3.1. Total Polyphenol Content and Polyphenol Profile of Wheat Beers

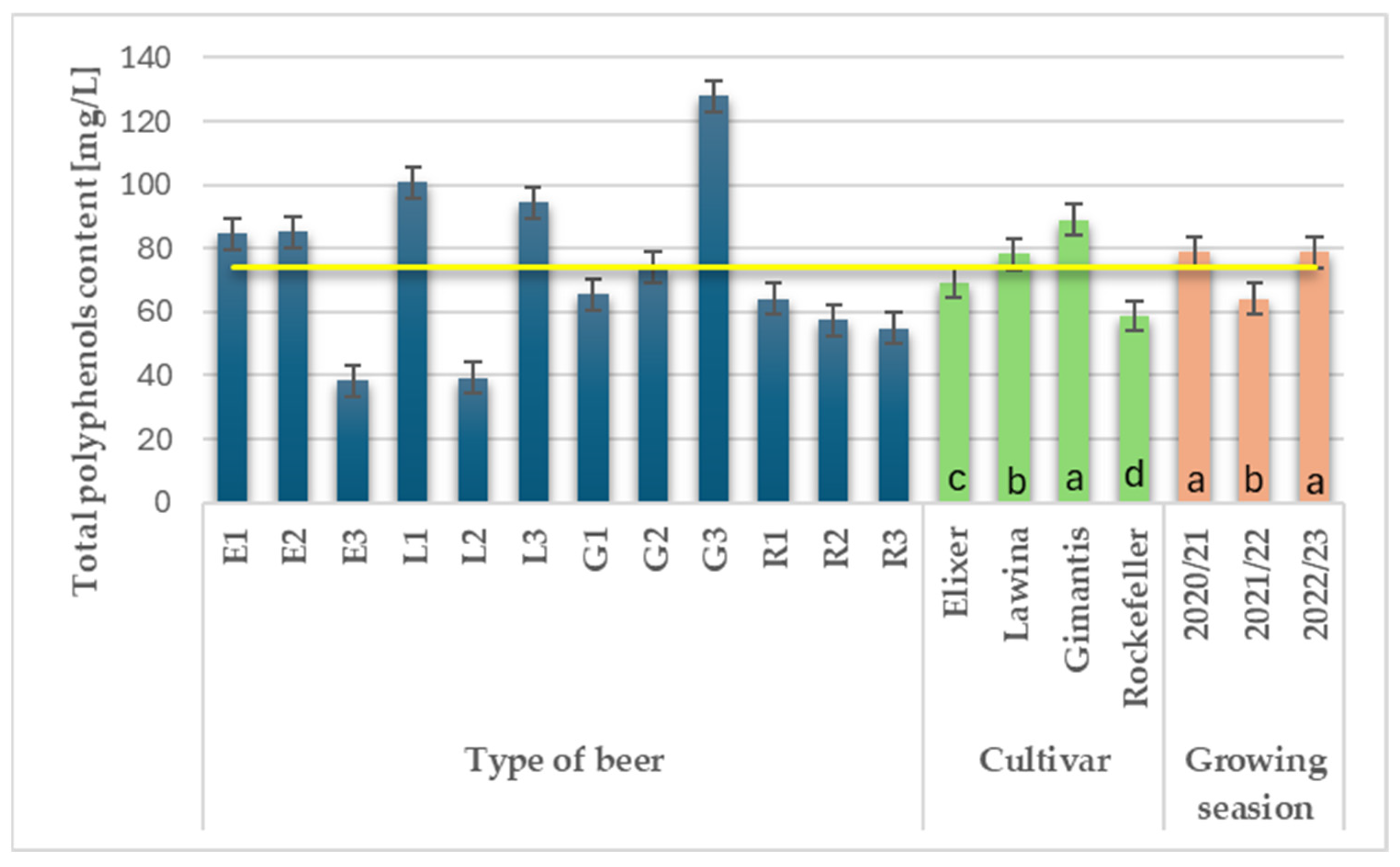

The average content of total polyphenols in wheat beers obtained from the analyzed wheat malts during the study years was 73.9 mg·L

−1 and was dependent on the cultivar used and the growing season (

Figure 1). Wheat beers obtained from malt obtained from winter wheat of the Rockefeller cultivar were characterized by the lowest average content of total polyphenols (58.77 mg·L

−1), while significantly the highest content of total polyphenols was possessed by beers obtained from the malt obtained from wheat of the Gimantis cultivar (89.07 mg·L

−1); With an increase in the analyzed parameter of 34.01%. The average content of total polyphenols in the obtained wheat beers varied between the individual growing seasons. The highest value was obtained in the third year of the study (78.9 mg·L

−1) and was on average 18.88% higher compared to the second year of the study, while the results obtained in the first and third years of the study did not differ.

In the study by Belcar et al. [

21] for wheat beers produced in the American Wheat Beer style from malt derived from wheat grain of the Elixer, Rockefeller, and Gimantis cultivars (pilot field experiment, 2019/2020 season), the total polyphenol content was 210 mg·L

−1, 211 mg·L

−1, and 187 mg·L

−1, respectively. In wheat beers, the total polyphenol content ranged from 125 to 142 mg·L

−1 [

22]; 123.6 mg·L

−1 (beer brewed with 50% German wheat malt), 102.8 mg·L

−1 (beer brewed with American wheat malt) and from 86.9 to 89.2 mg·L

−1 (wheat beers brewed with Korean wheat malt; [

23]). In the study by Mascia et al. [

24], German commercial wheat beer had a total polyphenol content of 139 mg·L

−1, while Czech wheat beer had a total polyphenol content of 148 mg·L

−1. The lower content of total polyphenols obtained in this study limits the health-promoting properties of the obtained beer product and, moreover, limits the degree of interaction between polyphenols and proteins (especially with the optimal content of this component in grain and wheat malt [

13]), which results in limited haze, which is characteristic for wheat beers and unfavorable in the case of barley beers. Polyphenols are chemical compounds with diverse structures, thanks to which they possess both antiradical and antioxidant properties associated with biologically active reactions occurring during beer production and storage [

9]. The proportion of wheat malt in the raw material positively affects the total polyphenol content compared to wheat beers produced with the addition of unmalted grain [

25]. Malting and drying the grain are two processes that significantly affect the total polyphenol content in the finished product, and thus, they are transferred to wheat beer during subsequent technological processes (mashing, boiling, fermentation). Gradually increasing the temperature of the air drying of the malt increases the intensity of transformations and the formation of new compounds, including Maillard reaction products. The temperature of the drying process (its gradual increase) causes isomerization of the produced polyphenolic compounds, which is important in the sensory analysis of the finished product, as it influences the perception of flavor (including flavanol polymers), astringency, bitterness, body, and overall flavor. Polyphenols also influence the degree of haze in beers [

10,

11]. The mashing process of wheat and barley malt (the length and temperature range of the process) and the fineness of the mashed material also influence the content of polyphenolic compounds in the finished beer product [

1].

Polyphenolic compounds in the analyzed wheat beers were identified based on characteristic spectral data: mass-to-charge ratio (

m/

z) and absorption maximum. Seven polyphenolic compounds were identified, the spectral properties of which are presented in

Table 1. Chlorogenic acid belongs to the group of hydroxycinnamic acid derivatives, while the remaining identified compounds belonged to the group of flavonols, represented by (+)catechin and its derivative, as well as kaempferol derivatives (in the glycoside form). In beers, sugars such as rhamnose and glucose, as well as arabinose, rutinose, and xylose, are combined with kaempferol [

26]. These glycosides are responsible for taste sensations, including the sensation of astringency in the mouth and, to a lesser extent, the bitterness experienced during beer consumption [

27]. The basic raw materials used in beer production: hops, malt, and, to a lesser extent, cereal grains, are sources of phenolic compounds, including flavonols [

9]. Flavonols are antioxidant compounds that limit cell aging in the human body, have a beneficial effect on the cardiovascular system, and inhibit the development of certain cancer cells [

1,

5,

27].

