1. Introduction

In open-pit mining operations, the truck–shovel allocation problem is a central factor determining transportation efficiency and production cost. The transportation process typically accounts for 50–60% of total mine operating expenses, and improper truck–shovel allocation often leads to equipment idleness, increased waiting time, and excessive energy consumption, thereby becoming a critical bottleneck to production efficiency [

1,

2,

3,

4]. With the continuous expansion of production scale and the gradual increase in transportation distances, achieving efficient and stable truck–shovel allocation under complex operating conditions has become a key challenge for mining enterprises.

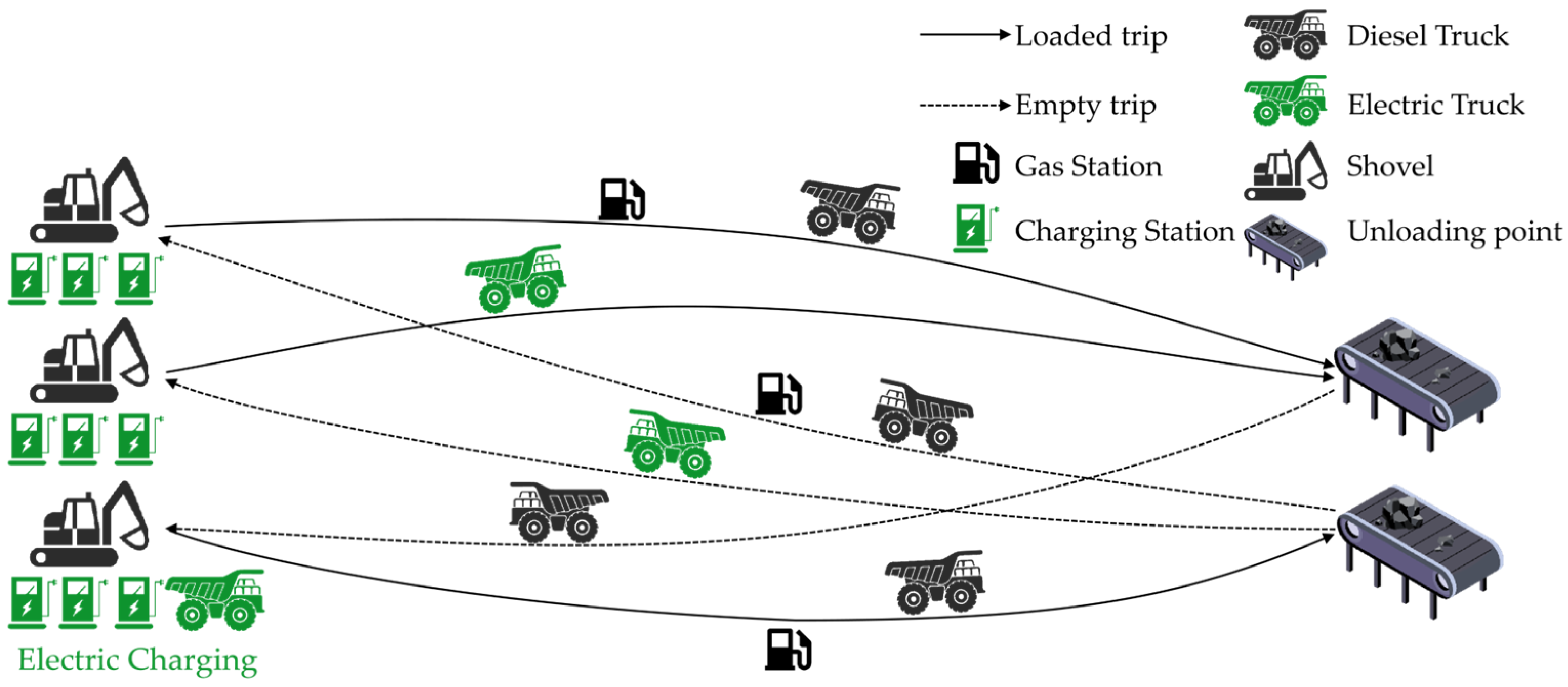

In recent years, driven by energy-saving and emission-reduction policies as well as the demand for green mine construction, more mining enterprises have introduced electric trucks in addition to traditional diesel fleets, gradually forming heterogeneous diesel–electric fleets [

5]. The term “heterogeneous” specifically refers to energy heterogeneity, where diesel and electric trucks differ fundamentally in their energy sources, refueling mechanisms, and operational characteristics. Compared with diesel trucks, electric trucks offer clear advantages in operating cost and environmental performance, but their limited range and frequent charging requirements constrain operational flexibility [

6]. Diesel trucks, by contrast, are capable of handling long-distance and high-intensity transportation tasks, but at the cost of high fuel consumption and substantial maintenance expenses [

7]. The differences between the two vehicle types create strong complementarity within the fleet but also introduce new challenges for scheduling [

8]. Traditional allocation and scheduling methods designed for homogeneous fleets often fail under heterogeneous conditions, leading to reduced system efficiency and increased transportation costs [

9]. Therefore, developing scientifically sound and efficient truck–shovel allocation strategies in heterogeneous diesel–electric fleet environments represent a critical issue in both research and practice.

To overcome these limitations, this paper proposes an integrated truck–shovel allocation framework for heterogeneous diesel–electric fleets in open-pit mines. The framework formulates a multi-objective optimization model that minimizes transportation cost and truck waiting time while explicitly considering shovel capacity, unloading throughput, and energy and charging constraints of electric trucks. The primary contributions of this paper are summarized as follows:

- (1)

An integrated multi-objective truck–shovel allocation model is developed for heterogeneous diesel–electric fleets in open-pit mines, explicitly incorporating practical constraints including shovel capacity, unloading throughput, battery energy consumption, and charging requirements.

- (2)

An improved multi-objective particle swarm optimization (MOPSO) algorithm with adaptive penalty mechanisms is designed to efficiently handle the complex, constraint-intensive scheduling problem and generate high-quality Pareto-optimal solutions.

- (3)

Comprehensive case studies and sensitivity analyses are conducted to compare homogeneous and heterogeneous fleet configurations, providing practical insights into cost–efficiency trade-offs and the operational roles of diesel and electric trucks under varying energy and technology conditions.

The rest of this study is organized as follows:

Section 2 reviews the relevant literature on truck–shovel allocation in open-pit mining, electric haulage systems, and evolutionary optimization methods, and identifies the research gaps addressed in this study.

Section 3 presents the multi-objective truck–shovel allocation model, including model assumptions, objective functions, and constraints.

Section 4 details the algorithm design and parameter configuration, outlining the solution procedure of the improved MOPSO.

Section 5 first validates the proposed MOPSO algorithm through a benchmark comparison with NSGA-II and SPEA2, and then applies it in a case study to compare different fleet configurations, demonstrating the overall effectiveness of the approach. Finally,

Section 6 summarizes the conclusions and discusses potential directions for future research.

2. Literature Review

In this section, we systematically review the current state of research on truck–shovel allocation in open-pit mining, electric haulage systems, and evolutionary optimization methods for complex scheduling problems.

- (1)

Truck–Shovel Allocation in Open-Pit Mining

Extensive research has been devoted to truck–shovel allocation in open-pit mining, as this problem directly determines hauling efficiency and system productivity. Early studies primarily relied on queuing theory and linear programming to capture the relationship between fleet size, shovel utilization, and overall system performance. Ercelebi and Bascetin [

10] combined queuing analysis with linear programming, demonstrating that coordinated fleet sizing and dispatching strategies could significantly reduce hauling costs. As research progressed, more sophisticated optimization models were developed to address allocation efficiency under realistic operational conditions. Ta et al. [

11] incorporated linearized shovel idle probabilities into an integer programming model, improving the balance between fleet size, throughput, and production targets. Zhang and Xia [

12] formulated an integer programming approach that minimized operating costs while meeting production requirements, while Bajany et al. [

13] developed a MILP-based scheduling model focusing on fuel consumption minimization under the m-trucks-for-n-shovels strategy. Simulation and stochastic modeling approaches have further enriched truck–shovel allocation studies. Mena et al. [

14] introduced an availability-based simulation-optimization framework that integrates RAM (reliability, availability, and maintainability) characteristics to guide dynamic fleet assignment. Dindarloo et al. [

15] developed a stochastic discrete-event simulation framework to account for uncertainties in loading, hauling, and queuing processes during equipment selection and sizing. More recent contributions emphasize multi-objective and uncertainty-aware allocation models. Bakhtavar et al. [

16] employed scenario-based robust optimization to capture variations in shovel capacity and crusher throughput. Mohtasham et al. [

17] introduced a chance-constrained goal programming approach that jointly considers production, grade, tonnage, and fuel consumption targets under uncertainty. Matamoros and Dimitrakopoulos [

18] proposed a stochastic integer programming formulation for short-term mine scheduling that integrates fleet allocation decisions. Upadhyay and Askari-Nasab [

19] designed a multi-objective goal programming framework that simultaneously optimizes production, grade stability, feed consistency, and cost control in truck–shovel operations.

