Low-Temperature RF Magnetron Sputtering of TiW Thin Films: Effects of the Bulk Plasma Characteristics on Film Growth

Abstract

1. Introduction

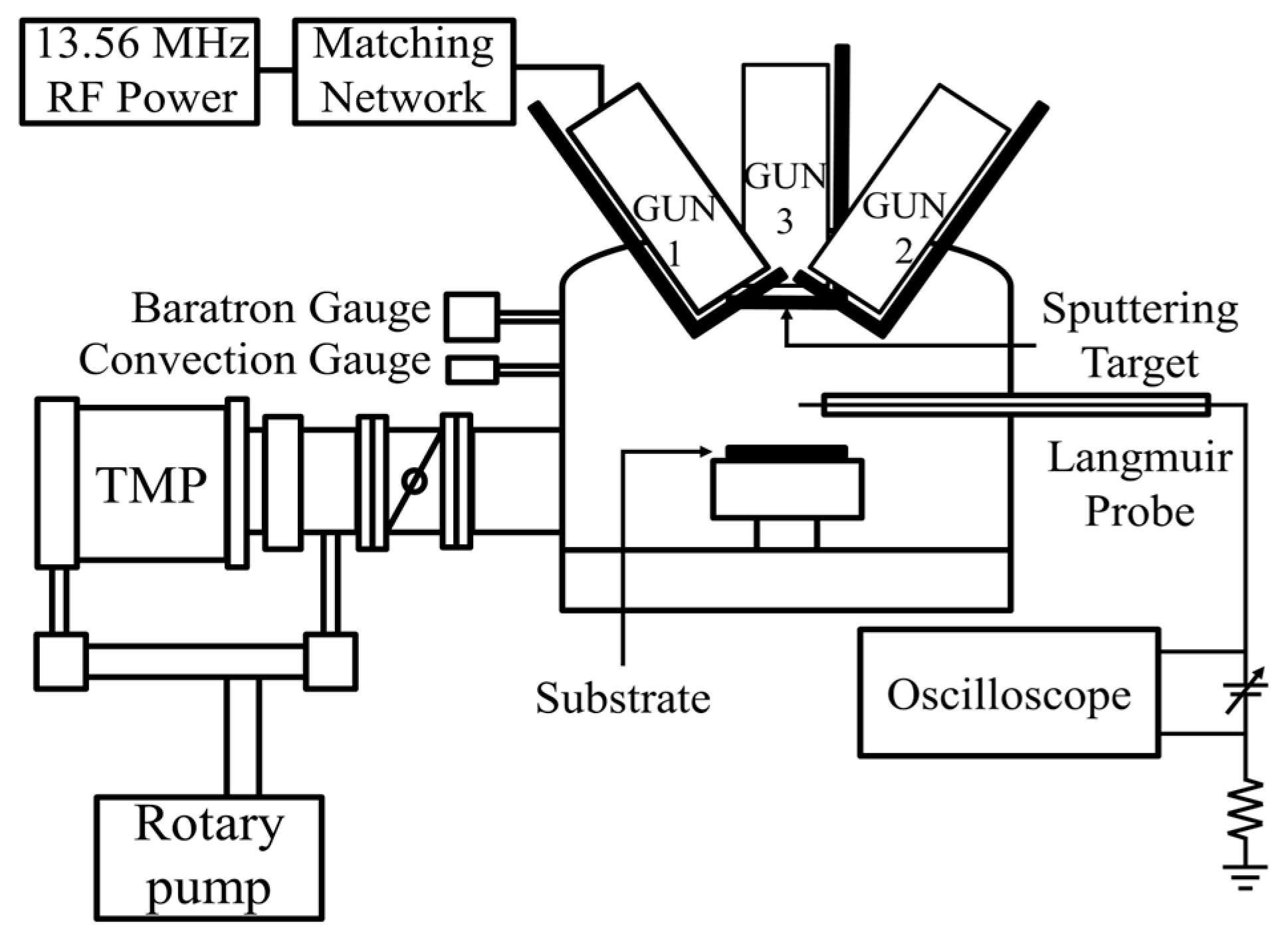

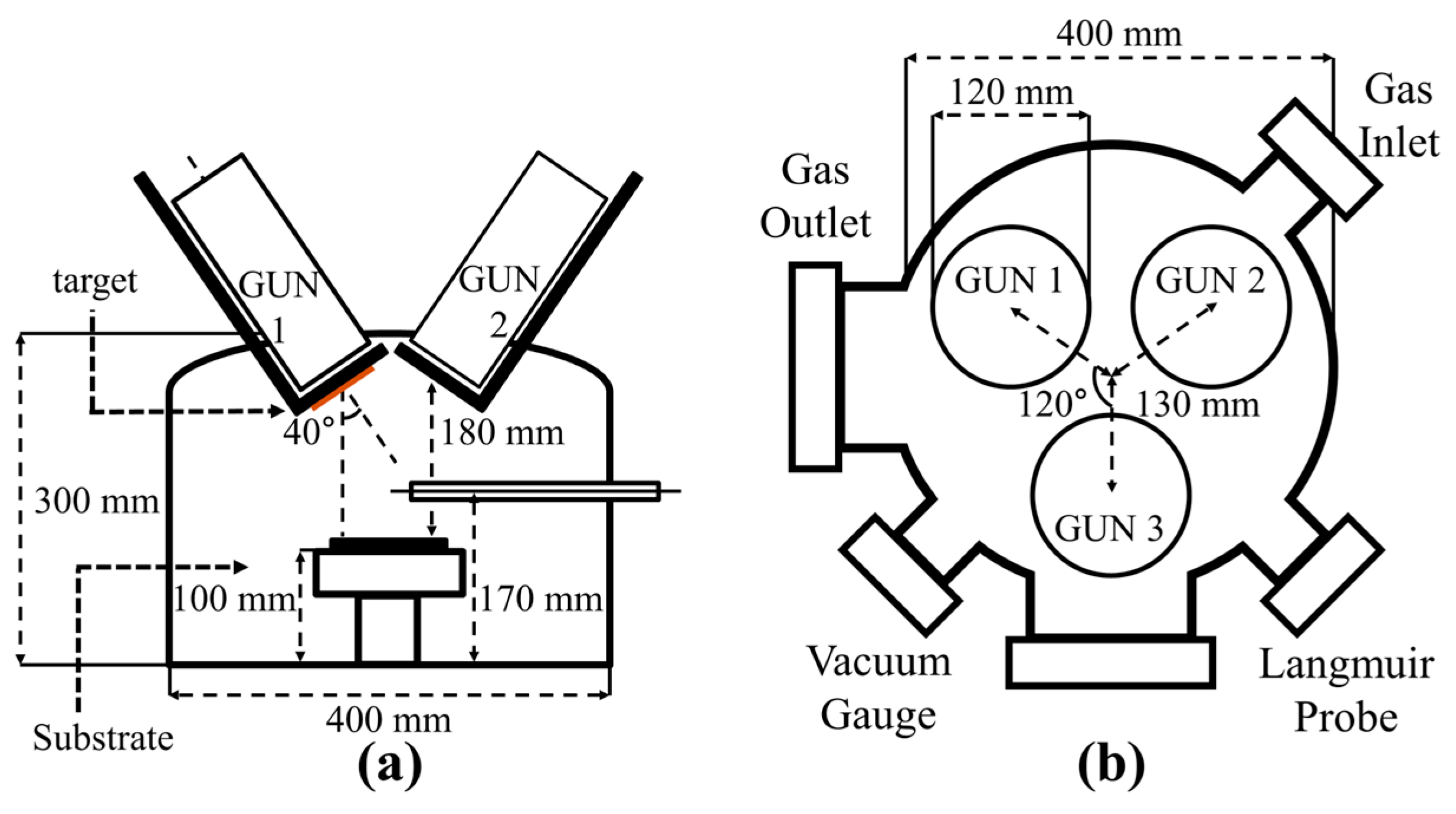

2. Experimental Setup and Method

3. Results

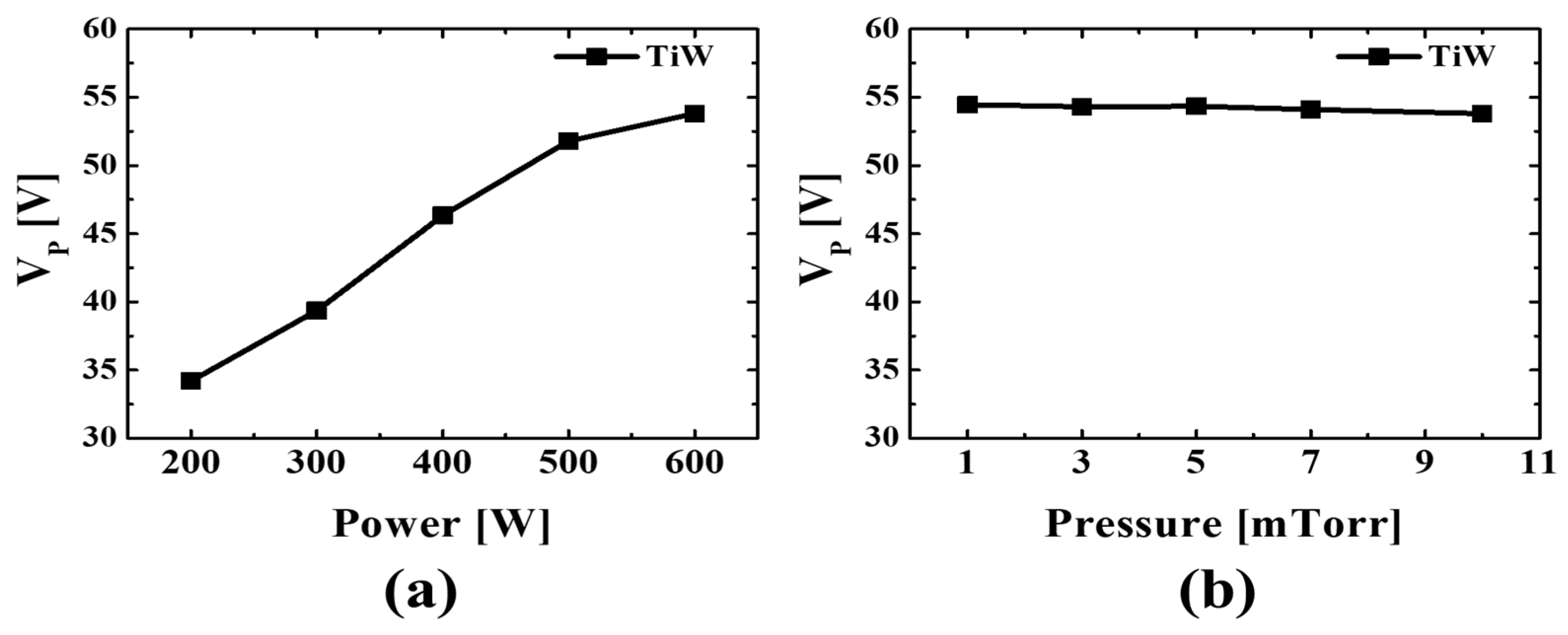

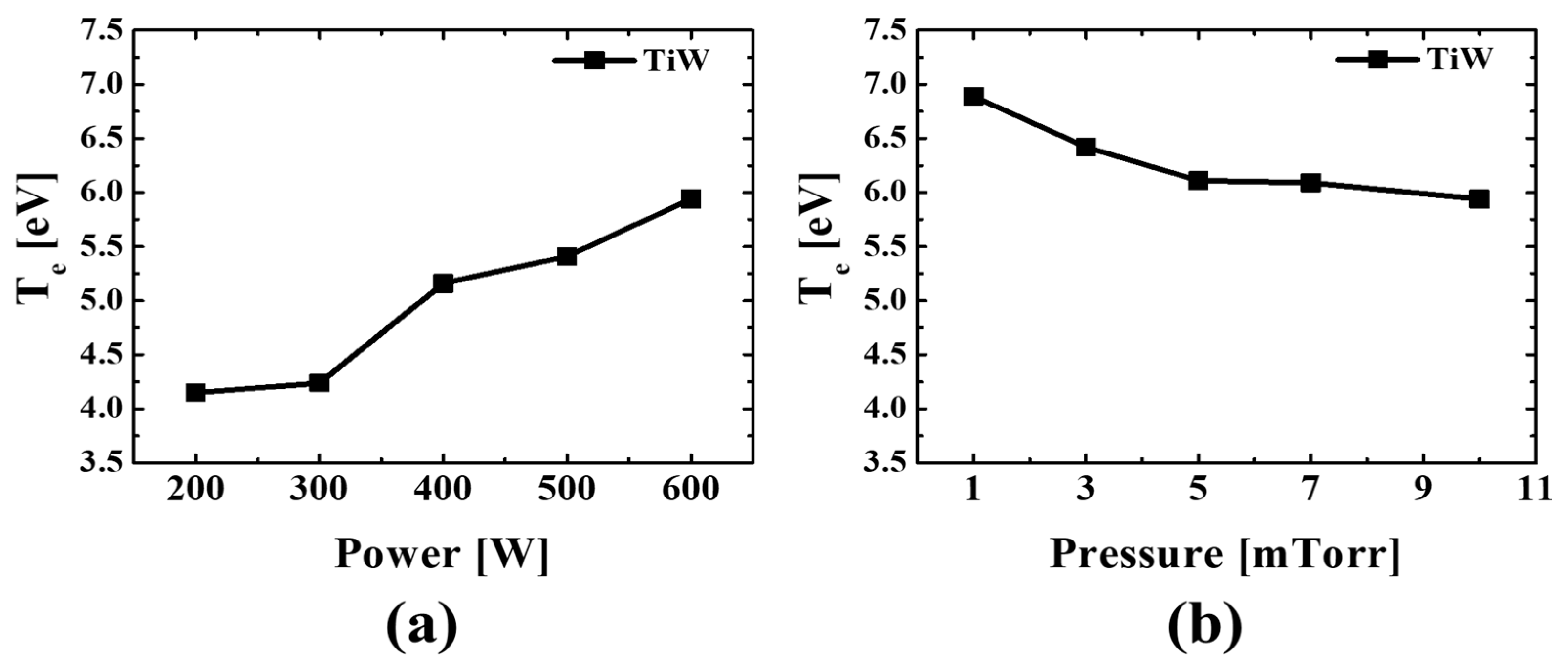

3.1. Bulk Plasma Characteristics

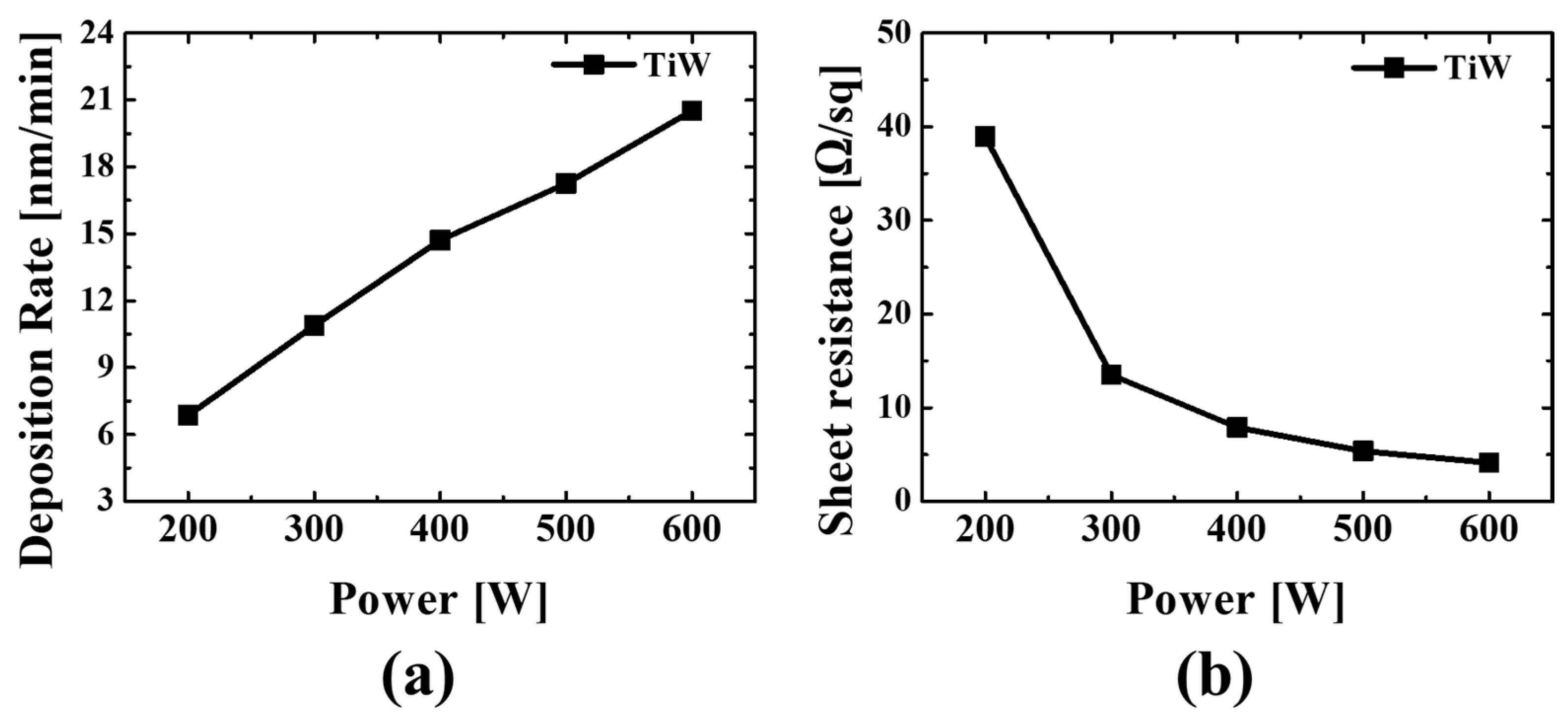

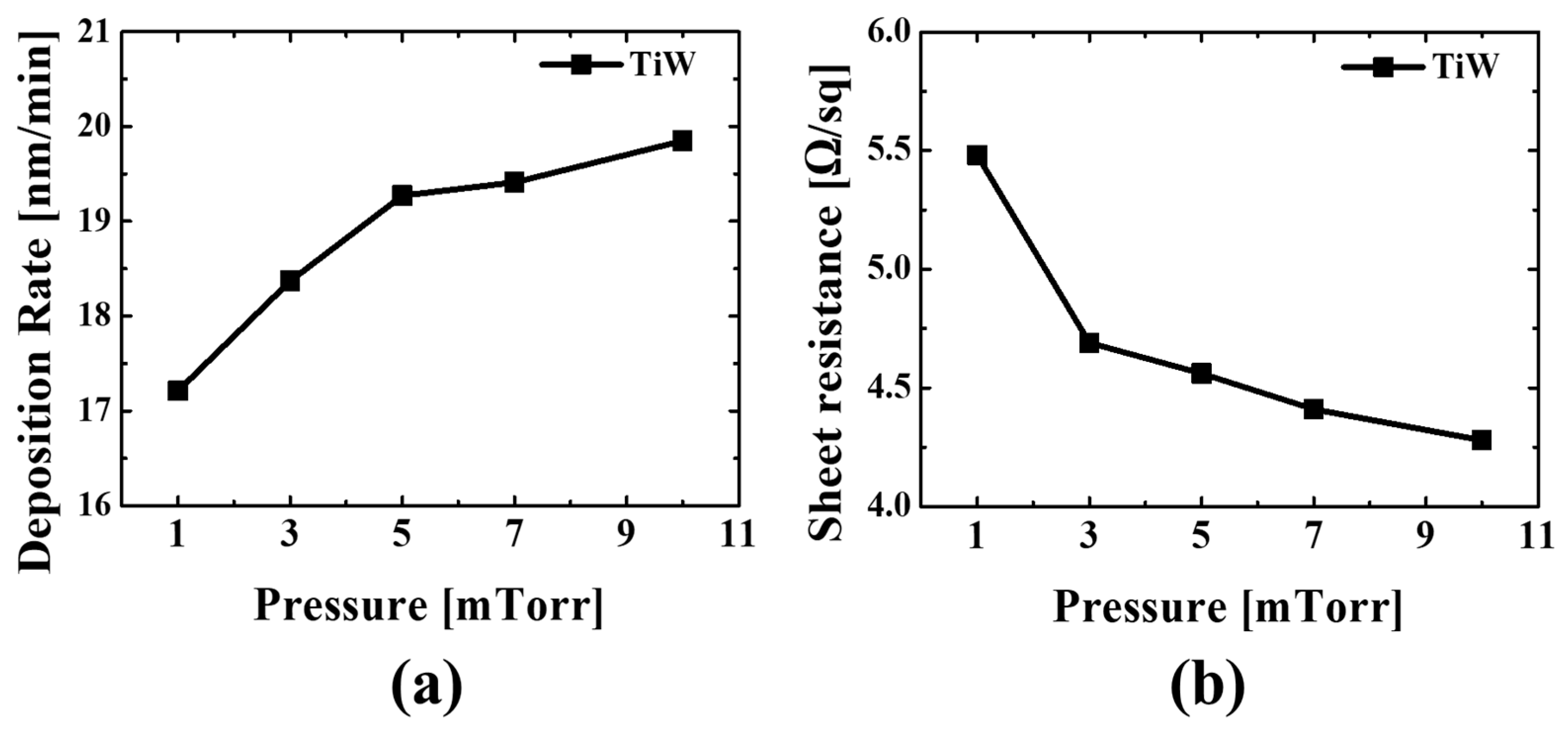

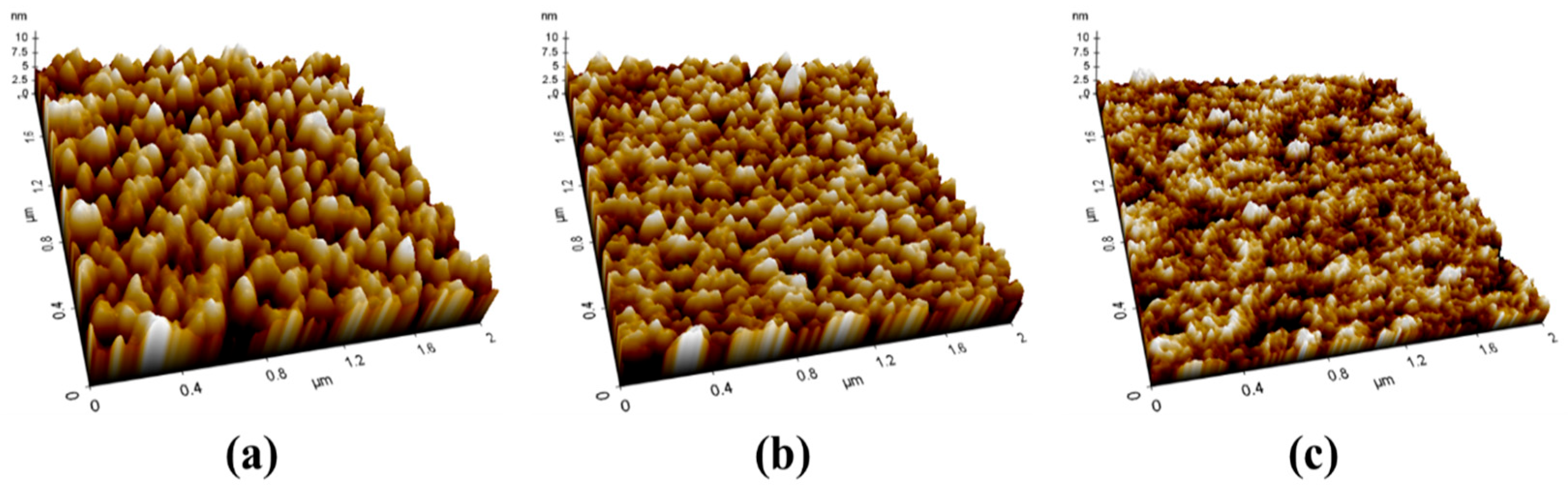

3.2. Properties of Sputtered TiW Thin Films

