Strength and Strain Properties of Coal Sludge

Abstract

1. Introduction

2. Materials and Methods

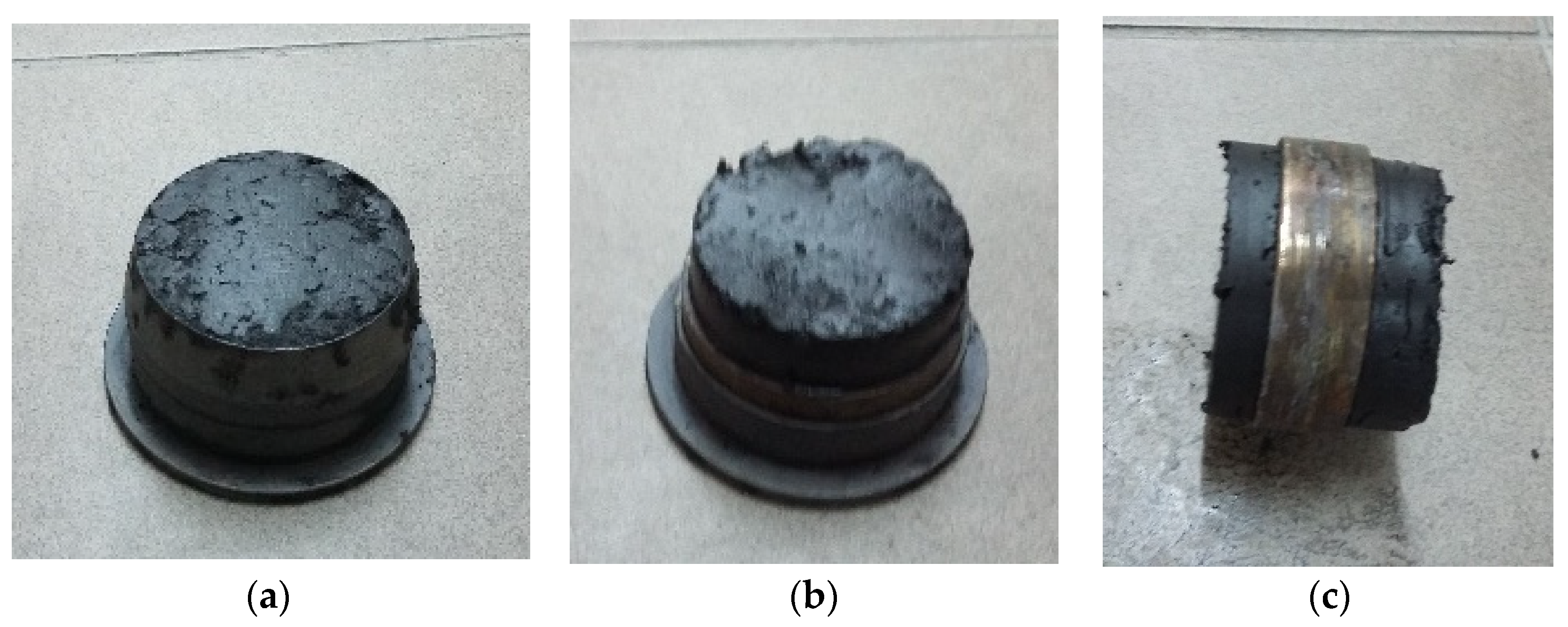

2.1. Material Characteristic

2.2. Research Methodology

2.2.1. Strength Parameters Determination

2.2.2. Strain Parameters Determination

3. Results

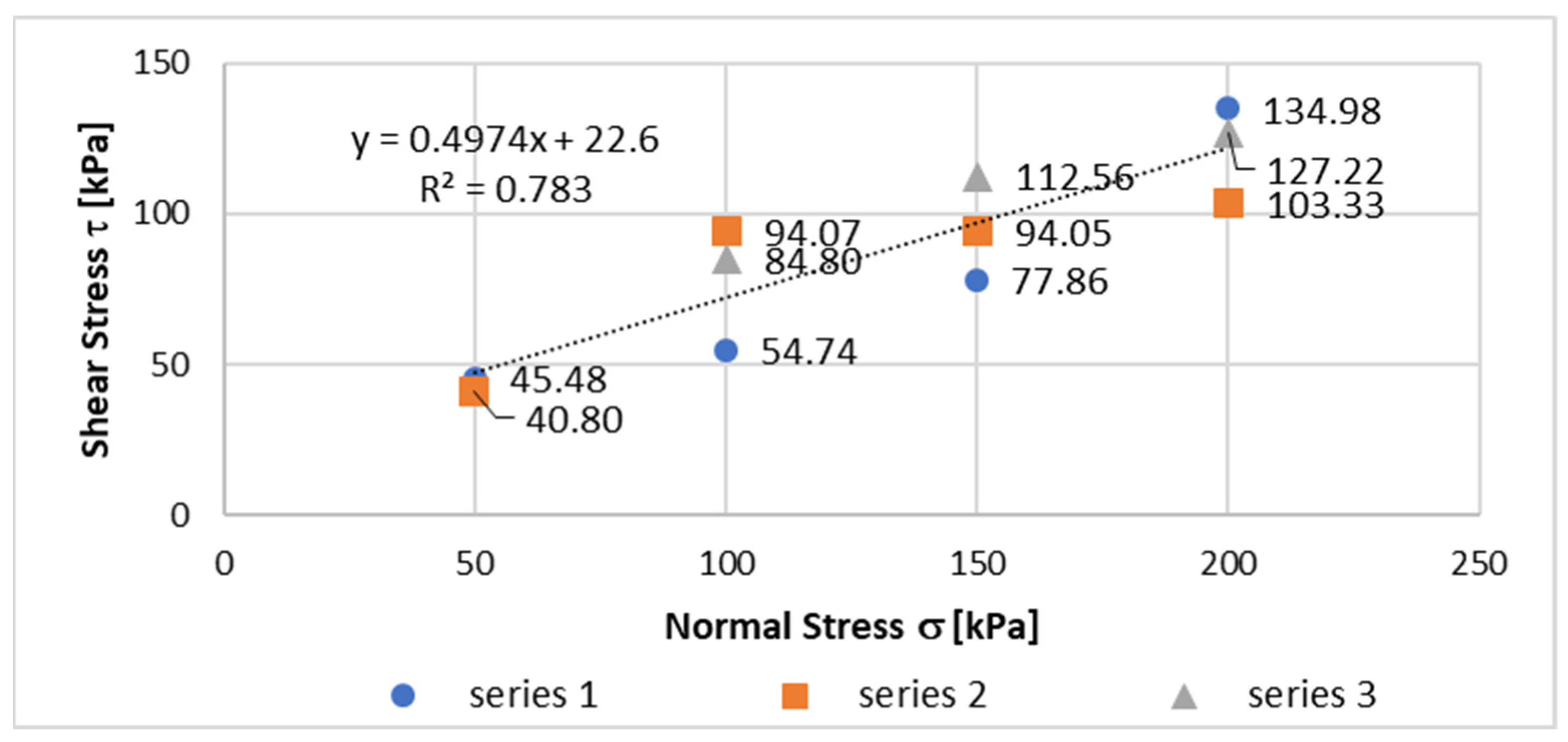

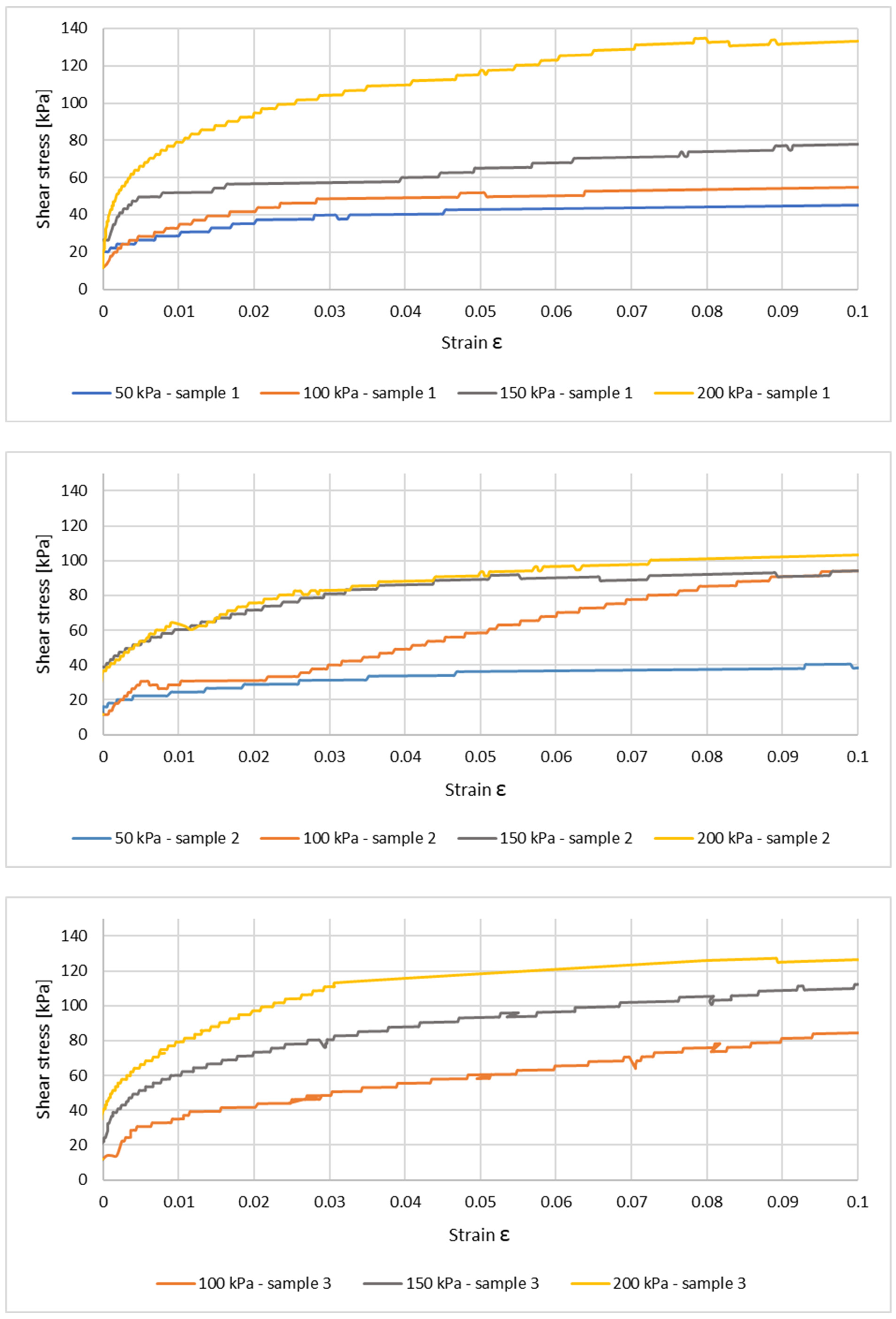

