A Numerical Study on the Influence of CO2 Injection Location and Flow Rate on the Oxidation Zone in Goaf

Abstract

1. Introduction

2. Methods

2.1. Continuity Equation

2.2. Momentum Equation

2.3. Energy Equation

2.4. Seepage Parameters for the Goaf Model

3. Model Verifications

3.1. Simulation Case

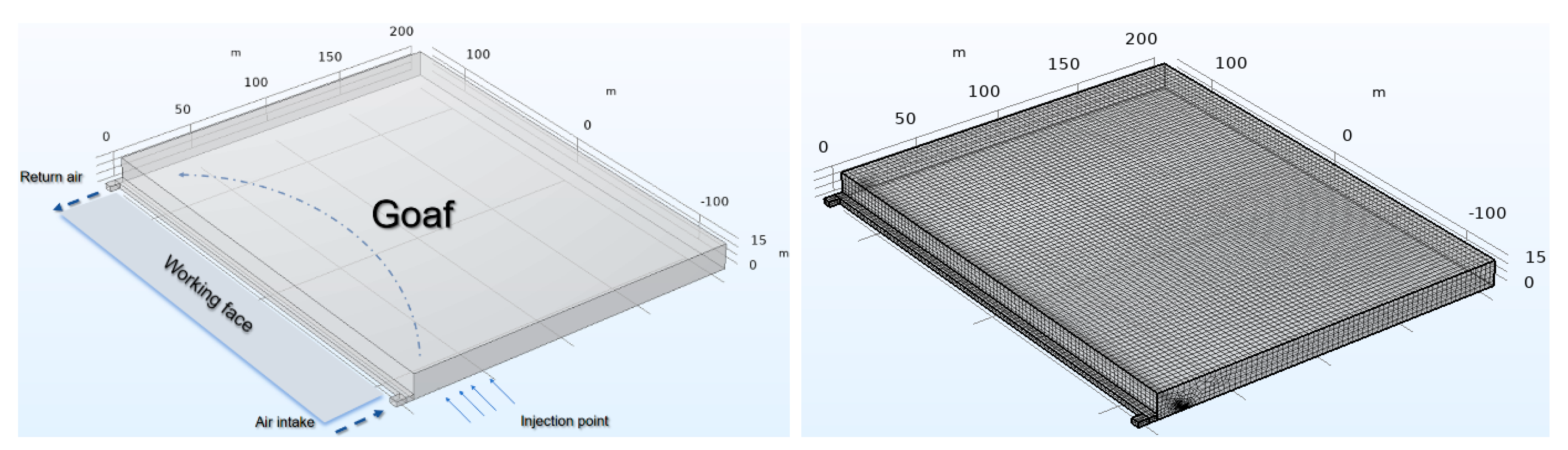

3.2. Physical Model

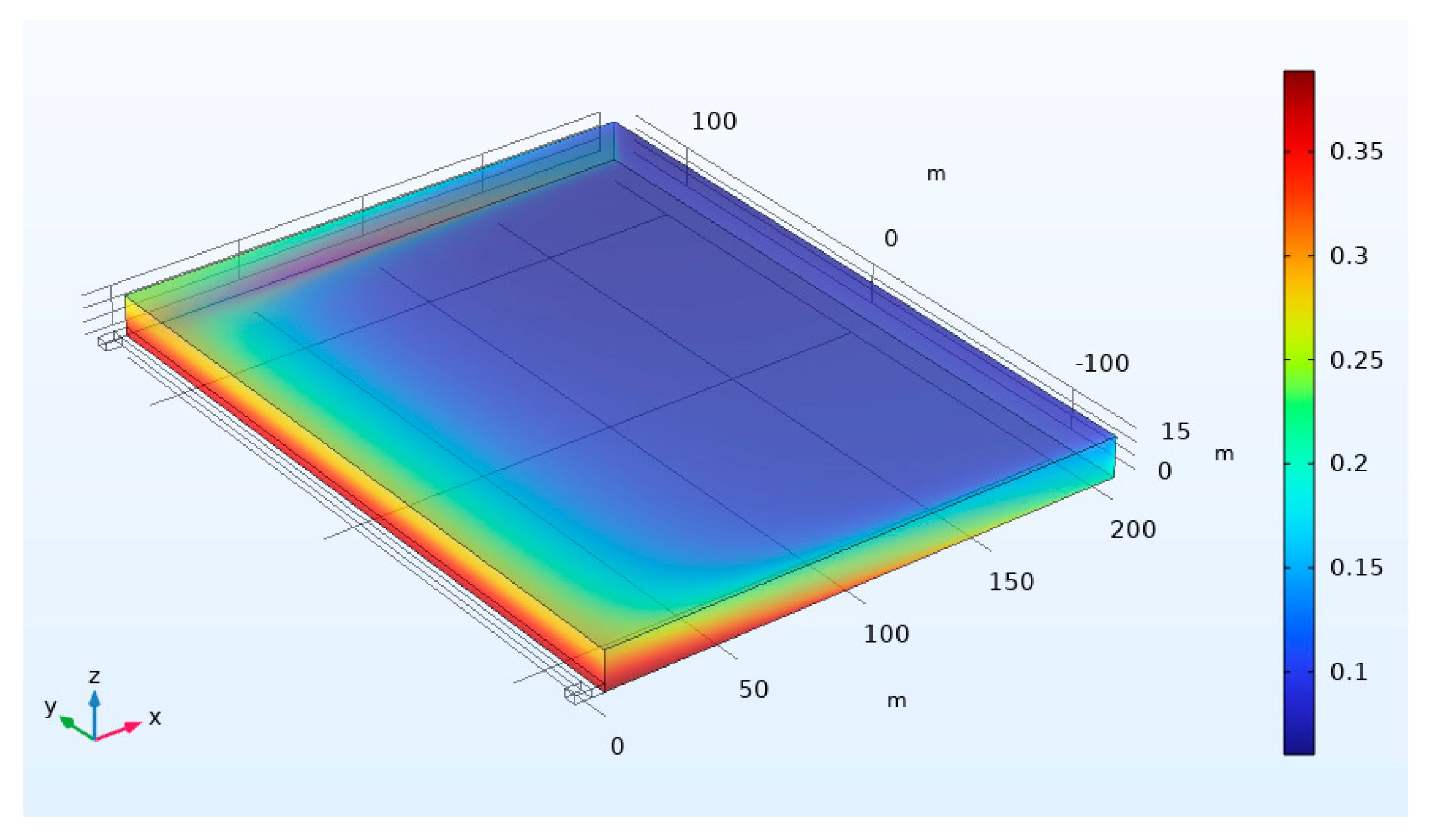

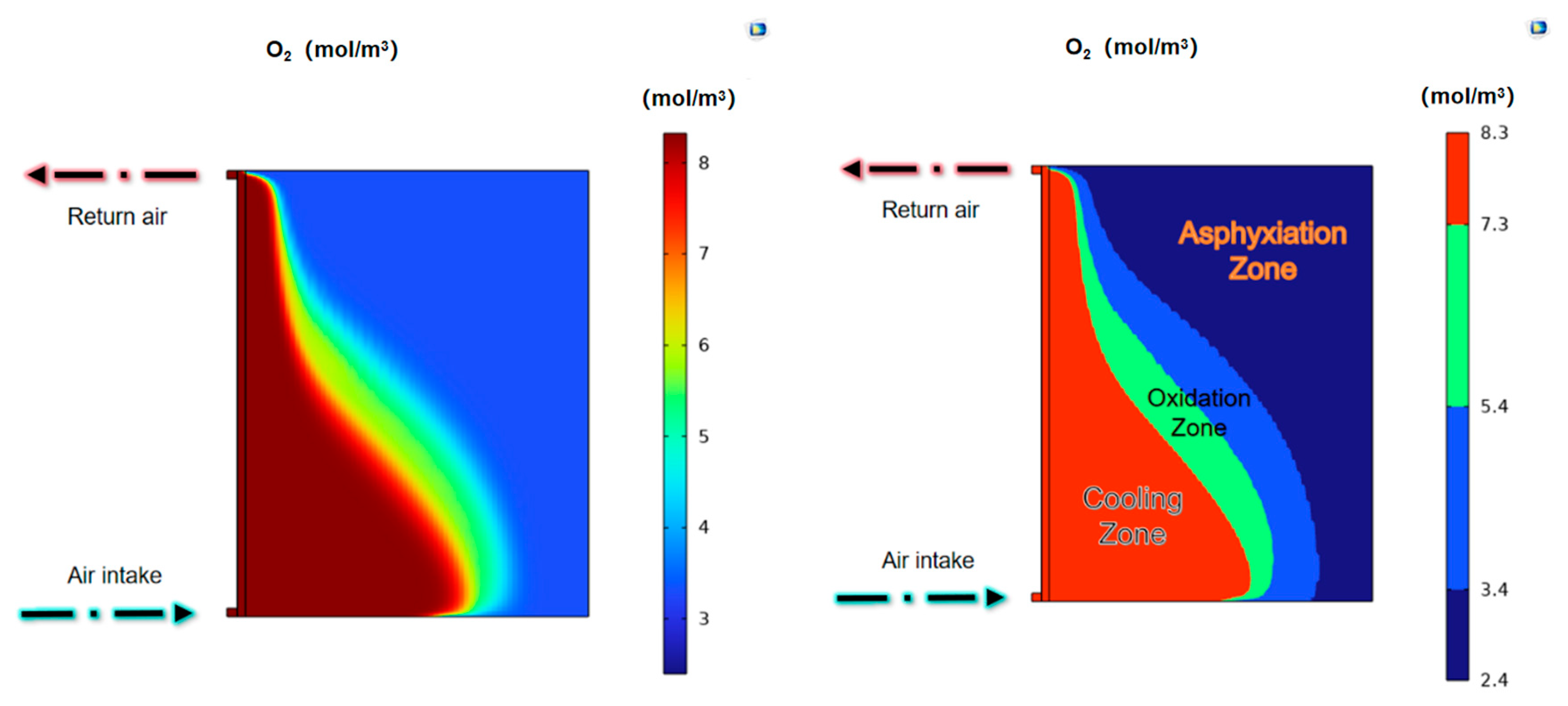

3.3. Numerical Simulation Results

3.4. Model Validation and Comparative Analysis

