Experimental Research on the Strength Characteristics of Artificial Freeze–Thaw Cement-Improved Soft Clay

Abstract

1. Introduction

2. Materials and Methods

2.1. Experiment Materials

2.2. Experimental Methods

2.3. Experimental Results

2.3.1. Influence of Cement Dosage

2.3.2. Influence of Moisture Content

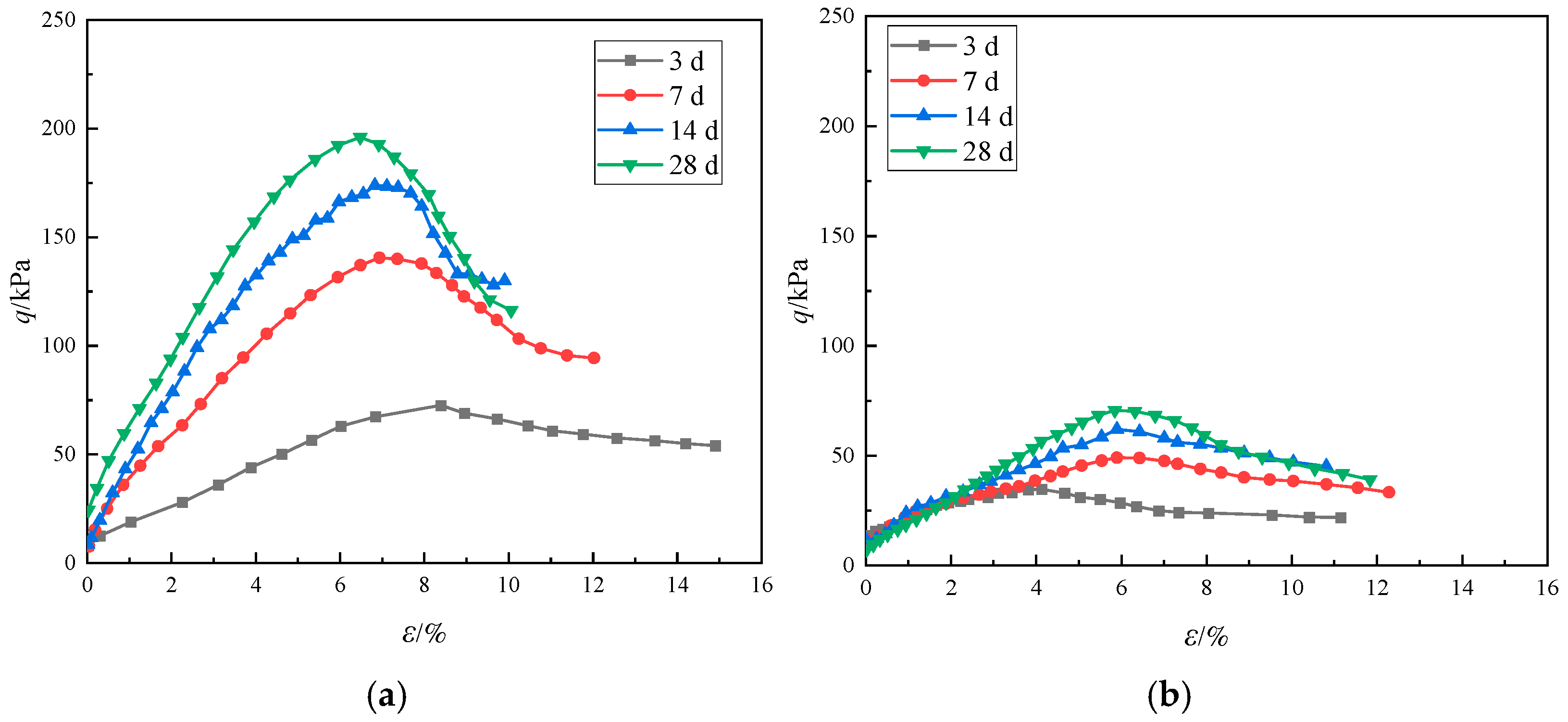

2.3.3. Influence of Aging

3. Analysis of Strength Variation Patterns

3.1. Factors Influencing the Compressive Strength

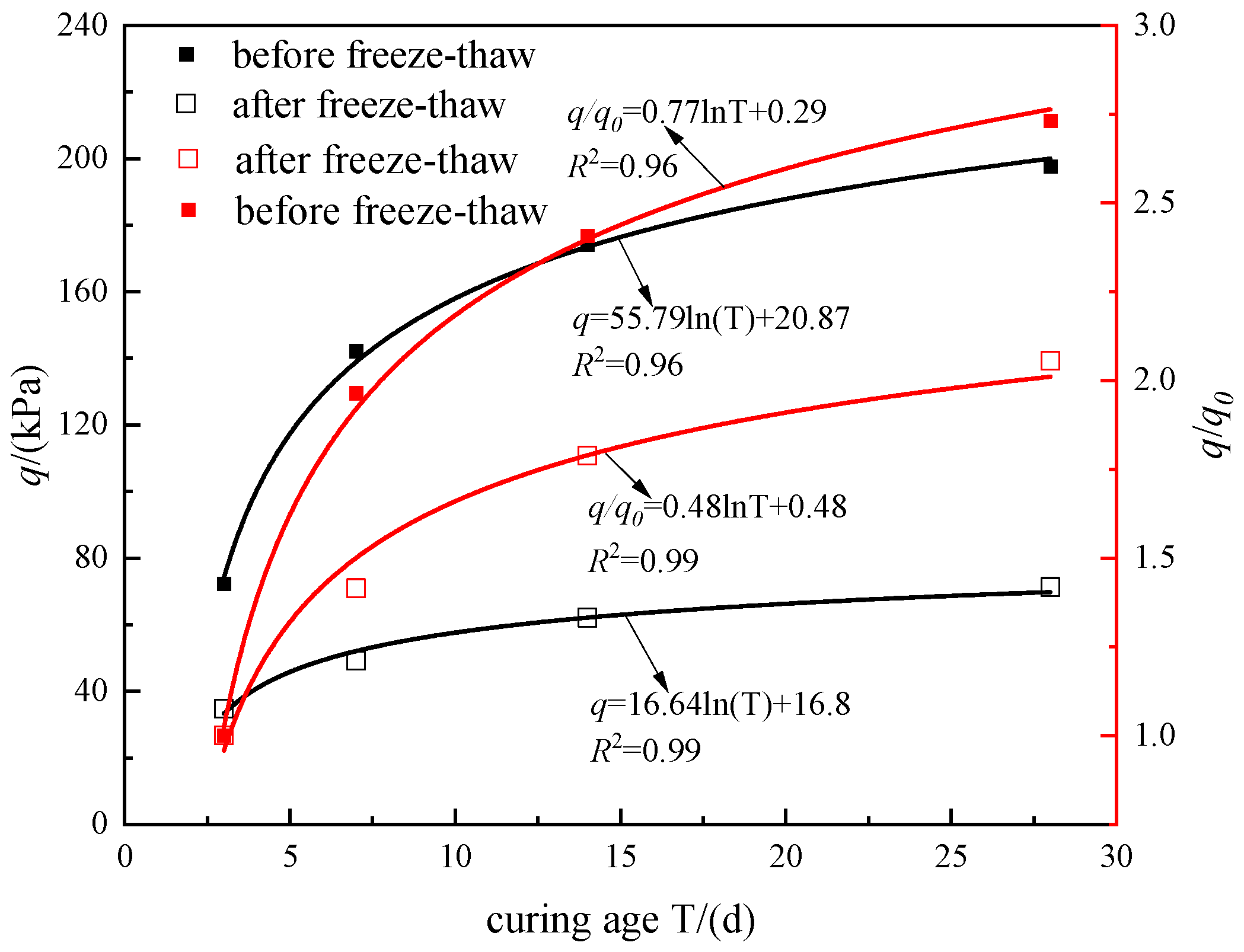

3.2. Variations in the Growth Rate of Strength

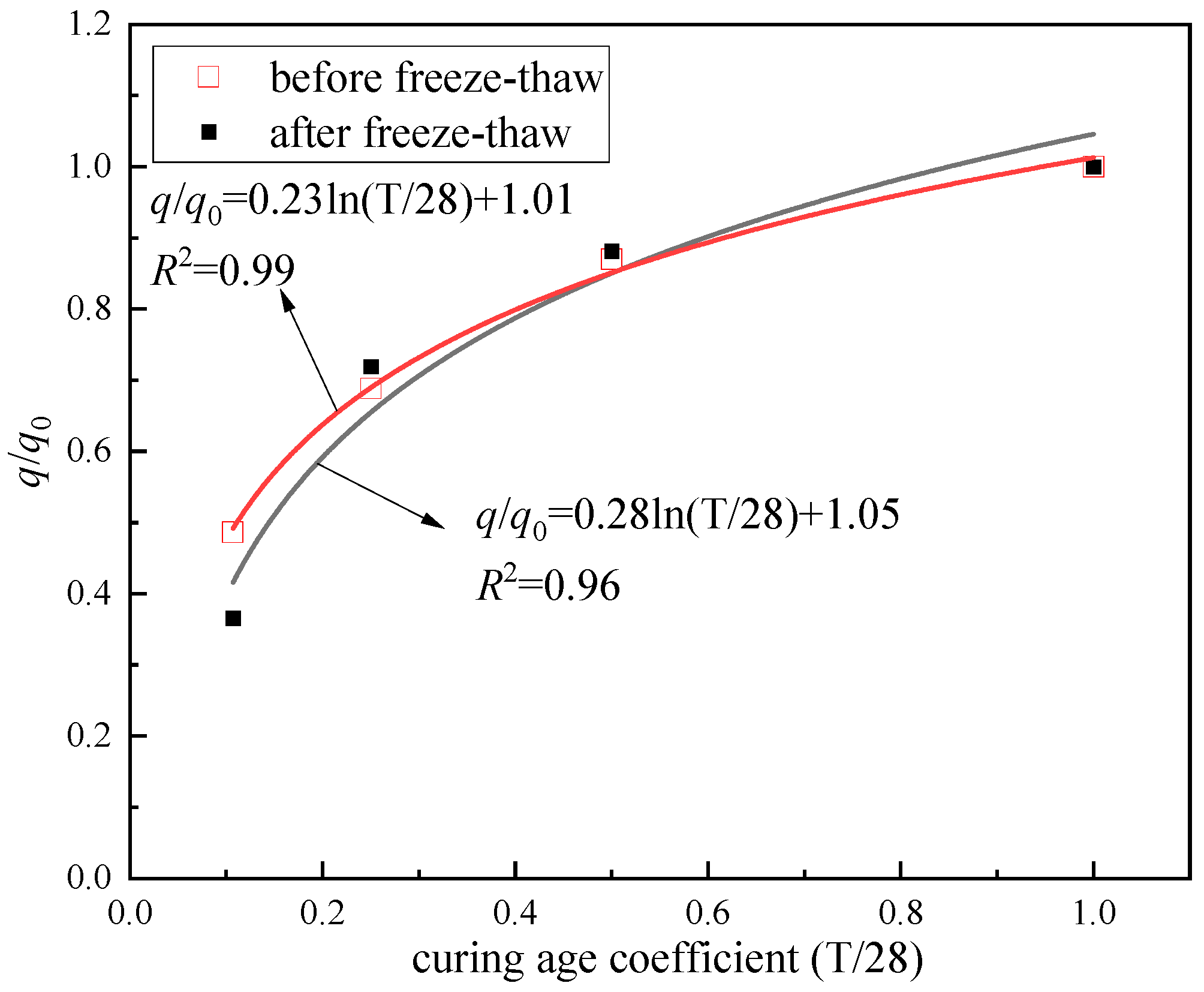

4. Strength Prediction Model

5. Conclusions

- Increasing the cement dosage promoted a shift in the failure mode of the cement soil from plastic to brittle; conversely, freeze–thaw action induced the reverse effect, weakening the brittleness of the material while enhancing its ductility, leading to strength deterioration.

