3.1. Real Thermographic Image Dataset Generation

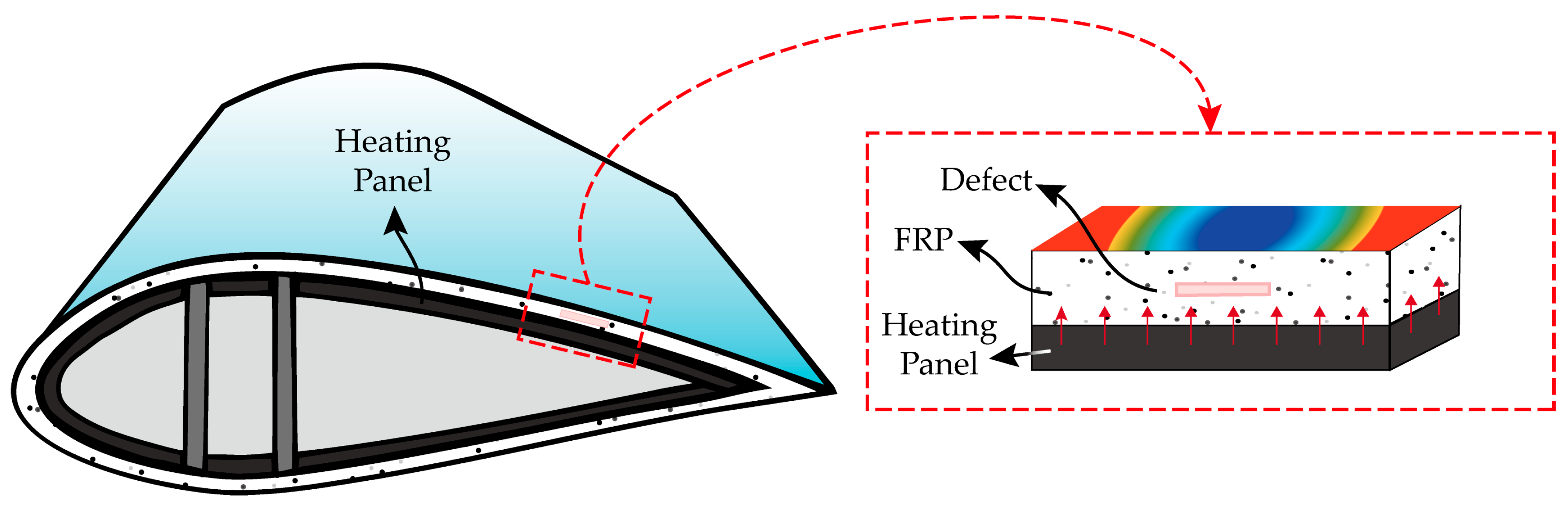

To evaluate the defect detection performance of the deep learning model through experimental methods, 24 real specimens with varying depths and sizes of defects, as well as 6 non-defect real specimens, were fabricated to acquire a real thermographic dataset. The specimens were composed of composite materials with a layered structure of CFRP and GFRP, simulating the cross-section of a wind turbine blade.

CFRP was manufactured using the pultrusion method, with a longitudinal modulus of 145. Each GFRP layer has a thickness of 0.91 mm and is stacked in a [0°/90°] orientation. The epoxy matrix used was KFR-1258L/KFH-164. The entire specimen was fabricated using the resin infusion process.

Table 2 and

Figure 2 display the ID of the real specimens, the thickness of CFRP and GFRP, and the depth and size of the defects. Specimens with an ID starting with RN indicate non-defect specimens, while those starting with RD indicate specimens with defects. The number following RD represents the depth (in tenths of a millimeter, 0.1 mm) of the inserted defect, and the last two digits indicate the size of the defect (

). The thickness of CFRP and GFRP are shown in

Figure 2a, and the defects were simulated using Teflon tape with a thickness of 1 mm. The depth of the defect is measured from the heating panel. The defects are square-shaped and consist of five sizes:

and

.

Figure 2b shows photographs of specimens from RD42-10 to RD42-50, with the white areas representing the defects inserted inside.

