Author Contributions

Conceptualization, S.H.; methodology, Q.L.; software, H.Y.; validation, Q.L. and H.Y.; formal analysis, Q.L.; investigation, Q.L.; resources, S.H.; data curation, Q.L.; writing—original draft preparation, Q.L.; writing—review and editing, Q.L.; visualization, H.Y.; supervision, Q.L.; project administration, H.Y.; funding acquisition, S.H. All authors have read and agreed to the published version of the manuscript.

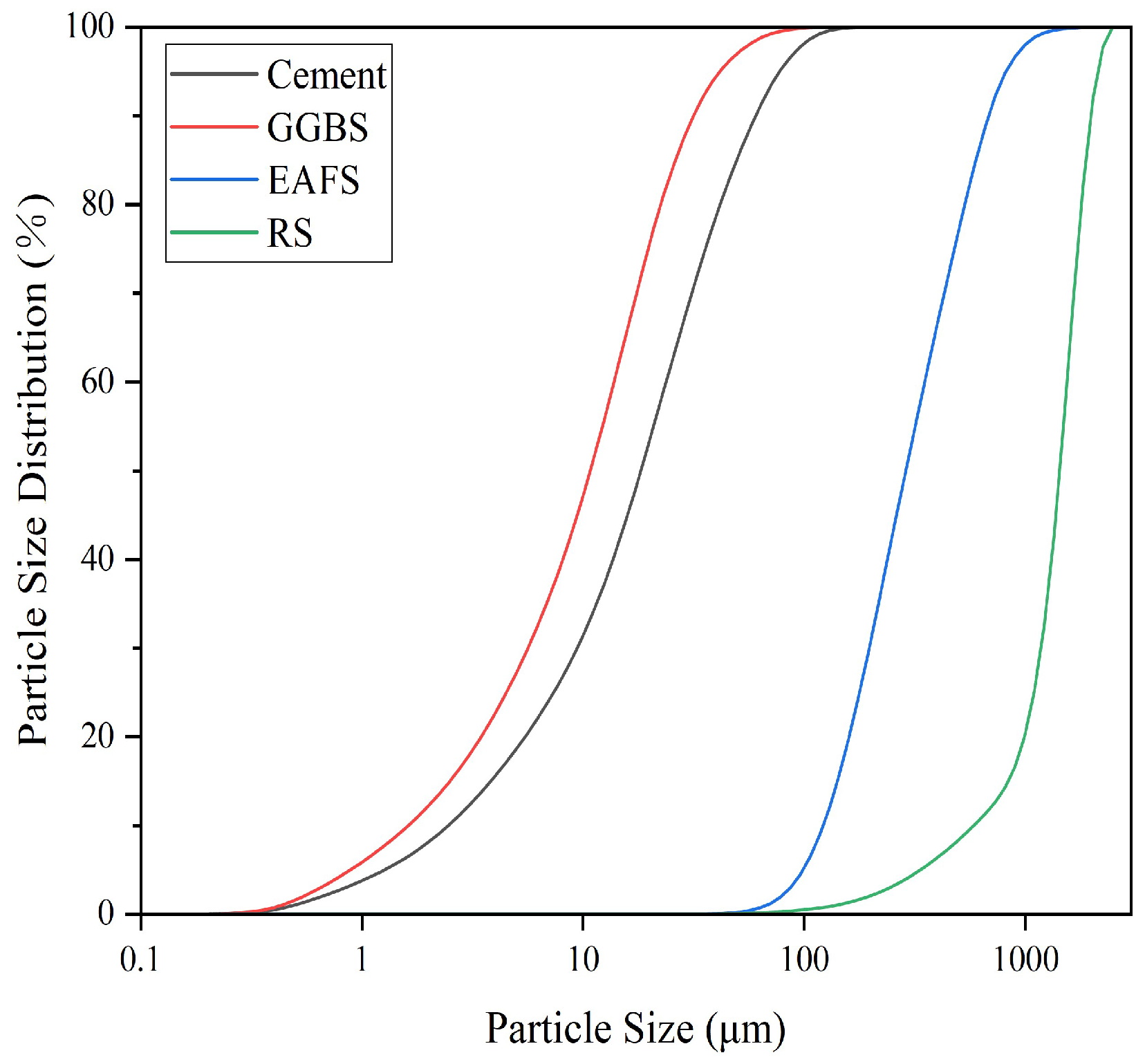

Figure 1.

Particle size distribution.

Figure 1.

Particle size distribution.

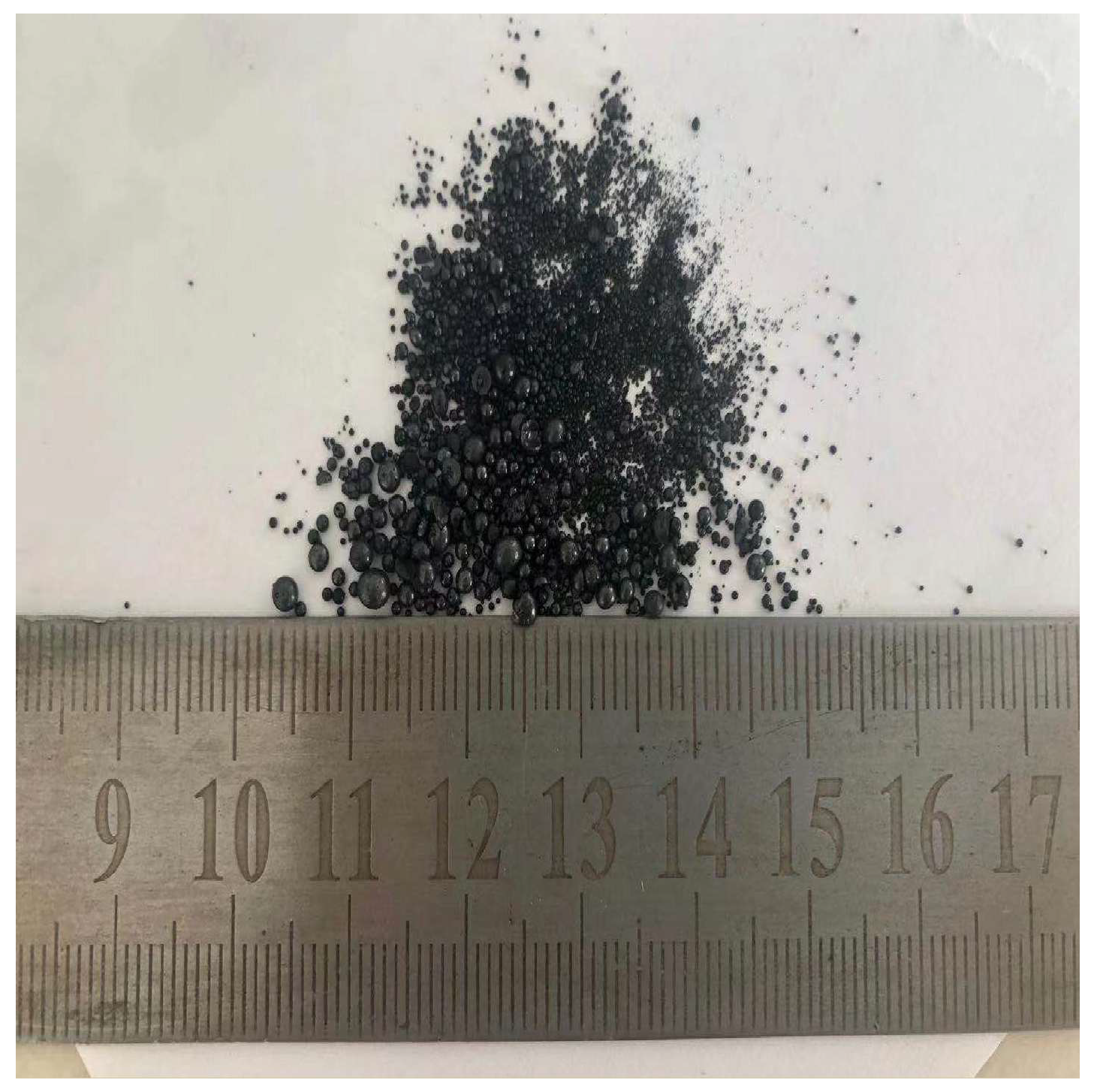

Figure 2.

Spherical EAFS fine aggregate.

Figure 2.

Spherical EAFS fine aggregate.

