Permeability of Broken Coal Around CBM Drainage Boreholes with the Compound Disaster of the Rockburst and Outburst

Abstract

1. Introduction

2. Materials and Methods

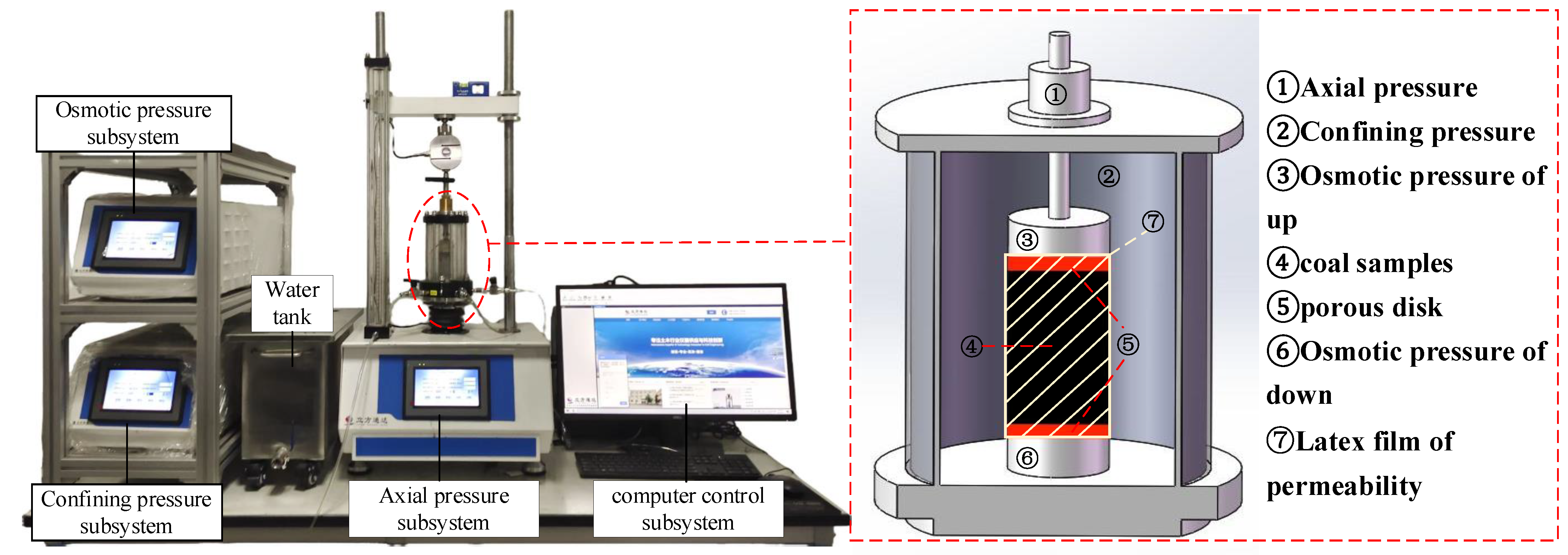

2.1. Instruments

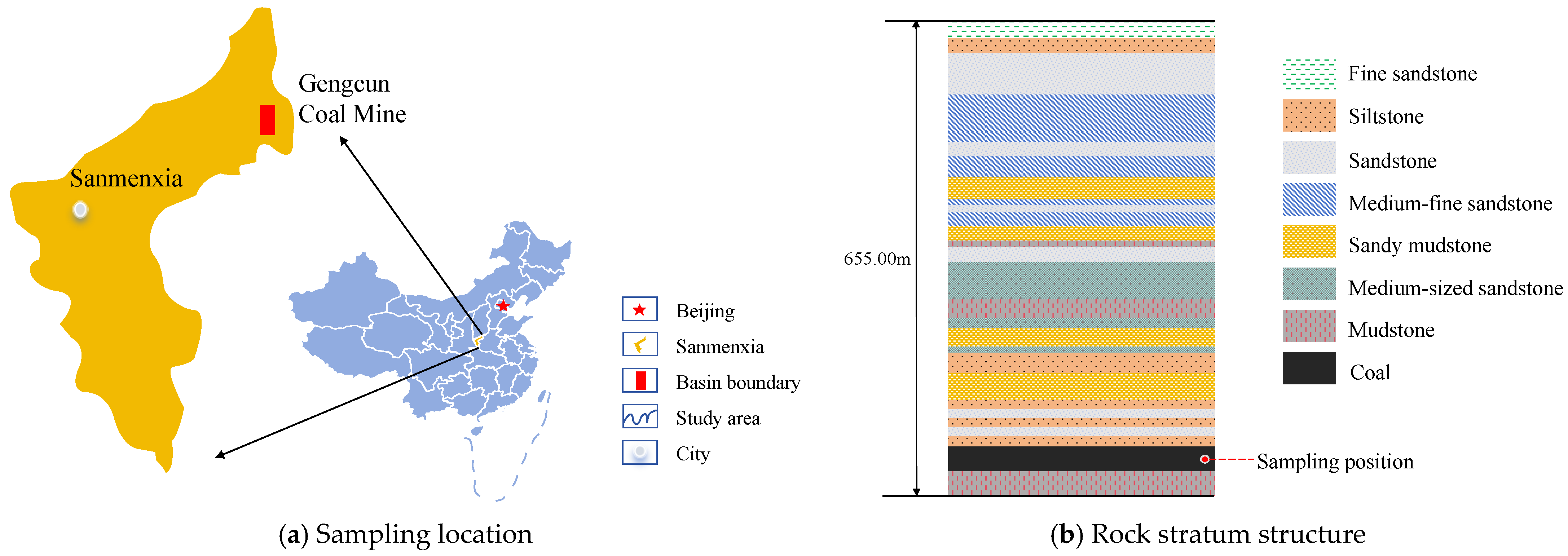

2.2. Specimen Preparation

