Railway Track Structural Health Monitoring: Identifying Emerging Trends and Research Agendas Using Bibliometric and Topic Modeling

Abstract

1. Introduction

2. Methodology

2.1. Data Collection Following the PRISMA Protocol

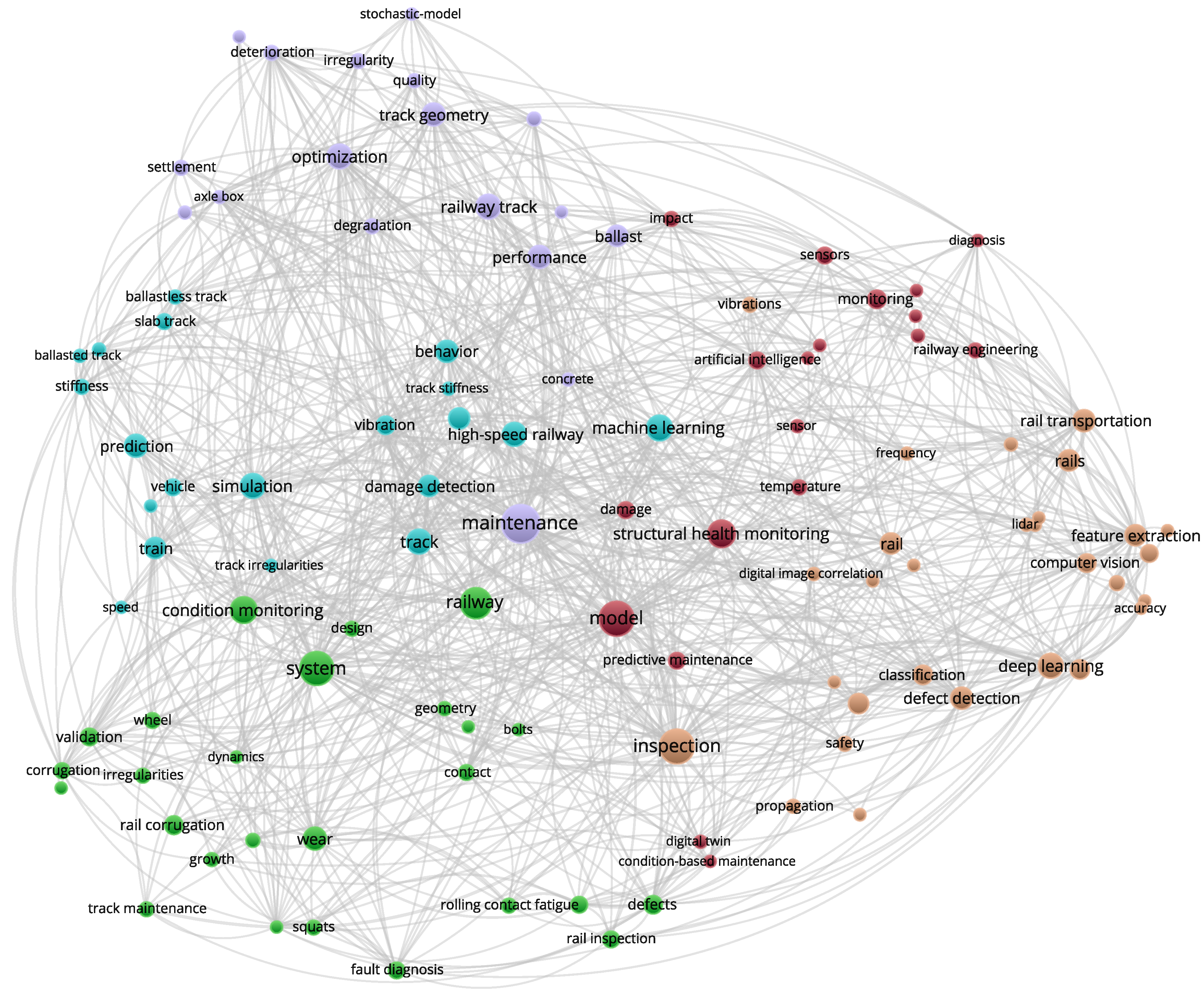

2.2. Bibliometric Analysis Using the VOSviewer Software

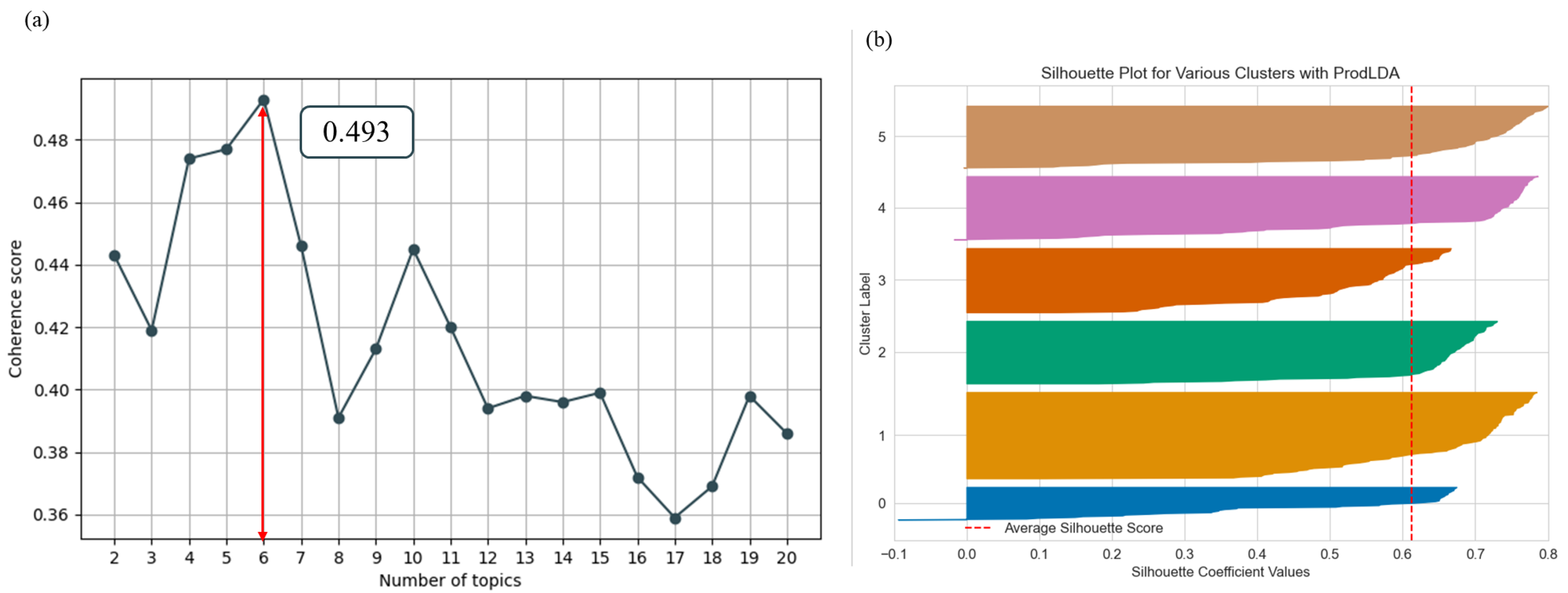

2.3. Topic Modeling Using the PRODLDA Model

3. Bibliometric Analysis

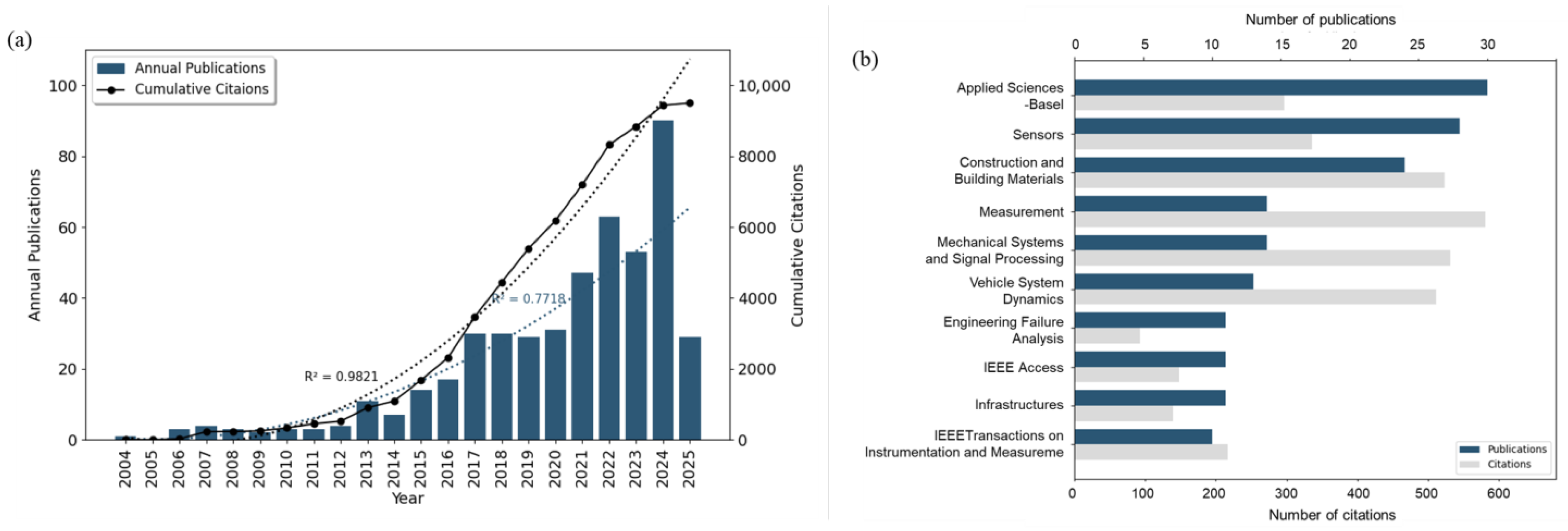

3.1. Publication Trend

3.1.1. Annual Publications, Citations, and Leading Journals

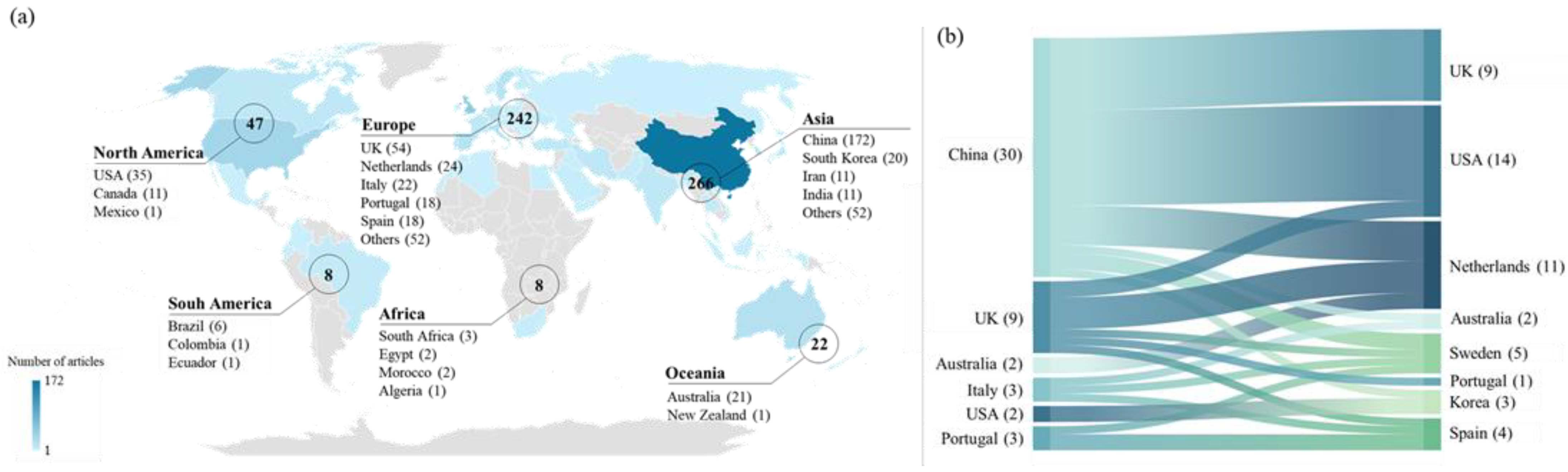

3.1.2. Countries’ Collaboration Networks

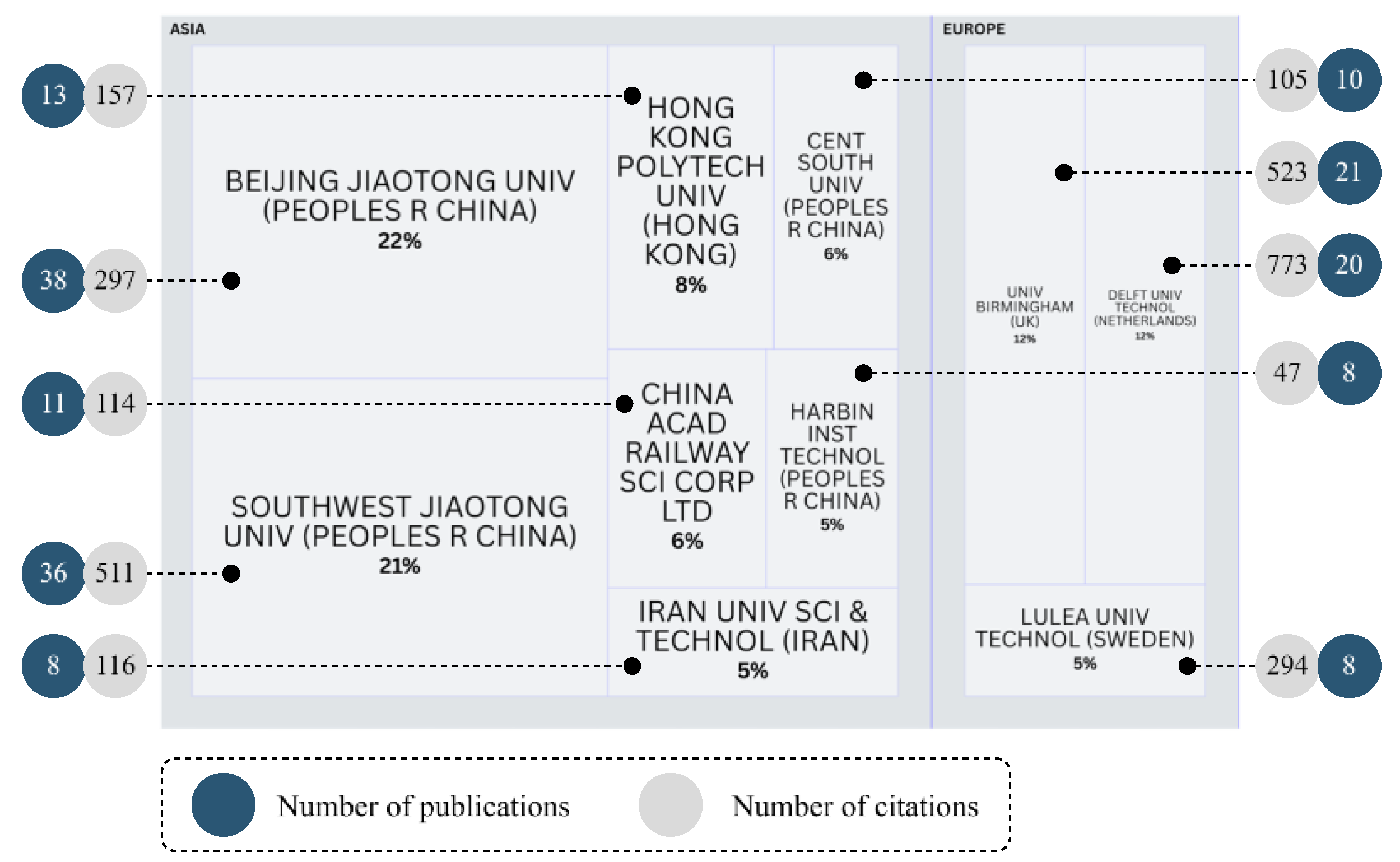

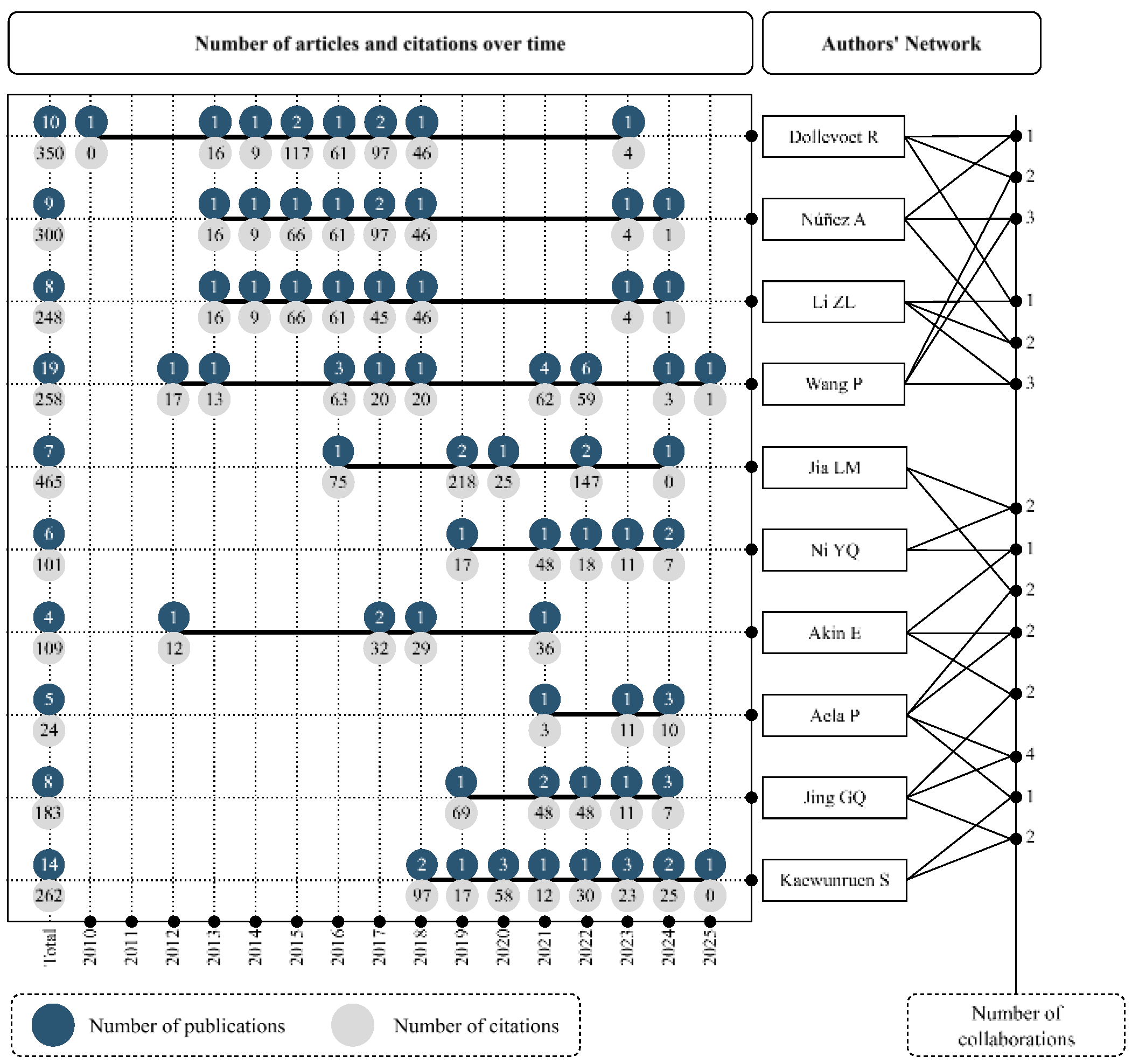

3.2. Leading Institutions and Key Contributors

3.3. Keyword Co-Occurrence Networks

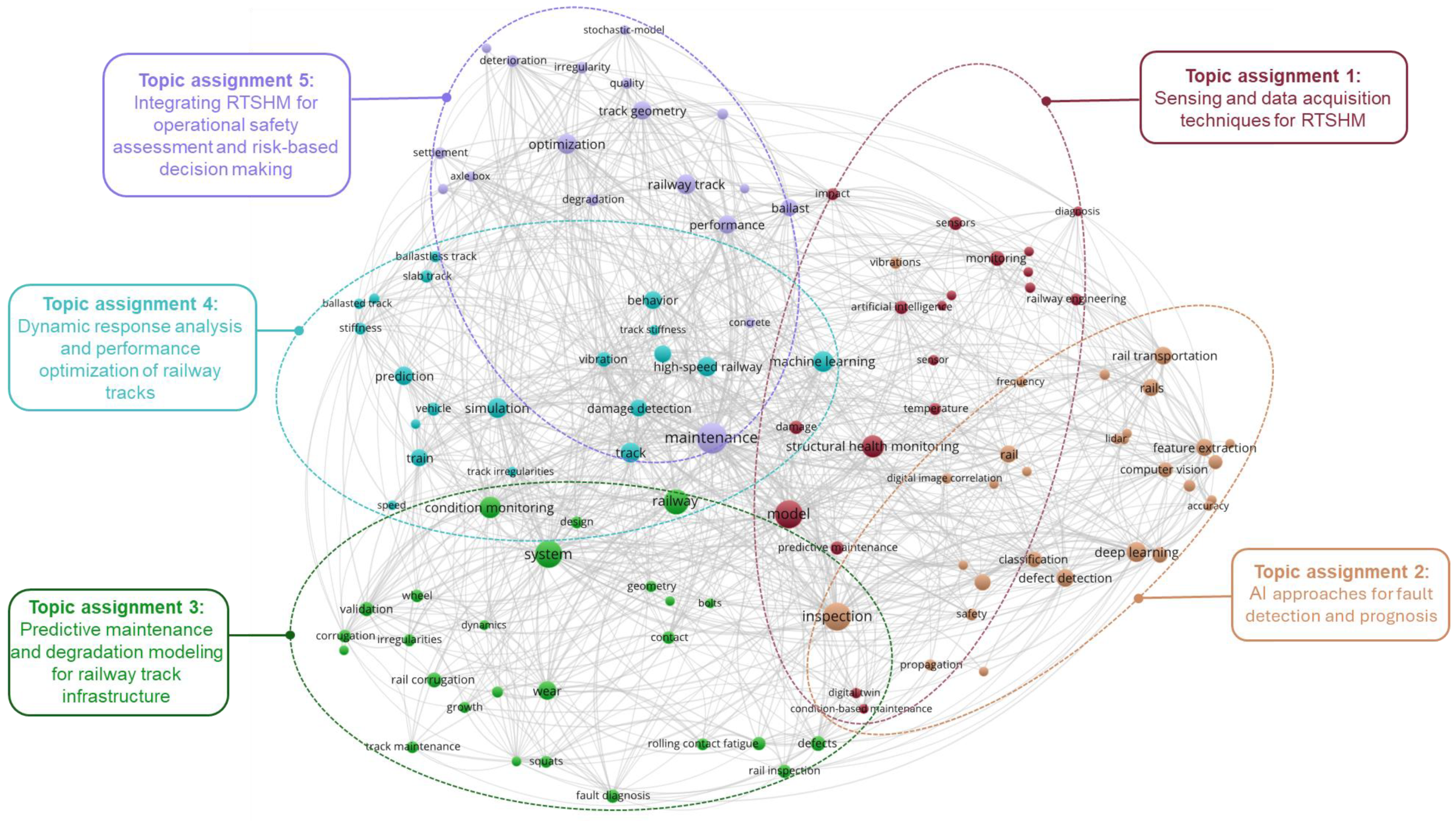

3.4. Topic Mapping

4. Content Analysis

4.1. Sensing and Data Acquisition Techniques for RTSHM

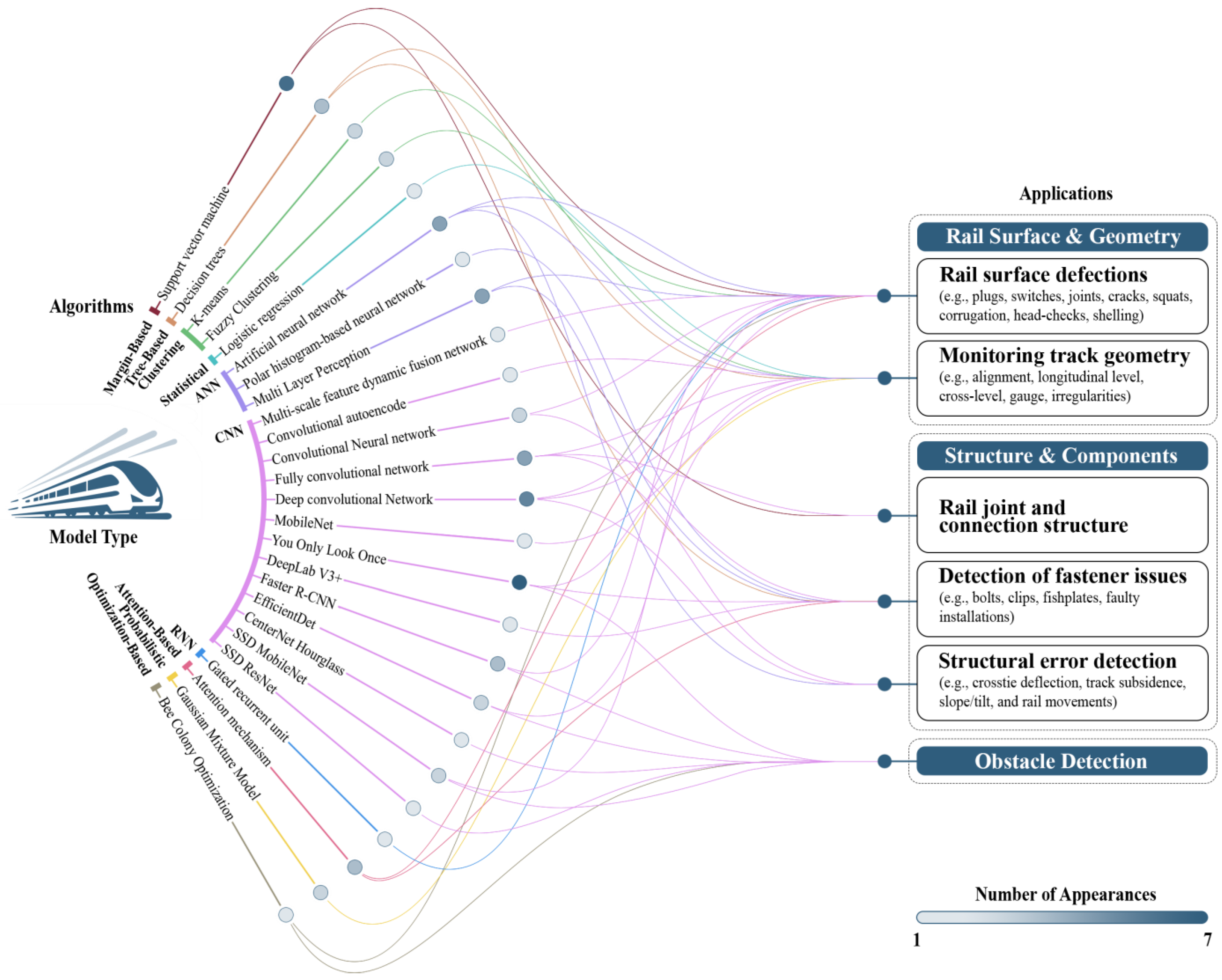

4.2. AI Approaches for Fault Detection and Prognosis

4.3. Predictive Maintenance and Degradation Modeling for Railway Track Infrastructure

4.4. Dynamic Response Analysis and Performance Optimization of Railway Tracks

4.5. Integrating RTSHM for Operational Safety Assessment and Risk-Based Decision-Making

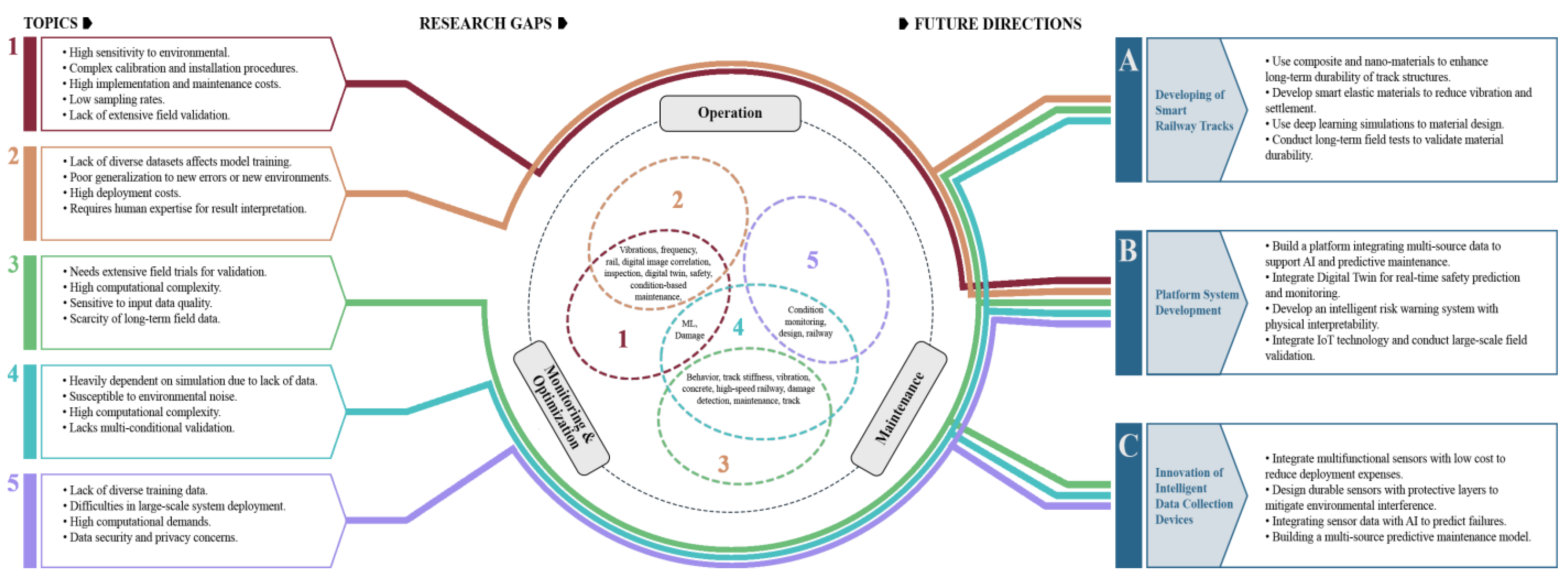

5. Discussion

5.1. Identified Gaps in RTSHM

5.2. Future Research Agenda

6. Conclusions

Supplementary Materials

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Theme | Topic Modeling |

|---|---|

| Sensor technology in defect detection | (0.045*“sensor” + 0.045*“detection” + 0.035*“fiber” + 0.025*“measurement” + 0.046*“defect” + 0.029*“surface” + 0.027*“signal” + 0.022*“condition “ + 0.031*“damage” + 0.017*“bragg” + 0.024*“magnetic” + 0.022*“test” + 0.026*“fastener” + 0.017*“grate” + 0.016*“acceleration “ + 0.015*“measure” + 0.025*“crack” + 0.017*“vibration” + 0.026*“image”) |