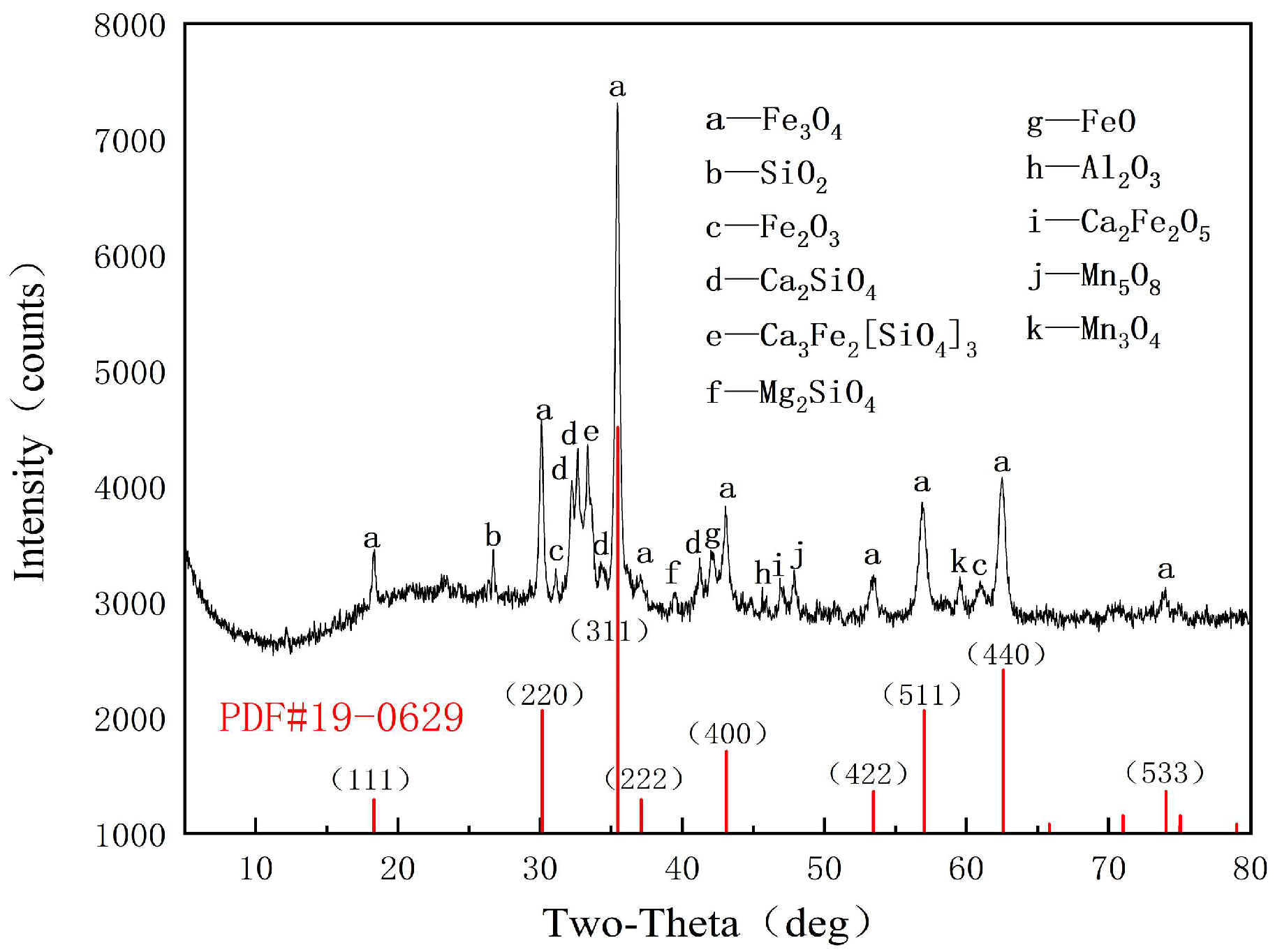

Figure 3.

XRD pattern of EAFS.

Figure 3.

XRD pattern of EAFS.

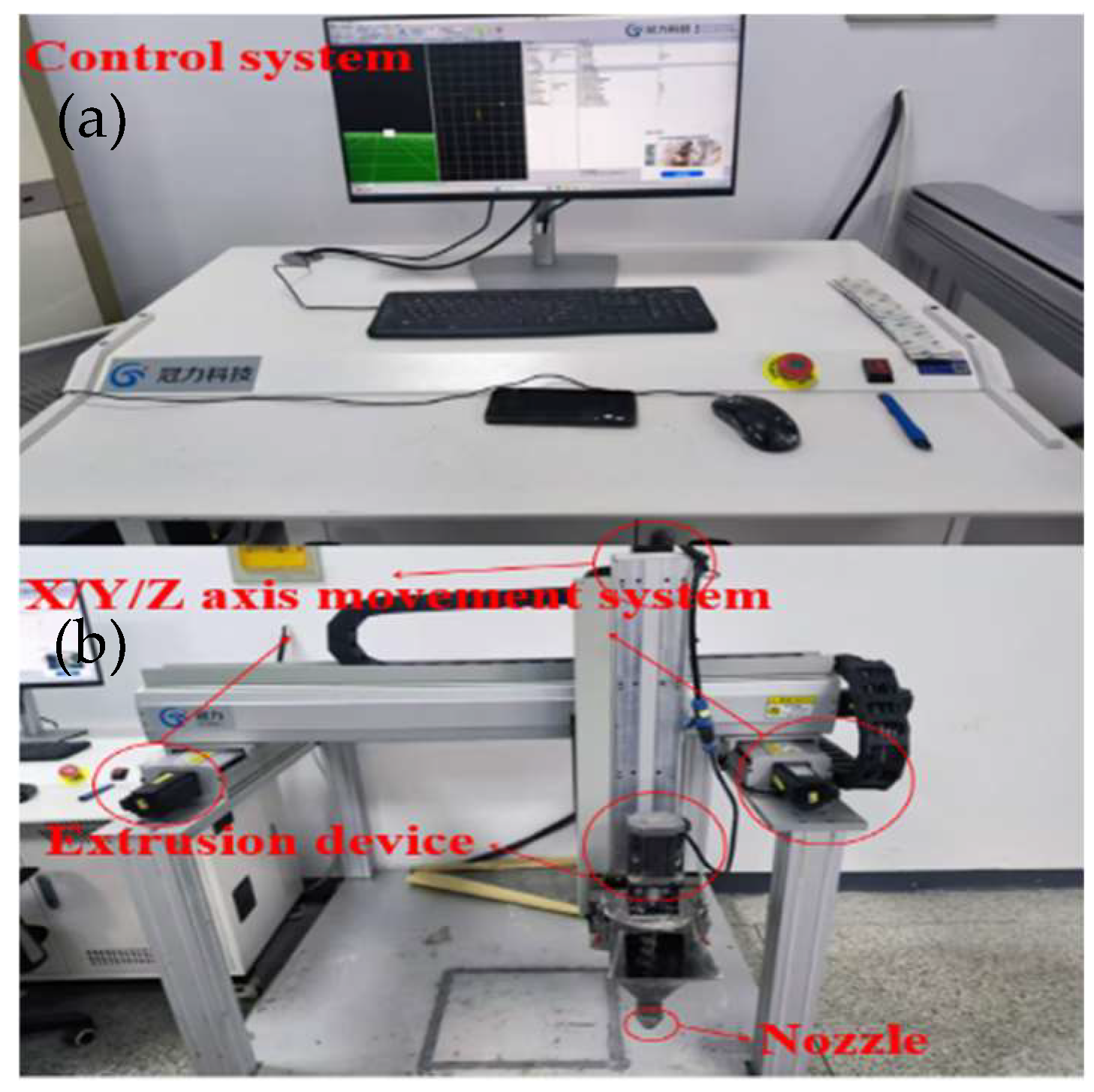

Figure 4.

Schematics of the 3D printing system: (a) control system and (b) printing equipment.

Figure 4.

Schematics of the 3D printing system: (a) control system and (b) printing equipment.

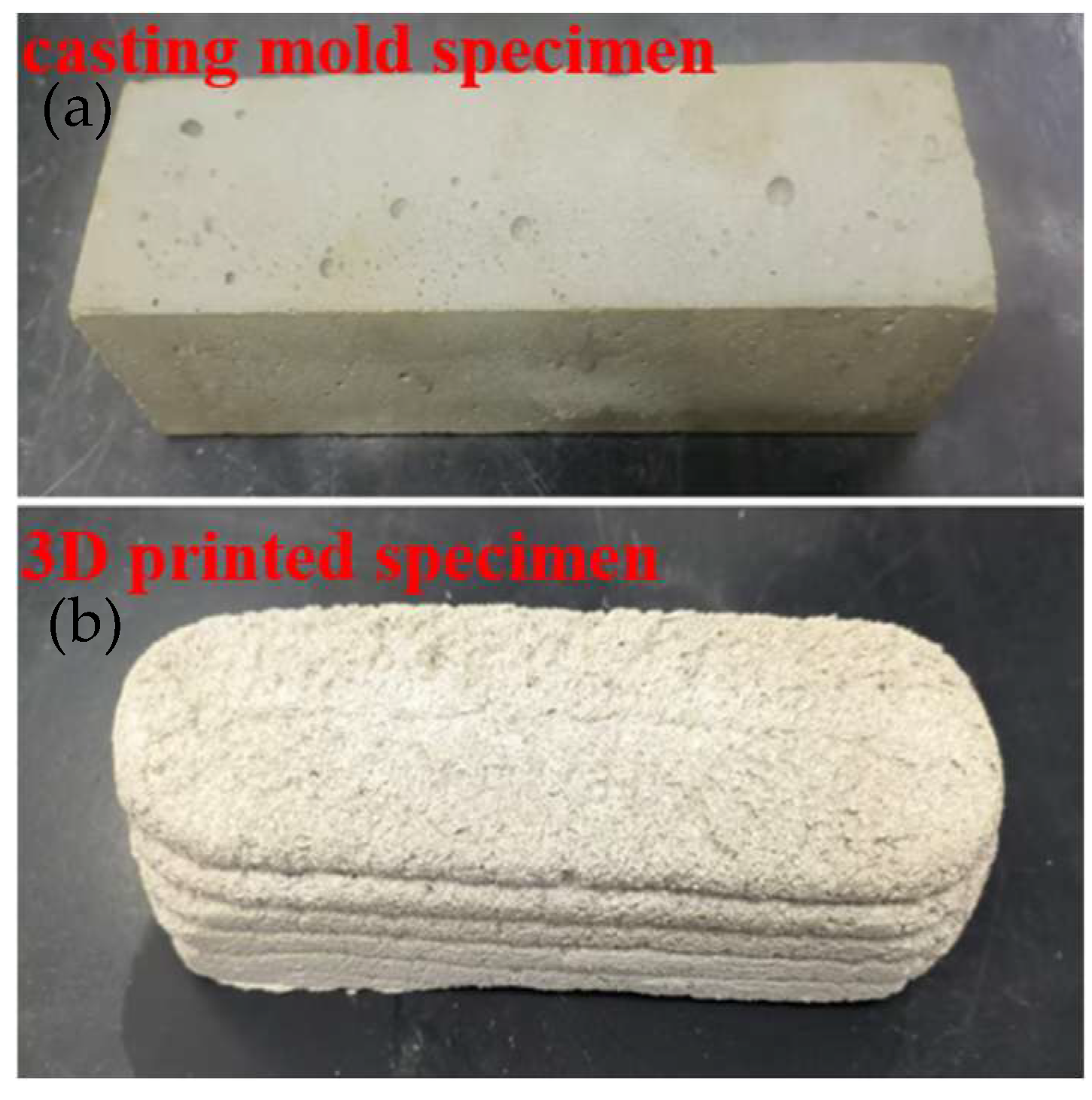

Figure 5.

(a) Casting mold and (b) 3D-printed specimen.

Figure 5.

