Synergistic Effects of Hybrid Basalt Fibers on the Durability of Recycled Aggregate Concrete Under Freeze–Thaw and Chloride Conditions

Abstract

1. Introduction

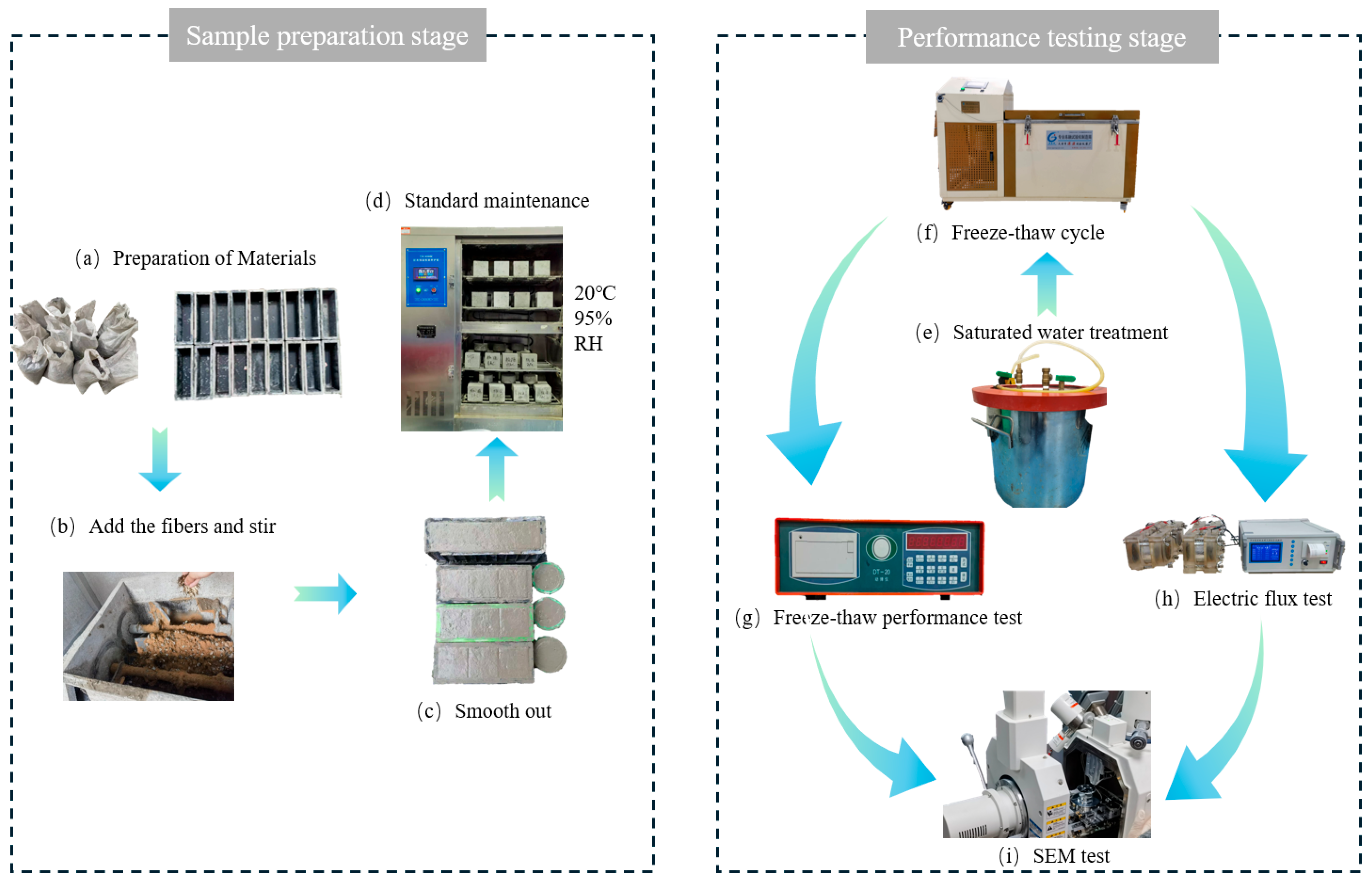

2. Materials and Methods

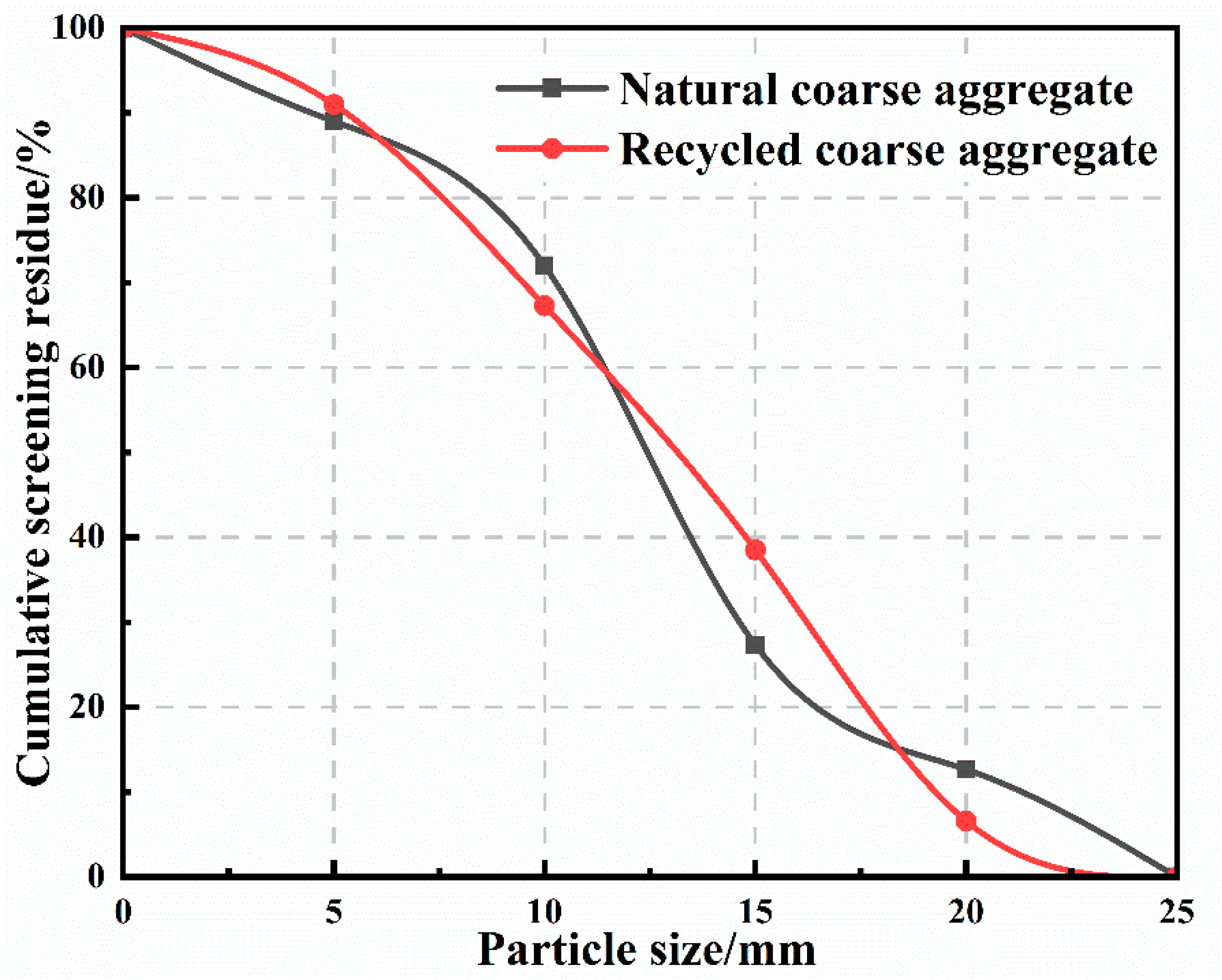

2.1. Materials

2.2. Mix Proportion Design

2.3. Test Methods

2.3.1. Freeze–Thaw Cycle Test

2.3.2. Rapid Chloride Permeability Test

2.3.3. SEM Microscopic Testing

2.4. Error Analysis

3. Results and Discussion

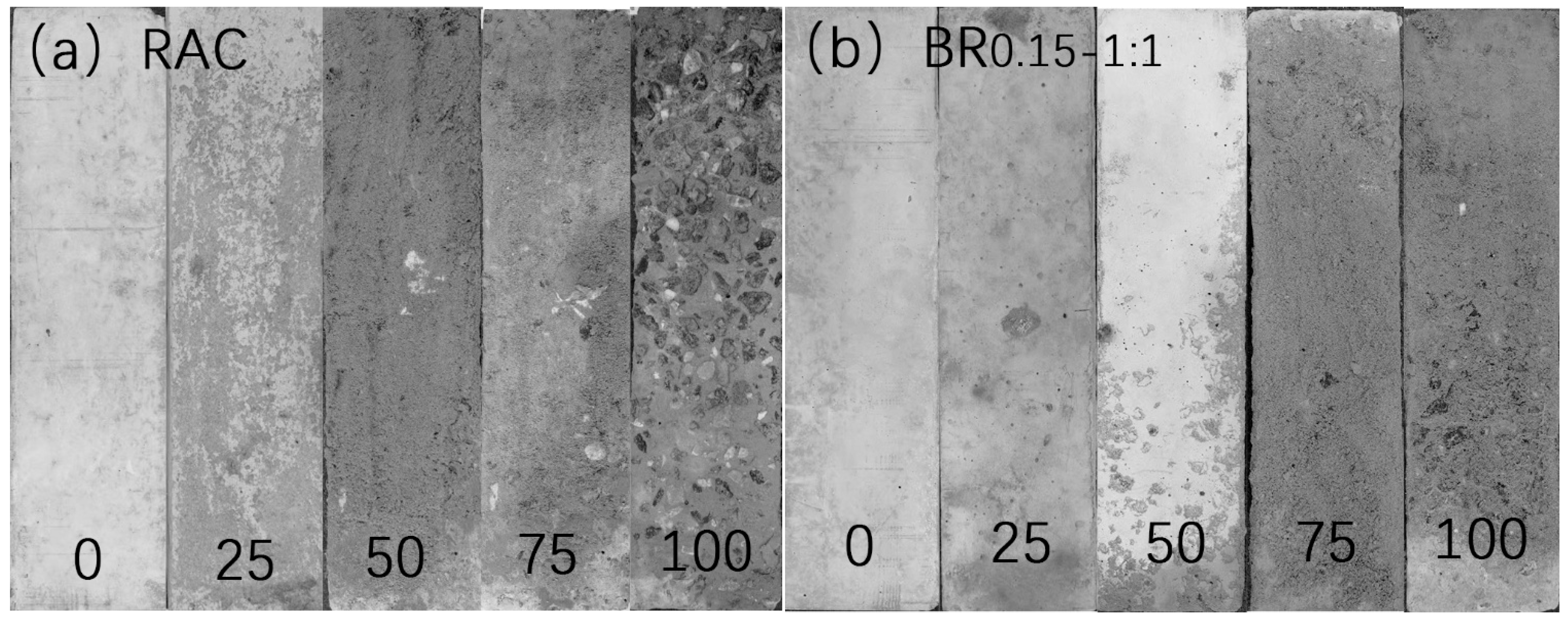

3.1. Apparent Damage

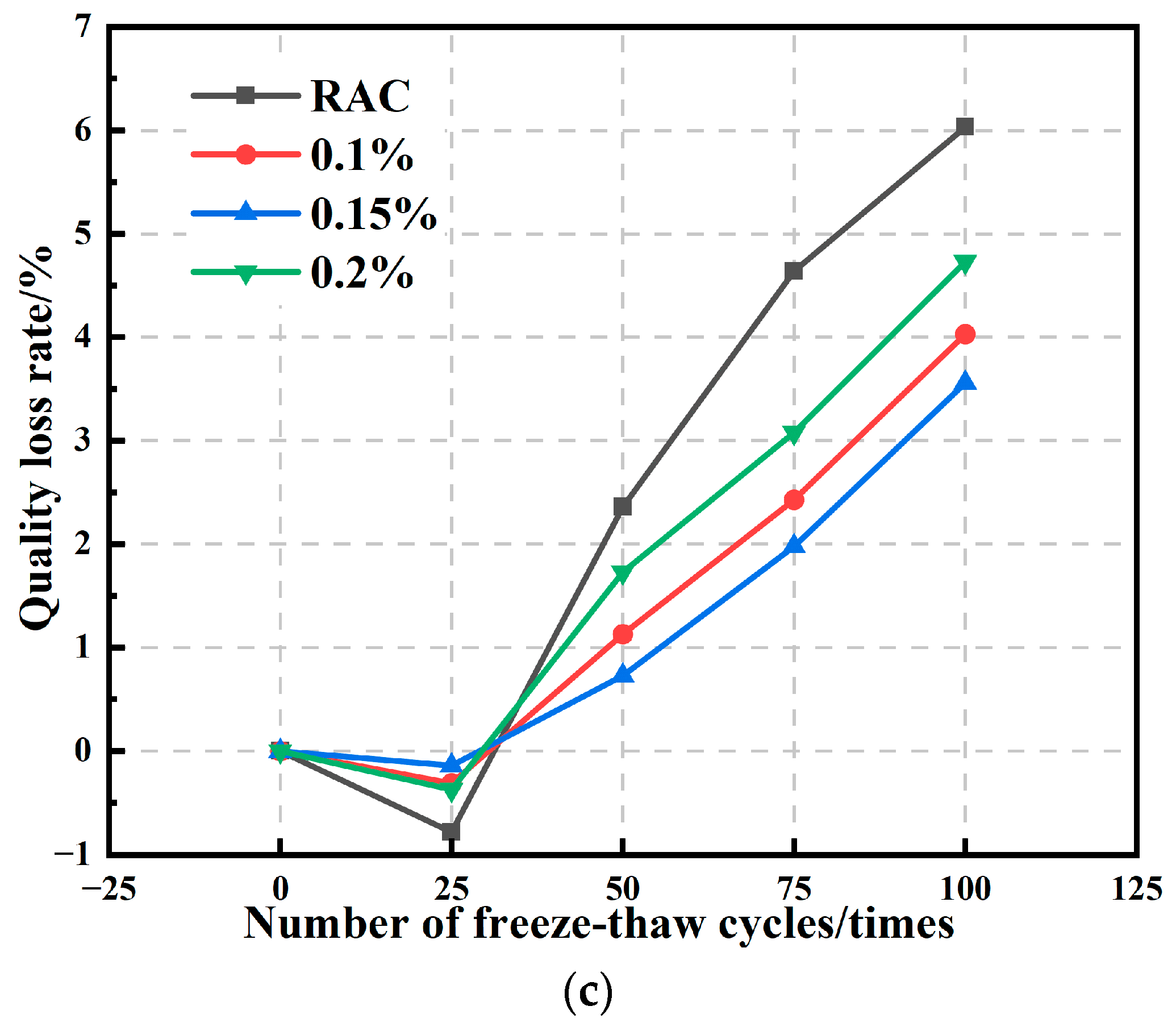

3.2. Quality Loss Rate

3.3. Relative Dynamic Elastic Modulus

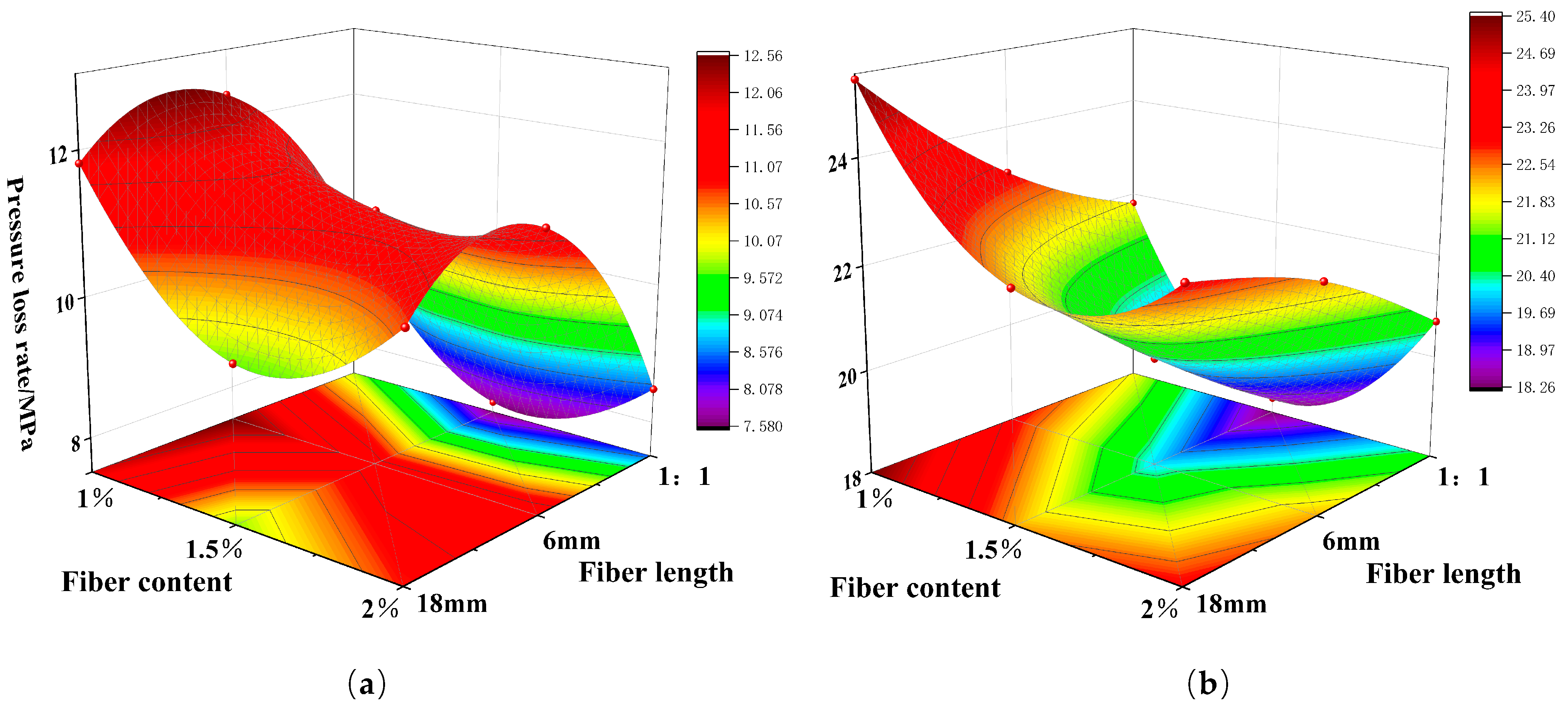

3.4. Loss Rate of Compressive Strength

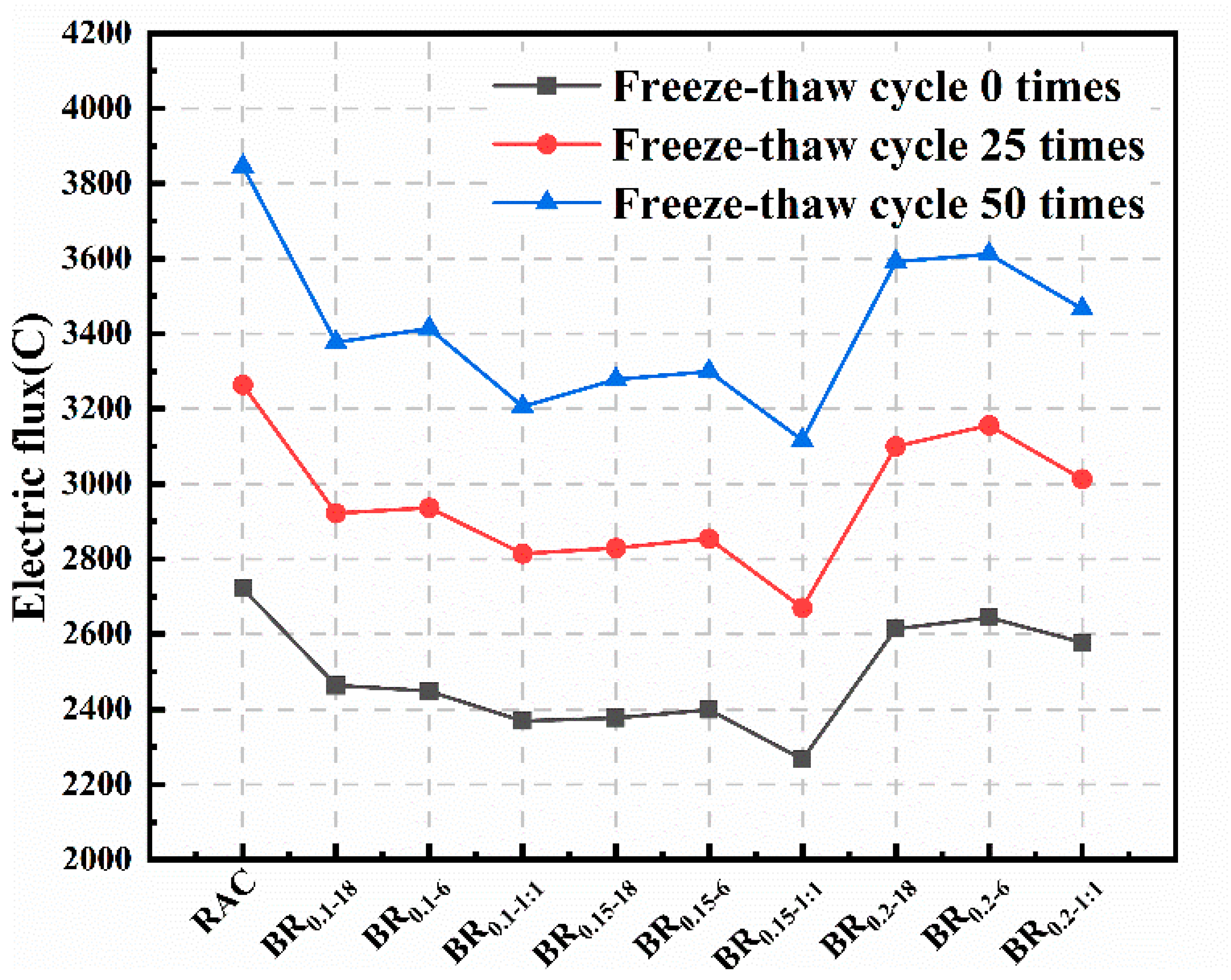

