3.1. Stress–Strain Behavior and AE Characteristics of the Pre-Cracked Sandstone Specimens

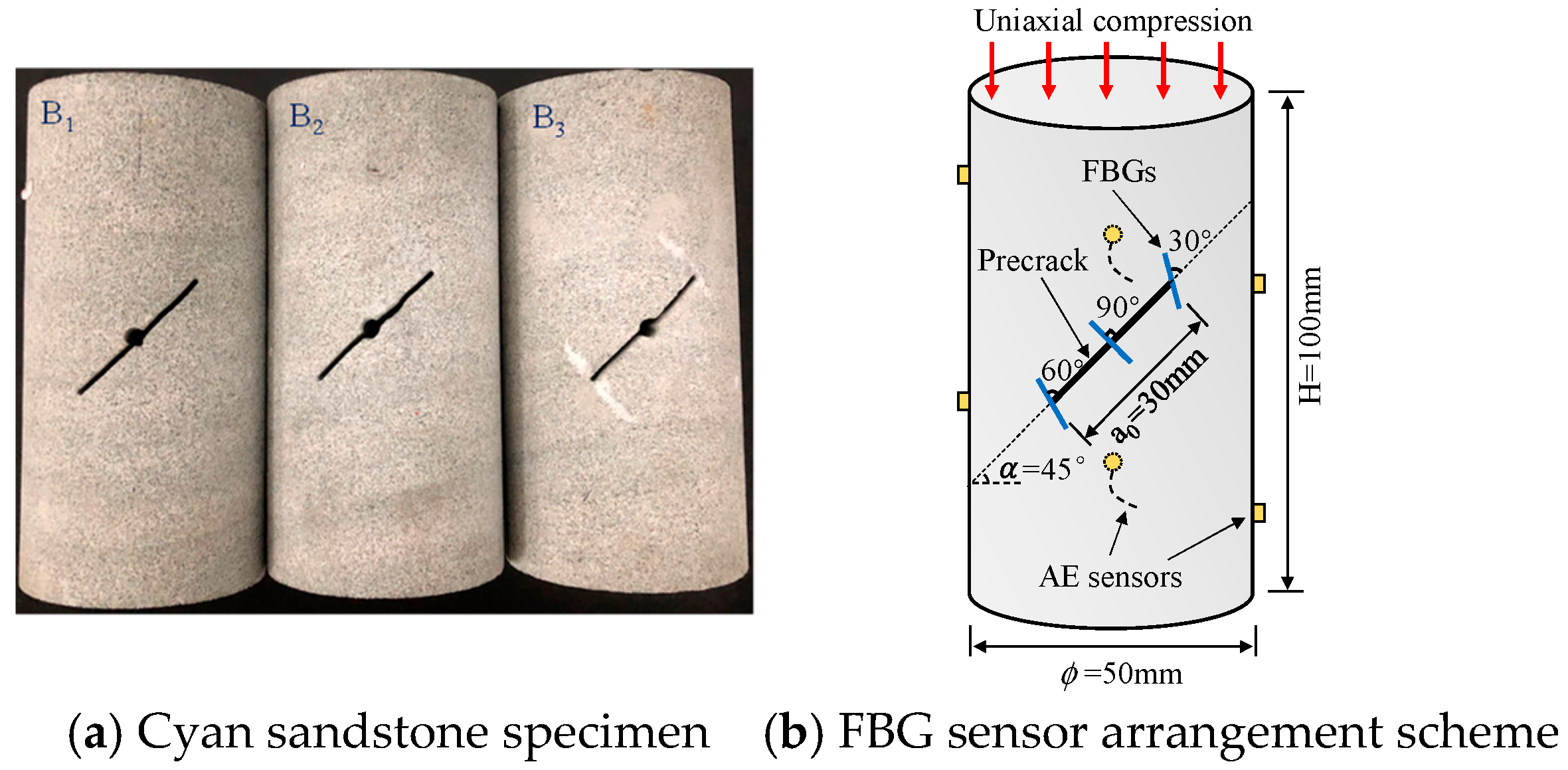

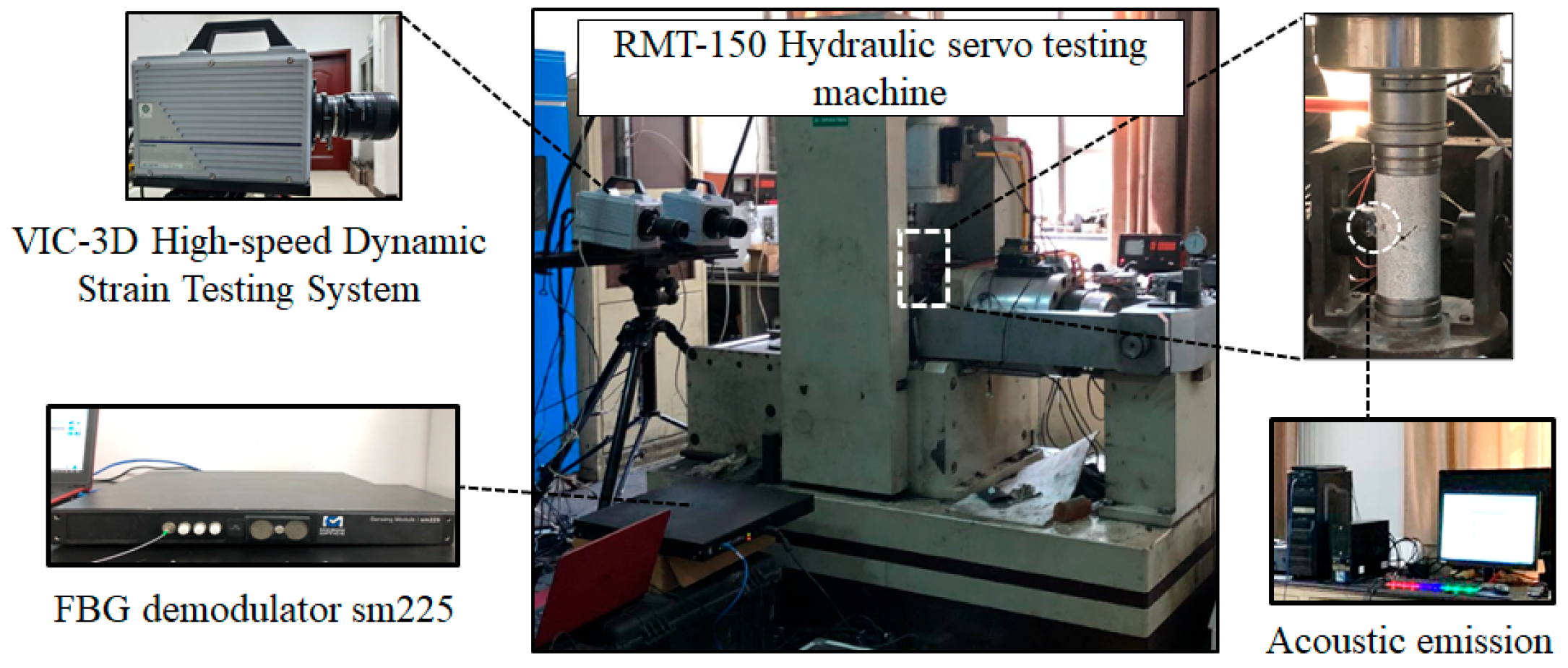

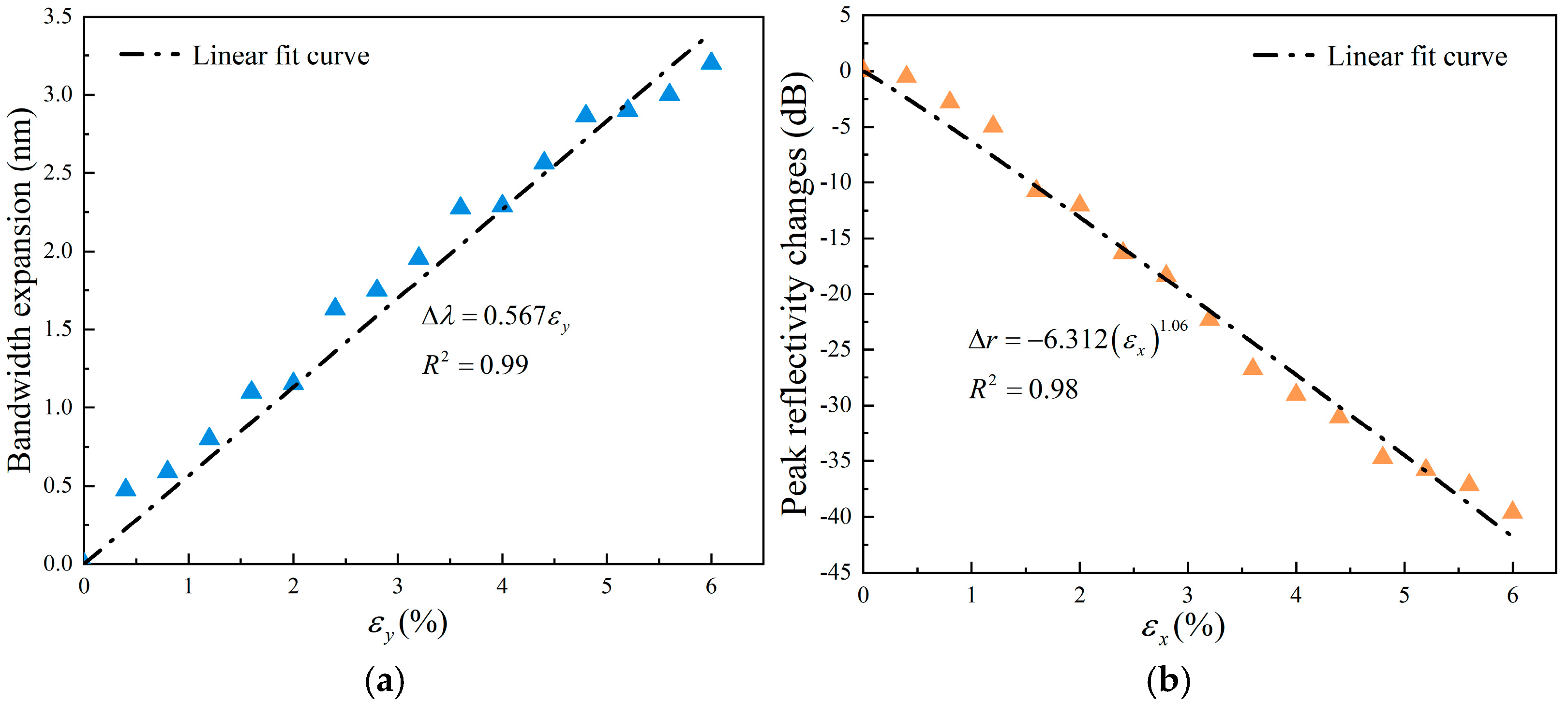

The failure processes of pre-cracked rocks usually involve compaction, elastic deformation, crack propagation, and coalescence. The use of AE parameters has become an important method of studying the characteristic stress thresholds of rocks. The stress–strain curve and AE characteristics of the B

