Hybrid Drying of Apples: A Comparison of Continuous and Intermittent Process Modes

Abstract

1. Introduction

2. Methodology of the Study

2.1. Experimental Material

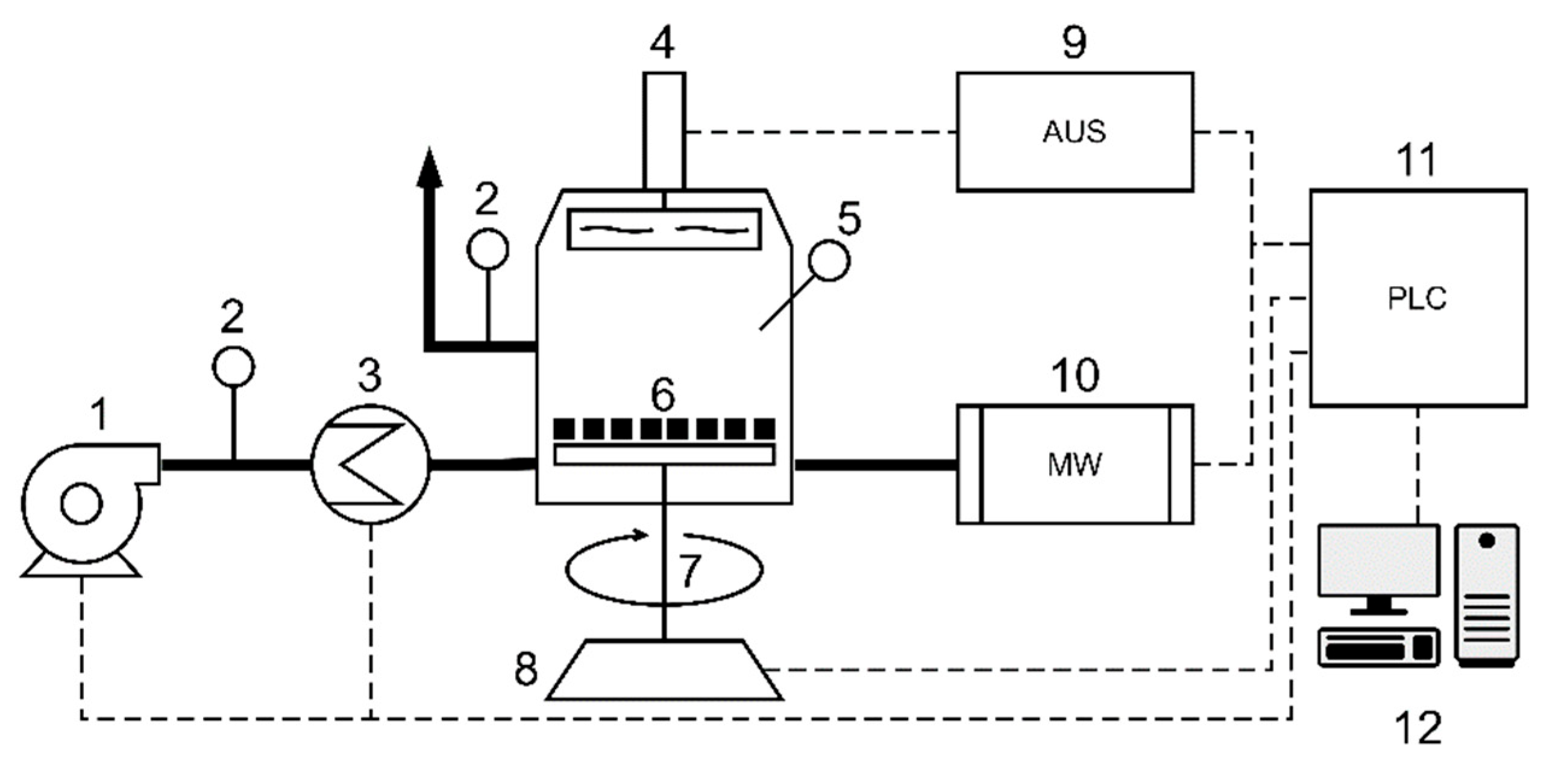

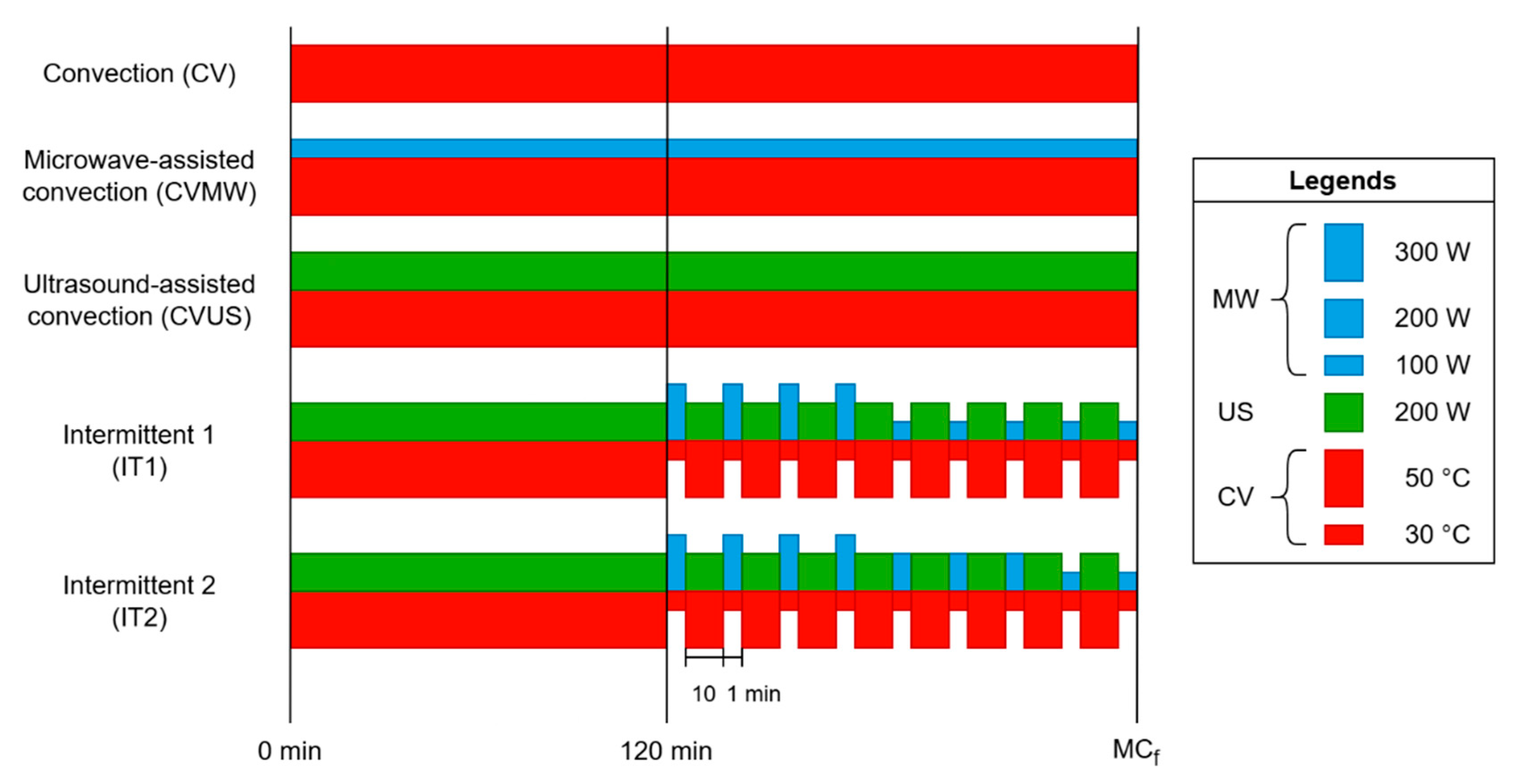

2.2. Drying Processes

2.3. Kinetics and Energy Intensity of Drying Processes

- It is assumed that moisture diffusion is symmetrical relative to the center of the slab, which means that the moisture concentration gradient at the center is zero:

- On the surface of the slab (half the thickness L), there is a constant moisture concentration value corresponding to the equilibrium between the moisture content of the material and the environment, known as equilibrium moisture content:

