IoT-Based Off-Grid Solar Power Supply: Design, Implementation, and Case Study of Energy Consumption Control Using Forecasted Solar Irradiation

Abstract

1. Introduction

2. Related Works

3. Materials and Methods

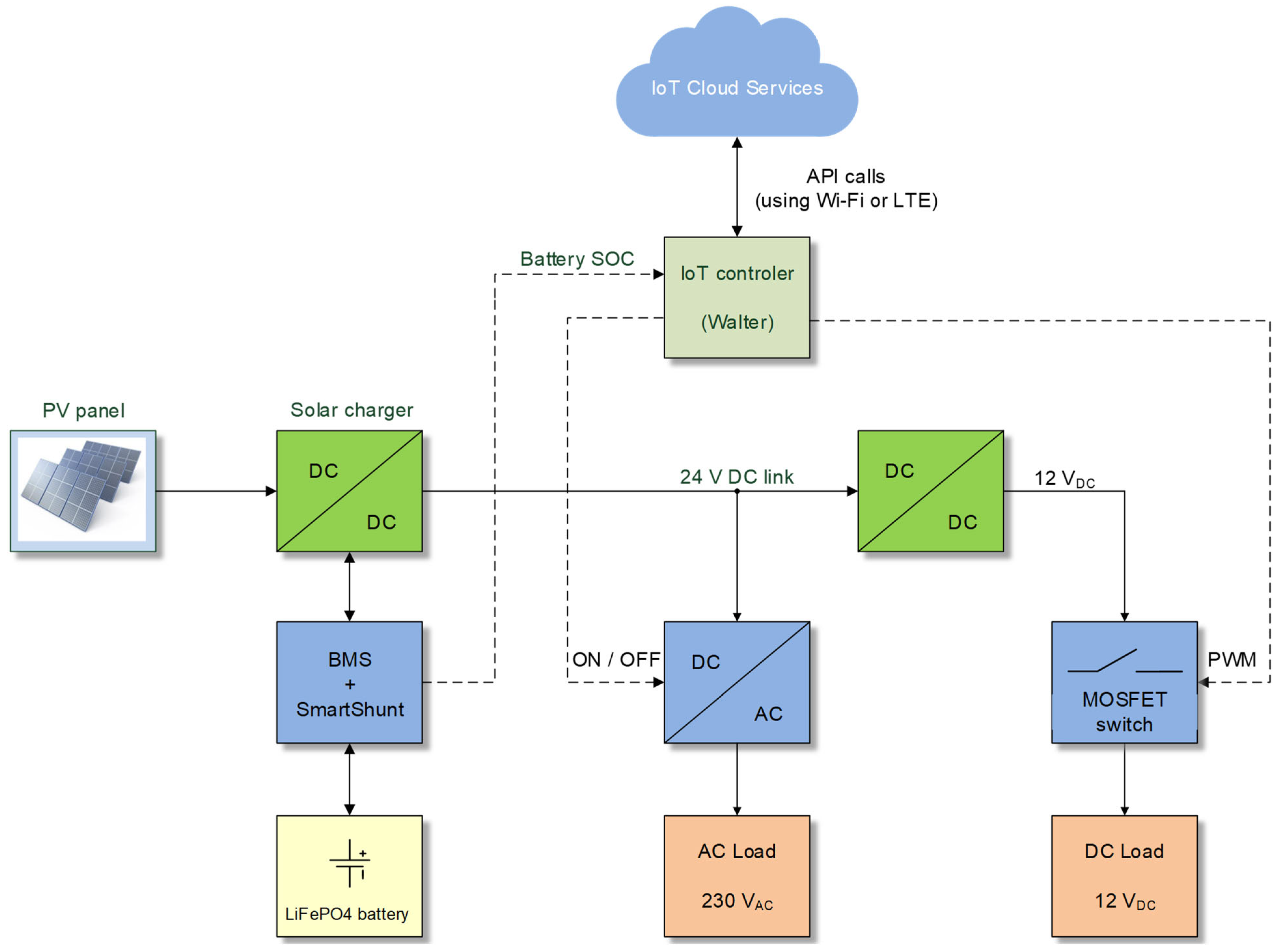

3.1. System Architecture

- Captures the measurement data from the SmartShunt module (SoC, voltage, current, power).

- Obtains data from online sources.

- Based on a combination of locally captured and online data, it executes an algorithm for automatic control of the DC and AC loads.

- Sends selected processed data to the IoT web platform for further analysis and visualization.

