Electric and Hybrid Vehicle Fires—Metal Emission Hazard

Abstract

1. Introduction

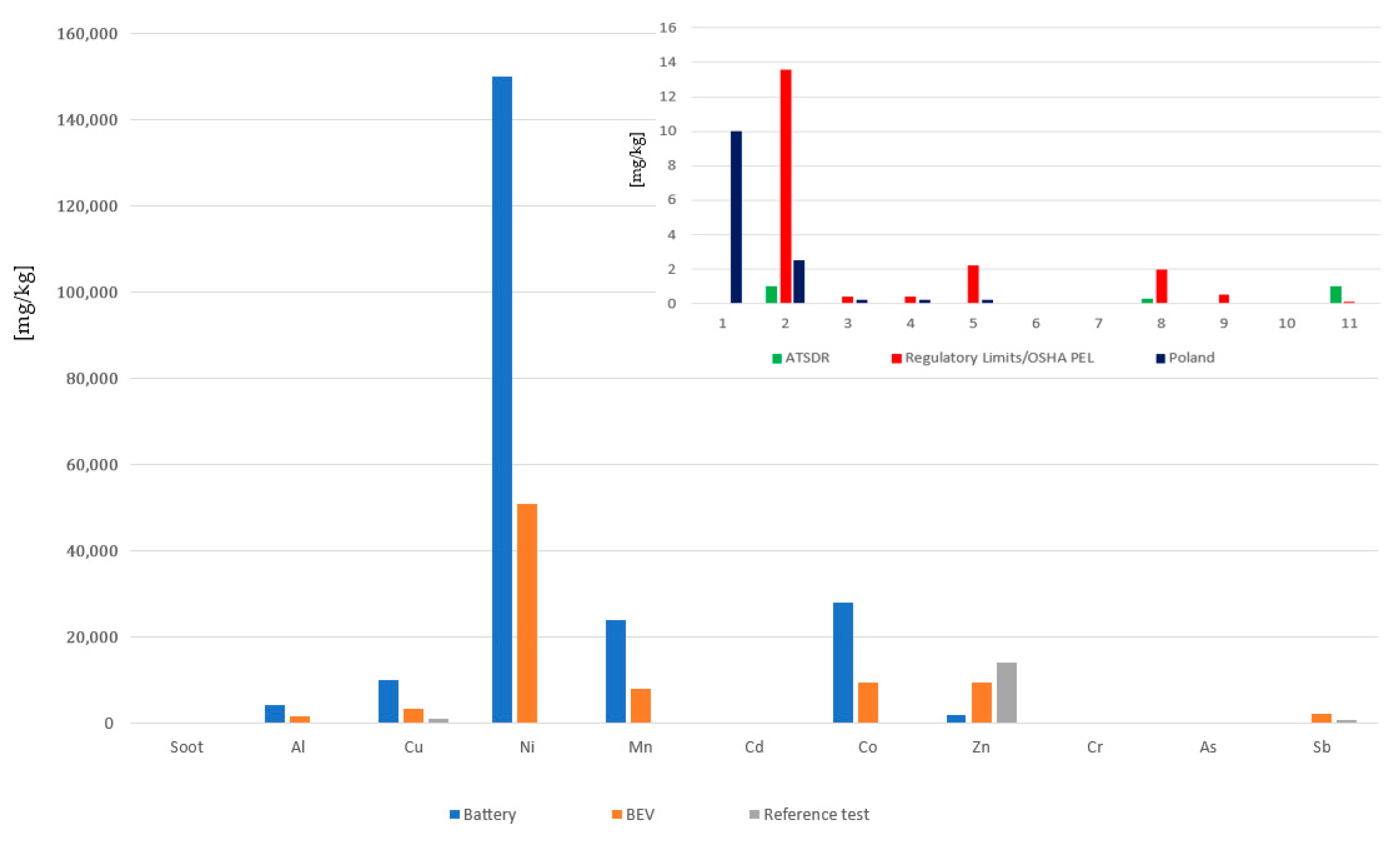

2. Electric and Hybrid Vehicle Fires

3. Metal Emissions During EV and HEV/PHEV Car Fires

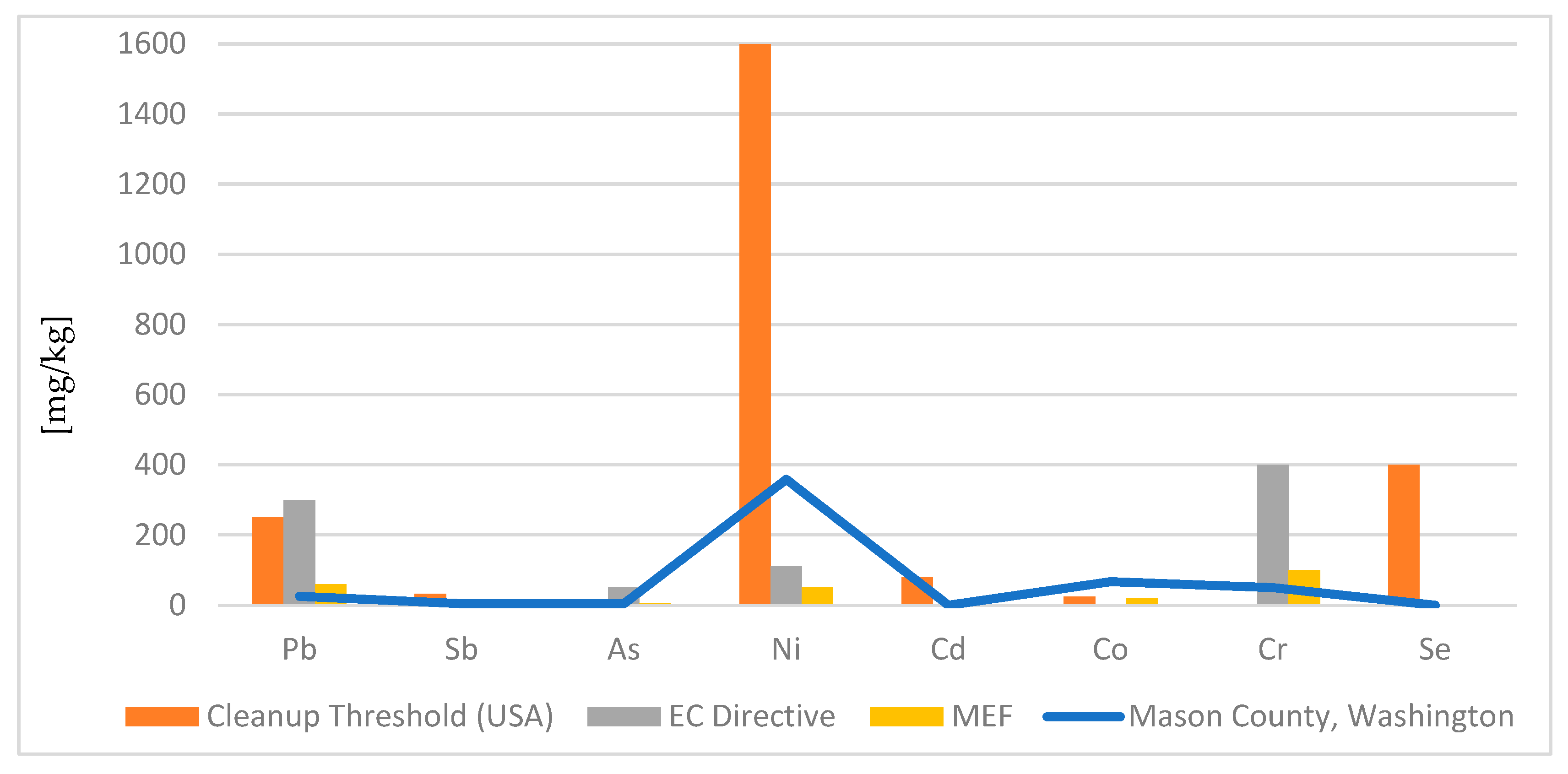

4. Metals in the Environment After Electric and Hybrid Vehicle Fires

- -

- Flow fractionation in a gravity or centrifugal field (FFF),

- -

- Size exclusion chromatography (SEC) or hydrodynamic chromatography (HDC),

- -

- Laser-induced emission spectroscopy (LIBS/LIBD),

- -

- Scanning electron microscopy (SEM), transmission electron microscopy (TEM), atomic force microscopy (AFM), or scanning transmission electron microscopy (STEM),

- -

- X-ray diffraction (XRD) or X-ray fluorescence (XRF),

- -

- Secondary ion mass spectrometry (SIMS).

5. Conclusions

- -

- Emission levels, including not only greenhouse gases but also all toxic organic and inorganic substances during a fire,

- -

- The impact of extinguishing agents on the emission levels of individual substances,

- -

- The quality of air, water, and soil at the site of fires,

- -

- A speciation of pollutants in the context of vehicle type,

- -

- A determination of the impact of generated pollutants on living organisms,

- -

- A determination of the actions to minimize contamination and neutralize pollutants, including legal guidelines and technologies that can be applied on-site.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AFM | Atomic Force Microscopy |

| BEV | Battery Electric Vehicles |

| CAFS | Compressed Air Foam Systems |

| EV | Electric Vehicles |

| FFF | Flow Fractionation in a Gravity or Centrifugal Field |

| GHG | Greenhouse Gases |

| HDC | Hydrodynamic Chromatography |

| HEV | Hybrid Electric Vehicle |

| ICE | Internal Combustion Engine |

| LCO | Lithium Cobalt Oxide Batteries |

| LFP | Lithium Iron Phosphate Batteries |

| LIB | Lithium-Ion Battery |

| LIBS/LIBD | Laser-Induced Emission Spectroscopy |

