A Review of Alfalfa Drying Technology and Equipment Throughout the Whole Process

Abstract

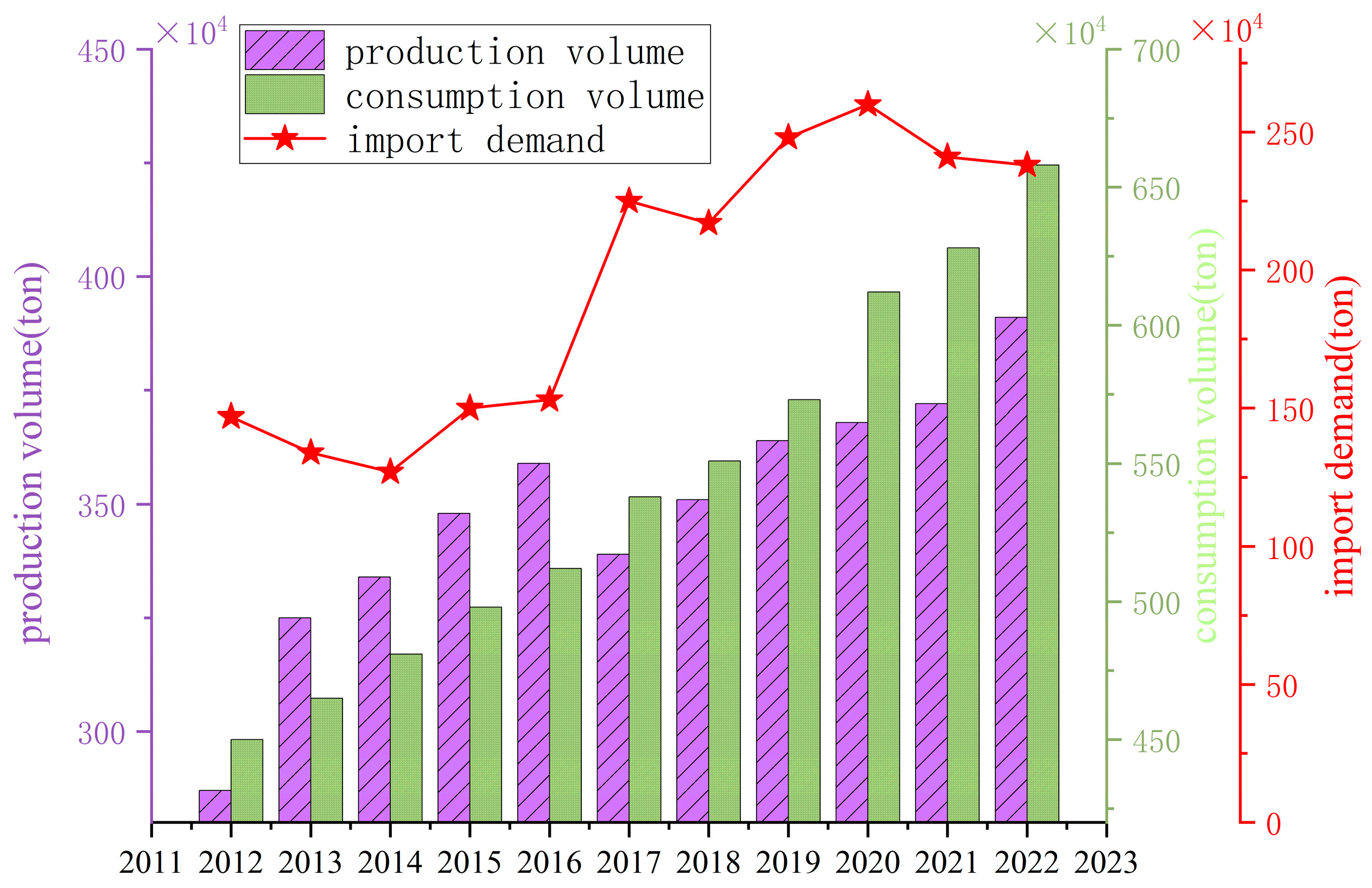

1. Introduction

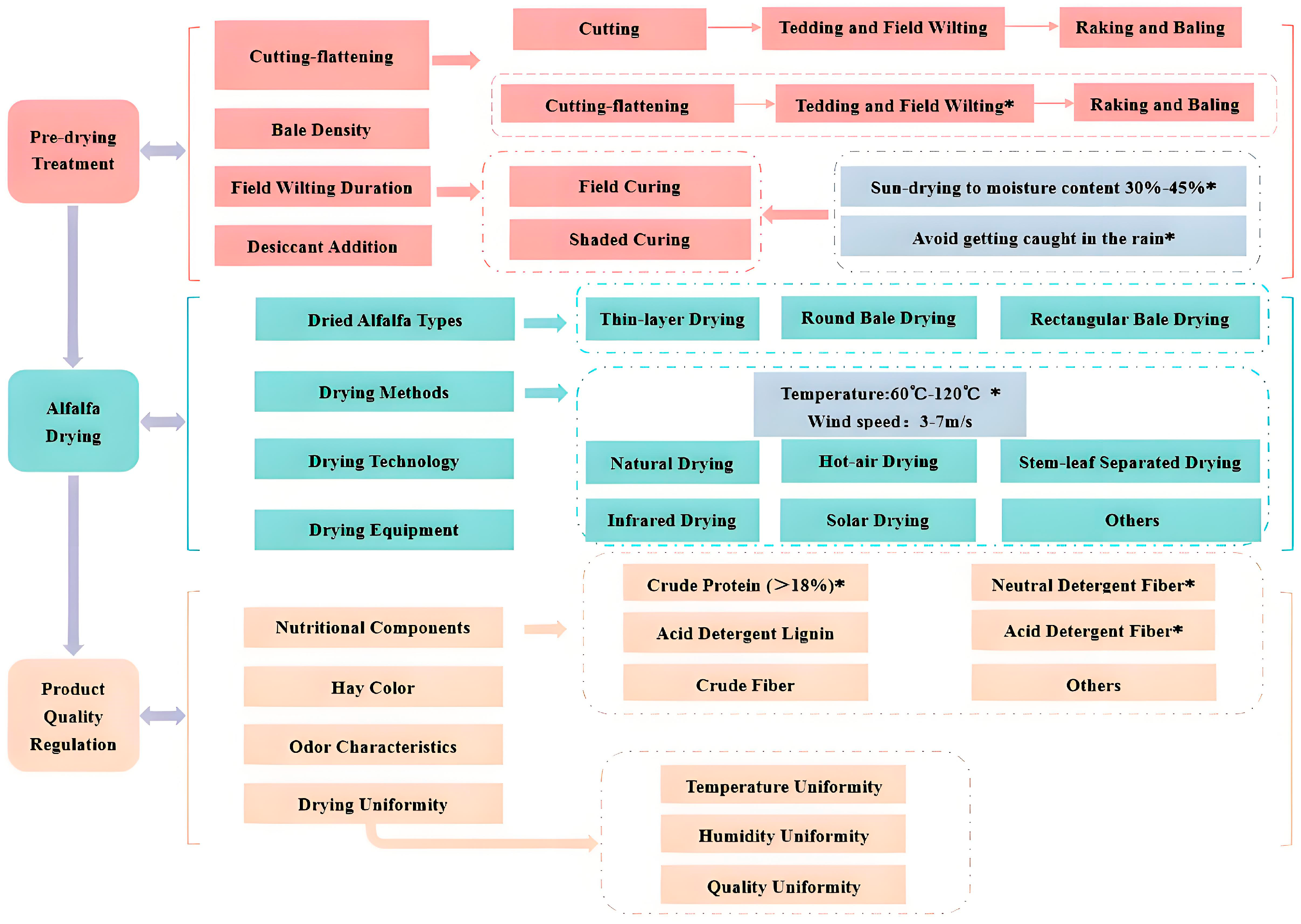

2. The Whole-Process Drying Technological Model for Alfalfa

- (1)

- Material property adaptability. The alfalfa drying technology must be adapted to the relevant material properties. Significant variations exist in the nutritional content at different growth stages and plant positions, as well as in drying rates. Cutting time significantly affects initial moisture content and nutritional composition, which directly influences subsequent drying. Furthermore, bale density and shape significantly impact drying equipment selection, process parameters, and drying uniformity. Therefore, when selecting alfalfa harvesting and processing methods, appropriate cutting times must be chosen based on these material characteristics. Developing and adopting suitable technologies—such as cutting and flattening, and matching bale density—maximizes nutrient retention and enhances drying rates.

