Implications of Discrete vs. Continuously Adjustable Current for Electrically Heated Catalytic Converters

Abstract

1. Introduction

2. Diesel Internal Combustion Engine Pollutant Assessment—From Regulatory and Testing Requirements to Typical EHC Arrangements

2.1. Pollutant Emissions and Catalytic Converter

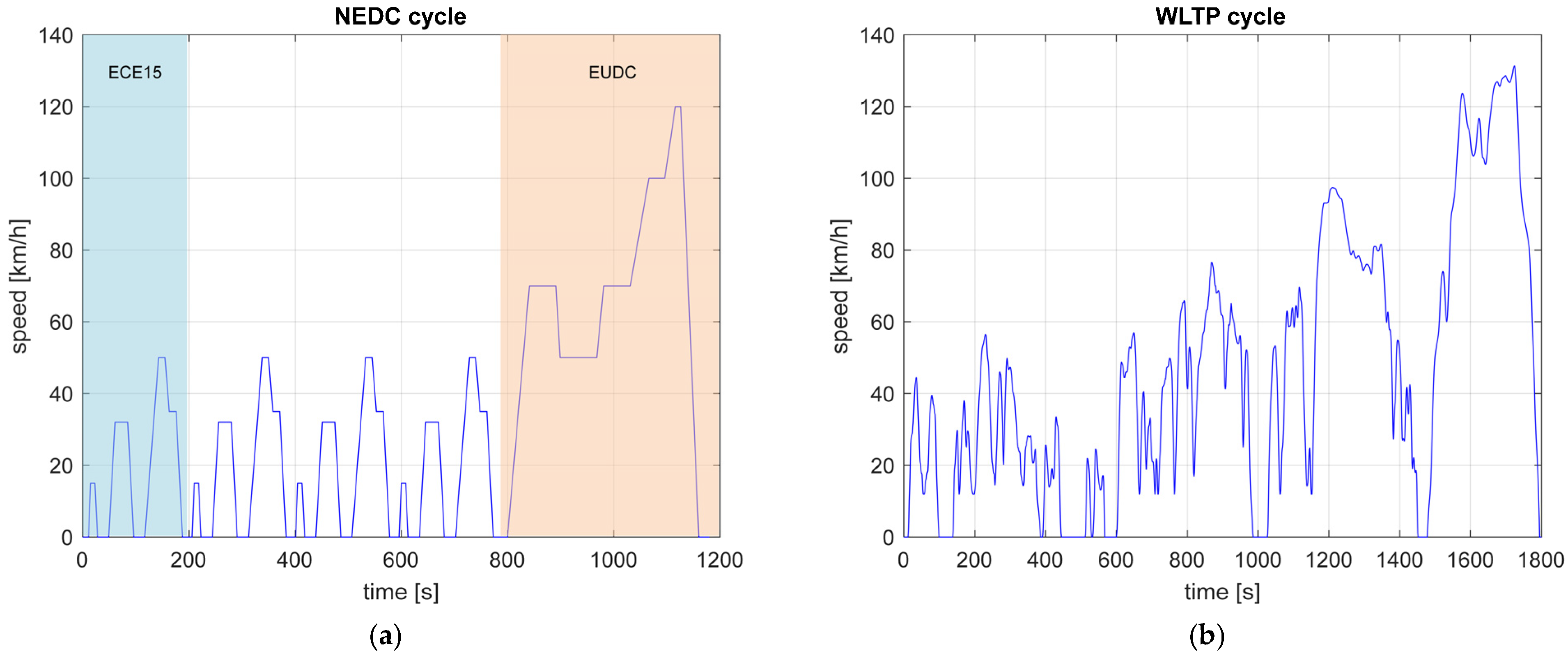

