Mechanism and IPOA-ELM Predictive Modeling of Slippage in Traction Elevators

Abstract

1. Introduction

- Through mechanism analysis, the relationships among traction sheave wear, traction capacity, and slippage amount are examined. Based on these analyses, key experimental design input parameters, such as wear amount, load capacity, and wire rope tension, are identified, providing a theoretical foundation for the subsequent model construction and optimization.

- Improvements are made to the POA by introducing adaptive nonlinear weighting factors and Gaussian perturbations to significantly enhance the convergence and global optimization capabilities of IPOA. This enhancement not only improves the model’s stability with small sample data but also enables the more accurate adjustment of ELM parameters when handling specific conditions, such as severe wear or large tension differences, thus enhancing the slippage prediction accuracy. In contrast to the existing POA variants that mainly target the detection or avoidance of local extrema, the proposed IPOA further integrates a bounded sine-based adaptive weight with Halton sequence initialization and Gaussian perturbation. This design expands the effective exploration region in the early iterations while enforcing a controlled late-stage contraction, thereby mitigating premature convergence and yielding faster, smoother convergence under heterogeneous wear and load conditions. Combined with the mechanism-based slippage descriptors adopted in this study, these improvements strengthen robustness and reproducibility relative to prior POA-based approaches.

2. Analysis of the Mechanism of Traction Elevator Slippage

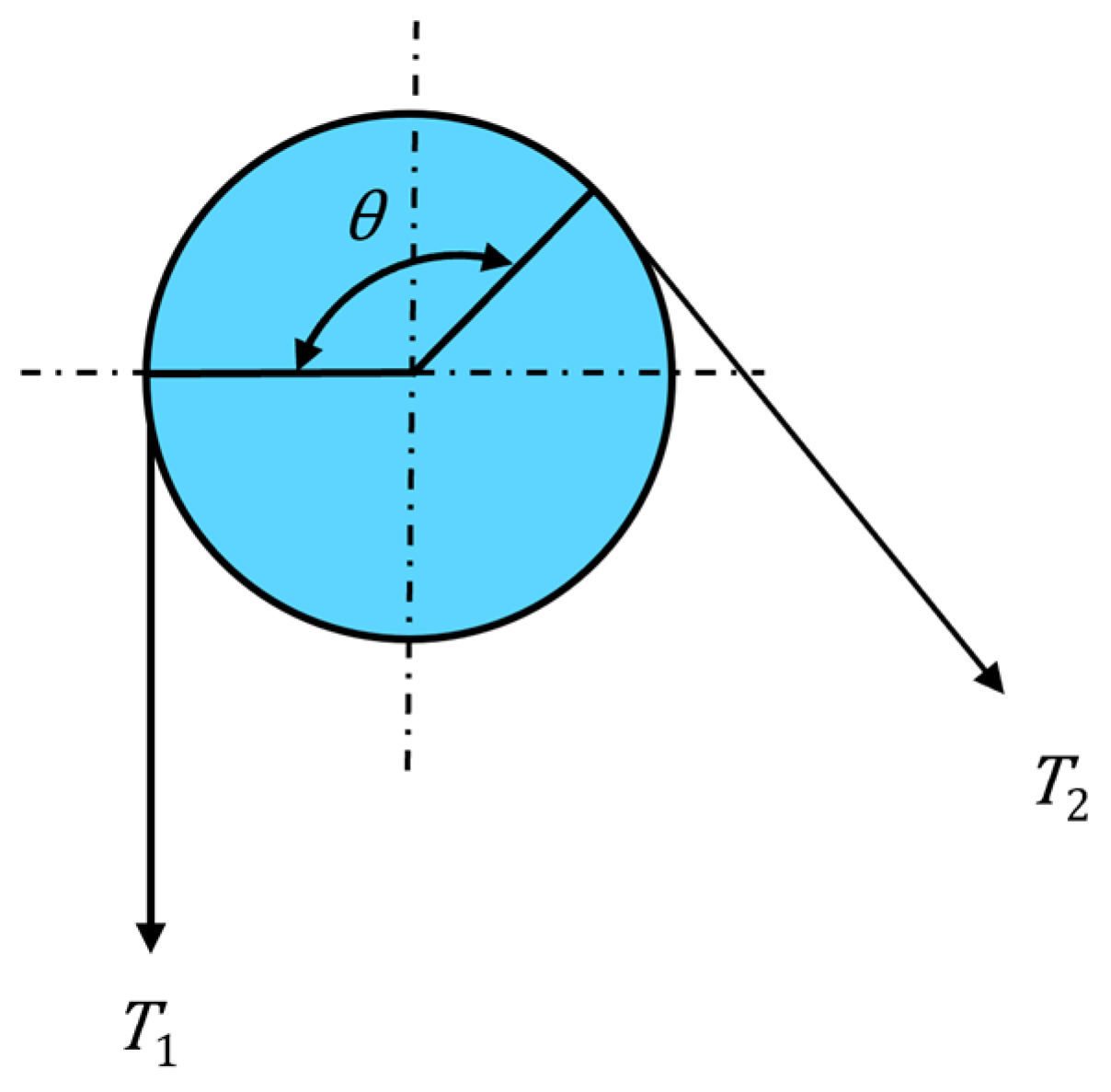

2.1. Traction Conditions of the Sheave Groove

- (1)

- If , the system has sufficient traction force and can operate normally.

- (2)

- If , the system reaches the critical traction force, and the wire rope may slip.

- (3)

- If , the wire rope slips on the traction sheave, and the traction system is in an unsafe state.