2.4. Quality of Products

2.5. Statistical Analysis

3. Results and Discussion

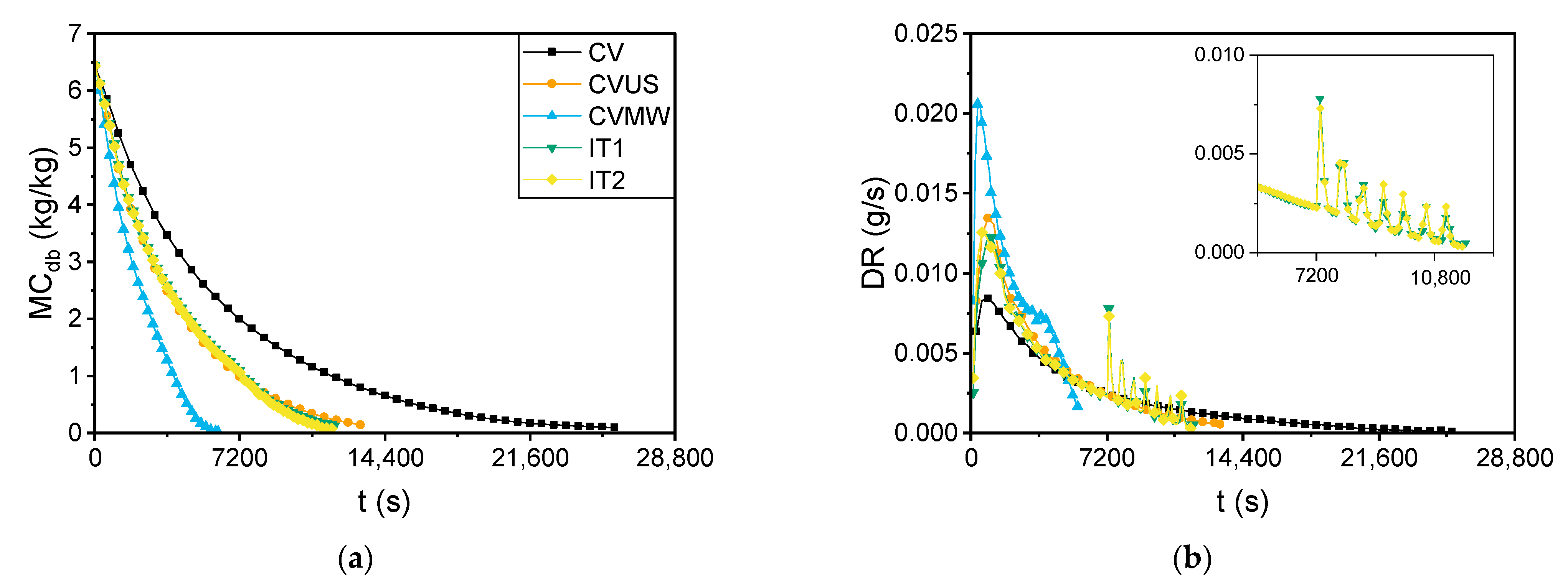

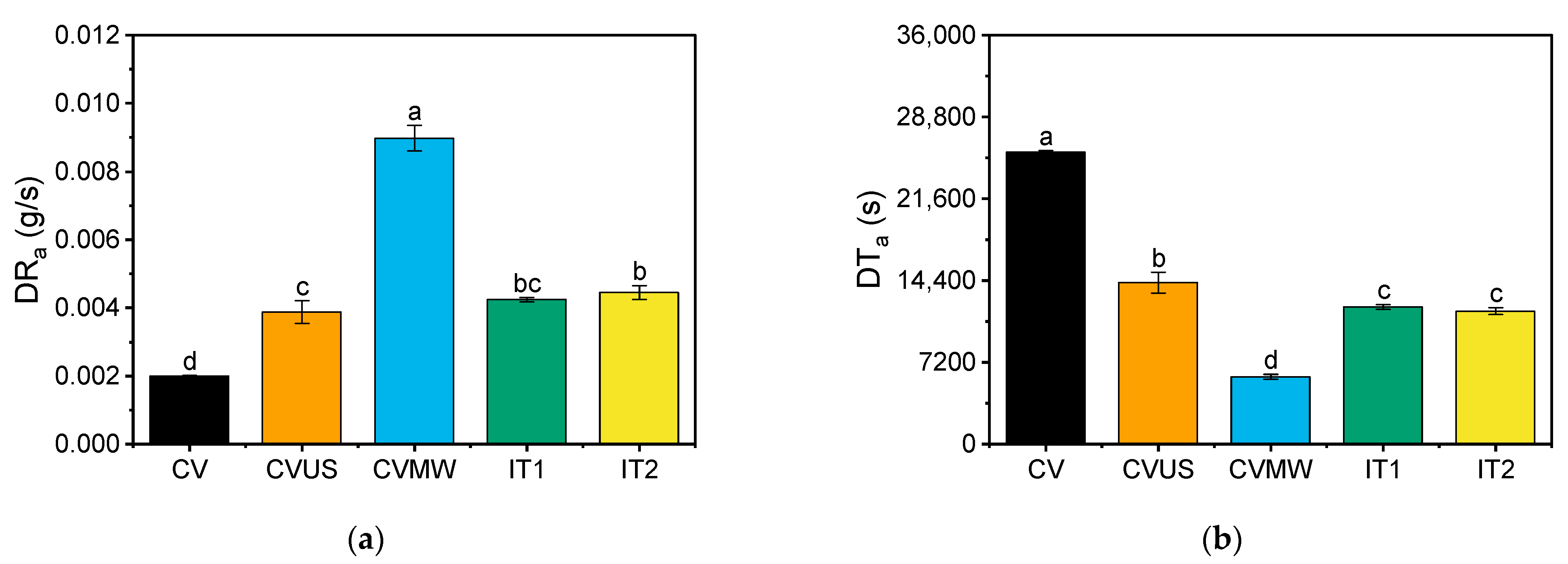

3.1. Drying Kinetics

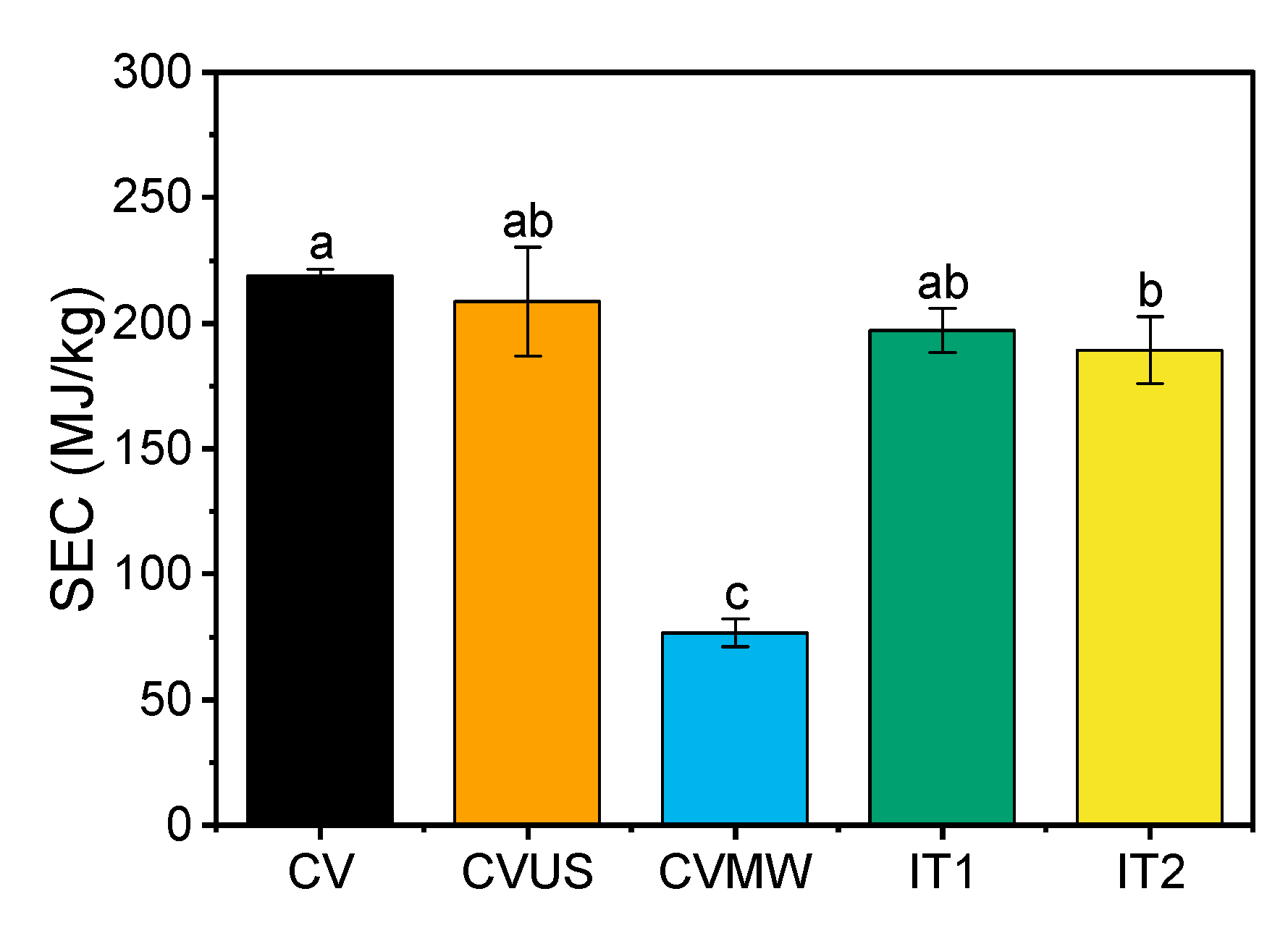

3.2. Energy Intensity of Drying

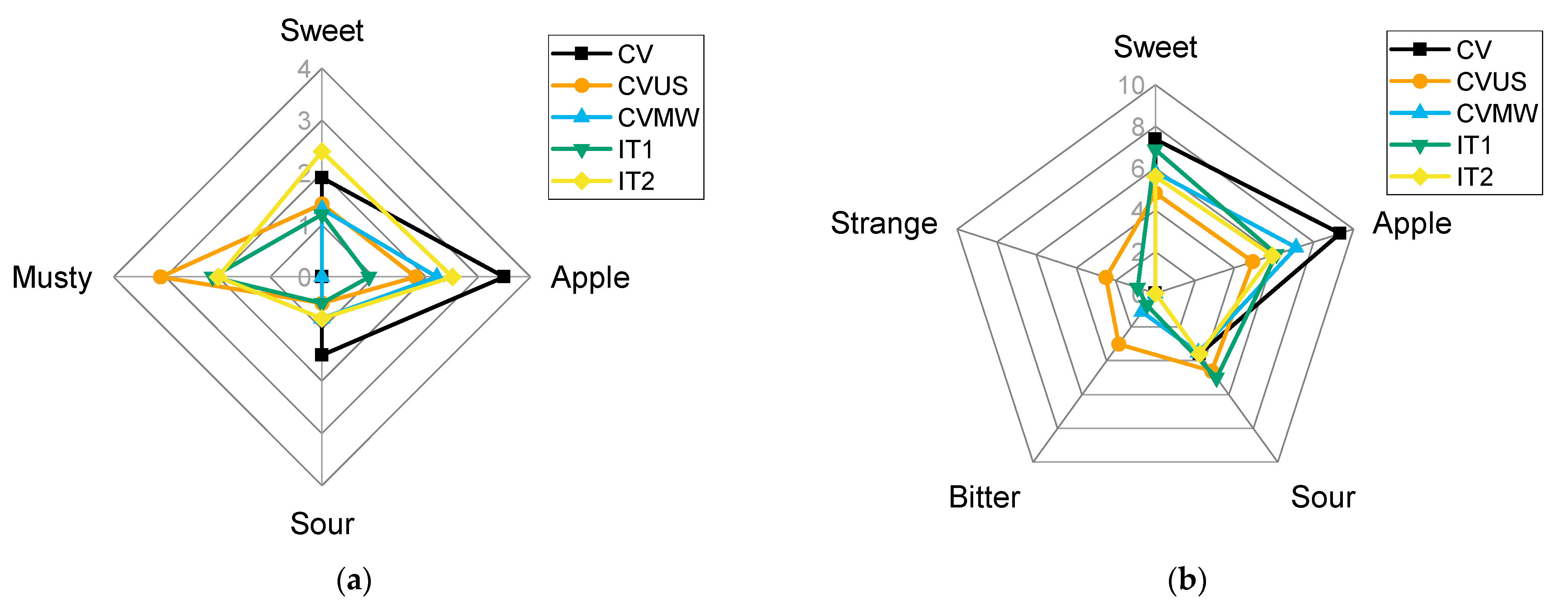

3.3. Product Quality

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Maltini, E.; Torreggiani, D.; Venir, E.; Bertolo, G. Water Activity and the Preservation of Plant Foods. Food Chem. 2003, 82, 79–86. [Google Scholar] [CrossRef]

- Moses, J.A.; Norton, T.; Alagusundaram, K.; Tiwari, B.K. Novel Drying Techniques for the Food Industry. Food Eng. Rev. 2014, 6, 43–55. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, M.; Mujumdar, A.S. Microwave-Assisted Drying of Foods–Equipment, Process and Product Quality. In Modern Drying Technology, Volume 5: Process Intensification; Tsotsas, E., Mujumdar, A.S., Eds.; Wiley: Weinheim, Germany, 2014; Volume 5, pp. 279–315. ISBN 978-3-527-63172-8. [Google Scholar]

- Zahoor, I.; Khan, M.A. Microwave Assisted Convective Drying of Bitter Gourd: Drying Kinetics and Effect on Ascorbic Acid, Total Phenolics and Antioxidant Activity. J. Food Meas. Charact. 2019, 13, 2481–2490. [Google Scholar] [CrossRef]

