Study of the Particle Breakage Characteristics of Coral Sand Under the Effect of Freezing–Seepage Coupling

Abstract

1. Introduction

2. Test Materials and Methods

2.1. Test Materials

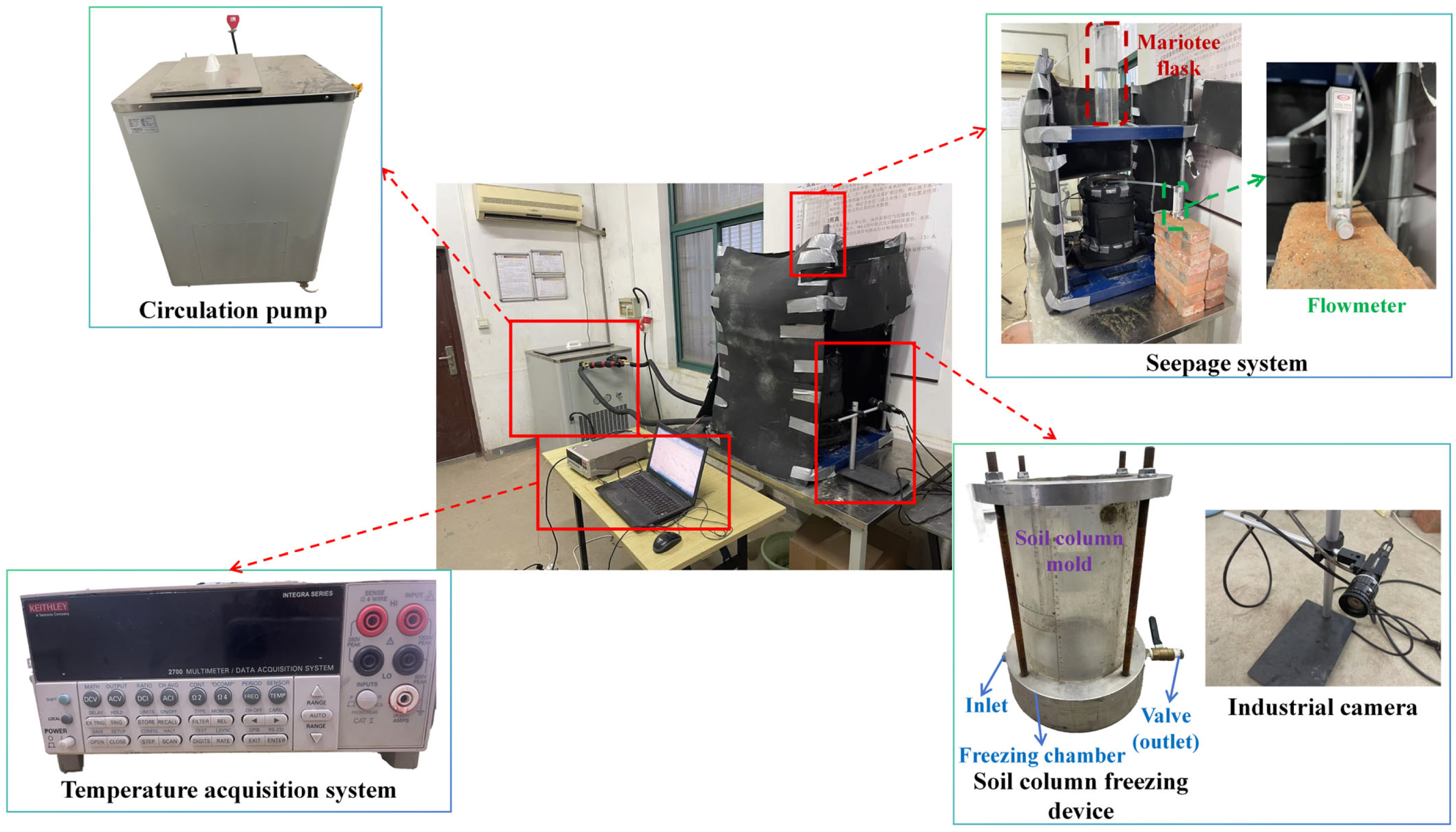

2.2. Test Instruments and Methods

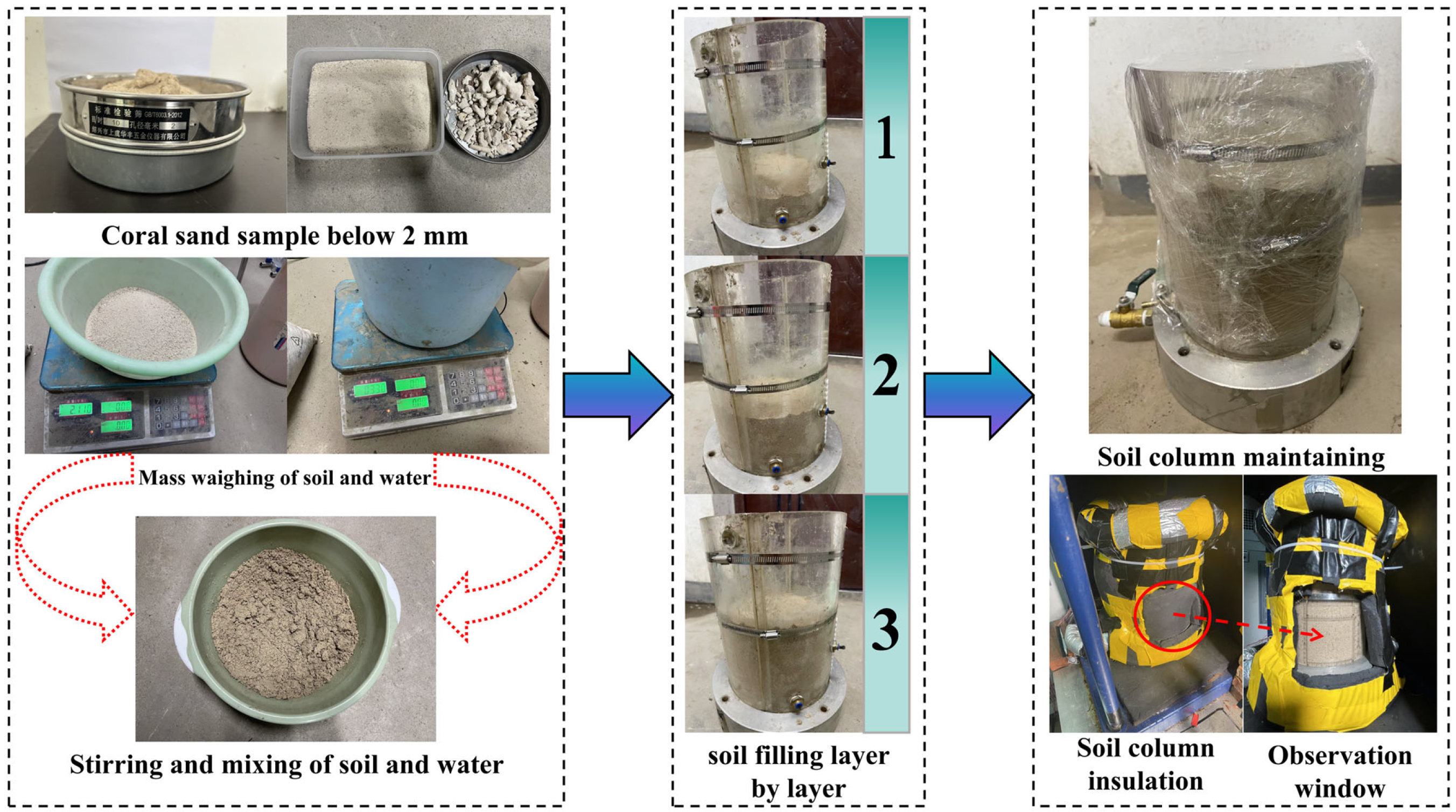

2.2.1. One-Dimensional Soil Column Unidirectional Freezing Test

- Sample preparation

- 2.

