Developing Productivity–Safety Effectiveness Index Using Data Envelopment Analysis (DEA)

Abstract

1. Introduction

2. Background

2.1. Importance of Safety Management for Social Responsibility

2.2. Methodological Background

2.2.1. Productivity and Safety Performance Indexes

2.2.2. Data Envelopment Analysis (DEA)

- : amount of output k produced by DMU j;

- : amount of input i used by DMU j;

- : weight assigned to output k;

- : weight assigned to input i;

- n: number of outputs;

- n: number of outputs;

- m: number of inputs;

2.3. Research Gap and Motivation

3. Proposed Approach

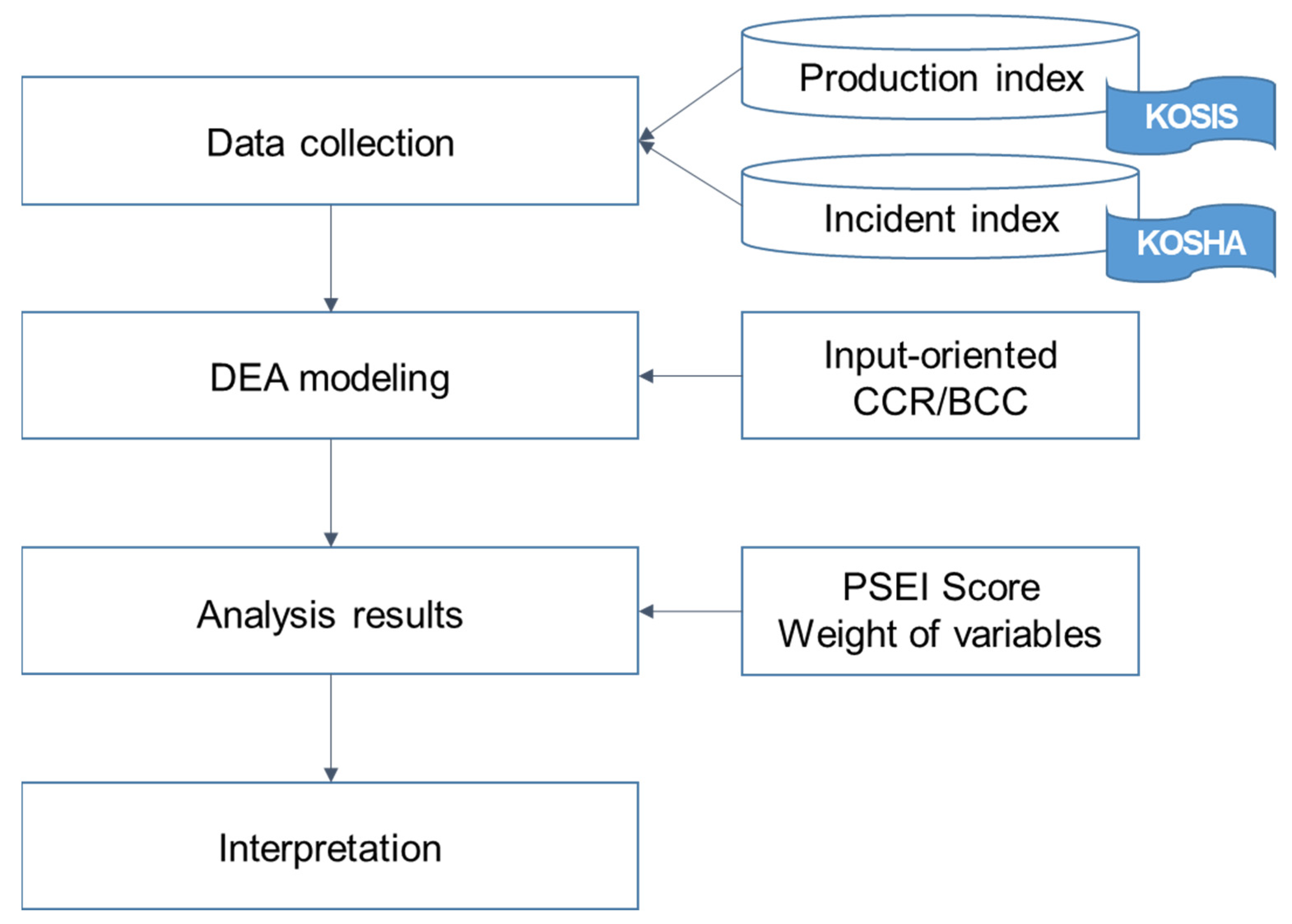

3.1. Research Framework

3.2. Data and Variables

3.3. Productivity–Safety Effectiveness Index

4. Result

4.1. Overall DEA

4.2. Dynamic DEA

5. Discussion

5.1. Implications

5.1.1. Pattern of Productivity–Safety Effectiveness

5.1.2. Benchmarking for Improving PSEI

5.1.3. Trend Adjustment of PSEI

5.2. Limitations

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Díaz-Chao, Á.; Sainz-González, J.; Torrent-Sellens, J. ICT, innovation, and firm productivity: New evidence from small local firms. J. Bus. Res. 2015, 68, 1439–1444. [Google Scholar] [CrossRef]

- Pan, W.; Xie, T.; Wang, Z.; Ma, L. Digital economy: An innovation driver for total factor productivity. J. Bus. Res. 2022, 139, 303–311. [Google Scholar] [CrossRef]

- Wu, L.; Hitt, L.; Lou, B. Data analytics, innovation, and firm productivity. Manag. Sci. 2020, 66, 2017–2039. [Google Scholar] [CrossRef]

- Psomas, E.; Antony, J. The effectiveness of the ISO 9001 quality management system and its influential critical factors in Greek manufacturing companies. Int. J. Prod. Res. 2015, 53, 2089–2099. [Google Scholar] [CrossRef]

