Study on Breakdown Characteristics of On-Train High-Voltage Combined Electrical Apparatus Under Lightning Transient Conditions

Abstract

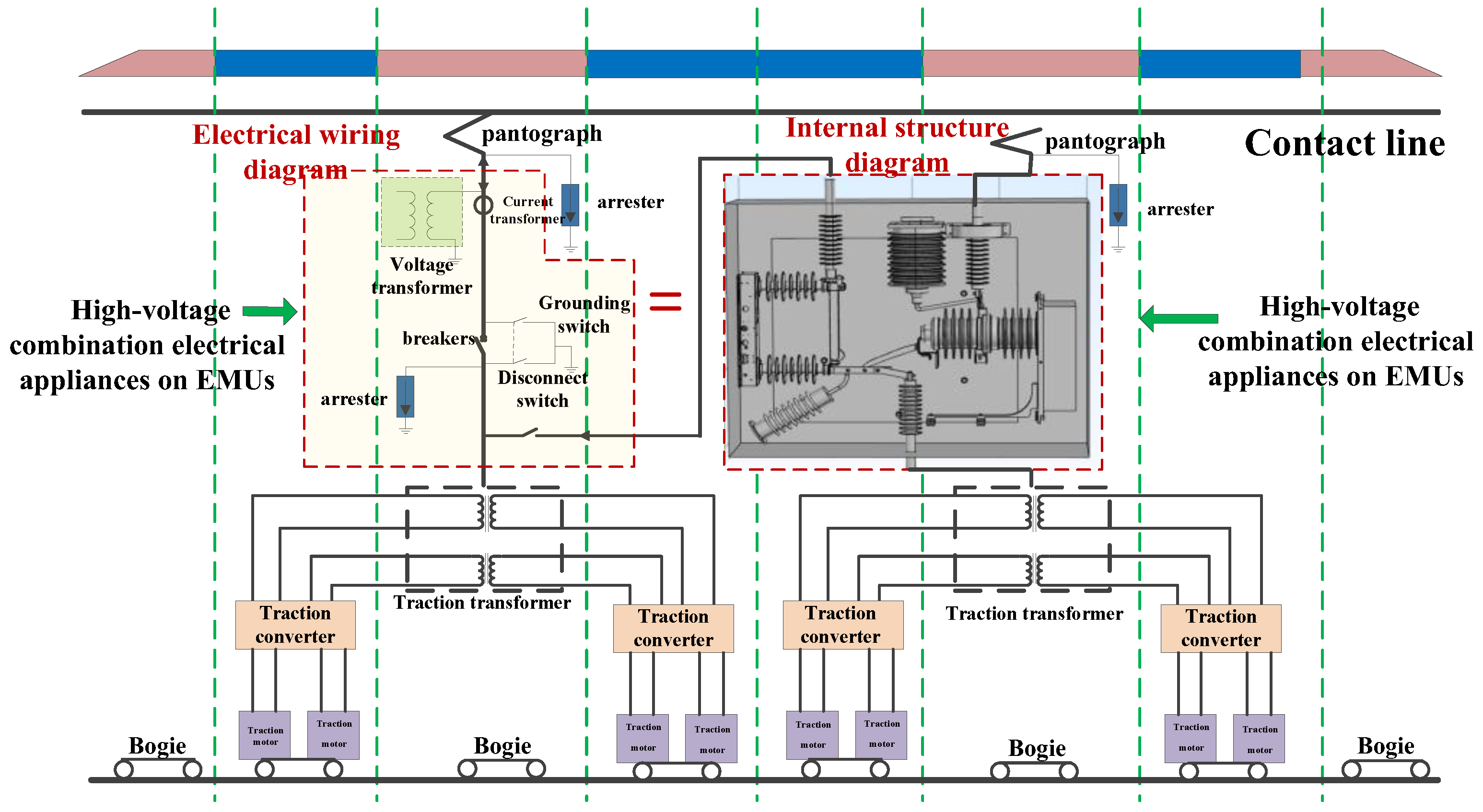

1. Introduction

2. Internal Discharge Model of the Combined Electrical Apparatus

2.1. Analysis of the Development Process of Medium and Long Gap Discharges