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Beyne, E.; De Moor, P.; Ruythooren, W.; Labie, R.; Jourdain, A.; Tilmans, H.; Tezcan, D.S.; Soussan, P.; Swinnen, B.; Cartuyvels, R. Through-Silicon via and Die Stacking Technologies for Microsystems-Integration. In Proceedings of the 2008 IEEE International Electron Devices Meeting, San Francisco, CA, USA, 15–17 December 2008; pp. 1–4. [Google Scholar]

- Gambino, J.P.; Adderly, S.A.; Knickerbocker, J.U. An Overview of Through-Silicon-via Technology and Manufacturing Challenges. Microelectron. Eng. 2015, 135, 73–106. [Google Scholar] [CrossRef]

- Knickerbocker, J.U.; Andry, P.S.; Dang, B.; Horton, R.R.; Patel, C.S.; Polastre, R.J.; Sakuma, K.; Sprogis, E.S.; Tsang, C.K.; Webb, B.C. 3D Silicon Integration. In Proceedings of the 2008 58th Electronic Components and Technology Conference, Lake Buena Vista, FL, USA, 27–30 May 2008; pp. 538–543. [Google Scholar]

- Diehl, D.; Kitada, H.; Maeda, N.; Fujimoto, K.; Ramaswami, S.; Sirajuddin, K.; Yalamanchili, R.; Eaton, B.; Rajagopalan, N.; Ding, R.; et al. Formation of TSV for the Stacking of Advanced Logic Devices Utilizing Bumpless Wafer-on-Wafer Technology. Microelectron. Eng. 2012, 92, 3–8. [Google Scholar] [CrossRef]

- Zhang, W. Fine Pitch Cu/Sn Solid State Diffusion Bonding for Advanced Three-Dimensional Chip Stacking. Jpn. J. Appl. Phys. 2015, 54, 030203. [Google Scholar] [CrossRef]