(a) Casting mold and (b) 3D-printed specimen.

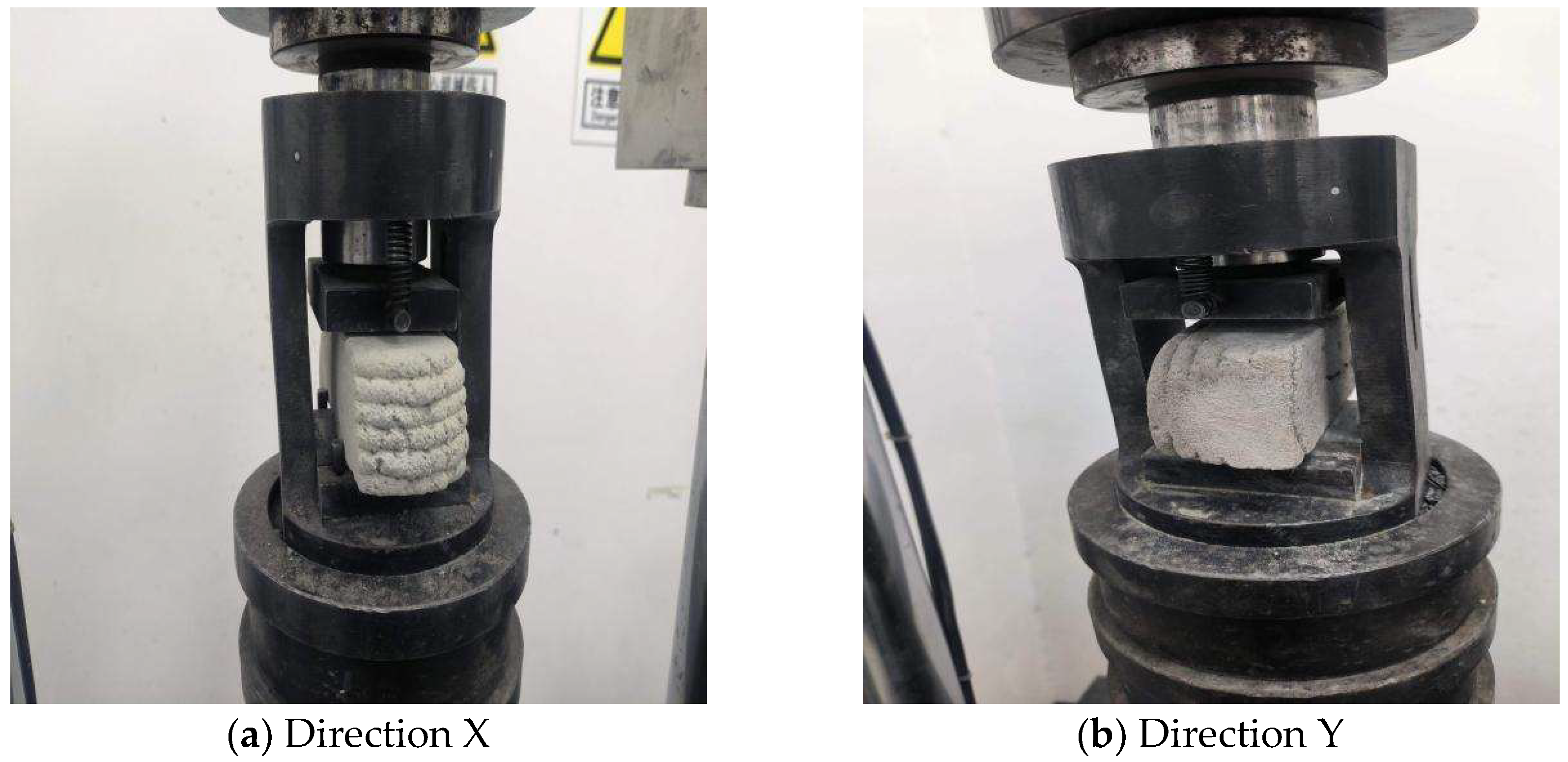

Figure 6.

The compressive strength of 3DPC: (a) direction X and (b) direction Y.

Figure 6.

The compressive strength of 3DPC: (a) direction X and (b) direction Y.

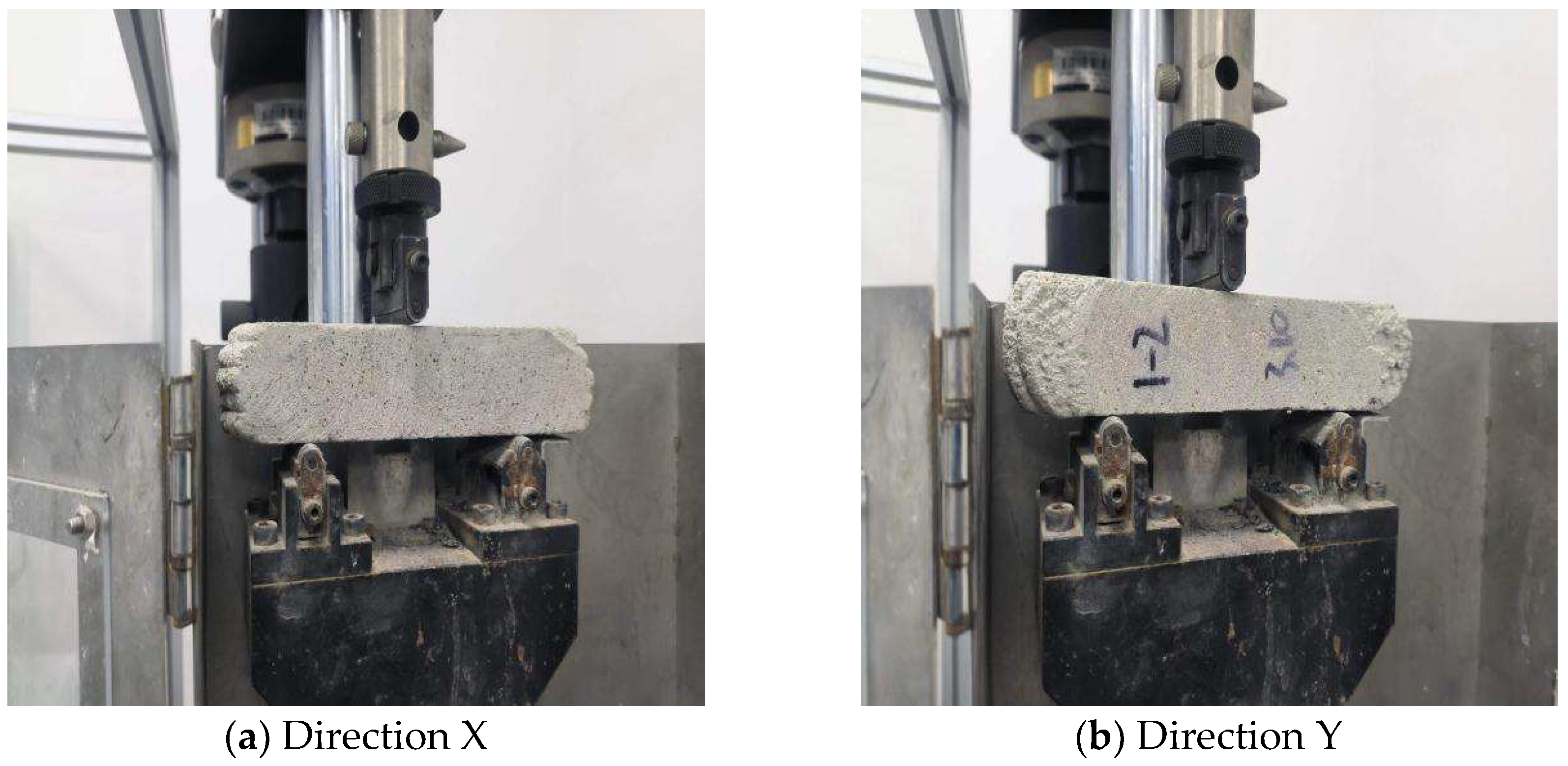

Figure 7.

The flexural strength of 3DPC: (a) direction X and (b) direction Y.

Figure 7.

The flexural strength of 3DPC: (a) direction X and (b) direction Y.