The chlorogenic acid content in wheat beers obtained from wheat malt prepared from the Elixer winter wheat grain ranged from 0.08 to 0.15 mg·L

−1 during the study period (

Table 1). Among the analyzed flavonols, their content varied significantly, with the highest content being found in the following compounds: kaempferol rhamnoside-pentoside (1.50–2.22 mg·L

−1), and (+)catechin 3-

O-glucoside (0.31–0.40 mg·L

−1) at much lower concentrations. The total content of identified polyphenolic compounds ranged from 2.53 mg·L

−1 for beer obtained from the third year of study to 3.53 mg·L

−1 for beer obtained from the second year of study. The average content of polyphenolic compounds in wheat beers brewed with malt from winter wheat cultivar Elixer was 3.01 mg·L

−1 (

Table 1). In the study by Belcar et al. [

25] on Witbier-type beers with the addition of 25% wheat malt and with a 50% share of wheat grain of the Elixer cultivar, the total content of identified polyphenolic compounds was 6.43 and 6.53 mg·L

−1, respectively, including kaempferol 3-

O-rutinoside at concentrations of 0.57 and 0.65 mg·L

−1, respectively; kaempferol pentoside-rhamnoside at concentrations of 1.39 and 1.31 mg·L

−1, and kaempferol 3-

O-glucoside at concentrations of 0.58 and 0.64 mg·L

−1, respectively. In the study by Gorzelany et al. [

28] on wheat beer, the total content of identified polyphenolic compounds was 3.22 mg·L

−1, with the main compounds detected being kaempferol-3-

O-rutinoside-7-

O-glucoside at a concentration of 0.92 mg·L

−1 and kaempferol-3-

O-glucoside-7-

O-glucoside at a concentration of 1.35 mg·L

−1. In a subsequent study by Belcar and Gorzelany [

29], the total content of identified polyphenolic compounds was 3.15 mg·L

−1, with the main compounds detected being the aforementioned compounds at concentrations of 0.92 mg·L

−1 and 1.31 mg·L

−1, respectively.

Depending on the year of study, the content of chlorogenic acid in wheat beers obtained from wheat malt prepared from winter wheat grain of the Lawina cultivar ranged from 0.09 to 0.10 mg·L

−1 (

Table 1). Among the analyzed flavonols, their content varied significantly, with the highest content being found in the compounds: kaempferol rhamnoside-pentoside (0.97–1.84 mg·L

−1), and (+)catechin 3-

O-glucoside (0.26–0.35 mg·L

−1) at much lower concentrations. The total content of identified polyphenolic compounds ranged from 1.79 mg·L

−1 for beer obtained from wheat grain of the Lawina cultivar (third year of study) to 2.87 mg·L

−1 (first year of study). The average content of polyphenolic compounds in wheat beers brewed with malt from winter wheat of the Lawina cultivar was 2.22 mg·L

−1 (

Table 1). The content of chlorogenic acid in wheat beers obtained from wheat malt prepared from winter wheat grain of the Gimantis cultivar during the study years ranged from 0.07 to 0.10 mg·L

−1 (

Table 1). Among the analyzed flavonols, their content varied significantly, with the highest content being found in the following compounds: kaempferol rhamnoside-pentoside (1.29–1.63 mg·L

−1), and (+)catechin 3-

O-glucoside (0.25–0.40 mg·L

−1) at much lower concentrations. The total content of identified polyphenolic compounds ranged from 2.43 mg·L

−1 (for beer obtained from malt in the third year of the study) to 2.87 mg·L

−1 for beer obtained in the second year of the study (

Table 1). The average content of polyphenolic compounds identified using UPLC-PDA-TQD-MS in wheat beers brewed with malt from winter wheat of the Gimantis cultivar was 2.60 mg·L

−1. The content of chlorogenic acid in wheat beers obtained from wheat malt prepared from the Rockefeller winter wheat grain during the study years ranged from 0.08 to 0.13 mg·L

−1 (

Table 1). Among the analyzed flavonols, their content varied significantly, with the highest content of kaempferol rhamnoside-pentoside compounds (0.82–1.58 mg·L

−1), and (+)catechin 3-

O-glucoside at a much lower concentration (0.18–0.33 mg·L

−1). The total content of identified polyphenolic compounds ranged from 1.57 mg·L

−1 for beer from the second year of study to 2.60 mg·L

−1 for beer obtained from malt from the third year of study. The average content of polyphenolic compounds in wheat beers brewed with malt from winter wheat of the Rockefeller cultivar was 2.24 mg·L

−1 (

Table 1).

In the study by Belcar et al. [

25] in Witbier-type beers, with the addition of 25% wheat malt and 50% share of wheat grain of the Lawina cultivar, the total content of identified polyphenolic compounds was 5.79 and 5.80 mg·L

−1, respectively, including kaempferol 3-

O-rutinoid in concentrations of 0.58 and 0.55 mg·L

−1, respectively; kaempferol pentoside-rhamnoside was present in both beers in concentrations of 1.04 mg·L

−1, and kaempferol 3-

O-glucoside in concentrations of 0.58 and 0.59 mg·L

−1, respectively; with the addition of 25% wheat malt and 50% of Gimantis wheat grain, the total content of identified polyphenolic compounds was 6.18 and 6.24 mg·L

−1, respectively. Among the polyphenolic compounds analyzed, the main ones were kaempferol 3-

O-rutinoside at concentrations of 0.65 and 0.67 mg·L

−1, respectively; kaempferol pentoside-rhamnoside at concentrations of 1.12 and 1.14 mg·L

−1; and kaempferol 3-

O-glucoside at concentrations of 0.61 and 0.64 mg·L

−1, respectively. And with the addition of 25% wheat malt and 50% Rockefeller wheat grain, the total content of identified polyphenolic compounds in both beers was 6.34 mg·L

−1. Among the analyzed polyphenolic compounds, kaempferol 3-

O-rutinoid can be distinguished in concentrations of 0.63 and 0.61 mg·L

−1, respectively; kaempferol pentoside-rhamnoside in concentrations of 1.14 and 1.22 mg·L

−1, respectively; and kaempferol 3-

O-glucoside in concentrations of 0.69 and 0.60 mg·L

−1, respectively. In another study by Belcar and Gorzelany [

29], the total content of identified polyphenolic compounds in wheat beer obtained from the Lawina cultivar was 2.18 mg·L

−1, with the main detected compounds being kaempferol-3-

O-rutinoside-7-

O-glucoside at a concentration of 0.73 mg·L

−1 and kaempferol-3-

O-glucoside-7-

O-glucoside at a concentration of 0.81 mg·L

−1.

Among the analyzed winter wheat cultivars from which wheat malts were prepared and then brewed, the highest average content of polyphenolic compounds was found in wheat beers obtained from malt derived from the Elixer winter wheat cultivar (3.01 mg·L−1). The polyphenolic content in wheat beers obtained from malt derived from the Gimantis, Rockefeller, and Lawina cultivars was significantly lower by 13.62%, 25.58%, and 26.25%, respectively. The highest average polyphenolic content was found in the beers from the first year of the study, which were 8.46% and 13.97% higher compared to the second and third years of the field study.