4. Analysis of the Impact of CO2 Injection Parameters on Spontaneous Combustion in the Goaf

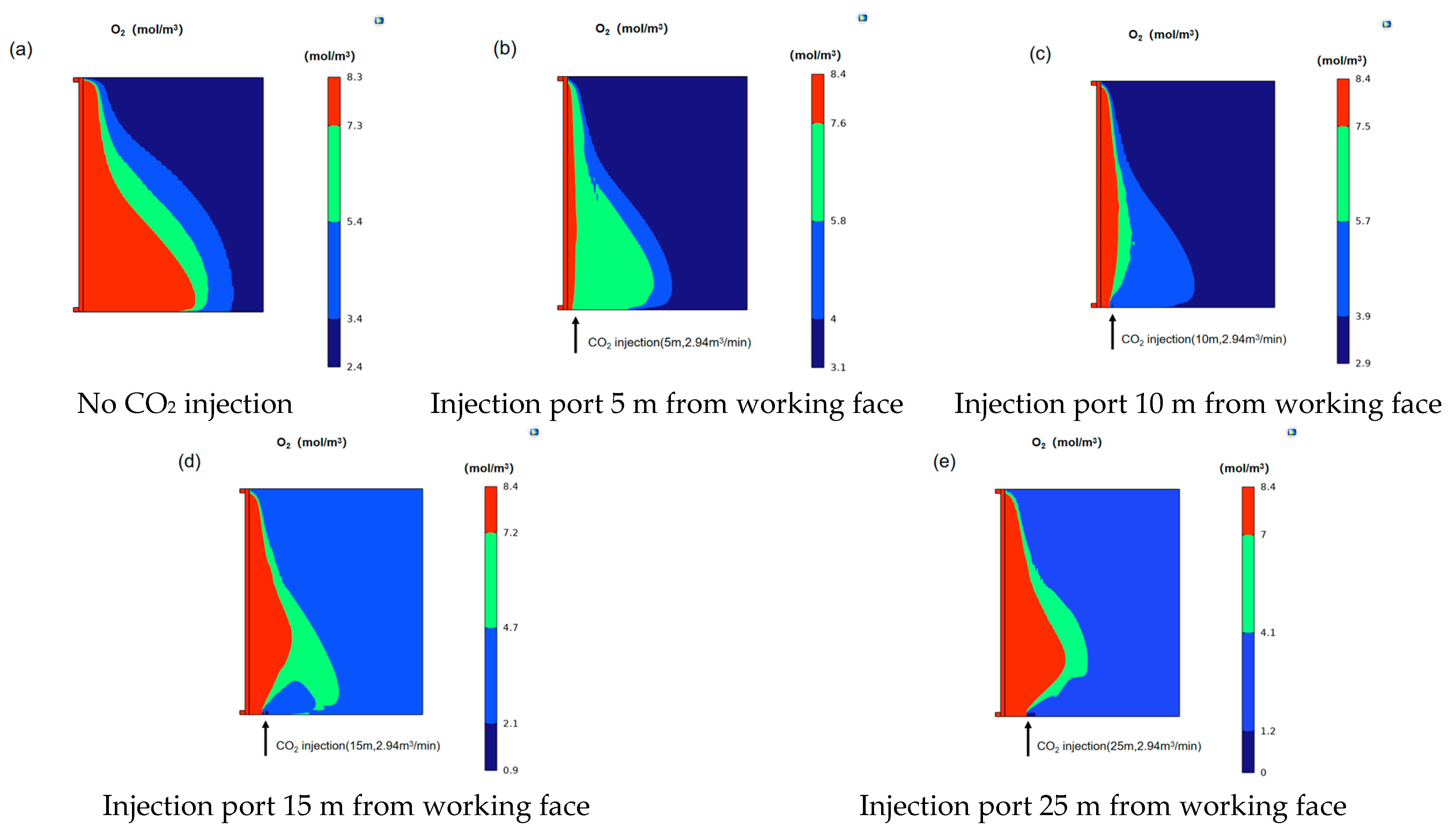

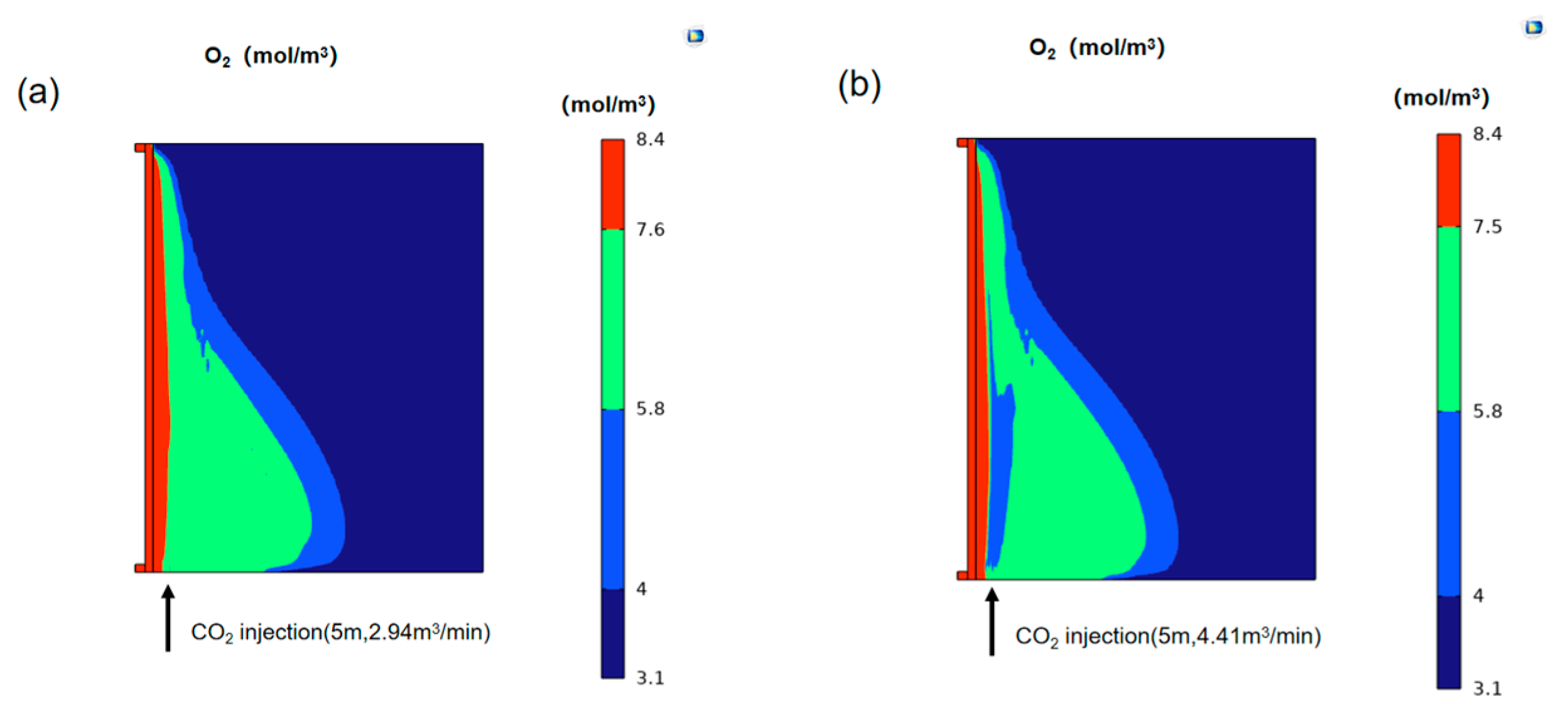

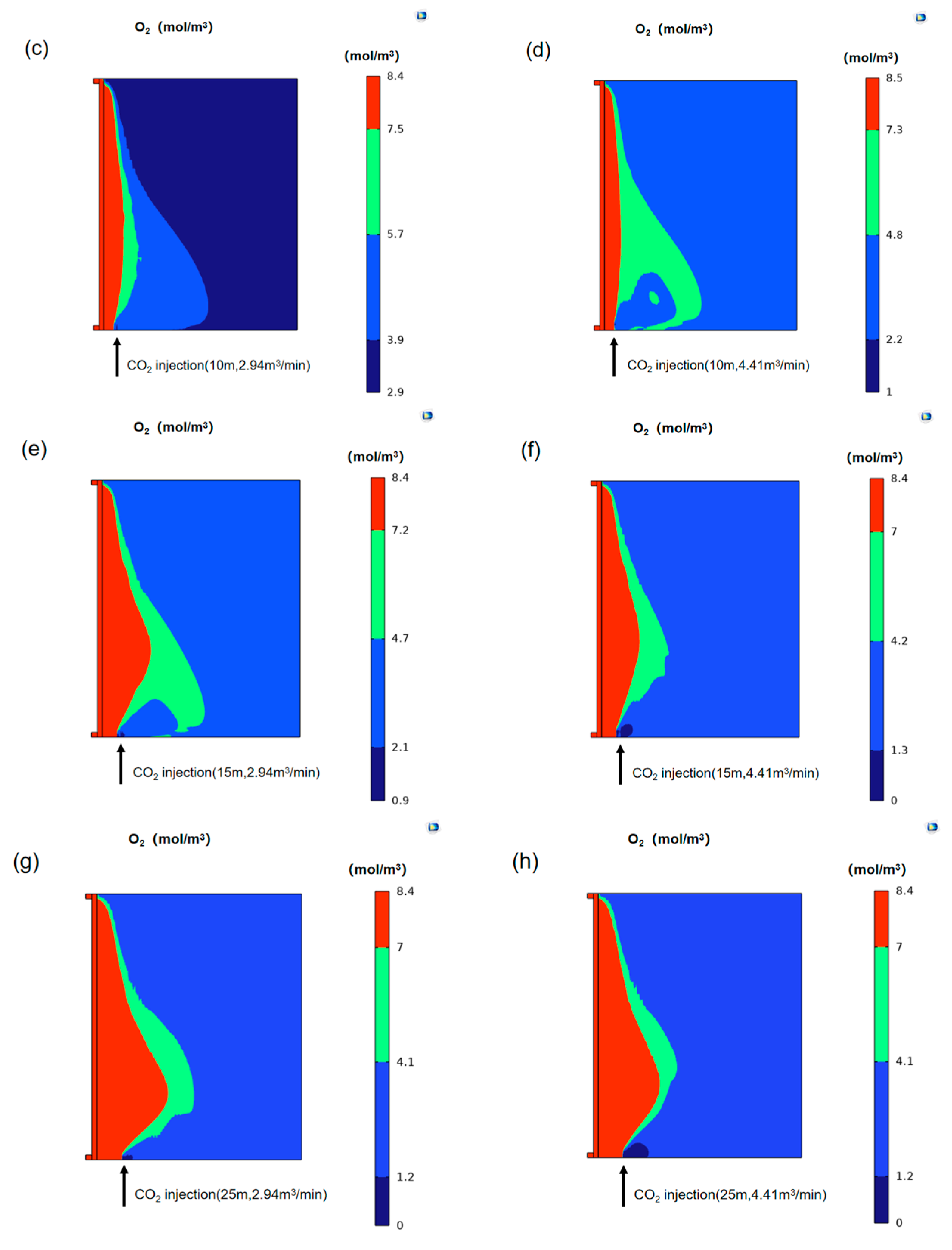

4.1. Injection Location

4.2. Injection Flow Rate

5. Conclusions

- (1)

- Using numerical simulation methods to evaluate the effectiveness of CO2 injection in the goaf, it was found that injecting CO2 at a location at least 10 m from the working face on the intake side significantly reduces oxygen concentration and shrinks the oxidation zone area, thereby mitigating the low-temperature oxidation and spontaneous combustion of residual coal.

- (2)

- Comparative analysis of different injection parameters confirmed that CO2 injection displaces oxygen within a certain range in the goaf, which is closely related to the distribution of airflow velocity in the goaf.

- (3)