| Data processing techniques in condition detection | (0.022*“measurement” + 0.032*“geometry” + 0.037*“condition” + 0.028*“detection” + 0.016*“measure” + 0.022*“inspection” + 0.033*“vehicle” + 0.029*“defect” + 0.029*“ learn “ + 0.015*“sensor” + 0.024*“corrugation” + 0.029*“fault” + 0.016*“algorithm” + 0.016*“irregularity” + 0.019*“wear” + 0.014*“quality” + 0.025*“machine” + 0.017*“degradation” + 0.031*“network”) |

| Application of an AI model in RTSHM | (0.013*“inspection” + 0.019*“detection” + 0.014*“defect” + 0.018*“condition” + 0.044*“ wheel” + 0.025*“vehicle” + 0.029*“fault” + 0.027*“image” + 0.036*“measurement” + 0.015*“geometry” + 0.028*“sensor” + 0.015*“surface” + 0.022*“learn” + 0.021*“process” + 0.017*“time” + 0.014*“acceleration” + 0.020*“approach” + 0.020*“deep” + 0.019*“artificial”) |

| Predictive maintenance strategies | (0.018*“wheel” + 0.024*“condition” + 0.017*“vehicle” + 0.028*“damage” + 0.033*“geometry” + 0.018*“ballast” + 0.027*“wear” + 0.025*“contact” + 0.024*“force” + 0.024*“sensor” + 0.023*“prediction” + 0.028*“defect” + 0.014*“network” + 0.031*“measurement” + 0.013*“analysis” + 0.018*“study” + 0.021*“impact” + 0.017*“approach” + 0.020*“load”) |

| Track performance and operational efficiency | (0.051*“ballast” + 0.040*“sleeper” + 0.030*“slab” + 0.020*“sensor” + 0.021*“speed” + 0.017*“high” + 0.022*“load” + 0.025*“condition” + 0.018*“measurement” + 0.023*“fiber” + 0.021*“study” + 0.014*“inspection” + 0.019*“defect” + 0.016*“stiffness” + 0.021*“test” + 0.016*“structural” + 0.020*“increase” + 0.020*“temperature” + 0.020*“stress”) |

| Safety management and risk mitigation | (0.058*“detection” + 0.034*“defect” + 0.037*“network” + 0.030*“learn” + 0.037*“image” + 0.035*“obstacle” + 0.026*“feature” + 0.017*“fastener” + 0.029*“inspection” + 0.026*“surface” + 0.025*“algorithm” + 0.020*“performance” + 0.021*“improve” + 0.024*“accuracy” + 0.019*“sensor” + 0.014*“information” + 0.020*“deep” + 0.017*“high” + 0.019*“time”) |

References

- Mahmood, B.; Kim, S. Framework of Scan to Building Information Modeling for Geometric Defect Localization in Railway Track Maintenance. Buildings 2024, 14, 3578. [Google Scholar] [CrossRef]