- (2)

Electrification and Electric Haulage Systems in Open-Pit Mining

With the growing awareness of energy conservation, emission reduction, and sustainable development in the mining industry, mine electrification has attracted increasing attention from both academia and industry. Halim et al. [

20] conducted a field trial at the Kittilä gold mine, comparing battery-electric vehicles (BEVs) with diesel machines, and reported substantial reductions in harmful gas and particulate emissions, noise, and heat generation, along with improved working conditions and predominantly positive worker feedback. Building upon such findings, recent research has increasingly shifted toward addressing the operational constraints and optimization challenges of electric haulage fleets. Lindgren et al. [

21] proposed a combined electric road-battery electric truck scheme for open-pit mines, developing a simulation model based on field measurements and demonstrating its feasibility in reducing both CO

2 emissions and operating costs compared to diesel alternatives. From the perspective of route and energy modeling, Junhuathon et al. [

22] introduced a route feature-based energy consumption model for electric trucks that incorporates regenerative braking probability into traditional models and uses genetic algorithm-based parameter optimization to enhance both consumption prediction and state-of-charge estimation accuracy. Similarly, Zhang et al. [

23] developed an electric vehicle routing problem (EVRP) model with recharging stations to minimize energy consumption, solved via an ant colony optimization approach, which better reflects the impact of load and speed on consumption compared to traditional distance-minimization models. In terms of scheduling optimization specifically tailored for electric truck operations, Zhang et al. [

24] proposed a rolling-horizon MILP model for heterogeneous electric trucks under charging and service queue constraints, introducing branch-and-price and labeling algorithms to manage large-scale constraints. Xiao et al. [

25] examined battery-swapping trucks in open-pit mining, formulating a multi-objective optimization model solved by both standard and adaptive genetic algorithms; results showed that the adaptive approach reduced transportation costs by 5.6% and waiting times by 17.4% without violating operational constraints. Beyond static charging, Zähringer et al. [

26] developed an online dynamic programming-based charging strategy for long-haul battery-electric trucks that explicitly considers actual charging curves, driver rest regulations, and station occupancy, halving the time losses compared to driver-led decisions and providing actionable infrastructure planning recommendations. These advances in energy modeling, routing, and scheduling for electric haul trucks lay a solid methodological and technological foundation for addressing the truck–shovel allocation challenge in heterogeneous diesel–electric fleets.

Given that the literature specifically focusing on electric haulage systems in open-pit mining remains relatively limited, it is appropriate to draw methodological insights from related research areas, such as electric vehicle fleet routing and charging optimization. These studies provide useful approaches for modeling energy consumption and charging behavior of electric vehicles. However, truck–shovel systems in open-pit mining exhibit distinct operational characteristics, including cyclic hauling processes and strong coupling between loading, hauling, and unloading activities. Accordingly, this study extends existing methods by integrating charging constraints into a truck–shovel allocation framework that is explicitly tailored to heterogeneous diesel–electric fleets.

- (3)

Evolutionary Algorithms for Complex Scheduling Problems

Complex scheduling and allocation problems are typically characterized by large-scale decision spaces, nonlinear relationships, multiple conflicting objectives, and various operational constraints. Traditional exact optimization methods often struggle to obtain high-quality solutions within acceptable computational time under such conditions. Consequently, evolutionary algorithms have been widely adopted due to their population-based search mechanisms and strong global exploration capability.

To improve convergence efficiency and solution diversity, Akopov [

27] addressed bi-objective optimization problems by developing an improved parallel hybrid real-coded genetic algorithm with clustering-based selection. By introducing clustering-based parent selection and parallel computation strategies, the proposed method achieved higher computational efficiency while preserving high-quality Pareto-optimal solutions. Building upon genetic-based evolutionary frameworks, PSO has gained increasing attention because of its simple structure and fast convergence. However, conventional PSO and its multi-objective variants often suffer from premature convergence when applied to constrained and high-dimensional problems. To address this issue, Akopov [

28] proposed a clustering-based hybrid particle swarm optimization (CBHPSO) algorithm for multisectoral agent-based models. In this approach, clustering strategies were introduced to enhance information sharing among particles, while real-coded genetic operators were incorporated to improve population diversity and convergence stability in multi-objective optimization. Further improvements have been achieved by hybridizing PSO with other evolutionary mechanisms. Asija and Choudekar [

29] developed a multi-objective hybrid differential evolution-particle swarm optimization (DE-PSO) algorithm by embedding differential evolution mutation and crossover operators into the PSO updating process, the proposed method enhanced global search capability and significantly improved Pareto-front approximation quality compared with conventional PSO-based approaches. To improve adaptability in dynamic and complex optimization environments, Xu et al. [

30] proposed a hybrid differential evolution-particle swarm optimization algorithm based on dynamic strategies. Their method introduced adaptive inertia weights and dynamically adjusted acceleration coefficients together with differential evolution operators, enabling faster convergence and improved ability to escape local optima. Hybrid evolutionary algorithms have also been increasingly applied to practical scheduling problems. Shao et al. [

31] addressed task scheduling problems by proposing a hybrid PSO-GA method in which genetic crossover and mutation operators were directly integrated into the PSO framework. This hybridization effectively alleviated premature convergence while preserving fast convergence speed, demonstrating the effectiveness of evolutionary algorithm hybridization for complex scheduling applications.

Overall, research on truck–shovel allocation has evolved from early queuing theory and linear programming approaches to advanced optimization models capable of addressing multi-objective, multi-constraint, and uncertainty conditions, with significant progress made in simulation, robust optimization, and goal programming. However, most existing studies focus on homogeneous diesel fleets and cannot be directly applied to heterogeneous fleets that include electric trucks. Although recent studies have explored aspects such as energy consumption modeling, route optimization, and scheduling strategies for electric haul trucks, they largely address single vehicle types, lacking a systematic framework that jointly considers the operational characteristics of diesel and electric trucks, energy supply constraints, and loading-unloading capacity. In addition, recent evolutionary optimization studies further indicate that hybridization strategies integrating clustering mechanisms, genetic operators, and differential evolution can effectively enhance convergence efficiency and solution quality. However, most of these methods are designed for generic optimization problems and are rarely tailored to the operational characteristics and energy-related constraints of truck–shovel allocation in heterogeneous diesel–electric fleets.

To overcome the limitations of existing methods, this study develops a multi-objective truck–shovel allocation model for heterogeneous diesel–electric fleets in open-pit mines, aiming to minimize both transportation cost and waiting time. The model systematically incorporates practical constraints such as battery energy consumption, charging requirements, shovel capacity, and unloading point throughput. To effectively solve this complex problem, an improved MOPSO algorithm with embedded constraint-handling mechanisms is developed to generate truck–shovel allocation schemes. The proposed approach not only addresses the lack of systematic scheduling methods for heterogeneous fleets in existing research but also enables a dynamic trade-off between cost and efficiency, thereby significantly enhancing the overall performance of the transportation system.

4. Algorithm

The multi-objective heterogeneous truck–shovel allocation model developed in this study simultaneously addresses two interdependent objectives, transportation cost and truck waiting time, while incorporating multiple operational constraints arising in open-pit mining. The resulting problem is characterized by a high-dimensional decision space and strong coupling among constraints, making exact optimization methods impractical for large-scale instances due to excessive computational complexity and poor scalability. Metaheuristic algorithms with global search capability therefore provide a more suitable solution framework [

35].

The MOPSO algorithm, an extension of PSO, has been widely applied in scheduling and resource allocation problems due to its high efficiency, simple implementation, and adaptability to complex scenarios. By simulating swarm intelligence and using Pareto dominance with external archiving, MOPSO maintains diverse non-dominated solutions and provides a robust framework for complex scheduling optimization [

36,

37,

38].