| LTO | Lithium Titanate Batteries |

| NCA | Lithium Nickel Cobalt Aluminum Oxide Batteries |

| NMC | Nickel Manganese Cobalt Batteries |

| PAH | Polycyclic Aromatic Hydrocarbon |

| PFAS | Per- and Polyfluoroalkyl Substances |

| PHEV | Plug-in Hybrid Electric Vehicle |

| PPE | Personal Protective Equipment |

| SEC | Size Exclusion Chromatography |

| SEM | Scanning Electron Microscopy |

| SIMS | Secondary Ion Mass Spectrometry |

| STEM | Scanning Transmission Electron Microscopy |

| TEM | Transmission Electron Microscopy |

| XRD | X-ray Diffraction |

| XRF | X-ray Fluorescence |

References

- Ioakimidis, C.S.; Murillo-Marrodán, A.; Bagheri, A.; Thomas, D.; Genikomsakis, K.N. Life Cycle Assessment of a Lithium Iron Phosphate (LFP) Electric Vehicle Battery in Second Life Application Scenarios. Sustainability 2019, 11, 2527. [Google Scholar] [CrossRef]

- Global Market Insights (GMI). Consumer Electronics Market Size; Report ID: GMI2383; Global Market Insights: Selbyville, DE, USA, 2025; Available online: https://www.gminsights.com/industry-analysis/consumer-electronics-market (accessed on 29 August 2025).

- Akyildiz, A.; Ergun, B.E.; Uzun, E.; Zehir, M.A.; Kucuktezcan, C.F.; Kocaarslan, I.; Gulbahce, M.O. Optimum Selection of Lithium Iron Phosphate Battery Cells for Electric Vehicles. IEEE Access 2025, 13, 55070–55080. [Google Scholar] [CrossRef]

- Celadon, A.; Sun, H.; Sun, S.; Zhang, G. Batteries for electric vehicles: Technical advancements, environmental challenges, and market perspectives. SusMat 2024, 4, e234. [Google Scholar] [CrossRef]

- Andersen, P.H.; Mathews, J.A.; Rask, M. Integrating private transport into renewable energy policy: The strategy of creating intelligent recharging grids for electric vehicles. Energy Policy 2009, 37, 2481–2486. [Google Scholar] [CrossRef]

- U.S. Department of Energy. Alternative Fuels Data Center. Emissions from Electric Vehicles. Available online: https://afdc.energy.gov/vehicles/electric-emissions (accessed on 20 August 2025).

