The Possibilities for Using Ash and Slag Waste in Civil Engineering

Abstract

1. Introduction

- Backfilling mines;

- The hardening of land surfaces;

- As a seal to prevent sewage seepage from the landfills;

- As a material incorporated into the lower layers of road and railway embankments, provided that they are stored in dry places or isolated from water;

- As a valuable construction material for the creation of earth embankments;

- As materials for the construction of non-reinforced layers in the base of the road surface;

- In the cores of hydrotechnical and other structures, including foundations;

- As a base for temporary and improved light road surfaces of categories IV–V;

- As a material used in lower layers of the base for improved light and permanent road surfaces of category III.

2. Materials

- Portland cement CEM I 42.5R;

- Standard sand;

- Bottom sand;

- Water.

3. Experimental Procedures

- SEP1—initial, specific experimental plan—replacing the standard sand with the bottom sand in the mortar samples;

- SEP 2—the second specific experimental plan—replacing the standard sand with the bottom sand in the mortar samples and adjusting the water content to achieve the standard consistency.

4. Results and Discussion

4.1. Consistency of the Fresh Mortar

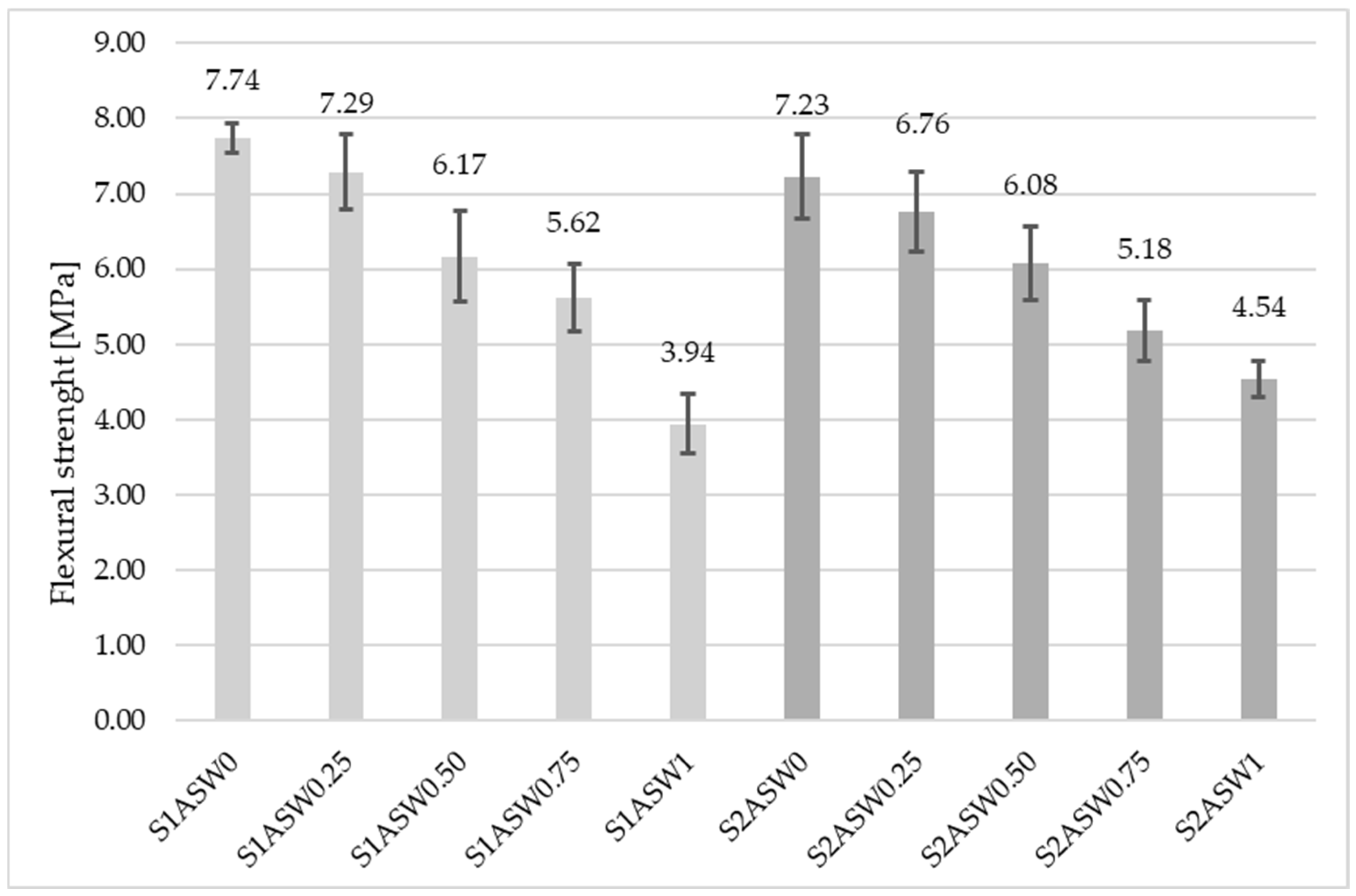

4.2. Flexural Strength

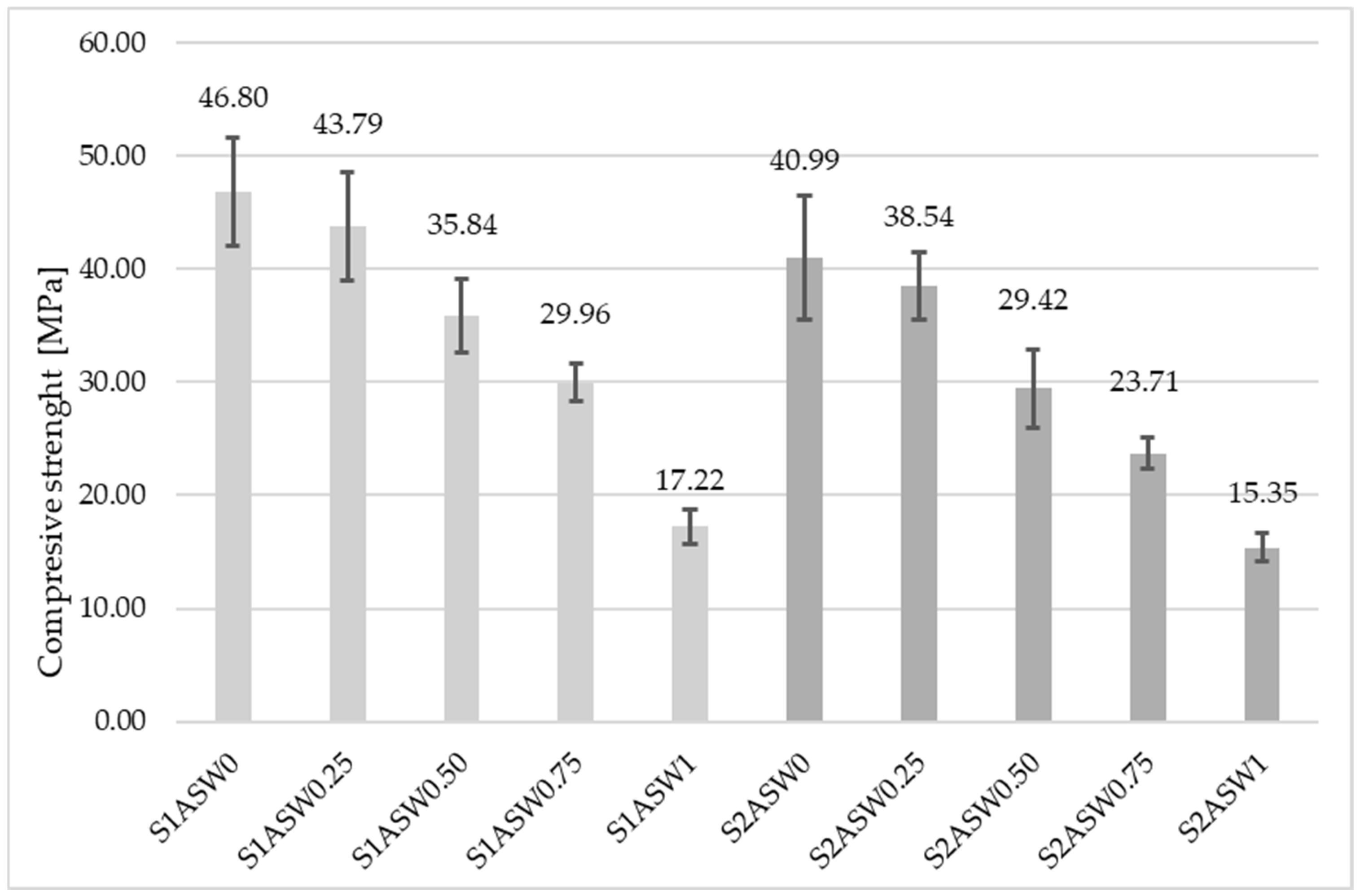

4.3. Compressive Strength

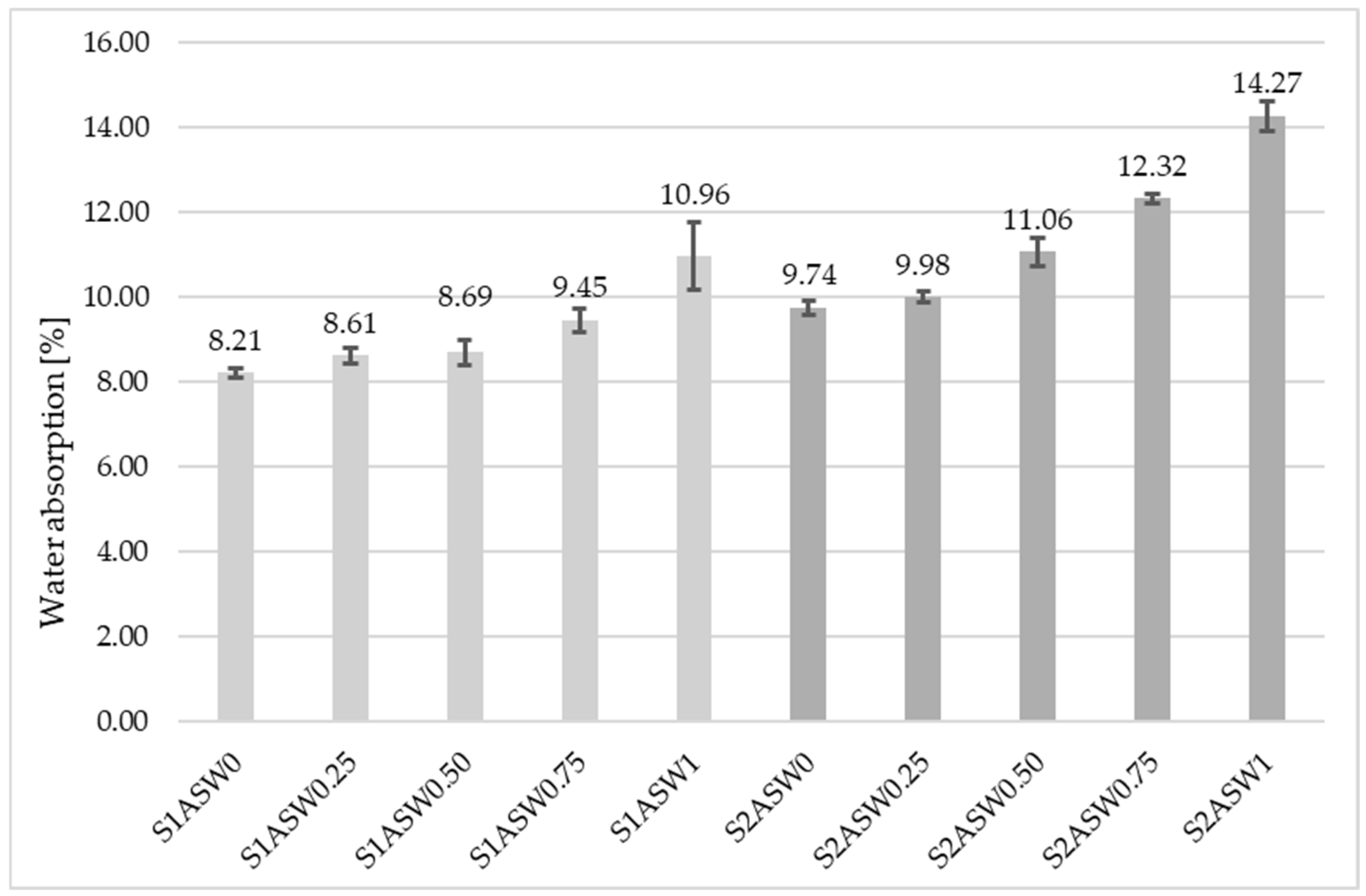

4.4. Water Absorption

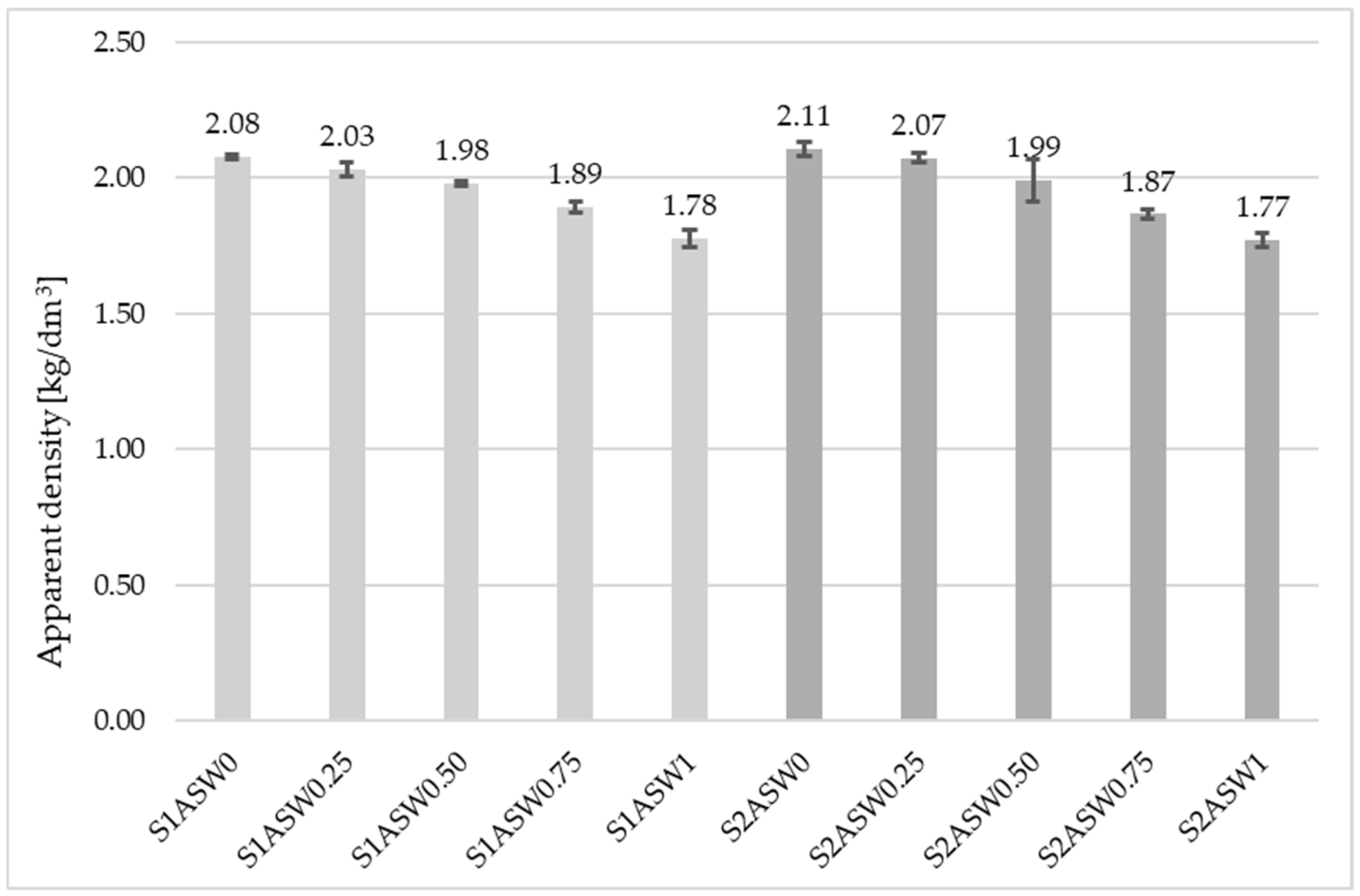

4.5. Apparent Density

4.6. Pozzolanic Activity Index

- The calcium hydroxide content increased from 2.79% to 3.0% after 28 days and from 2.75% to 3.04% after 90 days (Table 20).