2.2. Discharge Control Equations for High-Voltage Combined Electrical Systems

3. Electric Field Characteristics of AIS Under Lightning Voltage Conditions

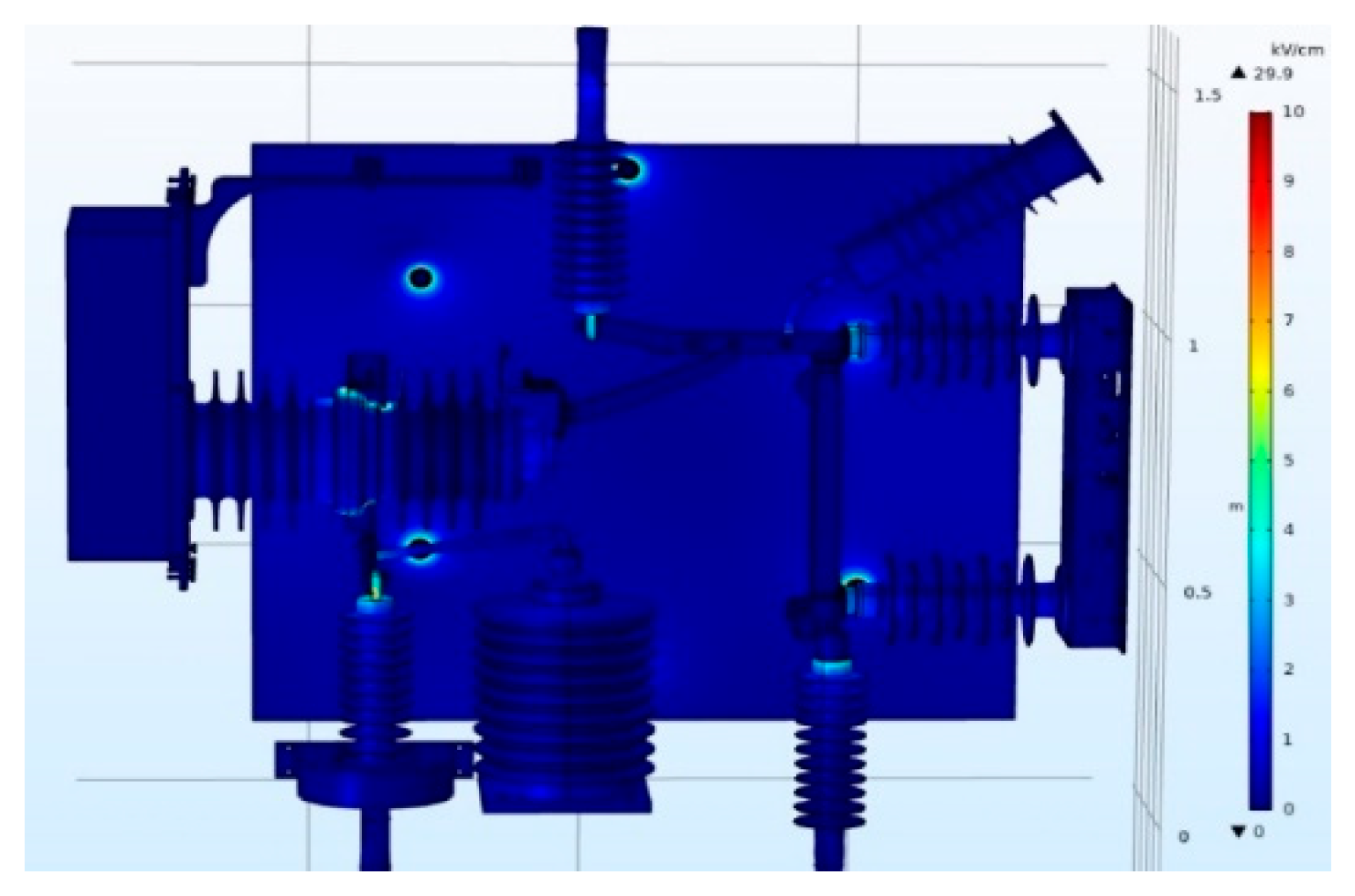

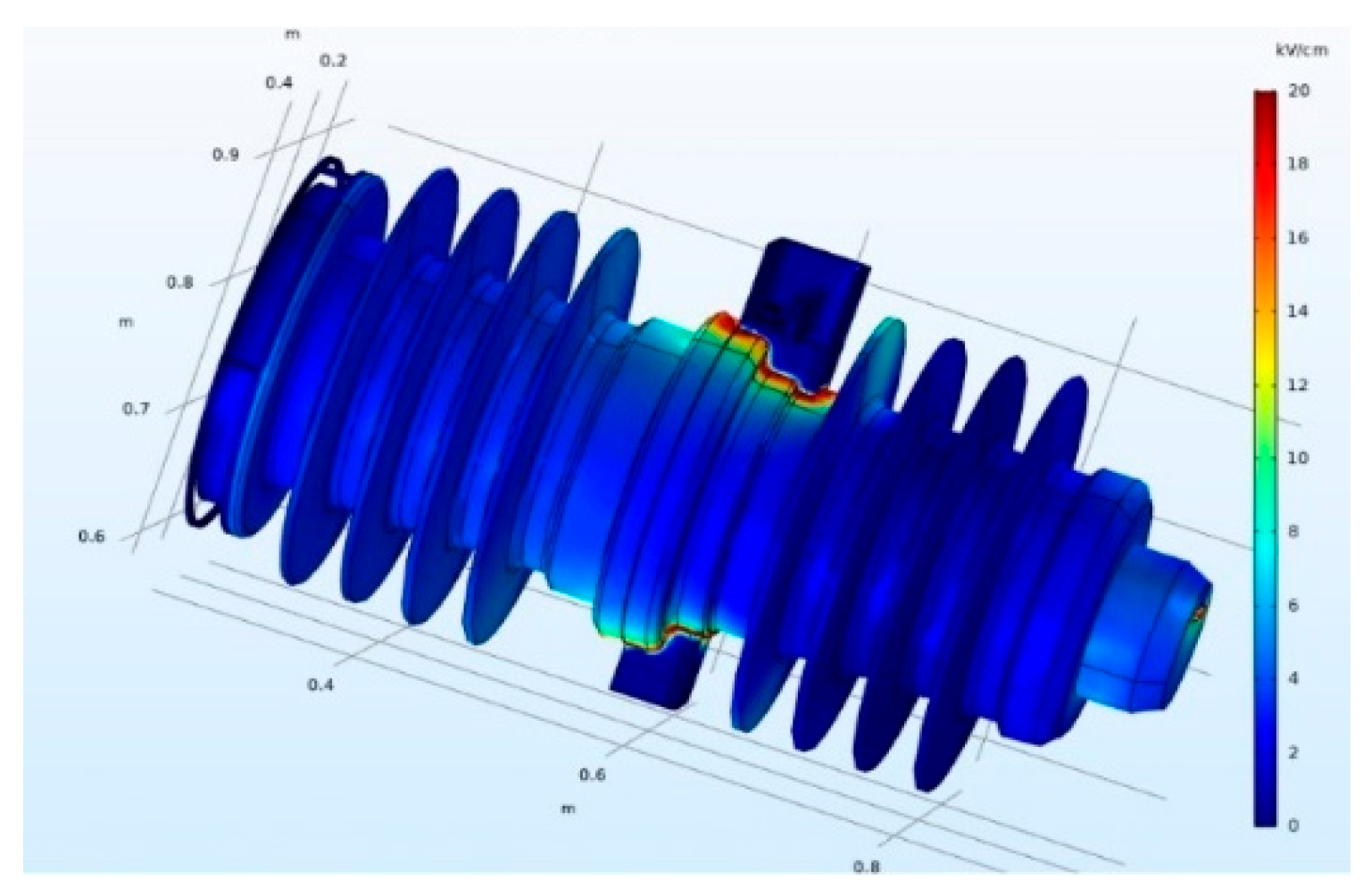

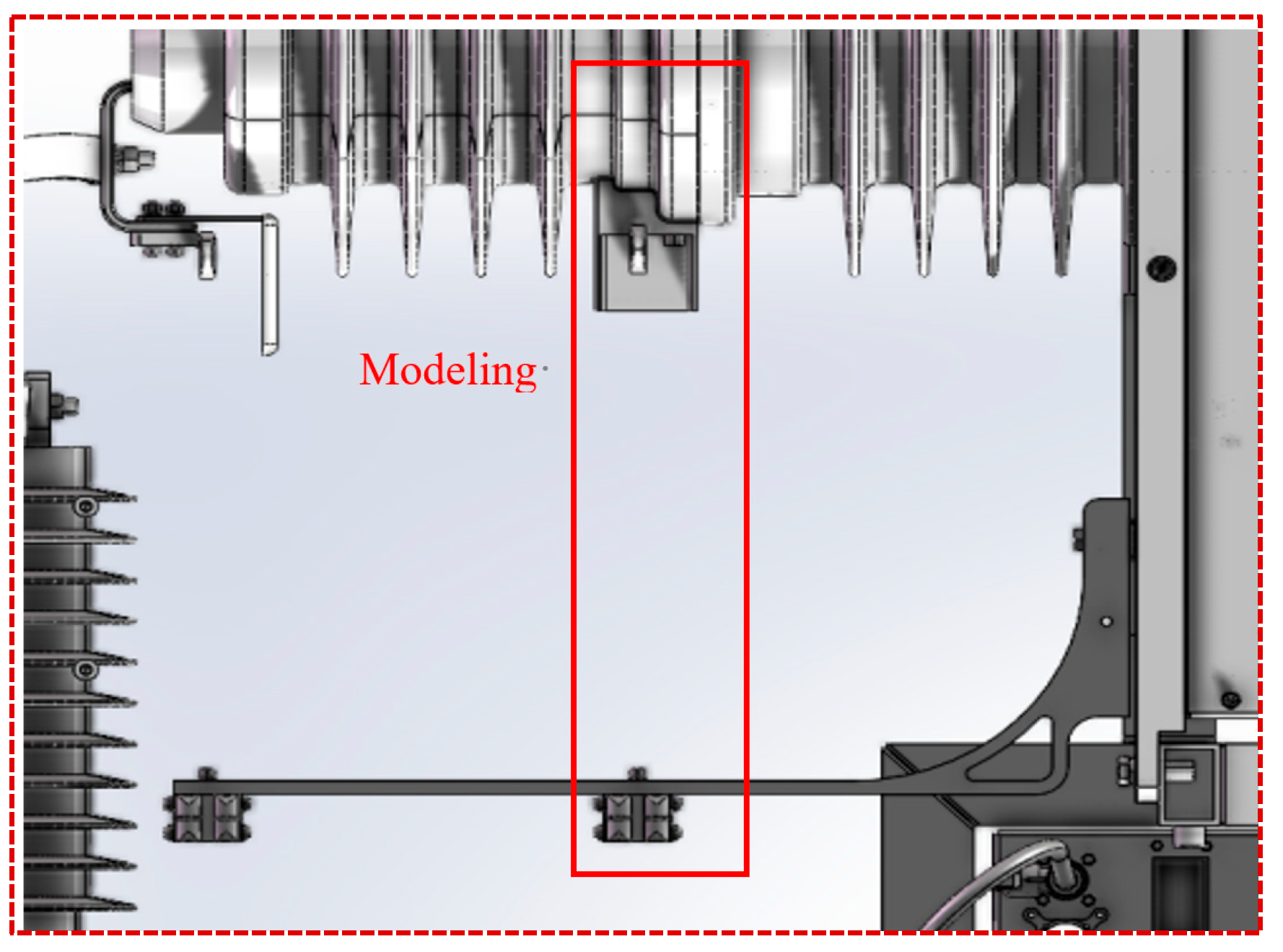

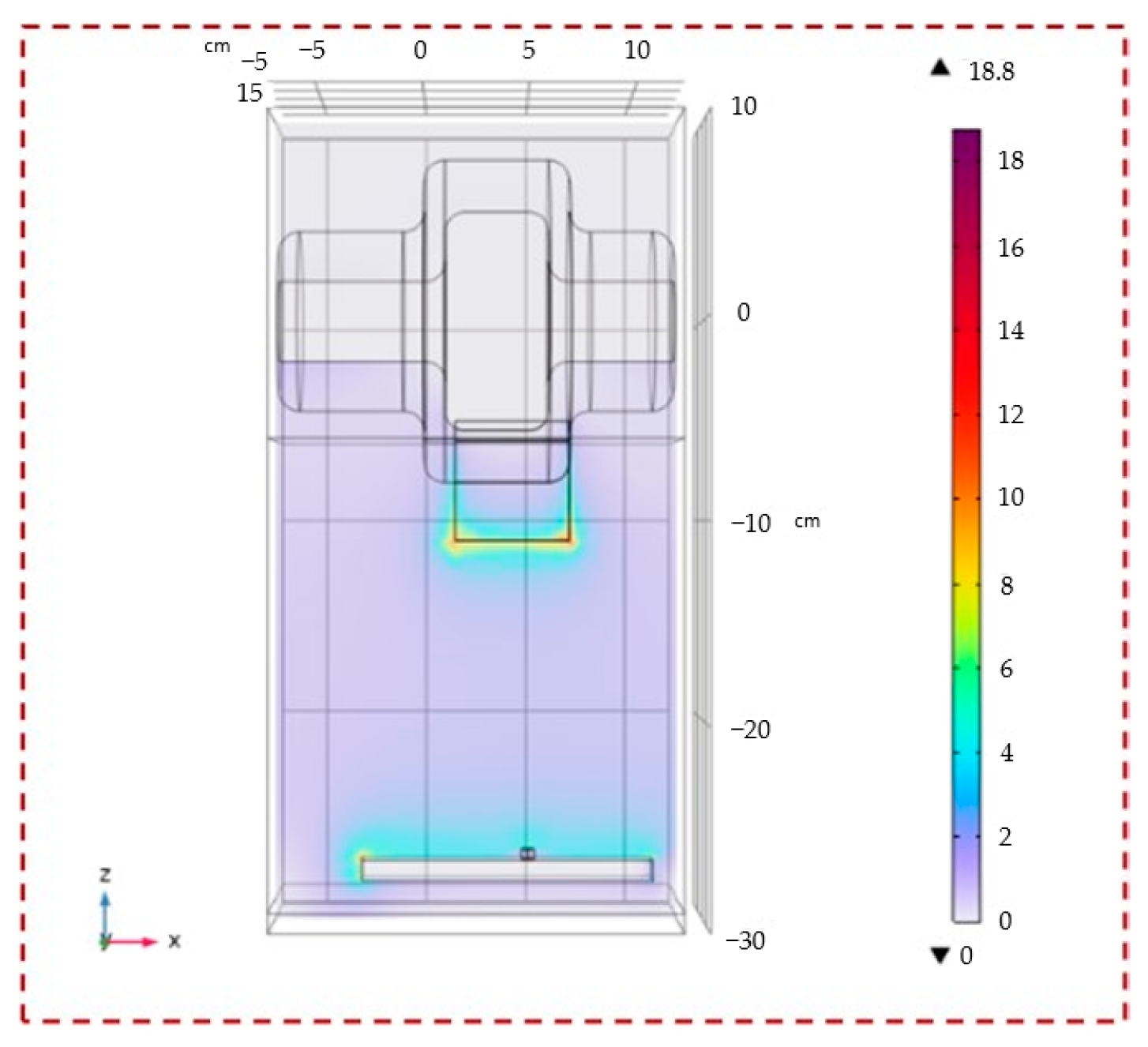

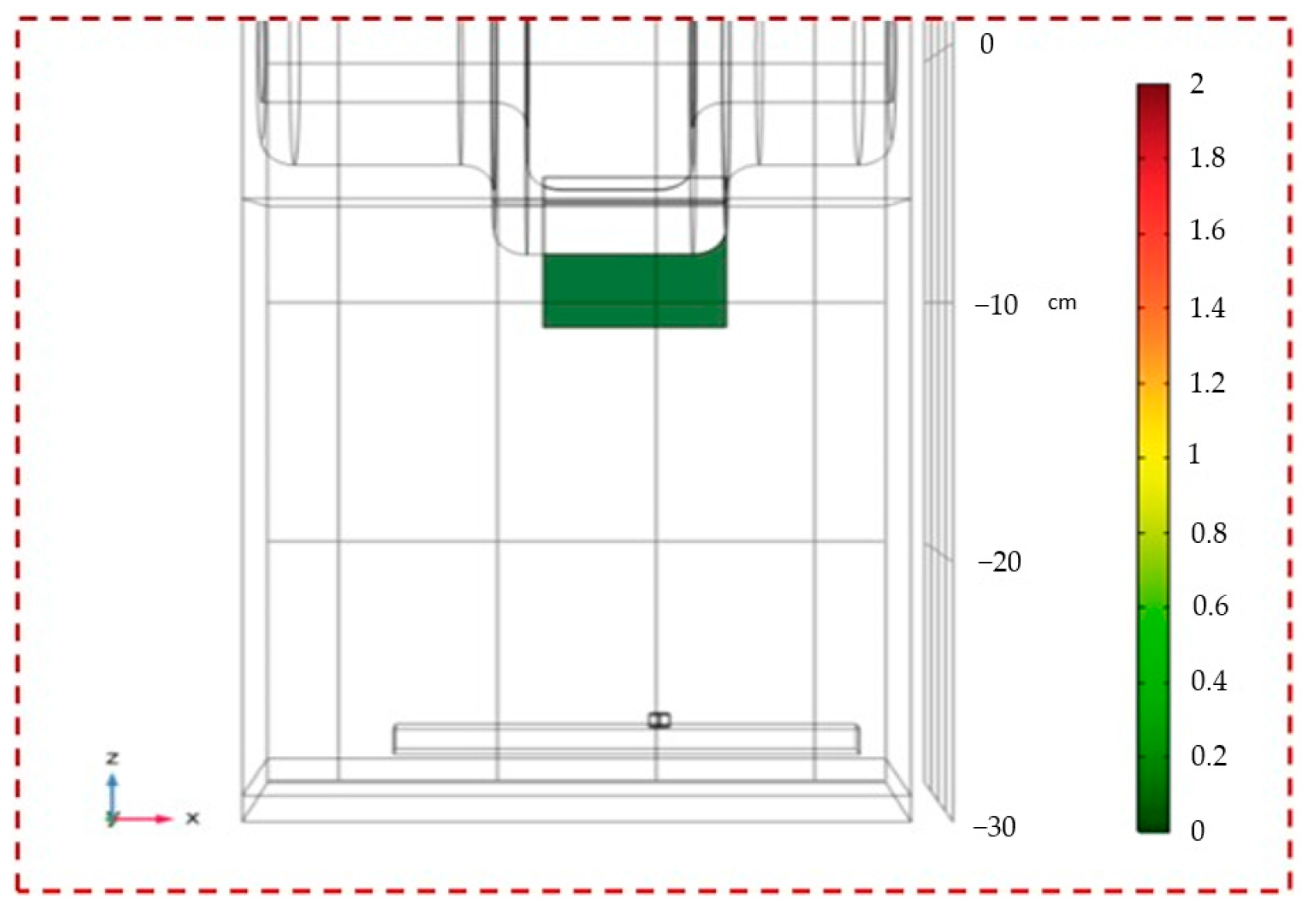

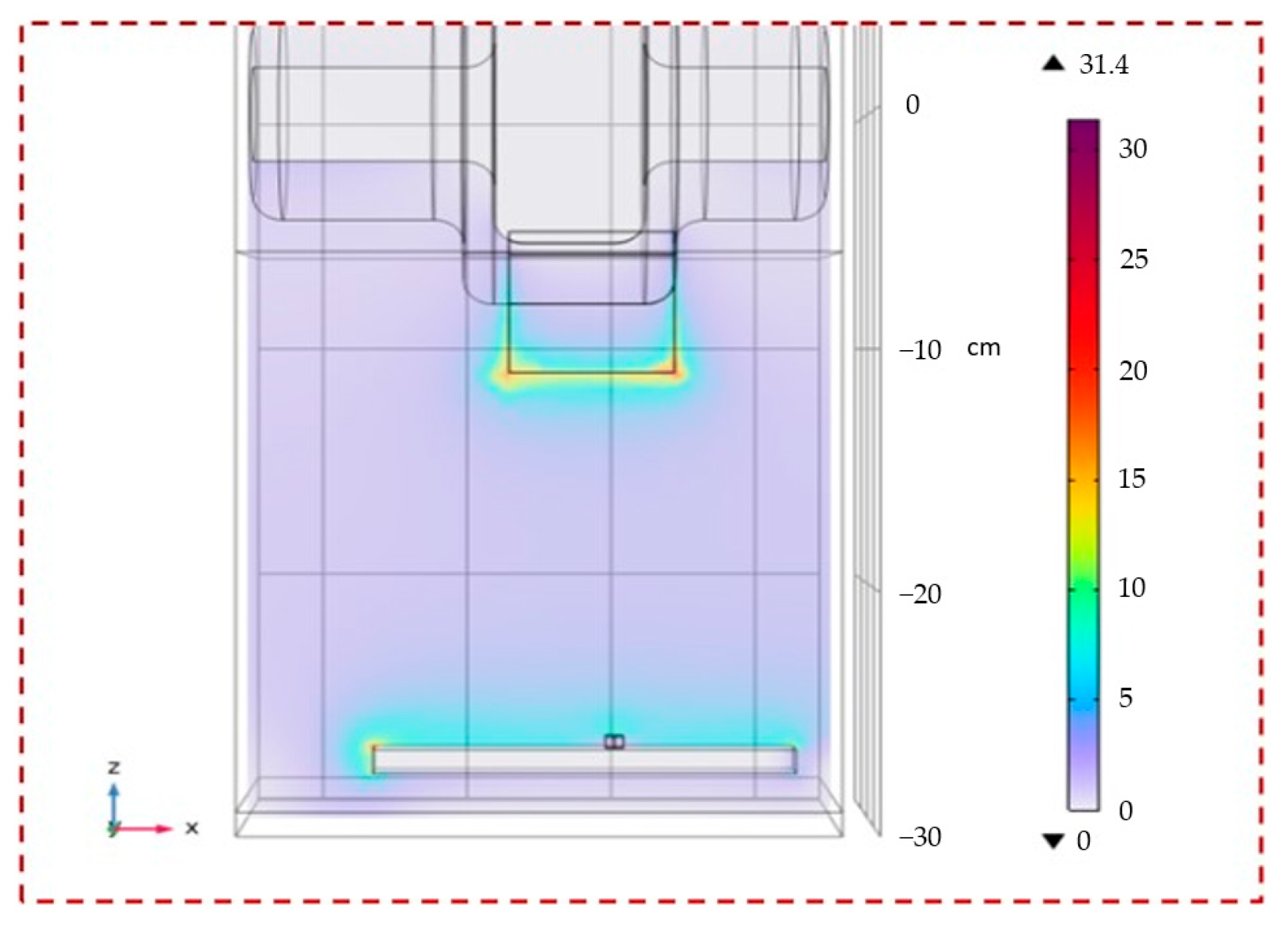

