3.1. Determination of Parametric Design Factors

With the increasing demand for artistic value and personalization in ceramic products, the selection and combination of modeling elements become crucial for enhancing the user experience. To systematically study the impact of shaping elements on the user experience, this research employs the principles of human factors engineering and the ErgoLAB human–machine environment synchronization platform V3.0. Focusing on core elements such as shape, volume, material, mouthpiece, handle, and bottom design [

13], advanced measurement techniques and data analysis methods are utilized to identify key parameters for parametric design.

This paper adopted the ErgoLAB human–machine environment synchronization platform V3.0 for experimental design and data collection. The platform can synchronously collect multi-modal data from participants, including physiological signals (such as electroencephalography, electrocardiography, heart rate variability, etc.), eye movement data, etc., providing strong support for a comprehensive analysis of participants’ behaviors and reactions when observing and using ceramic products.

To ensure the reliability and representativeness of the experimental results, we carefully recruited 50 representative participants through a combination of stratified sampling and quota sampling methods. Participants were recruited via online platforms (e.g., social media and academic forums) and offline channels (e.g., university campuses and community centers) to ensure diversity in recruitment sources. Eligibility criteria included age (18–65 years), gender (balanced male-to-female ratio), occupation (covering students, professionals, and artisans), and educational background (from high school to postgraduate levels). Each participant received monetary compensation to incentivize engagement and ensure data completeness.

To ensure the reliability and representativeness of the experimental results, we carefully balanced the sample distribution and addressed potential data skewness and outliers through several measures. We employed stratified sampling, dividing the population into subgroups based on age, gender, and occupation to ensure proportional representation from each subgroup. Specific quotas were allocated for underrepresented groups, such as older adults and artisans, to prevent the overrepresentation of dominant demographics. During data preprocessing, we applied statistical methods like Z-score analysis to detect and exclude extreme values caused by technical errors or non-compliance. Additionally, we weighted the data from underrepresented groups post-collection to align with the target population distribution. This comprehensive approach ensured that the participants, who had diverse backgrounds in terms of age, gender, occupation, and education, could fully reflect the needs and preferences of various user groups.

During the experiment, we showed the participants samples of ceramic products with various design elements and set observation times. Through the ErgoLAB human–machine environment synchronization platform V3.0, this study synchronously collected the following multimodal data (see

Figure 2, which shows a photo of an actual experimental scene): Firstly, physiological signals were recorded, including electroencephalogram (EEG) signals to capture cognitive processing activities, electrocardiogram (ECG) signals to analyze heart rate variability (HRV) and reflect emotional fluctuations, and galvanic skin response (GSR) signals to characterize emotional arousal and stress responses. Secondly, eye movement data were gathered, covering gaze heatmaps, gaze trajectories, time to first fixation, and total fixation duration. Lastly, behavioral data were collected, such as task completion time, preference selection records, and interactive behaviors during operation simulations.

To analyze the physiological parameters collected during the experiment, we employed specific methods for each type of data. For EEG data, we extracted the power value of frontal lobe θ waves (4–8 Hz) using the ErgoLAB EEG/ERP analysis module. This measurement helps evaluate the user’s concentration on the ceramic design and the intensity of their emotional responses, with higher θ wave power typically indicating positive emotions. For ECG and heart rate variability (HRV), we quantified users’ emotional stability through time-domain and frequency-domain analyses, with the LF/HF ratio reflecting the balance between the sympathetic and parasympathetic nervous systems. For GSR data, we analyzed the skin conductance level (SCL) and event-related skin conductance response (ER-SCR) to identify users’ instantaneous emotional arousal during design observation, such as surprise or stress. By combining these physiological parameters with eye movement data, such as gaze hotspot maps, we constructed a correlation model to link users’ visual attention patterns with their emotional preferences for ceramic design elements.

To ensure accurate data collection regarding participants’ behaviors and responses, the experiment was designed with four task scenarios. First, participants freely observed ceramic samples with different design elements (such as glaze color, patterns, and shapes) for 30 s to record their natural visual attention distribution. Second, participants were required to choose their preferred option among multiple contrast samples (e.g., “Shape A vs. Shape B”) and record the reasons for their choices to analyze the correlation between subjective preferences and physiological indicators. Third, participants simulated daily usage scenarios (e.g., holding a teacup to pour water) while motion capture and physiological signal analysis were used to assess operational comfort and cognitive load. Finally, the tasks were repeated under varying conditions of light (warm light vs. cold light) and observation angle (downward view vs. side view) to study the impact of environmental factors on user experience.