1 sample are depicted in

Figure 8. During the initial loading, internal microcracks closed and the rock was in the compaction stage. The compaction limit load at point a was 12.5 MPa, and the AE exhibited fluctuations, generating a series of low-amplitude AE events. The cumulative energy demonstrated a slow increase, following a near-linear trend, reflecting predominant steady dissipation of energy release. After point a, the deformation entered a linear growth stage, and no significant changes were evident in the AE signal during this elastic stage. Next, the failure process deviates from this linearity, and the primary failure mode was unstable propagation of the prefabricated fissure. When the axial loading reached point b in the curve (σ

b = 20.67 MPa), wing cracks began to propagate in the direction perpendicular to that of the prefabricated fissure. This crack propagation caused stress redistribution to occur, and the prefabricated fissure closed further. The local load-bearing capacity of the specimen decreased at point c, and the degree of decrease was proportional to the wing-crack extension length. The AE signal exhibited significant fluctuations. This point represents the initial yield point of the pre-cracked rock specimen, at which the yield strength was σ

c = 26.25 MPa. As the loading proceeded, shear stress appeared at the surface of the closed crack and generated a shear-interlocking effect with the insufficiently extended wing cracks. Therefore, the bearing capacity once again exhibited an upward trend; however, the slope of the deformation curve decreased during the second growth stage. As the strain increased until point d was reached, the local load-bearing capacity of the specimen decreased again; at this point, the yield strength was σ

d = 25.63 MPa. The shear-interlocking effect that was generated previously failed gradually, causing a reduction in the secondary stress, and the acoustic emission signal exhibited significant fluctuations. When the shear stress again produced a shear-interlocking effect with the fully extended wing cracks, the load-bearing capacity again followed an upward trend. When peak load was reached at point e (σ

e = 28.28 MPa), the wing cracks were compacted and the prefabricated fissure had coalesced, and the deformation curve exhibited a third drop at this point. During this phase, AE activity exhibited two distinct characteristics: First, the amplitude distribution of events significantly broadened, with numerous medium-intensity events in the 60–80 mV range. Second, the cumulative energy curve began displaying a stepped growth pattern. Notably, during three pronounced stress drops, cumulative energy surged abruptly by 23%, 37%, and 52%, respectively. This correlation indicates that stress drops represent abrupt energy releases resulting from internal crack reorganization during propagation.

Figure 8c displays the AF-RA scatter density plot of AE monitoring during specimen loading. Extensive research confirms distinct spectral characteristics in AE signals corresponding to different crack types: events with high AF values and low RA values indicate tensile crack formation, while those with low AF and high RA represent shear cracks. Du et al. [

37] demonstrated that shear failures typically generate AE events with frequencies below 150 kHz, whereas tensile failures produce higher-frequency emissions. Based on these findings, we established the discriminant boundary at k = 0.8, classifying events with AF/RA > 0.8 as tensile failures and AF/RA < 0.8 as shear failures. For fractured bluestone specimens, AE events concentrated densely during loading with tensile failures significantly outnumbering shear failures. Under normal stress conditions, tensile failure events substantially increased due to accumulated energy promoting wing crack initiation, secondary crack nucleation, and sustained propagation of both crack types through tensile-dominated mechanisms.

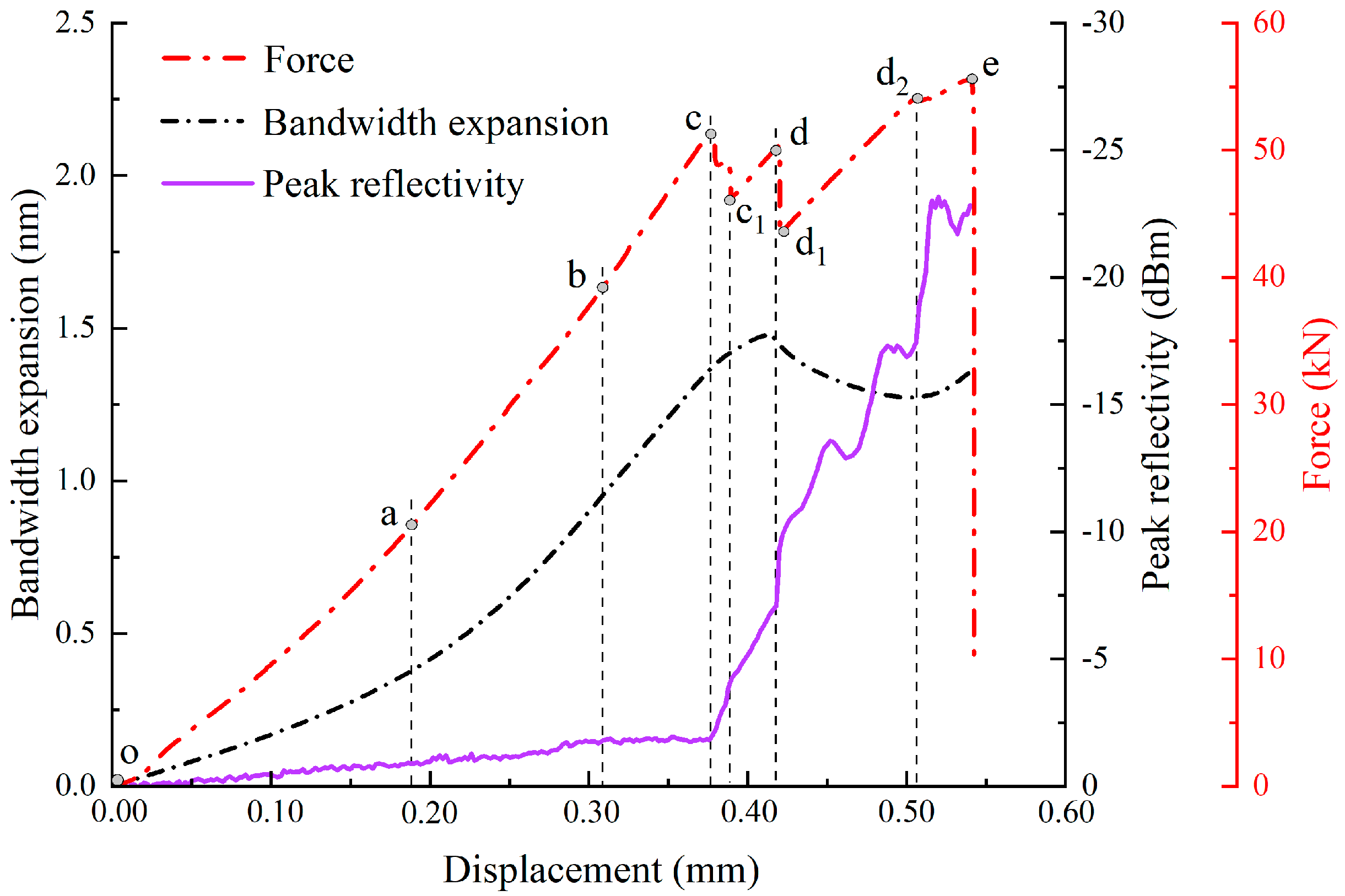

3.2. Characteristics of the FBG Spectral Variations

Figure 9 depicts the FBG spectral variations for pre-cracked specimen B

1 under uniaxial compression loading. Observations of the loading process revealed that, as the load increased, the FBG spectra exhibited not only central wavelength shifts but also systematic bandwidth expansion and significant changes in the peak reflectivity. Specifically, for the FBG oriented at 30° with respect to the prefabricated crack (

Figure 9a), when the load was 23.6 kN, the central wavelength was measured to be 1543.16 nm, the bandwidth expansion (Δλ) was 0.37 nm, and peak reflectivity was −12.7 dBm. When the load increased to 50.3 kN, the spectrum showed significant broadening, with an increase in Δλ to 2.62 nm, while the peak reflectivity gradually decreased, with a maximum reduction within −15 dBm. For the FBG oriented at 60° (

Figure 9b), when the load was 23.6 kN, the central wavelength was 1548.81 nm, Δλ was 0.34 nm, and the peak reflectivity was −13.6 dBm. As the loading progressed, the peak reflectivity of this FBG decreased significantly, dropping to −59 dBm in the post-peak stage (9.2 kN). The FBG oriented at 90° (

Figure 9c) also exhibited distinct spectral broadening characteristics when the load was 23.6 kN. It had a central wavelength of 1544.95 nm, a Δλ value of 0.48 nm, and a peak reflectivity of −16 dBm. When the load reached 63.9 kN, the peak reflectivity suddenly dropped to −50 dBm; however, due to preset measurement threshold limitations, the bandwidth expansion could no longer be accurately captured at this stage. The spectral response of the 90° FBG during initial loading (elastic stage, strain < 0.05%) is shown in

Figure 9d. No significant bandwidth broadening or peak reflectivity reduction was observed, but a distinct leftward shift of the central wavelength occurred. Through comparison with spectral variations during crack propagation stages, such spectral alterations were confirmed to exclude background strain fluctuations or environmental interference.