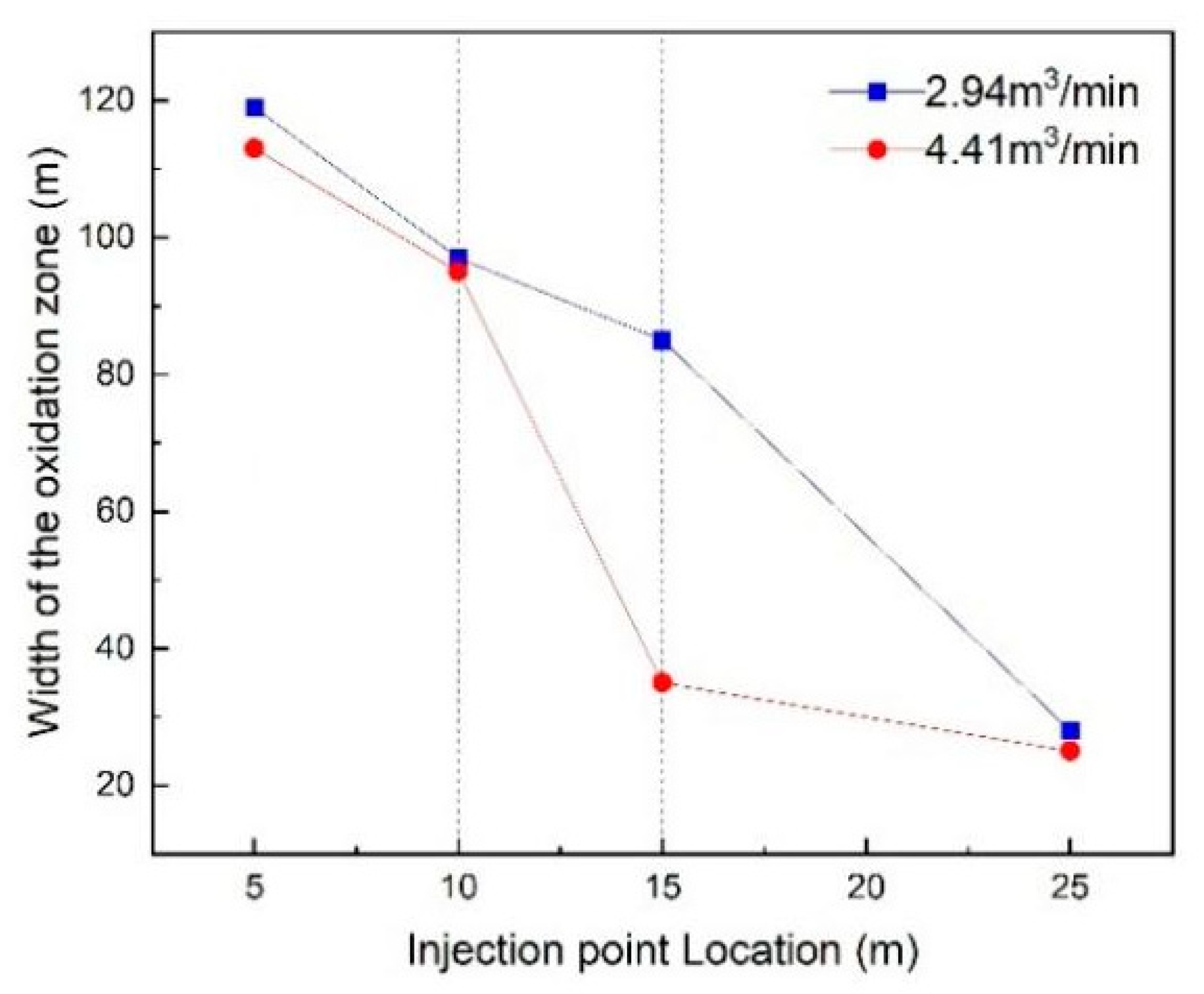

- By comparing eight injection scenarios, it was determined that the most significant reduction in oxidation zone width occurs when the injection port is 15 m from the working face with a flow rate of 4.41 m3/min. This study found that, within the tested range, the injection location has a more dominant influence on the oxidation zone width than the injection flow rate. To quantitatively substantiate the claim that injection location plays a dominant role over flow rate, the average change in oxidation zone width was calculated. Varying the injection location (across 5, 10, 15 and 25 m) led to an average change in oxidation zone width of approximately 45 m per 10-m shift in location, when averaged over the two flow rates. In contrast, varying the injection flow rate (between 2.94 and 4.41 m3/min) resulted in an average change of only about 10 m per 1.47 m3/min flow rate increase, when averaged across all locations. This finding provides a significant refinement to the existing understanding. While Li et al. [12] identified an optimal location for the Jiudaoling mine and Huang et al. [13] determined optimal parameters for a coking coal mine, their studies were context-specific. Our work generalizes this concept by demonstrating that the injection location is a primary controlling factor. This implies that in practice, engineers should prioritize the precise positioning of injection ports before fine-tuning the flow rate. This strategic insight can significantly enhance the efficiency of fire prevention planning.

- (4)

- This study provides a viable methodology for researching CO2 injection technology in goaf fire prevention. However, it is important to acknowledge its limitations. The numerical model, while consistent with literature findings [11], has not been directly validated against experimental or field measurement data from the specific mine, which introduces some uncertainty to the absolute quantitative results. The model assumed a uniform initial goaf temperature of 293.15 K and zero initial CO2 concentration. These assumptions, while simplifying the analysis, may not fully represent the actual conditions in deep mining environments where higher geothermal temperatures and pre-existing CO2 could influence gas behavior. Furthermore, the range of injection parameters investigated was limited [26], and a comprehensive sensitivity or uncertainty analysis of key input parameters was not conducted. These shortcomings will be addressed in future work. Our next steps include conducting detailed parametric sensitivity studies and collaborating with industry partners to collect in situ goaf monitoring data for direct model calibration and validation. Despite these limitations, the identified trends and the dominant role of injection location provide valuable strategic insights. For practical engineering applications, the model proposed by Li et al. [13] can be referenced to calculate the adsorption-compensated injection volume based on the goaf temperature field, thereby optimizing injection parameters for more precise and cost-effective fire prevention.

- (5)

- Furthermore, this modeling framework can be seamlessly extended beyond fire prevention to evaluate the synergistic potential of integrating CO2 injection with CO2 geological sequestration, a cornerstone of green mining initiatives. The same model that simulates O2 displacement for fire inerting can simultaneously track the transport, distribution, and long-term fate of the injected CO2 within the goaf. Key sequestration performance indicators, such as the effective CO2 storage capacity of the goaf, and its adsorption by residual coal, can be incorporated and assessed. This study observed that optimal fire prevention was achieved when CO2 accumulated and persisted in the deep goaf areas (15–25 m), forming a stable barrier. This very condition is also ideal for sequestration, as it indicates minimal CO2 leakage back to the working face and maximizes the contact time and volume for adsorption and dissolution. Therefore, the pursuit of optimal fire prevention parameters using this model inherently helps identify scenarios that favor higher CO2 sequestration efficiency, creating a dual benefit. Future work will explicitly integrate these sequestration metrics into the simulation outcomes, providing a comprehensive tool for designing combined safety and environmental management strategies in coal mines.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Y.; Wen, H.; Chen, C.; Guo, J.; Jin, Y.; Zheng, X.; Cheng, X.; Li, D. Research status and development trend of coal spontaneous combustion fire and prevention technology in China: A review. ACS Omega 2024, 9, 21727–21750. [Google Scholar] [CrossRef]