- Man, Y.; Tong, J.; Wang, T.; Wang, S.; Xu, H. Study on Intermittent Microwave Convective Drying Characteristics and Flow Field of Porous Media Food. Energies 2023, 16, 441. [Google Scholar] [CrossRef]

- Menon, A.; Stojceska, V.; Tassou, S.A. A Systematic Review on the Recent Advances of the Energy Efficiency Improvements in Non-Conventional Food Drying Technologies. Trends Food Sci. Technol. 2020, 100, 67–76. [Google Scholar] [CrossRef]

- Zielinska, M.; Ropelewska, E.; Xiao, H.-W.; Mujumdar, A.S.; Law, C.L. Review of Recent Applications and Research Progress in Hybrid and Combined Microwave-Assisted Drying of Food Products: Quality Properties. Crit. Rev. Food Sci. Nutr. 2020, 60, 2212–2264. [Google Scholar] [CrossRef]

- Kowalski, S.J. Intensification of Drying Processes Due to Ultrasound Enhancement. Chem. Process Eng. 2018, 39, 251–262. [Google Scholar] [CrossRef]

- Huang, D.; Men, K.; Li, D.; Wen, T.; Gong, Z.; Sunden, B.; Wu, Z. Application of Ultrasound Technology in the Drying of Food Products. Ultrason. Sonochem. 2020, 63, 104950. [Google Scholar] [CrossRef]