- Su, H.C.; Kao, T.W.D.; Linderman, K. Where in the supply chain network does ISO 9001 improve firm productivity? Eur. J. Oper. Res. 2020, 283, 530–540. [Google Scholar] [CrossRef]

- Astrini, N. ISO 9001 and performance: A method review. Total Qual. Manag. Bus. Excell. 2021, 32, 5–32. [Google Scholar] [CrossRef]

- Feng, Y.; Teo, E.A.L.; Ling, F.Y.Y.; Low, S.P. Exploring the interactive effects of safety investments, safety culture and project hazard on safety performance: An empirical analysis. Int. J. Proj. Manag. 2014, 32, 932–943. [Google Scholar] [CrossRef]

- Shirali, G.A.; Salehi, V.; Savari, R.; Ahmadiangali, K. Investigating the effectiveness of safety costs on productivity and quality enhancement by means of a quantitative approach. Saf. Sci. 2018, 103, 316–322. [Google Scholar] [CrossRef]

- Song, B.; Suh, Y. Identifying convergence fields and technologies for industrial safety: LDA-based network analysis. Technol. Forecast. Soc. Change 2019, 138, 115–126. [Google Scholar] [CrossRef]

- Flynn, M.A.; Eggerth, D.E.; Jacobson, C.J., Jr. Undocumented status as a social determinant of occupational safety and health: The workers’ perspective. Am. J. Ind. Med. 2015, 58, 1127–1137. [Google Scholar] [CrossRef] [PubMed]

- Zanko, M.; Dawson, P. Occupational health and safety management in organizations: A review. Int. J. Manag. Rev. 2012, 14, 328–344. [Google Scholar] [CrossRef]

- Fan, D.; Yeung, A.C.; Yiu, D.W.; Lo, C.K. Safety regulation enforcement and production safety: The role of penalties and voluntary safety management systems. Int. J. Prod. Econ. 2022, 248, 108481. [Google Scholar] [CrossRef]

- Feng, Y. Effect of safety investments on safety performance of building projects. Saf. Sci. 2013, 59, 28–45. [Google Scholar] [CrossRef]