- Burns, J.; Stucchi, M.; Patti, R.; Cong, J.; Lee, Y.-J.; Milojevic, D.; Carlson, D.; Xie, Y.; Vardaman, E.-J. Three Dimensional System Integration: IC Stacking Process and Design; Papanikolaou, A., Soudris, D., Radojcic, R., Eds.; Springer: New York, NY, USA, 2011. [Google Scholar]

- Banerjee, K.; Souri, S.J.; Kapur, P.; Saraswat, K.C. 3-D ICs: A Novel Chip Design for Improving Deep-Submicrometer Interconnect Performance and Systems-on-Chip Integration. Proc. IEEE 2001, 89, 602–633. [Google Scholar] [CrossRef]

- Knickerbocker, J.U.; Patel, C.S.; Andry, P.S.; Tsang, C.K.; Buchwalter, L.P.; Sprogis, E.J.; Gan, H.; Horton, R.R.; Polastre, R.J.; Wright, S.L. 3-D Silicon Integration and Silicon Packaging Technology Using Silicon Through-Vias. IEEE J. Solid-State Circuits 2006, 41, 1718–1725. [Google Scholar] [CrossRef]

- Lau, J.H. Overview and Outlook of Three-Dimensional Integrated Circuit Packaging, Three-Dimensional Si Integration, and Three-Dimensional Integrated Circuit Integration. J. Electron. Packag. 2014, 136, 040801. [Google Scholar] [CrossRef]

- Wei, T.; Cai, J.; Wang, Q.; Hu, Y.; Wang, L.; Liu, Z.; Wu, Z. Optimization and Evaluation of Sputtering Barrier/Seed Layer in through Silicon via for 3-D Integration. Tsinghua Sci. Technol. 2014, 19, 150–160. [Google Scholar] [CrossRef]

- Schmitz, J. Low Temperature Thin Films for Next-Generation Microelectronics. Surf. Coat. Technol. 2018, 343, 83–88. [Google Scholar] [CrossRef]

- Cheemalamarri, H.K.; Senthilkumar, D.; Rao, B.S.S.C. Through Silicon Via Oxide Etch Back for Via-Last Integration Scheme. In Proceedings of the 2022 IEEE 24th Electronics Packaging Technology Conference (EPTC), Singapore, 7–9 December 2022; pp. 973–976. [Google Scholar]

- Garrou, P.; Bower, C.; Roozeboon, F.; Lamy, Y.; Chang, S.-M.; Wieland, R.; Ritzdorf, T. Handbook of 3D Integration: Technology and Applications of 3D Integrated Circuits; Garrou, P., Ed.; Wiley-VCH: Weinheim, Germany, 2014. [Google Scholar]