- Laiton-Bonadiez, C.; Branch-Bedoya, J.W.; Zapata-Cortes, J.; Paipa-Sanabria, E.; Arango-Serna, M. Industry 4.0 Technologies Applied to the Rail Transportation Industry: A Systematic Review. Sensors 2022, 22, 2491. [Google Scholar] [CrossRef] [PubMed]

- Bianchi, G.; Fanelli, C.; Freddi, F.; Giuliani, F.; La Placa, A. Systematic review railway infrastructure monitoring: From classic techniques to predictive maintenance. Adv. Mech. Eng. 2025, 17, 16878132241285631. [Google Scholar] [CrossRef]

- Rahimi, M.; Liu, H.; Cardenas, I.D.; Starr, A.; Hall, A.; Anderson, R. A review on technologies for localisation and navigation in autonomous railway maintenance systems. Sensors 2022, 22, 4185. [Google Scholar] [CrossRef]

- Ngamkhanong, C.; Kaewunruen, S.; Costa, B.J.A. State-of-the-art review of railway track resilience monitoring. Infrastructures 2018, 3, 3. [Google Scholar] [CrossRef]

- Aytekin, Ç.; Rezaeitabar, Y.; Dogru, S.; Ulusoy, I. Railway fastener inspection by real-time machine vision. IEEE Trans. Syst. Man Cybern. Syst. 2015, 45, 1101–1107. [Google Scholar] [CrossRef]

- Chandran, P.; Asber, J.; Thiery, F.; Odelius, J.; Rantatalo, M. An investigation of railway fastener detection using image processing and augmented deep learning. Sustainability 2021, 13, 12051. [Google Scholar] [CrossRef]

- Avsievich, A.; Avsievich, V.; Avsievich, N.; Ovchinnikov, D.; Ivaschenko, A. Railway track stress–strain analysis using high-precision accelerometers. Appl. Sci. 2021, 11, 11908. [Google Scholar] [CrossRef]

- Uzarski, D.; Grussing, M. Beyond mandated track safety inspections using a mission-focused, knowledge-based approach. Int. J. Rail Transp. 2013, 1, 218–236. [Google Scholar] [CrossRef]

- Sasi, D.; Philip, S.; David, R.; Swathi, J. A review on structural health monitoring of railroad track structures using fiber optic sensors. Mater. Today Proc. 2020, 33, 3787–3793. [Google Scholar] [CrossRef]

- Gbadamosi, A.-Q.; Oyedele, L.O.; Delgado, J.M.D.; Kusimo, H.; Akanbi, L.; Olawale, O.; Muhammed-Yakubu, N. IoT for predictive assets monitoring and maintenance: An implementation strategy for the UK rail industry. Autom. Constr. 2021, 122, 103486. [Google Scholar] [CrossRef]