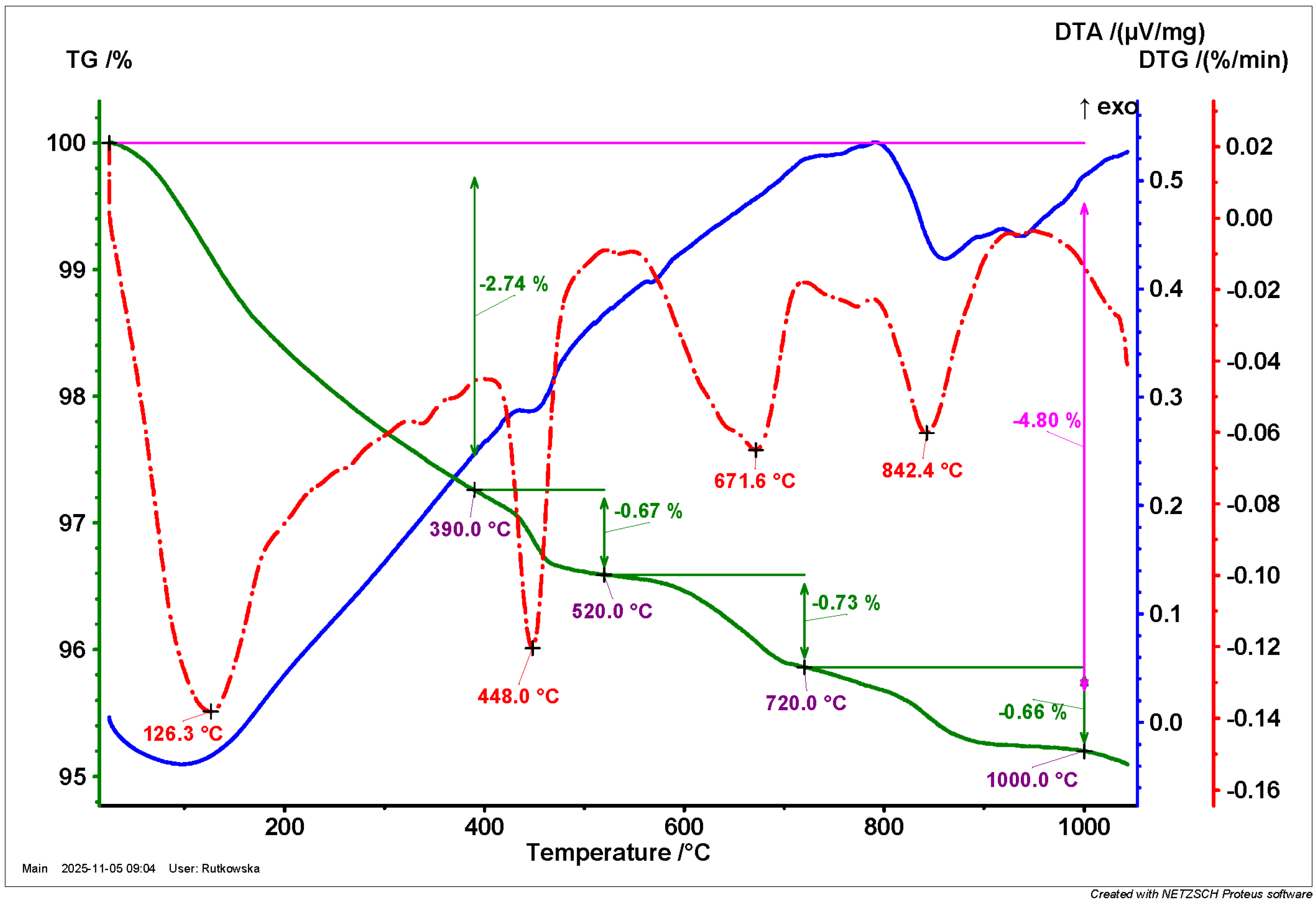

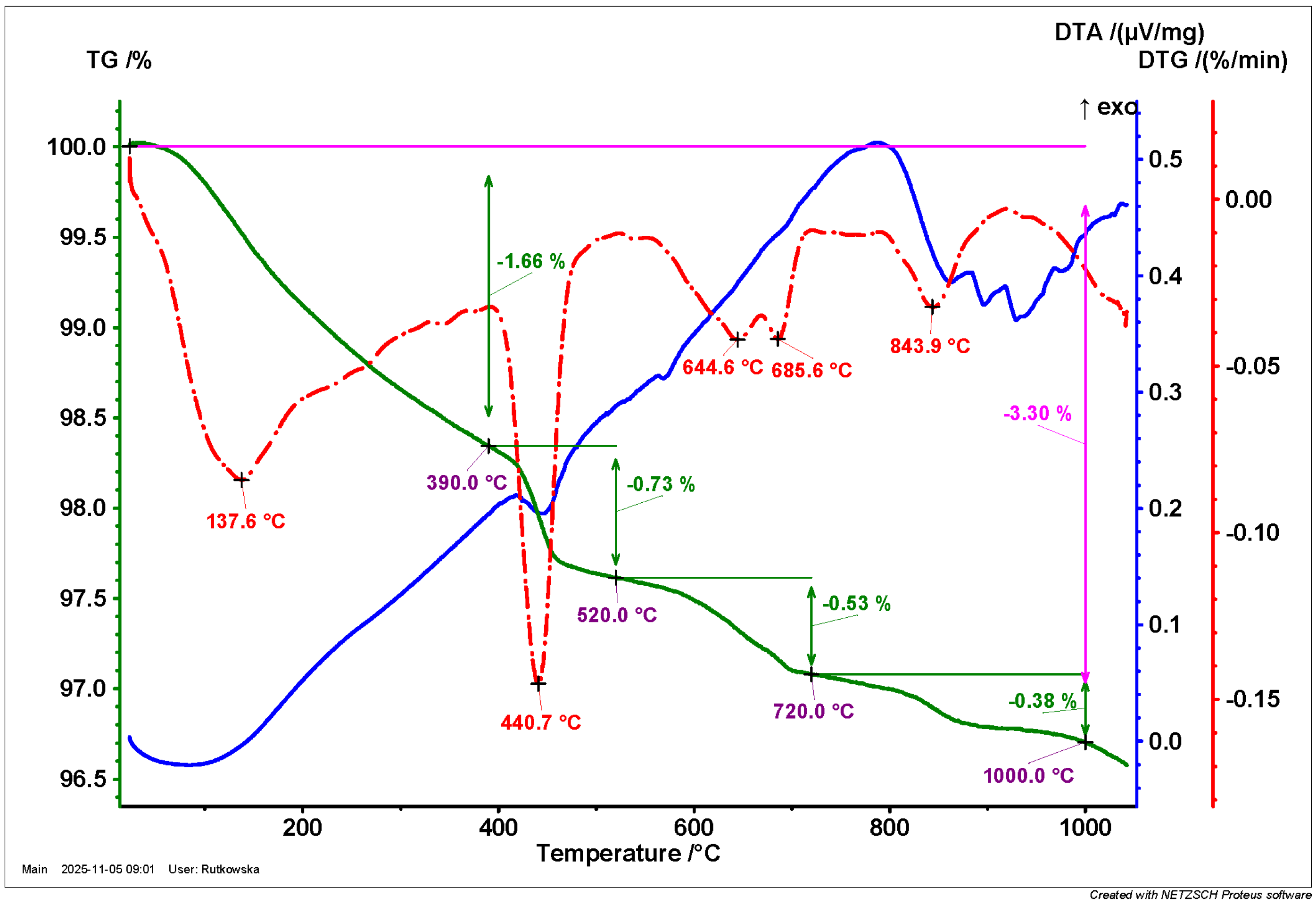

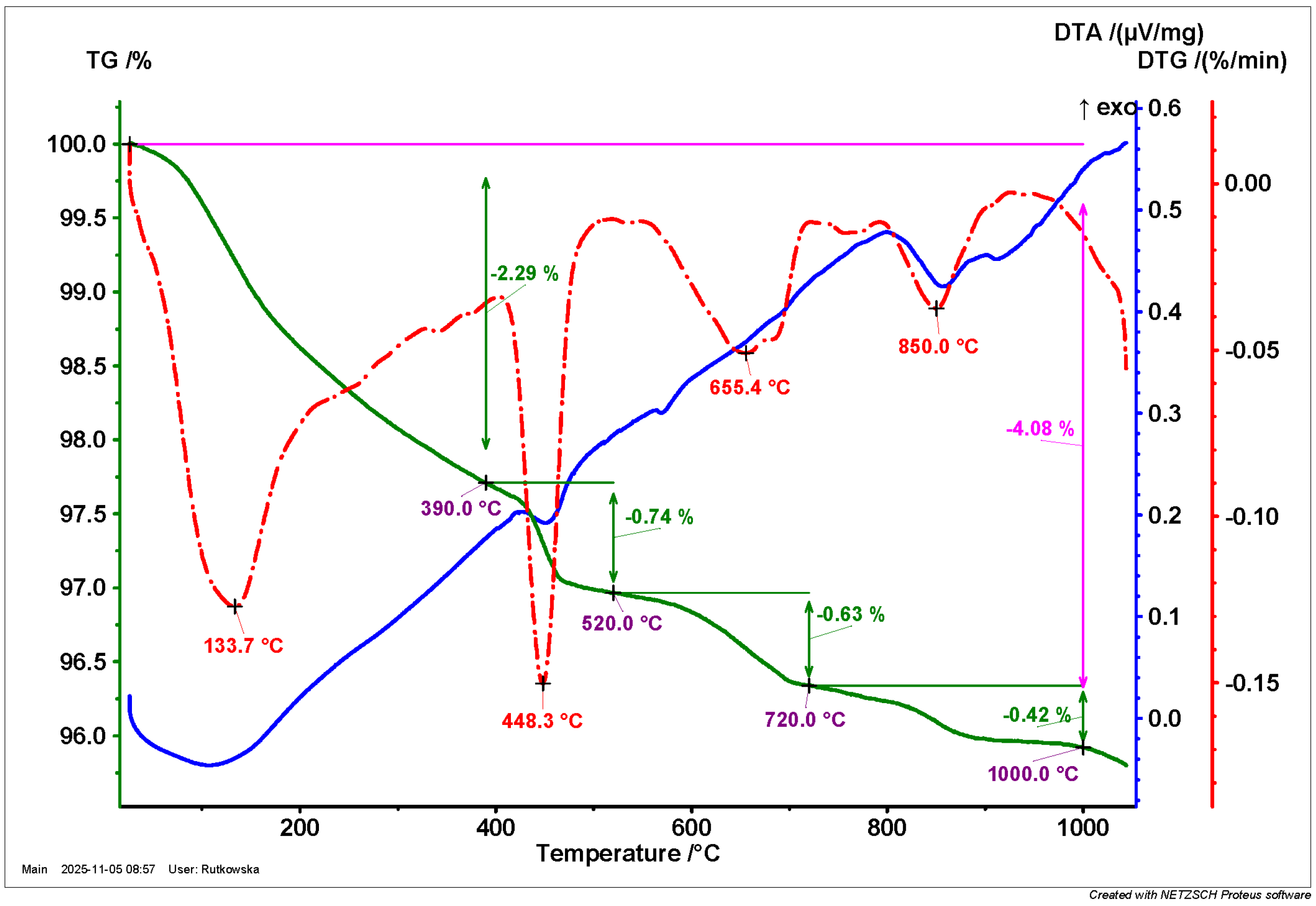

- The content of hydrated calcium silicates decreased from 2.15% to 1.66% after 28 days and from 2.74% to 2.29% after 90 days (Table 19, weight loss in the range of 23–390 °C).