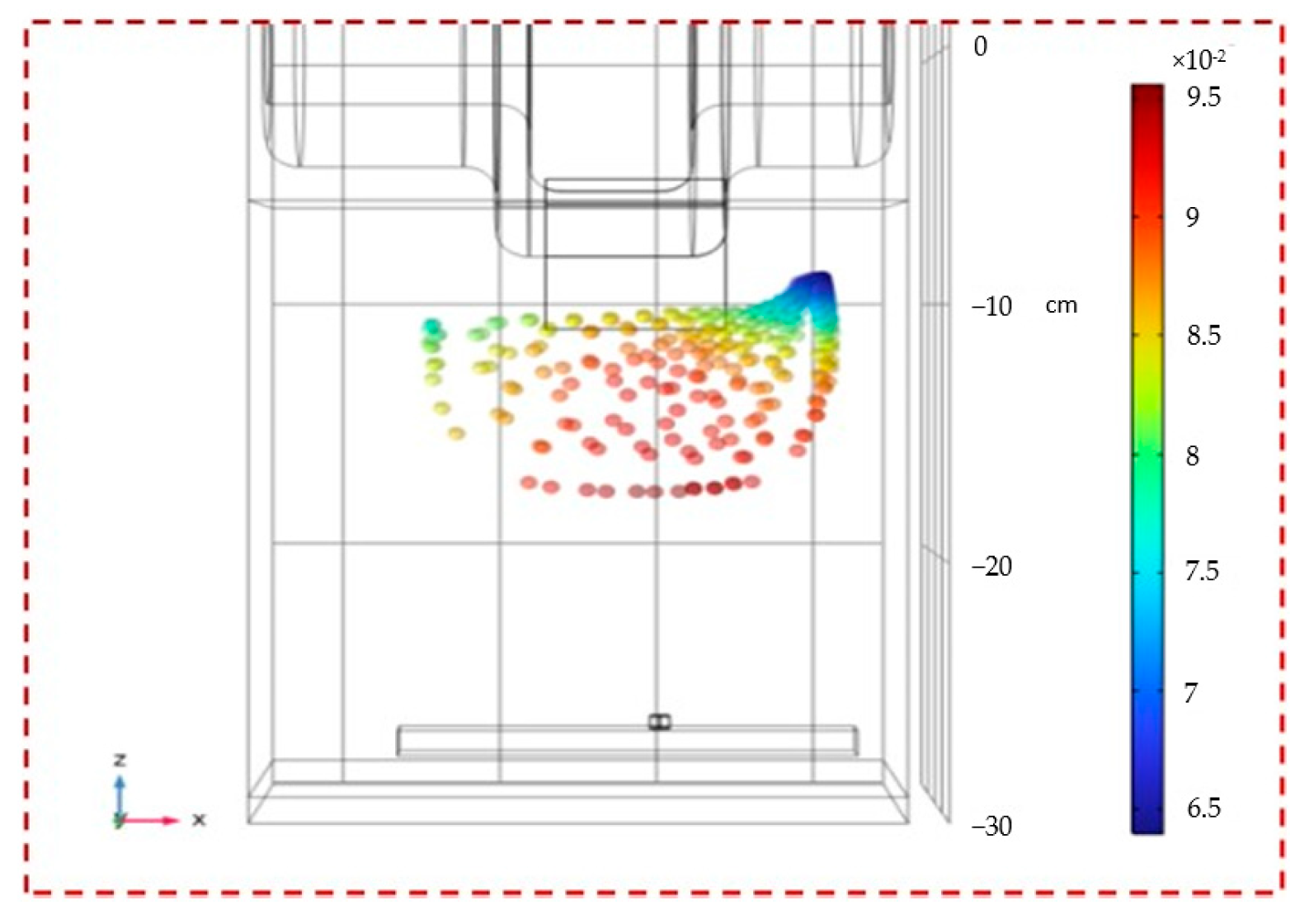

3.1. Electric Field Distribution Characteristics of AIS Under Overvoltage Conditions

- (1)

- For the geometric model of high-voltage enclosures, minor details such as small protrusions or grooves typically do not significantly affect the overall electric field distribution. This includes structures like bolts, through-holes, and flanges. Therefore, these minor geometric features can be simplified or omitted, focusing instead on larger structural elements.

- (2)

- Circular chamfers in support insulators and vacuum circuit breaker insulator skirt sections may be simplified.

- (3)

- Boundary conditions may be appropriately simplified in certain cases. For instance, if regions of the high-voltage enclosure far from boundaries contribute minimally to the electric field, far-field boundary conditions can be set to fixed potential or free space.

- (4)

- Environmental factors like temperature and humidity typically exert a minor influence on the electric field distribution. Under standard environmental conditions, these factors are not considered in detail within the simulation model.

