Design and Comparative Analysis of a Ground-Level Trellising Tool for Greenhouse Tomato Cultivation

Abstract

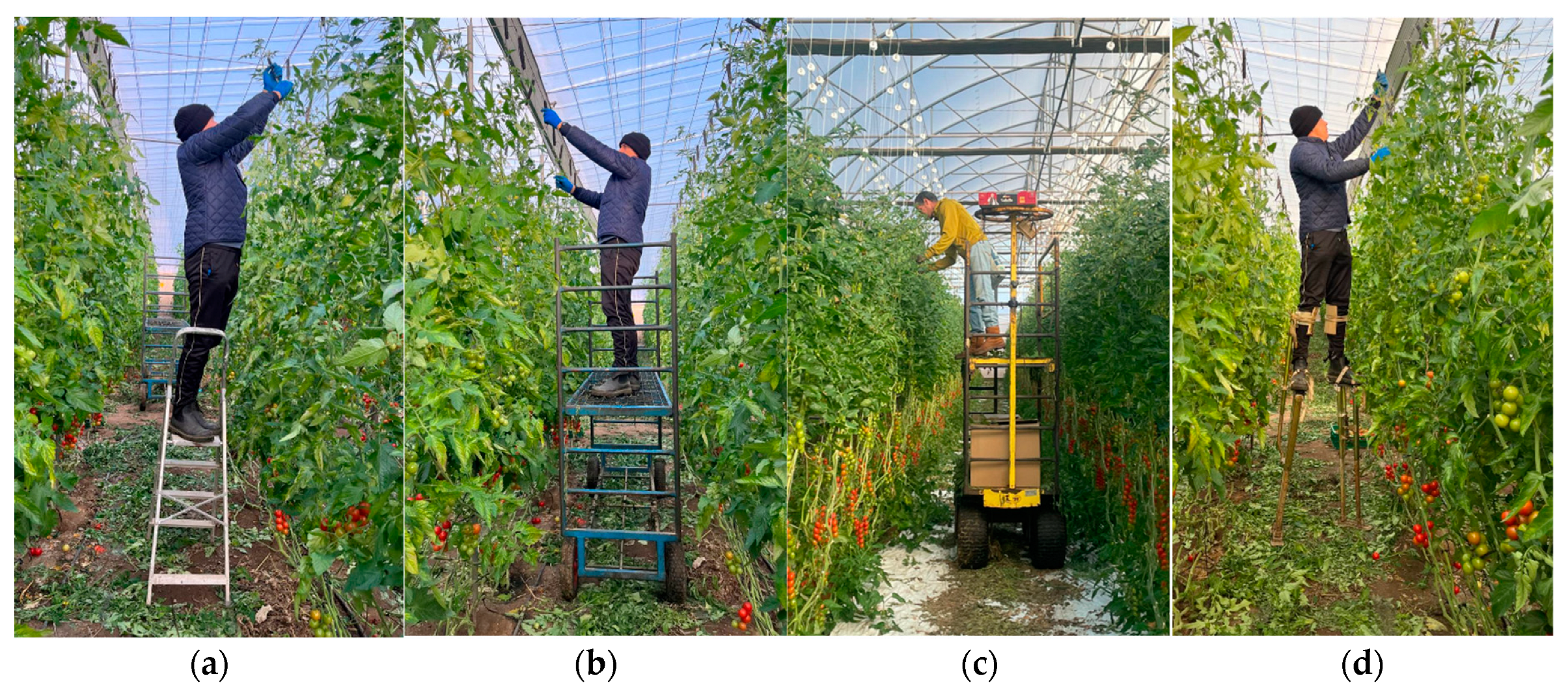

1. Introduction

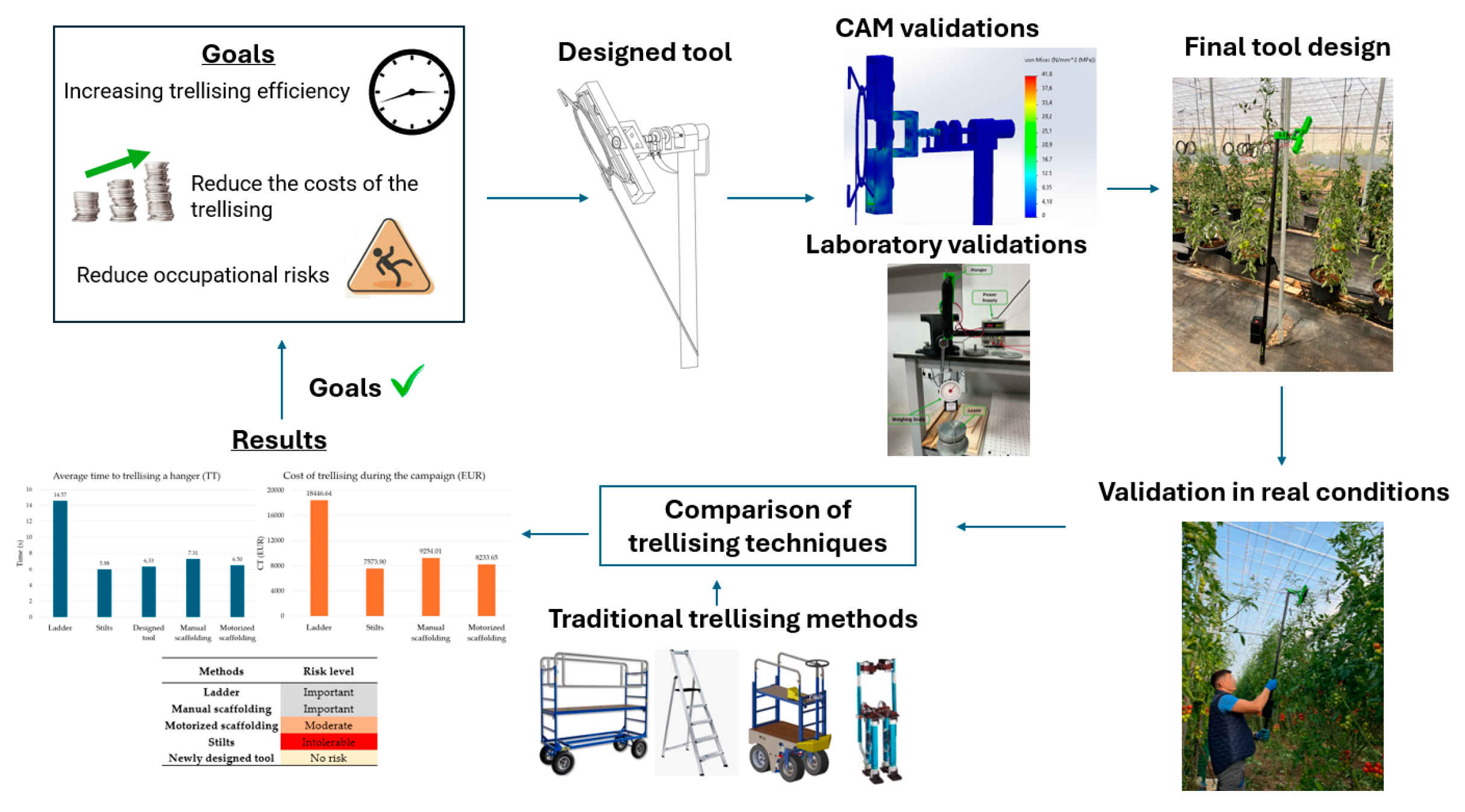

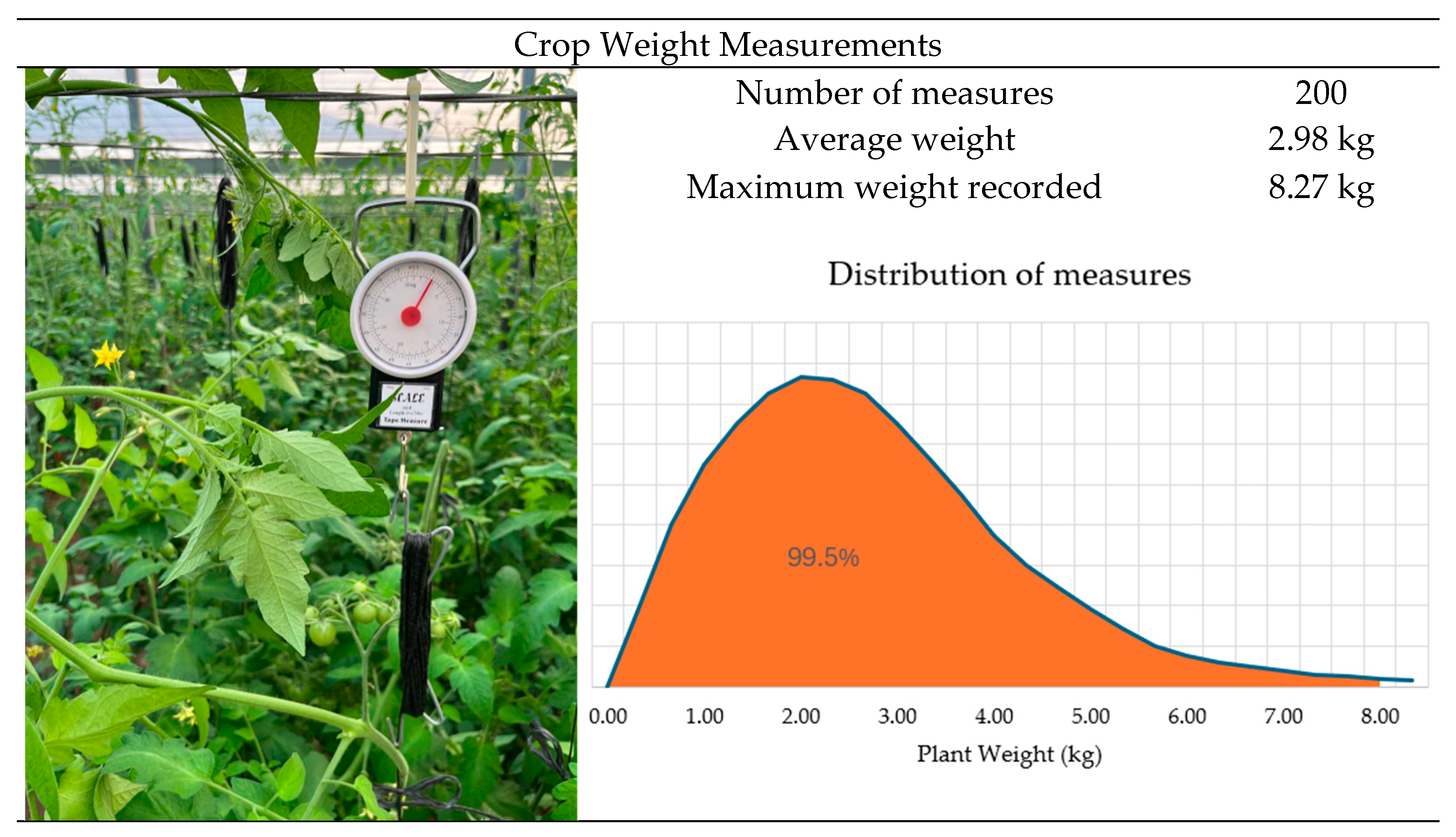

2. Materials and Methods

