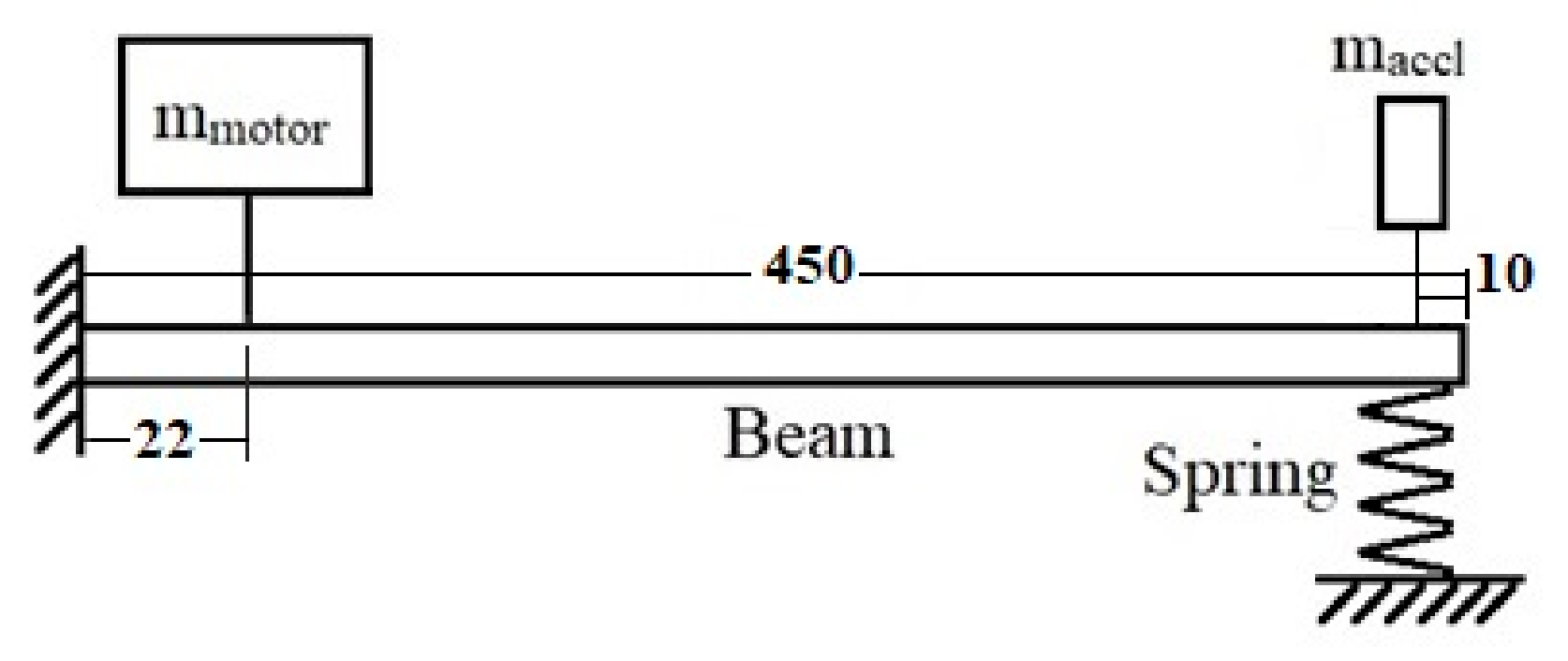

Vibration Analysis of Cantilever Beam with Free End Resting on 3D-Printed Spring and Considering the Effect of Accelerometer and Exciter Masses

Abstract

1. Introduction

2. Theory

- E = Modulus of elasticity (N/m2);

- Lbeam = Length of beam (m) = 0.45 m;

- I = Moment of inertia (m4), ;

- b, h = Width, thickness of beam (m);

- = Mass density (kg/m3);

- A = Cross-sectional area (m2).

- = The original frequency of the beam without the accelerometer mass.

- = Natural frequency of massless beam and accelerometer.

- Laccl = The centre of mass for the accelerometer from the free end.

