Investigation of Granular Organic Fertilizer Distribution Uniformity in Disk-Type Spreaders with Standard and Modified Vane Configurations

Abstract

1. Introduction

- To evaluate and compare the physical properties (particle size, density, and moisture content) of custom-produced grain husk granules and commercial poultry manure granules.

- To quantify the effect of vane geometry modifications on spreading performance by measuring the spread width, distribution uniformity, and mass flow using a custom-designed vane installed on the distribution machine.

2. Materials and Methods

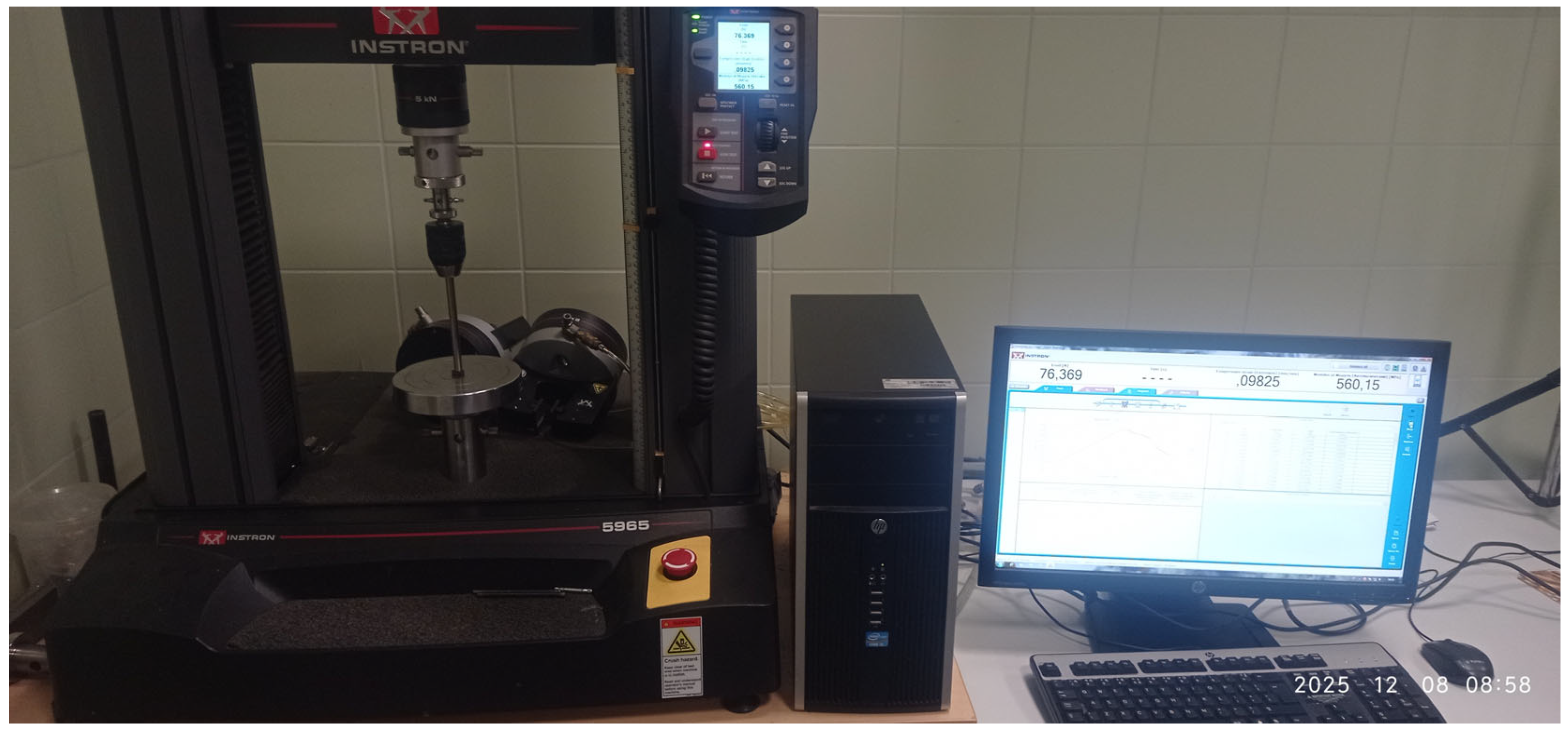

2.1. Laboratory Tests

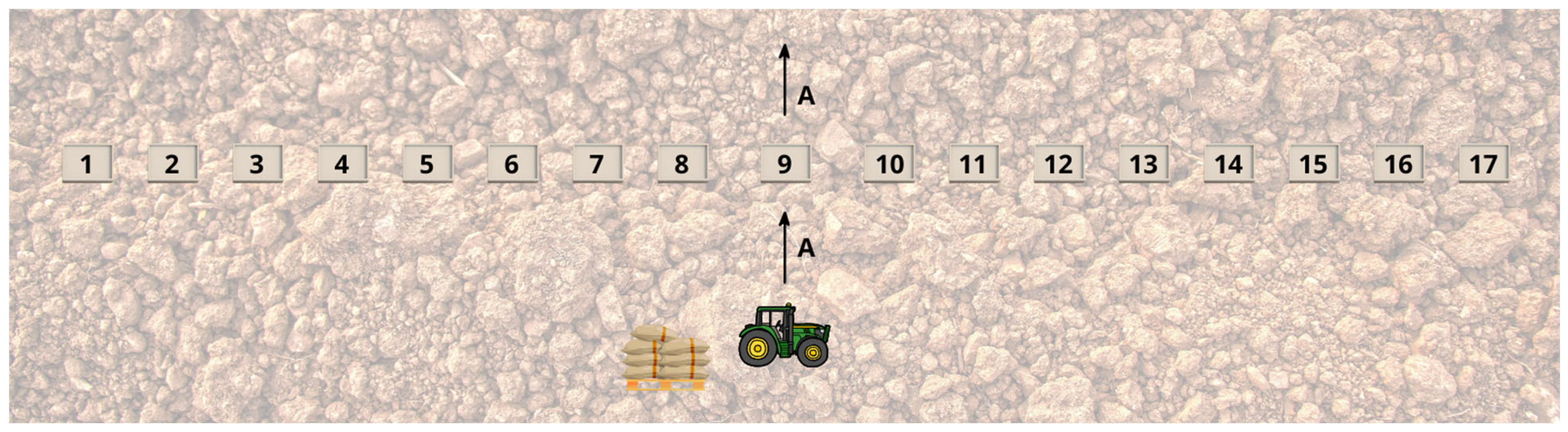

2.2. Field Tests

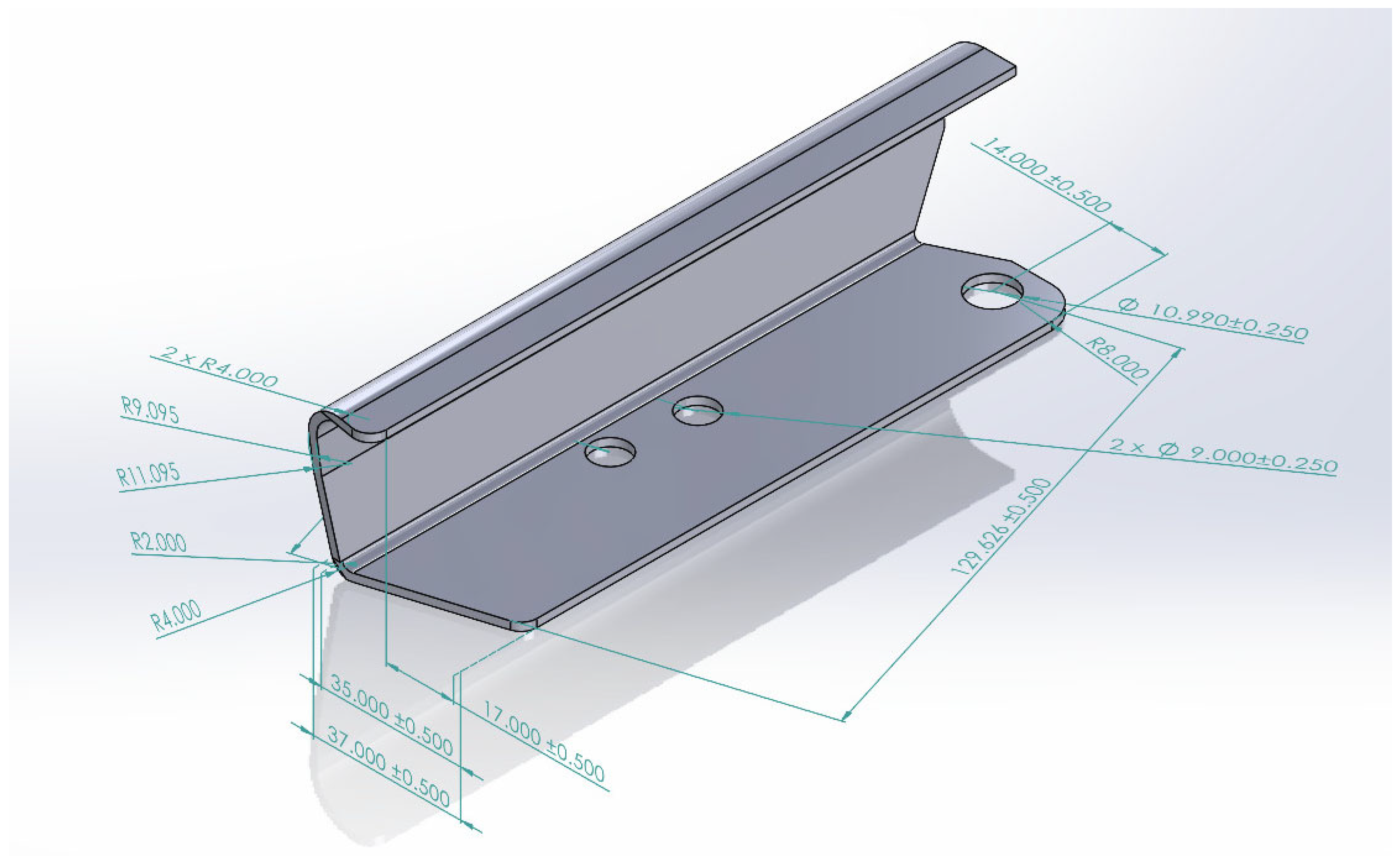

2.3. Design and Configuration of Spreader Disks

- The reference setup employed the manufacturer’s original disk equipped with its standard vane arrangement, which served as the control.

- The second configuration used the same disk body; however, the vanes were replaced with custom-designed elements developed and fabricated by the research team.