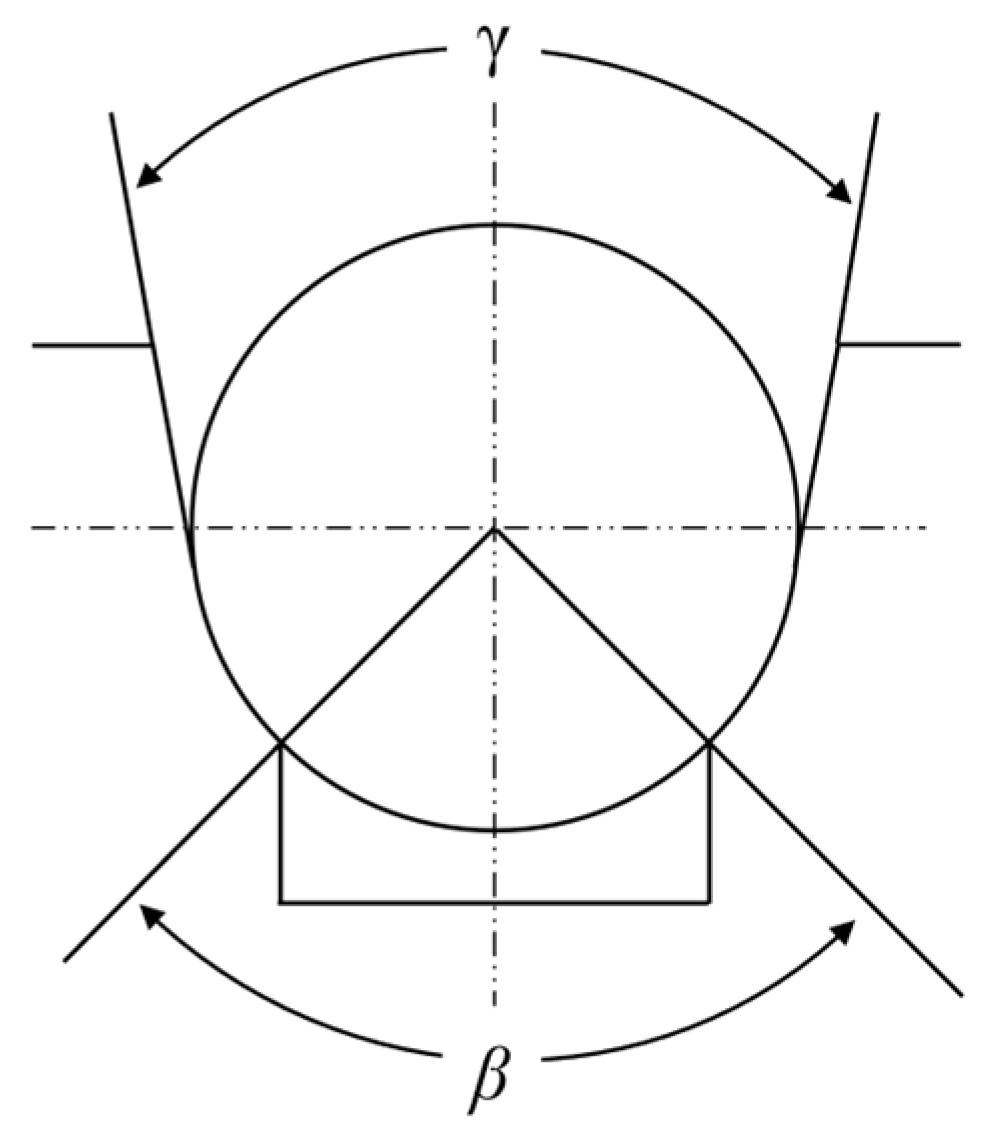

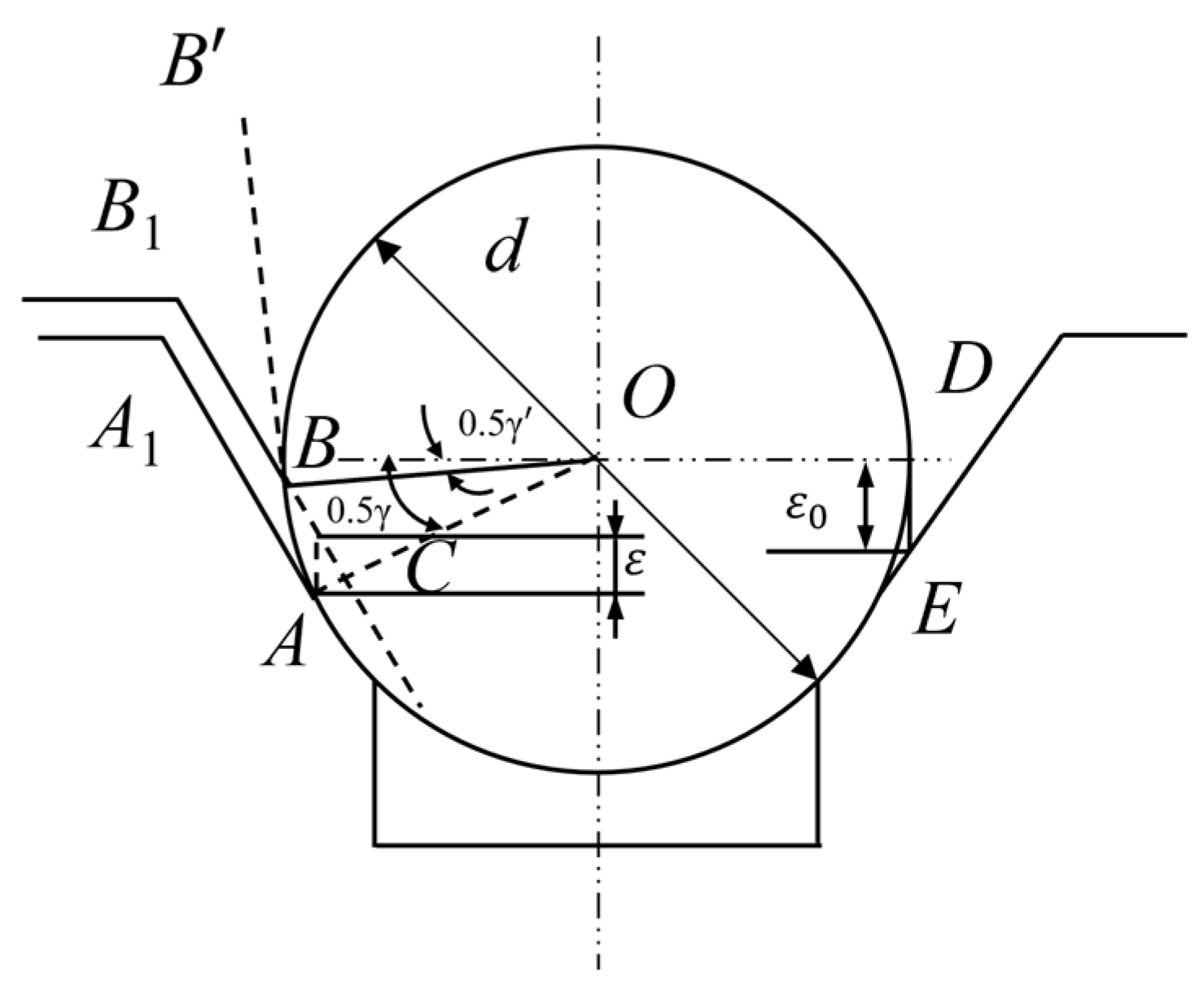

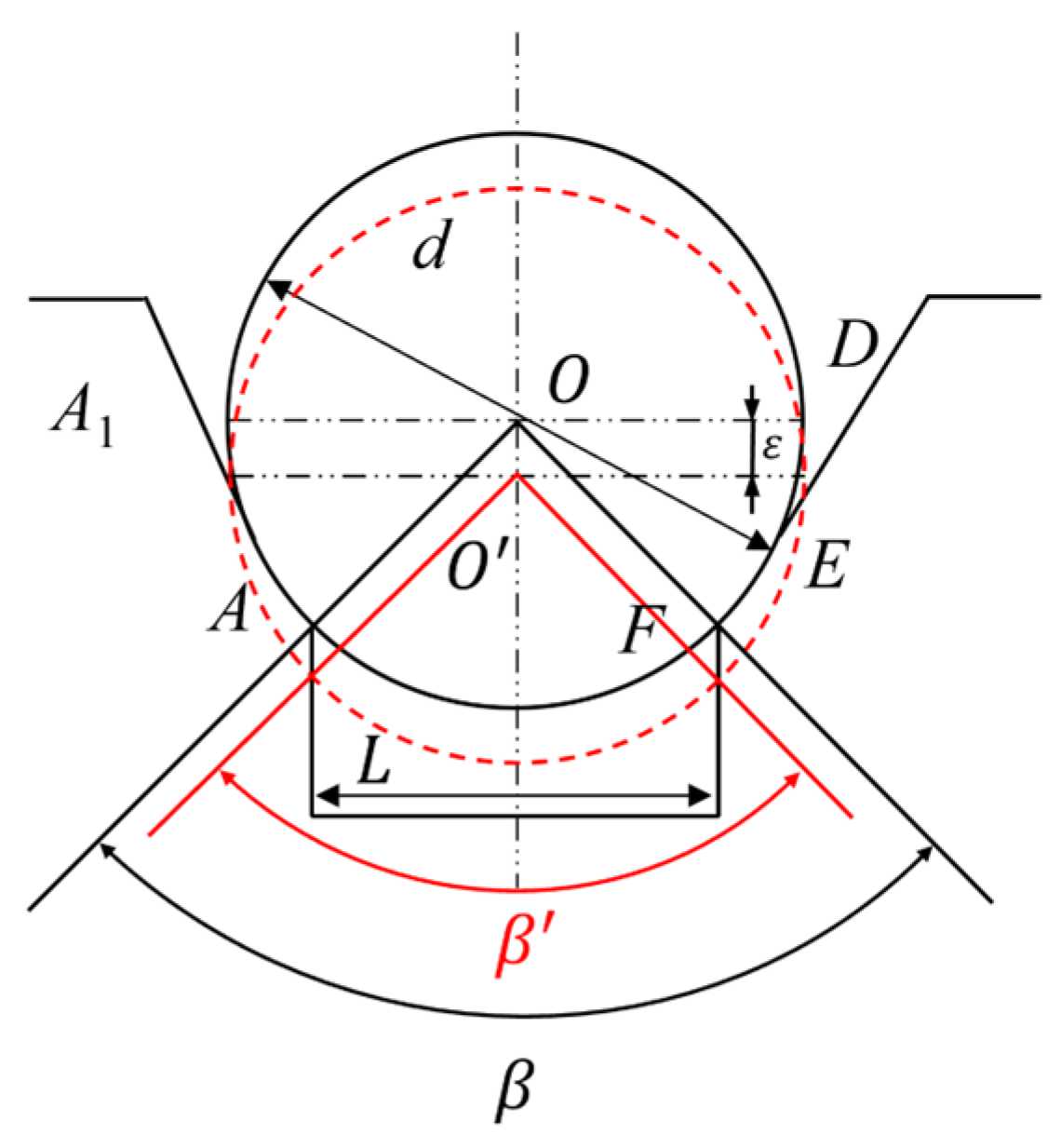

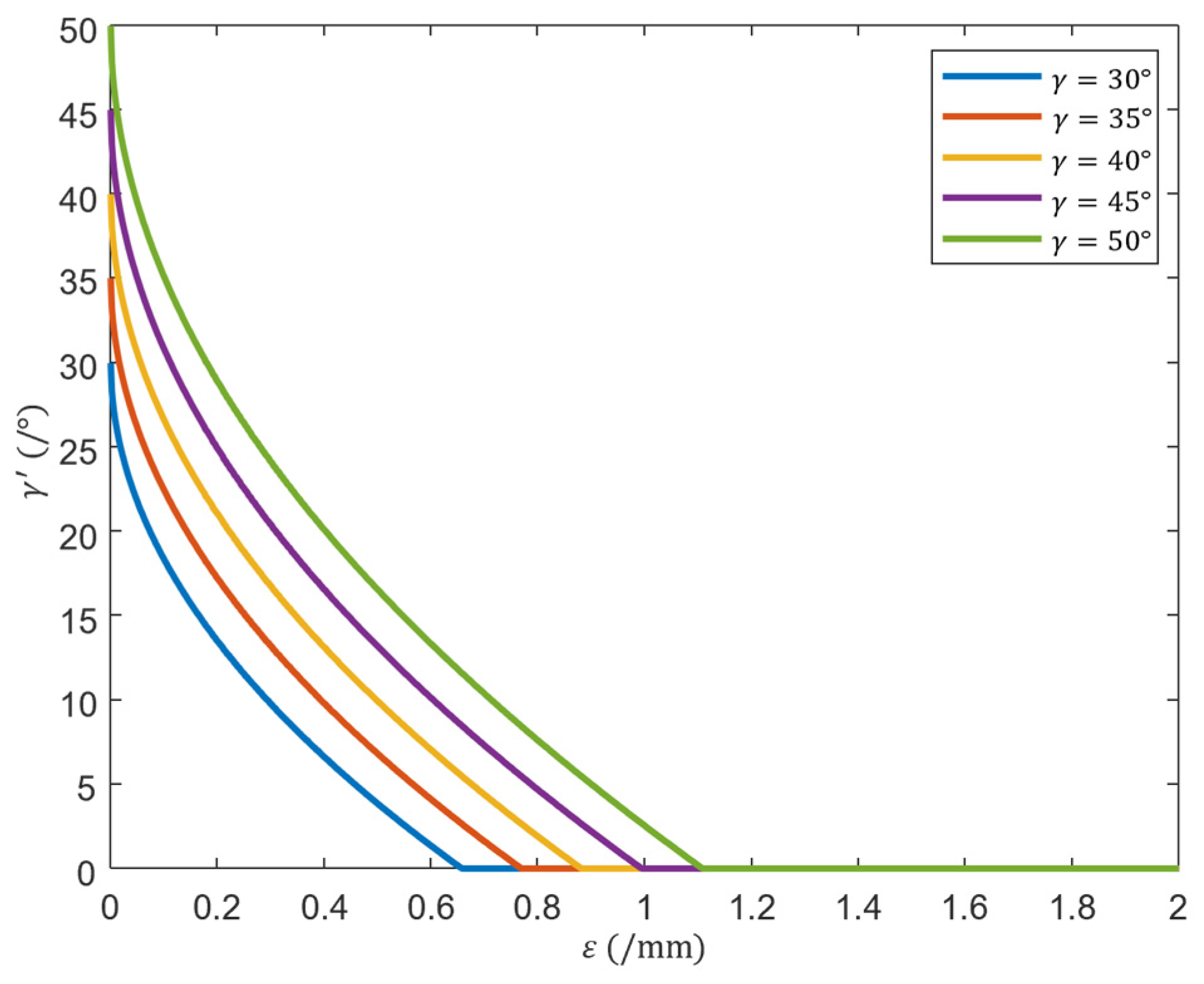