3. Numerical Modelling

4. Experimental Works

4.1. Material and Methods

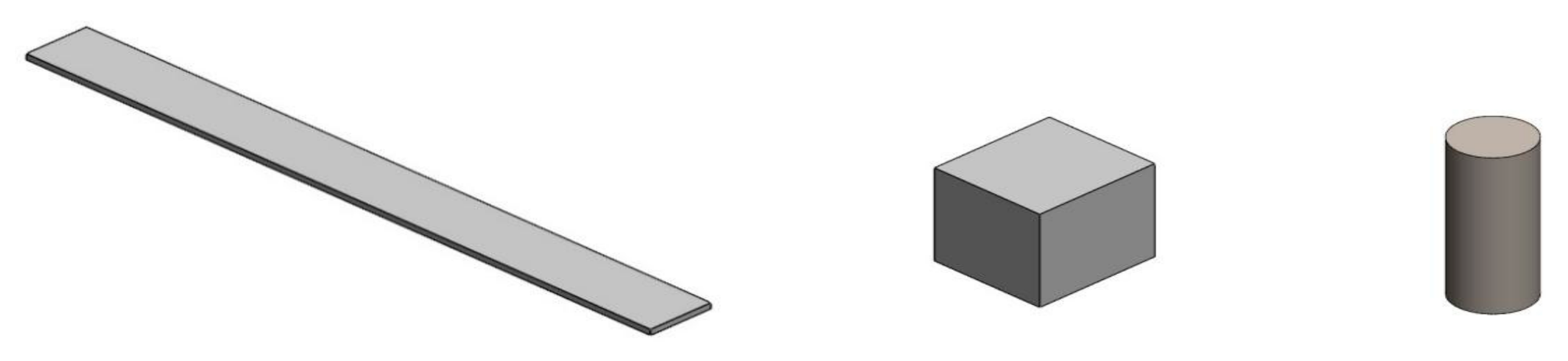

4.1.1. Aluminium Beam

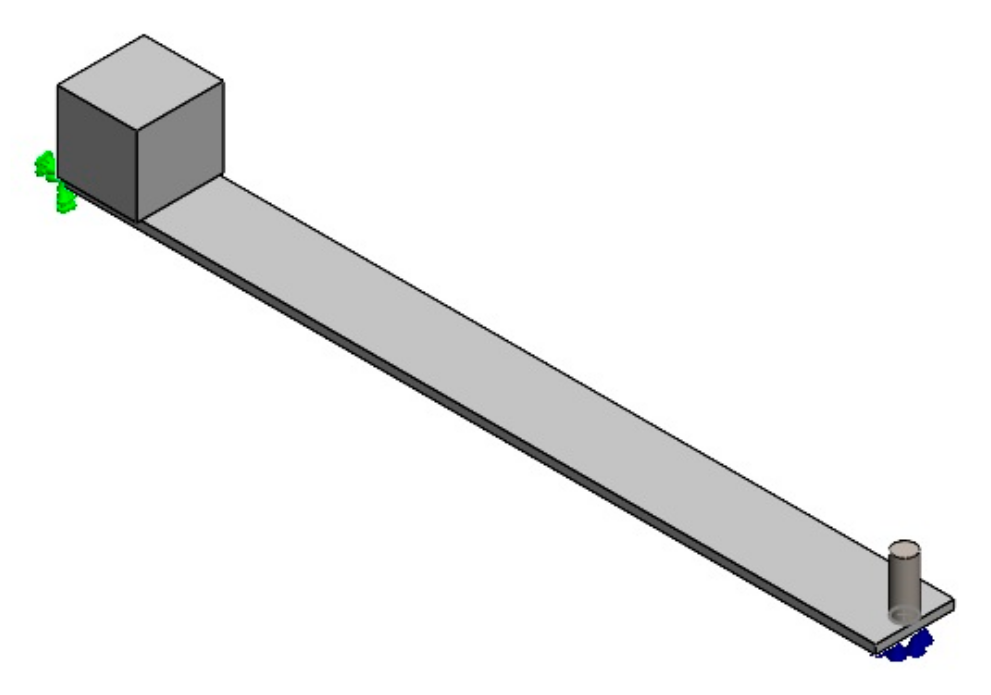

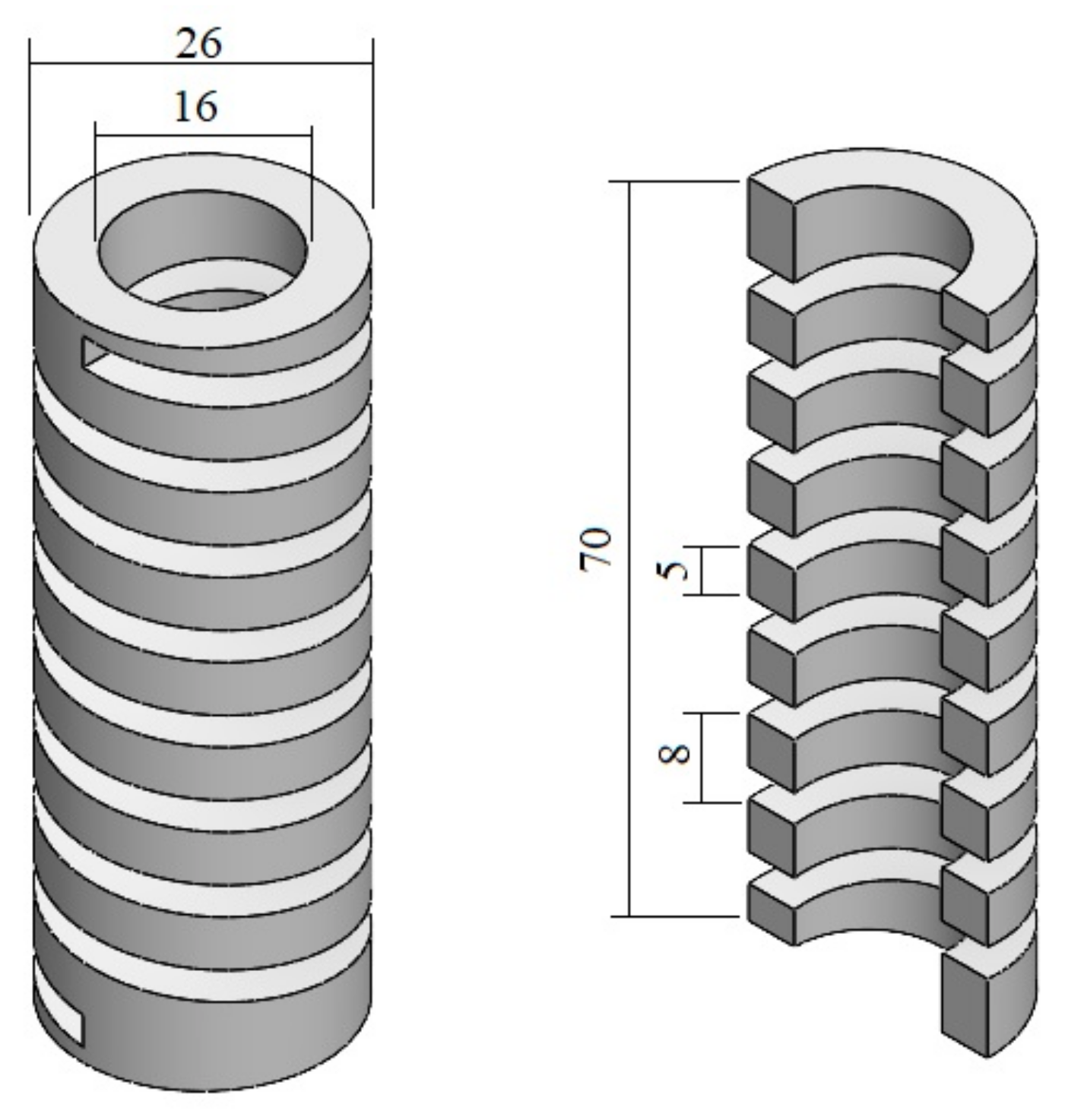

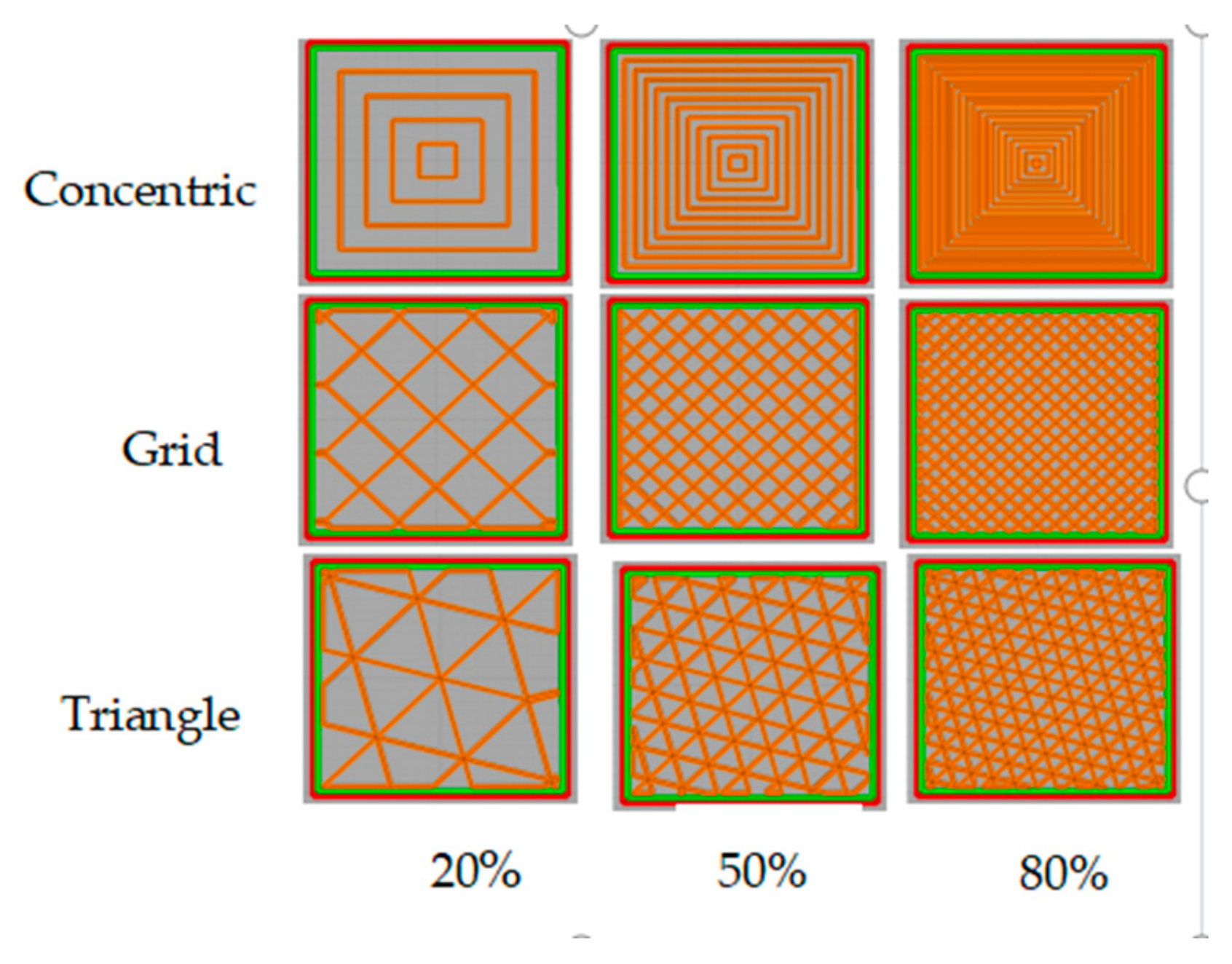