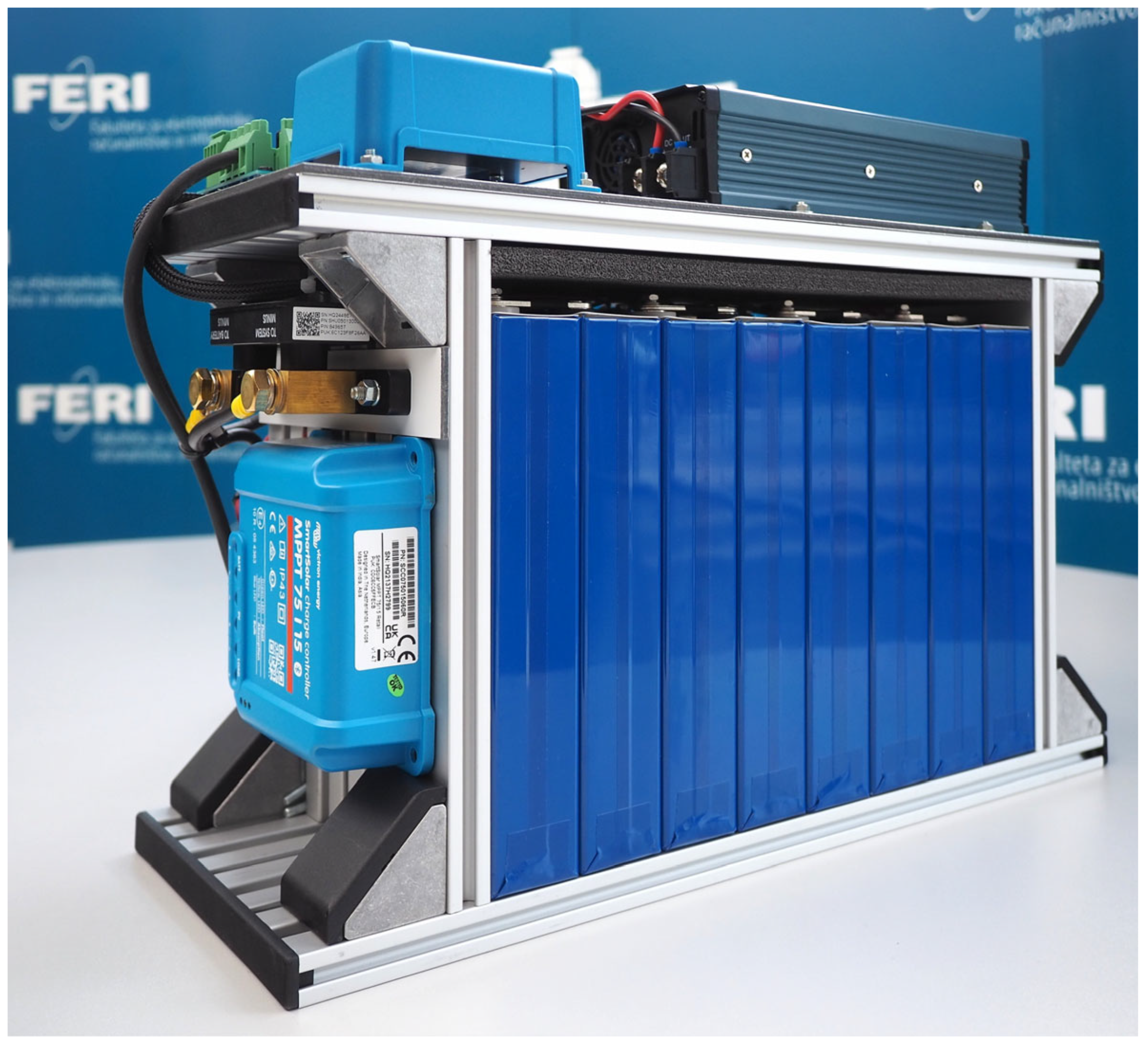

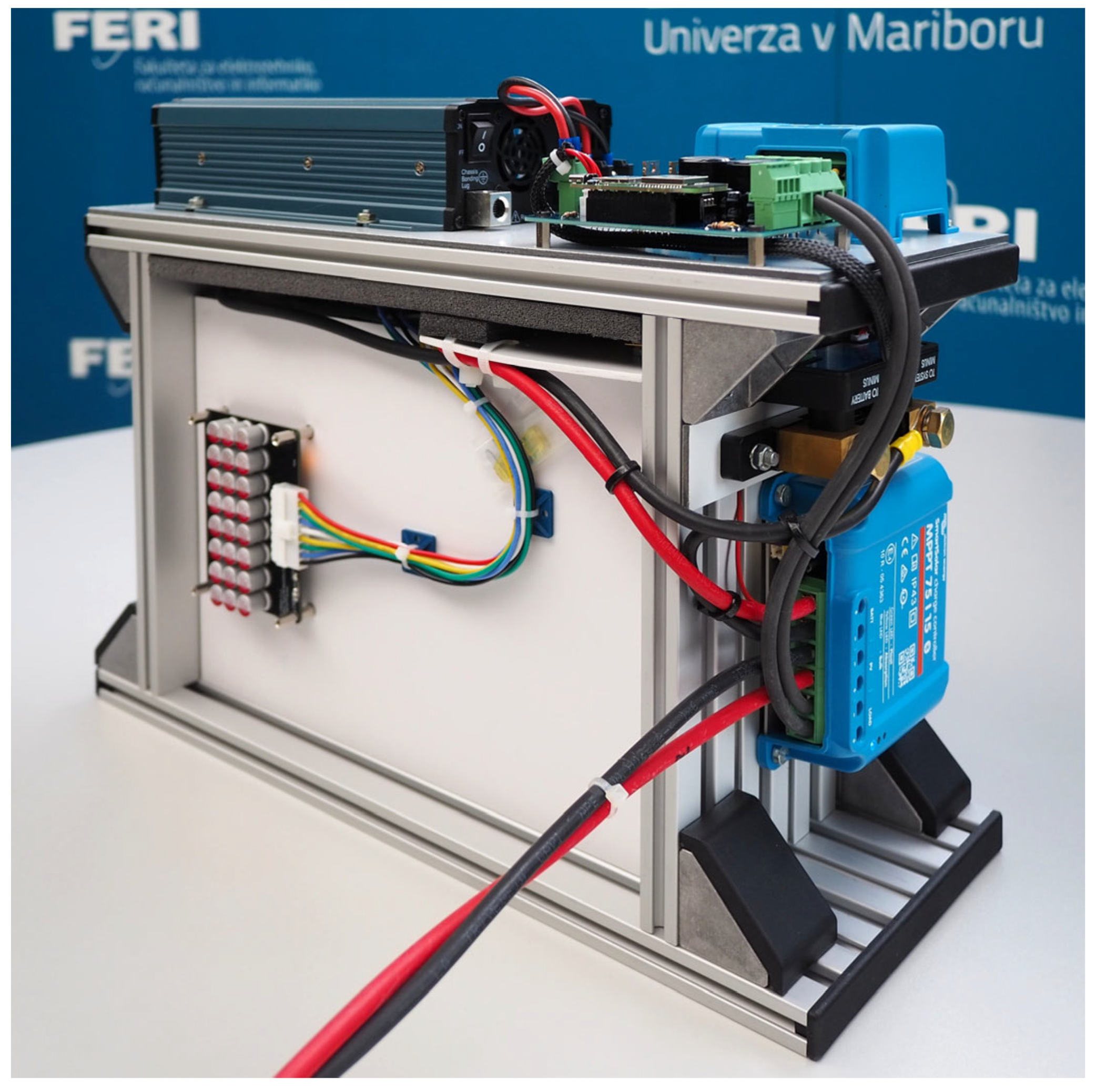

3.2. Hardware

3.2.1. Battery System

3.2.2. Solar Panel

3.2.3. MPPT Controller

3.2.4. SmartShunt

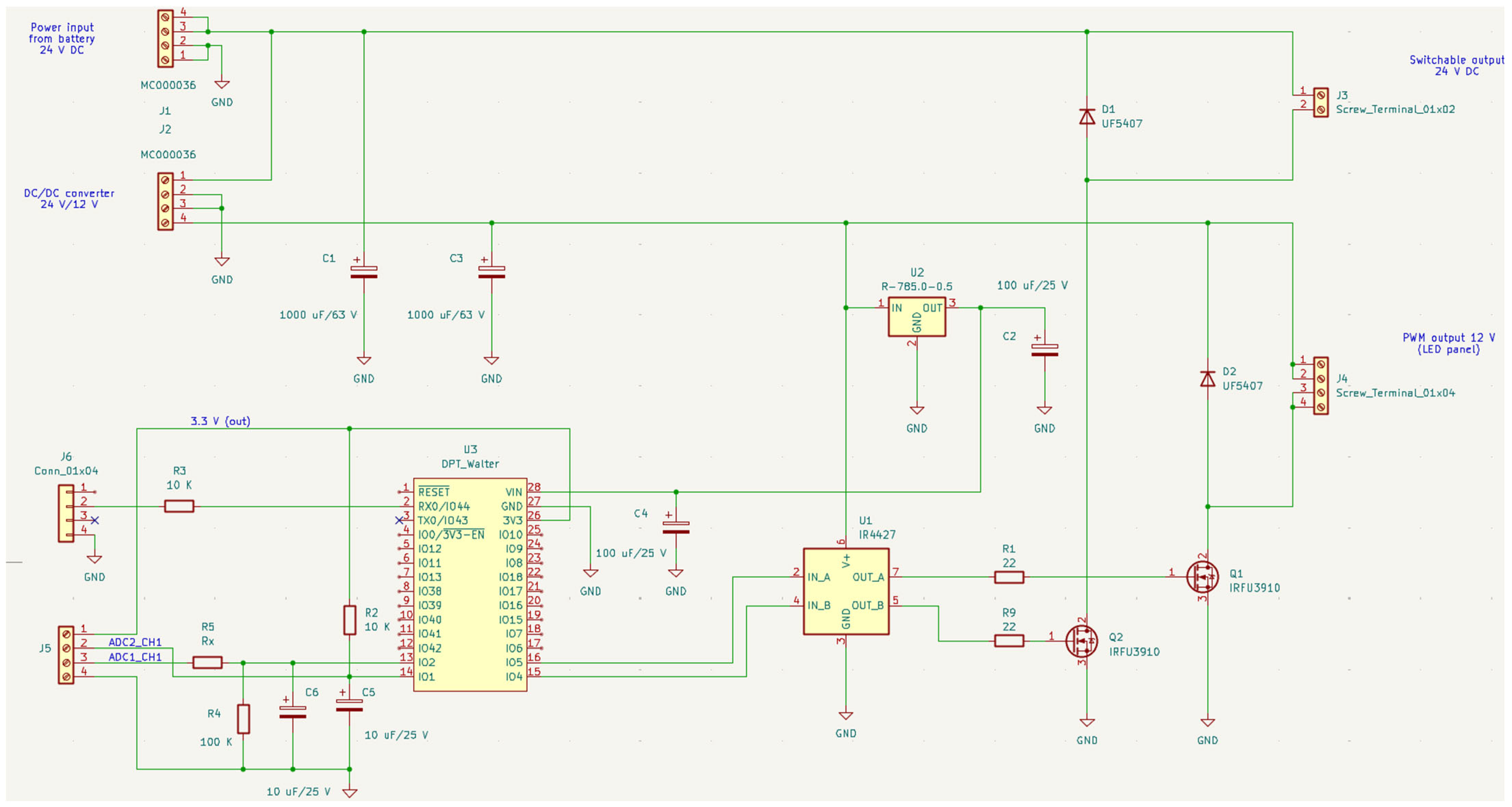

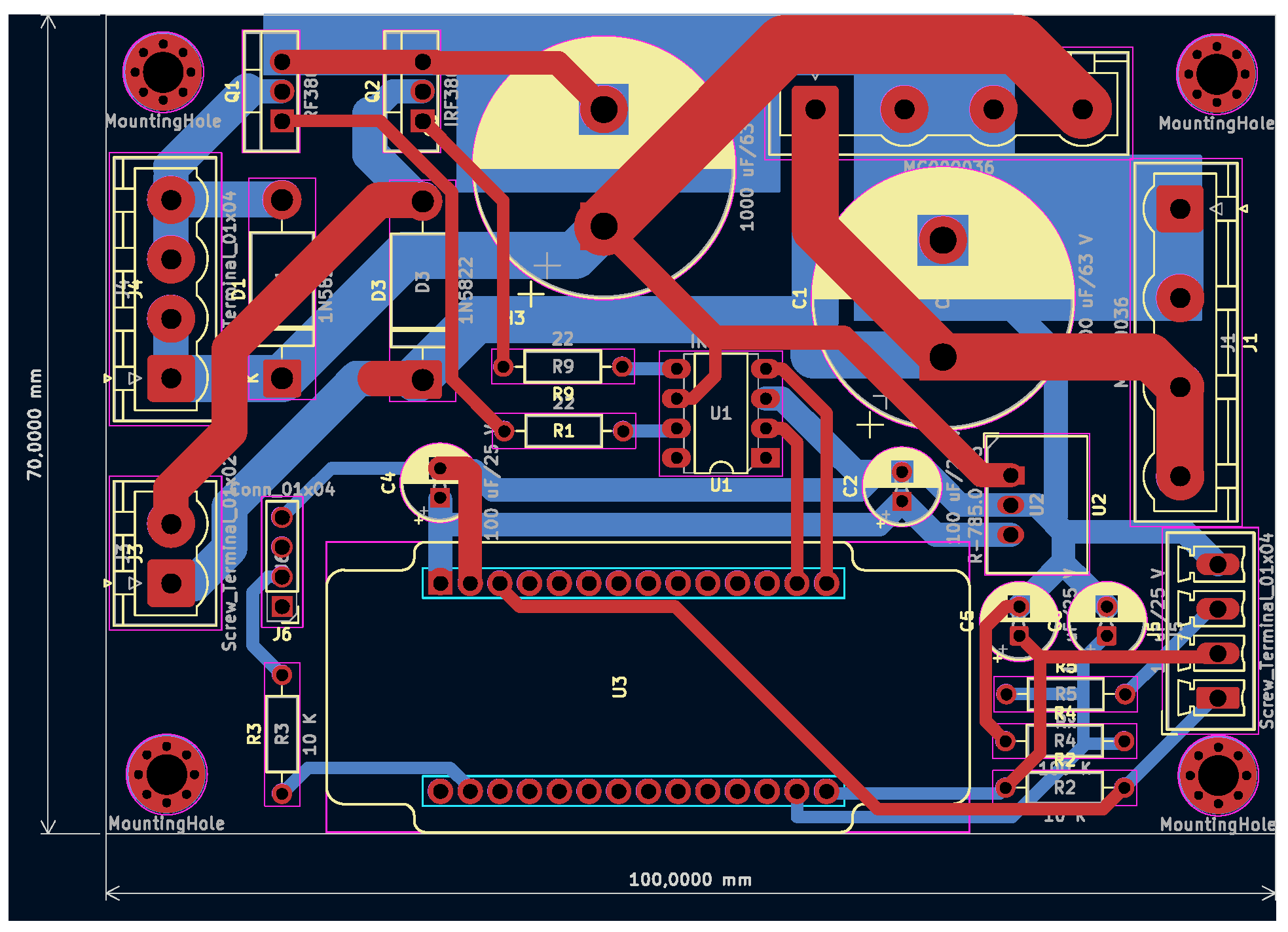

3.2.5. Control Circuit

- The AC Load power output is intended for loads with constant operating intensity (e.g., a standard LCD TV screen). The IoT controller generates a digital switching signal (0—the load is off, 1—the load is on). The MOSFET switch Q2 is switched on by the drive stage U2B, thereby transferring the 24 V(DC)battery voltage to the True Sine Wave DC-AC Power Inverter [46], which provides a standard sine wave voltage of 230 V/5 Hz and a maximum load power of up to 400 W at its output.

- Power output “DC Load” for loads with a nominal voltage of 12 VDC and adjustable operating power (e.g., a light board with LED lighting). The battery voltage is reduced and stabilized to 12.5 V using a buck converter. The operating power of the load varies proportionally with the PWM level, whereby the duty cycle can be set in the range from 0 to 100%. The IoT controller generates a PWM output signal, which controls the MOSFET switch Q1 via the U2A drive stage.