2.2. Pollutant Emissions Test Procedures

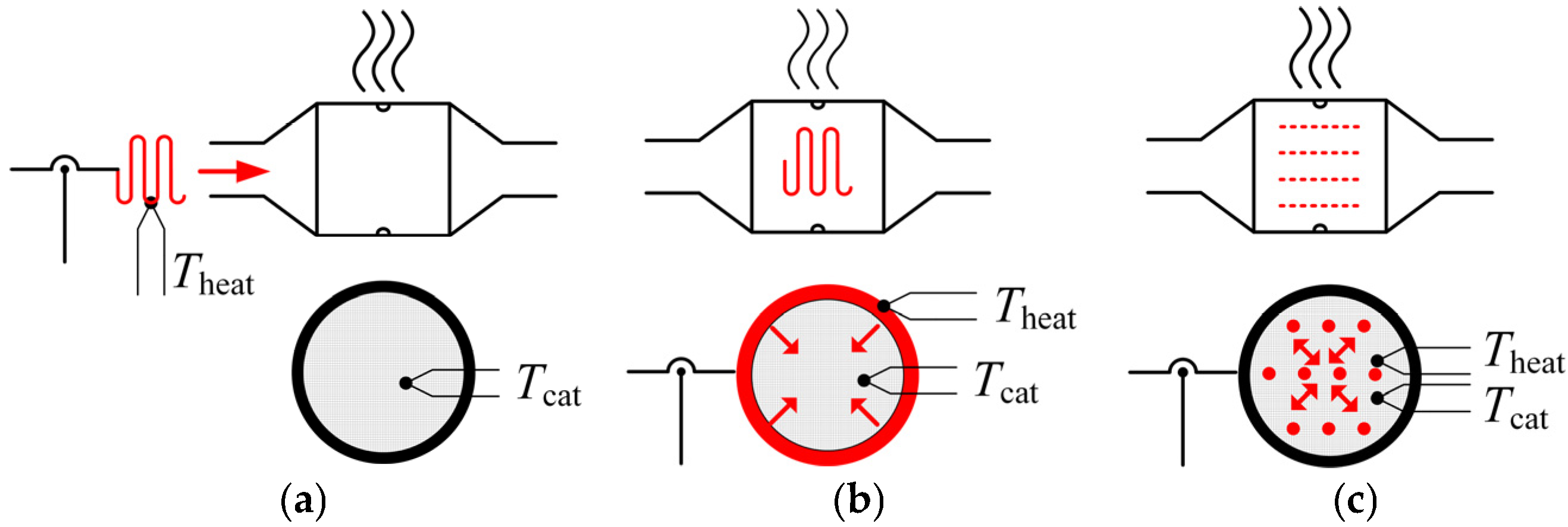

2.3. Typical Layouts/Arrangements of Electrically Heated Catalytic Converters

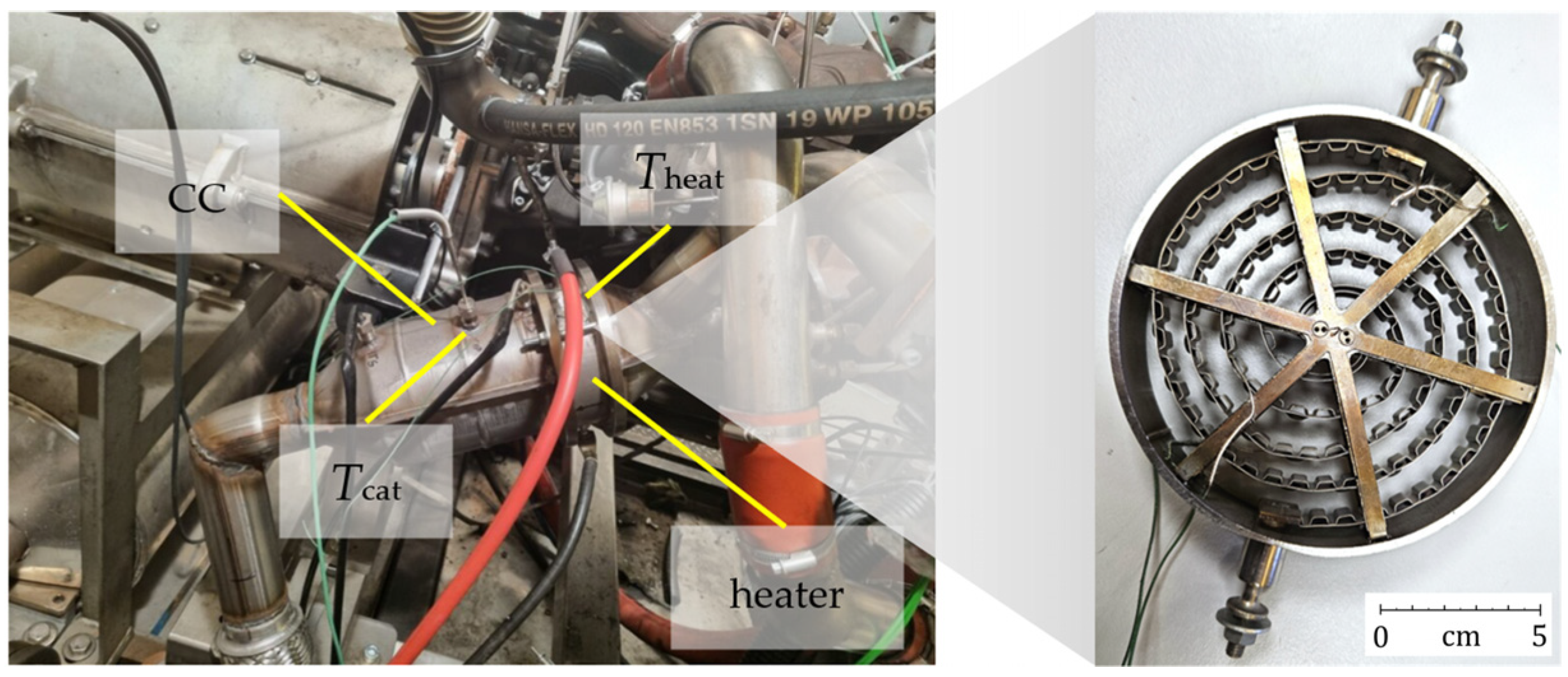

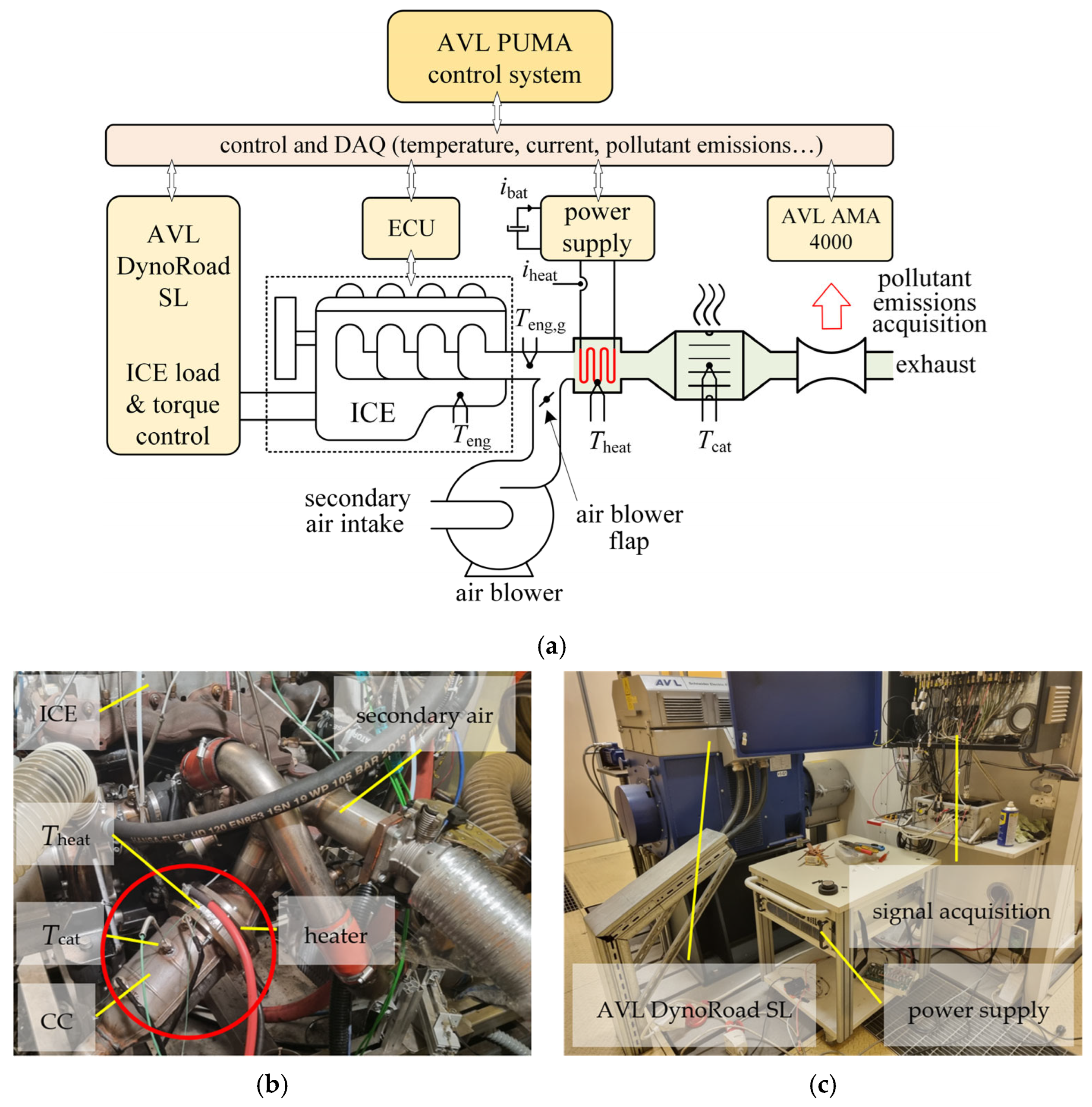

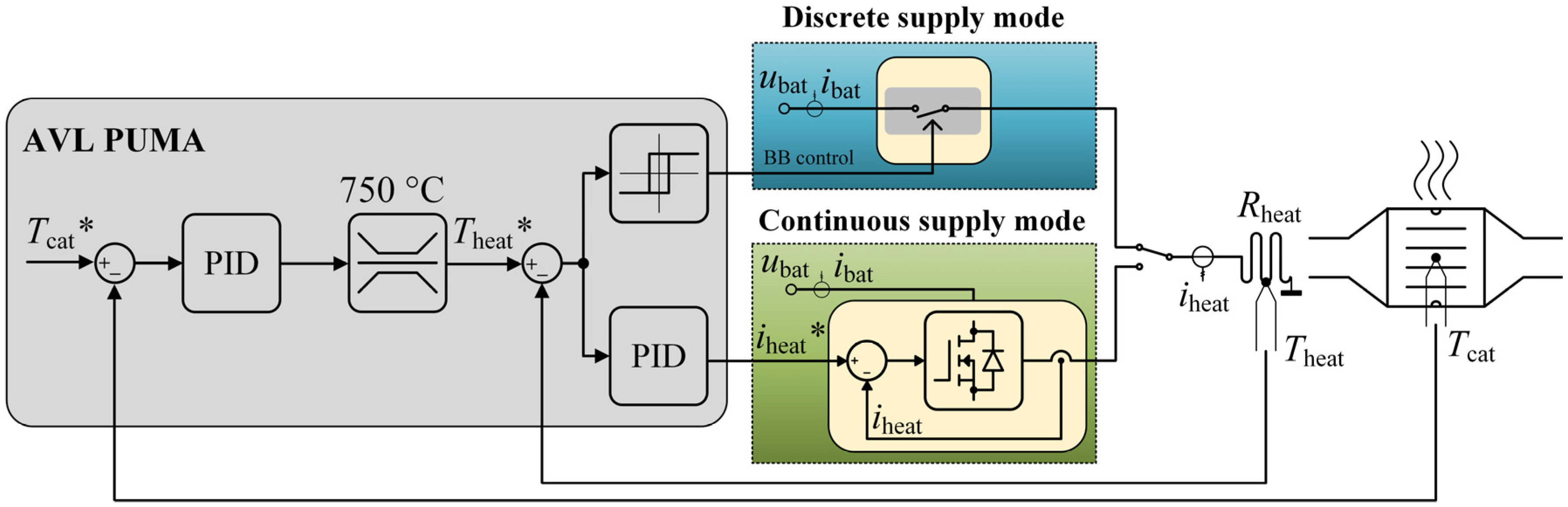

3. Experimental Setup with a Custom Upstream Heater Installed in Front of the CC