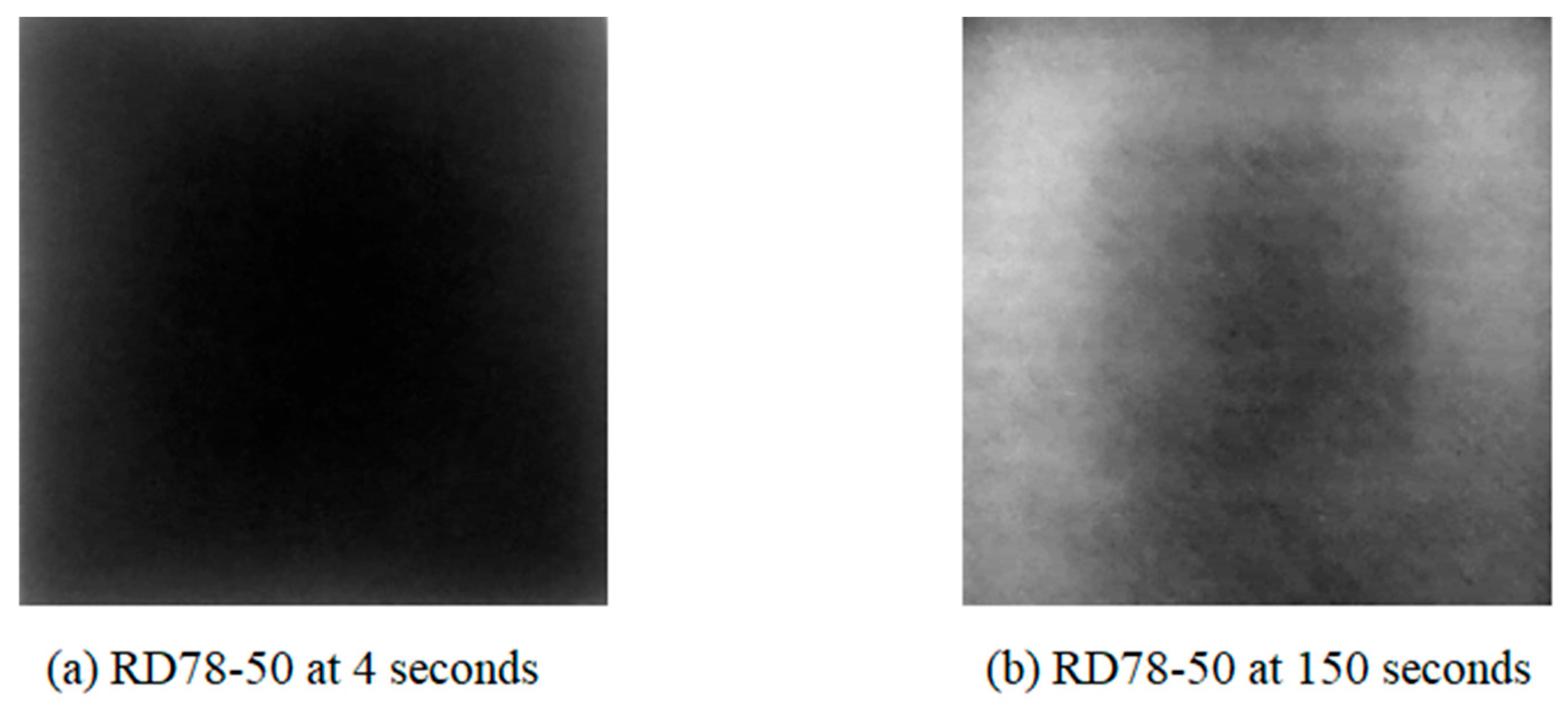

The real thermographic data were captured using the FLIR E96 infrared camera on the unheated side with a resolution of . The defect specimens in the real thermographic dataset were placed on a heating panel, maintaining a uniform temperature of 40 °C and heated using a steady-state thermography method until thermal equilibrium was reached. Due to the limited number of non-defect specimens compared to the defect specimens, these were captured under varying temperature conditions (30 °C, 40 °C) until thermal equilibrium was achieved. Among the non-defect specimens, RN-1 and RN-4 were filmed until the heating panel reached 50 °C from room temperature 22 °C. The thermographic data of RN-1 and RN-4 were used as non-defect class data for training the deep learning model.

The average time required for the heating panel and real specimens to reach thermal equilibrium was 300 s. The acquired thermographic data were cropped to focus on the specimen area and resized to a resolution of , forming the real thermographic dataset, that is, the real image sequences. Analysis revealed a subtle temperature difference of 0.1 °C to 0.3 °C between the defect and non-defect regions. When using this data as input for the deep learning model, a preprocessing method was necessary to enhance visual contrast by emphasizing the pixel values corresponding to the temperature differences.

Figure 3 illustrates the preprocessing method for the thermographic data from the real specimens. At time

, the region

of the thermographic data captured by the infrared camera, which corresponds to the specimen, is a square matrix composed of temperature values. Among the

thermographic data consecutively acquired over a certain period, the highest temperature,

, and the lowest temperature,

, can be defined. The temperature range between

and

is normalized by setting

to 255 and

to 0. Through this process, the square matrices from

to

are transformed into images.

The minimum temperature observed in a sequence of consecutive thermographic data is generally represented by at time , while the maximum temperature is typically represented by at time . Through this process, an image that visually maximizes the temperature difference between the defect and non-defect regions in the thermographic data acquired at time can be obtained.

Setting to 1 introduces significant noise in a single thermographic image, necessitating the determination of an optimal value. In this study, was set to 9 to minimize noise and produce an image that effectively maximizes the contrast between the defect and non-defect regions.

The preprocessing method was applied to the real thermographic dataset obtained from the actual specimens, and the processed thermographic images were assigned to the real thermographic image dataset. This generated dataset was then utilized for performance evaluation as validation data for defect detection in the deep learning model.

Table 3 presents the number of data samples in each class that constitute the real thermographic image dataset. Among these, approximately 9% (600 images) of the non-defect class, consisting of two image sequences, were used as the training dataset for the non-defect class of the deep learning model, while approximately 91% (6038 images) were employed for performance evaluation. All 7755 thermographic images from the defect class were used exclusively for performance evaluation.

3.2. Synthetic Thermographic Image Dataset Generation

The synthetic thermographic data were generated using temperature data obtained from the composite material heat transfer analysis, performed with the FEM in the transient thermal analysis module in Ansys 2021 R2.

The purpose of generating synthetic thermographic data, substituting for real thermographic data, was to replicate the temperature variations due to differing heat transfer rates between the defect and non-defect regions in the actual specimens.

The creation of the 3D models for analysis required the fabrication of 26 synthetic specimens, each matching the CFRP thickness, GFRP thickness, defect location, thickness, and size of the 26 real defect specimens. These models were referred to as synthetic specimens.

Figure 4 presents the synthetic specimen (SD78-35) corresponding to the real specimen (RD78-35). The synthetic specimens were labeled by modifying the corresponding real specimen IDs, in which ’RD’ was systematically replaced with ’SD’ to maintain consistency in identification. The material properties of the designed synthetic specimens were set as shown in

Table 4. Furthermore, to simulate delamination, defects represented by Teflon tape in the real specimens were modeled as air gaps in the synthetic specimens.