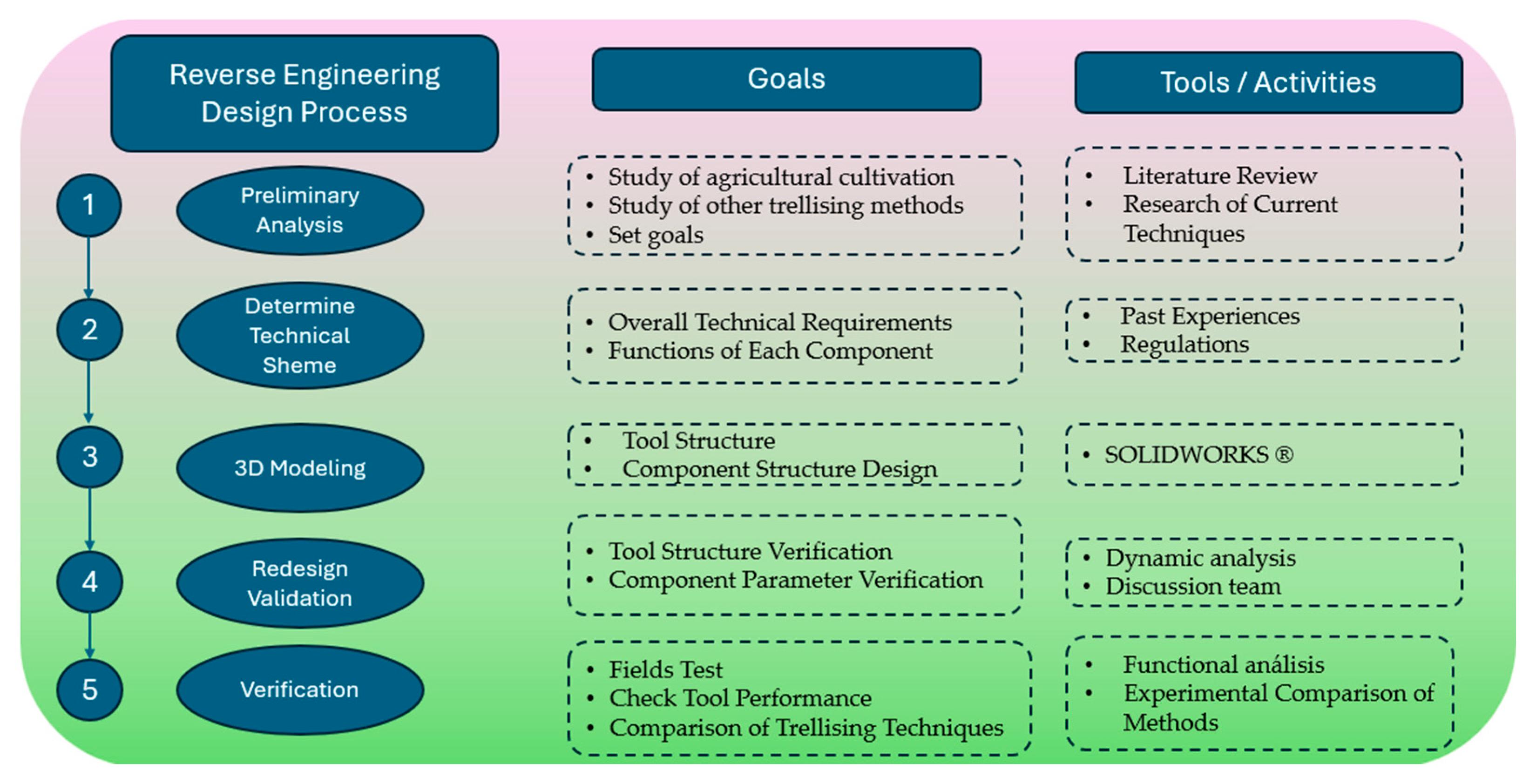

2.1. Research Method

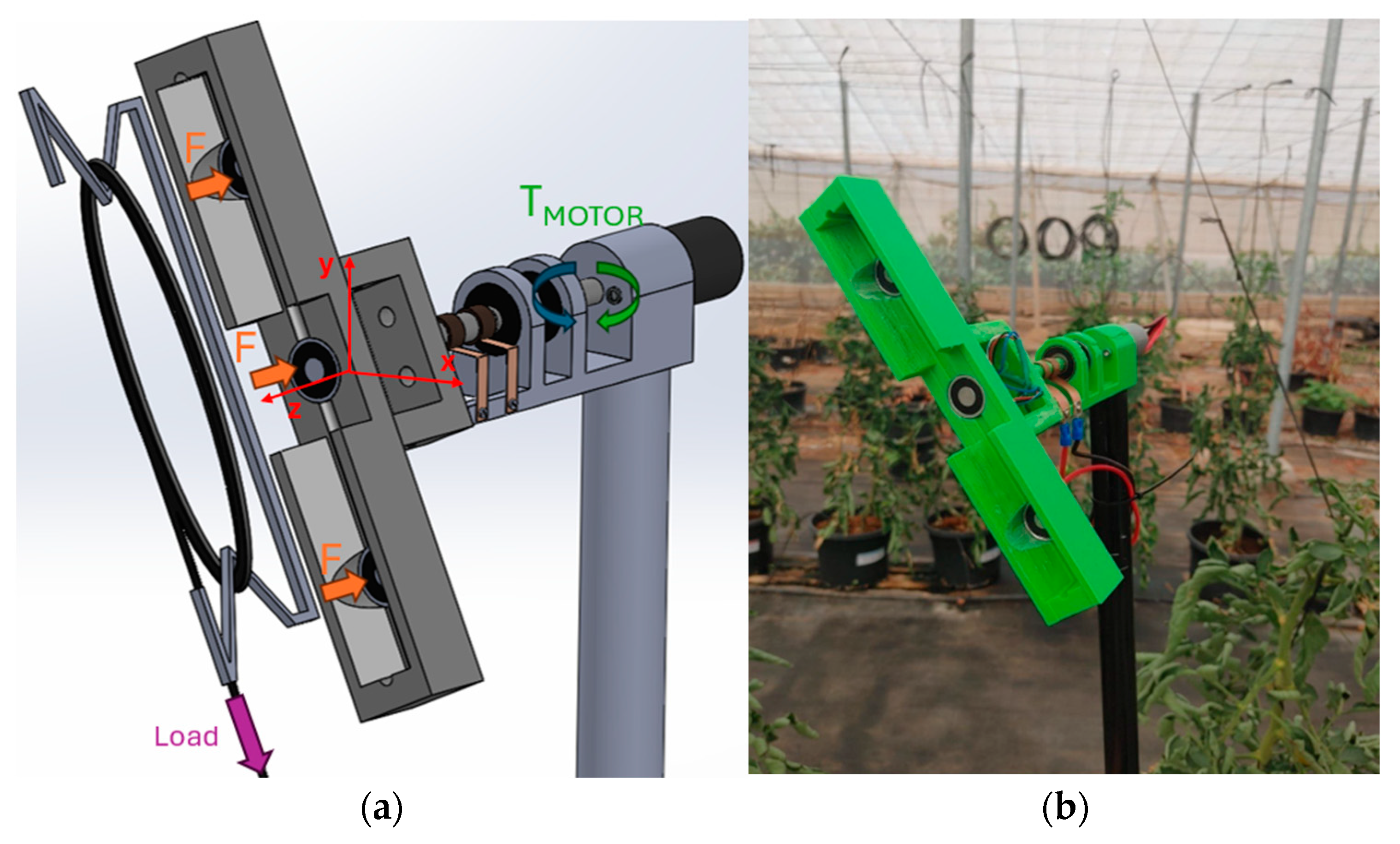

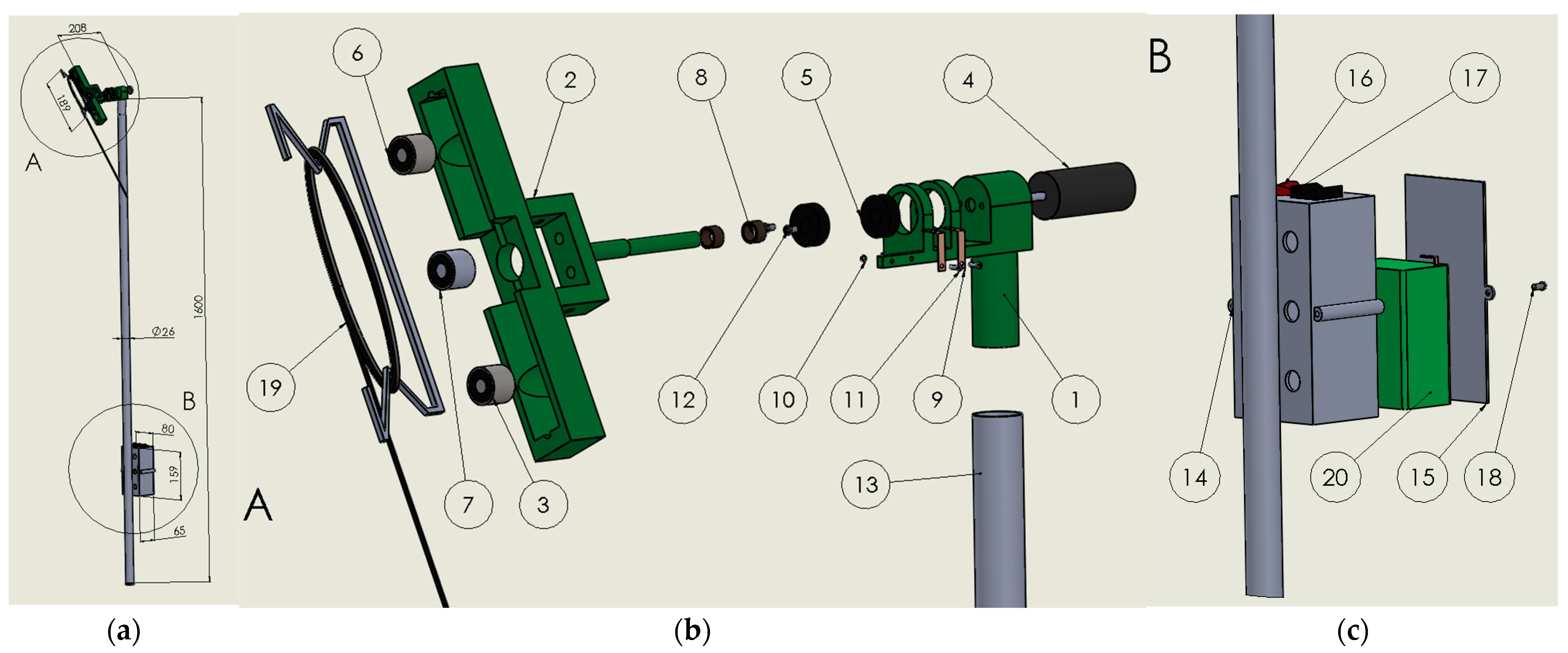

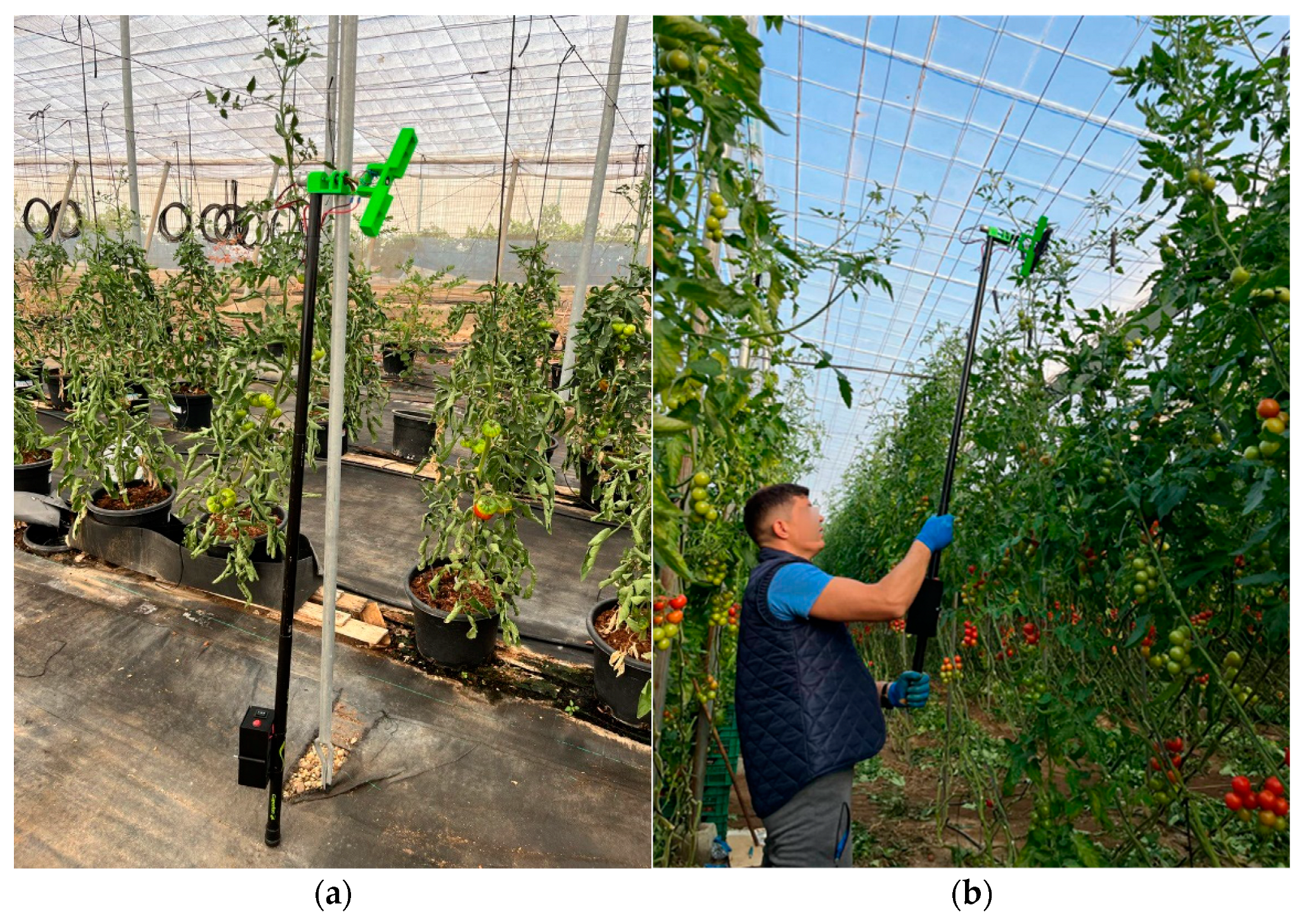

2.2. Description of the Machine’s Design and Operation

