Study and Application of a Pilot-Tunnel-First Method for Rapid Excavation of Large-Span Soft Rock Tunnels

Abstract

1. Introduction

2. Engineering Overview

2.1. Geological Conditions of the Engineering

2.2. Tunnel Cross-Section Design

- (1)

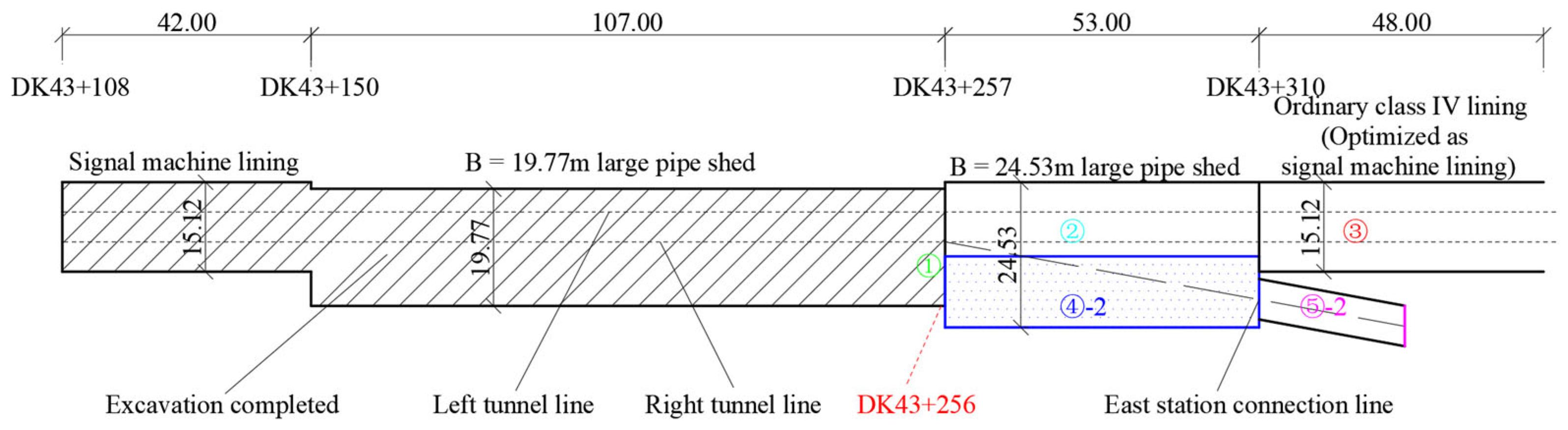

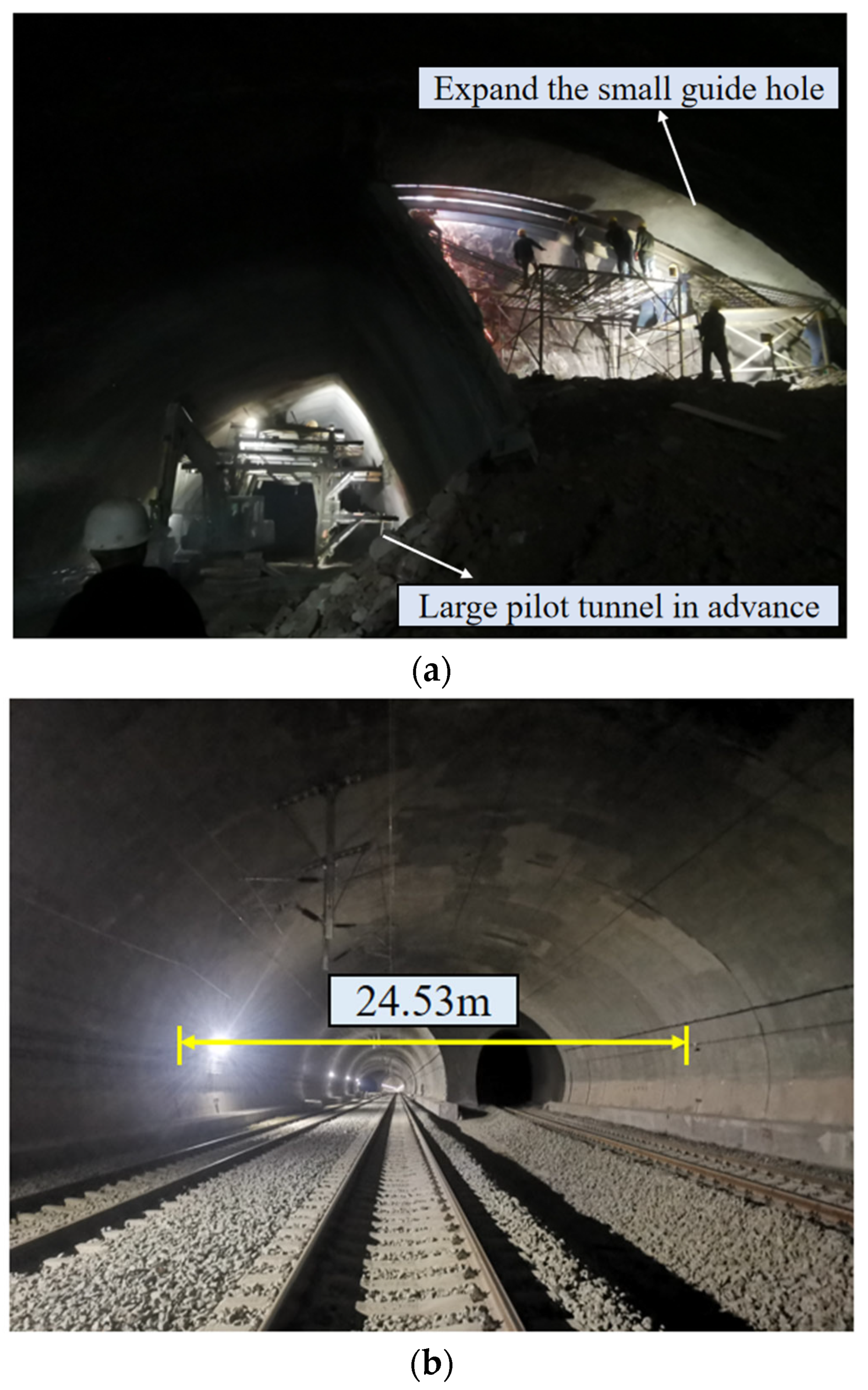

- The section of the tunnel from DK43 + 150 to DK43 + 310 is a large-span segment with three-track divergence on the right side of the right connecting line of a large city railway station in southwest China. The entire large-span segment is 160 m long. At DK43 + 150, the left side remains unchanged while the right side makes a direct turn; the tunnel cross-section abruptly changes from 15.12 m × 13.61 m to 19.77 m × 14.33 m. At DK43 + 257, the tunnel cross-section again abruptly changes to 24.53 m × 16.2 m with a direct right turn. The plan layout of this large-span segment is shown in Figure 1.

- (2)

