Experimental Investigation of Performance and Emissions for a Hybrid Electric Vehicle Operating on Gasoline, CNG, and Dual Fuel over the WLTC

Abstract

1. Introduction

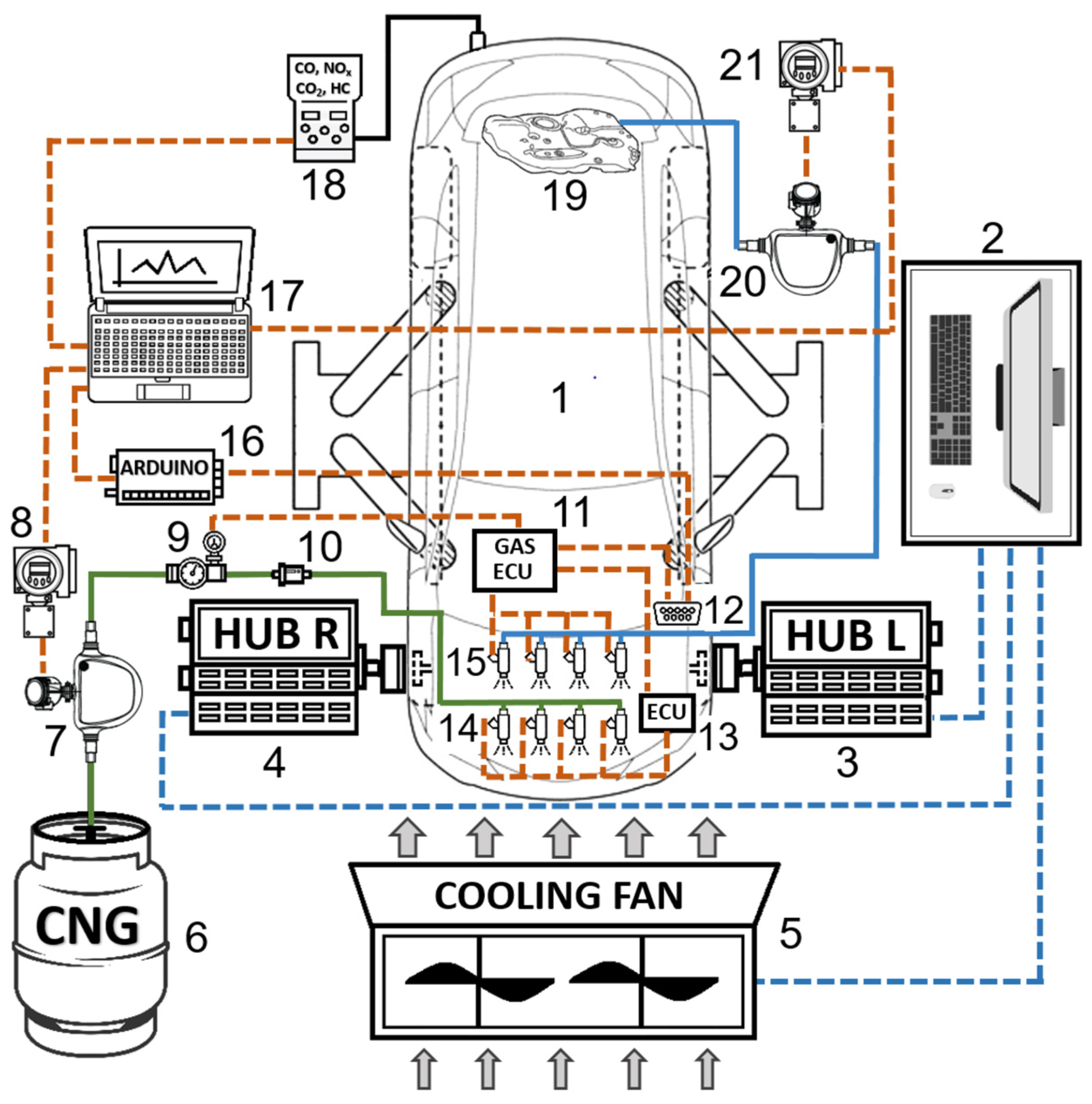

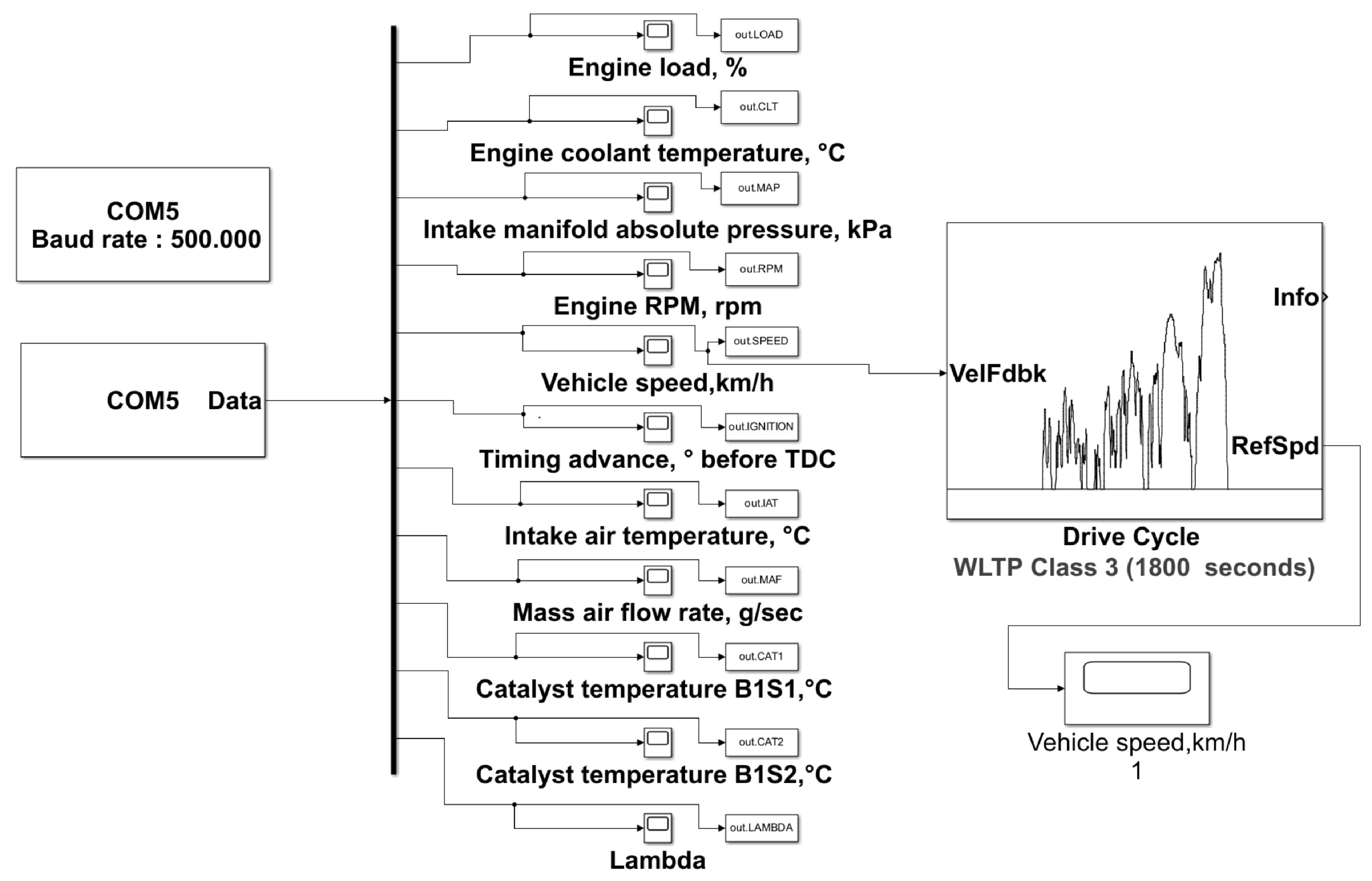

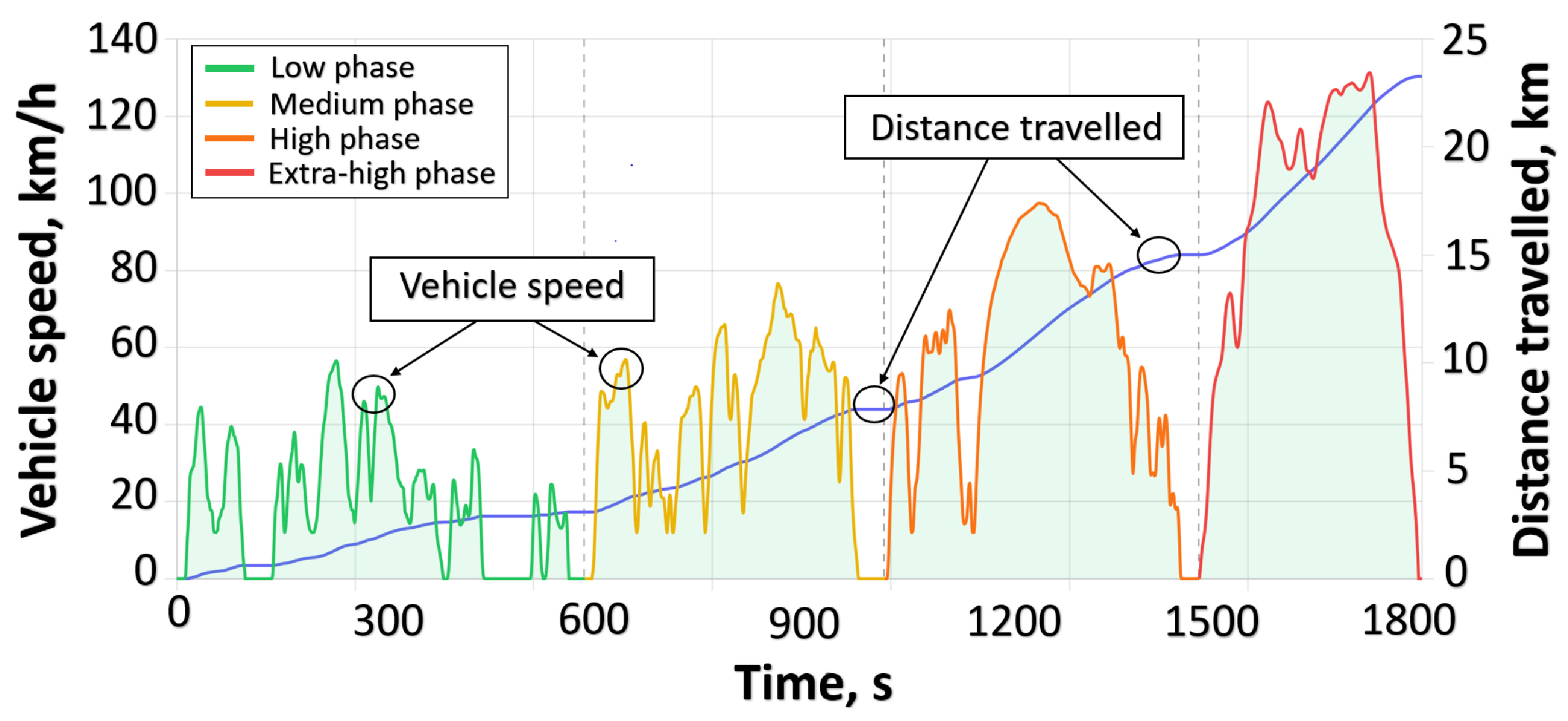

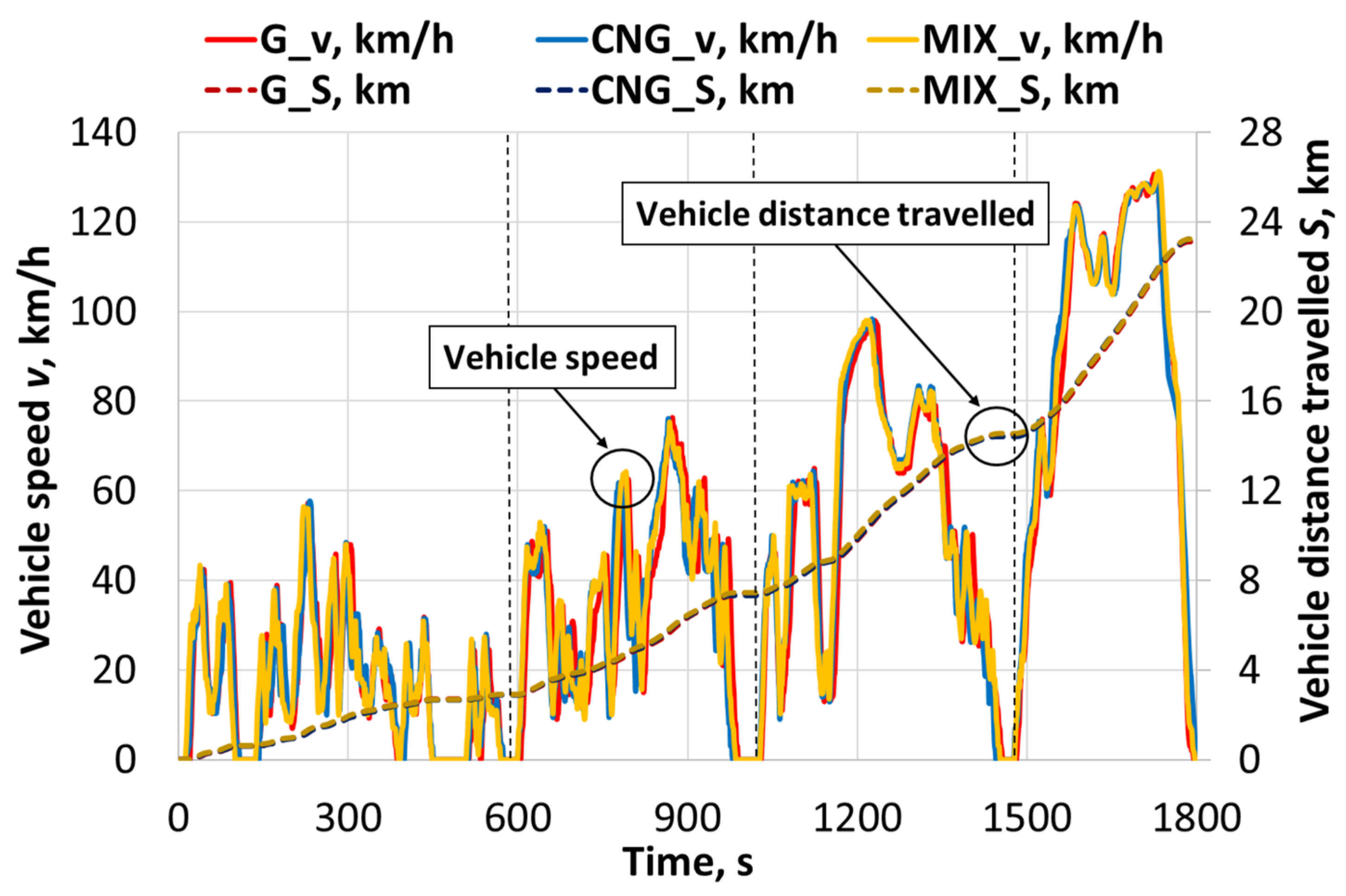

2. Materials and Methods

2.1. The Vehicle Specifications, Experimental Test Setup and Equipment