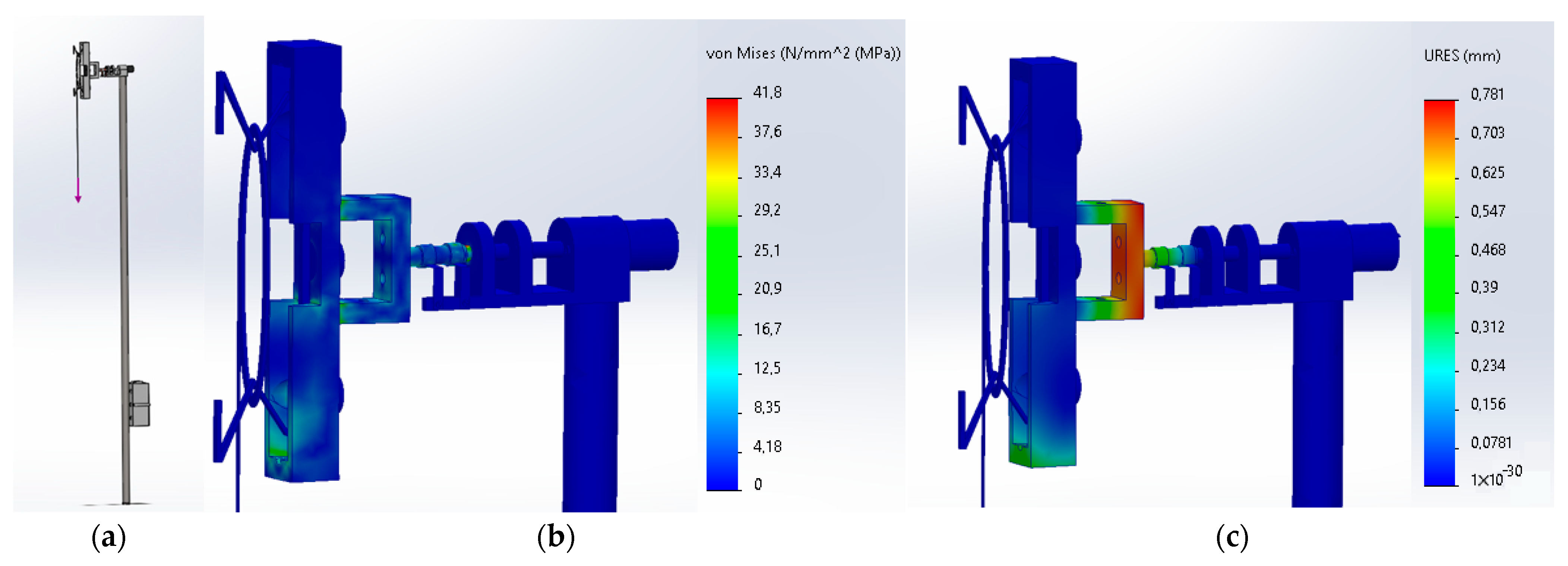

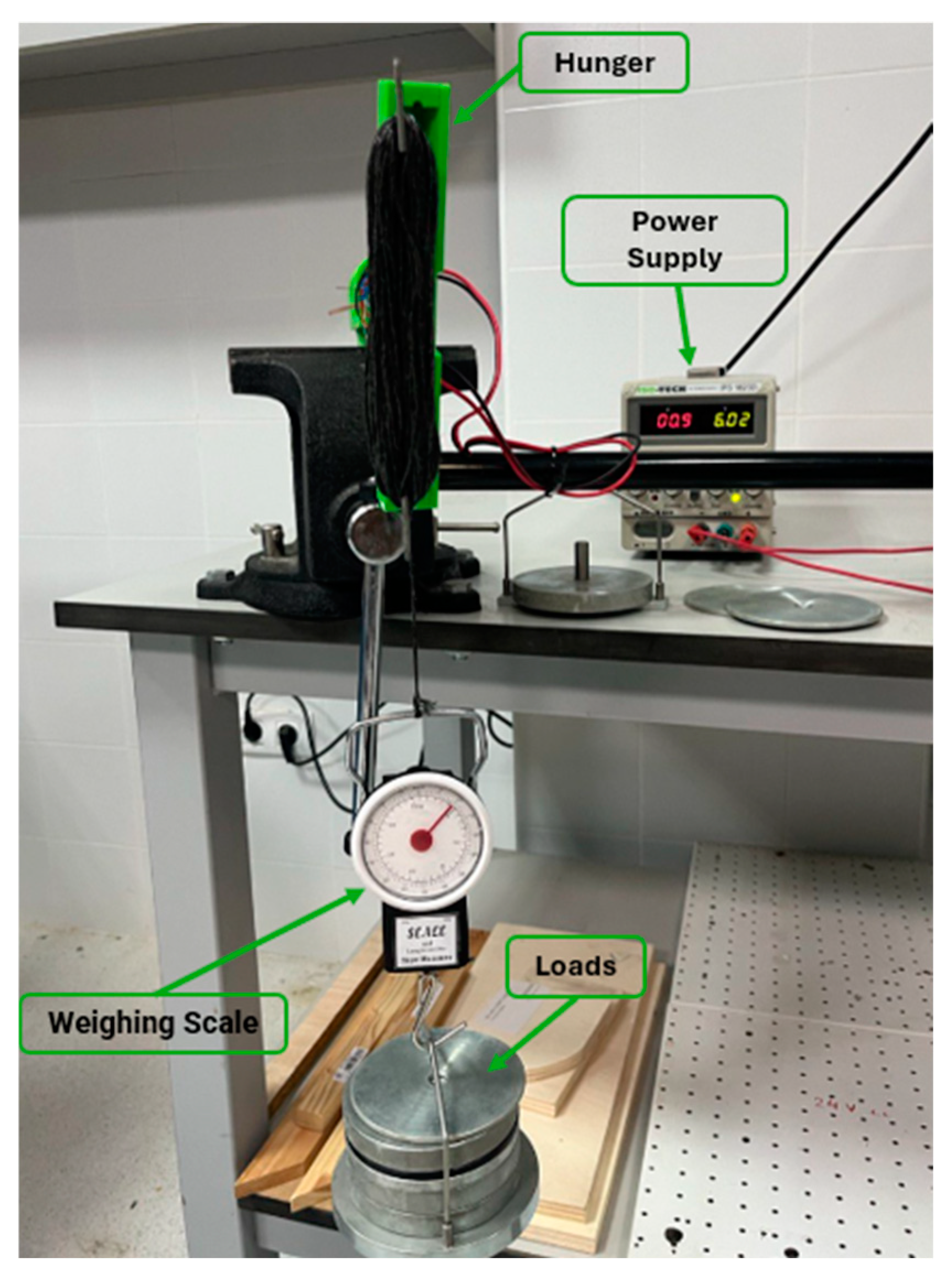

2.3. Methodology for Design Validation

2.4. Methods of Analysis and Experimentation

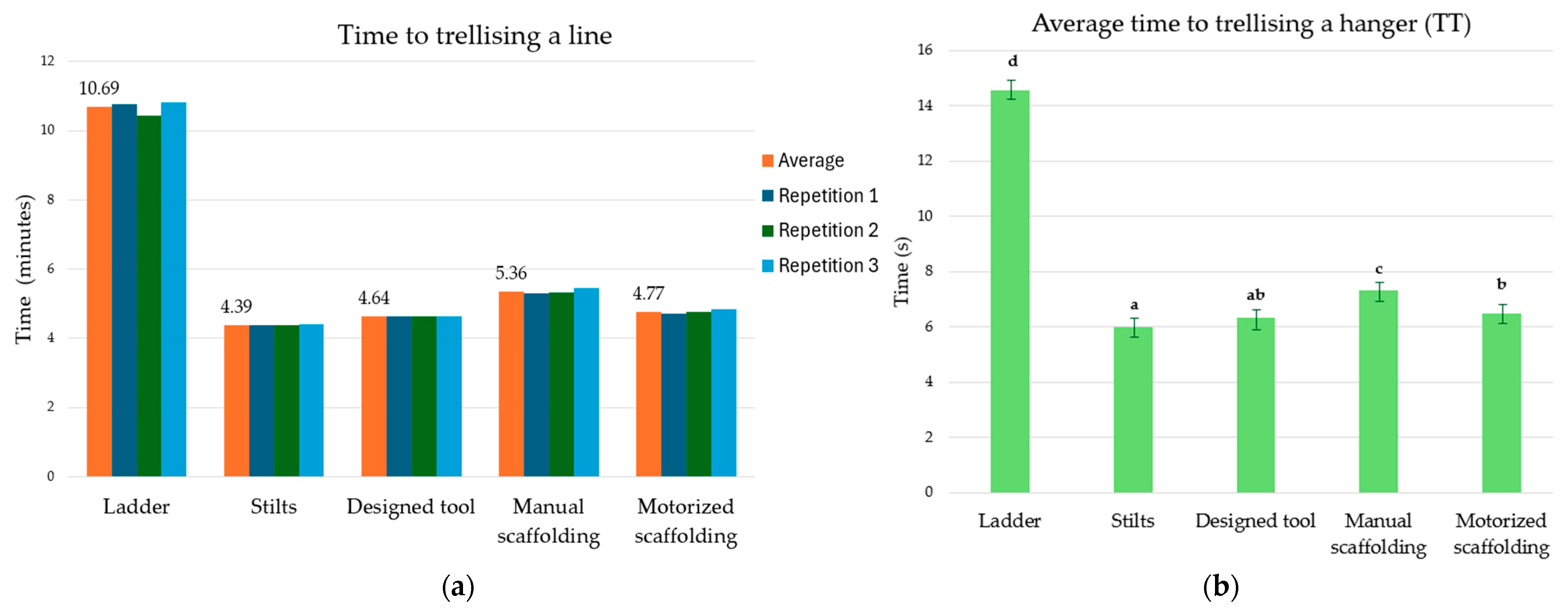

2.4.1. Comparison of Trellising Times According to the Trellising Method