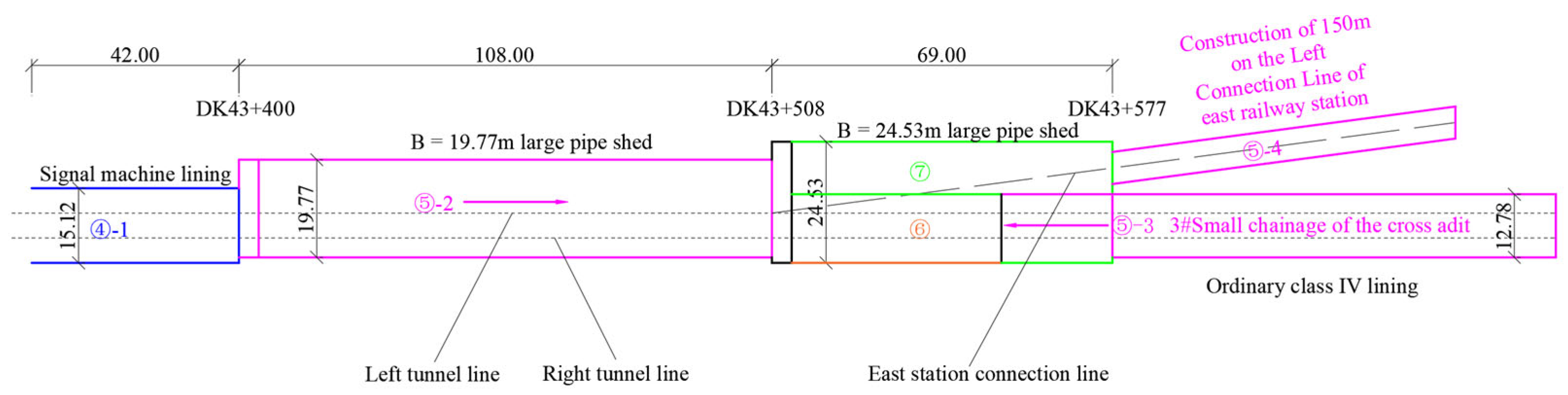

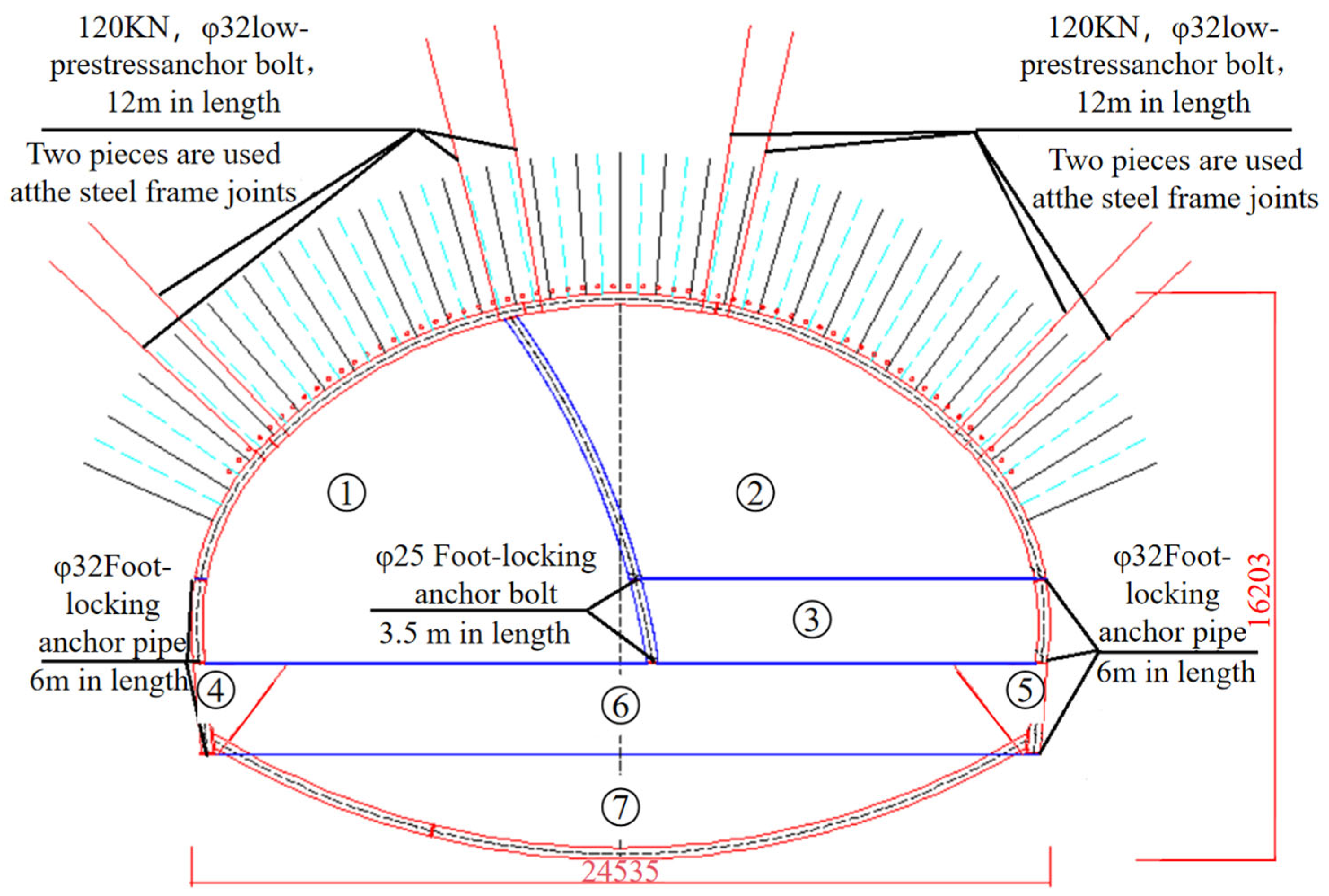

- The section from DK43 + 400 to DK43 + 577 is the three-line diverging large-span section of the station’s left connecting line. The total length of the large-span section is 184 m. At DK43 + 400, the right side remains unchanged while the left side makes a direct turn; the tunnel cross-section abruptly changes from 15.12 m × 13.61 m to 19.77 m × 14.33 m. At DK43 + 508, the tunnel cross-section abruptly changes to 24.53 m × 16.2 m with a direct left turn. The plan layout of this large-span section is shown in Figure 2. The comparative relationships of various cross-sections are shown in Figure 3.

3. Optimized Design of Excavation Cross-Section

3.1. Reasons for Section Optimization

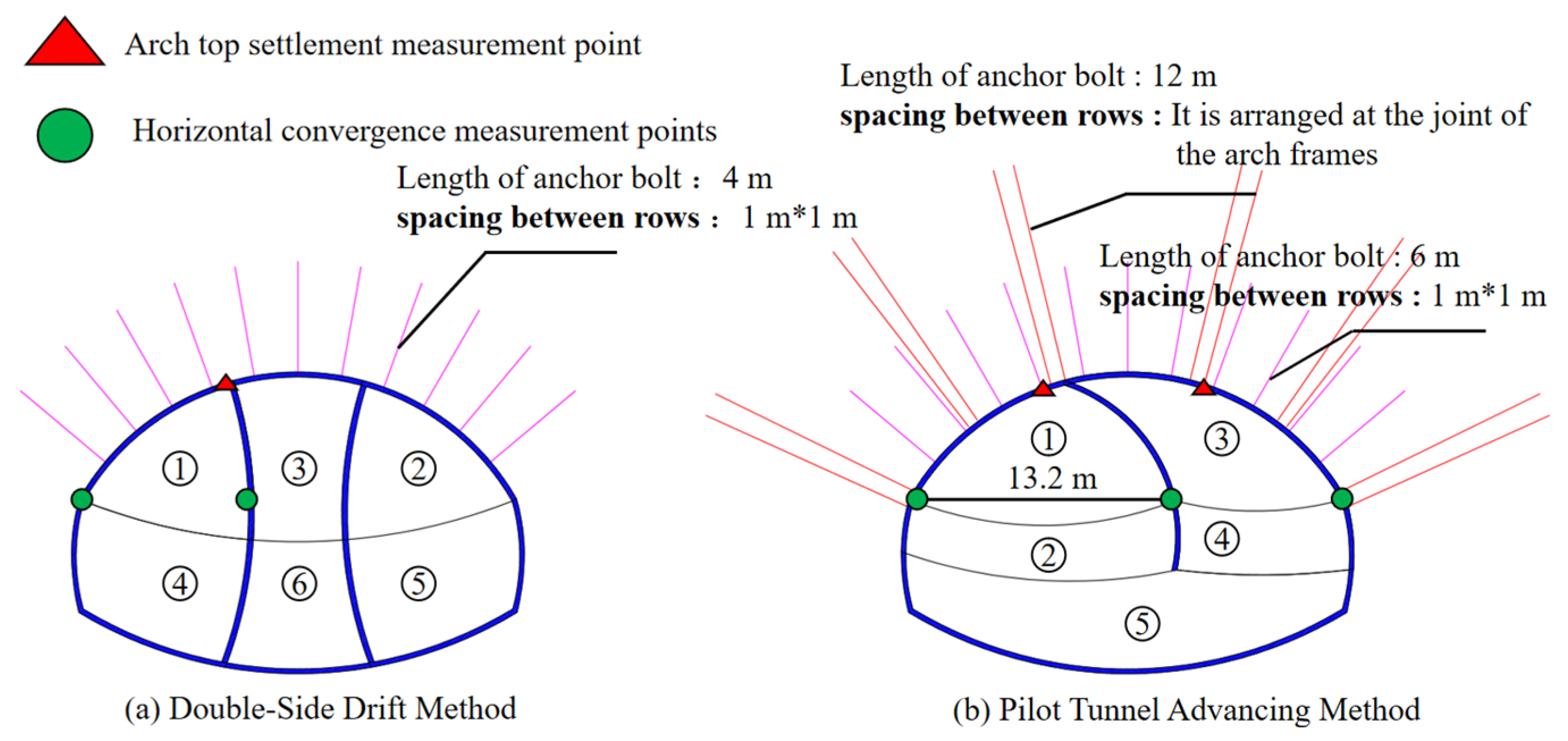

3.2. Construction Plan

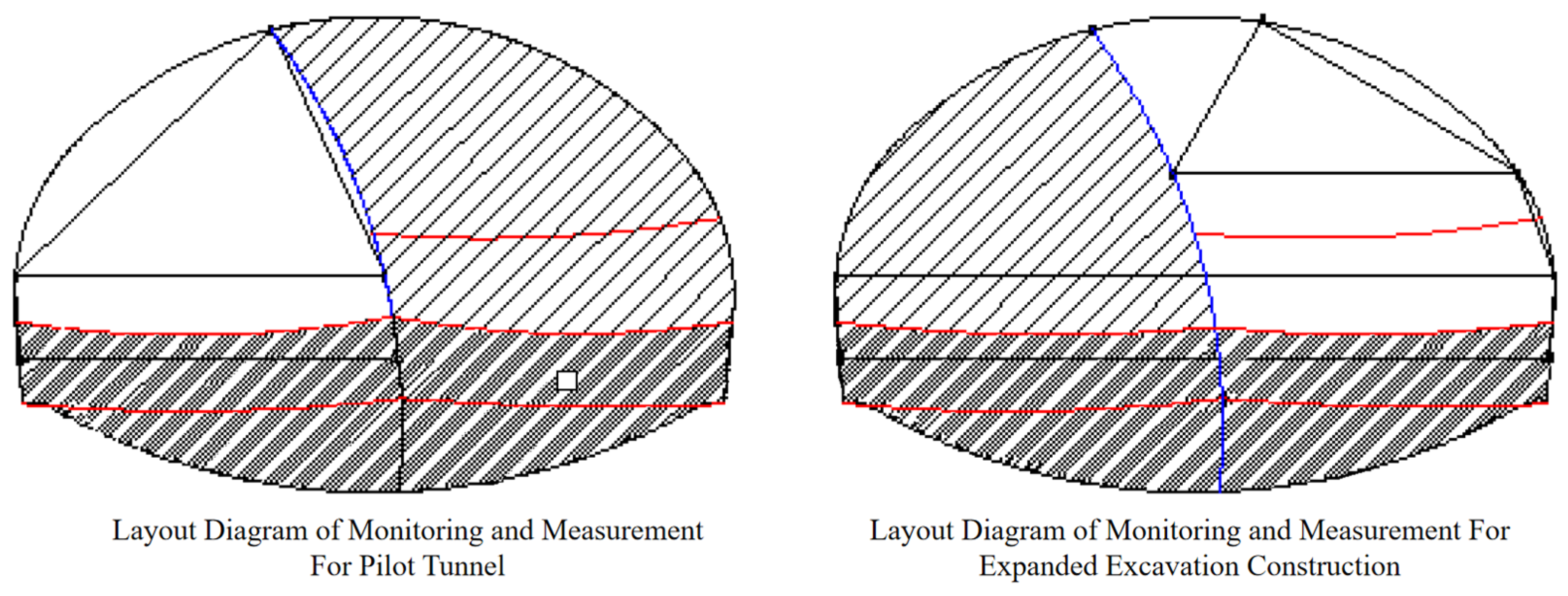

3.3. Cross-Section Monitoring Plan

- (1)

- Arch crown settlement and net space change

- (2)

- Special monitoring measurements

3.4. Optimized Costs and Schedule

- (1)

- Cost Comparison

- (2)