3.5. Electric Flux Test

3.6. SEM Microscopic Analysis

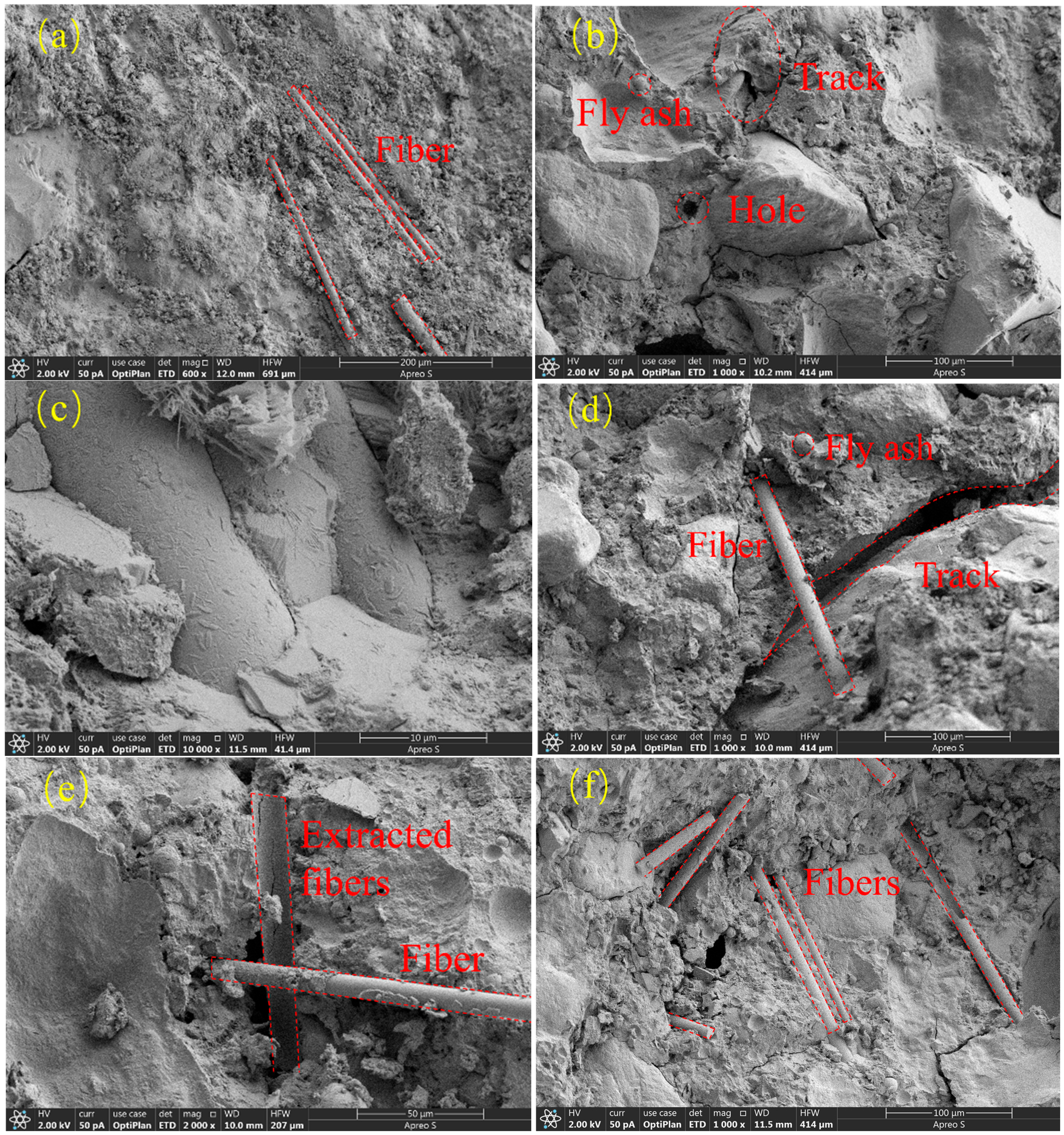

- (1)

- The SEM observations further corroborate the macroscopic findings that basalt fiber (BF) incorporation significantly enhances the mechanical and durability performance of RAC. The hygroscopic nature of both BF and RCA promotes uniform moisture distribution during mixing, thereby facilitating early hydration and refining the pore structure. As shown in Figure 8c, the BF is well bonded with the cementitious matrix, and the interfacial transition zone (ITZ) appears dense and continuous. This microstructural feature aligns with the microscopic results, where the relative dynamic modulus increased by 23.8% and the compressive strength loss decreased by 22.4%, indicating a substantial improvement in matrix compactness.

