Processing Performance Improvement in Electrical Discharge Machining of Deep Narrow Groove Using Rounded Corner Electrode

Abstract

1. Introduction

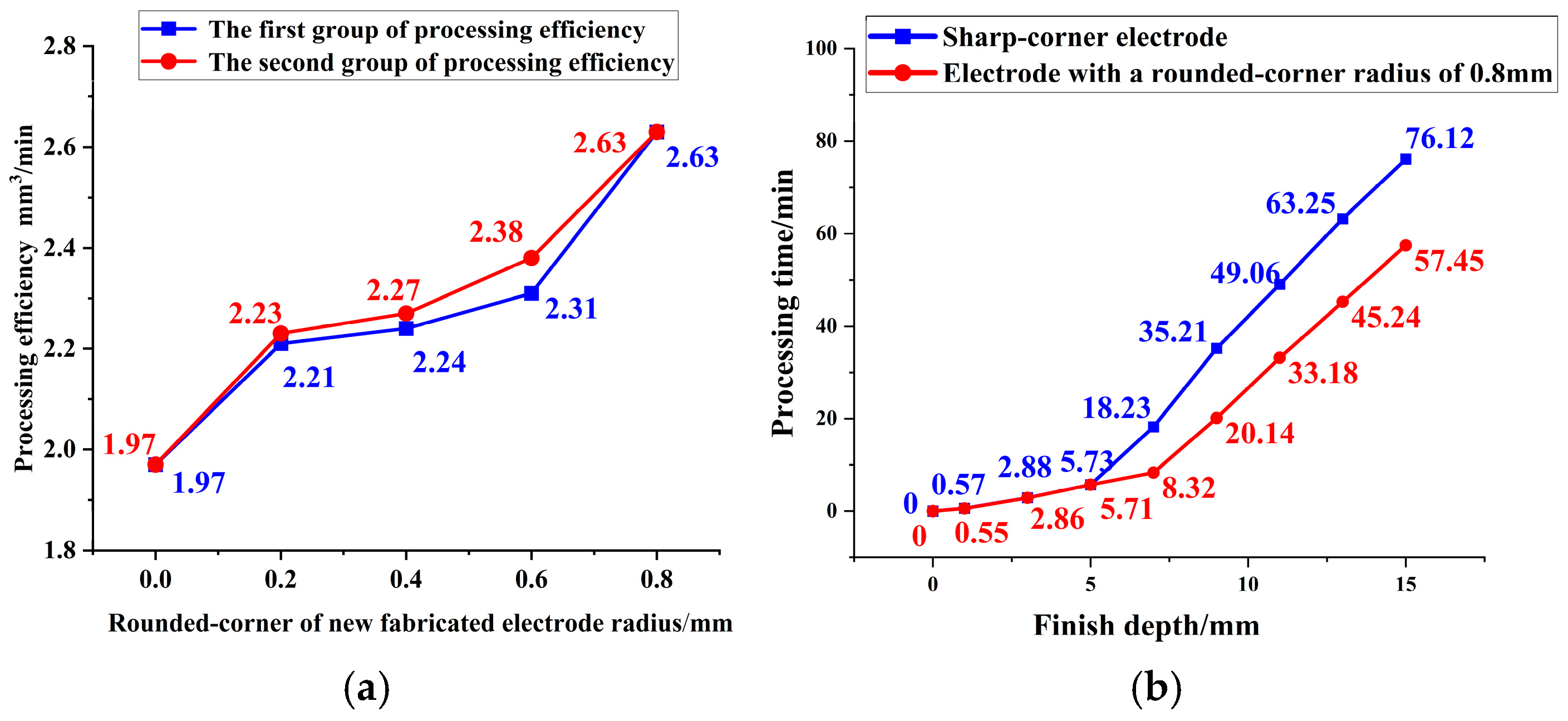

2. Processing Performance in EDM of Deep, Narrow Grooves via Sharp Corner Electrode

2.1. Experimental Design

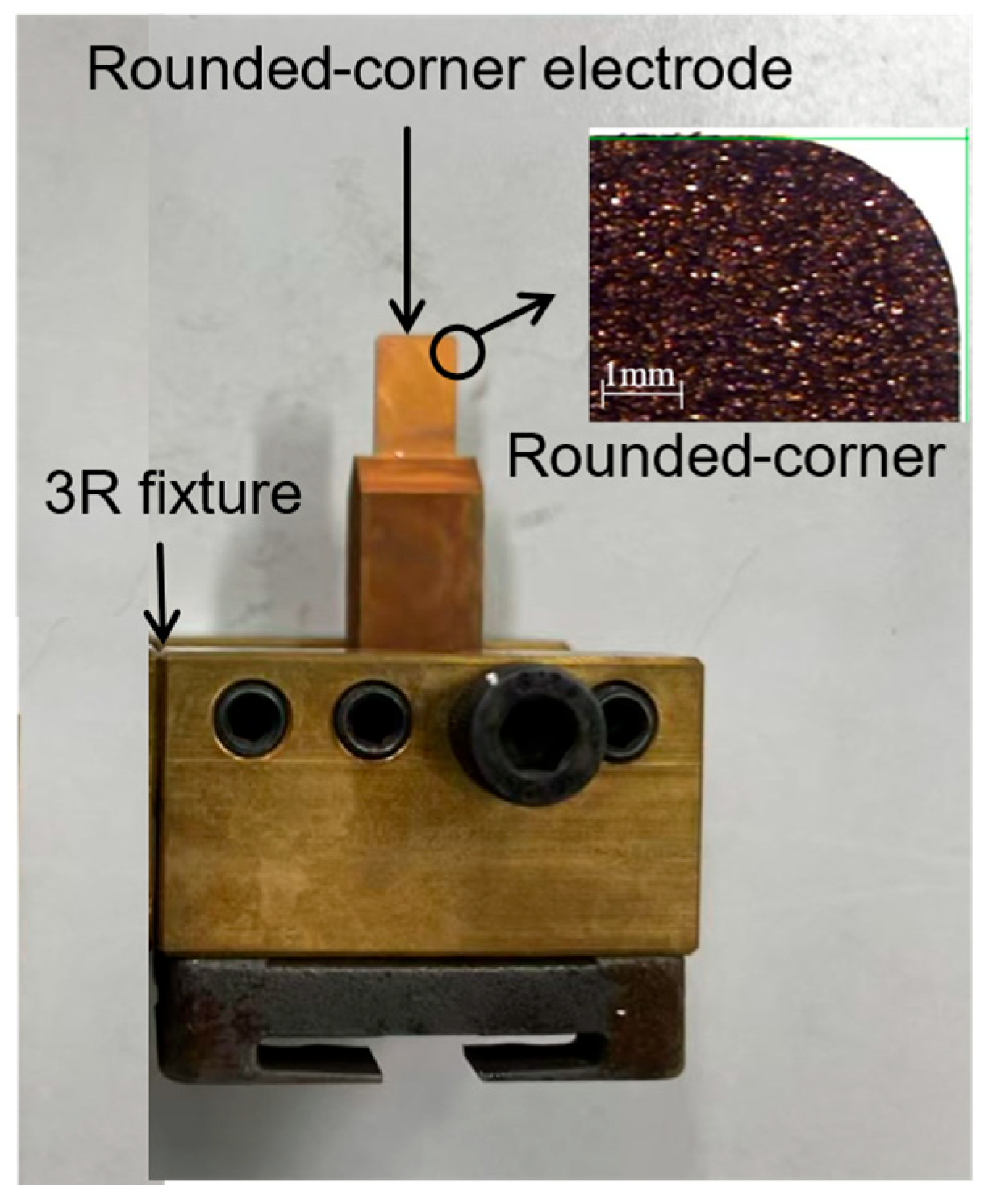