- The calcium carbonate content decreased from 2.47% to 2.07% after 28 days and from 3.16% to 2.38% after 90 days (Table 20).

- The amount of loss on ignition decreased from 3.91% to 3.30% after 28 days and from 4.80% to 4.08% after 90 days (Table 19).

- Calcium hydroxide remained consistent.

- Hydrated calcium silicates increased.

- Calcium carbonate increased.

- Loss on ignition increased.

5. Conclusions

- Bottom sand with the specified composition can be utilised as a substitute for aggregate in 25%. The incorporation of the material at this quantity does not result in a statistically significant reduction in flexural strength, compressive strength, water absorption, or apparent density.

- The properties under investigation are negatively impacted by quantities higher than 25%.

- The tested bottom sand is characterised by a higher content of finer fractions, which renders it more water-demanding. The high silica content of this material makes it a valuable substitute for standard sand.

- Adjusting the amount of water to maintain the standard consistency resulted in less favourable test results. Consequently, further studies should assess the impact of adding bottom sand when using admixtures that reduce the amount of water and superplasticisers of various origins.

- The analysis of the pozzolanic activity index confirmed that this particular bottom sand should not be used as a substitute for binder in composites. The material under consideration contains elevated levels of silica, yet it is found to be deficient in aluminium oxide. This combination of properties renders the material unsuitable for utilisation as a pozzolanic additive.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ASW | Ash and Slag Waste |

| MSWI | Municipal Solid Waste Incineration |

| MAS | Mixture of Ash and Slag |

| SCM | Supplementary Cementitious Materials |

| LC3 | Limestone Calcined Clay Cement |

| LOI | Loss on Ignition |

| PAI | Pozzolanic Activity Index |

| NAAC | Non-Autoclaved Aerated Concrete |

| MM | Modified Mortar |

| CM | Control Mortar |

| AFt | Ettringite |

| AFm | Monosulphate |

References

- Turner, L.K.; Collins, F.G. Carbon Dioxide Equivalent (CO2-e) Emissions: A Comparison between Geopolymer and OPC Cement Concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S.K. Geopolymer Concrete: A Review of Some Recent Developments. Constr. Build. Mater. 2015, 85, 78–90. [Google Scholar] [CrossRef]

- Ma, C.K.; Awang, A.Z.; Omar, W. Structural and Material Performance of Geopolymer Concrete: A Review. Constr. Build. Mater. 2018, 186, 90–102. [Google Scholar] [CrossRef]

- Huseien, G.F.; Mirza, J.; Ismail, M.; Ghoshal, S.K.; Hussein, A.A. Geopolymer Mortars as Sustainable Repair Material: A Comprehensive Review. Renew. Sustain. Energy Rev. 2017, 80, 54–74. [Google Scholar] [CrossRef]

- Stankiewicz, N. Modified Protective Concrete. Appl. Mech. Mater. 2015, 797, 166–173. [Google Scholar] [CrossRef]

- Stankiewicz, N. Effect of Admixtures on Selected Properties of Fly Ash-Based Geopolymer Composites. Appl. Sci. 2023, 13, 1803. [Google Scholar] [CrossRef]

- Bołtryk, M.; Granatyr, K.; Stankiewicz, N. Ecological Aspects in the Application of Geopolymer Composites on Road Surfaces. Ekon. I Sr. 2019, 68, 10. [Google Scholar] [CrossRef]

- Yagüe-García, S.; García-Giménez, R. Microstructure of Mortar with Ballast Waste as a Cement Replacement. Appl. Sci. 2025, 15, 5605. [Google Scholar] [CrossRef]

- Silva, Y.F.; Burbano-Garcia, C.; Rueda, E.J.; Reyes-Román, A.; Araya-Letelier, G. Short- and Long-Term Mechanical and Durability Performance of Concrete with Copper Slag and Recycled Coarse Aggregate Under Magnesium Sulfate Attack. Appl. Sci. 2025, 15, 8329. [Google Scholar] [CrossRef]

- Alemu, M.Y.; Yehualaw, M.D.; Nebiyu, W.M.; Nebebe, M.D.; Taffese, W.Z. Marble and Glass Waste Powder in Cement Mortar. Appl. Sci. 2025, 15, 3930. [Google Scholar] [CrossRef]

- Kapeluszna, E.; Kotwica, Ł.; Pichór, W.; Nocuń-Wczelik, W. Cement-Based Composites with Waste Expanded Perlite—Structure, Mechanical Properties and Durability in Chloride and Sulphate Environments. Sustain. Mater. Technol. 2020, 24, e00160. [Google Scholar] [CrossRef]

- Li, X.; Qin, D.; Hu, Y.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P. A Systematic Review of Waste Materials in Cement-Based Composites for Construction Applications. J. Build. Eng. 2022, 45, 103447. [Google Scholar] [CrossRef]

- Chinnu, S.N.; Minnu, S.N.; Bahurudeen, A.; Senthilkumar, R. Influence of Palm Oil Fuel Ash in Concrete and a Systematic Comparison with Widely Accepted Fly Ash and Slag: A Step towards Sustainable Reuse of Agro-Waste Ashes. Clean. Mater. 2022, 5, 100122. [Google Scholar] [CrossRef]

- Renuka, V.; Rao, S.V.; Tadepalli, T. State-of-the-Art Review on Limestone Calcined Clay Cement (LC3) and Its Recent Advances. Iran. J. Sci. Technol. Trans. Civ. Eng. 2025. [Google Scholar] [CrossRef]

- Collivignarelli, M.C.; Cillari, G.; Ricciardi, P.; Miino, M.C.; Torretta, V.; Rada, E.C.; Abbà, A. The Production of Sustainable Concrete with the Use of Alternative Aggregates: A Review. Sustainability 2020, 12, 7903. [Google Scholar] [CrossRef]

- Kirthika, S.K.; Singh, S.K.; Chourasia, A. Alternative Fine Aggregates in Production of Sustainable Concrete—A Review. J. Clean. Prod. 2020, 268, 122089. [Google Scholar] [CrossRef]