3.1. Internal Friction Angle and Cohesion Determination

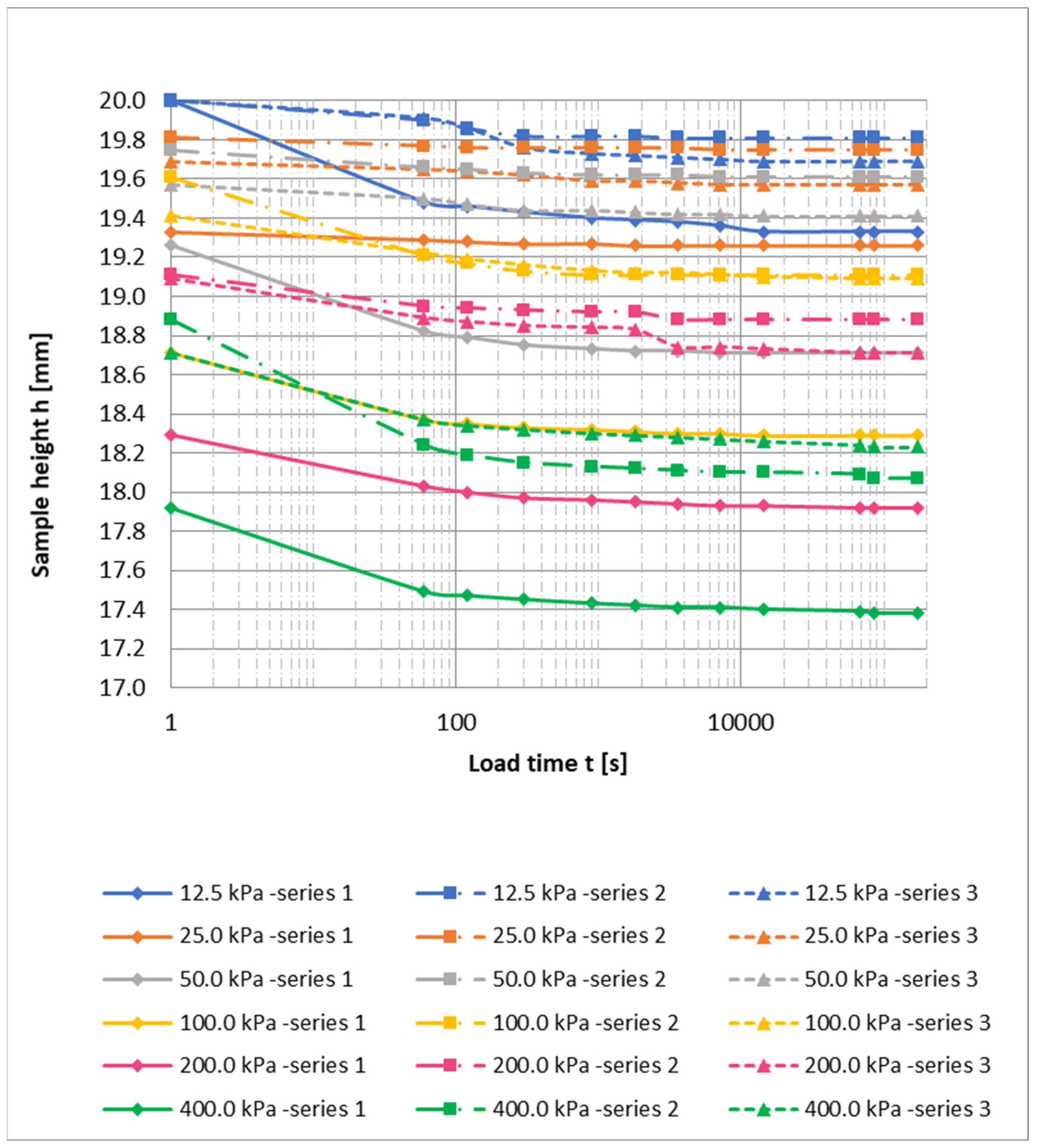

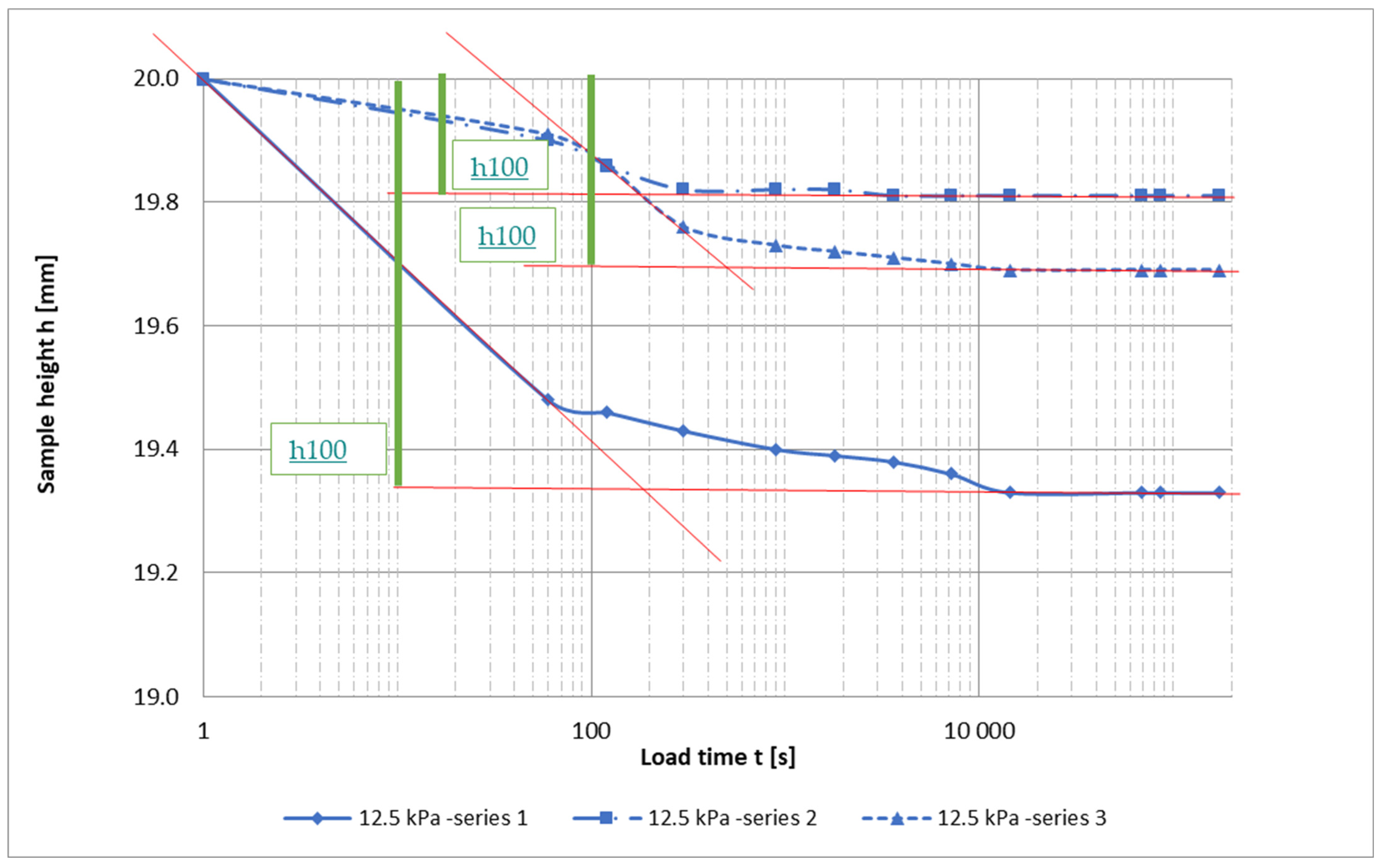

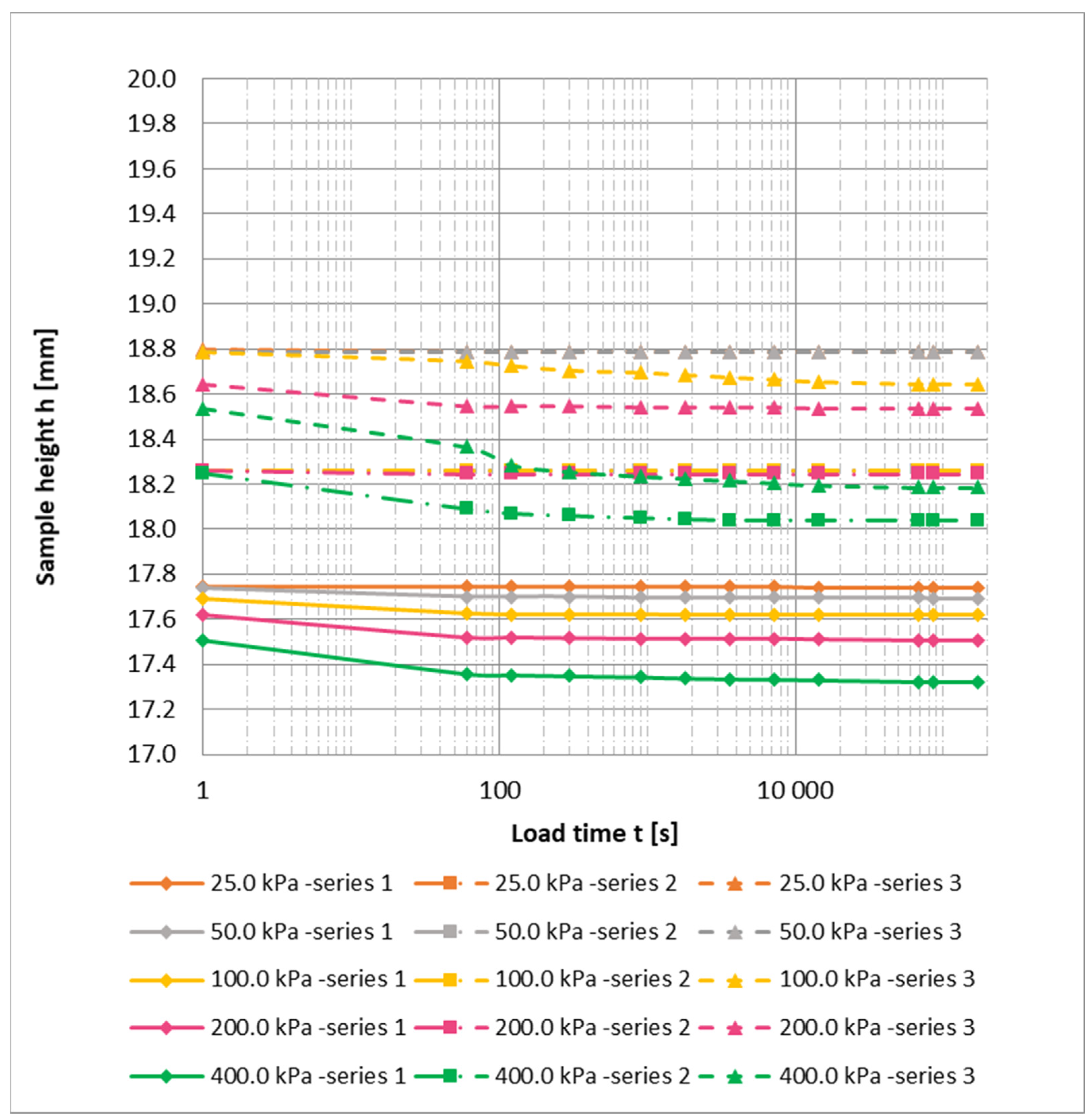

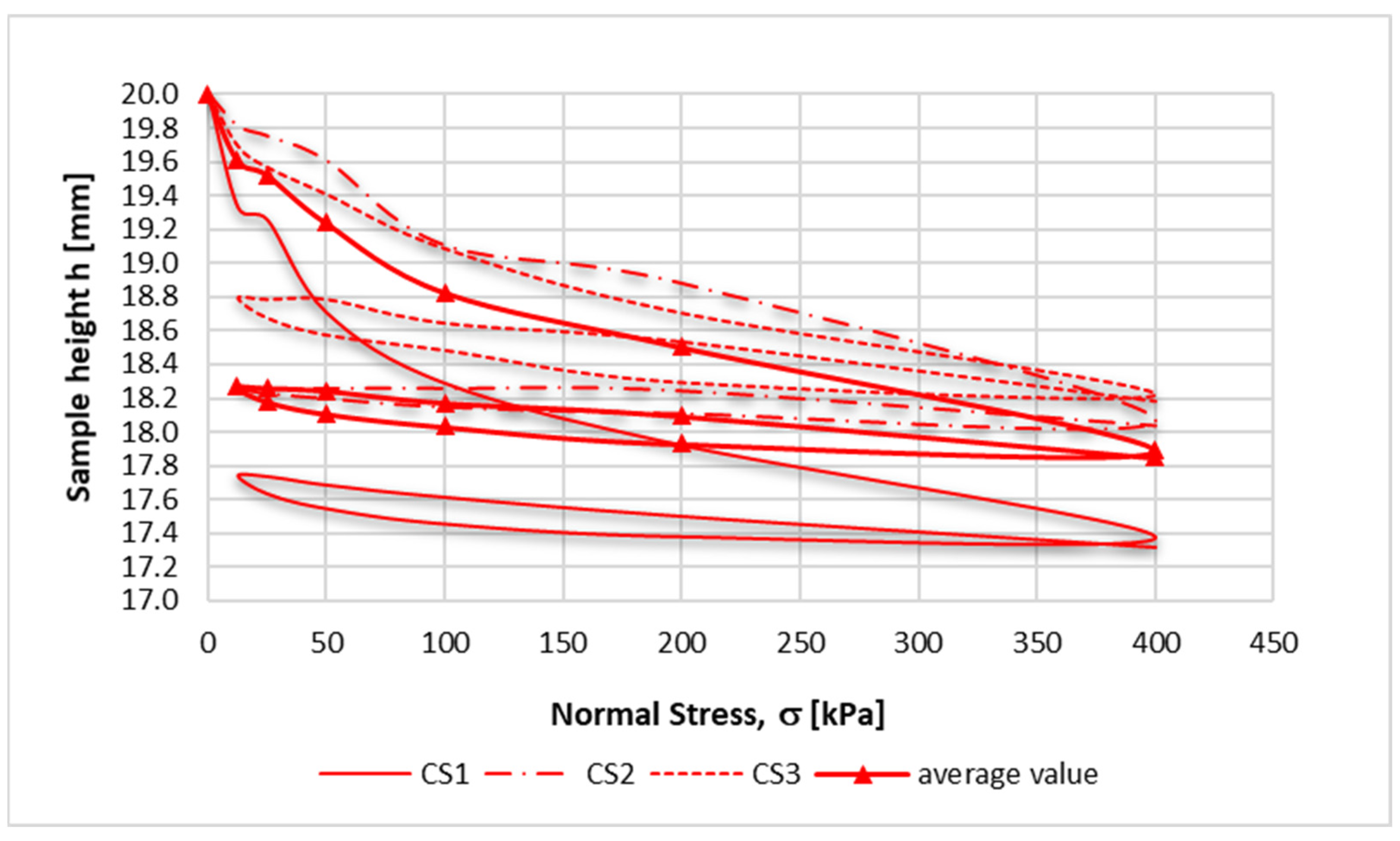

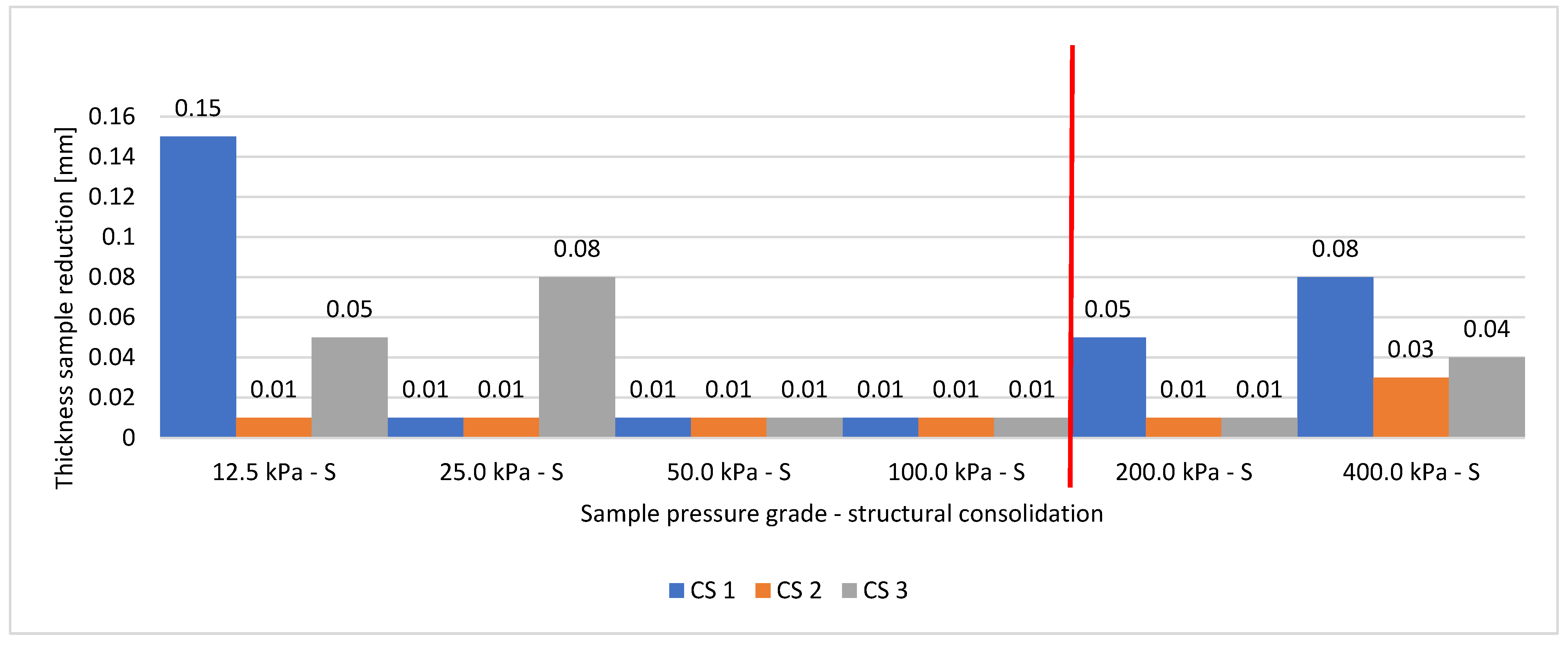

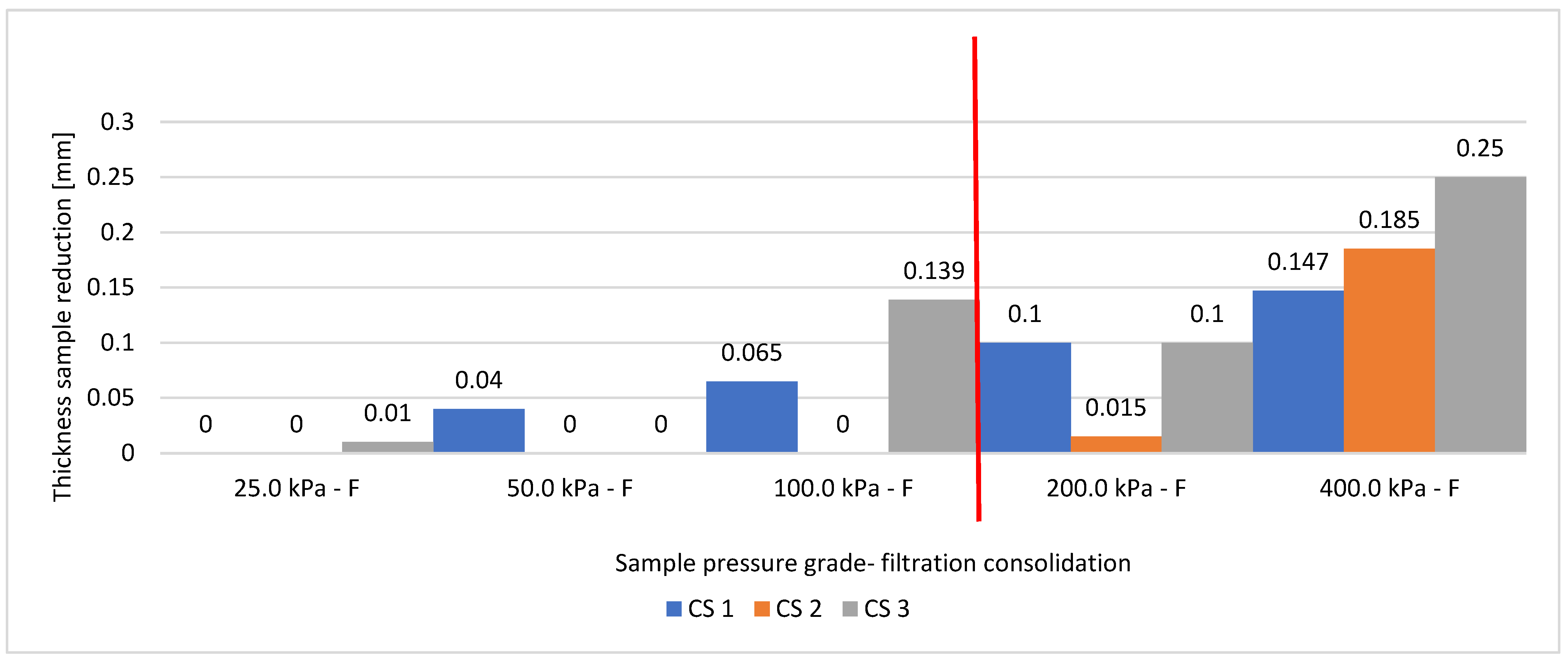

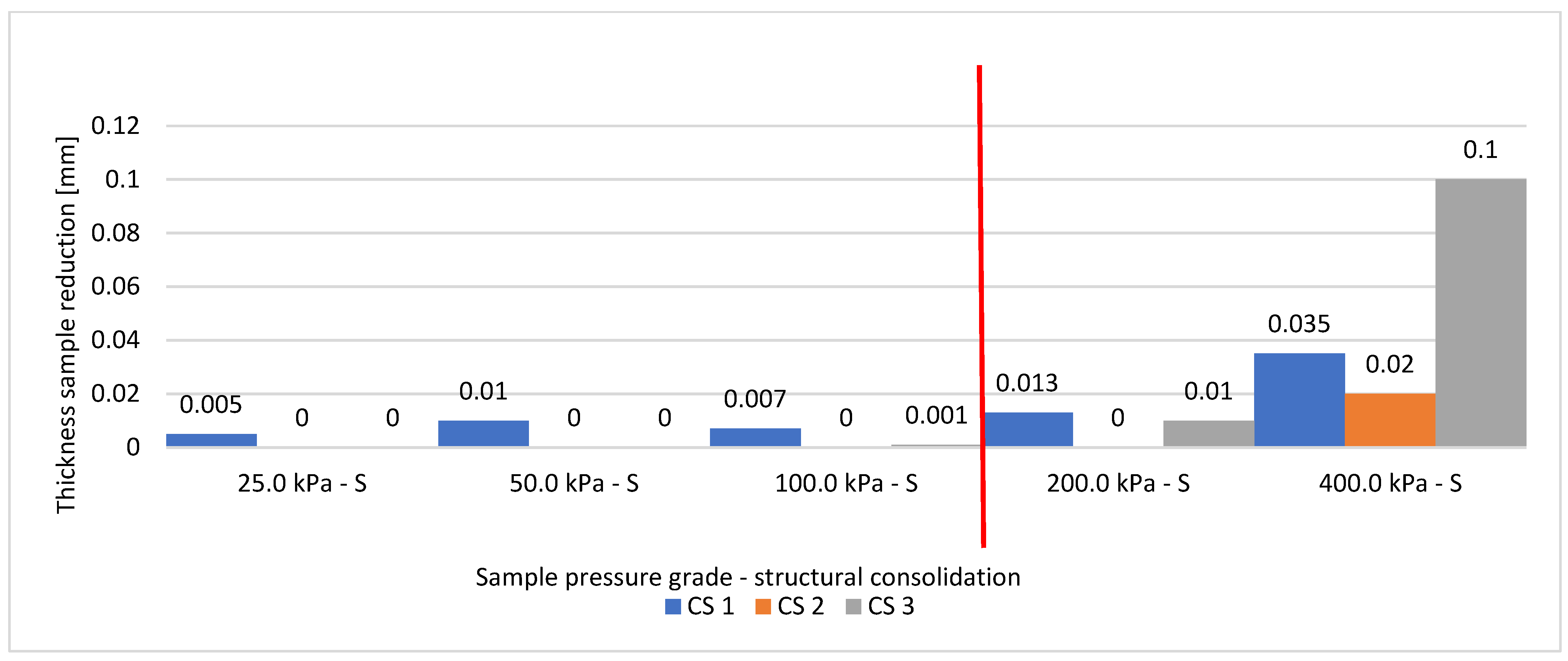

3.2. Primary and Recompression Modulus of Compressibility Determination

4. Discussion

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CS | Coal sludge |

| c | Cohesion |

| φ | Internal friction angle |

| M0 | Primary compressibility modulus |

| M | Re-compressibility modulus |

| Δεh | Vertical deformation increase |

References

- Mirkowski, Z.; Badera, J. Odpady górnictwa węgla kamiennego, zagrożenia i ochrona środowiska. In Raport z Monitoringu Zagospodarowania Odpadów Wydobywczych; Towarzystwo dla Natury i człowieka: Lublin, Poland, 2015. [Google Scholar]

- Śliwka, M.; Kępys, W.; Pawul, M. Analysis of the properties of coal sludge in the context of the possibility of using it in biological reclamation. Miner. Resour. Manag. PAN 2022, 38, 173–189. [Google Scholar] [CrossRef]

- Miroshnichenko, D.V. Crushing Properties of Coal. Coke Chem. 2013, 56, 49–455. [Google Scholar] [CrossRef]

- Irshek, I.; Orazbike, I.; Hypσek, A.; Kamalchan, S.K.E. Investigation of the Possibility of Using Coal Flotation Waste in Production of Agglomerate. Preprints 2024. [Google Scholar] [CrossRef]