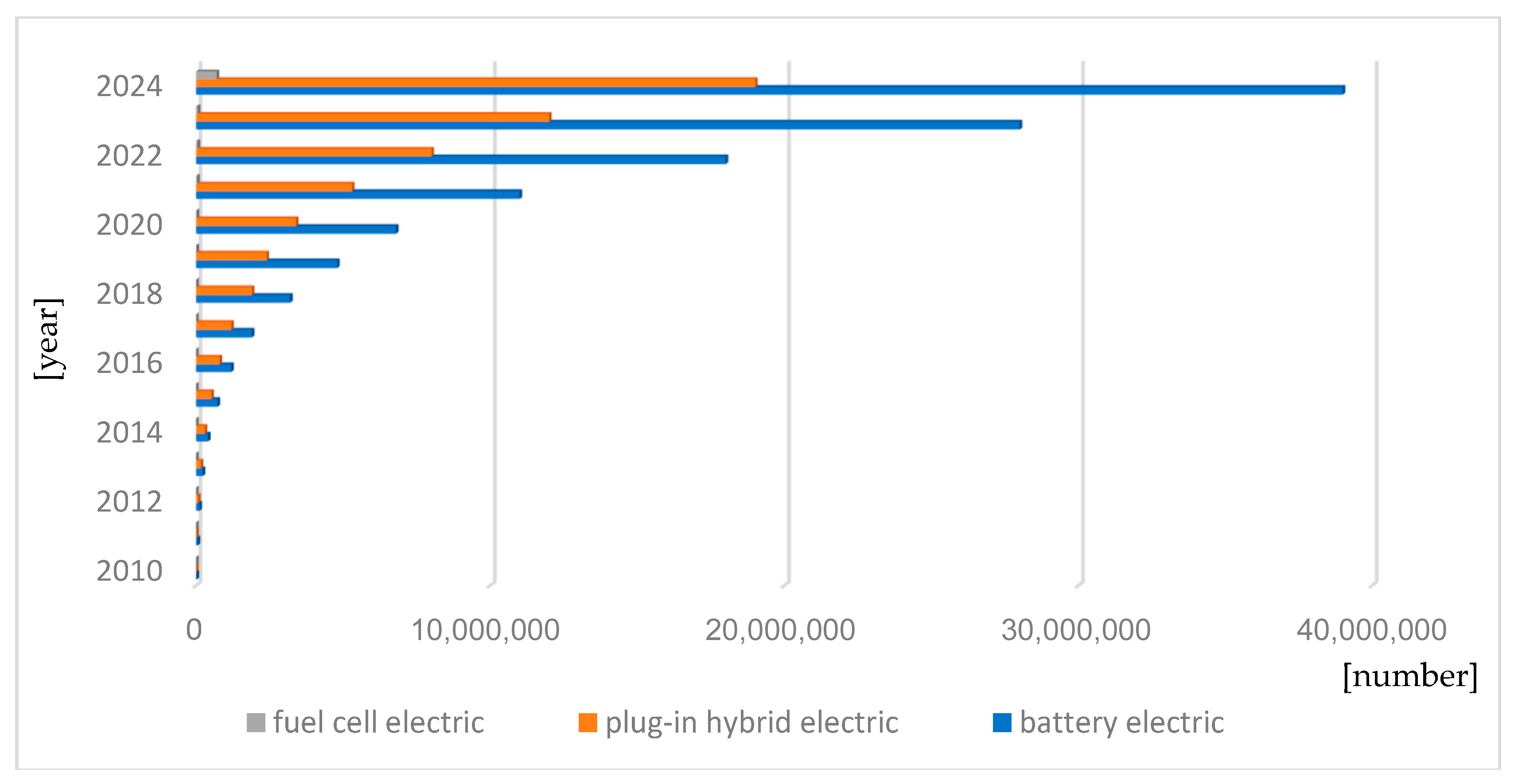

- Carlier, M. Number of Electric Vehicles in Use by Type 2010–2024. Statista. 2025. Available online: https://www.statista.com/statistics/1101415/number-of-electric-vehicles-by-type/ (accessed on 20 August 2025).

- Sanker, S.B.; Baby, R. Phase change material based thermal management of lithium ion batteries: A review on thermal performance of various thermal conductivity enhancers. J. Energy Storage 2022, 50, 104606. [Google Scholar] [CrossRef]

- Washington State Patrol State Fire Marshal’s Office, Electric Vehicle Fire Study. 2025. Available online: https://wsp.wa.gov/wp-content/uploads/2025/01/Electric-Vehicle-Fires-Study_SSB-5812.pdf (accessed on 8 October 2025).