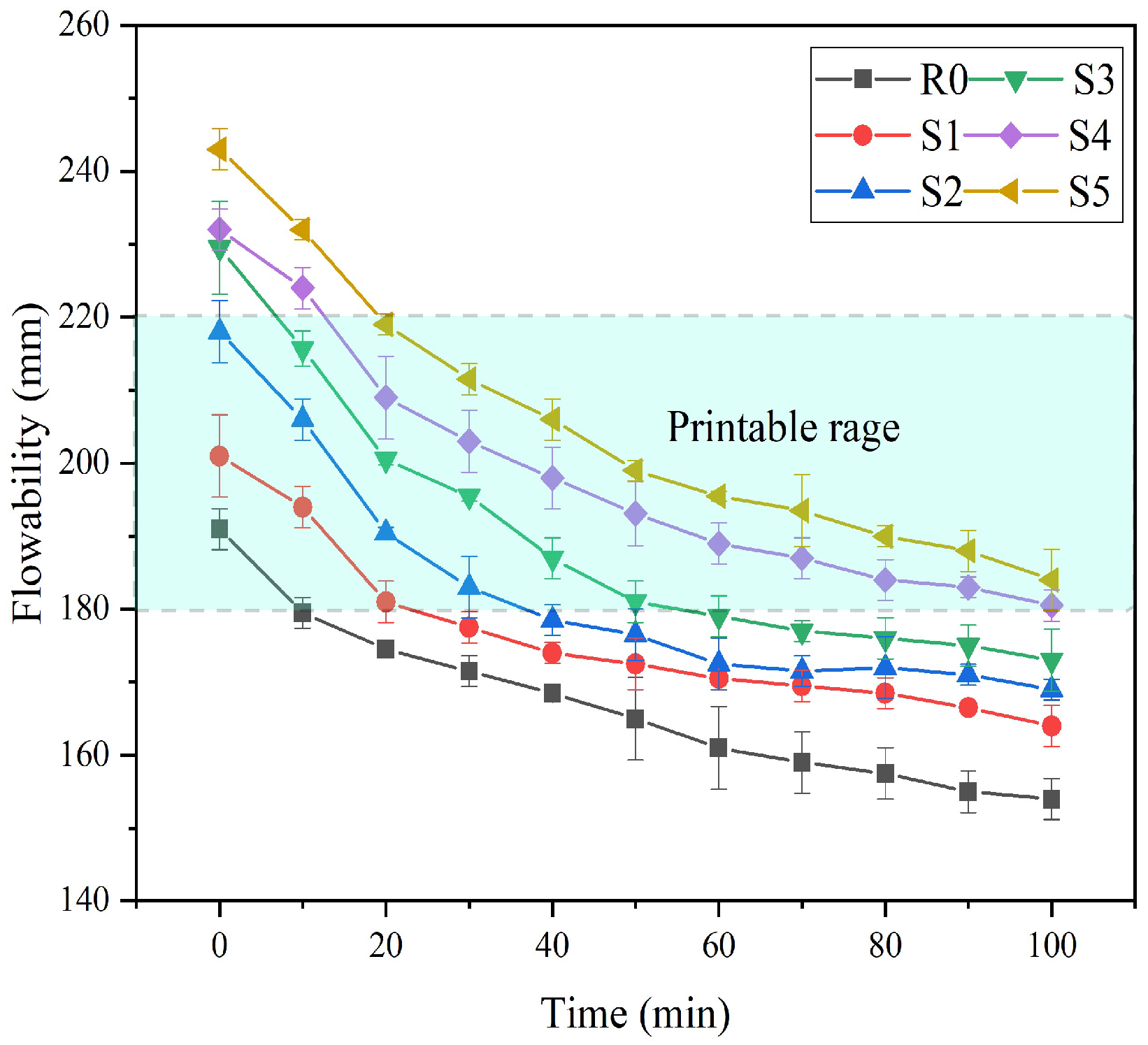

Figure 8.

Time-dependent flowability under different EAFS replacement ratios.

Figure 8.

Time-dependent flowability under different EAFS replacement ratios.

Figure 9.

Relationship between the mini-slump and rest time.

Figure 9.

Relationship between the mini-slump and rest time.

Figure 10.

Effect of different EAFS replacement ratios on apparent viscosity. (a) The group with a 0% EAFS replacement ratio. (b) The group with a 40% EAFS replacement ratio. (c) The group with a 100% EAFS replacement ratio.

Figure 10.

Effect of different EAFS replacement ratios on apparent viscosity. (a) The group with a 0% EAFS replacement ratio. (b) The group with a 40% EAFS replacement ratio. (c) The group with a 100% EAFS replacement ratio.

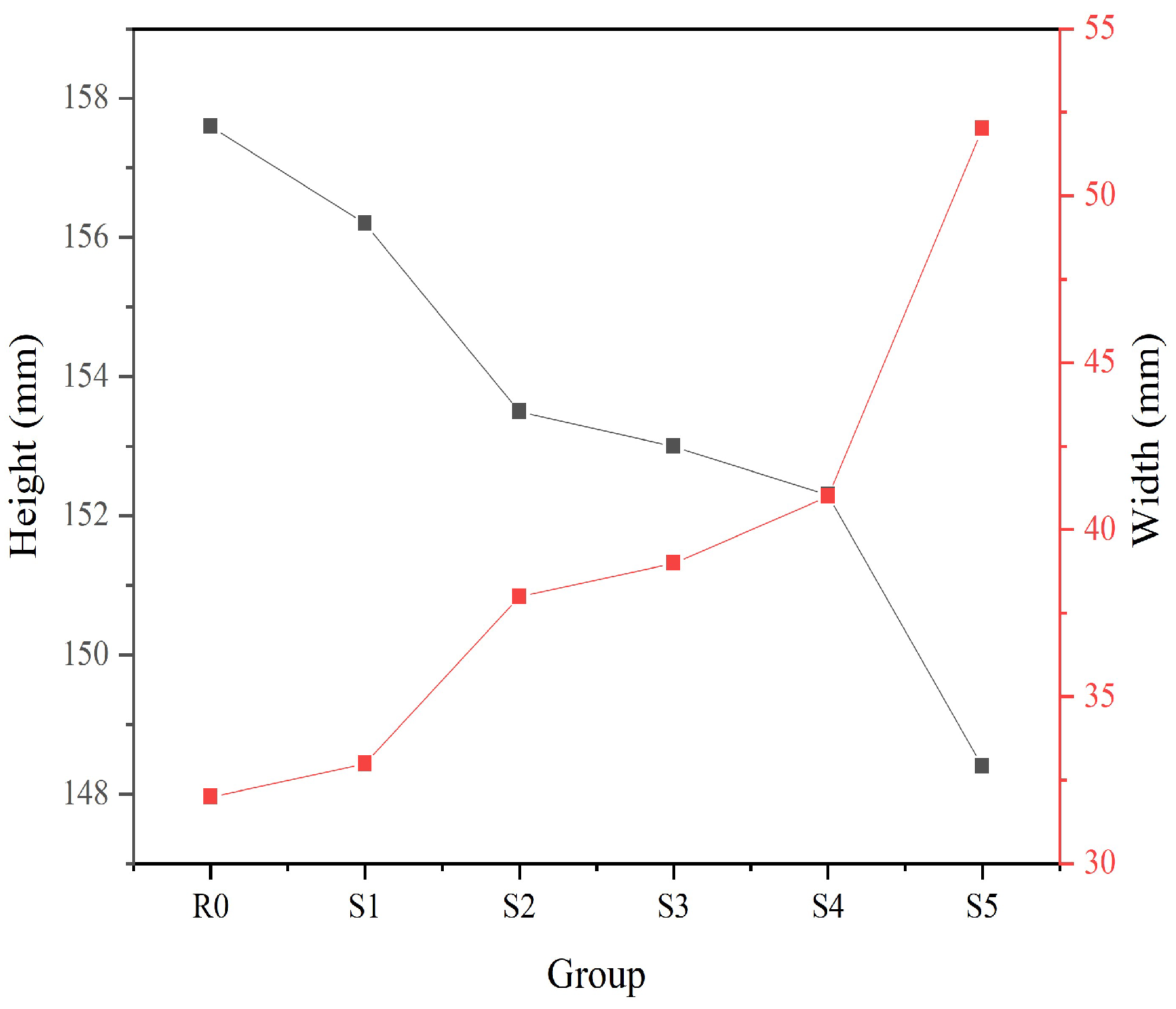

Figure 11.

Relationship between construction height, width, and EAFS content.

Figure 11.

Relationship between construction height, width, and EAFS content.

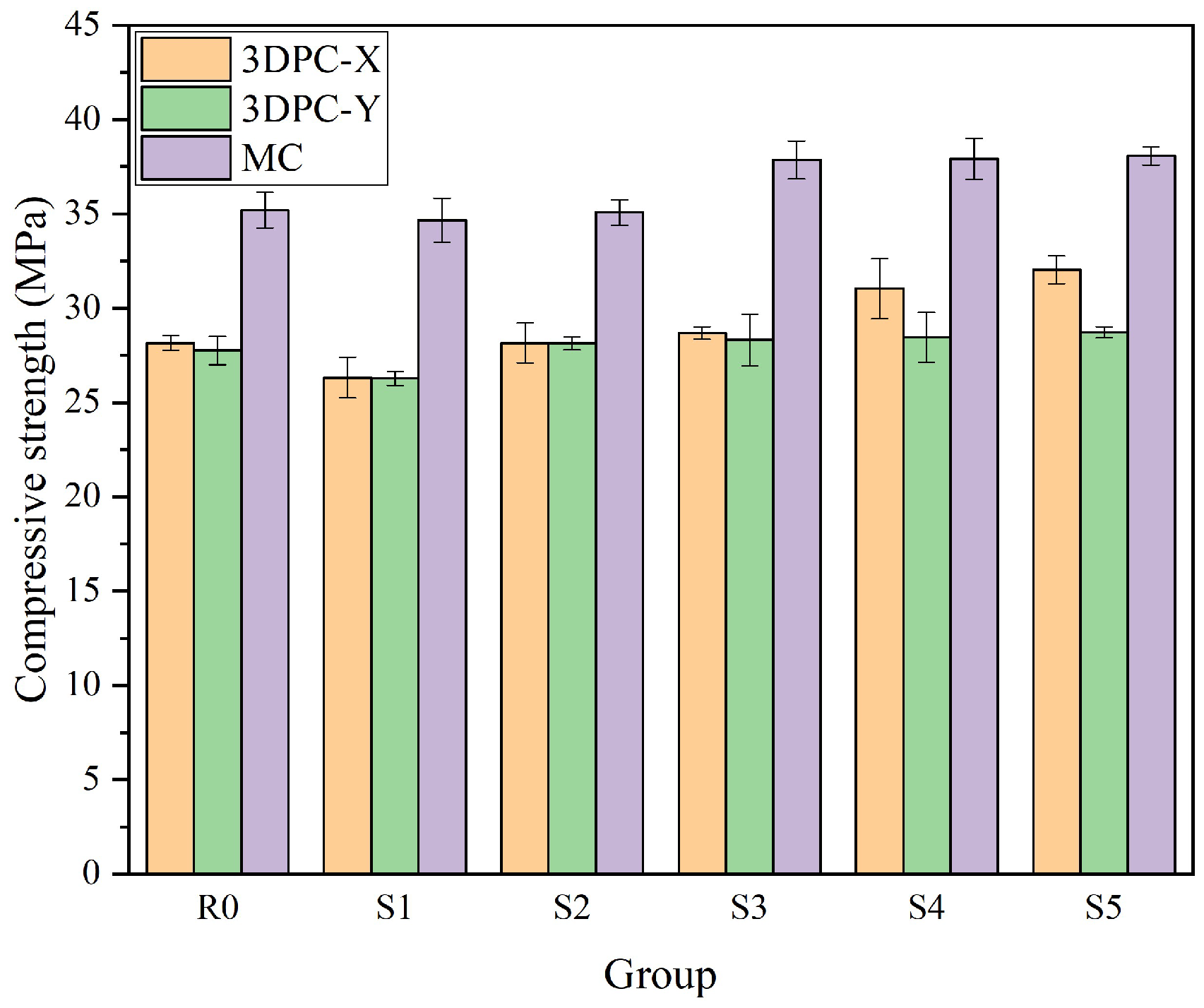

Figure 12.