- Magalhães, M.L.; Cartaxo, S.J.M.; Gallão, M.I.; García-Pérez, J.V.; Cárcel, J.A.; Rodrigues, S.; Fernandes, F.A.N. Drying Intensification Combining Ultrasound Pre-Treatment and Ultrasound-Assisted Air Drying. J. Food Eng. 2017, 215, 72–77. [Google Scholar] [CrossRef]

- Lykov, A.V. Teorija Suški (Theory of Drying), 1st ed.; Godenergolzdat Press: Moscow, Russia; Saint Petersburg, Russia, 1950. [Google Scholar]

- Karim, A.; Law, C.-L. (Eds.) Intermittent and Nonstationary Drying Technologies: Principles and Applications; CRC Press: Boca Raton, FL, USA, 2017; ISBN 978-1-351-25130-3. [Google Scholar]

- Chua, K.J.; Mujumdar, A.S.; Chou, S.K. Intermittent Drying of Bioproducts––An Overview. Bioresour. Technol. 2003, 90, 285–295. [Google Scholar] [CrossRef]

- Kumar, C.; Karim, M.A.; Joardder, M.U.H. Intermittent Drying of Food Products: A Critical Review. J. Food Eng. 2014, 121, 48–57. [Google Scholar] [CrossRef]

- De Souza, A.U.; Corrêa, J.L.G.; Tanikawa, D.H.; Abrahão, F.R.; de Jesus Junqueira, J.R.; Jiménez, E.C. Hybrid Microwave-Hot Air Drying of the Osmotically Treated Carrots. LWT 2022, 156, 113046. [Google Scholar] [CrossRef]