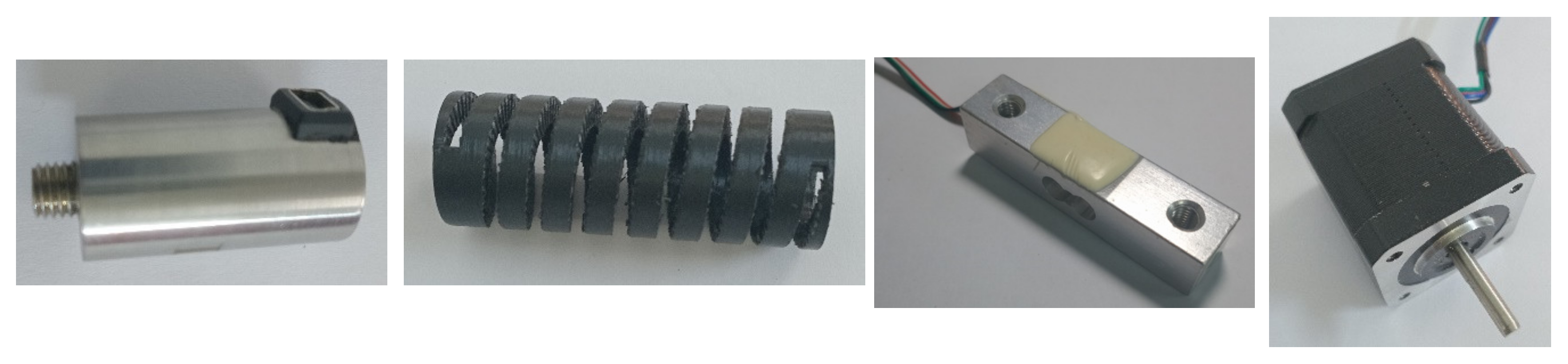

4.1.2. Springs

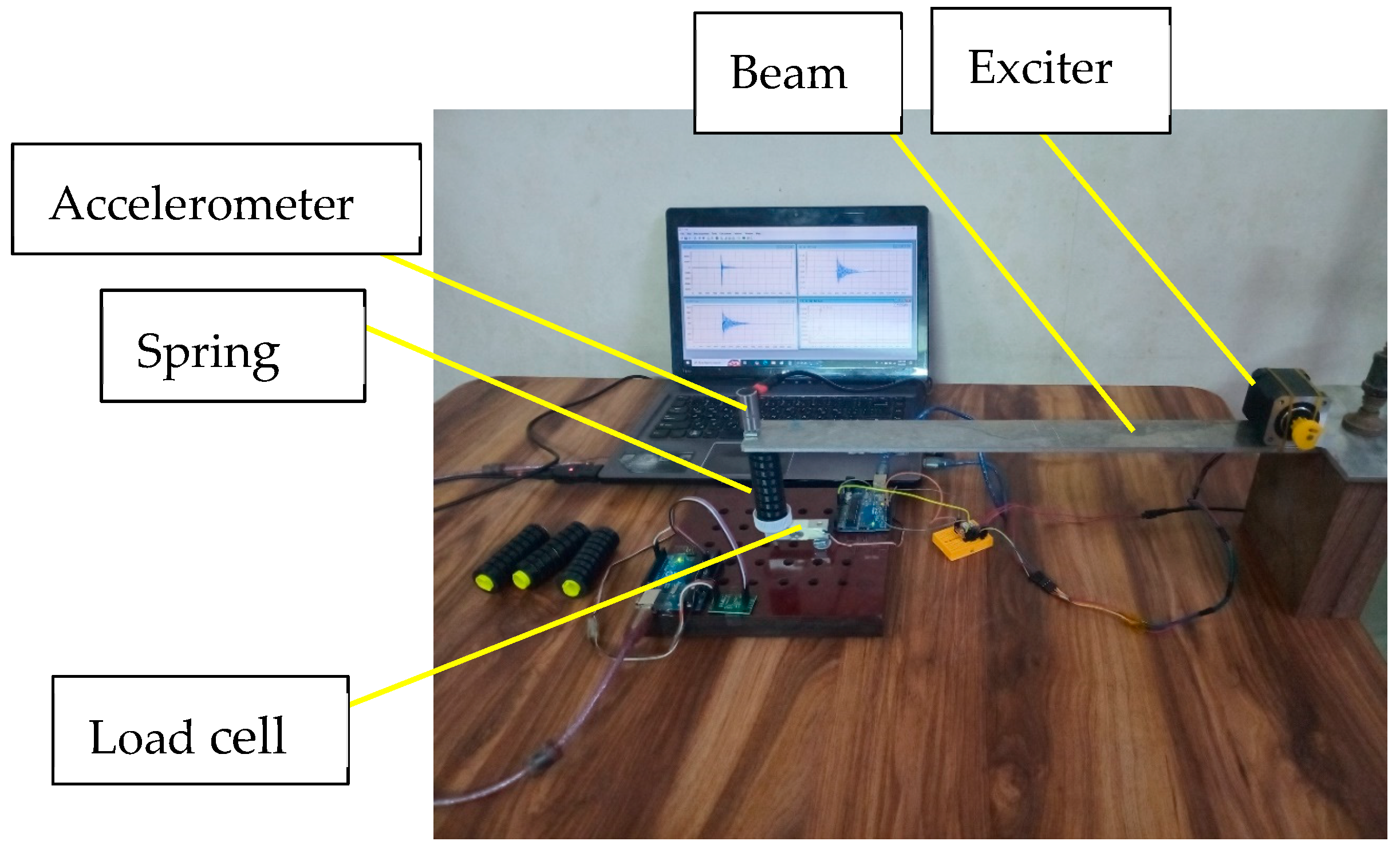

4.2. Rig Setup

4.2.1. Aluminium Cantilever Beam

4.2.2. Accelerometer

4.2.3. Printed Springs

4.2.4. Load Cell

4.2.5. Stepper Motor

5. Results

5.1. Free Vibration