Twenty-eight-day compressive strength of 3DPC and MC specimens under different EAFS replacement ratios.

Figure 12.

Twenty-eight-day compressive strength of 3DPC and MC specimens under different EAFS replacement ratios.

Figure 13.

Changes in the compressive strength of 3DPC specimens in (a) the direction X and (b) direction Y under different EAFS replacement ratios before freeze–thaw cycles.

Figure 13.

Changes in the compressive strength of 3DPC specimens in (a) the direction X and (b) direction Y under different EAFS replacement ratios before freeze–thaw cycles.

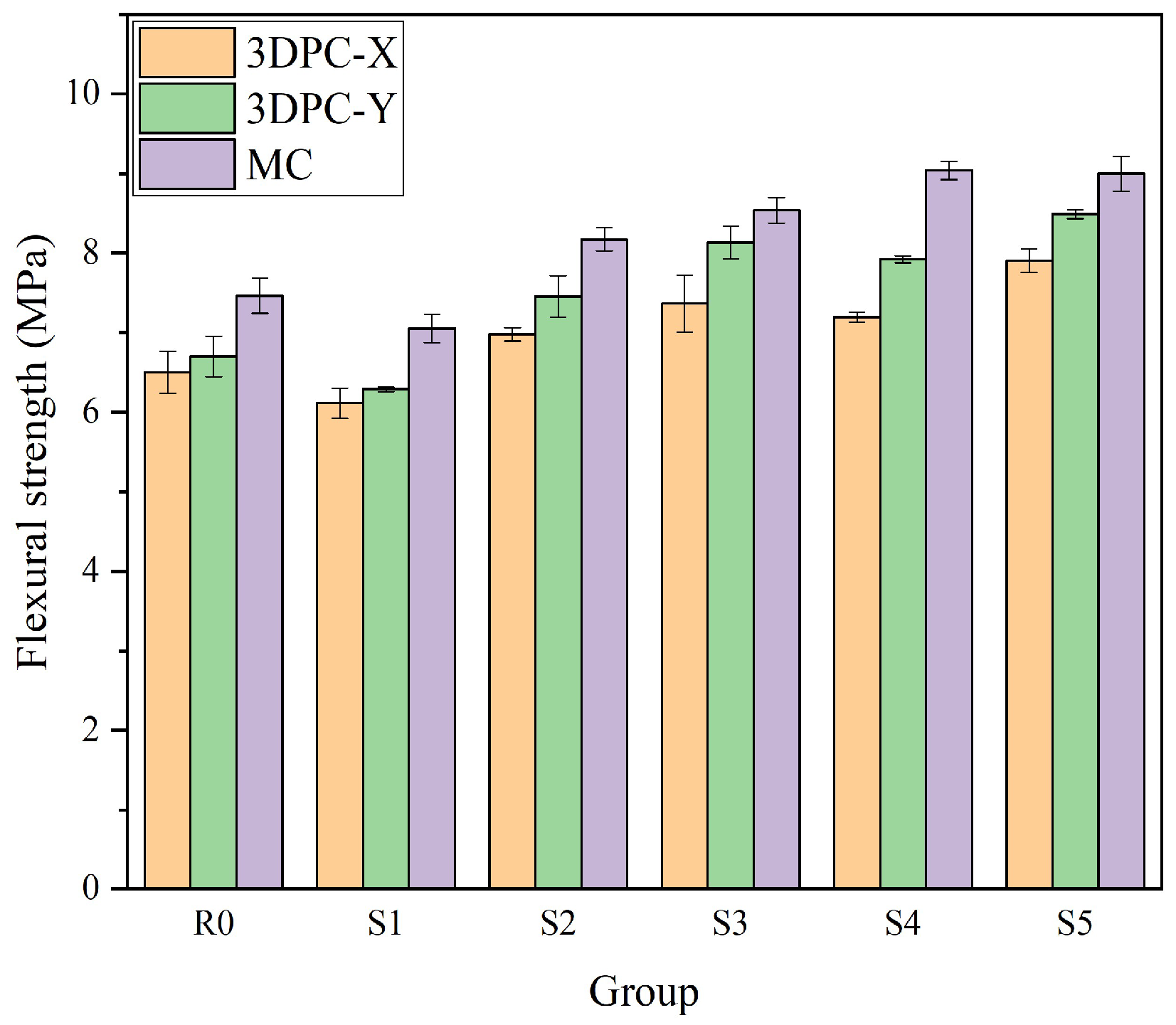

Figure 14.

Flexural strength of 3DPC at different EAFS replacement ratios.

Figure 14.

Flexural strength of 3DPC at different EAFS replacement ratios.

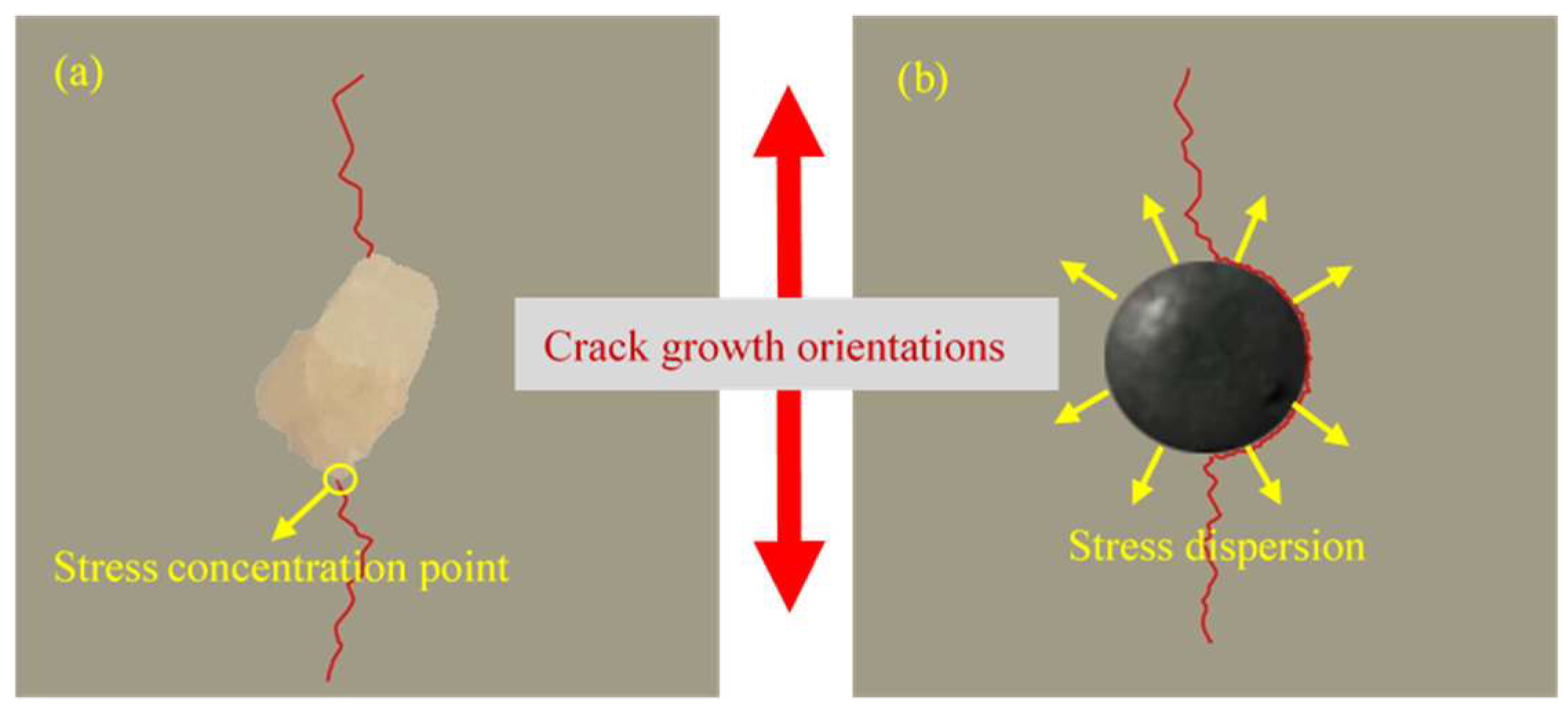

Figure 15.

Effect of aggregate morphology on crack propagation of (a) RS and (b) EAFS.

Figure 15.

Effect of aggregate morphology on crack propagation of (a) RS and (b) EAFS.