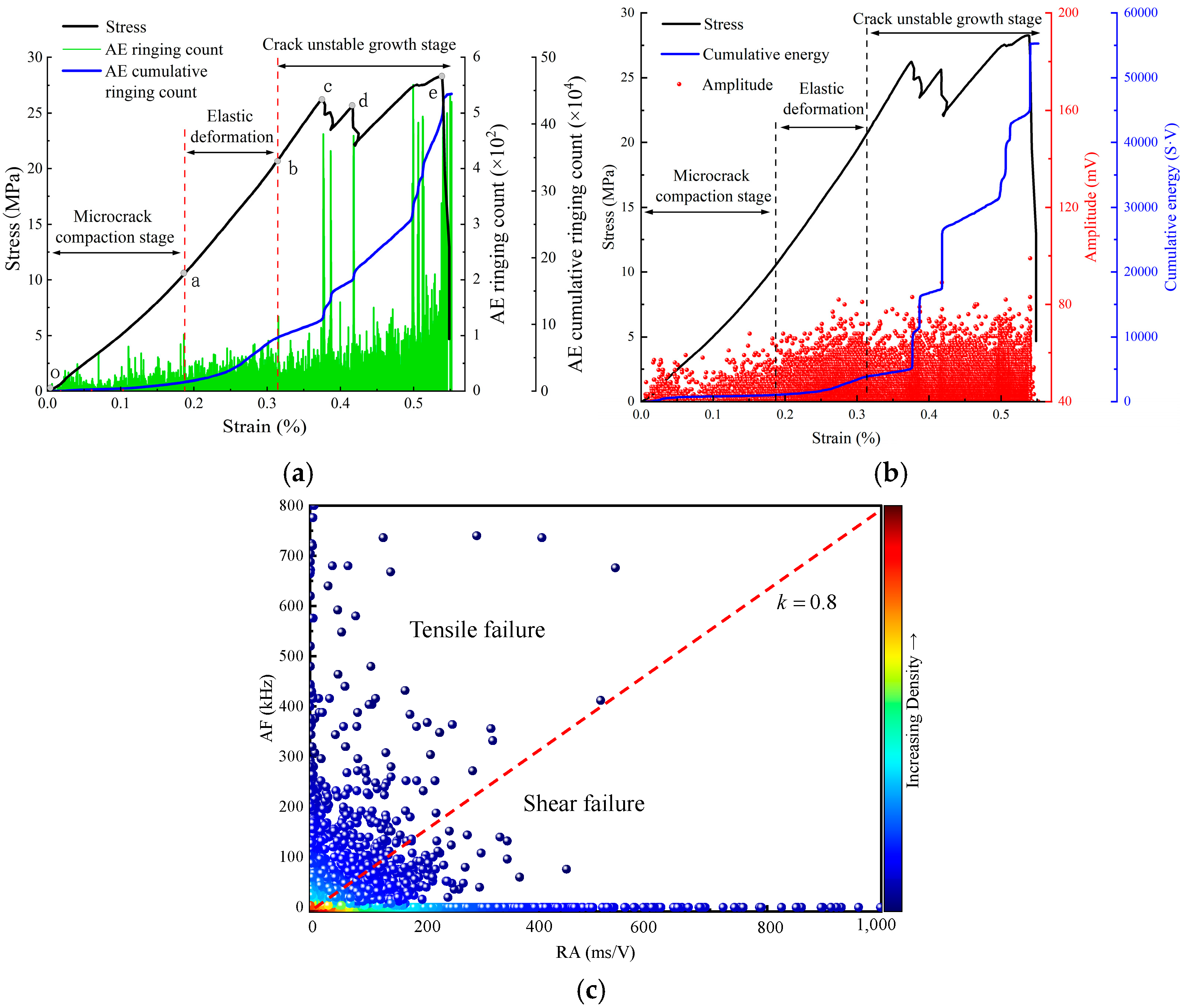

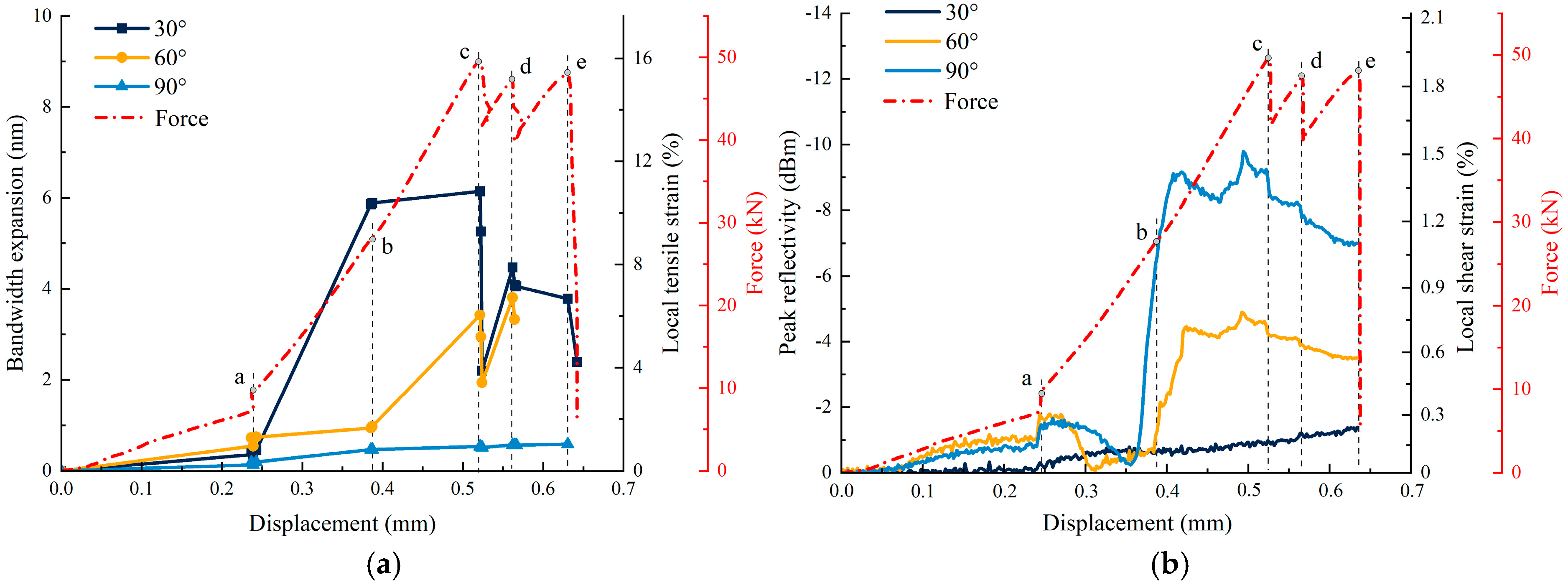

Figure 10 depicts the bandwidth-expansion and the peak-reflectivity variations of the FBGs of specimen B

1, which were placed at various orientations with respect to the pre-existing crack. These results were calculated from those presented in

Figure 8. The results demonstrate that, from the initial loading to complete failure, the FBG spectral bandwidth expansion exhibited distinct variation trends in different loading stages. Specifically, the FBG oriented at 30° had the most significant bandwidth expansion changes, while the FBG oriented at 90° displayed smaller variations and eventually was unable to capture bandwidth data in the later loading stages. Conversely, the peak-reflectivity variations had an opposite trend; the FBG oriented at 90° exhibited the most pronounced reflectivity variations, while the FBG oriented at 30° showed relatively minor changes. When the pre-cracked cyan sandstone was loaded to point a under uniaxial compression conditions, all the FBGs exhibited relatively small variations. Using the FBG calibration results, the local tensile and shear strains along the pre-existing crack were calculated to be 0.17% and 0.18%, respectively. These results indicate that, during the oa stage, the microcracks and inherent defects within the rock were being compacted, and only minor strains were generated around the pre-existing crack. Upon further loading to point b, the bandwidth expansion values of the FBGs oriented at 30, 60, and 90° increased to 1.68, 0.97, and 0.61 nm, respectively, while the corresponding peak reflectivity values decreased to −2.74, −1.83, and −1.55 dB, respectively. During this stage, the local tensile and shear strains along the pre-existing crack reached 0.65 and 0.27%, respectively. During the ab loading phase, all the FBGs (and particularly the 30° FBG) exhibited significant bandwidth-expansion increases, while peak reflectivity exhibited only modest decreases (which were most pronounced for the 30° FBG). These observations confirm that the specimen experienced elastic deformation during this stage; in addition, the local tensile stress dominated in the direction of the pre-existing crack, while shear stress remained relatively small.

When the loading progressed to point c, the local tensile and shear strains along the pre-existing crack reached 1.01 and 0.53%, respectively, during this stage. During the bc loading stage, the 30 and 60° FBGs exhibited significant bandwidth expansion increases, while the 90° FBG exhibited reduced broadening. All FBGs demonstrated peak reflectivity declines, and the 30° FBG had the most pronounced decrease. These measurements indicate that the local tensile stress remained dominant along the direction of the pre-existing crack, while the shear stress remained relatively low; these conditions led to the initiation and propagation of wing cracks in the direction perpendicular to that of the main fracture.

At point c1, the bandwidth expansion increases were negligible for all the FBG orientations, and the local tensile strain along the crack merely increased to 1.04%. However, the peak reflectivity values of the FBGs oriented at 30, 60, and 90° decreased significantly to −4.16, −4.24, and −8.48 dB, respectively, and the 90° FBG (which was oriented in a direction perpendicular to that of the crack) displayed the most dramatic reduction. The calculated local shear strain reached 1.32% during this stage. During the cc1 stage, the specimen experienced its first decrease in load; thus, this stage marked a transition during which the shear stress became dominant at the crack tip. This substantial shear strain promoted further wing-crack propagation, during which the extension length was directly proportional to the magnitude of the shear strain. When the loading process reached point d, the bandwidth expansion values of the FBGs oriented at 30, 60, and 90° increased to 2.62, 1.51, and 0.53 nm, respectively, and the calculated local tensile strain at the crack was 1.14%. In addition, the peak reflectivity values decreased to −5.42, −7.09, and −14.18 dB, respectively, and the local shear strain was 2.15%. During the c1d loading stage, although the bandwidth expansion continued to increase, it increased more slowly than during the bc phase. Meanwhile, the peak reflectivity declined significantly. During this stage, the shear strain exceeded the tensile strain, which indicates that shear stress developed at the closed crack surfaces. The interactions between this shear stress and the partially extended wing cracks created a shear-locking effect, which contributed to the recovery of the load-bearing capacity of the specimen. At point d1, the bandwidth expansion values of the FBGs oriented at 30, 60, and 90° abruptly decreased to 2.41, 1.39, and 0.48 nm, respectively. The local tensile strain at the crack dropped to 1.01%, while the peak reflectivity values further decreased to −5.90, −10.17, and −20.33 dB, respectively. The local shear strain reached 3.02%. During the dd1 phase, the specimen experienced a second decrease in load; this decrease was accompanied by a reduction in the tensile strain and a significant increase in the shear strain. These results suggest that the shear-locking effect partially failed during this stage, thereby allowing the shear stress to dominate and further cause the pre-existing crack to propagate, which ultimately reduced the load-bearing capacity of the specimen. At point e, the bandwidth expansion values of the FBGs oriented at 30 and 60° increased to 2.35 and 1.35 nm, respectively, while the local tensile strain stabilized at 1.0%. The peak reflectivity values of the FBGs oriented at 30, 60, and 90° dropped sharply to −13.24, −22.83, and −45.65 dB, respectively, while the local shear strain reached 6.45%. During the d1e stage, the load-bearing capacity of the specimen recovered; however, the tensile strain at the crack first decreased and then increased, and this behavior was accompanied by fluctuations in the shear strain. These results indicate unstable crack propagation and repeated shear-locking interactions between the main crack and the wing cracks. Beyond this point, the deformation curve exhibited three successive load decreases, and the FBGs fractured, which prevented further spectral measurements. These results confirm that the coalescence of pre-existing cracks led to a rapid and unstable specimen failure.