The mesh for analyzing the modeled synthetic specimens was constructed using a hex-dominant method, incorporating a combination of Quad and Tri elements, with an element size of 1 mm. The boundary conditions for the analysis, illustrated in

Figure 4c, included setting the temperature of the lower heating element to 40 °C and applying a film convection coefficient of 0.004 W/m

2 °C to the side and top surfaces, as shown in

Figure 4d. The coefficient was initially set to simulate natural convection, gradually increasing to 1 W/m

2 °C over time. For the interior of the defect, heat transfer was assumed to occur through a stagnant air environment and a very thin film, with a film convection coefficient of 0.004 W/m

2 °C applied under these conditions. The ambient temperature was set to 22 °C. The analysis was conducted using a time step of 0.1 s over a total duration of 360 s, with the temperature data from the top surface elements of the synthetic specimen recorded and output in matrix form.

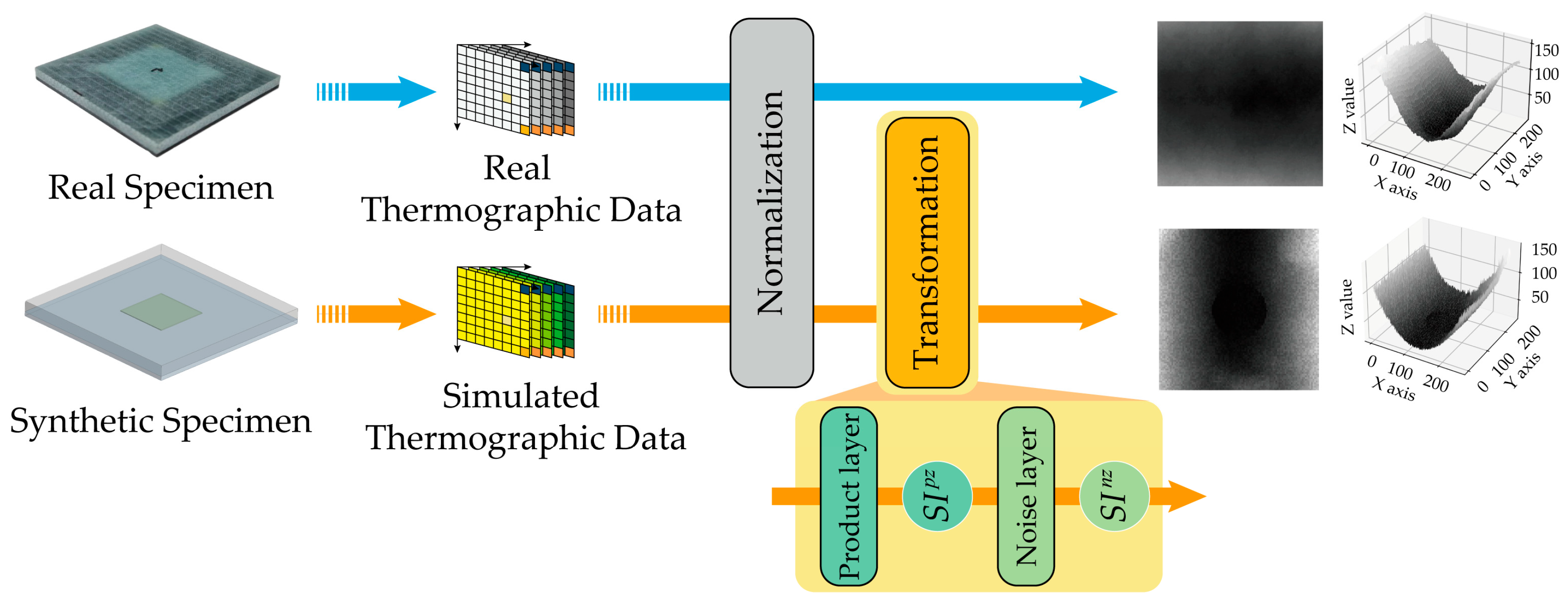

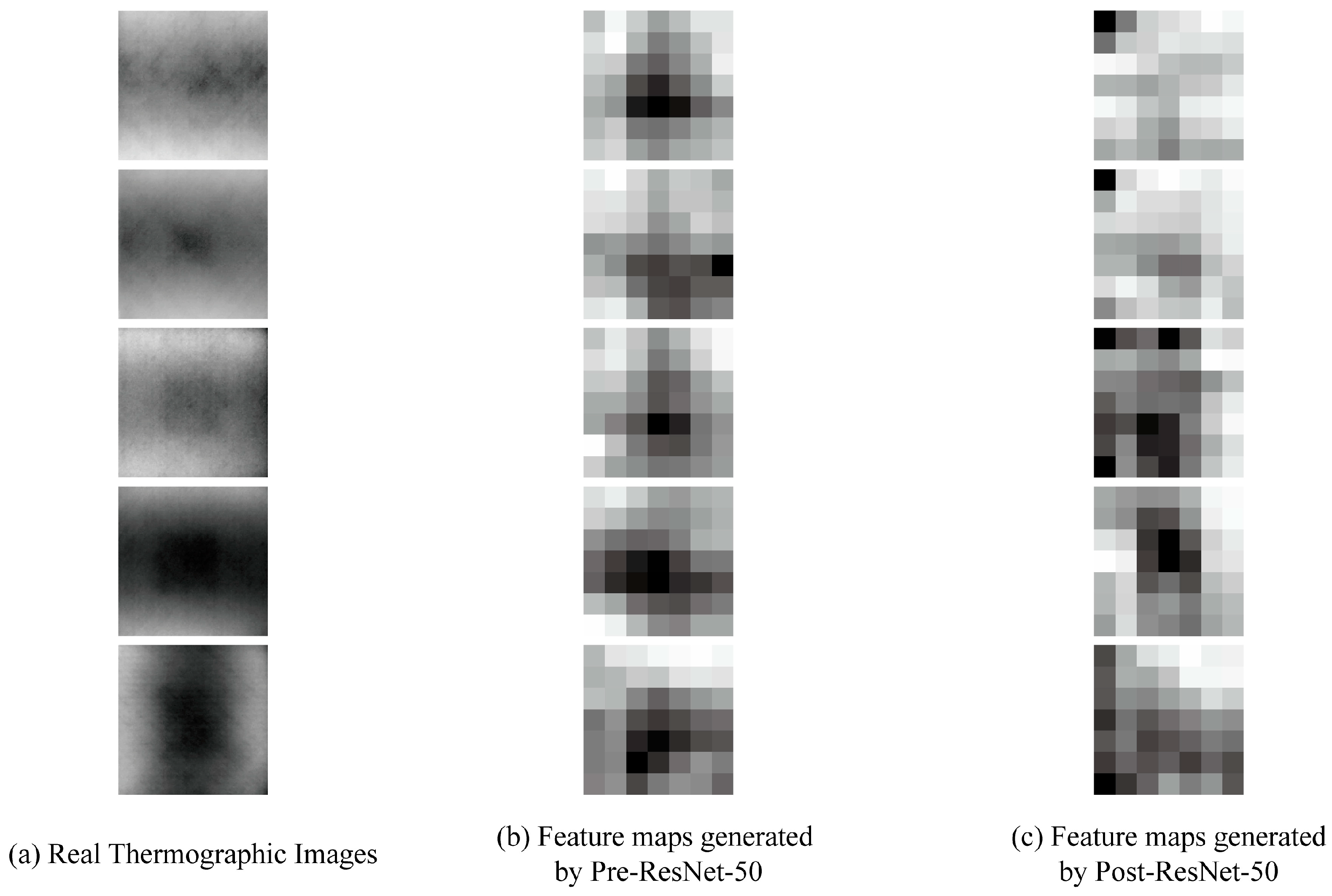

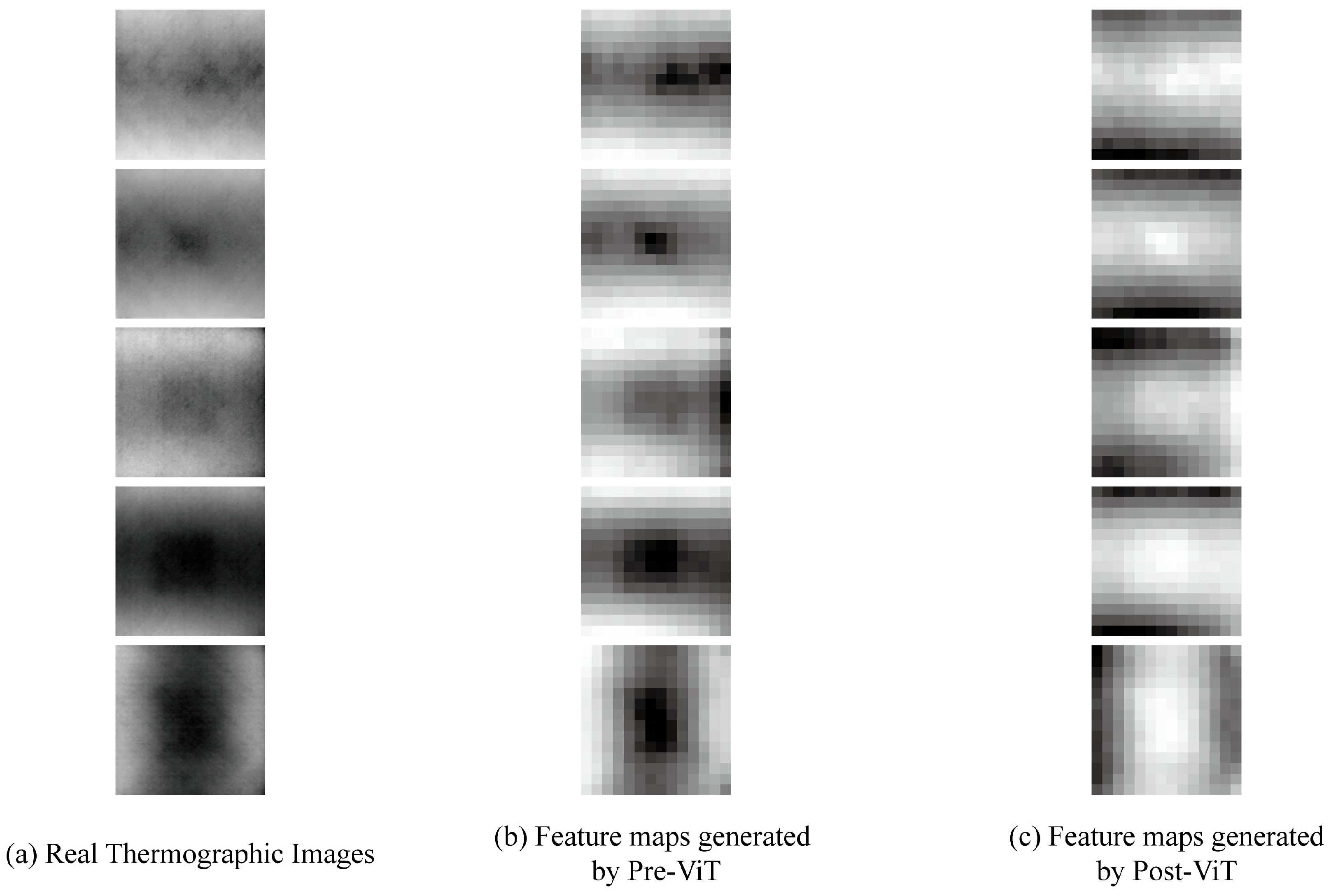

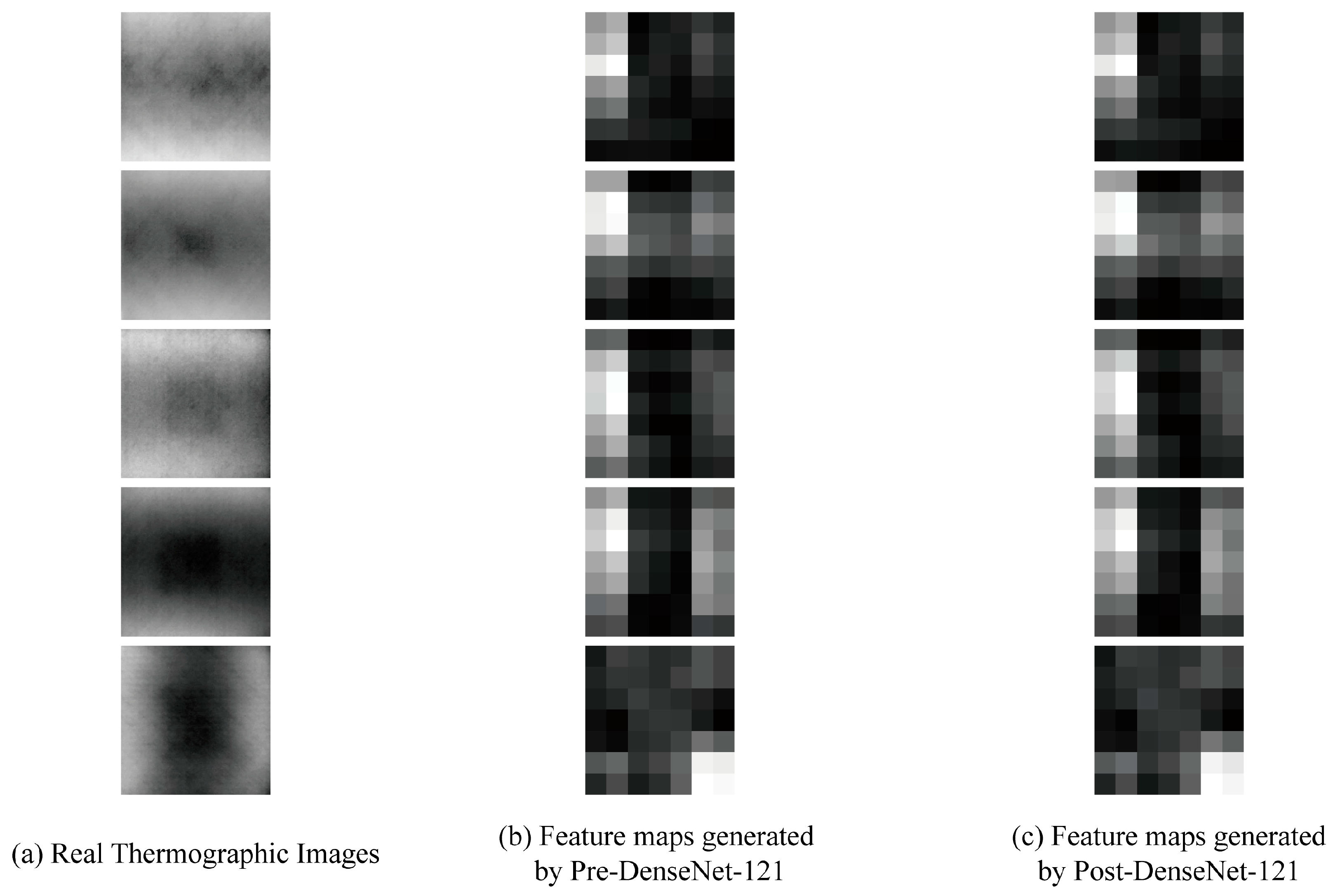

3.3. Transformation Process for Aligning Real and Synthetic Thermographic Image Datasets

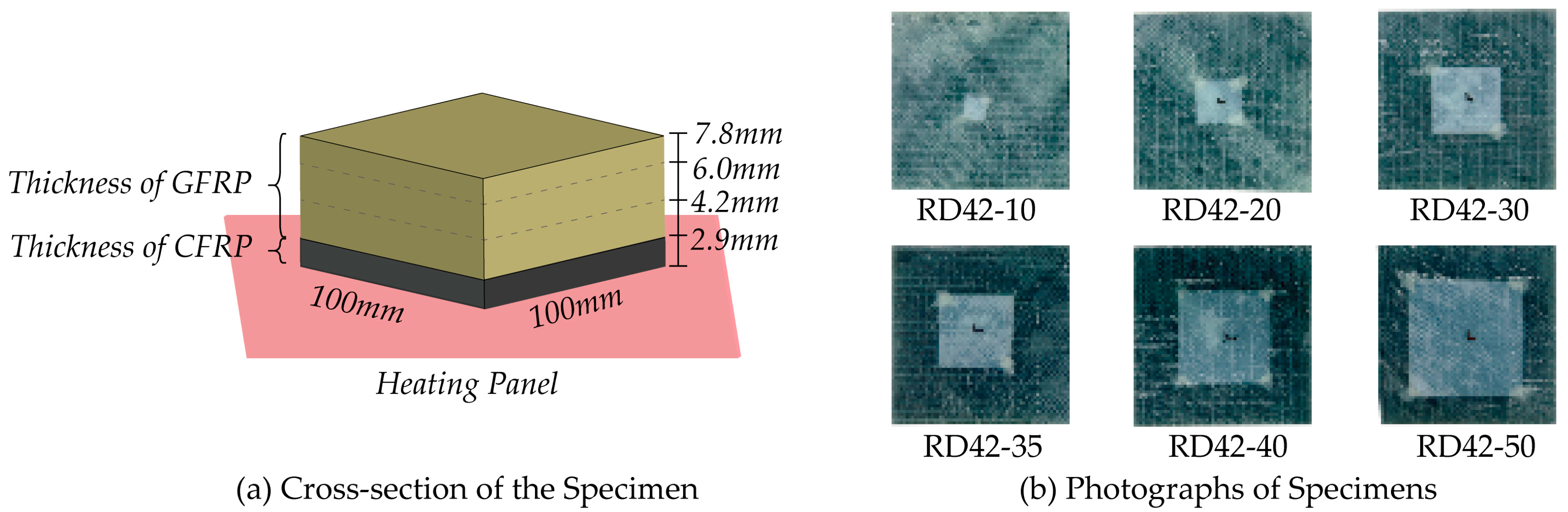

The real thermographic image generated from the actual specimen RD60-35 and the corresponding synthetic thermographic image generated from the synthetic specimen SD60-35 were analyzed for similarity at the same time point (100 s) using a 3D surface graph and histogram. The 3D surface graph represents the elements of a two-dimensional real matrix as depth values, plotted along the x, y, and z axes. The thermographic image of the real specimen at time

is denoted as

, while the thermographic image of the synthetic specimen, generated by normalizing its temperature data, is denoted as

. Both

and

are represented as grayscale images with a single channel. Since each pixel in a grayscale image is assigned a scalar

value, it can be represented using a 3D surface graph. The histogram visually illustrates the distribution of the

values from the 3D surface graph [

24].