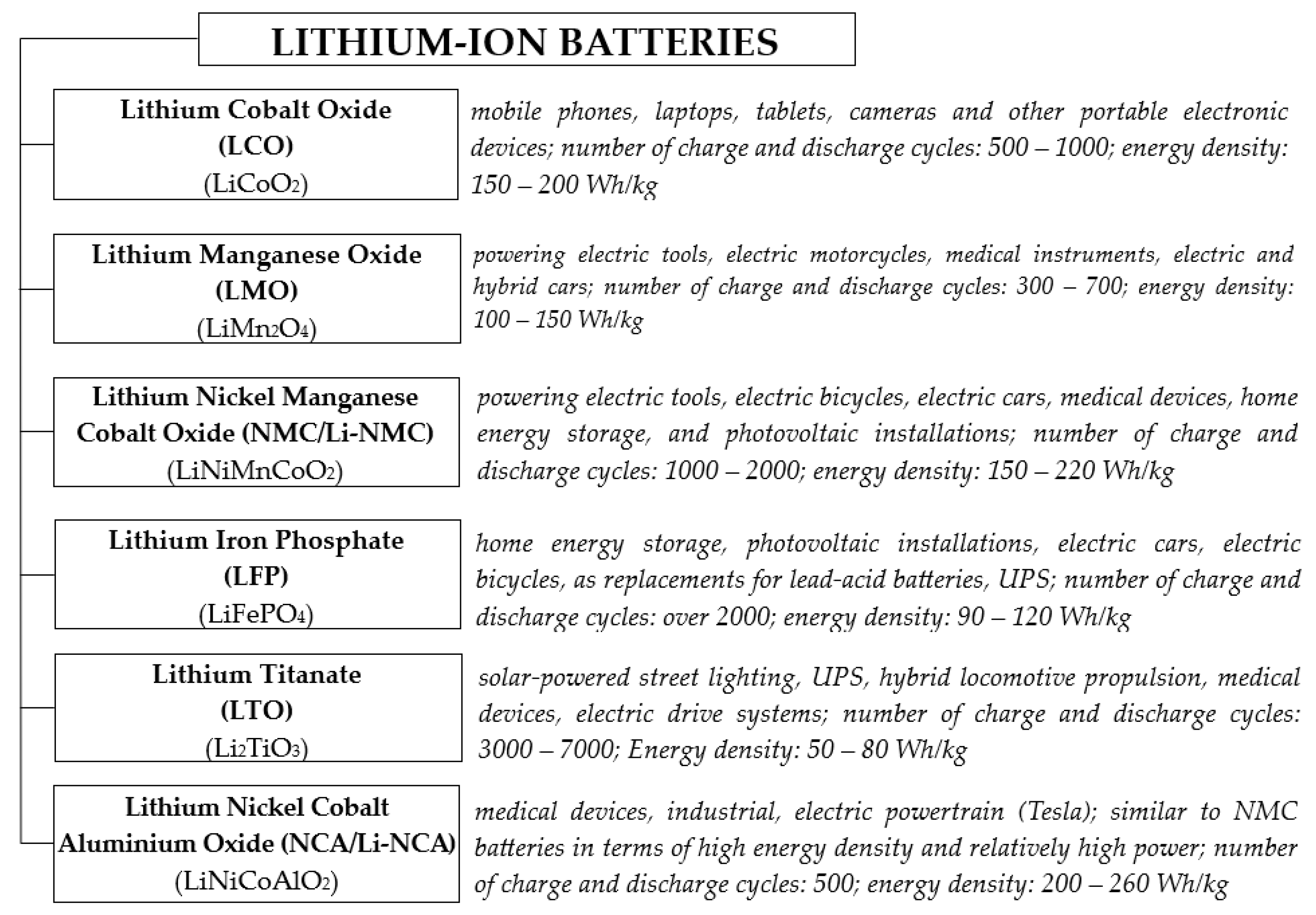

- Battery University. BU-205: Types of Lithium-Ion. 2023. Available online: https://batteryuniversity.com/article/bu-205-types-of-lithium-ion (accessed on 8 October 2025).

- Murden, D. What Are the Different Types of Lithium Batteries? Eco Tree Lithium. 2022. Available online: https://ecotreelithium.co.uk/news/lithium-batteries-types/ (accessed on 8 October 2025).

- Frith, L. A Closer Look at Lithium Iron Phosphate Batteries, Tesla’s New Choice of Battery. All About CIRCUITS. 2021. Available online: https://www.allaboutcircuits.com/news/a-closer-look-at-lithium-iron-phosphate-batteries-teslas-new-choice-of-battery/ (accessed on 21 August 2025).

- First Phosphate. How the LFP Battery Works. Available online: https://firstphosphate.com/phosphate-industry/about-the-lfp-battery/ (accessed on 21 August 2025).

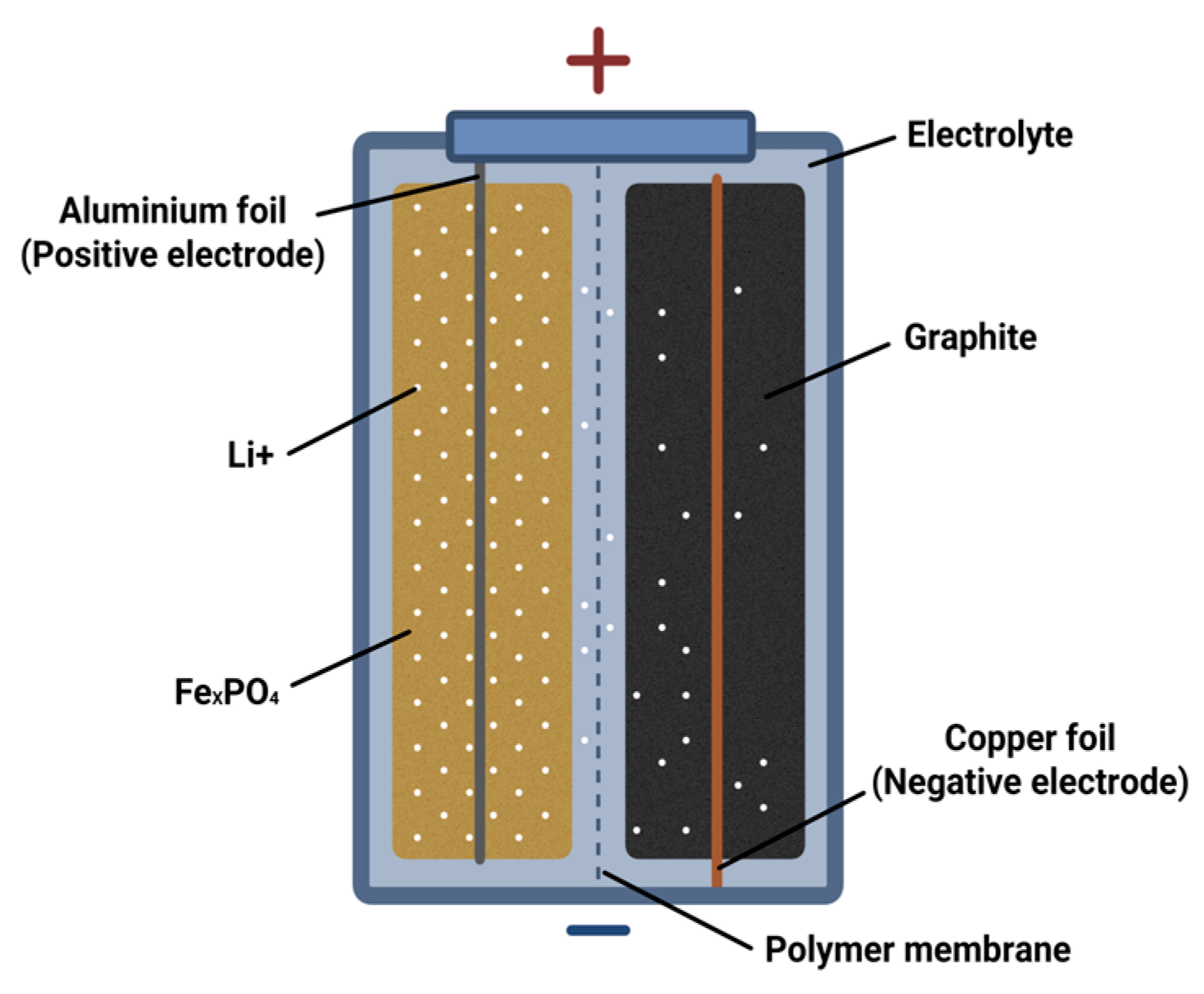

- Koech, A.K.; Mwandila, G.; Mulolani, F.; Mwaanga, P. Lithium-ion battery fundamentals and exploration of cathode materials: A review. S. Afr. J. Chem. Eng. 2024, 50, 321–339. [Google Scholar] [CrossRef]

- Menye, J.S.; Camara, M.-B.; Dakyo, B. Lithium Battery Degradation and Failure Mechanisms: A State-of-the-Art Review. Energies 2025, 18, 342. [Google Scholar] [CrossRef]

- National Transportation Safety Board. Safety Risks to Emergency Responders from Lithium-Ion Battery Fires in Electric Vehicles; Safety Report NTSB/SR-20/01 PB2020-101011; National Transportation Safety Board: Washington, DC, USA, 2020. Available online: https://www.ntsb.gov/safety/safety-studies/Documents/SR2001.pdf (accessed on 21 August 2025).