3.1. Experimental Results of Pollutant Emissions with OEM-Equipped CC

3.2. Comparative Bench-Test Assessment of Discrete Versus Continuously Adjustable Current for EHC Heating

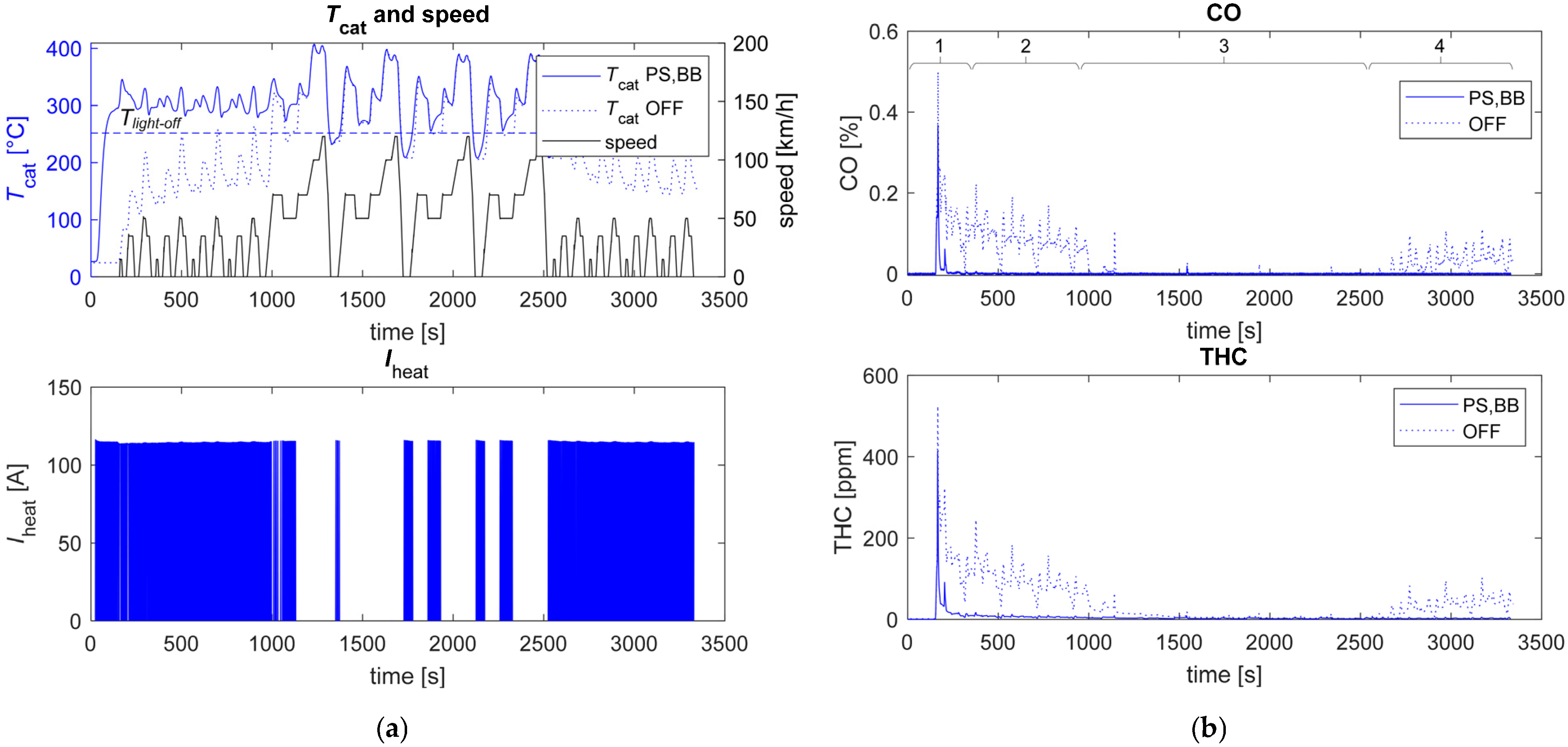

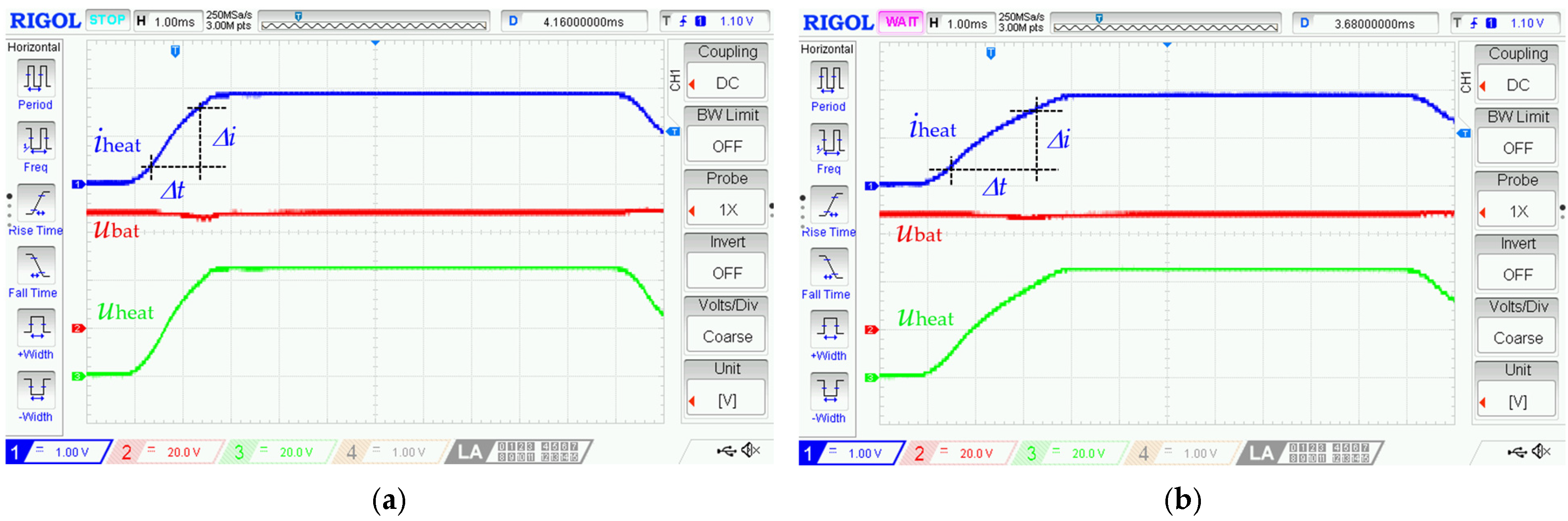

3.2.1. Discrete Supply Mode with Bang-Bang Control