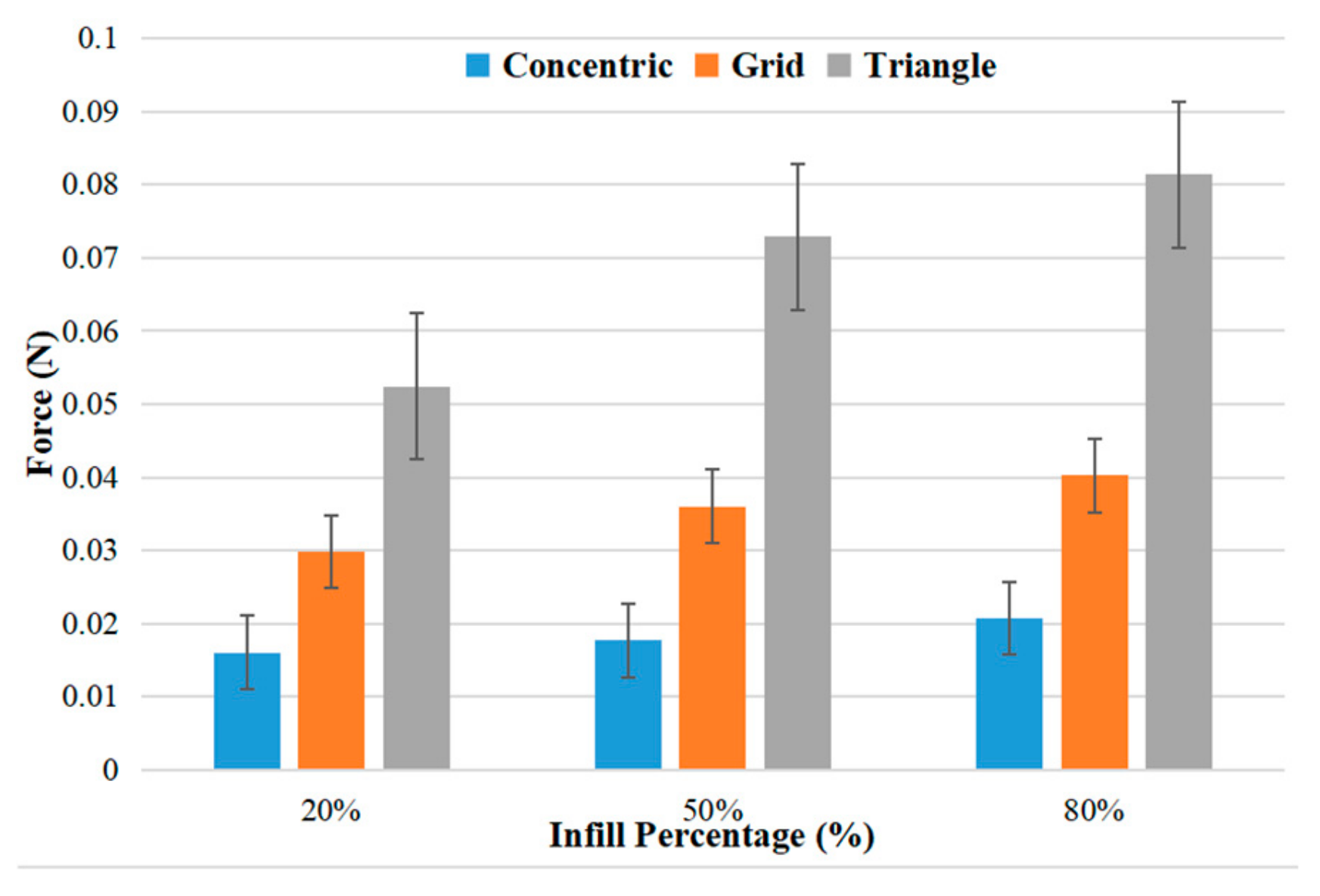

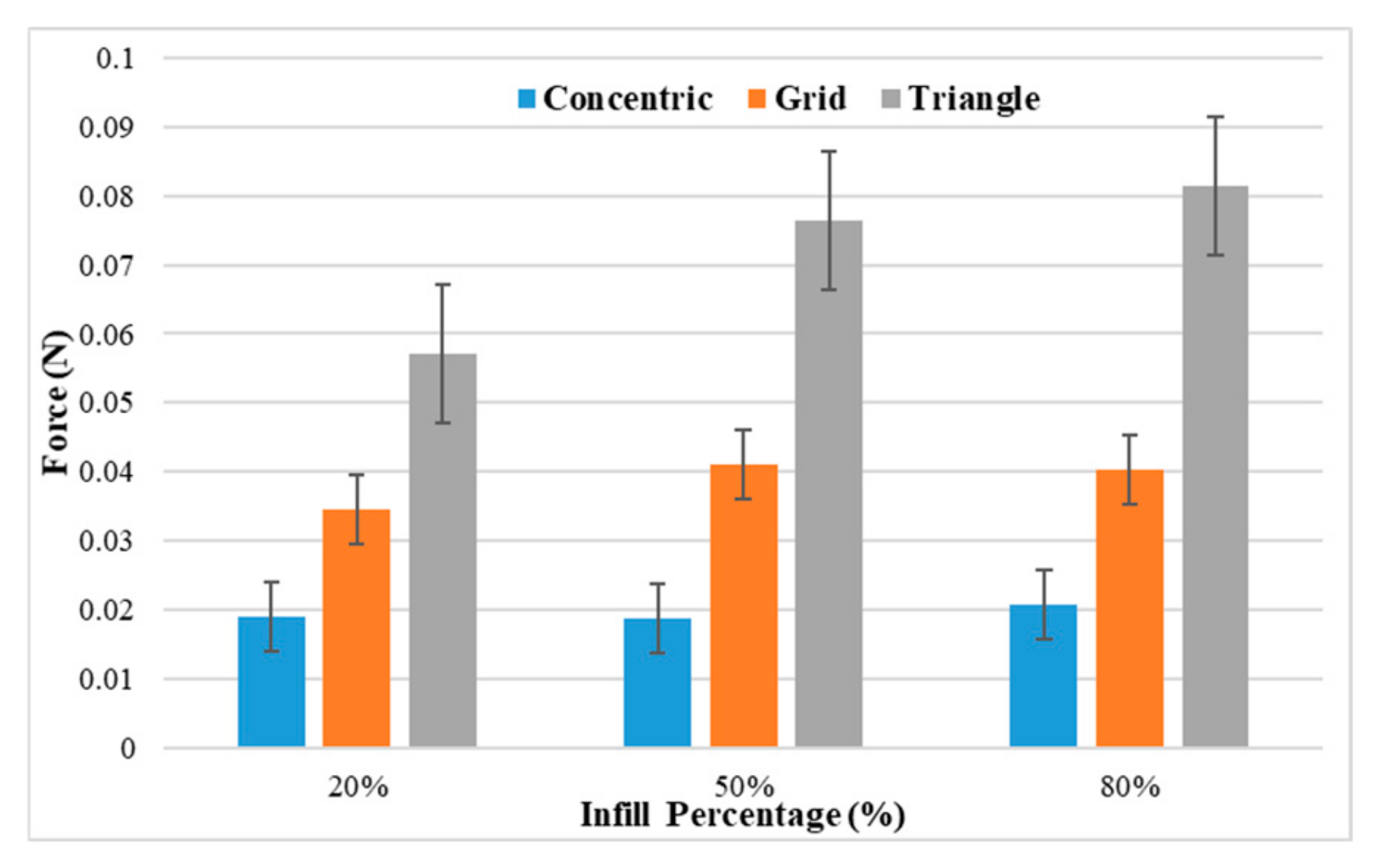

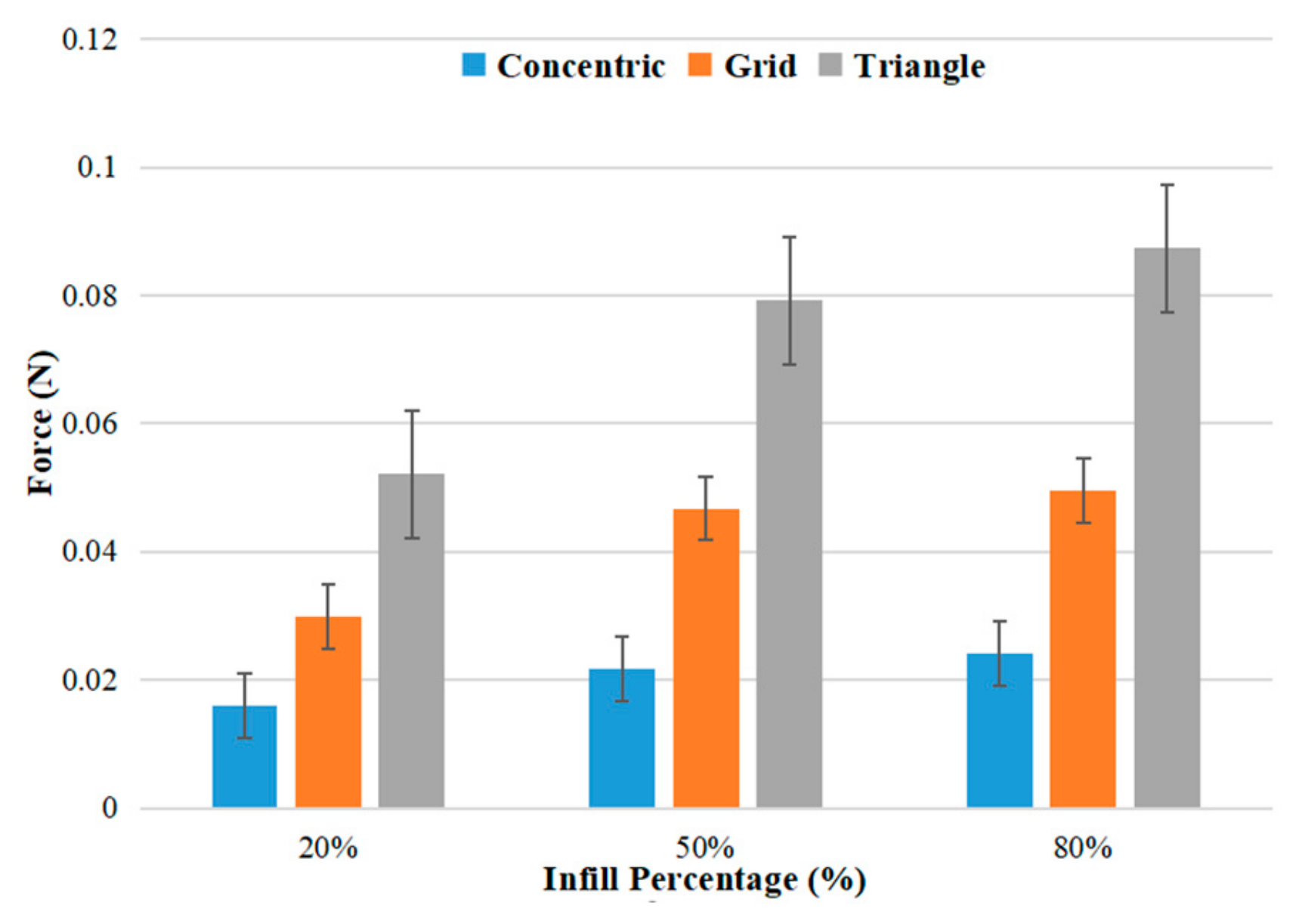

5.2. Force Measurement

6. Discussions

- The motor has a dynamic effect which causes beam vibration. Increasing the rotational speed causes the motor to exert more energy into the beam at a specific time. For the “grid” pattern at 50% infill percentage, increasing the rotational speed from 150 to 300 rpm increases the resulting force from 0.036 N to 0.047 N, which means an increase in force by 30%.