As reported by Radonjič et al. [

5] and Almaguer et al. [

30] the average kaempferol content in barley beers was 0.10–1.64 mg·L

−1. Mikyška et al. [

9] found that storage of lager beers causes a slight decrease in kaempferol-

O-glucoside (approximately 15% after six weeks of beer aging compared to fresh wort). In lager beers, the content of kaempferol-

O-glycosides was 0.17–0.26 mg·L

−1; the content was influenced by the method of hopping the wort (four weeks of storage [

9,

31]). During boiling of the wort with hops, kaempferol-

O-glycosides are transferred to the wort after about 30 min of boiling (depending on the hop dose) [

31]. The cultivar, cultivation conditions, or country of origin influence the average kaempferol content in hop cones, which was 1.2 mg·kg

−1 d.m. [

5,

31]. Cereal raw materials (wheat and barley malt) are also a substrate of kaempferol glycosides used in the production of wheat beers. In the study by Suchowilska et al. [

32], the average kaempferol content in wheat grain was 11.4 mg·kg

−1 d.m., while in the study by Buśko et al. [

33] it was slightly lower—6.0 mg·kg

−1 d.m. In the study by Özcan et al. [

34], the kaempferol content in barley grain was determined to be at 19.9 mg·kg

−1, while in malts produced from it, the content of this flavonol was slightly higher and amounted to 21.5 mg·kg

−1. Kaempferol, but also the high content of other flavonol derivatives, in the analyzed wheat beers is the result of various chemical reactions occurring during boiling of wort with hops: both the process of extraction of compounds contained in hops, but also the formation of glycoside derivatives by combining aglycones originating, among others, from malts with sugars present in the wort, e.g., glucose, creating

O-glycoside flavonol derivatives.

3.2. Antioxidant Activity of Wheat Beers

Compounds with antioxidant activity in the finished beer product are primarily polyphenols, but also fiber, vitamins, and bitter acids [

1,

2]. Technological processes that prepare the finished product for long-term consumption through oxidative stabilization, such as pasteurization, can negatively impact both the polyphenol content and the antioxidant activity of the beers [

6,

7,

8]. The use of pasteurization significantly improves the safety of beer beverages and at the same time extends their shelf life, but if we want to obtain beer with high health-promoting properties, other preservation methods should be used, e.g., microfiltration.

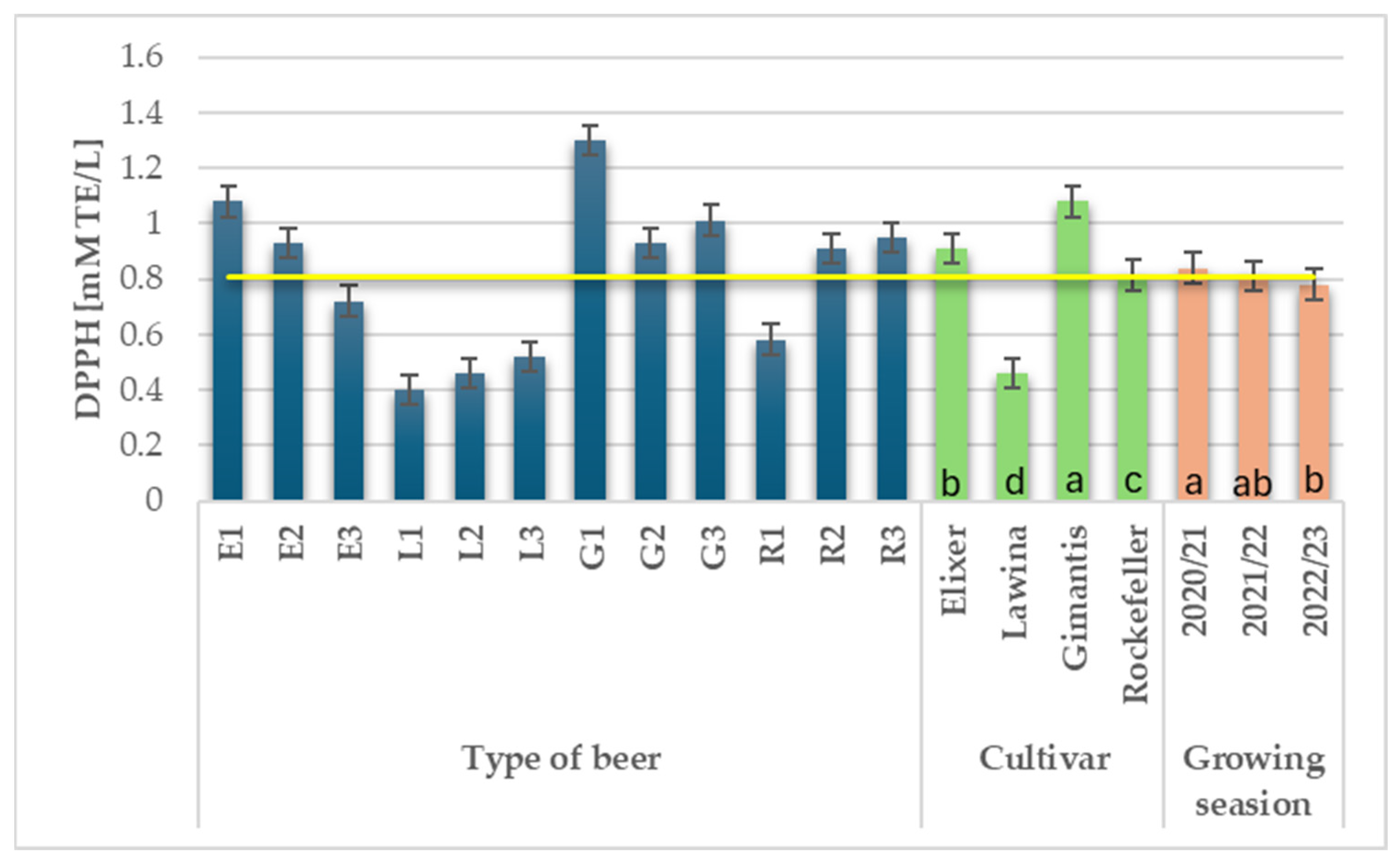

Higher DPPH radical activity in wheat beers indicates a reduced content of aldehydes that reduce flavor stability, such as trans-2-nonenal [

3]. The average value of antioxidant activity determined by the DPPH method in the analyzed wheat beers during the study years was 0.82 mM TE·L

−1 (

Figure 2). The wheat cultivar used and the growing season had a significant effect on the DPPH value in beers obtained from the analyzed wheat malts. The lowest average value of this parameter was obtained for wheat beers obtained from malt obtained from winter wheat of the Lawina cultivar (0.46 mM TE·L

−1), while the highest value was observed for beers obtained from malt obtained from wheat of the Gimantis cultivar (1.08 mM TE·L

−1), which represents a 57.41% increase compared to the Lawina cultivar. The average value of antioxidant activity determined by the DPPH method in the obtained wheat beers varied in the individual growing seasons; the highest value was obtained for the first year of the study (0.84 mM TE·L

−1) and it was 7.14% higher compared to the third year of the study, while the results obtained in the first and second year of the study were not different.

Wheat beers produced from unmalted wheat grain of the Elixer cultivar, and with the addition of malt obtained from it, were characterized by the highest antioxidant activity determined by the DPPH method [

25]. In subsequent studies on wheat beers brewed using wheat malt produced from wheat grain of the Elixer and Lawina cultivars, the DPPH value was 2.27 mM TE·L

−1 and 2.19 mM TE·L

−1, respectively [

29]. While wheat beers in the American Wheat Beer style, produced from malt from wheat grain of the Elixer, Rockefeller, and Gimantis cultivars, were characterized by an average antioxidant activity of 1.60 mM TE·L

−1, 1.17 mM TE·L

−1, and 1.21 mM TE·L

−1, respectively [

21]. Wheat beers made from wheat malt derived from the Elixer cultivar of winter wheat (field experiment) had an average DPPH of 2.27 mM TE·L

−1 [

28]; 1.04 mM TE·L

−1 [

35], while wheat beers made from wheat malt derived from the Lawina cultivar of winter wheat (field experiment) had an average DPPH of 2.38 mM TE·L

−1 [

36]. Significantly lower antioxidant activity (0.5 mM TE·L

−1) determined by the DPPH method was recorded in top-fermented wheat beer [

6].