- Davari, N.; Veloso, B.; Costa, G.d.A.; Pereira, P.M.; Ribeiro, R.P.; Gama, J. A survey on data-driven predictive maintenance for the railway industry. Sensors 2021, 21, 5739. [Google Scholar] [CrossRef] [PubMed]

- Sedghi, M.; Kauppila, O.; Bergquist, B.; Vanhatalo, E.; Kulahci, M. A taxonomy of railway track maintenance planning and scheduling: A review and research trends. Reliab. Eng. Syst. Saf. 2021, 215, 107827. [Google Scholar] [CrossRef]

- Hodge, V.J.; O’Keefe, S.; Weeks, M.; Moulds, A. Wireless sensor networks for condition monitoring in the railway industry: A survey. IEEE Trans. Intell. Transp. Syst. 2014, 16, 1088–1106. [Google Scholar] [CrossRef]

- Binder, M.; Mezhuyev, V.; Tschandl, M. Predictive maintenance for railway domain: A systematic literature review. IEEE Eng. Manag. Rev. 2023, 51, 120–140. [Google Scholar] [CrossRef]

- Agustin, D.; Wu, Q.; Ngamkhanong, C. A review on railway track buckling prediction methods. Constr. Build. Mater. 2025, 466, 140295. [Google Scholar] [CrossRef]

- Wang, Q.-A.; Huang, X.-Y.; Wang, J.-F.; Ni, Y.-Q.; Ran, S.-C.; Li, J.-P.; Zhang, J. Concise historic overview of rail corrugation studies: From formation mechanisms to detection methods. Buildings 2024, 14, 968. [Google Scholar] [CrossRef]

- Bosso, N.; Magelli, M.; Zampieri, N. Simulation of wheel and rail profile wear: A review of numerical models. Railw. Eng. Sci. 2022, 30, 403–436. [Google Scholar] [CrossRef]

- Rahman, M.; Liu, H.; Cardenas, I.D.; Starr, A.; Hall, A.; Anderson, R. A review on the prospects of mobile manipulators for smart maintenance of railway track. Appl. Sci. 2023, 13, 6484. [Google Scholar] [CrossRef]

- Pappaterra, M.J. A literature review for the application of artificial intelligence in the maintenance of railway operations with an emphasis on data. In Proceedings of the European Dependable Computing Conference, Zaragoza, Spain, 12–15 September 2022; pp. 59–75. [Google Scholar]

- Soleimanmeigouni, I.; Ahmadi, A.; Kumar, U. Track geometry degradation and maintenance modelling: A review. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2018, 232, 73–102. [Google Scholar] [CrossRef]

- Prasad, K.V.S.; Hussaini, S.K.K. Review of different stabilization techniques adapted in ballasted tracks. Constr. Build. Mater. 2022, 340, 127747. [Google Scholar] [CrossRef]

- Kurhan, D.; Kovalchuk, V.; Markul, R.; Kovalskyi, D. Development of Devices for Long-Term Railway Track Condition Monitoring: Review of Sensor Varieties. Acta Polytech. Hung. 2025, 22, 65–82. [Google Scholar] [CrossRef]

- Aela, P.; Chi, H.-L.; Fares, A.; Zayed, T.; Kim, M. UAV-based studies in railway infrastructure monitoring. Autom. Constr. 2024, 167, 105714. [Google Scholar] [CrossRef]

- Aela, P.; Cai, J.; Jing, G.; Chi, H.-L. Vision-based monitoring of railway superstructure: A review. Constr. Build. Mater. 2024, 442, 137385. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, Z.; Yi, D.; Yu, X.; Sha, X.; Li, L.; Sun, H.; Zhan, Z.; Li, W.J. A review on rail defect detection systems based on wireless sensors. Sensors 2022, 22, 6409. [Google Scholar] [CrossRef] [PubMed]

- Jing, G.; Qin, X.; Wang, H.; Deng, C. Developments, challenges, and perspectives of railway inspection robots. Autom. Constr. 2022, 138, 104242. [Google Scholar] [CrossRef]

- Gonzalo, A.P.; Horridge, R.; Steele, H.; Stewart, E.; Entezami, M. Review of data analytics for condition monitoring of railway track geometry. IEEE Trans. Intell. Transp. Syst. 2022, 23, 22737–22754. [Google Scholar] [CrossRef]

- Ren, J.; Deng, S.; Zhang, K.; Du, W.; Wu, Q. Design theories and maintenance technologies of slab tracks for high-speed railways in China: A review. Transp. Saf. Environ. 2021, 3, tdab024. [Google Scholar] [CrossRef]

- Higgins, C.; Liu, X. Modeling of track geometry degradation and decisions on safety and maintenance: A literature review and possible future research directions. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2018, 232, 1385–1397. [Google Scholar] [CrossRef]

- Matias, S.R.; Ferreira, P.A. Railway slab track systems: Review and research potentials. Struct. Infrastruct. Eng. 2020, 16, 1635–1653. [Google Scholar] [CrossRef]

- Sañudo, R.; Dell’Olio, L.; Casado, J.; Carrascal, I.; Diego, S. Track transitions in railways: A review. Constr. Build. Mater. 2016, 112, 140–157. [Google Scholar] [CrossRef]

- Srivastava, A.; Sutton, C. Autoencoding variational inference for topic models. arXiv 2017, arXiv:1703.01488. [Google Scholar] [CrossRef]

- Röder, M.; Both, A.; Hinneburg, A. Exploring the space of topic coherence measures. In Proceedings of the Eighth ACM International Conference on Web Search and Data Mining, Shanghai, China, 31 January–6 February 2015; pp. 399–408. [Google Scholar]

- Shahapure, K.R.; Nicholas, C. Cluster quality analysis using silhouette score. In Proceedings of the 2020 IEEE 7th International Conference on Data Science and Advanced Analytics (DSAA), Sydney, Australia, 6–9 October 2020; pp. 747–748. [Google Scholar]

- Obrien, E.J.; Quirke, P.; Bowe, C.; Cantero, D. Determination of railway track longitudinal profile using measured inertial response of an in-service railway vehicle. Struct. Health Monit. 2017, 17, 1425–1440. [Google Scholar] [CrossRef]

- Bocciolone, M.; Caprioli, A.; Cigada, A.; Collina, A. A measurement system for quick rail inspection and effective track maintenance strategy. Mech. Syst. Signal Process. 2007, 21, 1242–1254. [Google Scholar] [CrossRef]

- Oregui, M.; Li, Z.; Dollevoet, R. Identification of characteristic frequencies of damaged railway tracks using field hammer test measurements. Mech. Syst. Signal Process. 2015, 54–55, 224–242. [Google Scholar] [CrossRef]

- Sabato, A.; Niezrecki, C. Feasibility of digital image correlation for railroad tie inspection and ballast support assessment. Measurement 2017, 103, 93–105. [Google Scholar] [CrossRef]

- Mishra, M.; Odelius, J.; Thaduri, A.; Nissen, A.; Rantatalo, M. Particle filter-based prognostic approach for railway track geometry. Mech. Syst. Signal Process. 2017, 96, 226–238. [Google Scholar] [CrossRef]

- Li, P.; Long, Z.; Yang, Z. RF Energy Harvesting for Batteryless and Maintenance-Free Condition Monitoring of Railway Tracks. IEEE Internet Things J. 2021, 8, 3512–3523. [Google Scholar] [CrossRef]

- Ma, Z.; Gao, L.; Liu, X.; An, B. Detection of CRTS II slab track arching based on dynamic responses of the car body. Eng. Fail. Anal. 2021, 130, 105770. [Google Scholar] [CrossRef]

- Haji Abdulrazagh, P.; Hendry, M.T.; Roghani, A.; Toma, E. Evaluating Rail Surface Roughness from Axle-Box Acceleration Measurements: Computational Metrology Approach. J. Transp. Eng. Part A Syst. 2021, 147, 04021087. [Google Scholar] [CrossRef]

- Sresakoolchai, J.; Kaewunruen, S. Railway defect detection based on track geometry using supervised and unsupervised machine learning. Struct. Health Monit. 2022, 21, 1757–1767. [Google Scholar] [CrossRef]

- Xu, P.; Liu, R.; Sun, Q.; Jiang, L. Dynamic-Time-Warping-Based Measurement Data Alignment Model for Condition-Based Railroad Track Maintenance. IEEE Trans. Intell. Transp. Syst. 2015, 16, 799–812. [Google Scholar] [CrossRef]

- Sánchez, A.; Bravo, J.L.; González, A. Estimating the Accuracy of Track-Surveying Trolley Measurements for Railway Maintenance Planning. J. Surv. Eng. 2017, 143, 05016008. [Google Scholar] [CrossRef]

- Janatabadi, F.; Mohammadzadeh, S.; Nouri, M. A robust complementary index for railway maintenance planning based on a probabilistic approach. Int. J. Rail Transp. 2020, 9, 380–404. [Google Scholar] [CrossRef]

- Rahmani, A.; Seyed-Hosseini, S.M. Evaluation of railway track structural conditions using a fuzzy-logic method: A case study. Jordan J. Civ. Eng. 2021, 15, 102–115. [Google Scholar]

- Rebello, S.; Cholette, M.E.; Truong-Ba, H.; Reddy, V.; Rosser, A.; Watkin, T. Railway Track Geometry Degradation Modelling and Prediction for Maintenance Decision Support. In 15th WCEAM Proceedings; Lecture Notes in Mechanical Engineering; Springer: Berlin/Heidelberg, Germany, 2022; pp. 422–432. [Google Scholar]

- Sauni, M.; Luomala, H.; Kolisoja, P.; Nummi, T. Advancing Railway Asset Management Using Track Geometry Deterioration Modeling Visualization. J. Transp. Eng. Part A Syst. 2022, 148, 04021106. [Google Scholar] [CrossRef]

- An, B.; Wang, P.; Ma, S.; Ma, Z.; Zhong, Y.; Zhao, W. Influence of Metro Track Irregularities on Pantograph Vibration and Its Interaction with Catenary. Appl. Sci. 2022, 12, 6435. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Osman, M.H. Dealing with disruptions in railway track inspection using risk-based machine learning. Sci. Rep. 2023, 13, 2141. [Google Scholar] [CrossRef]

- Jia, Y.; Lu, Y.; Xiong, L.; Zhang, Y.; Wang, P.; Zhou, H. A Filtering Method for Suppressing the Lift-Off Interference in Magnetic Flux Leakage Detection of Rail Head Surface Defect. Appl. Sci. 2022, 12, 1740. [Google Scholar] [CrossRef]

- Zhao, Q.; Hao, J.; Yin, W. A simulation study of flaw detection for rail sections based on high frequency magnetic induction sensing using the boundary element method. Prog. Electromagn. Res. 2013, 141, 309–325. [Google Scholar] [CrossRef]

- Kwon, S.-J.; Seo, J.-W.; Kim, J.-M.; Kim, M.-S. Observation of the damage process of rolling contact fatigue using a non-contact electro-magnetic array sensor. Wear 2017, 390–391, 220–227. [Google Scholar] [CrossRef]

- Piao, G.; Li, J.; Udpa, L.; Qian, J.; Deng, Y. Finite-Element Study of Motion-Induced Eddy Current Array Method for High-Speed Rail Defects Detection. IEEE Trans. Magn. 2021, 57, 3119267. [Google Scholar] [CrossRef]

- Jia, Y.; Zhang, S.; Wang, P.; Ji, K. A Method for Detecting Surface Defects in Railhead by Magnetic Flux Leakage. Appl. Sci. 2021, 11, 9489. [Google Scholar] [CrossRef]

- Pires, A.C.; Viana, M.C.A.; Scaramussa, L.M.; Santos, G.F.M.; Ramos, P.G.; Santos, A.A. Measuring vertical track irregularities from instrumented heavy haul railway vehicle data using machine learning. Eng. Appl. Artif. Intell. 2024, 127, 107191. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, P.; Song, T.L.; Jiang, Y.; Zhou, W.T.; Xu, W.L. Evaluation of the Transverse Crack Depth of Rail Bottoms Based on the Ultrasonic Guided Waves of Piezoelectric Sensor Arrays. Sensors 2022, 22, 7023. [Google Scholar] [CrossRef]

- Li, Y.; Ou, L.; Li, N.; Tan, Z. Differential Triple Coils for Rail-bottom Flaw Detection Using Single-cycle Demodulation. Sens. Mater. 2023, 35, 2831–2843. [Google Scholar] [CrossRef]