- When the motor rotates, the excitation force is small and the vibration resulting from it is far from the resonance value; therefore, the beam properties can be modified so that the fundamental natural frequency can be lowered to be close to the motor frequency.

- The “triangle” printing pattern results in the highest force. It creates a “truss-like” structure which is efficient for carrying loads because the resulting forces act as axial tension along the filament lines. The “grid” pattern, which is composed of square shapes, is less efficient because these shapes are deformed by filament bending at the joints, which results in less stiffness and resulting force. The “concentric” pattern shows the lowest force because this pattern acts as multiple unsupported rings, which have the lowest stiffness and resulting force. At 80% infill and 300 rpm, the force resulting from the “triangle” pattern was 0.087 N, which is 3.6 times greater than the force of the “concentric” pattern (0.024 N).

- For the “triangle” pattern at a rotational speed of 150 rpm, increasing the infill percentage from 20% to 80% increases the force from 0.052 N to 0.081 N, which means an increase of 56%.

- The “triangle” pattern with 80% infill density is recommended for printing when compared with 100% infill density because the difference in results is very small; this reduces cost and weight when using 80% infill density.

- This system can be used to harvest electrical signals resulting from the vibration of the beam if a piezoelectric sensor is mounted under the spring.

- There was a slight difference between theoretical and experimental results of natural frequency, which may arise due to clamping conditions or effective stiffness of the spring.

7. Conclusions

- The stiffness of a printed spring is not just a material property; it is also affected by its internal geometry, which is defined by the printing pattern.

- The printing pattern is the most powerful factor affecting the printed spring stiffness, while infill percentage is used for fine-tuning the spring stiffness.

- Increasing the infill percentage means more printing material within the same volume, which increases spring stiffness.

- The stepper motor can be replaced by an electrical DC motor to obtain higher rotational speed. Also, an eccentric mass can be attached to this motor to control the value of the excitation vibration.

8. Future Works

- It is suggested to perform the study using other different printing patterns to find out the best pattern to use.

- Adding a piezoelectric sensor under the spring to harvest electrical signals resulting from beam vibration.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zannon, M. Free Vibration of Thin Film Cantilever Beam. Int. J. Eng. Tech. Res. (IJETR) 2014, 2, 304–316. [Google Scholar]

- Singh, S.; Singh, A. Free Vibration Analysis on cantilever beam—A review. Int. Res. J. Eng. Technol. (IRJET) 2017, 4, 1449–1452. [Google Scholar]

- Mia, S.; Islam, S.; Ghosh, U. Modal Analysis of Cracked Cantilever Beam by Finite Element Simulation. Procedia Eng. 2017, 194, 509–516. [Google Scholar] [CrossRef]

- Zheng, Y.; Yang, Y.; Wu, R.-J.; He, C.-Y.; Guang, C.-H. Dynamic Analysis of a Hybrid Compliant Mechanism with Flexible Central Chain and Cantilever Beam. Mech. Mach. Theory 2021, 155, 104095. [Google Scholar] [CrossRef]

- Lei, X.; Wang, Y.; Wang, X.; Lin, G.; Shi, S. Revisited on the Free Vibration of a Cantilever Beam with An Asymmetrically Attached Tip Mass. Math. Probl. Eng. 2021, 2021, 8024879. [Google Scholar] [CrossRef]

- Ahiwale, D.; Madake, H.; Phadtare, N.; Jarande, A.; Jambhale, D. Modal Analysis of Cracked Cantilever Beam Using ANSYS Software. Mater. Today Proc. 2022, 56, 165–170. [Google Scholar] [CrossRef]

- Ali, M.S. Vibration Analysis and Modelling of a Cantilever Beam; Technical Report No.381312144; ResearchGate: Berlin, Germany, 2024. [Google Scholar]

- Herisanu, N.; Marinca, B.; Marinca, V. Nonlinear Dynamics of an Electromagnetically Actuated Cantilever Beam Under Harmonic External Excitation. Appl. Sci. 2024, 14, 10335. [Google Scholar] [CrossRef]

- Skerys, P.; Gaidys, R. A Dynamic Analysis of a Cantilever Piezoelectric Vibration Energy Harvester with Maximized Electric Polarization Due to the Optimal Shape of the Thickness for First Eigen Frequency. Appl. Sci. 2025, 15, 7525. [Google Scholar] [CrossRef]

- Despotović, Ž.V.; Lecic, M.; Jovic, M.; Djuric, A. Vibration Control of Resonant Vibratory Feeders with Electromagnetic Excitation. FME Trans. 2014, 4, 281–289. [Google Scholar] [CrossRef]

- Chandravanshi, M.L.; Mukhopadhyay, A.K. Dynamic Analysis of Vibratory Feeder and Their Effect on Feed Particle Speed on Conveying Surface. Measurement 2017, 101, 145–156. [Google Scholar] [CrossRef]

- Vellingiri, V.; Sadasivam, U. Effect of Vibrator Parameters and Physical Characteristics of Parts on Conveying Velocity. Stroj. Vestn.-J. Mech. Eng. 2023, 69, 352–363. [Google Scholar] [CrossRef]

- Fragassa, C.; Pavlovic, A.; Berardi, L.; Vitali, G. Investigating the Dynamic Behavior of a Linear Vibratory Feeder. Proc. Eng. Sci. 2023, 5, 495–502. [Google Scholar] [CrossRef]

- Yadav, A.; Singh, N.K. Effects of Accelerometer Mass on Natural Frequency of a Magnesium Alloy Cantilever Beam. Vibroeng. Procedia 2019, 29, 207–212. [Google Scholar] [CrossRef]