- (2)

- Adaptability of methods and processes. For alfalfa drying, thin-layer drying methods (including natural drying, hot-air drying, and solar drying) have been relatively well-studied. Drying processes primarily encompass traditional drying, wet-harvest drying, phased drying, and dynamic drying. Different drying methods and processes require distinct equipment. Therefore, it is essential to develop specialized alfalfa drying machinery tailored to the major alfalfa cultivation and production regions in China. A key focus should be overcoming the bottleneck of lacking efficient, large-scale, bale-based drying equipment, thereby enhancing production efficiency to meet market demands.

- (3)

- Product quality adaptability. The ultimate goal of whole-process drying technology is to produce high-quality products. Alfalfa varieties exhibit differences in nutritional content. Factors such as mowing time, field drying duration, tedding frequency, bale moisture content, and drying processes all impact final product quality. Therefore, all production stages must be comprehensively considered to establish a holistic evaluation system to achieve the objective of efficient production of premium alfalfa.

- (4)

- Economic Viability. The whole-process drying technological model should integrate multiple factors affecting economic viability, including production scale, drying equipment, processing methods, and cost inputs. This integration enables the provision of tailored technical models and integrated equipment-process solutions aligned with practical production requirements.

3. Analysis of Alfalfa Drying Mechanism

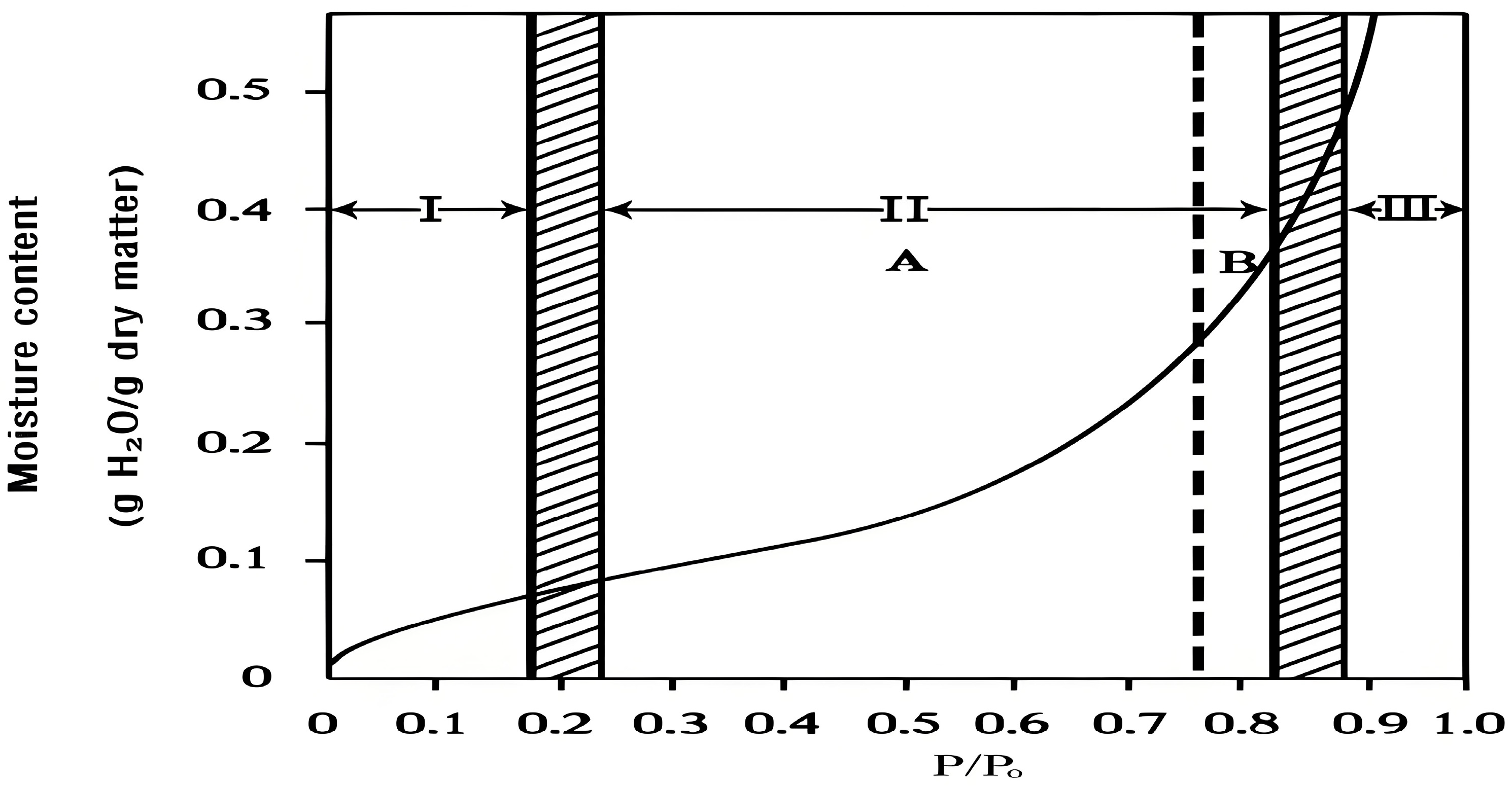

3.1. Forms of Water in Alfalfa

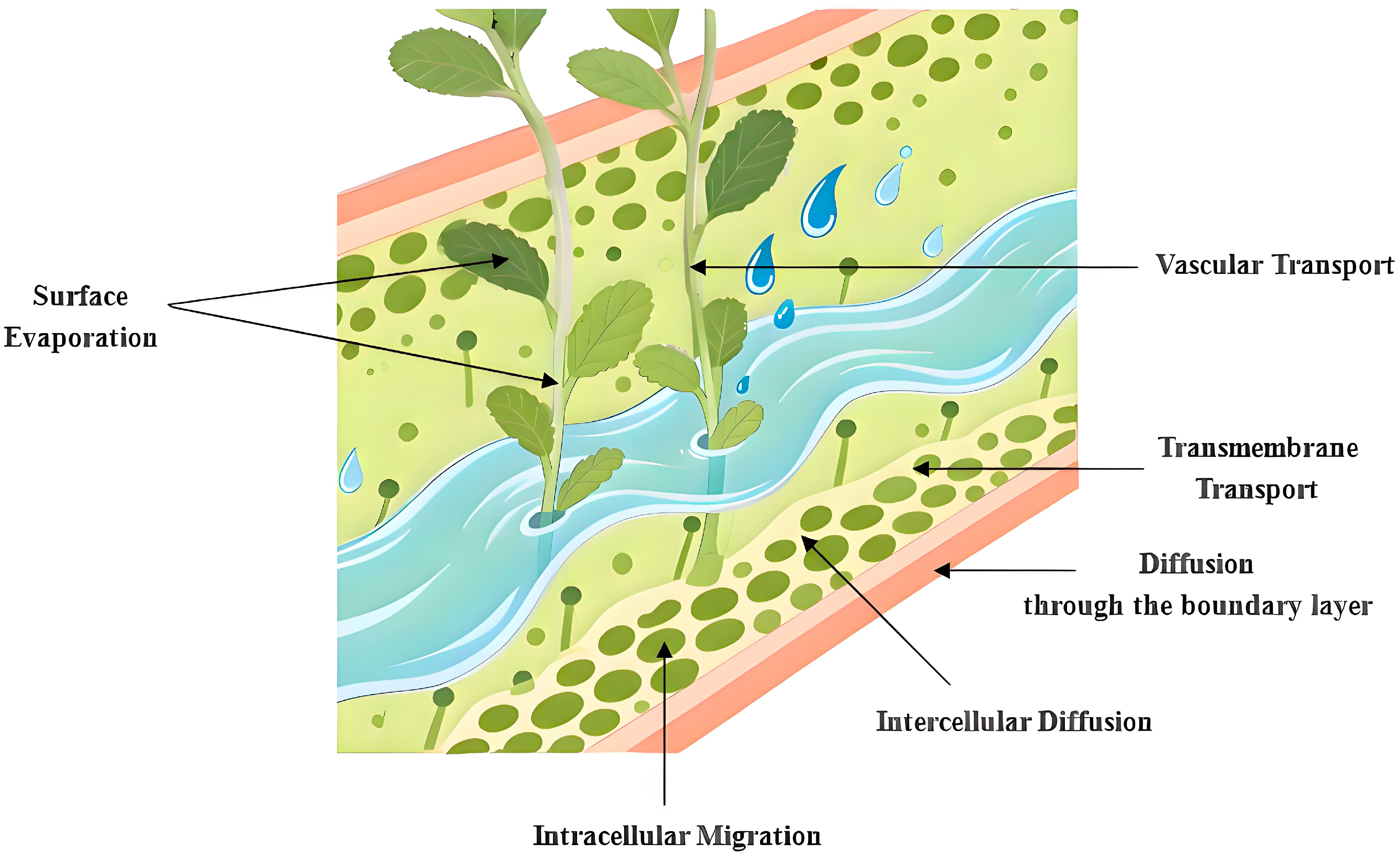

3.2. Analysis of Moisture Transfer Processes in Alfalfa

3.3. Analysis of Alfalfa Moisture Loss Patterns

3.4. Simulation Analysis of Alfalfa Drying

4. Alfalfa Drying Technology and Equipment

4.1. Alfalfa Pre-Drying Treatment Technology and Equipment

4.1.1. Alfalfa Cutting–Flattening Technology and Equipment

4.1.2. Mechanized Alfalfa Baling Technology and Equipment

4.2. Alfalfa Drying Methodology and Equipment

4.2.1. Air Drying (AD)

4.2.2. Hot-Air Drying (HAD) and Equipment

4.2.3. Solar-Energy Drying and Equipment

4.2.4. Microwave Drying (MD) and Equipment

4.2.5. Other Drying Methods and Equipment

5. Quality of Dried Alfalfa Products

5.1. Factors Affecting Alfalfa Hay Quality

5.2. Evaluation Methods for Alfalfa Hay Quality

5.2.1. Physical Evaluation Methods

5.2.2. Chemical Evaluation Methods

5.2.3. Biological Evaluation Methods

6. Conclusions

- (1)

- The whole-process drying technological model for alfalfa must balance material characteristics, process adaptability, energy costs, and economic feasibility. The drying strategy should be optimized based on material properties (such as initial moisture content and stem-leaf differences) and regional conditions to achieve efficient, low-loss drying. Establishing an intensive processing model combining “pre-treatment at production sites + centralized drying” is crucial for scalability.

- (2)

- Drying mechanisms and moisture migration patterns are key to optimizing drying processes. Alfalfa drying involves complex migration of free and bound water, progressing through constant-rate, first falling-rate, and second falling-rate periods. The primary challenge lies in asynchronous stem-leaf drying due to the waxy stem layer hindering moisture transfer. Cutting–flattening techniques that disrupt stem structure can significantly enhance drying efficiency. Future research should integrate multi-scale heat and mass transfer models to enable precise drying control.

- (3)

- Domestic drying equipment and intelligent technologies represent the future development direction. Currently, China relies on imported drying machinery, highlighting the urgent need for domestically developed systems tailored to local conditions. Integrating solar, heat pump, and other renewable energy sources can reduce energy consumption. Additionally, incorporating AI and deep learning into alfalfa processing will enable digital platforms for smart forage production, improve drying precision and efficiency. Promoting standardized, integrated, and intelligent drying technology models will effectively address the shortage of high-quality alfalfa hay in the industry.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Almuhayawi, M.S.; Hassan, A.H.A.; Al Jaouni, S.K.; Alkhalifah, D.H.M.; Hozzein, W.N.; Selim, S.; AbdElgawad, H.; Khamis, G. Influence of elevated CO2 on nutritive value and health-promoting prospective of three genotypes of Alfalfa sprouts (Medicago sativa). Food Chem. 2021, 340, 128147. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, Y.; Ge, G.; Wang, W.; Hou, M.; Sun, L.; Jia, Y. Optimization of continued drying conditions for high moisture alfalfa bales. J. Northwest A&F Univ. 2016, 44, 37–42, 68. [Google Scholar] [CrossRef]

