Dynamic Viscosity Analysis of Fuels and Their Blends with Bio-Additives as a Function of Temperature

Abstract

1. Introduction

2. Materials and Methods

2.1. Description of the Experimental Setup

2.2. Development of Empirical Models

- p0—matrix of initial parameter estimates;

- “b”—header keyword of the sequence;

- P—matrix of best-fit model parameters;

- Data—matrix of experimental data points;

- Wd—data weights (optional);

- G—computed error between the fitted model and the data;

- Wg—optional weight matrix for the error definition;

- algo—selection of the algorithm used for the fitting procedure;

- stop—sequence of optional arguments controlling the convergence of the fitting algorithm;

- status—completion status.

2.3. Development of Neural Network-Based Models

- P—input training data;

- T—training target;

- N—number of neurons in each layer, including the input and output layers;

- af—activation function from the first hidden layer to the output layer;

- mumax—maximum allowable value of mu;

- theta—mu multiplier;

- itermax—maximum number of iterations;

- mse_min—minimum error (target performance);

- gd_min—minimum gradient;

- W—output weight and bias.

- P—test input;

- W—output weight and bias;

- af—activation function;

- y—simulation result.

2.4. Fatty Acid Composition of the Oils

3. Results

3.1. Investigation of the Dynamic Viscosity of the Diesel–Vegetable Oil Blends Under Temperature Variation

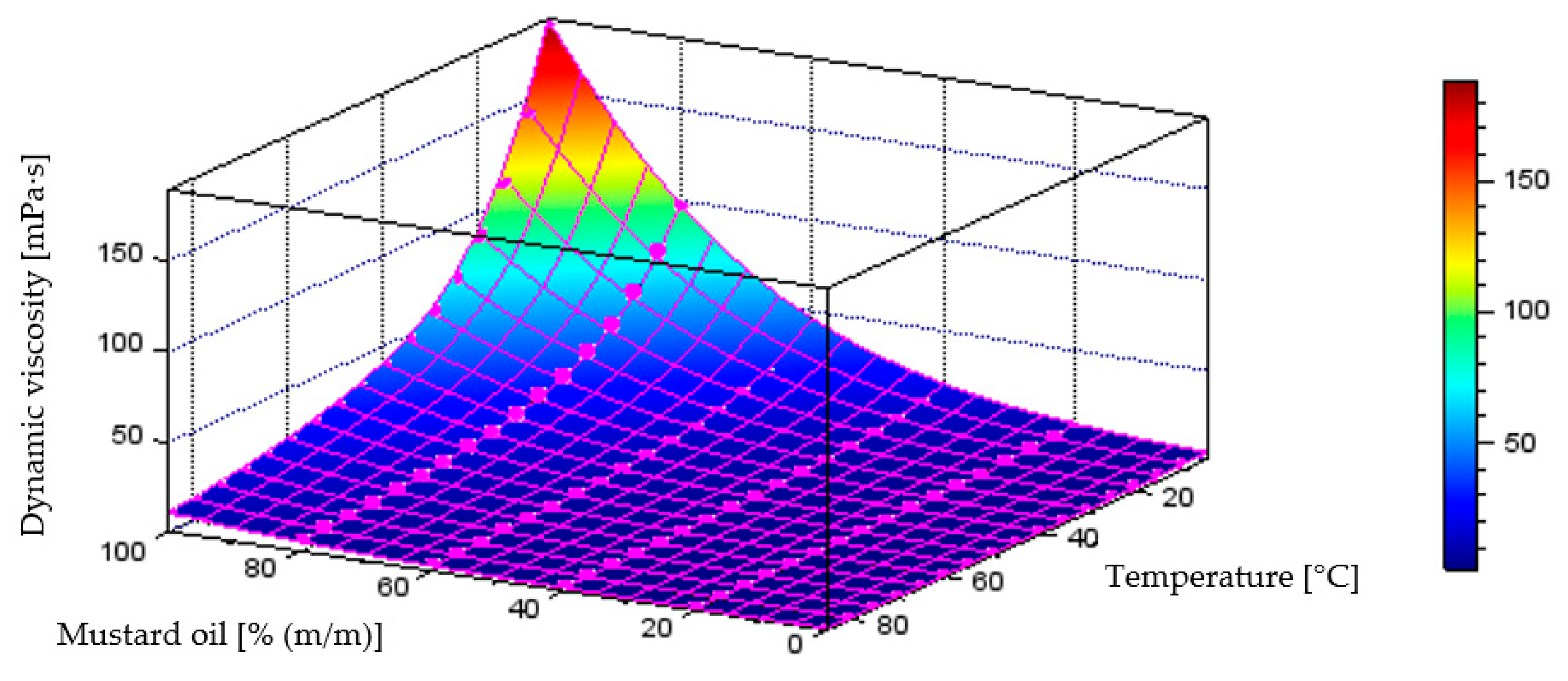

3.1.1. Diesel–Mustard Oil Blend

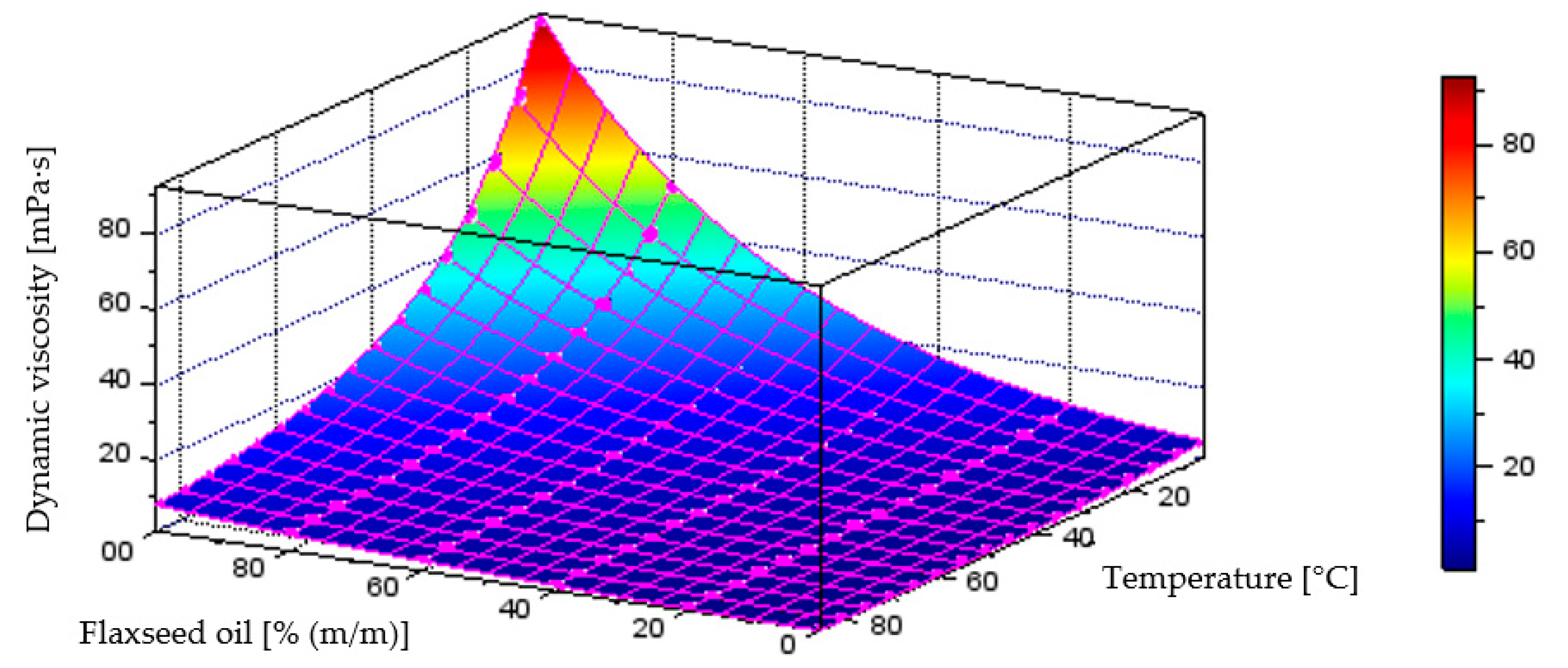

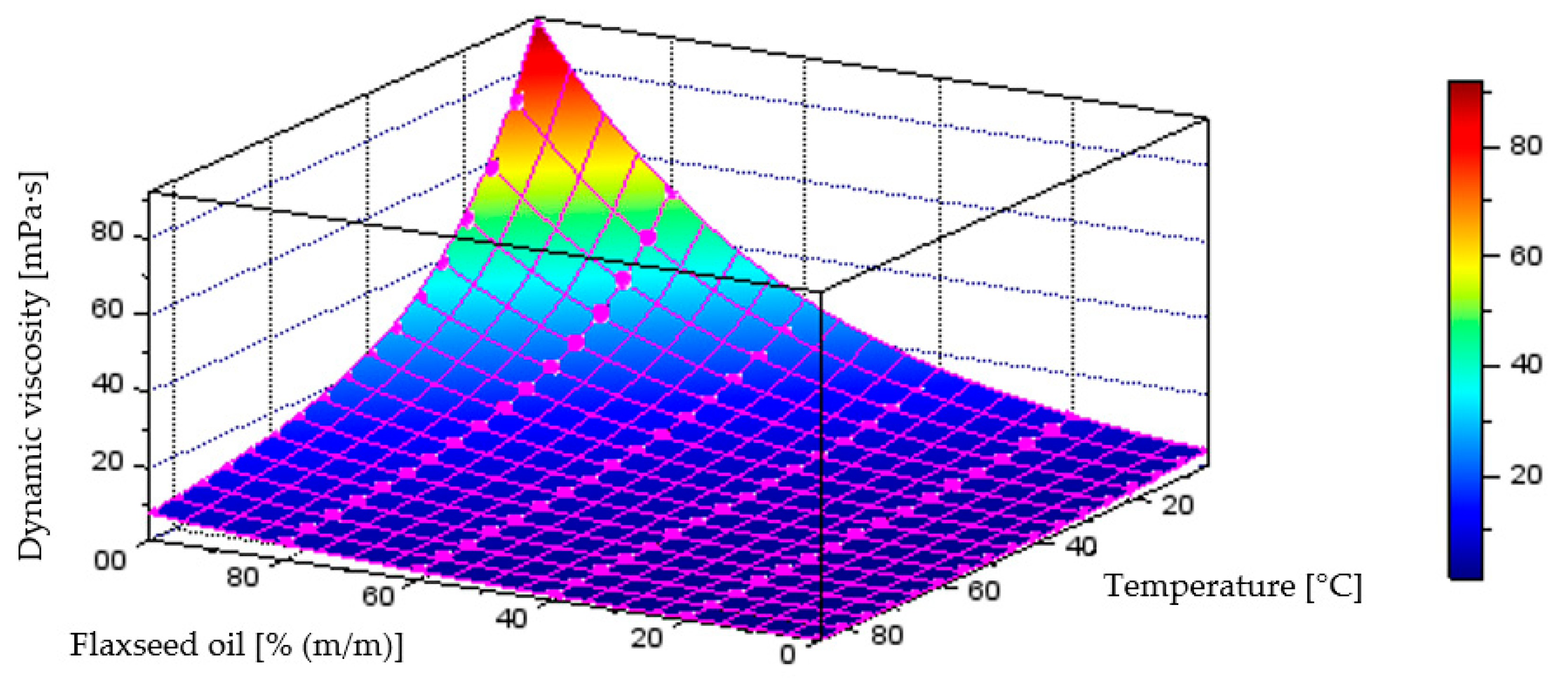

3.1.2. Diesel–Flaxseed Oil Blend

3.1.3. Diesel–Camelina Oil Blend

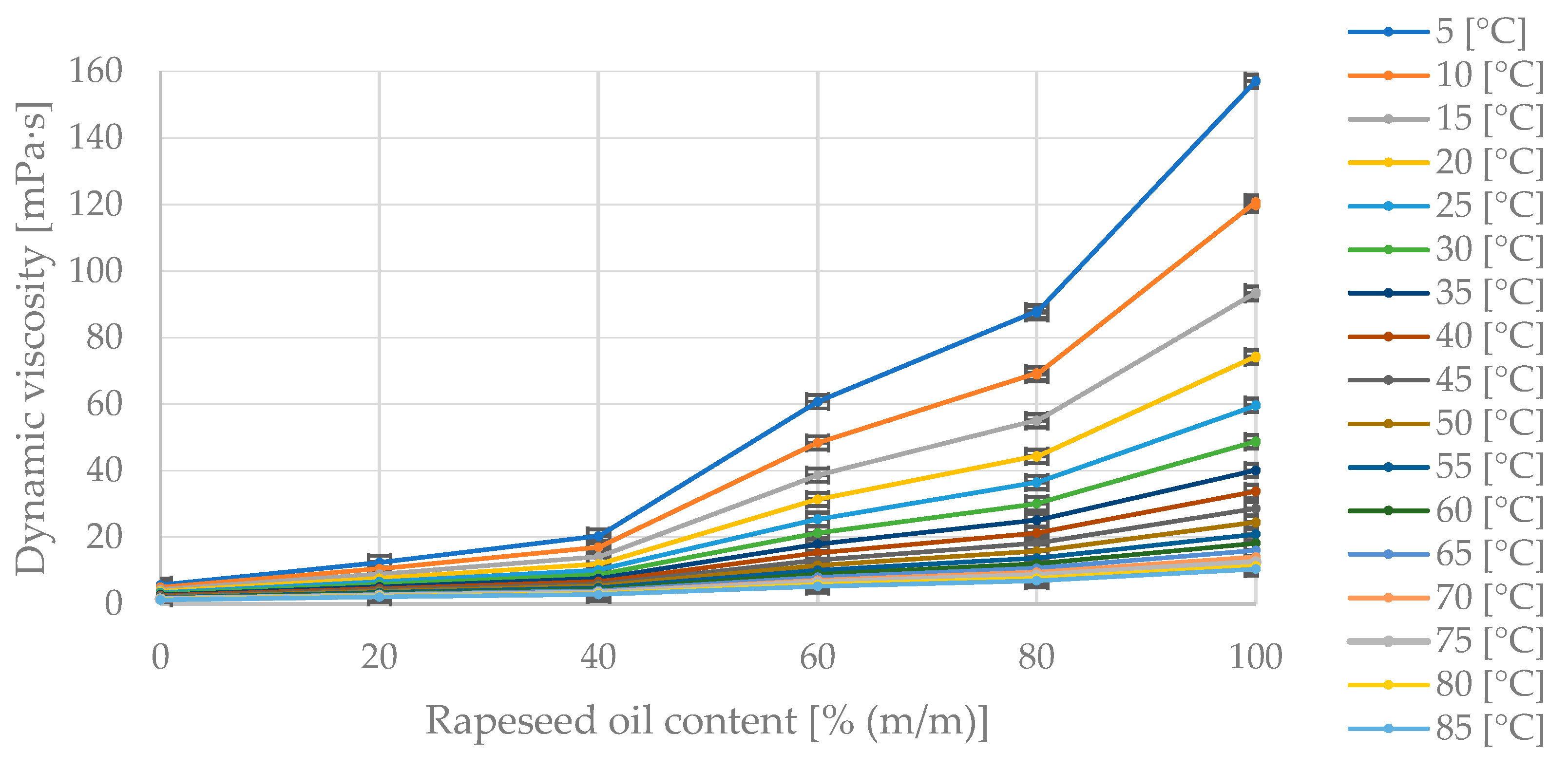

3.1.4. Diesel–Rapeseed Oil Blend

3.2. Mathematical Models of Changes in Dynamic Viscosity

- A, B, C—empirical coefficients;

- T—blend temperature [°C].

- µON(T)—dynamic viscosity of diesel fuel as a function of temperature [mPa·s];

- µOR(T)—dynamic viscosity of the vegetable oil as a function of temperature [mPa·s];