- Quant, M.; Willstrand, O.; Mallin, T.; Hynynen, J. Ecotoxicity Evaluation of Fire-Extinguishing Water from Large-Scale Battery and Battery Electric Vehicle Fire Tests. Environ. Sci. Technol. 2023, 57, 4821–4830. [Google Scholar] [CrossRef]

- Willstrand, O.; Quant, M.; Hynynen, J. Contaminations from Lithium-Ion Battery Fires—Per- and Polyfluoroalkyl Substances (PFAS) in Soot. Fire Technol. 2025, 61, 2889–2899. [Google Scholar] [CrossRef]

- Held, M.; Tuchschmid, M.; Zennegg, M.; Figi, R.; Schreiner, C.; Mellert, L.D.; Welte, U.; Kompatscher, M.; Hermann, M.; Nachef, L. Thermal runaway and fire of electric vehicle lithium-ion battery and contamination of infrastructure facility. Renew. Sust. Energ. 2022, 165, 112474. [Google Scholar] [CrossRef]

- Kang, S.W.; Lee, S.; Kwoun, J.; Lee, T.J.; Jo, Y.M. Analysis of Harmful Heavy Metals and Carbonaceous Components in Urban School PM2.5. Aerosol Air Qual. Res. 2023, 23, 220335. [Google Scholar] [CrossRef]

- Jones, W.D. Extinguishing the EV Battery Fire Hype. The Numbers don’t Support Persistent Fears of Lithium-Ion Conflagrations. 2023. Available online: https://spectrum.ieee.org/lithium-ion-battery-fires? (accessed on 22 September 2025).

- Kania, A.; Mazur, M. Electric Car Fires—Facts vs Myths. New Report by PSP and PSNM. 2025. Available online: https://polandinsight.com/electric-car-fires-facts-vs-myths-new-report-by-psp-and-psnm-44897/ (accessed on 29 September 2025).

- How Common Are Electric Vehicle Fires? Not Very. 2024. Available online: https://motorweek.org/this-just-in/how-common-are-electric-vehicle-fires-not-very/?utm_source (accessed on 20 August 2025).

- Biscarri, E. Fires in Conventional and Electrified Vehicles: Theory, Prevention, and Analysis; SAE International: Warrendale, PA, USA, 2024; Chapter 1.6; p. 272. Available online: https://books.google.pl/books?id=miczEQAAQBAJ (accessed on 29 September 2025).

- South Korean Network. Hybrid Vehicles Report Fewest Fire Incidents: Data. 2024. Available online: https://www.southkoreannetwork.com/2024/08/hybrid-vehicles-report-fewest-fire.html?utm (accessed on 20 August 2025).

- Sundin, M. Electric Cars Catch Fire Less Often than Fossil Fuel Cars. 2023. Available online: https://www.warpnews.org/transportation/electric-cars-catch-fire-less-often-than-fossil-fuel-cars/?utm_source=chatgpt.com (accessed on 21 August 2025).

- Czyżewski, R. Electric Cars Catch Fire Less Often Than Gas-Powered Vehicles, Despite Persistent Myths. 2025. Available online: https://polandinsight.com/electric-cars-catch-fire-less-often-than-gas-powered-vehicles-despite-persistent-myths-68253/ (accessed on 3 October 2025).

- Mazur, M. White Paper on battery fires. Fire safety of electric vehicles and battery systems. Report. Polish Alternative Fuels Association PSPA. F5A New Mobility Reearch & Consutling. Warsaw 2022. Available online: https://psnm.org/wp-content/uploads/2023/06/PSPA_Fire_Safety_of_EV_White_Paper_EN_online.pdf (accessed on 29 September 2025).

- E-Mobility Index—August 2025 PZPM. Available online: https://www.pzpm.org.pl/en/Electromobility/E-Mobility-Index/Year-2025 (accessed on 3 October 2025).

- Weil, G. Data Shows EVs are Less of a Fire Risk than Conventional Cars. 2024. Available online: https://www.fairfaxcounty.gov/environment-energy-coordination/climate-matters/EV-less-fire-risk (accessed on 3 October 2025).

- Linja-Aho, V. Perceived and Actual Fire Safety—Case of Hybrid and Electric Vehicle Fires in Finland 2015–2023. WSEAS Trans. Environ. Dev. 2023, 19, 1313–1328. [Google Scholar] [CrossRef]

- Szmytke, E.; Brzezińska, D.; Machnowski, W.; Kokot, S. Firefighters’ Clothing Contamination in Fires of Electric Vehicle Batteries and Photovoltaic Modules—Literature Review and Pilot Tests Results. Int. J. Environ. Res. Public Health 2022, 19, 12442. [Google Scholar] [CrossRef] [PubMed]

- Cui, Y.; Cong, B.; Liu, J.; Qiu, M.; Han, X. Characteristics and Hazards of Plug-In Hybrid Electric Vehicle Fires Caused by Lithium-Ion Battery Packs with Thermal Runaway. Front. Energy Res. 2022, 10, 878035. [Google Scholar] [CrossRef]

- Larsson, F.; Andersson, P.; Blomqvist, P.; Mellander, B.-E. Toxic fluoride gas emissions from lithium-ion battery fires. Sci. Rep. 2017, 7, 10018. [Google Scholar] [CrossRef]