- Available online: https://www.gbif.org/species/9151957 (accessed on 25 July 2025).

- Djordjević, M.; Djordjević, M.; Maravić, N.; Teofilović, V.; Šoronja-Simović, D.; Šereš, Z. Processing of alfalfa seeds by convective hot air drying, vacuum drying and germination: Proximate composition, techno-functional, thermal and structural properties evaluation. Food Chem. 2023, 402, 134300. [Google Scholar] [CrossRef]

- Shang, H.; Cao, Z.; Zhang, H.; Guo, Y.; Zhao, J.; Wu, H. Physicochemical characterization and in vitro biological activities of polysaccharides from alfalfa (Medicago sativa L.) as affected by different drying methods. Process Biochem. 2021, 103, 39–49. [Google Scholar] [CrossRef]

- Hadidi, M.; Orellana Palacios, J.C.; McClements, D.J.; Mahfouzi, M.; Moreno, A. Alfalfa as a sustainable source of plant-based food proteins. Trends Food Sci. Technol. 2023, 135, 202–214. [Google Scholar] [CrossRef]

- Sun, Q.Y.; Yu, Q.N.; Jia, Z.C.; Wu, W.X.; Zhao, F.; Han, M.L.; Wang, G.H. Research progress of forage drying technology and equipment. Acta Agrestia Sin. 2022, 30, 1–11. [Google Scholar]

- Ding, L.; Xue, H.; Wang, P.; Zhang, J.; He, C.; Lu, F. Design and experiment of a new type of forage baling drying equipment based on harvesting and processing technology. J. Chin. Agric. Mech. 2023, 44, 118–124, 146. [Google Scholar]

- Wang, D.; He, C.; Wu, H.; You, Y.; Wang, G. Review of alfalfa full-mechanized production technology. Trans. Chin. Soc. Agric. Mach. 2017, 48, 1–25. [Google Scholar]

- Adler, A. Qualitat von Futterkonserven und mikrobielle Kontamination; 8th Alpenlandisches Expertenforum; Bundesanstalt fur alpenlandische Landwirtschaft Gumpenstein: Irdning, Austria, 2002. [Google Scholar]

- Zheng, X.Z.; Wang, J.Y.; Dong, H.F. Effect of drying conditions on the quality characteristics of alfalfa forage. J. Northeast Agric. Univ. 2009, 40, 101–105. [Google Scholar] [CrossRef]

- Si, Q. Study on the Moisture Content Migration and Quality Change Mechanism of Dominant Grass in Typical Steppe During Drying Process After Mowing; Inner Mongolia Agricultural University: Hohhot, China, 2024. [Google Scholar]

- Arun, S. Mujumdar. Handbook of Industrial Drying, 4th ed.; CRC Press: New York, NY, USA, 2015; pp. 45–49. [Google Scholar]

- Rotz, C.A.; Muck, R.E. Changes in forage quality during harvest and storage. In Forage Quality, Evaluation, and Utilization, 1st ed.; Fahey, G.C., Jr., Collins, M., Mertens, D.R., Moser, L.E., Eds.; Wiley: Hoboken, NJ, USA; American Society of Agronomy, Crop Science Society of America, Soil Science Society of America: Hoboken, NJ, USA, 1994; Volume 1, pp. 828–868. [Google Scholar]

- Tiwari, A. A Review on Solar Drying of Agricultural Produce. J. Food Process. Technol. 2016, 7, 1–12. [Google Scholar] [CrossRef]

- Thompson, N. Modelling the Field Drying of Hay. J. Agric. Sci. 1981, 97, 241–260. [Google Scholar] [CrossRef]

- Hong, F.Z. Alfalfa Science, 1st ed.; China Agricultural Press: Beijing, China, 2009; pp. 401–403. [Google Scholar]

- Jiang, X.W. Study of the Drying Mechanism and Nutritional Quality of Hay in Typical Steppe; Inner Mongolia Agricultural University: Hohhot, China, 2019. [Google Scholar]

- Du, S.; You, S.H.; Bao, J.; Ge, G.T.; Jia, Y.S. Responses of natural grass hay quality on cutting time and drying time. Grassl. Pratac. 2017, 29, 38–42. [Google Scholar]

- Wang, Q.L.; Hua, L.M.; Yang, S.W. Effects of different drying methods on dehydration and nutrients of oats in different growth periods. Chin. J. Grassl. 2014, 36, 92–98. [Google Scholar]

- Wang, K.L. Study on Correlation of Alfalfa Haying Mechanism and Nutrition Changes; Inner Mongolia Agricultural University: Hohhot, China, 2014. [Google Scholar]

- Wu, H.Q. Alfalfa drying properties and technologies-in Review. Nat. Sci. 2004, 2, 65–67. [Google Scholar]

- Siles, J.A.; González-Tello, P.; Martín, M.A.; Martín, A. Kinetics of Alfalfa Drying: Simultaneous Modelling of Moisture Content and Temperature. Biosyst. Eng. 2015, 129, 185–196. [Google Scholar] [CrossRef]