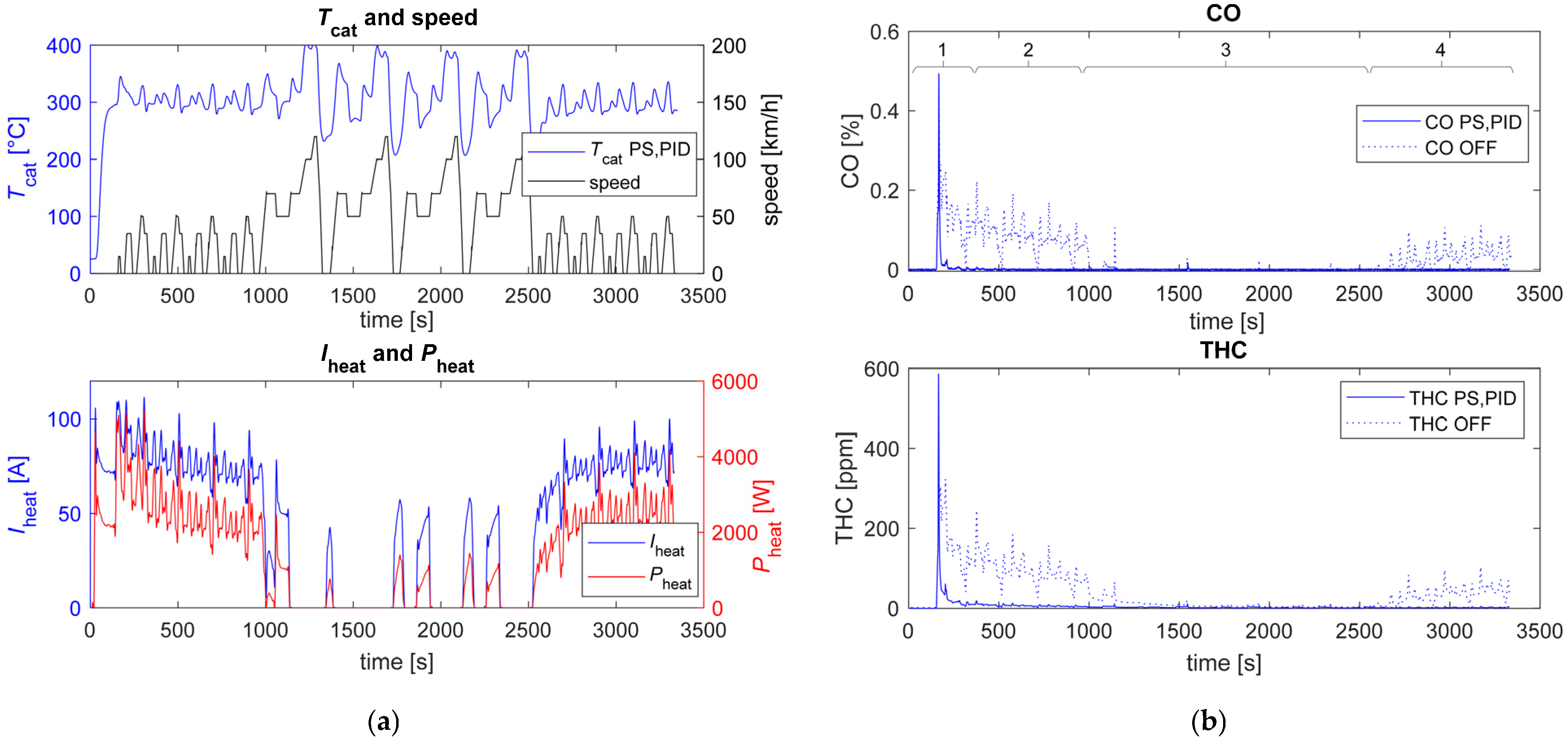

3.2.2. Continuous Supply Mode with PID Control

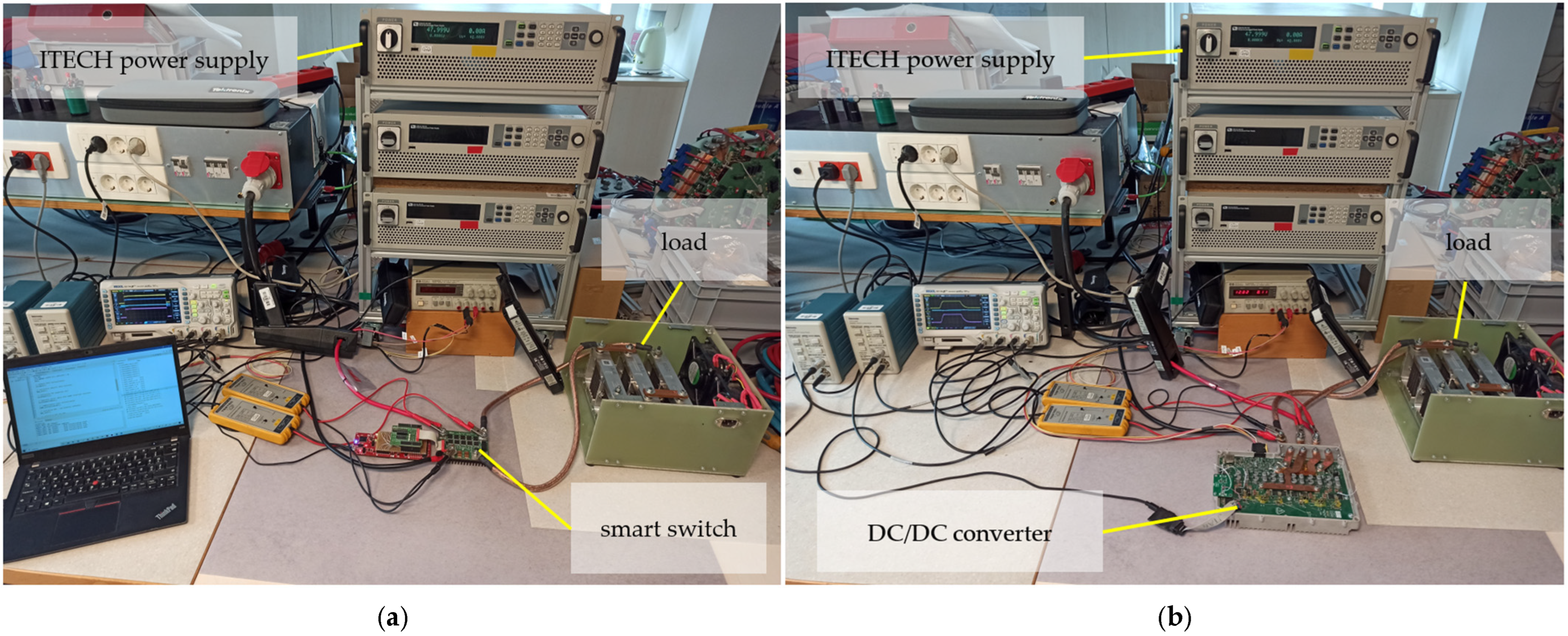

4. Implications of Discrete Versus Continuous Current Demand in Onboard Electrical Distribution Networks

4.1. Background for Control Strategy and Topology Selection

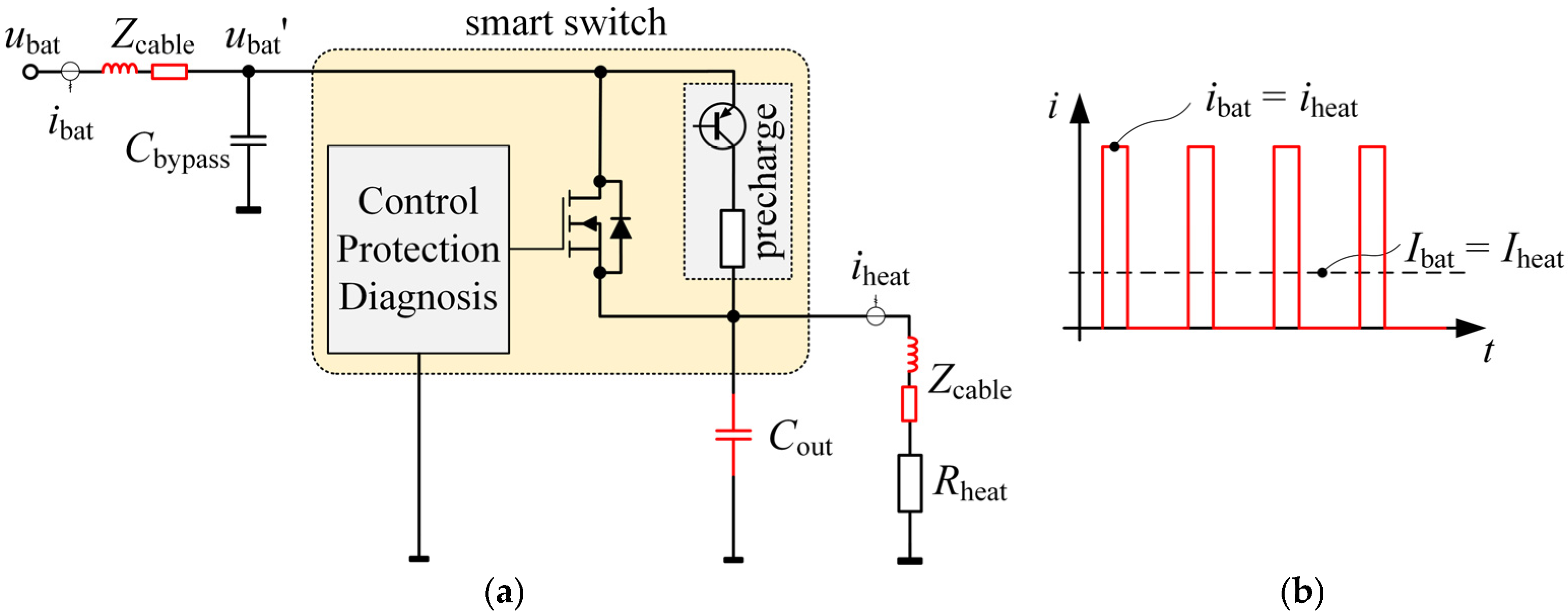