- Farid, M.; Neumann, W.P. Modelling the effects of employee injury risks on injury, productivity and production quality using system dynamics. Int. J. Prod. Res. 2020, 58, 6115–6129. [Google Scholar] [CrossRef]

- Abad, J.; Lafuente, E.; Vilajosana, J. An assessment of the OHSAS 18001 certification process: Objective drivers and consequences on safety performance and labor productivity. Saf. Sci. 2013, 60, 47–56. [Google Scholar] [CrossRef]

- Karanikas, N.; Weber, D.; Bruschi, K.; Brown, S. Identification of systems thinking aspects in ISO 45001: 2018 on occupational health safety management. Saf. Sci. 2022, 148, 105671. [Google Scholar] [CrossRef]

- Bautista-Bernal, I.; Quintana-García, C.; Marchante-Lara, M. Safety culture, safety performance, and financial performance. A longitudinal study. Saf. Sci. 2024, 172, 106409. [Google Scholar] [CrossRef]

- Deng, X.; Li, W.; Ren, X. More sustainable, more productive: Evidence from ESG ratings and total factor productivity among listed Chinese firms. Financ. Res. Lett. 2023, 51, 103439. [Google Scholar] [CrossRef]

- Fan, D.; Lo, C.K.; Ching, V.; Kan, C.W. Occupational health and safety issues in operations management: A systematic and citation network analysis review. Int. J. Prod. Econ. 2014, 158, 334–344. [Google Scholar] [CrossRef]

- Adaku, E.; Ankrah, N.A.; Ndekugri, I.E. Design for occupational safety and health: A theoretical framework for organizational capability. Saf. Sci. 2021, 133, 105005. [Google Scholar] [CrossRef]

- Laal, F.; Pouyakian, M.; Madvari, R.F.; Khoshakhlagh, A.H.; Halvani, G.H. Investigating the impact of establishing integrated management systems on accidents and safety performance indices: A case study. Saf. Health Work 2019, 10, 54–60. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Chang, S.; Suh, Y. Developing concentration index of industrial and occupational accidents: The case of European countries. Saf. Health Work 2020, 11, 266–274. [Google Scholar] [CrossRef]

- Lampe, H.W.; Hilgers, D. Trajectories of efficiency measurement: A bibliometric analysis of DEA and SFA. Eur. J. Oper. Res. 2015, 240, 1–21. [Google Scholar] [CrossRef]

- Liu, J.S.; Lu, L.Y.; Lu, W.M.; Lin, B.J. A survey of DEA applications. Omega 2013, 41, 893–902. [Google Scholar] [CrossRef]

- Sousa, V.; Almeida, N.M.; Dias, L.A. Risk-based management of occupational safety and health in the construction industry–Part 2: Quantitative model. Saf. Sci. 2015, 74, 184–194. [Google Scholar] [CrossRef]

- OSHA 1996; Regulations (Standards-29 CFR). OSHA: Washington, DC, USA, 1996. Available online: https://www.osha.gov/laws-regs/regulations/standardnumber/1996 (accessed on 6 January 2025).

- Suh, Y.; Seol, H.; Bae, H.; Park, Y. Eco-efficiency based on social performance and its relationship with financial performance: A cross-industry analysis of South Korea. J. Ind. Ecol. 2014, 18, 909–919. [Google Scholar] [CrossRef]

- Lee, S.; Lee, H. Measuring and comparing the R&D performance of government research institutes: A bottom-up data envelopment analysis approach. J. Informetr. 2015, 9, 942–953. [Google Scholar]

- Erdin, C.; Çağlar, M. National innovation efficiency: A DEA-based measurement of OECD countries. Int. J. Innov. Sci. 2023, 15, 427–456. [Google Scholar] [CrossRef]

- Chen, X.; Liu, X.; Gong, Z.; Xie, J. Three-stage super-efficiency DEA models based on the cooperative game and its application on the R&D green innovation of the Chinese high-tech industry. Comput. Ind. Eng. 2021, 156, 107234. [Google Scholar]