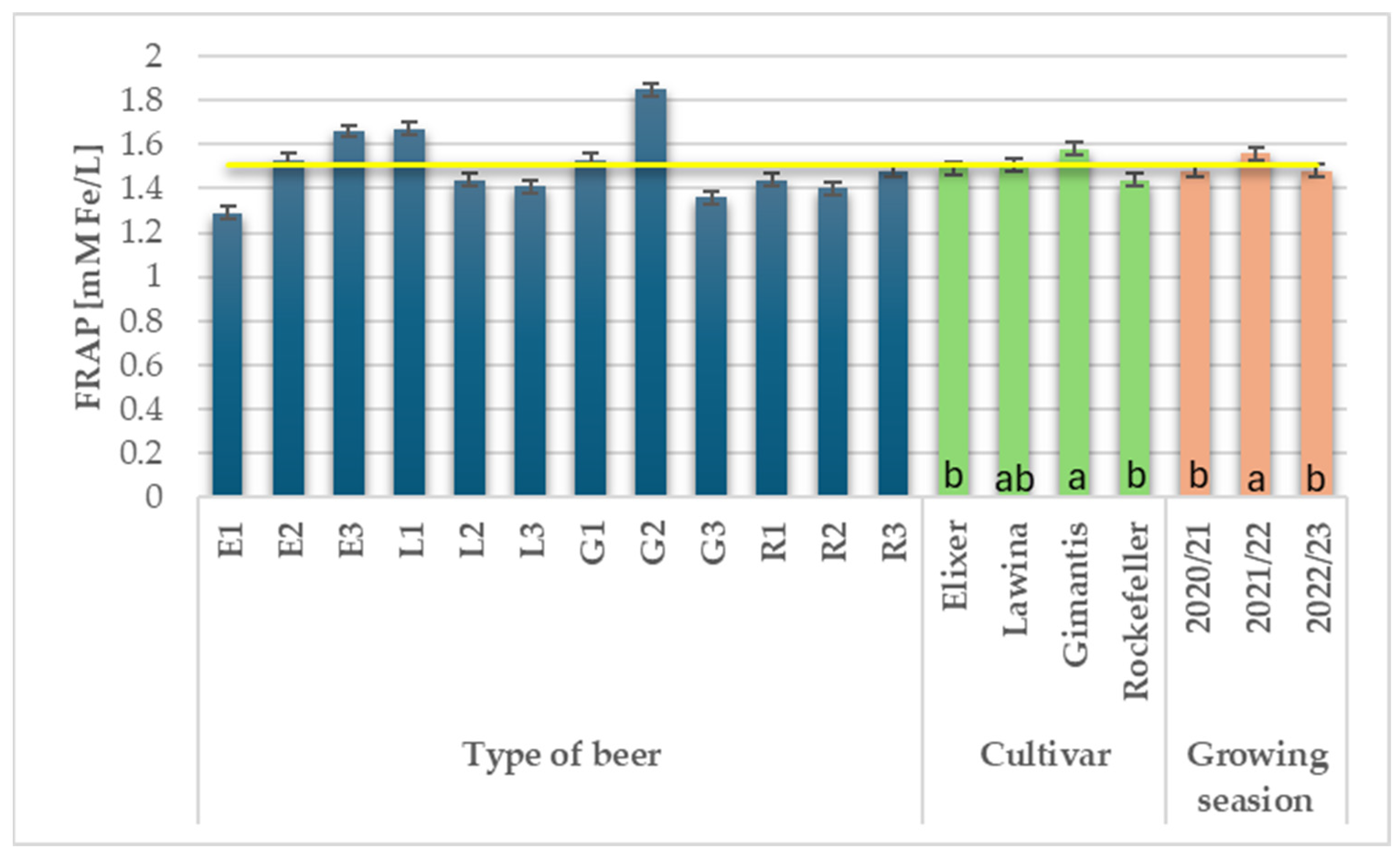

Compounds in beer that reduce oxidized lipid peroxidation products are biologically active compounds determined using the FRAP method [

3]. Ditrych et al. [

6] also observed that higher polyphenol content in beers positively affected the antioxidant potential of beers determined using the DPPH and FRAP tests. The average value of antioxidant activity determined by the FRAP method in the analyzed wheat beers during the study years was 1.51 mM Fe

2+·L

−1 (

Figure 3). The winter wheat cultivar used and the growing season had a significant impact on the FRAP value in beers obtained from the analyzed wheat malts. The lowest mean value of the analyzed parameter was obtained for the Rockefeller winter wheat cultivar (1.44 Fe

2+·L

−1), while the highest among the analyzed wheat beers was obtained for the Gimantis malt (1.58 Fe

2+·L

−1). The mean value of antioxidant activity determined by the FRAP method in the obtained wheat beers varied between growing seasons; the highest value was obtained on the second year of the study (1.56 mM Fe

2+·L

−1) and was 5.13% higher compared to the first and third years of the study, while the results obtained in the first and third years of the study were not different.

Wheat beers produced in the American Wheat Beer style with malt from wheat grain of the Elixer, Rockefeller, and Gimantis cultivars were characterized by FRAP values of 2.34 mM Fe

2+·L

−1, 2.55 mM Fe

2+·L

−1, and 1.83 mM Fe

2+·L

−1, respectively [

25]. In subsequent studies on wheat beers from wheat grain of the Elixer and Lawina cultivars, FRAP was 2.79 mM Fe

2+·L

−1 and 2.53 mM Fe

2+·L

−1, respectively [

29], while for wheat beers brewed with wheat malt obtained from winter wheat grain of the Elixer cultivar—2.19 mM Fe

2+·L

−1 [

28]; 0.86 mM Fe

2+·L

−1 [

35], and additionally for wheat beers brewed from winter wheat grain of the Lawina cultivar—2.42 mM Fe

2+·L

−1 [

36]. According to the authors He et al. [

3], the reducing capacity of unpasteurized wheat beers ranged from 1.28 to 1.71 mM Fe

2+·L

−1, while during storage, a decrease in the analyzed parameter was observed depending on the storage temperature (the highest decrease was observed at 5 °C, and the lowest at 20 °C). In the study by Ditrych et al. [

6], top-fermented wheat beers had a reducing capacity of 0.70 to 0.80 mM Fe

2+·L

−1.