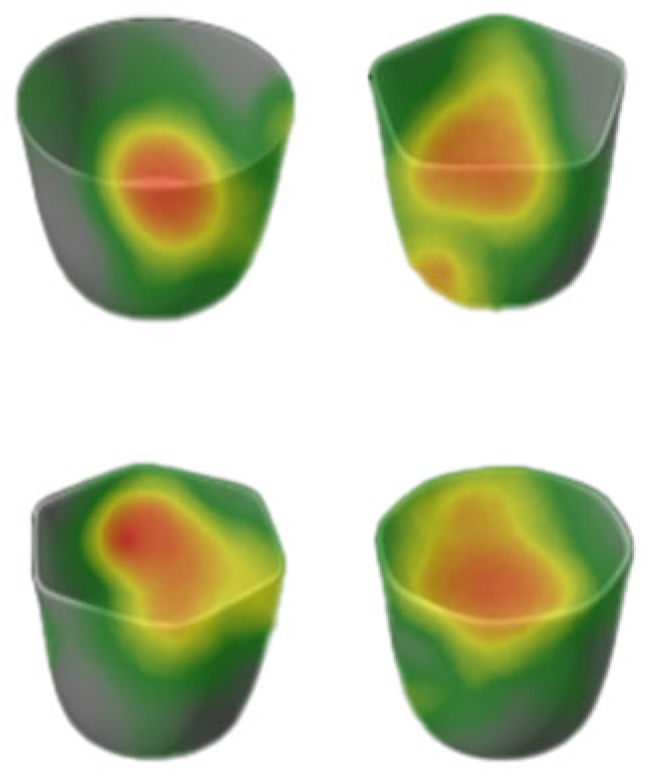

During the human experiment, based on the obtained thermographic information, it was found that when the subject viewed the ceramic product from below, their visual attention was mainly focused on the cup rim shape; while at an oblique viewing angle, the changes in the outer contour curves corresponding to the axis of the ceramic product became the focal point of attention (see

Figure 3 and

Figure 4).

Based on the results of eye movement hotspots, gaze trajectory, gaze duration, and brain wave analysis of the ErgoLAB platform, several key factors in ceramic product shape design are established: (1) final radius and starting radius; (2) number of segments; (3) starting angle and ending angle; and (4) end height and start height.

Among these, regarding the (1) final radius and starting radius, these two parameters in geometry, respectively, define the curvature characteristics of the terminal and initial points of a shaping curve or contour. The final radius, as a key indicator of the product’s top shape, is directly related to the width and smoothness of the cup rim or top opening, significantly impacting the overall proportion and visual focus of the product. The starting radius, on the other hand, lays the foundation for the product’s form, closely associated with the stability of the product and the design of the bottom support structure, while also visually establishing the “foundation” of the product. By precisely controlling these two radius values, designers can create various forms that transition smoothly from soft to sharp edges or maintain uniform curvature, thus meeting different aesthetic preferences and functional requirements.

With regard to the (2) number of segments, this factor plays a crucial role in parametric design, determining the degree of the subdivision of shapes or surfaces, which, in turn, affects the fineness and complexity of the form’s presentation. Increasing the number of segments means introducing more control points on the curve or surface, allowing designers to more accurately manipulate local changes in form, such as subtle indentations, ripples, or transitions, thereby enriching the visual hierarchy and tactile experience of the product, enhancing its overall refinement and artistry.

With respect to the (3) starting angle and ending angle, these two parameters define the starting and ending directions of the shaping curve or outline, which are crucial elements for creating the dynamism, symmetry, and stability of a product. The selection of the starting angle determines the position and direction of the form’s beginning, while the ending angle dictates the manner in which the form concludes. By skillfully adjusting these two key angles, designers can create a myriad of forms, from smooth transitions to sharp turns, all accurately guiding the user’s visual flow, thereby significantly enhancing the product’s visual impact and spatial hierarchy.

For the last key factor, (4) end height and start height, the height parameter defines the vertical dimension and spatial positioning of a product in 3D space. The endpoint height, which is the highest point on the top of the product, not only determines the overall height of the product but also influences the visual focus and spatial proportion relationship. The starting point height is closely related to the bottom or support surface of the product, serving as the foundation for ensuring stable placement and visual balance. A reasonable height design must comprehensively consider the actual application scenarios of the product, the scientific principles of ergonomics, and the aesthetic requirements of visual aesthetics, aiming to achieve a harmonious unity between functionality and aesthetics.