- Mereles, A.; Varanis, M.; Silva, A.; Balthazar, J.; Lopes, E.; Bavastri, C. Mathematical Modelling of a Cantilever Beam Driven by two Unbalanced Eletric Motors. In Proceedings of the 25th ABCM International Congress on Mechanical Engineering (COBEM 2019), Uberlândia, MG, Brazil, 20–25 October 2019. [Google Scholar] [CrossRef]

- Guo, G.; Zhong, S.; Zhang, Q.; Zhong, J.; Liu, D. Effect of Additional Mass on Natural Frequencies of Weight-Sensing Structures. Sensors 2023, 23, 7585. [Google Scholar] [CrossRef]

- Rossit, C.A.; Laura, P.A.A. Free Vibrations of a Cantilever Beam with a Spring–Mass System Attached to the Free End. Ocean Eng. 2001, 28, 933–939. [Google Scholar] [CrossRef]

- Jafari, M.; Djojodihardjo, H.; Ahmad, K. Vibration Analysis of a Cantilevered Beam with Spring Loading at the Tip as a Generic Elastic Structure. Appl. Mech. Mater. 2014, 629, 407–413. [Google Scholar] [CrossRef]

- Aydin, E. Minimum Dynamic Response of Cantilever Beams Supported by Optimal Elastic Springs. Struct. Eng. Mech. 2014, 51, 377–402. [Google Scholar] [CrossRef]

- Chang, J.-R.; Tu, T.-W.; Huang, C.J. An Analytic Solution for the Dynamic Behavior of a Cantilever Beam with a Time-Dependent Spring-Like Actuator. Axioms 2023, 12, 500. [Google Scholar] [CrossRef]

- Boisseau, S.; Despesse, G.; Ricart, T.; Defay, E.; Sylvestre, A. Cantilever-Based Electret Energy Harvesters. Smart Mater. Struct. 2011, 20, 105013. [Google Scholar] [CrossRef]

- Yao, F.; Meng, W.; Zhao, J.; Yin, H. Cantilever Beam Based Piezoelectric Energy Harvester. Int. J. Smart Sens. Intell. Syst. 2015, 8, 2018–2041. [Google Scholar] [CrossRef]

- Karpinski, P.; Ambrozkiewicz, B.; Czyż, Z.; Litak, G. Performance Analysis of Piezoelectric Energy Harvesting System Under Varying Bluff Body Masses and Diameters—Experimental Study and Validation with 0–1 Test. Appl. Sci. 2025, 15, 6972. [Google Scholar] [CrossRef]

- Atmajaya, A.; Jatisukamto, G.; Triono, A.; Syuhri, S. Add-On Energy Harvesting System Using Cantilever Beam in an Engine Mount. AIP Conf. Proc. 2020, 2278, 020015. [Google Scholar] [CrossRef]

- Tuma, C.; Phaoharuhansa, D. Vibration Energy Harvest for Low Frequency Using Double-Piezoelectric Cantilever Beam. In Proceedings of the 6th International Conference on Mechatronics and Mechanical Engineering (ICMME 2019), Osaka, Japan, 27–30 November 2019; Volume 306, p. 04006. [Google Scholar] [CrossRef]

- Xu, Q.; Gao, A.; Li, Y.; Jin, Y. Design and Optimization of Piezoelectric Cantilever Beam Vibration Energy Harvester. Micromachines 2022, 13, 675. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Zhang, M.; Xu, Z.; Chen, H.; Xu, J. A Multiple-Cantilever Piezoelectric Vibration Energy Harvester for Self-Powered CO2 Monitoring in Transformer Substations. Appl. Sci. 2024, 14, 10805. [Google Scholar] [CrossRef]

- Nisanth, A.; Suja, K.; Seena, V. A Novel Design Strategy for Cantilever Based MEMS Piezoelectric Vibration Energy Harvesters: FEM Parametric Analysis and Modeling. e-Prime-Adv. Electr. Eng. Electron. Energy 2024, 9, 100724. [Google Scholar] [CrossRef]

- He, L.; Peng, H.; Lin, M.; Konjeti, R.; Guimbretiere, F.; Froehlich, J. Designing and Controlling 3D Printable Springs. In Proceedings of the 32nd Annual ACM Symposium on User Interface Software and Technology, New Orleans, LA, USA, 20–23 October 2019; pp. 739–750. [Google Scholar] [CrossRef]

- Dalaq, A.S.; Daqaq, M.F. Experimentally-Validated Computational Modeling and Characterization of the Quasi-Static Behavior of Functional 3D-Printed Origami-Inspired Springs. Mater. Des. 2022, 216, 110541. [Google Scholar] [CrossRef]

- Mahdi, H.H.; Nama, S.A.; Khazaal, S.M. Experimental and Numerical Investigation on the Free Vibration Characteristics of 3D Printed Springs with Square Cross Sections. Math. Model. Eng. Probl. 2023, 10, 1961–1966. [Google Scholar] [CrossRef]

- Yang, Z.; He, F.; Khan, M. An Empirical Torsional Spring Model for the Inclined Crack in a 3D-Printed Acrylonitrile Butadiene Styrene (ABS) Cantilever Beam. Polymers 2023, 15, 496. [Google Scholar] [CrossRef]

- Kim, T.-H.; Moeinnia, H.; Kim, W.S. 3D Printed Vorticella-Kirigami Inspired Sensors for Structural Health Monitoring in Internet-of-Things. Mater. Des. 2023, 234, 112332. [Google Scholar] [CrossRef]

- He, F.; Ning, H.; Khan, M. Effect of 3D Printing Process Parameters on Damping Characteristic of Cantilever Beams Fabricated Using Material Extrusion. Polymers 2023, 15, 257. [Google Scholar] [CrossRef]

- Bakhtiari, H.; Aamir, M.; Tolouei-Rad, M. Effect of 3D Printing Parameters on the Fatigue Properties of Parts Manufactured by Fused Filament Fabrication: A Review. Appl. Sci. 2023, 13, 904. [Google Scholar] [CrossRef]

- Jasinski, K.; Murawski, L.; Kluczyk, M.; Wierzchowski, J.; Chodnicki, M.; Lipinski, K.; Szelezinski, A. Analysis of the Possibility of Using 3D Printing for Emergency Replacement of Damaged Elements in the Marine Industry. Appl. Sci. 2025, 15, 3458. [Google Scholar] [CrossRef]

- Chatpun, S.; Dissaneewate, T.; Kwanyuang, A.; Nouman, M.; Srewaradachpisal, S.; Movrin, D. Infill Pattern and Density of 3D-Printed Insoles Alter Energy and Pressure Distribution in Gait. Appl. Sci. 2025, 15, 3916. [Google Scholar] [CrossRef]

- Daniel, J. Inman: Engineering Vibrations, 4th ed.; Pearson Education Inc.: London, UK, 2013; pp. 46–52. [Google Scholar]

- Singiresu, S. Rao: Mechanical Vibrations; Pearson Education Inc.: London, UK, 2018; p. 702. [Google Scholar]

- Computer Control Electronic Universal Testing Machine. Available online: https://www.laryee.com/Electronic-utm (accessed on 10 June 2025).