3.2. Electric Field Increase Process Under Overvoltage Conditions

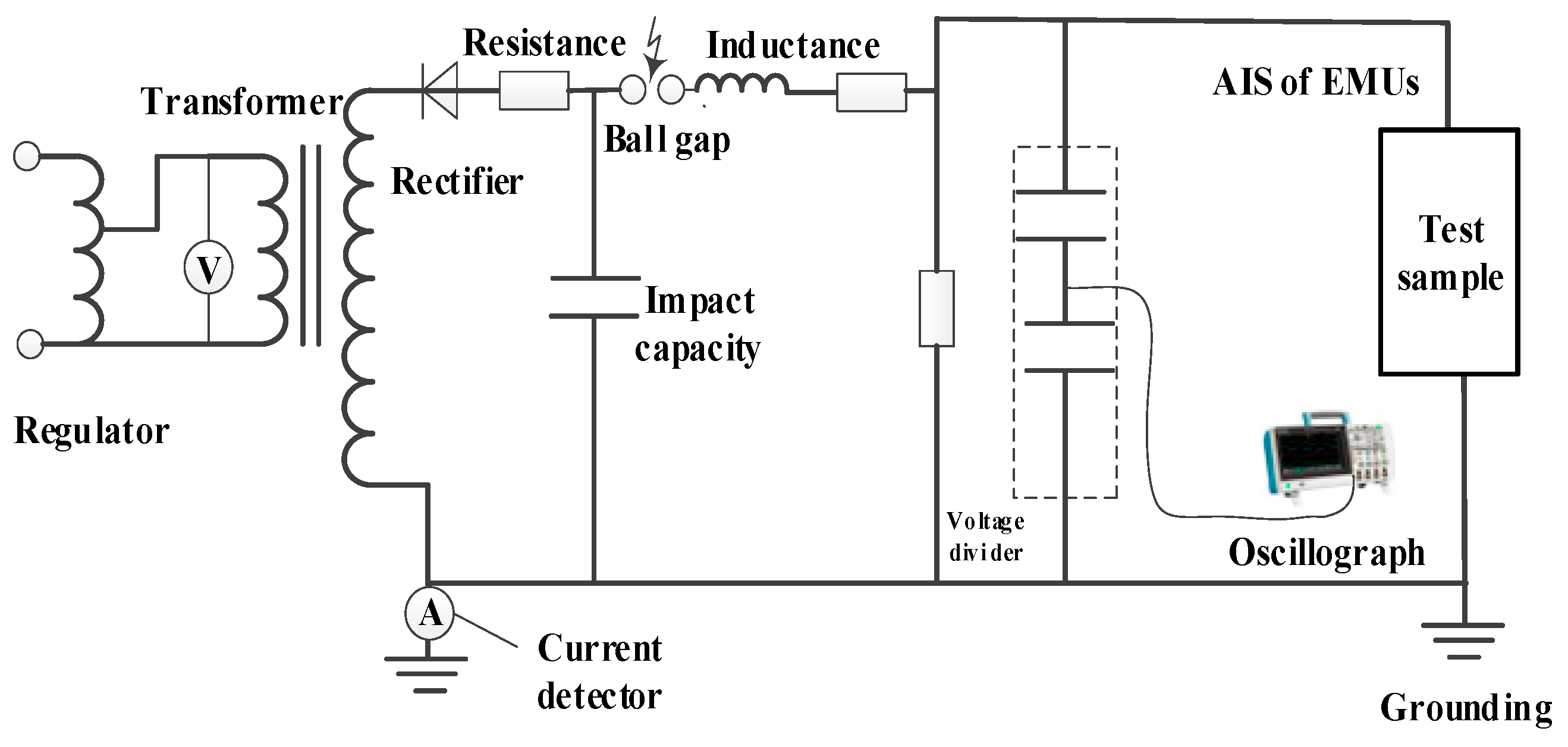

4. Insulation Characteristic of AIS Under AC and Lightning Impulse Voltage

4.1. Analysis of Discharge Initiation Under AC Withstand Voltage

4.2. Test Wiring and Test Procedure

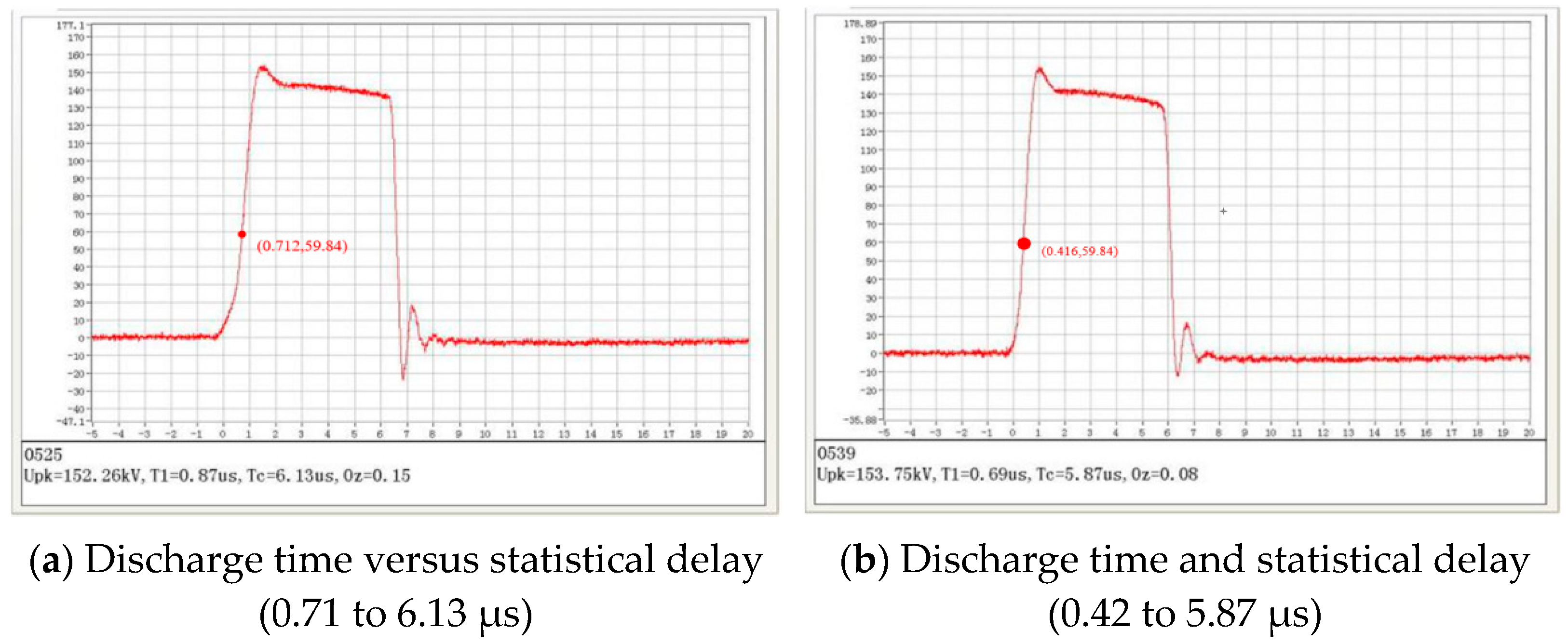

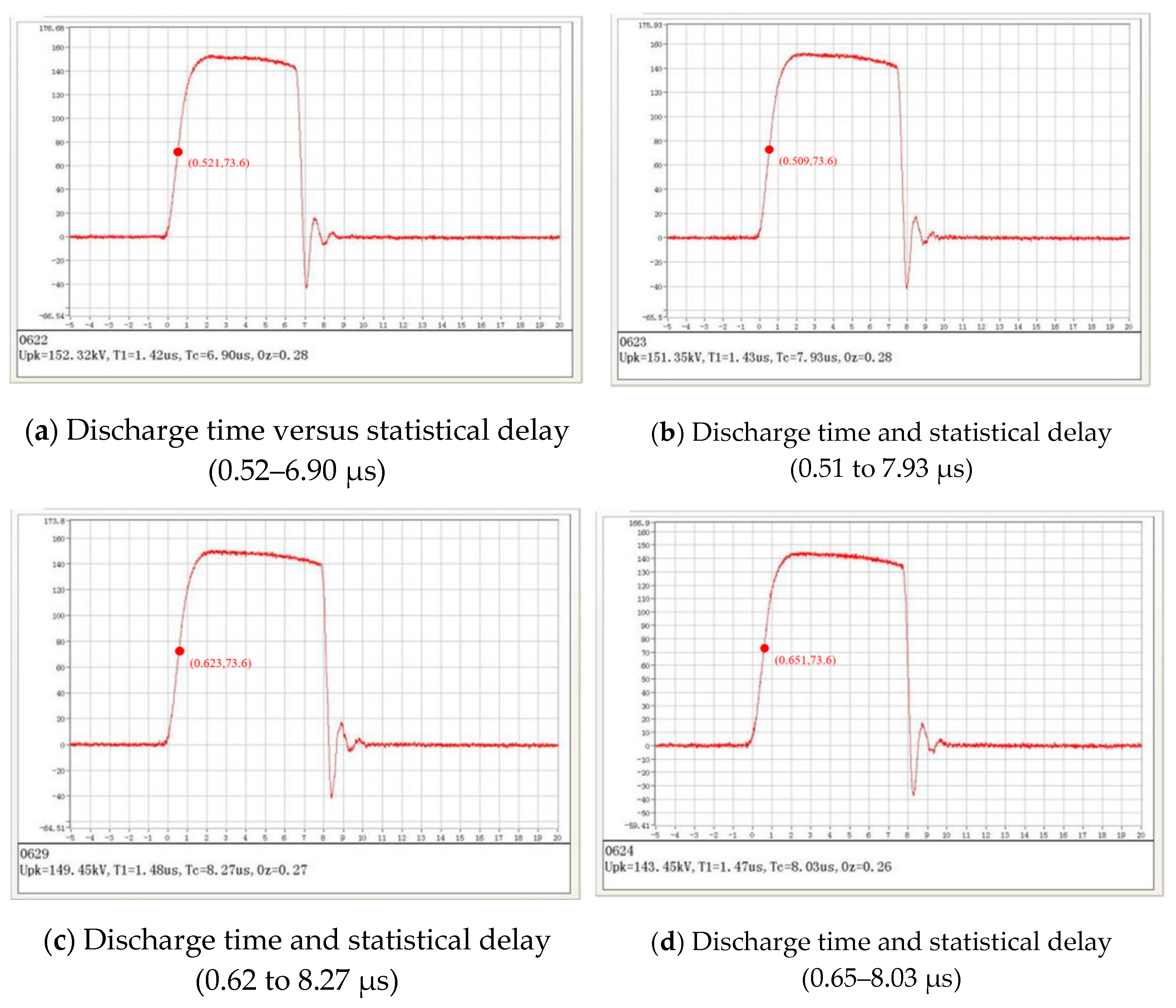

4.3. Analysis of Test Results

5. Conclusions

- (1)

- The local electric field intensity of the small-sized electrodes under overvoltage conditions is significantly higher than that of the air breakdown field, resulting in a shortened statistical time delay and a significantly increased discharge probability. Increasing the radius of curvature of the electrode can effectively reduce the coefficient of electric field non-uniformity, bringing the maximum field strength close to the air breakdown threshold and reducing the probability of discharge. By optimizing the electrode geometry, the local electric field intensity can be reduced and the statistical delay can be prolonged, thereby enhancing the insulation reliability of high-voltage combined electrical apparatus.

- (2)

- For the electrode gap inside the high-voltage box, the coefficient of electric field non-uniformity in the weak insulation area of the high-voltage box is obtained as 11.53, and the calculated theoretical gap breakdown voltage is 59.84 kV. When subjected to lightning impulse voltage, too short a discharge delay causes discharge, which affects the insulation inside the high-voltage box. This result provides a quantitative basis for the insulation design of high-voltage equipment.

- (3)

- The impulse test shows that when the electric field non-uniformity coefficient decreases from 11.53 to 9.40, the average statistical delay extends from 5.94 μs to 7.20 μs, and the discharge probability decreases, verifying the significant effect of the electric field concentration on discharge triggering. At the same time, the installation of insulating separators can better cooperate with the measure of increasing the electrode size. The insulation design criteria proposed in the study provide theoretical support for the miniaturization and high-reliability design of the high-voltage system of EMUs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| EMUs | Electric Multiple Units |

| AIS | Air-Insulated Metal-Enclosed Switchgear |