- Vidlar, J.; Pasiowiec, P. New directions in the research and development of reagents for flotation of coal and non-polar minerals. J. Pol. Miner. Eng. Soc. 2009, 2, 1–7. [Google Scholar]

- Wasilewski, R.; Raińczak, J. Formowalne paliwo stałe na bazie mułu węglowego. Inżynieria Chem. Proces. 2004, 25, 2385–2391. [Google Scholar]

- Jelonek, I.; Jelonek, Z.; Mirkowski, Z. Cechy flotokoncentratów i mułów węglowych stosowanych w piecach centralnego ogrzewania oraz charakterystyka produktów ubocznych powstałych w wyniku ich spalenia. Zesz. Nauk. IGSMiE PAN 2016, 96, 91–104. [Google Scholar]

- Klojzy-Karczmarczyk, B.; Mazurek, J. Propozycje rozszerzenia działań celem zagospodarowania materiałów odpadowych z górnictwa węgla kamiennego. Zesz. Nauk. IGSMiE PAN 2017, 98, 151–166. [Google Scholar]

- Klojzy-Kaczmarczyk, B.; Staszczak, J. Zastosowanie mułów węglowych do uszczelniania składowisk komunalnych—Rozpoznanie możliwości. Zesz. Nauk. Inst. Gospod. Surowcami Miner. Energią PAN 2018, 105, 95–108. [Google Scholar]

- Kępys, W.; Pomykała, R. The properties of the backfill mixtures based on own fine-grained waste. In Minefill 2020–2021; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Klatka, S.; Malec, M.; Ryczek, M.; Kruk, E.; Zając, E. Ocena zdolności retencyjnych wybranych odpadów przemysłowych. Acta Sci. Pol. Form. Circumiectus 2016, 15, 53–60. [Google Scholar] [CrossRef]

- Rećko, K.; Sanytsky, M. Możliwość wykorzystania mułu węglowego w ceramice budowlanej. Bud. Zoptymalizowanym Potencjale Energetycznym 2008, 5, 263–269. [Google Scholar]

- Kotlyar, V.D.; Lapunova, K.A.; Kozlov, G.A. Wall Ceramics Products Based on Opoka and Coal Slurry. Procedia Eng. 2016, 150, 1452–1460. [Google Scholar] [CrossRef][Green Version]

- Wysocka, A.; Stêpniewski, W.; Horn, R. Swelling-shrinkage properties and hydraulic conductivity of a compacted coal minetailing rock likely to be used for landfill capping. Int. Agrophysics 2007, 21, 405–408. [Google Scholar]

- Sobko, W.; Baic, I.; Blaschke, W. Depozyty mułów węglowych—Inwentaryzacja i identyfikacja ilościowa. Rocz. Ochr. Sr. 2011, 13, 1405–1416. [Google Scholar]

- PN-88/B-04481; Grunty Budowlane. Badania Próbek Gruntu. Polish Standards: Warsaw, Poland, 1988.

- Cała, M.; Pomykała, R.; Kępys, W.; Adamczyk, J.; Stopkowicz, A.; Blajer, M. Opracowanie opisujące wskazanie kierunków i możliwości zagospodarowania skały płonnej oraz odpadowych mułów węglowych w Grupie Tauron oraz na rynku zewnętrznym. Unpublished Work. 2015. [Google Scholar]

- Doniecki, T.; Siedlecka, E. Odpadowe muły węglowe jako element izolacji mineralnej na składowiskach odpadów. Górnictwo Geinżynieria 2006, 30, 41–46. [Google Scholar]

- EN-ISO 14688-2; Geotechnical Investigation and Testing—Identification and Classification of Soil—Part 2: Principles for Clasiffication. Edition 2, European Standard: Brussels, Belgium, 2017.

- Craig, R.F. Mechanics Soil, 6th ed.; Spon Press: London, UK, 1997. [Google Scholar]

- Salam, S.; Xiao, M.; Khosravifar, A.; Liew, M.; Liu, S.; Rostami, J. Characterization of static and dynamic geotechnical properties and behaviors of fine coal refuse. Can. Geotech. J. 2019, 56, 1901–1916. [Google Scholar] [CrossRef]

- Kutepova, N.A.; Mosekin, V.V.; Kondakova, V.N.; Pospehov, G.B.; Straupnik, I.A. Specifiy of properties of coal processing waste regarding their storage. Min. Informational Anal. Bull. 2022, 12, 77–79. [Google Scholar] [CrossRef]

- Hegazy, Y.A.; Cushing, A.G.; Lewis, C.J. Physical, mechanical, and hydraulic properties of coal refuse for slurry impoundment design. In Proceedings of the Second International Conference on Geotechnical and Geophysical Characterization (ISC-2), Porto, Portugal, 19–22 September 2004; Available online: https://www.researchgate.net/publication/333296010 (accessed on 11 November 2025).

- Salam, S.; Xiao, M.; Khosravifar, A.; Wang, J. Cyclic Behavior and Liquefaction Resistance of Fine Coal Refuse—Experimental and Numerical Modeling. In Proceedings of the Geo-Congress 2019, Philadelphia, PA, USA, 24–27 March 2019. [Google Scholar] [CrossRef]

- Jedari, C.; Palomino, A.M.; Drumm, E.C.; Boles, D.R. Compressibility of Fine Coal Refuse. In Proceedings of the IFCEE 2018, Orlando, FL, USA, 5–10 March 2018. [Google Scholar] [CrossRef]

- Charles-Cruz, C.A.; Cousens, T.W.; Stewart, D.I. Compressibility and Creep Behaviour of Hydraulically Placed PFA and Mine Tailings Fills. In Proceedings of the 12th International Conference of International Association for Computer Methods and Advances in Geomechanics (IACMAG), Goa, India, 1–6 October 2008. [Google Scholar]

- Kaliński, M.; Philips, J.L. Development of Methods to Predict the Dynamic Behavior of Fine Coal Refuse: Preliminary Results from Two Sites in Appalachia. In Proceedings of the Geotechnical Earthquake Engineering and Soil Dynamics Congress IV, Sacramento, CA, USA, 18–22 May 2008. [Google Scholar] [CrossRef]

- Jedari, C.; Palomino, A.M.; Drumm, E.C.; Boles, D.R. In situ Characteristics of Fine coal Refuse. In Proceedings of the Geo-Congress 2019, Philadelphia, PA, USA, 24–27 March 2019. [Google Scholar] [CrossRef]

- Coufal, R.; Olszewska, M. Numerical simulation of changing value of compression modulus of organic soil under overloaded embankment. Mater. Bud. 2016, 1, 105–107. [Google Scholar] [CrossRef]

- Brzeziński, B.; Olchawa, A.; Wierzbicka, M. Wybrane właściwości gruntowych materiałów kompozytowych jako materiału konstrukcyjnego do budowy niskich nasypów obwałowań przeciwpowodziowych. Mater. Bud. 2023, 1, 35–39. [Google Scholar] [CrossRef]

- Adamczyk, J.; Pomykała, R. Coal Sludge Permeability Assessment Based on Rowe Cell Consolidation and Filtration Investigations. Minerals 2022, 12, 212. [Google Scholar] [CrossRef]

- Olek, B.; Pilecka, E. Hydraulic conductivity of coal mine tailings. STEF92 Technology. In Proceedings of the 18th International Multidisciplinary Scientific GeoConference SGEM2018, Vienna, Austria, 3–6 December 2018. [Google Scholar] [CrossRef]