- fON—mass fraction of diesel fuel [% (m/m)];

- fOR—mass fraction of the vegetable oil [% (m/m)].

3.3. Neural Network-Based Models

- FunNet—computational structure of the neural network;

- T—blend temperature [°C];

- um—mass fraction of vegetable oil in the diesel blend [% (m/m)].

3.4. Sensitivity Analysis (Empirical & ANN)

4. Discussion

5. Conclusions

- The experiments produced measurement data characterised by high repeatability of dynamic viscosity values, indicating that the experimental setup was properly prepared and that the selected dynamic viscosity measurement ranges were appropriate. The experimental setup also demonstrates high precision in the obtained measurement results.

- The measurement results shown in the plots, along with their analysis, reveal that vegetable oils exhibit significantly higher dynamic viscosity values at identical temperatures compared with diesel fuel. This is an undesirable effect when raw vegetable oils are used as fuels in compression-ignition engines, as it may lead to malfunction or even damage of the fuel system (with modern Common Rail systems being particularly sensitive to changes in dynamic viscosity).

- The decrease in dynamic viscosity observed with increasing temperature in the examined blends follows an exponential pattern, confirming the validity of the empirical model forms adopted based on the literature.

- Empirical (mathematical) models were developed for each vegetable oil–diesel blend as functions of temperature and component content, all of which exhibited high coefficients of determination, with R2 values exceeding 0.99. This confirms that the mathematical relationship form selected on the basis of the literature was appropriate.

- The applied models describing dynamic viscosity changes as functions of temperature and component content in vegetable oil–diesel blends also achieved high goodness of fit to the measurement data, with R2 values above 0.99. This confirms that the neural network training process and the choice of optimal network structures were appropriate.