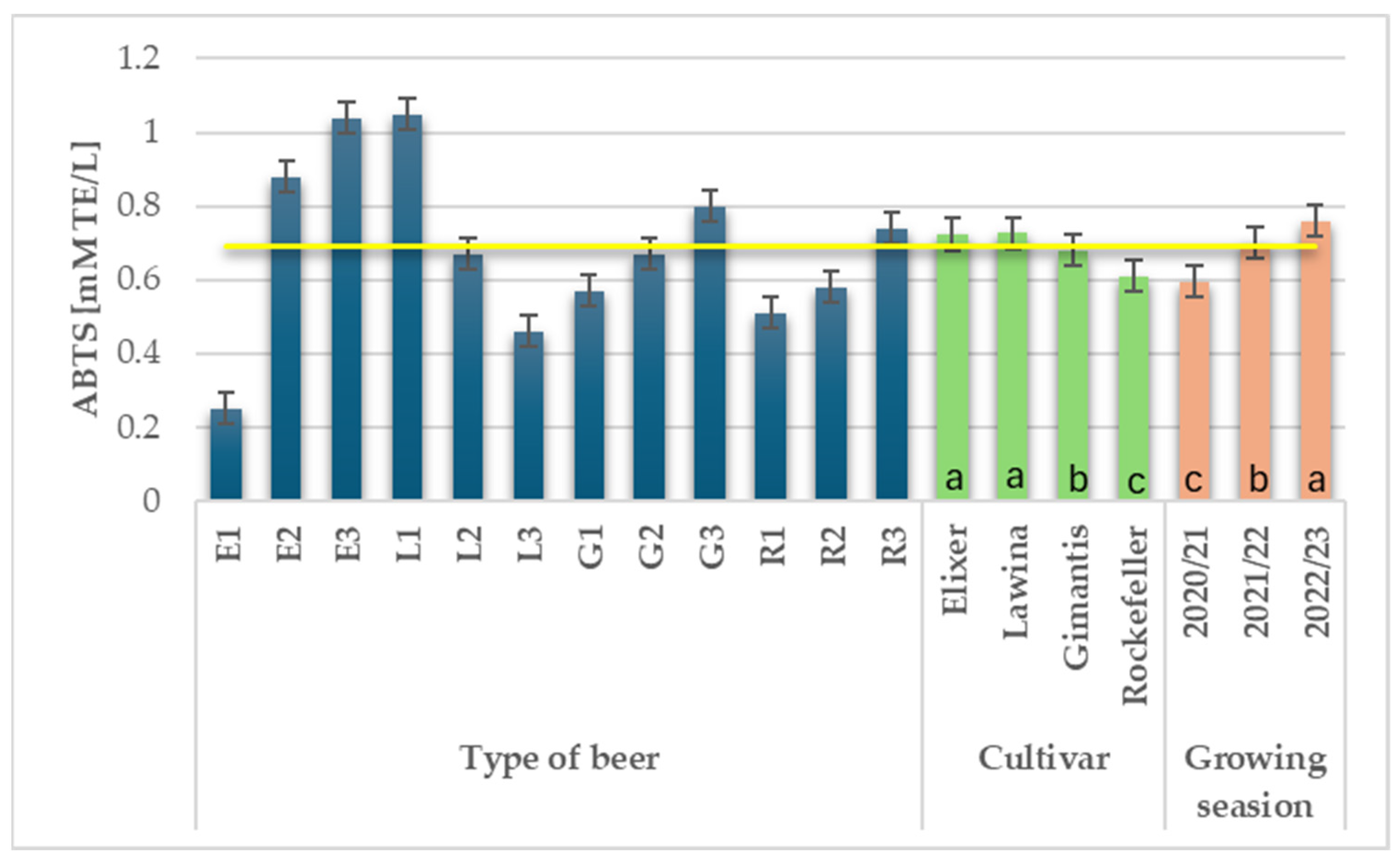

The average ABTS value in the analyzed wheat beers during the study years was 0.69 mM TE·L

−1 (

Figure 4). The ABTS value of beers produced from the analyzed wheat malts was influenced by the cultivar and the growing season. The highest ABTS value was found in wheat beers obtained from malts from the Elixer and Lawina wheat cultivars (0.72 mM TE·L

−1 and 0.73 mM TE·L

−1), while the significantly lowest value was obtained from the Rockefeller cultivar (0.61 mM TE·L

−1). The mean value of antioxidant activity determined by the ABTS method in the obtained wheat beers varied in the individual growing seasons; the highest value was obtained in the third year of the study (0.76 mM TE·L

−1) and was 21.05% higher than in the first year and 7.89% higher than in the second year. The average ABTS value in the second year of the study was 0.70 mM TE·L

−1 and was 14.29% higher than the average value obtained in the first year of the study.

In the study by Belcar and Gorzelany [

29], wheat beers brewed with wheat malt produced from wheat grain of the Elixer and Lawina cultivars (field experiment) were characterized by an average antioxidant activity, determined by the ABTS method, of 1.81 mM TE·L

−1 and 1.97 mM TE·L

−1, respectively. Wheat beers obtained in the American Wheat Beer style were characterized by ABTS at the level of 2.94 mM TE·L

−1, 2.18 mM TE·L

−1, and 2.06 mM TE·L

−1, respectively [

21]. In subsequent studies this parameter in wheat beers obtained from malt obtained from winter wheat grain of the Elixer cultivar was 1.81 mM TE·L

−1 [

28]; 1.01 mM TE·L

−1 [

35], and from the Lawina cultivar—0.92 mM TE·L

−1 [

36].