- Sakata, A.; Yamashita, S.; Omoto, S.; Hatano, M.; Wada, J.; Higashi, K.; Yamaguchi, H.; Yosho, T.; Imamizu, K.; Yamada, M.; et al. Reliability Improvement by Adopting Ti-Barrier Metal for Porous Low-k ILD Structure. AIP Conf. Proc. 2007, 945, 98–106. [Google Scholar]

- Jiang, T.; Im, J.; Huang, R.; Ho, P.S. Through-Silicon via Stress Characteristics and Reliability Impact on 3D Integrated Circuits. MRS Bull. 2015, 40, 248–256. [Google Scholar] [CrossRef]

- Wu, W.; Wu, H.-J.; Dixit, G.; Shaviv, R.; Gao, M.; Mountsier, T.; Harm, G.; Dulkin, A.; Fuchigami, N.; Kailasam, S.K. Ti-Based Barrier for Cu Interconnect Applications. In Proceedings of the 2008 International Interconnect Technology Conference, Burlingame, CA, USA, 1–4 June 2008; pp. 202–204. [Google Scholar]

- Bang, C.; Cha, J.-H. Properties of Titanium Thin Film Deposited by RF and DC Magnetron Sputtering at Low Temperatures. AIP Adv. 2025, 15, 065105. [Google Scholar] [CrossRef]

- Wasa, K.; Motohiro, T.; Adachi, H.; Tominaga, K.; Matsushima, K. Handbook of Sputter Deposition Technology: Fundamentals and Applications for Functional Thin Films, Nano-Materials and MEMS; Wasa, K., Kanno, I., Koetera, H., Eds.; William Andrew: New York, NY, USA, 2012. [Google Scholar]

- Ensinger, W. Low Energy Ion Assist during Deposition—An Effective Tool for Controlling Thin Film Microstructure. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 1997, 127, 796–808. [Google Scholar] [CrossRef]

- Loch, D.A.L.; Ehiasarian, A.P. Study of the Effect of RF-Power and Process Pressure on the Morphology of Copper and Titanium Sputtered by ICIS. Surf. Coat. Technol. 2017, 327, 200–206. [Google Scholar] [CrossRef]

- Saghaeian, F.; Keckes, J.; Woehlert, S.; Rosenthal, M.; Reisinger, M.; Todt, J. Microstructure and Stress Gradients in TiW Thin Films Characterized by 40 nm X-Ray Diffraction and Transmission Electron Microscopy. Thin Solid Films 2019, 691, 137576. [Google Scholar] [CrossRef]

- Kalha, C.; Reisinger, M.; Thakur, P.; Lee, T.-L.; Venkatesan, S.; Isaacs, M.; Nelhiebel, M.; Regoutz, A. Evaluation of the thermal stability of TiW/Cu heterojunctions using a combined SXPS and HAXPES approach. J. Appl. Phys. 2022, 131, 165301. [Google Scholar] [CrossRef]

- Glebovsky, V.G.; Yaschak, V.Y.; Baranov, V.V.; Sackovich, E.L. Properties of titanium-tungsten thin films obtained by magnetron sputtering of composite cast targets. Thin Solid Films 1995, 257, 1–6. [Google Scholar] [CrossRef]

- Pflug, A.; Siemers, M.; Schwanke, C.; Febty Kurnia, B.; Sittinger, V.; Szyszka, B. Simulation of Plasma Potential and Ion Energies in Magnetron Sputtering. Mater. Technol. 2011, 26, 10–14. [Google Scholar] [CrossRef]

- Kaltofen, R.; Sebald, T.; Weise, G. Ion Bombardment Diagnostics in a Nitrogen RF Magnetron Sputtering Discharge. Surf. Coat. Technol. 1997, 97, 131–139. [Google Scholar] [CrossRef]

- Han, J.G. Recent Progress in Thin Film Processing by Magnetron Sputtering with Plasma Diagnostics. J. Phys. D Appl. Phys. 2009, 42, 043001. [Google Scholar] [CrossRef]

- Lieberman, M.A.; Lichtenberg, A.J. Principles of Plasma Discharges and Materials Processing, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Kim, S.-W.; Cha, J.-H.; Jung, S.-H.; Shim, S.; Kim, C.H.; Lee, H.-J. Characteristics of Segmented Dielectric Window Inductively Coupled Plasma. AIP Adv. 2023, 13, 045022. [Google Scholar] [CrossRef]

- Behrisch, R.; Eckstein, W. Sputtering by Particle Bombardment: Experiments and Computer Calculations from Threshold to MeV Energies; Springer: Berlin, Germany, 2007. [Google Scholar]

- Koenig, H.R.; Maissel, L.I. Application of RF Discharges to Sputtering. IBM J. Res. Dev. 1970, 14, 168–171. [Google Scholar] [CrossRef]