- The strength of the improved soil increased with the increasing dosage of cement, but the strength was always lower after freeze–thaw action than before freeze–thaw action. The strength decreased by 41.5% at a dosage of 9%. The strength decreased with increasing moisture content. The strength of the sample with a moisture content of 32% was 63.5% lower than that of the sample with a moisture content of 24% before freeze–thaw action, and the reduction reached 65.2% after freeze–thaw action. The strength increased with increasing curing age, but the freeze–thaw action slowed its growth rate. The increase in strength during 28 days of curing was 2.73 times before freeze–thaw action, but it decreased to 2.05 times after freeze–thaw action. The strength was always lower after freeze–thaw action than before freeze–thaw action. A high cement dosage decreased the strength difference, a high moisture content exacerbated the decay after freeze–thaw action, and freeze–thaw action slowed the rate of strength growth with age.

- The strength growth rate η before and after freeze–thaw action increased with increasing cement dosage, with slightly higher growth rates after freeze–thaw action for the higher dosages. The growth rate decreased as a power function as the moisture content increased. As the age increased, the rate of strength growth decreased, and the strength growth coefficient after freeze–thaw action was only 29.8% of the value of 55.79 before freeze–thaw action. Freezing–thawing prevented strength growth, particularly in the early ages and at high moisture contents, but it may have accelerated the strength growth at high cement dosages.

- Based on the above-mentioned influencing factors, a strength prediction model for cement-improved soft clay that undergoes freeze–thaw cycles was developed.

6. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, L.; Qiao, Y.; Chai, J.; Ding, W. Effects of Confined Aquifer on Water-Sand Gushing Disasters in Soft Soil. J. Rock Mech. Geotech. Eng. 2025, in press. [Google Scholar] [CrossRef]

- Peng, S.; Huang, W.; Luo, G.; Cao, H.; Pan, H.; Mo, N. Failure Mechanisms of Ground Collapse Caused by Shield Tunnelling in Water-Rich Composite Sandy Stratum: A Case Study. Eng. Fail. Anal. 2023, 146, 107100. [Google Scholar] [CrossRef]

- Go, G.-H.; Le, V.D. Optimization Study on Artificial Ground Freezing in Elliptical Tunnel Construction: A Comprehensive Analysis of Groundwater Flow and Thermodynamic Parameters of Soil. Tunn. Undergr. Space Technol. 2025, 163, 106774. [Google Scholar] [CrossRef]

- Huang, J.; Yan, G.; Yang, L. Analysis of Freezing Temperature Field of Cement-Improved Soil in Connecting Channels. J. Civ. Eng. 2021, 54, 108–116. (In Chinese) [Google Scholar]

- Xu, X.; Yao, Z.; Chang, Y. Study on a Fractional-Order Constitutive Model for Frozen Cement-Modified Peat Soil. KSCE J. Civ. Eng. 2026, 30, 100331. [Google Scholar] [CrossRef]

- De Jesús Arrieta Baldovino, J.; Dos Santos Izzo, R.L.; Rose, J.L. Effects of Freeze–Thaw Cycles and Porosity/Cement Index on Durability, Strength and Capillary Rise of a Stabilized Silty Soil Under Optimal Compaction Conditions. Geotech. Geol. Eng. 2021, 39, 481–498. [Google Scholar] [CrossRef]

- Yang, X.; Hu, Z.; Li, H.; Wang, Y.; Zhang, Y.; She, H.; Wang, X. Effect of Freeze-Thaw Cycles on Mechanical Properties and Microstructure of Artificially Prepared Site Soil. Constr. Build. Mater. 2025, 485, 141878. [Google Scholar] [CrossRef]

- Yaqin, Z.; Ping, Y.; Ting, Z.; Linliang, H. Experimental Evaluation on Dynamic Strength Characteristics of Saline Clay Subjected to Freeze-Thaw. Appl. Ocean Res. 2025, 160, 104633. [Google Scholar] [CrossRef]

- Consoli, N.; DallaRosa, A. Porosity-Cement Ratio Controlling Strength of Artificially Cemented Clays. J. Mater. Civ. Eng. 2021, 23, 1249–1254. [Google Scholar] [CrossRef]

- Consoli, N.; Rosa, D.; Cruz, R. Water Content, Porosity and Cement Content as Parameters Controlling Strength of Artificially Cemented Silty Soil. Eng. Geol. 2011, 122, 328–333. [Google Scholar] [CrossRef]