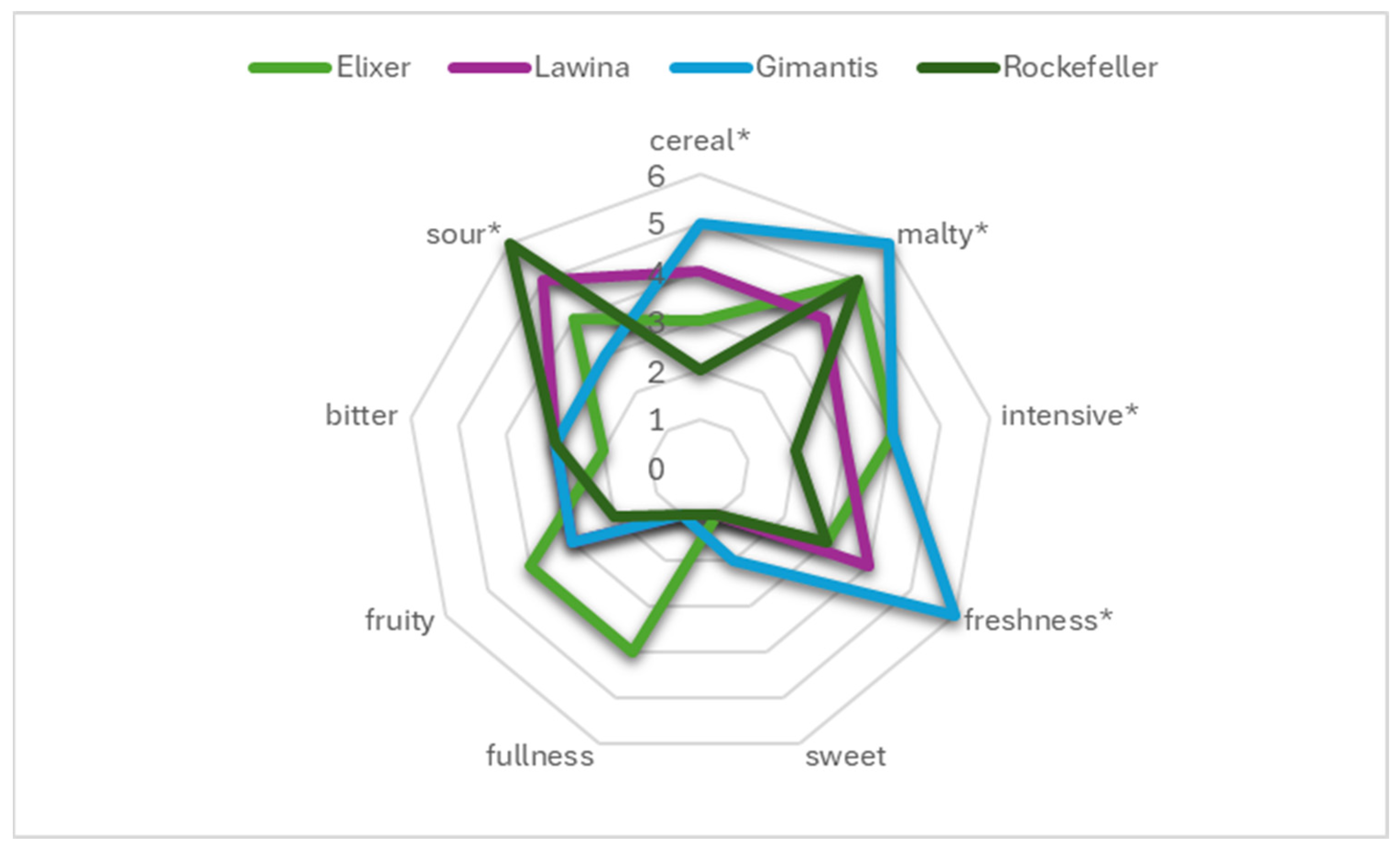

3.3. Organoleptic Analysis of Wheat Beers

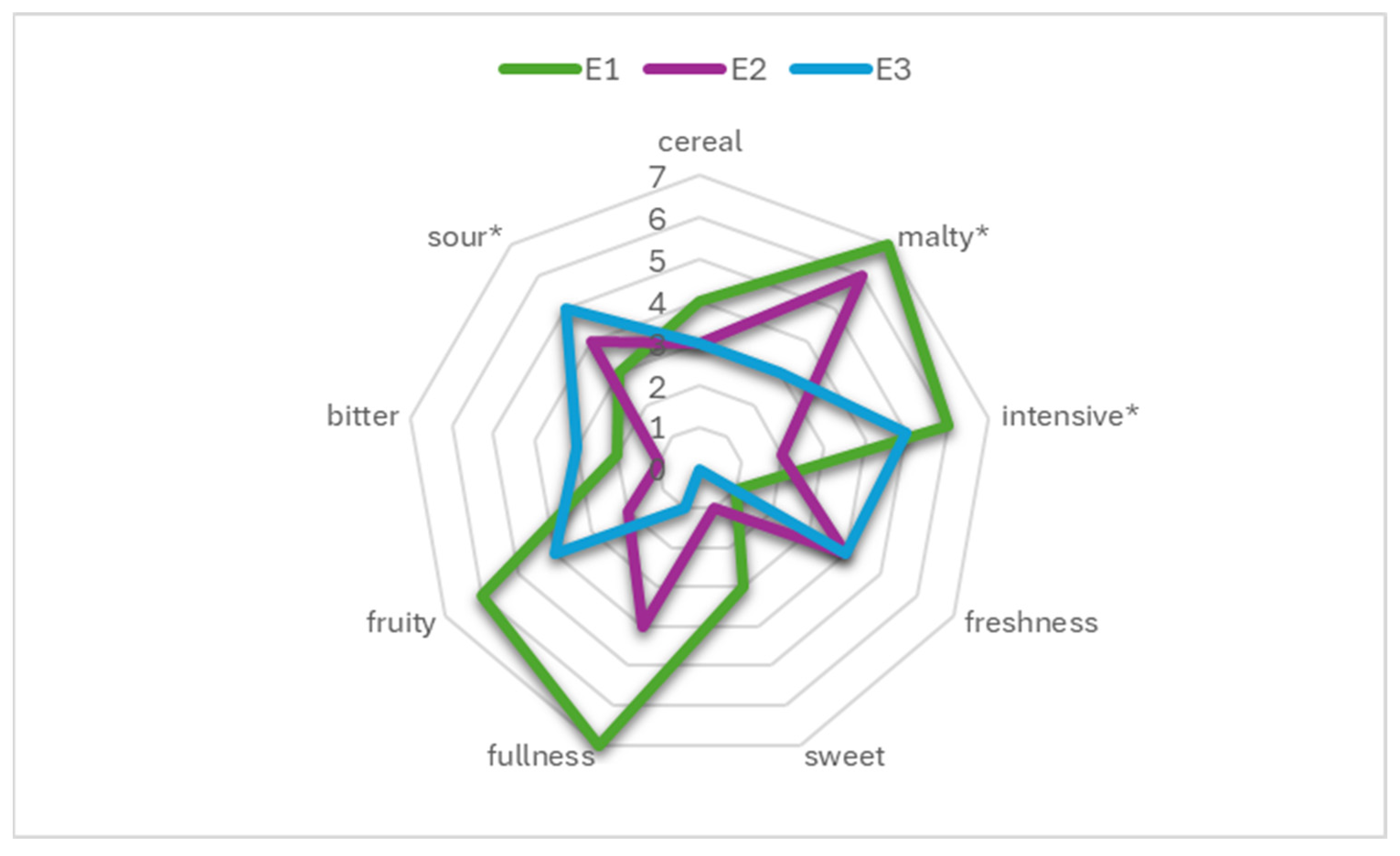

The organoleptic characteristics of the obtained wheat beers determine the specific beer style and shape the attractiveness and acceptance of a given beer among consumers. At the same time, they provide an opportunity to assess the use of the tested wheat cultivars in beer production. The organoleptic profile of wheat beers obtained from the four analyzed cultivars and from three years of field experiments conducted by an 11-person team of evaluators is presented in

Figure 5,

Figure 6,

Figure 7 and

Figure 8.

The organoleptic profile of the studied wheat beers varied slightly; wheat beers made with malt produced from the Elixer wheat grain (

Figure 5) were characterized by malty notes caused by, among others, maltol and furaneol [

37], a fresh, intense, and slightly fruity flavor, which is characteristic of wheat beers, but also with a slight sour aftertaste. Differences between the organoleptic profile results of wheat beers made with malt from different years of research were most noticeable for the attribute of full flavor; the highest value was obtained for wheat beer produced from malt obtained from the first year of the study. The beer products obtained in subsequent years of the study were characterized by an increasingly lower sensation of fullness of flavor. The perception of acidity in the beers (confirmed by the results of physicochemical analysis) led the evaluators to suggest that these beers might not be met with consumer acceptance. This was likely due to an inappropriate recipe selection or irregularities resulting from the fermentation process. Interactions occurring during fermentation and maturation of beer between esters, sulfur compounds, carbonyl and phenolic compounds, alcohols, and organic acids have a significant impact on the flavor of the resulting beer [

37]. Beers characterized by distinct fruity notes, a sweet aftertaste, and a pleasant aroma are more preferred and desired by consumers compared to traditional beers [

38,

39]. In several studies [

21,

25,

28,

29,

36], wheat beers brewed with wheat malt produced from wheat grain of the Elixer cultivar were characterized by intense cereal and malt notes and a fresh taste with a slightly bitter aftertaste.