2.1.1. Electrode Preparation

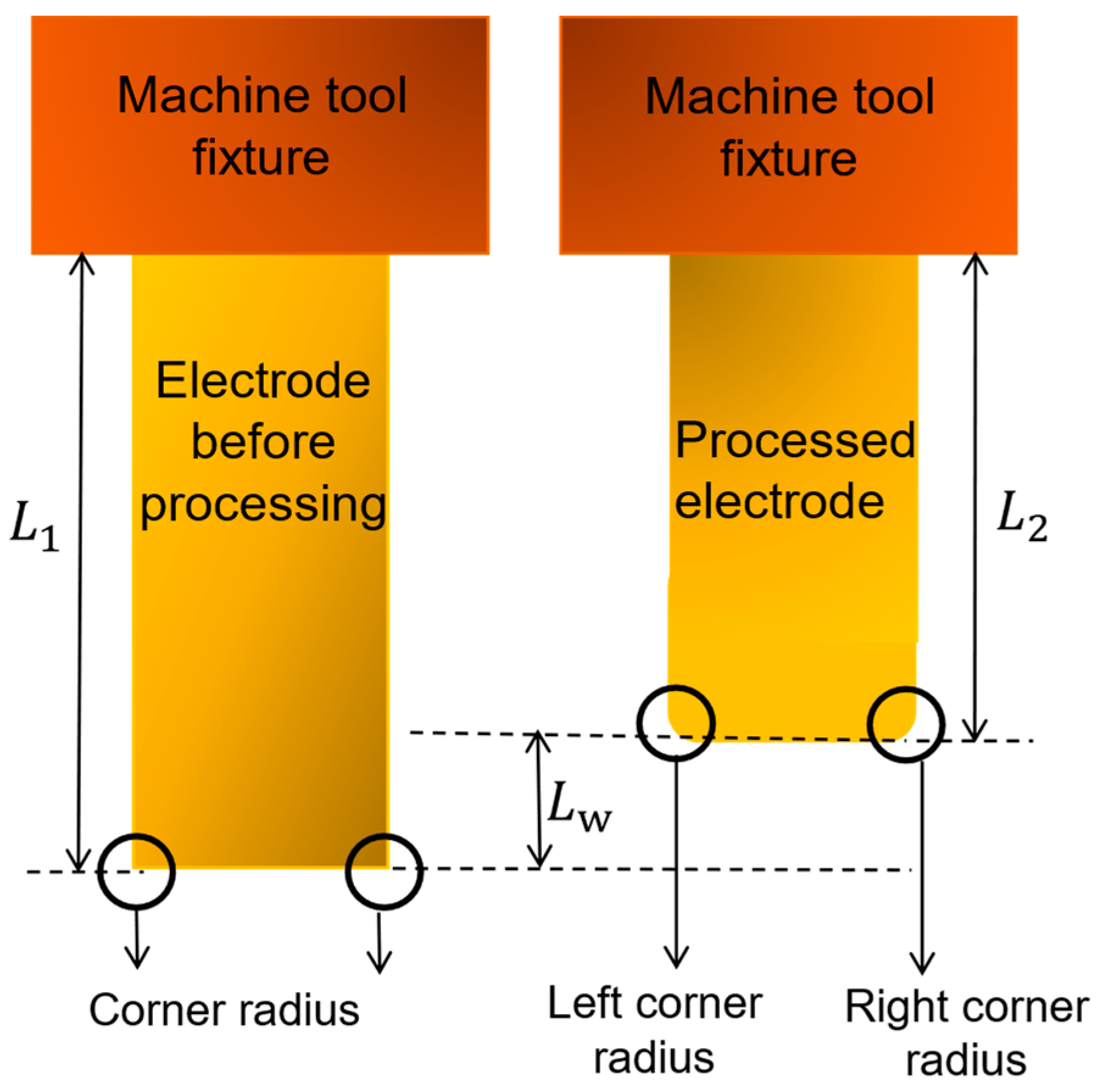

2.1.2. Evaluation of Electrode Wear

2.1.3. Experimental Parameter

2.2. Experimental Results and Discussion

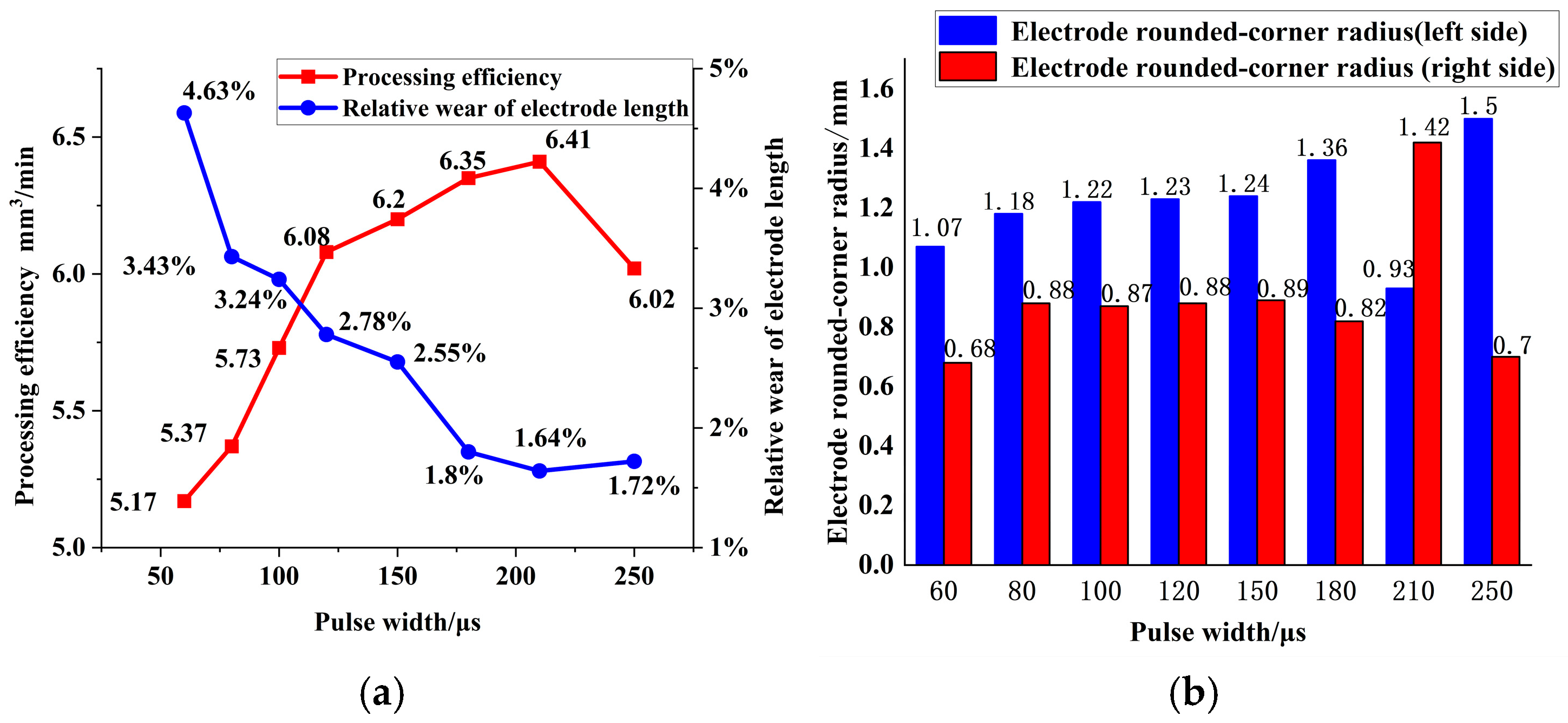

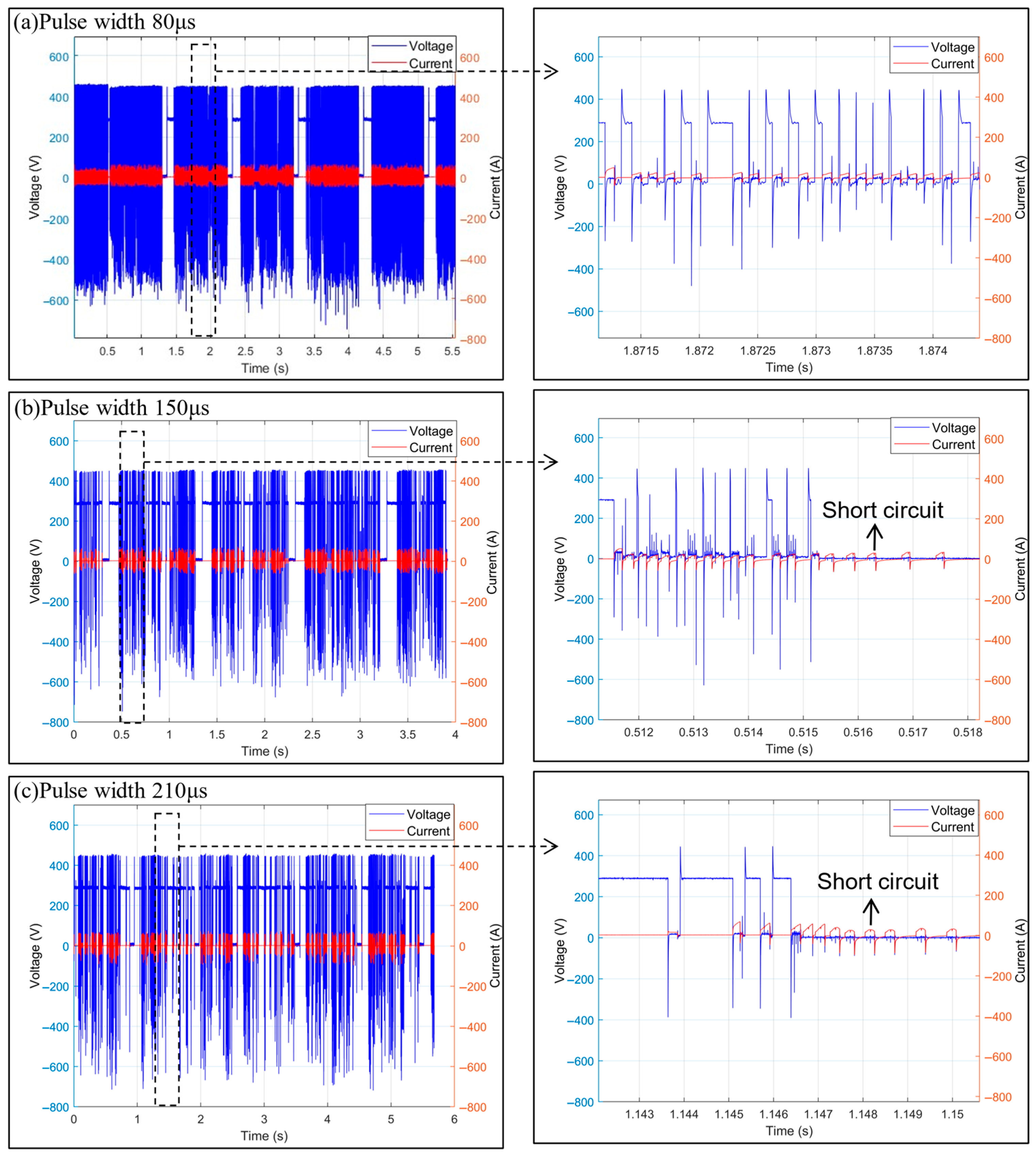

2.2.1. The Influence of Pulse Width

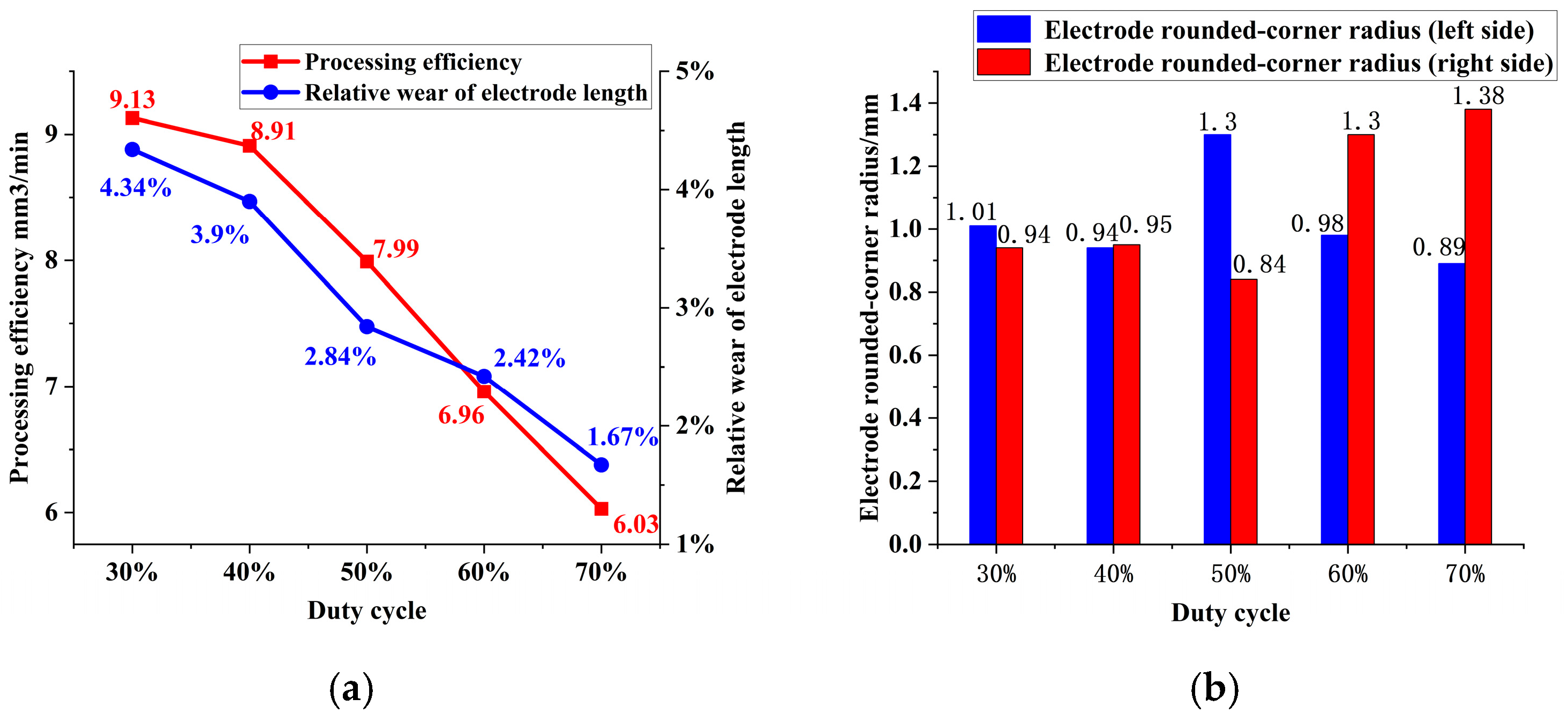