- Bugryniec, P.J.; Resendiz, E.G.; Nwophoke, S.M.; Khanna, S.; James, C.; Brown, S.F. Review of gas emissions from lithium-ion battery thermal runaway failure—Considering toxic and flammable compounds. J. Energy Storage 2024, 87, 111288. [Google Scholar] [CrossRef]

- Truchot, B.; Fouillen, F.; Collet, S. An experimental evaluation of toxic gas emissions from vehicle fires. Fire Saf. J. 2018, 97, 111–118. [Google Scholar] [CrossRef]

- Sturm, P.; Fößleitner, P.; Fruhwirt, D.; Galler, R.; Wenighofer, R.; Franz Heindl, S.; Krausbar, S.; Heger, O. Fire tests with lithium-ion battery electric vehicles in road tunnels. Fire Saf. J. 2022, 134, 103695. [Google Scholar] [CrossRef]

- Dahlbom, S.; Bjarnemark, F.; Nguyen, B.; Petronis, S.; Mallin, T. Analysis of per- and polyfluoroalkyl substances (PFAS) extraction from contaminated firefighting materials: Effects of cleaning agent, temperature, and chain-length dependencies. Emerging Contaminants. 2024, 10(3), 100335. [Google Scholar] [CrossRef]

- Rabajczyk, A.; Zielecka, M.; Hopke, P.; Porowski, R. Metal nanoparticles in the air—State of the art and future perspectives. Environ. Sci. Nano 2020, 7, 3233–3254. [Google Scholar] [CrossRef]

- Klippel, A.; Hofmann, A.; Gnutzmann, T.; Piechnik, K. Reaction-to-fire testing of bus interior materials: Assessing burning behaviour and smoke gas toxicity. Fire Mater 2023, 47, 665–680. [Google Scholar] [CrossRef]

- Jeevarajan, J.A.; Joshi, T.; Parhizi, M.; Rauhala, T.; Juarez-Robles, D. Battery Hazards for Large Energy Storage Systems. ACS Energy Lett. 2022, 7, 2725–2733. [Google Scholar] [CrossRef]

- Bordes, A.; Papin, A.; Marlair, G.; Claude, T.; El-Masri, A.; Durussel, T.; Bertrand, J.-P.; Truchot, B.; Lecocq, A. Assessment of Run-Off Waters Resulting from Lithium-Ion Battery Fire-Fighting Operations. Batteries 2024, 10, 118. [Google Scholar] [CrossRef]

- Long, R.T.; Blum, A.; Hill, B. Best Practices for Emergency Response to Incidents Involving Electric and Hybrid Vehicles—Full-Scale Testing Results. Quincy, MA: Fire Protection Research Foundation (NFPA). 2013. Available online: https://www.nfpa.org/-/media/Files/News-and-Research/Resources/Research-Foundation/Research-Foundation-reports/Electric-vehicles/FPRF-ElectricHybridVehicles.ashx (accessed on 3 September 2025).

- Schmidt, L. Electric Vehicle Fires Raise Cancer Risk for Firefighters and Communities. 2025. Available online: https://www.cancerhealth.com/article/electric-vehicle-fires-raise-cancer-risk-firefighters-communities (accessed on 5 September 2025).

- Kunkelmann, J. Untersuchung des Brandverhaltens von Lithium-Ionen- und Lithium-Metall-Batterien in Verschiedenen Anwendungen und Ableitung einsatztaktischer Empfehlungen; Forschungsbericht Nr. 175; Karlsruher Institut für Technologie (KIT) Forschungsstelle für Brandschutztechnik: Karlsruhe, German, 2015. [Google Scholar]

- Hynynen, J.; Willstrand, O.; Blomqvist, P.; Quant, M. Investigation of extinguishing water and combustion gases from vehicle fires. In Fire And Safety Fire Safe Transport; RISE Report 2023:22; RISE Research Institutes of Sweden: Gothenburg, Sweden, 2023; Available online: https://ukeirespill.org/wp-content/uploads/2024/02/ETOX2_final_report_0.pdf (accessed on 27 September 2025).

- Internetowy System Aktów Prawnych. Regulation of The Minister of Family, Labour and Social Policy of 12 June 2018 on the Maximum Permissible Concentrations and Intensities of Factors Harmful to Health in the Work Environment; Sejm RP: Szymon Hołownia, Poland, 2018; p. 1286. (In Polish) [Google Scholar]

- Institut für Arbeitsschutz der Deutschen Gesetzlichen Unfallversicherung (IFA), Sankt Augustin. Occupational Exposure Limit Values (OELs); IFA Report 2/2024; IFA: Grenzwerteliste, WA, USA, 2024. [Google Scholar]

- Standard Number 1910.1000; Air Contaminants. Toxic and Hazardous Substances. Permissible Exposure Limits—Annotated Tables. Occupational Safety and Health Standards: Washington, DC, USA, 2016. Available online: https://www.osha.gov/annotated-pels/table-z-1 (accessed on 12 November 2025).

- Hynynen, J.; Willstrand, O.; Blomqvist, P.; Andersson, P. Analysis of combustion gases from large-scale electric vehicle fire tests. Fire Saf. J. 2023, 139, 103829. [Google Scholar] [CrossRef]

- Dursun, Y.; Eleşkirtli, A. Fire Safety Precautions and Fire Intervention Techniques for Electric and Hybrid Vehicles. Int. J. New Find. Eng. Sci. Technol. 2025, 3, 44–58. [Google Scholar] [CrossRef]

- Vaught, V. Electric Vehicle (EV) Safety for the First Responder. Texas A&M Engineering Extension Service. 2024. Available online: https://teex.org/news/teex-initiates-tests-on-first-responder-ppe-exposed-to-lithium-ion-battery-fires/ (accessed on 5 September 2025).

- Lönnermark, A.; Blomqvist, P. Emissions from an Automobile Fire. Chemosphere 2006, 62, 1043–1056. [Google Scholar] [CrossRef]

- UNEP. International Resource Panel of UNEP. Environmental Risks and Challenges of Anthropogenic Metals Flows and Cycles; UNEP: Paris, France, 2014; p. 234. ISBN 978-92-807-3266-5. Available online: https://www.wrforum.org/wp-content/uploads/2015/03/Environmental-risks-and-challenges-of-anthropogenic-metals-flows-and-cycles-20138.-Environmental-Risks-and-Challenges-of-Anthropogenic-Metals-Flows-and-Cycles-1.pdf? (accessed on 5 September 2025).