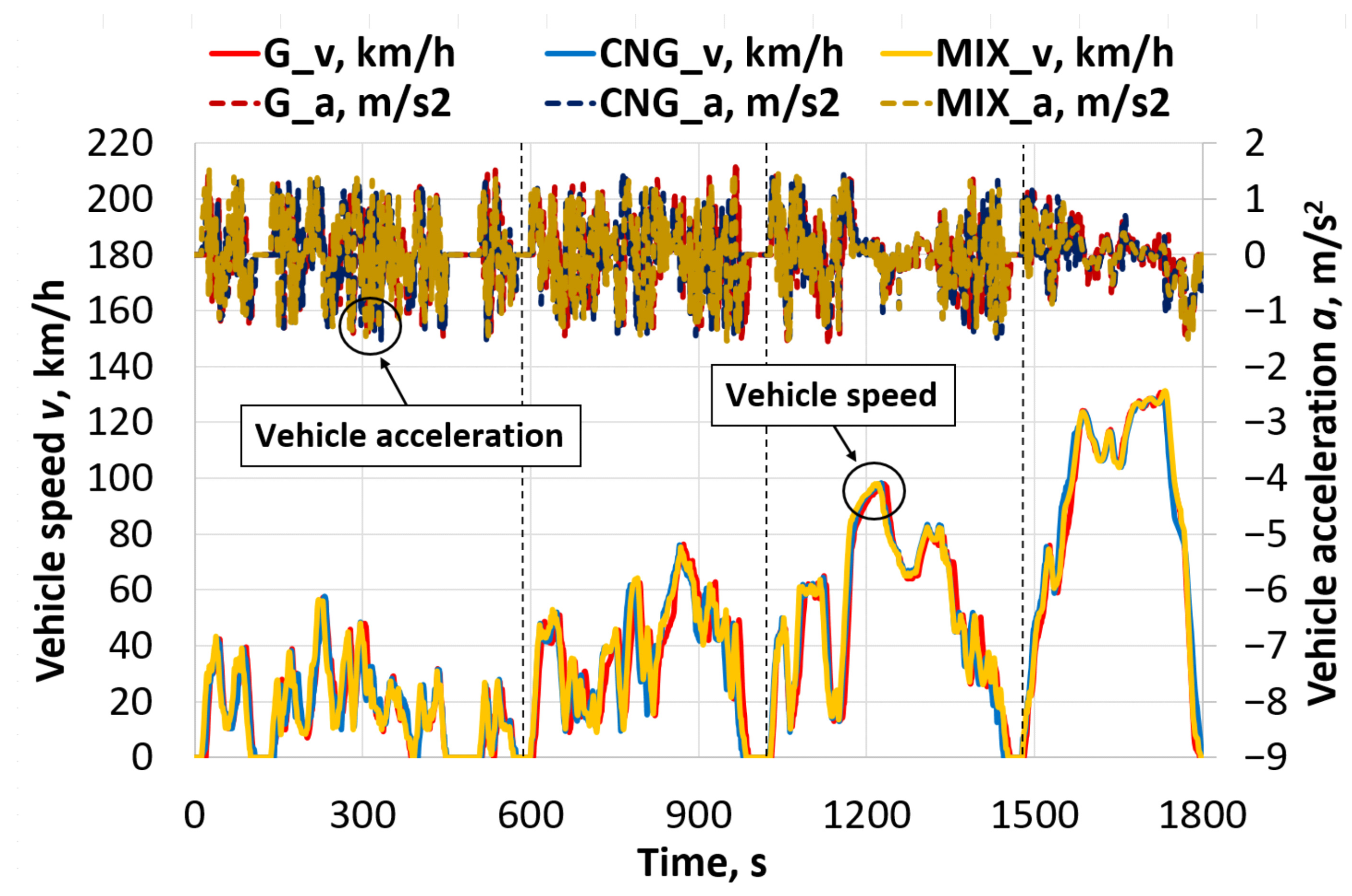

2.2. Experimental Testing Conditions and Fuel Properties

2.3. Evaluation of Engine Energy and Emission Characteristics

3. Results

4. Conclusions

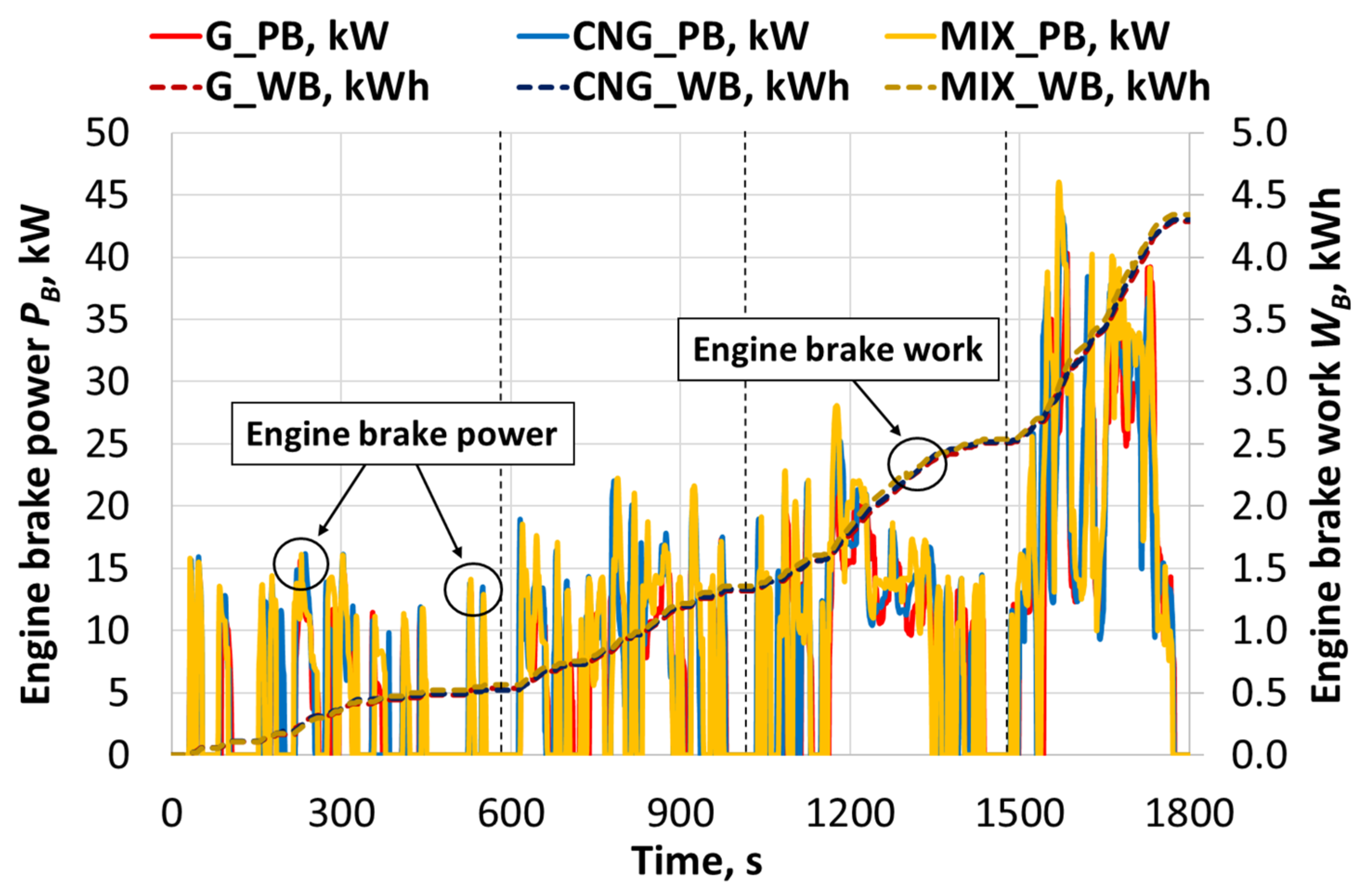

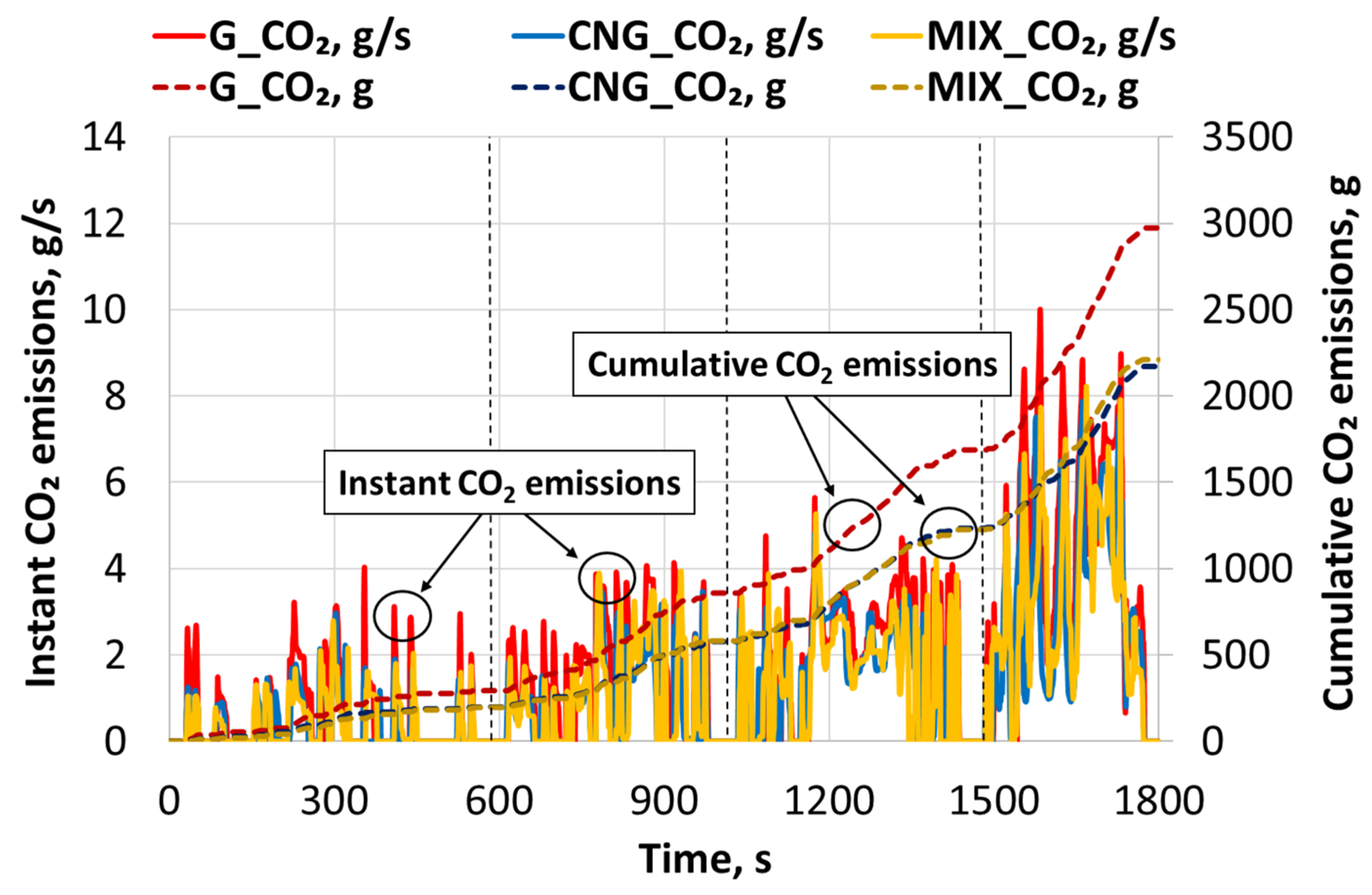

- The mechanical work performed by the engine over the WLTC was nearly identical for all three fuel modes (averaging ~17.8 kWh/100 km), ensuring an objective comparison of the energy and ecological indicators and confirming successful cycle replication under different fuel conditions. Using CNG reduced fuel consumption by 18.7% and CO2 emissions by 27.5% compared to gasoline, and this can be attributed to the higher LHV of CNG and ~4.3% higher BTE for CNG (0.360) in comparison with gasoline (0.345), proving that CNG can have high potential as alternative fuel.