- Savoie, P. Forage harvesting and conservation. In Grassland: A Global Resource, 1st ed.; McGilloway, P.S., Ed.; Wageningen Academic Publishers: Gelderland, The Netherlands, 2001; Volume 1, pp. 331–346. [Google Scholar]

- Gao, D.M.; Luo, G. Effect of drying parameters on drying characteristics and energy consumption during alfalfa drying process. J. Jiangsu Univ. (Nat. Sci. Ed.) 2020, 41, 685–693. [Google Scholar]

- Oyelade, O.; Tunde-Akintunde, T.; Igbeka, J.; Oke, M.; Raji, O. Modelling moisture sorption isotherms for maize flour. J. Stored Prod. Res. 2008, 44, 179–185. [Google Scholar] [CrossRef]

- Oyelade, O.; Tunde-Akintunde, T.; Igbeka, J. Predictive equilibrium moisture content equations for yam (Dioscorea rotundata, Poir) flour and hysteresis phenomena under practical. J. Food Eng. 2008, 87, 229–235. [Google Scholar] [CrossRef]

- Gao, D.M.; Huang, Z.G.; Li, J.; Wang, D.C. Water Desorption Isotherm Models and Parameters Optimization of Alfalfa (Medicago sativa) Stems and Leaves. Acta Agrestia Sin. 2017, 25, 851–856+879. [Google Scholar]

- Arabhosseini, A.; Huismanb, W.; Müller, J. Modeling of desorption of Alfalfa (Medicago sativa) stems and leaves. Ind. Crops Prod. 2011, 34, 1550–1555. [Google Scholar] [CrossRef]

- Sokhansanj, S.; Rezaei, H. Dual objectives of forage drying and insect disinfestation. Dry. Technol. 2022, 40, 2510–2518. [Google Scholar] [CrossRef]

- Ren, G.Y.; Zhu, L.W.; Duan, X.; Liu, W.; Li, G.; Wei, X. Volume shrinkage mechanism for combined vacuum freeze drying-hot air drying of diced apples. Trans. CSAE 2024, 40, 63–71. [Google Scholar]

- Sanghi, A.; Ambrose, R.P.K.; Maier, D. CFD simulation of corn drying in a natural convection solar dryer. Dry. Technol. 2018, 36, 859–870. [Google Scholar] [CrossRef]

- Tan, L.; Yuan, Y.; Zhao, Z.; Xu, Y.; Yuan, Y. Insights in mechanism of drying shrinkage by pore-scale modeling of heat-moisture and stress-strain distribution for high-moisture porous media. Int. J. Therm. Sci. 2023, 188, 108226. [Google Scholar] [CrossRef]

- Pei, Y.; Li, Z.; Song, C.; Li, J.; Xu, W.; Zhu, G. Analysis and modelling of temperature and moisture gradient for ginger slices in hot air drying. J. Food Eng. 2022, 323, 111009. [Google Scholar] [CrossRef]

- Du, J.; Sun, Z.; Chen, Z. Design and experiment of drying equipment for alfalfa bales. Agriculture 2025, 15, 2000. [Google Scholar] [CrossRef]

- Gao, X.; Xuan, C.; Tang, Z.; Hong, B.; Ma, Y.; Qian, S. A dynamic drying process: Mathematical modeling and energy consumption optimization of alfalfa bales using hot air drying. Renew. Energy 2025, 246, 122961. [Google Scholar] [CrossRef]

- Román, F.D.; Hensel, O. Numerical simulations and experimental measurements on the distribution of air and drying of round hay bales. Biosyst. Eng. 2014, 122, 1–15. [Google Scholar] [CrossRef]

- Shinners, K.J.; Koegel, R.G.; Straub, R.J. Leaf Loss and Drying Rate of Alfalfa as Affected by Conditioning Roll Type. Appl. Eng. Agric. 1991, 7, 46–49. [Google Scholar] [CrossRef]

- Gonda, L.; Kunsky, M. Conditioners in grassland harvesting. J. Agric. Sci. 2000, 46, 506–518. [Google Scholar]

- Gonda, L.; Kunsky, M.; Gaborcik, N. Effects of a mower-conditioner on herbage at forage harvesting. Res. Agric. Eng. 2001, 47, 13–17. [Google Scholar]

- Shinners, K.J. Engineering principles of silage harvesting equipment. In Silage Science and Technology, 1st ed.; Buxton Richard, D.R., Muck, E., Harrison, J.H., Eds.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2003; Volume 1, pp. 361–408. [Google Scholar]

- Liu, X.L. The Experimental Design on the Performance of 9GBQ-3.0 Model Rubbing Chopper; Inner Mongolia Agricultural University: Hohhot, China, 2012. [Google Scholar]

- Fu, Z.L.; Wang, D.C.; Li, W.; Huang, X.; Zhu, R. Design and experiment of two-disc rotary mower of alfalfa. Trans. Chin. Soc. Agric. Mach. 2018, 49, 214–220. [Google Scholar]

- Wang, D.C.; Fu, Z.L.; Wang, G.H.; Gao, D.M.; Yuan, H.F.; Ma, X.G.; Liang, F.; Sun, J. Small Self-Propelled Alfalfa Mower-Conditioner. CN Patent CN210210203705.4, 20 June 2012. [Google Scholar]

- Zhao, J.Z.; Sun, F.T.; Chen, H.W.; Sun, J.; Wang, D.C. A kind of full hydraulic mountains alfalfa cutting and flattening machine design and test study. J. Agric. Mech. Res. 2017, 39, 89–92. [Google Scholar]

- Li, X.; Yang, M.; Lu, G.; Kang, W.; Ding, H. Transfer rule of compression and spring-back stress in compression process of alfalfa. Trans. CSAE 2014, 30, 61–67. [Google Scholar]

- OBB, J. Agricultural Baler. U.S. Patent 4644739, 24 February 1987. [Google Scholar]

- Kenneth, A.A.; van Ness, T. Hay Baler. U.S. Patent 2775930. 1 January 1957.

- Shang, Y.; Meng, Z.; Cong, Y.; Dong, J.; Luo, C.; Song, Z. Development of a control system with remote monitoring function for round baler. Comput. Electron. Agric. 2021, 182, 106044. [Google Scholar] [CrossRef]

- Hua, R.J.; Tang, Z.F.; Ye, H.Y.; Wang, Y.Y.; Jia, J.X. Research and development tendency about baler in domestic and overseas. J. Chin. Agric. Mech. 2012, 3, 23–26. [Google Scholar]

- Collings, A. Krone unveils first-ever non-stop round baler. Farm. Wkly. 2012, 17, 20–21. [Google Scholar]

- Simmons, S.C.; Chow, M.K.; Schlotterbeck, S.C. Even Bale Block for Monitoring Bale Shape in a Round Baler. U.S. Patent 8935979, 20 January 2015. [Google Scholar]

- Dutertre, M.; Gresset, P. Baling Roller and Round Agricultural Baler with Such a Roller. U.S. Patent 10080331, 25 September 2018. [Google Scholar]

- Sun, G.B.; Li, M.L.; Meng, W.; Li, R.S. Design of buckle-type square baler knotter. Trans. CSAM 2008, 39, 210–212. [Google Scholar]

- Yin, J.J.; Li, S.; Li, Y.M. Kinematic simulation and time series analysis of d-knotter and its ancillary mechanisms. Trans. Chin. Soc. Agric. Mach. 2011, 6, 103–107. [Google Scholar]

- Zhang, J.; Geng, H.; Geng, A.; Li, R. Integration and experiment of clip bale knotter. Trans. CSAE 2015, 31, 64–68. [Google Scholar]

- Yin, J.J.; Gao, Q.; Chen, Y.M. Virtual knotting method of knotter based on rigid flexible contact dynamics. Trans. Chin. Soc. Agric. Mach. 2016, 47, 85–92. [Google Scholar]

- Ya, X.; Haitao, L.; Longjian, C.; Shaoying, Z.; Wenjun, W.; Lujia, H. Analysis and modification of interaction between wiper mechanism and billhook mechanism for knotter. Trans. Chin. Soc. Agric. Mach. 2016, 47, 44–50+27. [Google Scholar]

- Wang, W.M. Parameter Analysis and Improving Design of Spring-Finger Cylinder Pickup Collector; Inner Mongolia Agricultural University: Hohhot, China, 2014. [Google Scholar]