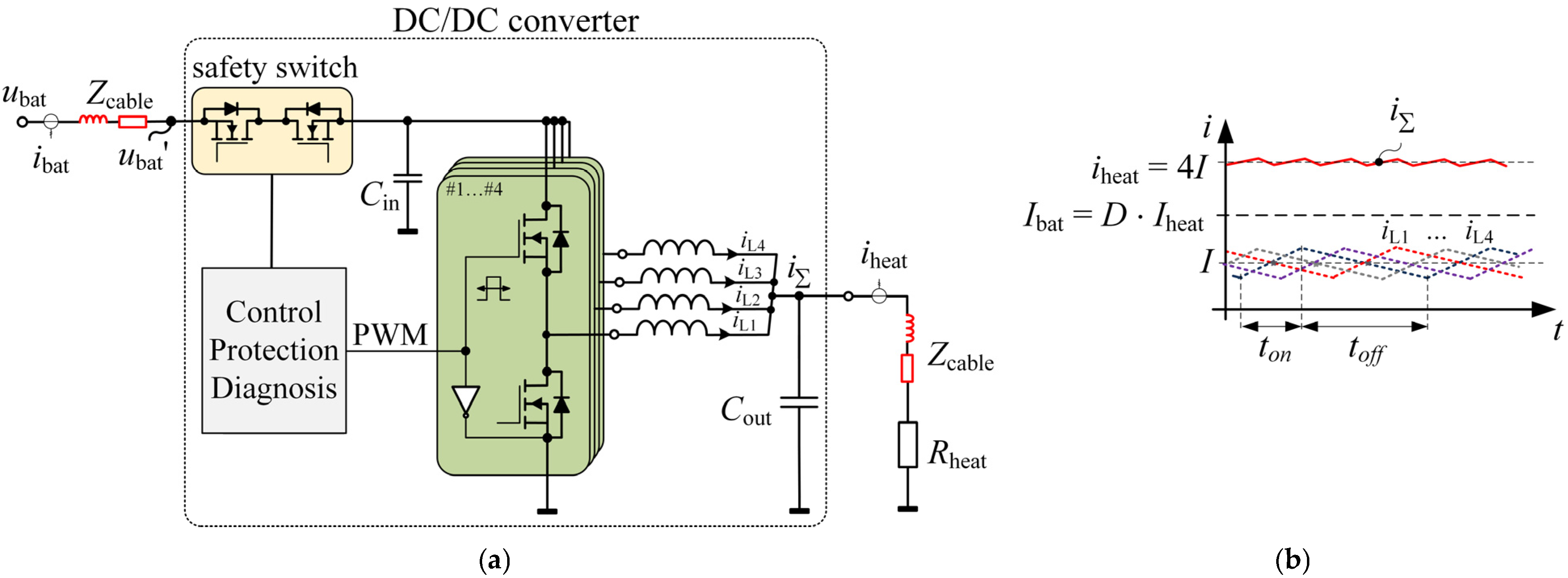

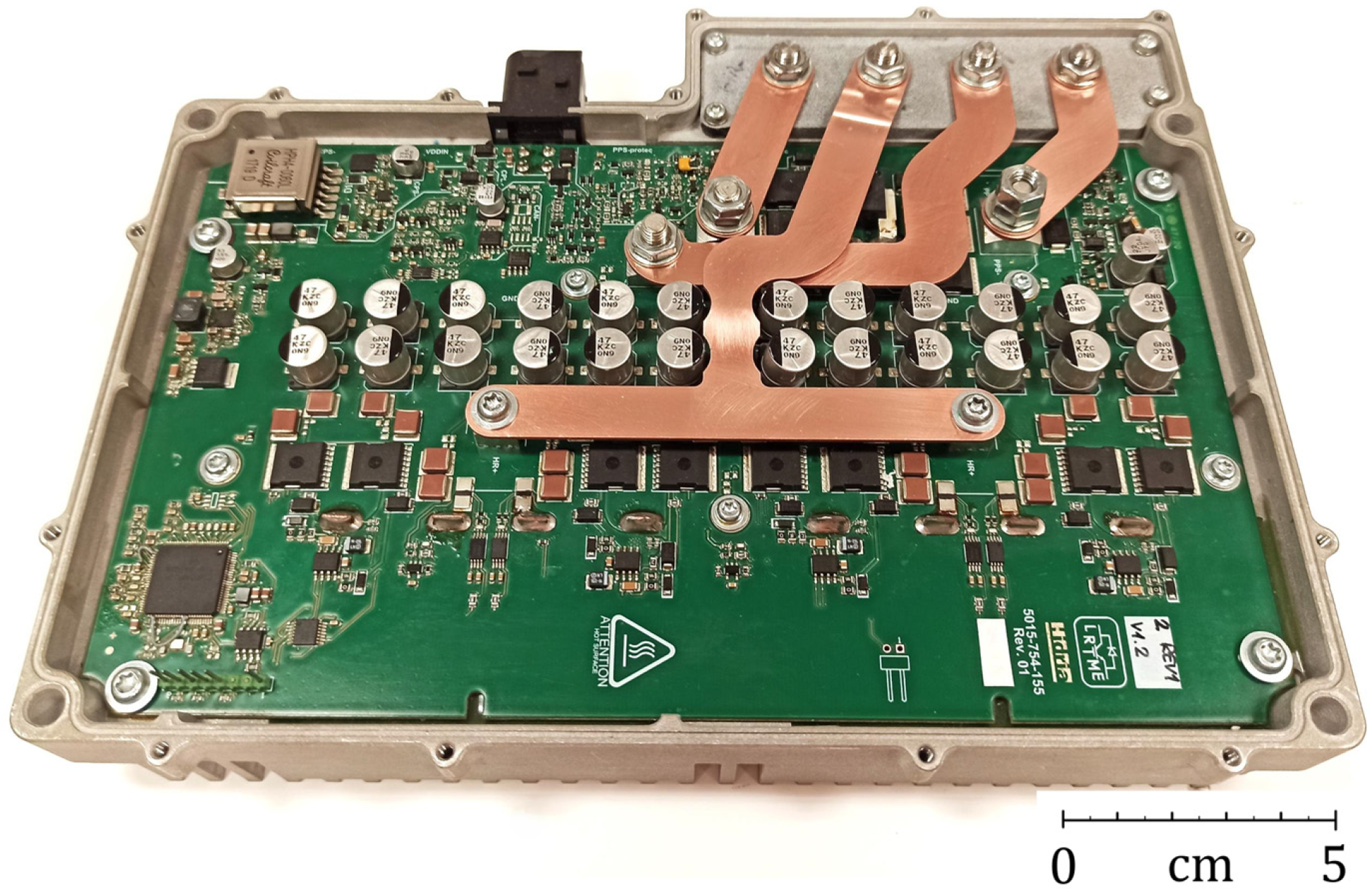

4.2. Custom-Made DC/DC Converter

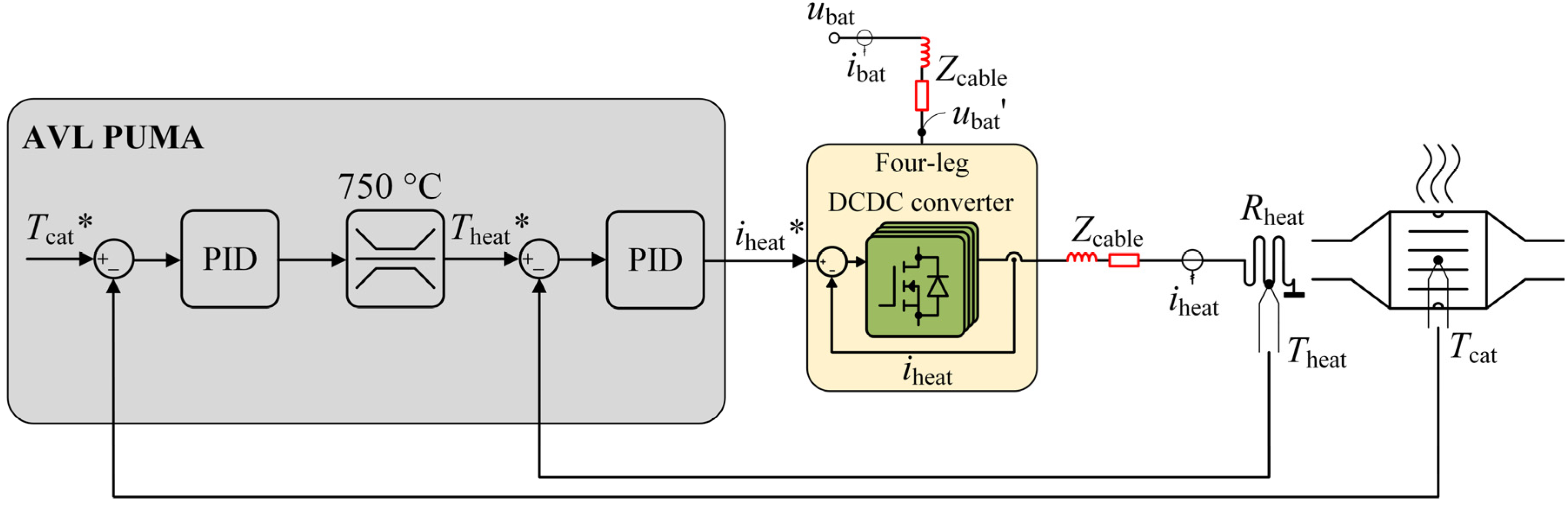

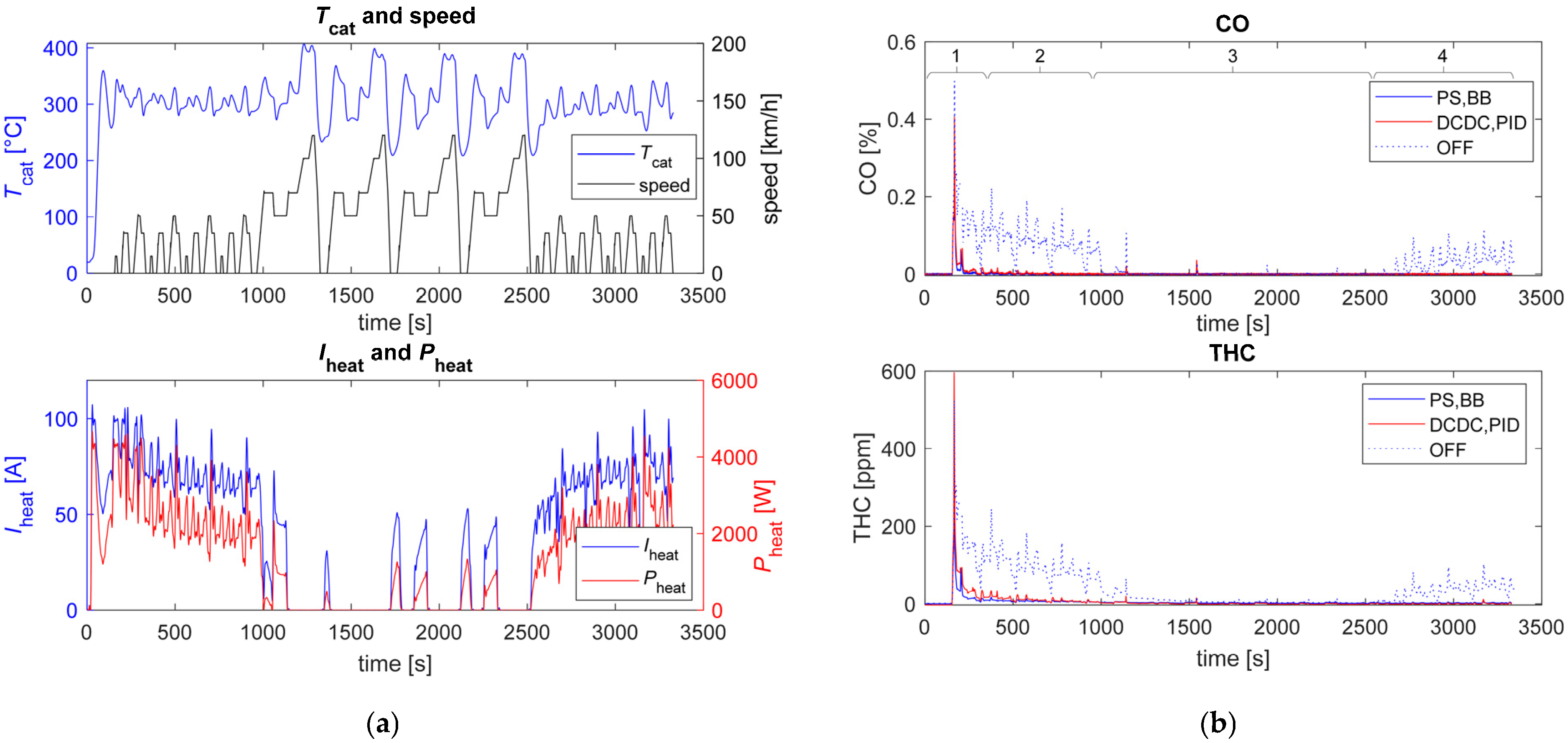

5. Assessment and Analysis of Experimental Results Using a Custom-Made DC/DC Converter with Emphasis on Pollutant Emissions and Electrical Parameters