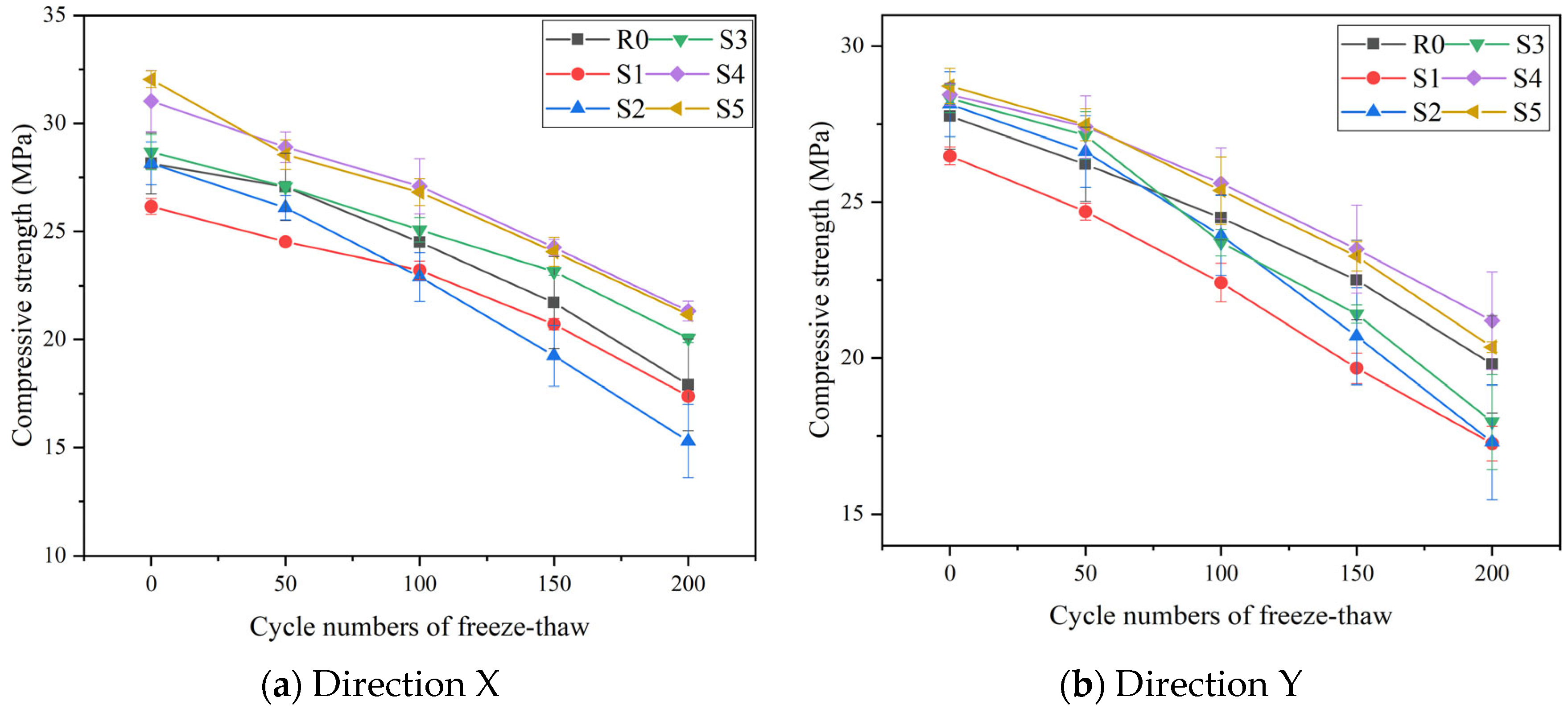

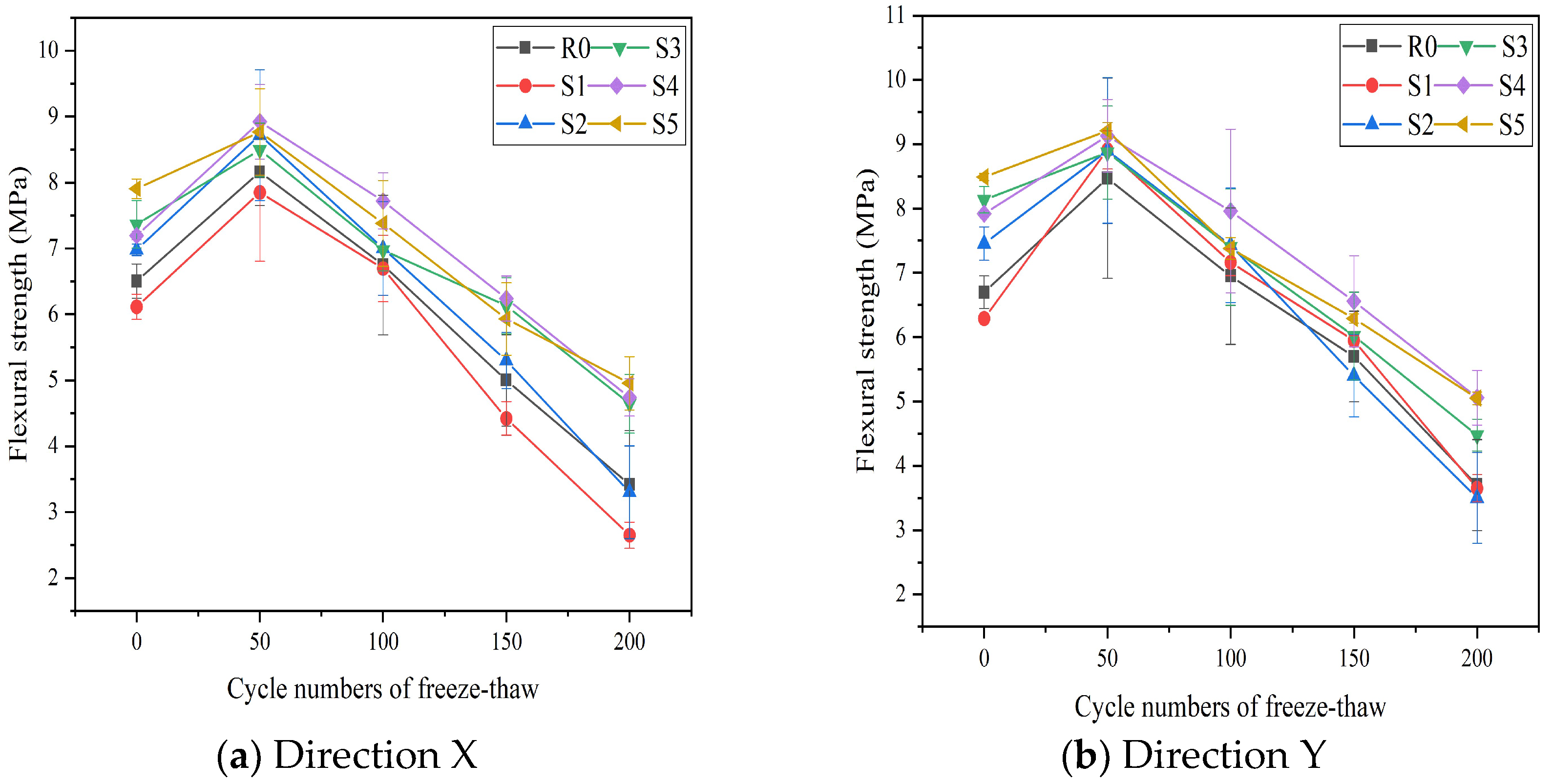

Figure 16.

Changes in compressive strength of 3DPC specimens in (a) direction X and (b) direction Y under different EAFS replacement ratios after freeze–thaw cycles.

Figure 16.

Changes in compressive strength of 3DPC specimens in (a) direction X and (b) direction Y under different EAFS replacement ratios after freeze–thaw cycles.

Figure 17.

Mass loss rate of 3DPC specimens under different EAFS replacement ratios after freeze–thaw cycles.

Figure 17.

Mass loss rate of 3DPC specimens under different EAFS replacement ratios after freeze–thaw cycles.

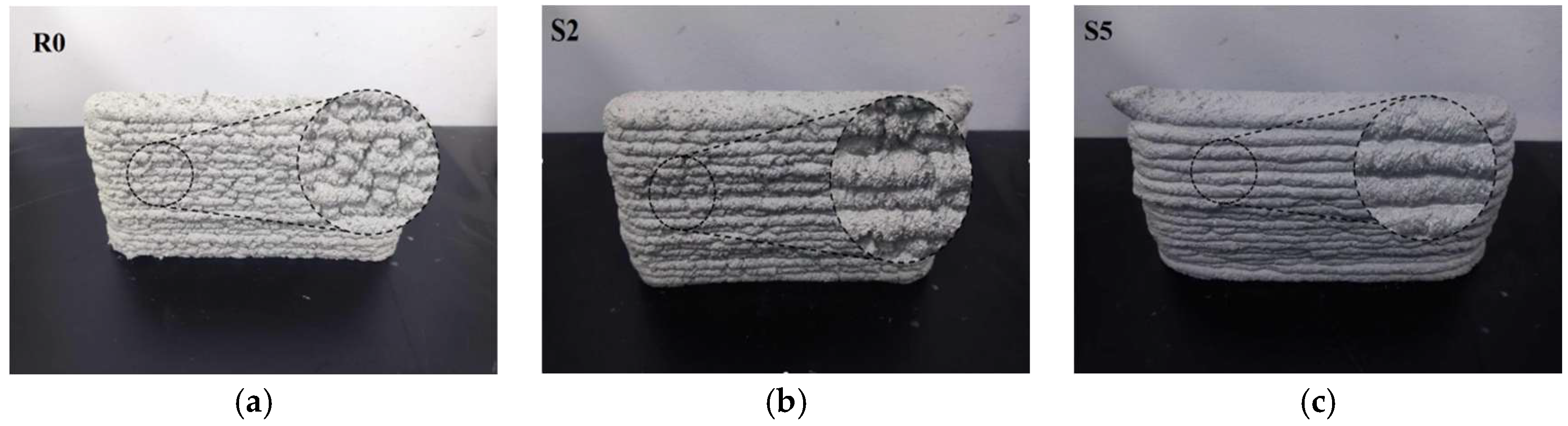

Figure 18.

The apparent morphology of (a) R0, (b) S1, (c) S2, (d) S3, (e) S4, and (f) S5 with different replacement ratios of EAFS after 200 freeze–thaw cycles.

Figure 18.

The apparent morphology of (a) R0, (b) S1, (c) S2, (d) S3, (e) S4, and (f) S5 with different replacement ratios of EAFS after 200 freeze–thaw cycles.