- The resulting empirical models and neural network models may serve as a foundation for developing simulations and control systems in hydraulic (fuel) systems involving the flow of vegetable oil–diesel blends.

- Implications for fuel systems: High viscosity at low temperatures affects injector dynamics, spray atomisation and pump load, particularly in blends with high vegetable oil content.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yalcin, H.; Toker, O.S.; Dogan, M. Effect of Oil Type and Fatty Acid Composition on Dynamic and Steady Shear Rheology of Vegetable Oils. J. Oleo Sci. 2012, 61, 181–187. [Google Scholar] [CrossRef]

- Kim, J.; Kim, D.N.; Lee, S.H.; Yoo, S.H.; Lee, S. Correlation of Fatty Acid Composition of Vegetable Oils with Rheological Behaviour and Oil Uptake. Food Chem. 2010, 118, 398–402. [Google Scholar] [CrossRef]

- Stanciu, I. A New Mathematical Model for the Viscosity of Vegetable Oils Based on Freely Sliding Molecules. Grasas Aceites 2019, 70, e318. [Google Scholar] [CrossRef]

- Stanciu, I. Rheological behavior of biodegradable lubricant based on soybean oil. J. Sci. Arts 2019, 19, 703–708. [Google Scholar]

- Barisa, A.; Rosa, M. A system dynamics model for CO2 emission mitigation policy design in road transport sector. Energy Procedia 2018, 147, 419–427. [Google Scholar] [CrossRef]

- Shepel, O.; Matijošius, J.; Rimkus, A.; Orynycz, O.; Tucki, K.; Świć, A. Combustion, Ecological, and Energetic Indicators for Mixtures of Hydrotreated Vegetable Oil (HVO) with Duck Fat Applied as Fuel in a Compression Ignition Engine. Energies 2022, 15, 7892. [Google Scholar] [CrossRef]

- Tucki, K.; Mruk, R.; Orynycz, O.; Gola, A. The Effects of Pressure and Temperature on the Process of Auto-Ignition and Combustion of Rape Oil and Its Mixtures. Sustainability 2019, 11, 3451. [Google Scholar] [CrossRef]

- Krzywonos, M.; Tucki, K.; Wojdalski, J.; Kupczyk, A.; Sikora, M. Analysis of Properties of Synthetic Hydrocarbons Produced Using the ETG Method and Selected Conventional Biofuels Made in Poland in the Context of Environmental Effects Achieved. Rocz. Ochr. Sr. 2017, 19, 394–410. [Google Scholar]

- Xiao, H.; Guo, F.; Li, S.; Wang, R.; Yang, X. Combustion performance and emission characteristics of a diesel engine burning biodiesel blended with n-butanol. Fuel 2019, 258, 115887. [Google Scholar] [CrossRef]

- Tucki, K. A Computer Tool for Modelling CO2 Emissions in Driving Cycles for Spark Ignition Engines Powered by Biofuels. Energies 2021, 14, 1400. [Google Scholar] [CrossRef]

- Herran, D.S.; Tachiiri, K.; Matsumoto, K. Global energy system transformations in mitigation scenarios considering climate uncertainties. Appl. Energy 2019, 243, 119–131. [Google Scholar] [CrossRef]

- Engström, E.; Algers, S.; Hugosson, M.B. The choice of new private and benefit cars vs. climate and transportation policy in Sweden. Transp. Res. Part D Transp. Environ. 2019, 69, 276–292. [Google Scholar] [CrossRef]

- Brodny, J.; Tutak, M. The analysis of similarities between the European Union countries in terms of the level and structure of the emissions of selected gases and air pollutants into the atmosphere. J. Clean. Manuf. 2021, 279, 123641. [Google Scholar] [CrossRef]

- Borucka, A.; Wiśniowski, P.; Mazurkiewicz, D.; Świderski, A. Laboratory measurements of vehicle exhaust emissions in conditions reproducing real traffic. Measurement 2021, 174, 108998. [Google Scholar] [CrossRef]

- Giampieri, A.; Ling-Chin, J.; Ma, Z.; Smallbone, A.; Roskilly, A.P. A review of the current automotive manufacturing practice from an energy perspective. Appl. Energy 2020, 261, 114074. [Google Scholar] [CrossRef]

- Tucki, K. A Computer Tool for Modelling CO2 Emissions in Driving Tests for Vehicles with Diesel Engines. Energies 2021, 14, 266. [Google Scholar] [CrossRef]

- Mikulski, M.; Ambrosewicz-Walacik, M.; Duda, K.; Hunicz, J. Performance and emission characterization of a common-rail compression-ignition engine fuelled with ternary mixtures of rapeseed oil, pyrolytic oil and diesel. Renew. Energy 2020, 148, 739–755. [Google Scholar] [CrossRef]

- Gwardiak, H.; Rozycki, K.; Ruszkarska, M.; Tylus, J.; Walisiewicz-Niedbalska, W. Evaluation of fatty acid methyl esters (FAME) obtained from various feedstock. Rośliny Oleiste Oilseed Crops 2011, 32, 137–147. [Google Scholar]

- Söyler, H.; Balki, M.K. Chemical fingerprinting and cluster-based evaluation of vegetable oils for biodiesel applications. Case Stud. Therm. Eng. 2025, 73, 106703. [Google Scholar] [CrossRef]

- Kumar, A.; Mohan, I.; Lata, D.B. Modelling to predict performance and emission parameters of hydrogen, additive and nano-particles blended fuel in a dual-fuel diesel engine through artificial neural network. Int. J. Hydrogen Energy 2024, 80, 599–611. [Google Scholar]

- Thiagarajan, S.; Damodaran, A.; Seetharaman, S.; Varuvel, E.G. Influence of hydrogen-assisted combustion in compression ignition engines fueled with fuel blends of pine oil and waste cooking oil biodiesel using toroidal combustion chamber. Int. J. Hydrogen Energy 2024, 74, 246–258. [Google Scholar] [CrossRef]

- Ghiasi, M.M.; Mohammadzadeh, O.; Zendehboudi, S. Reliable connectionist tools to determine biodiesel cetane number based on fatty acids methyl esters content. Energy Convers. Manag. 2022, 264, 115601. [Google Scholar] [CrossRef]

- Noushabadi, A.S.; Dashti, A.; Raji, M.; Zarei, A.; Mohammadi, A.H. Estimation of cetane numbers of biodiesel and diesel oils using regression and PSO-ANFIS models. Renew. Energy 2020, 158, 465–473. [Google Scholar] [CrossRef]

- Yahya, S.I.; Aghel, B. Estimation of kinematic viscosity of biodiesel-diesel blends: Comparison among accuracy of intelligent and empirical paradigms. Renew. Energy 2021, 177, 318–326. [Google Scholar] [CrossRef]

- DeOliveira, E.; Quirino, R.L.; Suarez, P.A.Z.; Prado, A.G.S. Heats of combustion of biofuels obtained by pyrolysis and by transesterification and of biofuel/diesel blends. Thermochim. Acta 2006, 450, 87–90. [Google Scholar] [CrossRef]

- Alabi, O.O.; Gbadeyan, O.J.; Bala, A.; Ogunsiji, G.O.; Deenadayalu, N. Study of combustion characteristics of diesel-vegetable oil blends utilizing an industrial fuel burner. Fuel Commun. 2024, 18, 100104. [Google Scholar] [CrossRef]

- Karthickeyan, V. Effect of combustion chamber bowl geometry modification on engine performance, combustion and emission characteristics of biodiesel fuelled diesel engine with its energy and exergy analysis. Energy 2019, 176, 830–852. [Google Scholar] [CrossRef]

- Atmanli, A.; Ileri, E.; Yilmaz, N. Optimization of diesel–butanol–vegetable oil blend ratios based on engine operating parameters. Energy 2016, 96, 569–580. [Google Scholar] [CrossRef]

- Naik, B.D.; Meivelu, U.; Thangarasu, V.; Annamalai, S.; Sivasankaralingam, V. Experimental and empirical analysis of a diesel engine fuelled with ternary blends of diesel, waste cooking sunflower oil biodiesel and diethyl ether. Fuel 2022, 320, 123961. [Google Scholar] [CrossRef]

- Franco, Z.; Nguyen, Q.D. Flow properties of vegetable oil–diesel fuel blends. Fuel 2011, 90, 838–843. [Google Scholar] [CrossRef]

- Esteban, B.; Riba, J.R.; Baquero, G.; Rius, A.; Puig, R. Temperature dependence of density and viscosity of vegetable oils. Biomass Bioenergy 2012, 42, 164–171. [Google Scholar] [CrossRef]

- Dabi, M.; Saha, U.K. Application potential of vegetable oils as alternative to diesel fuels in compression ignition engines: A review. J. Energy Inst. 2019, 92, 1710–1726. [Google Scholar] [CrossRef]

