1. Introduction

Reinforced concrete structures have become the predominant solution in modern construction due to their exceptional load-bearing capacity and cost-effectiveness, widely implemented in civil buildings (e.g., residences, offices, commercial centers) and military protective facilities. However, such structures remain vulnerable to blast threats arising from terrorist attacks, industrial accidents, and common hazards [

1]. These extreme dynamic loads can induce severe damage or structural collapse, endangering lives and property while potentially triggering catastrophic secondary disasters such as progressive collapse or the release of toxic materials. Consequently, rigorous analysis of the dynamic response of reinforced concrete slabs under blast loading provides critical theoretical foundations for blast-resistant retrofitting of existing structures and guides the design of new protective facilities.

Due to the prohibitive costs of blast testing on reinforced concrete slabs, numerical simulations have become the predominant research approach. Current mainstream computational methods include direct blast load curve application, CONWEP algorithm, and ALE algorithm. The CONWEP algorithm applies explosive loads directly to structural surfaces, offering computational efficiency particularly advantageous for uncomplicated scenarios without structural shadowing effects. Lin et al. [

2] numerically optimized offshore sandwich blast walls with various honeycomb cores using the CONWEP algorithm, finding that concave arc honeycomb cores exhibit best anti-blast performance. Kim et al. [

3] analyzed protection walls under hydrogen tank explosion via CONWEP and ALE algorithms, 3.6 m minimum distance between the storage tank and the protection wall was recommended. Tian et al. [

4] conducted field blast tests of precast concrete (PC) slabs and numerical simulations. The validated LS-DYNA model with the CONWEP algorithm effectively predicted overpressure, displacement, and damage, aiding the PC slab blast resistance study. Santos et al. [

5] conducted eight improvised explosive device (IED) detonation tests on a RC building and performed LS-DYNA simulations using the CONWEP algorithm. Goel et al. [

6] used ABAQUS (v2024) to perform numerical analysis on underground structures under internal blast loading, comparing CONWEP, Smoothed Particle Hydrodynamics (SPH), and coupled Eulerian–Lagrangian (CEL) methods. They found that explosive weight and concrete grade significantly affected structural stability, with buried parts more blast-resistant. Shirbhate et al. [

7] investigated the blast response of hexagonal honeycomb sandwich structures with perforations via the CONWEP algorithm. They analyzed parameters like perforation size, shape, number, and sheet thickness, showing that perforations enhance blast mitigation and energy absorption. Kumar et al. [

8] conducted experimental and finite element studies on RC panels under nearby explosions, using three gelatin masses and detonation distances. Simulations utilizing the multi-detonation CONWEP algorithm accurately predicted the damage.

The ALE algorithm accounts for interaction between air and structures, thus generally yielding higher computational accuracy than CONWEP. The fluid–structure interaction refers to the coupling of a medium described by conservation laws in Eulerian perspective with a medium described by conservation laws in Lagrangian perspective. Concurrently, the deformation and movement of the structure itself alter the surrounding flow field, influencing the pressure distribution through effects such as wave reflection, rarefaction, and trapping. In recent years, ALE has been extensively applied to study failure modes of reinforced concrete members (e.g., beams, columns, slabs, and walls) under various blast scenarios including contact, near-field, and far-field explosions [

9,

10,

11,

12,

13,

14]. Lee et al. [

15] numerically investigated RC and High Performance Fiber Reinforced Concrete (HPFRCC) slabs under near-ground TNT explosions using the ALE method and found that HPFRCC slabs exhibited better blast resistance. Jiang et al. [

16] conducted vulnerability analysis of a high-speed railway bridge system under near-field blasts using the ALE algorithm. Dynamic responses under four car-bomb blasts were calculated, and component damage levels were evaluated, providing references for post-blast safety evaluation. Guo et al. [

17] performed implosion tests and numerical simulations on Masonry Infilled Reinforced Concrete (MIRC) frames using the ALE algorithm, analyzing internal explosion load characteristics and structure-shock wave interaction. Wijesooriya et al. [

18] investigated band-beam slabs under close-in detonations via experiments and validated the ALE numerical framework. Parametric studies showed confinement detailing improved performance, and design recommendations for reinforcement were proposed. Fan et al. [

19] conducted underwater explosion tests on a normal strength reinforced concrete (NSRC) arch and a high strength reinforced concrete (HSRC) arch, establishing ALE-based multi-media coupling models. They proposed prediction formulas for peak displacement, with HSRC arches showing better blast resistance. Zhou et al. [

20] used the ALE algorithm to investigate the dynamic response and damage mechanism of sea-crossing bridge piers under underwater explosions, finding that detonation point below pier cap caused worst damage and 350 kg explosive risked collapse.

The pursuit of simulating severe material distortions and complex fluid–structure interaction phenomena has driven the adoption of meshless methods. Notably, SPH method has emerged as a powerful Lagrangian technique for modeling explosive detonation, shockwave propagation in air, and large deformation failure in solids, circumventing the mesh tangling issues associated with traditional FEM in extreme events. Li et al. [

21] Numerically investigated the damage and failure of plain Ultra-High Performance Concrete (UHPC) panels under contact explosion, utilizing the SPH algorithm to capture the interaction between the blast wave and the slab. Liu et al. [

22] established a SPH-FEM coupling model in LS-DYNA software (v2025) to investigate the dynamic fracture characteristics of granite after heat treatment. Peng et al. [

23] employed the SPH algorithm to numerically investigate the effects of slab thickness and TNT charge weight on the blast response of UHPC slabs under contact explosions.