- (2)

- The incorporation of BF and RCA facilitates a uniform distribution of BFs and promotes the formation of an effective overlapping layer of cement mortar adhered to the RCA surfaces, thereby increasing their roughness. As BFs are flexible fibers, their simultaneous addition to the concrete allows them to be evenly dispersed throughout the matrix, forming a connected BF network that helps bear loads. Consequently, BFRRC exhibits enhanced toughness. Thereby achieving a higher compressive strength retention rate.

- (3)

- As illustrated in Figure 8f, the random distribution of long and short fibers forms a three-dimensional interwoven network that enables multi-scale crack control and stress dispersion at the microscale. Meanwhile, the fiber network increases the tortuosity of chloride ion transport paths, effectively delaying ion migration per unit time. These microstructural observations are consistent with the 16.7% reduction in electric flux measured in the experiments, jointly confirming the beneficial role of hybrid basalt fibers in enhancing both the mechanical integrity and chloride resistance of RAC.

4. Conclusions

- (1)

- Through systematic experimental validation, it was demonstrated that basalt fibers can effectively improve the resistance of recycled aggregate concrete (RAC) to both chloride ingress and freeze–thaw deterioration. The hybrid fiber system with a 0.15% volume fraction exhibited the most balanced performance, achieving superior durability and mechanical stability. This finding provides a reliable design reference for the incorporation of fiber reinforcement in sustainable concrete applications under coupled environmental stresses.

- (2)

- The enhancement mechanism arises primarily from the formation of a multi-scale fiber network that refines the pore structure and densifies the interfacial transition zone (ITZ). The hybrid distribution of long and short fibers increases the tortuosity of chloride diffusion paths and enhances crack resistance across different scales. This mechanism aligns with Fick’s second law, where reduced pore connectivity and increased path complexity effectively decrease the material’s effective diffusion coefficient. Thus, the study offers new insight into the physicochemical coupling between microstructural evolution and macroscopic durability improvement in fiber-reinforced RAC.

- (3)

- The reinforcing effect of basalt fibers exhibits a “first increase, then decrease” trend. When the fiber content exceeds approximately 0.15%, fiber dispersion deteriorates and agglomeration occurs, leading to an increased number of interfacial defects that weaken the densification effect. This threshold behavior reflects the competitive mechanism between matrix densification and fiber-induced porosity. From an engineering perspective, optimizing fiber dispersion and interfacial bonding quality is essential to achieve synergistic improvements in the durability and structural reliability of recycled concrete, thereby providing both theoretical and practical foundations for the design of low-carbon recycled concrete systems.

5. Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hasheminezhad, A.; King, D.; Ceylan, H.; Kim, S. Comparative life cycle assessment of natural and recycled aggregate concrete: A review. Sci. Total Environ. 2024, 950, 175310. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Sun, X.; Wang, F.; Wang, J. Mechanical Properties and Durability of Geopolymer Recycled Aggregate Concrete: A Review. Polymers 2023, 15, 615. [Google Scholar] [CrossRef] [PubMed]

- Tam, V.W.; Gao, X.F.; Tam, C.M.; Ng, K.M. Physio-chemical reactions in recycle aggregate concrete. J. Hazard. Mater. 2009, 163, 823–828. [Google Scholar] [CrossRef]

- Erdem, S.; Blankson, M.A. Environmental performance and mechanical analysis of concrete containing recycled asphalt pavement (RAP) and waste precast concrete as aggregate. J. Hazard. Mater. 2014, 264, 403–410. [Google Scholar] [CrossRef]

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A comprehensive review on recycled aggregate and recycled aggregate concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, C. Experimental study on the influence of mix proportion of high volume building solid waste recycled concrete on strength. Concrete 2024, 11, 129–133. [Google Scholar]

- Li, Z.; Liu, X.; Zhao, C.; Wang, C.; Tian, X. Pore structure and mechanical properties of steel fiber reinforced geopolymer recycled aggregate concrete. Acta Mater. Compos. Sin. 2024, 41, 5516–5526. [Google Scholar]

- Marvila, M.; de Matos, P.; Rodríguez, E.; Monteiro, S.N.; de Azevedo, A.R. Recycled Aggregate: A Viable Solution for Sustainable Concrete Production. Materials 2022, 15, 5276. [Google Scholar] [CrossRef]

- Sim, J.; Park, C. Compressive strength and resistance to chloride ion penetration and carbonation of recycled aggregate concrete with varying amount of fly ash and fine recycled aggregate. Waste Manag. 2011, 31, 2352–2360. [Google Scholar] [CrossRef]

- Bu, C.; Liu, L.; Lu, X. The Durability of Recycled Fine Aggregate Concrete: A Review. Materials 2022, 15, 1110. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Wang, L.; Liu, R.; Yu, J.; Liu, H.; Wu, J. Chloride Penetration of Recycled Fine Aggregate Concrete under Drying-Wetting Cycles. Materials 2023, 16, 1306. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Niu, D.; Su, L. Chloride Diffusion Property of Hybrid Basalt-Polypropylene Fiber-Reinforced Concrete in a Chloride-Sulphate Composite Environment under Drying-Wetting Cycles. Materials 2021, 14, 1138. [Google Scholar] [CrossRef] [PubMed]

- Akbas, M.; Iyisan, R.; Dayioglu, A.Y.; Hatipoglu, M. Stiffness properties of recycled concrete aggregates as unbound base and subbase materials under freeze and thaw cycles. Arab. J. Sci. Eng. 2021, 46, 10569–10584. [Google Scholar] [CrossRef]

- Liang, G.; Yao, W.; Wei, Y. A green ultra-high performance geopolymer concrete containing recycled fine aggregate: Mechanical properties, freeze-thaw resistance and microstructure. Sci. Total Environ. 2023, 895, 165090. [Google Scholar] [CrossRef]

- Li, L.; Kang, K.; Feng, Z.; Xiao, Q.; Xiao, Q. Study on Performance Degradation of Recycled Concrete under Freeze-Thaw and Sulphate Action. J. Xi’an Univ. Archit. Technol. (Nat. Sci. Ed.) 2023, 55, 571–577. [Google Scholar]

- Sun, M.; Xin, D.; Zou, C. Damage evolution and plasticity development of concrete materials subjected to freeze-thaw during the load process. Mech. Mater. 2019, 139, 103192. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, T.; Wang, Y.; Wang, P. Study on Chloride Permeation Resistance and Freeze-Thaw Resistance of Marine Environment Concrete in Cold Regions. Concr. Cem. Prod. 2019, 24–28. [Google Scholar]

- Jean, B.; Liu, H.; Zhu, X.; Wang, X.; Yan, X.; Ma, T. Enhancing the Mechanical and Durability Properties of Fully Recycled Aggregate Concrete Using Carbonated Recycled Fine Aggregates. Materials 2024, 17, 1715. [Google Scholar] [CrossRef]

- Wei, S. Research on the Influence of Mineral Admixtures on the Resistance to Chloride Erosion and Frost Resistance of Recycled Concrete. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2020. [Google Scholar]

- Limbachiya, M.C.; Leelawar, T.; Dhir, R.K. Use of recycled concrete aggregate in high-strength concrete. Mater. Struct. 2000, 33, 257–274. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.; Chan, D. Properties of steam cured recycled aggregate fly ash concrete. In Construction and Demolition Waste, Proceedings of the International Concrete on Sustainable Waste Management and Recycling; Hong Kong Polytechnic University: Hong Kong, China, 2004. [Google Scholar]