- Schedule Comparison

4. Feasibility Analysis of the Large-Pilot-Tunnel-First Method

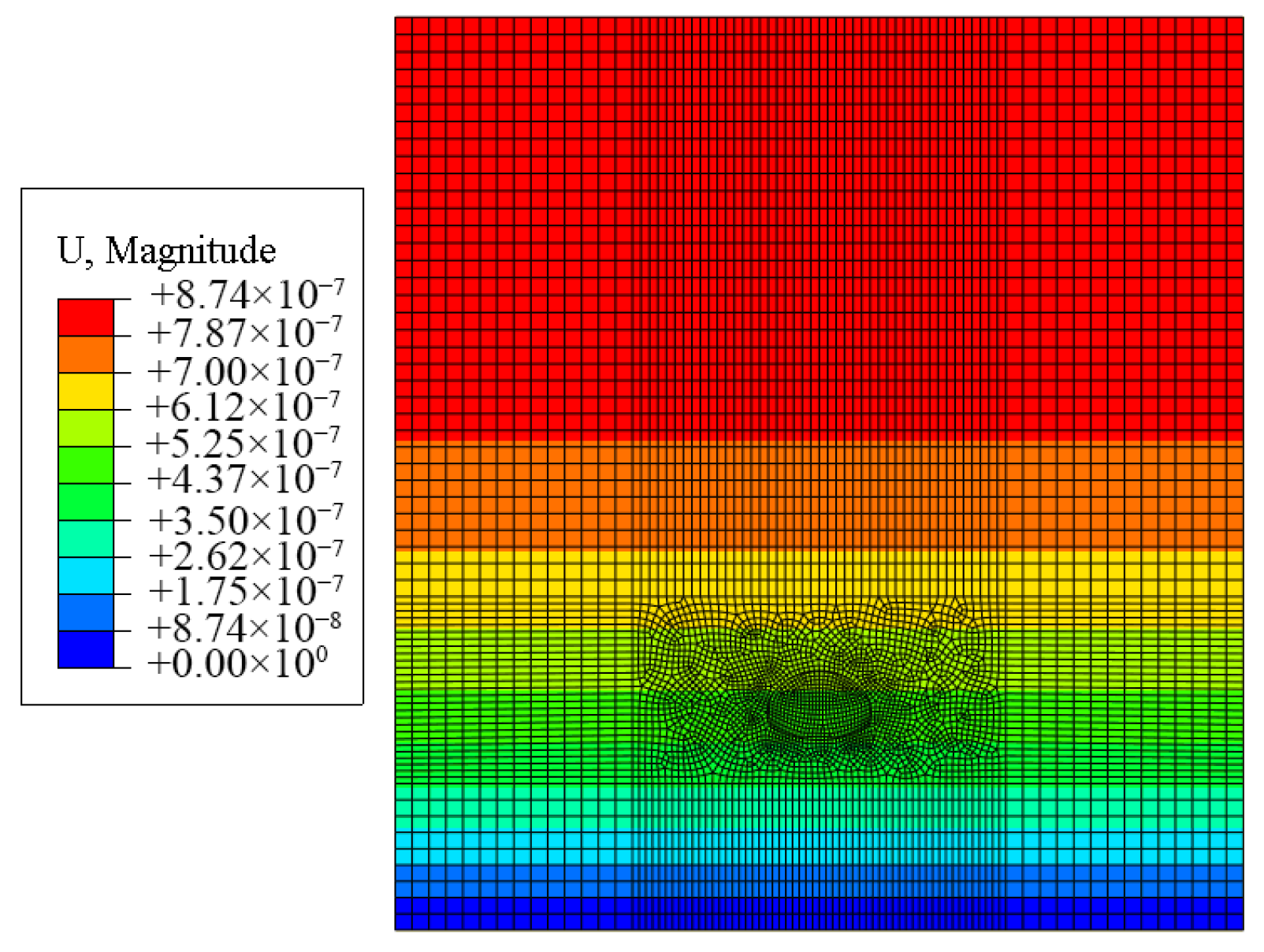

4.1. Numerical Simulation Scheme

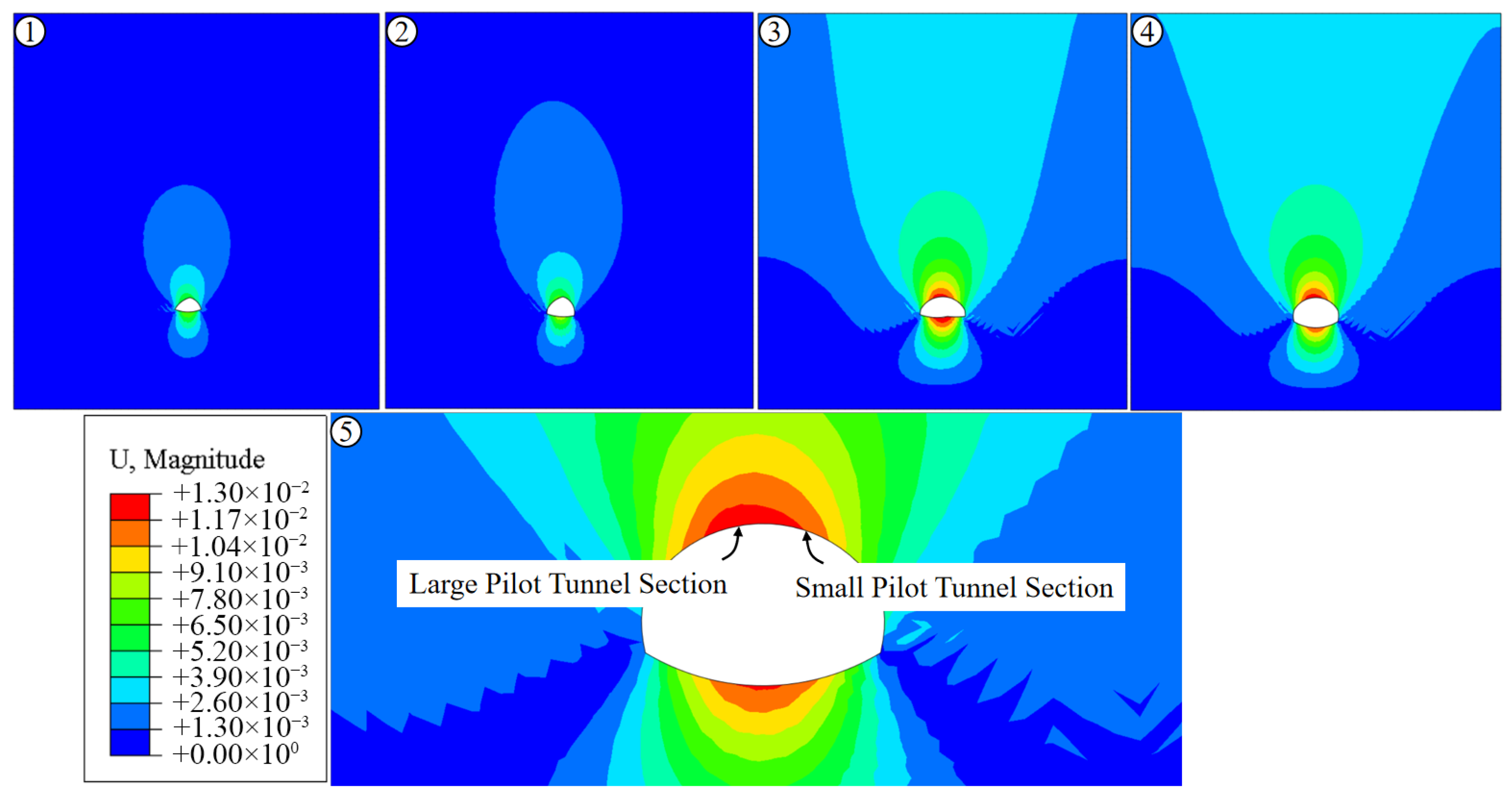

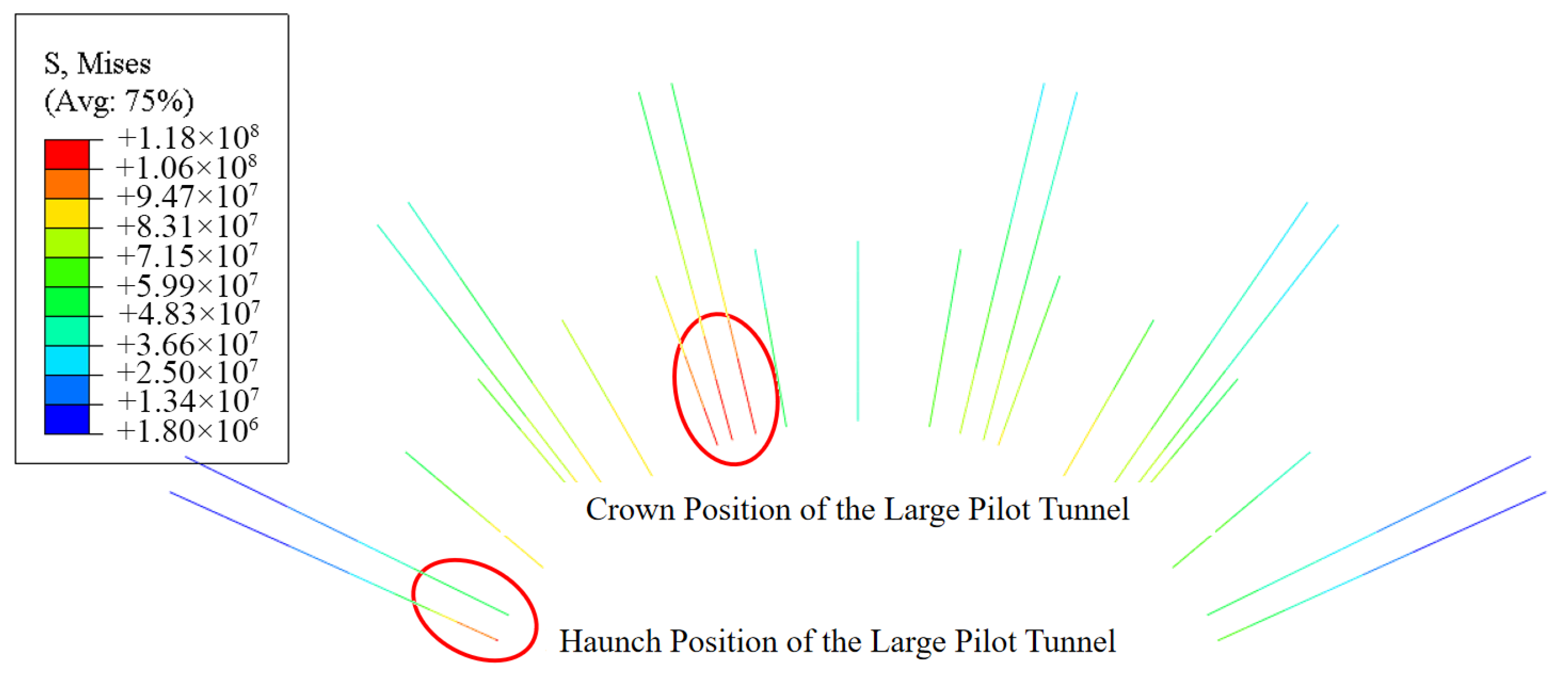

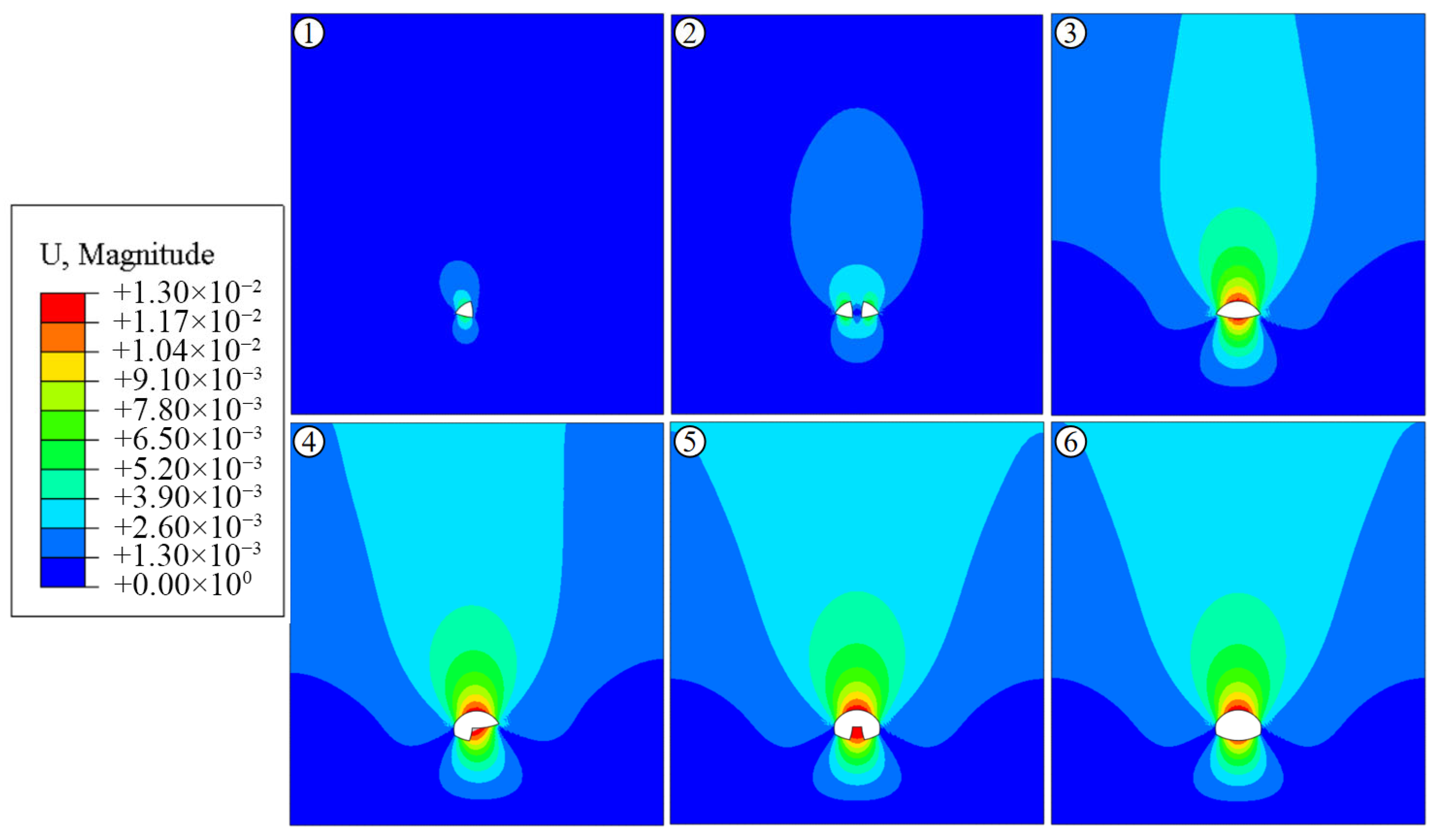

4.2. Numerical Simulation Results

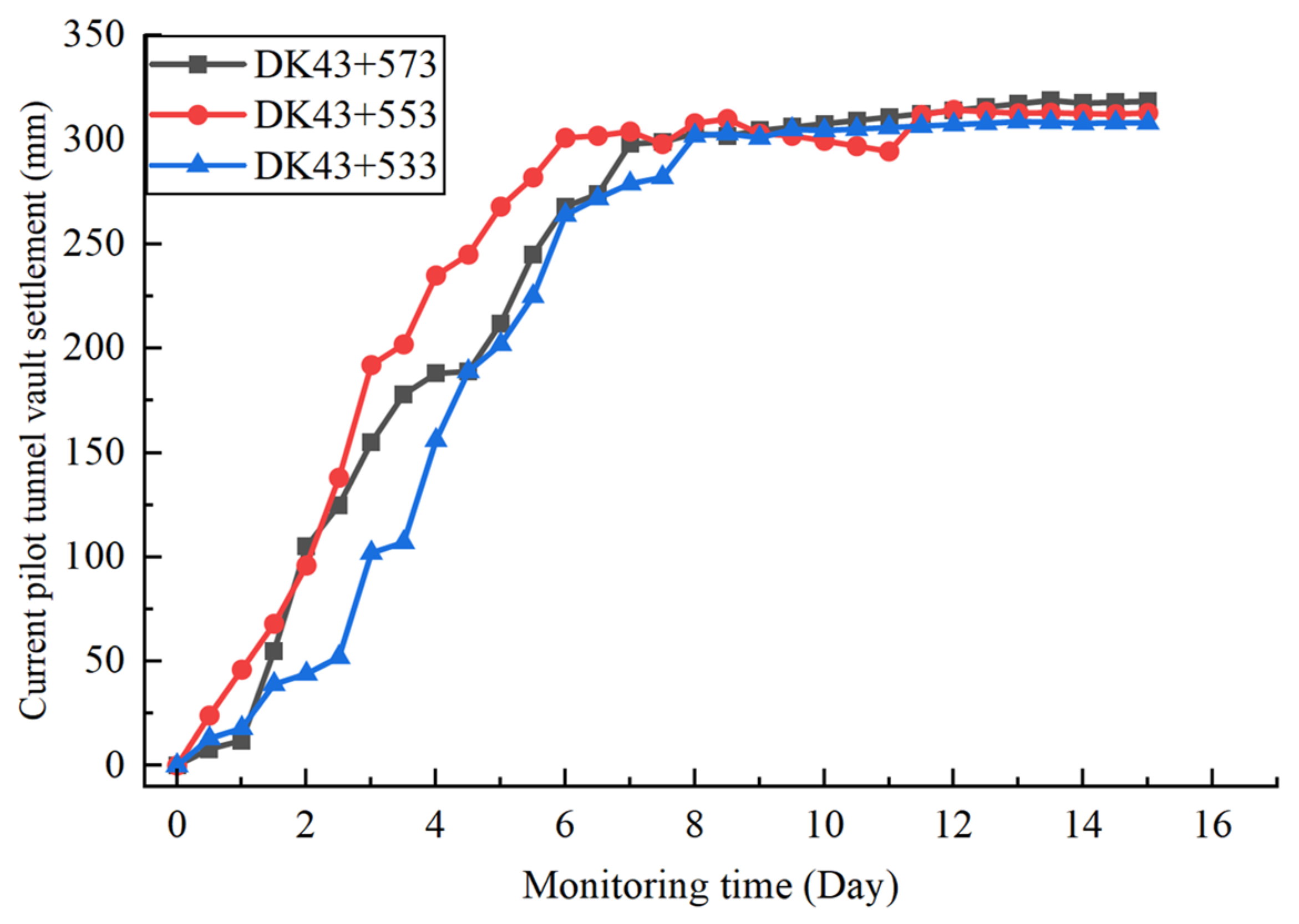