- Adamczyk, J. Ocena Przydatności Mieszanek Kruszywa i Odpadowego Mułu Węglowego w Budowlach Ziemnych. Doctoral Dissertation, AGH University of Cracow, Kraków, Poland, 2019. [Google Scholar]

- Witczak, S.; Adamczyk, A. A Catalogue of Selected Physical, and Chemical Coefficients for Underground Waters Contamination, and the Methods to Determine Such Ones; Biblioteka Monitoringu Środowiska: Warsaw, Poland, 1994. [Google Scholar]

- Dowgiałło, J.; Kozerski, B.; Krajewski, S.; Macher, J.; Macioszczyk, T.; Malinowski, J.; Paczyński, B.; Płochniewski, Z.; Stenzel, P.; Szymanko, J.; et al. A Guidebook for Hydrogeologist; Wydawnictwo Geologiczne: Warsaw, Poland, 2007. [Google Scholar]

- Gavich, I.K. Teoreticheskiye osnowy izuczenija dwi zenija podziemnych wod v zemnoj kore. In Osnovy Gidrogeologii, T.II: Gidrogeodinamika; Zekcer, I.S., Ed.; Izdatelstvo Nauka: Novosybirsk, Russia, 1983. [Google Scholar]

- Wysokinski, L. Rules for the Construction of Waste Landfills, Building Research Institute, Instructions, Guidelines, Guides No 444/2009; Instytut Techniki Budowlanej: Warsaw, Poland, 2009. [Google Scholar]

- Darkin, M.G.; Gilpin, C.; Sangha, C.M. Direct wet surface imaging of an anaerobic biofilm by environmental scanning electronmicroscopy: Application to landfill clay liner barriers. Scanning 2001, 23, 346–350. [Google Scholar] [CrossRef]

- Luczak-Wilamowska, B. Neogene clays from Poland as mineral sealing barriers for landfills: Experimental study. Appl. Clay Sci. 2020, 21, 22–43. [Google Scholar] [CrossRef]

- Zabielska-Adamska, K.; Wasil, M. Tensile Strength of Barrier Material. In Proceedings of the 10th International Conference of Environmental Engineering (10th ICEE), Vilnius, Lithuania, 27–28 April 2017. [Google Scholar]

- Terzaghi, K.; Peck, R.B.; Mesri, G. Soil Mechanics in Engineering Practise, 3rd ed.; John Wiley & Sons, Inc.: Honoken, NJ, USA, 1996. [Google Scholar]

- Kowalski, J. Hydrogeologia z Podstawami Geologii, 3rd ed.; Wydawnictwo Uniwersytetu Przyrodniczego we Wrocławiu: Wrocław, Poland, 2007. [Google Scholar]

- Coduto, D.P.; Yeung, M.R.; Kitch, W.A. Geotechnical Engineering. Principles and Practices, 2nd ed.Prentice Hall: Englewood Cliffs, NJ, USA, 2011. [Google Scholar]

- Mbonimpa, M.; Ngabu, E.T.; Belem, T.; Kanteye, O.; Maqsoud, A. Optimization of Soil-Sludge Mixtures by Compaction for Potential Use in Mine Site Reclamation. Minerals 2023, 13, 806. [Google Scholar] [CrossRef]

- Skarżyńska, K.M. Reuse of coal mining wastes in civil engineering—Part 1: Properties of minestone. Waste Manag. 1995, 15, 3–42. [Google Scholar] [CrossRef]

- Pisarczyk, S. Gruntoznawstwo Inżynierskie, 1st ed.; Wydawnictwo Naukowe PWN: Warsaw, Poland, 2001. [Google Scholar]

- Sadowski, W. Small Encyclopedia of Statistics; PWE: Warsaw, Poland, 1976. [Google Scholar]

- Zeliaś, A. Statistical Methods; PWE: Warsaw, Poland, 2000. [Google Scholar]

- Coefficient of Variation—Formula, Interpretation and Application in Statistics. Available online: https://www.geeksforgeeks.org/data-science/coefficient-of-variation-meaning-formula-and-examples/ (accessed on 11 November 2025).

- Wiłun, Z. Zarys Geotechniki, 8th ed.; Wydawnictwa Komunikacji i Łączności: Warsaw, Poland, 2007. [Google Scholar]

- Lambe, T.W.; Whitman, R.V. Mechanika Gruntów; Wydawnictwo Arkady: Warsaw, Poland, 1977. [Google Scholar]

- Woźniak, H. Osiadania Gruntów Zwałowych w Świetle Badań Modelowych, 1st ed.; PAN Instytut Gospodarki Surowcami Mineralnymi i Energia: Cracow, Poland, 2009. [Google Scholar]

- Meyer, Z.; Bednarek, R. Prognozowanie osiadania gruntów słabych na podstawie modelu nieliniowego. Inżynieria Morska Geotech. 2008, 4, 211–214. [Google Scholar]

- Meyer, Z.; Kowalów, M.; Plucińska, A. Modelowanie osiadań podłoża słabego na podstawie badań in situ. Inżynieria Morska Geotech. 2008, 5, 268–274. [Google Scholar]

- Meyer, Z.; Olszewska, M. Methods Development for the Constrained Elastic Modulus Investigation of Organic Material in Natural Soil Conditions. Materials 2021, 14, 6842. [Google Scholar] [CrossRef]

- Gruchot, A.; Zydroń, Z. Shear Strength of Industrial Wastes and Their Mixtures and Stability of Embankments Made of These Materials. Appl. Sci. 2020, 10, 250. [Google Scholar] [CrossRef]

- Myślińska, E. Grunty Organiczne i Laboratoryjne Metody ich Badania, 3rd ed.; Wydawnictwo Naukowe PWN: Warsaw, Poland, 2001. [Google Scholar]

- Cheng, G.; Zhu, H.H.; Wen, Y.N.; Shi, B.; Gao, L. Experimental Investigation of Consolidation Properties of Nano-Bentonite Mixed Clayey Soil. Sustainability 2020, 12, 459. [Google Scholar] [CrossRef]

- Wan, T.; Lu, Y.; Zeng, Z.; Xie, Z.; Lin, S.; Nong, X. Compression Behavior of Rubber-Betnonite Mixture under different Salinities. Appl. Sci. 2023, 13, 8134. [Google Scholar] [CrossRef]

- PN-B-03020:1981; Posadowienie Bezpośrednie Budowli. Oblcizenia Statyczne i Projektowanie. Polish Standards: Warsaw, Poland, 1981.

- Jaremski, J. Parametry geotechniczne niektórych gruntów występujących na obszarze województwa karpackiego. Zesz. Politech. Śląskiej 2003, 97, 421–430. [Google Scholar]

- Blajer, M.; Stopkowicz, A.; Adamczyk, J.; Cala, M. The Preliminary Research of the Physico-Mechanical Properties of Aggregates based on the Colliery Shale, Supplemented by Fly Ash, Arch. Min. Sci. 2019, 1, 21–34. [Google Scholar] [CrossRef]

- Pisarczyk, S. Grunty Nasypowe. Właściwości Geotechniczne i Metody ich Badania; Oficyna Wydawnicza Politechnika Warszawskiej: Warszawa, Poland, 2004. [Google Scholar]

- Das, B.M. Principles of Geotechnical Engineering, 10th ed.; Cengage Learning: Boston, MA, USA, 2022. [Google Scholar]

- Head, K.H. Manual of Soil Laboratory Testing. Volume 2: Permeability, Shear Strength and Compressibility Tests; Pentech Press: London, UK, 1994. [Google Scholar]