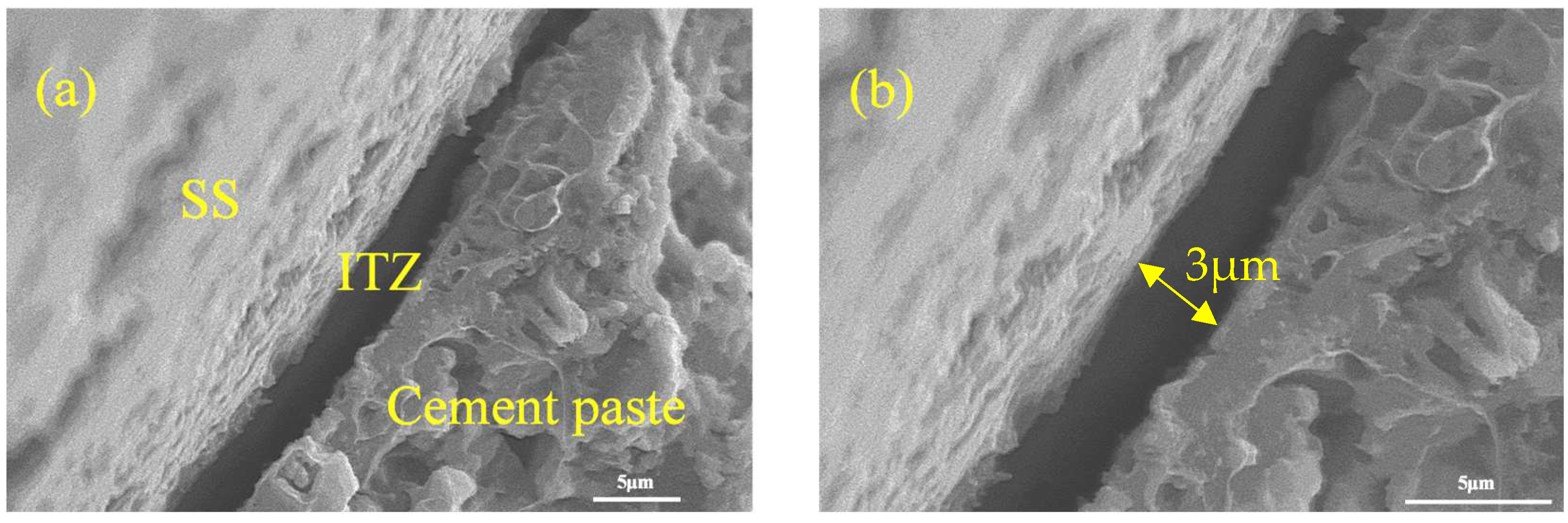

Figure 19.

(a,b) SEM images of 3DPC samples with RS aggregate after 28 days.

Figure 19.

(a,b) SEM images of 3DPC samples with RS aggregate after 28 days.

Figure 20.

(a,b) SEM images of 3DPC samples with EAFS aggregate after 28 days.

Figure 20.

(a,b) SEM images of 3DPC samples with EAFS aggregate after 28 days.

Figure 21.

SEM images of 3DPC: (a) sample of R0; (b) sample of S1; (c,d) sample of S4 with different EAFS replacement ratios after freeze–thaw cycles.

Figure 21.

SEM images of 3DPC: (a) sample of R0; (b) sample of S1; (c,d) sample of S4 with different EAFS replacement ratios after freeze–thaw cycles.

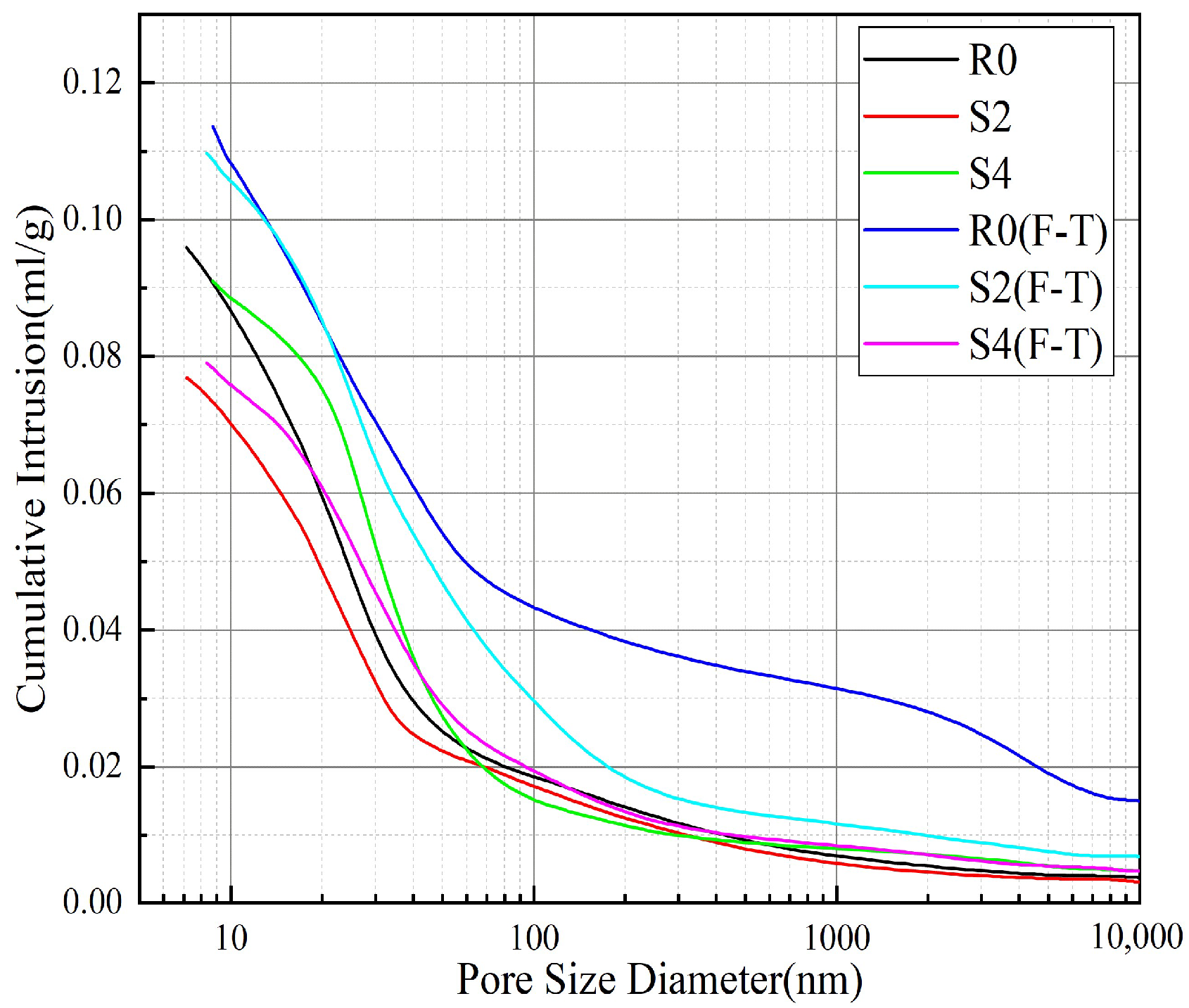

Figure 22.

Cumulative porosity before and after freeze–thaw cycles.

Figure 22.

Cumulative porosity before and after freeze–thaw cycles.

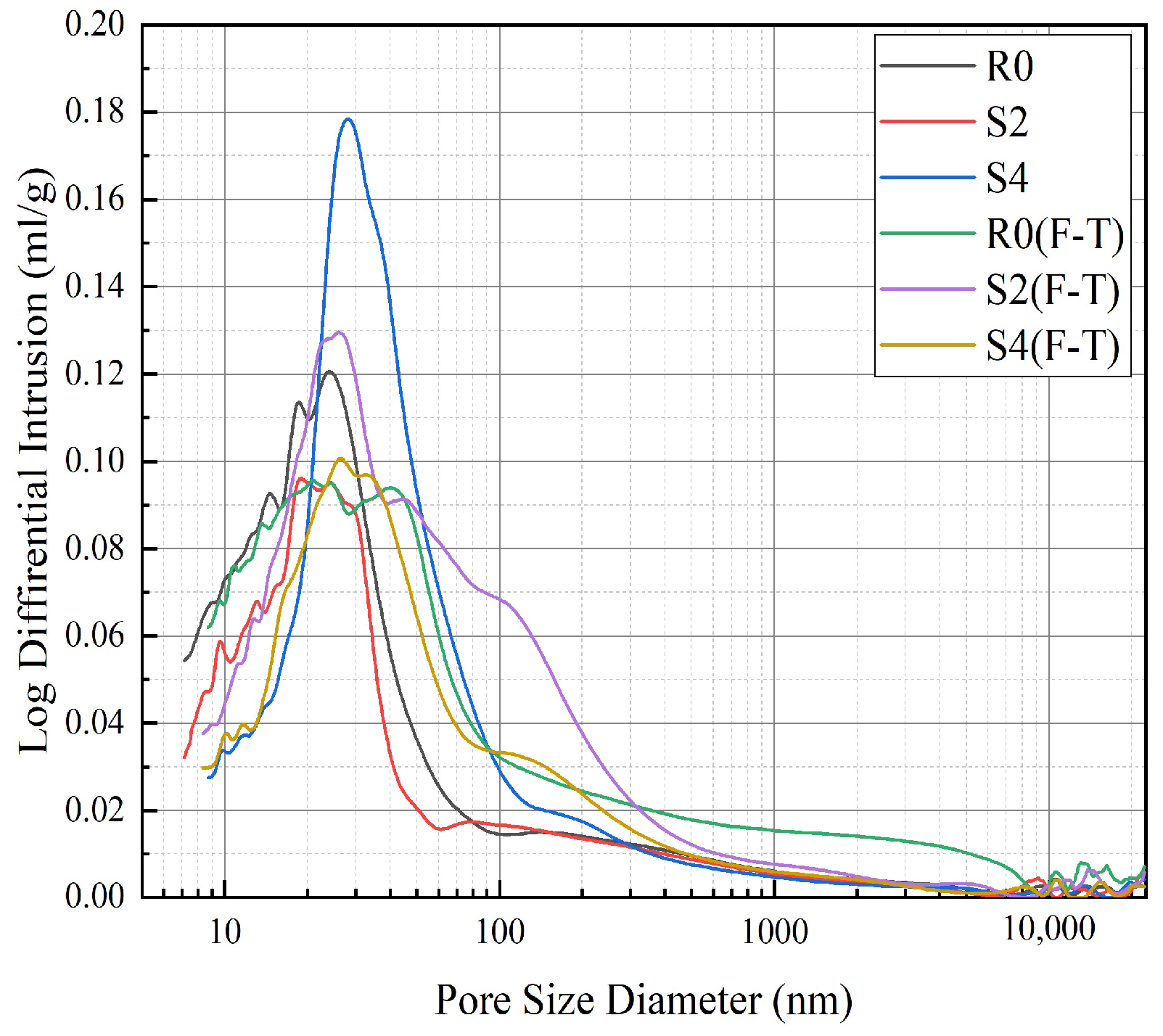

Figure 23.