During the loading process, the significant increase in Δλ for the 30° FBG (from 0.37 nm to 2.62 nm) indicates its alignment with the tensile propagation direction of the wing crack, while the sharp decrease in Δr for the 90° FBG (from −16 dBm to −50 dBm) reflects the concentration of shear strain on the plane perpendicular to the crack surface (

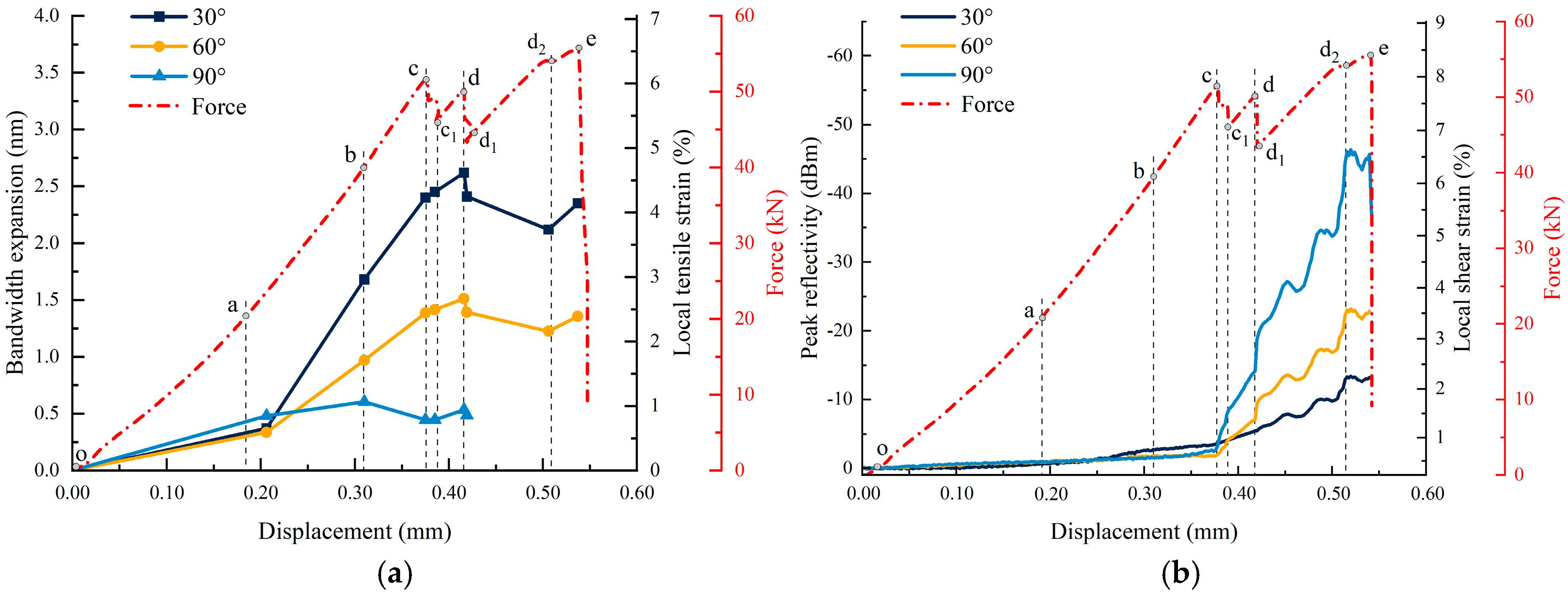

Figure 8). This directional sensitivity verifies the model’s ability to resolve local stress components. The variations in the bandwidth expansion and peak reflectivity values for specimens B2 and B3 are shown in

Figure 11 and

Figure 12, respectively, and these curves exhibit similar trends to those described for specimen B

1.

3.3. Failure Modes of the Pre-Cracked Sandstone Specimens

Under external-loading conditions, various types of cracks with different trajectories and initiation mechanisms (tensile or shear) may develop in fractured rocks. As was summarized by Wong [

38], seven typical crack patterns exist.

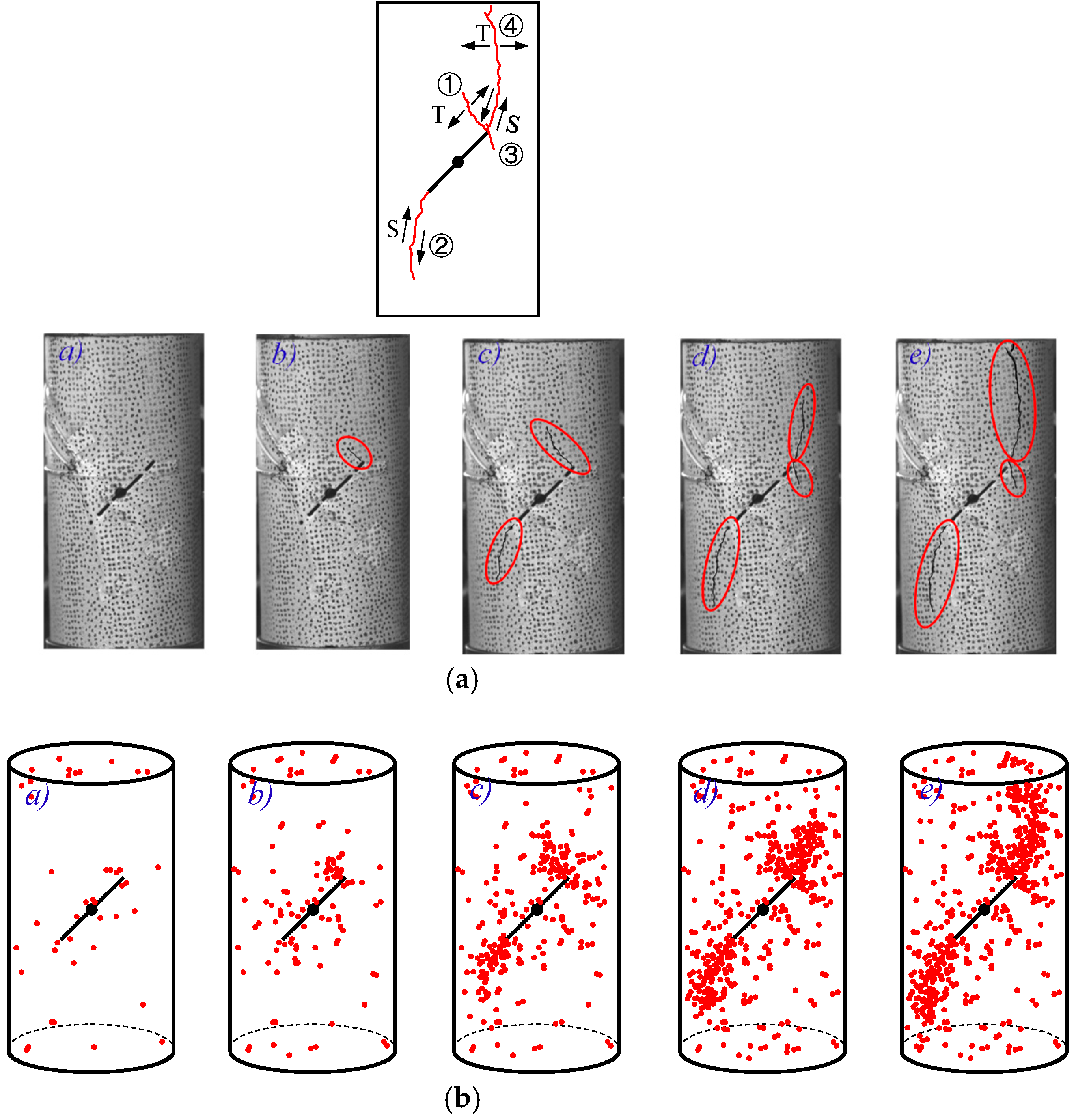

Figure 13 and

Figure 14 illustrate the surface-crack propagation processes in the single-fracture cyan sandstone specimens. During the initial loading, all three specimens developed wing cracks in the direction perpendicular to that of the pre-existing fracture and at its tips. However, these wing cracks had different orientations in the different specimens: specimens B

1 and B

2 exhibited wing cracks at the top of the fracture, while specimen B

3 had bottom-initiated wing cracks. In specimens B

1 and B

3, the wing cracks eventually became compacted during the later loading stages, and the final failure patterns were not determined by these initial cracks. However, in specimen B

2, after the top wing cracks propagated sufficiently, anti-tensile cracks emerged. This phenomenon typically accompanies tensile failure, and in this case, it ultimately resulted in a combined failure mode in which the wing cracks coalesced with the pre-existing fracture. All the specimens ultimately developed both tensile and shear cracks, and mixed-mode (tension–shear) cracks appeared during the propagation process.