- Ministry of the Environment, Finland. Government Decree on the Assessment of Soil Contamination and Remediation Needs; 214/2007; Ministry of the Environment: Helsinki, Finland, 2007; Available online: https://faolex.fao.org/docs/pdf/fin113198.pdf (accessed on 1 March 2007).

- European Union. Council Directive of 12 June 1986 on the Protection of the Environment, and in Particular of the Soil, When Sewage Sludge is Used in Agriculture (86/278/EEC); OJ L 181; European Union: Maastricht, The Netherlands, 1986; p. 6. Available online: http://data.europa.eu/eli/dir/1986/278/2022-01-01 (accessed on 12 November 2025).

- LionCare GmbH. Extinguishing Fires in Electric Cars. Available online: https://www.lion-care.com/en/extinguishing-fires-in-electric-cars (accessed on 7 October 2025).

- Lesiak, P.; Pietrzela, D.; Mortka, P. Methods Used to Extinguish Fires in Electric Vehicles. SFT 2021, 58, 38–57. [Google Scholar] [CrossRef]

- Xie, J.; Zhang, J.; Ding, C.; Wang, X. Hydrophobic nano SiO2 as flow-enhancing additives and flame retardant synergizes with CaCO3 to suppress gas explosion. RSC Adv. 2021, 11, 4672–4681. [Google Scholar] [CrossRef]

- Rabajczyk, A.; Zielecka, M.; Gniazdowska, J. Application of Nanotechnology in Extinguishing Agents. Materials 2022, 15, 8876. [Google Scholar] [CrossRef]

- Leyssens, L.; Vinck, B.; Van Der Straeten, C.; Wuyts, F.; Maes, L. Cobalt toxicity in humans-A review of the potential sources and systemic health effects. Toxicology 2017, 387, 43–56. [Google Scholar] [CrossRef]

- Nordberg, G.F.; Fowler, B.A.; Nordberg, M. Handbook on the Toxicology of Metals, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2015; p. 1024. [Google Scholar]

- Namieśnik, J.; Rabajczyk, A. The speciation and physico-chemical forms of metals in surface waters and sediments. CS&B 2010, 22, 1–24. [Google Scholar] [CrossRef]

- Rabajczyk, A.; Namieśnik, J. Speciation of iron in the aquatic environment. WER 2014, 86, 741–758. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Hu, X.; Pan, D.; Han, H.; Lin, M.; Lu, Y.; Wang, C.; Zhu, R. Speciation determination of iron and its spatial and seasonal distribution in coastal river. Sci. Rep. 2018, 8, 2576. [Google Scholar] [CrossRef] [PubMed]

- Lou, C.; Zhang, W.; Gao, P.; Zhou, Y.; Zhi, Y.; Ye, F.; Yan, W.; Xu, S.; Wei, Y.; Liu, Z. Aluminum speciation identification reveals water interactions in silicoaluminophosphate zeolites. Proc. Natl. Acad. Sci. USA 2025, 122, e2507802122. [Google Scholar] [CrossRef]

- Namieśnik, J.; Rabajczyk, A. The Speciation of Aluminium in Environmental Samples. CRC 2010, 40, 68–88. [Google Scholar] [CrossRef]

- Rabajczyk, A. Possibilities for analysis of selected nanometals in solid environmental samples. Desalination Water Treat. 2016, 57, 1598–1610. [Google Scholar] [CrossRef]

- Khan, I.; Saeed, K.; Khan, I. Nanoparticles: Properties, applications and toxicities. Arab. J. Chem. 2019, 12, 908–931. [Google Scholar] [CrossRef]

- Prasad, R.D.; Prasad, R.S.; Prasad, R.B.; Prasad, S.R.; Singha, S.B.; Singha, D.; Prasad, R.J.; Sinha, P.; Saxena, S.; Vaidya, A.K. A review on modern characterization techniques for analysis of nanomaterials and biomaterials. ES Energy Environ. 2024, 23, 1087. [Google Scholar] [CrossRef]

- Nadkarni, A.; Rana, D.; Desai, N.; Benival, D.; Joshi, V.; Salave, S.; Khunt, D. Advanced Characterization and Sample Preparation Strategies for Nanoformulations. J. Nanotheranostics 2024, 5, 104–127. [Google Scholar] [CrossRef]

- Zhu, Q.; Ji, J.; Tang, X.; Wang, C.; Sun, H. Bioavailability Assessment of Heavy Metals and Organic Pollutants in Water and Soil Using DGT: A Review. Appl. Sci. 2023, 13, 9760. [Google Scholar] [CrossRef]

- Garman, E.R.; Meyer, J.S.; Bergeron, C.M.; Blewett, T.A.; Clements, W.H.; Elias, M.C.; Farley, K.J.; Gissi, F.; Ryan, A.C. Validation of Bioavailability-Based Toxicity Models for Metals. Environ. Toxicol. Chem. 2020, 39, 101–117. [Google Scholar] [CrossRef]

| Country | Years | Number of Vehicle Fires | Percentage of Vehicle Fire [%] | Ref | ||||

|---|---|---|---|---|---|---|---|---|

| HEV/PHEV | EV | ICE | HEV/PHEV | EV | ICE | |||

| USA/number per 100,000 sold | 2021 | 3474.5 | 25.1 | 1529.9 | 3.47 | 0.025 | 1.52 | [23,24] |

| South Korea/number per 1.54 million registered vehicles | 2020–2025 | 131 | ND | ND | 0.002 | 0.013 | ND | [25] |

| Sweden | 2020–2022 annually | 16–24 EV and HEV fires/611,000 vehicles | 3384/4.4 million vehicles | 0.004 | 0.08 | [26] | ||

| Poland | 2020–June 2025 | 222 | 87 | 50 833 | 0.43 | 0.17 | 99.39 | [27,28,29] |