3.2.6. Overall System Efficiency

| Efficiency of power transmission through wires | |

| Power efficiency of AC load (LCD TV) | |

| Power efficiency of the DC load (LED panel) | |

| Efficiency of MPPT controller | |

| Efficiency of DC/DC converter | |

| Efficiency of DC/AC converter | |

| Efficiency of the LFP battery |

3.2.7. IoT Controller

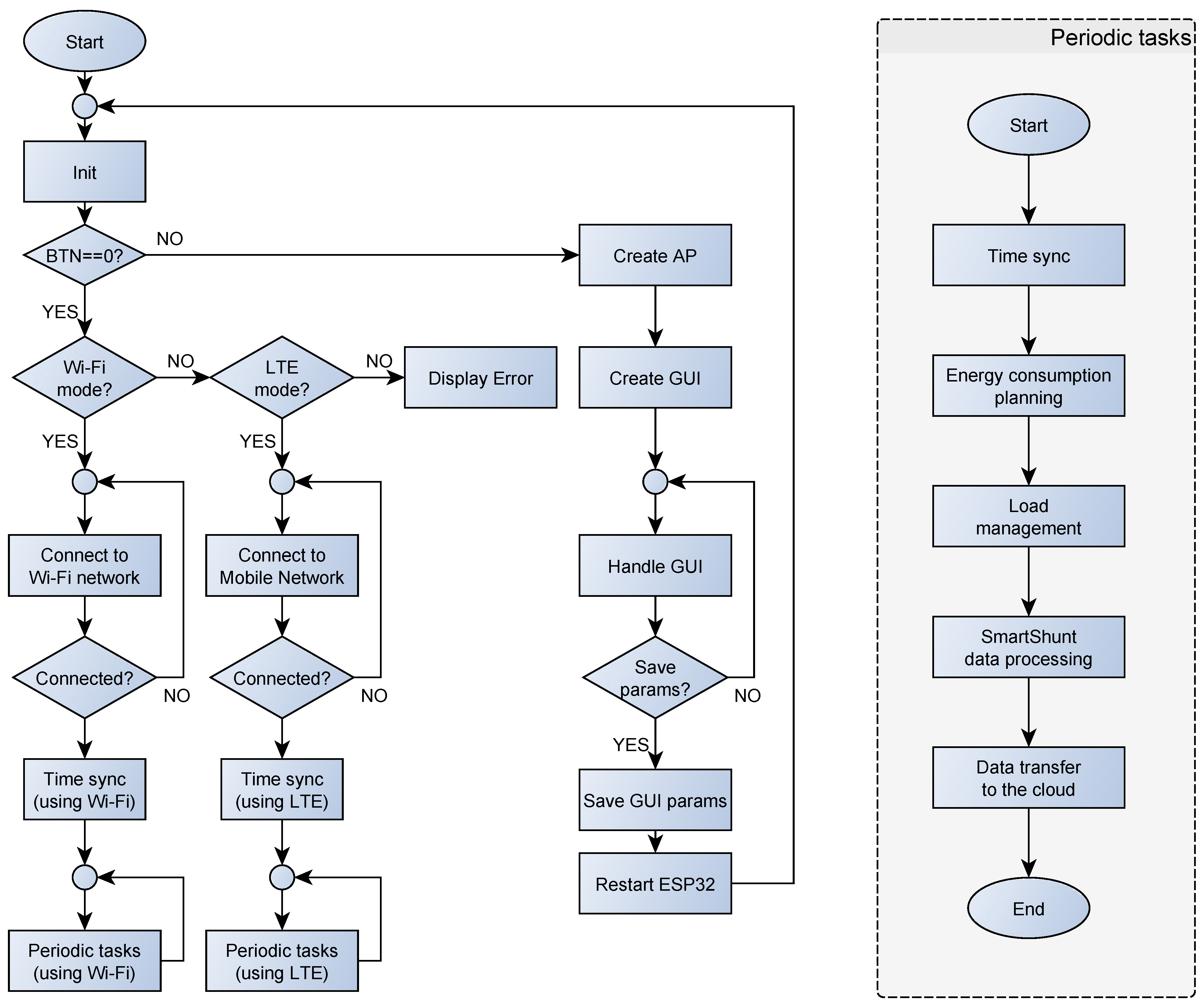

3.3. Software

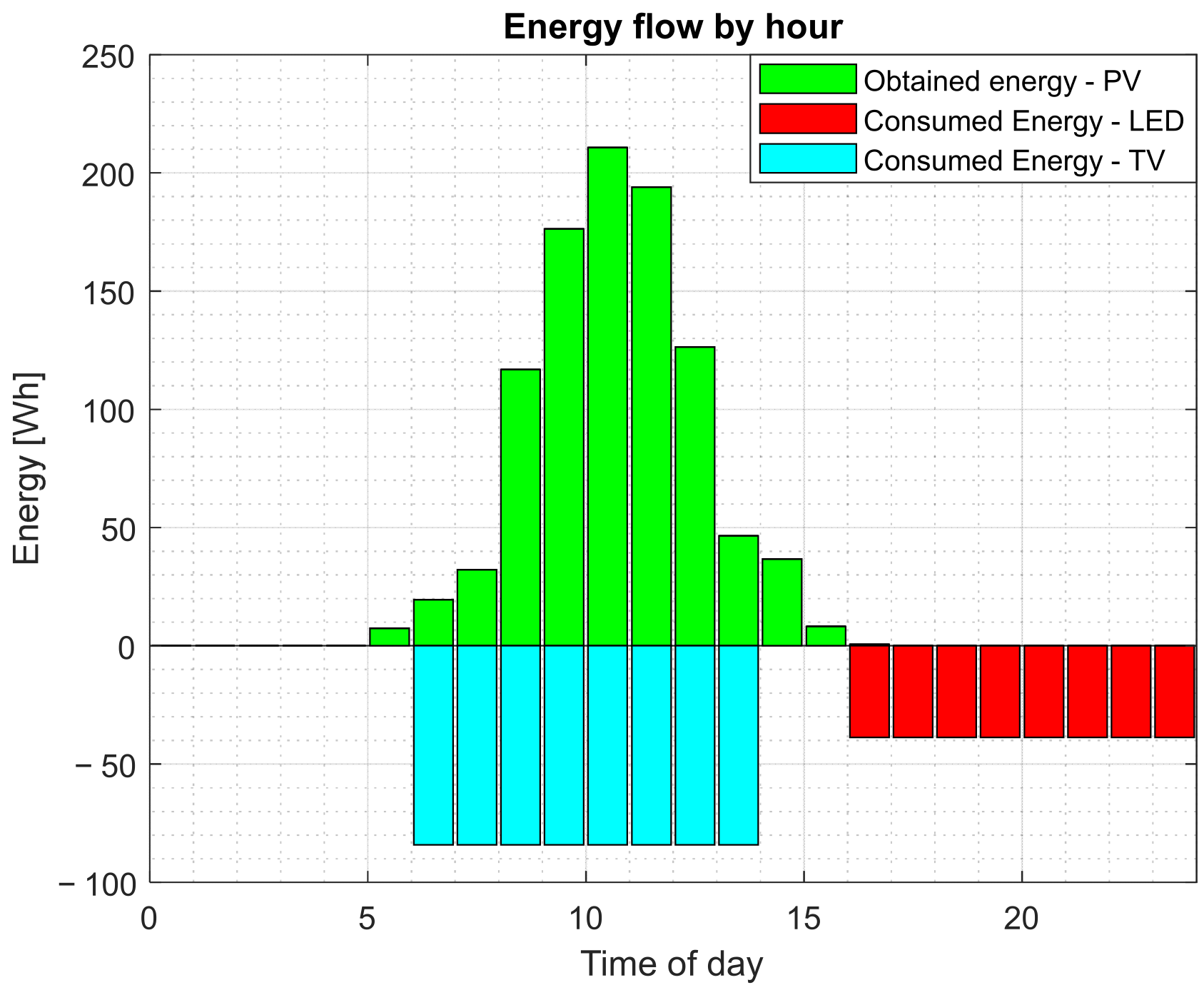

4. Case Study

4.1. Case Description

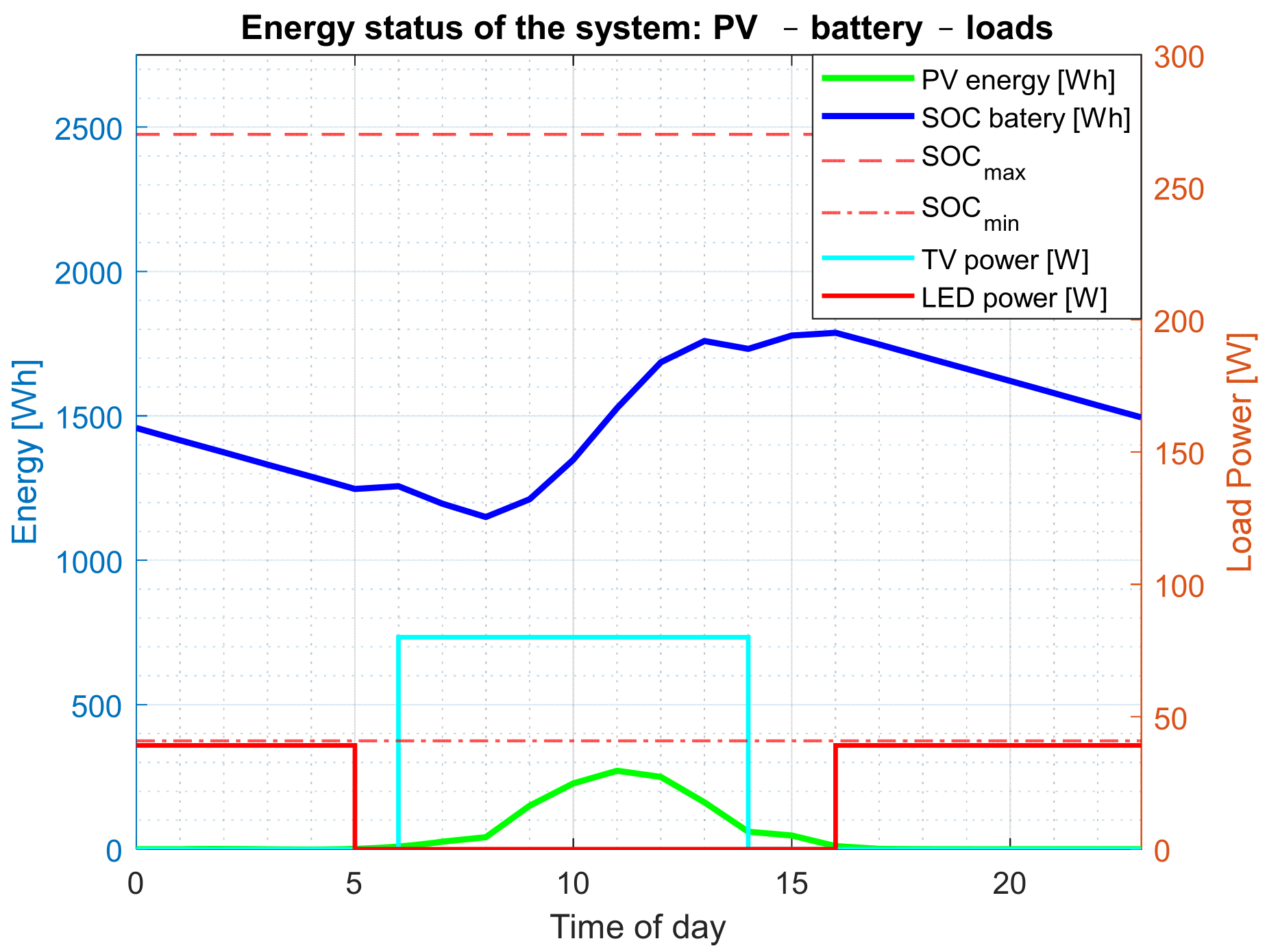

- the longest possible operating time of both loads,

- maintaining the battery SoC above a predetermined minimum threshold, and

- respecting the hierarchy between loads, whereby the operation of the TV takes precedence over the LED lighting.