The AE localization patterns that appeared during the failure process of specimen B

1 are shown in

Figure 13b. During the initial loading stage, the AE events exhibited a random and scattered distribution, though concentration of the stresses led to the formation of localized micro-crack clusters near the fracture tips with no visible macroscopic cracking. When the loading progressed to point b, concentrated AE clusters appeared at the top fracture tip as wing cracks initiated and propagated in the direction perpendicular to that of the pre-existing fracture; this phenomenon resulted in a significant increase in the number of AE events. When the loading process reached point c, AE clusters began to develop at the bottom fracture tip, which indicated the beginning of macroscopic crack propagation, and the wing cracks continued to extend. During this stage, the AE events that were aligned with the direction of the top fracture revealed the development of micro-cracks in this region. At point d, many dense AE clusters formed along the direction of the fracture; this occurrence marked substantial macroscopic crack growth in which most of the AE events were concentrated along the propagation path. The final failure was characterized by complete coalescence of the top cracks while the bottom cracks remained unconnected, as well as by intensive AE activity along all the crack propagation paths.

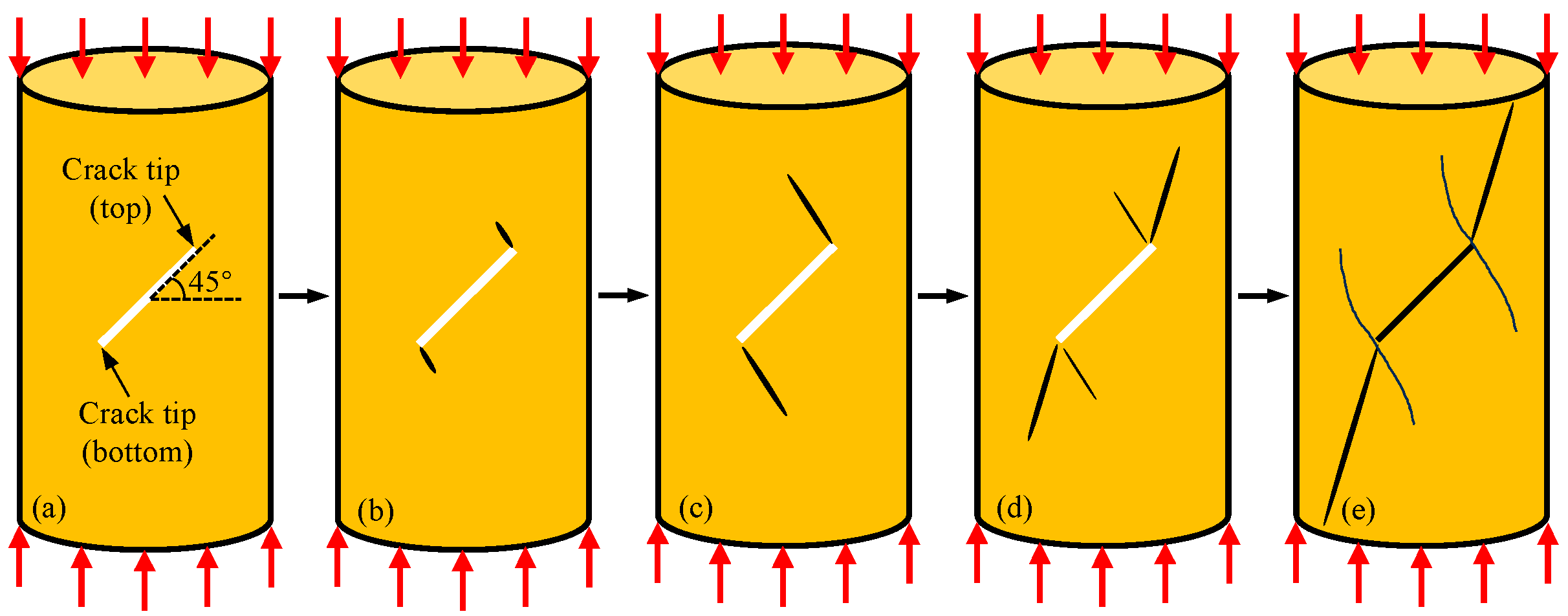

The stress–strain behavior and failure patterns collectively demonstrate the crack propagation mechanism, which is illustrated in

Figure 15. The stress–strain curves for the fractured cyan sandstone specimens exhibit five characteristic stages: initial compaction, elastic deformation, first stress decrease, intermittent failure of the shear-locking effects, and final stress decrease [

39,

40]. The shear-locking phenomenon is responsible for the multiple peaks that appear in the stress–strain curves. The AE monitoring results show that the pre-cracked specimens generated fewer micro-fracture events than did intact rocks; this occurred because the failure process was predominantly controlled by the pre-existing fractures, while the formation of new cracks was limited. However, the high-energy micro-fracture events that occurred during the stress decreases released substantially more energy than those that occurred in intact specimens; this result clearly demonstrates that pre-existing fractures promote brittle post-peak behavior in sandstone.

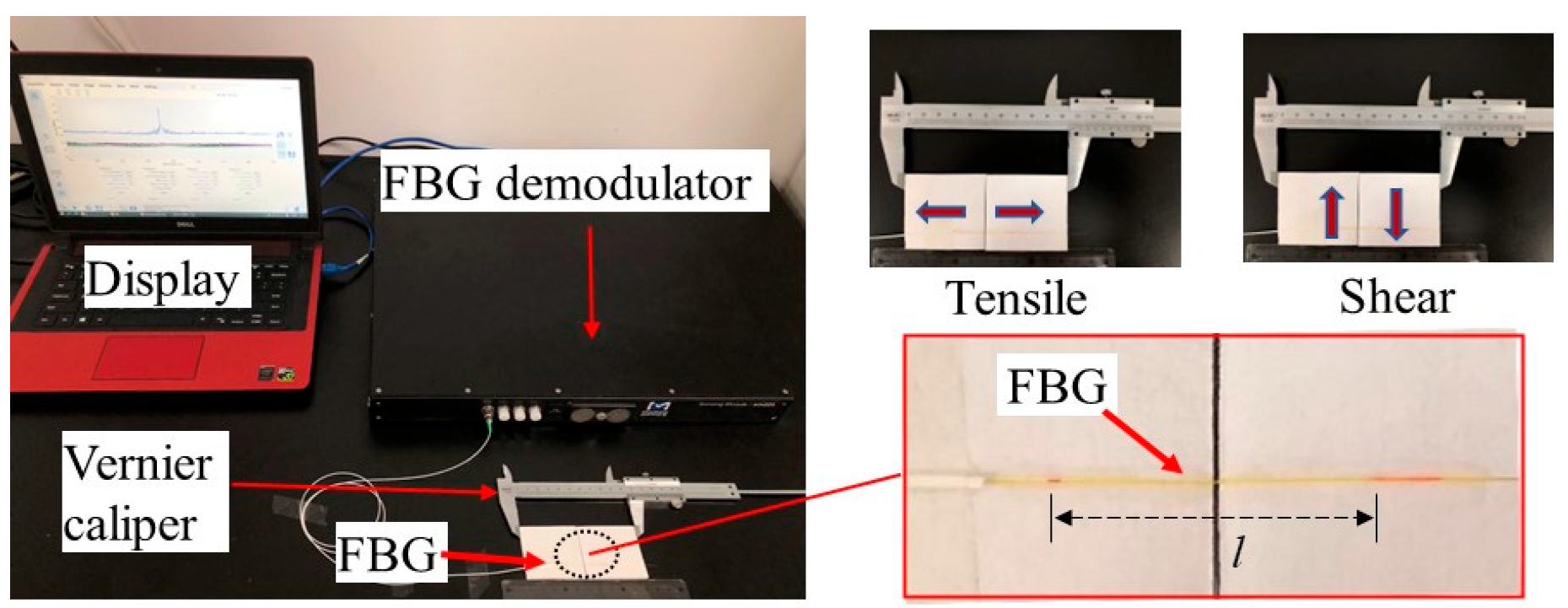

3.4. Analyses of the Propagation Process and Mechanism of the Pre-Crack Sandstone

When exposed to prolonged geological tectonic activity, rocks develop many complex structural discontinuities, such as joints and fractures, which significantly alter their physical and mechanical properties [

41]. The propagation and coalescence of cracks within rocks generally occur in three distinct phases. First, in the initial stress application phase, while no macroscopic crack propagation occurs, the damaged zones at the crack tips expand. Second, in the sustained loading phase, rapid crack extension occurs in the rock matrix. Third, the cracks continuously propagate until they are completely interconnected. The evolution of the crack-propagation process is depicted in

Figure 16. When FBGs are used to monitor fractured rock specimens, crack propagation induces non-uniform strains at the fracture locations, which cause measurable spectral distortions. The crack-propagation process can be quantitatively characterized by calculating the changes in both bandwidth expansion and the peak reflectivity.

Figure 17 shows the spectral variations for the FBG oriented at 60° in specimen B1. Before the initial yield strength is reached at point c, the bandwidth expansion progressive increased at various rates, while the peak reflectivity decreased with a nearly constant slope. During the initial loading stage (the oa stage), Δλ gradually and linearly increased to 0.36 nm, while Δr decreased linearly to −0.93 dBm; these results indicate that the micro-crack compaction phase was dominated by a small linear tensile strain around the pre-existing fracture. During the ab stage, Δλ increased nonlinearly to 0.97 nm with an accelerating slope, while Δr decreased linearly to −1.83 dBm. Although the load–displacement curve exhibits linear elastic deformation, the spectral data reveal a significant stress concentration around the pre-existing fracture, which produced a locally nonlinear tensile strain and a linearly increasing shear strain. During the bc stage, both Δλ and Δr varied linearly.

Figure 16 shows that this stage marked the initiation of wing cracks, which was primarily driven by the linearly increasing tensile strain (which was quantified by the Δλ measurements), while local shear stress concentrations developed at the crack tips. After the initial yield strength was reached at point c, the first stress decrease in the load–displacement curve occurred. In the cc1 stage, Δλ increased nonlinearly with a decelerating slope, while Δr decreased sharply from −3.21 to −8.48 dBm (which represents a reduction of approximately 150%); these results indicate shear-dominated failure with large shear strains that initiated crack propagation. During the c1d load-recovery stage, the Δλ slope gradually decreased and Δr continued to decline, though it declined more slowly than during the cc

1 stage. These results demonstrate the development of a stress concentration in which shear stress was dominant, and which generated shear-locking effects between the main crack and the partially extended wing cracks. At point d, the second stress decrease occurred, and Δλ peaked at 1.49 nm. In the subsequent d1d stage, Δλ decreased nonlinearly, while Δr dropped nearly vertically; thus, continued shear-driven crack advancement was confirmed. The d

1e stage, which preceded the final failure at point e, featured step-like reductions in Δr, which revealed discontinuous fracture progression. Throughout the loading process, the slope variations in both the Δλ and Δr curves consistently aligned with the mechanical response; thus, the ability of the FBGs to characterize real-time crack evolution was validated.