2.4.2. Comparison of Trellising Costs During an Agricultural Campaign According to the Trellising Method

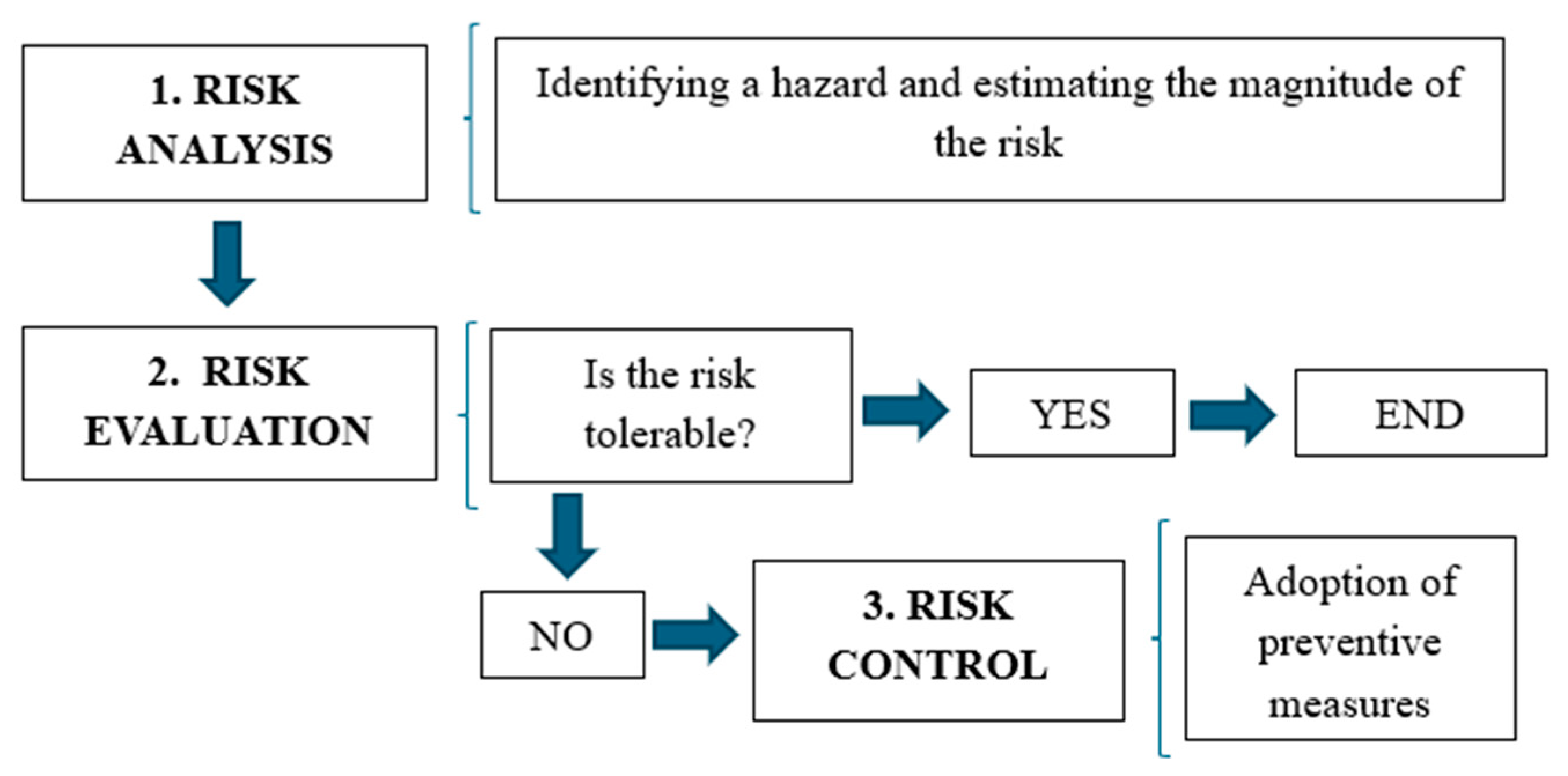

2.4.3. Analysis and Comparison of Occupational Risks According to the Trellising Method

- Identification of the tasks to be assessed: the agricultural work to be analyzed is trellising in greenhouse tomato cultivation and it is carried out using five different methods (using a manual ladder, manual scaffolding, motorized scaffolding, stilts, and the newly designed tool).