- Raju, A.; Singh, A.; Chandniha, S.K. A synergetic approach for quantification and analysis of coal fires in Jharia Coalfield, India. Phys. Chem. Earth Parts A/B/C 2023, 131, 103441. [Google Scholar] [CrossRef]

- Muduli, L.; Jana, P.K.; Mishra, D.P. Wireless sensor network based fire monitoring in underground coal mines: A fuzzy logic approach. Process Saf. Environ. Prot. 2018, 113, 435–447. [Google Scholar] [CrossRef]

- Deng, J.; Bai, Z.J.; Xiao, Y.; Song, Z. Present situation and challenge of coal spontaneous combustion disasters prevention and control technology. Saf. Coal Mines 2020, 51, 118–125. [Google Scholar] [CrossRef]

- Li, Q.-W.; Xiao, Y.; Zhong, K.-Q.; Shu, C.-M.; Lü, H.-F.; Deng, J.; Wu, S. Overview of commonly used materials for coal spontaneous combustion prevention. Fuel 2020, 275, 117981. [Google Scholar] [CrossRef]

- Guo, L.; Du, H.; Cui, X.; Zhang, J.; Wang, K.; Wu, J.; Guo, H. Research progress and prospects of CO2 fire prevention and extinguishing technology in mine goafs. Thermochim. Acta 2025, 747, 179977. [Google Scholar] [CrossRef]

- Fan, J. Effects of CO2 injection factors on preventing spontaneous coal combustion in coal mine gobs: A simulation approach. Front. Earth Sci. 2023, 11, 1191049. [Google Scholar] [CrossRef]

- Zhou, H.; Wu, Y.; Liu, C.; Geng, H.; Yao, C. Study on the diffusion and migration law of CO2 sequestrated in abandoned coal mine goaf. Deep. Undergr. Sci. Eng. 2025, 10, 1–18. [Google Scholar] [CrossRef]

- Zhang, Y.; Niu, K.; Du, W.; Zhang, J.; Wang, H.; Zhang, J. A method to identify coal spontaneous combustion-prone regions based on goaf flow field under dynamic porosity. Fuel 2021, 288, 119690. [Google Scholar] [CrossRef]

- Perera, M.; Ranjith, P.; Choi, S.; Bouazza, A. A parametric study of coal mass and cap rock behaviour and carbon dioxide flow during and after carbon dioxide injection. Fuel 2013, 106, 129–138. [Google Scholar] [CrossRef]

- Li, Z.; Liu, Y.; Wang, Z.; Lin, L. Study on numerical simulation of CO2 injection fire prevention and extinguishing technique in goaf of Jiudaoling Mine. Coal Sci. Technol. 2018, 46, 153–157. [Google Scholar] [CrossRef]

- Huang, S.; Li, Z.; Liu, Y.; Wu, J. Optimization study of CO2 inerting parameters in goaf based on coal sample oxidation characteristics. Arab. J. Chem. 2025, 18, 1. [Google Scholar] [CrossRef]

- Li, Z.; Li, L.; Si, J.; Yang, X. New exploration on the goaf inerting with hidden fire source under CO2 injection volume of adsorption compensation. Case Stud. Therm. Eng. 2024, 62, 105203. [Google Scholar] [CrossRef]

- Si, J.; Li, L.; Cheng, G.; Shao, H.; Wang, Y.; Li, Z. Characteristics and safety of CO2 for the fire prevention technology with gob-side entry retaining in goaf. Acs Omega 2021, 6, 18518–18526. [Google Scholar] [CrossRef] [PubMed]

- Ma, Q.; Xue, J.; Shi, Y.; Zeng, X. Characteristics of porosity distribution and gas migration in different layers of comprehensive working face goaf. Energies 2023, 16, 2325. [Google Scholar] [CrossRef]

- Wang, Y.; Si, G.; Oh, J.; Belle, B. CFD modelling of longwall goaf atmosphere under vertical boreholes gas drainage. Int. J. Coal Geol. 2023, 280, 104400. [Google Scholar] [CrossRef]

- Xia, T.; Zhou, F.; Wang, X.; Kang, J.; Pan, Z. Safety evaluation of combustion-prone longwall mining gobs induced by gas extraction: A simulation study. Process Saf. Environ. Prot. 2017, 109, 677–687. [Google Scholar] [CrossRef]