Pore distribution before and after freeze–thaw cycles.

Figure 23.

Pore distribution before and after freeze–thaw cycles.

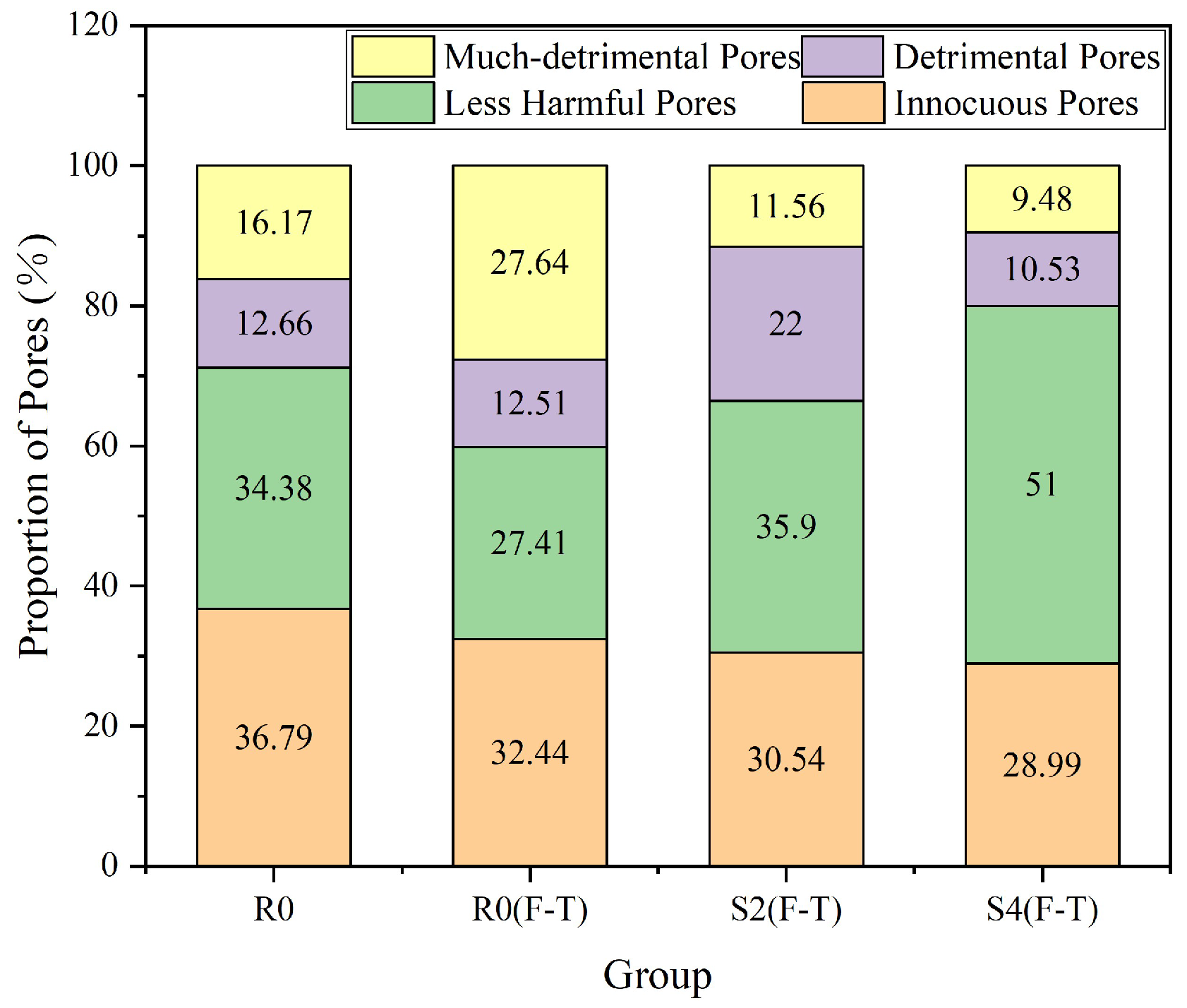

Figure 24.

Proportion of pores.

Figure 24.

Proportion of pores.

Table 1.

Chemical composition (%) of raw materials.

Table 1.

Chemical composition (%) of raw materials.

| Composition | SiO2 | CaO | Al2O3 | Fe2O3 | TiO2 | MgO | SO3 | MnO | Other | LOI |

|---|

| GGBS | 31.86 | 39.55 | 15.97 | 0.23 | 0.64 | 9.27 | 1.14 | No | 0.408 | 1.23 |

| OPC | 27.61 | 48.98 | 10.34 | 3.39 | 0.47 | 2.32 | 1.85 | 0.092 | 0.37 | 3.66 |

| EAFS | 12.77 | 24.53 | 4.93 | 46.74 | 0.46 | 3.14 | 0.14 | 4.85 | 1.802 | 0.55 |

Table 2.

Mix proportions and notation.

Table 2.

Mix proportions and notation.

| Group Number | RS/A (%) | EAFS/A (%) | Activator (%) | Accelerator (%) | PVA (%) | EVA (%) | ATm (%) |

|---|

| R0 | 100 | 0 | 2 | 0.13 | 0.16 | 0.8 | 2.3 |

| S1 | 80 | 20 | 2 | 0.13 | 0.16 | 0.8 | 2.3 |

| S2 | 60 | 40 | 2 | 0.13 | 0.16 | 0.8 | 2.3 |

| S3 | 40 | 60 | 2 | 0.13 | 0.16 | 0.8 | 2.3 |

| S4 | 20 | 80 | 2 | 0.13 | 0.16 | 0.8 | 2.3 |

| S5 | 0 | 100 | 2 | 0.13 | 0.16 | 0.8 | 2.3 |

Table 3.

Aggregate physical properties.

Table 3.

Aggregate physical properties.

| Aggregate | Apparent Density/(kg/m3) | Bulk Density/(kg/m3) | Fineness Modulus | Absorption (%) |

|---|

| EAFS | 3688 | 2235 | 2.86 | 0.02 |

| RS | 2593 | 1596 | 2.37 | 0.21 |

Table 4.

Compressive and flexural strengths of specimens at different EAFS replacement ratios.

Table 4.

Compressive and flexural strengths of specimens at different EAFS replacement ratios.

| Group | Compressive Strength (MPa) | Flexural Strength (MPa) |

|---|

| Direction X | Direction Y | MC | Direction X | Direction Y | MC |

|---|

| R0 | 28.15 | 27.75 | 35.20 | 6.50 | 6.70 | 7.46 |

| S1 | 26.32 | 26.28 | 34.66 | 6.11 | 6.29 | 7.05 |

| S2 | 28.15 | 28.13 | 35.09 | 6.98 | 7.45 | 8.17 |

| S3 | 28.68 | 28.31 | 37.85 | 7.36 | 8.13 | 8.54 |

| S4 | 31.03 | 28.44 | 37.92 | 7.19 | 7.92 | 9.04 |

| S5 | 32.03 | 28.72 | 38.08 | 7.90 | 8.49 | 8.99 |

Table 5.

Compressive and flexural strengths of specimens at different EAFS replacement ratios after freeze–thaw cycles (e.g., direction X).

Table 5.

Compressive and flexural strengths of specimens at different EAFS replacement ratios after freeze–thaw cycles (e.g., direction X).

| Freeze–Thaw Cycles Group | 0 | 50 | 100 | 150 | 200 | 0 | 50 | 100 | 150 | 200 |

|---|

| Compressive Strength (MPa) | Flexural Strength (MPa) |

|---|

| R0 | 28.15 | 27.06 | 24.50 | 21.71 | 17.9 | 6.50 | 8.16 | 6.75 | 5.00 | 3.42 |

| S1 | 26.32 | 24.52 | 23.20 | 20.71 | 17.38 | 6.11 | 7.85 | 6.69 | 4.42 | 2.65 |

| S2 | 28.15 | 26.10 | 22.90 | 19.25 | 15.30 | 6.98 | 8.72 | 7.00 | 5.30 | 3.30 |

| S3 | 28.68 | 27.07 | 25.07 | 23.15 | 20.06 | 7.36 | 8.49 | 6.97 | 6.13 | 4.64 |

| S4 | 31.03 | 28.91 | 27.10 | 24.26 | 21.32 | 7.19 | 8.92 | 7.72 | 5.68 | 4.74 |

| S5 | 32.03 | 28.56 | 26.82 | 24.06 | 21.16 | 7.90 | 8.76 | 7.38 | 5.93 | 4.95 |

Table 6.

The total porosity of 3DPC specimens before and after freeze–thaw cycles.

Table 6.

The total porosity of 3DPC specimens before and after freeze–thaw cycles.

| Group | R0 | R0 (F-T) | S2 (F-T) | S4 (F-T) |

|---|

| Total porosity | 18.69% | 21.82% | 22.0% | 20.02% |

Table 7.

A comparative analysis between this study and the relevant studies.

Table 7.

A comparative analysis between this study and the relevant studies.

| Comparison Items | This Study | Ref. [20] | Ref. [13] |

|---|

| Forming method | 3D printing | Casting mold | Casting mold |

| Cementitious material mix ratio | GGBS:OPC = 7:3 | GGBFS:FA:SF = 688:172:45 | CEM II-A/L 42.5R (330–355 kg/m3) |

| EAFS replacement ratio (%) | 0–100 | 55.46 | 0–100 |

| Compressive strength improvement rate (%) | −6.50–13.78 | −2.21–−9.93 | −7.20–1.77 |

| Other relevant properties | Flowability shows an increasing trend with the rise of the EAFS replacement ratio. Flexural strength of 3DPC specimens increases by 7.3–26.71% with the rise of the EAFS replacement ratio. The ITZ between EAFS and paste is narrower than that between RS and cement. After freeze–thaw cycles, the total porosity of group S4 is 1.8% lower than that of R0, with the pore structure optimized.

| EAF slag-containing mixtures show higher fluidity (mini-slump: 200–230 mm) than silica sand-containing ones (180–190 mm). Self-sensing performance: EAF slag group shows low FCR noise (EAF_0.7% RMSE = 0.5710) and sensitive initial crack detection; the sand group still has high noise even with carbon fibers.

| |