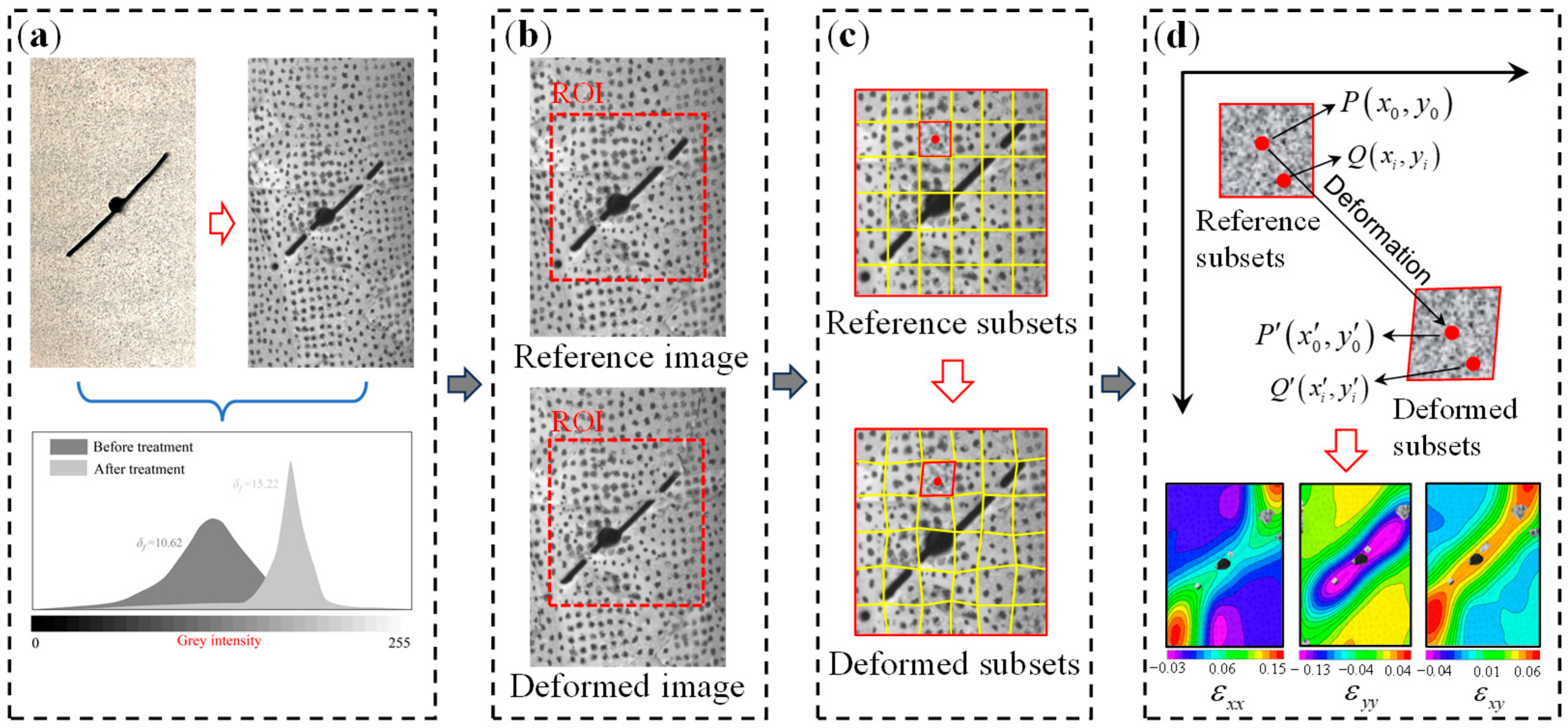

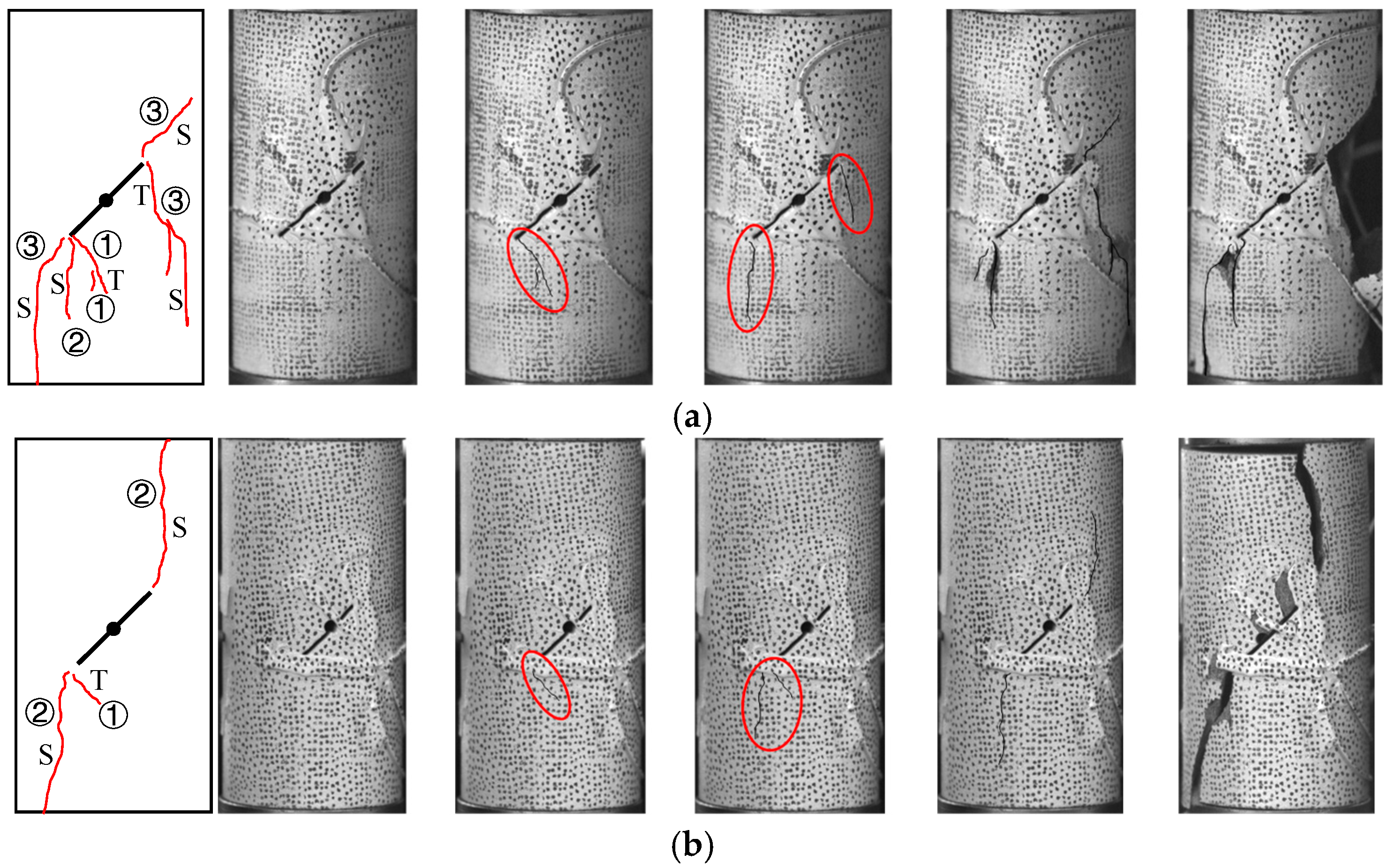

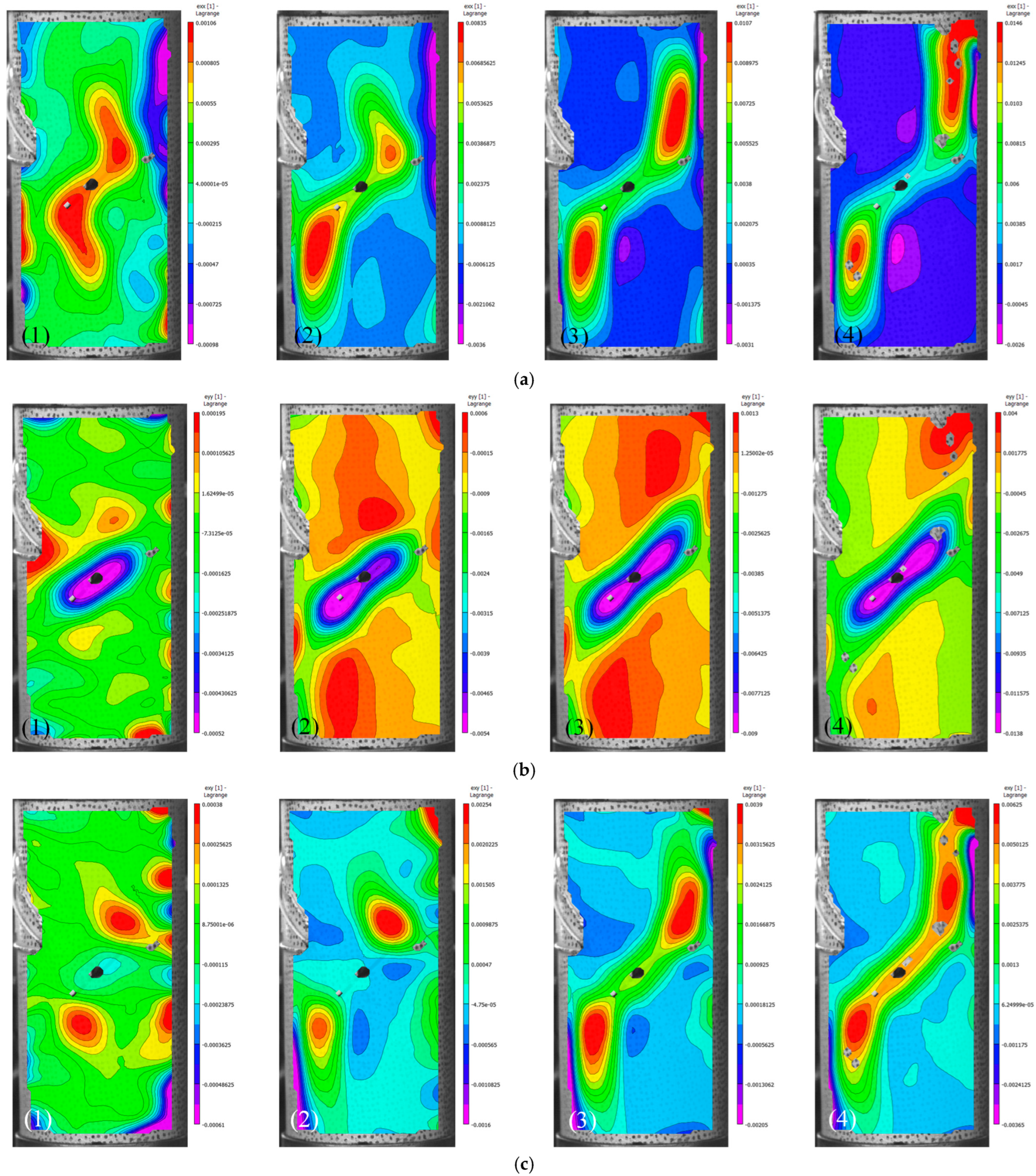

During the crack-propagation process, the local tensile and shear strains collectively determine the direction of crack growth. DIC monitoring revealed the strain-field evolution on the specimen surface (