2.2.2. The Influence of Duty Cycle

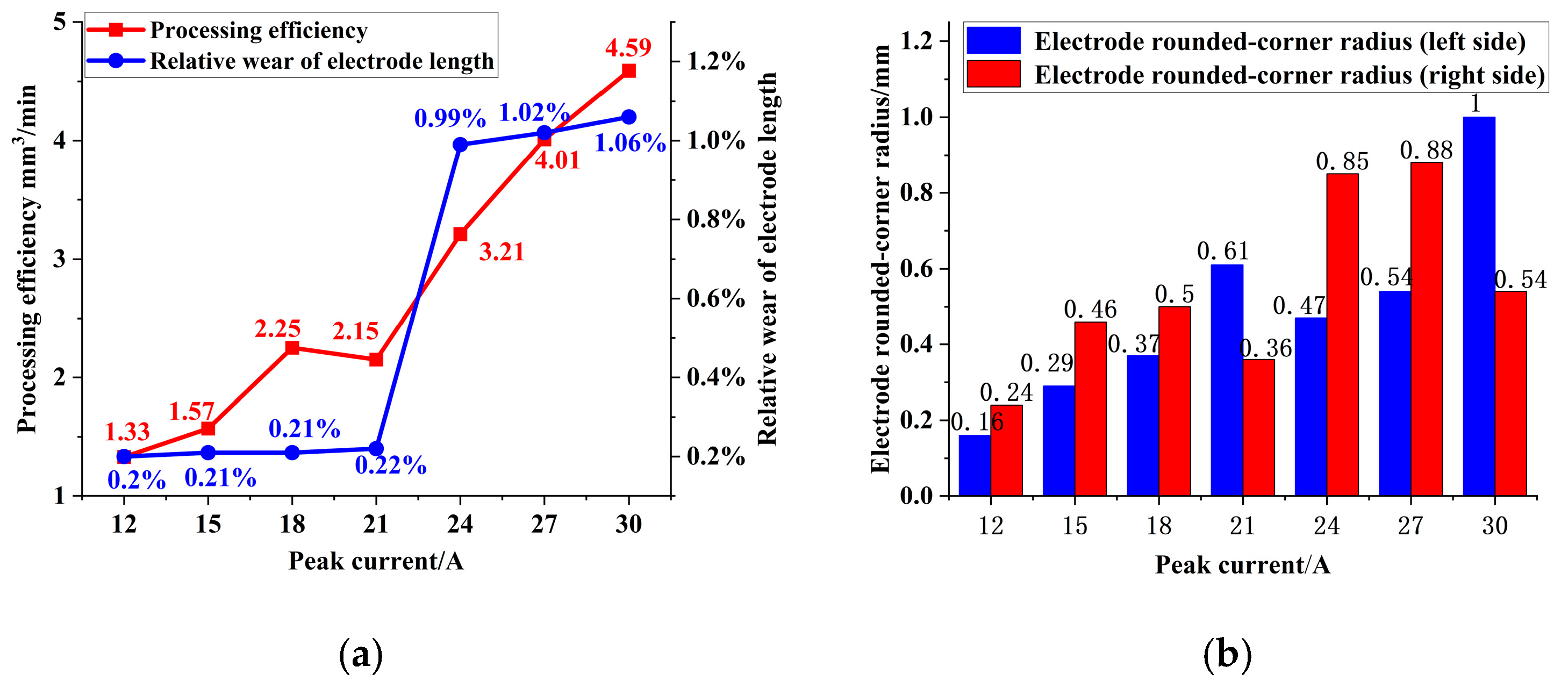

2.2.3. Influence of Peak Current

3. EDM of Deep Narrow Groove Using Rounded Corner Electrode

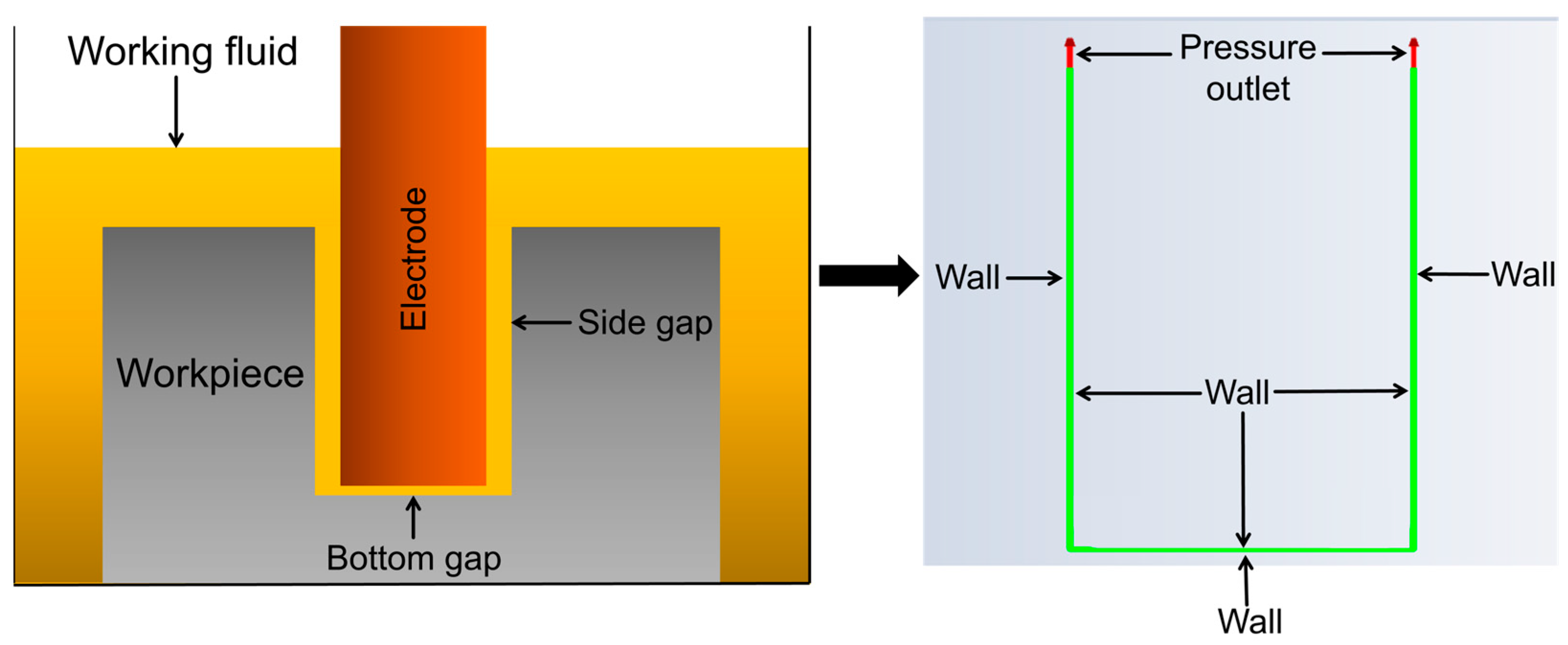

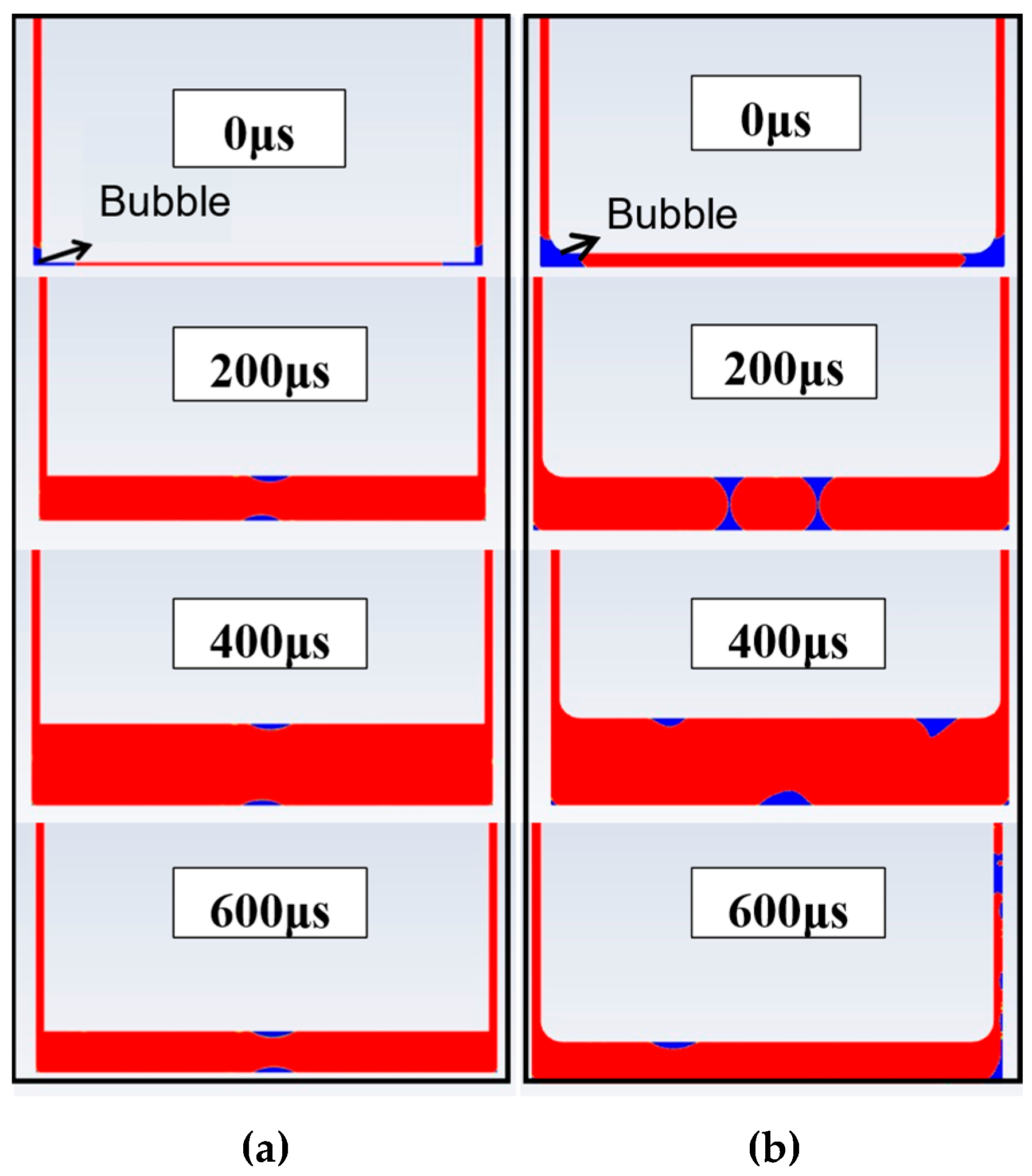

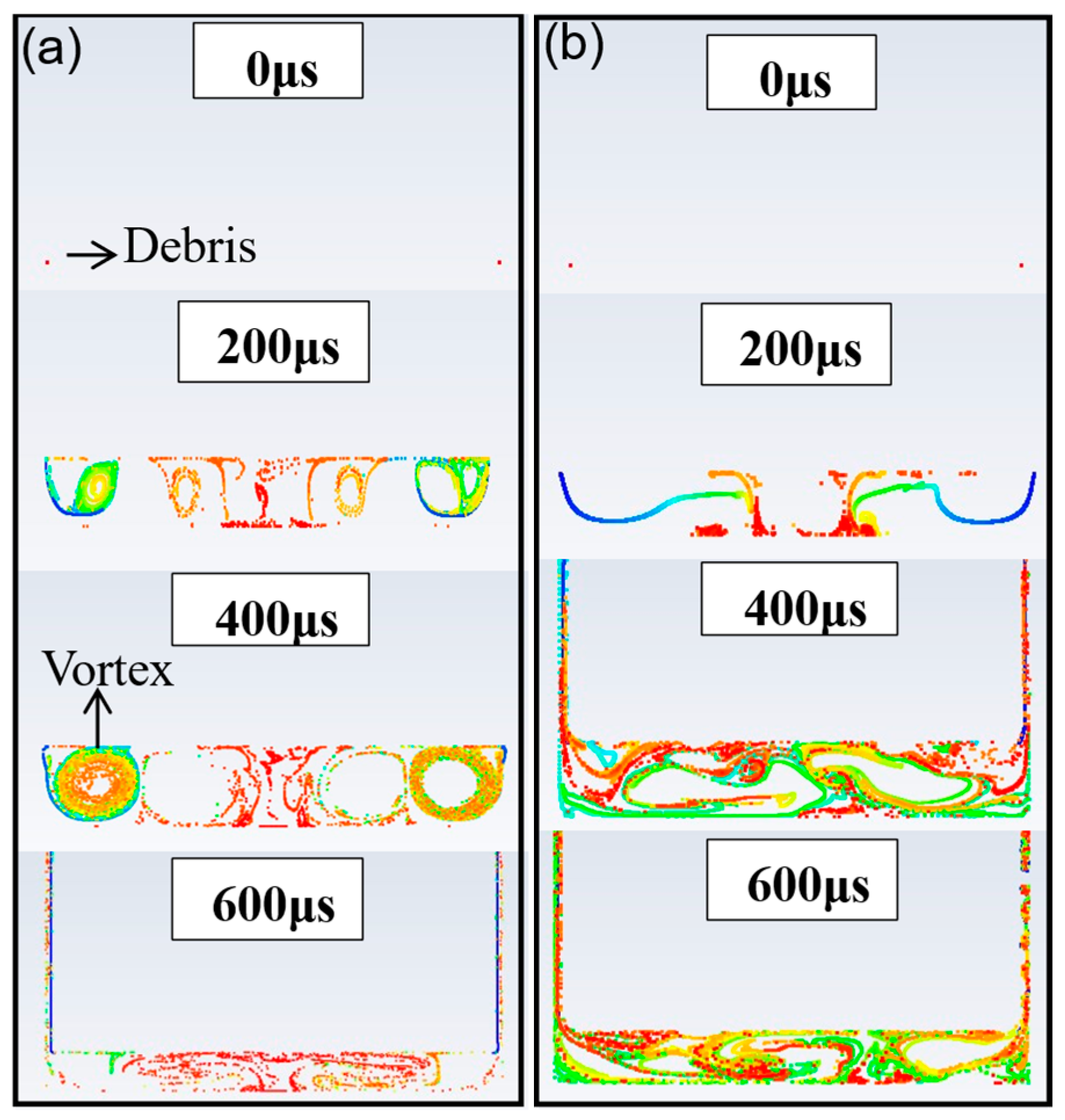