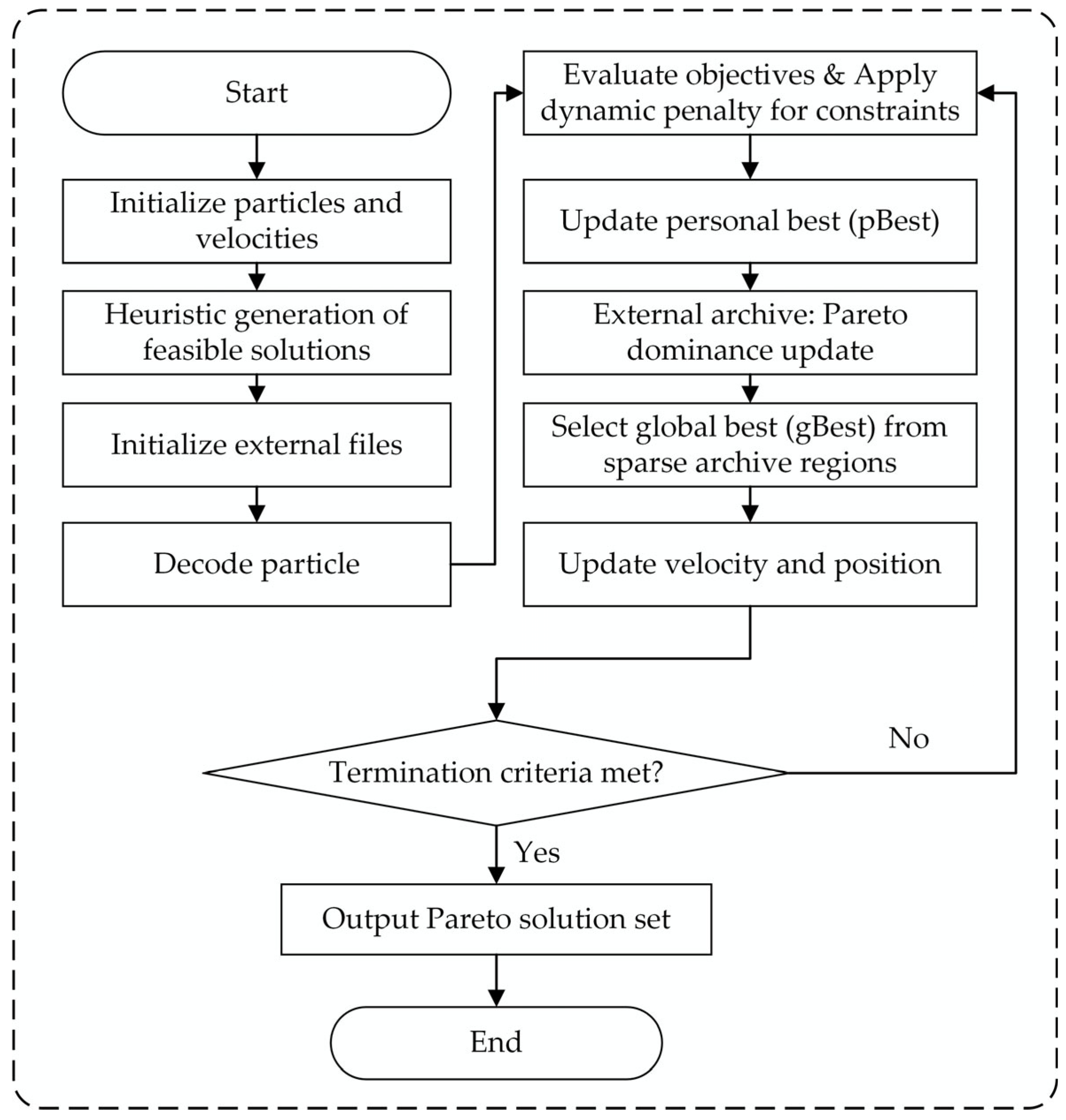

Based on these advantages, this study develops a tailored MOPSO algorithm to solve the proposed heterogeneous truck–shovel allocation problem. The overall solution framework, including particle representation, constraint-aware initialization, multi-objective evaluation, and archive management, is illustrated in

Figure 3.

4.1. Particle Encoding and Initialization

In the proposed MOPSO framework, each particle represents a complete truck–shovel allocation and scheduling scheme for a single production shift. The particle position vector encodes the number of trips assigned to each truck on specific routes, including loaded trips from shovel i to unloading point j and empty return trips from unloading point j to shovel i.

Given the high dimensionality of the decision space and the presence of multiple operational constraints, a heuristic-based initialization strategy is adopted instead of purely random initialization. The objective of this strategy is to generate an initial population that satisfies key production and operational constraints as much as possible, thereby improving feasibility and accelerating convergence.

During initialization, trips are assigned sequentially to individual trucks. For each shovel and unloading point, the available production capacity and throughput are continuously tracked. A candidate trip is accepted only if the corresponding shovel production and unloading capacity constraints are not violated. In this way, the total tonnage assigned to each shovel and unloading point remains within its allowable range throughout the initialization process.

Truck working-time constraints are enforced at the individual vehicle level. For each truck, the remaining available working time within the shift is updated after each assigned trip. A new trip is allocated only if the sum of travel time, loading time, unloading time, and associated auxiliary time does not exceed the remaining shift duration. This mechanism prevents infeasible schedules in which a truck is assigned more tasks than can be completed within a single shift.

For electric trucks, charging time is explicitly incorporated into the working-time feasibility check. The charging time required for assigned trips is estimated based on the cumulative electricity consumption and the charging rate of the vehicle, and it is treated as part of the total working time. This ensures that electric trucks remain schedulable under the same shift-length constraint as diesel trucks.

By jointly considering shovel production limits, unloading throughput constraints, truck working-time restrictions, and charging-time requirements during initialization, the proposed heuristic significantly reduces the number of infeasible particles in the initial population. This constraint-aware initialization provides a high-quality starting point for the subsequent multi-objective particle swarm optimization process and enhances both convergence stability and solution quality.

4.2. Multi-Objective PSO with Adaptive Penalty Mechanism

Each particle is decoded into a detailed operational plan and evaluated using two conflicting objective functions: total transportation cost and total truck waiting time. Transportation cost includes fuel or electricity consumption and vehicle maintenance cost, while waiting time reflects system inefficiency and resource underutilization.

Due to the presence of multiple operational constraints, an adaptive penalty mechanism is introduced to guide the swarm toward feasible and high-quality solutions. All constraint violations are aggregated into a unified violation measure

V(

x), representing the total degree of infeasibility of a particle. The penalized objective functions are defined as:

where

fk(

x) denotes the original objective values and

is an iteration-dependent penalty coefficient. The penalty coefficient increases linearly over iterations:

where

t is the current iteration number and

T is the maximum number of iterations,

and

denote the minimum and maximum penalty coefficients, respectively. A smaller penalty coefficient in the early iterations allows the swarm to explore a wider solution space, including mildly infeasible regions, whereas a larger penalty coefficient in later iterations gradually strengthens constraint enforcement and guides the search toward feasible and high-quality solutions. This adaptive strategy enables broad exploration in the early search stage and progressively enforces feasibility as the optimization proceeds.

Particle velocity and position are updated according to the standard PSO mechanism. The velocity update rule is given by:

and the position update is expressed as:

where

is the inertia weight,

a1 and

a2 are acceleration coefficients,

r1 and

r2 are random vectors,

denotes the personal best position of particle

i, and

gt is a global guide selected from the Pareto archive. Since the decision variables represent discrete truck trip numbers, updated positions are rounded to the nearest integer and bounded within predefined limits to ensure feasibility.

4.3. Pareto Archive Management and Termination

An external archive is maintained to store non-dominated solutions based on Pareto dominance relations. Only constraint-satisfying solutions are admitted into the archive, ensuring that the resulting Pareto front consists of operationally implementable schedules. When the archive becomes crowded, a crowding-distance strategy is applied to preserve solution diversity by removing densely populated solutions. Global guide particles are preferentially selected from sparsely populated regions of the archive to enhance exploration and prevent premature convergence.

The algorithm terminates when the maximum number of iterations is reached. The final external archive provides an approximation of the Pareto front, offering decision-makers multiple alternative truck–shovel allocation strategies that reflect different trade-offs between transportation cost and truck waiting time under practical operational constraints.