- Diaz, A.A.; Bouteiller, F.; Wu, H.F.; Grisso, B.L.; Peairs, D.M.; Doctor, S.R.; Bar-Cohen, Y.; Inman, D.J. Broken rail track detection using smart materials. In Proceedings of the Nonintrusive Inspection, Structures Monitoring, and Smart Systems for Homeland Security, San Diego, CA, USA, 27–28 February 2006. [Google Scholar]

- Cui, H.; Hu, Q.; Mao, Q. Real-Time Geometric Parameter Measurement of High-Speed Railway Fastener Based on Point Cloud from Structured Light Sensors. Sensors 2018, 18, 3675. [Google Scholar] [CrossRef]

- Han, Q.; Wang, S.; Fang, Y.; Wang, L.; Du, X.; Li, H.; He, Q.; Feng, Q. A Rail Fastener Tightness Detection Approach Using Multi-source Visual Sensor. Sensors 2020, 20, 1367. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, J.; Ma, Z.; Zhang, H.; Zhang, S. Three-Dimensional Measurement of Full Profile of Steel Rail Cross-Section Based on Line-Structured Light. Electronics 2023, 12, 3194. [Google Scholar] [CrossRef]

- Bernstein, A.V.; Olaru, A.; Zhou, J.; Chen, P.; Wang, P.; Lauer, M.; Tang, X.; Wang, J. A rail wear measurement method based on structured light scanning. In Proceedings of the 2016 International Conference on Robotics and Machine Vision, Moscow, Russia, 14–16 September 2016; 2017. [Google Scholar]

- Chen, P.; Hu, Y.; Li, W.-T.; Wang, P.-J. Rail wear inspection based on computer-aided design model and point cloud data. Adv. Mech. Eng. 2018, 10, 1687814018816782. [Google Scholar] [CrossRef]

- Mennella, F.; Laudati, A.; Esposito, M.; Cusano, A.; Cutolo, A.; Giordano, M.; Campopiano, S.; Breglio, G. Railway monitoring and train tracking by fiber Bragg grating sensors. In Proceedings of the Third European Workshop on Optical Fibre Sensors, Napoli, Italy, 4–6 July 2007; pp. 556–559. [Google Scholar]

- Topalov, I.; Georgieva, M. Investigation the possibilities for implementation of fiber optic detection of damaged rails. In Proceedings of the 2008 31st International Spring Seminar on Electronics Technology, Budapest, Hungary, 7–11 May 2008; pp. 240–242. [Google Scholar]

- Barreda, A.; Molina-Jimenez, T.; Valero, E.; Recuero, S. Measurement of vibrations at different sections of rail through fiber optic sensors. In Proceedings of the Photonics, Devices, and Systems V, Budapest, Hungary, 7–11 May 2008; 2011; pp. 91–97. [Google Scholar]

- Zhang, Z.; Yan, L.; Pan, W.; Luo, B.; Wang, P.; Guo, L.; Zhou, W. Sensitivity enhancement of strain sensing utilizing a differential pair of fiber Bragg gratings. Sensors 2012, 12, 3891–3900. [Google Scholar] [CrossRef]

- Chapeleau, X.; Sedran, T.; Cottineau, L.M.; Cailliau, J.; Taillade, F.; Gueguen, I.; Henault, J.M. Study of ballastless track structure monitoring by distributed optical fiber sensors on a real-scale mockup in laboratory. Eng. Struct. 2013, 56, 1751–1757. [Google Scholar] [CrossRef]

- Roveri, N.; Carcaterra, A.; Sestieri, A. Remote condition monitoring of railway track using FBG sensors. In Proceedings of the ISMA, Le Mans, France, 15–17 September 2014. [Google Scholar]

- Roveri, N.; Carcaterra, A.; Sestieri, A. Real-time monitoring of railway infrastructures using fibre Bragg grating sensors. Mech. Syst. Signal Process. 2015, 60–61, 14–28. [Google Scholar] [CrossRef]

- Shao, L.Y.; Zhang, M.; Xie, K.; Zhang, X.; Wang, P.; Yan, L. The Longitudinal Force Measurement of CWR Tracks with Hetero-Cladding FBG Sensors: A Proof of Concept. Sensors 2016, 16, 2184. [Google Scholar] [CrossRef] [PubMed]

- Lai, C.C.; Au, H.Y.; Liu, M.S.Y.; Ho, S.L.; Tam, H.Y. Development of Level Sensors Based on Fiber Bragg Grating for Railway Track Differential Settlement Measurement. IEEE Sens. J. 2016, 16, 6346–6350. [Google Scholar] [CrossRef]

- Wang, P.; Xie, K.; Chen, R.; Shao, L.; Yan, L.; Liu, H.; Zhang, M. Test Verification and Application of a Longitudinal Temperature Force Testing Method for Long Seamless Rails Using FBG Strain Sensor. J. Sens. 2016, 2016, 3917604. [Google Scholar] [CrossRef]

- Yüksel, K.; Kinet, D.; Moeyaert, V.; Kouroussis, G.; Caucheteur, C. Railway monitoring system using optical fiber grating accelerometers. Smart Mater. Struct. 2018, 27, 105033. [Google Scholar] [CrossRef]

- Wheeler, L.N.; Pannese, E.; Hoult, N.A.; Take, W.A.; Le, H. Measurement of distributed dynamic rail strains using a Rayleigh backscatter based fiber optic sensor: Lab and field evaluation. Transp. Geotech. 2018, 14, 70–80. [Google Scholar] [CrossRef]

- Yucel, M.; Ozturk, N.F. Real-time monitoring of railroad track tension using a fiber Bragg grating-based strain sensor. Instrum. Sci. Technol. 2017, 46, 519–533. [Google Scholar] [CrossRef]

- Wang, Q.A.; Ni, Y.Q. Measurement and Forecasting of High-Speed Rail Track Slab Deformation under Uncertain SHM Data Using Variational Heteroscedastic Gaussian Process. Sensors 2019, 19, 3311. [Google Scholar] [CrossRef]

- Xu, S.; Sun, J.; Wang, C.; Xing, F. Novel Method for Insulation Degradation Location of Rail Transit System Based on Fiber Grating. IEEE Trans. Veh. Technol. 2024, 73, 1899–1909. [Google Scholar] [CrossRef]

- Li, J.; Shen, B.; Zhang, H.; Song, Y. Fiber Bragg Grating Accelerometer and Its Application to Measure Wheel-Rail Excitation. Struct. Control. Health Monit. 2024, 2024, 8442782. [Google Scholar] [CrossRef]

- Barker, C.; Hoult, N.A.; Zhang, M. Development of an axial strain measurement system for rails. J. Perform. Constr. Facil. 2021, 35, 04020145. [Google Scholar] [CrossRef]

- Sun, F.; Hoult, N.A.; Butler, L.J.; Zhang, M. Distributed monitoring of rail lateral buckling under axial loading. J. Civ. Struct. Health Monit. 2021, 12, 757–774. [Google Scholar] [CrossRef]

- Sun, F.; Febrianto, E.; Fernando, H.; Butler, L.J.; Cirak, F.; Hoult, N.A. Data-informed statistical finite element analysis of rail buckling. Comput. Struct. 2023, 289, 107163. [Google Scholar] [CrossRef]

- Gan, W.; Tu, S.; Tao, Y.; Ai, L.; Zhang, C.; Tang, J. Opto-Mechatronics System for Train-Track Micro Deformation Sensing. Sensors 2021, 22, 296. [Google Scholar] [CrossRef]

- Laudat, A.; Lanza, G.; Cusano, A.; Cutolo, A.; Giordano, M.; Breglio, G.; Antonelli, A. Railway monitoring and train tracking by fiber Bragg grating sensors: A case study in Italy. Struct. Health Monit. 2008, 6619, 556–559. [Google Scholar]

- Bureika, G.; VaiČIŪNas, G.; Shi, D.; Zanuy, A.C. Influence of Track Geometry Condition Monitoring on Railway Infrastructure Maintenance Processing. Transp. Probl. 2022, 17, 211–220. [Google Scholar] [CrossRef]

- Skrickij, V.; Sabanovic, E.; Shi, D.; Ricci, S.; Rizzetto, L.; Bureika, G. Visual Measurement System for Wheel-Rail Lateral Position Evaluation. Sensors 2021, 21, 1297. [Google Scholar] [CrossRef]

- Mohammadzadeh, S.; Heydari, H.; Karimi, M.; Mosleh, A. Correlation Analysis of Railway Track Alignment and Ballast Stiffness: Comparing Frequency-Based and Machine Learning Algorithms. Algorithms 2024, 17, 372. [Google Scholar] [CrossRef]

- Maire, F. Vision based anti-collision system for rail track maintenance vehicles. In Proceedings of the 2007 IEEE Conference on Advanced Video and Signal Based Surveillance, London, UK, 5–7 September 2007; pp. 170–175. [Google Scholar]

- Zhu, W.; Ma, H.; Liu, H.; Yang, W. Online monitoring system for track slab temperature. In Proceedings of the 2017 International Seminar on Artificial Intelligence, Networking and Information Technology (ANIT 2017), Bangkok, Thailand, 2–3 December 2017; pp. 37–41. [Google Scholar]

- Guerrieri, M.; Parla, G.; Celauro, C. Digital image analysis technique for measuring railway track defects and ballast gradation. Measurement 2018, 113, 137–147. [Google Scholar] [CrossRef]

- Yang, S.; Yu, G.; Wang, Z.; Zhou, B.; Chen, P.; Zhang, Q. A Topology Guided Method for Rail-Track Detection. IEEE Trans. Veh. Technol. 2022, 71, 1426–1438. [Google Scholar] [CrossRef]

- Ye, J.; Stewart, E.; Chen, Q.; Chen, L.; Roberts, C. A vision-based method for line-side switch rail condition monitoring and inspection. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2022, 236, 986–996. [Google Scholar] [CrossRef]

- Mauz, F.; Wigger, R.; Wahl, T.; Kuffa, M.; Wegener, K. Acoustic Roughness Measurement of Railway Tracks: Laboratory Investigation of External Disturbances on the Chord-Method with an Optical Measurement Approach. Appl. Sci. 2022, 12, 7732. [Google Scholar] [CrossRef]

- Ye, J.; Stewart, E.; Roberts, C. Use of a 3D model to improve the performance of laser-based railway track inspection. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2018, 233, 337–355. [Google Scholar] [CrossRef]

- Teng, Y.; Liu, H.; Liu, J.; Wang, C.; Ma, Z. A rail corrugation measurement method based on data splicing. Measurement 2020, 156, 107560. [Google Scholar] [CrossRef]

- Amaral, V.; Marques, F.; Lourenço, A.; Barata, J.; Santana, P. Laser-Based Obstacle Detection at Railway Level Crossings. J. Sens. 2016, 2016, 1719230. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, L.; Yi, B.; Chen, F. An Accurate and Fast Method to Inspect Rail Wear Based on Revised Global Registration. IEEE Access 2018, 6, 57267–57278. [Google Scholar] [CrossRef]

- Madejski, J. Track Geometry Measurement as Preventive Maintenance Data Source. In Proceedings of the 3rd International Conference on Road and Rail Infrastructure, Spilt Dalmatia, Croatia, 28–30 April 2014. [Google Scholar] [CrossRef]

- Hackel, T.; Stein, D.; Maindorfer, I.; Lauer, M.; Reiterer, A. Track detection in 3D laser scanning data of railway infrastructure. In Proceedings of the 2015 IEEE International Instrumentation and Measurement Technology Conference (I2MTC) Proceedings, Pisa, Italy, 11–14 May 2015; pp. 693–698. [Google Scholar]

- Fedorko, G.; Molnár, V.; Blaho, P.; Gašparík, J.; Zitrický, V. Failure analysis of cyclic damage to a railway rail—A case study. Eng. Fail. Anal. 2020, 116, 104732. [Google Scholar] [CrossRef]

- Bahati, P.A.; Le, V.D.; Lim, Y. A Multi-Depth Deflectometer/Global Navigation Satellite System Method for Measuring Concrete Slab Track Deformation. Appl. Sci. 2023, 14, 82. [Google Scholar] [CrossRef]

- Chacón Muñoz, J.M.; García Márquez, F.P.; Papaelias, M. Railroad inspection based on ACFM employing a non-uniform B-spline approach. Mech. Syst. Signal Process. 2013, 40, 605–617. [Google Scholar] [CrossRef]

