google Scholar] [CrossRef]

- Deng, F.; Cao, C.; Xu, L.; Chi, Y. Interfacial bond characteristics of polypropylene fiber in steel/polypropylene blended fiber reinforced cementitious composite. Constr. Build. Mater. 2022, 341, 127897. [Google Scholar]

- Zhang, J.-c.; Li, B.-j.; Chen, W.-y.; Guo, R.-x. Experimental investigations on tensile strength and fracture toughness of a polyoxymethylene fiber reinforced concrete. Theor. Appl. Fract. Mech. 2024, 130, 104250. [Google Scholar]

- Zhang, L.; Liu, J.; Zhou, H.; Yang, Z. Effect of Polyoxymethylene Fiber on the Properties of Concrete. China Concr. Cem. Prod. 2018, 1, 58–62. [Google Scholar]

- Wang, F.; Xue, X.; Hua, J.; Wang, N.; Yao, Y. Properties of polyoxymethylene fibre-reinforced seawater sea sand concrete exposed to high temperatures. Constr. Build. Mater. 2023, 409, 133854. [Google Scholar] [CrossRef]

- Rui, Y.; Kangning, L.; Tianyi, Y.; Liwen, T.; Mengxi, D.; Zhonghe, S. Comparative study on the effect of steel and polyoxymethylene fibers on the characteristics of Ultra-High Performance Concrete (UHPC). Cem. Concr. Compos. 2022, 127, 104418. [Google Scholar]

- Xue, X.; Wang, F.; Hua, J.; Wang, N.; Huang, L.; Chen, Z.; Yao, Y. Effects of polyoxymethylene fiber on fresh and hardened properties of seawater sea-sand concrete. Polymers 2022, 14, 4969. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Xu, X.; Wang, H.; Wei, F.; Zhang, Y. Experimental and numerical analysis of interfacial bonding strength of polyoxymethylene reinforced cement composites. Constr. Build. Mater. 2019, 207, 1–9. [Google Scholar] [CrossRef]

- Zhang, L.; Luo, L.; Pan, J.; Li, X.; Sun, W.; Tian, S. Seepage characteristics of coal under complex mining stress environment conditions. Energy Fuels 2024, 38, 16371–16384. [Google Scholar] [CrossRef]

- Zhang, L.; Yuan, X.; Luo, L.; Tian, Y.; Zeng, S. Seepage characteristics of broken carbonaceous shale under cyclic loading and unloading conditions. Energy Fuels 2023, 38, 1192–1203. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, K.; Han, Q.; Ni, J.; Wu, Z. Crack imaging of underwater concrete components using interfacial waves and transducer array. Mech. Syst. Signal Process. 2025, 224, 111998. [Google Scholar] [CrossRef]

- Lv, X.; Zhang, R.; Zhang, A.; Ren, L.; Zhang, Z.; Xie, J. Influence of groundwater on micro-cracking behaviour and failure mechanism of deep hard rock. Measurement 2024, 237, 115175. [Google Scholar] [CrossRef]

- Peng, Z.; Feng, K.; Xiao, M.; He, C.; Jiang, C.; Chen, H. Study on reasonable overburden thickness of underwater tunnel based on pressure arch theory. Rock Soil Mech. 2018, 39, 2609–2616. [Google Scholar]

- Wang, W.; Gao, S.; Min, Y.; Liu, L.; Chen, J. Three-dimensional fluid–solid coupling numerical simulation of effects of underlying karst cave on shield tunnel through sand stratum. Geotech. Geol. Eng. 2019, 37, 4825–4836. [Google Scholar] [CrossRef]

- Sun, Q.; De Corte, W.; Liu, X.; Taerwe, L. Model Test and Numerical Simulation for Tunnel Leakage-Induced Seepage Erosion in Different Strata. Appl. Sci. 2024, 14, 3908. [Google Scholar] [CrossRef]

- Wang, Y.; Jin, F.; Xie, Y. Experimental study on effects of casting procedures on compressive strength, water permeability, and interfacial transition zone porosity of rock-filled concrete. J. Mater. Civ. Eng. 2016, 28, 04016055. [Google Scholar] [CrossRef]

- Haidong, C.; Hechao, M.; Zan, C.; Sihua, G. Water cutoff curtain technology of open-pit coal mine based on low strength impermeable concrete. Coal Geol. Explor. 2020, 48, 10. [Google Scholar]

- Wang, L.; He, T.; Zhou, Y.; Tang, S.; Tan, J.; Liu, Z.; Su, J. The influence of fiber type and length on the cracking resistance, durability and pore structure of face slab concrete. Constr. Build. Mater. 2021, 282, 122706. [Google Scholar]

- Zhang, P.; Li, Q.-f. Effect of polypropylene fiber on durability of concrete composite containing fly ash and silica fume. Compos. Part B Eng. 2013, 45, 1587–1594. [Google Scholar]

- Li, K.; Zhang, A.; Wang, Q.; Wu, B.; Liu, R.; Wang, Y.; Yi, X. Study on the mechanical characteristics of magnesium oxychloride cement composites reinforced with polyformaldehyde fibers. Constr. Build. Mater. 2023, 409, 134048. [Google Scholar]

- Chen, L.; Zheng, S.; Li, X.; Cheng, Z.; Wang, X. Experimental investigation of cracking and impact resistance of polymer-and fiber-enhanced concrete for ultra-thin whitetopping. Polymers 2022, 14, 4472. [Google Scholar] [CrossRef]

- Liu, X.; Chia, K.S.; Zhang, M.-H. Water absorption, permeability, and resistance to chloride-ion penetration of lightweight aggregate concrete. Constr. Build. Mater. 2011, 25, 335–343. [Google Scholar] [CrossRef]