References

- Wang, W.; Li, S. Research on insulation breakdown of engineering solid dielectrics. Chin. Sci. Bull. 2020, 65, 3461–3474. [Google Scholar] [CrossRef]

- Shi, T.; Wang, H.; Niu, L.; Niu, B.; Han, X.; Zhong, L.; Li, J. Motion and Discharge Characteristics of Mixed Submillimeter Metal Particles and Diverse Insulating Impurities Under AC Voltages. IEEE Trans. Dielectr. Electr. Insul. 2025; Early Access. [Google Scholar] [CrossRef]

- Wang, X.; Long, Y.; Wang, S.; Peng, Z.; Qiu, P.; Zhou, D. Research on the Mechanism of Extra Fast Transient Overvoltage of Gas Insulated Switchgear Equipment Based on the Tripping Event of 500kV Huangping Plant Station. In Proceedings of the 2025 4th International Conference on New Energy System and Power Engineering (NESP), Fuzhou, China, 25–27 April 2025; pp. 539–542. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, X.; Li, F.; Cao, H.; Luo, L.; Sheng, G.; Jiang, X. Research on the Inversion of Hot Spot Temperature in GIS Equipment Considering Multiphysics Simulation Data. In Proceedings of the 2025 5th Power System and Green Energy Conference (PSGEC), Hong Kong, 20–23 August 2025; pp. 108–112. [Google Scholar] [CrossRef]

- Hu, J.; Xu, X.; Che, J.; Zhang, W.; Cheng, C.; He, H. Study on the initiation characteristics of low-pressure positive 1 m air gap impulse flow discharge. Hunan Electr. Power 2023, 43, 70–78. [Google Scholar]

- Deng, Z.; Peng, Z.; Yin, F.; Zhao, Z.; Wu, H. Calculation of electric field distribution and insulation failure analysis of traction transformer bushing. High Volt. Appar. 2016, 52, 78–84. [Google Scholar]

- Liu, X.; Zhao, X.; Ma, Y.; Du, Y.; He, J. Analysis of arc channel characteristics after air gap breakdown. Proc. CSEE 2023, 43, 5302–5311. [Google Scholar]

- Liu, X.; Dong, M.; Deng, H.; Zhao, X.; He, J. Gas motion characteristics in the discharge channel after air gap breakdown. Chin. J. Electr. Eng. Technol. 2021, 36, 2667–2674. [Google Scholar]

- Lu, F.; Zhang, B.; Geng, J.; Wang, P.; Ding, Y.; Gao, S. Ball-plate gap flow discharge characteristics under the influence of burr defects. Insul. Mater. 2022, 55, 67–72. [Google Scholar] [CrossRef]

- Lu, F.; Qin, Y.; Wang, P.; Geng, J.; Ding, Y.; Yao, X. Spatial electric field variation during the development of positive polarity operating impulse voltage current injection. High Volt. Technol. 2019, 45, 2964–2970. [Google Scholar]