5.1. Pollutant Emissions

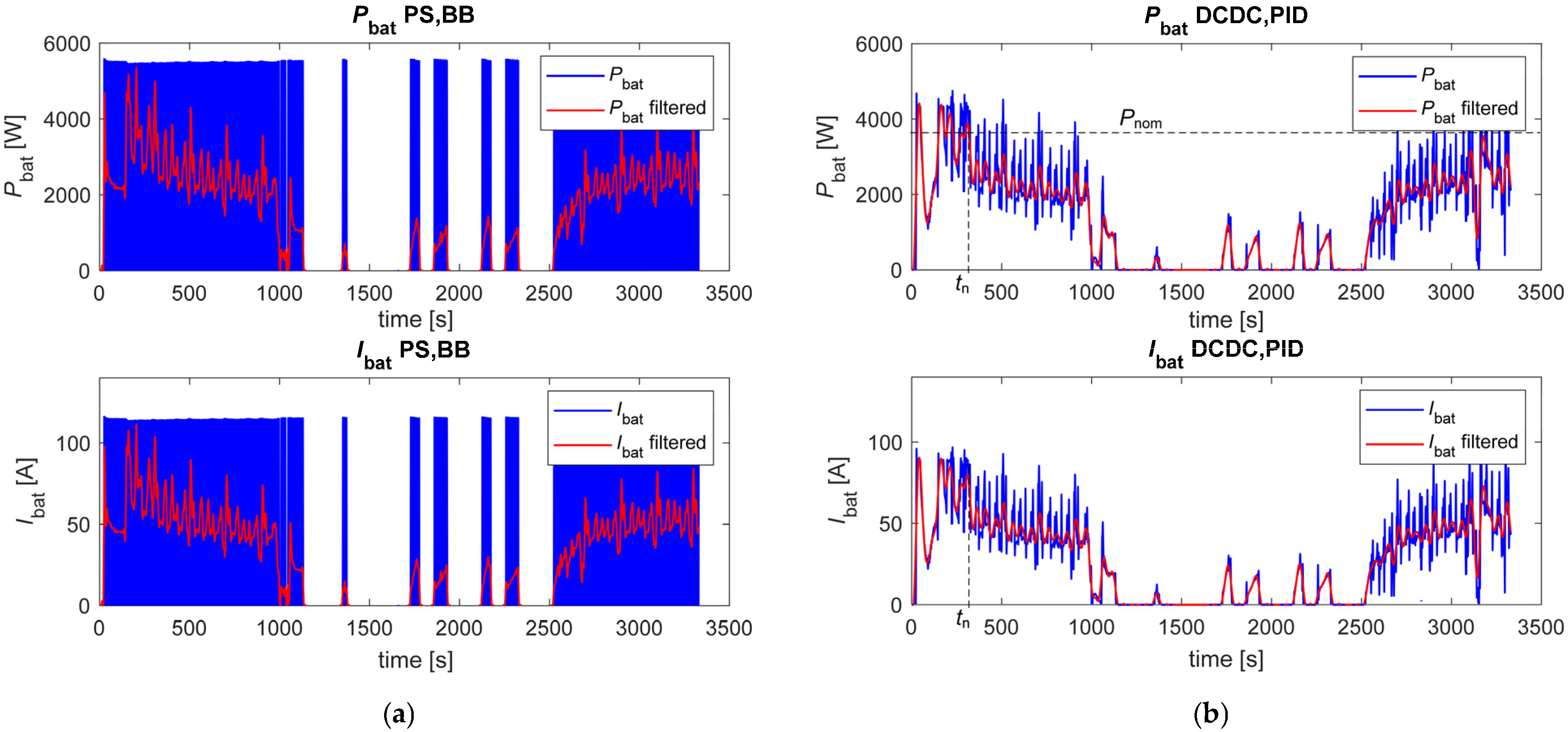

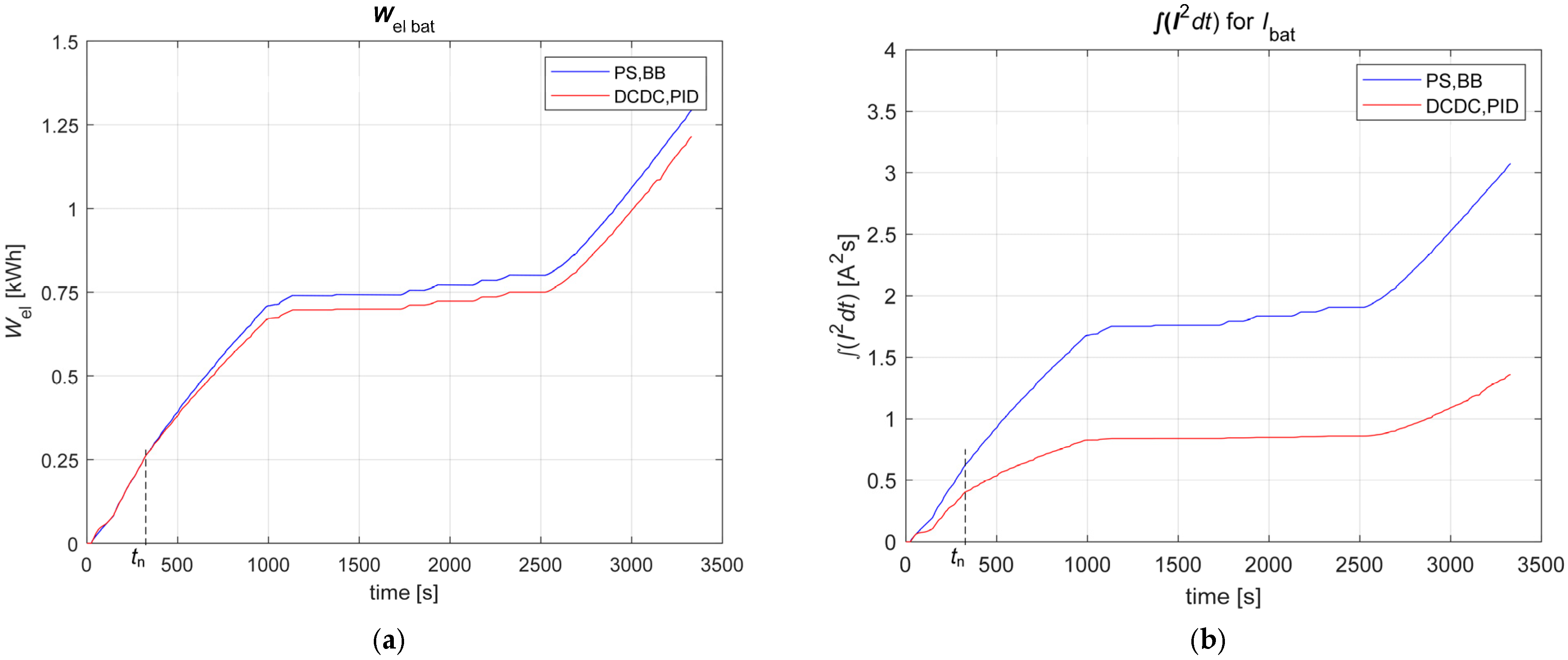

5.2. Battery-Side Power and Current Delivery

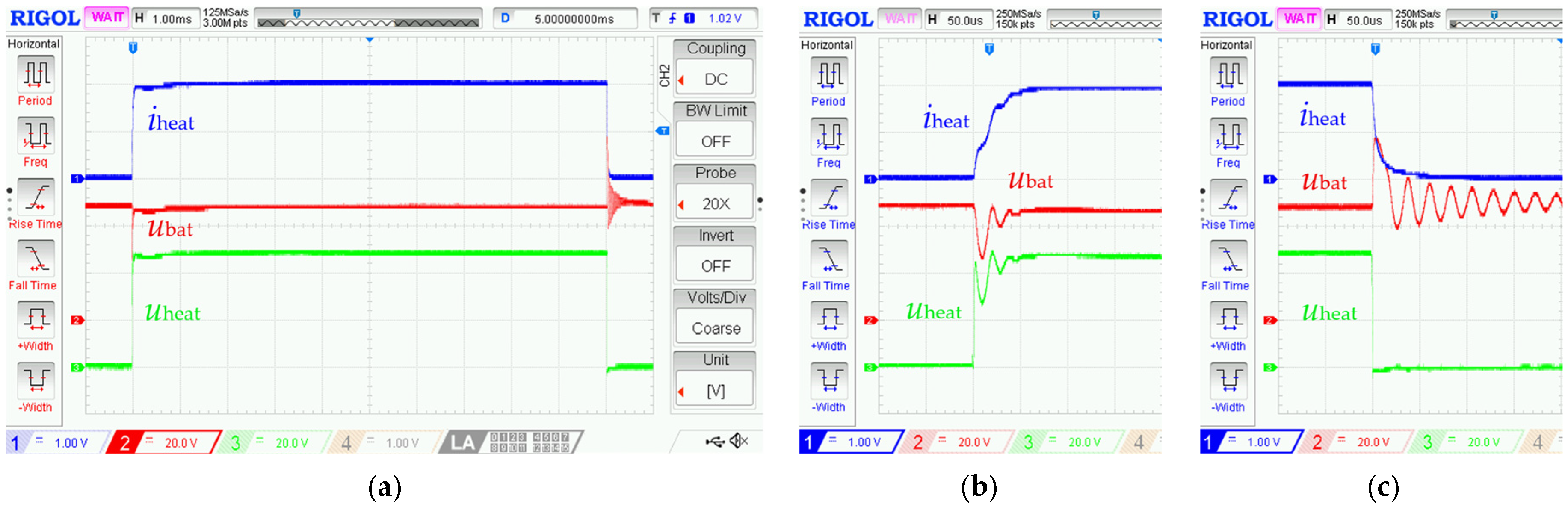

5.3. Onboard Distribution Network Quality Phenomena

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Migration Data Portal. The Bigger Picture. Urbanization and Migration. Available online: https://www.migrationdataportal.org/themes/urbanisierung-und-migration (accessed on 26 October 2025).

- Eurostat. Urban-Rural Europe—Demographic Developments in Cities. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Urban-rural_Europe_-_demographic_developments_in_cities#Context (accessed on 22 October 2025).

- ACEA. New Car Registrations in 2024. Available online: https://www.acea.auto/pc-registrations/new-car-registrations-0-8-in-2024-battery-electric-13-6-market-share/ (accessed on 26 August 2025).

- Giménez-Nadal, J.I.; Molina, J.A.; Velilla, J. Trends in Commuting Time of European Workers: A Cross-Country Analysis. Transp. Policy 2022, 116, 327–342. [Google Scholar] [CrossRef]

- Armoogum, J.; Garcia, C.; Gopalapillai, Y.; Borgato, S.; Fiorello, D.; Maffii, S.; Mars, K.J.; Popovska, T.; Schlemmer, L.; Gayda, S.; et al. Study on New Mobility Patterns in European Cities, Task A: EU Wide Passenger Mobility Survey; IFSTTAR: Champs-sur-Marne, France, 2022; Available online: https://op.europa.eu/en/publication-detail/-/publication/adfc18f1-80e1-11ed-9887-01aa75ed71a1 (accessed on 17 April 2025).