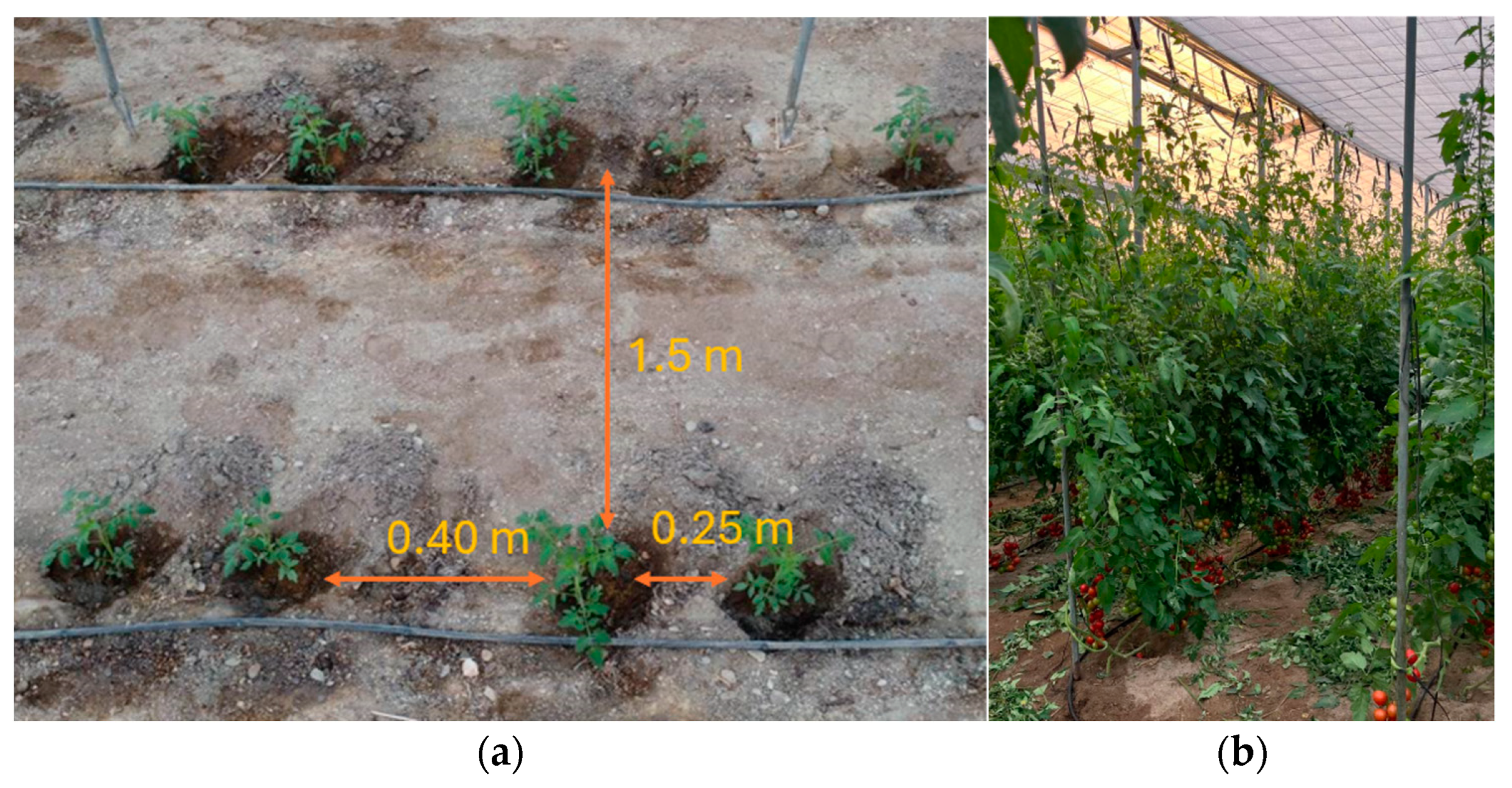

- Collection of information on site: Two Almería-type greenhouses were selected (Table 1). The information was gathered by a professional qualified in occupational risk prevention through observation and interviews. In each greenhouse, the evaluation focused on a single worker performing the trellising tasks using the respective methods.

- Hazard identification: In this study, the only hazard that had to be assessed was the falling of workers at different levels. This is considered a major risk in this work.

- Risk assessment: the probability of a fall from height occurring for each trellising method and the consequences that it could have were analyzed.

- The probability was classified as high (damage always or almost always occurs), medium (occurs sometimes), and low (occurs rarely). Preventive measures that were already implemented were considered to establish the probability.

- The consequences of damage were classified as slightly damaging (superficial damage, discomfort, etc.), damaging (musculoskeletal disorders, severe sprains, minor fractures, etc.), and extremely damaging (serious fractures, multiple injuries, etc.).

Knowing the probability and the consequences, the risk level was obtained (Table 2). - Based on the risk obtained, the need to apply improvements and the urgency with which they should be carried out was decided. According to the risk, the following classifications were made:

- Trivial: no modifications were required.

- Tolerable: No changes were necessary, but more cost-effective options should be considered. Periodic checks should be carried out on the measures.

- Moderate: Measures should be implemented over a specific period of time to reduce the risk. If this risk is associated with extremely harmful consequences, additional measures should be taken to more accurately assess the likelihood of harm, which will serve as a basis for deciding whether control measures need to be improved.

- Important: Risk should be reduced before starting work. If the work is in progress, the time to solve the problem should be less than for moderate risk.

- Intolerable: Risk should be reduced before starting or continuing work. If this is not possible, the work should be stopped.

3. Results

3.1. Final Design of the Tool

3.2. Results of the Experimental Validations

3.3. Results of Field Experiments

3.3.1. Analysis of the Registered Times

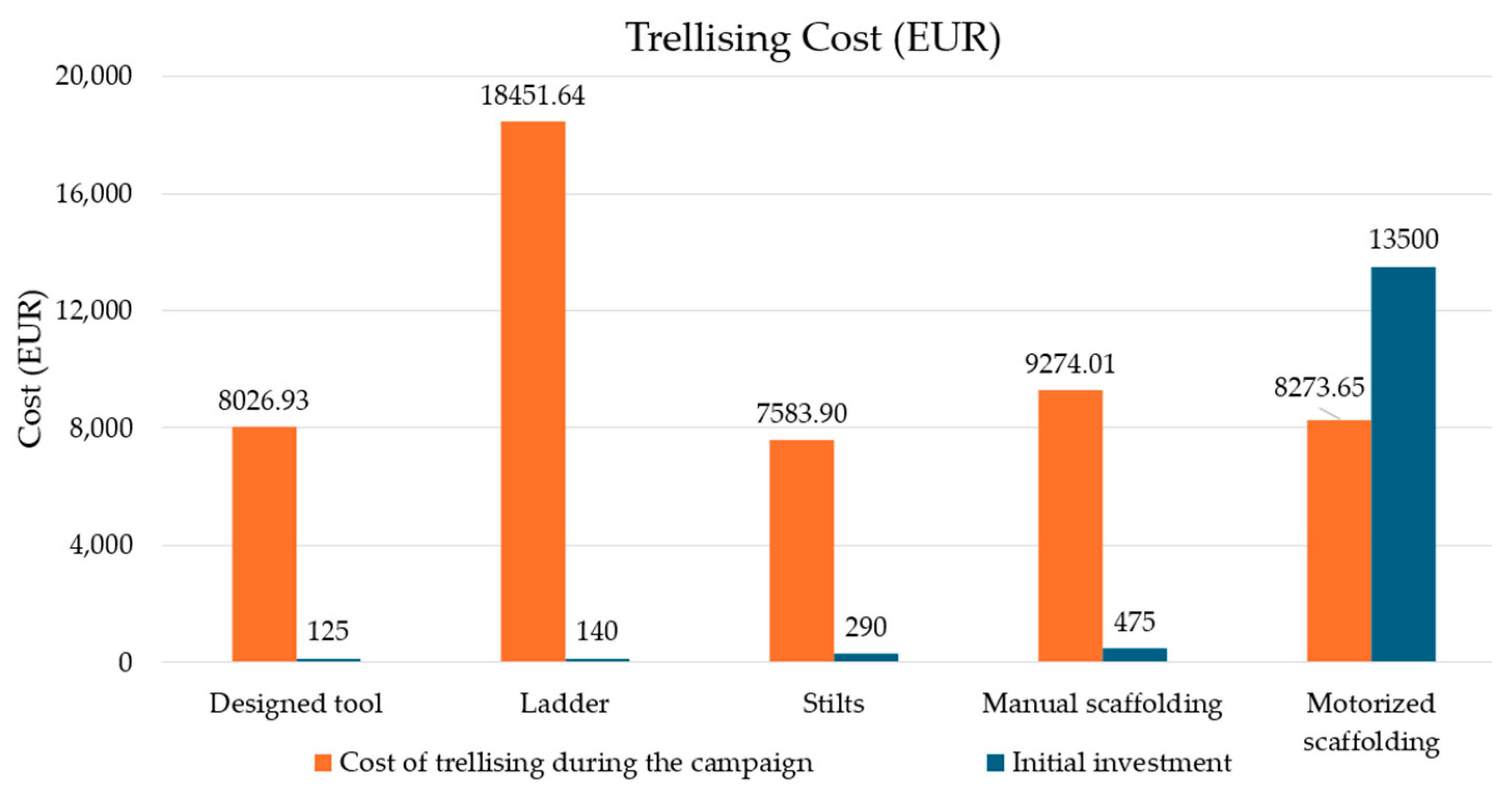

3.3.2. Analysis of Trellising Costs According to the Trellising Method

3.3.3. Analysis of Risk Reduction for Farmers with the Designed Tool

- Workplace: In both greenhouses, the support was laid along 1.5 m wide lines, so the worker could comfortably place bulky tools such as ladders and scaffolding. The sandy ground made the ladder unstable.

- Tools used: Farmers often used ladders, stilts, or scaffolding to carry out their work. During the observation, one of the farmers also used the newly designed tool for comparison.

- The materials used were hangers and raffia, so they should not have increased the risk.

- The working height was approximately 3 m. Work could not be carried out from the ground without the assistance of a tool for this purpose.

- The ladders and stilts did not have safety measures against falls from height. The scaffolding had railings on some parts of its perimeter. The ladder and manual scaffolding involved repeated climbs up and down throughout the work being carried out.

- The new tool allowed work to be carried out at the ground level.

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ministerio de Agricultura, Pesca y Alimentación (MAPA). HORTALIZAS: Balance de campaña 2021/22 y Previsiones 2022/23. 2022. Available online: https://www.mapa.gob.es/es/agricultura/temas/producciones-agricolas/balancecampana2021-22perspectivascampana2022-23hortalizas_tcm30-635291.pdf (accessed on 19 September 2024).