- Vera-Rozo, J.R.; Sáez-Bastante, J.; Carmona-Cabello, M.; Riesco-Ávila, J.M.; Avellaneda, F.; Pinzi, S.; Dorado, M.P. Cetane Index Prediction Based on Biodiesel Distillation Curve. Fuel 2022, 321, 124063. [Google Scholar] [CrossRef]

- Mehra, K.S.; Goel, V. Unveiling Next-Generation Biodiesel Technologies: Techno-Economic and Energy Breakthroughs for Sustainable Production. Biomass Bioenergy 2025, 199, 107910. [Google Scholar] [CrossRef]

- Mohammadpour, J.; Salehi, F. A review of alternative liquid fuels in marine engines. Appl. Energy Combust. Sci. 2025, 24, 100394. [Google Scholar] [CrossRef]

- Satapathy, C.; Nayak, S.K.; Mishra, P.C.; Kaliappan, N.; Priya, K.K. Assessment of engine characteristics in dual-fuel mode using post-mixed biodiesel and coconut shell producer gas. Results Eng. 2025, 27, 106976. [Google Scholar] [CrossRef]

- Yang, F.; Wang, X.; Tan, H.; Liu, Z. Improvement the viscosity of imidazolium-based ionic liquid using organic solvents for biofuels. J. Mol. Liq. 2017, 248, 626–633. [Google Scholar] [CrossRef]

- Yang, X.; Liu, Q.; Ma, Y.; Xie, J.; Cao, B. Molecular dynamics study on the kinematic viscosity, density and structure of fuel blends containing n-decane and biofuel compound of ethyl decanoate or ethyl dodecanoate. J. Mol. Liq. 2023, 379, 121680. [Google Scholar] [CrossRef]

- Cengiz, E.; Babagiray, M.; Aysal, F.E.; Aksoy, F. Kinematic viscosity estimation of fuel oil with comparison of machine learning methods. Fuel 2022, 316, 123422. [Google Scholar] [CrossRef]

- Shu, Q.; Yu, C.; Cai, D.; Xiong, D. Application of mixture topological index method to predict the dynamic viscosity of the hypothetical acidic oils-based biodiesel fuels. Renew. Energy 2012, 41, 152–158. [Google Scholar] [CrossRef]

- Wcisło, G. Determining rheological properties of diesel fuel and biofuels obtained from false flax (Camelina sativa). Inżynieria Rol. 2009, 5, 295–301. [Google Scholar]

- Wcisło, G. Determination of temperature impact on dynamic viscosity of plant biofuels. Inżynieria Rol. 2008, 10, 277–282. [Google Scholar]

- Abdellatief, T.M.M.; Handawy, M.K.M.; Kamel, A.; Abdelmotalib, H.M.; Mustafa, A.; Jamil, F.; Duan, X.; Salameh, T.; Hamid, A.-K.; Hussein, M. Fueling the future: Emission characteristics and sustainability of high-octane gasoline biofuels derived from lignocellulosic biomass. Results Eng. 2025, 26, 105347. [Google Scholar] [CrossRef]

- Küüt, A.; Ilves, R.; Küüt, K.; Raide, V.; Ritslaid, K.; Olt, J. Influence of European Union Directives on the Use of Liquid Biofuel in the Transport Sector. Procedia Eng. 2017, 187, 30–39. [Google Scholar] [CrossRef]

- Tucki, K.; Bączyk, A.; Klimkiewicz, M.; Mączyńska, J.; Sikora, M. Crude rapeseed oil as a fuel for vehicle propulsion. IOP Conf. Ser. Earth Environ. Sci. 2019, 214, 012103. [Google Scholar] [CrossRef]

- Tucki, K.; Bączyk, A.; Klimkiewicz, M.; Mączyńska, J.; Sikora, M. Comparison of energy performance and toxicity of diesel engine fuelled with diesel oil, rapeseed oil and oil mixture. IOP Conf. Ser. Earth Environ. Sci. 2019, 214, 012102. [Google Scholar] [CrossRef]

- Guo, T.; Li, G.; Li, H.; Huo, H.; Zhang, X.; Wang, Z.; Bai, H. Experimental study on the effects of fuel properties on spray macroscopic characteristics, particle size distribution, and velocity field in a constant volume chamber. Exp. Therm. Fluid Sci. 2026, 171, 111602. [Google Scholar] [CrossRef]

- Hafis, M.; Balaji, K.; Tamilarasan, N.; Senthilkumar, D.; Sakthivel, R. A review on alternative fuels: Spray characteristics, engine performance and emissions effect. Sustain. Futures 2025, 9, 100456. [Google Scholar] [CrossRef]

- Meffan, C.; Menges, J.; Mak, D.; Dolamore, F.; Fee, C.; Nock, V.; Dobson, R.C.J. A versatile capillaric circuits microfluidic viscometer. Sens. Actuators A Phys. 2023, 359, 114497. [Google Scholar] [CrossRef]

- Lee, E.; Kim, B.; Choi, S. Hand-held, automatic capillary viscometer for analysis of Newtonian and non-Newtonian fluids. Sens. Actuators A Phys. 2020, 313, 112176. [Google Scholar] [CrossRef]

- Hapanowicz, J. Influence of the adopted rheological model of plant suspension on the predicted resistance of its flow in the pipe. Powder Technol. 2022, 410, 117912. [Google Scholar] [CrossRef]

- Wichterle, K.; Večeř, M. Simple problems in fluid flows. In Transport and Surface Phenomena; Wichterle, K., Večeř, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 79–88. [Google Scholar] [CrossRef]

- Singh, P.; Sharma, K.; Puchades, I.; Agarwal, P.B. A comprehensive review on MEMS-based viscometers. Sens. Actuators A Phys. 2022, 338, 113456. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, Y.; Dong, X.; Wang, F.; Li, H.; Zhong, Q.; Yao, X.; Gong, M. Corrigendum to “A vibrating-wire viscometer and measured viscosity data of compressed liquid carbon dioxide at temperatures from 218.150 to 273.150 K and pressures up to 13 MPa” [J. Mol. Liq. 310 (2020) 113208]. J. Mol. Liq. 2021, 329, 115575. [Google Scholar] [CrossRef]

- Málek, J.; Rajagopal, K.R. Mathematical issues concerning the Navier–Stokes equations and some of its generalizations. In Handbook of Differential Equations: Evolutionary Equations; Dafermos, C.M., Feireisl, E., Eds.; North-Holland: Amsterdam, The Netherlands, 2005; Volume 2, pp. 371–459. [Google Scholar] [CrossRef]

- Tokpavi, D.L.; Magnin, A.; Jay, P. Very slow flow of Bingham viscoplastic fluid around a circular cylinder. J. Non-Newton. Fluid Mech. 2008, 154, 65–76. [Google Scholar] [CrossRef]

- Takeuchi, A.; Kato, H.; Inoue, A. Vogel–Fulcher–Tammann plot for viscosity scaled with temperature interval between actual and ideal glass transitions for metallic glasses in liquid and supercooled liquid states. Intermetallics 2010, 18, 406–411. [Google Scholar] [CrossRef]

- Haj-Kacem, R.B.; Ouerfelli, N.; Herráez, J.V.; Guettari, M.; Hamda, H.; Dallel, M. Contribution to modeling the viscosity Arrhenius-type equation for some solvents by statistical correlations analysis. Fluid Phase Equilibria 2014, 383, 11–20. [Google Scholar] [CrossRef]

- Bajić, D.M.; Šerbanović, S.P.; Živković, E.M.; Jovanović, J.; Kijevčanin, M.L. Prediction and correlation of viscosity of binary mixtures of ionic liquids with organic solvents. J. Mol. Liq. 2014, 197, 1–6. [Google Scholar] [CrossRef]

- DVNext Rheometer. Available online: https://www.perlan.com.pl/uploaded/AppBundleEntityBlockFilesWithImageElement/filePath/107/wiskozymetr-reometr-ametek-brookfield-dvnext.pdf (accessed on 20 November 2025).

- PN-EN ISO 5508:1996; Oleje i Tłuszcze Roślinne oraz Zwierzęce—Analiza Estrów Metylowych Kwasów Tłuszczowych Metodą Chromatografii Gazowej. Polski Komitet Normalizacyjny: Warsaw, Poland, 1996.

- PN-EN ISO 5509:2001; Oleje i Tłuszcze Roślinne oraz Zwierzęce—Przygotowanie Estrów Metylowych Kwasów tłuszczowych. Polski Komitet Normalizacyjny: Warsaw, Poland, 2001.