A common challenge in blast simulation lies in balancing computational efficiency and accuracy. The CONWEP algorithm, based on empirical formulas, offers low computational costs by eliminating the need for air domain modeling or explosive simulations. However, it neglects superposition effects between incident and reflected shockwaves, resulting in lower accuracy compared to the ALE algorithm [

24]. While the ALE algorithm precisely simulates blast wave propagation and structural interactions, it requires large-scale air domains with refined meshing, leading to significantly higher computational demands. To balance computational efficiency and accuracy, this study adopted a CONWEP-ALE coupling algorithm. Near the RC slab—where shockwave effects were most pronounced—a localized ALE air domain was incorporated to accurately model the interaction of the air with the RC slab. In the far field, the CONWEP load model was retained. A mapping relationship between CONWEP loads and the ALE domain boundary enabled efficient transfer of blast loads from far-field to near-field regions. This methodology maintained high fidelity for near-field fluid–structure interactions while substantially reducing computational resource requirements. Its reliability was validated through comparisons with the CONWEP algorithm, the ALE algorithm, and existing experimental data.

This paper is organized as follows: First, the blast-loading methodology, finite element model development, and material constitutive models employed in this study are described. Subsequently, key parameters including incident overpressure, peak displacement, residual displacement, and computational time are evaluated and compared across three algorithms at varying scaled distances. Differences in algorithmic outcomes and their underlying causes are analyzed. Finally, the principal research findings are summarized. The advantages, limitations, and applicable scope of the three algorithms are discussed, with specific emphasis placed on the superior computational efficiency and applicability of the CONWEP-ALE coupling algorithm for blast analysis of RC slabs.