- Chandran, P.; Thierry, F.; Odelius, J.; Famurewa, S.M.; Lind, H.; Rantatalo, M. Supervised Machine Learning Approach for Detecting Missing Clamps in Rail Fastening System from Differential Eddy Current Measurements. Appl. Sci. 2021, 11, 4018. [Google Scholar] [CrossRef]

- Shao, Y.; Xia, Z.; Ding, Y.; Crocker, B.; Saunders, S.; Bai, X.; Peyton, A.; Conniffe, D.; Yin, W. Eddy Current Sensor Array for Electromagnetic Sensing and Crack Reconstruction with High Lift-Off in Railway Tracks. Sensors 2024, 24, 4216. [Google Scholar] [CrossRef] [PubMed]

- Ji, K.; Wang, P.; Jia, Y.; Ye, Y.; Ding, S. Adaptive Filtering Method of MFL Signal on Rail Top Surface Defect Detection. IEEE Access 2021, 9, 87351–87359. [Google Scholar] [CrossRef]

- Heindler, L.; Hüttmayr, H.; Thurner, T.; Zagar, B. Magnetic Railway Sleeper Detector. Electronics 2024, 13, 4005. [Google Scholar] [CrossRef]

- Gong, W.; Akbar, M.F.; Jawad, G.N.; Shrifan, N.H.M.M.; Zhang, F. A Magnetic Field Concentration Method for Magnetic Flux Leakage Detection of Rail-Top Surface Cracks. IEEE Access 2024, 12, 43245–43254. [Google Scholar] [CrossRef]

- Jeong, W.; Jeong, D. Acoustic Roughness Measurement of Railhead Surface Using an Optimal Sensor Batch Algorithm. Appl. Sci. 2020, 10, 2110. [Google Scholar] [CrossRef]

- Liu, G.; Liu, H.; Wei, A.; Xiao, J.; Wang, P.; Li, S. A new device for stress monitoring in continuously welded rails using bi-directional strain method. J. Mod. Transp. 2018, 26, 179–188. [Google Scholar] [CrossRef]

- Zhu, X.; Lanza di Scalea, F. Thermal Stress Measurement in Continuous Welded Rails Using the Hole-Drilling Method. Exp. Mech. 2016, 57, 165–178. [Google Scholar] [CrossRef]

- Lee, J.-I.; Oh, K.-H.; Park, Y.-G. Separate Track Impact Factor Application Depending on Track Types through Correlative Analysis with Track Support Stiffness. Infrastructures 2020, 5, 17. [Google Scholar] [CrossRef]

- Goodarzi, S.; Kashani, H.F.; Oke, J.; Ho, C.L. Data-driven methods to predict track degradation: A case study. Constr. Build. Mater. 2022, 344, 128166. [Google Scholar] [CrossRef]

- Dennig, D.; Bureick, J.; Link, J.; Diener, D.; Hesse, C.; Neumann, I. Comprehensive and Highly Accurate Measurements of Crane Runways, Profiles and Fastenings. Sensors 2017, 17, 1118. [Google Scholar] [CrossRef]

- Bin Osman, M.H.; Kaewunruen, S.; Jack, A. Optimisation of schedules for the inspection of railway tracks. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2017, 232, 1577–1587. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, Q.; Niu, X.; Liu, J. Semi-analytical assessment of the relative accuracy of the GNSS/INS in railway track irregularity measurements. Satell. Navig. 2021, 2, 25. [Google Scholar] [CrossRef]

- Chen, W.; Li, D.; Liu, Y.; Zhu, Z.; Huang, Z.; Yan, J. Development and application of a multi-sensor integration detection and analysis device for metro gauge and track geometric state. AIP Adv. 2021, 11, 065033. [Google Scholar] [CrossRef]

- Yao, L.; Sun, H.; Wang, X.; Zhou, Y. Detection of Track Static Regularities Based on a Laser Tracker. J. Surv. Eng. 2017, 143, 04016026. [Google Scholar] [CrossRef]

- Escalona, J.L.; Urda, P.; Munoz, S. A Track Geometry Measuring System Based on Multibody Kinematics, Inertial Sensors and Computer Vision. Sensors 2021, 21, 683. [Google Scholar] [CrossRef] [PubMed]

- Akpinar, B.; Gulal, E. Multisensor Railway Track Geometry Surveying System. IEEE Trans. Instrum. Meas. 2012, 61, 190–197. [Google Scholar] [CrossRef]

- Khosravi, M.; Soleimanmeigouni, I.; Ahmadi, A.; Nissen, A. Reducing the positional errors of railway track geometry measurements using alignment methods: A comparative case study. Measurement 2021, 178, 109383. [Google Scholar] [CrossRef]

- Pathak, M.; Alahakoon, S.; Spiryagin, M.; Cole, C. Rail foot flaw detection based on a laser induced ultrasonic guided wave method. Measurement 2019, 148, 106922. [Google Scholar] [CrossRef]

- Velha, P.; Nannipieri, T.; Signorini, A.; Morosi, M.; Solazzi, M.; Barone, F.; Frisoli, A.; Ricciardi, L.; Eusepi, R.; Icardi, M.; et al. Monitoring large railways infrastructures using hybrid optical fibers sensor systems. IEEE Trans. Intell. Transp. Syst. 2019, 21, 5177–5188. [Google Scholar] [CrossRef]

- Kudo, T.; Shimizu, T.; Oda, A. A Sensor Calibration Method Based on Rail Detection. IEEJ J. Ind. Appl. 2024, 13, 348–356. [Google Scholar] [CrossRef]

- Sun, X.; Guo, C.; Yuan, L.; Kong, Q.; Ni, Y. Diffuse Ultrasonic Wave-Based Damage Detection of Railway Tracks Using PZT/FBG Hybrid Sensing System. Sensors 2022, 22, 2504. [Google Scholar] [CrossRef] [PubMed]

- Counter, B.; Abu-Tair, A.; Franklin, A.; Tann, D. Refurbishment of ballasted track systems; the technical challenges of quality and decision support tools. Constr. Build. Mater. 2015, 92, 51–57. [Google Scholar] [CrossRef]

- Popov, K.; De Bold, R.; Chai, H.K.; Forde, M.C.; Ho, C.L.; Hyslip, J.P.; Kashani, H.F.; Kelly, R.; Hsu, S.S.; Rippin, M. Data-driven track geometry fault localisation using unsupervised machine learning. Constr. Build. Mater. 2023, 377, 131141. [Google Scholar] [CrossRef]

- Sadeghi, J.; Askarinejad, H. Quality condition assessment and determination of effective maintenance activities in railway slab tracks. Int. J. Pavement Eng. 2012, 13, 554551. [Google Scholar] [CrossRef]

- Šestáková, J.; Gocálová, Z. Comparison of Results of Geometrical Position of the Track Diagnostics—Spot and Continuous Measurement. Procedia Eng. 2014, 91, 447–452. [Google Scholar] [CrossRef]

- Ižvolta, L.; Šmalo, M. Assessment of the Track Geometry Quality from the Aspect of Safe and Reliable Operation of the Railway Track. Procedia Eng. 2015, 111, 344–350. [Google Scholar] [CrossRef]

- Ižvolt, L.; Šestáková, J.; Šmalo, M. Tendencies in the development of operational quality of ballasted and ballastless track superstructure and transition areas. In IOP Conference Series: Materials Science Engineering; IOP Publishing: Bristol, UK, 2017; Volume 236, p. 012038. [Google Scholar]

- Mahtani, A.; Chouchani, N.; Herbreteau, M.; Rafin, D. Enhancing Autonomous Train Safety Through A Priori-Map Based Perception. In Reliability, Safety, and Security of Railway Systems. Modelling, Analysis, Verification, and Certification; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2022; pp. 115–129. [Google Scholar]

- Lu, H.; He, Y. Monitoring and Research on Temperature Field and Juncture Deformation of CRTS II Slab BallastlessTrack in High Temperature. In Proceedings of the 2017 International Seminar on Artificial Intelligence, Networking and Information Technology (ANIT 2017), Bangkok, Thailand, 2–3 December 2017; pp. 132–136. [Google Scholar]

- Del Álamo, M.; Heusel, J.; Narezo Guzmán, D. Synthetic data generation for condition monitoring of railway switches. In Proceedings of the European Dependable Computing Conference, Zaragoza, Spain, 12–15 September 2022; pp. 76–88. [Google Scholar]

- Tang, R.; De Donato, L.; Besinović, N.; Flammini, F.; Goverde, R.M.; Lin, Z.; Liu, R.; Tang, T.; Vittorini, V.; Wang, Z. A literature review of Artificial Intelligence applications in railway systems. Transp. Res. Part C Emerg. Technol. 2022, 140, 103679. [Google Scholar] [CrossRef]

- Minguell, M.G.; Pandit, R. TrackSafe: A comparative study of data-driven techniques for automated railway track fault detection using image datasets. Eng. Appl. Artif. Intell. 2023, 125, 106622. [Google Scholar] [CrossRef]

- Ye, J.; Stewart, E.; Chen, Q.; Roberts, C.; Hajiyavand, A.M.; Lei, Y. Deep Learning and Laser-Based 3-D Pixel-Level Rail Surface Defect Detection Method. IEEE Trans. Instrum. Meas. 2023, 72, 3272033. [Google Scholar] [CrossRef]

- Du, X.; Cheng, Y.; Gu, Z. Change Detection: The Framework of Visual Inspection System for Railway Plug Defects. IEEE Access 2020, 8, 152161–152172. [Google Scholar] [CrossRef]

- Niebling, J.; Baasch, B.; Kruspe, A. Analysis of Railway Track Irregularities with Convolutional Autoencoders and Clustering Algorithms. In Dependable Computing—EDCC 2020 Workshops; Communications in Computer and Information Science; Springer: Berlin/Heidelberg, Germany, 2020; pp. 78–89. [Google Scholar]

- Shen, Y.; Zhong, Q.; Zheng, S.; Li, L.; Peng, L. A Multi-Modal Approach to Rail Surface Condition Analysis: The MFDF-Net. IEEE Access 2024, 12, 132480–132494. [Google Scholar] [CrossRef]

- Hao, X.; Yang, J.; Yang, F.; Sun, X.; Hou, Y.; Wang, J. Track geometry estimation from vehicle–body acceleration for high-speed railway using deep learning technique. Veh. Syst. Dyn. 2022, 61, 239–259. [Google Scholar] [CrossRef]

- Popov, K.; De Bold, R.; Chai, H.K.; Forde, M.C.; Ho, C.L.; Hyslip, J.P.; Kashani, H.F.; Long, P.; Hsu, S.S. Big-data driven assessment of railway track and maintenance efficiency using Artificial Neural Networks. Constr. Build. Mater. 2022, 349, 128786. [Google Scholar] [CrossRef]

- Nagy, R.; Horvát, F.; Fischer, S. Innovative approaches in railway management: Leveraging big data and artificial intelligence for predictive maintenance of track geometry. Teh. Vjesn. 2024, 31, 1245–1259. [Google Scholar] [CrossRef]

- Brown, L.; Afazov, S.; Scrimieri, D. Towards Autonomous Health Monitoring of Rails Using a FEA-ANN Based Approach. In Advances in Computational Intelligence Systems; Advances in Intelligent Systems and Computing; Springer: Berlin/Heidelberg, Germany, 2022; pp. 569–576. [Google Scholar]

- Ghiasi, R.; Khan, M.A.; Sorrentino, D.; Diaine, C.; Malekjafarian, A. An unsupervised anomaly detection framework for onboard monitoring of railway track geometrical defects using one-class support vector machine. Eng. Appl. Artif. Intell. 2024, 133, 108167. [Google Scholar] [CrossRef]

- Tsunashima, H. Condition Monitoring of Railway Tracks from Car-Body Vibration Using a Machine Learning Technique. Appl. Sci. 2019, 9, 2734. [Google Scholar] [CrossRef]

- Gallo, V.; Shallari, I.; Carratu, M.; O’Nils, M. Metrological Characterization of a Clip Fastener assembly fault detection system based on Deep Learning. In Proceedings of the 2023 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Kuala Lumpur, Malaysia, 22–25 May 2023; pp. 1–6. [Google Scholar]

