Macro-Mechanical Property and Microfracture Evolution of Layered Rock Mass: Effects of Confining Pressure and Bedding Direction

Abstract

1. Introduction

2. Material and Testing Results

2.1. Sample Preparation

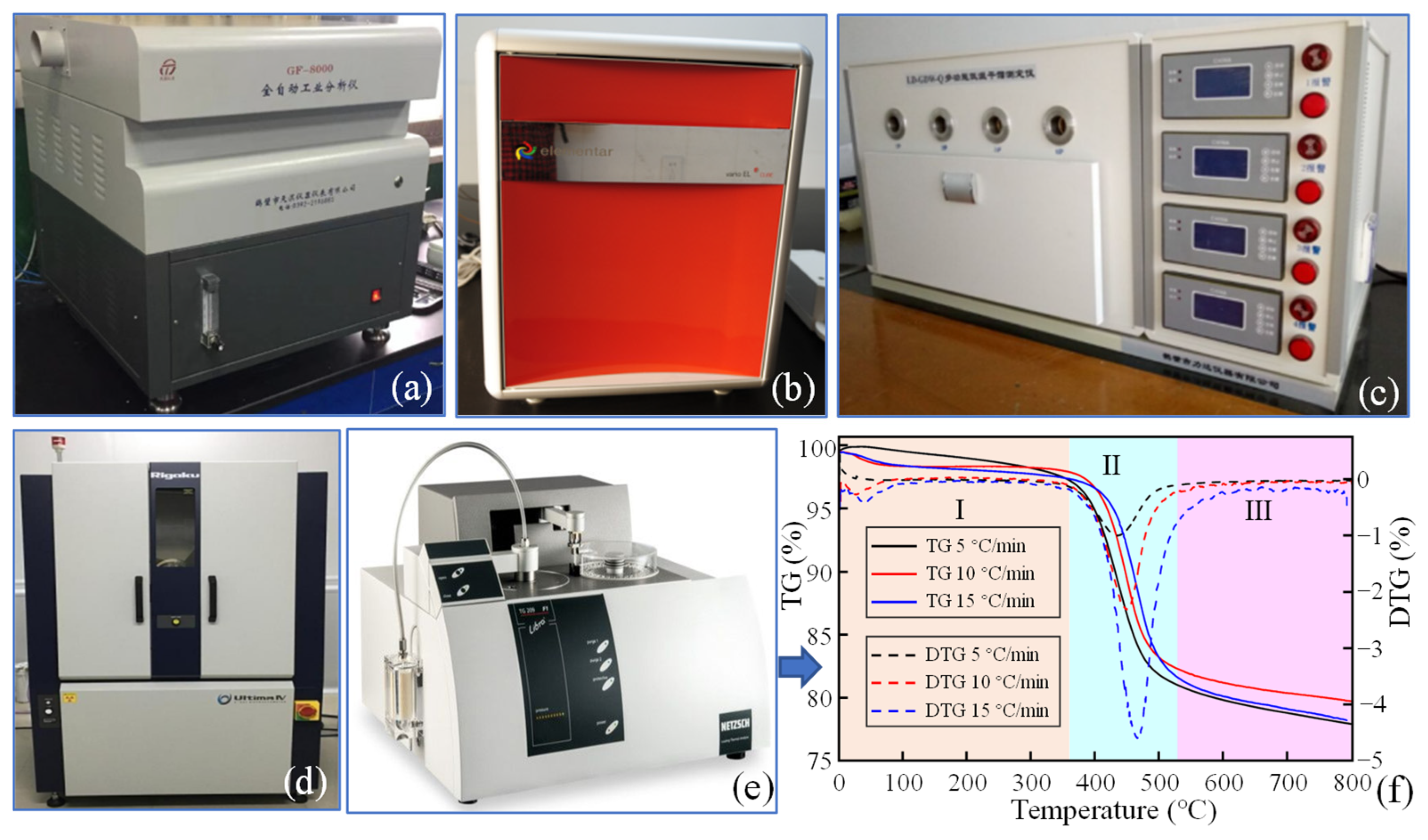

2.2. Test Results of Physical Properties

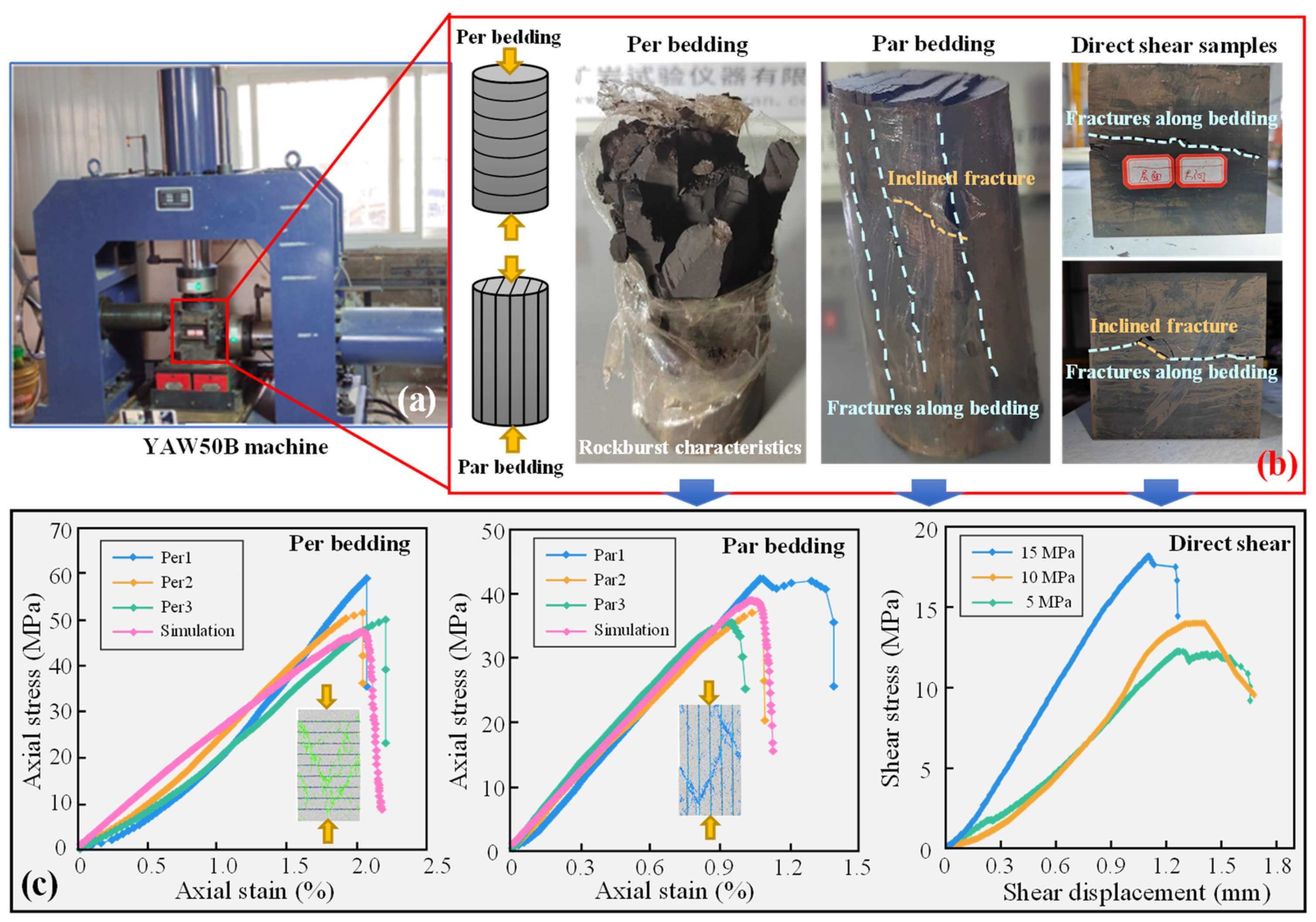

2.3. Test Results of Mechanical Properties

3. Macro-Mechanical Property of Layered Rock Mass Based on Numerical Simulation

3.1. Layered Rock Mass Model Construction

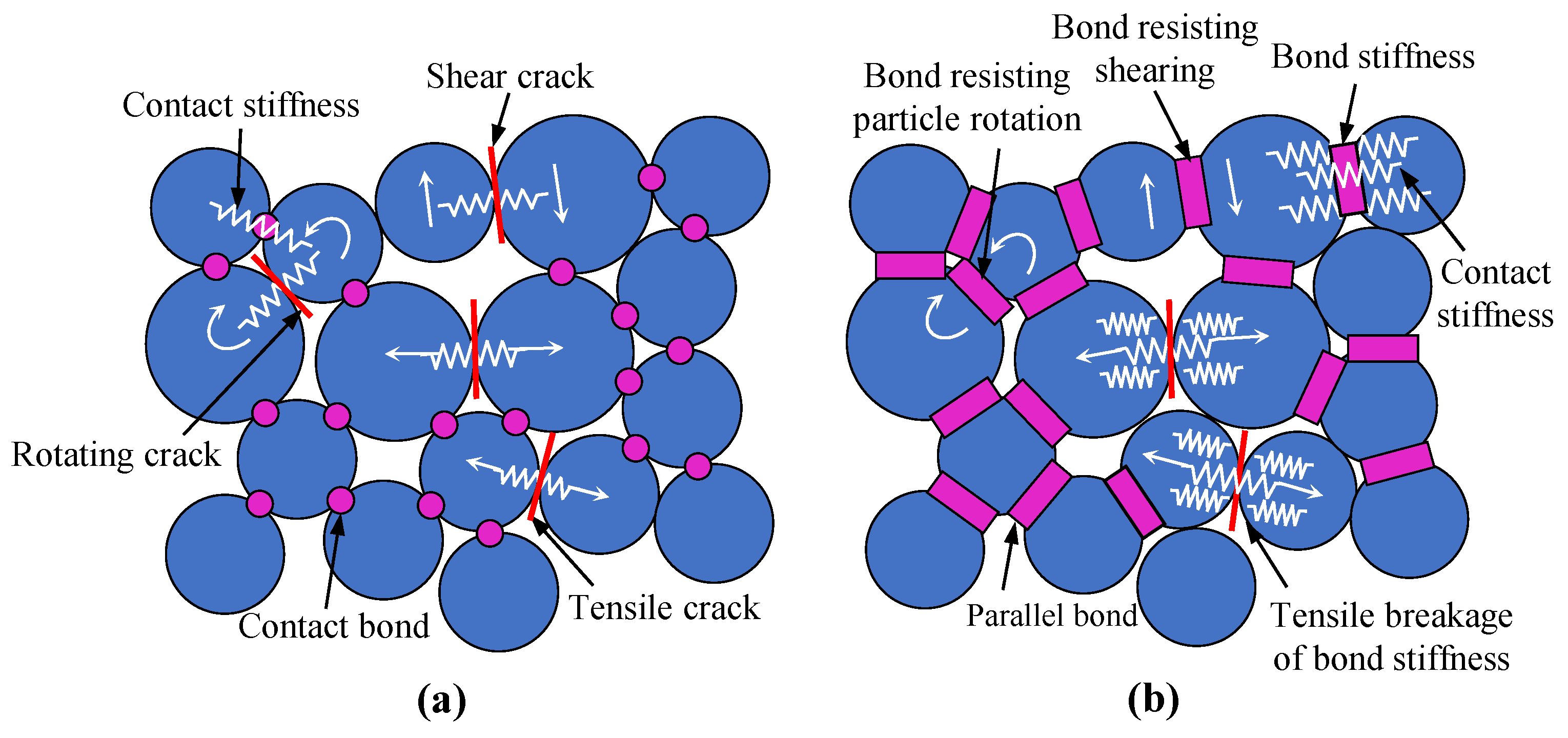

3.1.1. Parallel Bond Model of Rock Material

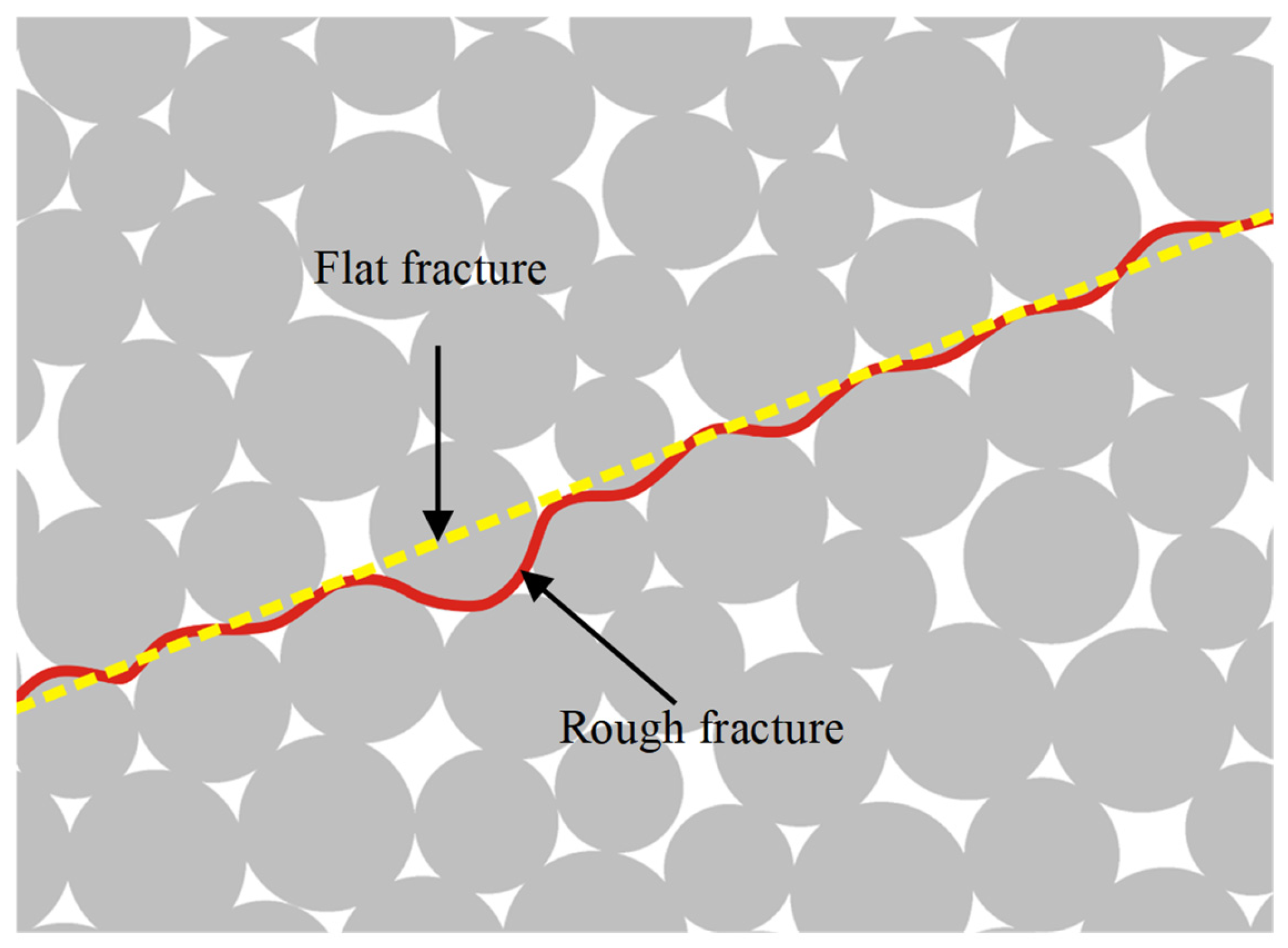

3.1.2. Generation of Beddings

3.1.3. Model Setup

3.2. Macro-Mechanical Properties

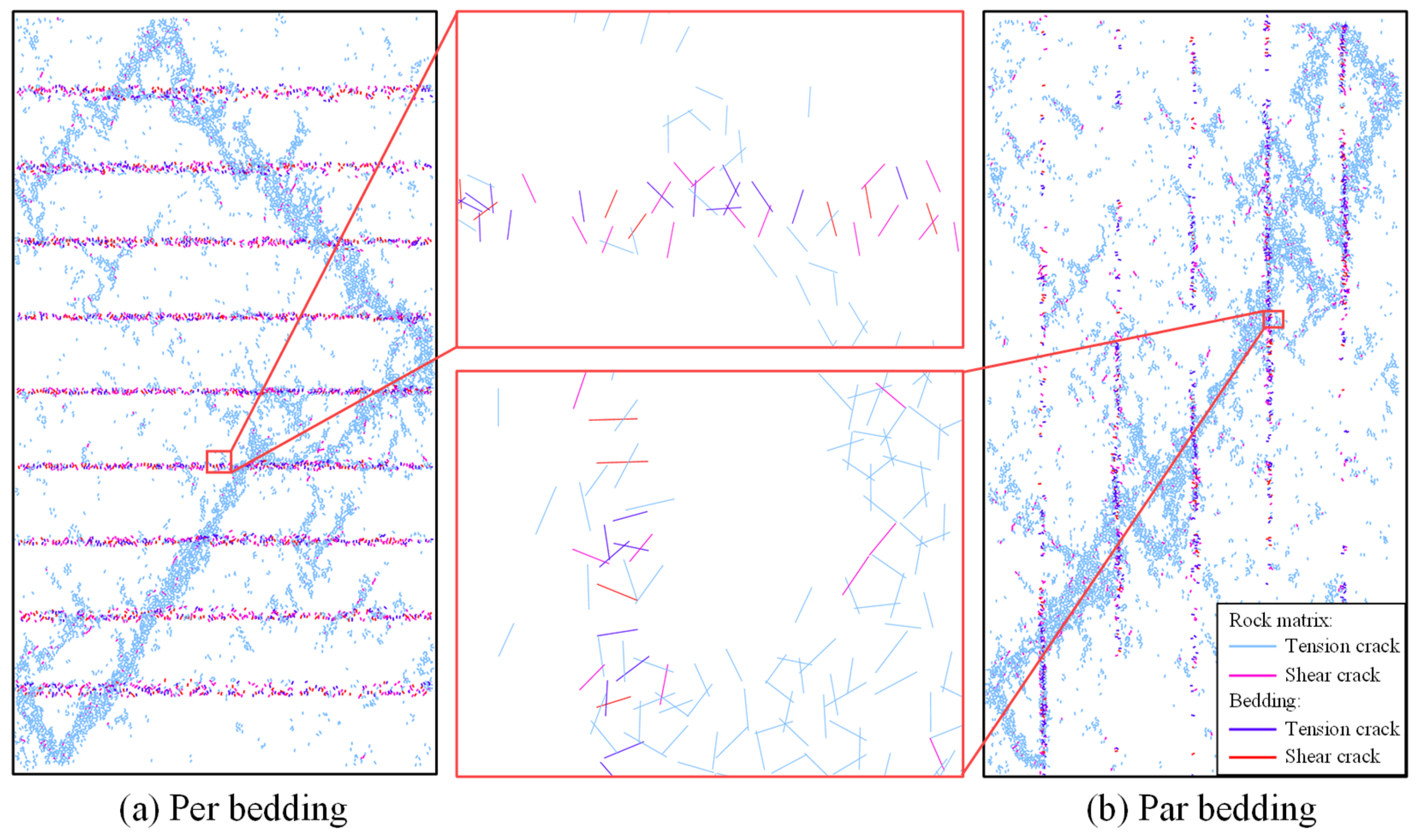