4. Analysis and Discussion of Numerical Results

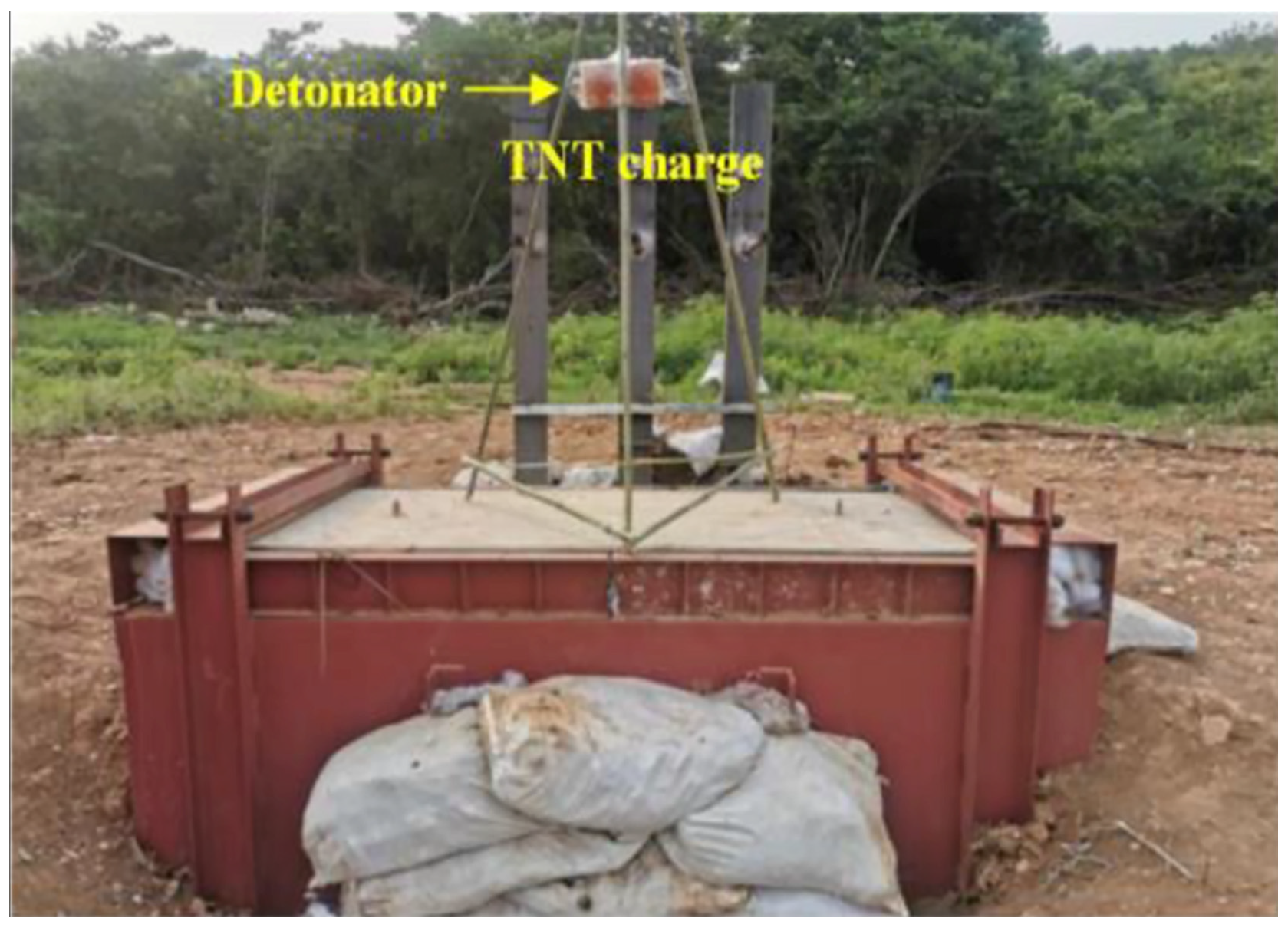

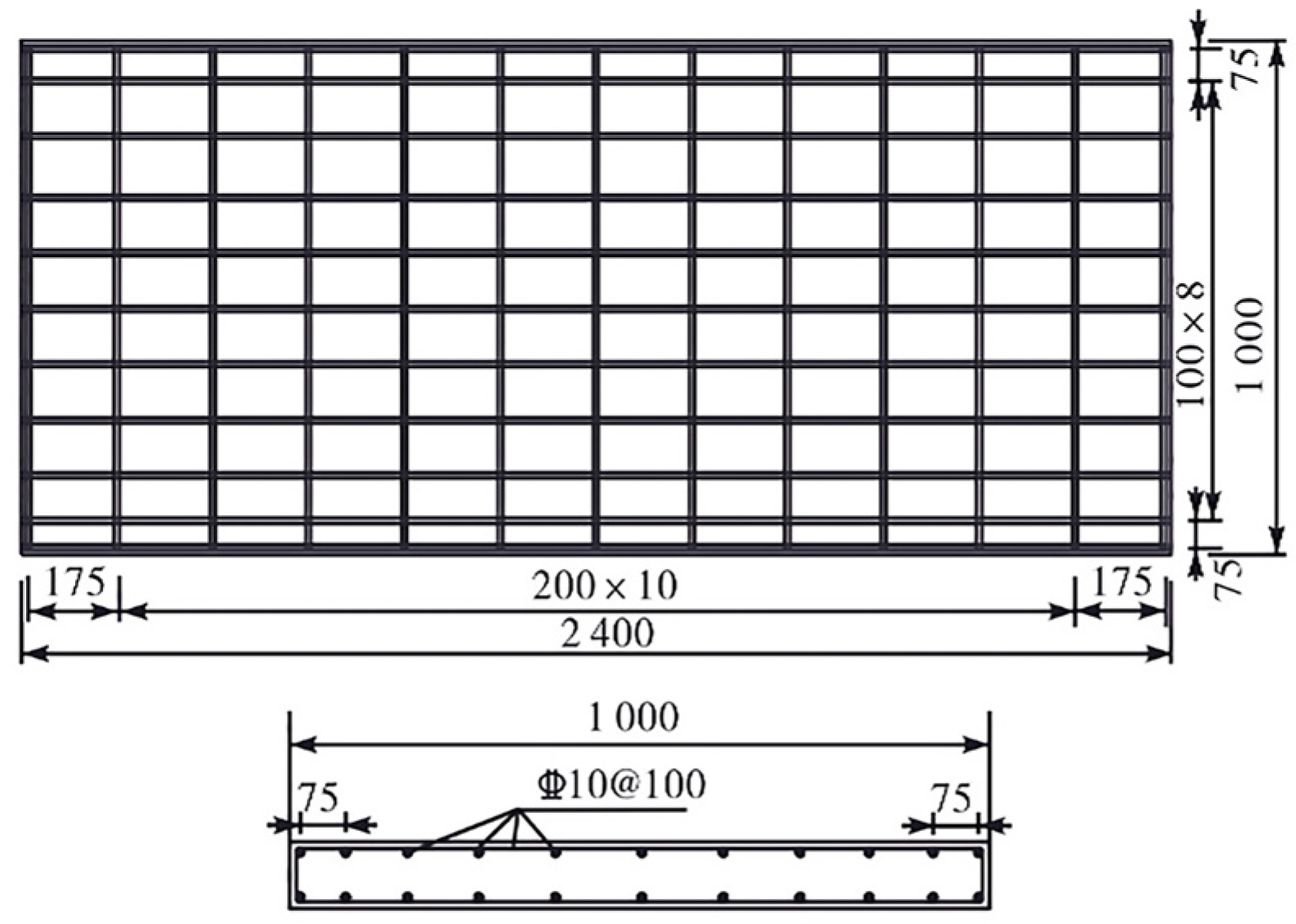

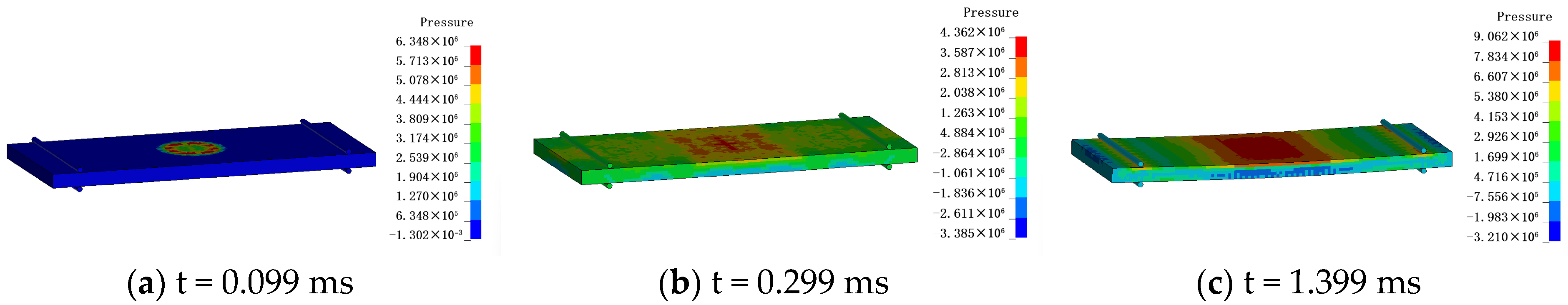

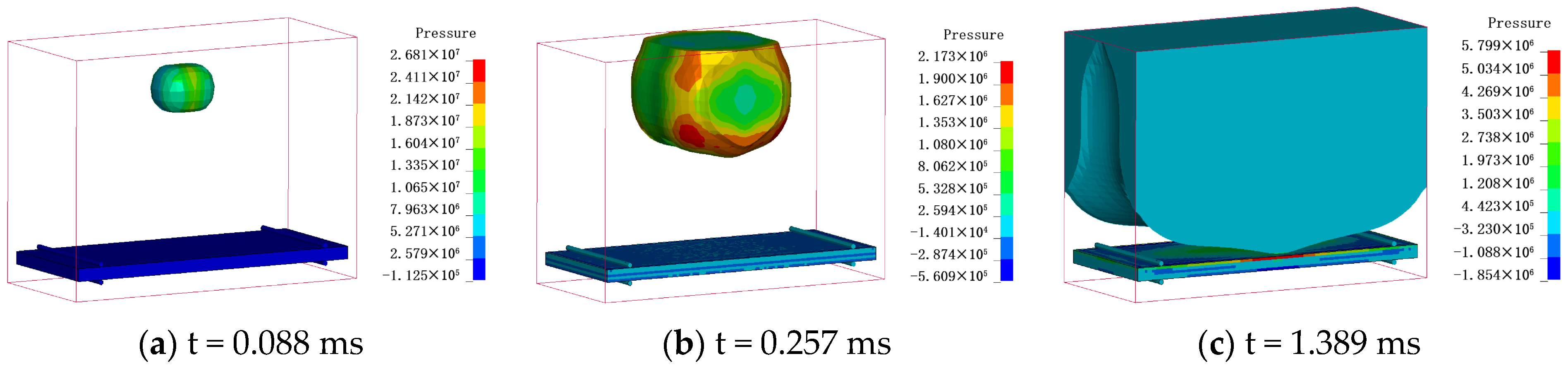

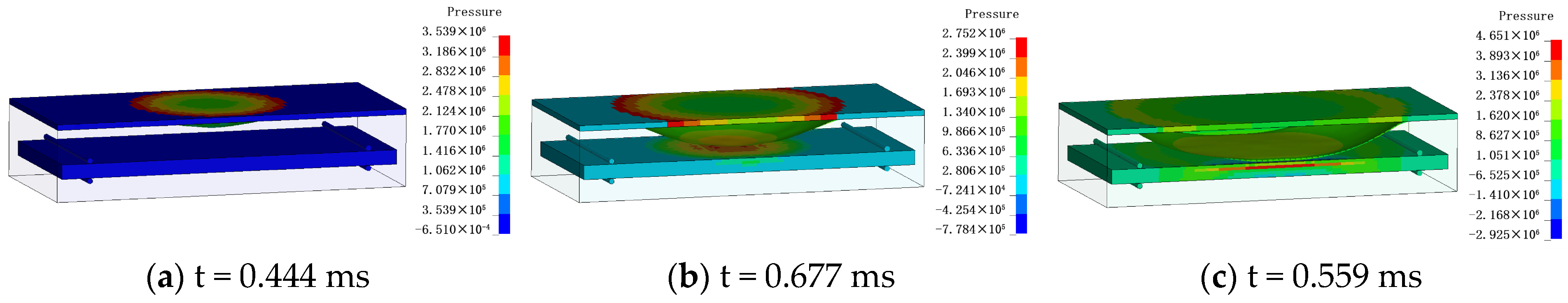

To ensure parametric consistency across blast simulations, the explosive load parameters in both CONWEP and CONWEP-ALE coupling algorithms, along with explosive placement in the ALE algorithm, strictly corresponded to the three experimental scenarios detailed in

Table 7 [

35]. For the 0.8 m/kg

1/3 scaled distance scenario,

Figure 5,

Figure 6 and

Figure 7 depict shockwave propagation patterns in the CONWEP algorithm, ALE algorithm, and CONWEP-ALE coupling algorithm, respectively.