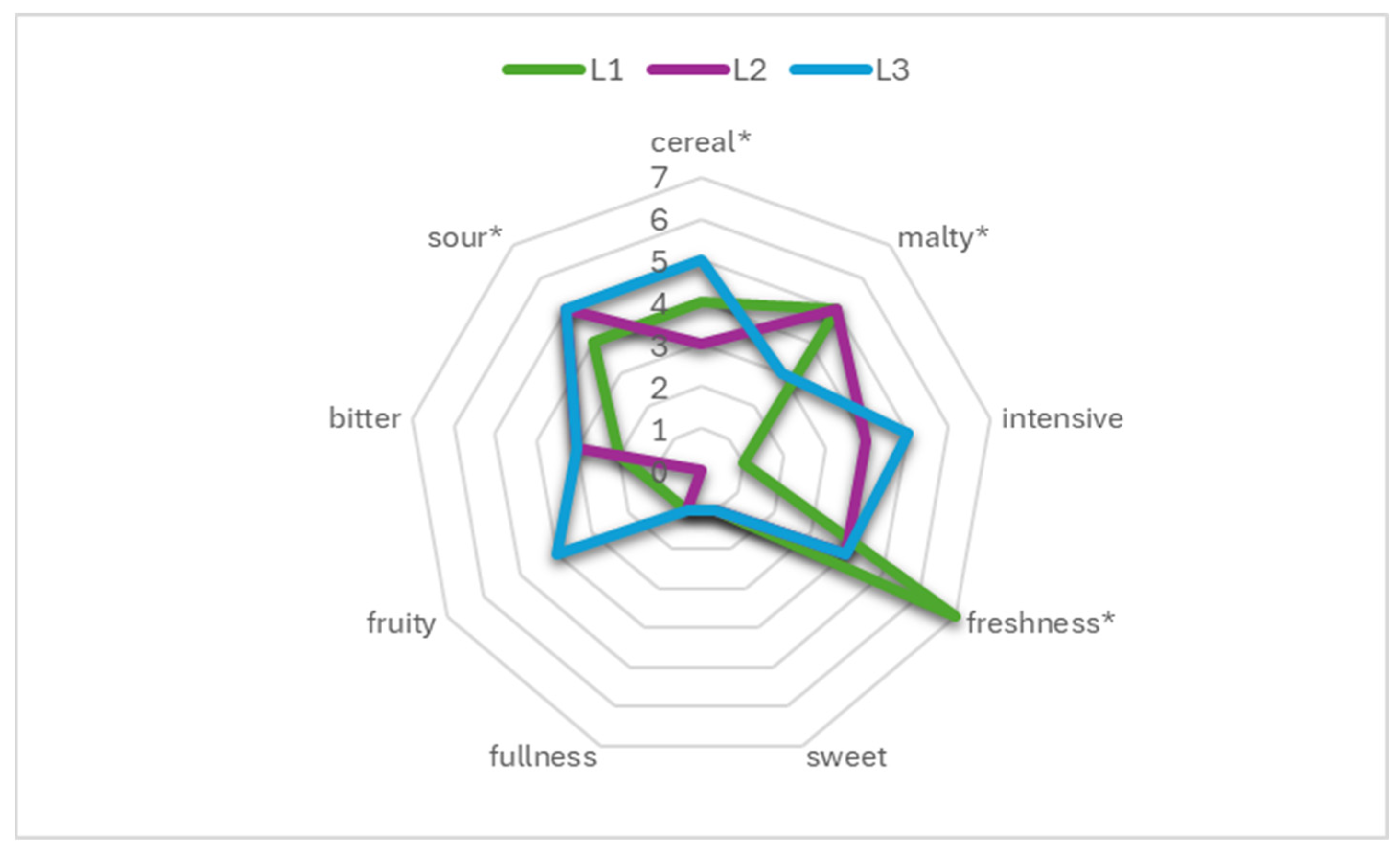

The organoleptic profile of the studied wheat beers varied slightly; wheat beers made with malt produced from the Lawina wheat grain (

Figure 6) were characterized by cereal-malty notes, a fresh and slightly fruity flavor, especially for beer L3, which is a characteristic feature of wheat beers, but also a slight sour aftertaste. Differences between the organoleptic profile results of wheat beers made with malt from different years of research were most noticeable for the attribute of flavor intensity; the highest value was obtained for wheat beer produced from malt obtained from the third year of the study. Beer products obtained in previous years of the study were characterized by a decreasing perception of flavor intensity. The perception of acidity in the beers (confirmed by the results of physicochemical analysis) led the evaluators to suggest that these beers might not be met with consumer acceptance. This was likely due to an inappropriate recipe selection or irregularities resulting from the fermentation process. In the studies by Belcar and Gorzelany [

29] and Belcar et al. [

21], wheat beers brewed from wheat malt produced from the Lawina variety of wheat were characterized by intense cereal and malty notes, as well as a fresh and intense flavor with a slightly sour aftertaste.

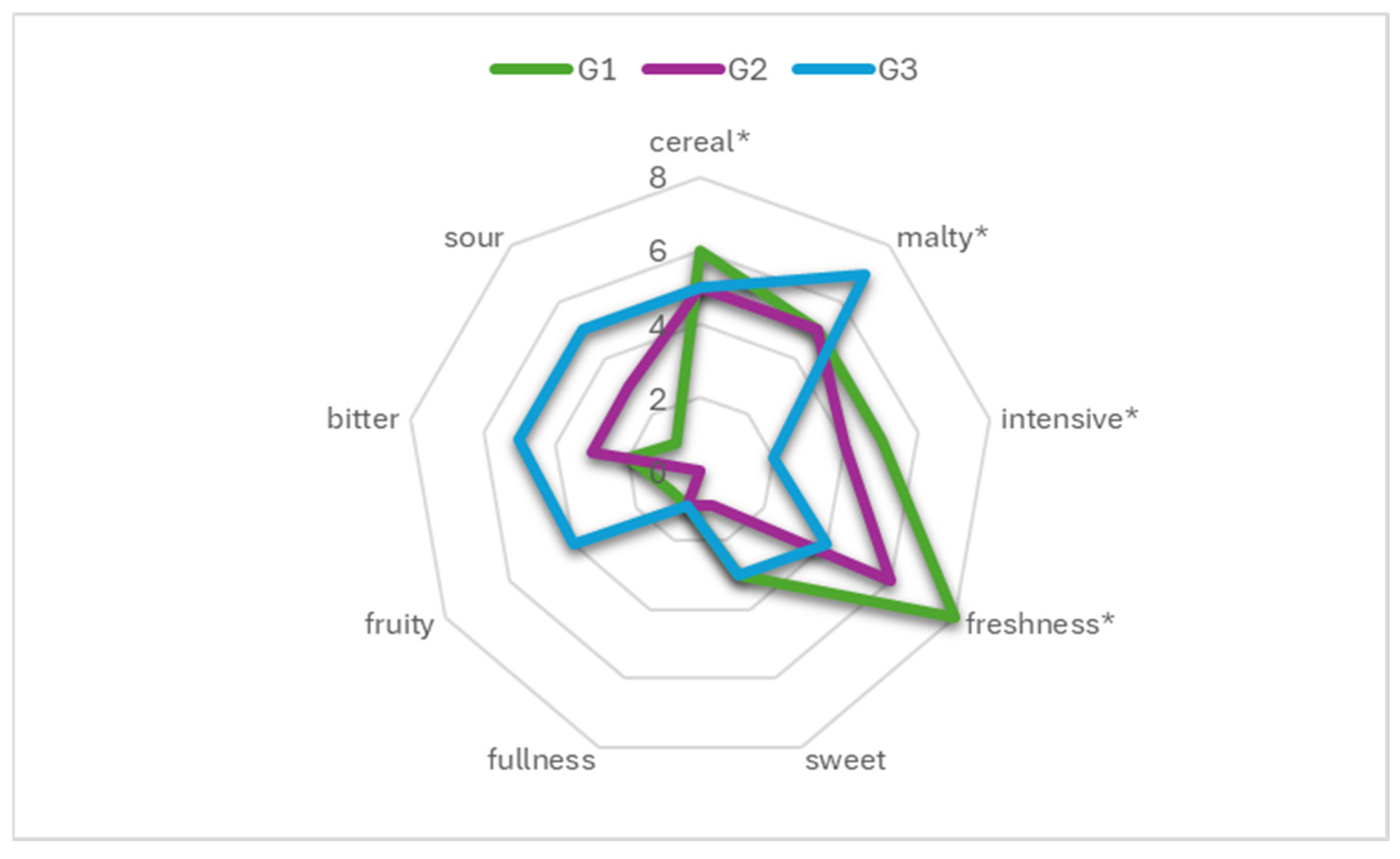

The organoleptic profile of the analyzed wheat beers varied slightly; wheat beers made with malt produced from the Gimantis wheat grain (

Figure 7) were characterized by cereal-malty notes and a fresh, intense, and slightly sweet flavor, which is characteristic of wheat beers. Differences between the organoleptic profile results of wheat beers made with malt from individual years of research were most noticeable for the sour and fruity flavor attributes; the highest value was obtained for wheat beer produced from malt obtained from the third year of the study. Beer products obtained in previous years of the study were characterized by increasingly lower perception of the discussed flavor attributes. The lower perception of acidity in the beers (confirmed by the results of physicochemical analysis) led the evaluators to suggest that these beers might be met with consumer acceptance after appropriate recipe selection or improvement of fermentation conditions. In the study by Belcar et al. [

21], wheat beers brewed from wheat malt produced from the Gimantis wheat grain were characterized by intense malty notes, a full flavor, and a bitter aftertaste.