- Sagan, A.; Blicharz-Kania, A.; Szmigielski, M.; Andrejko, D.; Sobczak, P.; Zawiślak, K.; Starek, A. Assessment of the Properties of Rapeseed Oil Enriched with Oils Characterized by High Content of α-linolenic Acid. Sustainability 2019, 11, 5638. [Google Scholar] [CrossRef]

- Zaborowska, Z. Effect of rape seeds dehulling process on quality and nutritive value of cold-pressed rapeseed oils. Postępy Nauk. I Technol. Przemysłu Rolno-Spożywczego 2016, 71, 46–57. [Google Scholar]

- Lewinska, A.; Zebrowski, J.; Duda, M.; Gorka, A.; Wnuk, M. Fatty Acid Profile and Biological Activities of Linseed and Rapeseed Oils. Molecules 2015, 20, 22872–22880. [Google Scholar] [CrossRef]

- Ratusz, K.; Symoniuk, E.; Wroniak, M.; Rudzińska, M. Bioactive Compounds, Nutritional Quality and Oxidative Stability of Cold Pressed Camelina (Camelina sativa L.) Oils. Appl. Sci. 2018, 8, 2606. [Google Scholar] [CrossRef]

- Rakita, S.; Spasevski, N.; Savić, I.; Savić Gajić, I.; Lazarević, J.; Dragojlović, D.; Đuragić, O. Comparative Evaluation of Camelina Seed Oils Obtained by Cold Pressing and Solvent Extraction. Foods 2024, 13, 3605. [Google Scholar] [CrossRef]

- Gandova, V.; Teneva, O.; Petkova, Z.; Iliev, I.; Stoyanova, A. Lipid Composition and Physicochemical Parameters of Flaxseed Oil (Linum usitatissimum L.) from Bulgaria. Appl. Sci. 2023, 13, 10141. [Google Scholar] [CrossRef]

- López Argüello, E.; Barrera Vázquez, C.; Bosch Bosch, N. Analytical study of the composition of fatty acid of mustard and mustard sauces. Grasas Y Aceites 1999, 50, 444–447. [Google Scholar] [CrossRef]

- Özcan, M.M.; Uslu, N.; Yalım, N.; Kandil, M.; Namalan, Z.; Atasoy, Z.B. White mustard (Sinapis alba L.) seeds: The role of oven and microwave roasting on their bioactive components, antioxidant potential, fatty acids and mineral contents. Eur. Food Res. Technol. 2024, 250, 1563–1572. [Google Scholar] [CrossRef]

- Loss Functions and Their Use In Neural Networks. Available online: https://towardsdatascience.com/loss-functions-and-their-use-in-neural-networks-a470e703f1e9/ (accessed on 10 December 2025).

- Bonilla, D.; Bishop, J.D.K.; Axon, C.J.; Banister, D. Innovation, the diesel engine and vehicle markets: Evidence from OECD engine patents. Transp. Res. Part D Transp. Environ. 2014, 27, 51–58. [Google Scholar] [CrossRef]

- Abadie, L.M.; Goicoechea, N. Powering newly constructed vessels to comply with ECA regulations under fuel market prices uncertainty: Diesel or dual fuel engine? Transp. Res. Part D Transp. Environ. 2019, 67, 433–448. [Google Scholar] [CrossRef]

- Tabarnoust, E.; Mghari, M.; Zaz, Y. Moroccan used cars dataset: Insights into the used car market. Data Brief 2025, 63, 112087. [Google Scholar] [CrossRef] [PubMed]

- Skribans, V.; Kotlars, A. European cargo vehicle market dataset for 2023. Data Brief 2024, 55, 110648. [Google Scholar] [CrossRef]

- Ülgen, A.I.; Çelebi, Y.; Aydın, H. High proportion of biofuel replacement for conventional diesel using safflower biodiesel and diethyl ether blends in a CNG-powered RCCI operation of a diesel engine. Renew. Energy 2025, 246, 122919. [Google Scholar] [CrossRef]

- Tucki, K.; Mruk, R. Experimental research on the influence of the composition of the fuel mixture on the operating parameters of a single-cylinder Common Rail diesel engine. Adv. Sci. Technol. Res. J. 2022, 16, 100–109. [Google Scholar] [CrossRef] [PubMed]

- Çakmak, A. Comparative research on acetone-butanol-ethanol (ABE) and butanol (Bu) as next-generation biofuels in compression ignition engine. Therm. Sci. Eng. Prog. 2024, 55, 102956. [Google Scholar] [CrossRef]

- Zikri, J.M.; Sani, M.S.M.; Adam, A. Exploring the world of diesel engines: Analyzing noise and vibration characteristics with biodiesel application. Renew. Sustain. Energy Rev. 2026, 226, 116168. [Google Scholar] [CrossRef]

- Lotko, W. Vegatable fuels and the toxic component emission in exhaust gas. Arch. Motoryz. 2000, 3, 153–163. [Google Scholar]

- Szczypiński-Sala, W. Influence of rape oil addition to mineral diesel fuel on electromagnetic fuel injectors characteristic. Logistyka 2014, 5, 1521–1526. [Google Scholar]

- Wielligh, A.V.; Burger, N.D.L.; Wilcocks, T.L. Diesel engine failures due to combustion disturbances, caused by fuel with insufficient lubricity. Ind. Lubr. Tribol. 2003, 55, 65–75. [Google Scholar] [CrossRef]

- Skrzyńska, E.; Matyja, M. Comparison of the physicochemical properties of select natural fats and their methyl esters. Chemik 2011, 65, 923–935. [Google Scholar]

- Ramadhas, A.S.; Muraleedharan, C.; Jayaraj, S. Performance and emission evaluation of a diesel engine fueled with methyl esters of rubber seed oil. Renew. Energy 2005, 30, 1789–1800. [Google Scholar] [CrossRef]

- Lotko, W. Estimation of exhaust gas emission of diesel engine fuelled with blends of diesel oil with rapeseed oil methyl esters. Arch. Motoryz. 2006, 4, 403–410. [Google Scholar]

- Plotnikov, L.; Grigoriev, N. Modernization of the Mechanical Fuel System of a Diesel Locomotive Engine through Physical and Numerical Modeling. Energies 2021, 14, 8554. [Google Scholar] [CrossRef]

- El Marnissi, Y.; Hwang, J. Microscopic Imaging on Diesel Spray and Atomization Process. Processes 2024, 12, 359. [Google Scholar] [CrossRef]

- Liu, R.; Huang, K.; Qiao, Y.; Ji, H.; Zhong, L.; Wu, H. Effects of Low Pressure Injection on Fuel Atomization and Mixture Formation for Heavy Fuel Engines. Processes 2022, 10, 2276. [Google Scholar] [CrossRef]

- Zhai, C.; Li, K.; Dong, P.; Jin, Y.; Luo, H.; Zhou, B.; Liu, Y. Experimental Study on the Spray Characteristics of Diesel and Hydrotreated Vegetable Oil (HVO) Fuels under Different Injection Pressures. Processes 2024, 12, 1697. [Google Scholar] [CrossRef]

- Naruemon, I.; Liu, L.; Liu, D.; Ma, X.; Nishida, K. An Analysis on the Effects of the Fuel Injection Rate Shape of the Diesel Spray Mixing Process Using a Numerical Simulation. Appl. Sci. 2020, 10, 4983. [Google Scholar] [CrossRef]

- Nguyen, T.Q.; Dunin, A.Y. Investigation into the Impact of Piston Bowl Size on Diesel Engine Characteristics with Changes in Fuel Injection Pressure and Boost Pressure. Appl. Sci. 2024, 14, 4334. [Google Scholar] [CrossRef]

- Tesfa, B.; Mishra, R.; Gu, F.; Powles, N. Prediction Models for Density and Viscosity of Biodiesel and Their Effects on Fuel Supply System in CI Engines. Renew. Energy 2010, 35, 2752–2760. [Google Scholar] [CrossRef]

- Gao, Y.; Deng, J.; Li, C.; Dang, F.; Liao, Z.; Wu, Z.; Li, L. Experimental Study of the Spray Characteristics of Biodiesel Based on Inedible Oil. Biotechnol. Adv. 2009, 27, 616–624. [Google Scholar] [CrossRef]

- Krisnangkura, K.; Yimsuwan, T.; Pairintra, R. An Empirical Approach in Predicting Biodiesel Viscosity at Various Temperatures. Fuel 2006, 85, 107–113. [Google Scholar] [CrossRef]

- Rajak, U.; Verma, T.N.; Allamraju, K.V.; Kumar, R.; Le, Q.H.; Pugazhendhi, A. Effects of Different Biofuels and Their Mixtures with Diesel Fuel on Diesel Engine Performance and Exhausts. Sci. Total Environ. 2023, 903, 166501. [Google Scholar] [CrossRef]

- Khan, E.; Ozaltin, K.; Spagnuolo, D.; Bernal-Ballen, A.; Piskunov, M.V.; Di Martino, A. Biodiesel from Rapeseed and Sunflower Oil: Effect of the Transesterification Conditions and Oxidation Stability. Energies 2023, 16, 657. [Google Scholar] [CrossRef]

- Markov, V.; Kamaltdinov, V.; Devyanin, S.; Sa, B.; Zherdev, A.; Furman, V. Investigation of the Influence of Different Vegetable Oils as a Component of Blended Biofuel on Performance and Emission Characteristics of a Diesel Engine for Agricultural Machinery and Commercial Vehicles. Resources 2021, 10, 74. [Google Scholar] [CrossRef]