- He, P.; Sun, Y.; Shen, H.; Jian, J.; Yu, Z. Does Environmental Tax Affect Energy Efficiency? An Empirical Study of Energy Efficiency in OECD Countries Based on DEA and Logit Model. Sustainability 2019, 11, 3792. [Google Scholar] [CrossRef]

- Sueyoshi, T.; Goto, M. Efficiency-based rank assessment for electric power industry: A combined use of Data Envelopment Analysis (DEA) and DEA-Discriminant Analysis (DA). Energy Econ. 2012, 34, 634–644. [Google Scholar] [CrossRef]

- Moon, H.; Min, D. A DEA approach for evaluating the relationship between energy efficiency and financial performance for energy-intensive firms in Korea. J. Clean. Prod. 2020, 255, 120283. [Google Scholar] [CrossRef]

- Wang, Q.; Tang, J.; Choi, G. A two-stage eco-efficiency evaluation of China’s industrial sectors: A dynamic network data envelopment analysis (DNDEA) approach. Process Saf. Environ. Prot. 2021, 148, 879–892. [Google Scholar] [CrossRef]

- Song, M.; Jia, G.; Zhang, P. An evaluation of air transport sector operational efficiency in China based on a three-stage DEA analysis. Sustainability 2020, 12, 4220. [Google Scholar] [CrossRef]

- Yu, M.; Xu, S.; Zhou, F.; Xu, H. A study on the relationship between urban spatial structure evolution and ecological efficiency in Shandong Province. Appl. Sci. 2024, 14, 818. [Google Scholar] [CrossRef]

- García-Quevedo, J.; Jové-Llopis, E. Environmental policies and energy efficiency investments. An industry-level analysis. Energy Policy 2021, 156, 112461. [Google Scholar] [CrossRef]

- Tong, H.; Hou, Q.; Dong, X.; Duan, Y.; Gao, W.; Lei, K. Assessing the spatial efficiency of Xi’an rail transit station areas using a data envelopment analysis (DEA) model. Appl. Sci. 2025, 15, 384. [Google Scholar] [CrossRef]

| Variables | Operational Definition | Normal Formula |

|---|---|---|

| Labor Productivity (LP) | The amount of output produced per unit of labor input. It measures the efficiency of workers in producing goods or services. | (Total outputs/total man-hours of year)/(Total outputs/total man-hours of base year) × multiplier(100) |

| Production Capacity (PC) | The maximum amount of goods or services that a business can produce given its resources. It measures the capability of a company or a facility to produce output within a specified period. | (Production capacity of year/Production capacity of base year × weight of production items)/(Total weight of all production items) × multiplier(100) |

| Operation Ratio (OR) | Also known as the capacity utilization rate, it measures how effectively a company or a facility is utilizing its production capacity. | (Production outputs of year/Production capacity of year)/(production outputs of base year/Production capacity of base year) × weight of operation ratio of items)/(Total weight of all operation ratio of items) × multiplier(100) |

| Injury Rate (IR) | The frequency of workplace injuries and illnesses within a specific time frame. | The number of workers injured by incidents/The number of employees × multiplier(1000) |

| Frequency Rate (FR) | It measures the number of workplace injuries or incidents relative to a standard unit of exposure, typically expressed per a certain number of hours worked or per a specific number of employees. | The number of occupational incidents/The number of employees × multiplier(1,000,000) |

| Severity Rate (SR) | The number of lost workdays associated with each incident. The total severity scores are divided by the total number of hours worked or another unit of exposure. | The number of loss of working hours/The number of employees × multiplier(1000) |

| Topic | Purpose | Level |

|---|---|---|

| R&D | R&D efficiency based investment and knowledge outputs (academic publication, patent, etc.) | National [30], |

| Industry [31] | ||

| Corporate/Project [30] | ||

| Energy | Energy efficiency based on raw material inputs and energy use | National [32] |