- Alif, M.A.R.; Hussain, M.; Tucker, G.; Iwnicki, S. BoltVision: A Comparative Analysis of CNN, CCT, and ViT in Achieving High Accuracy for Missing Bolt Classification in Train Components. Machines 2024, 12, 93. [Google Scholar] [CrossRef]

- Lin, Y.-W.; Hsieh, C.-C.; Huang, W.-H.; Hsieh, S.-L.; Hung, W.-H. Railway track fasteners fault detection using deep learning. In Proceedings of the 2019 IEEE Eurasia Conference on IOT, Communication and Engineering (ECICE), Yunlin, Taiwan, 3–6 October 2019; pp. 187–190. [Google Scholar]

- Mazzeo, P.; Nitti, M.; Stella, E.; Ancona, N.; Distante, A. An automatic inspection system for the hexagonal headed bolts detection in railway maintenance. In Proceedings of the 7th International IEEE Conference on Intelligent Transportation Systems (IEEE Cat. No. 04TH8749), Washington, WA, USA, 3–6 October 2004; pp. 417–422. [Google Scholar]

- Mammeri, A.; Siddiqui, A.J.; Zhao, Y. Detection of Rail-track and Floodwater in UAV Imaging sensors Using Deep Learning. In Proceedings of the 2024 IEEE International Systems Conference (SysCon), Montreal, QC, Canada, 15–18 April 2024; pp. 1–6. [Google Scholar]

- Wang, Y.; Liu, H.; Yang, L.; Durazo-Cardenas, I.; Namoano, B.; Zhong, C.; Zhao, Y. A full 3D reconstruction of rail tracks using a camera array. Measurement 2024, 225, 114034. [Google Scholar] [CrossRef]

- Ooppakaew, W.; Onshaunjit, J.; Khrueakhrai, S.; Srinonchat, J. Improving Railway Track Detection with a Mixed-Modality Deep Learning Approach. IEEE Access 2025, 13, 134541–134551. [Google Scholar] [CrossRef]

- Kapoor, R.; Goel, R.; Sharma, A. An intelligent railway surveillance framework based on recognition of object and railway track using deep learning. Multimed. Tools Appl. 2022, 81, 21083–21109. [Google Scholar] [CrossRef] [PubMed]

- Rampriya, R.S.; Suganya, R.; Nathan, S.; Perumal, P.S. A Comparative Assessment of Deep Neural Network Models for Detecting Obstacles in the Real Time Aerial Railway Track Images. Appl. Artif. Intell. 2022, 36, 2018184. [Google Scholar] [CrossRef]

- Fantini, A.; Fiorucci, M.; Martino, S. Rock Falls Impacting Railway Tracks: Detection Analysis through an Artificial Intelligence Camera Prototype. Wirel. Commun. Mob. Comput. 2017, 2017, 9386928. [Google Scholar] [CrossRef]

- Perić, S.; Milojković, M.; Stan, S.-D.; Banić, M.; Antić, D. Dealing with Low Quality Images in Railway Obstacle Detection System. Appl. Sci. 2022, 12, 3041. [Google Scholar] [CrossRef]

- Aydin, I.; Akin, E.; Karakose, M. Defect classification based on deep features for railway tracks in sustainable transportation. Appl. Soft Comput. 2021, 111, 107706. [Google Scholar] [CrossRef]

- Molodova, M.; Oregui, M.; Núñez, A.; Li, Z.; Dollevoet, R. Health condition monitoring of insulated joints based on axle box acceleration measurements. Eng. Struct. 2016, 123, 225–235. [Google Scholar] [CrossRef]

- Cho, H.; Park, J.; Park, K. Analysis of Axial Acceleration for the Detection of Rail Squats in High-Speed Railways. CivilEng 2023, 4, 1143–1156. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, B.-K.; Li, J.; Xing, Z.-Y. Rail corrugation identification method based on parameter optimization VMD and SPWVD. In Proceedings of the 2019 IEEE 16th International Conference on Networking, Sensing and Control (ICNSC), Banff, AB, Canada, 9–11 May 2019; pp. 110–115. [Google Scholar]

- Wei, X.; Yin, X.; Hu, Y.; He, Y.; Jia, L. Squats and corrugation detection of railway track based on time-frequency analysis by using bogie acceleration measurements. Veh. Syst. Dyn. 2019, 58, 1167–1188. [Google Scholar] [CrossRef]

- Sun, H.; He, D.; Ma, H.; Wen, Z.; Deng, J. The parameter identification of metro rail corrugation based on effective signal extraction and inertial reference method. Eng. Fail. Anal. 2024, 158, 108043. [Google Scholar] [CrossRef]

- Hua, J.; Zhiquan, W. Resolving mode mixing in wheel–rail surface defect detection using EMD based on binary time scale. Meas. Sci. Technol. 2023, 35, 035015. [Google Scholar] [CrossRef]

- Bergseth, E.; Höjer, M.; Lyu, Y.; Nilsson, R.; Olofsson, U. A Wear Detection Parameter for the Wheel–Rail Contact Based on Emitted Noise. Tribol. Trans. 2019, 62, 496–503. [Google Scholar] [CrossRef]

- Tang, W.; Peng, L.; Li, Z.; Liu, K.; Pan, Z.; Yuan, S.; Xie, L.; Peng, G.-D.; Yang, M.; Fan, X. Detection of railway wheel and rail diseases based on distributed optical fiber acoustic sensing. In Advanced Sensor Systems and Applications XII; SPIE: Cergy Pontoise, France, 2022. [Google Scholar]

- Yuan, Z.; Zhu, S.; Chang, C.; Yuan, X.; Zhang, Q.; Zhai, W. An unsupervised method based on convolutional variational auto-encoder and anomaly detection algorithms for light rail squat localization. Constr. Build. Mater. 2021, 313, 125563. [Google Scholar] [CrossRef]

- Traquinho, N.; Vale, C.; Ribeiro, D.; Meixedo, A.; Montenegro, P.; Mosleh, A.; Calçada, R. Damage Identification for Railway Tracks Using Onboard Monitoring Systems in In-Service Vehicles and Data Science. Machines 2023, 11, 981. [Google Scholar] [CrossRef]

- Chellaswamy, C.; Krishnasamy, M.; Balaji, L.; Dhanalakshmi, A.; Ramesh, R. Optimized railway track health monitoring system based on dynamic differential evolution algorithm. Measurement 2020, 152, 107332. [Google Scholar] [CrossRef]

- Hubbard, P.; Harrison, T.; Ward, C.; Abduraxman, B. Creep slope estimation for assessing adhesion in the wheel/rail contact. IET Intell. Transp. Syst. 2024, 18, 1931–1942. [Google Scholar] [CrossRef]

- Namoano, B.; Emmanouilidis, C.; Starr, A. Detecting wheel slip from railway operational data through a combined wavelet, long short-term memory and neural network classification method. Eng. Appl. Artif. Intell. 2024, 137, 109173. [Google Scholar] [CrossRef]

- Zeng, C.; Zhao, G.; Xie, J.; Huang, J.; Wang, Y. An explainable artificial intelligence approach for mud pumping prediction in railway track based on GIS information and in-service train monitoring data. Constr. Build. Mater. 2023, 401, 132716. [Google Scholar] [CrossRef]

- Zhuang, Y.; Tang, Y.; Qiu, Y.; Liu, R. Short-term prediction of railway track degradation using ensemble deep learning. Comput. Aided Civ. Infrastruct. Eng. 2025, 40, 1314–1343. [Google Scholar] [CrossRef]

- Tumanishvili, G.; Chelidze, M.; Zviadauri, V. Loading and damageability of wheels and rails. Transp. Probl. 2009, 4, 33–42. [Google Scholar]

- Oregui, M.; Li, Z.; Dollevoet, R. Relating track parameter conditions to squat and corrugation initiation and growth. In ISMA2010; Tu Delft Repository: Leuven, Belgium, 2010. [Google Scholar]

- Johansson, A.; Pålsson, B.; Ekh, M.; Nielsen, J.C.; Ander, M.K.; Brouzoulis, J.; Kassa, E. Simulation of wheel–rail contact and damage in switches & crossings. Wear 2011, 271, 472–481. [Google Scholar] [CrossRef]

- Li, S.; Li, Z.; Núñez, A.; Dollevoet, R. New Insights into the Short Pitch Corrugation Enigma Based on 3D-FE Coupled Dynamic Vehicle-Track Modeling of Frictional Rolling Contact. Appl. Sci. 2017, 7, 807. [Google Scholar] [CrossRef]

- Kou, L.; Sysyn, M.; Liu, J. Influence of Crossing Wear on Rolling Contact Fatigue Damage of Frog Rail. Facta Univ. Ser. Mech. Eng. 2024, 22, 025–044. [Google Scholar] [CrossRef]

- H-Nia, S.; Flodin, J.; Casanueva, C.; Asplund, M.; Stichel, S. Predictive maintenance in railway systems: MBS-based wheel and rail life prediction exemplified for the Swedish Iron-Ore line. Veh. Syst. Dyn. 2023, 62, 3–20. [Google Scholar] [CrossRef]

- Soleimanmeigouni, I.; Ahmadi, A.; Nissen, A.; Xiao, X. Prediction of railway track geometry defects: A case study. Struct. Infrastruct. Eng. 2019, 16, 987–1001. [Google Scholar] [CrossRef]

- Liu, J.-H.; Yang, W.-H.; He, J.; Wang, Z.-M.; Jia, L.; Zhang, C.-F.; Yang, W.-W. Intelligent prediction of rail corrugation evolution trend based on self-attention bidirectional TCN and GRU. Intell. Robot. 2024, 4, 318–338. [Google Scholar] [CrossRef]

- Lee, M.L.; Chiu, W.K. Determination of railway vertical wheel impact magnitudes: Field trials. Struct. Health Monit. 2007, 6, 49–65. [Google Scholar] [CrossRef]

- Bian, J.; Gu, Y.; Murray, M. Numerical study of impact forces on railway sleepers under wheel flat. Adv. Struct. Eng. 2013, 16, 127–134. [Google Scholar] [CrossRef]

- Jin, Z.; Zhang, W.; Yin, Z.-Y.; Zhang, N.; Geng, X. Estimating track geometry irregularities from in-service train accelerations using deep learning. Autom. Constr. 2025, 173, 106114. [Google Scholar] [CrossRef]

- Trollé, B.; Baietto, M.C.; Gravouil, A.; Mai, S.H.; Nguyen-Tajan, T.M.L. XFEM Crack Propagation Under Rolling Contact Fatigue. Procedia Eng. 2013, 66, 775–782. [Google Scholar] [CrossRef]

- Rhylane, H.; Ajdour, M. Dynamic analysis of railway track response subjected to train moving loads using finite element simulation. Transp. Infrastruct. Geotechnol. 2024, 11, 650–674. [Google Scholar] [CrossRef]

- Ren, Y.; Yao, D.; Yue, X.; Li, X.; Yang, J.; Huo, J.; Zhu, B.; Dai, Y. Vibration reduction and dynamic response analysis of urban railway steel-spring floating slabs under periodic track irregularities. J. Vib. Control. 2025, 0, 10775463251357330. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Y.; Zhou, R.; Xu, J.; Sheng, X.; Xu, F. Refined dynamic analysis of three slab tracks on bridge structures under various high-speed train loads. J. Low Freq. Noise Vib. Act. Control. 2024, 43, 1437–1455. [Google Scholar] [CrossRef]

- Huang, X.; Zeng, Z.; Wang, D.; Luo, X.; Li, P.; Wang, W. Experimental study on the vibration reduction characteristics of the floating slab track for 160 km/h urban rail transit. Structures 2023, 51, 1230–1244. [Google Scholar] [CrossRef]

- Sresakoolchai, J.; Hamarat, M.; Kaewunruen, S. Automated machine learning recognition to diagnose flood resilience of railway switches and crossings. Sci. Rep. 2023, 13, 2106. [Google Scholar] [CrossRef] [PubMed]

- Kennedy, J.; Woodward, P.K.; Medero, G.; Banimahd, M. Reducing railway track settlement using three-dimensional polyurethane polymer reinforcement of the ballast. Constr. Build. Mater. 2013, 44, 615–625. [Google Scholar] [CrossRef]

- Park, D.-W.; Choi, C.; Phan, T.M.; Minh Le, T.H. Mobilizing railway track stability with nonionic cement asphalt mortar for floating sleeper mitigation—2D/3D numerical investigation and full-scale testing verification. Case Stud. Constr. Mater. 2024, 20, e03088. [Google Scholar] [CrossRef]