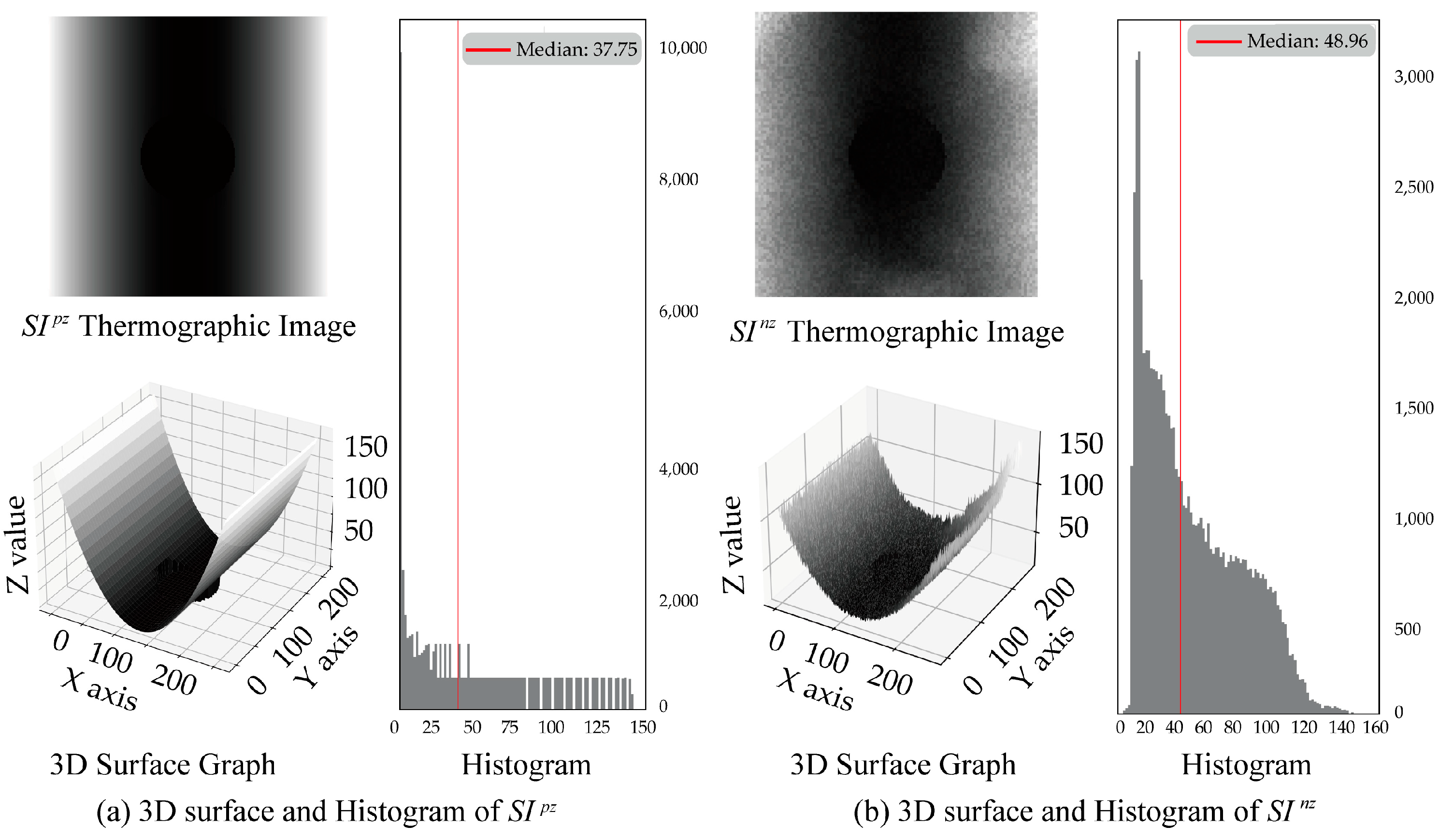

Figure 5a shows the thermographic image

of the real specimen, obtained at

, with normalization applied. The pixel values of

are treated as the depth in the z-direction and reconstructed into a 3D surface graph, along with a histogram representing the distribution of the

values. The curved temperature distribution observed in the 3D surface graph of

RI can be attributed to the curvature inherent in the real blade. Since the specimen was fabricated by cutting a portion of the CFRP used in manufacturing the real blade, the blade’s curvature remains. This residual curvature led to heat loss in areas that were not in direct contact during the heating process.

Figure 5b presents the thermographic image

of the synthetic specimen, generated by normalizing the temperature into a 3D surface graph, with a histogram displaying the distribution of the

values.

The median of the

values for

is 50, with an average of 58, while the median of the

values for

is 151, with an average of 148. By comparing the 3D surface graph and histogram, the analysis of the images obtained from the real specimen RD60-35 and the corresponding synthetic specimen SD60-35 reveals that the

value distributions of the real thermographic image

in

Figure 5a and the synthetic thermographic image

in

Figure 5b differ significantly. The difference in the

value distributions between the real thermographic image and the synthetic thermographic image, both processed using the same normalization method, can be attributed to the disparity between real and simulated data. Therefore, additional preprocessing is necessary for the synthetic specimen thermographic image

to minimize this disparity and better align it with the real specimen thermographic image

.