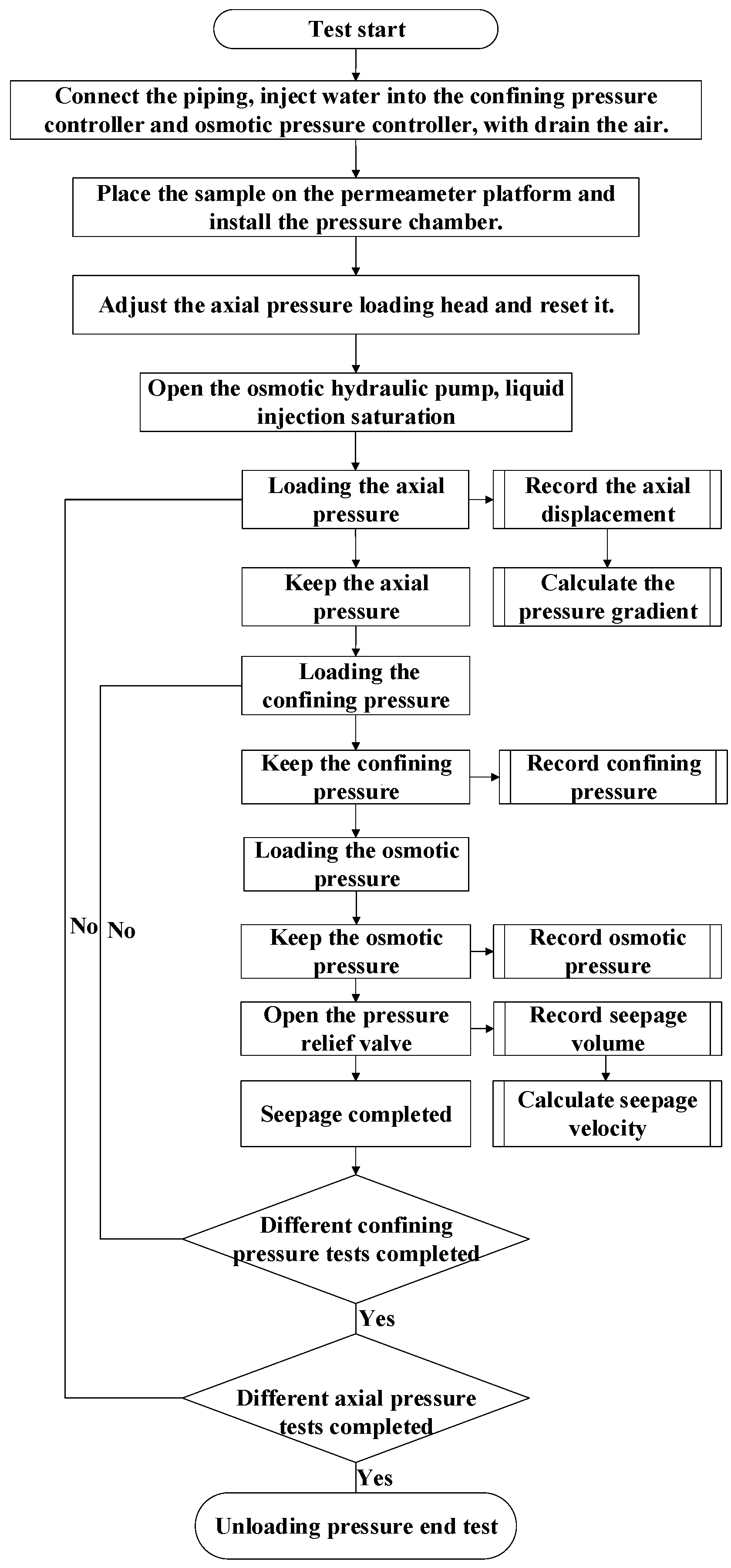

2.3. Test Procedure

3. Results

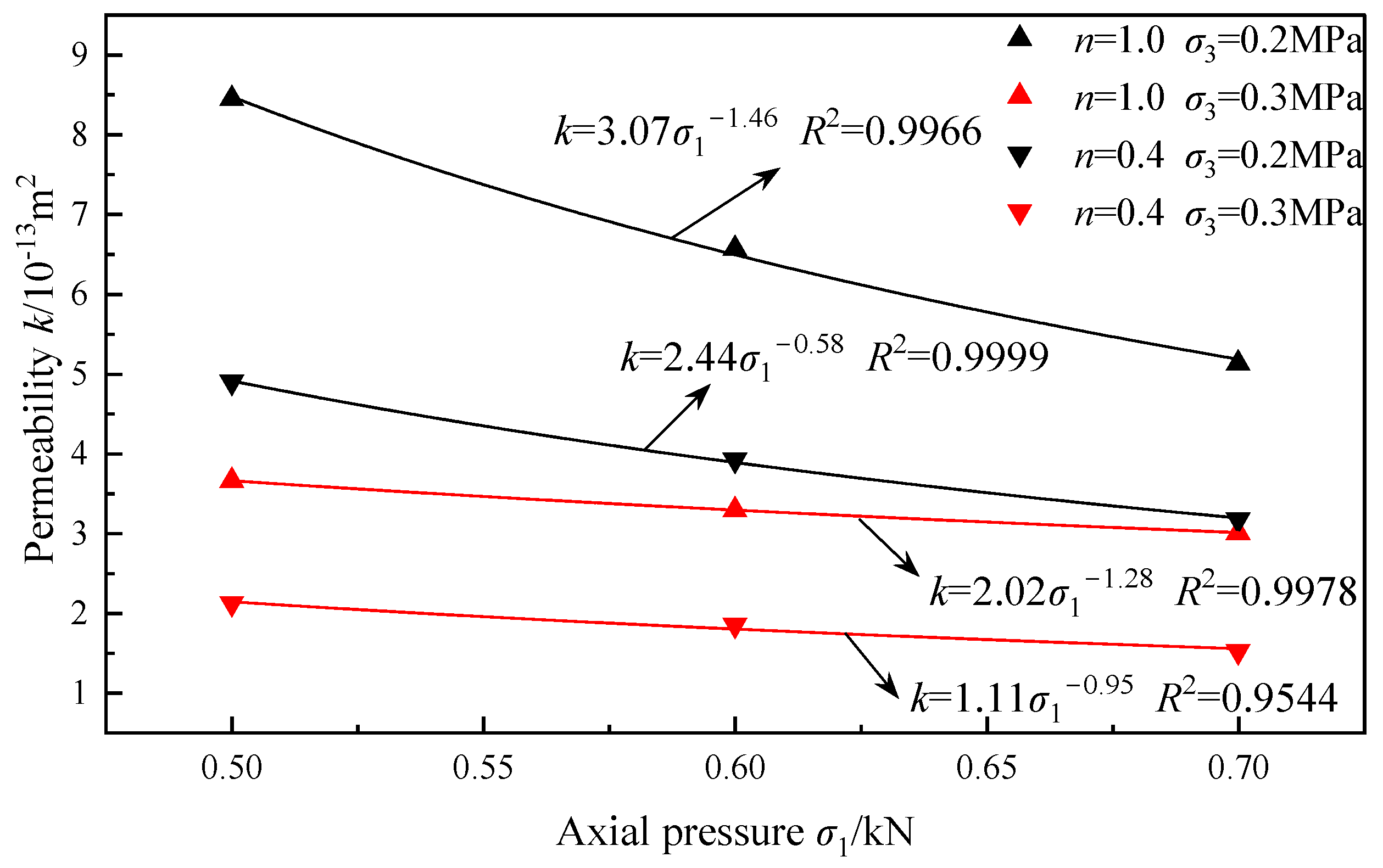

3.1. Effect of Axial Pressure on Permeability

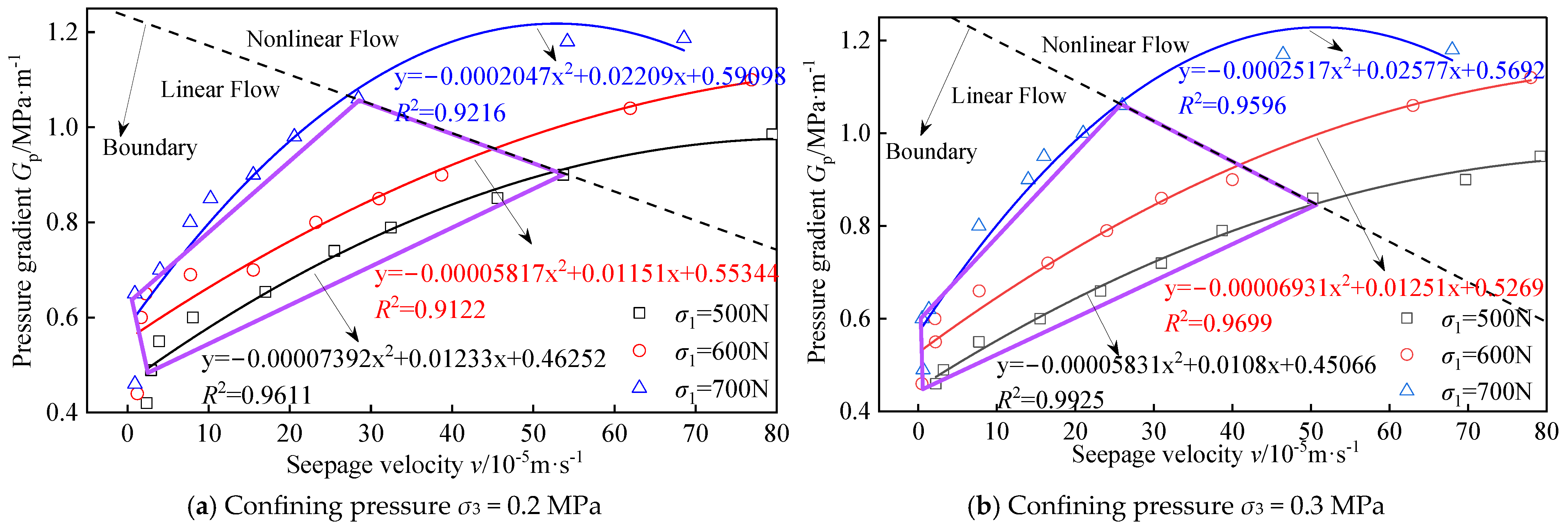

3.2. Effect of Axial Pressure on Seepage Velocity