| Industry [33] | ||

| Corporate/project [34] | ||

| Ecology | Eco-efficiency based on raw material inputs and emission of greenhouse gases | Industry [28,35] National [36] |

| Transport | Transportation service efficiency based on resources (e.g. capital, infrastructure) and quality of transportation services (e.g. speed, channel) | Industry [37] Corporate/project [38] |

| Manufacturing Industry | IR | FR | SR | LP | PC | OR |

|---|---|---|---|---|---|---|

| 1. Food and Beverage | 7.82 | 3.50 | 1.58 | 98.45 | 101.30 | 101.53 |

| 2. Textile (except apparel) | 3.60 | 1.62 | 0.83 | 98.25 | 99.70 | 95.95 |

| 3. Wood | 17.36 | 7.79 | 4.13 | 97.73 | 101.20 | 100.45 |

| 4. Pulp and paper | 8.91 | 4.01 | 2.28 | 97.15 | 98.15 | 100.13 |

| 5. Coal and petroleum products | 4.49 | 1.97 | 3.72 | 105.05 | 103.70 | 105.13 |

| 6. Chemicals | 5.92 | 2.64 | 1.58 | 105.13 | 103.58 | 101.53 |

| 7. Rubber and plastic products | 9.49 | 4.25 | 1.97 | 97.53 | 100.03 | 98.85 |

| 8. Non-metallic mineral | 14.25 | 6.43 | 4.06 | 106.50 | 103.63 | 103.90 |

| 9. Basic metal | 2.00 | 0.89 | 1.00 | 102.20 | 100.27 | 101.30 |

| 10. Metal fabrication | 10.53 | 4.67 | 3.26 | 101.18 | 100.20 | 101.81 |

| 11. General machinery and equipment | 7.39 | 3.33 | 1.77 | 105.50 | 100.30 | 99.63 |

| 12. Precision instruments | 2.45 | 1.11 | 0.51 | 104.63 | 106.57 | 98.60 |

| 13. Electrical equipment | 2.94 | 1.32 | 0.61 | 100.53 | 100.87 | 102.23 |

| 14. Automobile | 6.00 | 2.70 | 1.16 | 98.49 | 100.15 | 90.98 |

| 15. Transportation equipment | 5.95 | 2.67 | 1.58 | 98.57 | 92.37 | 88.43 |

| Average | 7.27 | 3.26 | 2.00 | 101.13 | 100.80 | 99.36 |

| Standard deviation | 4.35 | 1.96 | 1.23 | 3.41 | 3.15 | 4.51 |

| Measures | Explanation |

|---|---|

| Efficiency | When the efficiency of DMU is higher, the lower the safety performance values, the higher the productivity values. |

| Weight | When the weight of one variable of inputs (outputs) is higher than that of other variables of inputs (outputs) in the industry i, it means that this variable has relatively more influence on increasing PSEI of the industry i compared to other industries. |

| Manufacturing Industry | Average % Score (CCR) | Rank | Average % Score (BCC) | Rank |