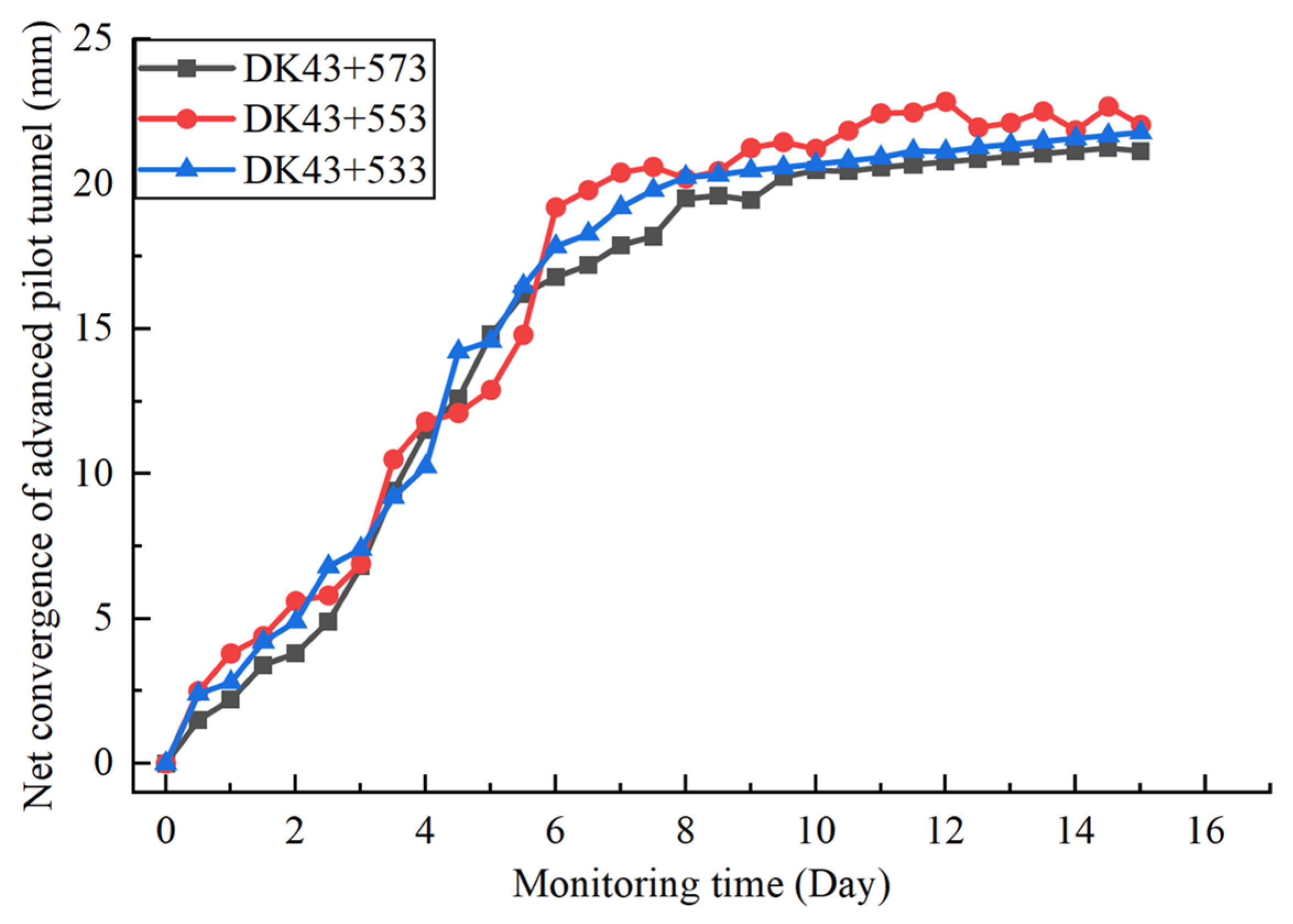

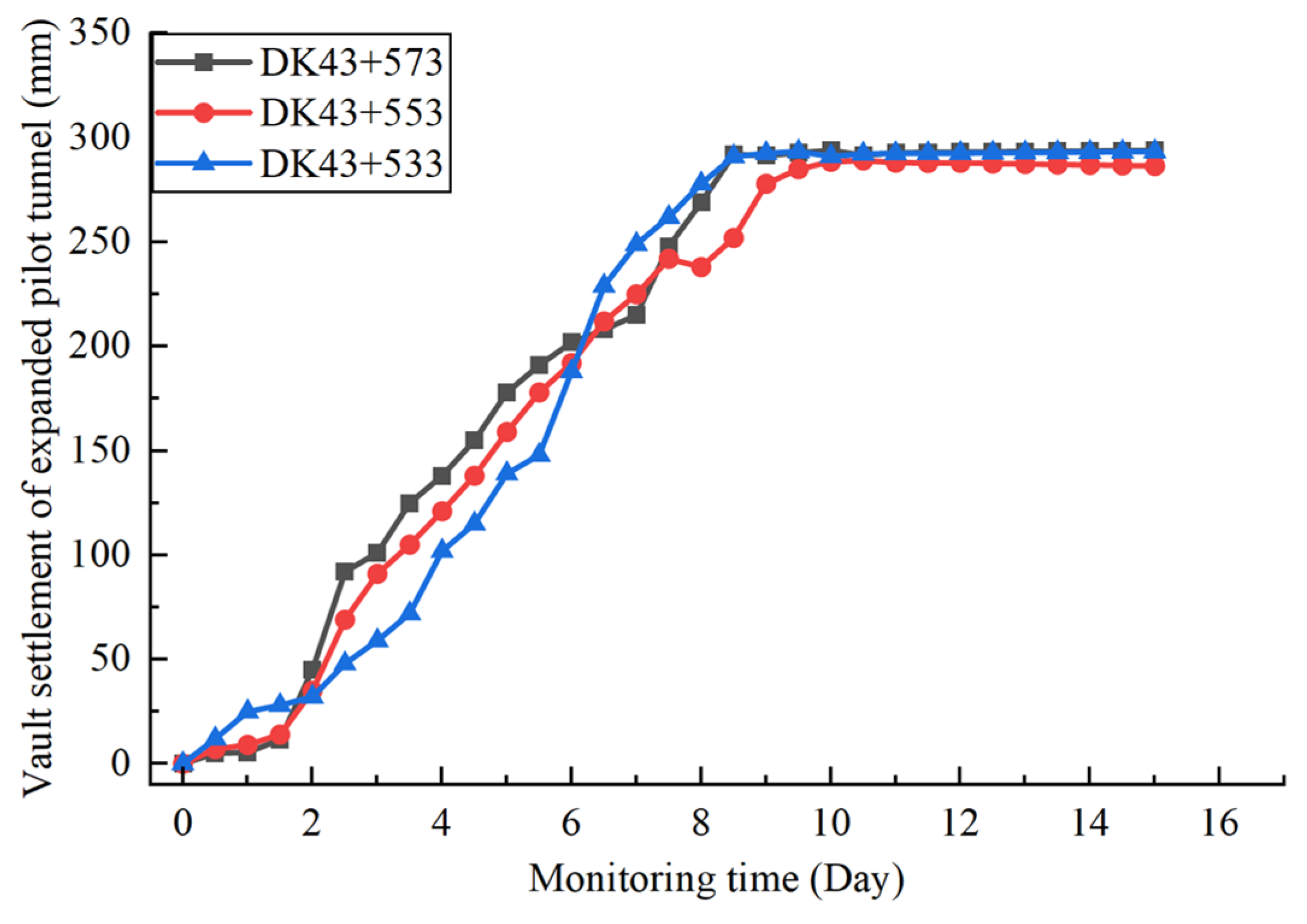

5. On-Site Application Effects

6. Discussions

7. Conclusions

- (1)

- To facilitate the rapid construction of a large-span tunnel in soft rock under high ground stress, the construction design for a 24.53 m span tunnel in southwestern China was optimized. The traditional double-side drift method was replaced by the pilot-tunnel-first method. Support measures were enhanced by increasing the bolt length from 4 m to 6 m, installing 12 m long reinforced mortar bolts at steel arch frame joints, and strengthening the steel arches themselves. This enabled the preliminary excavation of a 13.2 m large pilot tunnel.

- (2)