- Thermal insulation of soil column

- 3.

- Equipment debugging, connection, and test description

2.2.2. Particle Sieving Test

2.2.3. Scanning Electron Microscope Test

3. Test Results

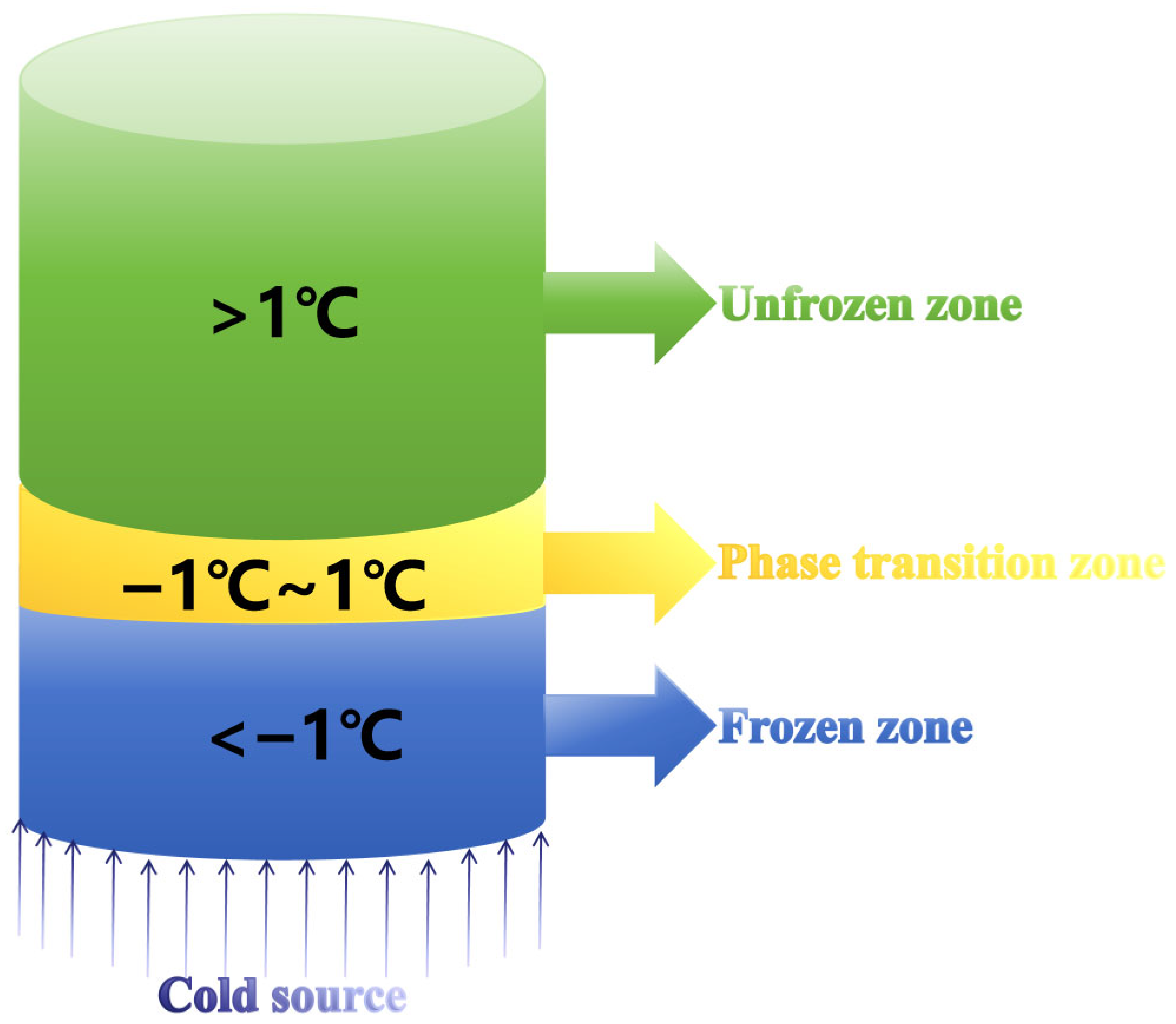

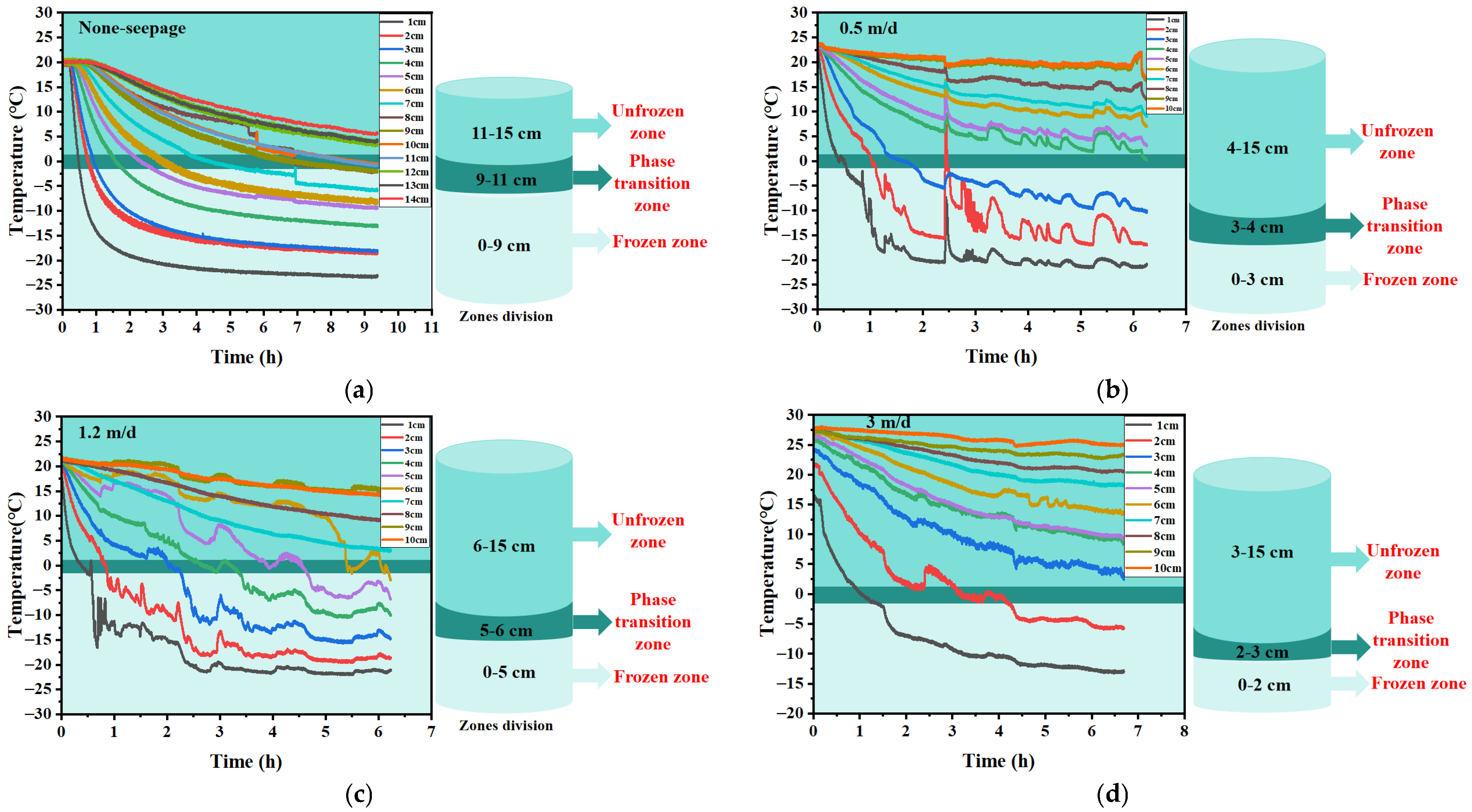

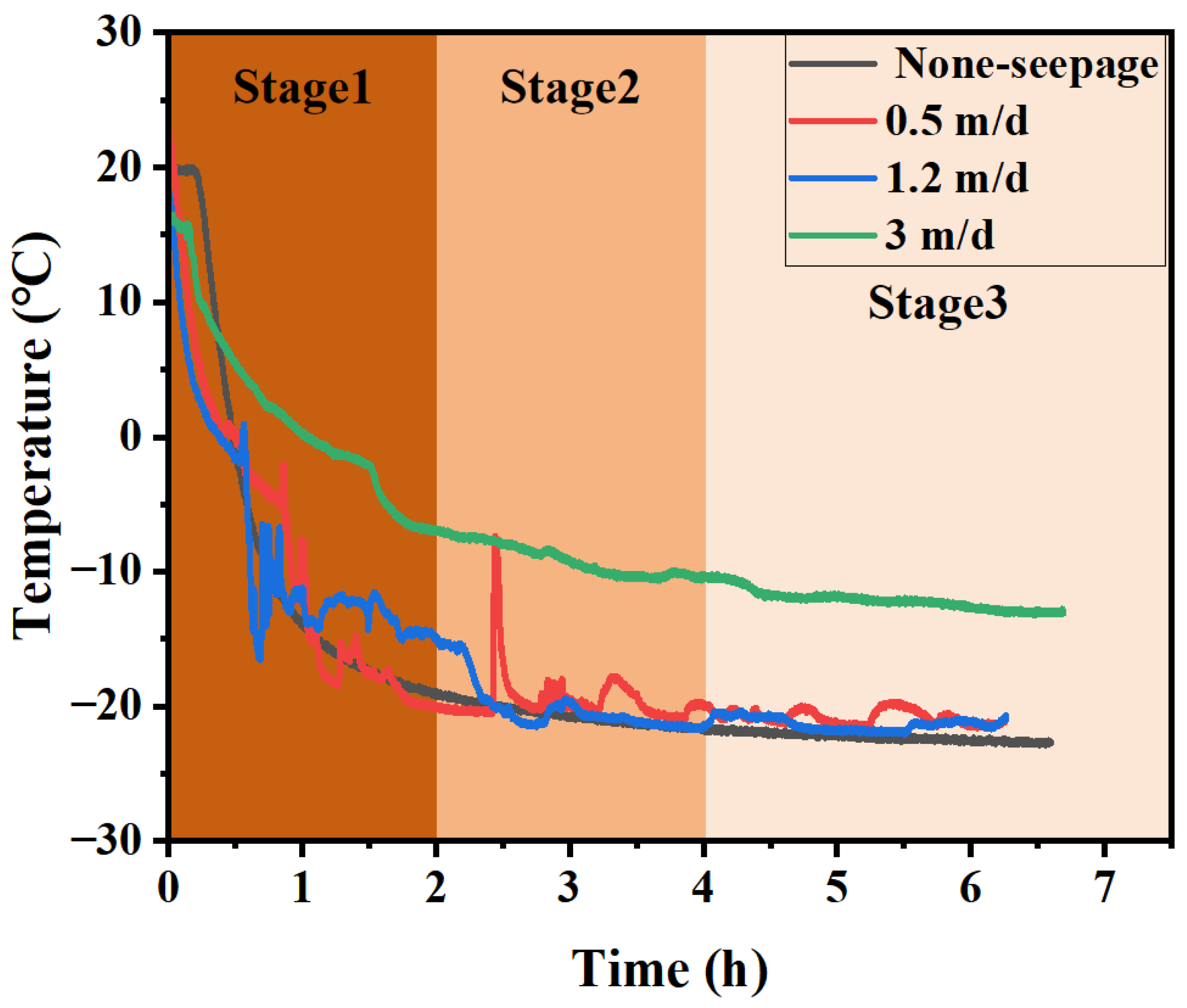