- Li, K.; Xiao, B.; Wang, Y.; Jia, J.; Wu, X. Applications of Electric Heating Technology in Vehicle Exhaust Pollution Control. Processes 2024, 12, 298. [Google Scholar] [CrossRef]

- Dong, H.; Fu, J.; Zhao, Z.; Liu, Q.; Li, Y.; Liu, J. A Comparative Study on the Energy Flow of a Conventional Gasoline-Powered Vehicle and a New Dual Clutch Parallel-Series Plug-in Hybrid Electric Vehicle under NEDC. Energy Convers. Manag. 2020, 218, 113019. [Google Scholar] [CrossRef]

- Hamedi, M.R.; Doustdar, O.; Tsolakis, A.; Hartland, J. Energy-Efficient Heating Strategies of Diesel Oxidation Catalyst for Low Emissions Vehicles. Energy 2021, 230, 120819. [Google Scholar] [CrossRef]

- Benaitier, A.; Krainer, F.; Jakubek, S.; Hametner, C. Optimal Control of Aftertreatment Electric Heaters for Mild Hybrid Vehicles during Cold Start. In Proceedings of the 2022 IEEE Vehicle Power and Propulsion Conference (VPPC), Merced, CA, USA, 1–4 November 2022; pp. 1–6. [Google Scholar]

- Uralde, J.; Barambones, O.; Del Rio, A.; Calvo, I.; Artetxe, E. Rule-Based Operation Mode Control Strategy for the Energy Management of a Fuel Cell Electric Vehicle. Batteries 2024, 10, 214. [Google Scholar] [CrossRef]

- Kozina, A.; Vidović, T.; Radica, G.; Vučetić, A. A New Vehicle-Specific Power Model for the Estimation of Hybrid Vehicle Emissions. Energies 2023, 16, 8094. [Google Scholar] [CrossRef]

- Umezawa, Y.; Seto, H.; Imamura, T.; Namerikawa, T. Reducing NOx Emissions and Optimizing Fuel Economy by Controlling Torque and Catalyst Warm-up in Mild HEVs. In Proceedings of the 2022 13th Asian Control Conference (ASCC), Jeju, Republic of Korea, 4–7 May 2022; pp. 1914–1919. [Google Scholar]

- Gao, J.; Tian, G.; Sorniotti, A. On the Emission Reduction through the Application of an Electrically Heated Catalyst to a Diesel Vehicle. Energy Sci. Eng. 2019, 7, 2383–2397. [Google Scholar] [CrossRef]

- Zhu, T.; Wills, R.G.A.; Lot, R.; Kong, X.; Yan, X. Optimal Sizing and Sensitivity Analysis of a Battery-Supercapacitor Energy Storage System for Electric Vehicles. Energy 2021, 221, 119851. [Google Scholar] [CrossRef]

- Maus, W.; Brück, R.; Konieczny, R.; Scheeder, A. Electrically Heated Catalyst for Thermal Management in Modern Vehicle Applications. MTZ Worldw. 2010, 71, 34–39. [Google Scholar] [CrossRef]

- Gao, J.; Tian, G.; Sorniotti, A.; Karci, A.E.; Di Palo, R. Review of Thermal Management of Catalytic Converters to Decrease Engine Emissions during Cold Start and Warm Up. Appl. Therm. Eng. 2019, 147, 177–187. [Google Scholar] [CrossRef]

- Culbertson, D.; Khair, M.; Zhang, S.; Tan, J.; Spooler, J. The Study of Exhaust Heating to Improve SCR Cold Start Performance. SAE Int. J. Engines 2015, 8, 1187–1195. [Google Scholar] [CrossRef]

- Velmurugan, D.V.; McKelvey, T.; Olsson, J.-O. Data-Driven Near-Optimal On-Line Control for an Electrically Heated Catalyst-Equipped Gasoline Engine. SAE Int. J. Engines 2023, 16, 335–346. [Google Scholar] [CrossRef]

- Fricke, F.; Steinhuber, T.; Grußmann, E.; Rusche, U. Concept Studies for Electrically Heated Catalysts. MTZ Worldw. 2021, 82, 28–33. [Google Scholar] [CrossRef]

- Ning, J.; Yan, F. Temperature Control of Electrically Heated Catalyst for Cold-Start Emission Improvement. IFAC-PapersOnLine 2016, 49, 14–19. [Google Scholar] [CrossRef]

- Robles-Lorite, L.; Dorado-Vicente, R.; Torres-Jiménez, E.; Bombek, G.; Lešnik, L. Recent Advances in the Development of Automotive Catalytic Converters: A Systematic Review. Energies 2023, 16, 6425. [Google Scholar] [CrossRef]

- Getsoian, A.B.; Theis, J.R.; Lambert, C.K. Sensitivity of Three-Way Catalyst Light-Off Temperature to Air-Fuel Ratio. Emiss. Control Sci. Technol. 2018, 4, 136–142. [Google Scholar] [CrossRef]

- Mahadeven, G.; Sendilvelan, S. Temperature Analysis of Dynamic Catalytic Convertor System with Pre-Catalyst in a Multi Cylinder Spark Ignition Engine to Reduce Light-off Time. Int. J. Heat Technol. 2017, 35, 97–102. [Google Scholar] [CrossRef]

- Kritsanaviparkporn, E.; Baena-Moreno, F.M.; Reina, T.R. Catalytic Converters for Vehicle Exhaust: Fundamental Aspects and Technology Overview for Newcomers to the Field. Chemistry 2021, 3, 630–646. [Google Scholar] [CrossRef]

- Mahadevan, G.; Subramanian, S. Experimental Investigation of Cold Start Emission Using Dynamic Catalytic Converter with Pre-Catalyst and Hot Air Injector on a Multi Cylinder Spark Ignition Engine; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Yang, L.; Franco, V.; Campestrini, A.; German, J.; Mock, P. NOx Control Technologies for Euro 6 Diesel Passenger Cars: Market Penetration and Experimental Performance Assessment; White paper; International Council on Clean Transportation: Brussels, Belgium, 20 September 2015. [Google Scholar]

- Hanel, F.-J.; Otto, E.; Brück, R. Electrically Heated Catalytic Converter (EHC) in the BMW ALPINA B12 5.7 Switch-Tronic. SAE Trans. 1996, 105, 228–236. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, J.; Li, J.; Cao, C.; Wang, S.; Lv, J.; Zheng, W.; Tan, D. The Development of Diesel Oxidation Catalysts and the Effect of Sulfur Dioxide on Catalysts of Metal-Based Diesel Oxidation Catalysts: A Review. Fuel Process. Technol. 2022, 233, 107317. [Google Scholar] [CrossRef]

- Tong, H.Y.; Hung, W.T. A Framework for Developing Driving Cycles with On-Road Driving Data. Transp. Rev. 2010, 30, 589–615. [Google Scholar] [CrossRef]

- Wang, Y.; Hao, C.; Ge, Y.; Hao, L.; Tan, J.; Wang, X.; Zhang, P.; Wang, Y.; Tian, W.; Lin, Z.; et al. Fuel Consumption and Emission Performance from Light-Duty Conventional/Hybrid-Electric Vehicles over Different Cycles and Real Driving Tests. Fuel 2020, 278, 118340. [Google Scholar] [CrossRef]

- Chen, H.; Song, Z.; Zhao, X.; Zhang, T.; Pei, P.; Liang, C. A Review of Durability Test Protocols of the Proton Exchange Membrane Fuel Cells for Vehicle. Appl. Energy 2018, 224, 289–299. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, S.; Zheng, T. The Influence of NEDC and CATC Type Approval Test Procedure on the E-Range of Battery Electric Vehicles. Energy Rep. 2022, 8, 36–42. [Google Scholar] [CrossRef]

- Achour, H.; Olabi, A.G. Driving Cycle Developments and Their Impacts on Energy Consumption of Transportation. J. Clean. Prod. 2016, 112, 1778–1788. [Google Scholar] [CrossRef]

- André, M.; Joumard, R.; Vidon, R.; Tassel, P.; Perret, P. Real-World European Driving Cycles, for Measuring Pollutant Emissions from High- and Low-Powered Cars. Atmos. Environ. 2006, 40, 5944–5953. [Google Scholar] [CrossRef]

- UNECE.org. New European Driving Cycle (NEDC Driving Cycle Data). Available online: https://unece.org/fileadmin/DAM/trans/main/wp29/wp29regs/2015/R101r3e.pdf (accessed on 17 August 2025).

- UNECE.org. Worldwide Harmonised Light Vehicles Test Procedure (WLTP Driving Cycle Data). Available online: http://www.unece.org/fileadmin/DAM/trans/doc/2012/wp29grpe/WLTP-DHC-12-07e.xls (accessed on 17 August 2025).

- Pavlovic, J.; Marotta, A.; Ciuffo, B. CO2 Emissions and Energy Demands of Vehicles Tested under the NEDC and the New WLTP Type Approval Test Procedures. Appl. Energy 2016, 177, 661–670. [Google Scholar] [CrossRef]

- Dimaratos, A.; Tsokolis, D.; Fontaras, G.; Tsiakmakis, S.; Ciuffo, B.; Samaras, Z. Comparative Evaluation of the Effect of Various Technologies on Light-Duty Vehicle CO2 Emissions over NEDC and WLTP. Transp. Res. Procedia 2016, 14, 3169–3178. [Google Scholar] [CrossRef]

- Gong, M.; Chen, J.; Chen, J.; Zhao, X. Study on Discharge Characteristic Performance of New Energy Electric Vehicle Batteries in Teaching Experiments of Safety Simulation under Different Operating Conditions. Energies 2024, 17, 2845. [Google Scholar] [CrossRef]

- Jaworski, A.; Kuszewski, H.; Balawender, K.; Woś, P.; Lew, K.; Jaremcio, M. Assessment of CH4 Emissions in a Compressed Natural Gas-Adapted Engine in the Context of Changes in the Equivalence Ratio. Energies 2024, 17, 2095. [Google Scholar] [CrossRef]

- Serrano, L.; Santana, B.; Pires, N.; Correia, C. Performance, Emissions, and Efficiency of Biodiesel versus Hydrotreated Vegetable Oils (HVO), Considering Different Driving Cycles Sensitivity Analysis (NEDC and WLTP). Fuels 2021, 2, 448–470. [Google Scholar] [CrossRef]

- García, A.; Monsalve-Serrano, J.; Lago Sari, R.; Martinez-Boggio, S. Energy Assessment of an Electrically Heated Catalyst in a Hybrid RCCI Truck. Energy 2022, 238, 121681. [Google Scholar] [CrossRef]

- Zagar, U. Heating Device. 2024. Available online: https://data.epo.org/publication-server/rest/v1.2/patents/EP4455463NWA1/document.html (accessed on 17 April 2025).