- Dias, S.; Almeida, J.; Tadeu, A.; de Brito, J. Alternative Concrete Aggregates—Review of Physical and Mechanical Properties and Successful Applications. Cem. Concr. Compos. 2024, 152, 105663. [Google Scholar] [CrossRef]

- Luhar, I.; Luhar, S.; Abdullah, M.M.A.B.; Nabiałek, M.; Sandu, A.V.; Szmidla, J.; Jurczyńska, A.; Razak, R.A.; Aziz, I.H.A.; Jamil, N.H.; et al. Assessment of the Suitability of Ceramic Waste in Geopolymer Composites: An Appraisal. Materials 2021, 14, 3279. [Google Scholar] [CrossRef]

- Jha, A.K.; Parihar, R.S.; Lodhi, V.; Misra, R.; Kumar, B.; Udeniya, A. A Review on the Recycling Waste Materials for Green Concrete. Eur. J. Appl. Sci. Eng. Technol. 2024, 2, 74–82. [Google Scholar] [CrossRef]

- Hashmi, A.F.; Khan, M.S.; Bilal, M.; Shariq, M.; Baqi, A. Baqi Green Concrete: An Eco-Friendly Alternative to the OPC Concrete. Construction 2022, 2, 93–103. [Google Scholar] [CrossRef]

- Kalombe, R.M.; Ojumu, V.T.; Eze, C.P.; Nyale, S.M.; Kevern, J.; Petrik, L.F. Fly Ash-Based Geopolymer Building Materials for Green and Sustainable Development. Materials 2020, 13, 5699. [Google Scholar] [CrossRef]

- Liew, K.M.; Sojobi, A.O.; Zhang, L.W. Green Concrete: Prospects and Challenges. Constr. Build. Mater. 2017, 156, 1063–1095. [Google Scholar] [CrossRef]

- Suhendro, B. Toward Green Concrete for Better Sustainable Environment. Procedia Eng. 2014, 95, 305–320. [Google Scholar] [CrossRef]

- Sivakrishna, A.; Adesina, A.; Awoyera, P.O.; Kumar, K.R. Green Concrete: A Review of Recent Developments. Mater. Today Proc. 2020, 27, 54–58. [Google Scholar] [CrossRef]

- Regulation of the Minister of Climate of 2 January 2020 on a Catalog of Waste (Polish Journal of Laws 2020, Item 10). Available online: https://www.sejm.gov (accessed on 3 November 2025).

- Kozioł, W.; Ciepliński, A.; Machniak, Ł.; Borcz, A. Aggregates in Construction Industry. Part 2. Alternative Aggregates. Nowocz. Bud. Inżynieryjne (Mod. Eng. Constr.) 2015, 5, 35–40. [Google Scholar]

- Aldungarova, A.; Aryngazin, K.; Larichkin, V.; Abisheva, A.; Alibekova, K. Modern Trends in the Development of the Construction Industry in the Production of Building Materials. Technobius 2021, 1, 0003. [Google Scholar] [CrossRef]

- Menshov, P.V.; Khlupin, Y.V.; Nalesnik, O.I.; Makarovskikh, A.V. Ash and Slag Waste as a Secondary Raw Material. Procedia Chem. 2014, 10, 184–191. [Google Scholar] [CrossRef]

- Novytskyi, Y.; Yatsenko, V.; Topylko, N. Prerequisites for the Implementation of the European Experience in the Use of Ash-Slag Materials in the Construction of Highways: A Review. Theory Build. Pract. 2022, 2022, 90–97. [Google Scholar] [CrossRef]

- Malchik, A.G.; Litovkin, S.V.; Rodionov, P.V.; Kozik, V.V.; Gaydamak, M.A. Analyzing the Technology of Using Ash and Slag Waste from Thermal Power Plants in the Production of Building Ceramics. IOP Conf. Ser. Mater. Sci. Eng. 2016, 127, 012024. [Google Scholar] [CrossRef]

- Yatsenko, E.A.; Goltsman, B.M.; Izvarin, A.I.; Kurdashov, V.M.; Smoliy, V.A.; Ryabova, A.V.; Klimova, L.V. Recycling Ash and Slag Waste from Thermal Power Plants to Produce Foamed Geopolymers. Energies 2023, 16, 7535. [Google Scholar] [CrossRef]

- Gruchot, A.; Zydroń, T. Geotechnical Parameters of the Ash-Slag Mixture from Hard Coal Burning Concerning Its Usability for Earthworks. Annu. Set. Environ. Prot. 2013, 15, 1719–1737. [Google Scholar]

- Bieliatynskyi, A.; Yang, S.; Pershakov, V.; Akmaldinova, O.; Krayushkina, K.; Shao, M. Prospects for the Use of Ash and Slag Waste in the Construction of Road Pavement. Balt. J. Road Bridge Eng. 2022, 17, 80–94. [Google Scholar] [CrossRef]

- Regulation of the Minister of the Environment of 11 May 2015 on Waste Recovery Outside Installations and Equipment (Polish Journal of Laws 2015, Item 796). Available online: https://www.sejm.gov (accessed on 3 November 2025).

- Klyuev, S.V.; Slobodchikova, N.A.; Saidumov, M.S.; Abumuslimov, A.S.; Mezhidov, D.A.; Khezhev, T.A. Application of Ash and Slag Waste from Coal Combustion in the Construction of the Earth Bed of Roads. Constr. Mater. Prod. 2024, 7, 3. [Google Scholar] [CrossRef]

- Zawisza, E.; Gruchot, A. Shear Strength of Ash-Slag Mixture Stabilised with Hydraulic Binders. J. Civ. Eng. Environ. Archit. 2017, 34, 115–122. (In Polish) [Google Scholar] [CrossRef]

- Zawisza, E.; Bigos, M.; Gruchot, A. Stabilisation of Ash–Slag Mixtures with Hydraulic binders for Road Engineering Purposes. Sci. C Rev.-Eng. Environ. Sci. 2018, 27, 123–131. (In Polish) [Google Scholar] [CrossRef]

- Kalinowska-Wichrowska, K.; Pawluczuk, E.; Bołtryk, M.; Nietupski, A. Geopolymer Concrete with Lightweight Artificial Aggregates. Materials 2022, 15, 3012. [Google Scholar] [CrossRef]

- Yatsenko, E.A.; Zubekhin, A.P.; Smolii, V.A.; Grushko, I.S.; Kosarev, A.S.; Gol’tsman, B.M. Resource-Conserving Technology of Heat-Insulation-Decorative Glass-Composite Material Based on Ash-Slag Wastes. Glass Ceram. 2015, 72, 216–219. [Google Scholar] [CrossRef]

- Rudenko, O.; Beisekenov, N.; Sadenova, M.; Galkina, D.; Kulenova, N.; Begentayev, M. Physical–Mechanical and Microstructural Properties of Non-Autoclaved Aerated Concrete with Ash-and-Slag Additives. Sustainability 2024, 17, 73. [Google Scholar] [CrossRef]

- Tkaczewska, E. Application of Ash-and-Slag Mixture Formed during Bituminous Coal Combustion in Cement Production. Ceram. Mater. 2018, 70, 257–266. [Google Scholar]

- EN 450-1:2012; Fly Ash for Concrete—Part 1: Definition. Specifications and Conformity Criteria. European Committee for Standardization: Brussels, Belgium, 2012.