- Yang, W.; Tang, Z.; Wu, W.; Zhang, K.; Yuan, J.; Li, H.; Feng, Z. Effect of different fibers on impermeability of steam cured recycled concrete. Constr. Build. Mater. 2022, 328, 127063. [Google Scholar]

- Guo, C.; Pei, L.; Guan, H.; Chu, X.; Wang, H.; Shi, F.; An, Z.; Qin, L. Experimental study on interfacial damage mechanisms of polymer-concrete composite structure. J. Build. Eng. 2023, 75, 106968. [Google Scholar]

- Wang, W.; Wang, L.; Xiong, H.; Luo, R. A review and perspective for research on moisture damage in asphalt pavement induced by dynamic pore water pressure. Constr. Build. Mater. 2019, 204, 631–642. [Google Scholar]

- Dawson, A. Water in Road Structures: Movement, Drainage & Effects; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008; Volume 5. [Google Scholar]

| Number | Fiber Type | POM Fiber Length (mm) | POM Fiber Content (kg/m3) | Fiber Manufacturer |

|---|---|---|---|---|

| 1 | Polyformaldehyde | 30 | 5 | Yuntianhua Co., Ltd., Chongqing, China |

| 2 | Polyformaldehyde | 30 | 7 | Yuntianhua Co., Ltd., Chongqing, China |

| 3 | Polyformaldehyde | 30 | 9 | Yuntianhua Co., Ltd., Chongqing, China |

| 4 | Polyformaldehyde | 36 | 5 | Yuntianhua Co., Ltd., Chongqing, China |

| 5 | Polyformaldehyde | 36 | 7 | Yuntianhua Co., Ltd., Chongqing, China |

| 6 | Polyformaldehyde | 36 | 9 | Yuntianhua Co., Ltd., Chongqing, China |

| 7 | Polyformaldehyde | 42 | 5 | Yuntianhua Co., Ltd., Chongqing, China |

| 8 | Polyformaldehyde | 42 | 7 | Yuntianhua Co., Ltd., Chongqing, China |

| 9 | Polyformaldehyde | 42 | 9 | Yuntianhua Co., Ltd., Chongqing, China |

| Blank control group | - | 0 | 0 | - |

| Number | Fiber Ratio | Hydrostatic Pressure (MPa) |

|---|---|---|

| 1 | 30 mm—5 kg/m3 | 0.8 |

| 2 | 30 mm—7 kg/m3 | 0.8 |

| 3 | 30 mm—9 kg/m3 | 0.7 |

| 4 | 36 mm—5 kg/m3 | 0.8 |

| 5 | 36 mm—7 kg/m3 | 0.7 |

| 6 | 36 mm—9 kg/m3 | 0.7 |

| 7 | 42 mm—5 kg/m3 | 0.8 |

| 8 | 42 mm—7 kg/m3 | 0.7 |

| 9 | 42 mm—9 kg/m3 | 0.7 |

| Blank control group | 0 | 0.7 |

| Boundary | System | Series | Group | Designation | Thickness (m) |

|---|---|---|---|---|---|

| Cenozoic erathem | Quaternary system | Q | <20 | ||

| Paleozoic erathem Pt | Permian system | Lower series | Tipping group | P1d | 3.5~16.5 |

| Carboniferous system | Middle series | Weining formation | C2w | 25~30 | |

| Lower series | Datang formation | C1d | 9~28 | ||

| Devonian system | Upper series | Zage formation | D3z | 40.41~153.52 | |

| Middle series | Haikou formation | D2h | 5.16~28.93 | ||

| Cambrian system | Lower series | Canglangpu formation | Є1c | 10~66.89 | |

| Zhusi formation | Є1q | 121.72~272.45 | |||

| Zhongyi Village formation | Є1z | 2.86~29.76 | |||

| Yuhu Village formation | Є1y | 101~170 | |||

| Algonkian Pt | Sinian system | Upper series | Intercept of isochron | Z2dn | 200~270 |

| Rock | Thickness (m) | Bulk Modulus (GPa) | Shear Modulus (GPa) | Tensile Strength (MPa) | Cohesive Force (MPa) | Angle of Internal Friction (°) |

|---|---|---|---|---|---|---|

| dolomite | \ | 21.43 | 6.62 | 1.3 | 2.35 | 43.8 |

| sandstone | 9.28 | 14.04 | 6.11 | 1.6 | 1.09 | 43.3 |

| shale | 46.81 | 13.33 | 8.00 | 3.3 | 4.37 | 47.2 |

| mudstone | 3.17 | 11.31 | 7.79 | 2.6 | 2.35 | 43.3 |

| dolomitic siltstone | 8.00 | 12.00 | 7.20 | 1.5 | 2.38 | 43.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sang, Y.; Wang, G. Study on Seepage Effect of Roadway Based on Polyformaldehyde (POM) Fiber Concrete. Appl. Sci. 2025, 15, 3503. https://doi.org/10.3390/app15073503

Sang Y, Wang G. Study on Seepage Effect of Roadway Based on Polyformaldehyde (POM) Fiber Concrete. Applied Sciences. 2025; 15(7):3503. https://doi.org/10.3390/app15073503

Chicago/Turabian StyleSang, Yongshuai, and Guangjin Wang. 2025. "Study on Seepage Effect of Roadway Based on Polyformaldehyde (POM) Fiber Concrete" Applied Sciences 15, no. 7: 3503. https://doi.org/10.3390/app15073503

APA StyleSang, Y., & Wang, G. (2025). Study on Seepage Effect of Roadway Based on Polyformaldehyde (POM) Fiber Concrete. Applied Sciences, 15(7), 3503. https://doi.org/10.3390/app15073503