- Si, Z.; Tian, S.; Huangfu, B.; Huang, L.; Du, X.; Zhang, F. Effect of basalt–polyvinyl alcohol fibers on the frost resistance of recycled concrete. J. Yangtze River Sci. Res. Inst. 2024, 41, 187–193. [Google Scholar]

- Huang, Y.; Yang, W.; Liu, L.; Zhou, H.; Zhang, X.; Li, C.; Xiong, X. Study on freeze–thaw damage and service life prediction of glass fiber recycled concrete. Build. Struct. 2024, 54, 136–143. [Google Scholar]

- Wei, K.; Li, B.; Sun, Q. Study on basalt fiber improving the chloride ion penetration resistance of recycled concrete. Bull. Silic. 2022, 41, 1656–1662. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard Test Methods for Long-Term Performance and Durability of Normal Concrete; China Architecture & Building Press: Beijing, China, 2009. [Google Scholar]

- Cai, X.; Wu, K.; Huang, W.; Yu, J.; Yu, H. Application of recycled concrete aggregates and crushed bricks on permeable concrete road base. Road Mater. Pavement Des. 2021, 22, 2181–2196. [Google Scholar] [CrossRef]

| Particle Size (mm) | Apparent Density (g·cm−3) | Crushing Index (%) | Water Absorption Rate (%) | Bulk Density (g·cm−3) |

|---|---|---|---|---|

| 5~20 mm | 2.78 | 14 | 13 | 1.5 |

| Fiber Diameter (mm) | Density (kg/m−3) | Elastic Strength (GPa) | Tensile Strength (GPa) | Bonding Temperature (°C) | Thermal Conductivity (W/(m·K) |

|---|---|---|---|---|---|

| 7–15 | 2.63–2.65 | 991–110 | 1800–2200 | 1050 | 0.03–0.038 |

| Test Part Number | Water | Sand | Cement | Fly Ash | Regenerated Aggregate | Natural Aggregate | Basalt Fiber Content | Basalt Fiber Length | Water-Reducing Agent |

|---|---|---|---|---|---|---|---|---|---|

| RAC | 192.0 | 649.0 | 297.5 | 127.5 | 602.5 | 602.5 | 0% | 0 | 1.1 g |

| BR0.1-18 | 192.0 | 649.0 | 297.5 | 127.5 | 602.5 | 602.5 | 0.10% | 18 mm | 1.1 g |

| BR0.1-6 | 192.0 | 649.0 | 297.5 | 127.5 | 602.5 | 602.5 | 0.10% | 6 mm | 1.1 g |

| BR0.1-1:1 | 192.0 | 649.0 | 297.5 | 127.5 | 602.5 | 602.5 | 0.10% | 6 mm + 18 mm | 1.1 g |

| BR0.15-18 | 192.0 | 649.0 | 297.5 | 127.5 | 602.5 | 602.5 | 0.15% | 18 mm | 1.1 g |

| BR0.15-6 | 192.0 | 649.0 | 297.5 | 127.5 | 602.5 | 602.5 | 0.15% | 6 mm | 1.1 g |

| BR0.15-1:1 | 192.0 | 649.0 | 297.5 | 127.5 | 602.5 | 602.5 | 0.15% | 6 mm + 18 mm | 1.1 g |

| BR0.2-18 | 192.0 | 649.0 | 297.5 | 127.5 | 602.5 | 602.5 | 0.2% | 18 mm | 1.1 g |

| BR0.2-6 | 192.0 | 649.0 | 297.5 | 127.5 | 602.5 | 602.5 | 0.2% | 6 mm | 1.1 g |

| BR0.2-1:1 | 192.0 | 649.0 | 297.5 | 127.5 | 602.5 | 602.5 | 0.2% | 6 mm + 18 mm | 1.1 g |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Q.; Ye, Z.; Cai, R.; Li, D. Synergistic Effects of Hybrid Basalt Fibers on the Durability of Recycled Aggregate Concrete Under Freeze–Thaw and Chloride Conditions. Appl. Sci. 2025, 15, 12520. https://doi.org/10.3390/app152312520

Sun Q, Ye Z, Cai R, Li D. Synergistic Effects of Hybrid Basalt Fibers on the Durability of Recycled Aggregate Concrete Under Freeze–Thaw and Chloride Conditions. Applied Sciences. 2025; 15(23):12520. https://doi.org/10.3390/app152312520

Chicago/Turabian StyleSun, Qiao, Zehui Ye, Renjie Cai, and Dongwei Li. 2025. "Synergistic Effects of Hybrid Basalt Fibers on the Durability of Recycled Aggregate Concrete Under Freeze–Thaw and Chloride Conditions" Applied Sciences 15, no. 23: 12520. https://doi.org/10.3390/app152312520

APA StyleSun, Q., Ye, Z., Cai, R., & Li, D. (2025). Synergistic Effects of Hybrid Basalt Fibers on the Durability of Recycled Aggregate Concrete Under Freeze–Thaw and Chloride Conditions. Applied Sciences, 15(23), 12520. https://doi.org/10.3390/app152312520