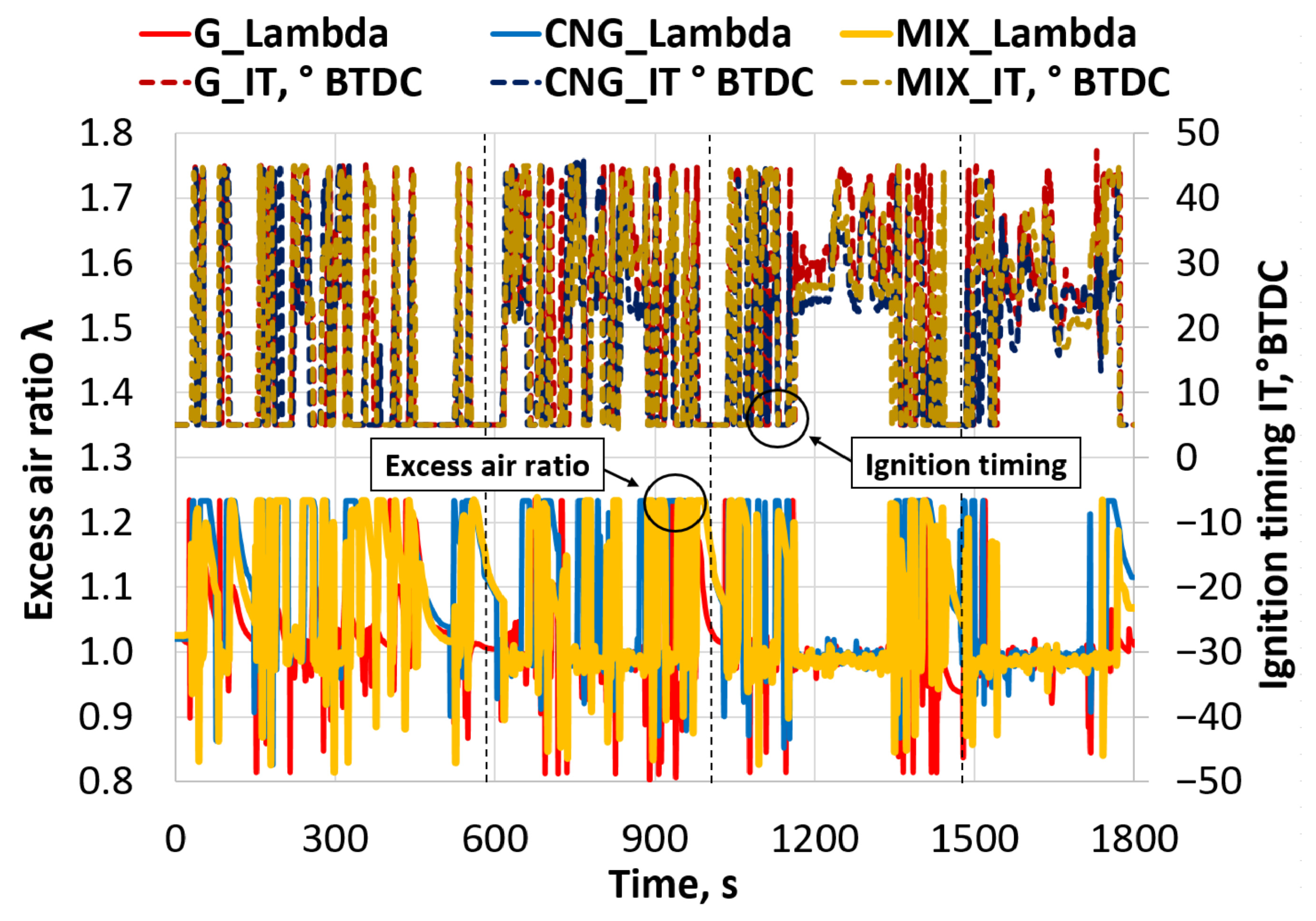

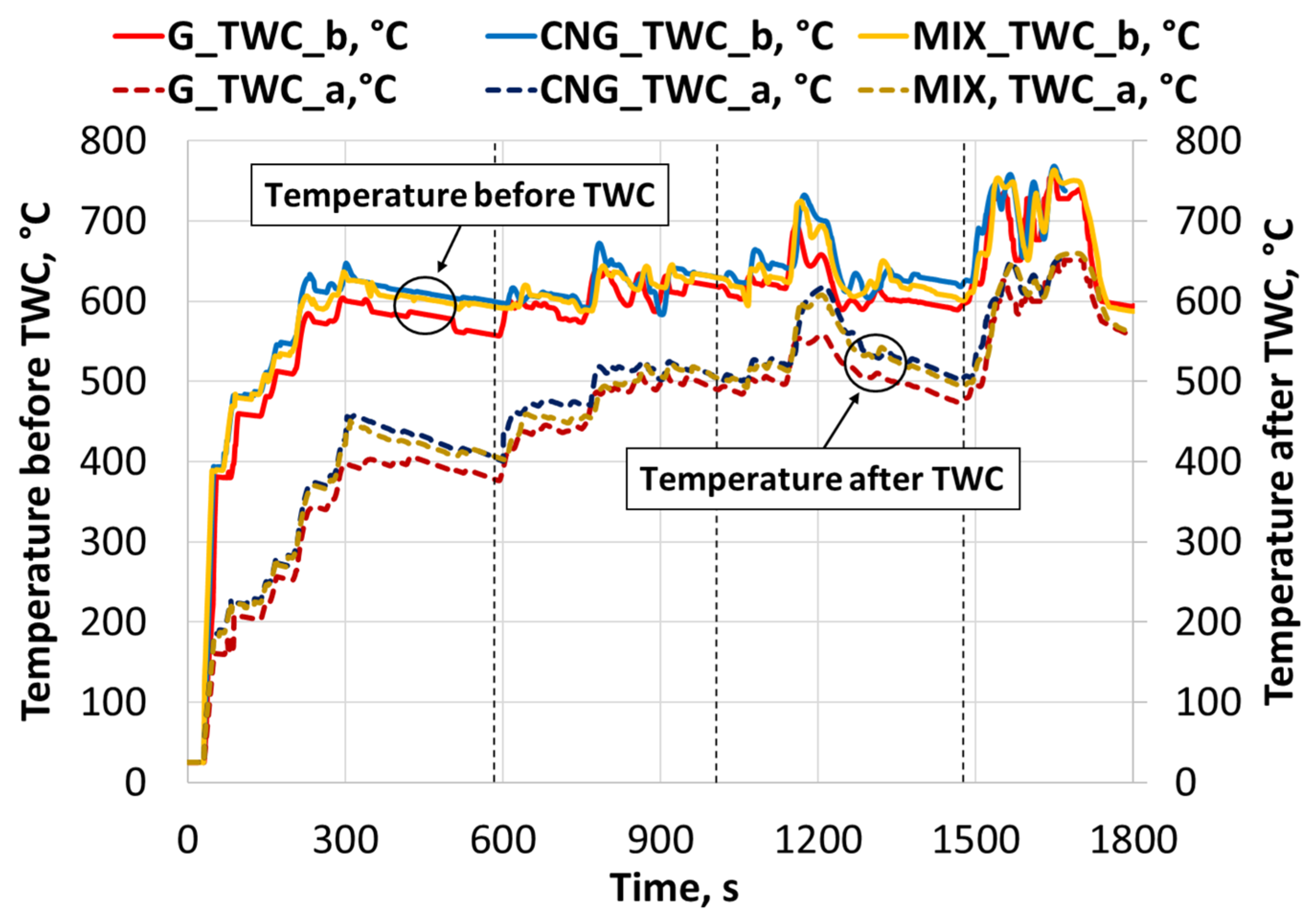

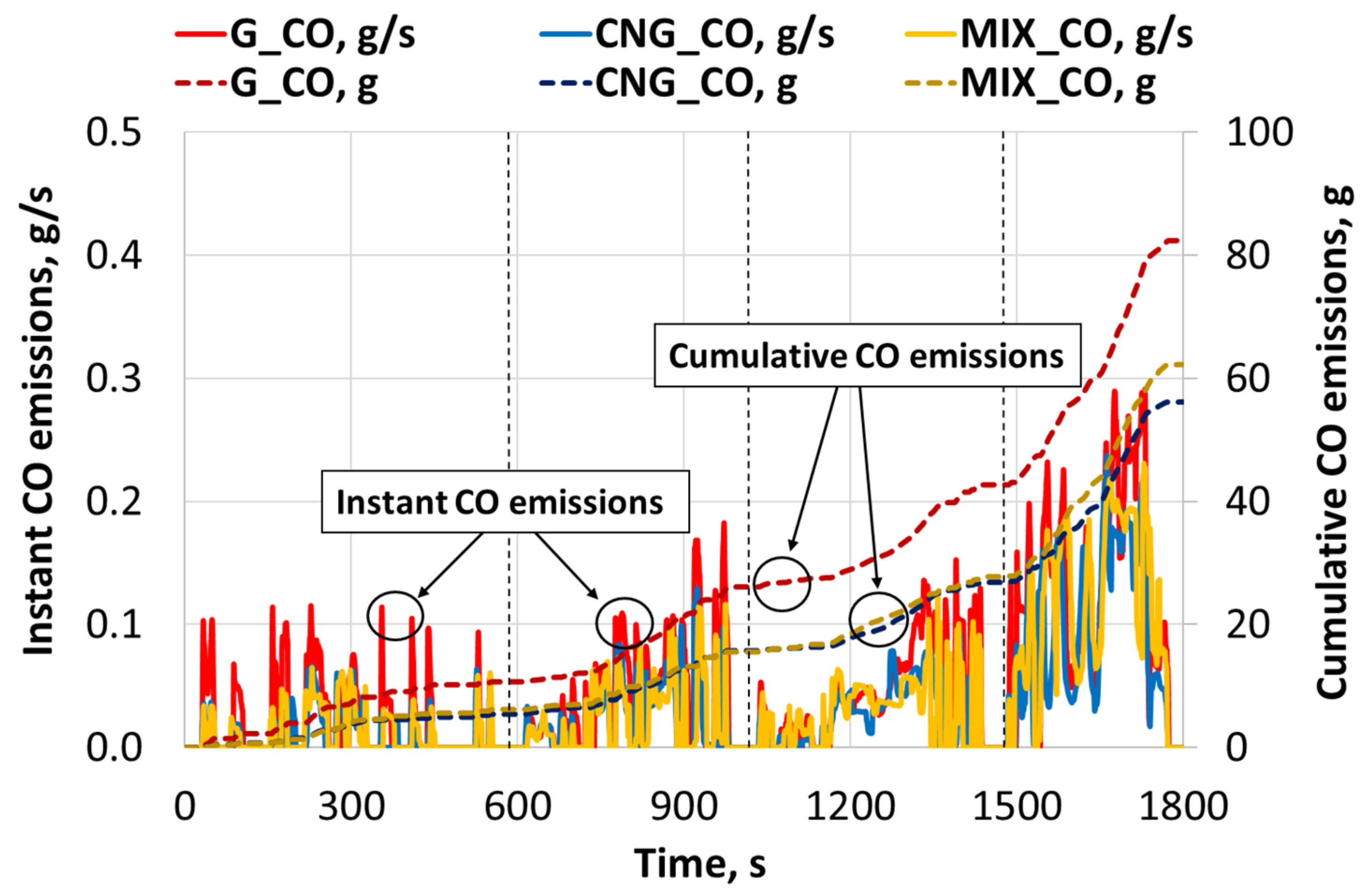

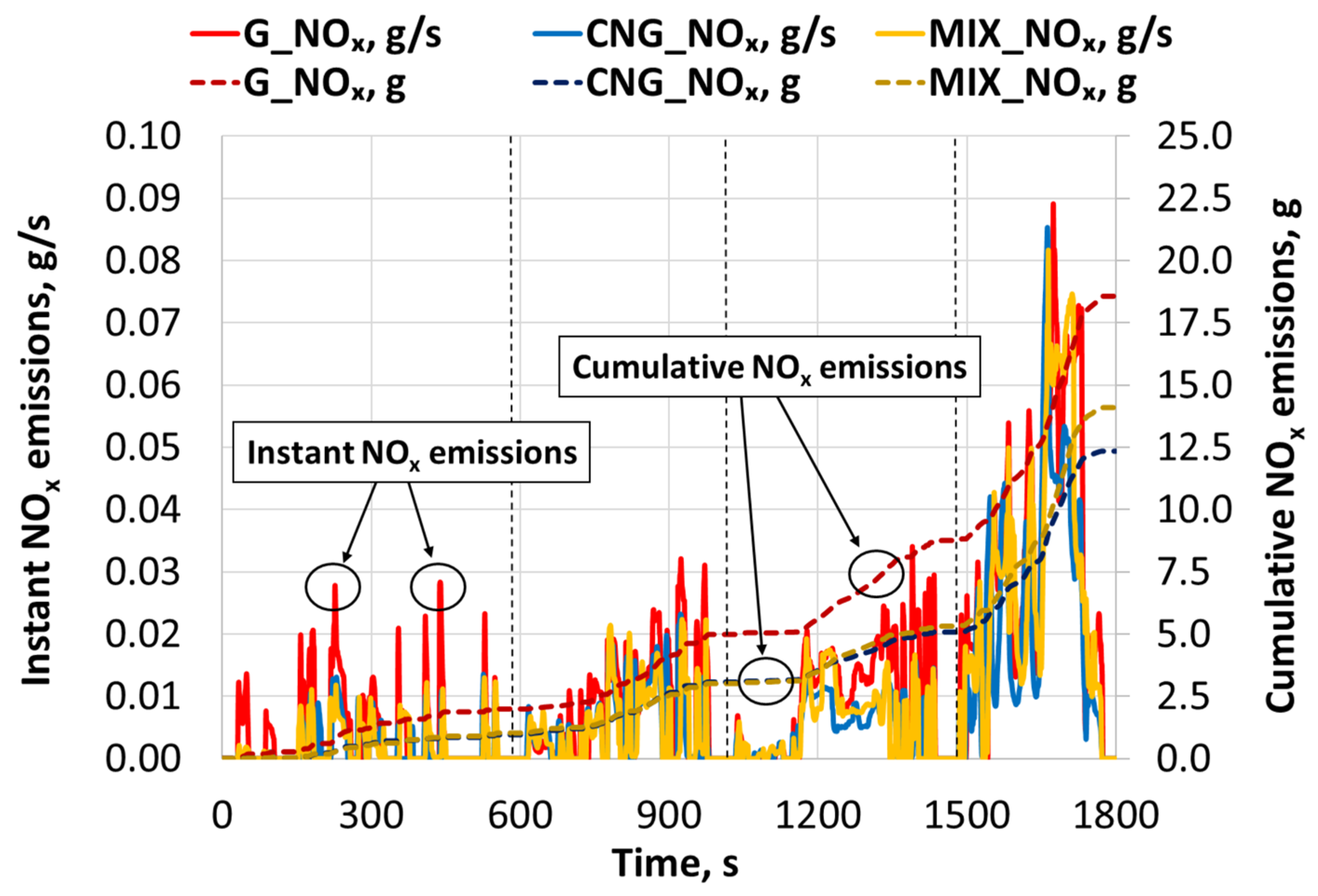

- The engine control logic in CNG mode successfully balanced efficiency and emissions. The system operated on a lean mixture (λ ≈ 1.056), which increased the BTE by reducing pumping losses. To control the NOx emissions typically associated with the lean-burn strategy, significantly retarded ignition timing (avg. 26.5° BTDC) was employed, successfully reducing engine-out NOx by 34.0%. Crucially, the BTE improvement was achieved despite the retarded timing, indicating that the benefits of lean operation outweighed the penalty of non-optimal ignition phasing. The ignition retard strategy also resulted in a 4.5% higher pre-TWC exhaust gas temperature, which is favorable for catalyst operation in a hybrid electric vehicle.