- Wang, D.F.; Jiang, Y.Y.; Wang, J.Q. Structure-improving and experiment of steel-roll round baler. Trans. Chin. Soc. Agric. Mach. 2010, 41, 84–88. [Google Scholar]

- Lei, J.L.; Wang, D.F.; Li, D.H.; Zhang, Q.C.; Ynag, X.; Na, M.J. Influence factors analysis and optimization of forming rotary straw core by steel-roll round baler. Trans. Chin. Soc. Agric. Mach. 2015, 46, 18–25. [Google Scholar]

- Li, Y.; Wang, D.; Li, D.; Wang, M.; Lei, J. Theoretical analysis and experiment of baling mechanism of roll-disk round baler. Trans. Chin. Soc. Agric. Mach. 2016, 47, 45–52. [Google Scholar]

- Zhang, J.; Fu, H.; Song, Z.H.; Li, F.; Yang, Q.L.; Sun, Z.Y. Research status and development trend of press mechanism for silage round baler. J. Chin. Agric. Mech. 2025, 46, 204–210. [Google Scholar] [CrossRef]

- Wan, Q.H.; Bu, K. Maintenance and Troubleshooting of Forage Machinery, 1st ed.; China Agricultural Science and Technology Press: Beijing, China, 2016; pp. 146–159. [Google Scholar]

- Wang, C.J.; Han, M.; Gong, Z.Q. Structural design and simulation analysis of baler with variable bale chamber. J. Chin. Agric. Mech. 2022, 43, 1–6. [Google Scholar]

- Su Gang, S.G.; Shi JianXin, S.J.; Ge Ju, G.J. Measurement the spatial angle of square knotter on the basis of reverse engineering. Trans. Chin. Soc. Agric. Mach. 2008, 39, 81–83. [Google Scholar]

- Wang, Z.H.; Wang, D.C.; Liu, G.L.; Dong, Z.Y.; Zhai, G.X. Pickup parameters design of square baler. Trans. Chin. Soc. Agric. Mach. 2010, 41, 107–109. [Google Scholar]

- Gao, D.; Wang, D.; Li, J.; Liu, Y.; Qiao, X. Design and test of logarithmic spiral round baler chamber. Trans. Chin. Soc. Agric. Mach. 2015, 46, 118–121. [Google Scholar]

- Li, L.; Wang, D.; Yang, X. Study on round rice straw bale wrapping silage technology and facilities. Int. J. Agric. Biol. Eng. 2018, 11, 88–95. [Google Scholar] [CrossRef]

- Wang, F.D.; Chen, Z.; Wang, J.Y.; Wang, X.W.; Chen, F. Design and experiment of 4YF-1300 large rectangular baler. Trans. Chin. Soc. Agric. Mach. 2009, 40, 36–41. [Google Scholar]

- Ma, X.G. Optimal Design and Experiment on the Key Parts of Self-Propelled Rectangular Baler; China Agricultural University: Beijing, China, 2014. [Google Scholar]

- Yang, L.; Liu, G.L.; Wang, Z.H. Design and experiment of engine-driven constant frequency rectangular pickup baler. Trans. Chin. Soc. Agric. Mach. 2011, 42, 147–151. [Google Scholar]

- Yin, J.J.; Liu, D.P.; Li, Y.M. Design and parameters analyses of automatic height profiling device of quadrate-bale baler pickup. Trans. Chin. Soc. Agric. Mach. 2014, 45, 86–92. [Google Scholar]

- Wang, C.G.; Ao, E.C.; Xing, J.H.; Zhai, G.X.; He, G. Design and experimental round baler with revolute steel roller. Trans. Chin. Soc. Agric. Mach. 2010, 41, 103–106. [Google Scholar]

- Sun, Y.; Cheng, Q.; Meng, F.; Buescher, W.; Maack, C.; Ross, F.; Lin, J. Image-based comparison between a γ-ray scanner and a dual-sensor penetrometer technique for visual assessment of bale density distribution. Comput. Electron. Agric. 2012, 82, 1–7. [Google Scholar] [CrossRef]

- Zhang, W.-P.; Yang, X.-H.; Mujumdar, A.; Ju, H.-Y.; Xiao, H.-W. The influence mechanism and control strategy of relative humidity on hot air drying of fruits and vegetables: A review. Dry. Technol. 2021, 40, 2217–2234. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, H.; Mujumdar, A.S.; Tang, J.; Miao, S.; Wang, Y. Recent developments in high-quality drying of vegetables, fruits, and aquatic products. Crit. Rev. Food Sci. 2017, 57, 1239–1255. [Google Scholar] [CrossRef]

- Defraeye, T. Advanced computational modelling for drying processes-A review. Appl. Energy 2014, 131, 23–344. [Google Scholar] [CrossRef]

- Ihediwa, V.E.; Akpan, G.E.; Akuwueke, L.; Oriaku, L.; Ndubuisi, C.; Mbanasor, J.; Ndukwu, M.C. Thermal dehydration of some forage grasses for livestock feeding: Effect of different methods on moisture diffusivity and the quality of dried leaves. Energy Nexus 2022, 8, 100156. [Google Scholar] [CrossRef]

- Mattioli, S.; Bosco, A.D.; Castellini, C.; Falcinelli, B.; Sileoni, V.; Marconi, O.; Mancinelli, A.C.; Cotozzolo, E.; Benincasa, P. Effect of heat- and freeze-drying treatments on phytochemical content and fatty acid profile of alfalfa and flax sprouts. J. Sci. Food Agric. 2019, 99, 4029–4035. [Google Scholar] [CrossRef]

- Zhang, A.-A.; Ni, J.-B.; Martynenko, A.; Chen, C.; Fang, X.-M.; Ding, C.-J.; Chen, J.; Zhang, J.-W.; Xiao, H.-W. Electrohydrodynamic drying of citrus (Citrus sinensis L.) peel: Comparative evaluation on the physiochemical quality and volatile profiles. Food Chem. 2023, 429, 136832. [Google Scholar] [CrossRef]

- Nascimento, J.M.; Costa, C.; Silveira, A.C.; Arrigoni, M.D.B. Haying method and storage length effects on chemical composition and mold growth on alfalfa hay (Medicago sativa L. cv. Florida 77). Rev. Bras. Zootec. 2000, 29, 669–677. [Google Scholar] [CrossRef]

- Che, G.; Wen, H.J.; Wan, L.; Qing, Y.R.; Wang, X. Kinematic Simulation and Experimental Study on Rotating Air Flow for Drying Alfalfa. Dry. Technol. 2015, 33, 1720–1727. [Google Scholar] [CrossRef]

- Patil, R.T.; Sokhansanj, S.; Arinze, E.A.; Schoenau, G. Thin layer drying of components of fresh alfalfa. Can. Agric. Eng. 1992, 34, 343–346. [Google Scholar]

- Dimitriadis, A.N.; Akritidis, C.B. A Model to Simulate Chopped Alfalfa Drying in a Fixed Deep Bed. Dry. Technol. 2004, 22, 479–490. [Google Scholar] [CrossRef]

- Higgins, T.R.; Spooner, A.E. Microwave drying of alfalfa compared to field-and oven-drying: Effects on forage quality. Anim. Feed Sci. Technol. 1986, 16, 1–6. [Google Scholar] [CrossRef]

- Adapa, P.K.; Schoenau, G.J.; Sokhansanj, S. Performance study of a heat pump dryer system for specialty crops—Part 1: Development of a simulation model. Int. J. Energy Res. 2002, 26, 1001–1019. [Google Scholar] [CrossRef]

- Wang, L.Y. Research on the Detection System for Alfalfa Solar Drying Based on S3C2440A; Inner Mongolia Agricultural University: Hohhot, China, 2014. [Google Scholar]

- Arinze, E.A.; Schoenau, G.J.; Sokhansanj, S.; Adapa, P. Aerodynamic separation and fractional drying of alfalfa leaves and stems: A review and new concept. Dry. Technol. 2003, 21, 1669–1698. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Wang, W.; Hou, M.L. Effect of different drying methods on alfalfa hay modulation. Chin. J. Grassl. 2015, 37, 76–82. [Google Scholar]

- Yin, Q. Study on Spatial and Temporal Heterogeneity of Alfalfa Hay Making and Storing Technology; Inner Mongolia Agricultural University: Hohhot, China, 2013. [Google Scholar]

- Liu, L.Y. Study on the Response Mechanism of Nutrients to Environmental Factors and Field Regulation Strategy in the Process of Alfalfa Drying; Inner Mongolia Agricultural University: Hohhot, China, 2018. [Google Scholar]