- Eremeeva, A.M.; Ilyushin, Y.V. Temperature Control During Storage of Raw Materials in the Process of Biodiesel Fuel Production. Inventions 2025, 10, 7. [Google Scholar] [CrossRef]

- Jankowski, K.J.; Sokólski, M.; Załuski, D. Winter Oilseed Rape: Agronomic Management in Different Tillage Systems and Energy Balance. Energy 2023, 277, 127590. [Google Scholar] [CrossRef]

| Parameter Value | Parameter Value |

|---|---|

| Rotational speed | 0.01–250 rpm |

| Measurement error | ±1% of the measurement range |

| Viscosity measurement range using Enhanced Brookfield UL Adapter | from 1 to 2000 cP, mPa·s |

| Measurement range in research | to 200 cP, mPa·s |

| Fatty Acids | Rapeseed Oil | Camelina Oil | Flaxseed Oil | Mustard Oil |

|---|---|---|---|---|

| Myristic acid 14:0 | 0.05 ± 0.01 | 0.05 ± 0.01 | 0.10 ± 0.02 | 0.10 ± 0.02 |

| Palmitic acid 16:0 | 5.00 ± 0.20 | 7.80 ± 0.20 | 5.50 ± 0.25 | 4.50 ± 0.20 |

| Palmitoleic acid16:1 | 0.20 ± 0.01 | 0.10 ± 0.01 | 0.10 ± 0.01 | 0.20 ± 0.02 |

| Stearic acid 18:0 | 2.50 ± 0.10 | 3.00 ± 0.15 | 3.00 ± 0.20 | 1.50 ± 0.10 |

| Oleic acid 18:1 | 62.00 ± 1.00 | 17.50 ± 1.00 | 17.00 ± 1.00 | 25.00 ± 1.20 |

| Linoleic acid18:2 | 20.00 ± 1.00 | 22.00 ± 1.00 | 14.50 ± 0.90 | 10.00 ± 1.10 |

| α-linolenic acid 18:3 (n-3) | 10.00 ± 0.80 | 30.00 ± 1.50 | 58.00 ± 2.50 | 10.50 ± 0.60 |

| γ-linolenic acid18-3 (n-6) | – | – | – | – |

| Arachidic acid 20:0 | 0.25 ± 0.01 | 1.20 ± 0.10 | 0.20 ± 0.02 | 1.00 ± 0.10 |

| Eicosaenoic acid 20:1 | 1.50 ± 0.05 | 14.00 ± 0.80 | 0.20 ± 0.02 | 12.50 ± 0.80 |

| Eicosadienoic acid 20:2 | – | 0.80 ± 0.10 | 0.20 ± 0.02 | 0.30 ± 0.05 |

| Eicosatrienoic acid 20:3 | – | 0.40 ± 0.05 | – | 0.10 ± 0.02 |

| Behenic acid 22:0 | 0.30 ± 0.02 | 0.40 ± 0.05 | 0.10 ± 0.01 | 1.00 ± 0.10 |

| Erucic acid 22:1 | 0.10 ± 0.02 | 2.50 ± 0.30 | <0.50 ± 0.05 | 40.00 ± 5.00 |

| Lignoceric acid 24:0 | 0.10 ± 0.01 | 0.10 ± 0.02 | – | 0.20 ± 0.02 |

| Nervonic acid 24:1 | 0.10 ± 0.01 | 0.10 ± 0.02 | – | 0.10 ± 0.01 |

| ΣSFA 1 | 8.20 | 11.10 | 8.80 | 6.00 |

| ΣMUFA 2 | 63.80 | 34.20 | 17.50 | 58.00 |

| ΣPUFA 3 | 28.00 | 54.00 | 73.50 | 20.50 |

| n-6/n-3 | 2.0 | 1.2 | 0.25 | 1.0 |

| Temperature [°C] | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 85 | ||

| Mustard oil content [% (m/m)] | 0 | 5.71 | 5 | 4.36 | 3.84 | 3.4 | 3.03 | 2.74 | 2.48 | 2.26 | 2.08 | 1.91 | 1.76 | 1.64 | 1.54 | 1.43 | 1.29 | 1.22 |

| 0 | 5.71 | 4.98 | 4.35 | 3.83 | 3.39 | 3.03 | 2.74 | 2.48 | 2.26 | 2.07 | 1.91 | 1.76 | 1.64 | 1.54 | 1.43 | 1.29 | 1.22 | |

| 0 | 5.7 | 4.97 | 4.34 | 3.82 | 3.38 | 3.02 | 2.73 | 2.48 | 2.25 | 2.07 | 1.91 | 1.76 | 1.64 | 1.53 | 1.42 | 1.3 | 1.22 | |

| 20 | 10.33 | 8.8 | 7.52 | 6.46 | 5.65 | 5.08 | 4.52 | 4.03 | 3.63 | 3.3 | 3.01 | 2.75 | 2.53 | 2.33 | 2.17 | 2.02 | 1.89 | |

| 20 | 10.34 | 8.81 | 7.54 | 6.49 | 5.78 | 5.09 | 4.52 | 4.04 | 3.63 | 3.31 | 3.01 | 2.75 | 2.53 | 2.34 | 2.17 | 2.02 | 1.89 | |

| 20 | 10.36 | 8.81 | 7.54 | 6.5 | 5.8 | 5.09 | 4.52 | 4.04 | 3.63 | 3.31 | 3.01 | 2.75 | 2.53 | 2.34 | 2.17 | 2.02 | 1.89 | |

| 40 | 18.64 | 15.5 | 12.94 | 10.92 | 9.41 | 8.21 | 7.2 | 6.32 | 5.65 | 5.17 | 4.66 | 4.22 | 3.84 | 3.52 | 3.22 | 2.98 | 2.75 | |

| 40 | 18.6 | 15.52 | 12.94 | 11.05 | 9.47 | 8.24 | 7.21 | 6.35 | 5.75 | 5.18 | 4.67 | 4.22 | 3.85 | 3.53 | 3.23 | 2.98 | 2.75 | |

| 40 | 18.58 | 15.52 | 12.88 | 11.09 | 9.5 | 8.24 | 7.22 | 6.36 | 5.75 | 5.18 | 4.67 | 4.22 | 3.85 | 3.53 | 3.23 | 2.98 | 2.75 | |

| 60 | 39.06 | 31.56 | 25.86 | 21.63 | 18.12 | 15.3 | 13.04 | 11.28 | 9.92 | 8.81 | 7.82 | 6.98 | 6.25 | 5.68 | 5.27 | 4.79 | 4.41 | |

| 60 | 39.06 | 31.62 | 26.19 | 21.57 | 18.16 | 15.3 | 13.04 | 11.3 | 9.96 | 8.82 | 7.82 | 7 | 6.26 | 5.8 | 5.27 | 4.81 | 4.42 | |

| 60 | 39.12 | 31.68 | 26.13 | 21.57 | 18.14 | 15.32 | 13.06 | 11.32 | 9.98 | 8.82 | 7.84 | 7.01 | 6.28 | 5.81 | 5.27 | 4.81 | 4.42 | |

| 80 | 100.2 | 78.96 | 62.16 | 50.5 | 40.86 | 33.72 | 28.38 | 24.06 | 20.49 | 17.73 | 15.48 | 13.52 | 11.96 | 10.58 | 9.49 | 8.56 | 7.72 | |

| 80 | 100.3 | 79.32 | 62.28 | 50.52 | 41.1 | 33.72 | 28.62 | 23.85 | 20.37 | 17.82 | 15.44 | 13.5 | 11.94 | 10.64 | 9.52 | 8.57 | 7.72 | |

| 80 | 100.6 | 78.96 | 62.4 | 50.52 | 41.16 | 33.78 | 28.5 | 23.85 | 20.43 | 17.82 | 15.44 | 13.48 | 11.96 | 10.67 | 9.54 | 8.59 | 7.74 | |

| 100 | 189 | 145.4 | 112.8 | 88.92 | 71.04 | 58 | 48 | 39.66 | 33.48 | 28.68 | 24.72 | 21.27 | 18.6 | 16.42 | 14.56 | 12.86 | 11.54 | |

| 100 | 189.2 | 145.4 | 113.3 | 89.16 | 71.04 | 58.26 | 47.76 | 39.78 | 33.3 | 28.86 | 24.69 | 21.3 | 18.74 | 16.48 | 14.54 | 12.9 | 11.58 | |

| 100 | 189 | 145.4 | 113 | 89.28 | 71.16 | 58.2 | 47.64 | 39.72 | 33.3 | 28.86 | 24.72 | 21.33 | 18.78 | 16.52 | 14.54 | 12.92 | 11.58 | |

| Temperature [°C] | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 85 | ||