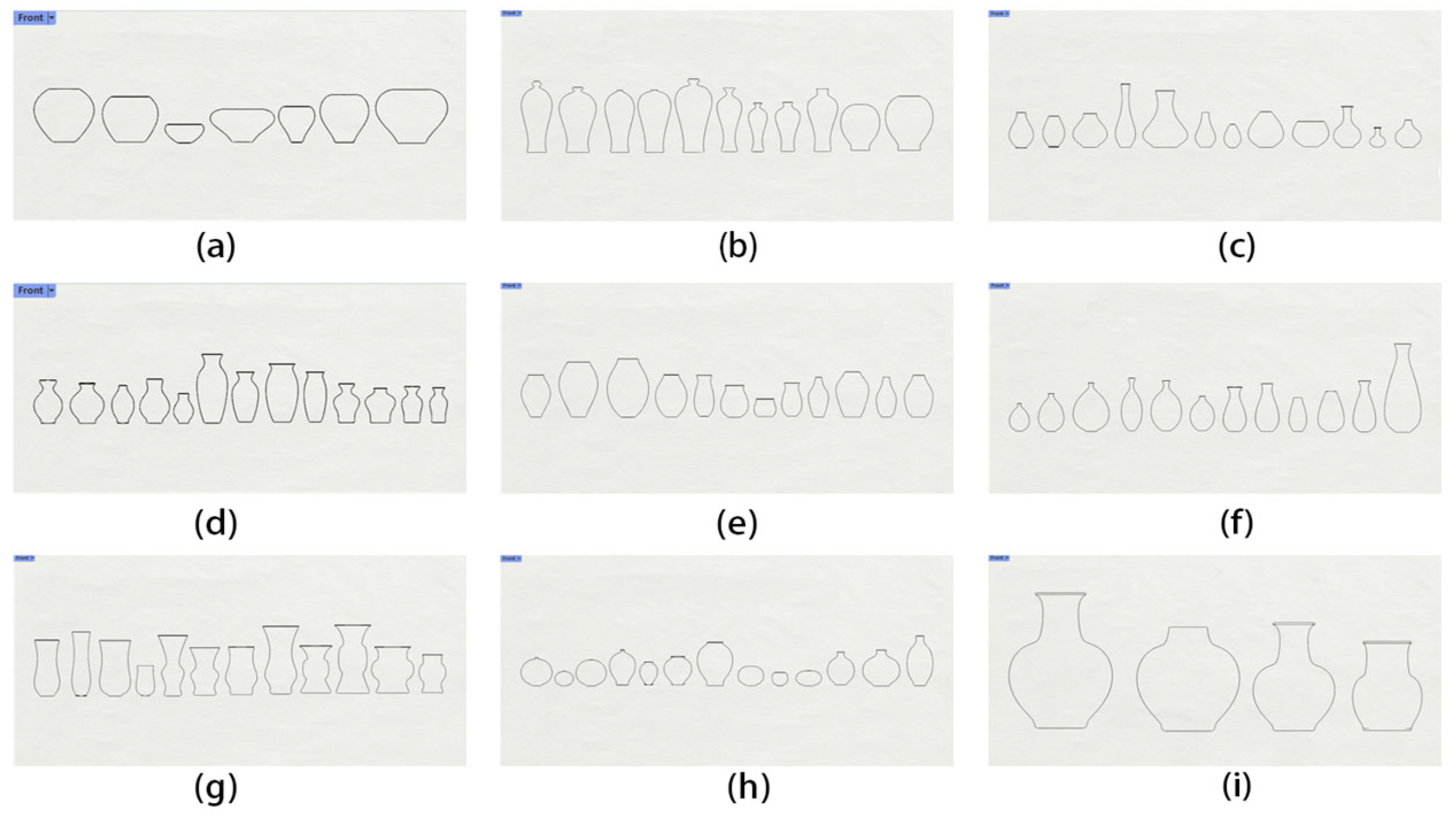

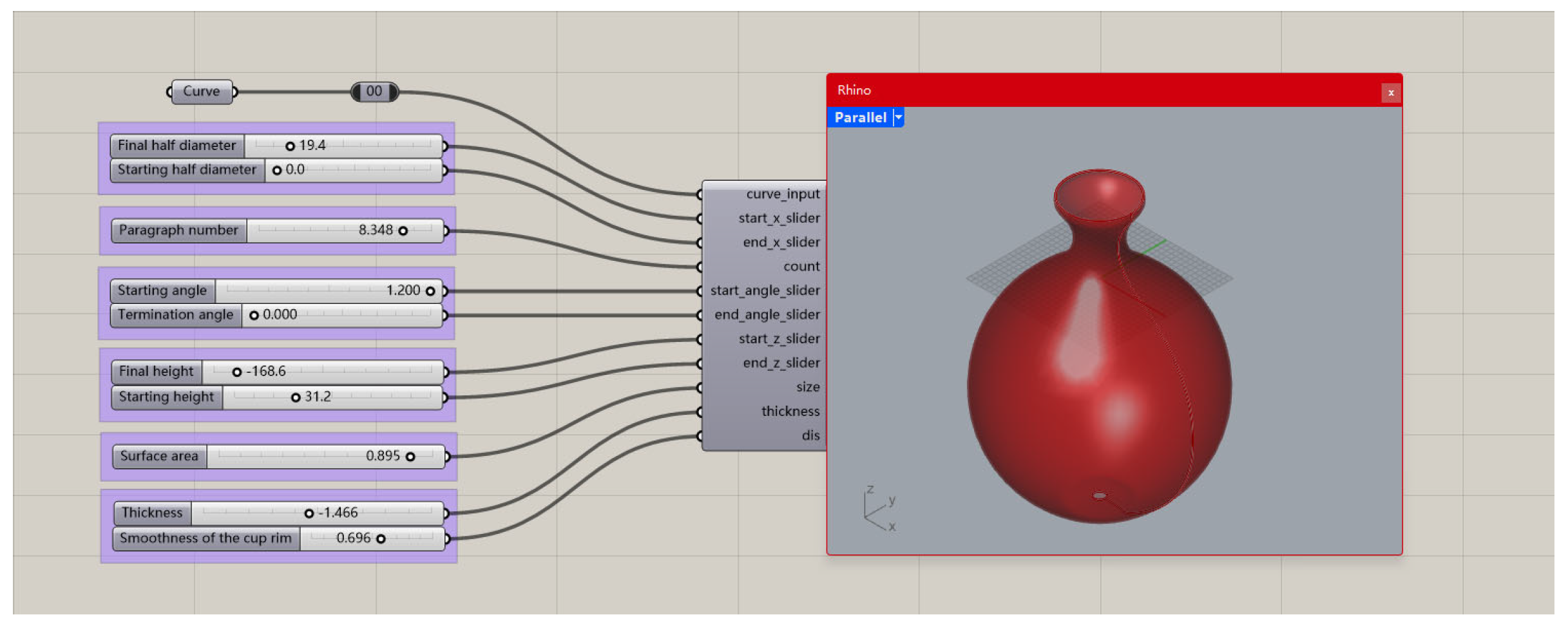

Based on the above data analysis results, we carry out parametric design and optimization of the shaping elements of ceramic products (see

Figure 5).