3.1. Flow Field Simulation in EDM of Deep Narrow Groove

3.1.1. Geometric Model of the Flow Field

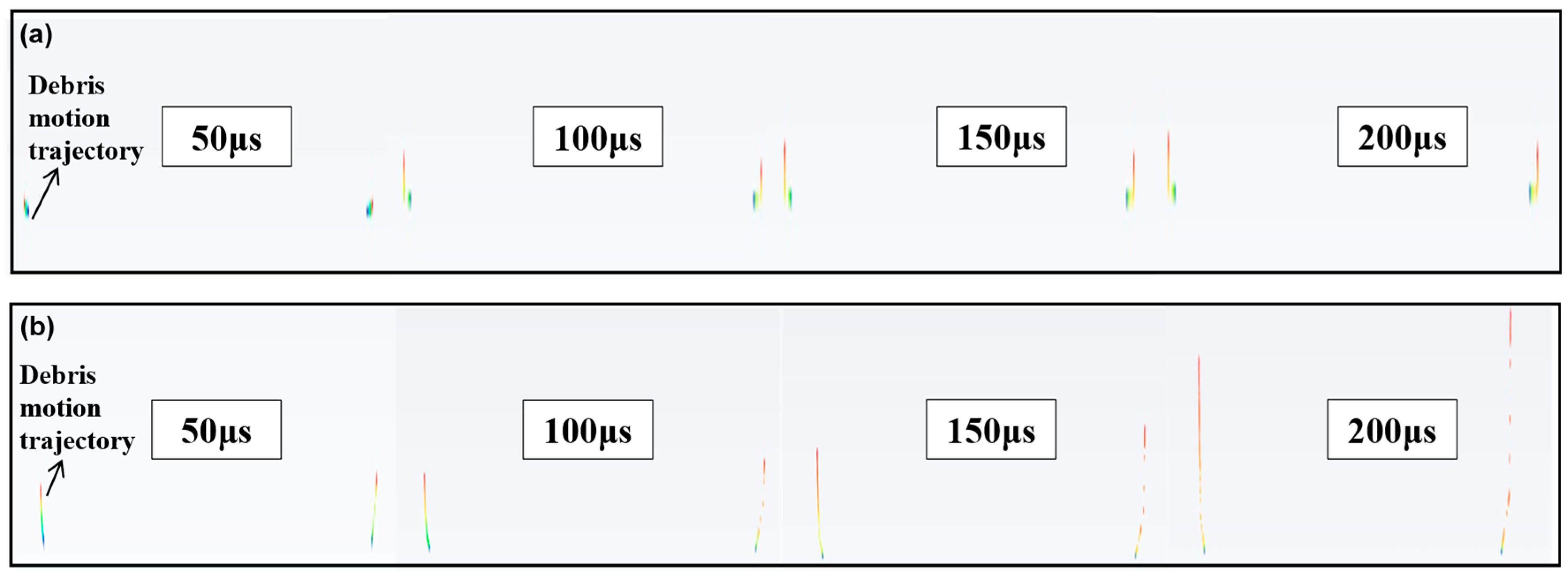

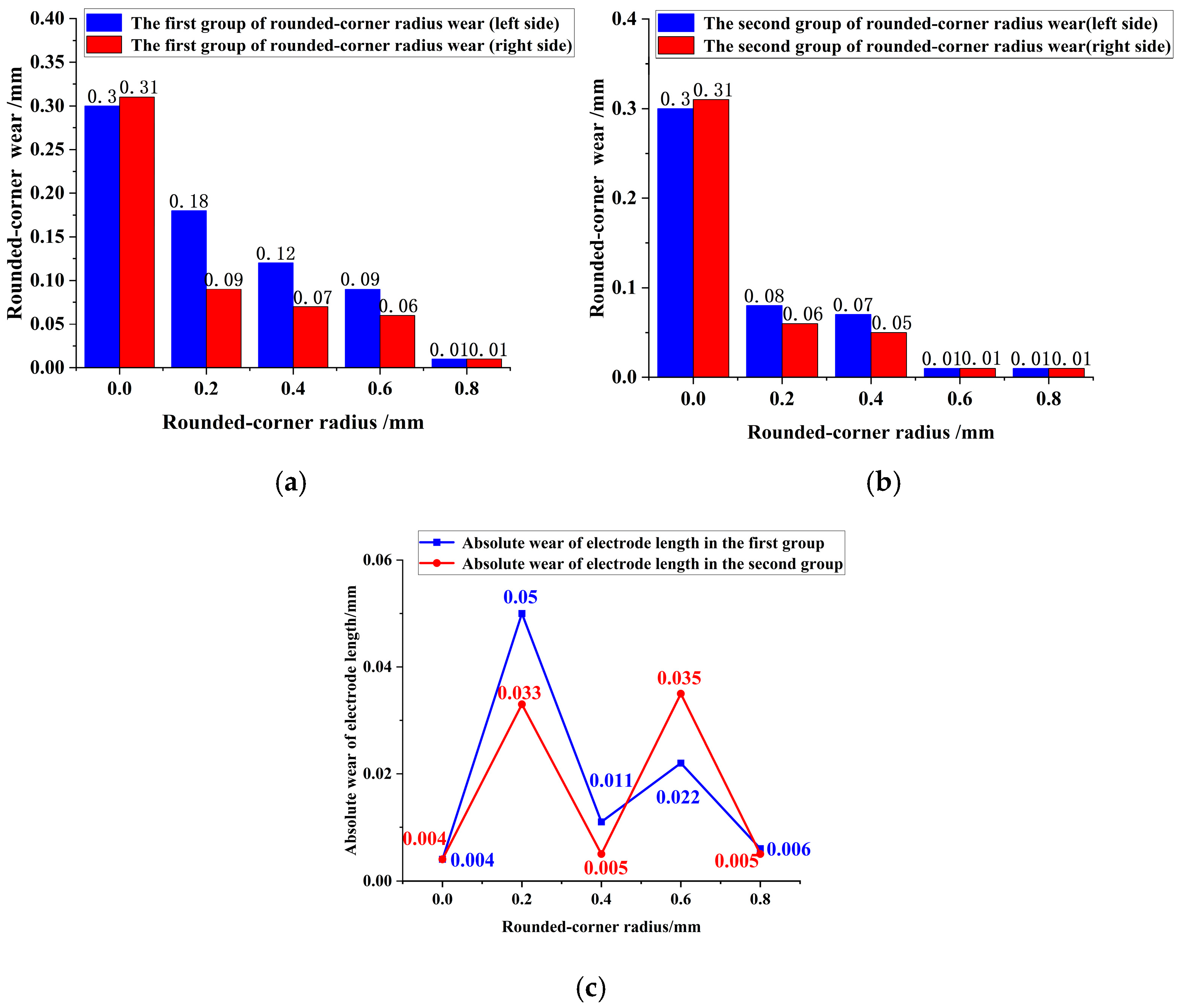

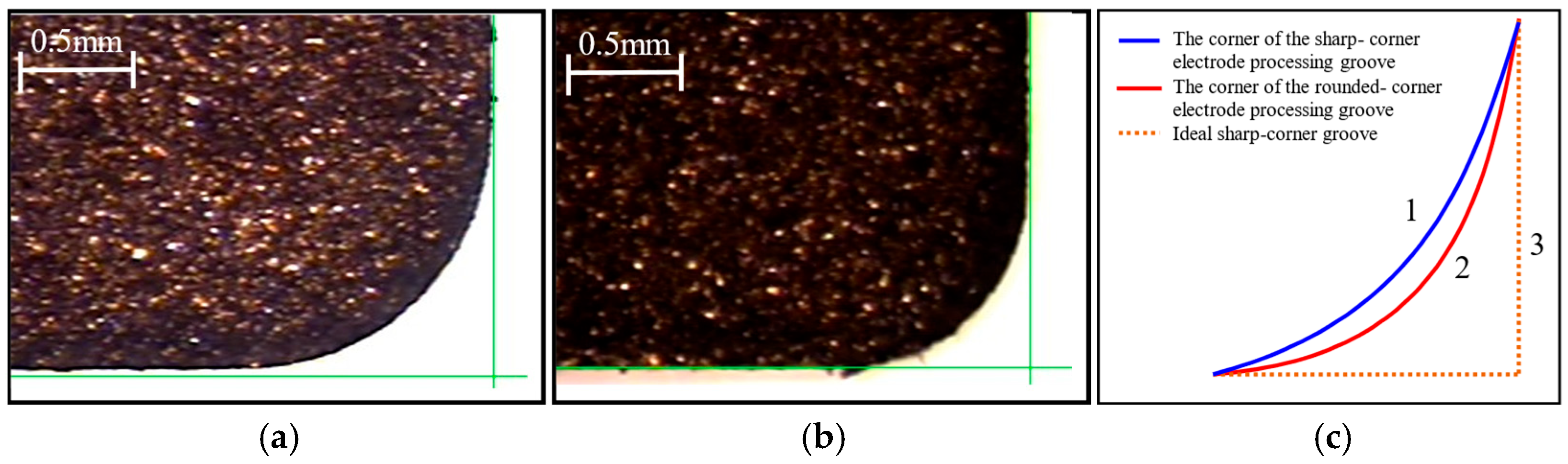

3.1.2. Simulation Results

3.2. Experimental Verification

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bai, Y.Y.; Lu, M.; Li, W.B.; Liang, G.X.; Guo, J.Y. Research review and prospect of narrow deep groove processing technology. Manuf. Technol. Mach. Tool 2014, 10, 45–49. [Google Scholar]

- Cao, F.G. Electrical Discharge Machining; Chemical Industry Press: Beijing, China, 2014. [Google Scholar]

- Flaño, O.; Zhao, Y.H.; Kunieda, M.; Abe, K. Approaches for improvement of EDM performance of SiC with foil electrode. Precis. Eng. 2017, 49, 33–40. [Google Scholar]

- Flaño, O.; Ayesta, I. Improvement of EDM performance in high-aspect ratio slot machining using multi-holed electrodes. Precis. Eng. 2018, 51, 223–231. [Google Scholar]

- Tang, J.J.; Yang, X.D. Deep narrow slot electrical discharge machining method based on high-speed rotating disc electrode. Electr. Mach. Die Mould 2014, 1, 1–4. [Google Scholar]

- Li, J.; Su, G.; Chen, X.; Liu, G.; Zhang, Y. Study of electrical discharge machining of narrow grooves with foil tool electrode. Int. J. Adv. Manuf. Technol. 2023, 128, 5405–5423. [Google Scholar] [CrossRef]