| Flaxseed oil content [% (m/m)] | 0 | 5.71 | 5 | 4.36 | 3.84 | 3.4 | 3.03 | 2.74 | 2.48 | 2.26 | 2.08 | 1.91 | 1.76 | 1.64 | 1.54 | 1.43 | 1.29 | 1.22 |

| 0 | 5.71 | 4.98 | 4.35 | 3.83 | 3.39 | 3.03 | 2.74 | 2.48 | 2.26 | 2.07 | 1.91 | 1.76 | 1.64 | 1.54 | 1.43 | 1.29 | 1.22 | |

| 0 | 5.7 | 4.97 | 4.34 | 3.82 | 3.38 | 3.02 | 2.73 | 2.48 | 2.25 | 2.07 | 1.91 | 1.76 | 1.64 | 1.53 | 1.42 | 1.3 | 1.22 | |

| 20 | 9.82 | 8.4 | 7.22 | 6.24 | 5.58 | 4.93 | 4.39 | 3.93 | 3.55 | 3.25 | 2.96 | 2.72 | 2.5 | 2.32 | 2.15 | 2.02 | 1.88 | |

| 20 | 9.82 | 8.41 | 7.21 | 6.25 | 5.58 | 4.93 | 4.39 | 3.93 | 3.55 | 3.25 | 2.96 | 2.72 | 2.5 | 2.32 | 2.16 | 2.01 | 1.88 | |

| 20 | 9.8 | 8.4 | 7.2 | 6.24 | 5.58 | 4.93 | 4.39 | 3.92 | 3.55 | 3.25 | 2.96 | 2.72 | 2.21 | 2.32 | 2.15 | 2.01 | 1.88 | |

| 40 | 15.02 | 12.7 | 10.85 | 9.25 | 8.02 | 7 | 6.14 | 5.55 | 4.97 | 4.49 | 4.07 | 3.71 | 3.39 | 3.12 | 2.89 | 2.68 | 2.49 | |

| 40 | 15.06 | 12.68 | 10.84 | 9.25 | 8.02 | 6.98 | 6.16 | 5.57 | 4.97 | 4.5 | 4.06 | 3.71 | 3.4 | 3.13 | 2.89 | 2.68 | 2.5 | |

| 40 | 15.04 | 12.66 | 10.82 | 9.26 | 8.02 | 6.98 | 6.14 | 5.57 | 4.97 | 4.5 | 4.06 | 3.71 | 3.4 | 3.13 | 2.89 | 2.66 | 2.5 | |

| 60 | 28.32 | 23.43 | 19.38 | 16.4 | 13.84 | 11.88 | 10.38 | 9.08 | 8.02 | 7.14 | 6.38 | 5.76 | 5.3 | 4.81 | 4.4 | 4.03 | 3.72 | |

| 60 | 28.29 | 23.31 | 19.52 | 16.34 | 13.84 | 11.95 | 10.4 | 9.08 | 8.03 | 7.14 | 6.4 | 5.85 | 5.3 | 4.82 | 4.41 | 4.03 | 3.72 | |

| 60 | 28.26 | 23.31 | 19.48 | 16.34 | 13.82 | 11.95 | 10.42 | 9.08 | 8.02 | 7.15 | 6.4 | 5.86 | 5.3 | 4.82 | 4.41 | 4.03 | 3.72 | |

| 80 | 53.1 | 42.9 | 34.92 | 28.98 | 24.39 | 20.61 | 17.64 | 15.3 | 13.2 | 11.66 | 10.43 | 9.26 | 8.28 | 7.48 | 6.77 | 6.16 | 5.65 | |

| 80 | 52.92 | 42.96 | 34.86 | 29.25 | 24.42 | 20.52 | 17.76 | 15.28 | 13.22 | 11.81 | 10.45 | 9.28 | 8.29 | 7.5 | 6.8 | 6.18 | 5.65 | |

| 80 | 52.92 | 42.96 | 34.8 | 29.28 | 24.42 | 20.55 | 17.76 | 15.3 | 13.24 | 11.82 | 10.45 | 9.28 | 8.28 | 7.51 | 6.8 | 6.19 | 5.66 | |

| 100 | 92 | 74.2 | 59 | 48.72 | 40.2 | 33.36 | 28.5 | 24.18 | 20.73 | 18.18 | 15.94 | 14.1 | 12.5 | 11.24 | 10.08 | 9.08 | 8.23 | |

| 100 | 92.3 | 73.9 | 59.82 | 48.42 | 40.02 | 33.36 | 28.47 | 24.15 | 20.73 | 18.26 | 15.98 | 14.08 | 12.5 | 11.27 | 10.09 | 9.1 | 8.24 | |

| 100 | 92.3 | 73.7 | 59.64 | 48.3 | 39.96 | 33.36 | 28.44 | 24.12 | 20.76 | 18.24 | 15.98 | 14.06 | 12.48 | 11.27 | 10.09 | 9.1 | 8.24 | |

| Temperature [°C] | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 85 | ||

| Camelina oil content [% (m/m)] | 0 | 5.71 | 5 | 4.36 | 3.84 | 3.4 | 3.03 | 2.74 | 2.48 | 2.26 | 2.08 | 1.91 | 1.76 | 1.64 | 1.54 | 1.43 | 1.29 | 1.22 |

| 0 | 5.71 | 4.98 | 4.35 | 3.83 | 3.39 | 3.03 | 2.74 | 2.48 | 2.26 | 2.07 | 1.91 | 1.76 | 1.64 | 1.54 | 1.43 | 1.29 | 1.22 | |

| 0 | 5.7 | 4.97 | 4.34 | 3.82 | 3.38 | 3.02 | 2.73 | 2.48 | 2.25 | 2.07 | 1.91 | 1.76 | 1.64 | 1.53 | 1.42 | 1.3 | 1.22 | |

| 20 | 10.06 | 8.56 | 7.32 | 6.35 | 5.6 | 4.94 | 4.39 | 3.92 | 3.53 | 3.22 | 2.93 | 2.68 | 2.47 | 2.29 | 2.12 | 1.97 | 1.85 | |

| 20 | 10.08 | 8.56 | 7.34 | 6.34 | 5.62 | 4.95 | 4.39 | 3.94 | 3.53 | 3.22 | 2.93 | 2.69 | 2.48 | 2.29 | 2.12 | 1.97 | 1.85 | |

| 20 | 10.08 | 8.58 | 7.34 | 6.35 | 5.63 | 4.95 | 4.39 | 3.93 | 3.53 | 3.22 | 2.93 | 2.69 | 2.48 | 2.29 | 2.12 | 1.97 | 1.85 | |

| 40 | 15.58 | 13.66 | 11.62 | 9.95 | 8.51 | 7.4 | 6.48 | 5.74 | 5.21 | 4.66 | 4.22 | 3.83 | 3.5 | 3.22 | 2.97 | 2.75 | 2.56 | |

| 40 | 15.6 | 13.7 | 11.69 | 9.95 | 8.51 | 7.42 | 6.48 | 5.84 | 5.2 | 4.67 | 4.22 | 3.84 | 3.5 | 3.23 | 2.97 | 2.75 | 2.56 | |

| 40 | 15.64 | 13.68 | 11.66 | 9.94 | 8.53 | 7.43 | 6.49 | 5.8 | 5.2 | 4.67 | 4.22 | 3.84 | 3.5 | 3.23 | 2.97 | 2.75 | 2.56 | |

| 60 | 27.21 | 22.26 | 18.54 | 15.72 | 13.26 | 11.36 | 9.91 | 8.65 | 7.66 | 6.82 | 6.1 | 5.55 | 5.06 | 4.6 | 4.19 | 3.85 | 3.54 | |

| 60 | 27.21 | 22.26 | 18.7 | 15.7 | 13.22 | 11.5 | 9.92 | 8.69 | 7.66 | 6.83 | 6.11 | 5.6 | 5.06 | 4.61 | 4.21 | 3.85 | 3.54 | |

| 60 | 27.18 | 22.29 | 18.68 | 15.7 | 13.2 | 11.48 | 9.92 | 8.7 | 7.66 | 6.83 | 6.11 | 5.6 | 5.06 | 4.61 | 4.22 | 3.86 | 3.54 | |

| 80 | 62.28 | 49.59 | 40.68 | 33.18 | 27.84 | 23.61 | 19.89 | 17.16 | 14.86 | 12.94 | 11.36 | 10.18 | 9 | 8.1 | 7.33 | 6.64 | 6.02 | |

| 80 | 61.8 | 50.2 | 40.68 | 33.3 | 28.08 | 23.43 | 19.93 | 17.18 | 14.76 | 12.92 | 11.53 | 10.2 | 9.02 | 8.12 | 7.34 | 6.64 | 6.02 | |

| 80 | 61.92 | 50.28 | 40.8 | 33.24 | 28.11 | 23.43 | 20.01 | 17.2 | 14.82 | 12.94 | 11.54 | 10.2 | 9.05 | 8.14 | 7.34 | 6.66 | 6.04 | |