- Wang, T.; Zhang, W.H. Priorities for the development of alfalfa pasture in northern China. Fundam. Res. 2023, 3, 225–228. [Google Scholar] [CrossRef]

- Zhou, Q.; Wei, Y.Y.; Yu, Z.; Wu, Z. Effects of different treatments on the quality of alfalfa after rain. Chin. J. Grassl. 2018, 40, 68–72. [Google Scholar]

- Jia, T.T.; Zhao, M.M.; Wu, Z.; Chen, W.H.; Liu, Z.G.; Yu, Z. Effect of raining and drying method on the quality of alfalfa hay. Acta Agrestia Sin. 2017, 25, 1362–1367. [Google Scholar]

- Orphanides, A.; Goulas, V.; Gekas, V. Drying Technologies: Vehicle to High-Quality Herbs. Food Eng. Rev. 2016, 8, 164–180. [Google Scholar] [CrossRef]

- Antal, T. Inspection of the Technological Characteristics Influencing the Quality of Dried Fruits and Vegetables; University of Debrecen: Debrecen, Hungary, 2010. [Google Scholar]

- Chen, H.Y. Heated-Air Drying Characteristics and Technological Parameters Optimization Research of Alfalfa; Inner Mongolia Agricultural University: Hohhot, China, 2012. [Google Scholar]

- Al-Gaadi, K.A. Impact of raking and baling patterns on alfalfa hay dry matter and quality losses. Saudi J. Biol. Sci. 2018, 25, 1040–1048. [Google Scholar] [CrossRef]

- Chua, L.Y.W.; Chong, C.H.; Chua, B.L.; Figiel, A. Influence of Drying Methods on the Antibacterial, Antioxidant and Essential Oil Volatile Composition of Herbs: A Review. Food Bioprocess Technol. 2019, 12, 450–476. [Google Scholar] [CrossRef]

- Fennell, C.; Light, M.; Sparg, S.; Stafford, G.; van Staden, J. Assessing African medicinal plants for efficacy and safety: Agricultural and storage practices. J. Ethnopharmacol. 2004, 95, 113–121. [Google Scholar] [CrossRef]

- Morad, M.; El-Shazly, M.; Wasfy, K.; El-Maghawry, H.A. Thermal analysis and performance evaluation of a solar tunnel greenhouse dryer for drying peppermint plants. Renew. Energy 2017, 101, 92–1004. [Google Scholar] [CrossRef]

- Du, J.Q.; Yang, S.K.; Liu, G.L.; Guo, Z. Optimization process of forage drying with solar energy. Agric. Eng. 2013, 3, 44–47. [Google Scholar]

- Wang, Q.X.; Wang, D.C.; Du, J.Q.; Zhai, G. Design and experiment of heat pump assisted solar energy heat-storage drying equipment for herbage seeds. Trans. Chin. Soc. Agric. Mach. 2012, 43, 222–226, 265. [Google Scholar]

- Sevik, S. Experimental investigation of a new design solar-heat pump dryer under the different climatic conditions and drying behavior of selected products. Sol. Energy 2014, 105, 190–205. [Google Scholar] [CrossRef]

- Amer, B.M.A.; Gottschalk, K.; Hossain, M.A. Integrated hybrid solar drying system and its drying kinetics of chamomile. Renew. Energy 2018, 121, 539–547:S0960148118300612. [Google Scholar] [CrossRef]

- Yu, J.; Yu, J. Simulation study of a heat pump drying system using a solar assisted flash tank vapor injection cycle. Sol. Energy 2023, 251, 223–239. [Google Scholar] [CrossRef]

- Naemsai, T.; Jareanjit, J.; Thongkaew, K. Experimental investigation of solar-assisted heat pump dryer with heat recovery for the drying of chili peppers. J. Food Process Eng. 2019, 42, e13193. [Google Scholar] [CrossRef]

- Rocha, T.T.M.; de Paula, C.H.; Maia, A.A.T.; Paulino, T.d.F.; de Oliveira, R.N. Experimental assessment of a CO2 direct-expansion solar-assisted heat pump operating with capillary tubes and air-solar heat source. Sol. Energy 2021, 218, 413–424. [Google Scholar] [CrossRef]

- Du, J.Q.; Li, F.M.; Guo, W.B. Design of an Internet of things based solar-powered hay bale drying and storage system. J. Shanxi Agric. Univ. (Nat. Sci. Ed.) 2022, 42, 46–53. [Google Scholar]

- Qian, S.Z.; Yang, H.W.; Guo, W.B.; Qian, D.Z.; Zhang, Q.Y.; Wang, Z.B.; Tu, X.J.; Huang, C.H. Study on heating performance of solar-air source heat pump pasture drying system. J. Agric. Mech. Res. 2024, 46, 235–241. [Google Scholar]

- Mortezapour, H.; Ghobadian, B.; Minaei, S.; Khoshtaghaza, M.H. Saffron drying with a heat pump–assisted hybrid photovoltaic–thermal solar dryer. Dry. Technol. 2012, 30, 560–566. [Google Scholar] [CrossRef]

- Wray, D.; Ramaswamy, H.S. Novel Concepts in Microwave Drying of Foods. Dry. Technol 2015, 33, 769–783. [Google Scholar] [CrossRef]

- Di Cesare, L.F.; Forni, E.; Viscardi, D.; Nani, R.C. Changes in the chemical composition of basil caused by different drying procedures. J. Agric. Food Chem. 2003, 51, 3575–3581. [Google Scholar] [CrossRef]

- Kathirvel, K.; Naik, K.R.; Gariepy, Y.; Orsat, V.; Raghavan, G.S.V. Microwave drying-a promising alternative for the herb processing industry. In Proceedings of the 2006 ASAE Annual Meeting, Portland, OR, USA, 9 July 2006. [Google Scholar]

- Moses, J.A.; Norton, T.; Alagusundaram, K.; Tiwari, B.K. Novel Drying Techniques for the Food Industry. Food Eng. Rev. 2014, 6, 43–55. [Google Scholar] [CrossRef]

- Soysal, Y. Microwave Drying Characteristics of Parsley. Biosyst. Eng. 2004, 89, 167–173. [Google Scholar] [CrossRef]

- Divya, P.; Puthusseri, B.; Neelwarne, B. Carotenoid content, its stability during drying and the antioxidant activity of commercial coriander (Coriandrum sativum L.) varieties. Food Res. Int. 2012, 45, 342–350. [Google Scholar] [CrossRef]

- Hamrouni-Sellami, I.; Rahali, F.Z.; Rebey, I.B.; Bourgou, S.; Limam, F.; Marzouk, B. Total phenolics, flavonoids, and antioxidant activity of sage (Salvia officinalis L.) plants as affected by different drying methods. Food Bioprocess Technol. 2013, 6, 806–817. [Google Scholar] [CrossRef]

- Sukadeetad, K.; Nakbanpote, W.; Heinrich, M.; Nuengchamnong, N. Effect of drying methods and solvent extraction on the phenolic compounds of Gynura pseudochina (L.) DC. leaf extracts and their anti-psoriatic property. Ind. Crop. Prod. 2018, 120, 34–46. [Google Scholar] [CrossRef]

- Ozkan, I.A.; Akbudak, B.; Akbudak, N. Microwave drying characteristics of spinach. J. Food Eng. 2007, 8, 577–583. [Google Scholar] [CrossRef]

- Rotz, C.A.; Abrams, S.M.; Davis, R.J. Alfalfa Drying, Loss and Quality as Influenced by Mechanical and Chemical Conditioning. Trans. Chin. Soc. Agric. Mach. 1987, 30, 0630–0635. [Google Scholar] [CrossRef]

- Woolford, M.K.; Tetlow, R.M. The effect of anhydrous ammonia and moisture content on the preservation and chemical composition of perennial ryegrass hay. Anim. Feed Sci. Technol 1984, 11, 159–166. [Google Scholar] [CrossRef]

- Grncarevic, M. Effect of various dipping treatments on the drying rate of grapes for raisins. Am. J. Enol Vitic. 1993, 31, 230–234. [Google Scholar] [CrossRef]

- Digman, M.F.; Runge, T.M.; Shinners, K.J.; Hatfield, R.D. Wet fractionation for improved utilization of alfalfa leaves. Biol. Eng. 2013, 6, 29–42. [Google Scholar]

- Hu, W.; Song, Z.; Ma, Q.; Li, B.; Zhang, M.; Ding, C.; Chen, H.; Zhao, S. Study on the drying characteristics and physicochemical properties of alfalfa under high-voltage discharge plasma. Agriculture 2024, 14, 1134. [Google Scholar] [CrossRef]