4.2. Control Algorithm

- Time sync: Once a day, the controller synchronizes its internal clock with an NTP server to ensure accurate system timing.

- Energy consumption planning: At the start of each day, the controller queries about the predicted solar energy. Based on this forecast and the current battery SoC, it determines the optimal timing for switching the connected loads on and off, thereby optimizing the use of the available energy.

- Load management: Every hour, the controller adjusts the brightness of the LEDs (via PWM settings) and the status of the LCD according to the planned operating schedule of the system.

- SmartShunt data processing: At specific time intervals, the controller obtains data from the SmartShunt device via the UART interface. Communication between the devices is carried out using the VE.Direct protocol, which enables the reliable transmission of the measurement data. From the data received the controller extracts key information about the battery system’s status, including the voltage, current, power, and battery SoC.

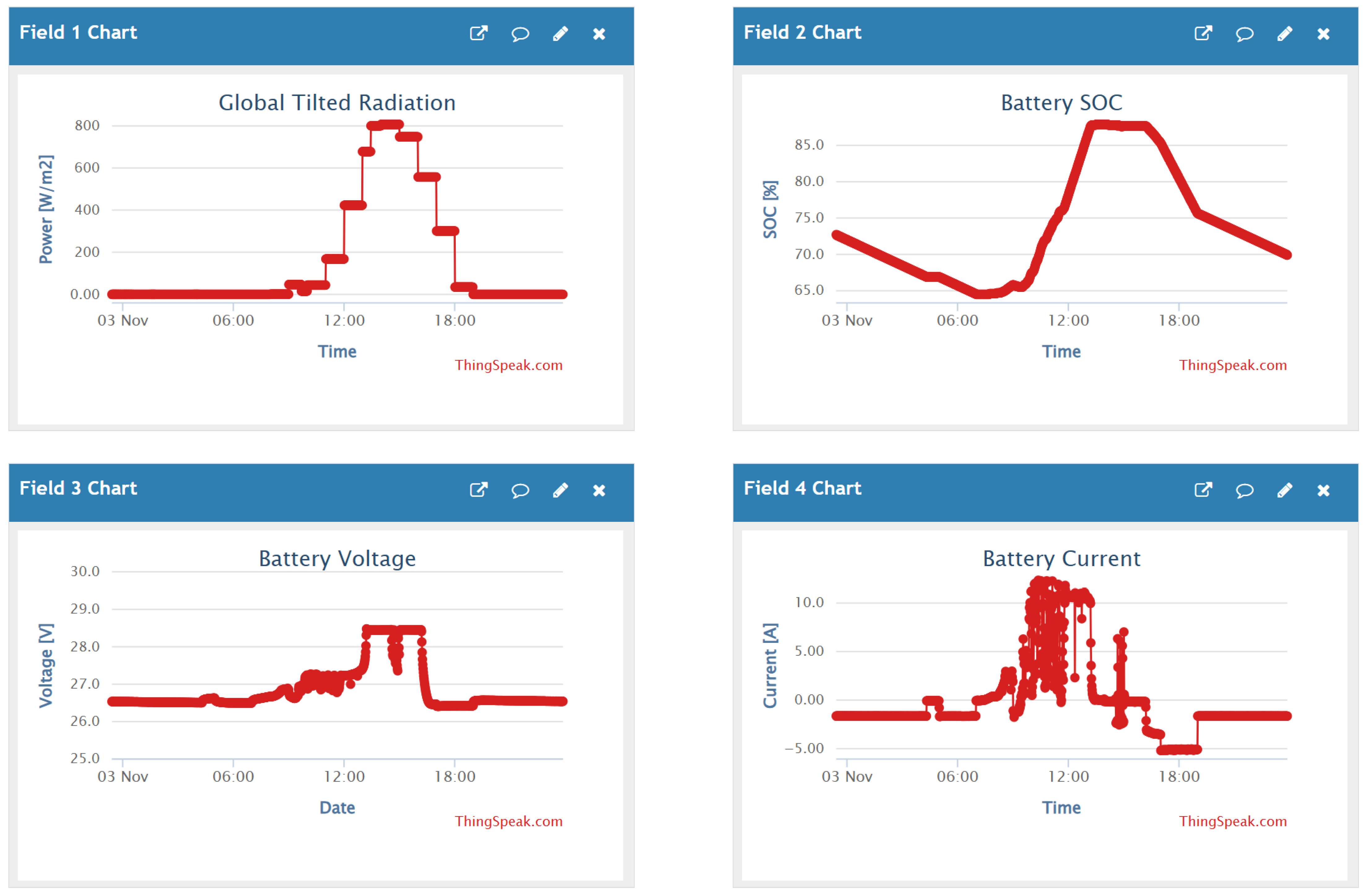

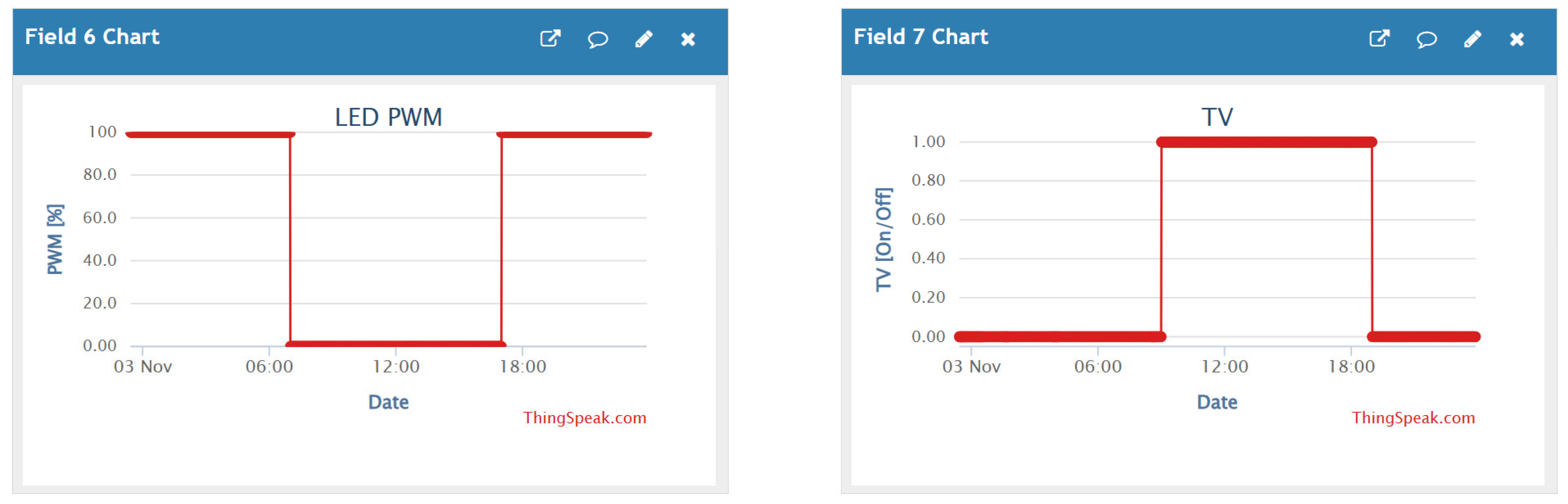

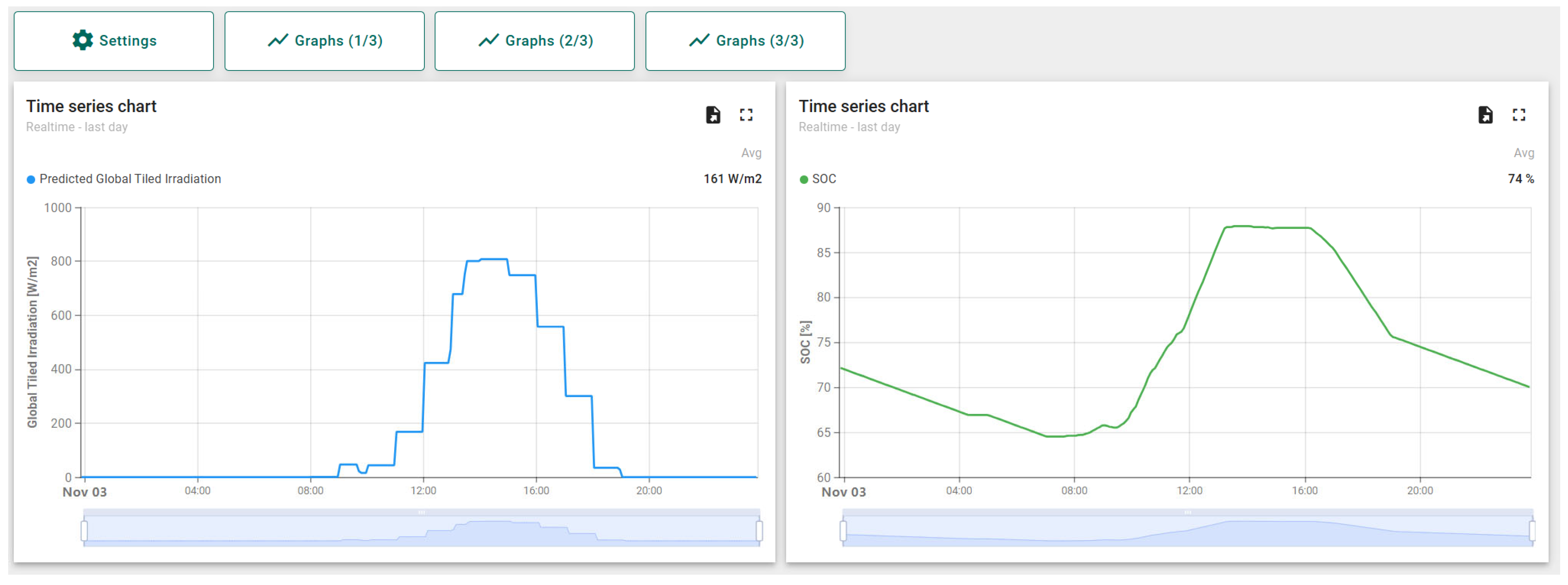