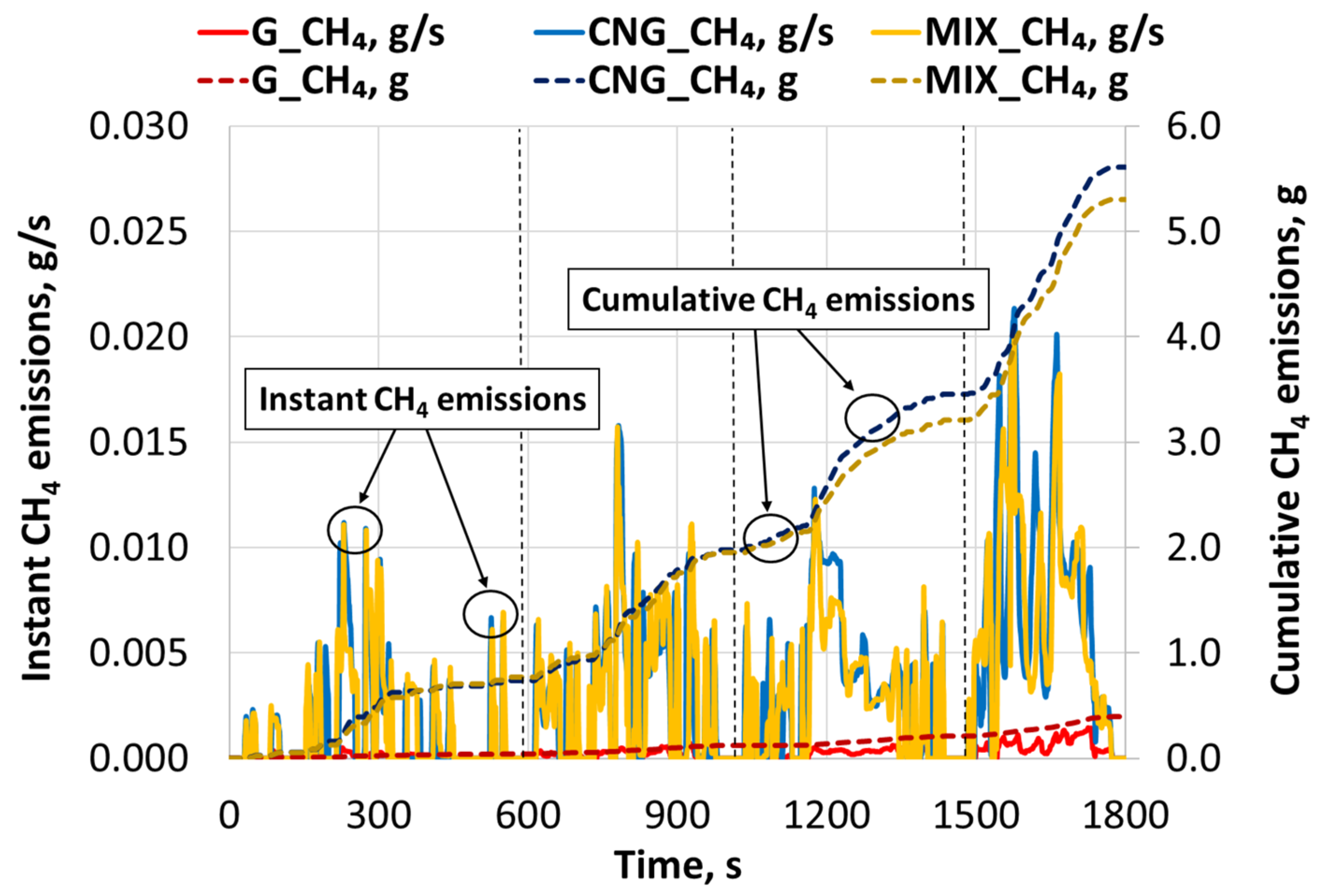

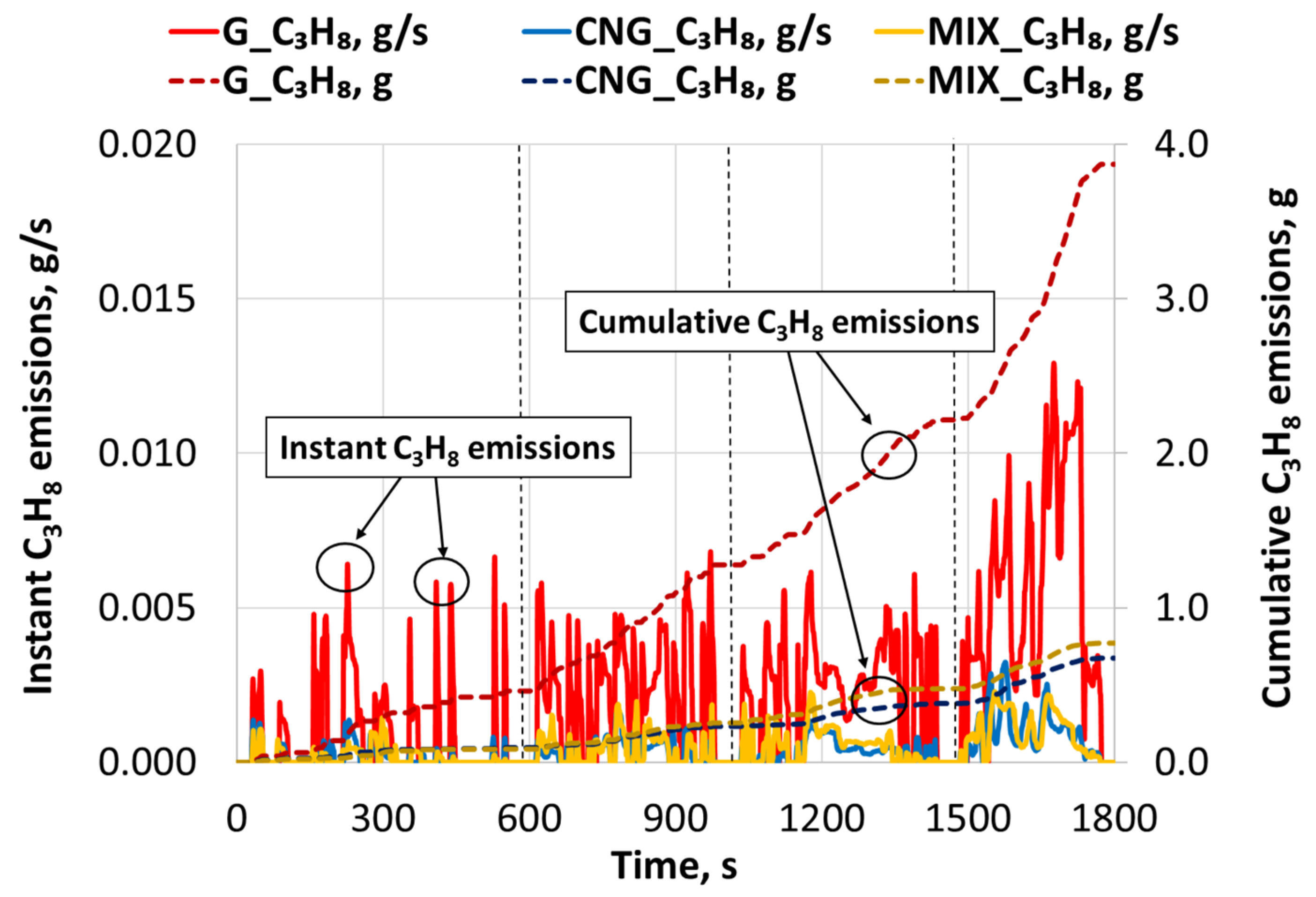

- While CNG reduced engine-out CO (−32.3%) and NMHC (−82.7%) emissions, it drastically increased engine-out CH4 emissions by ~14.1-fold (0.241 g/km vs. 0.017 g/km for gasoline). However, even when factoring in methane’s high global warming potential, the significant CO2 reduction outweighed the methane penalty. This resulted in a net 22.2% reduction in total engine-out greenhouse gas emissions (CO2-eq) for CNG (100.44 g/km CO2-eq) compared to gasoline (129.11 g/km CO2-eq). This confirms that the engine-out climate benefit is positive, but highlights that this benefit is heavily reliant on the TWC’s mitigation of the substantial methane slip.

- The experimentally obtained WLTC gasoline consumption (~5.95 L/100 km) and CO2 emissions (128.6 g/km) were 12.3% and 10.9% higher, respectively, than the manufacturer’s specified NEDC equivalent values, confirming the stringency and higher realism of the WLTC test compared to NEDC, as well as the influence of using G fuel.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ABDC | After Bottom Dead Center |

| ATDC | After Top Dead Center |

| BBDC | Before Bottom Dead Center |

| BDC | Bottom Dead Center |

| BMEP | Brake Mean Effective Pressure |

| BSFC | Brake Specific Fuel Consumption |

| BTE | Brake Thermal Efficiency |

| BTDC | Before Top Dead Center |

| Cd | Drag Coefficient |

| CH4 | Methane |

| CNG | Compressed Natural Gas |

| CO | Carbon Monoxide |

| CO2 | Carbon Dioxide |

| CO2-eq | Carbon Dioxide Equivalent |

| C3H8 | Propane |

| DIS | Direct Ignition System |

| DOHC | Double Overhead Camshaft |

| ECM | Electronic Control Module |

| ECU | Electronic Control Unit |

| EHC | Electrically Heated Catalyst |

| ES | Electrochemical Sensor |

| ETCS-i | Electronic Throttle Control System-Intelligent |

| EU | European Union |

| FWD | Front-Wheel Drive |

| G | Gasoline |

| GHG | Greenhouse Gas |

| GVW | Gross Vehicle Weight |

| H/C | Hydrogen-to-Carbon Ratio |

| HC | Hydrocarbons |

| HEV | Hybrid Electric Vehicle |

| HV | High-Voltage |

| ICE | Internal Combustion Engine |

| IT | Ignition Timing |

| JRC | Joint Research Center |

| LHV | Lower Heating Value |

| MG | Motor-Generator |

| MG1/MG2 | Motor-Generator 1/Motor-Generator 2 |

| MIX | Dual-Fuel Mixture (Gasoline/CNG) |

| NDIR | Non-Dispersive Infrared Technology |

| NEDC | New European Driving Cycle |

| NG | Natural Gas |

| Ni-MH | Nickel–Metal Hydride |

| NMHC | Non-Methane Hydrocarbons |

| NOx | Nitrogen Oxides |

| N2 | Nitrogen |

| N2O | Nitrous Oxide |

| OBD-II | On-Board Diagnostics II |

| RPM | Revolutions Per Minute |

| SI | Spark Ignition |

| SOC | State of Charge |

| TESS | Thermal Energy Storage System |

| THS-II | Toyota Hybrid System II |

| TWC | Three-Way Catalyst/Catalytic Converter |

| VVT-i | Variable Valve Timing-Intelligent |

| WLTC | Worldwide Harmonized Light Vehicles Test Cycle |

| WLTP | Worldwide Harmonized Light Vehicles Test Procedure |

| λ | Excess Air Coefficient |

References

- CO2 Emissions in 2023—Analysis, IEA. Available online: https://www.iea.org/reports/co2-emissions-in-2023 (accessed on 9 September 2025).

- Greenhouse Gas Emissions from Transport in Europe. Available online: https://www.eea.europa.eu/en/analysis/indicators/greenhouse-gas-emissions-from-transport (accessed on 9 September 2025).

- Milojevic, S. Sustainable application of natural gas as engine fuel in city buses: Benefit and restrictions. Istraz. Proj. Privredu 2017, 15, 81–88. [Google Scholar] [CrossRef]

- Karagöz, Y.; Balcı, Ö.; Gezer, O.; Köten, H.; Işın, Ö. Performance and emissions of spark-ignition engines fuelled with petrol and methane. Proc. Inst. Civ. Eng.—Energy 2021, 174, 156–169. [Google Scholar] [CrossRef]

- Atkins, P.; Milton, G.; Atkins, A.; Morgan, R. A Local Ecosystem Assessment of the Potential for Net Negative Heavy-Duty Truck Greenhouse Gas Emissions through Biomethane Upcycling. Energies 2021, 14, 806. [Google Scholar] [CrossRef]

- Vipartas, T.; Rimkus, A.; Stravinskas, S.; Pitrėnas, A.; Matulis, A. Spark Ignition (SI) Engine Energy and Ecological Performance Using Natural Gas and Late Intake Valve Close (LIVC). Appl. Sci. 2025, 15, 6185. [Google Scholar] [CrossRef]

- Liang, Y. A Review of the Effect of Compressed Natural Gas (CNG) on Combustion and Emission Performance of Internal Combustion Engines. Trends Renew. Energy 2022, 8, 119–129. [Google Scholar] [CrossRef]

- Jaworski, A.; Kuszewski, H.; Balawender, K.; Woś, P.; Lew, K.; Jaremcio, M. Assessment of CH4 Emissions in a Compressed Natural Gas-Adapted Engine in the Context of Changes in the Equivalence Ratio. Energies 2024, 17, 2095. [Google Scholar] [CrossRef]

- Prati, M.V.; Costagliola, M.A. Real driving emissions of Euro 6 electric/gasoline hybrid and natural gas vehicles. Transp. Res. Part D Transp. Environ. 2022, 113, 103509. [Google Scholar] [CrossRef]

- Niu, Q.; Sun, B.; Zhang, D.; Luo, Q. Research on performance optimization and fuel-saving mechanism of an Atkinson cycle gasoline engine at low speed and part load. Fuel 2020, 265, 117010. [Google Scholar] [CrossRef]

- Kwak, Y.; Kim, G.; Bae, C. Effect of the Late Intake Valve Closing(LIVC) Strategy on In-Cylinder Flow in a Gasoline Direct Injection Engine. KSAE 2025, 33, 337–384. [Google Scholar] [CrossRef]

- Feng, R.; Li, Y.; Yang, J.; Fu, J.; Zhang, D.; Zheng, G. Investigations of Atkinson Cycle Converted from Conventional Otto Cycle Gasoline Engine. In Proceedings of the SAE 2016 World Congress and Exhibition, Detroit, MI, USA, 12–14 April 2016; p. 2016-01-0680. [Google Scholar] [CrossRef]

- DiPierro, G.; Millo, F.; Cubito, C.; Ciuffo, B.; Fontaras, G. Analysis of the Impact of the WLTP Procedure on CO2 Emissions of Passenger Cars. In Proceedings of the Conference on Sustainable Mobility, Graz, Austria, 2–4 October 2019; p. 2019-24-0240. [Google Scholar] [CrossRef]

- Karamangil, M.İ.; Tekin, M. Comparison of fuel consumption and recoverable energy according to NEDC and WLTP cycles of a vehicle. CTF Cienc. Tecnol. Futuro 2022, 12, 31–38. [Google Scholar] [CrossRef]

- Marotta, A.; Pavlovic, J.; Ciuffo, B.; Serra, S.; Fontaras, G. Gaseous Emissions from Light-Duty Vehicles: Moving from NEDC to the New WLTP Test Procedure. Environ. Sci. Technol. 2015, 49, 8315–8322. [Google Scholar] [CrossRef]

- Xian, T.J.; Morris, S.; Wai, C.K. Evaluation of worldwide harmonised light vehicles test procedure for electric vehicles using simulation. IJVP 2021, 7, 364. [Google Scholar] [CrossRef]

- Tsiakmakis, S.; Fontaras, G.; Cubito, C.; Pavlovic, J.; Anagnostopoulos, K.; Ciuffo, B. From NEDC to WLTP: Effect on the Type-Approval CO2 Emissions of Light-Duty Vehicles, JRC Publications Repository. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC107662 (accessed on 17 September 2025).