3.1. Temperature Variation During Freezing–Seepage Coupling Process

3.2. Particle Breakage of Coral Sand Under Freezing–Seepage Coupling Effect

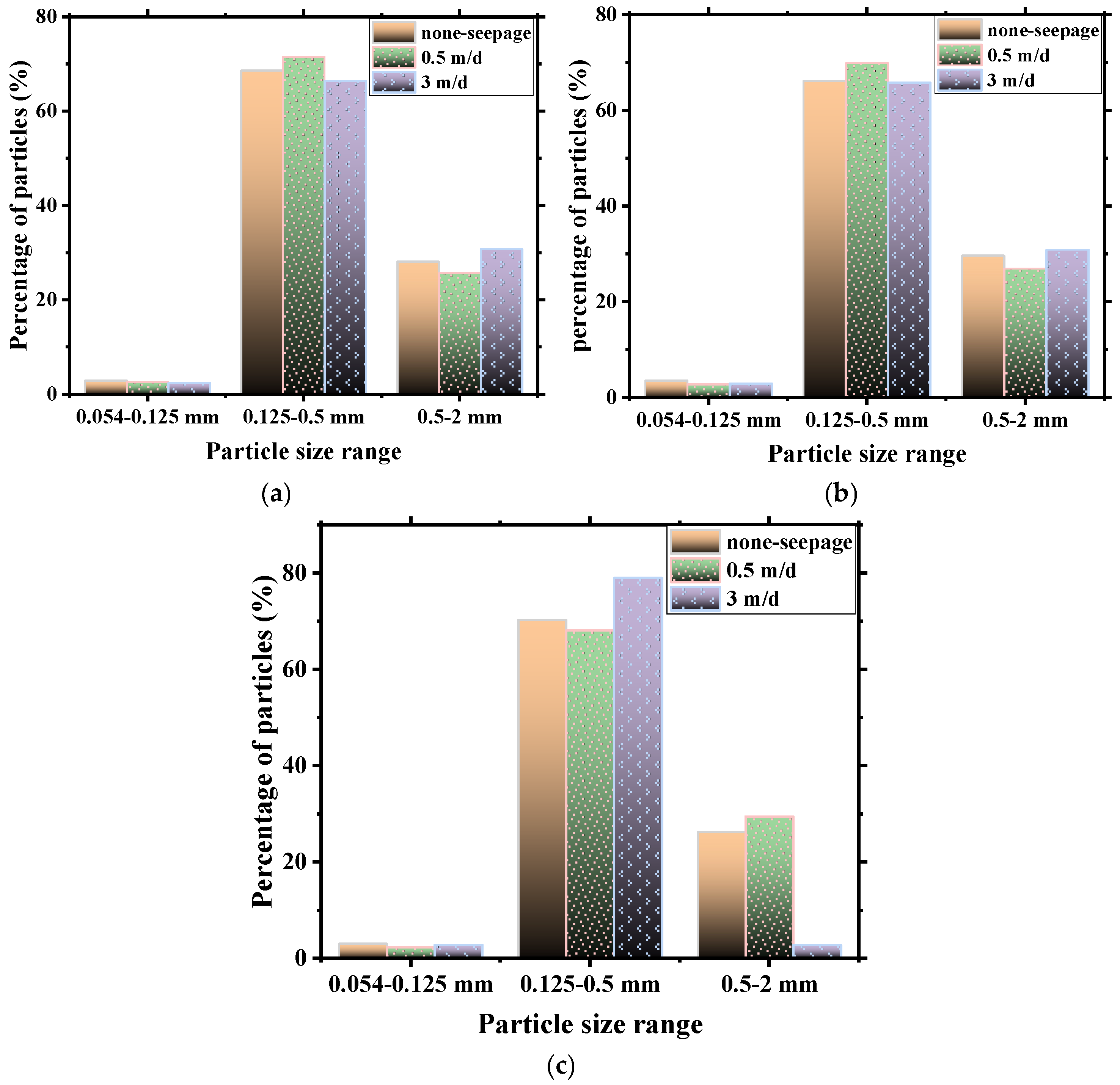

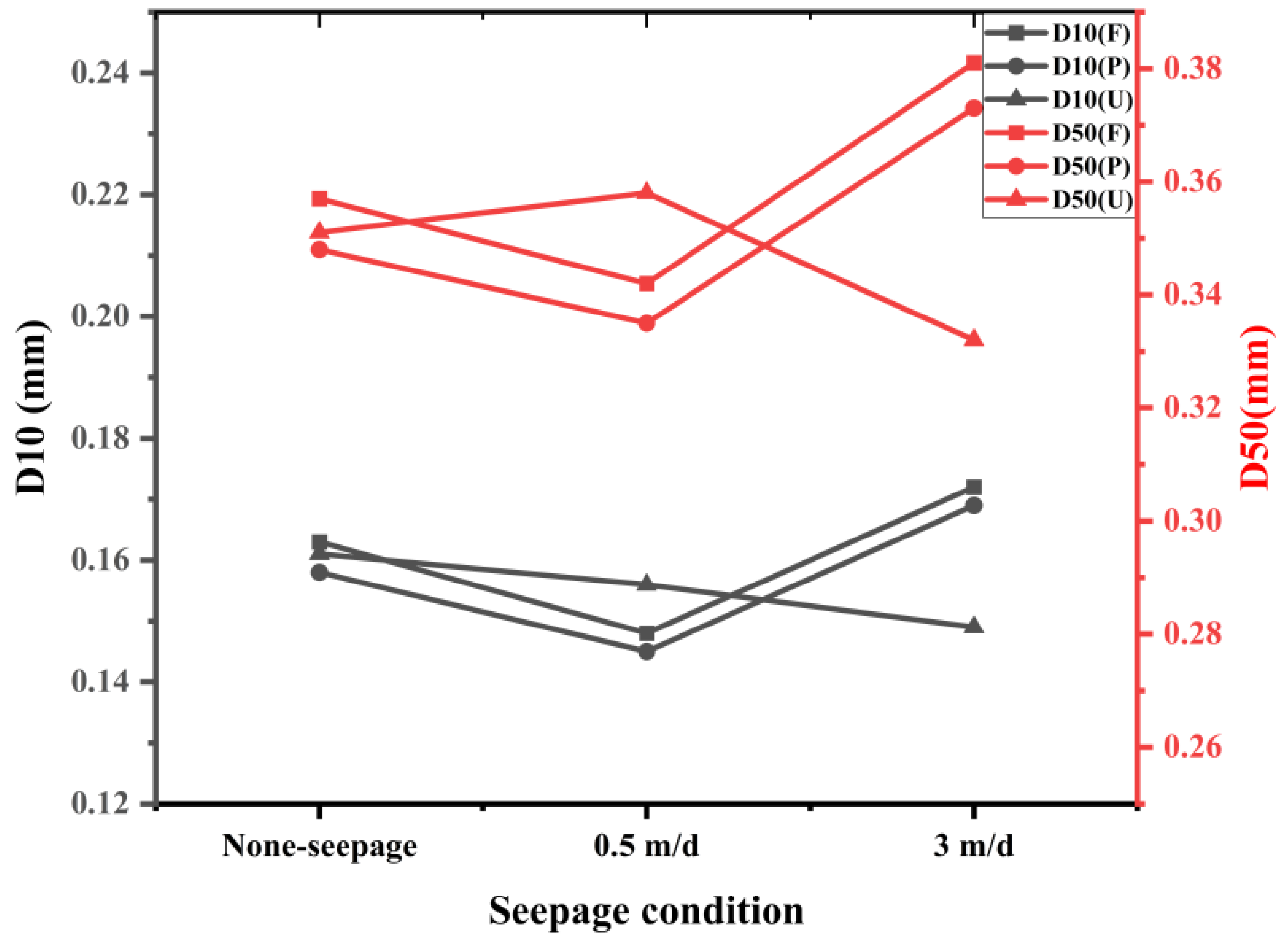

3.2.1. Particle Size Distribution Analysis of Coral Sand

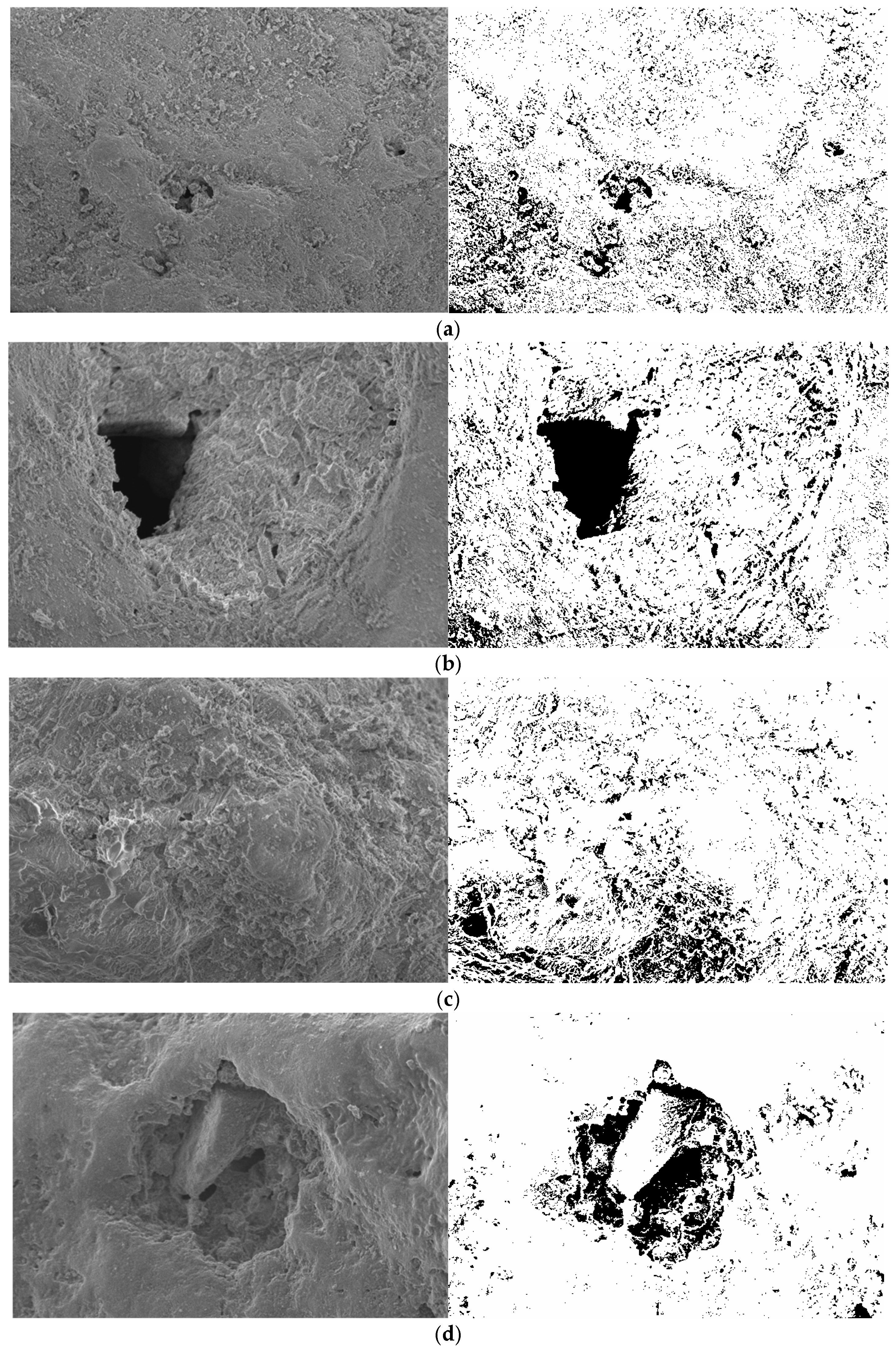