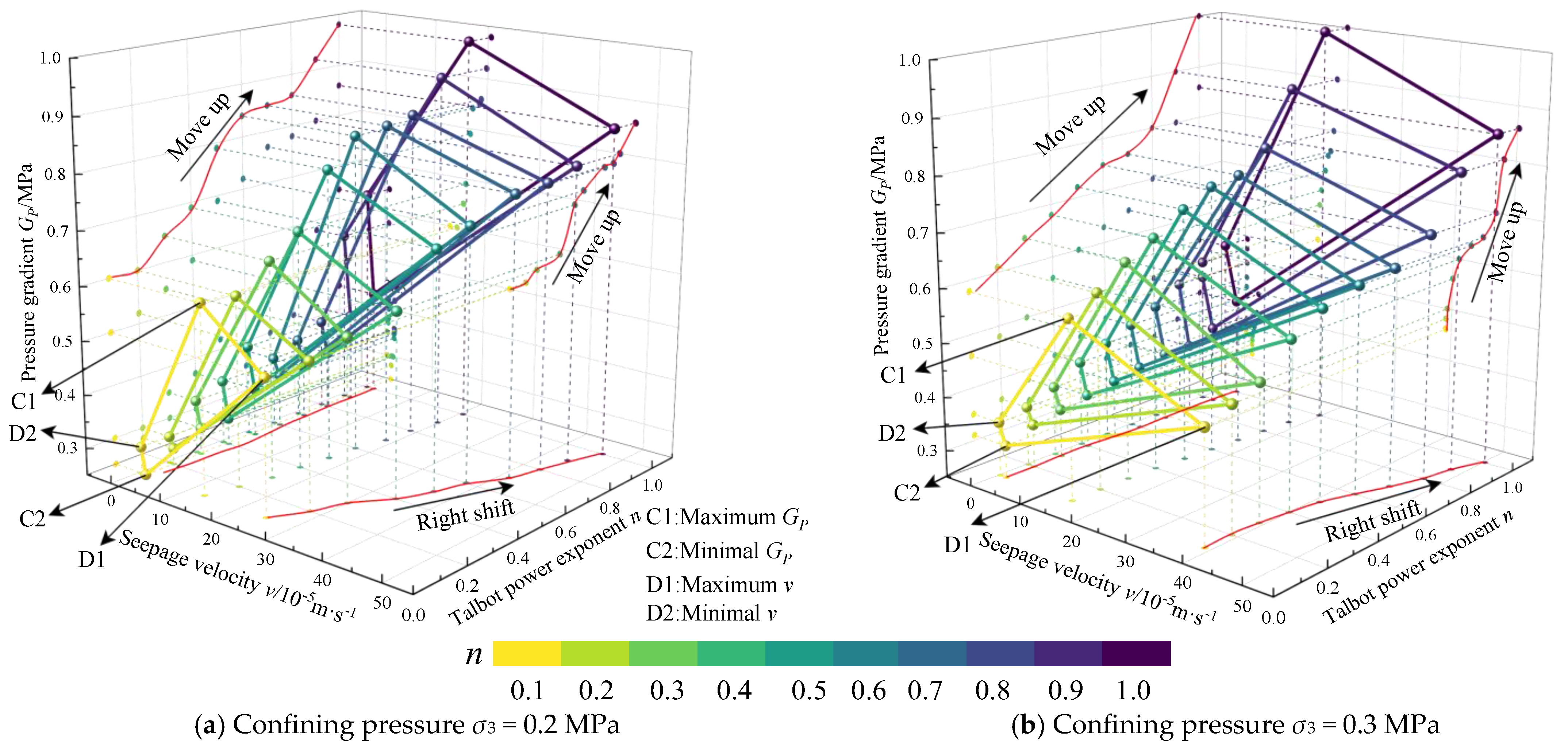

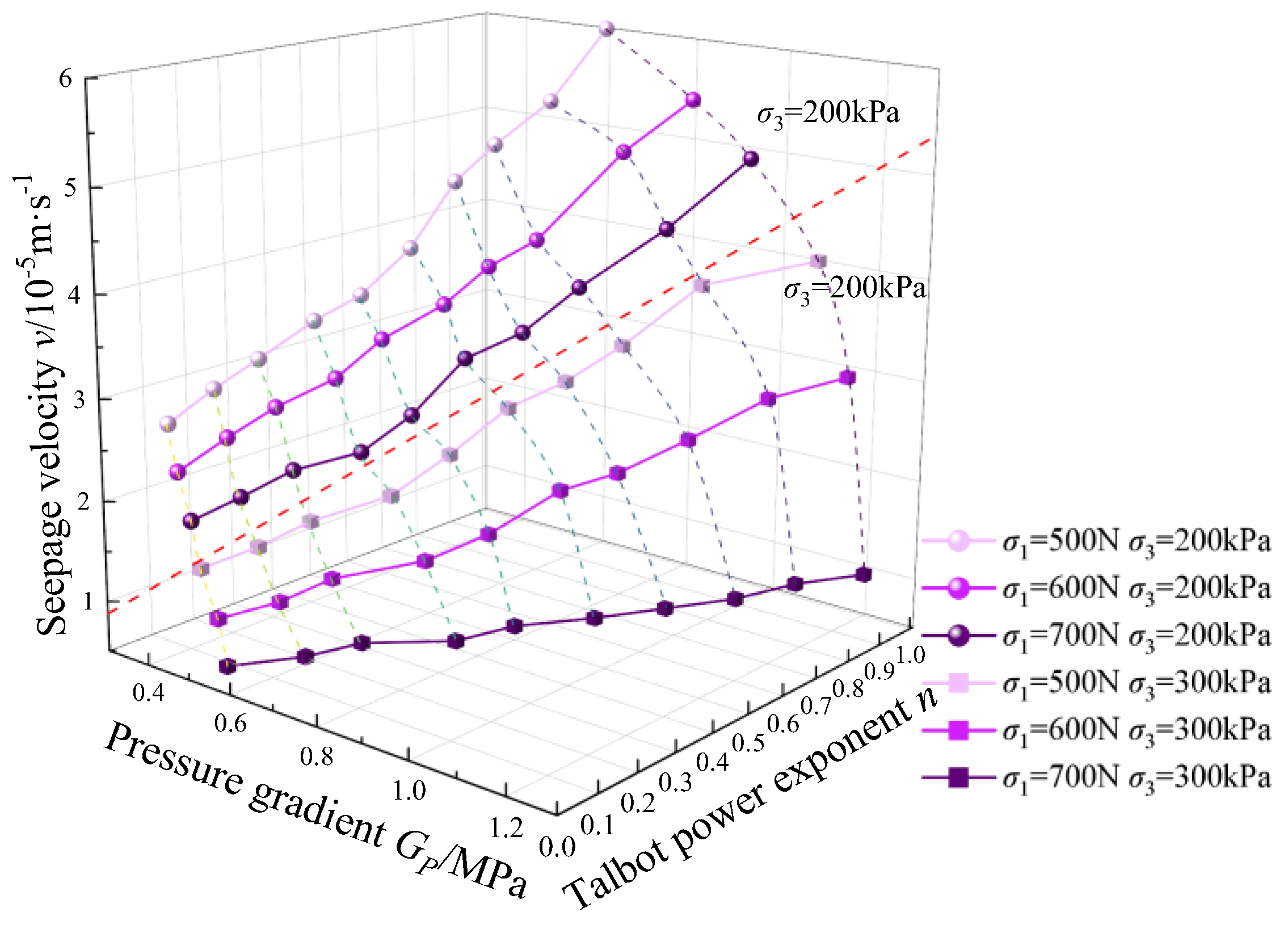

3.3. The Influence of Talbot Power Exponent on Seepage Velocity

3.4. The Influence of Talbot Power Exponent on Permeability

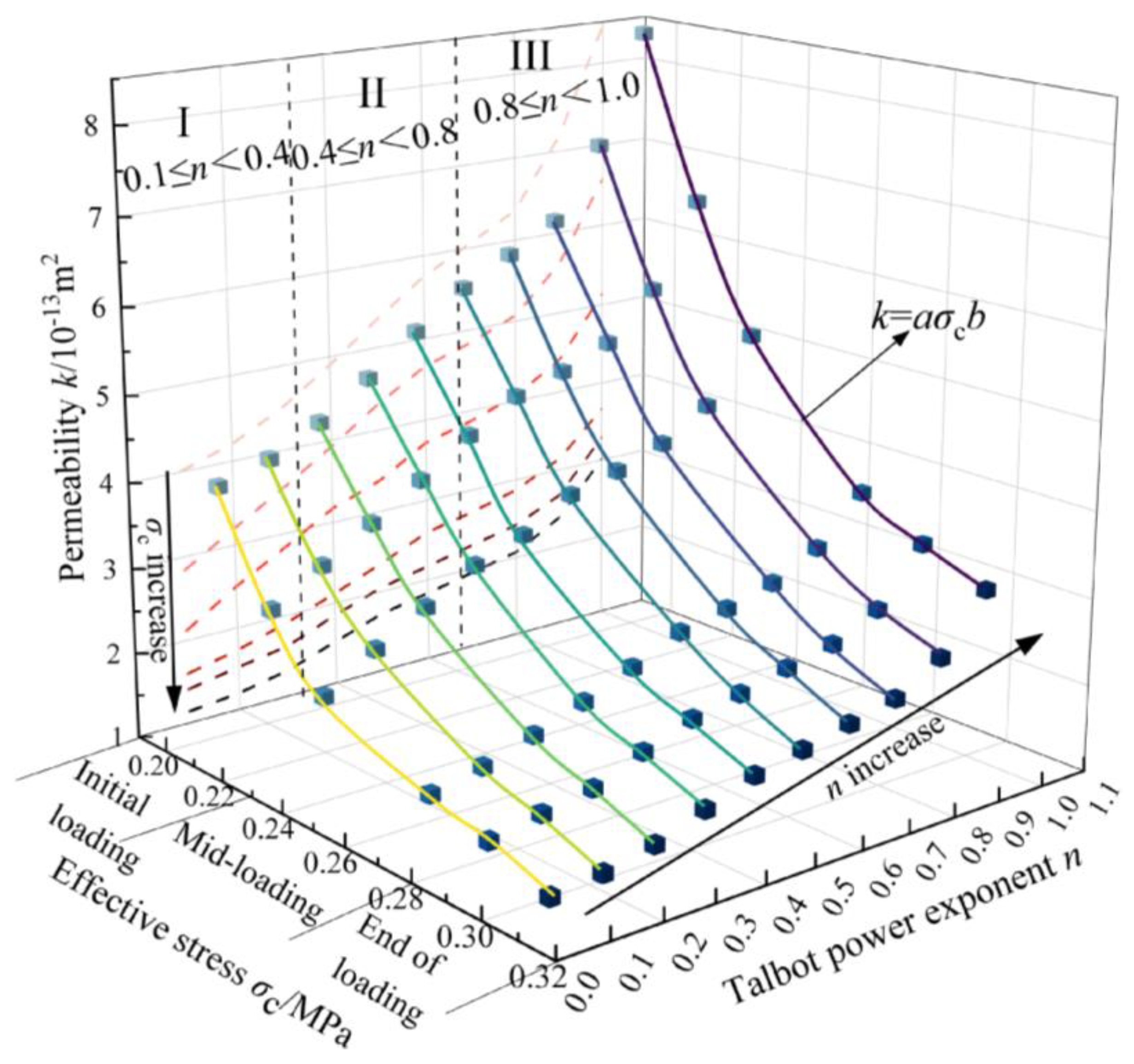

3.5. Permeability in the Coordination of the Effective Stress

3.6. Considering the Permeability Law of Gradation and Effective Stress

4. Conclusions

- (1)

- A specific correlation exists between the permeability of broken coal and axial pressure. Axial pressure affects permeability by altering the pore structure of broken coal samples. During the loading process, as the axial pressure increases, the permeability of broken coal decreases exponentially. This decrease is accompanied by the compression of the pore structure, the gradual closure of permeability channels, and a consequent decrease in permeability.