3.2. Parametrically Adjusted Battery Pack

Within the complex framework of parametric design, parametrically adjustable battery packs play a crucial role, serving not only as a bridge between designers and computer algorithms but also as the key to seamlessly integrating creative precision with technical implementation. Leveraging Grasshopper, an excellent parametric design platform, we have developed a highly integrated, flexible, and real-time feedback parametric adjustable battery pack, aiming to drive the infinite possibilities of ceramic product shaping through precise parameter control.

According to the logical flow of parametric design, the battery pack is divided into multiple levels, including the basic parameter input layer, computational processing layer, shape generation layer, and feedback optimization layer. Each level bears specific functions, progressively deepening to form a closed design cycle process. Within the battery pack, we have established logical chains between parameters to ensure that any adjustment is accurately transmitted to every stage of shape generation. Through advanced programming techniques such as conditional judgment and iterative loops, we have achieved mutual dependence and constraints between parameters, enhancing the flexibility and controllability of the design. For key parameters (such as curve radius, angle, height, number of segments), we have specifically designed input components that support various input methods, including numerical input, slider drag, and preset value selection, aiming to meet diverse design requirements. Leveraging Grasshopper’s instant update mechanism, we have achieved real-time dynamic parameter adjustments. Whenever a parameter changes, the battery pack immediately recalculates and updates the shape, ensuring designers can see the adjustment effects in real-time, thus achieving more precise personalized choices.