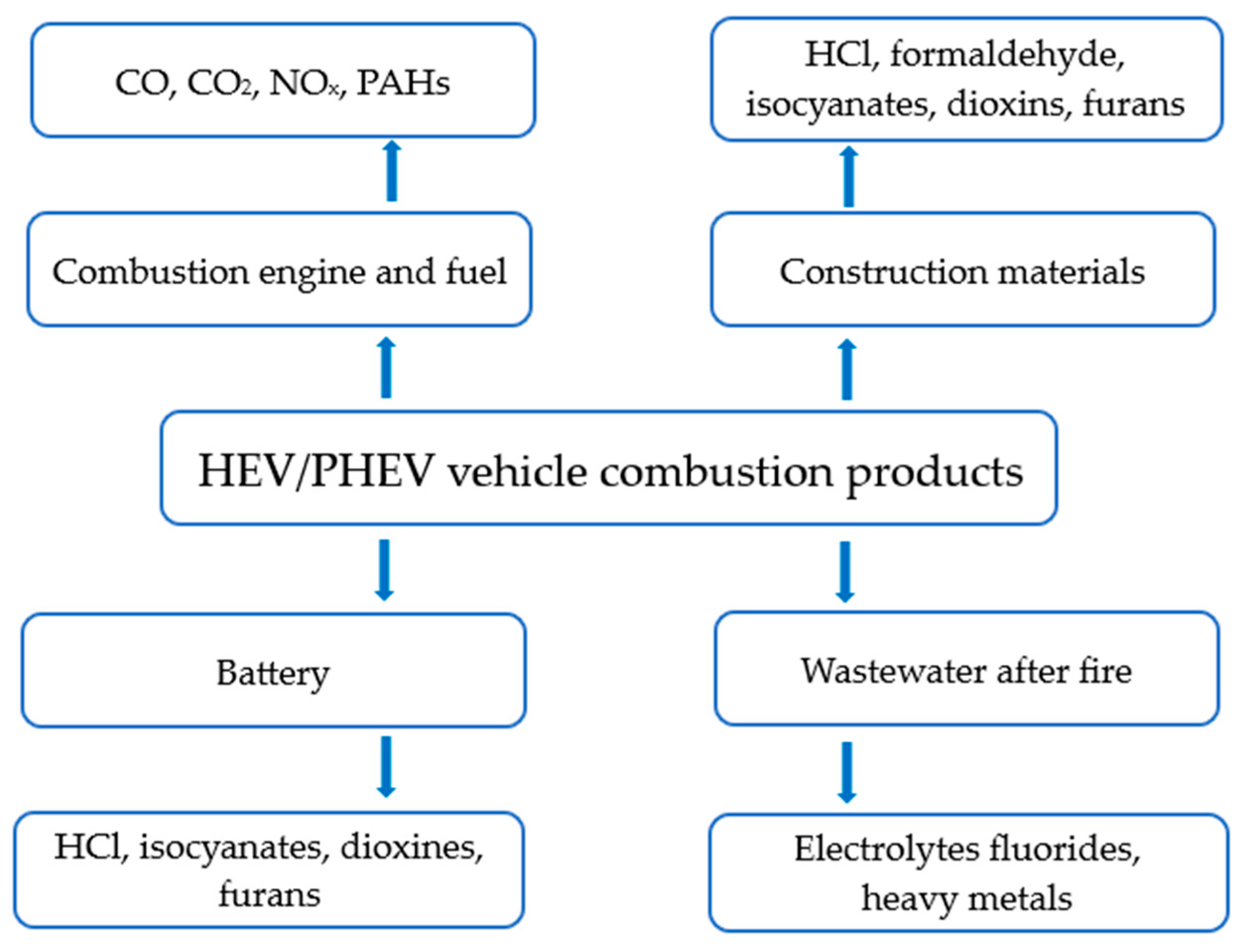

| Emission Source | Substance | Notes | Ref |

|---|---|---|---|

| Lithium-ion battery (LIB) | HF | Very toxic and corrosive, damages the respiratory tract and causes chemical burns | [34,35] |

| HCN | Highly toxic, disrupts oxygen transport in the body | [36] | |

| CO, CO2 | Products of electrolyte and organic material decomposition | [36] | |

| Fluorophosphates, phosphorus compounds | Irritating and toxic gases | [37,38] | |

| Metals (Ni, Co, Mn, Al, and Li) | May settle in the environment, toxic to aquatic organisms and humans | [18] | |

| Combustion engine and fuel (in case of HEV/PHEV) | CO | Highly toxic, binds to hemoglobin, leading to hypoxia | [31] |

| CO2 | Greenhouse gas, displaces oxygen in high concentrations | [31] | |

| NOx | Irritates respiratory tract, may create tropospheric ozone | [31] | |

| PAH | Strong carcinogenic effect | [31] | |

| Heavy metals (macro and nano) | Toxic substances, harmful to the respiratory system, threat to the health and life of organisms | [39] | |

| Soot and dust | Carriers of toxic substances, harmful to the respiratory system | [31] | |

| Construction materials and interior | HCl | Irritating gas produced by burning PVC | [40] |

| Formaldehyde | Toxic, carcinogenic, irritates mucous membranes | [40] | |

| Isocyanates (from the combustion of PUR foams) | Irritating, sensitizing, may cause asthma | [40] | |

| Dioxins and furans | Produced when burning plastics, very toxic and persistent in the environment | [40] | |

| Firefighting water after fires | Heavy metals and fluorides | Concentrations hazardous to the environment, threat to the health and life of organisms, degradation of soil and water | [41,42,43] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rabajczyk, A.; Gniazdowska, J.; Zielecka, M.; Bąk, D.; Dziechciarz, A.; Klapsa, W.; Rabajczyk, M.N. Electric and Hybrid Vehicle Fires—Metal Emission Hazard. Appl. Sci. 2025, 15, 12165. https://doi.org/10.3390/app152212165

Rabajczyk A, Gniazdowska J, Zielecka M, Bąk D, Dziechciarz A, Klapsa W, Rabajczyk MN. Electric and Hybrid Vehicle Fires—Metal Emission Hazard. Applied Sciences. 2025; 15(22):12165. https://doi.org/10.3390/app152212165

Chicago/Turabian StyleRabajczyk, Anna, Justyna Gniazdowska, Maria Zielecka, Damian Bąk, Anna Dziechciarz, Wojciech Klapsa, and Magdalena N. Rabajczyk. 2025. "Electric and Hybrid Vehicle Fires—Metal Emission Hazard" Applied Sciences 15, no. 22: 12165. https://doi.org/10.3390/app152212165

APA StyleRabajczyk, A., Gniazdowska, J., Zielecka, M., Bąk, D., Dziechciarz, A., Klapsa, W., & Rabajczyk, M. N. (2025). Electric and Hybrid Vehicle Fires—Metal Emission Hazard. Applied Sciences, 15(22), 12165. https://doi.org/10.3390/app152212165