- Khoshnam, F. Drying of Zucchini and Carrot Slices: Influence of Tissue Structure on Mass Transfer Parameters: Dehydration Characteristics of Microwave-Dried Zucchini and Carrot. Lat. Am. Appl. Res. Int. J. 2022, 52, 49–54. [Google Scholar] [CrossRef]

- Mierzwa, D.; Szadzińska, J. An Investigation of the Use of Microwaves and Airborne Ultrasound in the Convective Drying of Kale: Process Efficiency and Product Characteristics. Sustainability 2023, 15, 16200. [Google Scholar] [CrossRef]

- Dardashti, M.; Yagoobi, J. Drying of Strawberries with Airborne Ultrasound and Other Integrated Dehydration Mechanisms. Dry. Technol. 2025, 43, 705–725. [Google Scholar] [CrossRef]

- Gao, Q.; Wang, F.; Wang, J.; Raghavan, V.; Wu, J.; Song, F.; Jin, G.; Song, W.; Song, C. Temperature Control for Microwave Vacuum Drying of Raspberries. Dry. Technol. 2023, 41, 2464–2475. [Google Scholar] [CrossRef]

- Celejewska, K.; Mieszczakowska-Frąc, M.; Konopacka, D. The Effect of Hybrid Drying (Convective-Microwave-Ultrasound) on the Bioactive Properties of Osmo-Treated Sour Cherries. J. Hortic. Res. 2018, 26, 23–36. [Google Scholar] [CrossRef]

- Zhang, J.; Li, M.; Ding, Z.; Wang, C.; Cheng, J. Evaluation of Ultrasound-Assisted Microwave Hot Air Convective Drying Chinese Hickory—Drying Kinetics and Product’s Quality Properties. J. Food Process Eng. 2021, 44, e13842. [Google Scholar] [CrossRef]

- Tu, D.; Cheng, L.; Xu, Y.; Cheng, Y.; Huang, Y.; Zhao, Y.; Xiang, Q.; Tian, Y. Effects of Airborne Ultrasonic Coupled Microwave Vacuum Drying on Moisture-Heat Migration and Quality Characteristics of Shiitake Mushrooms. Food Res. Int. 2025, 218, 116758. [Google Scholar] [CrossRef]

- Zottola, E.A. Spoilage: Bacterial Spoilage. In Encyclopedia of Food Sciences and Nutrition, 2nd ed.; Caballero, B., Ed.; Academic Press: Cambridge, MA, USA, 2003; pp. 5506–5510. ISBN 978-0-12-227055-0. [Google Scholar]

- USDA Foreign Agricultural Service. USDA Apples. Available online: https://www.fas.usda.gov/data/production/commodity/0574000 (accessed on 16 October 2025).

- Musielak, G.; Mieszczakowska-Frąc, M.; Mierzwa, D. Convective Drying of Apple Enhanced with Microwaves and Ultrasound—Process Kinetics, Energy Consumption, and Product Quality Approach. Appl. Sci. 2024, 14, 994. [Google Scholar] [CrossRef]

- Jangam, S.V.; Mujumdar, A.S. Basic Concepts and Definitions. In Drying of Foods, Vegetables and Fruits; Jangam, S.V., Law, C.L., Mujumdar, A.S., Eds.; Published in Singapore; 2010; Volume 1, pp. 1–30, ISBN 978-981-08-6759-1. Available online: https://arunmujumdar.com/wp-content/uploads/2020/03/Drying-of-Foods-Vegetables-and-Fruits-Volume-1.pdf (accessed on 23 September 2025).

- Pei, J.; Huang, D.; Fu, Y.; Huang, S.; Zhang, L.; Ren, H.; Ling, X.; Huang, W. Drying Performance of Gastrodia Elata by Intermittent Microwave Combined with Hot Air Drying. Int. Commun. Heat Mass Transf. 2025, 165, 109089. [Google Scholar] [CrossRef]

- Lopez, A.; Iguaz, A.; Esnoz, A.; Virseda, P. Thin-Layer Drying Behaviour of Vegetable Wastes from Wholesale Market. Dry. Technol. 2000, 18, 995–1006. [Google Scholar] [CrossRef]

- Onwude, D.I.; Norhashila, H.; Rimfiel, B.J.; Nawi, N.M.; Abdan, K. Modeling the Thin-Layer Drying of Fruits and Vegetables: A Review. Compr. Rev. Food Sci. Food Saf. 2016, 15, 599–618. [Google Scholar] [CrossRef]

- Cushman-Roisin, B. Diffusion. In Environmental Transport and Fate; Thayer School of Engineering at Dartmouth: Hanover, NH, USA, 2023. [Google Scholar]

- Sherwood, T.K. The Drying of Solids—I. Ind. Eng. Chem. 1929, 21, 12–16. [Google Scholar] [CrossRef]

- Crank, J. The Mathematics of Diffusion, 2nd ed.; reprint; Clarendon Press: Oxford, UK, 1976; ISBN 978-0-19-853344-3. [Google Scholar]