2.4. Statistical Analysis

3. Results

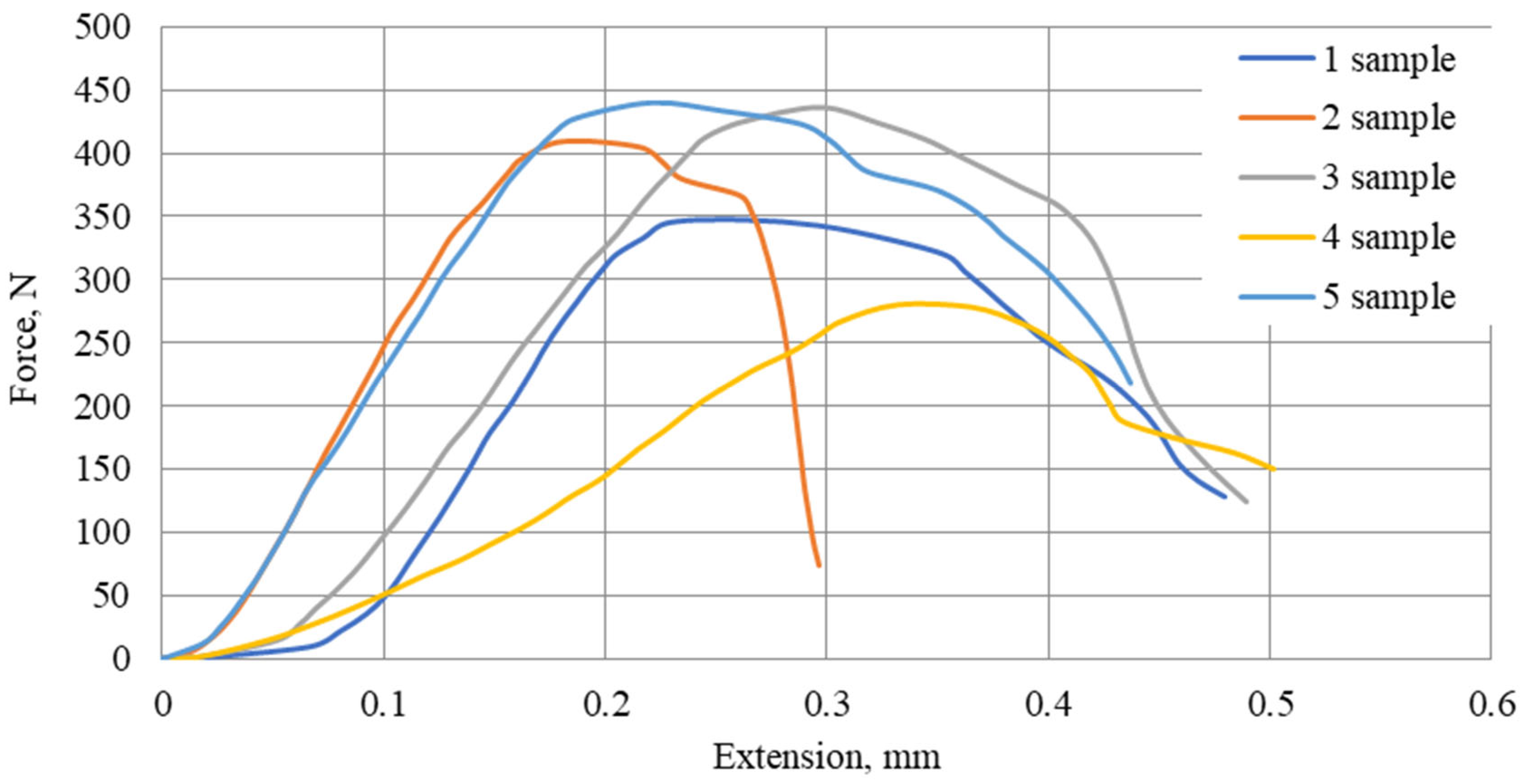

3.1. Physical and Mechanical Properties of Fertilizer Granules

3.2. Experimental Assessment of Granule Distribution in Field Application

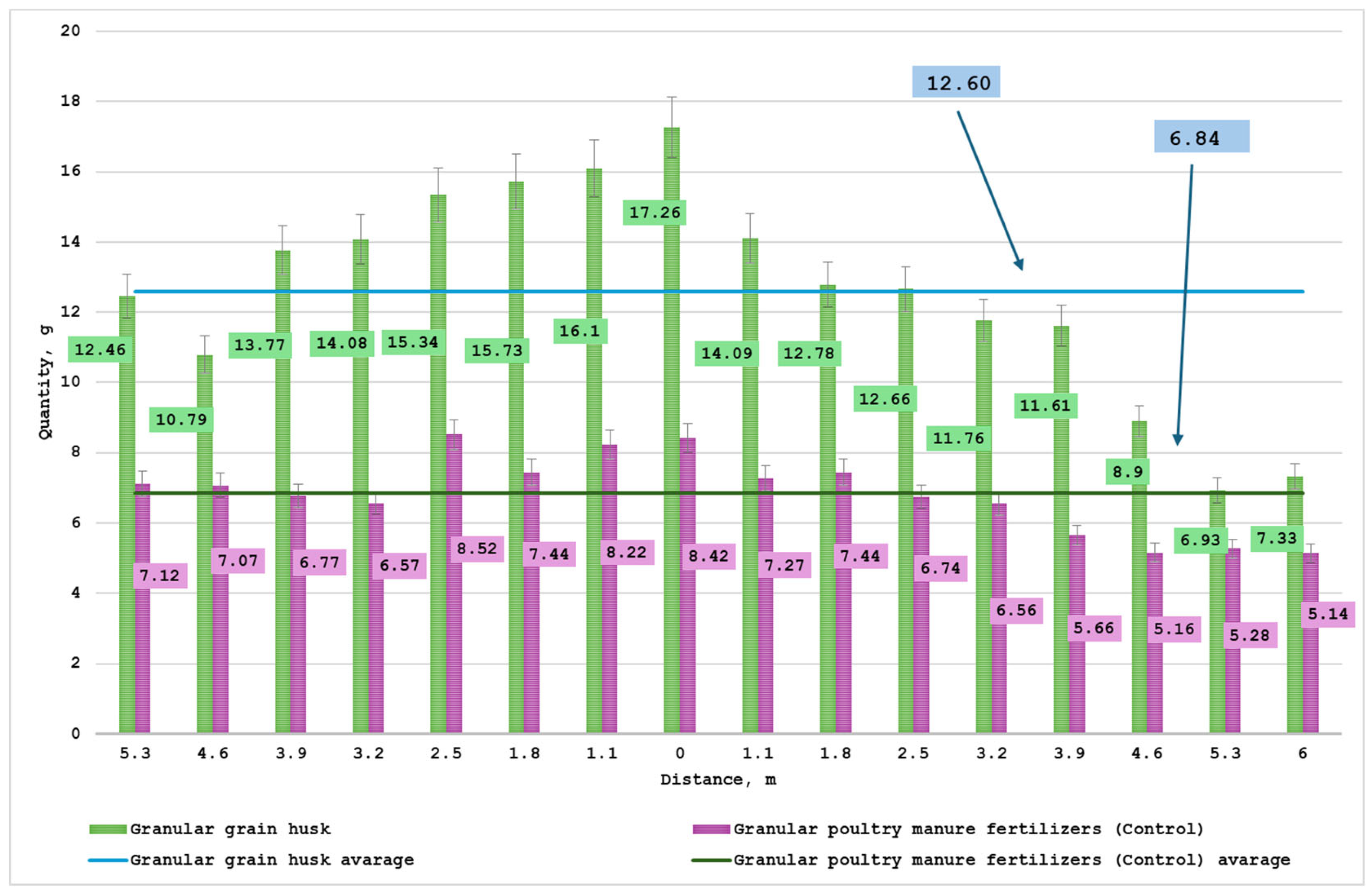

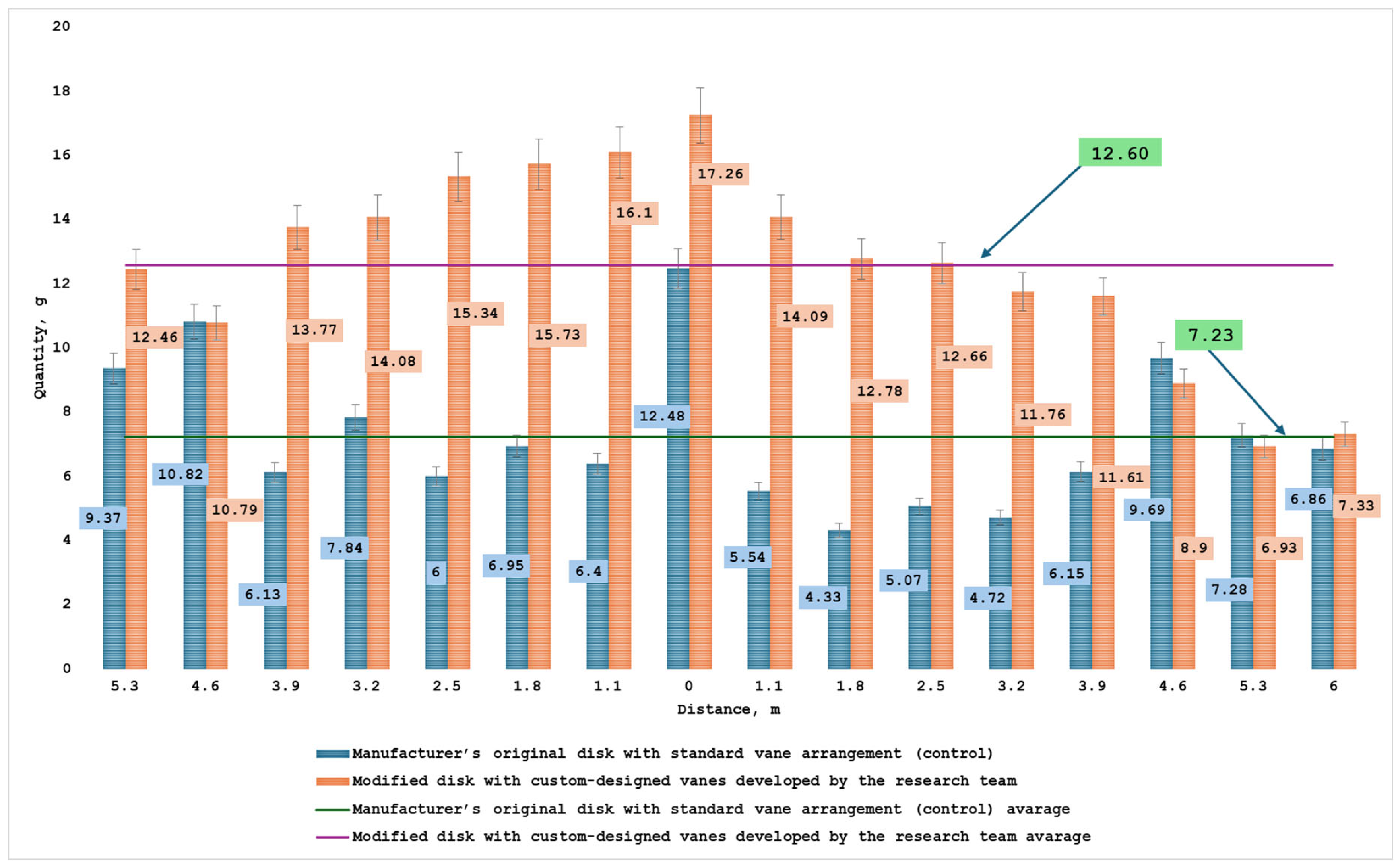

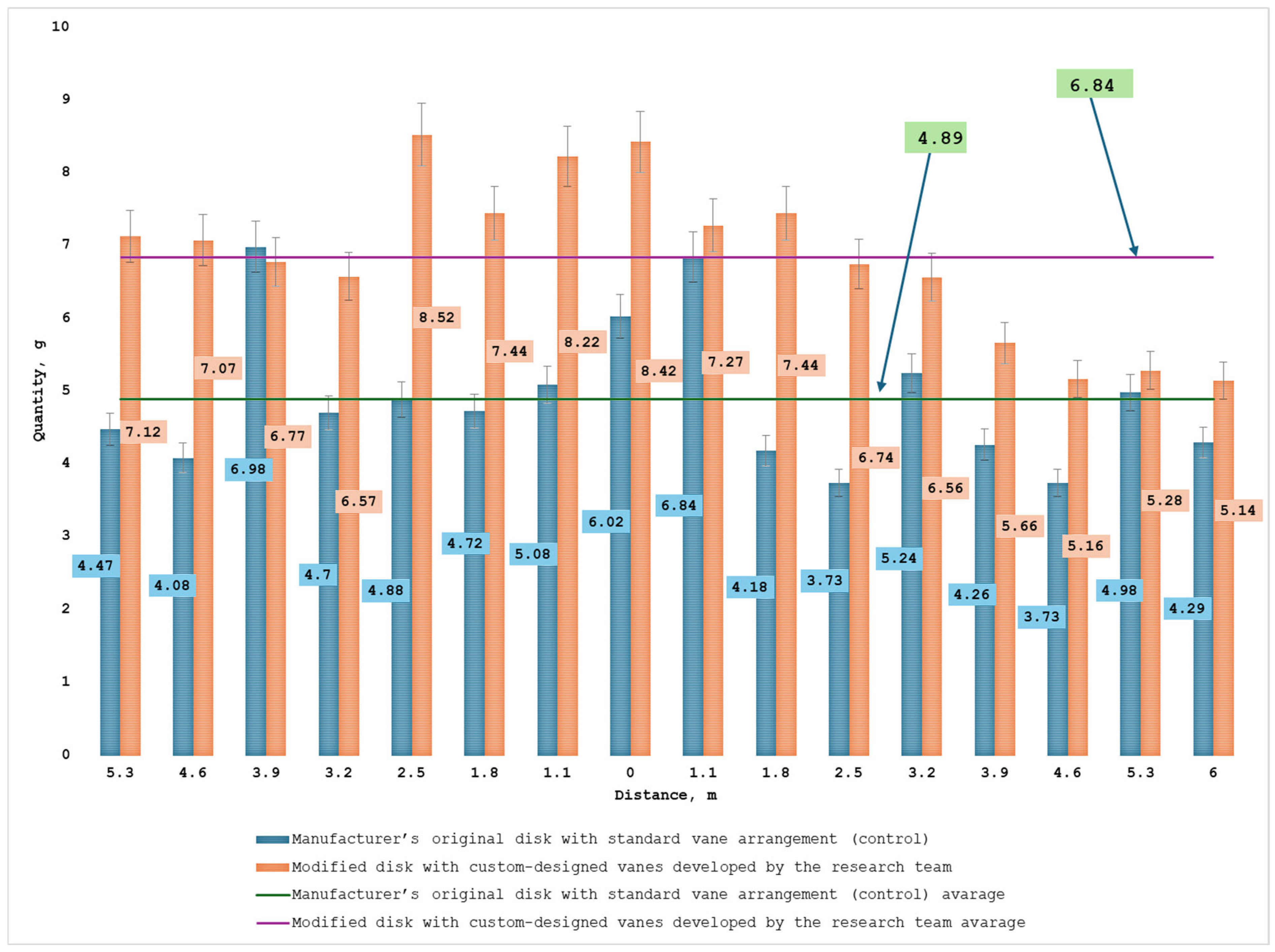

3.2.1. Experimental Results of Granular Grain Husk and Granular Poultry Manure Fertilizer Distribution

3.2.2. Assessment of Experimental Test Results Granular Grain Husk and Granular Poultry Manure Fertilizer Distribution

4. Discussion

- Grain husk granules, despite their lower density, possess adequate mechanical strength and can serve as viable alternative organic fertilizers.

- Modified vanes significantly improve the spreading uniformity and quantity, especially when working with irregularly shaped or low-density granules.

- Both the fertilizer properties and spreader design must be evaluated holistically to optimize field performance.

- Modeling granule dispersion under varying meteorological conditions.

- Assessing long-term effects on soil structures and crop yields.

- Developing algorithms for vane geometry optimization tailored to specific granule characteristics.

- Evaluating the economic and environmental efficiency of alternative fertilizer applications.