- EN 197-1:2011; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Committee for Standardization: Brussels, Belgium, 2011.

- EN 196-1:2016; Methods of Testing Cement—Part 1: Determination of Strength. European Committee for Standardization: Brussels, Belgium, 2016.

- EN 1015-3:1999/A2:2006; Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table). European Committee for Standardization: Brussels, Belgium, 2006.

- EN 1015-4:1998; Methods of Test for Mortar for Masonry—Part 4: Determination of Consistence of Fresh Mortar (by Plunger Penetration). European Committee for Standardization: Brussels, Belgium, 1988.

- EN 933-1:2012; Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method. European Committee for Standardization: Brussels, Belgium, 2012.

- PN-B-04500:1985; Zaprawy Budowlane—Badania Cech Fizycznych i Wytrzymałościowych. Polish Committee for Standardization: Warsaw, Poland, 1985.

- Microsoft Excel, Microsoft 365 Subscription; Microsoft: Redmond, WA, USA, 2025.

| Material/ Application | Series Code | Chemical Compositions [%] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | K2O | SO3 | TiO2 | P2O5 | LOI | ||

| Mixture of Fly Ash and Boiler Slag (MAS) [31]/ Foamed Geopolymers | ASW_N | 51.2 | 18.8 | 10.3 | 3.1 | 2.1 | 0.9 | 3.0 | 0.3 | 0.8 | 0.1 | 9.3 |

| ASW_S | 61.6 | 17.9 | 6.8 | 2.1 | 2.8 | 3.6 | 2.3 | 0.3 | 0.8 | 0.2 | 2.3 | |

| Ash-slag mixture (ASW) [39]/Cellular Glass and Slag-sital | ASW | 56.32 | 20.08 | 11.97 | 4.02 | 1.43 | 0.51 | 3.54 | - | 0.24 | 0.01 | 1.53 |

| Ash and Slag Waste (ASW) [40]/NAAC | ASW | 51.27 | 22.49 | 9.32 | 2.95 | 1.69 | 4.67 (Na2O K2O) | 0.93 | 0.95 | - | 5.63 | |

| Fly ash-slag mixture (MAS) [41]/Pozzolan Additive in Cement | AS (0–30 μm) | 47.9 | 24.2 | 9.9 | 3.8 | 2.4 | 2.2 | 0.8 | 0.2 | 8.2 | 8.6 | |

| AS_0–15 (0–15 μm) | 44.0 | 28.8 | 4.3 | 4.6 | 1.7 | 2.7 | 1.1 | 0.3 | - | 13.5 | 12.6 | |

| AS_15–30 (15–30 μm) | 46.4 | 29.4 | 7.1 | 3.6 | 1.9 | 2.5 | 1.0 | 0.2 | 10.0 | 8.0 | ||

| Material/ Application | Series Code | Grain size Distribution [%] | ||||||||||

| 63–2 mm | 2–0.063 mm | 0.063–0.002 mm | <0.002 mm | |||||||||

| Geotechnical Ash and Slag Waste (ASW) [32]/ Earth Embankments | ASW | 13.7 | 63.5 | 21.1 | 1.7 | |||||||

| Ash and Slag Waste (ASW) [36,37]/ Embankment Slopes | ASW2004 | 11.50 | 50.10 | 36.50 | 1.9 | |||||||

| ASW2015 | 7.0 | 58.90 | 32.50 | 1.7 | ||||||||

| ASW2016 | 11.65 | 53.81 | 32.24 | 1.15 | ||||||||

| Ash and Slag Waste | Grain Size Distribution [%] | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 20–10 | 10–5 | 5–2.5 | 2.5–1.25 | 1.25–0.63 | 0.63–0.315 | 0.315–0.14 | 0.14–0.05 | <0.05 | |

| [mm] | |||||||||

| No 1 | 18.51 | 12.91 | 7.56 | 12.96 | 16.34 | 6.41 | 3.49 | 6.28 | 15.54 |

| No 2 | 0 | 0 | 0.06 | 0.26 | 0.09 | 0.18 | 0.26 | 4.68 | 94.47 |

| No 3 | 0.99 | 1.29 | 1.5 | 2.15 | 2.24 | 3.17 | 9.62 | 29.71 | 49.33 |

| No 4 | 0 | 0.28 | 0.2 | 0.54 | 0.98 | 1.64 | 10.7 | 36.9 | 48.76 |

| No 5 | 0 | 0 | 0.03 | 0.06 | 0.24 | 0.64 | 2.13 | 20.72 | 76.18 |

| No 6 | 0.22 | 0.23 | 0.77 | 0.74 | 2.19 | 7.58 | 22.58 | 33.94 | 31.75 |

| No 7 | 0.27 | 0.28 | 0.24 | 0.3 | 0.4 | 2.15 | 18.65 | 55.99 | 21.72 |

| No 8 | 5.52 | 8.44 | 11.42 | 25.26 | 15.19 | 5.51 | 6.21 | 12.96 | 9.49 |

| No 9 | 0.61 | 1.08 | 0.38 | 0.77 | 1.32 | 3.12 | 10.12 | 24.77 | 57.83 |

| Material | 2.0–1.0 mm | 1.0–0.5 mm | 0.50–0.25 mm | 0.250–0.125 mm | 0.125–0.063 mm | 0.063–0.000 mm |

|---|---|---|---|---|---|---|

| Standard sand | 23.0 | 22.0 | 31.0 | 10.0 | 13.0 | 1.0 |

| Bottom sand | 0.33 | 3.69 | 36.53 | 51.04 | 7.26 | 1.15 |

| Oxide | Content After Burning at 815 °C | Content Calculated Based on the Initial State |