- Pavlovic, J.; Ciuffo, B.; Fontaras, G.; Valverde, V.; Marotta, A. How much difference in type-approval CO2 emissions from passenger cars in Europe can be expected from changing to the new test procedure (NEDC vs. WLTP)? Transp. Res. Part A Policy Pract. 2018, 111, 136–147. [Google Scholar] [CrossRef]

- Zhao, D.; Ran, C.; Chen, C.; Yu, R. From NEDC to WLTP for Vehicles: The Impact on Fuel Efficiency Calculation and Algorithm Optimization. In Proceedings of the 2022 International Conference on Data Analytics, Computing and Artificial Intelligence (ICDACAI), Zakopane, Poland, 15–16 August 2022; IEEE: New York, NY, USA, 2022; pp. 311–315. [Google Scholar] [CrossRef]

- Rimkus, A.; Mejeras, G.; Dittrich, A.; Pukalskas, S.; Barta, D. Effect of the Concentration of Bioethanol Mixed with Gasoline on the Energy and Environmental Performance of a Hybrid Vehicle in the Worldwide Harmonized Light Vehicles Test Cycle (WLTC). Appl. Sci. 2024, 14, 10805. [Google Scholar] [CrossRef]

- Kafle, S.; Kalwar, A.; Valera, H.; Agarwal, A.K. Compressed Natural Gas Utilization in Dual-Fuel Internal Combustion Engines. In Advanced Combustion for Sustainable Transport; Energy, Environment, and Sustainability; Agarwal, A.K., Martínez, A.G., Kalwar, A., Valera, H., Eds.; Springer: Singapore, 2022; pp. 273–296. [Google Scholar] [CrossRef]

- Zhang, F.; Nader, W.B.; Zoughaib, A.; Luo, X. Well-to-Wheel analysis of natural gas for hybrid electric truck application. E3S Web Conf. 2021, 266, 04011. [Google Scholar] [CrossRef]

- Mattson, J.M.S.; Langness, C.; Depcik, C. An Analysis of Dual-Fuel Combustion of Diesel with Compressed Natural Gas in a Single-Cylinder Engine. In Proceedings of the WCX World Congress Experience, Detroit, MI, USA, 10–12 April 2018; p. 2018-01-0248. [Google Scholar] [CrossRef]

- Pan, J.; Li, N.; Wei, H.; Hua, J.; Shu, G. Experimental investigations on combustion acceleration behavior of methane/gasoline under partial load conditions of SI engines. Appl. Therm. Eng. 2018, 139, 432–444. [Google Scholar] [CrossRef]

- Sevik, J.; Pamminger, M.; Wallner, T.; Scarcelli, R.; Wooldridge, S.; Boyer, B.; Miers, S.; Hall, C. Influence of Charge Motion and Compression Ratio on the Performance of a Combustion Concept Employing In-Cylinder Gasoline and Natural Gas Blending. In Volume 1: Large Bore Engines; Fuels; Advanced Combustion; American Society of Mechanical Engineers: Seattle, WA, USA, 2017; p. V001T03A018. [Google Scholar] [CrossRef]

- Da Costa, R.B.R.; Hernández, J.J.; Teixeira, A.F.; Netto, N.A.D.; Valle, R.M.; Roso, V.R.; Coronado, C.J. Combustion, performance and emission analysis of a natural gas-hydrous ethanol dual-fuel spark ignition engine with internal exhaust gas recirculation. Energy Convers. Manag. 2019, 195, 1187–1198. [Google Scholar] [CrossRef]

- Sun, P.; Zhu, H.; Yang, S.; Dong, W.; Yu, X.; Fu, Z. Combustion and emission characteristics of CNG/gasoline DFSI engine with CNG direct injection. Fuel 2024, 359, 130537. [Google Scholar] [CrossRef]

- Hall, C.M.; Sevik, J.; Pamminger, M.; Wallner, T. Hydrocarbon Speciation in Blended Gasoline-Natural Gas Operation on a Spark-Ignition Engine. In Proceedings of the SAE 2016 International Powertrains, Fuels & Lubricants Meeting, Baltimore, MD, USA, 24–26 October 2016; p. 2016-01-2169. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, X.; Ke, J.; Tong, X.; Jiang, Z.; Yue, Z.; Wen, Y.; Yin, D.; Yang, X.; Wang, Y.; et al. Reducing ultra-high particulate number (PN) emissions from high-mileage vehicles: The effective role of compressed natural gas (CNG). J. Hazard. Mater. 2025, 495, 138814. [Google Scholar] [CrossRef] [PubMed]

- Mandloi, D.; Dhinagar, S.; Das, H. An Optimization-Based Framework for Dynamic Model Development for a Three-Way Catalytic Converter Suitable for Urban Driving Condition. In Proceedings of the 15th International Conference on Engines & Vehicles, Capri, Italy, 12–16 September 2021; p. 2021-24-0078. [Google Scholar] [CrossRef]

- Srivastava, V.; Schaub, J.; Pischinger, S. Advanced model-based closed-loop combustion control strategies with combustion rate shaping. Int. J. Engine Res. 2023, 24, 3688–3706. [Google Scholar] [CrossRef]

- Tan, Y.; Kou, C.; Feng, C.; Han, D. Effect of different exhaust parameters on conversion efficiency enhancement of a Pd–Rh three-way catalytic converter for heavy-duty natural gas engines. Energy 2024, 292, 130483. [Google Scholar] [CrossRef]

- Nandi, S.; Chaillou, C.; Dujardin, C.; Granger, P.; Laigle, E.; Nicolle, A.; Norsic, C.; Richard, M. Evaluating Different Strategies to Minimize cold-start Emissions from Gasoline Engines in steady-state and Transient Regimes. Top. Catal. 2023, 66, 875–885. [Google Scholar] [CrossRef]

- Majumdar, S.S.; Pihl, J.A. Impact of Selected High-Performance Fuel Blends on Three-Way Catalyst Light Off under Synthetic Spark-Ignition Engine-Exhaust Conditions. Energy Fuels 2020, 34, 12900–12910. [Google Scholar] [CrossRef]

- Benegiamo, M.; Valletta, A.; Carlucci, A.; Mulone, V. Impact of Thermal Management of the Three-Way Catalyst on the Energy Efficiency of a P2 Gasoline FHEV. In Proceedings of the CO2 Reduction for Transportation Systems Conference, Turin, Italy, 7–9 June 2020; p. 2020-37-0019. [Google Scholar] [CrossRef]

- Okajima, T.; Sivakumar, S.; Shingyouchi, H.; Yamaguchi, K.; Kusaka, J.; Nagata, M. Modeling on a Three-Way Catalyst Used in Series Hybrid Electric Vehicles Focusing on Its Catalytic Behavior at Cold Start. Ind. Eng. Chem. Res. 2021, 60, 14069–14086. [Google Scholar] [CrossRef]

- Velmurugan, D.V.; McKelvey, T.; Olsson, J.-O. Data-Driven Near-Optimal On-Line Control for an Electrically Heated Catalyst-Equipped Gasoline Engine. SAE Int. J. Engines 2023, 16, 335–346. [Google Scholar] [CrossRef]

- Bohm, M.; Stetina, J.; Svida, D. Exhaust Gas Temperature Pulsations of a Gasoline Engine and Its Stabilization Using Thermal Energy Storage System to Reduce Emissions. Energies 2022, 15, 2365. [Google Scholar] [CrossRef]

- Brinklow, G.; Herreros, J.M.; Zeraati-Rezaei, S.; Tsolakis, A.; Millington, P.; Kolpin, A. Primary and Secondary Emissions Reduction Using Cylinder Deactivation Strategies for Gasoline Direct Injection Engines in Hybrid Vehicles. Automot. Innov. 2025, 8, 508–518. [Google Scholar] [CrossRef] [PubMed]

- Teymoori, M.M.; Chitsaz, I.; Zarei, A. Three-way catalyst modeling and fuel switch optimization of a natural gas bi-fuel-powered vehicle. Fuel 2023, 341, 126979. [Google Scholar] [CrossRef]

- Sahoo, S.; Srivastava, D.K. Effect of injection timing on combustion and IMEP variation of a bi-fuel compressed natural gas SI engine. Environ. Prog. Sustain. Energy 2021, 40, e13694. [Google Scholar] [CrossRef]

- Montanaro, A.; Allocca, L.; De Vita, A.; Ranieri, S.; Duronio, F.; Meccariello, G. Experimental and Numerical Characterization of High-Pressure Methane Jets for Direct Injection in Internal Combustion Engines. In Proceedings of the SAE Powertrains, Fuels & Lubricants Meeting, Kraków, Poland, 22–24 September 2020; p. 2020-01-2124. [Google Scholar] [CrossRef]

- Le, S.V.; Chan, H.H.; Quoc, T.D. A Study on the Effect of Compression Ratio and Bowl-In-Piston Geometry on Knock Limit in Port Injection Natural Gas Converted Engine. In The AUN/SEED-Net Joint Regional Conference in Transportation, Energy, and Mechanical Manufacturing Engineering; Le, A.-T., Pham, V.-S., Le, M.-Q., Pham, H.-L., Eds.; Lecture Notes in Mechanical Engineering; Springer Nature: Singapore, 2022; pp. 56–73. [Google Scholar] [CrossRef]

- Huang, C.; Shan, W.; Lian, Z.; Zhang, Y.; He, H. Recent advances in three-way catalysts of natural gas vehicles. Catal. Sci. Technol. 2020, 10, 6407–6419. [Google Scholar] [CrossRef]

- Lou, D.; Ren, Y.; Zhang, Y.; Sun, X. Study on the Effects of EGR and Spark Timing on the Combustion, Performance, and Emissions of a Stoichiometric Natural Gas Engine. ACS Omega 2020, 5, 26763–26775. [Google Scholar] [CrossRef]