- Budhu, M. Soil Mechanics and Foundations, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- United Nations, Department of Economic and Social Affairs. Sustainable Development. Available online: https://sdgs.un.org/goals (accessed on 11 November 2025).[Green Version]

| Component | P2O5 | Mn2O5 | SiO2 | TiO2 | Al2O3 | Fe2O3 |

|---|---|---|---|---|---|---|

| Content [%] | 0.10 | 0.02 | 33.50 | 0.02 | 21.00 | 3.76 |

| Component | CaO | MgO | Na2O | Li2O | K2O | SO3 |

| Content [%] | 0.26 | 0.61 | 0.53 | 0.01 | 1.10 | 0.89 |

| Parameter Name | Unit | Value |

|---|---|---|

| Moisture | [%] | 30.1 ÷ 38 |

| Specific density | [g/cm3] | 1.97 ÷ 2.03 |

| Volumetric density | [g/cm3] | 1.5 ÷ 1.54 |

| Porosity | [-] | 0.44 |

| Porosity index | [-] | 0.76 |

| Saturation moisture | [%] | 38 |

| Moisture degree | [-] | 0.94 |

| Coal Sludge | Sample 1 | Sample 2 | Sample 3 |

|---|---|---|---|

| Internal friction angle ϕ [°] | 30.25 | 20.56 | 22.99 |

| Cohesion c [kPa] | 5.36 | 36.18 | 44.56 |

| Test Series Number | Normal Stress | Max. Shear Stress | Average Value | Standard Deviation | Coefficient of Variation |

|---|---|---|---|---|---|

| [kPa] | [kPa] | σ | V [%] | ||

| Serie 1 | 50 | 45.48 | 43.14 | 2.34 | 5.42% |

| Serie 2 | 40.8 | ||||

| Serie 3 | - | - | - | - | |

| Serie 1 | 100 | 54.74 | 77.87 | 16.79 | 21.56 |

| Serie 2 | 94.07 | ||||

| Serie 3 | 84.8 | ||||

| Serie 1 | 150 | 77.86 | 94.82 | 14.18 | 14.95 |

| Serie 2 | 94.05 | ||||

| Serie 3 | 112.56 | ||||

| Serie 1 | 200 | 134.98 | 121.84 | 13.47 | 11.05 |

| Serie 2 | 103.33 | ||||

| Serie 3 | 127.22 |

| Test Series Number | Parameter | Max. Shear Stress | Average Value | Standard Deviation | Coefficient of Variation |

|---|---|---|---|---|---|

| [kPa] | σ | V [%] | |||

| Serie 1 | Internal friction angle, φ [°] | 30.25 | 24.60 | 4.12 | 16.73 |

| Serie 2 | 20.56 | ||||

| Serie 3 | 22.99 | ||||

| Serie 1 | Cohesion, c [kPa] | 5.36 | 28.70 | 16.85 | 58.73 |

| Serie 2 | 36.18 | ||||

| Serie 3 | 44.56 |

| Lp. | Load Range ∆σi [MPa] | M0 [MPa] | M [MPa] | ||||

|---|---|---|---|---|---|---|---|

| Serie 1 | Serie 2 | Serie 3 | Serie1 | Serie 2 | Serie 3 | ||

| 1 | 0.0 ÷ 0.0125 | 0.37 | 1.32 | 0.81 | - | - | - |

| 2 | 0.0125 ÷ 0.025 | 3.22 | 4.13 | 2.05 | 44.36 | Δh = 0 | 23.5 |

| 3 | 0.025 ÷ 0.05 | 0.88 | 3.53 | 3.06 | 8.87 | Δh = 0 | Δh = 0 |

| 4 | 0.05 ÷ 0.1 | 2.23 | 1.96 | 3.03 | 12.64 | Δh = 0 | 6.71 |

| 5 | 0.1 ÷ 0.2 | 5.01 | 8.31 | 5.02 | 15.32 | Δh ≈ 0 | 16.95 |

| 6 | 0.2 ÷ 0.4 | 6.58 | 4.66 | 7.8 | 19.45 | 17.38 | 10.59 |

| 7 | 0.0 ÷ 0.05 | 0.78 | 2.56 | 1.69 | 16.13 | Δh = 0 | Δh ≈ 0 |

| 8 | 0.0 ÷ 0.1 | 1.17 | 2.25 | 2.2 | 14.2 | Δh = 0 | 12.53 |

| 9 | 0.0 ÷ 0.2 | 1.93 | 3.57 | 3.1 | 14.79 | Δh ≈ 0 | 14.46 |

| 10 | 0.0 ÷ 0.4 | 3.05 | 4.15 | 4.52 | 16.9 | 33.2 | 12.33 |

| Lp. | Load Range | M0 [MPa] | M [MPa] | ||||

|---|---|---|---|---|---|---|---|

| Average Value | Standard Deviation | Coefficient of Variation | Average Value | Standard Deviation | Coefficient of Variation | ||

| ∆σi [MPa] | σ | V [%] | σ | V [%] | |||

| 1 | 0.0 ÷ 0.0125 | 0.83 | 0.39 | 46.58 | - | - | - |

| 2 | 0.0125 ÷ 0.025 | 3.13 | 0.85 | 27.17 | 33.93 | 10.43 | 30.74 |

| 3 | 0.025 ÷ 0.05 | 2.49 | 1.15 | 46.37 | 8.87 | 0.00 | 0.00 |

| 4 | 0.05 ÷ 0.1 | 2.41 | 0.45 | 18.88 | 9.68 | 2.97 | 30.65 |

| 5 | 0.1 ÷ 0.2 | 6.11 | 1.55 | 25.41 | 16.14 | 0.82 | 5.05 |

| 6 | 0.2 ÷ 0.4 | 6.35 | 1.29 | 20.36 | 15.81 | 3.78 | 23.94 |

| 7 | 0.0 ÷ 0.05 | 1.68 | 0.73 | 43.34 | 16.13 | 0.00 | 0.00 |

| 8 | 0.0 ÷ 0.1 | 1.87 | 0.50 | 26.57 | 13.37 | 0.84 | 6.25 |

| 9 | 0.0 ÷ 0.2 | 2.87 | 0.69 | 24.05 | 14.63 | 0.17 | 1.13 |

| 10 | 0.0 ÷ 0.4 | 3.91 | 0.62 | 15.98 | 20.81 | 8.96 | 43.04 |

| Load Range [kPa] | CS [kPa] | Peat |

|---|---|---|

| 25–50 | 880–3530 | 199–980 [53,54,55] |

| 50–100 | 1960–3030 | 180–600 [53,54,55] |

| 100–200 | 5010–8310 | 600–1570 [53,54,55] 250–2260 [56] |

| 0–100 | 1170–2250 | 1660–1726, near Konstancin–Poland, Central Europe [55,57] 100–770, near Warsaw–Poland, Central Europe [55,57] |

| 0–400 | 3050–4520 | 498–846, West Pomerania–Poland, Central Europe [55,57] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adamczyk, J. Strength and Strain Properties of Coal Sludge. Appl. Sci. 2025, 15, 12360. https://doi.org/10.3390/app152312360

Adamczyk J. Strength and Strain Properties of Coal Sludge. Applied Sciences. 2025; 15(23):12360. https://doi.org/10.3390/app152312360

Chicago/Turabian StyleAdamczyk, Justyna. 2025. "Strength and Strain Properties of Coal Sludge" Applied Sciences 15, no. 23: 12360. https://doi.org/10.3390/app152312360

APA StyleAdamczyk, J. (2025). Strength and Strain Properties of Coal Sludge. Applied Sciences, 15(23), 12360. https://doi.org/10.3390/app152312360