- Pellegrini, G.; Ravasio, C. Investigation on electrode wear in micro-EDM drilling. MM Sci. J. 2024. [Google Scholar] [CrossRef]

- Selvarajan, L.; Elango, T.; Kannan, P.R.; Perumal, K.P.; Arun, C.; Sadhishkumar, S.; Kannan, S. Investigation of electrical Discharge machining efficiency with cryogenic copper electrodes for AISI D2 Steel: Enhancing material removal rate, reducing electrode wear rate, and minimizing machining time. J. Mater. Eng. Perform. 2025, 34, 11334–11348. [Google Scholar]

- Aghdeab, S.H.; Hasan, M.M.; Makhrib, G.A. Study impact of gap distance on electrode wear rate in electrical discharge machining (EDM). AIP Conf. Proc. 2024, 2885, 070003. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Y.; Yu, P.; Gao, Y.; Dong, S. High-quality and efficiency machining of micro-EDM. In Proceedings of the IEEE International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale, Zhongshan, China, 29 July–2 August 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 105–110. [Google Scholar]

- Huu, P.N.; Shirguppikar, S.; Duc, T.N. Optimizing micro-EDM with carbon-coated electrodes: A multi-criteria approach. Int. J. Mod. Phys. B 2024, 38, 2440019. [Google Scholar] [CrossRef]

- Che, B.; Tao, M.; Luo, Z. Effect of ultrasonic assisted EDM based on horizontal vibration on deep and small hole machining. Sci. Rep. 2024, 14, 28146. [Google Scholar] [CrossRef]

- Pham, H.V.; Nguyen, H.P.; Shailesh, S.; Nguyen, D.T.; Bui, N.T. Investigating technological parameters and TiN-coated electrodes for enhanced efficiency in Ti-6Al-4V micro-EDM machining. Metals 2024, 14, 162. [Google Scholar] [CrossRef]

- Pham, H.V.; Nguyen, H.P.; Shailesh, S.; Nguyen, D.T.; Bui, N.T. Improving Micro-EDM machining efficiency for titanium alloy fabrication with advanced coated electrodes. Micromachines 2024, 15, 692. [Google Scholar] [CrossRef]

- Li, W.T. Experimental Research on High-Efficiency and Low-Loss Electrical Discharge Machining Technology for Deep Narrow Grooves. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2018. [Google Scholar]

- Chu, Z.; Zhao, W.; Gu, L. Effect of electrode jump motion on machining debris concentration. J. Mech. Eng. 2013, 49, 185–192. [Google Scholar] [CrossRef]

- Chu, Z.L. Research on Electrode Tool Lifting Motion and Electrical Discharge Machining Performance. Master’s Thesis, Shanghai Jiao Tong University, Shanghai, China, 2013. [Google Scholar]

- Uhlmann, E.; Domingos, D.C. Investigation on vibration-assisted EDM-maching of seal slot in high-temperature resistant materials for turbin components-part II. Procedia CIRP 2016, 42, 334–339. [Google Scholar] [CrossRef]

- Zhang, R.X. Study on dynamically variable attitude EDM machining method of deep narrow slots. Int. J. Adv. Manuf. Technol. 2022, 121, 4601–4623. [Google Scholar] [CrossRef]

- Zhang, R.X. Influence of electrode feed directions on EDM machining efficiency of deep narrow slots. Int. J. Adv. Manuf. Technol. 2021, 117, 3415–3429. [Google Scholar] [CrossRef]

- Zhang, R.X. Study on particle size distribution of debris in electrical discharge machining of deep narrow slots. Procedia CIRP 2020, 95, 476–481. [Google Scholar] [CrossRef]

- Jiang, M.; Li, L.; Sun, X.; Wang, W.; Liu, Z. Research on the mechanism and process of polycrystalline diamond by EDM. Int. J. Adv. Manuf. Technol. 2023, 125, 819–830. [Google Scholar] [CrossRef]

- Wang, Z.; Tong, H.; Li, Y.; Li, C. Dielectric flushing optimization of fast hole EDM drilling based on debris status analysis. Int. J. Adv. Manuf. Technol. 2018, 97, 2409–2417. [Google Scholar] [CrossRef]

- Wang, J.Y. Research on the Realization of Current Control Affecting the Thickness of Electrode Carbon Deposit Layer. Master’s Thesis, East China Jiaotong University, Nanchang, China, 2008. [Google Scholar]

- Maradia, U.; Knaak, R.; Dal Busco, W.; Boccadoro, M.; Wegener, K. A strategy for low electrode wear in meso–micro-EDM. Precis. Eng. 2015, 42, 302–310. [Google Scholar] [CrossRef]

- Huang, Q.Y. Simulation Study on the Distribution State of Etched Materials and Bubbles in the Gap by Electrical Discharge Machining. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2017. [Google Scholar]

- Wang, J.; Han, F.Z. Simulation model of debris and bubble movement in electrode jump of electrical discharge machining. Int. J. Adv. Manuf. Technol. 2014, 74, 591–598. [Google Scholar] [CrossRef]

| Electrical Parameter | Value | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pulse Width | 60 μs | 80 μs | 100 μs | 120 μs | 150 μs | 180 μs | 210 μs | 250 μs | ||||||||||

| Duty cycle | 30% | 40% | 50% | 60% | 70% | |||||||||||||

| Peak current | 12A | 15A | 18A | 21A | 24A | 27A | 30A | |||||||||||

| Pulse Width (μs) | Duty Cycle | Peak Current (A) | High Voltage (V) | Low Voltage (V) |

|---|---|---|---|---|

| 150 | 70% | 40 | 280 | 150 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Qiao, C.; Ma, K.; He, H.; Jia, Z. Processing Performance Improvement in Electrical Discharge Machining of Deep Narrow Groove Using Rounded Corner Electrode. Appl. Sci. 2025, 15, 13081. https://doi.org/10.3390/app152413081

Wang J, Qiao C, Ma K, He H, Jia Z. Processing Performance Improvement in Electrical Discharge Machining of Deep Narrow Groove Using Rounded Corner Electrode. Applied Sciences. 2025; 15(24):13081. https://doi.org/10.3390/app152413081

Chicago/Turabian StyleWang, Jin, Chunkai Qiao, Kejun Ma, Hu He, and Zhixin Jia. 2025. "Processing Performance Improvement in Electrical Discharge Machining of Deep Narrow Groove Using Rounded Corner Electrode" Applied Sciences 15, no. 24: 13081. https://doi.org/10.3390/app152413081

APA StyleWang, J., Qiao, C., Ma, K., He, H., & Jia, Z. (2025). Processing Performance Improvement in Electrical Discharge Machining of Deep Narrow Groove Using Rounded Corner Electrode. Applied Sciences, 15(24), 13081. https://doi.org/10.3390/app152413081