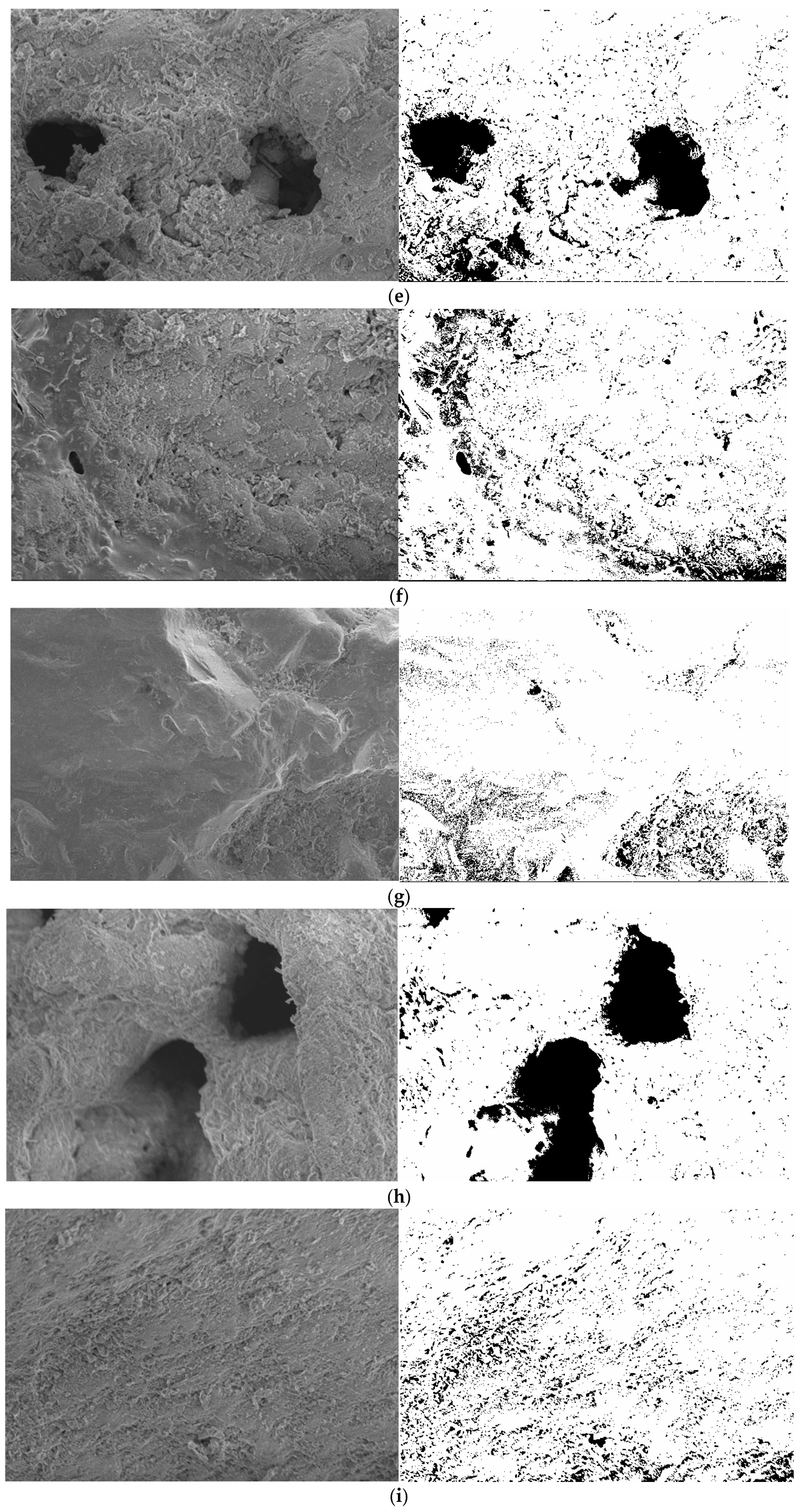

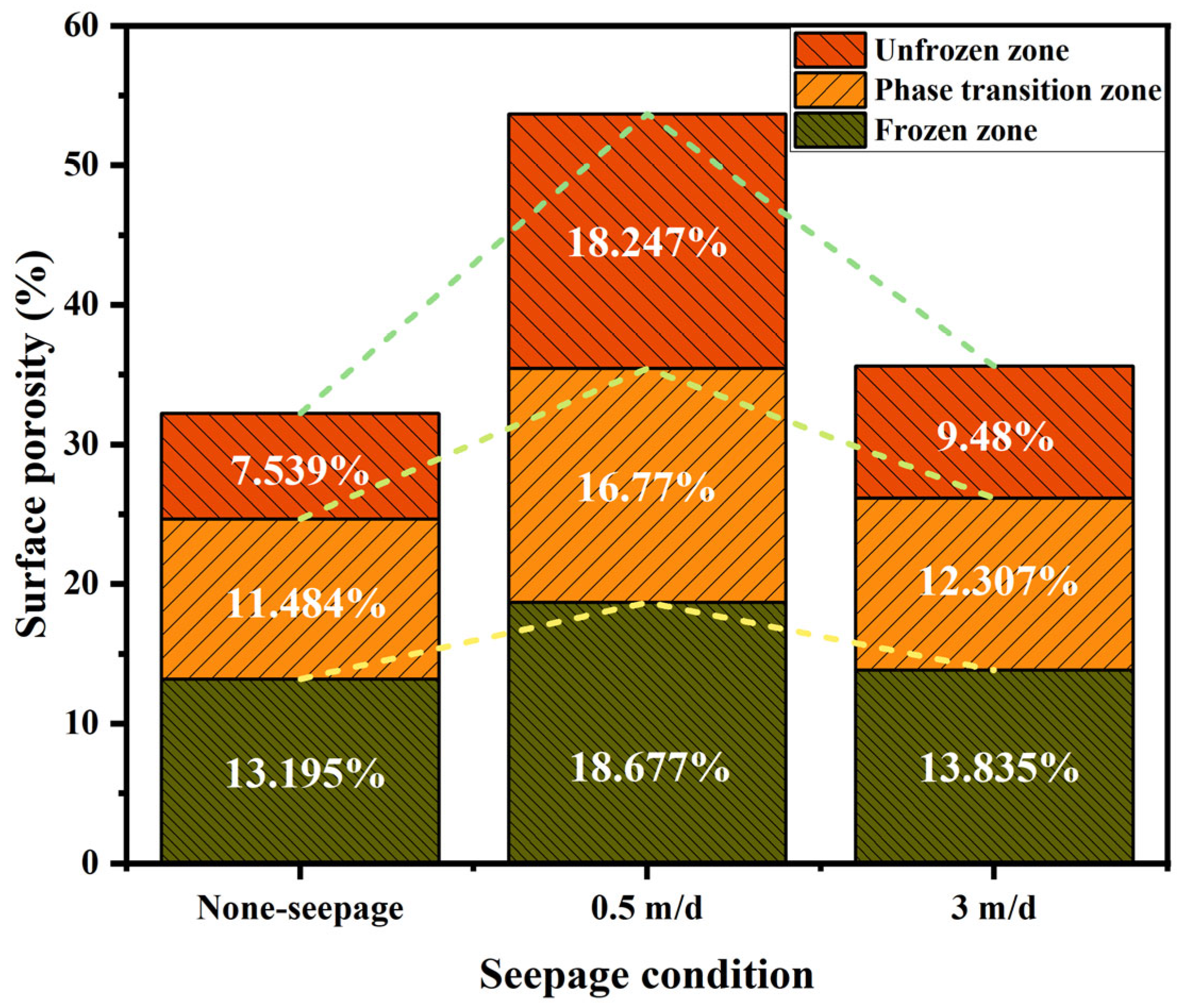

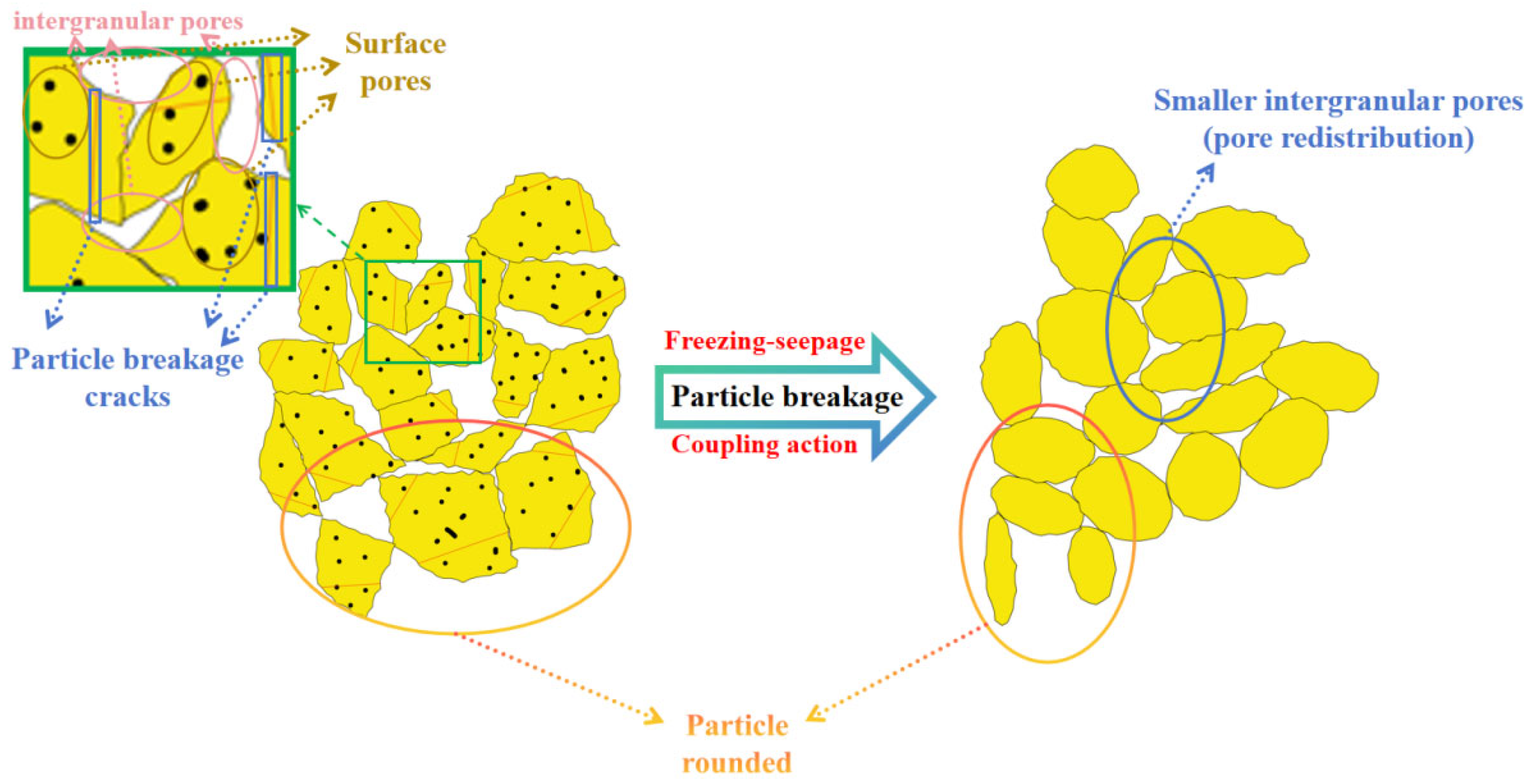

3.2.2. Particle Microstructure Analysis of Coral Sand

4. Discussion

5. Conclusions

- Seepage could significantly reduce the advancing height of the frozen front of coral sand. Meanwhile, it influenced the freezing rate and final stable freezing temperature. Under conditions of low-velocity seepage (0–1.2 m/d), the impact of seepage on freezing temperature of coral sand was not obvious. However, under high-velocity seepage conditions (3 m/d), seepage exerted a continuous influence on the entire freezing process of coral sand. It not only significantly decreased the freezing rate in the early freezing stage but also remarkably increased the final stable freezing temperature. Consequently, it is feasible to use the AGF method for construction in coral sand strata under low-velocity seepage conditions. In contrast, when the seepage velocity is high, the AGF method is not feasible.