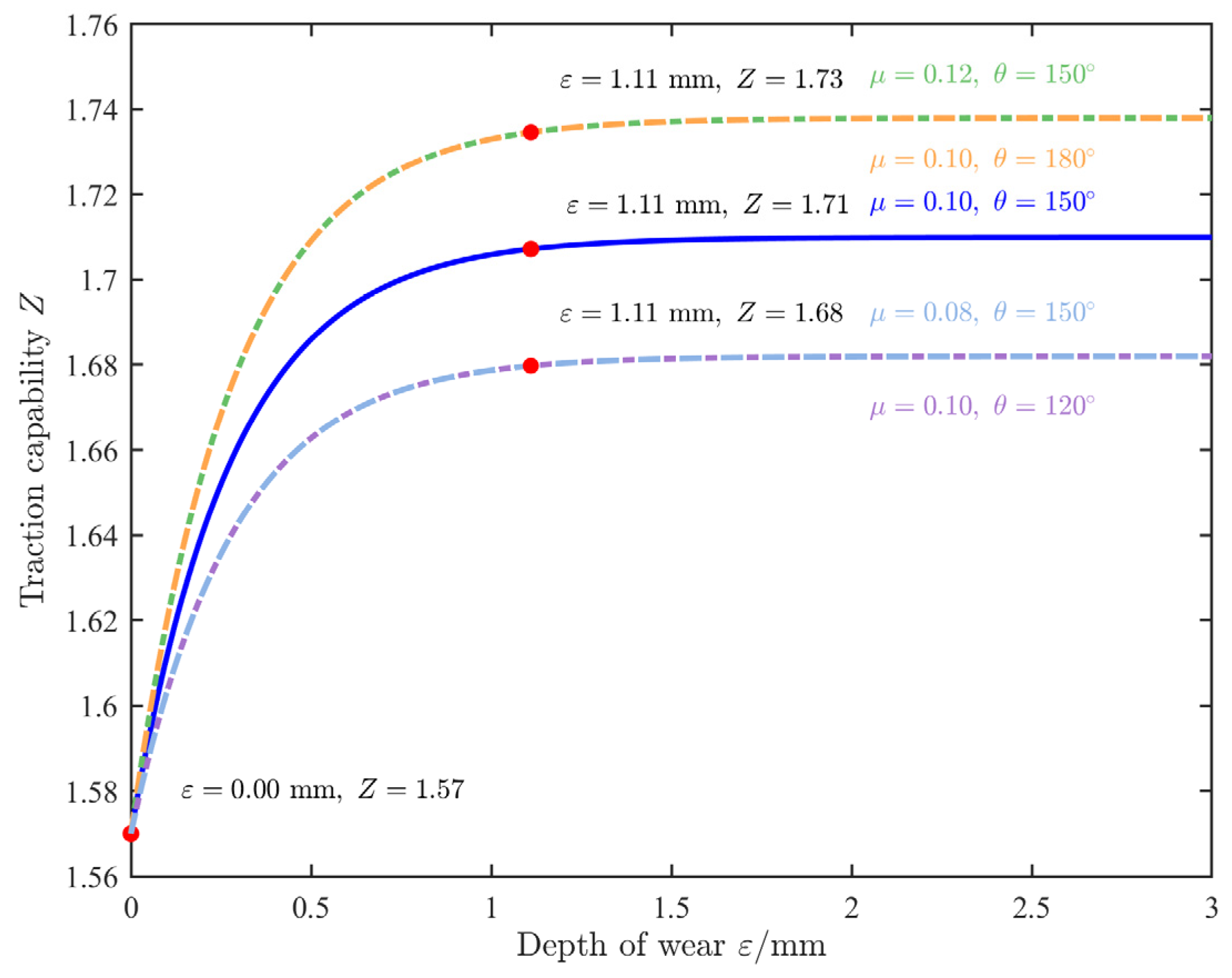

2.1.1. The Impact of Traction Sheave Wear on Traction Capacity

2.1.2. The Relationship Between