3.2.1. Macroscopic Failure Pattern

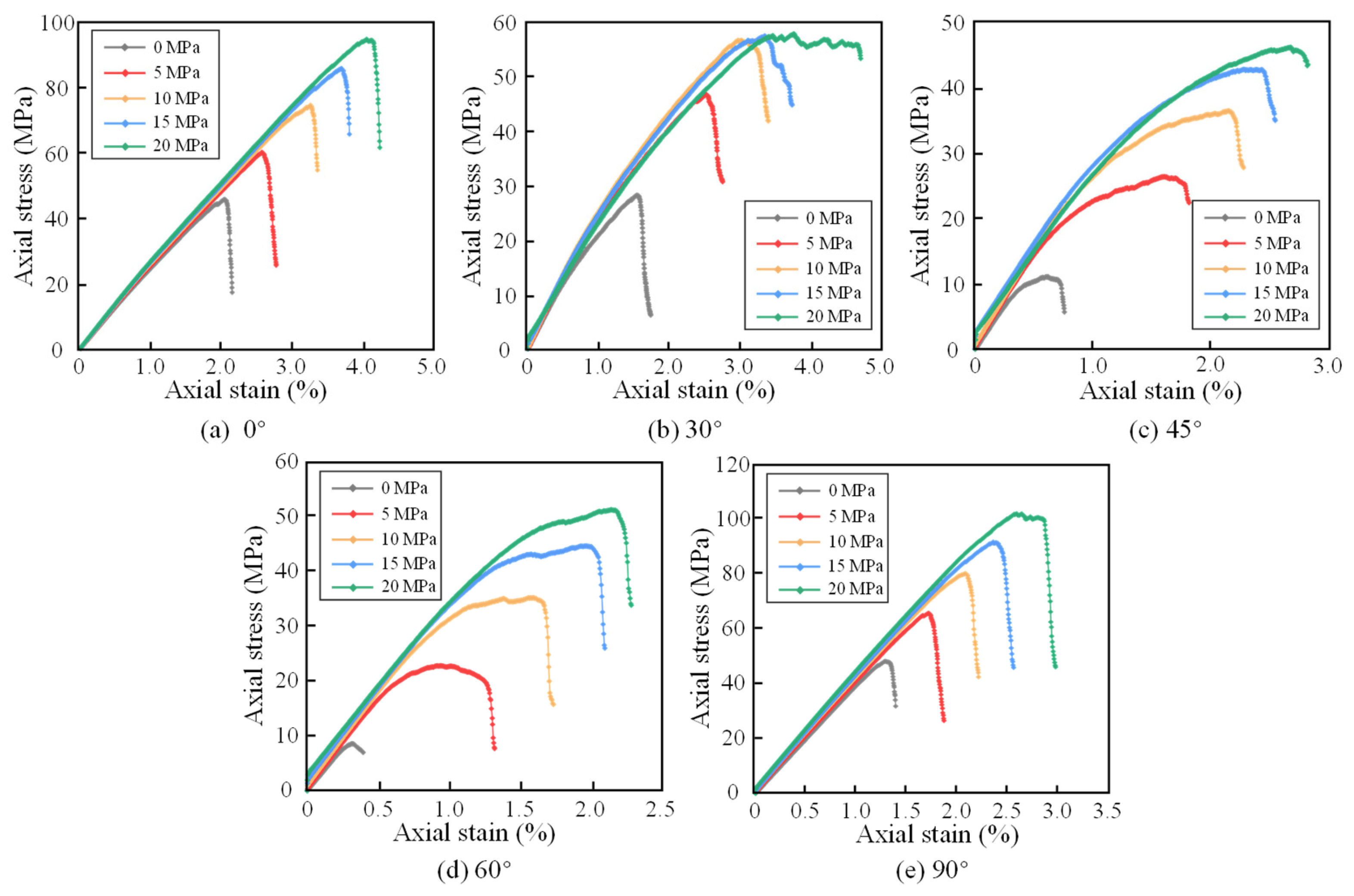

3.2.2. Stress–Strain Characteristics

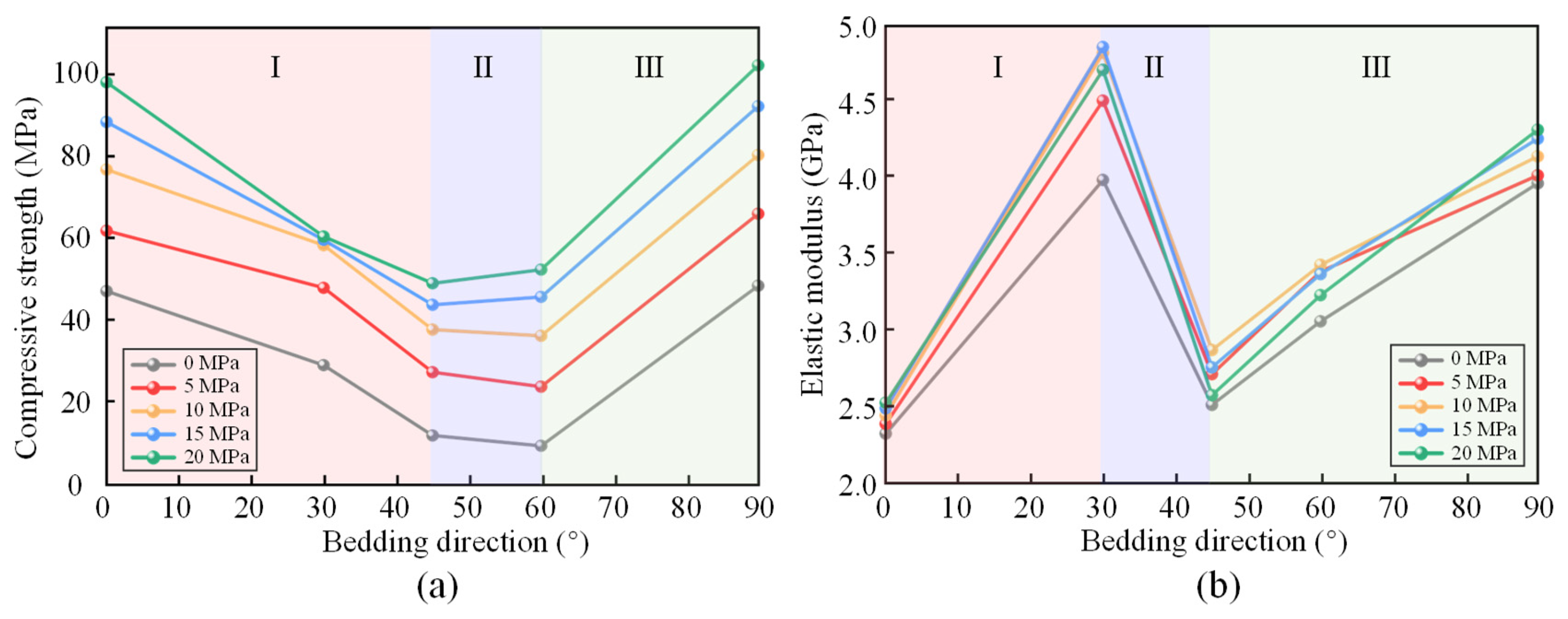

3.2.3. Compressive Strength and Elastic Modulus

4. Microfracture Evolution Mechanism of Layered Rock Mass

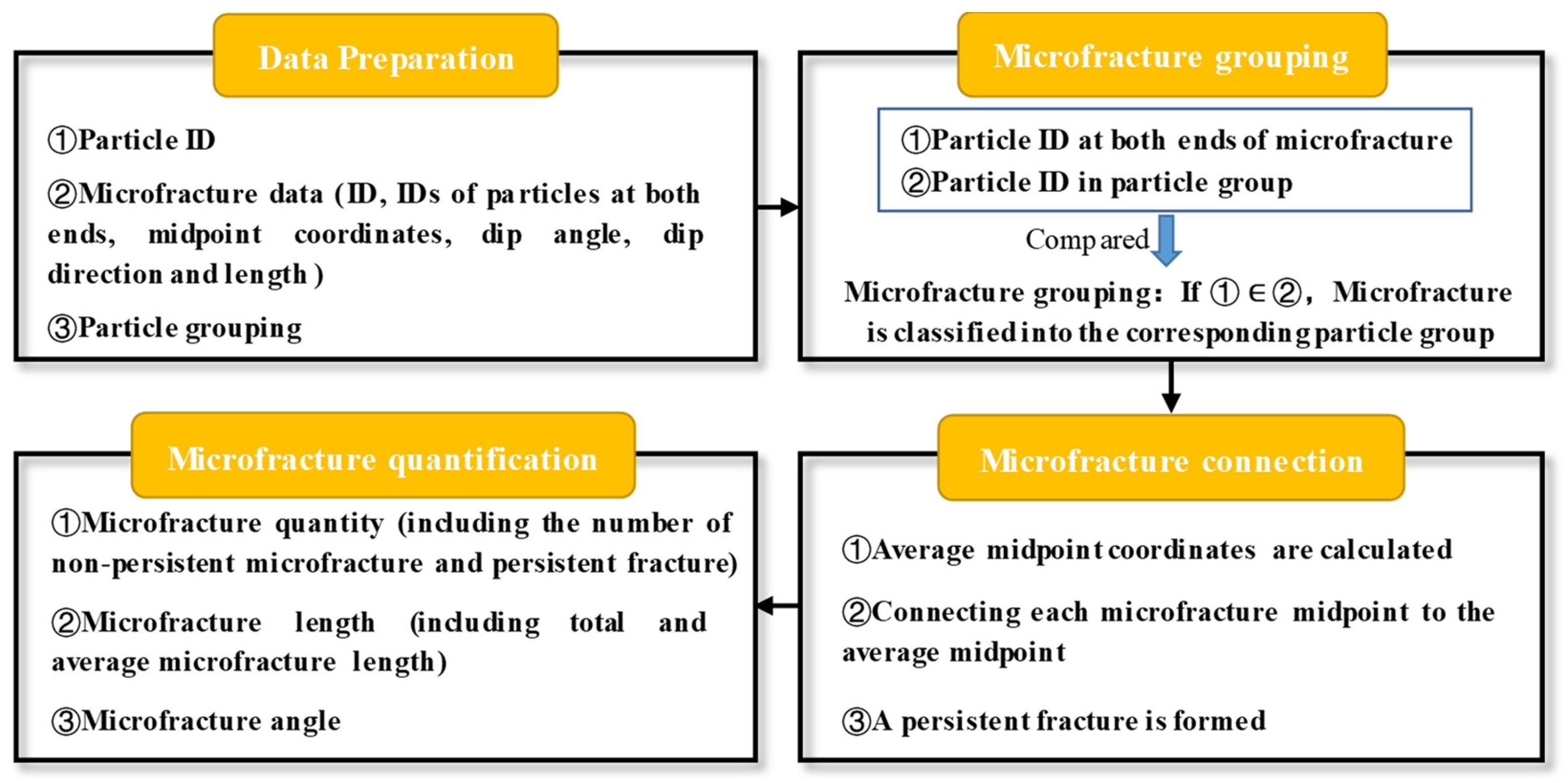

4.1. Quantification Method of Microfracture Properties

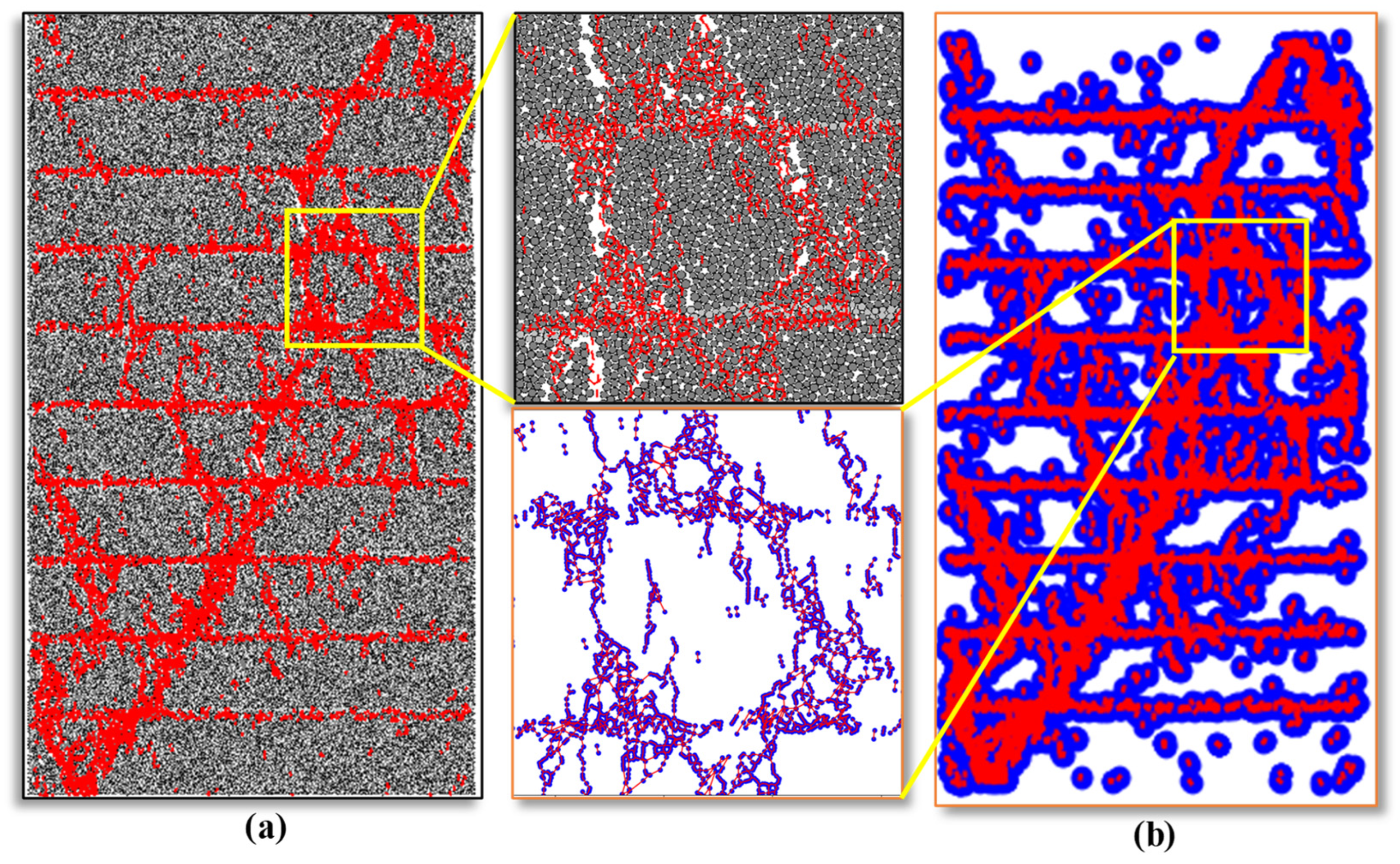

4.1.1. Data Preparation

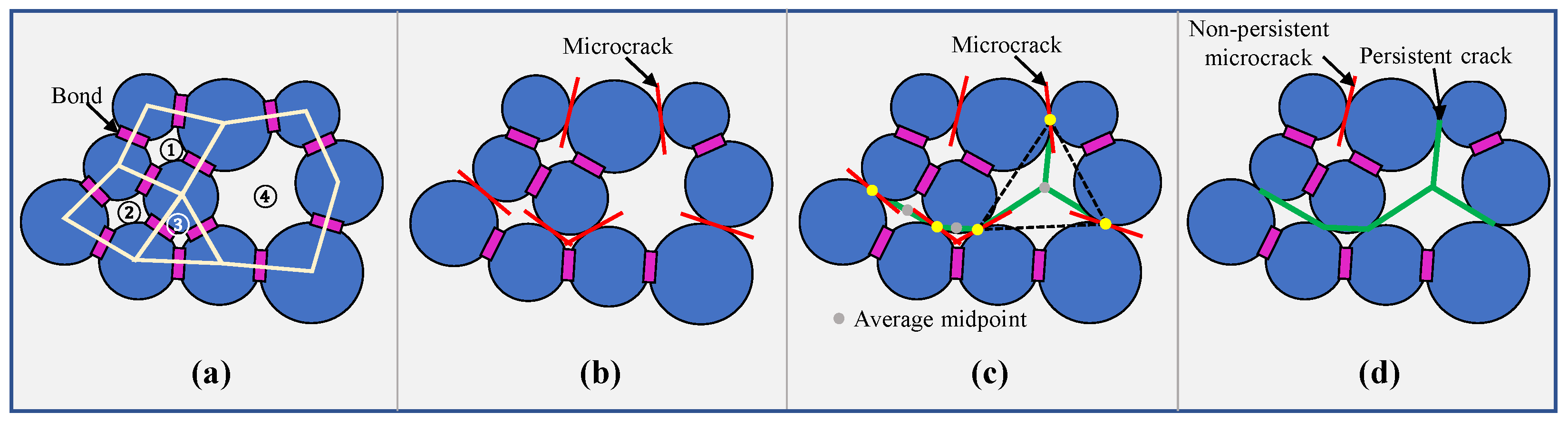

4.1.2. Microfracture Grouping and Connection

4.1.3. Microfracture Quantification

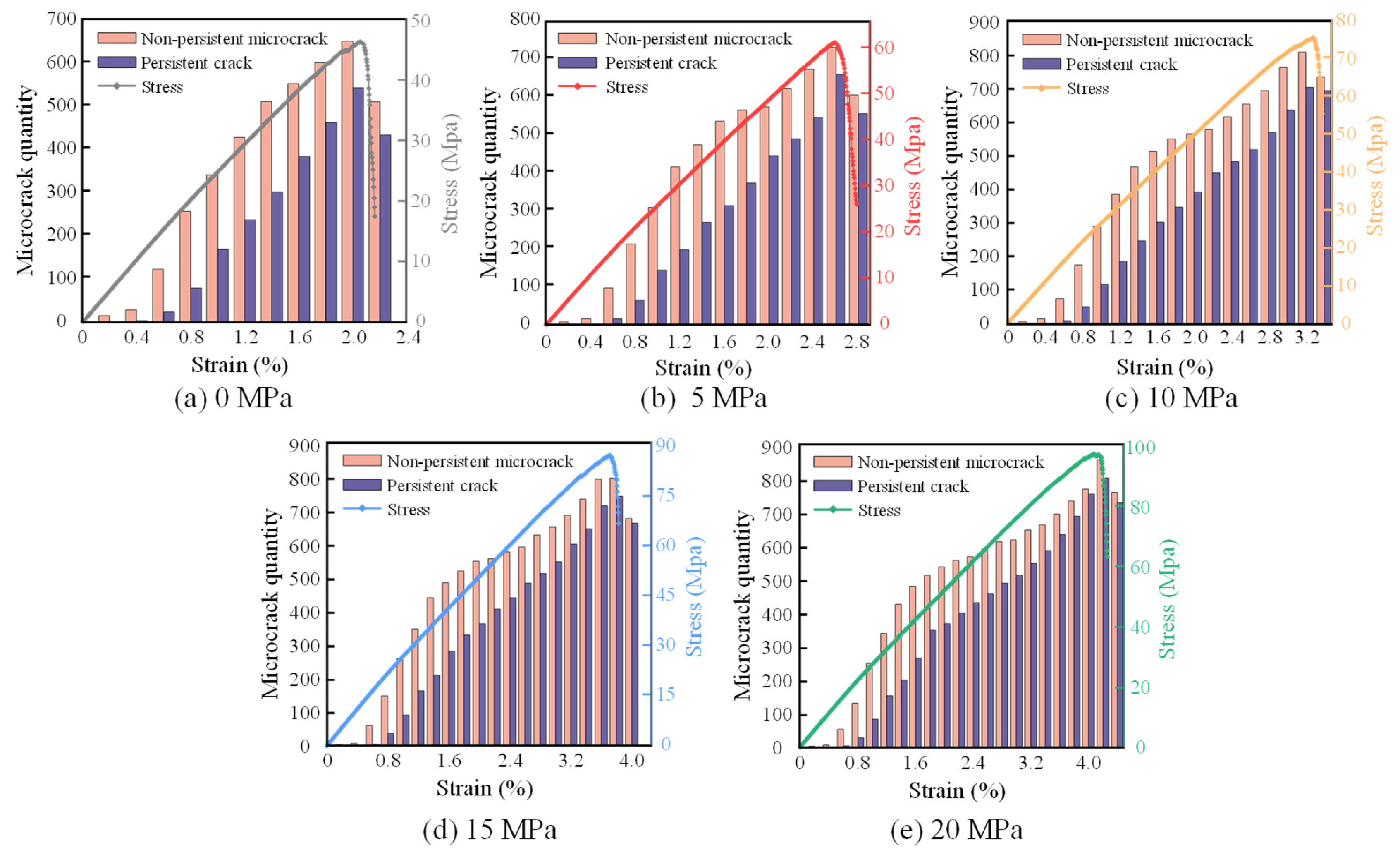

4.2. Evolution of Microfracture Quantity

4.3. Evolution of Microfracture Length

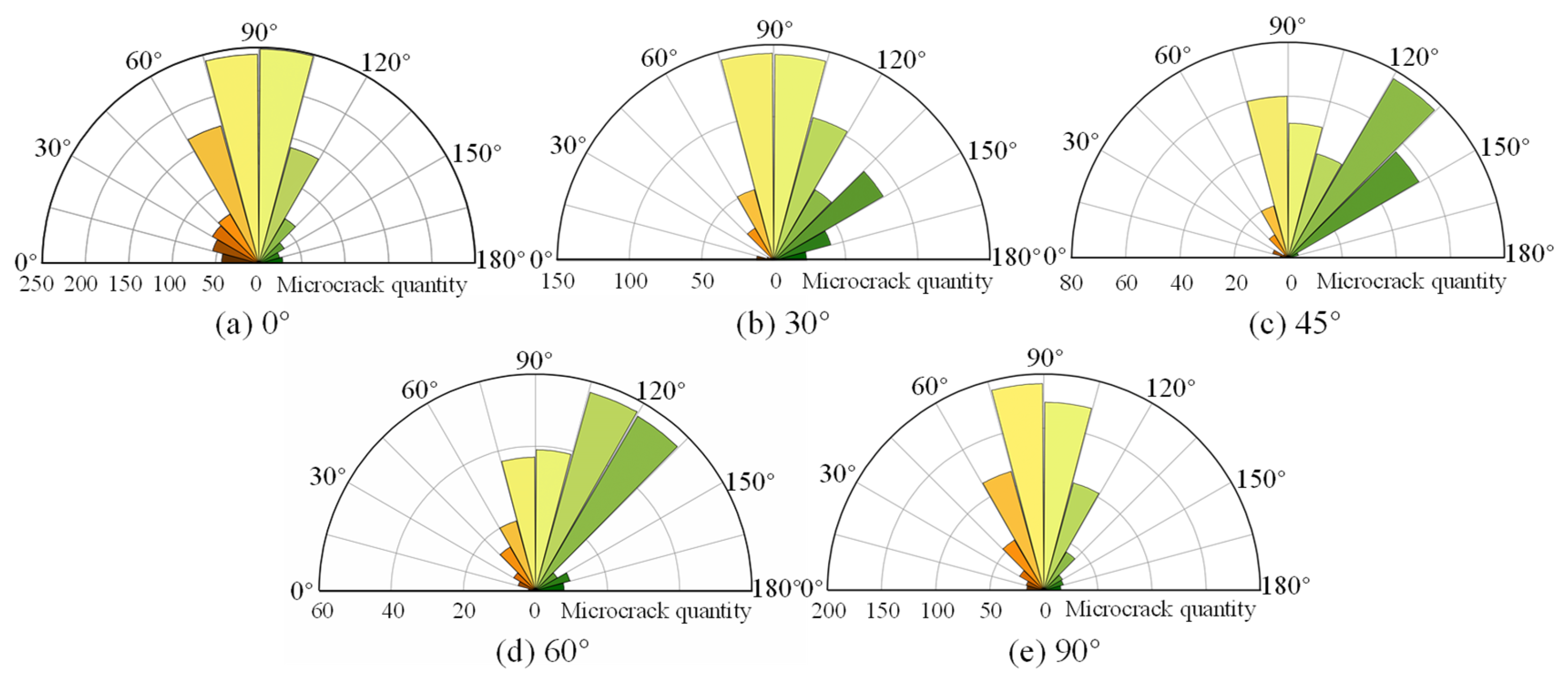

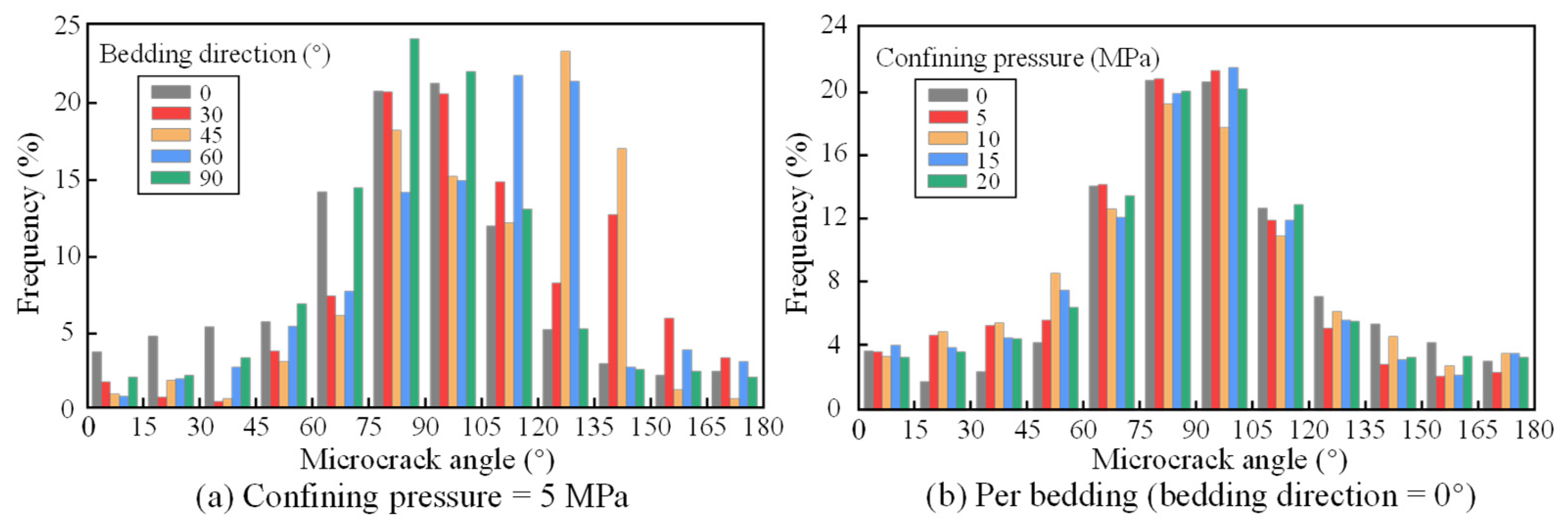