| 100 | 122 | 95.7 | 75.45 | 60.3 | 49.95 | 41.04 | 34.44 | 29.1 | 24.96 | 21.51 | 18.78 | 16.52 | 14.54 | 12.9 | 11.54 | 10.42 | 9.4 | |

| 100 | 121.7 | 95.7 | 75.9 | 60.45 | 50.04 | 41.1 | 34.38 | 29.34 | 25.02 | 21.54 | 18.82 | 16.54 | 14.58 | 12.92 | 11.62 | 10.42 | 9.42 | |

| 100 | 121.8 | 95.85 | 75.75 | 60.6 | 50.01 | 41.16 | 34.38 | 29.34 | 25.02 | 21.54 | 18.82 | 16.56 | 14.58 | 12.92 | 11.64 | 10.43 | 9.42 | |

| Temperature [°C] | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 85 | ||

| 0 | 5.71 | 5 | 4.36 | 3.84 | 3.4 | 3.03 | 2.74 | 2.48 | 2.26 | 2.08 | 1.91 | 1.76 | 1.64 | 1.54 | 1.43 | 1.29 | 1.22 | |

| Rapeseed oil content [% (m/m)] | 0 | 5.71 | 4.98 | 4.35 | 3.83 | 3.39 | 3.03 | 2.74 | 2.48 | 2.26 | 2.07 | 1.91 | 1.76 | 1.64 | 1.54 | 1.43 | 1.29 | 1.22 |

| 0 | 5.7 | 4.97 | 4.34 | 3.82 | 3.38 | 3.02 | 2.73 | 2.48 | 2.25 | 2.07 | 1.91 | 1.76 | 1.64 | 1.53 | 1.42 | 1.3 | 1.22 | |

| 20 | 12.46 | 10.62 | 8.98 | 7.68 | 6.68 | 5.84 | 5.17 | 4.58 | 4.18 | 3.79 | 3.43 | 3.13 | 2.87 | 2.65 | 2.45 | 2.28 | 2.12 | |

| 20 | 12.46 | 10.58 | 8.96 | 7.74 | 6.68 | 5.84 | 5.16 | 4.57 | 4.17 | 3.79 | 3.43 | 3.13 | 2.87 | 2.65 | 2.45 | 2.28 | 2.12 | |

| 20 | 12.46 | 10.56 | 8.96 | 7.74 | 6.68 | 5.83 | 5.16 | 4.57 | 4.17 | 3.78 | 3.43 | 3.13 | 2.87 | 2.65 | 2.45 | 2.28 | 2.12 | |

| 40 | 20.4 | 17.04 | 14.19 | 11.98 | 10.2 | 8.82 | 7.67 | 6.71 | 5.95 | 5.4 | 4.84 | 4.38 | 3.97 | 3.62 | 3.33 | 3.07 | 2.84 | |

| 40 | 20.34 | 17.04 | 14.14 | 11.94 | 10.25 | 8.81 | 7.66 | 6.7 | 5.94 | 5.39 | 4.84 | 4.38 | 3.97 | 3.63 | 3.33 | 3.08 | 2.84 | |

| 40 | 20.37 | 17.01 | 14.1 | 11.94 | 10.24 | 8.81 | 7.64 | 6.7 | 5.92 | 5.39 | 4.84 | 4.38 | 3.97 | 3.63 | 3.33 | 3.08 | 2.84 | |

| 60 | 60.75 | 48.45 | 38.7 | 31.48 | 25.52 | 21.32 | 17.98 | 15.36 | 13.16 | 11.6 | 10.14 | 8.94 | 7.99 | 7.1 | 6.41 | 5.8 | 5.29 | |

| 60 | 60.75 | 48.38 | 38.68 | 31.48 | 25.44 | 21.28 | 18 | 15.34 | 13.16 | 11.59 | 10.14 | 8.94 | 7.98 | 7.12 | 6.4 | 5.8 | 5.29 | |

| 60 | 60.82 | 48.38 | 38.68 | 31.4 | 25.4 | 21.28 | 17.98 | 15.34 | 13.16 | 11.59 | 10.14 | 8.94 | 7.97 | 7.12 | 6.41 | 5.8 | 5.29 | |

| 80 | 87.96 | 69.36 | 55.2 | 44.52 | 36.56 | 30.12 | 25.2 | 21.32 | 18.31 | 15.89 | 13.8 | 12.1 | 10.76 | 9.58 | 8.58 | 7.72 | 6.97 | |

| 80 | 87.48 | 69.12 | 54.96 | 44.34 | 36.44 | 30.2 | 25.12 | 21.36 | 18.29 | 15.86 | 13.78 | 12.1 | 10.76 | 9.58 | 8.57 | 7.72 | 6.97 | |

| 80 | 87.6 | 68.88 | 54.9 | 44.22 | 36.44 | 30.2 | 25.12 | 21.34 | 18.26 | 15.86 | 13.78 | 12.1 | 10.75 | 9.55 | 8.56 | 7.72 | 6.97 | |

| 100 | 157.2 | 120.8 | 93.6 | 74.4 | 59.6 | 48.87 | 40.2 | 33.87 | 28.68 | 24.6 | 20.96 | 18.24 | 16.08 | 14.12 | 12.52 | 11.36 | 10.5 | |

| 100 | 157 | 120.2 | 93.2 | 74 | 59.8 | 48.67 | 40.07 | 33.88 | 28.6 | 24.52 | 20.97 | 18.24 | 16.08 | 14.1 | 12.52 | 11.38 | 10.5 | |

| 100 | 157 | 119.8 | 93.2 | 74 | 59.7 | 48.6 | 40 | 33.76 | 28.6 | 24.4 | 20.97 | 18.21 | 16.06 | 14.1 | 12.5 | 11.39 | 10.5 | |

| 0 | 5.71 | 5 | 4.36 | 3.84 | 3.4 | 3.03 | 2.74 | 2.48 | 2.26 | 2.08 | 1.91 | 1.76 | 1.64 | 1.54 | 1.43 | 1.29 | 1.22 | |

| Model | A | B | C | Coefficient of Determination R2 [-] |

|---|---|---|---|---|

| Mustard oil 100% (m/m) | −2.034 | 938.2 | 123.8 | 0.9999 |

| Flaxseed oil 100% (m/m) | −2.014 | 891.0 | 131.1 | 0.9999 |

| Camelina oil 100% (m/m) | −1.947 | 880.7 | 125.4 | 0.9999 |

| Rapeseed oil 100% (m/m) | −2.597 | 638.7 | 142.1 | 0.9998 |

| Diesel 100% (m/m) | −2.597 | 638.7 | 142.1 | 0.9998 |

| Model | Coefficient of Determination R2 [-] |

|---|---|

| Diesel fuel–mustard oil | 0.9975 |

| Diesel fuel–flaxseed oil | 0.9995 |

| Diesel fuel–camelina oil | 0.9986 |

| Diesel fuel–rapeseed oil | 0.9922 |

| Model | Coefficient of Determination R2 [-] | MAE [mPa·s] |

|---|---|---|

| Grunberg–Nissan | 0.995 | 0.15 |

| Arrhenius–Guzmán | 0.965 | 0.42 |

| Walther | 0.978 | 0.31 |

| Andrade | 0.972 | 0.38 |

| Model for the Blend | Number of Hidden Layer Neurons [-] | Coefficient of Determination R2 [-] |

|---|---|---|

| Diesel fuel–mustard oil | 2 | 0.9975 |

| Diesel fuel–flaxseed oil | 2 | 0.9995 |

| Diesel fuel–camelina oil | 2 | 0.9986 |

| Diesel fuel–rapeseed oil | 2 | 0.9922 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tucki, K.; Mruk, R.; Gruz, Ł.; Nowakowski, T.; Kulpa, K. Dynamic Viscosity Analysis of Fuels and Their Blends with Bio-Additives as a Function of Temperature. Appl. Sci. 2025, 15, 13210. https://doi.org/10.3390/app152413210

Tucki K, Mruk R, Gruz Ł, Nowakowski T, Kulpa K. Dynamic Viscosity Analysis of Fuels and Their Blends with Bio-Additives as a Function of Temperature. Applied Sciences. 2025; 15(24):13210. https://doi.org/10.3390/app152413210

Chicago/Turabian StyleTucki, Karol, Remigiusz Mruk, Łukasz Gruz, Tomasz Nowakowski, and Krzysztof Kulpa. 2025. "Dynamic Viscosity Analysis of Fuels and Their Blends with Bio-Additives as a Function of Temperature" Applied Sciences 15, no. 24: 13210. https://doi.org/10.3390/app152413210

APA StyleTucki, K., Mruk, R., Gruz, Ł., Nowakowski, T., & Kulpa, K. (2025). Dynamic Viscosity Analysis of Fuels and Their Blends with Bio-Additives as a Function of Temperature. Applied Sciences, 15(24), 13210. https://doi.org/10.3390/app152413210