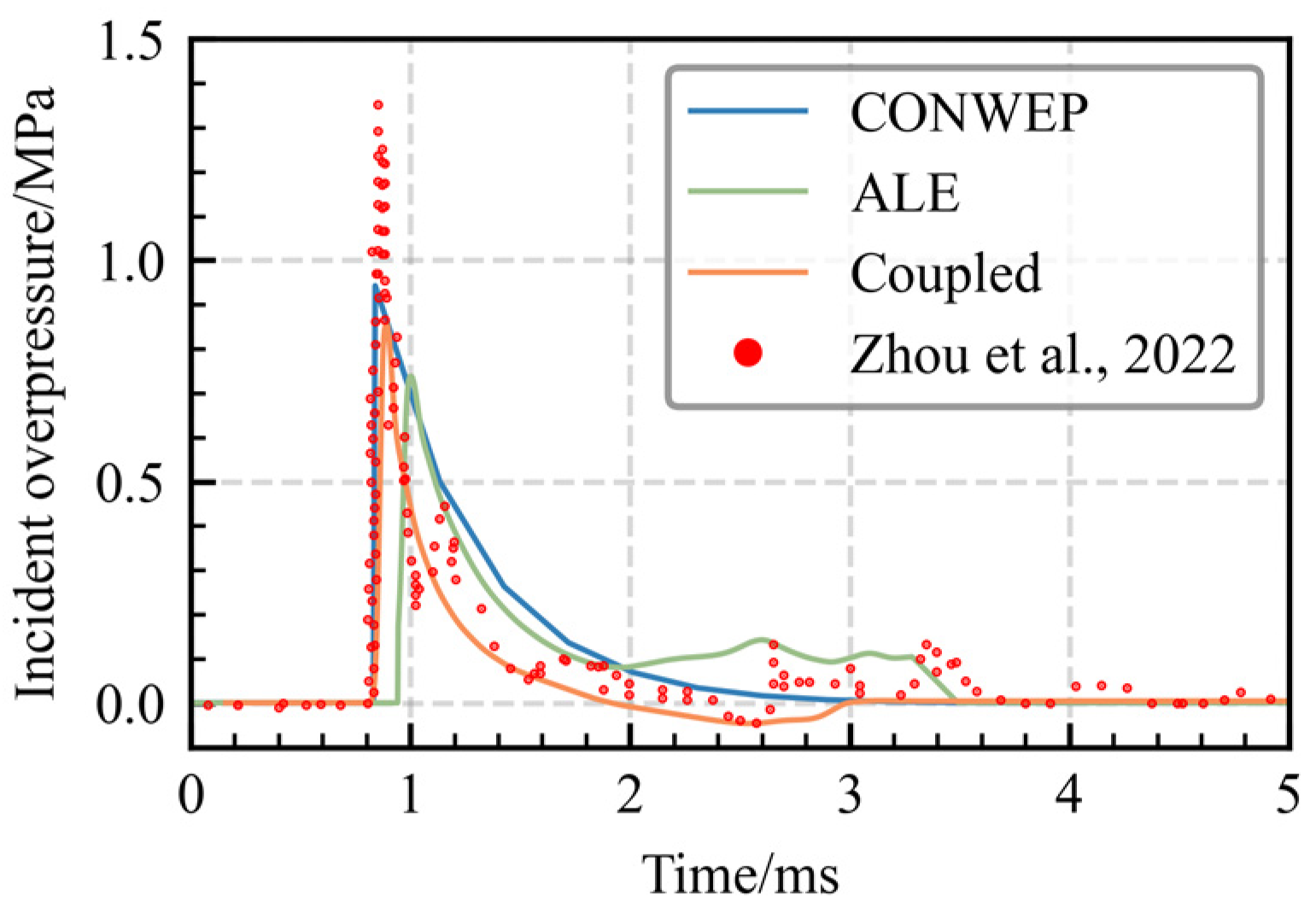

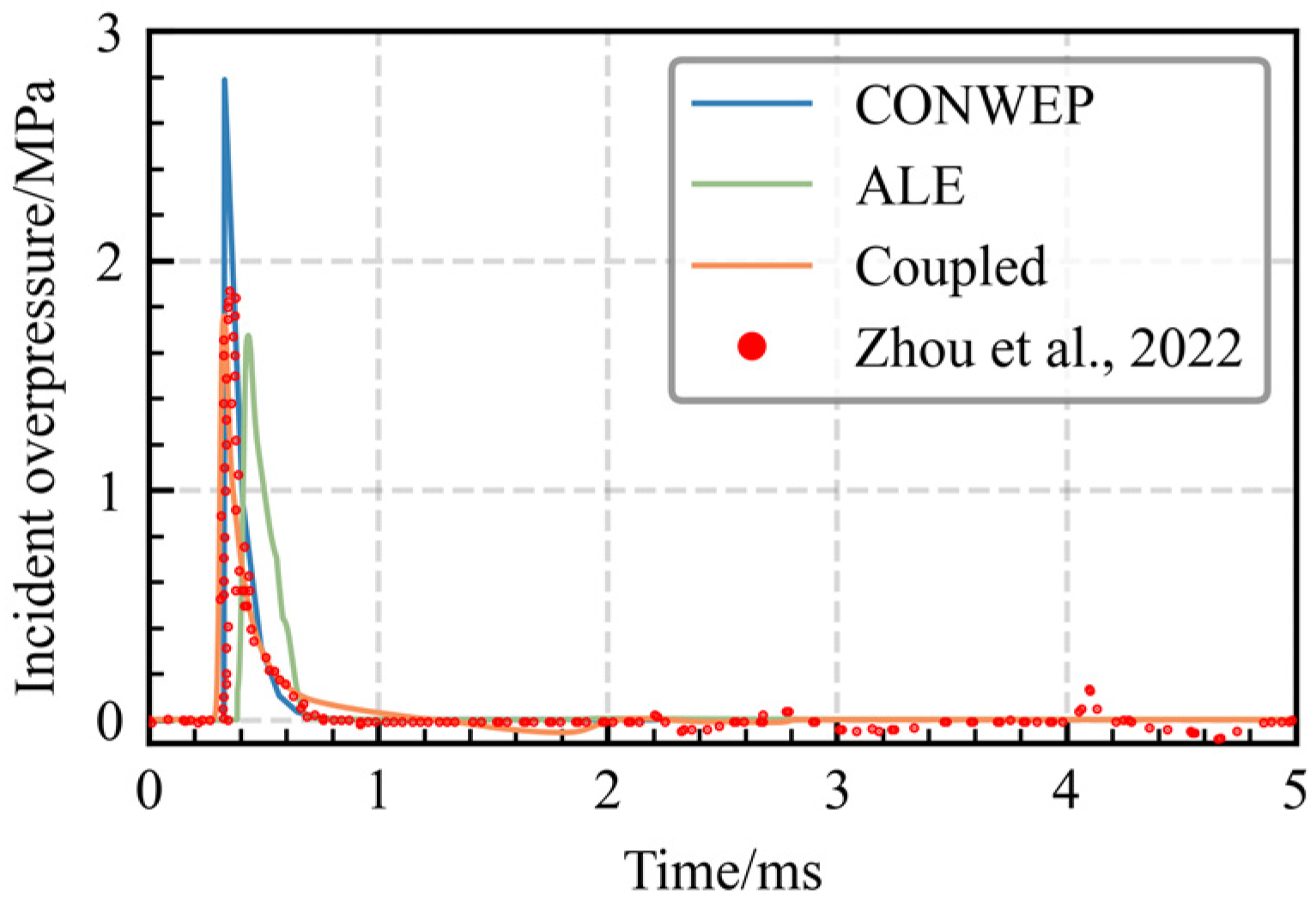

4.1. Incident Overpressure

Figure 8,

Figure 9 and

Figure 10 present incident overpressure results from the CONWEP, ALE, and CONWEP-ALE coupling algorithms. The CONWEP algorithm calculated incident overpressure using empirical formulas. In both the ALE and CONWEP-ALE coupling algorithms, incident overpressure was monitored using a single tracer point located in the air domain. The tracer was positioned 0.01 m from the center of the blast-facing surface of the RC slab. Pressure-time histories were recorded at a sampling frequency of 10

5 Hz to adequately capture the blast wave characteristics.

All three algorithms predict incident overpressure-time histories exhibiting rapid initial peak escalation followed by gradual decay.