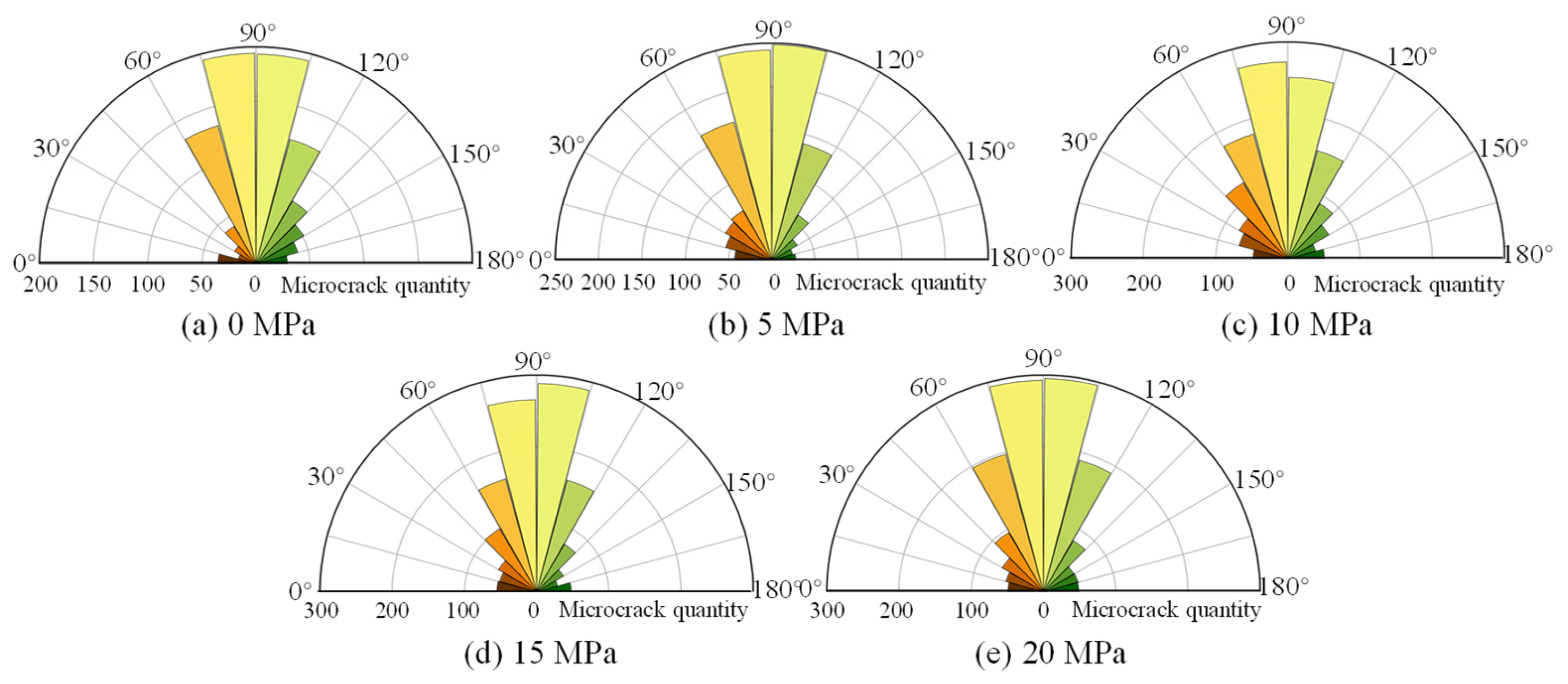

4.4. Evolution of Microfracture Angle

5. Conclusions

- (1)

- The macroscopic failure patterns of layered rock masses are governed by both bedding direction and confining pressure. Per bedding primarily exhibits splitting failure, while inclined beddings (30° to 60°) present combined shear-tension or shear-slip failures. For Par bedding, numerous vertical and intersecting fractures are observed along the loading direction.

- (2)

- The stress–strain behavior transforms from brittle to ductile as the bedding direction changes, and compressive strength displays a U-shaped variation with bedding direction. The lowest strength occurs at 45° to 60°, and higher confining pressures enhance both