- Under the coupling effect of freezing and seepage, obvious particle breakage of coral sand was observed. Regarding particle size distribution, under the conditions of none-seepage and 0.5 m/d seepage the freezing–seepage coupling process caused a decrease in the proportion of particles in the 0.5–2 mm size range in both the frozen zone and phase transition zone. In contrast, the proportion of particles in the 0.125–0.5 mm size range increased. Moreover, seepage exacerbated the damage to particles. In the size range of 0.054–0.125 mm, there were no significant differences in the mass proportion of coral sand under different seepage conditions, indicating that particle breakage was not obvious.

- Based on SEM images, under different seepage conditions the coral sand particles in the frozen zone decreased in angularity and showed a significant breakage after the freezing–seepage coupling effect. In the phase transition zone and unfrozen zone, since the influence of freezing was less than that in the frozen zone the particle breakage was less obvious. Under the influence of seepage, the coral sand particles became more rounded due to the erosion effect of seepage, thereby enhancing the degree of roundness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hu, J.; Gan, H.; Zhang, S.; Ye, T.; Liu, B.; Wei, K. Temperature field study of forced thawing by pipe curtain freezing method in Sanya submarine tunnel. Mar. Georesour. Geotechnol. 2024, 43, 1523–1539. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, S.; Li, X.; Wang, Y.; Long, H. Study on dynamic properties of saturated coral gravelly sand based on dynamic centrifuge tests. Ocean Eng. 2024, 312, 119325. [Google Scholar] [CrossRef]

- Zhang, X.; Meng, L.; Li, D.; Ye, Y.; Wei, K. Investigating correlations between microstructural characteristics and mechanical properties of coral sand mortar with different silica fume contents. Constr. Build. Mater. 2024, 438, 137180. [Google Scholar] [CrossRef]

- Gao, R.; Ye, J. Mechanical behaviors of coral sand and relationship between particle breakage and plastic work. Eng. Geol. 2023, 316, 107063. [Google Scholar] [CrossRef]

- Wang, Z.; Sheng, J.; Wang, Q.; Wu, X.; Liang, Z.; Xu, S.; Yao, Z. Experimental study on vertical seepage of coarse-grained calcareous sand. Soil Dynam. Earthq. Eng. 2024, 181, 108661. [Google Scholar] [CrossRef]

- Ding, H.; Wang, X.; Wen, D.; Huang, P. Seepage deformation characteristic of gap-graded coral sand in the South China Sea. Appl. Ocean Res. 2024, 143, 103865. [Google Scholar] [CrossRef]

- Li, X.; Zhou, W.-H.; Liu, J.; Wang, C. Elastic-plastic response and particle breakage in marine coral sand: Roles of fines and density state. Ocean Eng. 2025, 323, 120499. [Google Scholar] [CrossRef]

- Liu, F.; Tang, H.; Shahin, M.A.; Zhao, H.; Karrech, A.; Zhu, F.; Zhou, H. Multiscale simulation study for mechanical characteristics of coral sand influenced by particle breakage. Power Technol. 2025, 449, 120387. [Google Scholar] [CrossRef]

- Peng, Y.; Ding, X.; Yin, Z.-Y.; Wang, P. Micromechanical analysis of the particle corner breakage effect on pile penetration resistance dna formation of breakage zones in coral sand. Ocean Eng. 2022, 259, 111859. [Google Scholar] [CrossRef]

- Wan, Z.; Liu, Y.; Jin, J.; Hu, T.; Zhou, F.; Dai, G. Penetration behavior and particle breakage in coral calcareous sand for offshore pile foundations: Experimental and numerical analysis. Ocean Eng. 2025, 340, 122268. [Google Scholar] [CrossRef]

- Wang, G.; Wang, Z.; Ye, Q.; Zha, J. Particle breakage evolution of coral sand using triaxial compression tests. J. Rock Mech. Geotech. Eng. 2021, 13, 321–334. [Google Scholar] [CrossRef]

- Lin, L.; Li, S.; Huo, L.; Liu, X. Study on the relationship between fractal dimension and particle fragmentation for marine coral sand under impact load. Ocean Eng. 2023, 286, 115442. [Google Scholar] [CrossRef]

- Guo, L.; Fei, X.; Wu, J.; Zhao, L.; Lyu, B. High ductility cementitious composites incorporating seawater and coral sand (SCS-HDCC) for offshore engineering: Microstructure, mechanical performance and sustainability. Cem. Concr. Compos. 2024, 147, 105414. [Google Scholar]

- Zhang, X.; Wei, K.; Li, D.; Zhou, Y.; Liang, W. Characterization of mechanical properties and microstructure of silica mortar and coral sand mortar based on nuclear magnetic resonance technology. Mater. Today Commun. 2022, 33, 104909. [Google Scholar] [CrossRef]

- Zhang, X.; Zuo, J.; Wang, Z.; Cai, Y.; Zhou, Y. The evolution of the microstructure and mechanical properties of coral aggregate mortar under uniaxial compression using ultrasonic analysis. Constru. Build. Mater. 2021, 300, 124000. [Google Scholar] [CrossRef]

- Yang, Z.; Cao, S.; Chang, Z.; Wang, Y. Microstructure evolution of coral sand during impact liquefaction process. Soil Dynam. Earthq. Eng. 2025, 198, 109615. [Google Scholar] [CrossRef]

- Deng, G.; Guo, R.; Ma, L.; Long, Z.; Xu, F.; Yin, C.; Xu, X. Study on dynamic mechanical properties and microstructure of basalt fiber reinforced coral sand cement composite. Constr. Build. Mater. 2024, 425, 136024. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Standard for Geotechnical Testing Method. Ministry of Water Resources of the People’s Republic of China: Beijing, China; China Planning Press: Beijing, China, 2019.

- DG/TJ 08-092-2016; Technical Code for Crosspassage Freezing Method. Shanghai Shentong Rail Transit Research and Consulting Company: Shanghai, China, 2016.

- Zhou, J.; Li, Z.; Wan, P.; Tang, Y.; Zhao, W. Effects of seepage in clay-sand composite strata on artificial ground freezing and surrounding engineering environment. Chin. J. Geotech. Eng. 2021, 43, 471–480. (In Chinese) [Google Scholar]

- Gao, G.; Guo, W.; Zhu, X. Degree of artificial freezing analyses under high seepage condition. Int. J. Heat Mass Tran. 2025, 236, 126352. [Google Scholar] [CrossRef]

- Liu, Z.; Guo, C.; Cao, D.; Rui, H. Compression characteristics of coral calcareous sand in the South China Sea. Sci. Technol. Eng. 2022, 22, 2401–2408. (In Chinese) [Google Scholar]

- Liu, X.; Nowamooz, H.; Shen, Y.; Liu, Y.; Han, Y.; An, Y. Heat transfer analysis in artificial ground freezing for subway cross passage under seepage flow. Tunn. Undergr. Sp. Technol. 2023, 133, 104943. [Google Scholar] [CrossRef]