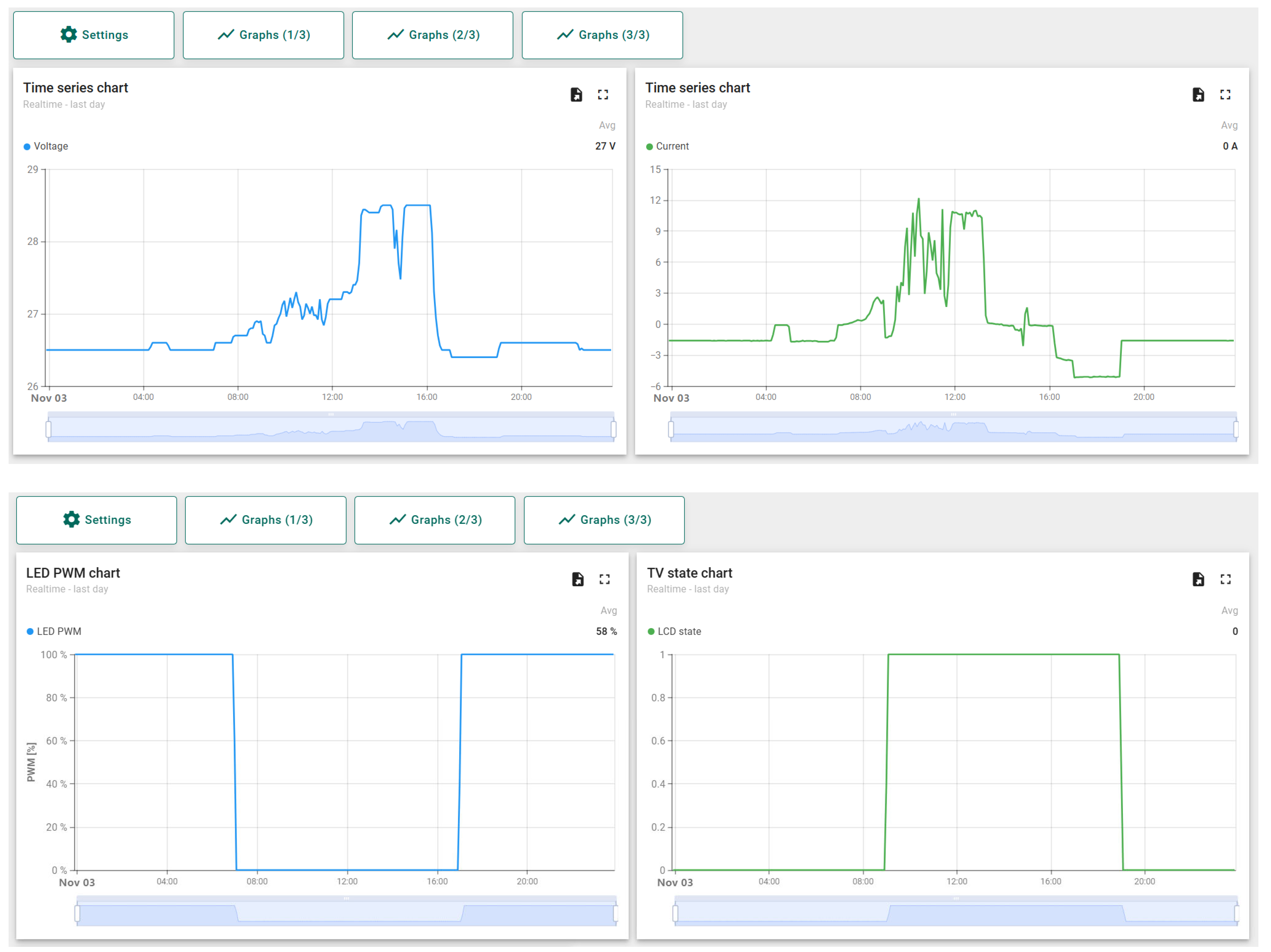

- Data transfer to the cloud: At specific intervals the controller sends the process data to the ThingSpeak web platform, where they are stored and displayed in graphical form.

- Data acquisition and electricity production forecast

- 2.

- Energy consumption forecast and distribution

- 3.

- Secondary consumer management (LED lighting)

- 4.

- Determining the LED brightness

- 5.

- Output vectors and control

- TV vector: logical values (on/off),

- LED vector: real values from 0 to 100 (PWM signal width).

Communication Error and Low SOC Handling

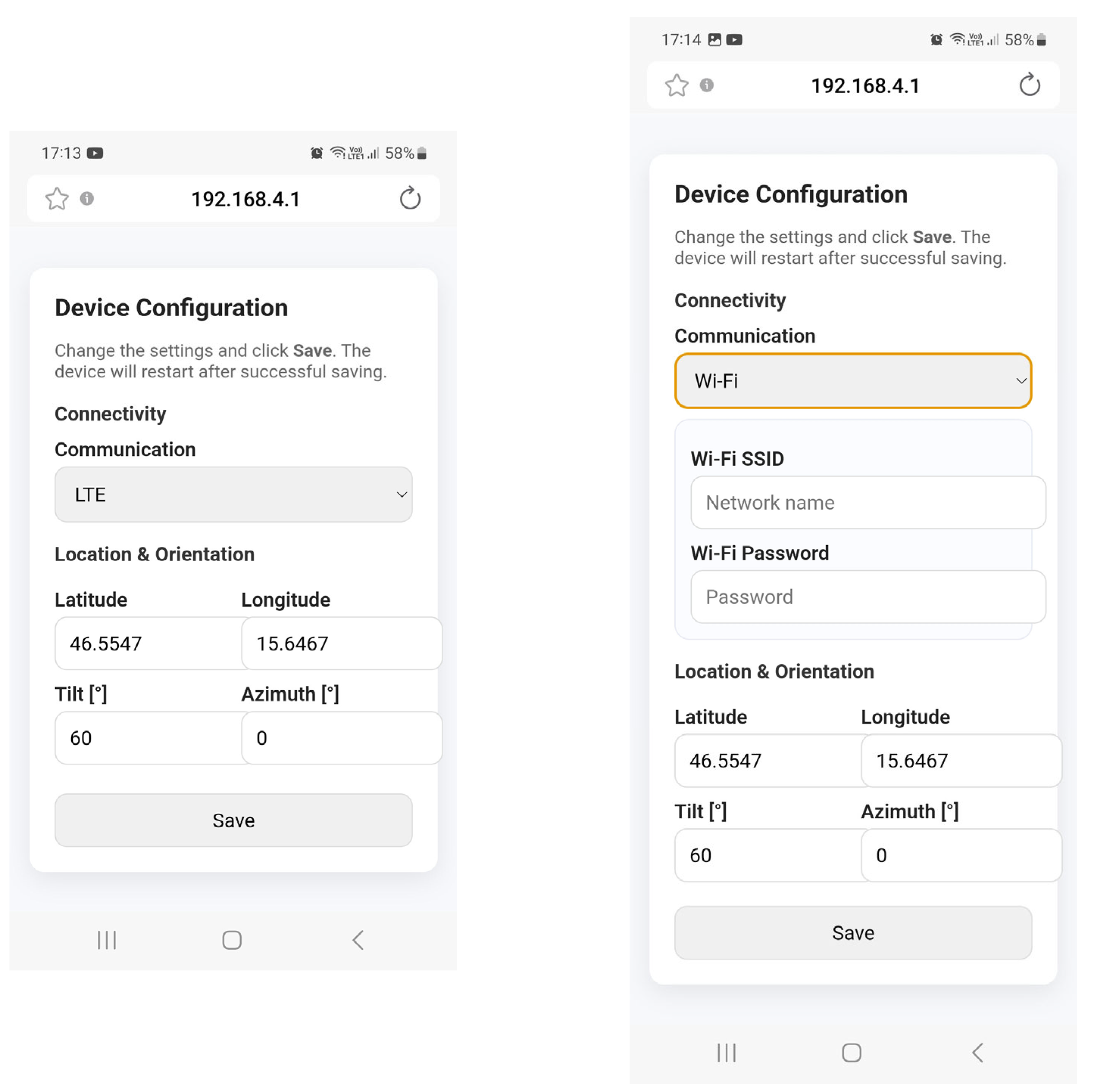

4.3. Configuration Utility

- Communication interface: This can be Wi-Fi or LTE. If Wi-Fi is selected, the user is presented with input fields for the Service Set Identifier (SSID) name of the selected wireless network and the corresponding password. If LTE is selected, no additional settings are required, as the IoT controller connects to the mobile network automatically based on the SIM card data. A SIM card from ThingsMobile was used in our case.

- Geographic data: The user enters the latitude and longitude of the panel’s location, as well as the azimuth and tilt of its position.