Figure 18). Initially, the surface strain field was uniformly distributed. When the axial stress reached 80% of the initial yield strength, strain localization emerged on the rock surface, as shown in

Figure 18a–c (1). The strain concentration zones in the x and xy directions were located at the crack tip and were oriented in the direction perpendicular to that of the fracture, while strain concentration zone in the y direction covered the entire fracture. This localization indicated the development of internal damage, and the deformation was concentrated in damaged zones where wing cracks were initiated in the direction perpendicular to that of the fracture, while the pre-existing crack gradually became compacted. As the load increased, the strain values in the x and xy concentration zones increased, and these zones migrated toward the crack bottom as the top wing-cracks extended. The rock deformation became discontinuous, and the process transitioned from the localized-concentration stage to the fracture-development stage, as shown in

Figure 18a–c (2). When the initial yield strength had been reached, the strain concentration zones expanded toward both ends of the fracture, and the direction of the concentration zone at the crack top gradually transitioned from perpendicular to parallel with respect to the crack propagation direction, as shown in

Figure 18a–c (3). The specimen exhibited crack propagation from both ends of the crack, and an extension length of 15 mm was reached. During this strain concentration zone transition, shear-locking effects were generated between the propagating cracks and the wing cracks, and intermittent failures occurred. The strain concentration path essentially followed the crack propagation path. When the axial stress reached the peak strength, the strain concentration zones expanded to the upper or lower ends or the side boundaries of the specimen. When the strain was 1.5%, fully penetrating fractures formed that triggered the final rock failure, as shown in

Figure 18a–c (4).

Zhang et al. [

42] proposed a quantitative method for directly characterizing rock cracking behavior using DIC, comprising four key steps: measurement point selection, displacement extraction, local coordinate transformation, and relative displacement calculation. To quantitatively characterize the crack-propagation process and identify the crack types, we implemented this methodology by analyzing the relative displacement evolution at characteristic points across fracture surfaces. If the relative strain demonstrated a separation and opening tendency, tensile cracks were indicated; however, if a shear-slippage tendency was demonstrated, shear cracks were indicated. The displacement evolution curves for characteristic points are presented in

Figure 19. For points A and B, the horizontal displacements on both sides of the fracture tended to decrease. This result occurred because, under boundary effects, a tensile crack first developed at the right side of the upper crack tip, which caused the left side of the rock mass to move leftward as a whole. However, because point A moved leftward faster than point B, the fracture had an opening tendency. For points C and D, the horizontal displacements on both sides of the crack had opposite directions (one was positive and one negative), which also indicated an opening tendency. When loading duration had reached 250 s, the width of the fracture opening suddenly decreased, which indicated that the fracture had begun a compaction and closure process. For points E and F, the displacements on both sides of the crack showed increasing trends, which resulted from the fracture compaction and closure effects. Since point F moved faster than point E, the fracture still demonstrated an opening tendency; however, the opening rate was slower. For points A, B, C, and D, the vertical displacements on both sides of the crack remained consistent, which indicates that there was no shear-slippage tendency between the fracture sides. However, for points E and F, significant differences between the vertical displacements of the two sides were observed, which demonstrates shear-dislocation phenomena. The roughness of the shear surface caused the fracture plane to exhibit a slow expansion tendency in the normal direction. In summary, the fractures at characteristic points A, B, C, and D were tension-dominated, while the fracture at points E and F was shear-dominated. These results indicate that the rock experienced a mixed tensile–shear failure.

The strain evolution curves for the characteristic points were used to quantitatively determine the crack initiation times and sequence. The strain evolution characteristics were analyzed at the points where the FBGs were bonded to the fracture surface. The principal strains at the characteristic points were calculated from the tensile and shear strains that were measured by the FBGs, and the resultant principal-strain evolution curves are presented in

Figure 20. At 50 s into the loading process, the principal strain at the crack tip began to increase slowly; the principal strain at point B started to increase at 70 s, which indicates that the pre-existing crack in the specimen had begun to close gradually. When the loading time approached 125 s and the axial stress reached 70% of the initial yield strength, the strain growth rate increased and strain localization appeared at the crack tip. At 150 s into the loading process, the principal strain at point A decreased and the wing crack that was perpendicular to the crack tip at point A began to propagate, which caused the stress to be redistributed and the pre-existing crack to close further. Since no wing crack appeared at the crack tip at point C, continued loading caused the principal strain at point C to gradually exceed that of point A. At 180 s, the principal strain briefly decreased and then rapidly increased, which marked the initiation of the pre-existing crack propagation. As the loading continued, shear-locking effects were generated with the insufficiently propagated wing cracks; however, these effects failed within a short time, after which the crack continued to propagate. At approximately 210 s into the loading process, the principal strain at the crack tip began to increase steadily, at which time new shear-locking effects were produced during the continued crack propagation. Due to the rapid failure of the second shear-locking event, the FBGs failed to capture this transient process. At 250 s, the principal strain at the crack tip increased rapidly as the cracks gradually coalesced and the pre-existing crack closed.

3.5. Spectral Damage Characteristics of the Pre-Crack Sandstone Monitored by the FBGs

During the failure processes of the pre-fractured rock specimens, the wavelength, bandwidth, and peak reflectivity values of the FBG spectra exhibited discontinuous variations. Extensive studies have demonstrated that the damage variable,

D, of a rock can be defined by various parameters [

43]. For instance, Zhang et al. [

44] conducted uniaxial compression tests on 3D-printed sandstone specimens featuring varied intermittent aperture densities, analyzing damage evolution processes using DIC monitoring results. Dong et al. [

45] performed uniaxial compression tests on specimens with prefabricated defects, utilizing AE ring-down counts as damage variables to characterize critical states during damage progression. Wang et al. [

46] established a loss-damage constitutive model through AE energy analysis during uniaxial compression tests on fractured rocks under diverse loading rates, quantitatively describing deformation and damage processes.

To characterize the damage evolution in the pre-fractured specimens during the loading process, the characteristic parameters of the FBG reflection spectra can serve as effective damage indicators. The reflection characteristics of FBGs can be described by the coupled-mode theory, in which periodic refractive-index modulation induces coupling between forward- and backward-propagating modes. The key spectral parameters, which are the peak reflectivity and the bandwidth, can be expressed by Equations (13) and (14), respectively:

In Equations (13) and (14),

κL represents the product of the coupling coefficient and the grating length, and it reflects the overall coupling strength. This parameter critically determines the FBG spectral characteristics because it influences both the peak reflectivity and the bandwidth while governing the spectral shape. Therefore,

κL was adopted as the damage indicator for the specimens investigated during this study. For cases in which the coupling is weak (

κL < 1), the peak reflectivity and bandwidth can be approximated by Equations (15) and (16), respectively:

Equations (15) and (16) demonstrate that, when the FBG is subjected to shear stress (and thus the grating length remains constant) the variations in the peak reflectivity can be primarily determined by the coupling coefficient, κ. Conversely, when the FBG is subjected to tensile stress, the spectral bandwidth variations are mainly governed by the grating length,

L. When the FBG experiences a combination of shear and tensile stresses,

κ and

L can be calculated separately. In this study, the initial grating length,

L0, was 1 cm; thus, the initial

κL product can be expressed by Equation (17):

Kachanov defined

D by the expression in Equation (17) [

47]:

where A is the initial effective cross-sectional area and A

d is the damaged area. The FBG coupling strength, g =

κL, was selected as the independent variable used to characterize the crack damage in the specimens during this study. The integrated coupling strength per unit of damaged area is defined by the expression in Equation (19):

where g

c is the coupling strength per unit of damaged area and g

w is the coupling strength at complete failure. When the rock damage reaches a certain state with A

d, the instantaneous coupling strength can be expressed by Equation (20):

By combining Equations (18) and (19), the damage variable can be rewritten as Equation (21):

During experimental processes, rock specimens cannot achieve complete damage failure and will retain some residual strength after the failure. When the maximum damage level is reached, the damage variable remains less than 1; therefore, modification of the damage variable is necessary. The damage variable was corrected according to Equation (22):

In Equation (22), g

w represents the coupling strength when the damage variable reaches the critical value. The critical damage value must be normalized according to Equation (23):

where

and

represent the peak strength and the residual strength, respectively, after the peak strength of the rock material has been reached. The modified damage variable can then be expressed by Equation (24):