- Lu, F.; Zhao, Y.; Wang, P.; Ding, Y.; Qin, Y.; Geng, J.; Xu, J.; Zhu, Y. Influence of burr defects on the impact discharge characteristics of ball-plate gap operation. Insul. Mater. 2018, 51, 82–86. [Google Scholar]

- Shen, J.; Xu, Z.; Liu, Z.; Geng, Y.; Wang, J. Breakdown polarity effect of series double vacuum gap under lightning impulse voltage. Trans. China Electrotech. Soc. 2025, 40, 5589–5600. [Google Scholar]

- Huang, Y.; Chen, W.; He, H.; Cheng, C.; Zhang, W.; Wu, Y.; Che, J. Calculation method of electric field in long-gap positive leading discharge channel. Proc. CSEE 2023, 43, 8977–8987. [Google Scholar]

- Cheng, C.; Chen, W.; He, H.; Huang, Y.; Fu, Z.; Zhao, A.; Hu, D. Study on temperature evolution law of unstable pilot channel for positive polarity long air gap discharge. J. Electr. Eng. China 2024, 44, 6238–6248. [Google Scholar]

- Ma, X.; Bao, Z.; Geng, J.; Zhang, C.; Li, Y.; Ding, Y.; Jiang, L.; Wang, S. Air gap operation impact discharge characteristics of ±800 kV ultra-high voltage valve hall in 2500 m altitude area. Power Capacit. React. Power Compens. 2024, 45, 88–97. [Google Scholar] [CrossRef]

- Vu-Cong, T.; Toigo, C.; Ortiz, G.; Dalstein, M.; Jacquier, F.; Girodet, A. Numerical simulation of partial discharge current pulse: Comparison between SF6, Fluoronitrile—CO2 mixture and Fluoroketone—CO2 mixture. In Proceedings of the 2020 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), East Rutherford, NJ, USA, 18–30 October 2020; pp. 403–406. [Google Scholar] [CrossRef]

- Li, S.; Yu, X.; Wang, H.; Chen, Y.; Yang, D.; Yu, C. Analysis and Experimental Study of an Internal Discharge Fault in a 220kV GIS. In Proceedings of the 2025 4th International Conference on New Energy System and Power Engineering (NESP), Fuzhou, China, 25–27 April 2025; pp. 691–696. [Google Scholar] [CrossRef]

- Qian, B.; Wan, X.; Chen, L.; Zhou, Y.; Chen, C. Analysis of Several Fault Cases and Rectification Measures for GIS Circuit Breaker Switch Operations in Substations. In Proceedings of the 2025 IEEE 8th Information Technology and Mechatronics Engineering Conference (ITOEC), Chongqing, China, 14–16 March 2025; pp. 121–124. [Google Scholar] [CrossRef]

- Bharanidharan, R.; Vijayalakshmi, V.J.; Maheswari, R.V. Simulation and Characterization of Dielectric Behavior of Pure SF6 and N2 for High-Voltage Applications Using FEM. In Proceedings of the 2025 11th International Conference on Electrical Energy Systems (ICEES), Chennai, India, 21–23 August 2025; pp. 313–318. [Google Scholar] [CrossRef]

- Baruah, N.; Bahdad, F.O.; Ranjan, P.; Han, Q.; Chen, L. Breakdown modeling of SF6 and its environmentally friendlier alternatives in quasi uniform fields. IEEE Trans. Dielectr. Electr. Insul. 2025; Early Access. [Google Scholar] [CrossRef]

| Serial Numbers | Material Name | Usage Location | Note |

|---|---|---|---|

| 1 | Silicone rubber | Insulator | Circuit breaker |

| 2 | Aluminum | Grounding arm | |

| 3 | GPO-3 | Insulation board | |

| 4 | Aluminum | Fastening screw |

| Serial Numbers | Device Name | Model | Quantity |

|---|---|---|---|

| 1 | High-voltage equipment box (AIS of EMUs, Beijing, China) | SFE32TP03-461-30000 | 1 |

| 2 | Impulse voltage generator (Wuhan Huagao Equipment New Technology Co., Ltd., Wuhan, China; Beijing CRRC S Railway Technology Co., Ltd., Beijing, China) | CDY-L400 kV/30 kJ | 1 |

| Temperature | Atmospheric Pressure | Discharge Gap | Atmospheric Calibration Positive Factor | Experiment Voltage Value |

|---|---|---|---|---|

| 17.5 °C | 1011 hPa | 230 mm | 0.992 | 149 kV |

| Serial Numbers | Theoretical Breakdown Moment/μs | Discharge Time/μs | Statistical Delay/μs |

|---|---|---|---|

| 1 | 0.712 | 6.13 | 5.418 |

| 2 | 0.416 | 5.87 | 5.454 |

| 3 | 0.396 | 6.78 | 6.384 |

| 4 | 0.784 | 8.22 | 7.436 |

| 5 | 0.910 | 5.95 | 5.040 |

| Serial Number | Theoretical Breakdown Time/μs | Discharge Time/μs | Statistical Time Delay/μs |

|---|---|---|---|

| 1 | 0.521 | 6.90 | 6.379 |

| 2 | 0.509 | 7.93 | 7.421 |

| 3 | 0.623 | 8.27 | 7.647 |

| 4 | 0.651 | 8.03 | 7.379 |

| Discharge Situation | |||||

|---|---|---|---|---|---|

| Number of tests | 1 | 2 | 3 | 4 | 5 |

| Ο | Ο | Ο | Ο | Ο | |

| 6 | 7 | 8 | 9 | 10 | |

| Ο | Ο | Ο | Ο | Ο | |

| 11 | 12 | 13 | 14 | 15 | |

| Ο | Ο | Ο | Ο | Ο | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Zhang, K.; Liu, Y.; Yang, S.; Tan, J. Study on Breakdown Characteristics of On-Train High-Voltage Combined Electrical Apparatus Under Lightning Transient Conditions. Appl. Sci. 2025, 15, 12238. https://doi.org/10.3390/app152212238

Sun J, Zhang K, Liu Y, Yang S, Tan J. Study on Breakdown Characteristics of On-Train High-Voltage Combined Electrical Apparatus Under Lightning Transient Conditions. Applied Sciences. 2025; 15(22):12238. https://doi.org/10.3390/app152212238

Chicago/Turabian StyleSun, Jixing, Kun Zhang, Yide Liu, Sile Yang, and Jiuding Tan. 2025. "Study on Breakdown Characteristics of On-Train High-Voltage Combined Electrical Apparatus Under Lightning Transient Conditions" Applied Sciences 15, no. 22: 12238. https://doi.org/10.3390/app152212238

APA StyleSun, J., Zhang, K., Liu, Y., Yang, S., & Tan, J. (2025). Study on Breakdown Characteristics of On-Train High-Voltage Combined Electrical Apparatus Under Lightning Transient Conditions. Applied Sciences, 15(22), 12238. https://doi.org/10.3390/app152212238