6. Conclusions

This study addresses the scheduling optimization of heterogeneous diesel–electric truck fleets in open-pit mines by developing a multi-objective truck–shovel allocation model that simultaneously considers transportation cost and waiting time. An enhanced MOPSO algorithm, tailored to the characteristics of heterogeneous fleets, is designed to solve the model. The model incorporates the distinctive features of diesel and electric trucks, including load capacity, range limitations, and operating time, while also accounting for practical operational constraints such as shovel loading capacity, unloading throughput, and charging requirements, thereby ensuring consistency with real production conditions.

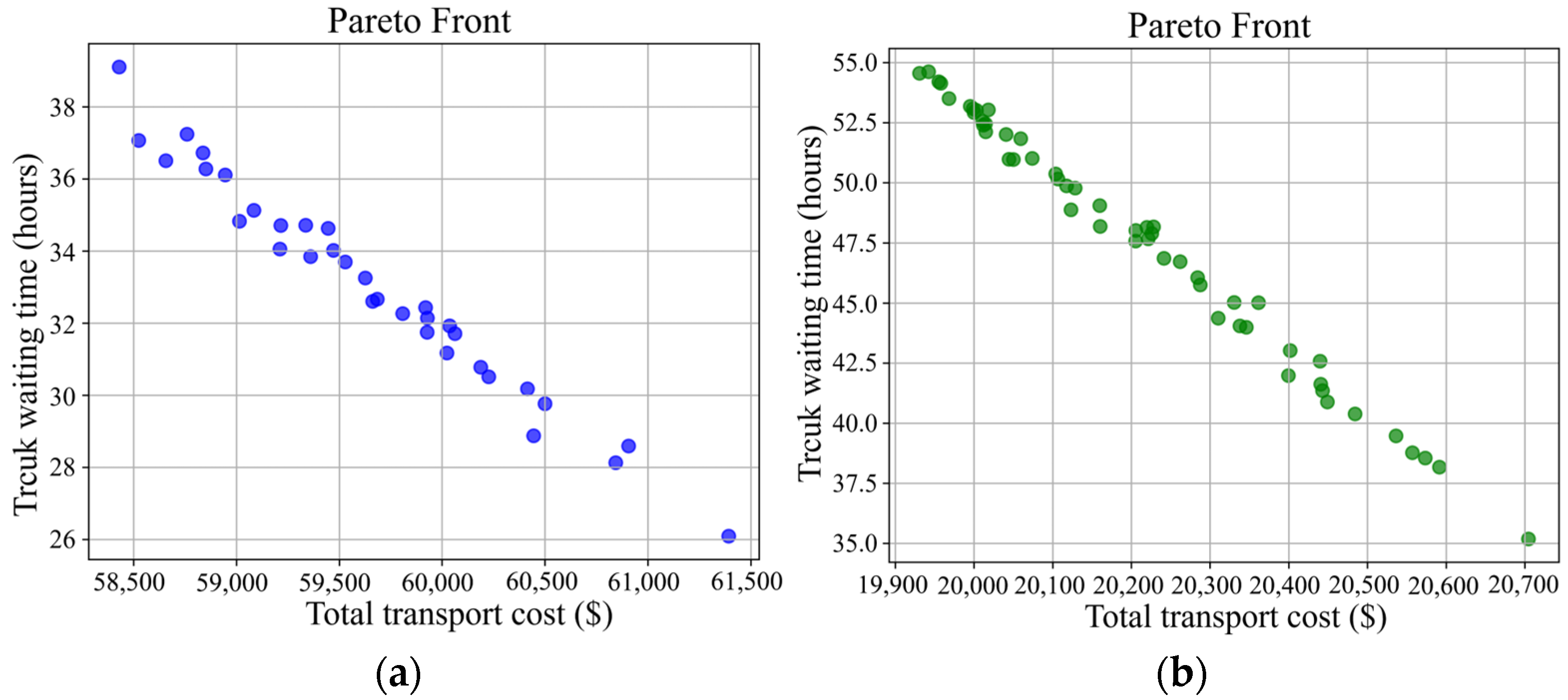

To validate the effectiveness of the solution method, the performance of the proposed MOPSO was benchmarked against other well-established algorithms, namely NSGA-II and SPEA2. The comparative results confirmed its superiority, as it excelled in generating a higher-quality and more diverse set of solutions—evidenced by a larger HV, a greater number of CPFs, and a better ACD, while also exhibiting remarkable efficiency with significantly less PT. Leveraging this validated and efficient algorithm, the case study demonstrated significant performance differences across fleet configurations. The diesel fleet achieves shorter waiting times but suffers from high transportation costs, while the electric fleet reduces costs by nearly 60% but incurs substantially longer delays. In contrast, heterogeneous fleets achieve a superior balance between these two objectives. In particular, the balanced configuration of 25 diesel and 25 electric trucks reduced transportation cost by approximately 26.1% relative to the pure diesel fleet while lowering waiting time by 19.2% compared with a pure electric fleet.

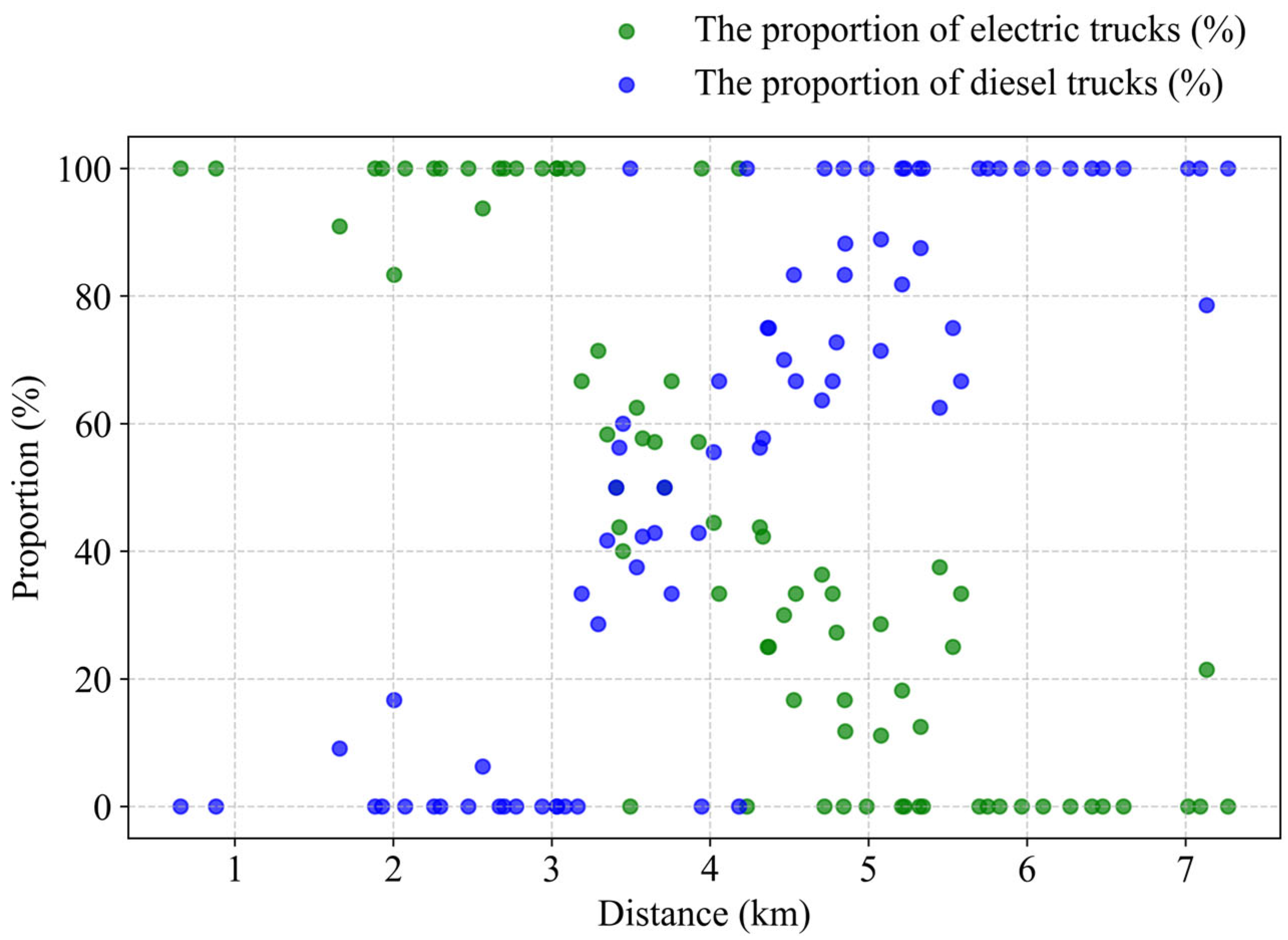

Further examination of task allocation reveals clear complementarities between diesel and electric trucks. Short-haul routes (less than 1 km) are almost exclusively served by electric trucks, taking advantage of their low operating costs and minimal charging needs. Long-haul routes (greater than 7 km) are primarily assigned to diesel trucks, which avoid delays from recharging. Medium-distance routes (1–4 km) follow a mixed allocation pattern, depending on energy consumption and operational urgency. This distance-based division of labor enhances fleet utilization and improves overall system stability.