- Cajamar. Análisis de la Campaña Hortofrutícola de Almería. Campaña 2021/2022. 2022. Available online: https://publicacionescajamar.es/series-tematicas/informes-coyuntura-analisis-de-campana/analisis-de-la-campana-hortofruticola-de-almeria-campana-2021-2022/ (accessed on 19 September 2024).

- Junta de Andalucía. Caracterización del Sector Agrario y Pesquero de Andalucía 2023. Ed: Consejería de Agricultura, Pesca, Agua y Desarrollo Rural. Junta de Andalucía. 2023. Available online: https://www.juntadeandalucia.es/sites/default/files/2024-04/Caracterizaci%C3%B3n%20Sector%20Agrario%20y%20Pesquero%20de%20Andaluc%C3%ADa%202023%20_0.pdf (accessed on 20 September 2024).

- Ministerio de Agricultura, Pesca y Alimentación (MAPA). ANÁLISIS CAMPAÑA 2022/23 DE HORTALIZAS DE INVERNADERO. 2023. Available online: https://www.mapa.gob.es/es/agricultura/temas/producciones-agricolas/analisishortalizasinvernaderobalancecampana2022_23yprevisiones2023_248noviembre2023_tcm30-665839.pdf (accessed on 20 September 2024).

- Valera, D.L.; Ureña, L.J.B.; Aiz, F.D.M.; Martínez, A. Los invernaderos de Almería: Análisis de su tecnología y rentabilidad; Cajamar Caja Rural: Almería, Spain, 2014; pp. 5–500. ISBN 978-84-95531-61-2. [Google Scholar]

- Camacho-Ferre, F. Técnicas de Producción de Cultivos Protegidos (Tomo II); Cajamar: Almería, Spain, 2004; pp. 1–389. ISBN 84-95531-17-X. [Google Scholar]

- López-Marín, J.; Gálvez, A.; del Amor, F.M.; Piñero, M.C.; Brotons-Martínez, J.M. The Cost-Benefits and Risks of Using Raffia Made of Biodegradable Polymers: The Case of Pepper and Tomato Production in Greenhouses. Horticulturae 2022, 8, 133. [Google Scholar] [CrossRef]

- Vazquez-Cabrera, F.J. Ergonomic evaluation, with the RULA method, of greenhouse tasks of trellising crops. Work 2016, 54, 517–531. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Alonso, J.; Carreño-Ortega, A.; Vázquez-Cabrera, F.J.; Callejón-Ferre, A.J. Accidents in the greenhouse-construction industry of SE Spain. Appl. Ergon. 2012, 43, 69–80. [Google Scholar] [CrossRef]

- Gázquez, J.C.; Meca, D.E.; Baeza, E.; Pérez, C.; García, R.; López, J.C. Evaluación de Tres Sistemas de Guiado para Tomate en Invernadero en Clima Cálido: Descuelgue Tradicional; Tradicional Intensivo y Perchas (Tipo Holandés); Actas Hortic: Almería, Spain, 2012. [Google Scholar]

- European Patent Application. Tutoring System for Greenhouse Cultivation. Available online: https://data.epo.org/publication-server/rest/v1.0/publication-dates/20161221/patents/EP3106026NWA1/document.pdf (accessed on 26 September 2024).

- Oliveira, L.F.P.; Moreira, A.P.; Silva, M.F. Advances in Agriculture Robotics: A State-of-the-Art Review and Challenges Ahead. Robotics 2021, 10, 52. [Google Scholar] [CrossRef]

- Ma, Y.; Feng, Q.; Sun, Y.; Guo, X.; Zhang, W.; Wang, B.; Chen, L. Optimized Design of Robotic Arm for Tomato Branch Pruning in Greenhouses. Agriculture 2024, 14, 359. [Google Scholar] [CrossRef]

- Grimstad, L.; Le, T.D.; From, J. A Novel Autonomous Robot for Greenhouse Applications. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 8270–8277. [Google Scholar]

- Vrochidou, E.; Tsakalidou, V.N.; Kalathas, I.; Gkrimpizis, T.; Pachidis, T.; Kaburlasos, V.G. An Overview of End Effectors in Agricultural Robotic Harvesting Systems. Agriculture 2022, 12, 1240. [Google Scholar] [CrossRef]

- Martinović, G.; Simon, J. Greenhouse microclimatic environment controlled by a mobile measuring station. NJAS—Wageningen J. Life Sci. 2014, 70–71, 61–70. [Google Scholar] [CrossRef]

- Garro, R.; Ordinez, L.; Alimenti, O. Design Patterns for Cyber-Physical Systems: The Case of a Robotic Greenhouse. In Proceedings of the 2011 Brazilian Symposium on Computing System Engineering, Florianopolis, Brazil, 7–11 November 2011; pp. 15–20. [Google Scholar]

- Garro, R.; Orozco, J.; Ordinez, L.; Santos, R. Estrategias de diseño basadas en patrones de un subsistema de movimiento para un robot pulverizador. In Proceedings of the 2014 IEEE Biennial Congress of Argentina (ARGENCON), Bariloche, Argentina, 11–13 June 2014; pp. 405–410. [Google Scholar]

- Mandow, A.; Gomez-de-Gabriel, J.M.; Martinez, J.L.; Munoz, V.F.; Ollero, A.; Garcia-Cerezo, A. The autonomous mobile robot AURORA for greenhouse operation. IEEE Robot. Autom. Mag. 1996, 3, 18–28. [Google Scholar] [CrossRef]

- González, R.; Rodríguez, F.; Sánchez-Hermosilla, J.; Donaire, J.G. Navigation Techniques for Mobile Robots in Greenhouses. Appl. Eng. Agric. 2009, 25, 153–165. [Google Scholar] [CrossRef]

- Sanchez-Hermosilla, J.; Rodriguez, F.; Gonzalez, R.; Luis, J.; Berenguel, M. A Mechatronic Description of an Autonomous Mobile Robot for Agricultural Tasks in Greenhouses. In Mobile Robots Navigation; InTech: London, UK, 2010. [Google Scholar] [CrossRef]

- Sánchez-Molina, J.A.; Rodríguez, F.; Moreno, J.C.; Sánchez-Hermosilla, J.; Giménez, A. Robotics in greenhouses. Scoping review. Comput. Electron. Agric. 2024, 219, 108750. [Google Scholar] [CrossRef]

- Darçın, E.S.; Darçın, M. Falling from a height injuries in Agriculture: A 8-year experience with 173 samples. Biomed. Res. 2016, 27, 825–828. [Google Scholar]

- Lopez-Aragon, L.; Lopez-Liria, R.; Callejon-Ferre, A.J.; Perez-Alonso, J. Musculoskeletal disorders of agricultural workers in the greenhouses of Almeria (Southeast Spain). Saf. Sci. 2018, 109, 219–235. [Google Scholar] [CrossRef]

- Gómez-Galán, M.; González-Parra, J.M.; Pérez-Alonso, J.; Golasi, I.; Callejón-Ferre, Á.J. Forced Postures in Courgette Greenhouse Workers. Agronomy 2019, 9, 253. [Google Scholar] [CrossRef]

- Junta de Andalucía. Estadística de accidents de trabajo en Andalucía. Instituto de Estadística y Cartografía de Andalucía. Available online: https://www.juntadeandalucia.es/institutodeestadisticaycartografia/badea/informe/anual?idNode=10302 (accessed on 5 January 2025).

- Wang, H.; Zhao, W.; Sun, W.; Liu, X.; Shi, R.; Zhang, H.; Chen, P.; Gao, K. The Design and Experimentation of a Wheeled-Chassis Potato Combine Harvester with Integrated Bagging and Ton Bag-Lifting Systems. Agriculture 2024, 14, 1461. [Google Scholar] [CrossRef]

- Torres-Moreno, J.L.; Cruz, N.C.; Álvarez, J.D.; Redondo, J.L.; Giménez-Fernandez, A. An open-source tool for path synthesis of four-bar mechanisms. Mech. Mach. Theory 2022, 169, 104604. [Google Scholar] [CrossRef]

- INSST. Instituto Nacional de Seguridad y Salud en el Trabajo. Evaluación de riesgos laborales. Available online: https://www.insst.es/documents/94886/96076/Evaluacion_riesgos.pdf/1371c8cb-7321-48c0-880b-611f6f380c1d (accessed on 2 October 2024).