- (2)

- A specific correlation also exists between the permeability of broken coal and the Talbot power exponent. As the Talbot power exponent (n) of the broken coal samples increases from 0.1 to 1.0, the permeability (k) shows a three-stage growth pattern. In the initial stage, the permeability increases slowly due to the predominance of smaller particle sizes. In the second stage, as the proportion of larger particles increases, the permeability increases linearly. In the third stage, with the dominance of larger particle sizes, the permeability exhibits exponential growth.

- (3)

- The seepage velocity may be influenced by the combined effect of the Talbot power exponent, pressure gradient, confining pressure, and axial pressure. Of these factors, the pressure gradient may have the most significant effect. The Talbot power exponent enhances the seepage velocity, while the axial and confining pressures inhibit it.

- (4)

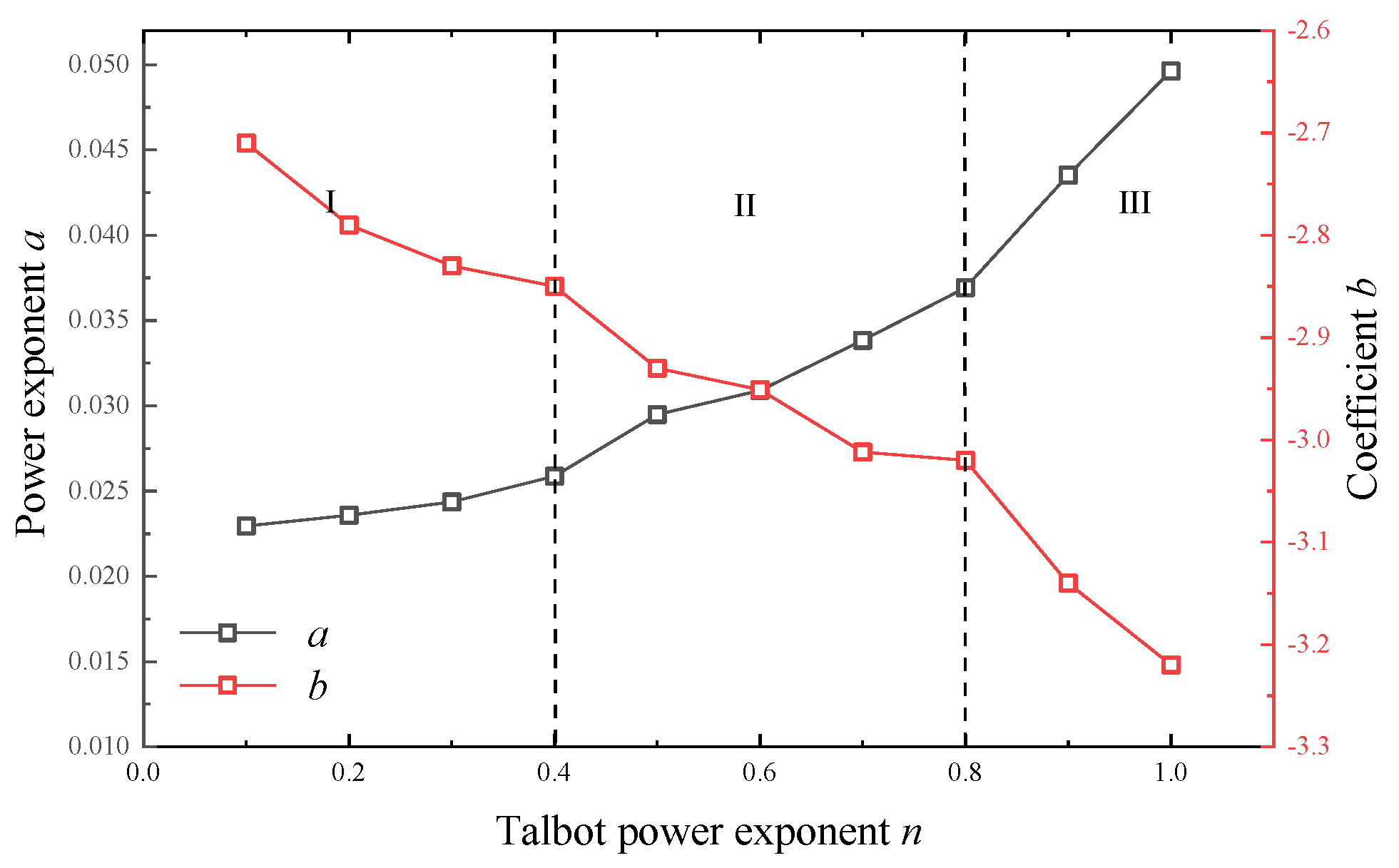

- The permeability of broken coal with different Talbot power exponents typically exhibits an exponential decay as the effective stress increases. Both the parameters and the permeability-Talbot power exponent curve display three stages. As the Talbot power exponent increases, the power exponent (a) gradually decreases, while the coefficient (b) increases. This indicates that broken particles increase both the inhibitory effect of the effective stress and the amplitude effect.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| d | pore diameter of the sieve |

| D | maximum particle size |

| n | Talbot power exponent |

| Pi | proportion of broken coal samples passing through d |

| P1 | pore pressure when the fluid flows into the coal sample |

| μ | hydrodynamic viscosity |

| k | permeability |

| β | non-Darcy factor |

| σc | effective stres |

| σ1 | axial stress |

| v | seepage velocity |

| Q | seepage discharge |

| pk | pore pressure |

| A | cross-sectional area |

| P2 | pore pressure when the fluid flows out of the coal sample |

| H | height of the coal sample |

| ρ | fluid density |

| σ3 | confining pressure |

| a | power exponent |

| b | coefficient |

References

- Aristizabal-H, G.; Goerke-Mallet, P.; Kretschmann, J.; Restrepo-Baena, O.J. Sustainability of coal mining. Is Germany a post-mining model for Colombia? Resour. Policy 2023, 81, 103358. [Google Scholar]