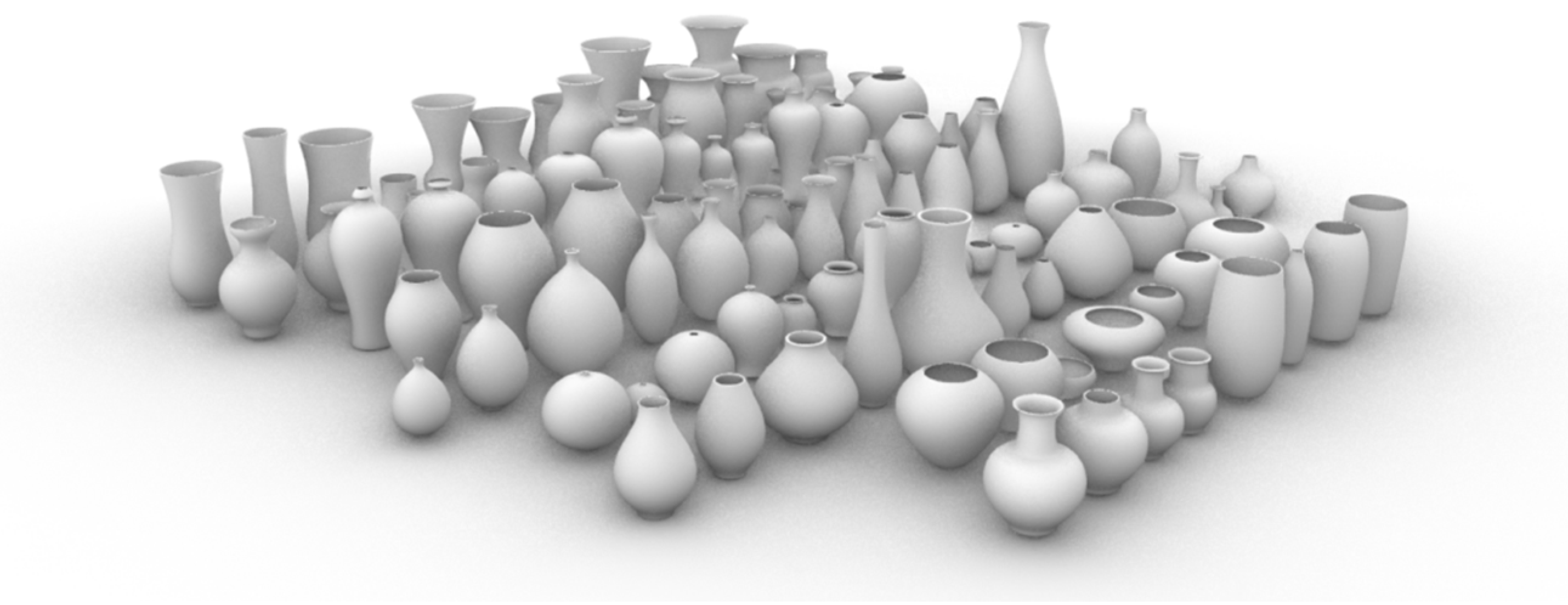

This article integrates Rhino’s 3D view function to display the parametrically generated ceramic product shapes in real-time for designers. This intuitive visual feedback significantly improves design efficiency, enabling designers to rapidly iterate and optimize their design solutions. In addition to real-time visual previews, we have introduced a performance evaluation module to assess the structural strength, material consumption, and other aspects of the generated shapes. The evaluation module is concerned with aspects such as structural strength and material consumption. The 3D model generated by the modeling software Rhino is imported into the slicing software. In the software, the structural strength and material consumption will be automatically displayed. It provides designers with intuitive feedback on the assessment results. This data-driven feedback mechanism helps designers find the optimal balance between creativity and practicality. We have optimized the battery pack algorithm, effectively reducing redundant calculations and, thus, enhancing overall operational efficiency. At the same time, we have modularized the battery pack for easier maintenance and upgrades in the future. To meet the future expansion needs of parametric design, we have meticulously designed multiple expansion interfaces for the battery pack. This means that designers can easily add new parameters, computational components, or shape generation methods according to actual needs, continuously expanding the boundaries of parametric design (see

Figure 6).

In summary, the parametric adjustment battery pack we built not only realizes the fine control and dynamic adjustment of ceramic product shape, but also provides designers with an efficient, flexible, and easy-to-iterate parametric design environment through the real-time preview and feedback mechanism, performance optimization, and scalability considerations and other design details.

3.3. Python Code Control Manufacturing Generation

The key parameters identified through ErgoLAB experiments (

Section 3.1) were mapped into the Python code as input variables. For example, the “number of segments” (determined from gaze duration analysis) controls the subdivision level of NURBS curves, while the “starting/ending angles” (derived from EEG-based cognitive load assessment) are encoded as rotational constraints. These parameters are dynamically linked to Grasshopper components, enabling real-time shape adjustments based on user-centric data.

In the field of parametric design and manufacturing, Python code serves as a powerful programming tool whose role in the ceramic modeling generation process is indispensable, especially in the two core aspects of curve rotation and forming, as well as the creation of wall thickness and blended surfaces. Adopting Python code plays a crucial controlling role in these two key steps, facilitating subsequent 3D model generation.

The primary task of the Python code is to receive the rotation parameters transmitted by the Grasshopper plugin, including the direction vector of the rotation axis, starting and ending angles, and the coordinates of the 2D contour control points, among other core information. Subsequently, the code needs to preprocess these input parameters, such as verifying the legality of the parameters, converting angles to radians (if necessary), and calculating the rotation matrix, etc. Based on the principles of ceramic engineering and 3D printing technology, the rationality of parameters is verified. The geometric parameters required include the radius parameters (Rstart and Rend), 10 mm ≤ R ≤ 250 mm (constrained by kiln size), and the thickness of the ceramic bottle (1 mm ≤ t ≤ 10 mm; t represents the thickness of the ceramic bottle), etc. The limitations for each parameter should be set based on the specific requirements of the actual production process and the actual environment. Based on the user-defined rotation axis and angle, the Python code employs linear algebra theory of rotation matrices to accurately construct a 3D matrix describing the curves rotation. This matrix will be used to spatially rotate each control point of the 2D contour curve. Using the rotation matrix, the Python code performs spatial coordinate transformations on each control point to achieve 3D rotation of the curve. Subsequently, using these rotated control points, combined with Rhinos API functions (such as AddRevSurface or AddNurbsSurface), an accurate 3D surface model is constructed. During this process, to ensure the smoothness and continuity of the surface, the code also needs to appropriately adjust and refine the control points to meet design requirements.

Thereafter, the Python code receives the wall thickness value set by the user, which directly determines the spatial distance between the inner and outer surfaces of the ceramic shape. The code must ensure that this parameter is within a reasonable range and perform necessary verification and conversion. Based on the outer surface (i.e., the curved surface generated by rotation) and wall thickness parameters, the Python code uses offset algorithms (such as Offset Surface) to generate the inner surface. This process requires the precise calculation of the offset amount for each curved surface point and ensuring that the geometric properties of the inner surface are consistent with those of the outer surface. Subsequently, the code must also perform necessary optimization processing on the inner surface, such as adjusting control points and increasing the number of subdivision segments to improve smoothness, to meet design requirements. The design requirements are divided into three aspects: (1) geometric feasibility (1 mm ≤ t ≤ 10 mm; t represents the thickness of the ceramic bottle) to ensure the plasticity of the 3D printing process; (2) maintaining the integrity of the structure and preventing surface self-intersection; and (3) conforming to ergonomics. Python codes leverage advanced geometric algorithms and mathematical theories—such as interpolation, approximation, and surface subdivision—to compute blended surfaces that preserve the structural integrity and aesthetic appeal of ceramic models. These algorithms ensure smooth, seamless transitions between blended surfaces and adjacent internal or external surfaces, adhering to specified geometric continuity criteria. The process further involves iterative adjustments and optimizations of the blended surfaces to enhance design precision and achieve optimal visual and functional results.