4.4. Data Visualization

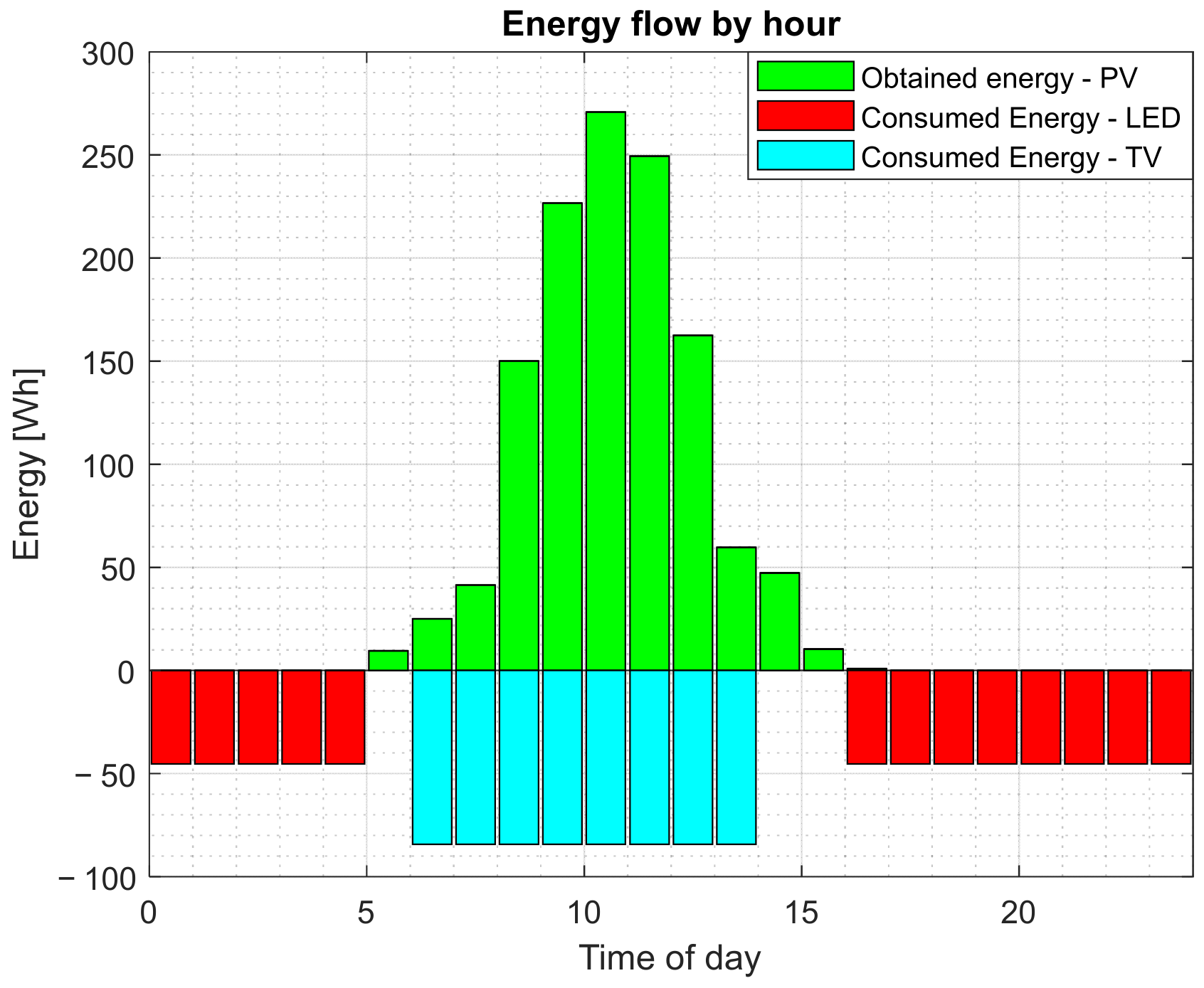

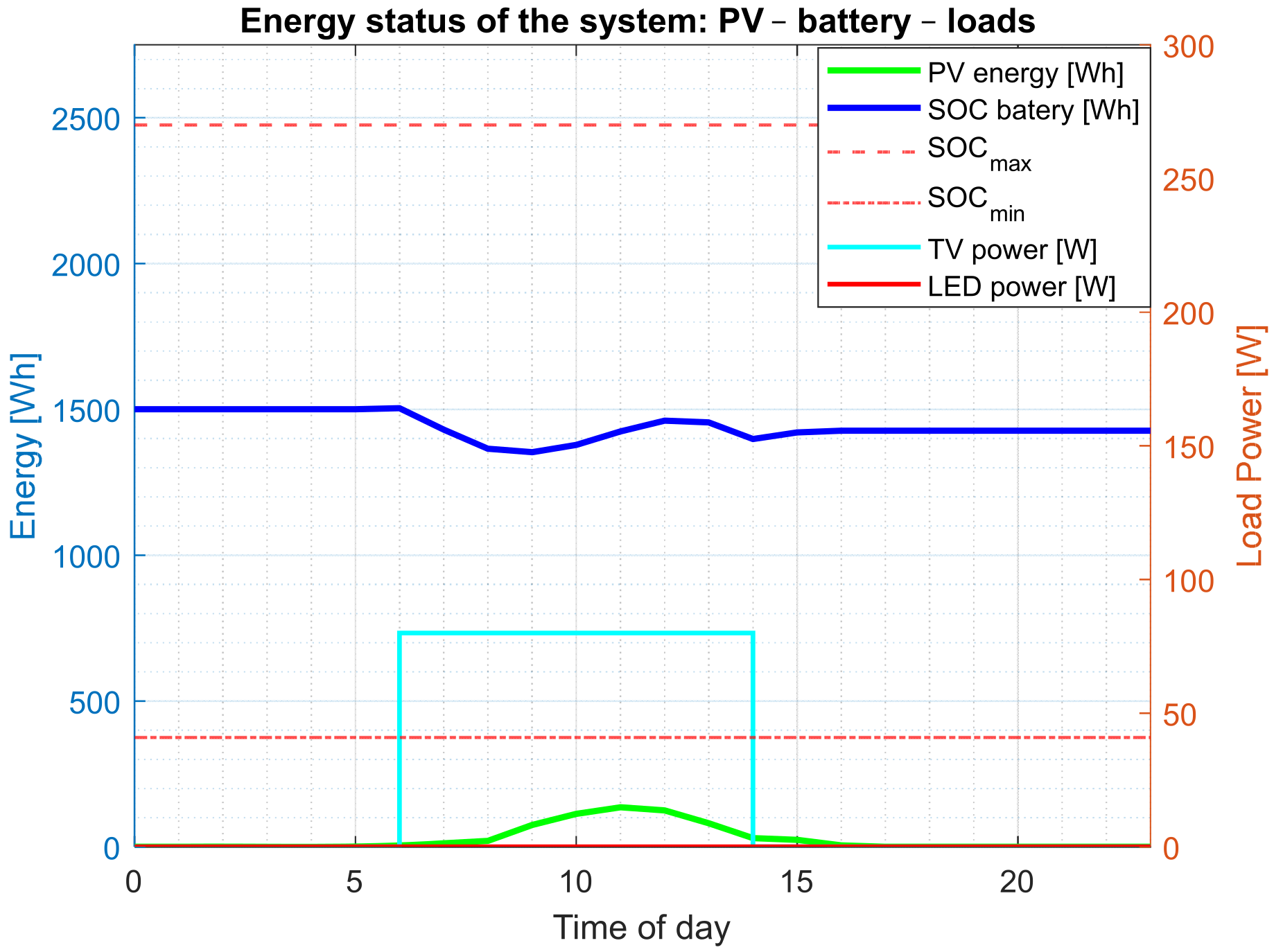

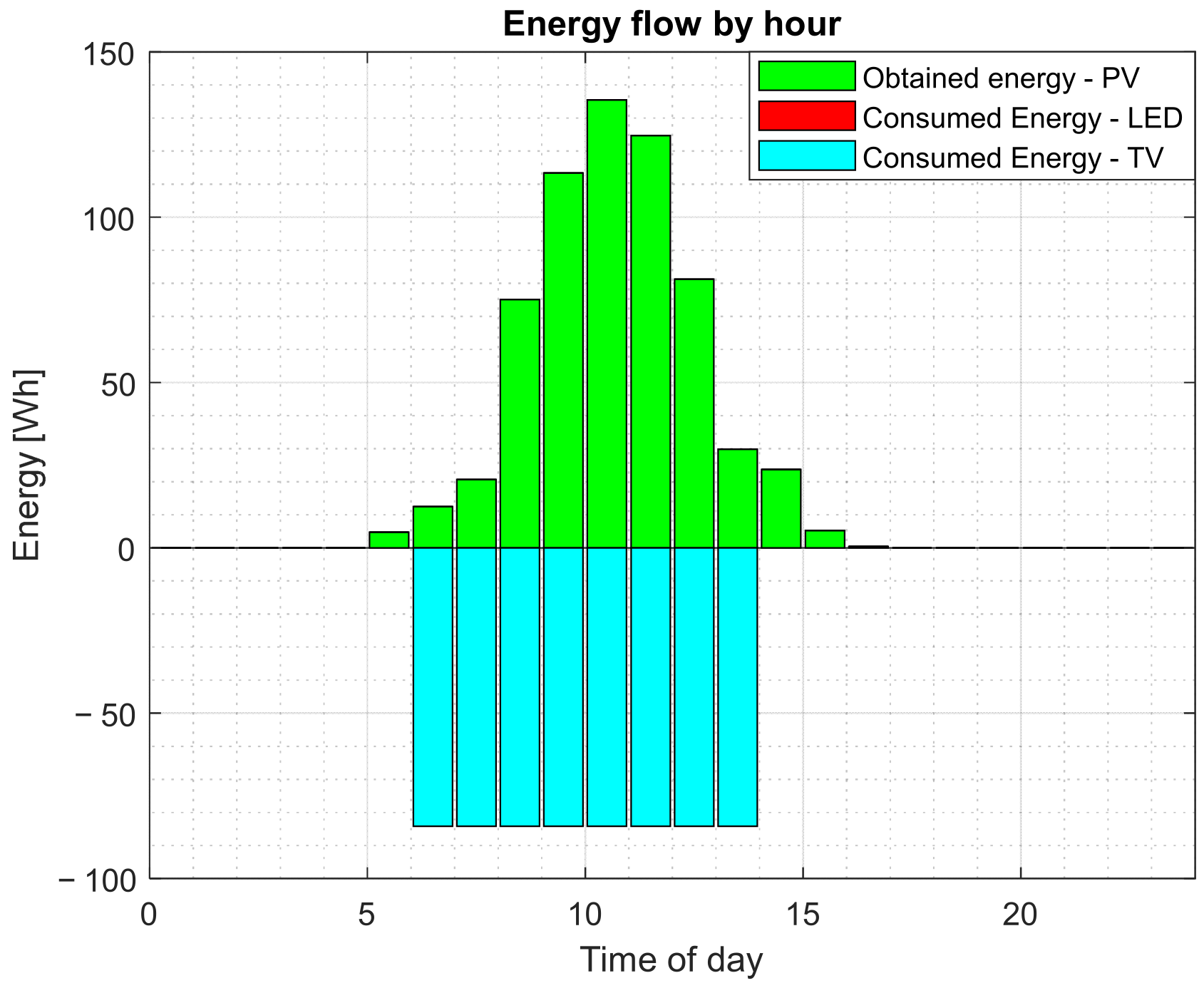

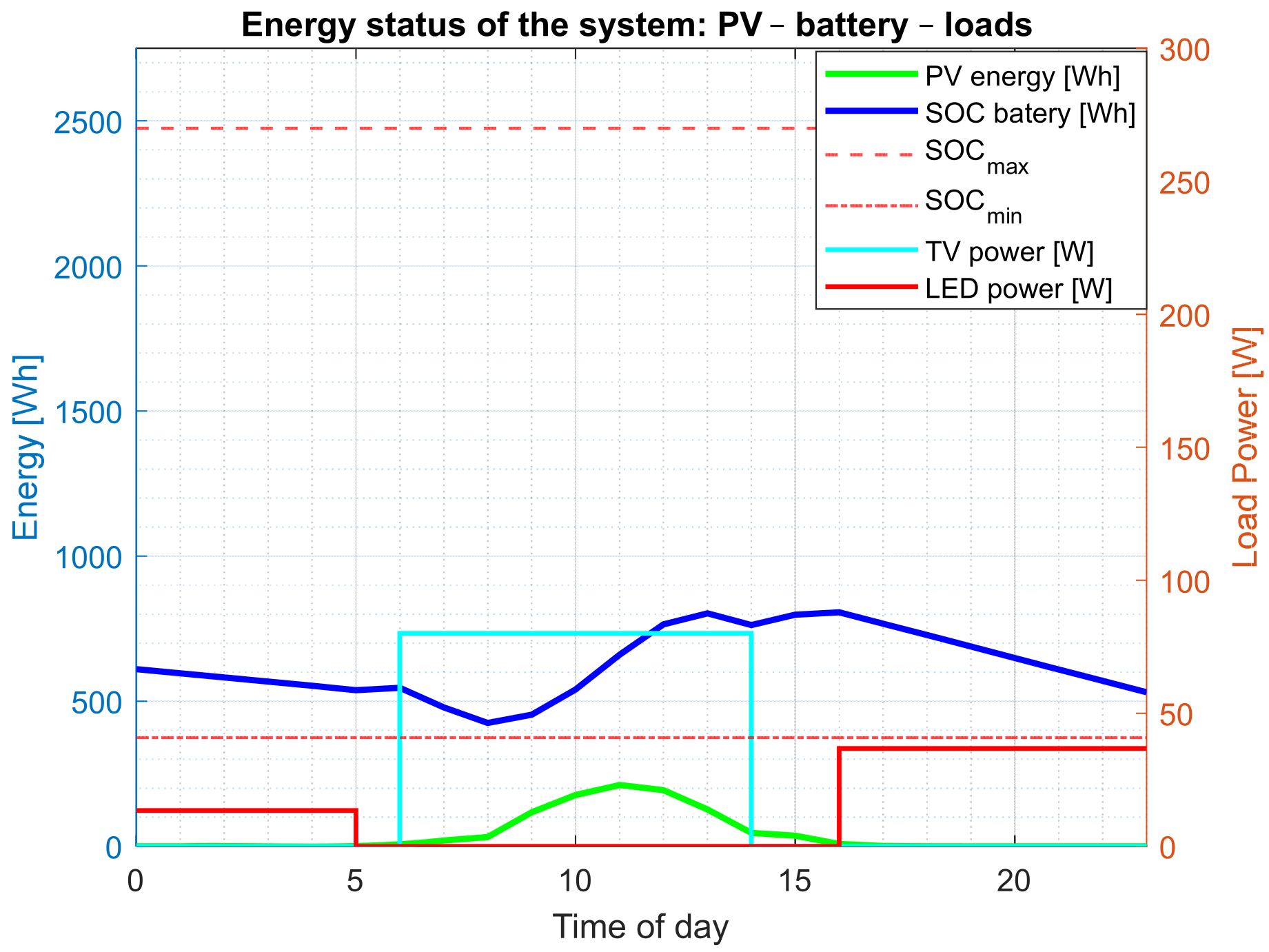

4.5. Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AC | Alternating Current |