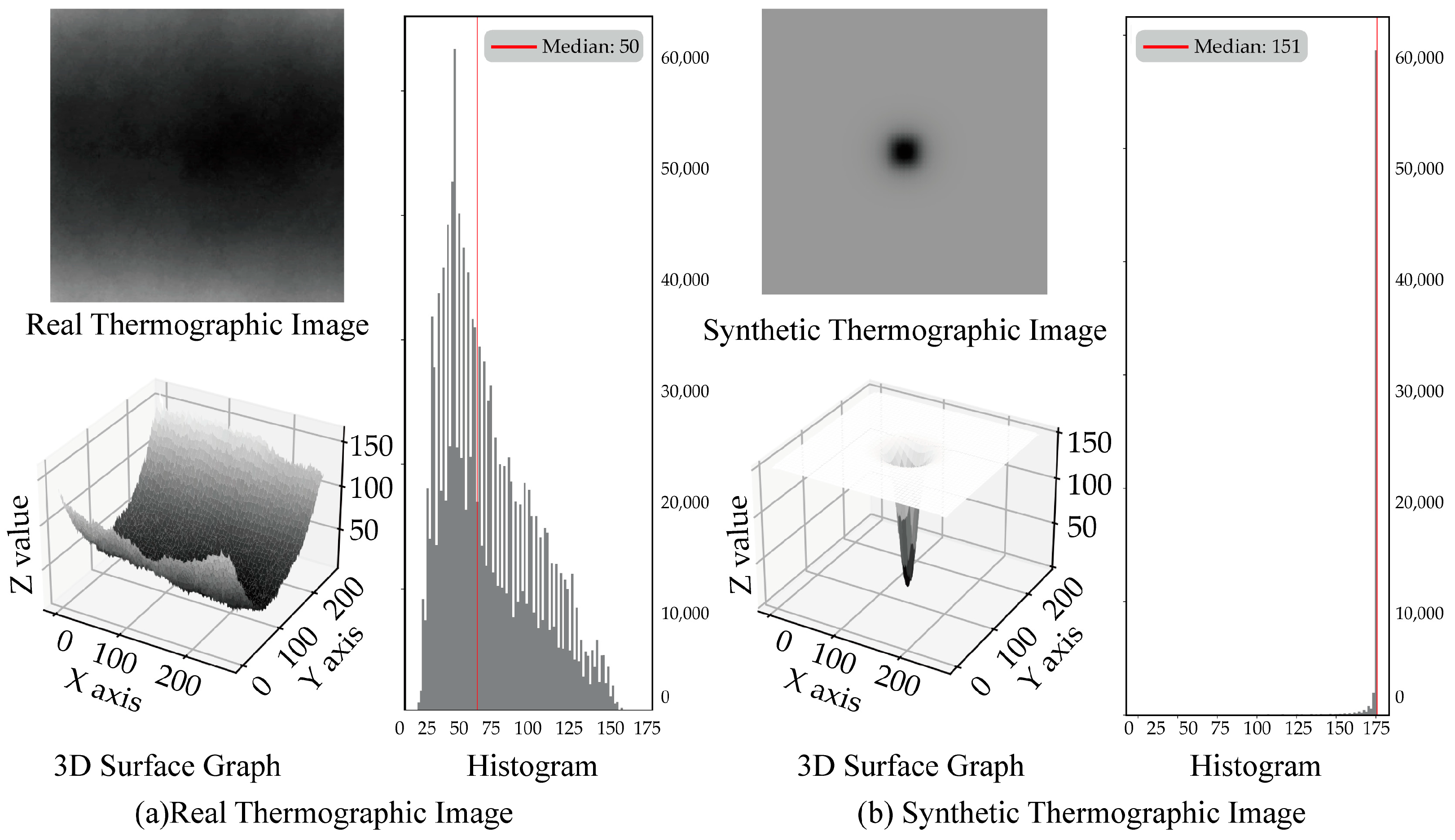

The preprocessing procedure for the synthetic specimen thermographic image

is shown in

Figure 6. The synthetic specimen temperature data passes through the same normalization module applied to the real specimen thermographic data, resulting in the synthetic specimen thermographic image

. Unlike the real specimen thermographic image

, the synthetic specimen thermographic image

is further processed through a transformation module, where it undergoes the product layer and noise layer stages.

The synthetic specimen thermographic image input into the product layer of the transformation module is a grayscale image, represented by the

value

corresponding to the pixel location

, as shown in Equation (1). The

input into the transformation module is reconstructed into a symmetric surface shape, retaining only the

values

greater than the mean

This reconstruction occurs within the range from the

to the

, symmetrically along the y-axis, with respect to the center of the data.

is the height of the image and

is the width of the image.

The reason for reconstructing only those

greater than the

is to preserve the characteristics of the

values corresponding to low-temperature data in the regions where

is smaller than the

, given that

has a standard deviation close to zero. The output

generated by inputting

into the multiplication layer is expressed as shown in Equation (2).

The synthetic specimen thermographic image

is reconstructed into the

matrix, consisting of the

values output from the computational process in the product layer, resulting in a surface shape similar to

, as shown in the 3D surface graph in

Figure 7a. In

Figure 7a the maximum and minimum

values in the

histogram remain unchanged from the maximum and minimum values of

, but the mean is 49 and the median is 37. This indicates that the data has become more dispersed around the mean, leading to an increase in variance.

However, even though the distribution of values in was reconstructed into a surface shape similar to , it displays a smooth distribution that does not capture the nonlinear characteristics caused by the noise in the real specimen thermographic data of . Therefore, was input into the noise layer to modify the data distribution.