Groove Wear and Traction Capacity

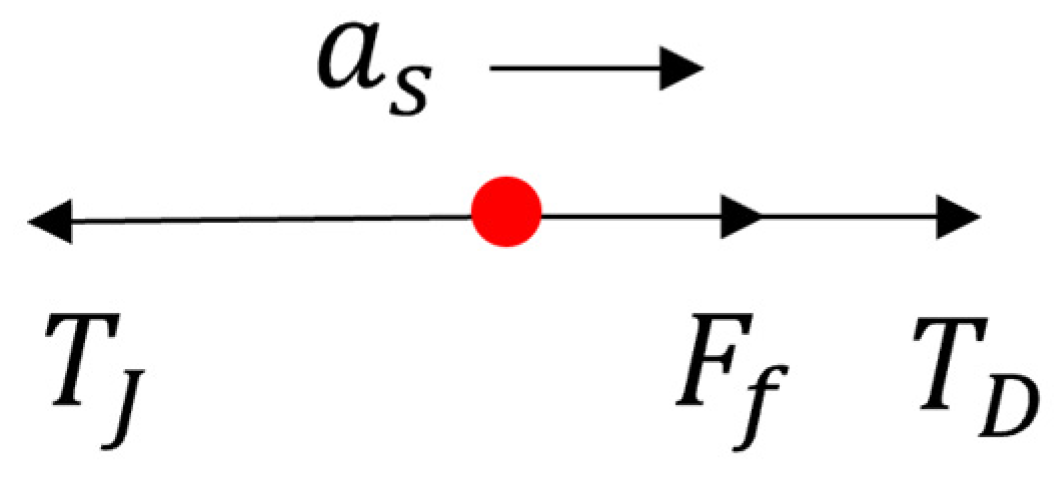

2.2. Analysis of the Slippage Mechanism

2.2.1. Analysis of Slippage in Uniform Motion