| BLE | Bluetooth Low Energy |

| BMS | Battery Management System |

| DC | Direct Current |

| DC-AC | Direct Current to Alternating Current |

| GPIO | General Purpose Input/Output |

| HTTP | Hypertext Transfer Protocol |

| HTTPS | Hypertext Transfer Protocol Secure |

| LCD | Liquid-Crystal Display |

| LED | Light-Emitting Diode |

| LFP | Lithium Iron Phosphate |

| LiFePO4 | Lithium Iron Phosphate |

| LTE | Long Term Evolution |

| LTE-M | Long Term Evolution for Machines |

| MOSFET | Metal–Oxide–Semiconductor Field-Effect Transistor |

| MPPT | Maximum Power Point Tracking |

| NB-IoT | Narrowband Internet of Things |

| NCA | Nickel Cobalt Aluminum |

| NMC | Nickel Manganese Cobalt |

| NTP | Network Time Protocol |

| PCB | Printed Circuit Board |

| PV | Photovoltaic |

| PWM | Pulse Width Modulation |

| SoC | State-of-Charge |

| SoH | State-of-Health |

| SSID | Service Set Identifier |

| UTC | Coordinated Universal Time |

| VDC | Direct Current Voltage |

| VE.Direct | Victron communication protocol |

| Wi-Fi | Wireless Fidelity |

References

- Nakamura, M.; Yamaguchi, K.; Kimoto, Y.; Yasaki, Y.; Kato, T.; Sugimoto, H. Cd-Free Cu(In,Ga)(Se,S)2 Thin-Film Solar Cell with Record Efficiency of 23.35%. IEEE J. Photovolt. 2019, 9, 1863–1867. [Google Scholar] [CrossRef]

- Taguchi, M.; Yano, A.; Tohoda, S.; Matsuyama, K.; Nakamura, Y.; Nishiwaki, T.; Fujita, K.; Maruyama, E. 24.7% Record Efficiency HIT Solar Cell on Thin Silicon Wafer. IEEE J. Photovolt. 2014, 4, 96–99. [Google Scholar] [CrossRef]

- Hayat, M.B.; Ali, D.; Monyake, K.C.; Alagha, L.; Ahmed, N. Solar energy—A look into power generation, challenges, and a solar-powered future. Int. J. Energy Res. 2019, 43, 1049–1067. [Google Scholar] [CrossRef]

- Kannan, N.; Vakeesan, D. Solar energy for future world: A review. Renew. Sustain. Energy Rev. 2016, 62, 1092–1105. [Google Scholar] [CrossRef]

- Ibrahim, H.; Ilinca, A.; Perron, J. Energy storage systems—Characteristics and comparisons. Renew. Sustain. Energy Rev. 2008, 12, 1221–1250. [Google Scholar] [CrossRef]

- Ferreira, H.L.; Garde, R.; Fulli, G.; Kling, W.; Lopes, J.P. Characterisation of electrical energy storage technologies. Energy 2013, 53, 288–298. [Google Scholar] [CrossRef]

- Wang, D.; Liu, N.; Chen, F.; Wang, Y.; Mao, J. Progress and prospects of energy storage technology research: Based on multidimensional comparison. J. Energy Storage 2024, 75, 109710. [Google Scholar] [CrossRef]

- Shan, R.; Reagan, J.; Castellanos, S.; Kurtz, S.; Kittner, N. Evaluating emerging long-duration energy storage technologies. Renew. Sustain. Energy Rev. 2022, 159, 112240. [Google Scholar] [CrossRef]

- Serchenko, M.; Bekh, Y.; Serdiuk, T. Dynamic Simulation of a Hybrid Solar Power System Under Fluctuating Irradiance Conditions. In Proceedings of the 2025 IEEE International Conference on Environment and Electrical Engineering and 2025 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Crete, Greece, 15–18 July 2025; pp. 1–5. [Google Scholar]

- Dyvak, M.; Petryshyn, N.; Kindzerskyi, O.; Papa, O.; Franko, Y.; Opalko, O. Modeling of the Efficiency of Electricity Generation Processes by a Solar Power Plant Research Using the Example of a 570 W Model. In Proceedings of the 2025 15th International Conference on Advanced Computer Information Technologies (ACIT), Šibenik, Croatia, 17–19 September 2025; pp. 92–97. [Google Scholar]

- George, A.; Anto, R. Analytical and experimental analysis of optimal tilt angle of solar photovoltaic systems. In Proceedings of the 2012 International Conference on Green Technologies (ICGT), Kerala, India, 18–20 December 2012; pp. 234–239. [Google Scholar]

- Mansour, R.B.; Khan, M.A.M.; Alsulaiman, F.A.; Mansour, R.B. Optimizing the Solar PV Tilt Angle to Maximize the Power Output: A Case Study for Saudi Arabia. IEEE Access 2021, 9, 15914–15928. [Google Scholar] [CrossRef]

- Khan, A.H.; Islam, M.; Islam, A.; Rahman, M.S. A systematic approach to find the optimum tilt angle for meeting the maximum energy demand of an isolated area. In Proceedings of the 2015 International Conference on Electrical Engineering and Information Communication Technology (ICEEICT), Dhaka, Bangladesh, 21–23 May 2015; pp. 1–6. [Google Scholar]

- Abdel-Salam, M.; EL-Mohandes, M.-T.; Goda, M. History of maximum power point tracking. In Modern Maximum Power Point Tracking Techniques for Photovoltaic Energy Systems; Springer: Berlin, Germany, 2019; pp. 1–29. [Google Scholar]

- Femia, N.; Petrone, G.; Spagnuolo, G.; Vitelli, M. Optimization of perturb and observe maximum power point tracking method. IEEE Trans. Power Electron. 2005, 20, 963–973. [Google Scholar] [CrossRef]

- Gules, R.; Pacheco, J.D.P.; Hey, H.L.; Imhoff, J. A maximum power point tracking system with parallel connection for PV stand-alone applications. IEEE Trans. Ind. Electron. 2008, 55, 2674–2683. [Google Scholar] [CrossRef]

- Mariadass, S.P.; Al-Humairi, S.N.S.; Daud, R.J. Design a Portable Solar Mobile System with an IoT Integration-based. In Proceedings of the 2021 IEEE 12th Control and System Graduate Research Colloquium (ICSGRC), Shah Alam, Malaysia, 7–8 August 2021; pp. 40–45. [Google Scholar]

- Zheng, K.; Zhao, S.; Yang, Z.; Xiong, X.; Xiang, W. Design and Implementation of LPWA-Based Air Quality Monitoring System. IEEE Access 2016, 4, 3238–3245. [Google Scholar] [CrossRef]

- Folea, S.C.; Mois, G.D. Lessons Learned From the Development of Wireless Environmental Sensors. IEEE Trans. Instrum. Meas. 2020, 69, 3470–3480. [Google Scholar] [CrossRef]

- Oton, C.N.; Iqbal, M.T. Low-Cost Open Source IoT-Based SCADA System for a BTS Site Using ESP32 and Arduino IoT Cloud. In Proceedings of the 2021 IEEE 12th Annual Ubiquitous Computing, Electronics & Mobile Communication Conference (UEMCON), New York, NY, USA, 1–4 December 2021; pp. 0681–0685. [Google Scholar]

- Fuentes, G.C.; Milov, J.M.; Do, T.V.; Garcia, J.S.; Shojaee, M.; Blinder, A.; Azizi, M. Board 110: Portable Solar-Powered Wireless Display Board. In Proceedings of the 2024 ASEE Annual Conference & Exposition, Portland, OR, USA, 23–26 June 2024. [Google Scholar]

- Zhu, Q.Y.; Wen, C.L.; Xie, W.Y.; Ye, J.J.; Yin, H. Solar Powered Automatic Controlled Advertising Light Box System. Appl. Mech. Mater. 2012, 148, 101–105. [Google Scholar] [CrossRef]

- Reinders, A.H.; de Boer, A.; de Winter, A.; Haverlag, M. Designing PV powered LED products-Integration of PV technology in innovative products. In Proceedings of the 24th European Photovoltaic Solar Energy Conference and Exhibition, EU PVSEC, Hamburg, Germany, 21–25 September 2009; pp. 3179–3183. [Google Scholar]

- LÓpez-Vargas, A.; Fuentes, M.; Vivar, M. On the application of IoT for real-time monitoring of small stand-alone PV systems: Results from a new smart datalogger. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), Waikoloa, HI, USA, 10–15 June 2018; pp. 605–607. [Google Scholar]

- Allafi, I.; Iqbal, T. Design and implementation of a low cost web server using ESP32 for real-time photovoltaic system monitoring. In Proceedings of the 2017 IEEE Electrical Power and Energy Conference (EPEC), Saskatoon, SK, Canada, 22–25 October 2017; pp. 1–5. [Google Scholar]

- Wibowo, L.; Wahyusari, R.; Yuwono, T.; Shofia, A. IoT-based high-accuracy monitoring system for on-grid photovoltaic power system using NodeMCU ESP8266 and PZEM004T. J. Mechatron. Electr. Power Veh. Technol. 2024, 15, 230–241. [Google Scholar] [CrossRef]

- Sutikno, T.; Purnama, H.S.; Pamungkas, A.; Fadlil, A.; Alsofyani, I.M.; Jopri, M.H. Internet of things-based photovoltaics parameter monitoring system using NodeMCU ESP8266. Int. J. Electr. Comput. Eng. 2021, 11, 5578–5587. [Google Scholar] [CrossRef]