- Understanding the importance of the interaction between structural design solutions, the physical properties of granules, and the mechanisms of fertilizer distribution.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Goodarzi, S.; Shafieinia, A. Review of Fertilizer Types, Benefits, and Sustainable Use in Modern Agriculture; Qom Azad University: Qom, Iran, 2025; Available online: https://hal.science/hal-05096247v1/document (accessed on 20 September 2025).

- Khan, M.T.; Aleinikovienė, J.; Butkevičienė, L.M. Innovative Organic Fertilizers and Cover Crops: Perspectives for Sustainable Agriculture in the Era of Climate Change and Organic Agriculture. Agronomy 2024, 14, 2871. [Google Scholar] [CrossRef]

- Kiss, N.É.; Tamás, J.; Mannheim, V.; Nagy, A. Comparing the Environmental Impact of Poultry Manure and Chemical Fertilizers. Front. Built Environ. 2023, 9, 1237476. [Google Scholar] [CrossRef]

- Jancewicz, L.J.; Gibb, D.J.; Swift, M.L.; Penner, G.B.; McAllister, T.A. Digestibility and Growth Performance of Feedlot Cattle Fed Pelleted Grain Screenings. Can. J. Anim. Sci. 2017, 97, 716–726. [Google Scholar] [CrossRef]

- Thomas, C.L.; Acquah, G.E.; Whitmore, A.P.; McGrath, S.P.; Haefele, S.M. The Effect of Different Organic Fertilizers on Yield and Soil and Crop Nutrient Concentrations. Agronomy 2019, 9, 776. [Google Scholar] [CrossRef]

- Martín-Lamerding, D.; Gabriel, J.L.; Zambrana, E.; Santín-Montanyá, I.; Tenorio, J.L. Organic Amendment vs. Mineral Fertilization under Minimum Tillage: Changes in Soil Nutrients, Soil Organic Matter, Biological Properties and Yield after 10 Years. Agriculture 2021, 11, 700. [Google Scholar] [CrossRef]

- Allam, M.; Radicetti, E.; Quintarelli, V.; Petroselli, V.; Marinari, S.; Mancinelli, R. Influence of Organic and Mineral Fertilizers on Soil Organic Carbon and Crop Productivity under Different Tillage Systems: A Meta-Analysis. Agriculture 2022, 12, 464. [Google Scholar] [CrossRef]

- Kolbe, H. Comparative Analysis of Soil Fertility, Productivity and Sustainability of Organic Farming in Central Europe—Part 1: Effect of Medium Manifestations on Conversion, Fertilizer Types and Cropping Systems. Agronomy 2022, 12, 2001. [Google Scholar] [CrossRef]

- Yu, Z.; Guo, B.; Sun, T.; Li, R.; Zhao, Z.; Yao, L. Effects of Organic Fertilizer Substitution for Mineral Fertilizer on Soil Fertility, Yield, and Quality of Muskmelons. Agronomy 2025, 15, 639. [Google Scholar] [CrossRef]

- Jotautienė, E.; Juostas, A.; Vaiciukevicius, E.; Domeika, R. Experimental Investigation on Dynamics of Precision Spreading of Granular Fertilizers. In Proceedings of the 24th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 21–23 May 2025; pp. 1021–1028. [Google Scholar]

- Bivainis, V.; Jotautienė, E.; Juodišius, G.; Zinkevičienė, R. A Study of the Effect of Disc Geometry and Flow Rate on the Spread Uniformity of Organic Granular Fertiliser. In Proceedings of the AGBIOL VI International Conference, Edirne, Turkey, 25–27 April 2024. [Google Scholar]

- Bulgakov, V.; Rucins, A.; Holovach, I.; Adamchuk, O.; Aboltins, A.; Zabolotnyi, H.; Kolomiiets, L.; Polishchuk, S. Computer Investigation of Mineral Fertiliser Particle Movement Along Centrifugal Spreader Disc Inclined Under Angle to Horizontal Plane. In Proceedings of the 22nd International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 24–26 May 2023; pp. 663–670. [Google Scholar]

- Przywara, A.; Santoro, F.; Kraszkiewicz, A.; Pecyna, A.; Pascuzzi, S. Experimental Study of Disc Fertilizer Spreader Performance. Agriculture 2020, 10, 467. [Google Scholar] [CrossRef]

- Bivainis, V.; Jotautienė, E.; Lekavičienė, K.; Mieldažys, R.; Juodišius, G. Theoretical and Experimental Verification of Organic Granular Fertilizer Spreading. Agriculture 2023, 13, 1135. [Google Scholar] [CrossRef]

- Xie, Y.; Liu, H.; Shang, J.; Guo, L.; Zheng, G. Effect of Angle Between Center-Mounted Blades and Disc on Particle Trajectory Correction in Side-Throwing Centrifugal Spreaders. Agriculture 2025, 15, 1392. [Google Scholar] [CrossRef]

- ISO 18847:2024; Solid Biofuels—Determination of Particle Density of Pellets and Briquettes. ISO: Geneva, Switzerland, 2024.