compressive strength and deformation capacity. The elastic modulus shows three stages of variation: an increase (Per bedding to 30°), a decrease (30° to 45°), and a re-increase (45° to Par bedding).

- (3)

- The proposed microfracture connection algorithm effectively links intersecting microfractures, enabling quantitative characterization of microfracture number, length, and orientation. The analysis reveals that inclined beddings contain more persistent and interconnected microfractures, which explains their lower compressive strength compared with Par and Per beddings.

- (4)

- The evolution of microfracture length reflects the transition from brittle to ductile failure. Under increasing bedding angle, the rate of fracture growth accelerates, while confining pressure mainly promotes microfracture interconnection without significantly altering their orientation.

- (5)

- This study establishes a multiscale framework that connects microfracture evolution with macroscopic mechanical behavior, providing theoretical support for the stability evaluation of layered rock slopes and practical guidance for optimizing in situ oil shale extraction. The proposed microfracture quantification method represents a novel tool for analyzing fracture mechanics in other layered geological materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CT | Computed tomography |

| UCS | Uniaxial compressive strength |

| FEM | Finite element method |

| FDM | Finite difference method |

| DEM | Discrete element method |

| UCT | Uniaxial compressive test |

| BPM | Bonded-particle model |

| PBM | Parallel bond model |

| CBM | Contact bond model |

| SJM | Smooth-joint contact model |

References

- Huang, H.W.; Yu, H.; Xu, W.L.; Lyu, C.S.; Micheal, M.; Xu, H.Y.; Liu, H.; Wu, H.A. A coupled thermo-hydro-mechanical-chemical model for production performance of oil shale reservoirs during in-situ conversion process. Energy 2023, 268, 126700. [Google Scholar] [CrossRef]

- Zhang, S.; Song, S.Y.; Zhang, W.; Zhao, J.M.; Cao, D.F.; Ma, W.L.; Chen, Z.J.; Ying, H. Research on the inherent mechanism of rock mass deformation of oil shale in-situ mining under the condition of thermal-fluid-solid coupling. Energy 2023, 280, 128149. [Google Scholar] [CrossRef]