Figure 7b shows the 3D surface graph and histogram of

, obtained by inputting

into the noise layer. Style transfer is a technique that modifies the style of one image to match that of another, commonly used to apply the style of artworks to photographs or to alter textures [

25]. In the noise layer, the style transfer matrix

, generated through style transfer, and a random variable matrix

with values ranging from 0.9 to 1.1, are used to introduce nonlinear characteristics to the input

.

One of the non-defect thermographic images from the real specimen dataset was used as the style image for the style transfer model, while the synthetic specimen thermographic image

, prior to its reconstruction into

values, served as the target image. The style transfer matrix

, as expressed in Equation (3), was constructed accordingly.

The random variable matrix

is a matrix composed of values randomly selected from a uniform distribution between 0.9 and 1.1. The random variable matrix

is expressed as shown in Equation (4).

In the noise layer, the reconstructed

is combined with the style transfer matrix

and the random variable matrix

, which uses the Hadamard product operation, as shown in Equation (5).

is reconstructed into the

matrix, consisting of the

values obtained through the computational process in the noise layer. As shown in

Figure 7b, the 3D surface graph and histogram of the reconstructed

distribution confirm that it has been transformed to exhibit a distribution similar to that of the real specimen thermographic image

.

The entire synthetic specimen temperature data were fed into the transformation module, and the resulting

matrix was converted into an image and assigned to the synthetic thermographic image dataset, which was then used as training data for the deep learning model. For the RD29 specimen, images showing the synthetic thermographic images before and after preprocessing, which vary according to the defect size, are attached in

Appendix A.

Table 5 shows the distribution of data by class in the synthetic thermographic image dataset. The non-defect class is composed of 14% of the non-defect class data from the real thermographic image dataset.

3.4. Analysis of Similarities Between Real and Synthetic Thermographic Image Datasets

The similarity of the synthetic thermographic image dataset, constructed for training the deep learning model, was analyzed in comparison to the real thermographic image dataset. Before inputting the synthetic thermographic image dataset obtained from the synthetic specimen into the transformation module, the variation in specific pixel values at certain coordinates in consecutive thermographic images was expressed as a normal distribution. After inputting the synthetic thermographic image dataset into the transformation module, the variation in specific pixel values at the same coordinates in consecutive thermographic images was again expressed as a normal distribution. This was then compared to the normal distribution representing the variation in specific pixel values at the corresponding coordinates in the real thermographic image dataset of the real specimen. The analysis evaluated the effectiveness of preprocessing via the transformation module in enhancing the similarity between the synthetic and real thermographic image datasets.

The difference in pixel values at specific coordinates between the synthetic thermographic images at time and in the synthetic thermographic image dataset was defined as the pixel value rate of change. This definition was designed to effectively simulate the contrast in the temperature rate of change resulting from the difference in heat transfer rates between the defect and non-defect regions observed in the real specimen. The similarity between the pixel value rate of change in the synthetic thermographic dataset and the rate of change distribution in the real thermographic image dataset indicates that the temperature data obtained from the synthetic specimen faithfully reproduces the physical characteristics of the real data.

Figure 8 presents the pixel value rates of change, ranging from 0 to 255, over time at 15 randomly selected coordinates in the defect region and 15 randomly selected coordinates in the non-defect region, from both the real thermographic image dataset obtained from the RD60-30 specimen and the synthetic thermographic image dataset obtained from the SD60-30 specimen. The pixel value rates of change are expressed as a normal distribution. By comparing the rate of change in pixel values over time of the real thermographic image dataset and the pre-transformation and post-transformation synthetic thermographic image datasets using the normal distributions shown in

Figure 8, the effectiveness of the transformation module, aimed at making the synthetic thermographic image dataset resemble the real thermographic image dataset, was evaluated.

In

Figure 8, the blue line represents RID, indicating the distribution of the rate of change in pixel values at specific coordinates extracted from the real thermographic image dataset. The gray line represents SID (pre-transformation), showing the distribution of the rate of change in pixel values extracted from the synthetic thermographic image dataset before being input into the transformation module. The yellow line represents SID (post-transformation), showing the distribution of the rate of change in pixel values extracted from the synthetic thermographic image dataset after processing by the transformation module. The x-axis (rate of change) of the graph displays the rate of change in pixel values at selected coordinates over time. The y-axis represents the probability density, indicating the likelihood of the occurring specific pixel value change rates (x-axis value).

The mean pixel value change rate distribution RID in the real thermographic image dataset is 0.139. In comparison, the mean pixel value change rate distribution SID of Pre-Transformation in the synthetic thermographic image dataset is 0.347, while the mean SID of Post-Transformation is 0.086. After transformation, the mean of the synthetic thermographic image dataset moves approximately 0.155 (74%) closer to the mean of the real thermographic image dataset compared to the pre-transformation dataset. Thus, the transformation module improves the similarity between the synthetic and real thermographic image datasets in terms of their means. This demonstrates that the transformation module effectively adjusts the central tendency of the synthetic thermographic image dataset to align more closely with that of the real thermographic image dataset.

The standard deviation of the pixel value change rate distribution RID in the real thermographic image dataset is 4.193. In comparison, the standard deviation of the pixel value change rate distribution SID (Pre-Transformation) in the synthetic thermographic image dataset before transformation is 0.902, while the standard deviation of SID (Post-Transformation) after transformation is 2.201. Following the transformation, the standard deviation of the synthetic thermographic image dataset becomes approximately 1.299 (39.5%) closer to that of the real thermographic image dataset compared to the pre-transformation dataset. This indicates that the transformation module improves the similarity between the synthetic and real thermographic image datasets in terms of standard deviation.

Since the standard deviation represents the spread of the data distribution, it can be concluded that the transformation module adjusts the distribution of the synthetic dataset to better match that of the real thermographic dataset. Across all specimen IDs, the transformation module proves to be an effective method for narrowing the gap between the synthetic and real thermographic datasets, particularly by improving their similarity in terms of the mean and the standard deviation.