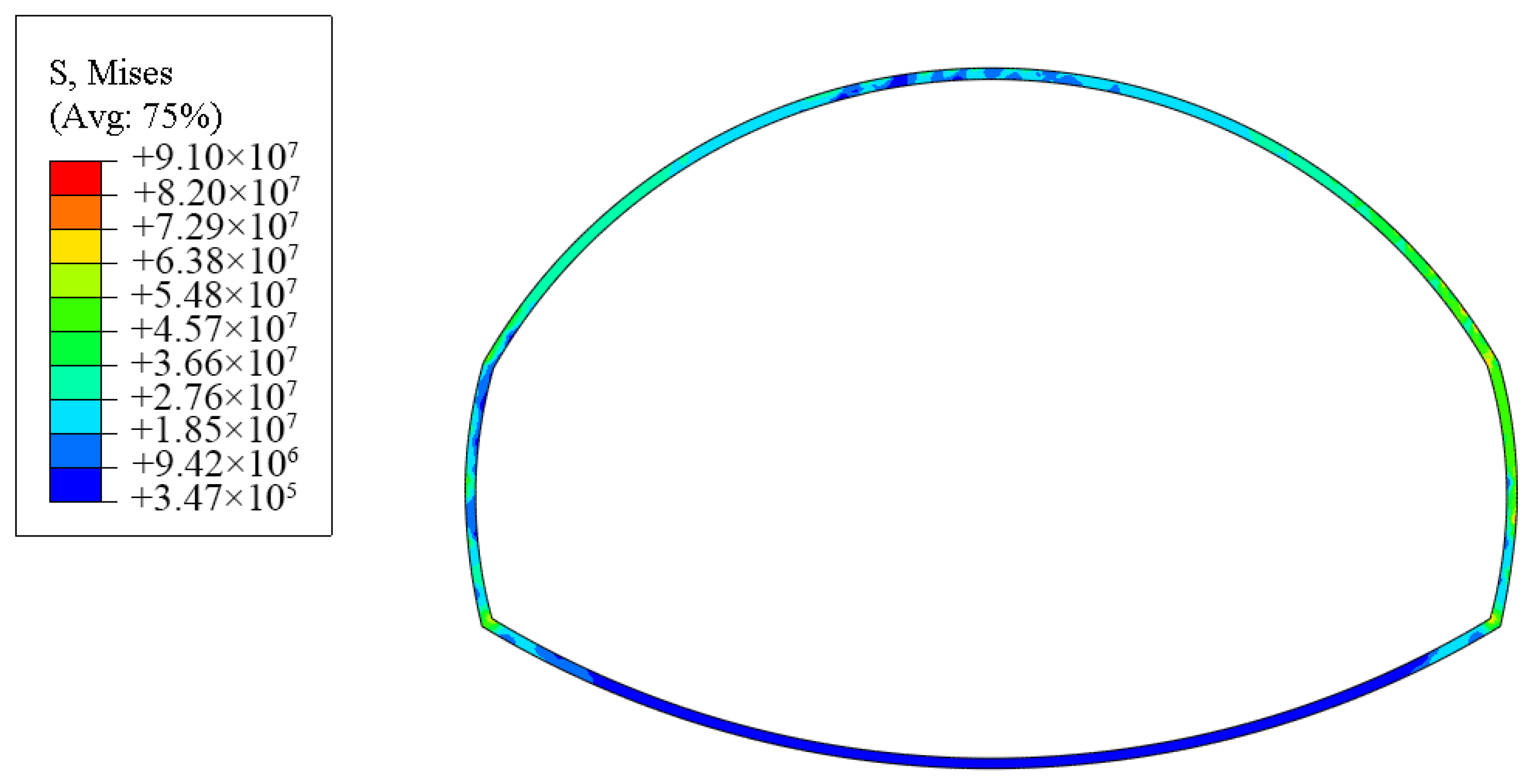

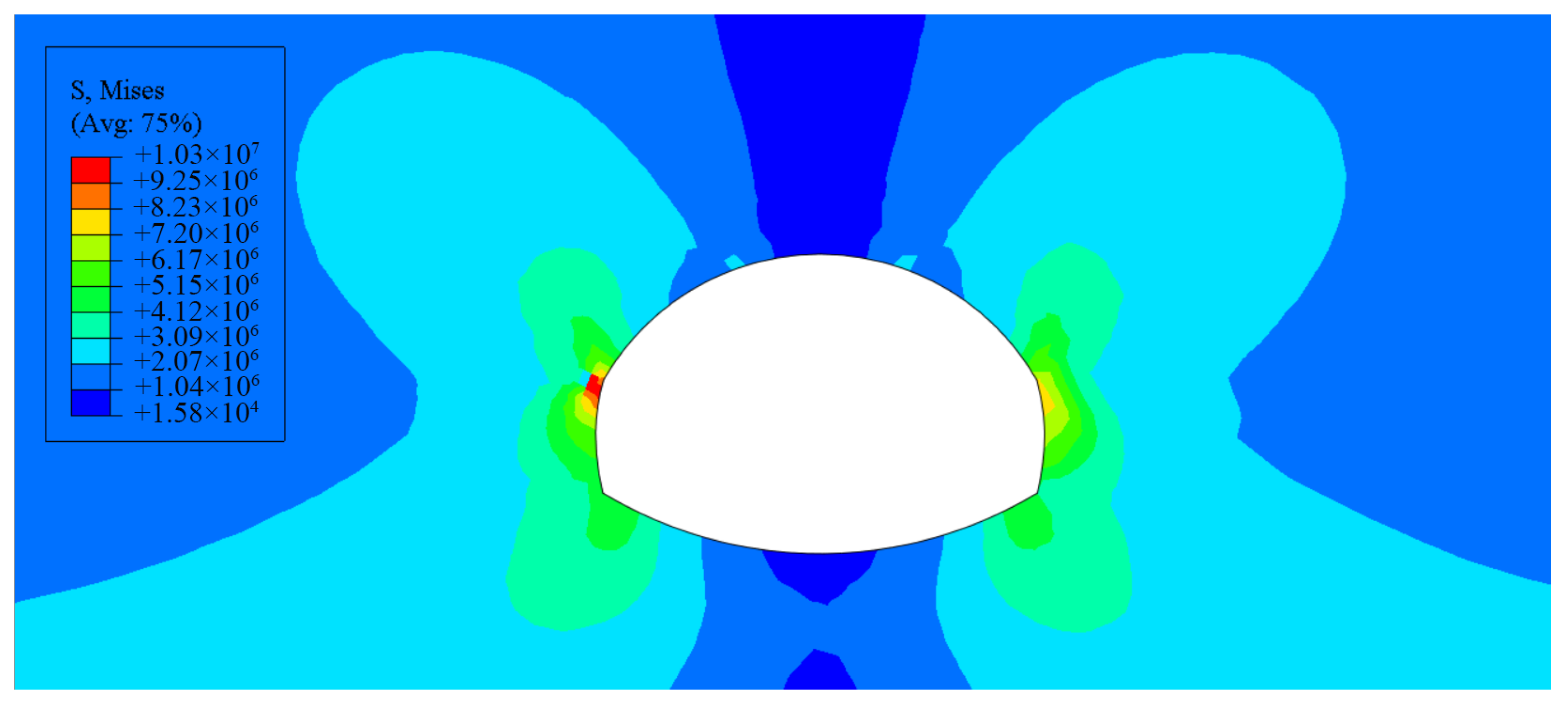

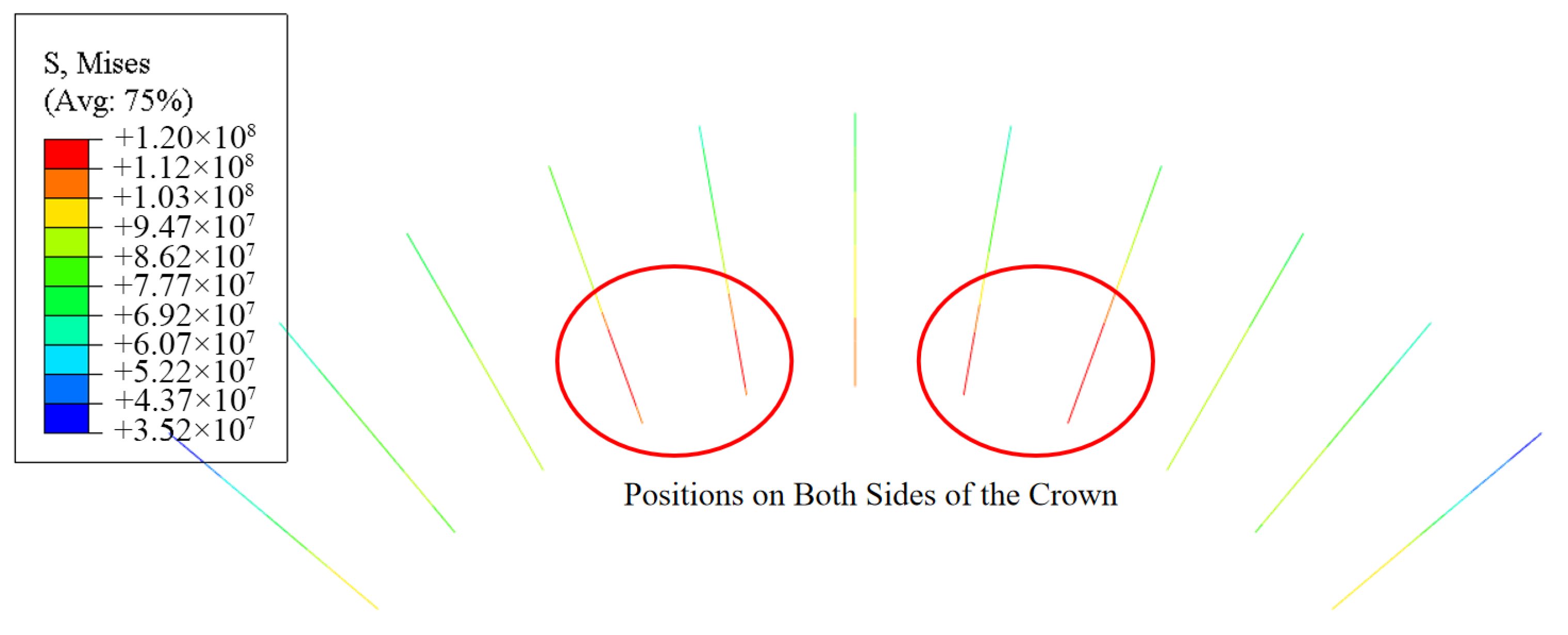

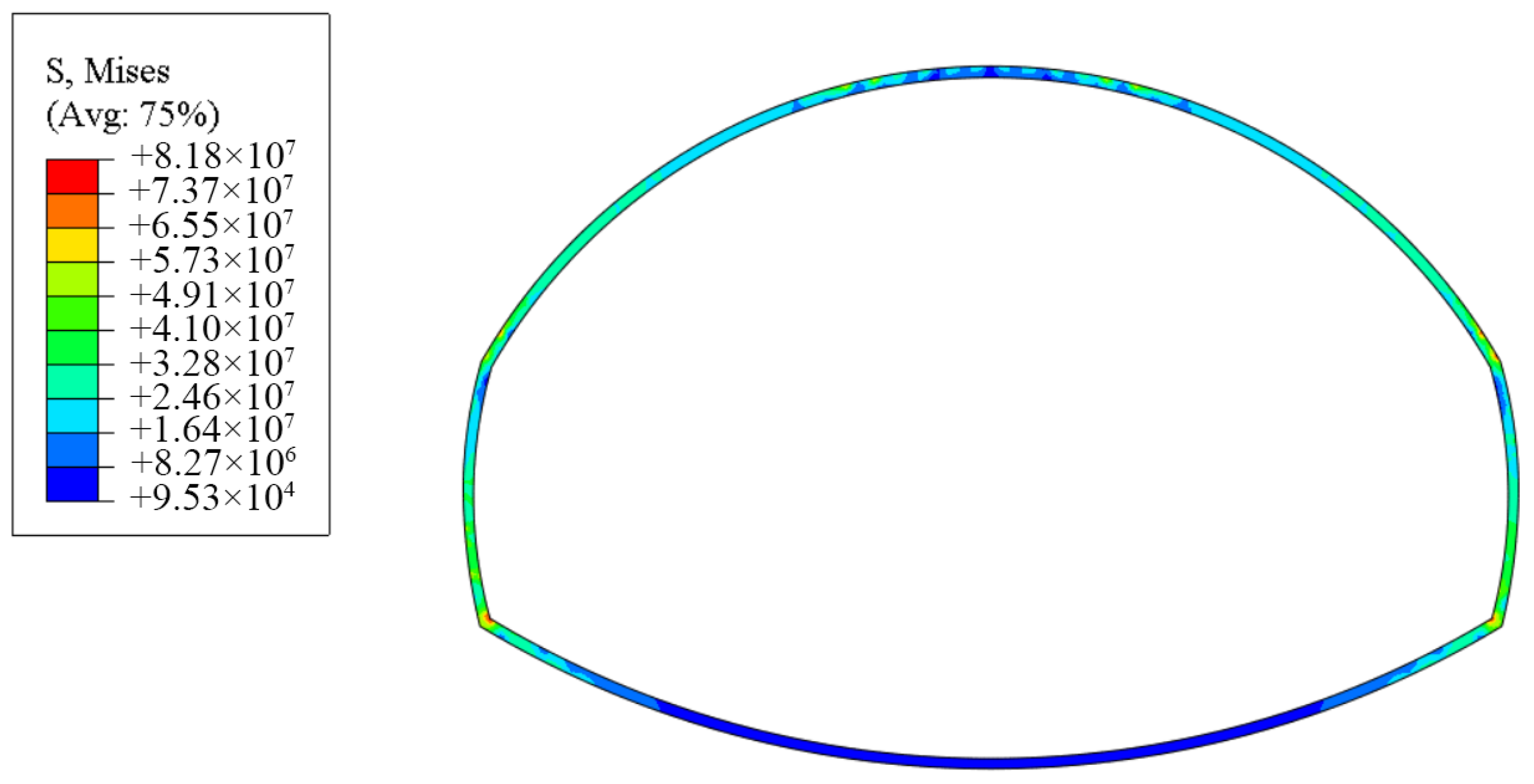

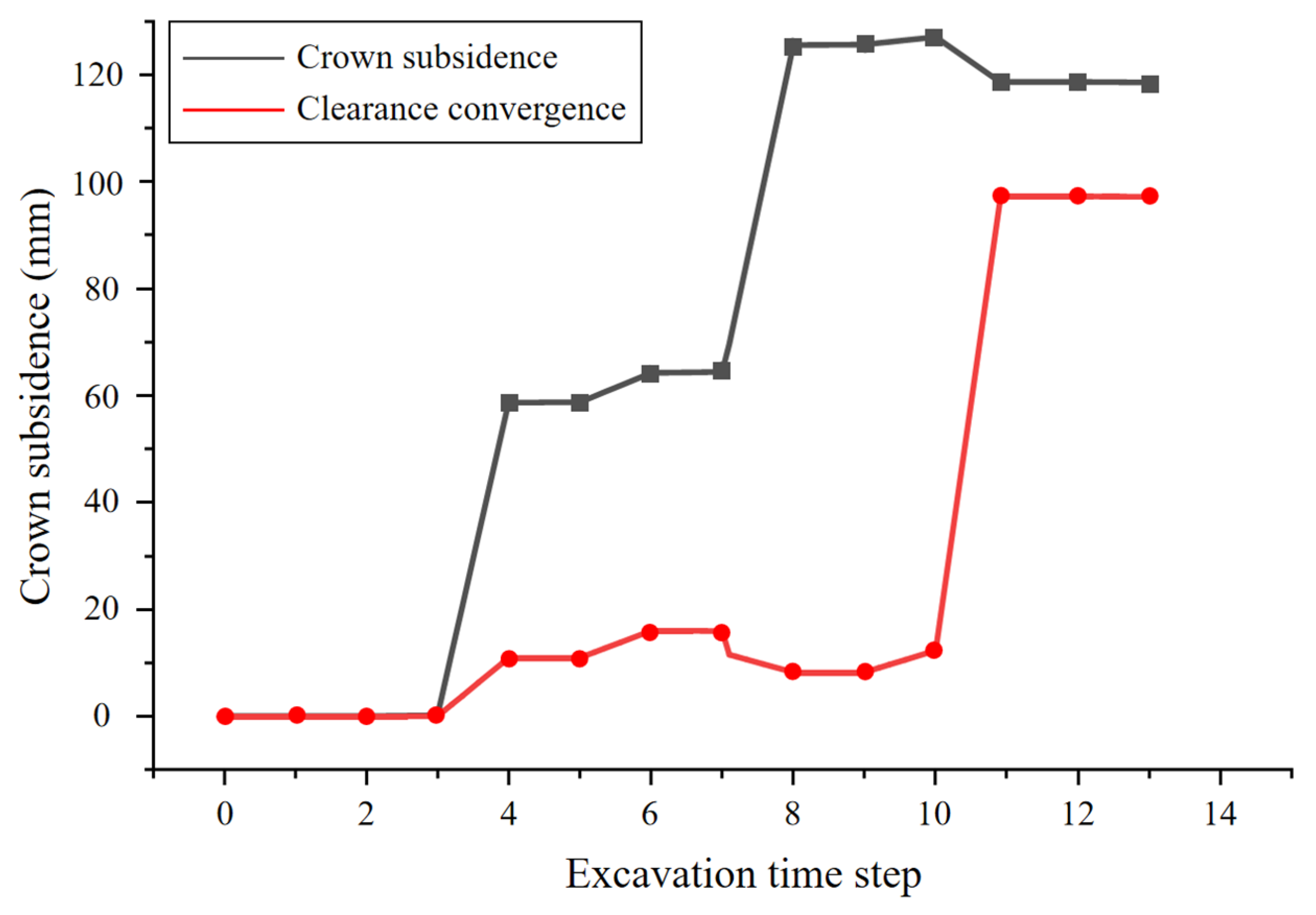

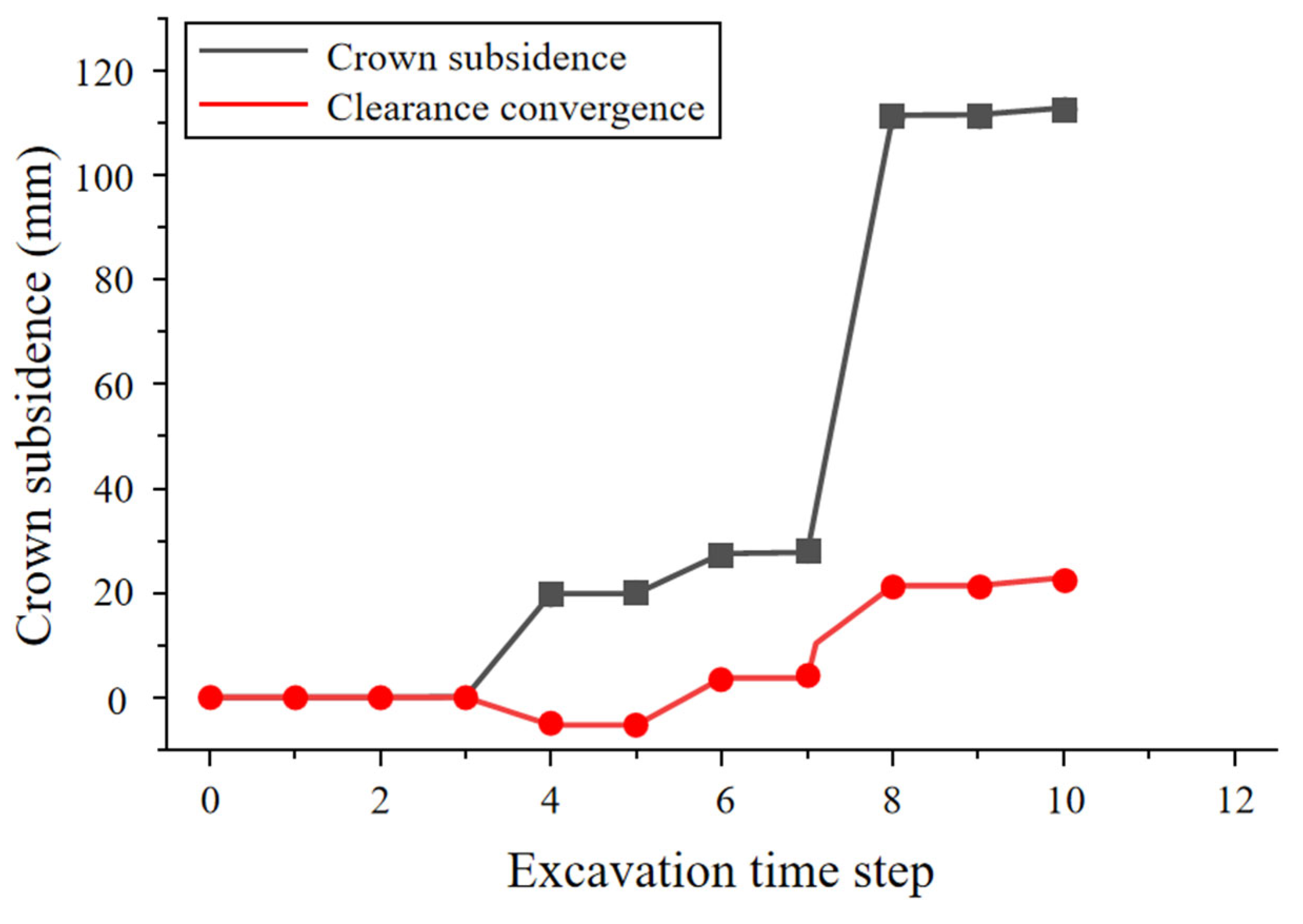

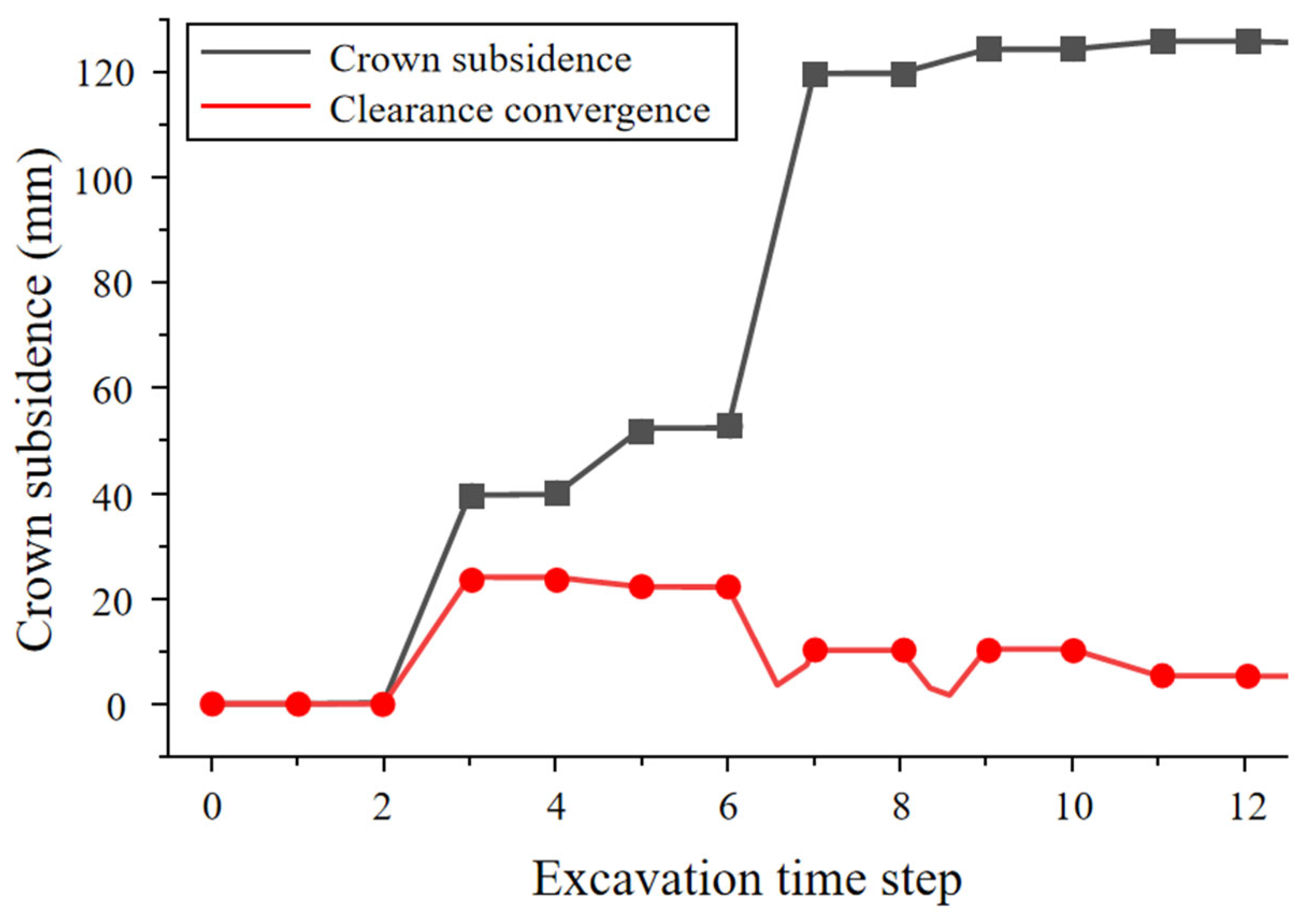

- The rationality of the optimized construction scheme was analyzed using the large-deformation finite element analysis software Abaqus, comparing the double-side drift method and the pilot-tunnel-first method. The results showed that the vault settlement and bolt axial forces in the large pilot tunnel section were greater than those in the small pilot tunnel section. The peak bolt stress (118 MPa) occurred at the steel arch joints in the large pilot tunnel, while the maximum lining stress (91 MPa) was located at the right arch waist. For the double-side drift method, the maximum vault settlement was 125 mm, the peak bolt stress (120 MPa) occurred near both sides of the vault, and the maximum lining stress (81.8 MPa) appeared on both sidewalls.