- Wang, G.Y.; Liu, S.W.; Yang, D.; Fu, M.X. Numerical study on the in-situ pyrolysis process of steeply dipping oil shale deposits by injecting superheated water steam: A case study on Jimsar oil shale in Xinjiang, China. Energy 2022, 239, 122182. [Google Scholar] [CrossRef]

- Pan, Y.; Jia, Y.H.; Zheng, J.B.; Yang, S.C.; Bttina, H. Research progress of fracture development during in-situ cracking of oil shale. J. Anal. Appl. Pyrol. 2023, 174, 106110. [Google Scholar] [CrossRef]

- Huang, X.D.; Yang, D.; Wang, G.Y.; Zhang, K.D.; Zhao, J. Evolution patterns and anisotropic connectivity characteristics of pores and fissures in oil shale after steam heating at different temperatures. Nat. Resour. Res. 2025, 34, 409–425. [Google Scholar] [CrossRef]

- Wang, Y.; Zhai, C.; Liu, T.; Yu, X.; Xu, J.Z.; Sun, Y.; Cong, Y.Z.; Tang, W.; Zheng, Y.F.; Luo, N. Analysis of fracture network formation mechanisms and main controlling factors of methane explosion fracturing in deep shale reservoir. Rock Mech. Rock Eng. 2024, 57, 7125–7147. [Google Scholar] [CrossRef]

- Zhou, J.; Wu, G.A.; Geng, Y.N.; Guo, Y.T.; Chang, X.; Peng, C.Y.; Ai, C.Z. Laboratory study of the factors affecting hydraulic fracturing effect for inter-salt oil shale layers, Qianjiang Depression, China. Petrol. Sci. 2023, 20, 1690–1706. [Google Scholar] [CrossRef]

- He, M.C.; Nie, W.; Zhao, Z.Y.; Guo, W. Experimental investigation of bedding plane orientation on the rockburst behavior of sandstone. Rock Mech. Rock Eng. 2012, 45, 311–326. [Google Scholar] [CrossRef]

- Liu, Y.; Dai, F.; Feng, P.; Xu, N.W. Mechanical behavior of intermittent jointed rocks under random cyclic compression with different loading parameters. Soil Dyn. Earthq. Eng. 2018, 113, 12–24. [Google Scholar] [CrossRef]

- Yin, P.F.; Yang, S.Q. Experimental investigation of the strength and failure behavior of layered sandstone under uniaxial compression and Brazilian testing. Acta Geophys. 2018, 66, 585–605. [Google Scholar] [CrossRef]

- Wen, S.; Huang, R.Z.; Zhang, C.S.; Zhao, X.W. Mechanical behavior and failure mechanism of composite layered rocks under dynamic tensile loading. Int. J. Rock Mech. Min. Sci. 2023, 170, 105533. [Google Scholar] [CrossRef]

- Xin, J.; Jiang, Q.; Gong, F.Q.; Liu, L.; Liu, C.; Liu, Q.; Yang, Y.; Chen, P.F. Mechanical behaviors of backfill-rock composites: Physical shear test and back-analysis. J. Rock Mech. Geotech. Eng. 2023, 16, 807–827. [Google Scholar] [CrossRef]

- Kimberley, J.; Ramesh, K.T.; Barnouin, O.S. Visualization of the failure of quartz under quasi-static and dynamic compression. J. Geophys. Res. 2010, 115, B08207. [Google Scholar] [CrossRef]

- Amitrano, D.; Gruber, S.; Girard, L. Evidence of frost-cracking inferred from acoustic emissions in a high-alpine rock-wall. Earth Planet. Sci. Lett. 2012, 341, 86–93. [Google Scholar] [CrossRef]

- Kumar, S.; Das, A.; Tiwari, G. A comparative study on the dynamic loading response of heat-treated soft and medium hard rocks. Eng. Fract. Mech. 2023, 292, 109579. [Google Scholar] [CrossRef]

- Miguel, C.R.S.; Petropoulos, N.; Yi, C.P.; Johansson, D. Experimental investigation of blast-induced crack propagation based on digital image correlation analysis. Shock Vib. 2024, 1, 4149322. [Google Scholar] [CrossRef]

- Okamoto, A.; Tanaka, H.; Watanabe, N.; Saishu, H.; Tsuchiya, N. Fluid pocket generation in response to heterogeneous reactivity of a rock fracture under hydrothermal conditions. Geophys. Res. Lett. 2017, 44, 10306–10315. [Google Scholar] [CrossRef]

- Xu, W.J.; Zhang, H.Y. Meso and macroscale mechanical behaviors of soil–rock mixtures. Acta Geotech. 2022, 17, 3765–3782. [Google Scholar] [CrossRef]

- Yang, S.Q.; Dong, J.P.; Yang, J.; Yang, Z.; Huang, Y.H. An experimental investigation of failure mechanical behavior in cylindrical granite specimens containing two non-coplanar open fissures under different confining pressures. J. Cent. South Univ. 2022, 29, 1578–1596. [Google Scholar] [CrossRef]

- Wang, X.Z.; Jiang, L.S.; Li, Y.Y.; Zhang, L.; Sainoki, A.; Mitri, H.S.; Yang, Y.M.; Peng, X.H. Experimental study on the mechanical behavior and failure characteristics of rock analogs with filled internal fractures: A new method by sand powder 3D printing. Constr. Build. Mater. 2024, 427, 136261. [Google Scholar] [CrossRef]

- Xu, J.; Pu, H.; Sha, Z.H. Influence of microstructure on dynamic mechanical behavior and damage evolution of frozen–thawed sandstone using computed tomography. Materials 2022, 16, 119. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Guo, P.F.; Gao, X.B.; Zou, C.J.; Wang, K.Y.; Hu, J.Z.; Sun, Y.; Lei, L. Crack and failure behaviors of sandstone subjected to dynamic loads visualized by micro-computed tomography. J. Rock Mech. Geotech. Eng. 2024, 17, 1459–1473. [Google Scholar] [CrossRef]

- Peta, K.; Stemp, W.J.; Stocking, T.; Chen, R.; Love, G.; Gleason, M.A.; Houk, B.A.; Brown, C.A. Multiscale geometric characterization and discrimination of dermatoglyphs (fingerprints) on hardened clay—A novel archaeological application of the GelSight Max. Materials 2025, 18, 2939. [Google Scholar] [CrossRef] [PubMed]

- Elmo, D.; Stead, D.; Eberhardt, E.; Vyazmensky, A. Applications of finite/discrete element modeling to rock engineering problems. Int. J. Geomech. 2013, 13, 565–580. [Google Scholar] [CrossRef]

- Mahabadi, O.K.; Tatone, B.S.A.; Grasselli, G. Influence of microscale heterogeneity and microstructure on the tensile behavior of crystalline rocks. J. Geophys. Res. 2014, 119, 5324–5341. [Google Scholar] [CrossRef]

- Gutiérrez-Ch, J.G.; Senent, S.; Melentijevic, S.; Jimenez, R. Distinct element method simulations of rock-concrete interfaces under different boundary conditions. Eng. Geol. 2018, 240, 123–139. [Google Scholar] [CrossRef]

- Koyama, T.; Fardin, N.; Jing, L.; Stephansson, O. Numerical simulation of shear-induced flow anisotropy and scale-dependent aperture and transmissivity evolution of rock fracture replicas. Int. J. Rock Mech. Min. Sci. 2006, 43, 89–106. [Google Scholar] [CrossRef]

- Zhang, H.H.; Guo, Q.L.; Wang, Y.W.; Tang, S.B.; Li, T.J.; Zhang, Q.; Tang, C.A. Cross-scale analysis on the mechanical behavior of the conglomerate of Yulin Grottoes in China. Int. J. Rock Mech. Min. Sci. 2024, 178, 105750. [Google Scholar] [CrossRef]

- Yu, H.D.; Chen, W.Z.; Ma, Y.S.; Gong, Z.; Tian, H.M.; Yuan, J.Q. Thermo-hydro-mechanical behavior of a clayey rock: A constitutive approach and numerical validation. Case Stud. Therm. Eng. 2022, 39, 102424. [Google Scholar] [CrossRef]

- Zhuo, X.; Liu, X.J.; Shi, X.C.; Liang, L.X.; Xiong, J. The anisotropic mechanical characteristics of layered rocks under numerical simulation. J. Pet. Explor. Prod. Tech. 2022, 12, 51–62. [Google Scholar] [CrossRef]

- Zhang, J.P.; Li, K.S.; Li, Y.; Liu, C.X.; Xu, J.H.; He, J.P. Applying novel micro–nano-siliceous grouting material improves mechanical behaviors of fractured rock masses and microscopic characteristics of slurry–rock interface: Experimental and numerical simulation investigations. Rock Mech. Rock Eng. 2024, 57, 8297–8321. [Google Scholar] [CrossRef]