Finally, the Python code is responsible for correctly closing the inner and outer surfaces as well as the blended surfaces to form a complete ceramic shape. This includes handling the matching of surface boundaries, adjusting normal vectors, and verifying the overall geometric characteristics. The code must comprehensively verify and inspect the generated ceramic shape to ensure it meets design requirements while also being feasible for actual production, covering multiple aspects such as surface continuity, smoothness, wall thickness uniformity, and overall shape accuracy.

In summary, Python code plays a core controlling role in the process of parametric ceramic shape generation. Through the precise calculation of rotation matrices, construction of 3D surfaces, generation of inner surfaces and blended surfaces, and overall verification, Python code ensures that ceramic shape generation is both rapid and accurate, laying a solid technical foundation for subsequent manufacturing and production. For example, NURBS-based modeling methods demonstrate their advantages in constructing vivid ceramic shapes [

14], while Python, as an advanced programming language, is widely used for rapid development and prototyping due to its concise syntax and rich libraries, which have been widely applied in the architectural field; however, it has not yet seen reasonable application in traditional ceramics industries. This paper presents the first use of Python programming to achieve simple to moderately complex ceramic shape designs. Its powerful computational capabilities and flexible programming features make parametric design possible, significantly improving the efficiency and quality of ceramic shape design (see

Figure 7).

3.4. Application of Parametric Design

To verify and demonstrate the practical application effects and advantages of the Python-based ceramic shape parametric design system, this section particularly selects the traditional Chinese bottle named by Yuhuchun as a representative case for in-depth discussion. The Yuhuchun bottle, as a typical form in Chinese porcelain design, evolved from the water purification bottles found in Tang dynasty temples, featuring a basic shape comprised of a flared mouth, slender neck, hanging abdomen, and ring foot, along with aesthetically pleasing lines formed by symmetrical “S”-shaped curves on both sides. Throughout the Song, Yuan, Ming, and Qing dynasties, the Republic of China era, and up to modern times, the Yuhuchun bottle has not only been widely used in practical applications but has also been highly esteemed in artistic appreciation. As a masterpiece of traditional Chinese ceramic art, the Yuhuchun bottle is renowned for its unique shape, elegant lines, and rich cultural heritage, demanding extremely high standards for design precision and detail processing, making it an ideal subject for testing the performance of parametric design systems [

15].