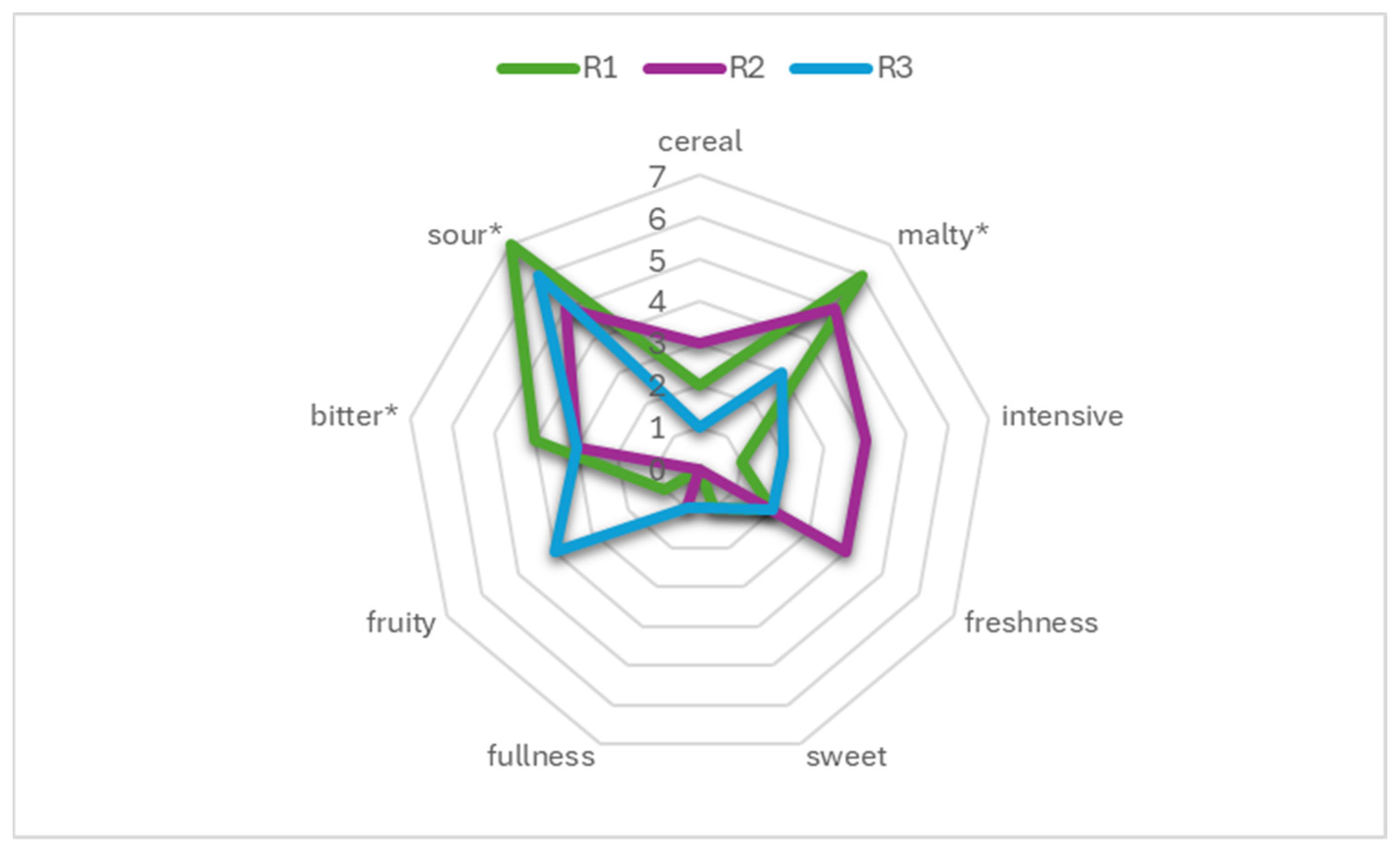

The organoleptic profile of the studied wheat beers varied slightly; wheat beers made with malt produced from the Rockefeller wheat grain (

Figure 8) were characterized by malty notes, a fresh, slightly intense, and fruity flavor, which is characteristic of wheat beers, but also a high perception of a sour and bitter aftertaste. Differences between the organoleptic profile results of wheat beers made with malt from different years of research were most noticeable for the fruity and intense flavor attributes; the most noticeable fruity flavor was observed in wheat beers from the third year of the study and was significantly less noticeable in beers brewed with malt from previous years of the study. The flavor intensity was most pronounced in beers brewed with malt from the second year of the study, and the third year of the study was characterized by a higher flavor intensity compared to the first year of the study. The perception of high acidity in the beers, combined with a bitter aftertaste (confirmed by the results of physicochemical analysis), could contribute to potential low consumer acceptance, likely due to poor recipe selection or irregularities resulting from the fermentation process. In the study by Belcar et al. [

36] wheat beers brewed with wheat malt produced from the Rockefeller wheat grain were characterized by a bitter-sweet taste and a full flavor.

The average organoleptic profile of the wheat beers studied varied, but all the beers were characterized by malty notes and, to a lesser extent, grainy notes (especially for beers brewed with malt obtained from the Gimantis and Lawina wheat cultivars), a sense of freshness, a light intensity, and a sour aftertaste, especially for those brewed with malt obtained from the Rockefeller and Lawina wheat grains. The high acidity obtained in wheat beers will most likely be the reason for a lack of acceptance by consumers (for the Rockefeller and Lawina wheat cultivars;

Figure 9). The evaluation panel determined that there is a correlation between the wheat cultivar from which the wheat malt used to brew the analyzed wheat beers was produced and the quality of the resulting beer. The most balanced organoleptic profile was observed in wheat beers produced from malt obtained from the Gimantis wheat grain, regardless of the year of testing. Fermentation process conditions and the use of appropriate yeast strains significantly influence the flavor of the produced wheat beer (especially its phenolic flavor), while the temperature conditions of the fermentation process have a lesser impact. The unpleasant aftertaste of wheat beers may be related to improperly maintaining the pH of the wort and beer, or the use of chlorinated water, which causes the formation of chemical compounds—chlorophenols—in the produced beer [

1]. Succinic acid, formed during fermentation, can impart a bitter aftertaste to beer [

40]. In the study by Gugino et al. [

41], wheat beer brewed from commercial wheat and barley malt in a 1:1 ratio was characterized by an intense yellow color, fruity, yeasty, and honeyed aroma notes, and intense flavor and carbonation. In a study by He et al. [

3], the quality of fresh, cloudy wheat beers, uncured for 18 days at various temperatures, was observed and found to be optimal for storage for 0–9 days at 5 °C. During this time, wheat beer exhibited slightly hoppy, malty, and spicy notes, with abundant, delicate beer foam and a mild, fresh, and full flavor. In a study by Mascia et al. [

24], Czech commercial wheat beer was characterized by fruity and phenolic notes with a full, fresh taste, while German commercial wheat beer was characterized by significantly lower sensory qualities compared to Czech wheat beer.