- Martynenko, A.A.; Vieira, G.N.A. Sustainability of Drying Technologies: System Analysis. Sustain. Food Technol. 2023, 1, 629–640. [Google Scholar] [CrossRef]

- Pathare, P.B.; Opara, U.L.; Al-Said, F.A.J. Colour Measurement and Analysis in Fresh and Processed Foods: A Review. Food Bioprocess Technol. 2013, 6, 36–60. [Google Scholar] [CrossRef]

- Mayor, L.; Sereno, A.M. Modelling Shrinkage during Convective Drying of Food Materials: A Review. J. Food Eng. 2004, 61, 373–386. [Google Scholar] [CrossRef]

- Lewicki, P.P. Some Remarks on Rehydration of Dried Foods. J. Food Eng. 1998, 36, 81–87. [Google Scholar] [CrossRef]

- Singleton, V.L.; Rossi, J.A. Colorimetry of Total Phenolics with Phosphomolybdic-Phosphotungstic Acid Reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar] [CrossRef]

- ISO 8586:2023; Sensory Analysis–Selection and Training of Sensory Assessors. International Organization for Standardization: Geneva, Switzerland, 2023.

- ISO 11035:1994; Sensory Analysis–Identification and Selection of Descriptors for Establishing a Sensory Profile by a Multidimensional Approach. International Organization for Standardization: Geneva, Switzerland, 1994.

- ISO 8589:2007; Sensory Analysis–General Guidance for the Design of Test Rooms. International Organization for Standardization: Geneva, Switzerland, 2007.

- OriginLab. Theory of Nonlinear Curve Fitting. Available online: https://www.originlab.com/doc/Origin-Help/NLFit-Theory (accessed on 10 October 2018).

- Kowalski, S.J.; Mierzwa, D.; Stasiak, M. Ultrasound-Assisted Convective Drying of Apples at Different Process Conditions. Dry. Technol. 2017, 35, 939–947. [Google Scholar] [CrossRef]

- Şen, S.; Aydin, F. Experimental Investigation of Drying Kinetics of Apple with Hot Air, Microwave and Ultrasonic Power. Sādhanā 2020, 45, 94. [Google Scholar] [CrossRef]

- Kroehnke, J.; Musielak, G. Ultrasound-Assisted Drying of Apples–Process Kinetics, Energy Consumption, and Product Quality. Dry. Technol. 2024, 42, 1757–1765. [Google Scholar] [CrossRef]

- Pittia, P.; Antonello, P. Chapter 2-Safety by Control of Water Activity: Drying, Smoking, and Salt or Sugar Addition. In Regulating Safety of Traditional and Ethnic Foods; Prakash, V., Martín-Belloso, O., Keener, L., Astley, S., Braun, S., McMahon, H., Lelieveld, H., Eds.; Academic Press: San Diego, CA, USA, 2016; pp. 7–28. ISBN 978-0-12-800605-4. [Google Scholar]

- Kroehnke, J.; Szadzińska, J.; Stasiak, M.; Radziejewska-Kubzdela, E.; Biegańska-Marecik, R.; Musielak, G. Ultrasound- and Microwave-Assisted Convective Drying of Carrots–Process Kinetics and Product’s Quality Analysis. Ultrason. Sonochem. 2018, 48, 249–258. [Google Scholar] [CrossRef]

- Nawirska-Olszańska, A.; Stępień, B.; Biesiada, A.; Kolniak-Ostek, J.; Oziembłowski, M. Rheological, Chemical and Physical Characteristics of Golden Berry (Physalis Peruviana L.) after Convective and Microwave Drying. Foods 2017, 6, 60. [Google Scholar] [CrossRef] [PubMed]

- Pham, N.D.; Karim, M.A. Investigation of Nutritional Quality Evolution of Papaya during Intermittent Microwave Convective Drying. Dry. Technol. 2022, 40, 3694–3707. [Google Scholar] [CrossRef]

- Matys, A.; Dadan, M.; Witrowa-Rajchert, D.; Parniakov, O.; Wiktor, A. Response Surface Methodology as a Tool for Optimization of Pulsed Electric Field Pretreatment and Microwave-Convective Drying of Apple. Appl. Sci. 2022, 12, 3392. [Google Scholar] [CrossRef]

- Araya-Farias, M.; Ratti, C. Dehydration of Foods: General Concepts. In Advances in Food Dehydration; Ratti, C., Ed.; Contemporary food engineering series; CRC Press: Boca Raton, FL, USA, 2009; pp. 1–36. ISBN 978-1-4200-5252-7. [Google Scholar]

- Chong, C.H.; Figiel, A.; Law, C.L.; Wojdyło, A. Combined Drying of Apple Cubes by Using of Heat Pump, Vacuum-Microwave, and Intermittent Techniques. Food Bioprocess Technol. 2014, 7, 975–989. [Google Scholar] [CrossRef]

- Tepe, T.K.; Tepe, B. The Comparison of Drying and Rehydration Characteristics of Intermittent-Microwave and Hot-Air Dried-Apple Slices. Heat Mass Transf. 2020, 56, 3047–3057. [Google Scholar] [CrossRef]