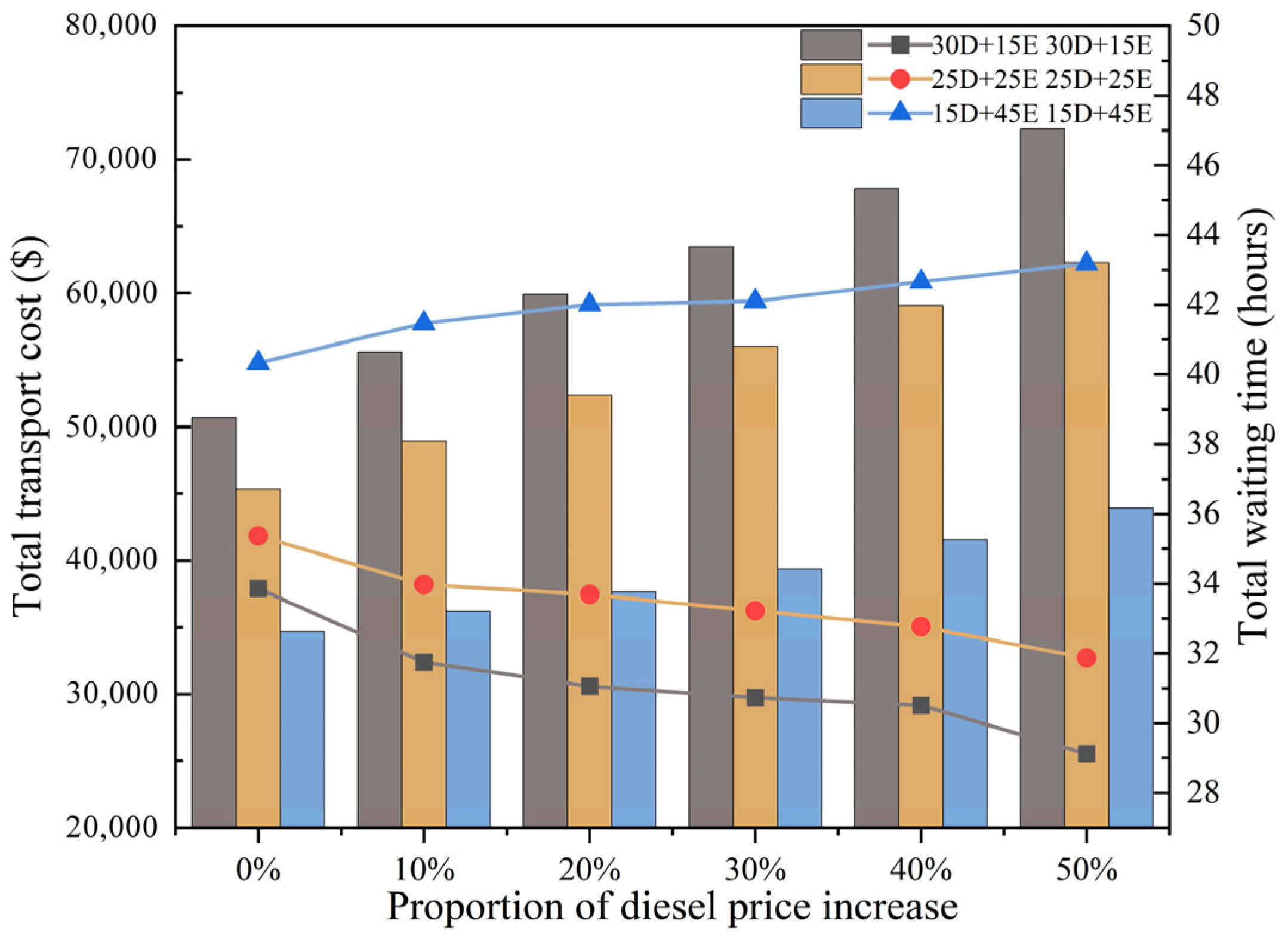

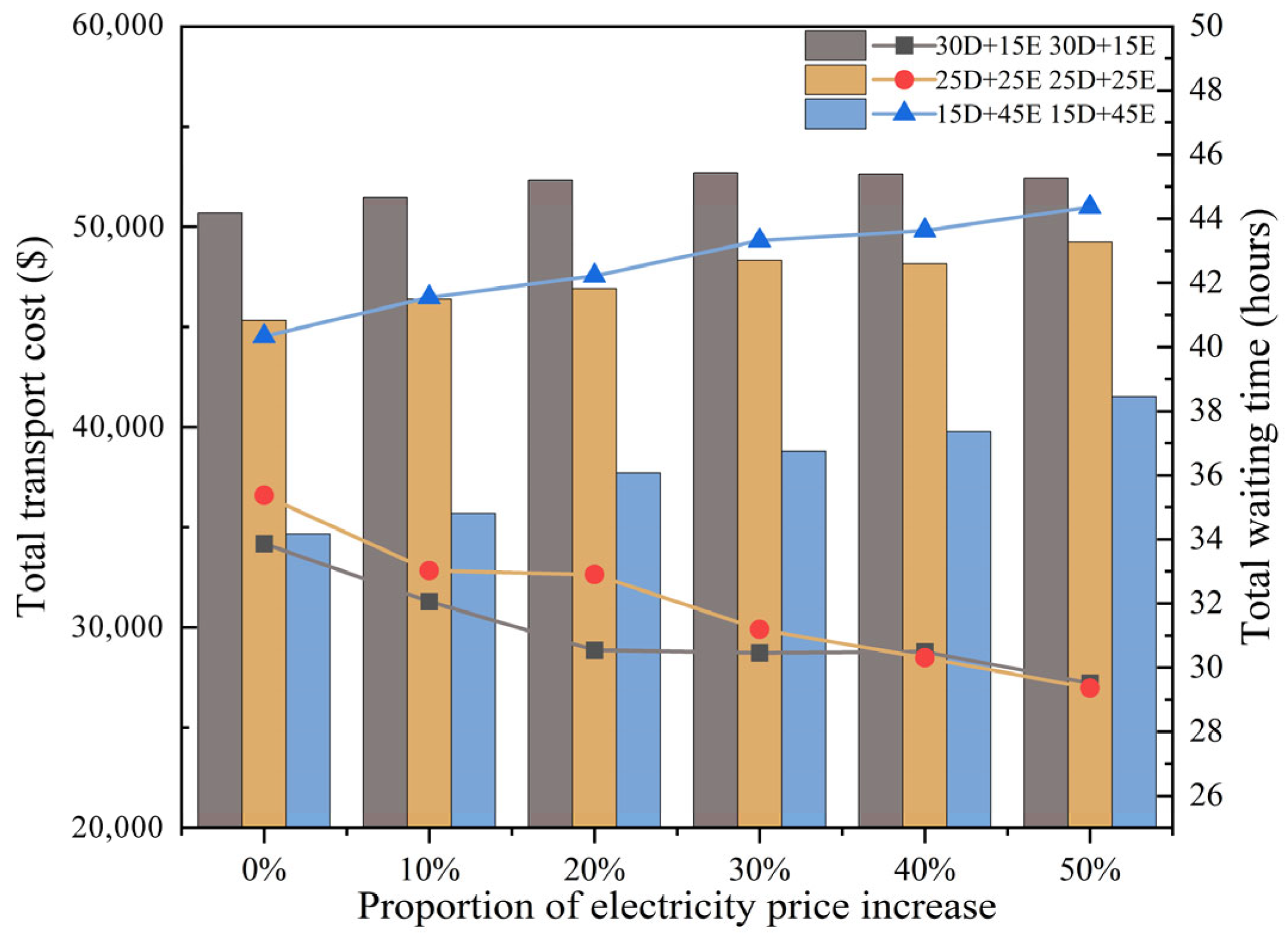

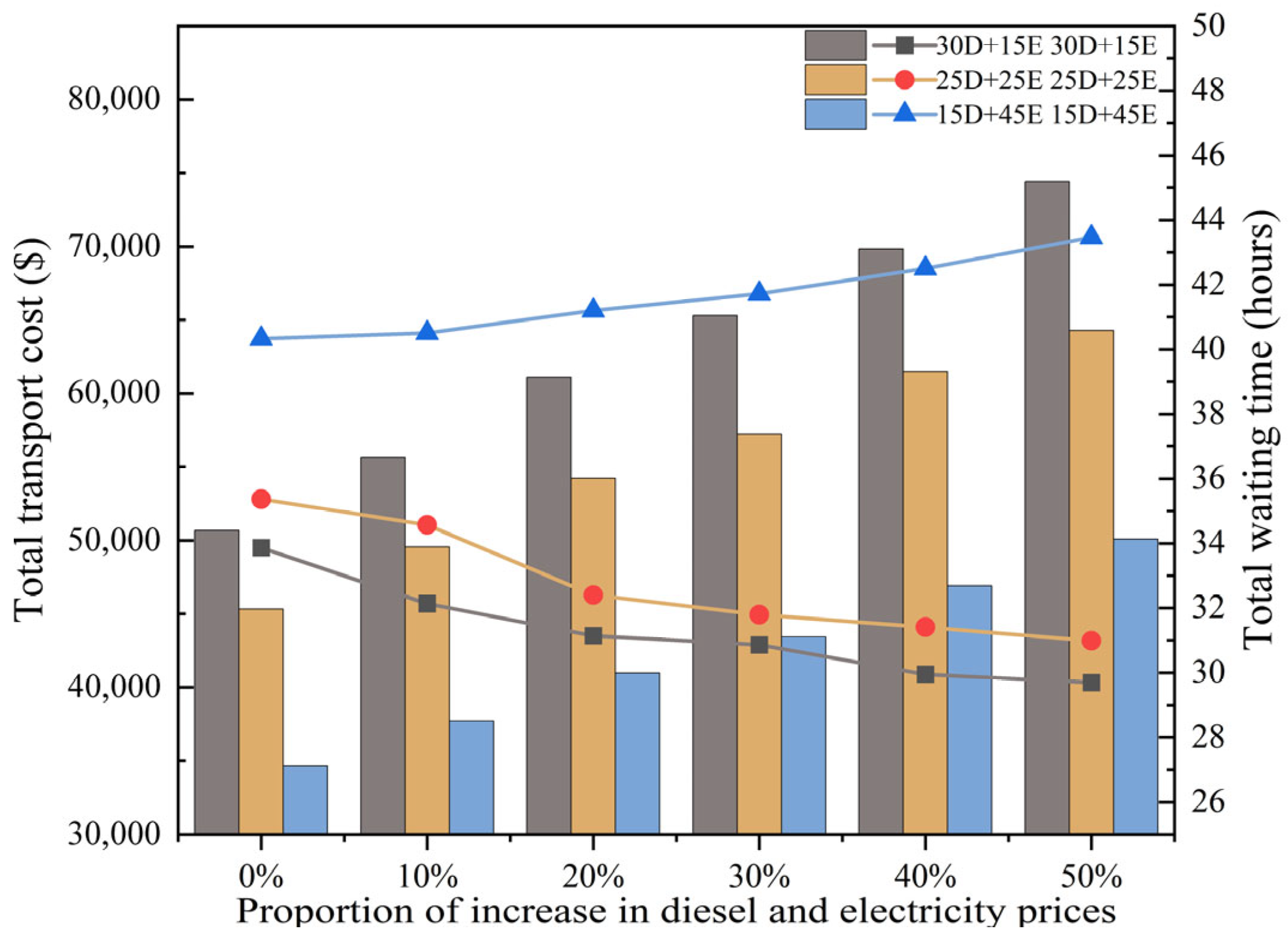

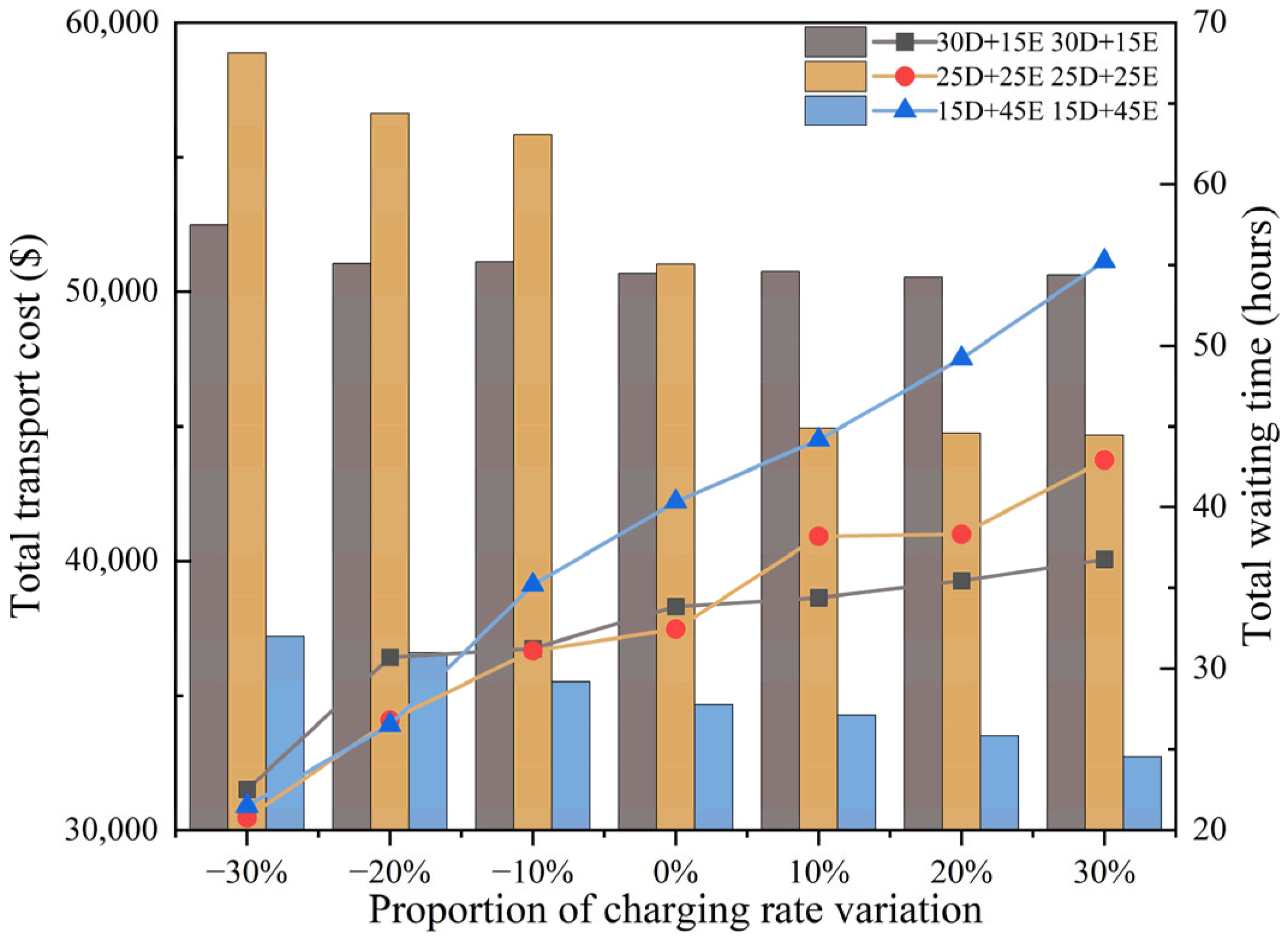

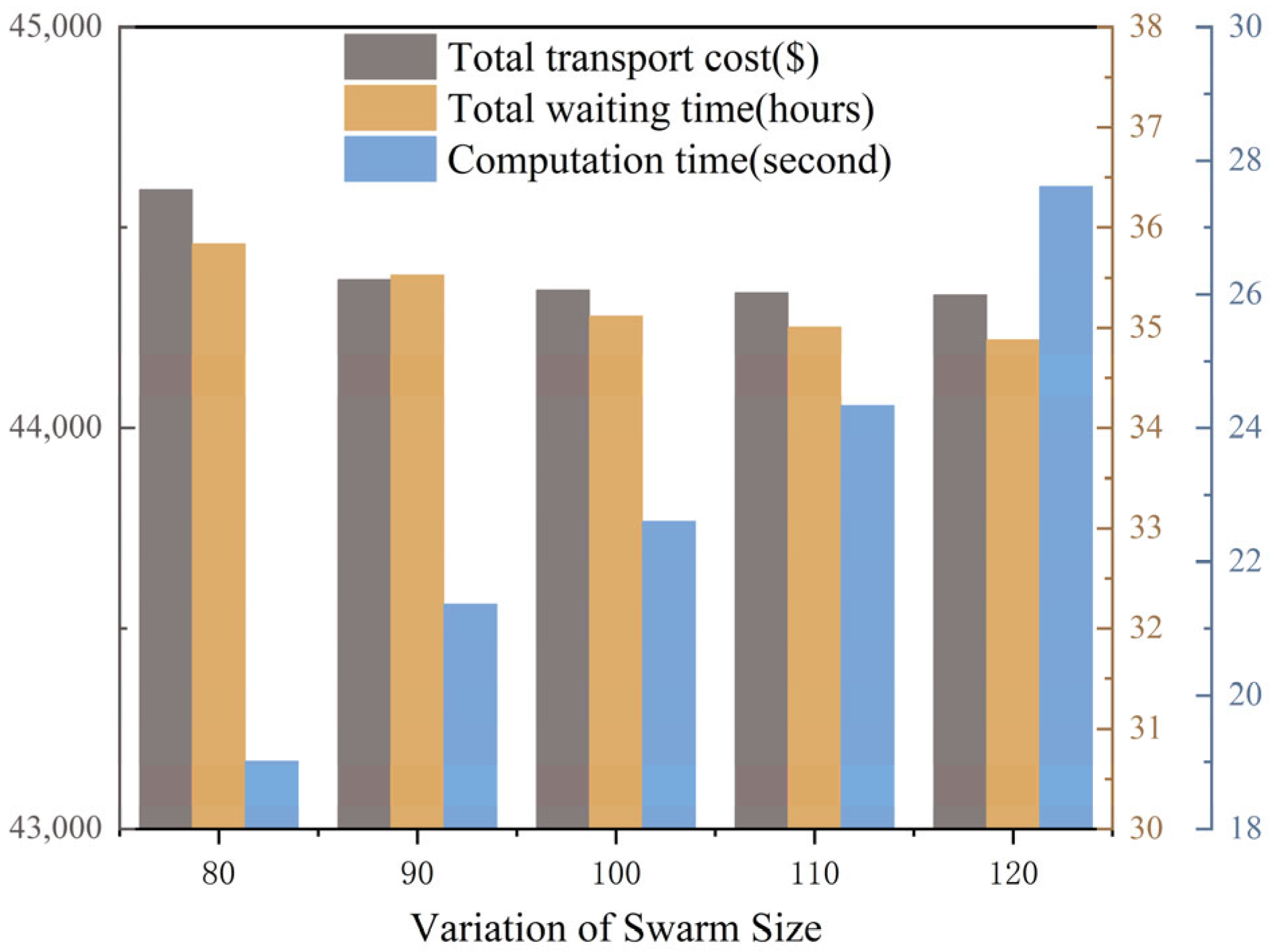

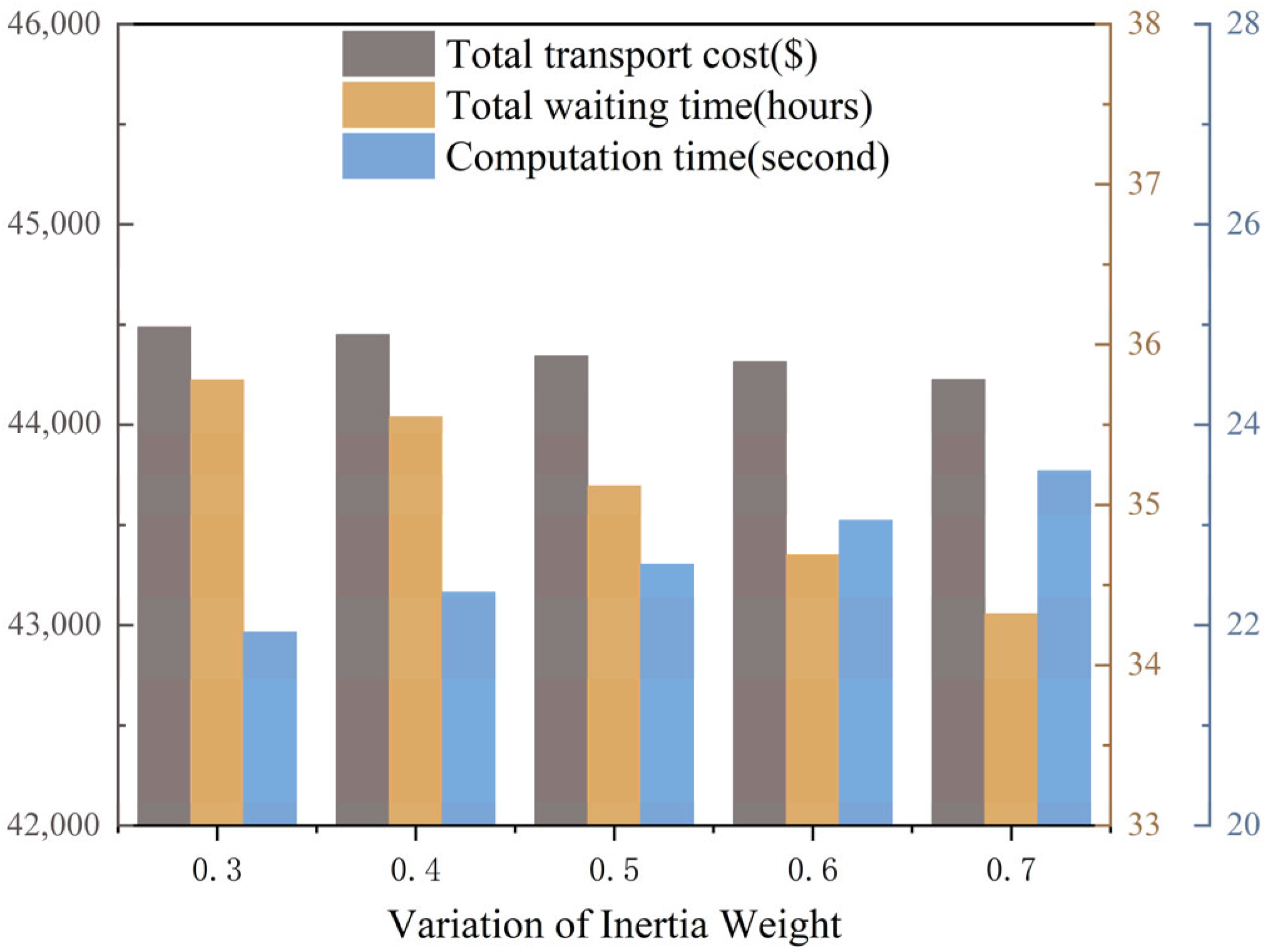

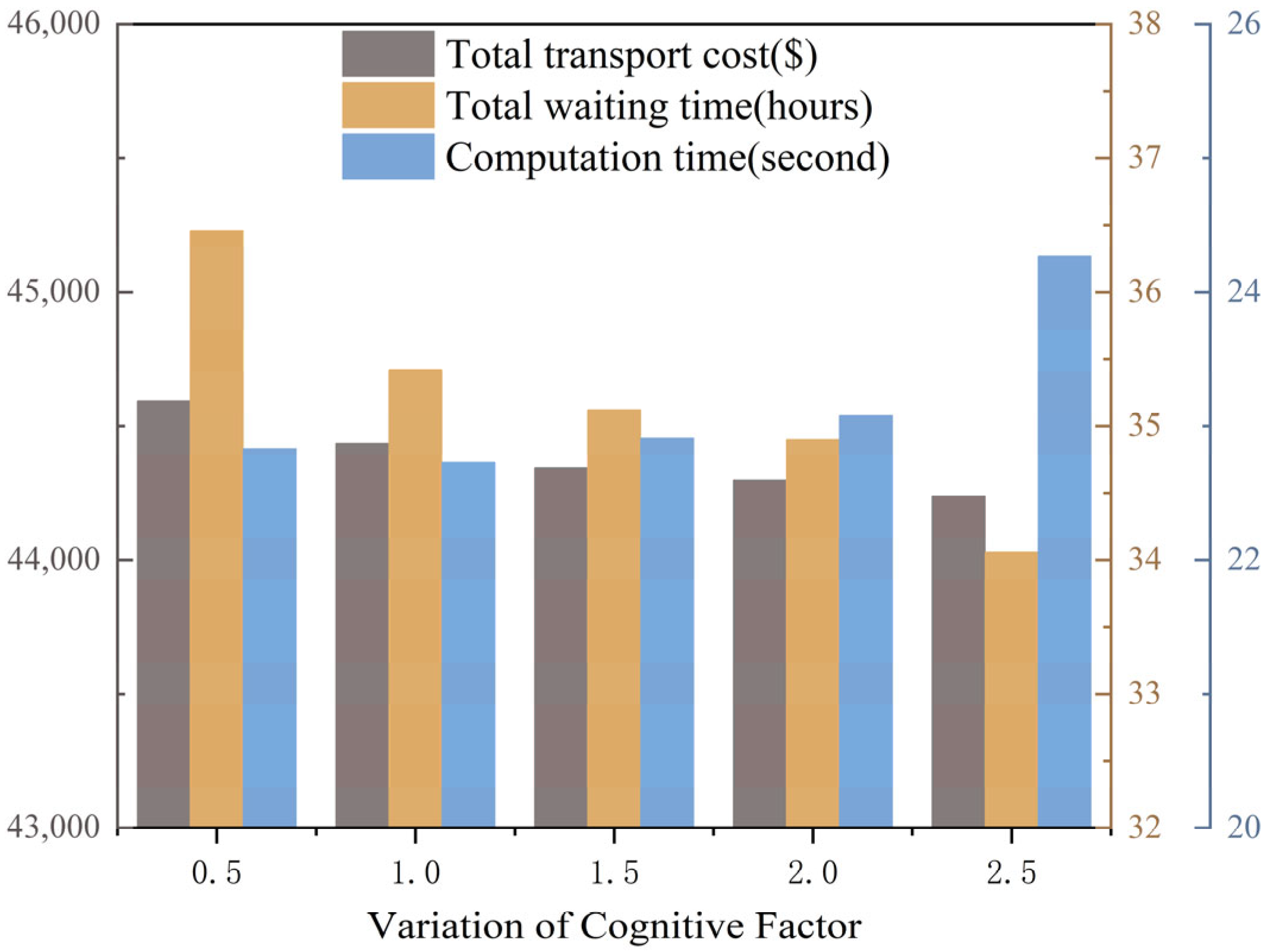

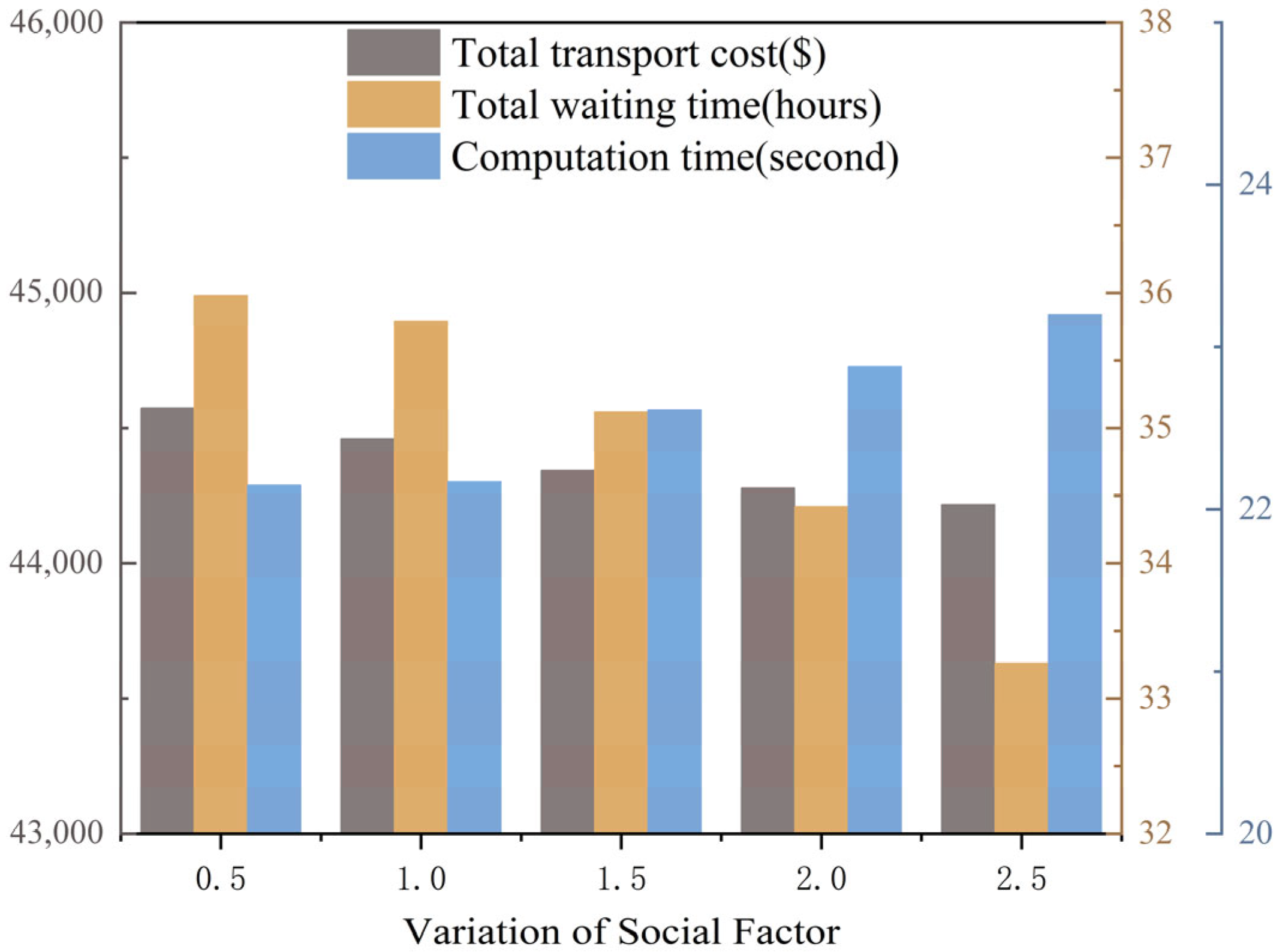

In addition, sensitivity analyses reveal the robustness of both the proposed model and algorithm. Fluctuations in fuel and electricity prices significantly reshape the cost–efficiency trade-off: diesel-intensive fleets remain more resilient to electricity price increases but are highly sensitive to fuel price