- He, W.; Baig, M.J.A.; Iqbal, M.T. An Open-Source Supervisory Control and Data Acquisition Architecture for Photovoltaic System Monitoring Using ESP32, Banana Pi M4, and Node-RED. Energies 2024, 17, 2295. [Google Scholar] [CrossRef]

- 1679.1-2017; IEEE Guide for the Characterization and Evaluation of Lithium-Based Batteries in Stationary Applications. IEEE: Washington, DC, USA, 2018. [CrossRef]

- Zheng, S.; Wang, L.; Feng, X.; He, X. Probing the heat sources during thermal runaway process by thermal analysis of different battery chemistries. J. Power Sources 2018, 378, 527–536. [Google Scholar] [CrossRef]

- Brand, M.; Gläser, S.; Geder, J.; Menacher, S.; Obpacher, S.; Jossen, A.; Quinger, D. Electrical safety of commercial Li-ion cells based on NMC and NCA technology compared to LFP technology. In Proceedings of the 2013 World Electric Vehicle Symposium and Exhibition (EVS27), Barcelona, Spain, 17–20 November 2013; pp. 1–9. [Google Scholar]

- Elmahallawy, M.; Elfouly, T.; Alouani, A.; Massoud, A.M. A Comprehensive Review of Lithium-Ion Batteries Modeling, and State of Health and Remaining Useful Lifetime Prediction. IEEE Access 2022, 10, 119040–119070. [Google Scholar] [CrossRef]

- Wei, J.; Dong, G.; Chen, Z. Remaining Useful Life Prediction and State of Health Diagnosis for Lithium-Ion Batteries Using Particle Filter and Support Vector Regression. IEEE Trans. Ind. Electron. 2018, 65, 5634–5643. [Google Scholar] [CrossRef]

- Li, R.; Bao, L.; Chen, L.; Zha, C.; Dong, J.; Qi, N.; Tang, R.; Lu, Y.; Wang, M.; Huang, R.; et al. Accelerated aging of lithium-ion batteries: Bridging battery aging analysis and operational lifetime prediction. Sci. Bull. 2023, 68, 3055–3079. [Google Scholar] [CrossRef]

- Quan, J.; Zhao, S.; Song, D.; Wang, T.; He, W.; Li, G. Comparative life cycle assessment of LFP and NCM batteries including the secondary use and different recycling technologies. Sci. Total Environ. 2022, 819, 153105. [Google Scholar] [CrossRef]

- EVE Energy Co. EVE Lithium LF105 Prismatic Lithium Iron Phosphate Battery 3.2V 105Ah Utility ESS Power Battery UPS Engineering Machinery Marine Power Battery. Available online: https://www.evemall.eu/power-battery/prismatic-lfp-cell/lf105 (accessed on 10 October 2025).

- Polóni, T.; Figueroa-Santos, M.A.; Siegel, J.B.; Stefanopoulou, A.G. Integration of Non-monotonic Cell Swelling Characteristic for State-of-Charge Estimation. In Proceedings of the 2018 Annual American Control Conference (ACC), Milwaukee, WI, USA, 27–29 June 2018; pp. 2306–2311. [Google Scholar]

- Tang, X.; Zou, C.; Wik, T.; Yao, K.; Xia, Y.; Wang, Y.; Yang, D.; Gao, F. Run-to-Run Control for Active Balancing of Lithium Iron Phosphate Battery Packs. IEEE Trans. Power Electron. 2020, 35, 1499–1512. [Google Scholar] [CrossRef]

- Wang, S.; Yang, S.; Yang, W.; Wang, Y. A New Kind of Balancing Circuit with Multiple Equalization Modes for Serially Connected Battery Pack. IEEE Trans. Ind. Electron. 2021, 68, 2142–2150. [Google Scholar] [CrossRef]

- Einhorn, M.; Roessler, W.; Fleig, J. Improved Performance of Serially Connected Li-Ion Batteries with Active Cell Balancing in Electric Vehicles. IEEE Trans. Veh. Technol. 2011, 60, 2448–2457. [Google Scholar] [CrossRef]

- Marcin, D.; Lacko, M.; Bodnár, D.; Pancurák, L.; Stach, L. Overview of Active Balancing Methods and Simulation of Capacitor Based Active Cell Balancing for Battery Pack in EV. In Proceedings of the 2023 International Conference on Electrical Drives and Power Electronics (EDPE), High Tatras, Slovakia, 25–27 September 2023; pp. 1–8. [Google Scholar]

- EnerKey BMS Technology Co. 4s 8s 16s BMS Active Cell Balancer 5A Lithium Lead Acid Battery Balancer Equalizer for Electrical Tools. Available online: https://www.enerkeybms.com/sale-43691918-4s-8s-16s-bms-active-cell-balancer-5a-lithium-lead-acid-battery-balancer-equalizer-for-electrical-to.html (accessed on 15 October 2025).

- TrinaSolar Co. Ltd. Vertex S+ 470W TSM—NEG9R.28. Available online: https://www.trinasolar.com/eu-en/product/VertexS-NEG9R.28 (accessed on 10 October 2025).

- Victron Energy B.V. BlueSolar Charge Controllers MPPT 75/10, 75/15, 100/15, 100/20-48V. Available online: https://www.victronenergy.com/upload/documents/Datasheet-Blue-Solar-Charge-Controller-MPPT-75-10,-75-15,-100-15,-100-20_48V-EN-.pdf (accessed on 13 October 2025).

- Victron Energy B.V. SmartShunt. Available online: https://www.victronenergy.com/battery-monitors/smart-battery-shunt (accessed on 15 October 2025).

- MEAN WELL Enterprises Co. 450W High Reliable True Sine Wave DC-AC Power Inverter. Available online: https://www.meanwell.com/webapp/product/search.aspx?prod=NTS-450 (accessed on 15 October 2025).

- Hercog, D.; Lerher, T.; Truntič, M.; Težak, O. Design and implementation of ESP32-based IoT devices. Sensors 2023, 23, 6739. [Google Scholar] [CrossRef]

- El-Khozondar, H.J.; Mtair, S.Y.; Qoffa, K.O.; Qasem, O.I.; Munyarawi, A.H.; Nassar, Y.F.; Bayoumi, E.H.; Abd El, A.A.E.B. A smart energy monitoring system using ESP32 microcontroller. e-Prime-Adv. Electr. Eng. Electron. Energy 2024, 9, 100666. [Google Scholar] [CrossRef]

- Khalid, W.; Jamil, M.; Khan, A.A.; Awais, Q. Open-source internet of things-based supervisory control and data acquisition system for photovoltaic monitoring and control using HTTP and TCP/IP protocols. Energies 2024, 17, 4083. [Google Scholar] [CrossRef]

- Rahmadani, A.A.; Syaifudin, Y.W.; Setiawan, B.; Panduman, Y.Y.F.; Funabiki, N. Enhancing campus environment: Real-time air quality monitoring through iot and web technologies. J. Sens. Actuator Netw. 2024, 14, 2. [Google Scholar] [CrossRef]

- Kairuz-Cabrera, D.; Hernandez-Rodriguez, V.; Schalm, O.; Martinez, A.; Laso, P.M.; Alejo-Sánchez, D. Development of a unified IoT platform for assessing Meteorological and Air Quality Data in a Tropical Environment. Sensors 2024, 24, 2729. [Google Scholar] [CrossRef]

- Aghenta, L.O.; Iqbal, M.T. Low-Cost, Open Source IoT-Based SCADA System Design Using Thinger.IO and ESP32 Thing. Electronics 2019, 8, 822. [Google Scholar] [CrossRef]

- Marques, G.; Pitarma, R. An Indoor Monitoring System for Ambient Assisted Living Based on Internet of Things Architecture. Int. J. Environ. Res. Public Health 2016, 13, 1152. [Google Scholar] [CrossRef]

- Stolojescu-Crisan, C.; Crisan, C.; Butunoi, B.-P. An IoT-Based Smart Home Automation System. Sensors 2021, 21, 3784. [Google Scholar] [CrossRef] [PubMed]

- Taştan, M.; Gökozan, H. Real-Time Monitoring of Indoor Air Quality with Internet of Things-Based E-Nose. Appl. Sci. 2019, 9, 3435. [Google Scholar] [CrossRef]

- Marques, G.; Pitarma, R. A Cost-Effective Air Quality Supervision Solution for Enhanced Living Environments through the Internet of Things. Electronics 2019, 8, 170. [Google Scholar] [CrossRef]

- DPTechnics. Walter, Open Source Cellular, GPS, and WiFi/BLE Module. Available online: https://www.dptechnics.com/en/products/walter.html (accessed on 14 October 2025).

- Espressif Systems. ESP32-S3. Available online: https://www.espressif.com/en/products/socs/esp32-s3 (accessed on 14 October 2025).

- QuickSpot. Walter Modem Library for Arduino. Available online: https://github.com/QuickSpot/walter-arduino (accessed on 14 October 2025).

- Chris Terwilliger. Ve Direct Frame Handler. Available online: https://github.com/cterwilliger/VeDirectFrameHandler (accessed on 14 October 2025).

- Victron Energy B.V. VE.Direct Protocol. Available online: https://www.victronenergy.com/upload/documents/VE.Direct-Protocol-3.34.pdf (accessed on 14 October 2025).

- Brundrett, G.W. Human sensitivity to flicker. Light. Res. Technol. 1974, 6, 127–143. [Google Scholar] [CrossRef]

- EVE Energy Co. LF105 Product Specification. Available online: https://www.gobelpower.com/download/EVE-LF105-LiFePO4-Battery-Cell-Product-Specification-20191202.pdf (accessed on 4 November 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Španer, M.; Truntič, M.; Hercog, D. IoT-Based Off-Grid Solar Power Supply: Design, Implementation, and Case Study of Energy Consumption Control Using Forecasted Solar Irradiation. Appl. Sci. 2025, 15, 12018. https://doi.org/10.3390/app152212018

Španer M, Truntič M, Hercog D. IoT-Based Off-Grid Solar Power Supply: Design, Implementation, and Case Study of Energy Consumption Control Using Forecasted Solar Irradiation. Applied Sciences. 2025; 15(22):12018. https://doi.org/10.3390/app152212018

Chicago/Turabian StyleŠpaner, Marijan, Mitja Truntič, and Darko Hercog. 2025. "IoT-Based Off-Grid Solar Power Supply: Design, Implementation, and Case Study of Energy Consumption Control Using Forecasted Solar Irradiation" Applied Sciences 15, no. 22: 12018. https://doi.org/10.3390/app152212018

APA StyleŠpaner, M., Truntič, M., & Hercog, D. (2025). IoT-Based Off-Grid Solar Power Supply: Design, Implementation, and Case Study of Energy Consumption Control Using Forecasted Solar Irradiation. Applied Sciences, 15(22), 12018. https://doi.org/10.3390/app152212018