- Szabó, J. Tests experiences in small radius curves of continuously welded rail tracks. Period. Polytech. Civ. Eng. 2011, 55, 177. [Google Scholar] [CrossRef]

- Jing, G.; Zong, L.; Ji, Y.; Aela, P. Optimization of FFU synthetic sleeper shape in terms of ballast lateral resistance. Sci. Iran. 2021, 28, 3046–3057. [Google Scholar] [CrossRef]

- Xiao, Y.; Shen, Z.; Tan, P.; Hua, W.; Wang, M.; Jitsangiam, P. Evaluating enhancement effect of bottom groove shape on lateral resistance of frictional sleepers in ballasted railway track via hybrid DEM-FDM approach. Constr. Build. Mater. 2024, 436, 136755. [Google Scholar] [CrossRef]

- Siahkouhi, M.; Wang, J.; Han, X.; Aela, P.; Ni, Y.-Q.; Jing, G. Railway ballast track hanging sleeper defect detection using a smart CNT self-sensing concrete railway sleeper. Constr. Build. Mater. 2023, 399, 132487. [Google Scholar] [CrossRef]

- Noppharat, S.; Raj, A.; Ngamkhanong, C.; Li, T.; You, R.; Kaewunruen, S. Dynamic train-track interactions over track stiffness discontinuities in railway track transitions mitigated by resilient materials. Innov. Infrastruct. Solut. 2024, 9, 322. [Google Scholar] [CrossRef]

- Cui, R.; Gao, L.; Ye, J.; Zhang, X. Long-term diagnostic technology for the monitoring of continuous welded rail on curves in a cold area. AIP Adv. 2021, 11, 075026. [Google Scholar] [CrossRef]

- Li, P.; Wang, M.; Yu, T.; Feng, N.; Lan, C.; Yang, K.; Li, S.; Zhang, H. A monitoring method of rail fastener reaction force based on iron pad strain. Constr. Build. Mater. 2024, 418, 135169. [Google Scholar] [CrossRef]

- Cañete, E.; Chen, J.; Díaz, M.; Llopis, L.; Rubio, B. Wireless sensor networks and structural health monitoring: Experiences with slab track infrastructures. Int. J. Distrib. Sens. Netw. 2019, 15, 1550147719826002. [Google Scholar] [CrossRef]

- Yong, G.; Lee, G. Trends, Topics, Leaders, Influential Studies, and Future Challenges of Machine Learning Studies in the Rail Industry. J. Infrastruct. Syst. 2022, 28, 03122001. [Google Scholar] [CrossRef]

- Kim, B.-K.; Kim, W.; Lee, C.; Yoo, M.; Lee, I. Validating Railway Infrastructure Deformation Monitoring: A Comparative Analysis of Field Data and TerraSAR-X PS-InSAR Results. KSCE J. Civ. Eng. 2024, 28, 1777–1786. [Google Scholar] [CrossRef]

- Koohmishi, M.; Kaewunruen, S.; Chang, L.; Guo, Y. Advancing railway track health monitoring: Integrating GPR, InSAR and machine learning for enhanced asset management. Autom. Constr. 2024, 162, 105378. [Google Scholar] [CrossRef]

- Agustin, D.; Wu, Q.; Bernal, E.; Spiryagin, M.; Cole, C. Railway track buckling evaluation using rigid-flexible multibody dynamic model and machine learning. Mech. Based Des. Struct. Mach. 2025, 53, 4830–4852. [Google Scholar] [CrossRef]

- Shi, S.; Wang, J.; Gao, L.; Zhang, Y.; Xiao, Y.; Ding, J. Intelligent optimization of tamping parameters using discrete element and radial basis function-multi-objective genetic algorithm (RBF-MOGA). Autom. Constr. 2024, 168, 105752. [Google Scholar] [CrossRef]

- Przybyłowicz, M.; Sysyn, M.; Gerber, U.; Kovalchuk, V.; Fischer, S. Comparison of the effects and efficiency of vertical and side tamping methods for ballasted railway tracks. Constr. Build. Mater. 2022, 314, 125708. [Google Scholar] [CrossRef]

- Amiel, E.; Anastasopoulos, M.; Chevaleyre, G.; Consilvio, A. On applying artificial intelligence techniques to maximise passengers comfort and infrastructure reliability in urban railway systems. In Proceedings of the 2023 8th International Conference on Models and Technologies for Intelligent Transportation Systems (MT-ITS), Nice, France, 14–16 June 2023; pp. 1–6. [Google Scholar]

- Merheb, A.; Palese, J.; Hartsough, C.M.; Zarembski, A.; Bernucci, L. The Influence of Seasonal Effects on Railway Vertical Track Modulus. Infrastructures 2024, 9, 120. [Google Scholar] [CrossRef]

- Chen, R.; Wang, P.; Xu, H. Integrated Monitoring System for Rail Damage in High Speed Railway Turnout. In Proceedings of the 2013 Fourth International Conference on Digital Manufacturing & Automation, Shinan, China, 29–30 June 2013; pp. 704–708. [Google Scholar]

- Du, C.; Dutta, S.; Kurup, P.; Yu, T.; Wang, X. A review of railway infrastructure monitoring using fiber optic sensors. Sens. Actuators A Phys. 2020, 303, 111728. [Google Scholar] [CrossRef]

- Zeng, C.; Huang, J.; Wang, H.; Xie, J.; Huang, S. Rail Break Prediction and Cause Analysis Using Imbalanced In-Service Train Data. IEEE Trans. Instrum. Meas. 2022, 71, 3527114. [Google Scholar] [CrossRef]

- Wei, X.; Yang, Z.; Liu, Y.; Wei, D.; Jia, L.; Li, Y. Railway track fastener defect detection based on image processing and deep learning techniques: A comparative study. Eng. Appl. Artif. Intell. 2019, 80, 66–81. [Google Scholar] [CrossRef]

- Iyer, S.; Velmurugan, T.; Gandomi, A.H.; Noor Mohammed, V.; Saravanan, K.; Nandakumar, S. Structural health monitoring of railway tracks using IoT-based multi-robot system. Neural Comput. Appl. 2020, 33, 5897–5915. [Google Scholar] [CrossRef]

- Nigam, S.; Kumar, D.; Mukherji, S.; Tomar, S.S.; Shastri, S.; Gupta, P. Predictive Maintenance of Railway Tracks Using LSTM. In Proceedings of the 2024 IEEE International Conference on Intelligent Signal Processing and Effective Communication Technologies (INSPECT), Gwalior, India, 7–8 December 2024; pp. 1–5. [Google Scholar]

- Zhang, Y.; Dang, D.-Z.; Wang, Y.-W.; Ni, Y.-Q. Damage identification for railway tracks using ultrasound guided wave and hybrid probabilistic deep learning. Constr. Build. Mater. 2024, 418, 135466. [Google Scholar] [CrossRef]

- Li, Q.; Gao, J.; Beck, J.L.; Lin, C.; Huang, Y.; Li, H. Probabilistic outlier detection for robust regression modeling of structural response for high-speed railway track monitoring. Struct. Health Monit. 2023, 23, 1280–1296. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, C.; Liu, X.; Liu, Y.; Lu, W.; Zhu, Z.; Yan, H.; Zhao, G.; Lin, X. High-precision laser monitoring system with enhanced non-uniform scanning for railway safety. Railw. Eng. Sci. 2024, 33, 79–93. [Google Scholar] [CrossRef]

- Chang, Y.; Zhang, X.; Song, S.; Song, Q.; Zhao, Z.; Wang, W.; Jie, H.; Shen, Y. EMAE-Based Rail Structural Health Monitoring Using Double-Layer Signal Processing and Spectrum Information Entropy. IEEE Trans. Intell. Transp. Syst. 2024, 25, 11370–11381. [Google Scholar] [CrossRef]

- Wei, D.; Wei, X.; Liu, Y.; Jia, L.; Zhang, W. The Identification and Assessment of Rail Corrugation Based on Computer Vision. Appl. Sci. 2019, 9, 3913. [Google Scholar] [CrossRef]

- Feng, Z.-C.; Yang, J.; Li, F.; Chen, Z.-C.; Kang, Z.; Jia, L.-M. An Efficient Foreign Object Recognition Model in Rail Transit Based on Real-Time Railway Region Extraction and Object Detection. J. Electr. Eng. Technol. 2024, 19, 3723–3734. [Google Scholar] [CrossRef]

- Zakaria, A.-R.; Oommen, T.; Lautala, P. Automated Flood Prediction along Railway Tracks Using Remotely Sensed Data and Traditional Flood Models. Remote Sens. 2024, 16, 2332. [Google Scholar] [CrossRef]

- Chen, J.; Li, Q.; Zhang, S.; Lin, C.; Wei, S. Adaptive Vibration Monitoring of Railway Track Structures Using the UWFBG by the Identification of Train-Load Patterns. Buildings 2024, 14, 1239. [Google Scholar] [CrossRef]

- Alif, M.A.R.; Hussain, M. Lightweight Convolutional Network with Integrated Attention Mechanism for Missing Bolt Detection in Railways. Metrology 2024, 4, 254–278. [Google Scholar] [CrossRef]

- Li, T.; Su, Q.; Kaewunruen, S. Saturated Ground Vibration Analysis Based on a Three-Dimensional Coupled Train-Track-Soil Interaction Model. Appl. Sci. 2019, 9, 4991. [Google Scholar] [CrossRef]

- Zhou, C.; Zhang, C.; Su, Z.; Yue, X.; Xiang, J.; Liu, G. Health monitoring of rail structures using guided waves and three-dimensional diagnostic imaging. Struct. Control. Health Monit. 2017, 24, e1966. [Google Scholar] [CrossRef]

- Cai, X.; Tang, X.; Pan, S.; Wang, Y.; Yan, H.; Ren, Y.; Chen, N.; Hou, Y. Intelligent recognition of defects in high-speed railway slab track with limited dataset. Comput. Aided Civ. Infrastruct. Eng. 2023, 39, 911–928. [Google Scholar] [CrossRef]

- Tang, X.; Wang, Y.; Cai, X.; Yang, F.; Hou, Y. Diagnosis of high-speed railway ballastless track arching based on unsupervised learning framework. Comput. Aided Civ. Infrastruct. Eng. 2024, 40, 1445–1465. [Google Scholar] [CrossRef]

- Wang, S.; Gao, J.; Lin, C.; Li, H.; Huang, Y. Condition assessment of high-speed railway track structure based on sparse Bayesian extreme learning machine and Bayesian hypothesis testing. Int. J. Rail Transp. 2022, 11, 364–388. [Google Scholar] [CrossRef]

- Han, C.; Wang, S.; Madan, A.; Zhao, C.; Mohanty, L.; Fu, Y.; Shen, W.; Liang, R.; Huang, E.S.; Zheng, T.; et al. Intelligent detection of loose fasteners in railway tracks using distributed acoustic sensing and machine learning. Eng. Appl. Artif. Intell. 2024, 134, 108684. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, T.; Wu, X.; Liu, C.; Yu, X. Improving rail transit security with enhanced YOLOv5 obstacle detection. Transp. Saf. Environ. 2024, 6, tdae020. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dinh, T.P.; Le, Q.H.; Thach, T.N.; Kim, B.; Ahn, Y. Railway Track Structural Health Monitoring: Identifying Emerging Trends and Research Agendas Using Bibliometric and Topic Modeling. Appl. Sci. 2025, 15, 12462. https://doi.org/10.3390/app152312462

Dinh TP, Le QH, Thach TN, Kim B, Ahn Y. Railway Track Structural Health Monitoring: Identifying Emerging Trends and Research Agendas Using Bibliometric and Topic Modeling. Applied Sciences. 2025; 15(23):12462. https://doi.org/10.3390/app152312462

Chicago/Turabian StyleDinh, Tien Phat, Quang Hoai Le, Thao Nguyen Thach, Byeol Kim, and Yonghan Ahn. 2025. "Railway Track Structural Health Monitoring: Identifying Emerging Trends and Research Agendas Using Bibliometric and Topic Modeling" Applied Sciences 15, no. 23: 12462. https://doi.org/10.3390/app152312462

APA StyleDinh, T. P., Le, Q. H., Thach, T. N., Kim, B., & Ahn, Y. (2025). Railway Track Structural Health Monitoring: Identifying Emerging Trends and Research Agendas Using Bibliometric and Topic Modeling. Applied Sciences, 15(23), 12462. https://doi.org/10.3390/app152312462