shocks, whereas electric-intensive fleets show the opposite pattern. Balanced configurations consistently achieve moderate outcomes, avoiding extreme cost surges or long delays. Improvements in charging rates enhance the competitiveness of electric trucks and reduce total costs but also increase diesel idle time, leading to longer overall waiting times. Analyses of algorithmic parameters—including swarm size, inertia weight, cognitive factor, and social factor—further confirm the stability of the optimization results, indicating that the proposed MOPSO maintains reliable convergence and robust performance under parameter variations. These results suggest that fleet composition should be dynamically adjusted to fully capture the benefits of electrification as charging technology advances.

Overall, the proposed model and algorithm effectively exploit the complementary strengths of diesel and electric trucks, enabling a dynamic balance between cost efficiency and operational continuity. By incorporating sensitivity analyses, this study demonstrates the adaptability of heterogeneous fleets to external uncertainties such as volatile energy prices and charging technology advances. The findings provide practical guidance for mine operators in configuring fleet composition and developing adaptive scheduling strategies.

Future research could further incorporate carbon-related factors into the optimization framework, such as carbon emission modeling, carbon pricing, and taxation mechanisms, to evaluate the environmental and economic trade-offs of heterogeneous fleet operations under emerging carbon regulation policies [

42]. Moreover, integrating real-time dispatching, battery degradation, and renewable energy-based charging infrastructure could enhance the applicability and sustainability of heterogeneous fleet scheduling in open-pit mining, contributing to the advancement of intelligent and sustainable mining operations.