2.2.2. Analysis of Slippage During Acceleration and Deceleration Phases

3. Slippage Prediction Method of Wire Rope Based on IPOA-ELM

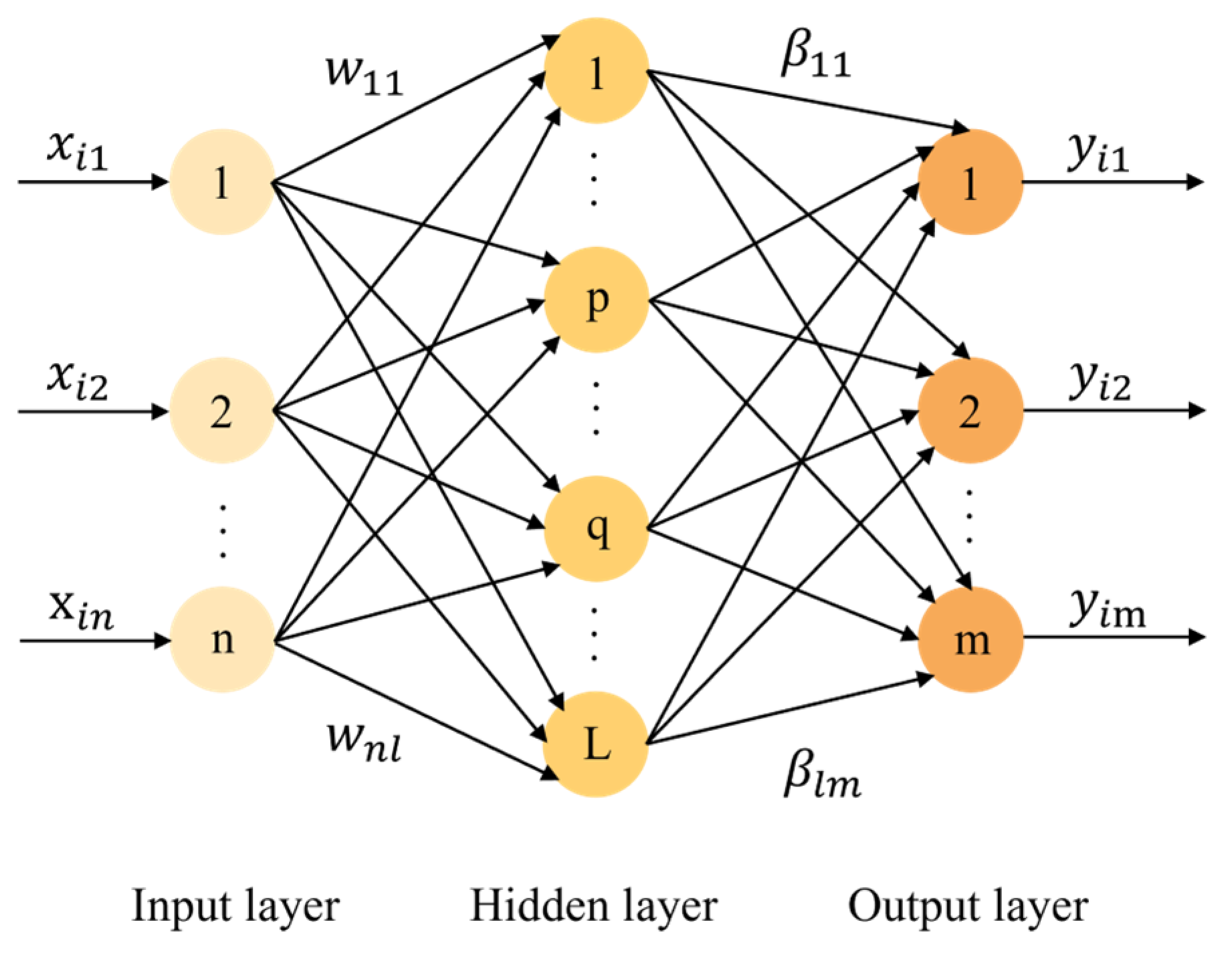

3.1. Extreme Learning Machine Network

3.2. Pelican Optimization Algorithm

- (1)

- Exploration Stage

- (2)