- Jin, L.; Zeng, Y.; Xia, L.; Ye, Y. Experimental and numerical investigation of mechanical behaviors of cemented soil–rock mixture. Geotech. Geol. Eng. 2017, 35, 337–354. [Google Scholar] [CrossRef]

- Gong, H.L.; Wang, G.; Luo, Y.; Liu, T.; Li, X.; Liu, X. Shear failure and mechanical behaviors of granite with discontinuous joints under dynamic disturbance: Laboratory tests and numerical simulation. Arch. Civ. Mech. Eng. 2023, 23, 171. [Google Scholar] [CrossRef]

- Huang, Y.H.; Yang, S.Q.; Tian, W.L. An experimental and numerical investigation on mechanical behavior of sandstone specimens saturated in brine. Comput. Geotech. 2023, 163, 105740. [Google Scholar] [CrossRef]

- Gong, X.; Zhao, C.; Chen, H.G.; Zhang, G.; Zhang, B.Y.; Xing, J.Q. Crack evolution and mechanical behavior of granite with topological flaws under uniaxial compression. Geotech. Geol. Eng. 2024, 43, 19. [Google Scholar] [CrossRef]

- Guo, P.Y.; Zhang, P.; Bu, M.H.; Wang, J.M.; Zheng, X.; He, M.C. Microcracking behavior and damage mechanism of granite subjected to high temperature based on CT-GBM numerical simulation. Comput. Geotech. 2023, 159, 105385. [Google Scholar] [CrossRef]

- Han, L.L.; Li, X.Z.; Liu, Z.Y.; Guo, W.; Cui, Y.; Qian, C.; Huang, Y.Z. Study on rock mechanics characteristics of deep shale in Luzhou block and the influence on reservoir fracturing. Energy Sci. Eng. 2023, 11, 4–21. [Google Scholar] [CrossRef]

- Yuan, W.; Wang, W.; Su, X.B.; Li, J.X.; Li, Z.H.; Wen, L.; Chang, J.F. Numerical study of the impact mechanism of decoupling charge on blasting-enhanced permeability in low-permeability sandstones. Int. J. Rock Mech. Min. Sci. 2018, 106, 300–310. [Google Scholar] [CrossRef]

- Han, J.L.; Wang, J.; Dong, W.C.; Wang, S.N.; Sun, Q.; Li, T.Y.; Xu, Z.X.; Zhang, Y.X.; Zhang, W. A new algorithm for high-speed identification of discontinuities on large-scale rock outcrop: A case study in Jinsha River suture zone. J. Rock Mech. Geotech. Eng. 2025, in press. [CrossRef]

- Wang, J.; Zhang, W.; Yin, H.; Wang, Y.; Han, J.; Chen, J. Stability analysis of a high-steep slope based on multi-scale structural geological model and 3D fracture connectivity. Landslides 2025, 22, 3081–3094. [Google Scholar] [CrossRef]

- Potyondy, D.O.; Cundall, P.A. A bonded-particle model for rock. Int. J. Rock Mech. Min. Sci. 2004, 41, 1239–1364. [Google Scholar] [CrossRef]

- Huang, D.; Cen, D.; Ma, G.; Huang, R.Q. Step-path failure of rock slopes with intermittent joints. Landslides 2015, 12, 911–926. [Google Scholar] [CrossRef]

- Huang, Y.H.; Yang, S.Q.; Zhao, J. Three-dimensional numerical simulation on triaxial failure mechanical behavior of rock-like specimen containing two unparallel fissures. Rock Mech. Rock Eng. 2016, 49, 4711–4729. [Google Scholar] [CrossRef]

- Ivars, D.M.; Pierce, M.E.; Darcel, C.; Reyes-Montes, J.; Potyondy, D.O.; Young, R.P.; Cundall, P.A. The synthetic rock mass approach for jointed rock mass modelling. Int. J. Rock Mech. Min. Sci. 2011, 48, 219–244. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Shao, J.F.; Saxcé, G.D.; Shi, C.; Liu, Z.B. Study of deformation and failure in an anisotropic rock with a three-dimensional discrete element model. Int. J. Rock Mech. Min. Sci. 2019, 120, 17–28. [Google Scholar] [CrossRef]

- Chen, C.; Wu, A.; Wang, S.; Gong, W.; Sun, W.; Gao, T. Effect of layering characteristics on compressive mechanical properties and damage mechanisms of rocks: Experiments and models. PLoS ONE 2025, 20, e0318603. [Google Scholar] [CrossRef]

- Liu, H.; Zuo, J.; Topal, E.; Liu, Y.; Lei, B.; Li, D. A new layered rock constitutive model incorporating confining pressure and bedding angle weights based on orthogonal matrix analysis. Environ. Earth Sci. 2024, 83, 280. [Google Scholar] [CrossRef]

- Bian, K.; Chen, Y.A.; Liu, J.; Cui, D.S.; Li, Y.R.; Liang, W.D.; Han, X. The unloading failure characteristics of shale under different water absorption time using the PFC numerical method. Rock Soil Mech. 2020, 41, 355–367. (In Chinese) [Google Scholar] [CrossRef]

- Fakhimi, A.; Villegas, T. Application of dimensional analysis in calibration of a discrete element model for rock deformation and fracture. Rock Mech. Rock Eng. 2007, 40, 193–211. [Google Scholar] [CrossRef]

- Xu, Z.H.; Wang, Z.Y.; Wang, W.Y.; Lin, P.; Wu, J. An integrated parameter calibration method and sensitivity analysis of microparameters on mechanical behavior of transversely isotropic rocks. Comput. Geotech. 2022, 142, 104573. [Google Scholar] [CrossRef]

| Industrial Components (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Ash | Fixed Carbon | Water | Volatiles | ||||||

| 70.36 | 7.09 | 3.11 | 19.44 | ||||||

| Organic elements (%) | |||||||||

| C | N | H | S | ||||||

| 18.174 | 0.755 | 2.489 | 0.936 | ||||||

| Physiochemical indicators | |||||||||

| Total moisture yield (%) | Oil content (%) | Semi-coke yield (%) | Gas loss rate (%) | ||||||

| 4.75 | 11.89 | 80.33 | 3.03 | ||||||

| Diffraction results | |||||||||

| Primary minerals (%) | Clay minerals (%) | ||||||||

| Q | Kfs | Pl | Py | I/S | K | I | C | ||

| 36.1 | 14.2 | 7.5 | 2.0 | 16.0 | 11.8 | 8.3 | 4.1 | ||

| Directions | No. | UCS (MPa) | E (GPa) |

|---|---|---|---|

| Per bedding | Per1 | 58.82 | 2.815 |

| Per2 | 51.35 | 2.490 | |

| Per3 | 49.80 | 2.236 | |

| Average | 53.34 | 2.514 | |

| Par bedding | Par1 | 42.29 | 3.265 |

| Par2 | 37.32 | 3.470 | |

| Par3 | 35.45 | 3.823 | |

| Average | 38.35 | 3.519 |

| Micro-Parameters | Value |

|---|---|

| Minimum particle diameter, (mm) | 0.16 |

| Particle size ratio, | 1.5 |

| Particle density, (kg/m3) | 2222 |

| Contact normal-to-shear stiffness ratio, | 1.5 |

| Parallel bond modulus, (GPa) | 2.6 |

| Parallel bond tensile strength, (MPa) | 32.0 |

| Parallel bond cohesion, (MPa) | 48.0 |

| Parallel bond friction angle, (°) | 32.0 |

| Reduction coefficients of strength | 0.08 |

| Reduction coefficients of stiffness | 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Zhang, S.; Wang, J.; Wei, P.; Yin, H.; Chen, J. Macro-Mechanical Property and Microfracture Evolution of Layered Rock Mass: Effects of Confining Pressure and Bedding Direction. Appl. Sci. 2025, 15, 12178. https://doi.org/10.3390/app152212178

Liu X, Zhang S, Wang J, Wei P, Yin H, Chen J. Macro-Mechanical Property and Microfracture Evolution of Layered Rock Mass: Effects of Confining Pressure and Bedding Direction. Applied Sciences. 2025; 15(22):12178. https://doi.org/10.3390/app152212178

Chicago/Turabian StyleLiu, Xin, Shuntao Zhang, Jia Wang, Ping Wei, Han Yin, and Junqi Chen. 2025. "Macro-Mechanical Property and Microfracture Evolution of Layered Rock Mass: Effects of Confining Pressure and Bedding Direction" Applied Sciences 15, no. 22: 12178. https://doi.org/10.3390/app152212178

APA StyleLiu, X., Zhang, S., Wang, J., Wei, P., Yin, H., & Chen, J. (2025). Macro-Mechanical Property and Microfracture Evolution of Layered Rock Mass: Effects of Confining Pressure and Bedding Direction. Applied Sciences, 15(22), 12178. https://doi.org/10.3390/app152212178