- Ashby, M.F. Materials and the Environment: Eco-Informed Material Choice, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Pan, C.S.; Chiou, S.S.; Hsiao, H.W.; Becker, P.; Akladios, M. Assessment of perceived traumatic injury hazards during drywall taping and sanding. Int. J. Ind. Ergon. 2000, 25, 621–631. [Google Scholar] [CrossRef]

- Pan, C.S.; Chiou, S.; Kau, T.Y.; Bhattacharya, A.; Ammons, D. Effects of foot placement on postural stability of construction workers on stilts. Appl. Ergon. 2009, 40, 781–789. [Google Scholar] [CrossRef]

- Chiou, S.; Pan, C.; Bhattacharya, A. Kinematics and kinetics of gait on stilts: Identification of risk factors associated with construction stilt use. Ergonomics 2008, 51, 1814–1829. [Google Scholar] [CrossRef]

- Wu, J.Z.; Chiou, S.S.; Pan, C.S. Analysis of Musculoskeletal Loadings in Lower Limbs During Stilts Walking in Occupational Activity. Ann. Biomed. Eng. 2009, 37, 1177–1189. [Google Scholar] [CrossRef]

- Smith, G.S.; Timmons, R.A.; Lombardi, D.A.; Mamidi, D.K.; Matz, S.; Courtney, T.K.; Perry, M.J. Work-related ladder fall fractures: Identification and diagnosis validation using narrative text. Accident Anal. Prev. 2006, 38, 973–980. [Google Scholar] [CrossRef]

- Sugama, A.; Ohnishi, A. Occupational accidents due to stepladders in Japan: Analysis of industry and injured characteristics. Procedia Manuf. 2015, 3, 6632–6638. [Google Scholar] [CrossRef]

- Ronk, C.J.; Dennerlein, J.T.; Hoffman, E.; Perry, M.J. Is Renovation Riskier Than New Construction? An Observational Comparison of Risk Factors for Stepladder-Related Falls. Am. J. Ind. Med. 2011, 54, 579–585. [Google Scholar] [CrossRef] [PubMed]

- Mattila, T.; Kaustell, K.; Rautiainen, R.; Pitkänen, T.; Lötjönen, T.; Suutarinen, J. Slip, trip and fall injuries in potato, sugar beet and open field vegetable production in Finland. Ergonomics 2008, 51, 1944–1959. [Google Scholar] [CrossRef] [PubMed]

- Solomon, C. Accidental injuries in agriculture in the UK. Occup. Med. 2022, 52, 461–466. [Google Scholar] [CrossRef] [PubMed]

- Ishimaru, T.; Arphorn, S.; Vudhironarit, C.; Thanachoksawang, C.; Theppitak, C.; Kiatkitroj, K.; Lertvarayut, T.; Manothum, A.; Hara, K. Effectiveness of Participatory Training for Prevention of Slips, Trips, and Falls: A Cluster Randomized Controlled Trial of Corn Farmers in Thailand. Asia-Pac. J. Public Health 2024, 36, 574–579. [Google Scholar] [CrossRef] [PubMed]

- Arphorn, S.; Ishimaru, T.; Lertvarayut, T.; Kiatkitroj, K.; Theppitak, C.; Manothum, A.; Hara, K. Risk Factors for Occupational Falls among Middle-aged and Elderly Farm Workers in Nan Province, Thailand. J. Agromed. 2022, 27, 402–408. [Google Scholar] [CrossRef]

- Warren, L.R.; Harley, S.; Dutschke, J.; van der Berg, A.; Dobbins, C. Bicycle helmet use to reduce the impact of head injuries in ladder users. ANZ J. Surg. 2017, 87, 1026–1029. [Google Scholar] [CrossRef]

- Blach, W.; Dobosz, D.; Gasienica-Walczak, B.; Grants, J.; Litwiniuk, A. Falls Are the Leading Cause of Injuries among Farmers-Limitations of Practicing Judo in Preventing These Incidents. Appl. Sci. 2021, 11, 7324. [Google Scholar] [CrossRef]

- International Labour Office (ILO). Safety and Health in Agriculture. Available online: https://www.ilo.org/sites/default/files/wcmsp5/groups/public/@ed_dialogue/@sector/documents/normativeinstrument/wcms_161135.pdf (accessed on 28 November 2024).

- Parmar, R.S.; Kamani, G.J.; Amin, B.A. Analysis of factorial experiments for agricultural research using digital tool. Gujarat J. Ext. Educ. 2022, 33. [Google Scholar] [CrossRef]

| Parameter | Greenhouse 1 | Greenhouse 2 |

|---|---|---|

| Soil and irrigation | Sandy soil and drip irrigation | |

| Surface | 5500 m2 | 10 000 m2 |

| Tomato variety | “Bacco Cocktail” | “Bacco Cocktail” |

| Professional experience of the evaluated worker | 9 years | 8 years |

| Knowledge about working at heights | Basic | Basic |

| Methods to be evaluated | Ladder, manual scaffolding, stilts, and the newly designed tool | Motorized scaffolding |

| Frequency of visits per evaluator | 4 days | 1 day |

| Risk Level | Consequences | |||

|---|---|---|---|---|

| Slightly Harmful | Harmful | Extremely Harmful | ||

| Probability | Low | Trivial | Tolerable | Moderate |

| Average | Tolerable | Moderate | Important | |

| High | Moderate | Important | Intolerable | |

| Item | Element | Material | Observations |

|---|---|---|---|

| 1 | Base | Polylactic acid (PLA) | Made with a Prusa i3 MK3S 3D printer. |

| 2 | Hanger rack | PLA | Made with a Prusa i3 MK3S 3D printer. |

| 3 | Electromagnet | Iron/copper | Input voltage: DC 12 V; power consumption: 3 W; suction: 20 kg. |

| 4 | DC motor | - | 12 V motor, 15 W power. Operating at 20 rpm. Efficiency 90%. |

| 5 | Bearings | Steel | NTN 12 × 32 × 10 wheel bearing 6201-2RS. |

| 6 | Electromagnet | Iron/copper | Input voltage: DC 12 V; power consumption: 3 W; suction: 20 kg. |

| 7 | Electromagnet | Iron/copper | Input voltage: DC 12 V; power consumption: 3 W; suction: 20 kg. |

| 8 | Ring | Copper | 4 mm thick copper ring with a 12 mm diameter. |

| 9 | Brushes | Copper | 2 mm copper sheet. |

| 10 | Screw | Steel | Stainless-steel screw M1.4 × 2 mm. |

| 11 | Nut | Steel | Stainless-steel Hexagon Nuts M1.4. |

| 12 | Screws | Steel | Stainless-steel screw M5 × 5 mm. |

| 13 | Mast | Carbon fiber | Carbon fiber telescopic mast. |

| 14 | Battery holder | PLA | Made with Prusa i3 MK3S 3D printer. |

| 15 | Front | PLA | Made with Prusa i3 MK3S 3D printer. |

| 16 | Button | Plastic | Two-position switch. |

| 17 | Switch | Plastic | Switch with three positions. |

| 18 | Screws | Steel | Stainless-steel screw M5 × 25 mm. |

| 19 | Hanger | Iron | Iron agricultural hanger. |

| 20 | Battery | Lithium | 12 V, 17 Ah battery. |

| Methods | Probability of Falling to Different Levels | Consequence of Falling to a Different Level | Risk Level |

|---|---|---|---|

| Ladder | High | Harmful | Important |

| Manual scaffolding | High | Harmful | Important |

| Motorized scaffolding | Average | Harmful | Moderate |

| Stilts | High | Extremely harmful | Intolerable |

| Newly designed tool | None | Not applicable | No risk |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Chica, A.; Torres-Moreno, J.L.; Fernández, A.G.; Gómez-Galán, M.; Chica, R.M. Design and Comparative Analysis of a Ground-Level Trellising Tool for Greenhouse Tomato Cultivation. Appl. Sci. 2025, 15, 3263. https://doi.org/10.3390/app15063263

García-Chica A, Torres-Moreno JL, Fernández AG, Gómez-Galán M, Chica RM. Design and Comparative Analysis of a Ground-Level Trellising Tool for Greenhouse Tomato Cultivation. Applied Sciences. 2025; 15(6):3263. https://doi.org/10.3390/app15063263

Chicago/Turabian StyleGarcía-Chica, Antonio, José Luis Torres-Moreno, Antonio Giménez Fernández, Marta Gómez-Galán, and Rosa María Chica. 2025. "Design and Comparative Analysis of a Ground-Level Trellising Tool for Greenhouse Tomato Cultivation" Applied Sciences 15, no. 6: 3263. https://doi.org/10.3390/app15063263

APA StyleGarcía-Chica, A., Torres-Moreno, J. L., Fernández, A. G., Gómez-Galán, M., & Chica, R. M. (2025). Design and Comparative Analysis of a Ground-Level Trellising Tool for Greenhouse Tomato Cultivation. Applied Sciences, 15(6), 3263. https://doi.org/10.3390/app15063263