- Consoli, N. Voids/Cement Ratio Controlling Tensile Strength of Cement-Treated Soils. J. Geotech. Geoenviron. Eng. 2011, 137, 1126–1131. [Google Scholar] [CrossRef]

- Wang, F.; Li, K.; Liu, Y. Optimal Water-Cement Ratio of Cement-Stabilized Soil. Constr. Build. Mater. 2022, 320, 126211. [Google Scholar] [CrossRef]

- Li, X.; Yang, Y.; Zhang, H.; Yi, Y. Mechanical Properties and Failure Mechanism of Cemented Red Clay under Chemical Erosion Environment. Int. J. Environ. Pollut. 2016, 59, 156–168. [Google Scholar] [CrossRef]

- Shi, X.; Yang, P.; Li, L.; Wu, F. Investigating Mechanical Properties of Cemented Soil under Static and Dynamic Loading after a Freeze-Thaw Cycle. KSCE J. Civ. Eng. 2023, 27, 978–991. [Google Scholar] [CrossRef]

- Yao, K.; Pan, Y.; Jia, L.; Yi, J.T.; Hu, J.; Wu, C. Strength Evaluation of Marine Clay Stabilized by Cementitious Binder. Mar. Georesources Geotechnol. 2020, 38, 730–743. [Google Scholar] [CrossRef]

- Yao, K.; Xiao, H.; Chen, D.-H.; Liu, Y. A Direct Assessment for the Stiffness Development of Artificially Cemented Clay. Géotechnique 2019, 69, 741–747. [Google Scholar] [CrossRef]

- Zhang, R.J.; Santoso, A.M.; Tan, T.S.; Phoon, K.K. Strength of High Water-Content Marine Clay Stabilized by Low Amount of Cement. J. Geotech. Geoenviron. Eng. 2013, 139, 2170–2181. [Google Scholar] [CrossRef]

- Horpibulsk, S.; Rachan, R.; Suddeepong, A.; Chinkulkijniwat, A. Strength Development in Cement Admixed Bangkok Clay: Laboratory and Field Investigations. Soils Found. 2011, 51, 239–251. [Google Scholar] [CrossRef]

- Lorenzo, G.A.; Bergado, D.T. Fundamental Characteristics of Cement-Admixed Clay in Deep Mixing. J. Mater. Civ. Eng. 2006, 18, 161–174. [Google Scholar] [CrossRef]

- Cao, Z.; Zhang, D. Study on characterization parameters of unconfined compressive strength of cement soil. Chin. J. Rock Mech. Eng. 2015, 34, 3446–3454. (In Chinese) [Google Scholar]

- Sahlabadi, S.H.; Bayat, M.; Mousivand, M.; Saadat, M. Freeze-Thaw Durability of Cement-Stabilized Soil Reinforced with Polypropylene/Basalt Fibers. J. Mater. Civ. Eng. 2021, 33, 04021232. [Google Scholar] [CrossRef]

- Eskişar, T.; Altun, S.; Kalıpcılar, İ. Assessment of Strength Development and Freeze–Thaw Performance of Cement Treated Clays at Different Water Contents. Cold Reg. Sci. Technol. 2015, 111, 50–59. [Google Scholar] [CrossRef]

- Ding, M.; Zhang, F.; Ling, X.; Lin, B. Effects of Freeze-Thaw Cycles on Mechanical Properties of Polypropylene Fiber and Cement Stabilized Clay. Cold Reg. Sci. Technol. 2018, 154, 155–165. [Google Scholar] [CrossRef]

- Lu, J.; Tan, L.; Yang, H.; Wan, X.; Wang, Y.; Yan, Z. Experimental Study on the Hydro-Thermal-Deformation Characteristics of Cement-Stabilized Soil Exposed to Freeze-Thaw Cycles. Front. Earth Sci. 2023, 10, 1041249. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, S.; Zhang, Y.; Li, Z.; Xu, L. Freeze-Thaw Performance of a Cement-Treated Expansive Soil. Cold Reg. Sci. Technol. 2020, 170, 102926. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Standard for Soil Test Method. National Standards Compilation Group of People’s Republic of China: Beijing, China, 2019. (In Chinese)