Table 8 compares peak incident overpressure values and relative errors (

) for the three algorithms across test scenarios. Key findings reveal: Under all working conditions, the CONWEP-ALE coupling algorithm demonstrates higher accuracy in predicting the peak incident overpressure compared to the ALE algorithm. Moreover, as the scaled distance decreases, the relative error of both algorithms exhibits a gradual reduction trend. It should be noted that the CONWEP algorithm achieved its best incident overpressure prediction at the 0.8 m/kg

1/3 scaled distance. This likely represents a special case where the empirical model for spherical charges coincidentally aligned with cylindrical charge experiment. This trend is consistent with the findings in the source experimental study [

35], which also reported relatively higher accuracy for CONWEP at this particular scaled distance. However, this does not indicate general superiority, as CONWEP algorithm exhibits substantial errors (>30%) at other distances.

Overall, the CONWEP-ALE coupling algorithm achieves an average error rate of 23.23% across the three scenarios, which is lower than the 27.22% of the CONWEP algorithm and the 30.72% of the ALE algorithm. This indicates that the CONWEP-ALE coupling algorithm offers higher reliability and accuracy in predicting incident overpressure under the given conditions.

A sensitivity analysis of the CONWEP-ALE coupling algorithm was performed to assess the influence of the ambient layer thickness and the local ALE domain height on the predicted incident overpressure. The analysis, conducted for the 0.8 m/kg

1/3 scaled distance scenario, varied the layer thickness (0.02 m, 0.04 m, 0.06 m) and the domain height (0.4 m, 0.6 m, 0.8 m). The results, summarized in

Table 9, demonstrate that the model exhibits low sensitivity to changes in the ambient layer thickness and ALE domain dimensions.

For the domain height of 0.6 m, increasing the thickness from 0.02 m to 0.06 m resulted in a modest increase in error (from 24.88% to 25.91%). This indicates that the performance of the coupling algorithm is not critically sensitive to this parameter within the tested range; for the layer thickness of 0.02 m, the results indicate a mild sensitivity to the ALE domain height. While a smaller domain (0.4 m) yielded a slightly lower overpressure error (24.09%) compared to the baseline (24.88%), and a larger domain (0.8 m) yielded a slightly higher error (25.79%), the variation is contained within a narrow band of approximately ±0.9%.

In conclusion, the sensitivity analysis confirms that the accuracy of the proposed CONWEP-ALE coupling algorithm is stable with respect to the tested numerical parameters.