- İzli, N.; Polat, A. Intermittent Microwave Drying of Apple Slices: Drying Kinetics, Modeling, Rehydration Ratio and Effective Moisture Diffusivity. J. Agric. Sci. 2020, 26, 32–41. [Google Scholar] [CrossRef]

- Naczk, M.; Shahidi, F. Extraction and Analysis of Phenolics in Food. J. Chromatogr. A 2004, 1054, 95–111. [Google Scholar] [CrossRef]

- Pandey, K.B.; Rizvi, S.I. Plant Polyphenols as Dietary Antioxidants in Human Health and Disease. Oxid. Med. Cell. Longev. 2009, 2, 270–278. [Google Scholar] [CrossRef]

- Filippin, A.P.; Molina Filho, L.; Fadel, V.; Mauro, M.A. Thermal Intermittent Drying of Apples and Its Effects on Energy Consumption. Dry. Technol. 2018, 36, 1662–1677. [Google Scholar] [CrossRef]

- Fiorentini, M.; Kinchla, A.J.; Nolden, A.A. Role of Sensory Evaluation in Consumer Acceptance of Plant-Based Meat Analogs and Meat Extenders: A Scoping Review. Foods 2020, 9, 1334. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhao, H.; Deng, H.; Song, X.; Zhang, W.; Wu, S.; Wang, J. Influence of Pretreatments on Microwave Vacuum Drying Kinetics, Physicochemical Properties and Sensory Quality of Apple Slices. Pol. J. Food Nutr. Sci. 2019, 69, 297–306. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, Y.; Zhu, C.; Wei, M. Effects of Different Drying Methods on the Physical Properties and Sensory Characteristics of Apple Chip Snacks. LWT 2022, 154, 112829. [Google Scholar] [CrossRef]

- Petikirige, J.; Karim, A.; Millar, G. Effect of Drying Techniques on Quality and Sensory Properties of Tropical Fruits. Int. J. Food Sci. Technol. 2022, 57, 6963–6979. [Google Scholar] [CrossRef]

| Process | a (SD) – | k × 104 (SD) 1/s | Deff × 109 (SD) m/s2 | red. χ2 | adj. R2 | RMSE |

|---|---|---|---|---|---|---|

| CV | 0.99 (0.00) c | 1.61 (0.05) c | 3.67 (0.11) c | 4.73 × 10−5 | 0.9993 | 0.0069 |

| CVUS | 1.01 (0.01) b | 2.65 (0.14) b | 6.05 (0.33) b | 6.78 × 10−5 | 0.9990 | 0.0081 |

| CVMW | 1.08 (0.01) a | 4.81 (0.06) a | 10.97 (0.13) a | 1.32 × 10−3 | 0.9848 | 0.0363 |

| IT1 | 1.03 (0.00) b | 2.68 (0.06) b | 6.11 (0.15) b | 2.99 × 10−4 | 0.9948 | 0.0172 |

| IT2 | 1.03 (0.01) b | 2.75 (0.12) b | 6.27 (0.27) b | 4.45 × 10−4 | 0.9925 | 0.0208 |

| Process | aw (SD) – | dE (SD) – | VS (SD) – | RR (SD) – | RPF (SD) – |

|---|---|---|---|---|---|

| CV | 0.227 (0.035) a | 14.28 (0.15) a | 0.758 (0.023) ab | 4.080 (0.017) b | 0.79 (0.00) a |

| CVUS | 0.273 (0.040) a | 10.08 (1.19) b | 0.763 (0.021) a | 4.330 (0.151) ab | 0.82 (0.01) a |

| CVMW | 0.172 (0.008) b | 11.56 (1.90) ab | 0.746 (0.027) abc | 4.083 (0.047) b | 0.73 (0.03) b |

| IT1 | 0.251 (0.024) a | 11.78 (0.07) ab | 0.716 (0.017) bc | 4.570 (0.155) a | 0.84 (0.00) a |

| IT2 | 0.245 (0.015) a | 10.96 (0.04) ab | 0.713 (0.008) c | 4.187 (0.083) b | 0.80 (0.02) a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szadzińska, J.; Waszkowiak, K.; Mierzwa, D. Hybrid Drying of Apples: A Comparison of Continuous and Intermittent Process Modes. Appl. Sci. 2025, 15, 12031. https://doi.org/10.3390/app152212031

Szadzińska J, Waszkowiak K, Mierzwa D. Hybrid Drying of Apples: A Comparison of Continuous and Intermittent Process Modes. Applied Sciences. 2025; 15(22):12031. https://doi.org/10.3390/app152212031

Chicago/Turabian StyleSzadzińska, Justyna, Katarzyna Waszkowiak, and Dominik Mierzwa. 2025. "Hybrid Drying of Apples: A Comparison of Continuous and Intermittent Process Modes" Applied Sciences 15, no. 22: 12031. https://doi.org/10.3390/app152212031

APA StyleSzadzińska, J., Waszkowiak, K., & Mierzwa, D. (2025). Hybrid Drying of Apples: A Comparison of Continuous and Intermittent Process Modes. Applied Sciences, 15(22), 12031. https://doi.org/10.3390/app152212031