- Kumar, S.; Karthi, R.; Ramakrishnan, M.S. Aggressive Catalyst Heating Strategy Using Advanced Mixture Formation and Combustion Timing Techniques in a GDI Engine. In Proceedings of the Symposium on International Automotive Technology, Pune, India, 29 September–1 October 2021; p. 2021-26-0185. [Google Scholar] [CrossRef]

- Kim, S.; Sim, J.; Cho, Y.; Sung, B.-S.; Park, J. Numerical Study on the Performance and NOx Emission Characteristics of an 800cc MPI Turbocharged SI Engine. Energies 2021, 14, 7419. [Google Scholar] [CrossRef]

- Marques, B.; Kostenidou, E.; Valiente, A.M.; Vansevenant, B.; Sarica, T.; Fine, L.; Temime-Roussel, B.; Tassel, P.; Perret, P.; Liu, Y.; et al. Detailed Speciation of Non-Methane Volatile Organic Compounds in Exhaust Emissions from Diesel and Gasoline Euro 5 Vehicles Using Online and Offline Measurements. Toxics 2022, 10, 184. [Google Scholar] [CrossRef]

- Lou, D.; Ren, Y.; Li, X.; Zhang, Y.; Sun, X. Effect of Operating Conditions and TWC Parameters on Emissions Characteristics of a Stoichiometric Natural Gas Engine. Energies 2020, 13, 4905. [Google Scholar] [CrossRef]

- Nsaif, O.; Kokjohn, S.; Hessel, R.; Dempsey, A. Reducing Methane Emissions from Lean Burn Natural Gas Engines with Prechamber Ignited Mixing-Controlled Combustion. J. Eng. Gas Turbines Power 2024, 146, 061023. [Google Scholar] [CrossRef]

- Zhang, R.; Chen, L.; Wei, H.; Li, J.; Chen, R.; Pan, J. Understanding the difference in combustion and flame propagation characteristics between ammonia and methane using an optical SI engine. Fuel 2022, 324, 124794. [Google Scholar] [CrossRef]

- Yusuf, A.A.; Inambao, F.L. Effect of cold start emissions from gasoline-fueled engines of light-duty vehicles at low and high ambient temperatures: Recent trends. Case Stud. Therm. Eng. 2019, 14, 100417. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, Y.; Gong, J.; Su, S.; Wei, Z. Combustion behaviours and emission characteristics of a retrofitted NG/gasoline duel-fuel SI engine with various proportions of NG-gasoline blends. Fuel 2020, 266, 116957. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (Ipcc). Climate Change 2021—The Physical Science Basis: Working Group I Contribution to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change, 1st ed.; Cambridge University Press: Cambridge, UK, 2023. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Curb weight | 1705 kg |

| Gross vehicle weight (GVW) | 2205 kg |

| Fuel tank capacity | 56 L |

| Maximum system output | 147 kW |

| Wheelbase | 2660 mm |

| Frontal area | 2.99 m2 |

| Drag coefficient (Cd) | 0.34 |

| Tire size | 235/55 R18 |

| Tire radius | 358 mm |

| Transaxle type | Hybrid P314 |

| Total speed reduction ratio | 3.750 |

| Parameter | Value |

|---|---|

| Engine type | 4-cylinder, in-line |

| Firing order | 1-3-4-2 |

| Fuel supply system | Multiport fuel injection |

| Engine displacement | 2494 cm3 |

| Engine compression ratio | 12.5:1 |

| Bore/stroke | 90.0 mm × 98.0 mm |

| Engine max. output | 114 kW @ 5700 rpm |

| Engine max. torque | 206 Nm @ 4400–4800 rpm |

| Valve mechanism | 16-valve DOHC, chain drive |

| Intake valve open | −23° to 22° BTDC 1 |

| Intake valve close | 103° to 58° ABDC 2 |

| Exhaust valve open | 35° BBDC 3 |

| Exhaust valve close | 9° ATDC 4 |

| Motor generator 1 (MG1) | Permanent magnet, starts engine |

| Motor generator 2 (MG2) | Permanent magnet, drives front wheels |

| MG2 max. output/torque | 105 kW/270 Nm |

| MG2 max. torque | 270 Nm |

| Max. system voltage | DC 650 V |

| HV battery nominal voltage | DC 244.8 V |

| HV battery capacity | 6.5 Ah |

| HV battery cell quantity | 204 |

| Parameter | Value |

|---|---|

| Type | Top feed, B-class |

| Voltage | DC 12 V |

| Resistance | 1.9 Ω |

| Opening time | 2.16 ms |

| Closing time | 1.20 ms |

| Max. flow rate | 90 L/min |

| Control peak/hold current | 4 A/2 A |

| Operating pressure | 1.2 bar |

| Max. open pressure | 5.0 bar |

| Operating temperature | −40 °C~120 °C |

| Component | Measuring Range | Technology | Resolution | Accuracy/Repeatability |

|---|---|---|---|---|

| O2 | 0–25% vol. | ES 1 | 0.01% vol. | ±0.25% vol. 3 |

| CO2 | 0–50% vol. | NDIR 2 | 0.01% vol. | 0.2% vol. 4 |

| CO | 0–10,000 ppm | NDIR 2 | 0.1 ppm | 2 ppm 4 |

| NO | 0–4000 ppm | NDIR 2 | 0.1 ppm | 2 ppm 4 |

| NO2 | 0–1000 ppm | NDIR 2 | 0.1 ppm | 1 ppm 4 |

| N2O | 0–500 ppm | NDIR 2 | 0.1 ppm | 2 ppm 4 |

| CH4 | 0–10,000 ppm | NDIR 2 | 0.1 ppm | 10 ppm 4 |

| C3H8 | 0–5000 ppm | NDIR 2 | 0.1 ppm | 2 ppm 4 |

| Parameter | Low Phase | Medium Phase | High Phase | Extra-High Phase | Total Cycle |

|---|---|---|---|---|---|

| Duration (s) | 589 | 433 | 455 | 323 | 1800 |

| Stop Duration (s) | 145 | 47 | 29 | 6 | 227 |

| Distance (km) | 3.095 | 4.756 | 7.162 | 8.254 | 23.267 |

| Average Speed (km/h) | 18.9 | 39.4 | 56.7 | 92 | 46.5 |

| Maximum Speed (km/h) | 56.5 | 76.6 | 97.4 | 131.3 | 131.3 |

| Properties | Gasoline | Compressed Natural Gas |

|---|---|---|

| Density, [kg/m3] | 748.3 * | 0.7512 |

| Lower heating value, [MJ/kg] | 41.90 | 49.22 ** |

| Research octane number | 96.5 | ~120 |

| Methane number | - | ~90 |

| Stoichiometric AFR, [kg/kg] | 14.11 | ~17.1 |

| Fuel composition, [%Vol.] | Gasoline 90.15 | Methane 95.38 |

| Ethanol 9.85 | Ethane 3.67 | |

| Propane 0.352 | ||

| i-Butane 0.0593 | ||

| n-Butane 0.057 | ||

| neo-Pentane 0.001 | ||

| i-Pentane 0.007 | ||

| n-Pentane 0.005 | ||

| C6 plus 0.001 | ||

| Nitrogen 0.320 | ||

| Carbon dioxide 0.144 | ||

| Hydrogen, [%Mass] | 13.66 | ~24.7 |

| Carbon, [%Mass] | 82.88 | ~74.7 |

| Oxygen, [%Mass] | 3.46 | - |

| H/C ratio | 1.96 | 3.98 |

| Cycle Part | Parameter | Standard Value | G | CNG | MIX |

|---|---|---|---|---|---|

| I (Low) | Average speed (km/h) | 18.9 | 18.56 | 18.64 | 19.08 |

| Speed deviation (%) | - | −1.80% | −1.40% | +1.0% | |

| II (Medium) | Average speed (km/h) | 39.4 | 38.70 | 39.89 | 38.62 |

| Speed deviation (%) | - | −1.80% | +1.2% | −2.00% | |

| III (High) | Average speed (km/h) | 56.7 | 56.21 | 57.74 | 57.24 |

| Speed deviation (%) | - | −0.90% | +1.8% | +1.0% | |

| IV (Extra-High) | Average speed (km/h) | 92.0 | 93.46 | 91.15 | 90.75 |

| Speed deviation (%) | - | +1.6% | −0.90% | −1.40% | |

| Total Cycle | Total distance (km) | 23.267 | 23.170 | 23.312 | 23.133 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vipartas, T.; Rimkus, A.; Stravinskas, S.; Pitrėnas, A.; Matulis, A. Experimental Investigation of Performance and Emissions for a Hybrid Electric Vehicle Operating on Gasoline, CNG, and Dual Fuel over the WLTC. Appl. Sci. 2025, 15, 12541. https://doi.org/10.3390/app152312541

Vipartas T, Rimkus A, Stravinskas S, Pitrėnas A, Matulis A. Experimental Investigation of Performance and Emissions for a Hybrid Electric Vehicle Operating on Gasoline, CNG, and Dual Fuel over the WLTC. Applied Sciences. 2025; 15(23):12541. https://doi.org/10.3390/app152312541

Chicago/Turabian StyleVipartas, Tadas, Alfredas Rimkus, Saulius Stravinskas, Aurelijus Pitrėnas, and Audrius Matulis. 2025. "Experimental Investigation of Performance and Emissions for a Hybrid Electric Vehicle Operating on Gasoline, CNG, and Dual Fuel over the WLTC" Applied Sciences 15, no. 23: 12541. https://doi.org/10.3390/app152312541

APA StyleVipartas, T., Rimkus, A., Stravinskas, S., Pitrėnas, A., & Matulis, A. (2025). Experimental Investigation of Performance and Emissions for a Hybrid Electric Vehicle Operating on Gasoline, CNG, and Dual Fuel over the WLTC. Applied Sciences, 15(23), 12541. https://doi.org/10.3390/app152312541