- (3)

- The numerical calculations and field application demonstrated that the pilot-tunnel-first method, combined with reinforced bolt-lining support measures, achieved a construction quality comparable to the original double-side drift design while significantly accelerating progress. Field monitoring indicated final stabilized vault settlements of 305 mm and 295 mm for the large and small pilot tunnels, respectively, with clearance convergences of 22 mm and 13 mm. For the 123 m advance in the 24.53 m large-span section, the optimized scheme increased costs by approximately CNY 782,000 but reduced the construction period by 1.96 months, substantially alleviating schedule pressure. This research provides theoretical reference and technical guidance for the design and construction of similar tunnel projects.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Q4dl + pl | Quaternary Holocene Alluvial–Pluvial Layer |

| Q4dl + el | Holocene Alluvium of Quaternary System |

| J2s | Middle Jurassic Shaximiao Formation |

| Grade IV surrounding rock | According to the “Highway Tunnel Design Specification” [33] to determine the level IV surrounding rock |

| DK43 + 150 to DK43 + 310 | The range of the mileage pile number is from 43 km 150 m to 43 km 310 m |

| φ | Bolt diameter |

References

- Hu, X.L.; Lin, S.L.; Lin, R.F. Influence from highways on regional economic growth based on the trade potential in China. Technol. Econ. Dev. Eco. 2025, 31, 184–210. [Google Scholar] [CrossRef]

- Moldovan, A. The impact of China’s road industry on the country’s economy. Mosc. Econ. J. 2024, 9, 35–46. [Google Scholar] [CrossRef]

- Lin, Y.M.; Huang, J.P. Can highway networks promote productivity? Evidence from China. J. Adv. Transport. 2021, 2021, 6860979. [Google Scholar] [CrossRef]

- Zou, Y.; Dong, X.J.; Feng, T.; Xu, Z.X.; He, H.L.; Wu, Z.L. Research on spatial prediction technology for mitigating tunnel inrush disasters under complex geological conditions in China’s Hengduan Mountain Range. Sci. Rep. 2025, 15, 1850. [Google Scholar] [CrossRef]

- Yang, X.J.; Kang, X.H.; He, M.C.; Wang, Y.J.; Zhang, J.; Shi, Z.; Chen, Y.W. Development characteristics and prediction methods of the “three zones” in overlying strata under the 110 mining method. Rock. Mech. Bull. 2026, 5, 100234. [Google Scholar] [CrossRef]

- Cui, T. Study on the Risk Forecast and Construction Technique of Karst Tunnel for Excavation and Support; Central South University: Changsha, China, 2011. [Google Scholar]

- Chen, Y.Y.; Xiao, P.W.; Li, P.; Zhou, X.; Liang, Z.Z.; Xu, N.W. Formation mechanism of rockburst in deep tunnel adjacent to faults: Implication from numerical simulation and microseismic monitoring. J. Cent. South Univ. 2022, 29, 4035–4050. [Google Scholar] [CrossRef]

- Hou, S.L.; He, M.C.; Yang, J.; Zhang, J.; Wang, Y.J.; Kang, X.H.; Han, Z.J.; Du, F.K. A green coal mining method for protecting roadways and overlying strata. Rock. Mech. Bull. 2025, 4, 100192. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Sheng, Q.; Zhang, Y.M.; Liu, S.W. Numerical modeling of stress disturbance characteristics during tunnel excavation. Adv. Mater. Sci. Eng. 2020, 2020, 4508905. [Google Scholar] [CrossRef]

- Liu, T.X.; Zhang, C.P.; Li, W.; Tu, S.Q.; Wang, L.B.; Jin, Z.X. Face failure mechanism of fault tunnels under high-temperature and high-pressure conditions using the discrete element method. Comput. Geotech. 2025, 179, 107059. [Google Scholar] [CrossRef]

- Zhang, L.X.; Chen, J.X.; Chen, L.J.; Luo, Y.B.; Liu, W.W. Deformation grading and prediction of heterogeneous layered soft rock tunnels under high ground-stress: A case study. Tunn. Undergr. Sp. Tech. 2026, 167, 107071. [Google Scholar] [CrossRef]

- Bai, C.H.; Xue, Y.G.; Qiu, D.H.; Yang, W.M.; Su, M.X.; Ma, X.M. Real-time updated risk assessment model for the large deformation of the soft rock tunnel. Int. J. Geomech. 2021, 21, 04020234. [Google Scholar] [CrossRef]

- Chen, L.H.; Xi, B.P.; Zhao, N.; He, S.X.; Dong, Y.S.; Liu, K.L.; Gao, P.L.; Liu, G.Q. Large deformation mechanism and support countermeasures of deep-buried soft rock tunnels under high geostress state. Buildings 2025, 15, 704. [Google Scholar] [CrossRef]

- Sun, J. Recent advances in rock rheological mechanics and its engineering applications. J. Rock. Mech. Geotech. Eng. 2007, 26, 1081–1106. [Google Scholar]

- Sun, J.; Jiang, Y.; Wang, B.; Fan, Y. Nonlinear rheological properties and yielding support technology for large squeezing deformation of soft rock tunnel with high ground stress. Tunn. Constr. 2021, 41, 1627. [Google Scholar]

- Li, S.C.; Wang, M.B. An elastic stress-displacement solution for a lined tunnel at great depth. Int. J. Rock. Mech. Min. 2008, 45, 486–494. [Google Scholar] [CrossRef]

- Li, Y.; Deng, F.; Zheng, J.; Wang, F.N.; Tao, Z.G. Study on the support strategy of NPR cable truss structure in large deformation soft rock tunnel across multistage faults. Rock. Mech. Rock. Eng. 2024, 57, 11261–11281. [Google Scholar] [CrossRef]

- Ren, L.X.; Wei, Z.F.; Liang, N.H.; Liu, X.R.; Deng, Z.Y. Mechanical behavior of multi-scale fiber-reinforced concrete for secondary tunnel lining: Field test and numerical simulation. Case Stud. Constr. Mat. 2022, 17, e01669. [Google Scholar] [CrossRef]

- Zhou, X.W.; Yang, S.; Ma, Z.G.; Ai, Z.B.; Tao, Z.G.; Sui, Q.R. A comparative study of soft rock tunnel control methods using NPR high preload anchor cables: Analysis of multiple cases. Ksce J. Civ. Eng. 2024, 28, 4703–4716. [Google Scholar] [CrossRef]

- Li, Y.K.; Wang, H.W.; Zhu, Z.B.; Deng, D.X.; Jiang, N.S. Integrative solution of stress evolution in overburden roof strata during the coal seam mining by application of complex variable functions methodology. Rock. Mech. Bull. 2026, 5, 100236. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, X.N.; Ma, M.J. A new method for calculating the load shared by the primary support of deep-buried rheological soft rock tunnels by considering the flexible primary support. Int. J. Appl. Mech. 2024, 16, 2450034. [Google Scholar] [CrossRef]

- Li, C.J.; Zhuang, Y.Z.; Lu, Y.Q.; Zheng, G.P.; Zheng, Y.H.; Li, W.H.; Xue, C.B.; Guo, H.Y.; Fang, Y.C. Experimental study of the mechanical behavior of a steel arch structure used in the main lining of a highway tunnel. Buildings 2024, 14, 2571. [Google Scholar] [CrossRef]

- Li, Y.; Zheng, J.; Huo, S.S.; Wang, F.N.; He, M.C.; Tao, Z.G. Case study on the mechanics of NPR anchor cable compensation for large deformation tunnel in soft rock in the Transverse Mountain area, China. J. Cent. South Univ. 2024, 31, 2054–2069. [Google Scholar] [CrossRef]

- Sun, Y.P.; Xu, N.W.; Xiao, P.W.; Sun, Z.Q.; Li, H.L.; Liu, J.; Li, B. Characterizing large deformation of soft rock tunnel using microseismic monitoring and numerical simulation. J. Rock. Mech. Geotech. 2025, 17, 309–322. [Google Scholar] [CrossRef]

- Yang, W.B.; Zhao, L.L.; Yao, C.F.; He, C.; Pan, W.T.; Wu, F.Y.; Tian, L.Q.; Yan, Q.X. The control effect of directional rock bolt on asymmetric deformation of layered soft rock tunnel with different grades of large deformation. Rock. Mech. Rock. Eng. 2025, 58, 5273–5297. [Google Scholar] [CrossRef]

- Zhu, H.H.; Yan, J.X.; Liang, W.H. Challenges and development prospects of ultra-long and ultra-deep mountain tunnels. Engineering 2019, 5, 384–392. [Google Scholar] [CrossRef]

- Xu, Q.W.; Xie, J.L.; Zhou, F.; Tang, Z.H. Numerical Simulation and Analysis of the Causes and Distribution of Secondary Lining Cracks in Overlapping Railway Tunnels. Appl. Sci. 2023, 13, 6436. [Google Scholar] [CrossRef]

- Su, X.K. Study on the determination of boundary ranges for surrounding rock in tunnel excavation numerical simulations. J. Railw. Eng. Sci. 2012, 29, 64–68. [Google Scholar]

- Zheng, G.; Li, H.; Zhang, T.; Sun, J.; Wang, R.; Qiu, H.; Diao, Y. Exploratory Application of a Novel Centre Cross Diaphragm Method for the Construction of Large Cross-Section Tunnels in Soft Ground. Can. Geotech. J. 2023, 60, 123–138. [Google Scholar] [CrossRef]

- Ma, L.; Dai, J.; Wang, B.; Mo, Y.; Liu, Y.; Tian, C. Structural Analysis of Large-Span Tunnel Excavated by Upper Bench Center Diaphragm Method: An Analytical Model and Its Application. Tunn. Undergr. Space Technol. 2026, 167, 107053. [Google Scholar]

- He, M.; Gong, W.; Wang, J.; Qi, P.; Tao, Z.; Du, S.; Peng, Y. Development of a Novel Energy-Absorbing Bolt with Extraordinarily Large Elongation and Constant Resistance. Int. J. Rock. Mech. Min. Sci. 2014, 67, 29–42. [Google Scholar] [CrossRef]

- Zhan, J.; Yang, J.; Bian, W.; Zhao, R.; Dong, M. Analytical Study and Engineering Application of NPR Prestressed Bolt Is Anchored by Mechanical-Type Anchorage and Resin. Tunn. Undergr. Space Technol. 2024, 145, 105616. [Google Scholar] [CrossRef]

- Q/CR 9230-2016; Technical Specification for Observation and Assessment of Settlement Deformation of Railway Tunnels. China Railway Publishing House: Beijing, China, 2016.

| Material | Density [kg/m3] | Elastic Modulus [GPa] | Poisson’s Ratio | Yield Strength [MPa] | Cohesion [KPa] | Angle of Internal Friction [°] |

|---|---|---|---|---|---|---|

| Bolt | 7850 | 210 | 0.25 | 335 | - | - |

| Lining | 2550 | 120 | 0.25 | 200 | - | - |

| Rock | 2200 | 5 | 0.32 | - | 80 | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, Q.; Yang, H.; Zhan, J.; Zhou, J.; Gao, H.; Xu, X.; Shi, Y. Study and Application of a Pilot-Tunnel-First Method for Rapid Excavation of Large-Span Soft Rock Tunnels. Appl. Sci. 2025, 15, 12194. https://doi.org/10.3390/app152212194

Fu Q, Yang H, Zhan J, Zhou J, Gao H, Xu X, Shi Y. Study and Application of a Pilot-Tunnel-First Method for Rapid Excavation of Large-Span Soft Rock Tunnels. Applied Sciences. 2025; 15(22):12194. https://doi.org/10.3390/app152212194

Chicago/Turabian StyleFu, Qiang, Hong Yang, Jiawang Zhan, Jianlin Zhou, Hainan Gao, Xiaoding Xu, and Yue Shi. 2025. "Study and Application of a Pilot-Tunnel-First Method for Rapid Excavation of Large-Span Soft Rock Tunnels" Applied Sciences 15, no. 22: 12194. https://doi.org/10.3390/app152212194

APA StyleFu, Q., Yang, H., Zhan, J., Zhou, J., Gao, H., Xu, X., & Shi, Y. (2025). Study and Application of a Pilot-Tunnel-First Method for Rapid Excavation of Large-Span Soft Rock Tunnels. Applied Sciences, 15(22), 12194. https://doi.org/10.3390/app152212194