|---|---|---|---|---|

| 1. Food and Beverage | 30.49 | 10 | 34.54 | 11 |

| 2. Textile (except apparel) | 61.88 | 4 | 64.08 | 5 |

| 3. Wood | 13.10 | 15 | 15.00 | 15 |

| 4. Pulp and paper | 24.79 | 11 | 25.81 | 12 |

| 5. Coal and petroleum products | 45.57 | 5 | 77.92 | 4 |

| 6. Chemicals | 38.28 | 7 | 50.17 | 8 |

| 7. Rubber and plastic products | 24.35 | 12 | 25.33 | 13 |

| 8. Non-metallic mineral | 15.76 | 14 | 60.27 | 6 |

| 9. Basic metal | 95.34 | 2 | 96.52 | 2 |

| 10. Metal fabrication | 19.13 | 13 | 20.19 | 14 |

| 11. General machinery and equipment | 31.35 | 9 | 53.58 | 7 |

| 12. Precision instruments | 96.79 | 1 | 98.29 | 1 |

| 13. Electrical equipment | 81.04 | 3 | 91.14 | 3 |

| 14. Automobile | 40.62 | 6 | 42.90 | 9 |

| 15. Transportation equipment | 35.49 | 8 | 37.15 | 10 |

| Average | 41.86 | 50.30 | ||

| Standard deviation | 26.41 | 27.18 |

| Manufacturing Industry | Input | Output | ||||

|---|---|---|---|---|---|---|

| IR | FR | SR | LP | PC | OR | |

| 1. Food and Beverage | 0.0 | 26.4 | 73.6 | 16.4 | 45.0 | 38.7 |

| 2. Textile (except apparel) | 38.4 | 35.3 | 26.3 | 41.4 | 17.0 | 41.8 |

| 3. Wood | 0.0 | 44.1 | 56.0 | 0.0 | 7.3 | 92.7 |

| 4. Pulp and paper | 29.7 | 28.5 | 41.8 | 0.0 | 0.0 | 100.0 |

| 5. Coal and petroleum products | 50.0 | 47.0 | 3.1 | 16.3 | 8.3 | 75.5 |

| 6. Chemicals | 0.0 | 47.4 | 52.6 | 15.3 | 0.3 | 84.4 |

| 7. Rubber and plastic products | 15.6 | 34.6 | 49.8 | 8.1 | 8.4 | 83.6 |

| 8. Non-metallic mineral | 0.0 | 18.3 | 81.7 | 24.6 | 0.4 | 75.0 |

| 9. Basic metal | 66.7 | 14.6 | 18.7 | 44.2 | 11.0 | 44.8 |

| 10. Metal fabrication | 0.0 | 80.2 | 19.8 | 16.3 | 29.2 | 54.6 |

| 11. General machinery and equipment | 0.0 | 43.8 | 56.2 | 50.1 | 0.0 | 49.9 |

| 12. Precision instruments | 0.0 | 46.3 | 53.7 | 66.7 | 0.0 | 33.3 |

| 13. Electrical equipment | 0.0 | 41.2 | 58.8 | 8.0 | 0.0 | 92.0 |

| 14. Automobile | 0.0 | 26.4 | 73.6 | 16.4 | 45.0 | 38.7 |

| 15. Transportation equipment | 25.9 | 42.4 | 31.8 | 45.4 | 11.2 | 43.5 |

| Average | 15.1 | 38.4 | 46.5 | 24.6 | 12.2 | 63.2 |

| Standard deviation | 22.0 | 15.7 | 22.6 | 20.1 | 15.6 | 23.5 |

| Industry | 2015 | 2016 | 2017 | 2018 | Trend |

|---|---|---|---|---|---|

| 1. Food and Beverage | 20.99 | 22.19 | 25.58 | 24.41 | Increase |

| 2. Textile (except apparel) | 54.71 | 43.93 | 45.63 | 35.65 | Decrease |

| 3. Wood | 8.2 | 9.34 | 10.13 | 10.57 | Increase |

| 4. Pulp and paper | 17.6 | 17.7 | 19.13 | 17.2 | Stable |

| 5. Coal and petroleum products | 41.1 | 37.62 | 46.38 | 30.05 | Decrease |

| 6. Chemicals | 26.12 | 26.86 | 29.32 | 27.27 | Stable |

| 7. Rubber and plastic products | 18.83 | 19.6 | 17.47 | 18.8 | Stable |

| 8. Non-metallic mineral | 10.48 | 12.07 | 12.35 | 16.27 | Increase |

| 9. Basic metal | 75.39 | 85.93 | 81.45 | 81.46 | Increase |

| 10. Metal fabrication | 14.05 | 16.02 | 16.02 | 16.27 | Stable |

| 11. General machinery and equipment | 20.21 | 21.44 | 22.85 | 16.27 | Decrease |