- Lyu, J.; Li, S.; Pan, Y.; Tang, Z. Promoting Sustainable Coal Mining: Investigating Multifractal Characteristics of Induced Charge Signals in Coal Damage and Failure Process. Sustainability 2024, 16, 3127. [Google Scholar] [CrossRef]

- Du, J.; Dabuo, F.T.; Madzikanda, B.; Boamah, K.B. The Influence of R&D in Mining on Sustainable Development in China. Sustainability 2021, 13, 5289. [Google Scholar] [CrossRef]

- Hu, L.J.; Feng, Z.C.; Zhou, D.; Wang, X. Mechanisms and field application of in-situ heat injection-enhanced gas drainage. Energy 2023, 284, 128729. [Google Scholar]

- Zhang, X.G.; Ranjith, P.G.; Perera, M.S.A.; Ranathunga, A.S.; Haque, A. Gas Transportation and Enhanced Coalbed Methane Recovery Processes in Deep Coal Seams: A Review. Energy Fuels 2016, 30, 8832–8849. [Google Scholar] [CrossRef]

- Yarmohammadtooski, Z.; Salmachi, A.; White, A.; Rajabi, M. Fluid flow characteristics of Bandanna Coal Formation: A case study from the Fairview Field, eastern Australia. Aust. J. Earth Sci. 2017, 64, 319–333. [Google Scholar]

- Li, G.; Qin, Y.; Yao, H.; Qu, J.; Zhang, H.; Fang, X.; Shang, F.; Zhang, L. 3D pore structure characterization and permeability anisotropy visualization simulation of fusain. Energy 2024, 291, 130422. [Google Scholar] [CrossRef]

- Lin, B.; Song, H.; Zhao, Y.; Liu, T.; Kong, J.; Huang, Z. Significance of gas flow in anisotropic coal seams to underground gas drainage. J. Pet. Sci. Eng. 2019, 180, 808–819. [Google Scholar]

- Savadogo, N.; Messan, A.; Hannawi, K.; Prince Agbodjan, W.; Tsobnang, F. Durability of Mortar Containing Coal Bottom Ash as a Partial Cementitious Resource. Sustainability 2020, 12, 8089. [Google Scholar] [CrossRef]

- Ren, C.; Li, B.; Xu, J.; Zhang, Y.; Li, J.; Gao, Z.; Yu, J. A Novel Damage-Based Permeability Model for Coal in the Compaction and Fracturing Process Under Different Temperature Conditions. Rock Mech. Rock Eng. 2020, 53, 5697–5713. [Google Scholar] [CrossRef]

- Pan, H.; Zhang, Y.; Zhang, L.; Cao, Y.; Chu, Y.; Yang, S. Permeability Characteristics of Combined Coal with Different Water Contents. Energies 2025, 18, 200. [Google Scholar] [CrossRef]

- Taha, M.; Patil, P.; Nguyen, Q.P. The effect of rock permeability and pore structure on foam in carbonate rocks. Fuel 2023, 346, 128246. [Google Scholar]

- Wang, J.H.; Wang, Y.; Wan, Z.J.; Zhang, H.W.; Cheng, J.Y.; Yan, W.Z. Effects of Stress and Temperature on the Permeability of Gas-Saturated Wet Coal. Energy Fuels 2020, 34, 14535–14547. [Google Scholar]

- Ziegler, M.O.; Heidbach, O.; Zang, A.; Martínez-Garzón, P.; Bohnhoff, M. Estimation of the differential stress from the stress rotation angle in low permeable rock. Geophys. Res. Lett. 2017, 44, 6761–6770. [Google Scholar]

- Ma, D.; Miao, X.X.; Jiang, G.H.; Bai, H.B.; Chen, Z.Q. An experimental investigation of permeability measurement of water flow in crushed rocks. Transp. Porous Media 2014, 105, 571–595. [Google Scholar] [CrossRef]

- Lei, G.H.; Chiu, A.C.F.; Ng, C.W.W. Is Terzaghi’s effective stress a stress variable under permeability conditions? J. Cent. South Univ. 2015, 22, 2316–2321. [Google Scholar] [CrossRef]

- Agheshlui, H.; Sedaghat, M.H.; Matthai, S. Stress influence on fracture aperture and permeability of fragmented rocks. J. Geophys. Res. Solid Earth 2018, 123, 3578–3592. [Google Scholar]

- Shahtalebi, A.; Khan, C.; Dmyterko, A.; Shukla, P.; Rudolph, V. Investigation of thermal stimulation of coal seam gas fields for accelerated gas recovery. Fuel 2016, 180, 301–313. [Google Scholar]

- Wen, P.; Han, S.; Guo, W.; Yang, W.; Bai, E. Study of the Internal Rebreaking Characteristics of Crushed Gangue in Mine Goaf during Compression. Appl. Sci. 2024, 14, 1682. [Google Scholar] [CrossRef]

- Hossein, A. Stress influence on the permeability of a sample heterogeneous rock. Geomech. Geophys. Geo-Energy Geo-Resour. 2019, 5, 159–170. [Google Scholar]

- Zhang, C.; Jin, Z.; Feng, G.; Zhang, L.; Gao, R.; Li, C. Promoting Sustainable Coal Gas Development: Microscopic Seepage Mechanism of Natural Fractured Coal Based on 3D-CT Reconstruction. Sustainability 2024, 16, 4434. [Google Scholar] [CrossRef]

- Soldi, M.; Guarracino, L.; Jougnot, D. The effect of pore geometry in constitutive hysteretic models for unsaturated water flow. Environ. Fluid Mech. 2022, 22, 1283–1305. [Google Scholar] [CrossRef]