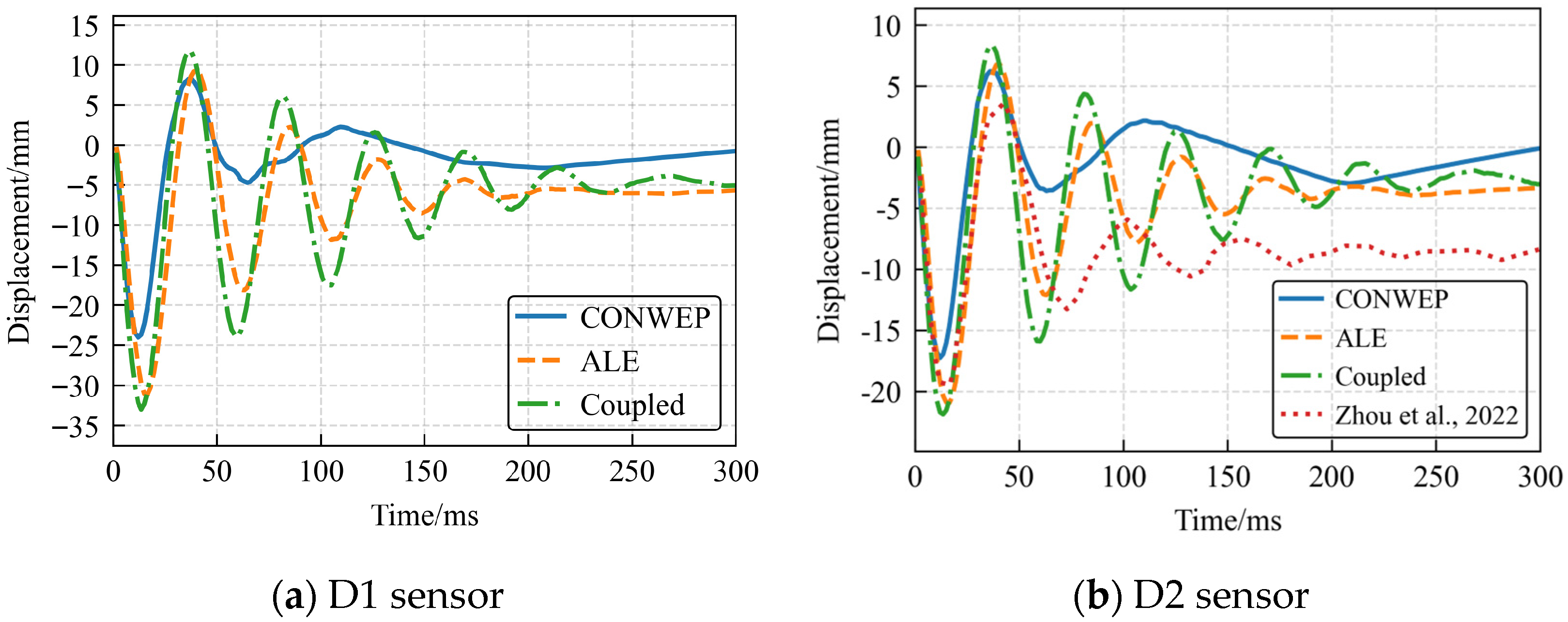

4.2. Displacement

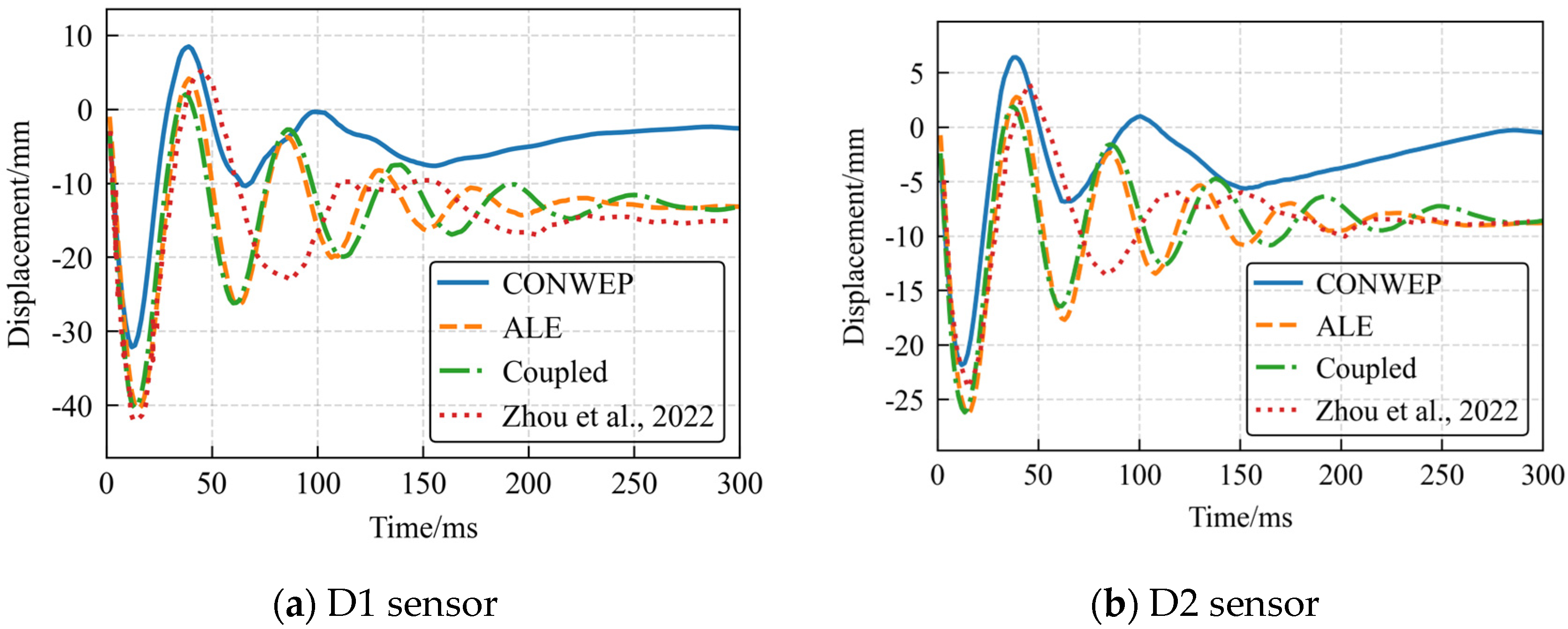

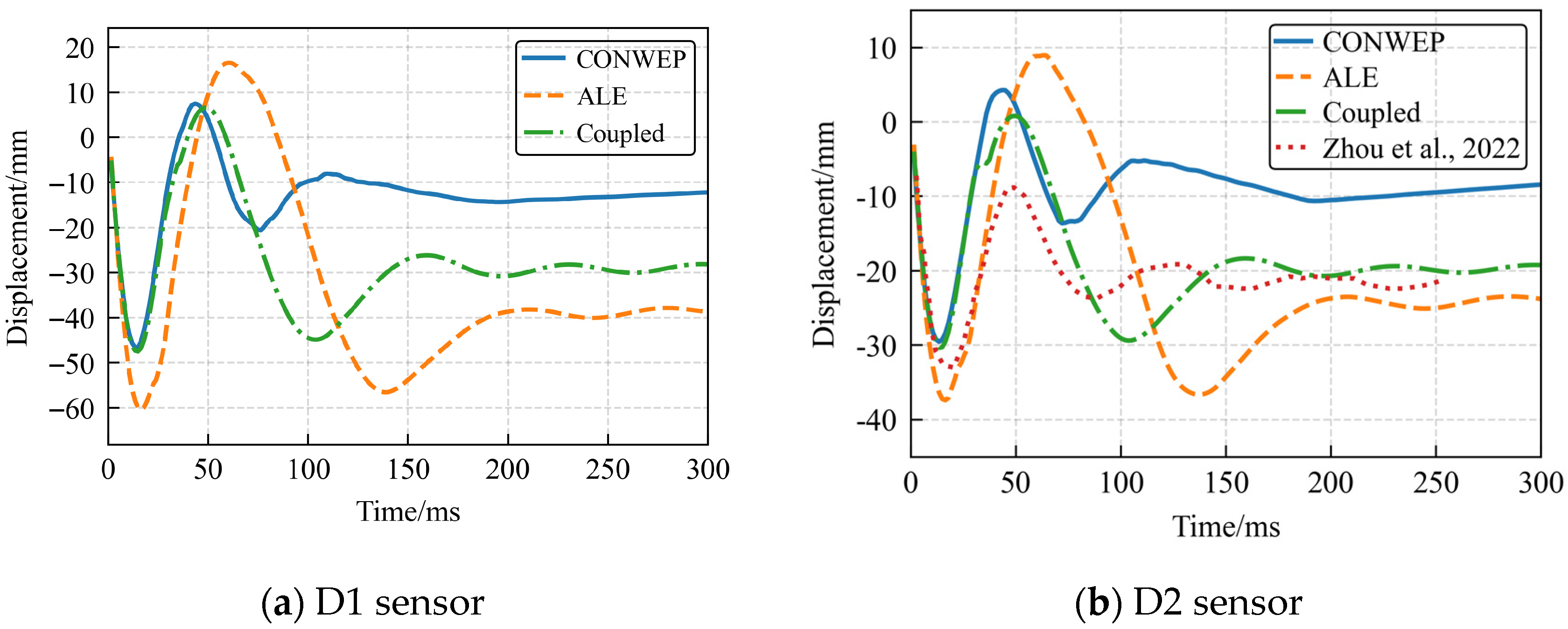

Given that measurement points D2 and D3 are symmetric and exhibit identical displacement responses under ideal simulation conditions, we plotted displacement–time history curves for points D1 and D2 across three test cases (

Figure 11,

Figure 12 and

Figure 13). These curves compare results from the CONWEP algorithm, the ALE algorithm, and the coupled CONWEP-ALE approach. Note: Displacement data for D1 at scaled distances of 1.0 m/kg

1/3 and 0.6 m/kg

1/3 were unavailable due to sensor detachment during intense slab vibrations [

35].