- Neres, M.A.; Castagnara, D.D.; Mesquita, E.E.; Zambom, M.A.; de Souza, L.C.; de Oliveira, P.S.R.; Jobim, C.C. Production of alfalfa hay under different drying methods. Rev. Bras. Zootec. 2010, 39, 1676–1683. [Google Scholar] [CrossRef]

- Kaplan, M.; Çetin, N.; Çiftci, B.; Karpuzcu, S. Comparison of drying methods for biochemical composition, energy aspects, and color properties of alfalfa hay. Biomass Convers. Biorefinery 2025, 15, 10331–10346. [Google Scholar] [CrossRef]

- Thamkaew, G.; Sjöholm, I.; Galindo, F.G. A review of drying methods for improving the quality of dried herbs. Crit. Rev. Food Sci. Nutr. 2021, 61, 1763–1786. [Google Scholar] [CrossRef] [PubMed]

- Ziemer, C.; Heinrichs, A.; Canale, C.; Varga, G. Chemical drying agents for alfalfa hay: Effect on nutrient digestibility and lactational performance. J. Dairy Sci. 1991, 74, 2674–2680. [Google Scholar] [CrossRef]

- Qian, W.; Yang, S.K.; Liu, G.L.; He, G.; Wang, Z. Optimization of drying process parameters of solar herbage dry equipment. Trans. Chin. Soc. Agric. Mach. 2018, 49, 110–118. [Google Scholar]

- Tian, W.N. Effect of Drying Temperature on Drying Rate and Nutrient Composition of Alfalfa; Inner Mongolia Agricultural University: Hohhot, China, 2019. [Google Scholar]

- Wang, W.M.; Chen, H.Y.; Zhao, M.Q. Technological parameters optimization for improving quality of heated-air dried alfalfa. Trans. Chin. Soc. Agric. Mach. 2015, 31, 337–345. [Google Scholar]

- Oellermann, S.O.; Arambel, M.J.; Walters, J.L. Effect of chemical drying agents on alfalfa hay and milk production response when fed to dairy cows in early lactation. J. Dairy Sci. 1989, 72, 501–504. [Google Scholar] [CrossRef]

- Jones, L. Laboratory studies on the effect of potassium carbonate solution on the drying of cut forage. Grass Forage Sci. 1991, 46, 153–158. [Google Scholar] [CrossRef]

- Liu, Y. The Impact of Harvest Technology on Alfalfa Hay Quality; Inner Mongolia Agricultural University: Hohhot, China, 2014. [Google Scholar]

- Cao, H.; Geng, Z.G.; Li, Q.; Han, Y. Adaptability of 11 Alfalfa Varieties in Southern Qingyang. Pratacult. Sci. 2018, 35, 1937–1947. [Google Scholar]

- Ghoorchi, T.; Arbabi, S. Study of protein characteristic of five feeds by CNCPS model. Asian J. Anim. Vet. Adv. 2010, 5, 584–591. [Google Scholar] [CrossRef]

- Xu, R.-X.; Li, D.-N.; Yang, D.-H.; Lin, J.-H.; Xiang, M.; Zhang, Y.-J. Alfalfa Quality Evaluation in the Field by Near-Infrared Reflectance Spectroscopy. Spectrosc. Spectr. Anal. 2013, 33, 3010–3013. [Google Scholar]

- Zhou, L.; Zhang, L.; Zhang, E.; Li, J.; Yang, W.; Wang, Z. Rapid Determination of Swine Available Energy and Amino Acids in Corn Distillers Dried Grains with Soluble by Near-Infrared Reflectance Spectroscopy. Anim. Feed Sci. Technol. 2012, 175, 198–202. [Google Scholar] [CrossRef]

- Chen, P.; Rong, Y.; Han, J. Evaluation of Fermentation Character of Alfalfa Silage through Near Infrared Reflectance Spectroscopy (NIRS). Spectrosc. Spectr. Anal. 2008, 28, 2799–2803. [Google Scholar]

- Butler, G.W.; Bailey, R.W. Chemistry and Biochemistry of Herbage, 1st ed.; Academic Press: New York, NY, USA, 1973; pp. 134–136. [Google Scholar]

- Buse, K.K.; Kononoff, P.J. Testing Preference of Alfalfa Hay of Different Relative Feed Value and Brome Hay in Lactating Jersey Cows. JDS Commun. 2025, 6, 223–226. [Google Scholar] [CrossRef] [PubMed]

- NY/T 1170-2006; The People’s Republic of China Agricultural Industry Standard: The Classification Standard of Legume Hay. Standardization Administration of China: Beijing, China, 2006.

- T/CAAA 001-2018; Group Standard: The Hay Quality Grade of Alfalfa. Standardization Administration of China: Beijing, China, 2018.

- Sun, L.; Xue, Y.L.; Jia, Y.S.; Ge, G.T.; Zhang, X.X.; Liu, G.H.; Wang, Z.J.; Zhang, F.J. Review on Quality Evaluation of Alfalfa Hay. Chin. J. Grassl. 2019, 41, 158–166. [Google Scholar] [CrossRef]

- Třináctý, J.; Šimek, M.; Homolka, P. Nylon capsule method and alfalfa hay crude protein digestibility evaluation. Anim. Feed Sci. Technol. 1999, 79, 269–278. [Google Scholar] [CrossRef]

- Chen, L. Effects of Different Lactic Acid Bacteria on Rumen In Vitro Fermentation Characteristics in Dairy Cattle; Hunan Agricultural University: Changsha, China, 2014. [Google Scholar]

- Zhuang, E.L. Evaluate of Associate Effects Between Alfalfa Hay and Millet Stalk; Northwest A&F University: Yangling, China, 2017. [Google Scholar]

- Qi, F.H.; Xu, C.S.; Wang, X.F.; Li, H.Y.; Pan, X.L.; Xiang, C.H.; Gao, W. Effect of Alfalfa of Exogenous Polysaccharide-Degrading Enzymes on Nutrient Degradability. J. Shihezi Univ. (Nat. Sci.) 2005, 23, 609–612. [Google Scholar]

| Forms | Location | Characteristics | Proportion | Removal Difficulty |

|---|---|---|---|---|

| Free water | The moisture is primarily found within the cell, including the vacuole (for the most part), the cytoplasm, as well as the vessels of the vascular system and the intercellular spaces. | The most readily removable moisture during drying exhibits vapor pressure essentially equivalent to that of pure water at identical temperatures, with free water constituting the primary evaporative component during the initial drying phase. | 85–90% | easy |

| Physicochemical bound water | Tightly bound to the surfaces of macromolecules within the alfalfa plant. | The water molecules are strongly bound to internal dry matter, capable of adsorbing onto surfaces or penetrating through surfaces into the interior. Its vapor pressure is significantly lower than that of pure water at equivalent temperatures. | 10–15% | hard |

| Chemically bound water | Combined with organic substances such as proteins, starch, and fats within the internal structure of alfalfa. | This restricted-mobility water exhibits limited fluidity and evaporative capacity. Excessive removal may damage plant tissue structure (such as protein denaturation and cell wall rupture), affecting hay quality. | very hard |

| Migration Pathways | Characteristics |

|---|---|

| Intracellular Migration | Intracellular water movement occurs through cytoplasmic streaming and diffusion. |

| Transmembrane Transport | Water traverses cell membranes to migrate between adjacent cells or into intercellular spaces through three principal pathways: the apoplastic route (via cell walls and intercellular spaces, exhibiting lower hydraulic resistance: 0.15–0.35 MPa·s/m), the symplastic pathway (through plasmodesmata connecting cytoplasms, pore diameter 30–60 nm), and the transcellular route. |

| Vascular Transport | In living tissues or immediately post-harvest, xylem vessels maintain transient water transport driven by capillary forces, though with limited efficacy and duration (typically <30 min). |

| Intercellular Diffusion | Water diffuses through intercellular spaces in both liquid and vapor phases. |

| Model | Cutting–Flattener | Structural Features and Key Performance |

|---|---|---|

| New Holland C320R Disk Cutting–Flattener |  | Featuring a three-dimensional suspension cutting unit, it adapts to various terrain conditions, ensuring uniform mowing results and offering multiple optional compacting rollers. The working width is 3.15 m, with 16 cutting blades. |

| CLAAS DISCO Series Cutting–Flattener |  | This suspended mower, equipped with the CLAAS MAX CUT cutting system, delivers validated cutting quality and reliable performance. Designed for medium-sized farms, the high-performance unit offers a selectable working width range of 2.6–3.4 m with 7–8 cutter disks. |