- Ursic, P.; Kunilo, D. Exhaust Gas Purification Device And Method For Manufacturing The Same. 2022. Available online: https://data.epo.org/publication-server/rest/v1.0/publication-dates/20210210/patents/EP3772575NWA1/document.pdf (accessed on 17 April 2025).

- Crawford, R.; Douglas, J. Induction Heating Apparatus and Methods. 2018. Available online: https://patents.justia.com/patent/20180185789 (accessed on 17 April 2025).

- Deutschmann, B.; Winkler, G.; Kastner, P. Impact of Electromagnetic Interference on the Functional Safety of Smart Power Devices for Automotive Applications. e & i Elektrotech. Inf. 2018, 135, 352–359. [Google Scholar] [CrossRef]

- Bala, D.; Ulbing, A.; Pathak, S. Advantages of System Level Testing and Modelling for Automotive Smart Power Switches. In Proceedings of the 2023 International Conference on Electrical Drives and Power Electronics (EDPE), The High Tatras, Slovakia, 25–27 September 2023; pp. 1–7. [Google Scholar]

- Kozak, J.P.; Zhang, R.; Porter, M.; Song, Q.; Liu, J.; Wang, B.; Wang, R.; Saito, W.; Zhang, Y. Stability, Reliability, and Robustness of GaN Power Devices: A Review. IEEE Trans. Power Electron. 2023, 38, 8442–8471. [Google Scholar] [CrossRef]

- Ngwashi, D.K.; Phung, L.V. Recent Review on Failures in Silicon Carbide Power MOSFETs. Microelectron. Reliab. 2021, 123, 114169. [Google Scholar] [CrossRef]

- Wei, J.; Wei, Z.; Fu, H.; Cao, J.; Wu, T.; Sun, J.; Zhu, X.; Li, S.; Zhang, L.; Liu, S.; et al. Review on the Reliability Mechanisms of SiC Power MOSFETs: A Comparison Between Planar-Gate and Trench-Gate Structures. IEEE Trans. Power Electron. 2023, 38, 8990–9005. [Google Scholar] [CrossRef]

- Hosseinabadi, F.; Chakraborty, S.; Bhoi, S.K.; Prochart, G.; Hrvanovic, D.; Hegazy, O. A Comprehensive Overview of Reliability Assessment Strategies and Testing of Power Electronics Converters. IEEE Open J. Power Electron. 2024, 5, 473–512. [Google Scholar] [CrossRef]

- Kotb, R.; Chakraborty, S.; Tran, D.-D.; Abramushkina, E.; El Baghdadi, M.; Hegazy, O. Power Electronics Converters for Electric Vehicle Auxiliaries: State of the Art and Future Trends. Energies 2023, 16, 1753. [Google Scholar] [CrossRef]

- Duan, M.; Sun, D.; Duan, J.; Sun, L.; Liu, Y. Interleaved Modulation Scheme With Optimized Phase Shifting for Double-Switch Buck-Boost Converter. IEEE Access 2021, 9, 55422–55435. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, G.; Yu, S.S. Review of Control Techniques for Interleaved Buck Converters: Control Strategies, Efficiency Optimization and Phase Shedding. Chin. J. Electr. Eng. 2025, 11, 40–58. [Google Scholar] [CrossRef]

- Infieneon. 48 V Battery Switch Reference Design. Available online: https://www.infineon.com/gated/infineon-infineon-r-48v-batt-switch10-ug-2021-20-en-usermanual-en_9c607b40-33d8-45e9-b870-03ec73b42fc2 (accessed on 9 April 2025).

- Kumar, R.R.; Bharatiraja, C.; Udhayakumar, K.; Devakirubakaran, S.; Sekar, K.S.; Mihet-Popa, L. Advances in Batteries, Battery Modeling, Battery Management System, Battery Thermal Management, SOC, SOH, and Charge/Discharge Characteristics in EV Applications. IEEE Access 2023, 11, 105761–105809. [Google Scholar] [CrossRef]

- Zhu, T.; Tomlin, R.; Garcia, C.; Rawat, S.; Holland, T.; Offer, G.; Marinescu, M. Lithium-Ion Battery Model Parametrisation: BatPar an All-in-One Toolkit for Equivalent Circuit Models. J. Energy Storage 2024, 92, 112220. [Google Scholar] [CrossRef]

- Lucaferri, V.; Quercio, M.; Laudani, A.; Riganti Fulginei, F. A Review on Battery Model-Based and Data-Driven Methods for Battery Management Systems. Energies 2023, 16, 7807. [Google Scholar] [CrossRef]

- Tomasov, M.; Kajanova, M.; Bracinik, P.; Motyka, D. Overview of Battery Models for Sustainable Power and Transport Applications. Transp. Res. Procedia 2019, 40, 548–555. [Google Scholar] [CrossRef]

- Lavrič, H.; Zajec, P.; Drobnič, K.; Rihar, A.; Ambrožič, V.; Vončina, D.; Nemec, M. Challenges for Large-Scale Deployment of WBG in Power Electronics. Inf. MIDEM 2025, 55, 3–23. [Google Scholar] [CrossRef]

- Abart, C.; Berberich, K.; Hegazy, O.; Abdel-Monem, M.; Vanegas, O.; Lis, A. Wide Bandgap Semiconductors Enabling Highly Efficient Electrified Vehicles. Transp. Res. Procedia 2023, 72, 17–23. [Google Scholar] [CrossRef]

- Subhashini, T.; Kavitha, M.; Manikandan, T. Energy Efficient Wide Bandgap Semiconductor SiC Based Electric Vehicle and Their Applications. Z. Wirtsch. Fabr. 2025, 120, 626–632. [Google Scholar] [CrossRef]

- Abualnaeem, M.M.; Zulkifli, S.A.B.M.; Bin Yahaya, N.Z.; Soomro, H.A. Comparison of Power Loss in SiC-MOSFET and Si-IGBT Traction Inverter with Variable Switching Frequency for Electric Vehicle Application. In Proceedings of the 2024 IEEE Symposium on Industrial Electronics & Applications (ISIEA), Kuala Lumpur, Malaysia, 6–7 July 2024; IEEE: Kuala Lumpur, Malaysia, 2024; pp. 1–6. [Google Scholar]

| Intervals | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 (From 0 s to 340 s) | 2 (From 340 s to 950 s) | 3 (From 950 s to 2530 s) | 4 (From 2530 s to 3350 s) | ||||||

| Pollutant | Control | Avg [ppm] | Red. [%] | Avg [ppm] | Red. [%] | Avg [ppm] | Red. [%] | Avg [ppm] | Red. [%] |

| CO | OFF | 1424.18 | / | 833.25 | / | 17.69 | / | 280.18 | / |

| PS,BB | 199.05 | 86.0 | 3.44 | 99.6 | 1.03 | 94.2 | 0.85 | 99.7 | |

| PS,PID | 224.63 | 84.2 | 2.98 | 99.6 | 0.61 | 96.5 | 1.68 | 99.4 | |

| THC | OFF | 165.17 | / | 94.46 | / | 9.62 | / | 32.25 | / |

| PS,BB | 32.37 | 80.4 | 6.94 | 92.7 | 2.85 | 70.4 | 2.51 | 92.2 | |

| PS,PID | 36.31 | 78.0 | 6.54 | 93.1 | 2.03 | 78.9 | 1.60 | 95.0 | |

| Parameters | Bang-Bang Control with Smart Switch | PID Control with DC/DC Converter |

|---|---|---|

| output power quality | low—larger ripple | high—small voltage ripple with no steady-state error |

| steady-state error | nonzero | (practically) zero |

| current (di/dt) and voltage (dv/dt) transients | high—large voltage and current stress | lower—smoothed by inductor and capacitor filtering |

| EMI/conducted noise | low | moderate-high—noise concentrated at switching frequency and harmonics |

| converter cost | low—few components (smart switch, capacitors, resistors) | higher—switches, capacitors, inductors, etc. |

| converter weight and PCB area | low | high |

| control algorithm complexity | low | high—PID tuning, stability margins |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petkovšek, M.; Zajec, P.; Nemec, M.; Rihar, A.; Vončina, D.; Ambrožič, V.; Golob, J.; Nedeljković, D. Implications of Discrete vs. Continuously Adjustable Current for Electrically Heated Catalytic Converters. Appl. Sci. 2025, 15, 12483. https://doi.org/10.3390/app152312483

Petkovšek M, Zajec P, Nemec M, Rihar A, Vončina D, Ambrožič V, Golob J, Nedeljković D. Implications of Discrete vs. Continuously Adjustable Current for Electrically Heated Catalytic Converters. Applied Sciences. 2025; 15(23):12483. https://doi.org/10.3390/app152312483

Chicago/Turabian StylePetkovšek, Marko, Peter Zajec, Mitja Nemec, Andraž Rihar, Danjel Vončina, Vanja Ambrožič, Jure Golob, and David Nedeljković. 2025. "Implications of Discrete vs. Continuously Adjustable Current for Electrically Heated Catalytic Converters" Applied Sciences 15, no. 23: 12483. https://doi.org/10.3390/app152312483

APA StylePetkovšek, M., Zajec, P., Nemec, M., Rihar, A., Vončina, D., Ambrožič, V., Golob, J., & Nedeljković, D. (2025). Implications of Discrete vs. Continuously Adjustable Current for Electrically Heated Catalytic Converters. Applied Sciences, 15(23), 12483. https://doi.org/10.3390/app152312483