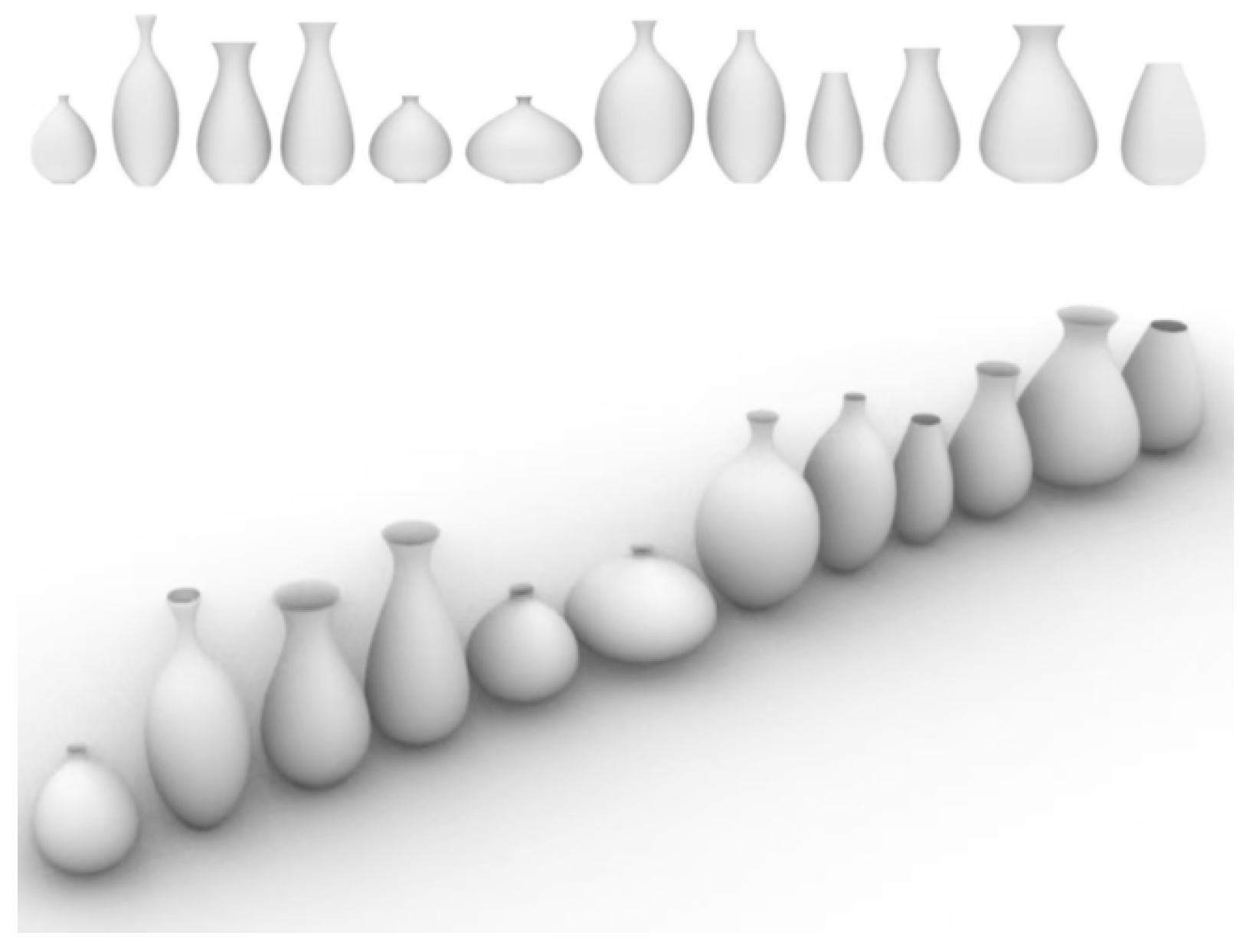

In the parametric design process of the Yuhuchun bottle, we strictly adhered to the parametric design procedures and technical details previously outlined. Firstly, through an in-depth analysis of the Yuhuchun bottle’s shape, we identified and defined the key parameters that influence its form, such as the bottles radius, the length and angle of the neck, and the diameter of the base. Subsequently, using Python programming language in conjunction with Rhino and Grasshopper plugins, we constructed a parametric model (see

Figure 8) [

16]. Through Python code, we precisely controlled key parameters such as curve rotation, surface generation, and wall thickness adjustments. By adjusting these core parameters (see

Figure 9 and

Figure 10), we rapidly generated and optimized the shape of the Yuhuchun bottle, ensuring the accuracy and aesthetics of the final design.