- GB/T 50145-2007; Standard for Engineering Classification of Soil. National Standards Compilation Group of People’s Republic of China: Beijing, China, 2007. (In Chinese)

- JGJ/T 233-2011; Specification for Mix Proportion Design of Cement Soil. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2011. (In Chinese)

- Ma, Z.; Xing, Z.; Zhao, Y.; Hu, Y. Dynamic Strength Characteristics of Cement-Improved Silty Clay under the Effect of Freeze-Thaw Cycles. Sustainability 2023, 15, 3333. [Google Scholar] [CrossRef]

- Ding, F.; Song, L.; Yue, F. Study on Mechanical Properties of Cement-Improved Frozen Soil under Uniaxial Compression Based on Discrete Element Method. Processes 2022, 10, 324. [Google Scholar] [CrossRef]

- Peethamparan, S.; Olek, J.; Diamond, S. Mechanism of Stabilization of Na-Montmorillonite Clay with Cement Kiln Dust. Cem. Concr. Res. 2009, 39, 580–589. [Google Scholar] [CrossRef]

- Lemaire, K.; Deneele, D.; Bonnet, S.; Legret, M. Effects of Lime and Cement Treatment on the Physicochemical, Microstructural and Mechanical Characteristics of a Plastic Silt. Eng. Geol. 2013, 166, 255–261. [Google Scholar] [CrossRef]

- Saadeldin, R.; Siddiqua, S. Geotechnical Characterization of a Clay–Cement Mix. Bull. Eng. Geol. Environ. 2013, 72, 601–608. [Google Scholar] [CrossRef]

| Natural Moisture Content (%) | Specific Gravity | Maximum Dry Density (g/cm3) | Liquid Limit (%) | Plastic Limit (%) | Permeability Coefficient (cm/s) |

|---|---|---|---|---|---|

| 27.73 | 2.69 | 1.69 | 23.8 | 44.7 | 2.13 × 10−7 |

| Condition | R2 | Adj. R2 | F-Value | p-Value | Reduced Chi-Sqr |

|---|---|---|---|---|---|

| before freeze–thaw | 0.9575 | 0.9363 | 249.75 | 0.00398 | 0.00484 |

| after freeze–thaw | 0.9963 | 0.9945 | 4463.29 | <0.001 | 2.76 × 10−4 |

| Condition | Parameter | Value | Std Error | t-Value | p-Value |

|---|---|---|---|---|---|

| before freeze–thaw | A | 0.28219 | 0.04203 | 6.71 | 0.0215 |

| B | 1.0459 | 0.05713 | 18.31 | 0.0030 | |

| after freeze–thaw | A | 0.23326 | 0.01004 | 23.23 | 0.0019 |

| B | 1.01273 | 0.01365 | 74.19 | <0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, F.; Wang, S.; Tian, C.; Lv, L.; Hu, Y.; Wang, T. Experimental Research on the Strength Characteristics of Artificial Freeze–Thaw Cement-Improved Soft Clay. Appl. Sci. 2025, 15, 12233. https://doi.org/10.3390/app152212233

Liu F, Wang S, Tian C, Lv L, Hu Y, Wang T. Experimental Research on the Strength Characteristics of Artificial Freeze–Thaw Cement-Improved Soft Clay. Applied Sciences. 2025; 15(22):12233. https://doi.org/10.3390/app152212233

Chicago/Turabian StyleLiu, Fangling, Shengfu Wang, Chengbao Tian, Liang Lv, Yanxiang Hu, and Tianyuan Wang. 2025. "Experimental Research on the Strength Characteristics of Artificial Freeze–Thaw Cement-Improved Soft Clay" Applied Sciences 15, no. 22: 12233. https://doi.org/10.3390/app152212233

APA StyleLiu, F., Wang, S., Tian, C., Lv, L., Hu, Y., & Wang, T. (2025). Experimental Research on the Strength Characteristics of Artificial Freeze–Thaw Cement-Improved Soft Clay. Applied Sciences, 15(22), 12233. https://doi.org/10.3390/app152212233