- Kelsey, L.; Kleinhans, A.R. Jackson. Hydraulic permeability of meniscus fibrocartilage measured via direct permeation: Effects of tissue anisotropy, water volume content, and compressive strain. J. Biomech. 2018, 72, 215–221. [Google Scholar]

- Guo, J.; Wang, L.; Ding, K.; Jiang, C.; Wang, S.; Ren, B. A Preliminary Experimental Study on the Effect of Confining Pressure or Gas Pressure on the Permeability of Coal Samples. Minerals 2022, 12, 1265. [Google Scholar] [CrossRef]

- Bandyopadhyay, K.; Mallik, J.; Shajahan, R.; Agarwal, N. Closing the gap between analytical and measured coal permeability. Fuel 2020, 281, 118752. [Google Scholar] [CrossRef]

- Shi, L.; Zhou, H.; Gao, Y.; Lu, J.; Li, Q. Experimental study on the acoustic emission response and permeability evolution of tunnel lining concrete during deformation and failure. Eur. J. Environ. Civ. Eng. 2020, 26, 3398–3417. [Google Scholar] [CrossRef]

- Bai, X.; Wang, Y.; He, G.; Zhou, Z.; Wang, D.; Zhang, D. Research on a permeability model of coal damaged under triaxial loading and unloading. Fuel 2023, 354, 129375. [Google Scholar] [CrossRef]

- Kami, V.B.; Mishra, A. Microstructural Analysis of Creep Behavior in Soft Clays during Cyclic Loading and Unloading. Geotech. Geol. Eng. 2024, 42, 7597–7615. [Google Scholar] [CrossRef]

- Kibikas, W.M.; Choens, R.C.; Bauer, S.J.; Shalev, E.; Lyakhovsky, V. Water-Weakening and Time-Dependent Deformation of Organic-Rich Chalks. Rock Mech. Rock Eng. 2023, 56, 8041–8059. [Google Scholar] [CrossRef]

- Li, B.; Wei, J.P.; Wang, K.; Li, P.; Wang, K. A method of determining the permeability coefficient of coal seam based on the permeability of loaded coal. Int. J. Min. Sci. Technol. 2014, 24, 637–641. [Google Scholar] [CrossRef]

- Meng, F.; Liu, W.; Pu, H.; Li, M.; Chen, Y. The Influence of Grain Size Gradation on Deformation and the Void Structure Evolution Mechanism of Broken Rock Mass in the Goaf. Appl. Sci. 2024, 14, 6764. [Google Scholar] [CrossRef]

- Pang, M.K.; Zhang, T.J.; Ji, X.; Wu, J.Y.; Song, S. Measurement of the coefficient of permeability characteristics in pore-crushed coal bodies around gas drainage boreholes. Energy 2022, 254, 124276. [Google Scholar]

- Li, B.; Zou, Q.; Liang, Y. Experimental Research into the Evolution of Permeability in a Broken Coal Mass under Cyclic Loading and Unloading Conditions. Appl. Sci. 2019, 9, 762. [Google Scholar] [CrossRef]

- Tyler, S.W.; Wheatcraft, S.W. Wheatcraft. Fractal Scaling of Soil Particle-Size Distributions: Analysis and Limitations. Soil Sci. Soc. Am. J. 1992, 56, 362–369. [Google Scholar] [CrossRef]

- Cai, J.; Song, C.; Gong, X.B.; Zhang, J.P.; Pei, J.Z.; Chen, Z.W. Gradation of limestone-aggregate-based porous asphalt concrete under dynamic crushing test: Composition, fragmentation and stability. Constr. Build. Mater. 2022, 323, 126532. [Google Scholar]

- Xiao, Y.J.; Chen, L.X.; Zhang, Z.; Lv, D.Q.; Tutumluer, E.; Zhang, J.S. Laboratory validation of a gradation design concept for sustainable applications of unbound granular materials in pavement construction. Constr. Build. Mater. 2016, 129, 125–139. [Google Scholar]

- Pang, M.K.; Zhang, T.J.; Li, Y.; Song, S. Experimental investigation of water-gas mixed permeability parameters characteristics in broken coal medium. Energy Rep. 2022, 8, 281–289. [Google Scholar]

- Zhang, T.; Wu, J.; Pang, M.; Zhang, L.; Meng, Y.; Liu, R. Experimental study on distribution characteristics of seepage resistance of coal body around extraction borehole. J. Min. Saf. Eng. 2024, 41, 645–654. (In Chinese) [Google Scholar]

- Kang, H.P.; Yi, B.D.; Gao, F.Q.; LÜ, H. Geostress database and geostress distribution law in underground coal mines in China. J. Coal 2019, 44, 23–33. (In Chinese) [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Yang, S.; Pan, H.; Zhang, T. Permeability of Broken Coal Around CBM Drainage Boreholes with the Compound Disaster of the Rockburst and Outburst. Appl. Sci. 2025, 15, 3439. https://doi.org/10.3390/app15073439

Zhang L, Yang S, Pan H, Zhang T. Permeability of Broken Coal Around CBM Drainage Boreholes with the Compound Disaster of the Rockburst and Outburst. Applied Sciences. 2025; 15(7):3439. https://doi.org/10.3390/app15073439

Chicago/Turabian StyleZhang, Lei, Shihua Yang, Hongyu Pan, and Tianjun Zhang. 2025. "Permeability of Broken Coal Around CBM Drainage Boreholes with the Compound Disaster of the Rockburst and Outburst" Applied Sciences 15, no. 7: 3439. https://doi.org/10.3390/app15073439

APA StyleZhang, L., Yang, S., Pan, H., & Zhang, T. (2025). Permeability of Broken Coal Around CBM Drainage Boreholes with the Compound Disaster of the Rockburst and Outburst. Applied Sciences, 15(7), 3439. https://doi.org/10.3390/app15073439