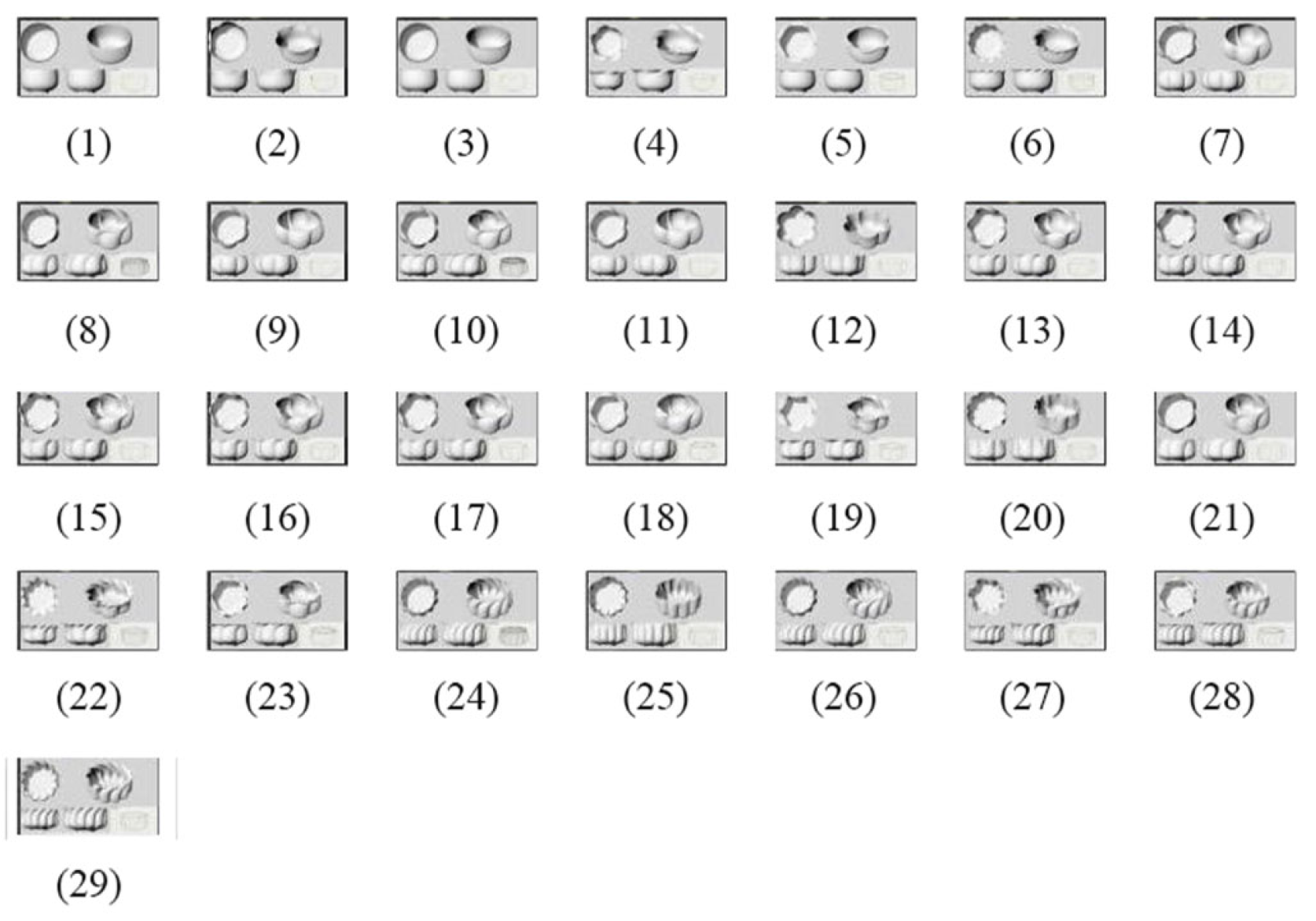

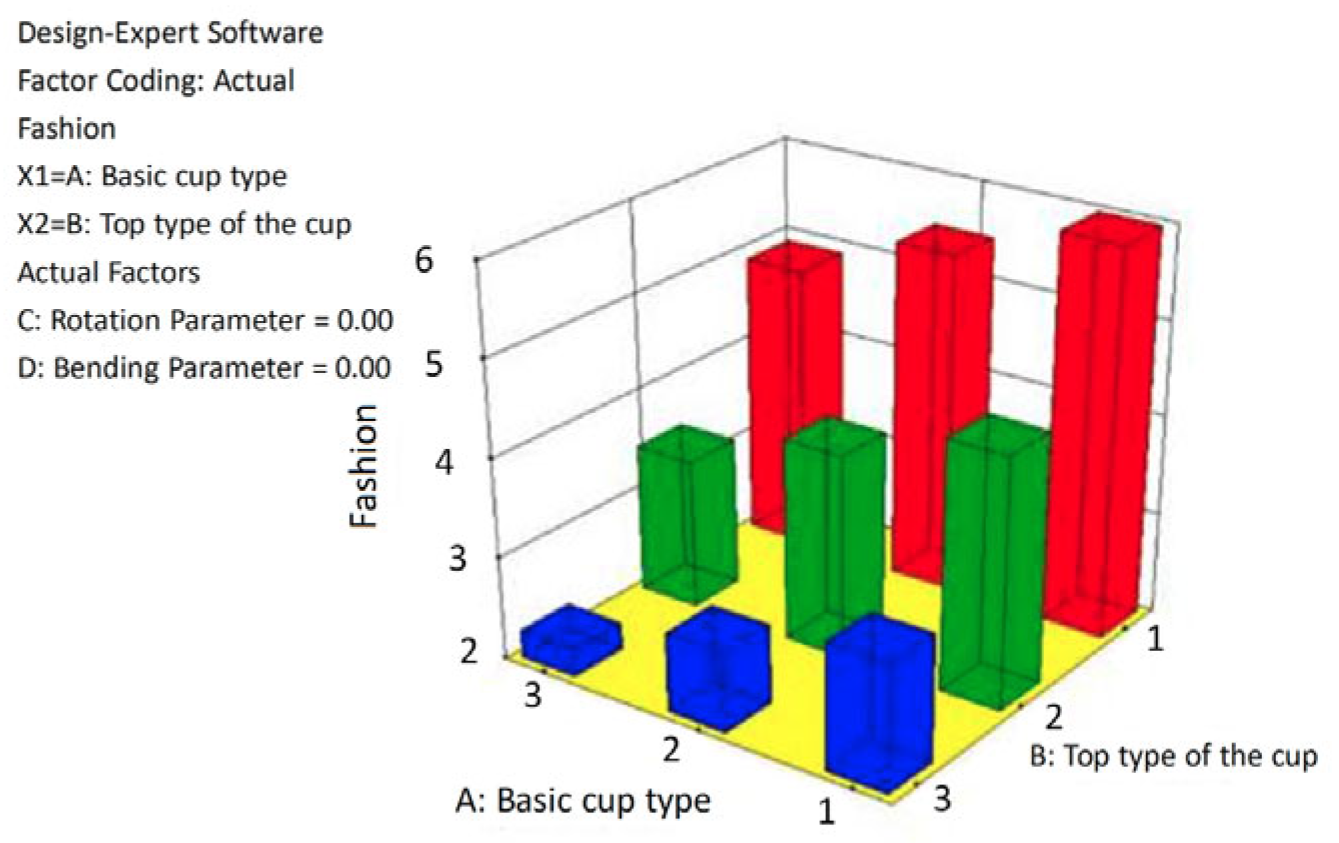

Through the aforementioned parametric design system, we successfully generated multiple jade pot spring vase designs in different styles and converted them into physical models using 3D printing technology (see

Figure 11). Compared with traditional manual design, parametric design combined with 3D printing takes about 1 h to print a model approximately 25 cm tall, which not only meets the personalized rapid customization needs of the cultural tourism industry at tourist attractions but also significantly improves design efficiency, allowing designers to easily explore more diverse design solutions [

17]. Meanwhile, we analyzed the generated models using fuzzy comprehensive evaluation [

18] (see

Figure 12), and the results showed that parametric design has significant advantages in enhancing the aesthetic characteristics of product shapes (see

Figure 13,

Figure 14 and

Figure 15).

In summary, through the parametric design practice of the classic Yuhuchun vase shape, we have fully verified the practicality and effectiveness of the ceramic shape parametric design system based on the Python platform. This system not only provides ceramic designers with powerful design tools but also offers strong support for the diversified and personalized development of the ceramic industry. In the future, we will continue to deepen our research and application of parametric design, promoting the deep integration of ceramic art and modern technology.