| Huade 9GBXQ-3.0 Cutting–Flattener |  | Featuring a traction suspension system for enhanced operational stability, the cutter head allows adjustment of stubble height and angle while delivering excellent ground contouring performance. With a working width of 3.0 m, it incorporates seven cutter disks operating at 2980 rpm, complemented by a flattening roller rotating at 980 rpm. |

| LOVOL MC290-Y Cutting–Flattener |  | Equipped with a 4.9 m wide header, it delivers fast operating speeds and high harvesting efficiency, with flexible adjustment of cutter speed and stubble height. Four flattening rollers perform two-stage flattening. |

| Model | Alfalfa Baling Equipment | Structural Features and Key Performance |

|---|---|---|

| MF2270XD High-Density Large Rectangular Baler |  | The system features a 2.26 m pickup width and produces 1.2m in length and 0.9m in width bales, demonstrating uniform feeding, high operational efficiency, high-density bale formation, proven reliability, and intuitive operator control. |

| John Deere L330 Large Rectangular Baler |  | The baler incorporates an extended pickup head with a 210 cm intake width, producing bales adjustable from 60 to 300 cm in length with standardized cross-sections of 80 cm (width) × 90 cm (height). It features a pre-compression chamber with a single-tine baler and feed rollers with an exceptionally large processing capacity. |

| STAR 9YFQ-1.8 (THB3060) Rectangular Balerx |  | The implement utilizes a low-profile spring-tooth pick-up roller with a 2240 mm working width, producing bales with a 360 mm × 460 mm cross-sectional area and adjustable density ranging from 110 to 180 kg/m3. |

| John Deere F441R Round baler |  | The baler features a five-row spring-tooth pick-up unit with a 2.2 m working width. Its baling chamber diameter is adjustable between 1.25 and 1.35 m, which, combined with a fixed chamber width of 1.21 m, enables high-density bale production. |

| CLAAS ROLLANT 540 RC Round baler |  | Equipped with a new-type grass-pressing roller and high-strength spiral cutting feed mechanism, it produces bales measuring 1.25 m in diameter and 1.2 m in width. With a pick-up width of 2.1 m, it features fast baling speed, low failure rate, and high reliability, making it suitable for harsh operating conditions. |

| Kvernel Fast Bale Round baler |  | The system incorporates wide dual-cam pickup guidance technology, non-stop baling with primary wrapping-chamber-only mode switching, and automatic bale-unloading and flipping technology. It can achieve continuous non-stop operation encompassing pick-up, cutting and feeding, baling, net wrapping, film wrapping, and bale unloading. |

| Model 9YGQ-2.2D Cutting-Pickup Round Baler |  | The baling chamber integrates 18 heavy-duty steel rollers to form uniformly dense round bales, operating at a 2.2 m pickup width with standardized bale dimensions of 1.2 m × 1.4 m. This system performs integrated field operations including cutting, tedding, feeding, baling, and net wrapping on both standing and windrowed crop residues, and is equipped with GPS positioning technology. |

| Drying Methods | Drying Equipment and Model | Energy Consumption | Color | Protein Loss | Drying Time and Features |

|---|---|---|---|---|---|

| AD [82,127] | No equipment | Utilizing natural airflow, temperature, and sunlight to remove moisture from object surfaces | Caused substantial color degradation | Significant protein loss | This approach reduces operational costs; however, it needs a long drying time and entails high labor intensity, significant susceptibility to environmental constraints. |

| HAD [98,128] |  Model: GREG M hay dryer Model: GREG M hay dryer | relatively high energy consumption | Optimal color properties were achieved with 60 °C air-convective drying. | Compared to natural drying, protein retention is higher. | This method features diverse equipment types with enhanced drying rates and comparatively reduced quality degradation. Drying times vary significantly depending on the equipment used, but they are shorter than natural drying times. |

| Solar-energy Drying [88,129] |  Model: AMS-150 solar dryer Model: AMS-150 solar dryer | Utilizing renewable resources to reduce energy consumption costs. | No data available | Compared to natural drying, protein loss is reduced. | Drying costs are relatively high, but energy-efficient and environmentally friendly. Drying time depends on the intensity of solar radiation and is sensitive to ambient temperature, making it suitable for regions with abundant solar resources. |

| Solar-Assisted Heat Pump Drying [111] |  Model: TGS-2 SASHP drying system Model: TGS-2 SASHP drying system | High energy efficiency and complementary advantages, subject to weather and climate conditions. | No data available | Compared to natural drying, protein loss is reduced. | This system necessitates the deployment of solar energy and heat pump equipment, resulting in high drying costs; though compared to solar drying, time is reduced, it incurs significant energy consumption intensity. |

| Infrared Radiation Drying [86] |  Model: DS-2500 Model: DS-2500 | Low energy consumption, energy-saving and environmentally friendly | Caused substantially higher color degradation compared to other drying methods | Showed good preservation of protein compounds | This approach offers reduced operational expenditure, enhanced drying efficiency, and superior nutrient retention rates; however, it exhibits impaired drying uniformity. |

| Chemical Desiccant Drying [90,130] | No equipment | Low energy consumption | Good color retention | Controls protein loss effectively | Chemical desiccants reduced drying time by altering plant epicuticular structures; however, they exhibit differential efficacy on stems and leaves, resulting in a slight reduction in hay color. |

| Leaf-stem Segregated Drying [89] |  Model: DS-2500 Model: DS-2500 | High energy consumption | Excellent at preserving color | Minimal protein loss | This technique necessitates investment in specialized separation equipment. Alfalfa leaves dry quickly, while the stems take relatively longer to dry. While enabling segregated stem-leaf drying to significantly reduce leaf loss and enhance nutritional specifications, it faces challenges in maintaining consistent separation efficiency. |

| Index | Level | ||||

|---|---|---|---|---|---|

| Premium | Level 1 | Level 2 | Level 3 | Level 4 | |

| CP (%) | >22 | 20–22 | 18–20 | 16–18 | <16 |

| ADF (%) | <27 | 27–29 | 29–32 | 32–35 | >35 |

| NDF (%) | <34 | 34–36 | 36–40 | 40–44 | >44 |

| RFV * | >185 | 170–185 | 150–170 | 130–150 | <130 |

| TDN (%) | >62 | 60.5–62 | 58–60 | 56–58 | <56 |

| TDN (90%DM) | >55.9 | 54.5–55.9 | 52.5–54.5 | 50.5–52.5 | <50.5 |

| Physicochemical Index | Level | ||||

|---|---|---|---|---|---|

| Super Grade | Super Grade | Level 1 | Level 2 | Level 3 | |

| CP (%DM) | ≥22.0 | ≥20.0, <22.0 | ≥18.0, <20.0 | ≥16.0, <18.0 | <16.0 |

| ADF (% DM) | <27.0 | ≥27.0, <29.0 | ≥29.0, <32.0 | ≥32.0, <35.0 | >35.0 |

| NDF (% DM) | <34.0 | ≥34.0, <36.0 | ≥36.0, <40.0 | ≥40.0, <44.0 | >44.0 |

| RFV | >185.0 | ≥170.0, <85.0 | ≥150.0, <170.0 | ≥130.0, <150.0 | <130.0 |

| Weed Content (%) | <3.0 | <3.0 | ≥3.0, <5.0 | ≥5.0, <8.0 | ≥8.0, <12.0 |

| Ash (%) | <12.5 | ||||

| Moisture Content (%) | ≤14.0 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Cen, H.; Guo, W.; She, P. A Review of Alfalfa Drying Technology and Equipment Throughout the Whole Process. Appl. Sci. 2025, 15, 12268. https://doi.org/10.3390/app152212268

Zhang W, Cen H, Guo W, She P. A Review of Alfalfa Drying Technology and Equipment Throughout the Whole Process. Applied Sciences. 2025; 15(22):12268. https://doi.org/10.3390/app152212268

Chicago/Turabian StyleZhang, Wei, Haitang Cen, Wang Guo, and Penghui She. 2025. "A Review of Alfalfa Drying Technology and Equipment Throughout the Whole Process" Applied Sciences 15, no. 22: 12268. https://doi.org/10.3390/app152212268

APA StyleZhang, W., Cen, H., Guo, W., & She, P. (2025). A Review of Alfalfa Drying Technology and Equipment Throughout the Whole Process. Applied Sciences, 15(22), 12268. https://doi.org/10.3390/app152212268