Displacement–time histories at measurement points reveal significant periodic oscillations in all three numerical simulations, consistent with experimental data. This demonstrates the algorithms’ capability to capture fundamental vibration responses of RC slabs under blast loading. The CONWEP algorithm achieves reasonable initial displacement correlation, though deviations progressively amplify over time. This divergence probably stems from its empirical loading formulation’s inability to accurately simulate fluid–structure interaction, compounded by insufficient mesh refinement that accumulates deflection errors in later stages. Conversely, both ALE and CONWEP-ALE coupling algorithms achieve superior peak displacement and period predictions. However, their late-stage response accuracy diminishes as shockwave energy dissipates and complex wave superposition develops in the air domain. At the 0.6 m/kg

1/3 scaled distance, all algorithms exhibit amplified oscillation amplitudes and period errors compared to experimental data. An interesting observation is that the vibration simulated by the CONWEP algorithm decays more rapidly than that of the ALE and coupled algorithms (

Figure 11,

Figure 12 and

Figure 13). This is despite the theoretical expectation that the absence of an air medium in the CONWEP model would remove a source of damping. This apparent discrepancy is attributed to the simplifying assumptions of the empirical method. The CONWEP algorithm applies a simplified blast load history, primarily encompassing the positive phase, and cannot capture the complex energy transfer from phenomena such as the negative (suction) phase or the entrapment and re-reflection of pressure waves between the deformed structure and its surroundings. These phenomena, which are naturally simulated in the ALE and CONWEP-ALE methods, act to impart additional energy into the structure, prolonging its vibrational response. Thus, the lack of these effects in the CONWEP model results in a response dominated by structural damping, leading to a quicker decay.

Table 10 summarizes peak and residual displacements recorded at measurement points on the reinforced concrete slab across all test scenarios. The results demonstrate a consistent trend: both displacement metrics systematically increase as scaled distance decreases. This correlation indicates progressively intensified bending deformation under higher blast intensities. Regarding predictive accuracy, the CONWEP algorithm shows deviations of 5–30% when estimating peak displacements. In contrast, both the ALE method and the CONWEP-ALE coupling algorithm achieve significantly higher precision, with prediction errors falling within 0–15%.

Regarding residual displacement, CONWEP shows significant inaccuracies in all scenarios. The ALE algorithm maintains 0–20% errors at 0.8 m/kg1/3 and 0.6 m/kg1/3 scaled distances but reaches 62.92% error at 1.0 m/kg1/3. The CONWEP-ALE coupling algorithm demonstrates approximately 0–20% residual displacement errors at closer scaled distances (0.6 m/kg1/3,0.8 m/kg1/3), matching ALE’s precision while substantially outperforming CONWEP.

4.3. Computational Efficiency

Computational efficiency was evaluated using a 24-core processor for Massively Parallel Processing (MPP) single-precision calculations, with execution times for the CONWEP, ALE, and CONWEP-ALE coupling algorithms across three scenarios detailed in

Table 11. Identical mesh discretization was applied to the reinforced concrete slab in all cases. While ALE and coupling algorithms incorporated additional ALE air domain meshing, CONWEP required no such domain.

Analysis reveals: CONWEP algorithm achieved the shortest computation time. The ALE algorithm demonstrated the longest runtime, where the total element count primarily determined efficiency. Scaled distance minimally impacted computation duration for any given algorithm. Notably, the CONWEP-ALE coupling algorithm reduced computation time by approximately 50% compared to the ALE algorithm while maintaining comparable or superior accuracy in predicting overpressure and displacement.

To provide a deeper insight into algorithmic efficiency,

Table 11 also presents the computational cost normalized by the seconds per 10

4 elements. The ALE algorithm shows the lowest normalized cost, indicating efficient per-element calculation within its fluid domain. The CONWEP-ALE coupling algorithm exhibits a higher normalized cost, which can be attributed to the additional computational overhead of the coupling interface (ambient layer). However, this is offset by an approximately 70% reduction in the number of air elements compared to the ALE model. Therefore, while the normalized efficiency of the coupled algorithm is lower, its strategic reduction in problem size results in a superior overall performance in terms of absolute computational time, making it a highly efficient approach for the intended application.

4.4. Discussion on Applicability to Confined and Reflective Conditions

A discussion on the performance of the proposed CONWEP-ALE coupling algorithm under confined or reflective conditions is warranted, given the open-field nature of the CONWEP empirical data. It is important to delineate the scope of the method’s applicability. The algorithm is not intended for scenarios with significant confinement, such as internal explosions in sealed chambers, where the empirical CONWEP input would be inherently inaccurate due to unmodeled global wave trapping and superposition.

However, the strength of the proposed CONWEP-ALE coupling algorithm is its demonstrated capability to handle localized reflections in the immediate vicinity of the structural component. In such scenarios, the CONWEP load provides an efficient representation of the initial, incident far-field shockwave. The ALE domain can be strategically designed to encompass any nearby reflective surfaces.

In summary, while the coupled algorithm inherits the inherent limitations of the CONWEP model for scenarios involving significant confinement, it avoids the prohibitive computational cost of a full-scale ALE simulation of the entire environment. This positions the CONWEP-ALE coupling algorithm as a balanced and efficient solution for a wide range of practical engineering scenarios where accuracy and computational cost are both paramount.