- Carbon Fiber 3D printing. Creality’s Official Website. Available online: https://www.creality.com/products/k1c-carbon-3d-printer?spm=..product_fc547c47-66f3-4ee3-a06c-e06eaa83904d.header%201.1 (accessed on 3 June 2025).

- New Weighting Modules. Available online: https://radwag.com/en/ (accessed on 30 June 2025).

- Vibration Measuring Instruments. Available online: https://www.erbessd-instruments.com/digivibe/ (accessed on 10 August 2025).

- Micro Load Cell. Available online: https://www.robotshop.com/products/micro-load-cell-50-kg (accessed on 6 July 2025).

- Steeper Motor. Available online: https://us.openbuilds.com/nema-17-stepper-motor/ (accessed on 6 July 2025).

| Infill % | Concentric | Grid | Triangle | |||

|---|---|---|---|---|---|---|

| Weight ×10−3 (kg) | Density (kg/m3) | Weight ×10−3 (kg) | Density (kg/m3) | Weight ×10−3 (kg) | Density (kg/m3) | |

| 20 | 10.773 | 709.625 | 13.299 | 876.015 | 15.181 | 999.984 |

| 50 | 11.301 | 744.405 | 13.739 | 905.051 | 16.015 | 1054.92 |

| 80 | 11.455 | 754.549 | 14.109 | 929.37 | 16.137 | 1062.96 |

| 100 | ----- | ----- | ----- | ----- | 17.677 | 1164.4 |

| Infill % | Spring Stiffness (N/m) | ||

|---|---|---|---|

| Concentric | Grid | Triangle | |

| 20 | 893.4 | 964.2 | 1123 |

| 50 | 1236 | 1243 | 1339.2 |

| 80 | 1379.1 | 1481.7 | 1503.8 |

| 100 | ------ | ------ | 1558.4 |

| Infill % and Infill Pattern | Stiffness (N/m) | Accelerometer–Spring System | Accelerometer–Spring–Motor System | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Practical (Hz) | Theoretical (Hz) | Deviation % | Numerical (Hz) | Deviation % | Practical (Hz) | Theoretical (Hz) | Deviation % | Numerical (Hz) | Deviation % | ||

| 20C | 893.4 | 23.047 | 23.107 | 0.26 | 22.718 | 1.68 | 23.222 | 23.384 | 0.69 | 22.662 | 3.09 |

| 50C | 1236 | 24.624 | 25.050 | 1.70 | 24.505 | 2.18 | 24.392 | 24.394 | 0.01 | 24.435 | 0.17 |

| 80C | 1379.1 | 24.897 | 25.818 | 3.57 | 25.21 | 2.35 | 24.565 | 24.685 | 0.49 | 25.136 | 1.83 |

| 20G | 964.2 | 23.553 | 23.522 | 0.13 | 23.099 | 1.80 | 23.216 | 23.216 | 0.00 | 23.04 | 0.76 |

| 50G | 1243 | 24.676 | 25.088 | 1.64 | 24.54 | 2.18 | 24.230 | 24.391 | 0.66 | 24.47 | 0.32 |

| 80G | 1481.7 | 25.297 | 26.355 | 4.01 | 25.702 | 2.48 | 25.237 | 25.404 | 0.66 | 25.626 | 0.87 |

| 20T | 1123 | 23.830 | 24.426 | 2.44 | 23.931 | 2.03 | 23.553 | 23.496 | 0.24 | 23.866 | 1.57 |

| 50T | 1339.2 | 25.011 | 25.606 | 2.32 | 25.016 | 2.30 | 24.561 | 24.562 | 0.00 | 24.942 | 1.55 |

| 80T | 1503.8 | 25.459 | 26.470 | 3.82 | 25.807 | 2.50 | 24.900 | 24.900 | 0.00 | 25.73 | 3.33 |

| 100T | 1558.4 | 25.914 | 26.750 | 3.13 | 26.064 | 2.56 | 25.908 | 25.908 | 0.00 | 25.985 | 0.30 |

| Infill % | Force (N) | ||

|---|---|---|---|

| Concentric | Grid | Triangle | |

| 20 | 0.016 | 0.03 | 0.052 |

| 50 | 0.018 | 0.036 | 0.072 |

| 80 | 0.021 | 0.04 | 0.081 |

| Infill % | Force (N) | ||

|---|---|---|---|

| Concentric | Grid | Triangle | |

| 20 | 0.019 | 0.035 | 0.056 |

| 50 | 0.019 | 0.041 | 0.076 |

| 80 | 0.023 | 0.043 | 0.082 |

| Infill % | Force (N) | ||

|---|---|---|---|

| Concentric | Grid | Triangle | |

| 20 | 0.021 | 0.041 | 0.061 |

| 50 | 0.022 | 0.047 | 0.079 |

| 80 | 0.024 | 0.049 | 0.087 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahdi, H.H.; Nama, S.A.; Mezher, M.T.; Trzepieciński, T. Vibration Analysis of Cantilever Beam with Free End Resting on 3D-Printed Spring and Considering the Effect of Accelerometer and Exciter Masses. Appl. Sci. 2025, 15, 12344. https://doi.org/10.3390/app152212344

Mahdi HH, Nama SA, Mezher MT, Trzepieciński T. Vibration Analysis of Cantilever Beam with Free End Resting on 3D-Printed Spring and Considering the Effect of Accelerometer and Exciter Masses. Applied Sciences. 2025; 15(22):12344. https://doi.org/10.3390/app152212344

Chicago/Turabian StyleMahdi, Hassan H., Sami A. Nama, Marwan T. Mezher, and Tomasz Trzepieciński. 2025. "Vibration Analysis of Cantilever Beam with Free End Resting on 3D-Printed Spring and Considering the Effect of Accelerometer and Exciter Masses" Applied Sciences 15, no. 22: 12344. https://doi.org/10.3390/app152212344

APA StyleMahdi, H. H., Nama, S. A., Mezher, M. T., & Trzepieciński, T. (2025). Vibration Analysis of Cantilever Beam with Free End Resting on 3D-Printed Spring and Considering the Effect of Accelerometer and Exciter Masses. Applied Sciences, 15(22), 12344. https://doi.org/10.3390/app152212344