| 12. Precision instruments | 63.89 | 90.46 | 70.08 | 100 | Increase |

| 13. Electrical equipment | 58.24 | 58.86 | 63.65 | 63.65 | Increase |

| 14. Automobile | 30.86 | 27.77 | 41.72 | 21.72 | Decrease |

| 15. Transportation equipment | 23.64 | 25.48 | 23.01 | 21.72 | Stable |

| Average | 32.29 | 34.35 | 34.98 | 33.42 |

| Pattern | Respective Industries | General Production Type |

|---|---|---|

| 1. Worker–Operation ratio | Coal and petroleum, Basic metal | Continuous production Flow shop system |

| 2. Injury–Labor productivity | Transportation equipment | Project production Job shop system |

| 3. Injury–Operation ratio | Metal fabrication | Mass production Flow shop system |

| 4. Loss time–Labor productivity | Precision instruments, Electrical equipment | Batch production Job shop system |

| 5. Loss time–Production capacity | Food and beverage, Automobile | Mass production Flow shop system |

| 6. Loss time–Operation ratio | Non-metallic mineral, Rubber and plastic, Wood, Pulp and paper, Chemicals, Textile, General machinery and equipment | Continuous production Flow shop system |

| Type | Example of Industry | Year | Score | Input | Output | ||||

|---|---|---|---|---|---|---|---|---|---|

| IR | FR | SR | LP | PC | OR | ||||

| Most efficient DMU | Precision instruments | 2018 | 100 | 0 | 0 | 0 | 0 | 0 | 0 |

| #1. Control only input | Chemicals | 2017 | 82.49 | −2.12 | −0.96 | −0.24 | 0 | 0 | 0 |

| Non-metallic mineral | 2016 | 66.22 | −9.11 | −4.1 | −1.37 | 0 | 0 | 0 | |

| #2 Control both input and output | Precision instruments | 2015 | 94.87 | −0.16 | −0.06 | −0.03 | 0.35 | 3.39 | 0 |

| Electrical equipment | 2016 | 92.63 | −0.26 | −0.1 | −0.05 | 1.71 | 2.31 | 0 | |

| Electrical equipment | 2015 | 80.80 | −0.67 | −0.27 | −0.12 | 0.05 | 4.08 | 0 | |

| Textile | 2015 | 74.65 | −0.91 | −0.39 | −0.17 | 0.01 | 4.17 | 0 | |

| Coal and petroleum products | 2016 | 62.83 | −1.92 | −0.72 | −1.34 | 3.09 | 0.25 | 0 | |

| Industry | Trend | IR | FR | SR | LP | PC | OR |

|---|---|---|---|---|---|---|---|

| 2. Textile(except apparel) | Decrease | 3.60 | 1.62 | 0.83 | 98.25 | 99.70 | 95.95 |

| 5. Coal and petroleum products | Decrease | 4.49 | 1.97 | 3.72 | 105.05 | 103.70 | 105.13 |

| 11. General machinery and equipment | Decrease | 7.39 | 3.33 | 1.77 | 105.50 | 100.30 | 99.63 |

| 14. Automobile | Decrease | 6.00 | 2.70 | 1.16 | 98.49 | 100.15 | 90.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suh, Y. Developing Productivity–Safety Effectiveness Index Using Data Envelopment Analysis (DEA). Appl. Sci. 2025, 15, 1989. https://doi.org/10.3390/app15041989

Suh Y. Developing Productivity–Safety Effectiveness Index Using Data Envelopment Analysis (DEA). Applied Sciences. 2025; 15(4):1989. https://doi.org/10.3390/app15041989

Chicago/Turabian StyleSuh, Yongyoon. 2025. "Developing Productivity–Safety Effectiveness Index Using Data Envelopment Analysis (DEA)" Applied Sciences 15, no. 4: 1989. https://doi.org/10.3390/app15041989

APA StyleSuh, Y. (2025). Developing Productivity–Safety Effectiveness Index Using Data Envelopment Analysis (DEA). Applied Sciences, 15(4), 1989. https://doi.org/10.3390/app15041989