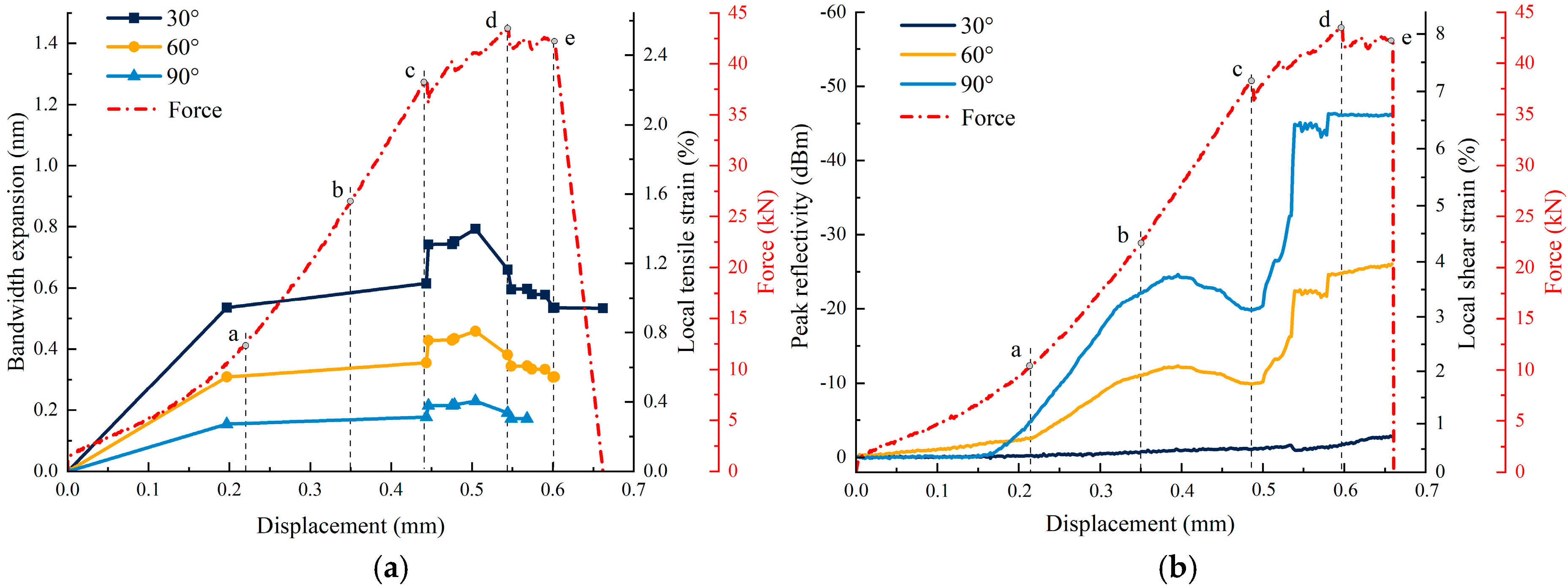

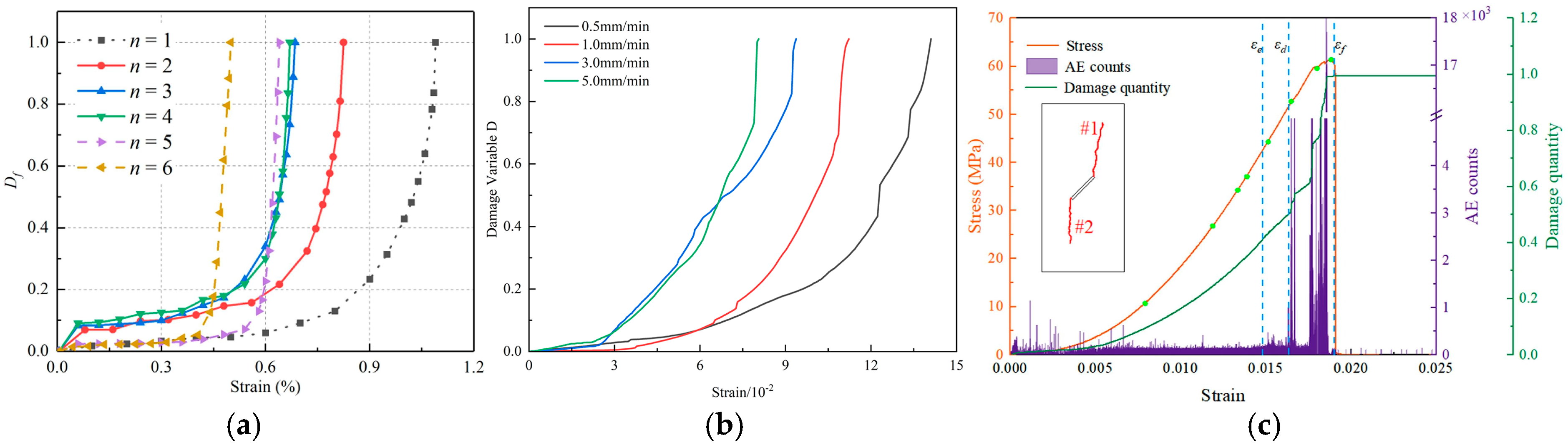

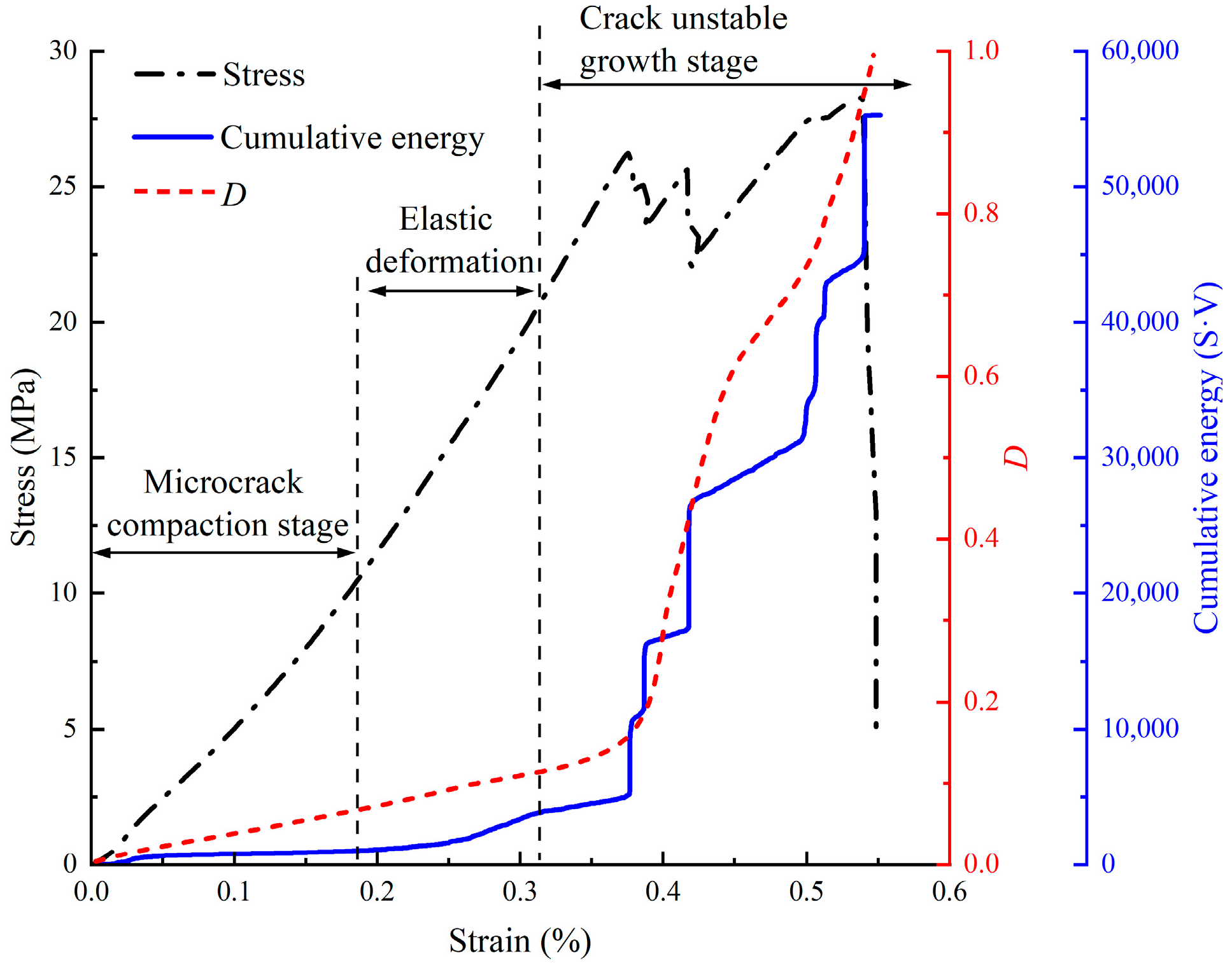

The damage evolution curves obtained from the experiments are depicted in

Figure 21. Under uniaxial compression conditions, the damage characteristic curves of the pre-cracked sandstone specimens monitored by FBGs can be divided into three stages: initial damage accumulation, damage acceleration, and final failure. During the initial damage accumulation stage (the ob stage), the damage variable, which was obtained by the FBGs mounted at different angles, remained low (with values of 0.13, 0.24, and 0.11 for the 30, 60, and 90° FBGs, respectively). These low values reflected the gradual accumulation of micro-damage caused by crack compaction and elastic deformation. In the damage acceleration stage (the bc stage),

D increased to 0.26 and 0.4 for the 30 and 60° FBGs, respectively, thereby indicating stress concentrations at the crack tips, which initiated wing-crack propagation. After the initial yield strength was reached at point c,

D of the 90° FBG increased abruptly; this sharp increase corresponded to crack propagation and a significant release of AE energy. This stage featured two stress decreases, during which

D increased rapidly (shear-locking failure); however,

D increased slowly again during the stress recovery. When the peak strength was reached at point e, D reached its maximum value and the specimen failed.

As shown in

Figure 22, the damage evolution curves defined by various methodologies in relevant studies consistently validate the feasibility of using FBG coupling strength as a damage metric. The damage curves in

Figure 22a, corresponding to different aperture densities, all exhibit typical staged characteristics: a slow increase during the initial loading phase, followed by a sharp rise upon entering the unstable crack propagation stage. This pattern is further corroborated by the curves under four loading conditions in

Figure 22b. Most importantly,

Figure 22c reveals synergistic effects between different monitoring techniques, where the accelerated increase in the damage variable is fully synchronized with the surge in acoustic emission counts and the stress drop, marking the onset of macroscopic damage. The high degree of consistency in the fundamental morphology of these damage evolution curves demonstrates that the damage curve derived from FBG coupling strength in this study reliably reflects the intrinsic damage evolution process in rocks, particularly the critical transition to unstable failure.