- EN 12048:1999; Solid Fertilizers and Liming Materials—Determination of Moisture Content—Gravimetric Method by Drying at (105 ± 2) °C (ISO 8190:1992 Modified). CEN: Brussels, Belgium, 1999.

- EN 13037:2012; Soil Improvers and Growing Media—Determination of pH. CEN: Brussels, Belgium, 2012.

- EN 13039:2012; Soil Improvers and Growing Media—Determination of Organic Matter Content and Ash. CEN: Brussels, Belgium, 2012.

- LST EN 13654-2002; Soil Improvers and Growing Media—Determination of Nitrogen—Modified Kjeldahl Method. LST: Vilnius, Lithuania, 2002.

- ISO 11261:1995; Soil Quality—Determination of Total Nitrogen—Modified Kjeldahl Method. ISO: Geneva, Switzerland, 1995.

- EN 13650:2006; Soil Improvers and Growing Media—Extraction of Aqua Regia Soluble Elements. CEN: Brussels, Belgium, 2006.

- LST ISO 6878:2004/ISO 6878:2004; Water Quality—Determination of Phosphorus—Ammonium Molybdate Spectrometric Method. LST: Vilnius, Lithuania, 2004.

- Gaudutis, A.; Jotautienė, E.; Mieldažys, R.; Bivainis, V.; Jasinskas, A. Sustainable use of biochar, poultry and cattle manure for the production of organic granular fertilizers. Agronomy 2023, 13, 1426. [Google Scholar] [CrossRef]

- Xin, M.; Jiang, Z.; Chen, T.; Song, Y.; Wang, Y.; Huang, W. Design and experiment of the fertilizer centrifugal broadcaster with guiding chute for paddy field. Trans. Chin. Soc. Agric. Eng. 2023, 39, 67–75. [Google Scholar] [CrossRef]

| Granular Grain Husk | Granular Poultry Manure Fertilizers (Control) | |

|---|---|---|

| Length, l, mm | 19.9 ± 1.82 | 12.11 ± 0.99 |

| Diameter d, mm | 6.34 ± 0.06 | 6.10 ± 0.02 |

| Mass, g | 0.76 ± 0.07 | 0.45 ± 0.05 |

| Density, kg.m−3 | 1205.61 ± 34.46 | 1279.96 ± 62.23 |

| Dry matter, % | 91 | 91.3 |

| Granular Grain Husk | Granular Poultry Manure Fertilizers (Control) | |

|---|---|---|

| pH | 5.6 | 6.9 |

| Organic matter, % | 4.21 | 65 |

| Total nitrogen (N), % | 2.36 | 4 |

| Total phosphorus (P2O5), % | 1.89 | 3 |

| Total potassium (K2O), % | 1.13 | 2.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Juodišius, G.; Zinkevičienė, R.; Jotautienė, E.; Karayel, D.; Mieldažys, R. Investigation of Granular Organic Fertilizer Distribution Uniformity in Disk-Type Spreaders with Standard and Modified Vane Configurations. Appl. Sci. 2025, 15, 13076. https://doi.org/10.3390/app152413076

Juodišius G, Zinkevičienė R, Jotautienė E, Karayel D, Mieldažys R. Investigation of Granular Organic Fertilizer Distribution Uniformity in Disk-Type Spreaders with Standard and Modified Vane Configurations. Applied Sciences. 2025; 15(24):13076. https://doi.org/10.3390/app152413076

Chicago/Turabian StyleJuodišius, Gražvydas, Raimonda Zinkevičienė, Eglė Jotautienė, Davut Karayel, and Ramūnas Mieldažys. 2025. "Investigation of Granular Organic Fertilizer Distribution Uniformity in Disk-Type Spreaders with Standard and Modified Vane Configurations" Applied Sciences 15, no. 24: 13076. https://doi.org/10.3390/app152413076

APA StyleJuodišius, G., Zinkevičienė, R., Jotautienė, E., Karayel, D., & Mieldažys, R. (2025). Investigation of Granular Organic Fertilizer Distribution Uniformity in Disk-Type Spreaders with Standard and Modified Vane Configurations. Applied Sciences, 15(24), 13076. https://doi.org/10.3390/app152413076