- Grill, A. Cold Plasma in Materials Fabrication: From Fundamentals to Applications; IEEE Press: Piscataway, NJ, USA, 1994. [Google Scholar]

- Seah, M.P.; Clifford, C.A.; Green, F.M.; Gilmore, I.S. An accurate semi-empirical equation for sputtering yields I: For argon ions. Surf. Interface Anal. 2005, 37, 444–458. [Google Scholar] [CrossRef]

- Petrović, S.; Bundaleski, N.; Peruško, D.; Radović, M.; Kovač, J.; Mitrić, M.; Gaković, B.; Rakočević, Z. Surface Analysis of the Nanostructured W–Ti Thin Film Deposited on Silicon. Appl. Surf. Sci. 2007, 253, 5196–5202. [Google Scholar] [CrossRef]

- Jeyachandran, Y.L.; Karunagaran, B.; Narayandass, S.K.; Mangalaraj, D.; Jenkins, T.E.; Martin, P.J. Properties of Titanium Thin Films Deposited by Dc Magnetron Sputtering. Mater. Sci. Eng. A 2006, 431, 277–284. [Google Scholar] [CrossRef]

- Oparowski, J.M.; Sisson, R.D.; Biederman, R.R. The Effects of Processing Parameters on the Microstructure and Properties of Sputter-Deposited TiW Thin Film Diffusion Barriers. Thin Solid Films 1987, 153, 313–328. [Google Scholar] [CrossRef]

- Liu, D.; Dew, S.K.; Brett, M.J.; Smy, T.; Tsai, W. Compositional Variations in Ti-W Films Sputtered over Topographical Features. J. Appl. Phys. 1994, 75, 8114–8120. [Google Scholar] [CrossRef]

- Le Priol, A.; Le Bourhis, E.; Renault, P.-O.; Muller, P.; Sik, H. Structure-Stress-Resistivity Relationship in WTi Alloy Ultra-Thin and Thin Films Prepared by Magnetron Sputtering. J. Appl. Phys. 2013, 113, 213504. [Google Scholar] [CrossRef]

| Sputtering Target | Operation Frequency | Ar Gas Flow [sccm] | Power [W] | Pressure [mTorr] |

|---|---|---|---|---|

| TiW | 13.56 MHz RF | 30 | 200 | 1 |

| 300 | 3 | |||

| 400 | 5 | |||

| 500 | 7 | |||

| 600 | 10 |

| Sputtering Target | Operation Frequency | Power [W] | Pressure [mTorr] | Negative DC Voltage [V] |

|---|---|---|---|---|

| TiW | 13.56 MHz RF | 200 | 10 | −76 |

| 300 | −92 | |||

| 400 | −106 | |||

| 500 | −119 | |||

| 600 | −129 |

| Input Power | Peak | 2theta [°] | FWHM [°] | DScherrer [nm] |

|---|---|---|---|---|

| 300 | (110) | 39.620 | 0.5285 | 15.98 |

| (200) | 57.320 | 0.6025 | 15.03 | |

| (211) | 72.020 | 0.4864 | 20.19 | |

| 600 | (110) | 39.540 | 0.5118 | 16.50 |

| (200) | 56.002 | 0.3980 | 22.61 | |

| (211) | 72.020 | 0.5110 | 19.22 |

| Sputtering Target | Operation Frequency | Power [W] | Pressure [mTorr] | Negative DC Voltage [V] |

|---|---|---|---|---|

| TiW | 13.56 MHz RF | 600 | 1 | −169 |

| 3 | −158 | |||

| 5 | −144 | |||

| 7 | −136 | |||

| 10 | −129 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bang, C.; Ji, C.Y.; Cha, J.-H. Low-Temperature RF Magnetron Sputtering of TiW Thin Films: Effects of the Bulk Plasma Characteristics on Film Growth. Appl. Sci. 2025, 15, 12300. https://doi.org/10.3390/app152212300

Bang C, Ji CY, Cha J-H. Low-Temperature RF Magnetron Sputtering of TiW Thin Films: Effects of the Bulk Plasma Characteristics on Film Growth. Applied Sciences. 2025; 15(22):12300. https://doi.org/10.3390/app152212300

Chicago/Turabian StyleBang, Chiyun, Chang Yeong Ji, and Ju-Hong Cha. 2025. "Low-Temperature RF Magnetron Sputtering of TiW Thin Films: Effects of the Bulk Plasma Characteristics on Film Growth" Applied Sciences 15, no. 22: 12300. https://doi.org/10.3390/app152212300

APA StyleBang, C., Ji, C. Y., & Cha, J.-H. (2025). Low-Temperature RF Magnetron Sputtering of TiW Thin Films: Effects of the Bulk Plasma Characteristics on Film Growth. Applied Sciences, 15(22), 12300. https://doi.org/10.3390/app152212300