- Jambhekar, V.A. Forchheimer Porous-Media Flow Models-Numerical Investigation and Comparison with Experimental Data. Master’s Thesis, Universität Stuttgart-Institut für Wasserund Umweltsystemmodellierung, Stuttgart, Germany, 2011. [Google Scholar]

- Kirsch, E.G. Zeitschrift des Vereines deutscher Ingenieure. In Die Theorie der Elastizität und die Bedurfrisse der Festigkeitslehre; Springer: Berlin/Heidelberg, Germany, 1898; Volume 42, pp. 797–807. [Google Scholar]

- Kuznetsov, A.V. Analytical study of fluid flow and heat transfer during forced convection in a composite channel partly filled with a Brinkman–Forchheimer porous medium. Flow Turbul. Combust. 1998, 60, 173–192. [Google Scholar] [CrossRef]

- Hooman, K.; Li, J.; Dahari, M. Thermal dispersion effects on forced convection in a porous-saturated pipe. Therm. Sci. Eng. Prog. 2017, 2, 64–70. [Google Scholar] [CrossRef]

- Nield, D.A.; Bejan, A. Convection in Porous Media; Springer: New York, NY, USA, 2006. [Google Scholar] [CrossRef]

- Taraba, B.; Michalec, Z. Effect of longwall face advance rate on spontaneous heating process in the gob area–CFD modelling. Fuel 2011, 90, 2790–2797. [Google Scholar] [CrossRef]

- Wang, G.; Xu, H.; Wu, M.; Wang, Y.; Wang, R.; Zhang, X. Porosity model and air leakage flow field simulation of goaf based on DEM-CFD. Arab. J. Geosci. 2018, 11, 148. [Google Scholar] [CrossRef]

- Shao, H.; Jiang, S.; Wang, L.; Wu, Z. Bulking factor of the strata overlying the gob and a three-dimensional numerical simulation of the air leakage flow field. Min. Sci. Technol. 2011, 21, 261–266. [Google Scholar] [CrossRef]

- Guo, J.; Gao, B.; Liu, Y.; Chen, C.; Cai, G.; Wang, L. Research and Application of CO2 Fire Prevention Mechanism and Key Technologies in Mines: A Review. Fire 2024, 7, 353. [Google Scholar] [CrossRef]

| Parameter | Symbol | Unit | Value |

|---|---|---|---|

| The initial temperature of goaf | K | 293.15 | |

| Initial oxygen concentration in goaf | mol/m3 | 8.3142 | |

| Initial CO2 concentration in goaf | mol/m3 | 0 | |

| Attenuation rates from the working face | Dimensionless | 0.08 | |

| Attenuation rates from the solid boundaries | Dimensionless | 0.368 | |

| Distribution shape adjustment coefficient | Dimensionless | 0.323 | |

| Minimum bulk factors | Dimensionless | 1.12 | |

| Maximum bulk factors | Dimensionless | 1.5 | |

| The CO2 diffusion coefficient in the standard state | m2/s | 3.5 × 10−5 | |

| The density of coal | kg/m3 | 1410 | |

| Goaf height | m | 15 |

| Cases | Injection Location | Injection Flow Rate |

|---|---|---|

| A1 | 5 m | 2.94 m3/min |

| A2 | 5 m | 4.41 m3/min |

| B1 | 10 m | 2.94 m3/min |

| B2 | 10 m | 4.41 m3/min |

| C1 | 15 m | 2.94 m3/min |

| C2 | 15 m | 4.41 m3/min |

| D1 | 25 m | 2.94 m3/min |

| D2 | 25 m | 4.41 m3/min |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, G.; Wei, B.; Xiao, C.; Dai, Y.; Wang, Y.; Zhang, S.; Zhang, X. A Numerical Study on the Influence of CO2 Injection Location and Flow Rate on the Oxidation Zone in Goaf. Appl. Sci. 2025, 15, 12181. https://doi.org/10.3390/app152212181

Cheng G, Wei B, Xiao C, Dai Y, Wang Y, Zhang S, Zhang X. A Numerical Study on the Influence of CO2 Injection Location and Flow Rate on the Oxidation Zone in Goaf. Applied Sciences. 2025; 15(22):12181. https://doi.org/10.3390/app152212181

Chicago/Turabian StyleCheng, Gang, Bin Wei, Chang Xiao, Yiming Dai, Yuqi Wang, Shiyi Zhang, and Xian Zhang. 2025. "A Numerical Study on the Influence of CO2 Injection Location and Flow Rate on the Oxidation Zone in Goaf" Applied Sciences 15, no. 22: 12181. https://doi.org/10.3390/app152212181

APA StyleCheng, G., Wei, B., Xiao, C., Dai, Y., Wang, Y., Zhang, S., & Zhang, X. (2025). A Numerical Study on the Influence of CO2 Injection Location and Flow Rate on the Oxidation Zone in Goaf. Applied Sciences, 15(22), 12181. https://doi.org/10.3390/app152212181