|---|---|---|

| SiO2 | 86.67 | 86.00 |

| Al2O3 | 2.81 | 2.79 |

| Fe2O3 | 0.91 | 0.90 |

| CaO | 3.19 | 3.17 |

| MgO | 0.38 | 0.38 |

| Na2O | 0.37 | 0.37 |

| K2O | 1.30 | 1.29 |

| SO3 | 0.55 | 0.55 |

| TiO2 | 0.40 | 0.40 |

| P2O5 | 0.15 | 0.15 |

| LOI | - | 0.77 |

| Total | 96.73 | 96.77 |

| Series Code | Cement | Standard Sand | Bottom Sand | Water |

|---|---|---|---|---|

| S1ASW0 | 450 | 1350 | 0 | 225 |

| S1ASW0.25 | 450 | 1012.5 | 337.5 | 225 |

| S1ASW0.50 | 450 | 675 | 675 | 225 |

| S1ASW0.75 | 450 | 337.5 | 1012.5 | 225 |

| S1ASW1 | 450 | 0 | 1350 | 225 |

| Series Code | Cement | Standard Sand | Bottom Sand | Water |

|---|---|---|---|---|

| S2ASW0 | 450 | 1350 | 0 | 225 |

| S2ASW0.25 | 450 | 1012.5 | 337.5 | 235 |

| S2ASW0.50 | 450 | 675 | 675 | 255 |

| S2ASW0.75 | 450 | 337.5 | 1012.5 | 290 |

| S2ASW1 | 450 | 0 | 1350 | 340 |

| Source of Variation | SS | df | MS | F |

|---|---|---|---|---|

| Between Groups | SSα | p − 1 | MSα = SSα/(p − 1) | Fα = MSα/MSe |

| Within Groups | SSe | r − p | MSe = SSe/(r − 1) | |

| Total | ΣSS | r − 1 |

| Series Code | Plunger Penetration [mm] | Flow Table (Diameter) [mm] |

|---|---|---|

| S1ASW0 | 21 | 170 |

| S1ASW0.25 | 12 | 145 |

| S1ASW0.50 | 5 | 120 |

| S1ASW0.75 | 2 | 105 |

| S1ASW1 | 1 | 100 |

| Series Code | Water Quantity [g] | Water/Binder Ratio | Plunger Penetration [mm] | Flow Table (Diameter) [mm] |

|---|---|---|---|---|

| S2ASW0 | 225 | 0.50 | 16 | 190 |

| S2ASW0.25 | 235 | 0.52 | 25 | 180 |

| S2ASW0.50 | 255 | 0.57 | 24 | 185 |

| S2ASW0.75 | 290 | 0.64 | 17 | 190 |

| S2ASW1 | 340 | 0.76 | 16 | 194 |

| Source of Variation | SS | df | MS | F | p-Value | Fcrit |

|---|---|---|---|---|---|---|

| Between Groups | 53.998 | 4 | 13.500 | 66.903 | 5.50 × 10−13 | 2.759 |

| Within Groups | 5.044 | 25 | 0.202 | |||

| Total | 59.043 | 29 |

| Source of Variation | SS | df | MS | F | p-Value | Fcrit |

|---|---|---|---|---|---|---|

| Between Groups | 29.461 | 4 | 7.365 | 34.817 | 6.99 × 10−10 | 2.759 |

| Within Groups | 5.289 | 25 | 0.212 | |||

| Total | 34.750 | 29 |

| Source of Variation | SS | df | MS | F | p-Value | Fcrit |

|---|---|---|---|---|---|---|

| Between Groups | 6140.830 | 4 | 1535.207 | 123.482 | 2.89 × 10−25 | 2.557 |

| Within Groups | 621.633 | 50 | 12.433 | |||

| Total | 6762.463 | 54 |

| Source of Variation | SS | df | MS | F | p-Value | Fcrit |

|---|---|---|---|---|---|---|

| Between Groups | 4477.144 | 4 | 1119.286 | 102.856 | 4.89 × 10−22 | 2.579 |

| Within Groups | 489.695 | 45 | 10.882 | |||

| Total | 4966.840 | 49 |

| Source of Variation | SS | df | MS | F | p-Value | Fcrit |

|---|---|---|---|---|---|---|

| Between Groups | 28.472 | 4 | 7.118 | 43.455 | 6.61 × 10−11 | 2.759 |

| Within Groups | 4.095 | 25 | 0.164 | |||

| Total | 32.567 | 29 |

| Source of Variation | SS | df | MS | F | p-Value | Fcrit |

|---|---|---|---|---|---|---|

| Between Groups | 83.519 | 4 | 20.880 | 358.546 | 1.11 × 10−21 | 2.759 |

| Within Groups | 1.456 | 25 | 0.058 | |||

| Total | 84.974 | 29 |

| Source of Variation | SS | df | MS | F | p-Value | Fcrit |

|---|---|---|---|---|---|---|

| Between Groups | 0.338 | 4 | 0.084 | 190.466 | 2.47 × 10−18 | 2.759 |

| Within Groups | 0.011 | 25 | 4.43× 10−4 | |||

| Total | 0.349 | 29 |

| Source of Variation | SS | df | MS | F | p-Value | Fcrit |

|---|---|---|---|---|---|---|

| Between Groups | 0.479 | 4 | 0.120 | 74.496 | 1.61 × 10−13 | 2.759 |

| Within Groups | 0.040 | 25 | 0.002 | |||

| Total | 0.519 | 29 |

| Series Code | Compressive Strength [MPa] After | |

|---|---|---|

| 28 Days | 90 Days | |

| MM | 27.01 | 33.28 |

| CM | 43.62 | 52.57 |

| PAI | 62% | 63% |

| Series Code | Mass Loss [%] | LOI [%] | |||

|---|---|---|---|---|---|

| 23–390 °C | 390–520 °C | 520–720 °C | 720–1000 °C | ||

| CM28 | 2.15 | 0.68 | 0.62 | 0.47 | 3.91 |

| CM90 | 2.74 | 0.67 | 0.73 | 0.66 | 4.80 |

| MM28 | 1.66 | 0.73 | 0.53 | 0.38 | 3.30 |

| MM90 | 2.29 | 0.74 | 0.63 | 0.42 | 4.08 |

| Series Code | Amount of | |||||

|---|---|---|---|---|---|---|

| H2O from Ca(OH)2 | Ca(OH)2 | CO2 (520–720 °C) | CO2 (720–1000 °C) | Total of CO2 from CaCO3 | CaCO3 | |

| Coefficient | ×4.11= | ×2.27= | ||||

| CM28 | 0.68 | 2.79 | 0.62 | 0.47 | 1.09 | 2.47 |

| CM90 | 0.67 | 2.75 | 0.73 | 0.66 | 1.39 | 3.16 |

| MM28 | 0.73 | 3.00 | 0.53 | 0.38 | 0.91 | 2.07 |

| MM90 | 0.74 | 3.04 | 0.63 | 0.42 | 1.05 | 2.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stankiewicz, N.; Rutkowska, W. The Possibilities for Using Ash and Slag Waste in Civil Engineering. Appl. Sci. 2025, 15, 11822. https://doi.org/10.3390/app152111822

Stankiewicz N, Rutkowska W. The Possibilities for Using Ash and Slag Waste in Civil Engineering. Applied Sciences. 2025; 15(21):11822. https://doi.org/10.3390/app152111822

Chicago/Turabian StyleStankiewicz, Natalia, and Wioleta Rutkowska. 2025. "The Possibilities for Using Ash and Slag Waste in Civil Engineering" Applied Sciences 15, no. 21: 11822. https://doi.org/10.3390/app152111822

APA StyleStankiewicz, N., & Rutkowska, W. (2025). The Possibilities for Using Ash and Slag Waste in Civil Engineering. Applied Sciences, 15(21), 11822. https://doi.org/10.3390/app152111822