- Zhou, J.; Zhou, H.; Wang, C.; Guo, Z.; Pei, W. Analysis of moisture migration, temperature, and pore structure characteristics of the muddy clay column to artificial ground freezing based on LF NMR. Tunn. Undergr. Sp. Technol. 2023, 133, 104948. [Google Scholar] [CrossRef]

- Xu, D.-S.; Shen, G.; Liu, Q.-M.; Du, W.-B. Dynamic mechanical response and particle breakage characteristics of calcareous sand. Soil Dynam. Earthq. Eng. 2024, 181, 108653. [Google Scholar] [CrossRef]

- Ma, W.; Chen, G.; Wu, Q. Experimental study on liquefaction resistance of coral sand under complex loading conditions. Rock Soil Mech. 2020, 41, 535–542. (In Chinese) [Google Scholar]

- Chai, M.; Luo, Y.; Gao, Y.; Ma, W.; Mu, Y. Seepage influence of supra-permafrost groundwater on thermal field of embankment on Qinghai-Tibet Plateau, China. Res. Cold Arid. Reg. 2023, 15, 132–140. [Google Scholar] [CrossRef]

- Hou, S.; Yang, Y.; Cai, C.; Chen, Y.; Li, F.; Lei, D. Modeling heat and mass transfer during artificial ground freezing considering the influence of water seepage. Int. J. Heat Mass Transf. 2022, 194, 123053. [Google Scholar] [CrossRef]

- Li, X.K.; Li, X.; Liu, S.; Qi, J.L. Thermal-seepage coupled numerical simulation methodology for the artificial ground freezing process. Comput. Geotech. 2023, 156, 105246. [Google Scholar] [CrossRef]

| Density (kN/m3) | Particle Size (mm) | Permeability Coefficient (cm/s) | Compress Modulus (MPa) |

|---|---|---|---|

| 18.0 | 0.05–2 | 8 × 10−2 | 10.0 |

| Test Number | Seepage Velocity |

|---|---|

| 1 | None-Seepage |

| 2 | 0.5 m/d |

| 3 | 1.2 m/d |

| 4 | 3 m/d |

| Particle Size (mm) | None-Seepage | 0.5 m/d (Compared with None-Seepage) | 3 m/d (Compared with None-Seepage) |

|---|---|---|---|

| 2 | 0.028% | 0.009% (−0.019%) | 0.152% (+0.124%) |

| 1 | 9.606% | 8.819% (−0.787%) | 12.134% (+2.528%) |

| 0.9 | 0.451% | 0.819% (+0.368%) | 0.725% (+0.274%) |

| 0.5 | 18.063% | 16.005% (−2.058%) | 17.860% (−0.203%) |

| 0.25 | 38.099% | 36.799% (−1.3%) | 35.074% (−3.025%) |

| 0.2 | 12.542% | 13.461% (+0.919%) | 11.575% (−0.967%) |

| 0.15 | 15.400% | 17.728% (+2.328%) | 16.834% (+1.434%) |

| 0.125 | 2.600% | 3.546% (0.946%) | 2.899% (+0.299%) |

| 0.1 | 2.180% | 2.093% (−0.087%) | 1.934% (−0.246%) |

| 0.075 | 0.246% | 0.236% (−0.01%) | 0.222% (−0.024%) |

| 0.063 | 0.271% | 0.161% (−0.1%) | 0.145% (−0.126%) |

| 0.054 | 0.202% | 0.078% (−0.124%) | 0.106% (−0.096%) |

| Particle Size (mm) | None-Seepage | 0.5 m/d (Compared with None-Seepage) | 3 m/d (Compared with None-Seepage) |

|---|---|---|---|

| 2 | 0.111% | 0.043% (−0.068%) | 0.087% (−0.024%) |

| 1 | 10.696% | 9.352% (−1.344%) | 12.014% (+1.318%) |

| 0.9 | 0.769% | 0.384% (−0.385%) | 0.539% (−0.23%) |

| 0.5 | 18.236% | 17.185% (−1.051%) | 18.370% (+0.134%) |

| 0.25 | 33.408% | 39.206% (+6.158%) | 33.861% (+0.453%) |

| 0.2 | 13.433% | 11.945% (−1.488%) | 13.356% (−0.077%) |

| 0.15 | 15.648% | 16.136% (+0.488%) | 15.699% (+0.051%) |

| 0.125 | 3.722% | 2.607% (−1.115%) | 2.910% (−0.812%) |

| 0.1 | 2.972% | 2.306% (−0.666%) | 2.426% (−0.546%) |

| 0.075 | 0.273% | 0.241% (−0.032%) | 0.204% (−0.069%) |

| 0.063 | 0.130% | 0.119% (−0.011%) | 0.139% (+0.009%) |

| 0.054 | 0.175% | 0.099% (−0.076%) | 0.115% (−0.06%) |

| Particle Size (mm) | None-Seepage | 0.5 m/d (Compared with None-Seepage) | 3 m/d (Compared with None-Seepage) |

|---|---|---|---|

| 2 | 0 | 0.084% (+0.084%) | 0.169% (+0.169%) |

| 1 | 8.809% | 11.008% (+2.199%) | 6.384% (−2.425%) |

| 0.9 | 0.770% | 0.752% (−0.018%) | 0.475% (−0.295%) |

| 0.5 | 16.680% | 17.695% (+1.015%) | 11.088% (−5.592%) |

| 0.25 | 35.157% | 35.131% (−0.026%) | 39.033% (+3.876%) |

| 0.2 | 13.430% | 12.560% (−0.87%) | 17.037% (+3.607%) |

| 0.15 | 18.447% | 17.559% (−0.888%) | 19.510% (+1.063%) |

| 0.125 | 3.257% | 2.842% (−0.415%) | 3.179% (−0.078%) |

| 0.1 | 2.587% | 1.888% (−0.707%) | 2.203% (−0.384%) |

| 0.075 | 0.227% | 0.164% (−0.063%) | 0.256% (+0.029%) |

| 0.063 | 0.139% | 0.150% (+0.011%) | 0.198% (+0.059%) |

| 0.054 | 0.112% | 0.108% (−0.004%) | 0.106% (−0.006%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Kong, X.; Zhou, H.; Ban, C.; Liu, C.; Hu, J. Study of the Particle Breakage Characteristics of Coral Sand Under the Effect of Freezing–Seepage Coupling. Appl. Sci. 2025, 15, 12301. https://doi.org/10.3390/app152212301

Zhou J, Kong X, Zhou H, Ban C, Liu C, Hu J. Study of the Particle Breakage Characteristics of Coral Sand Under the Effect of Freezing–Seepage Coupling. Applied Sciences. 2025; 15(22):12301. https://doi.org/10.3390/app152212301

Chicago/Turabian StyleZhou, Jie, Xiangzhen Kong, Huade Zhou, Chao Ban, Chengjun Liu, and Jun Hu. 2025. "Study of the Particle Breakage Characteristics of Coral Sand Under the Effect of Freezing–Seepage Coupling" Applied Sciences 15, no. 22: 12301. https://doi.org/10.3390/app152212301

APA StyleZhou, J., Kong, X., Zhou, H., Ban, C., Liu, C., & Hu, J. (2025). Study of the Particle Breakage Characteristics of Coral Sand Under the Effect of Freezing–Seepage Coupling. Applied Sciences, 15(22), 12301. https://doi.org/10.3390/app152212301