- Exploitation Stage

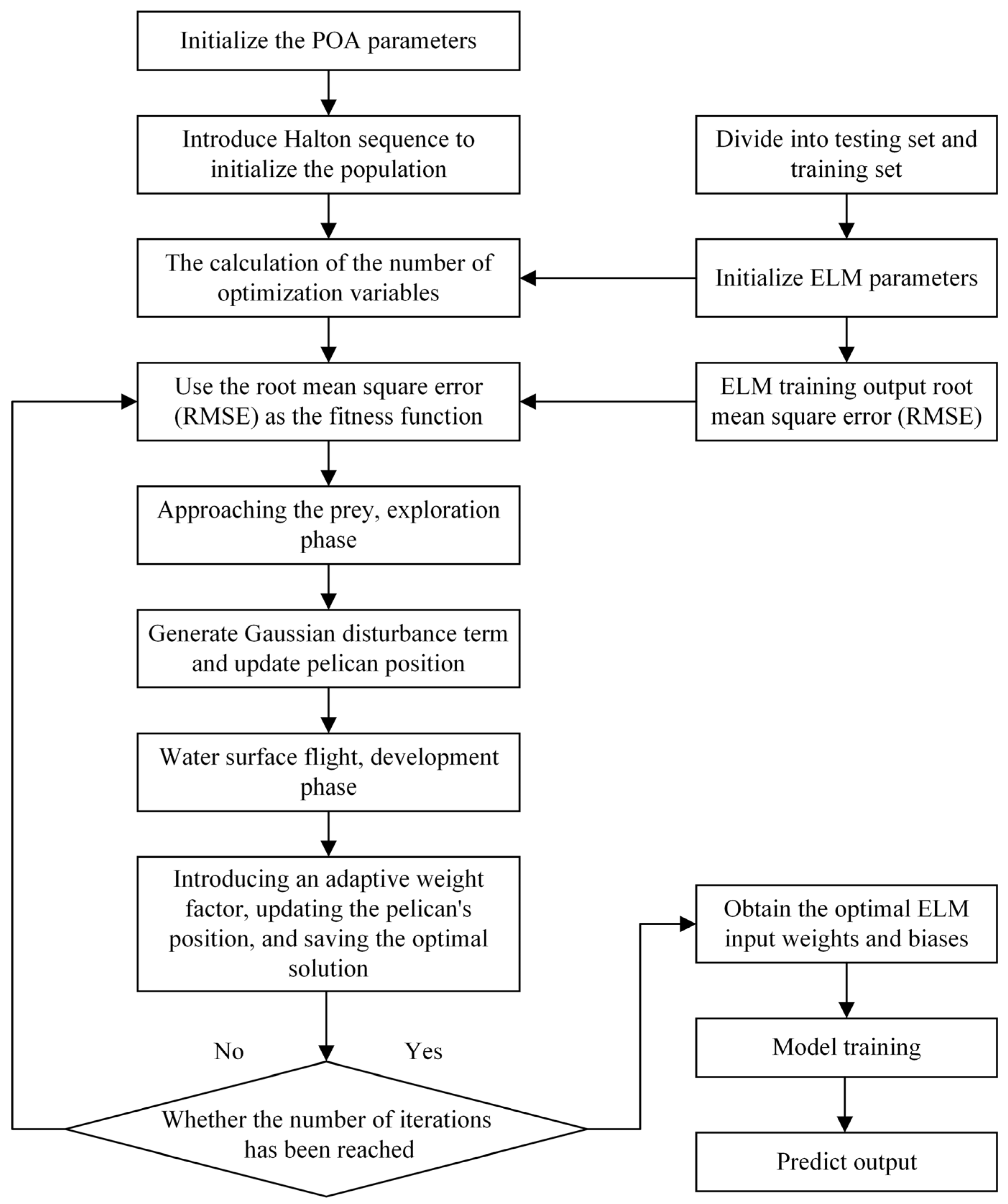

3.3. Improved POA-ELM Algorithm

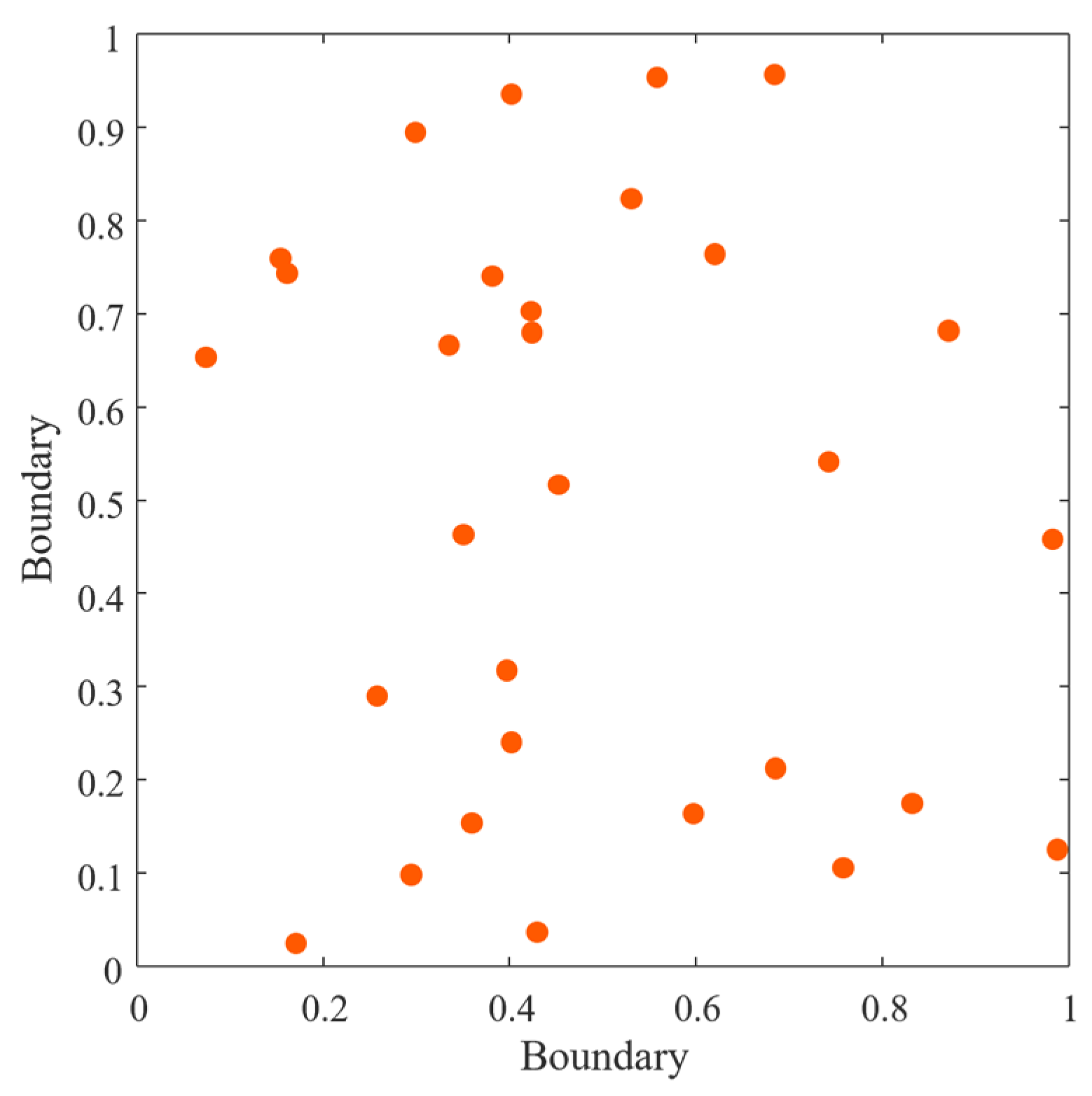

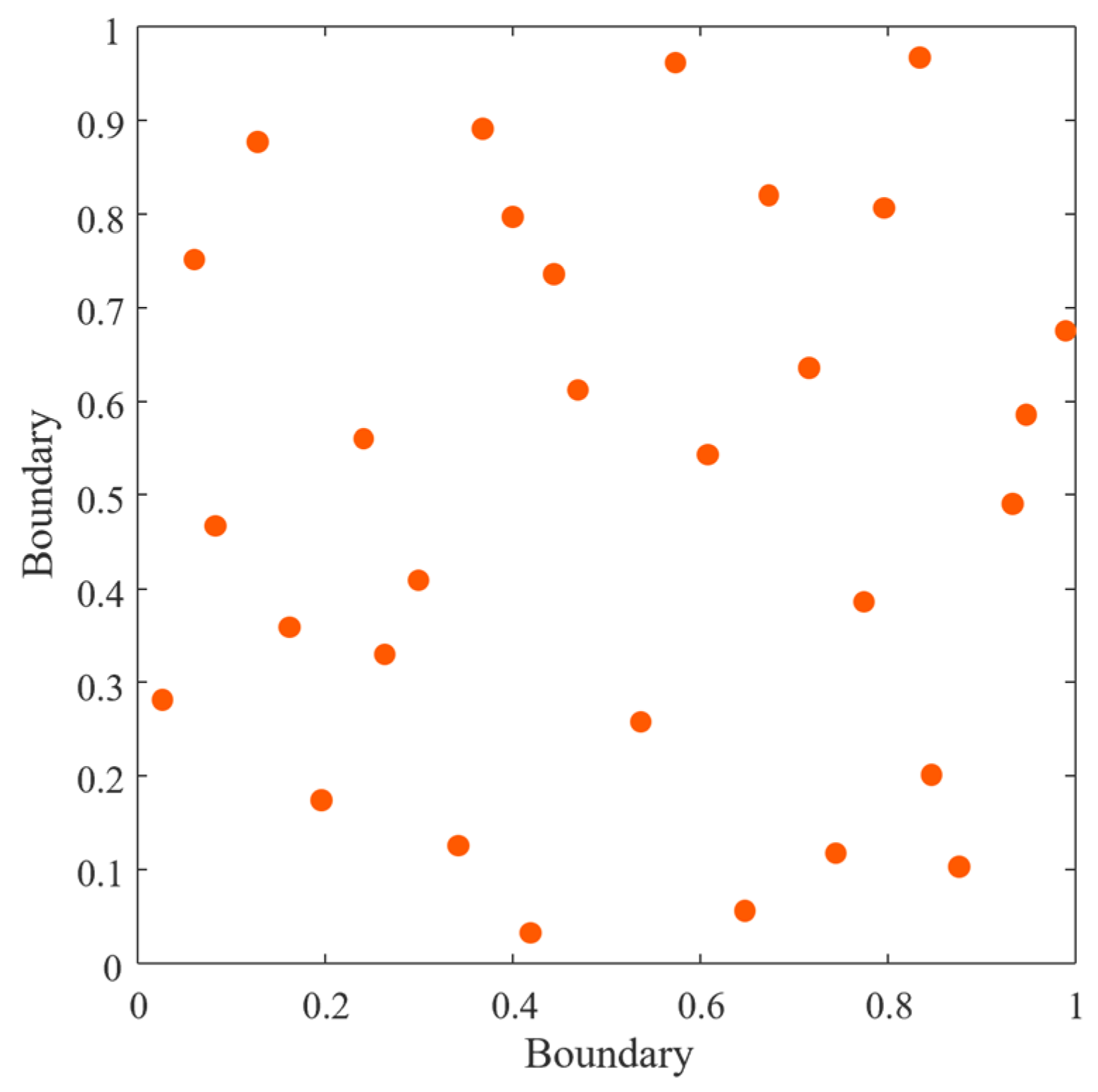

3.3.1. Population Initialization Based on Halton Sequence Mapping

3.3.2. Adaptive Weight Factor

3.3.3. Gaussian Perturbation

3.4. Development of the IPOA-ELM-Based Wire Rope Slippage Prediction Model

- Step 1: Normalize the slippage test dataset. The test data include the wear, load, and tension (T1, T2) of the wire ropes on both sides of the traction sheave, and slippage. To obtain a robust estimate of the generalization performance, we employed repeated k-fold cross-validation. The complete dataset was partitioned into k folds of approximately equal size. During each iteration, one fold was designated as the test set, with the remaining folds forming the training set. We configured and performed repetitions, ensuring that each sample was included in the test set multiple times under varying data partitions. This methodology effectively reduces the variance associated with individual random splits and yields a more stable and reliable estimation of prediction error.

- Step 2: Set the number of hidden-layer nodes of the ELM to 10, choose the Sigmoid activation function, set the pelican population size to 30, and set the maximum number of iterations to 100.

- Step 3: Initialize the pelican population positions using Equation (27), where each pelican’s position represents the weights and biases of the ELM.

- Step 4: Substitute the experimental data and the pelican positions into the ELM prediction model, using the Root Mean Square Error (RMSE) of the prediction model as the fitness value. The calculation formula is as follows:

- Step 5: Use Equations (21) and (22) for exploration updates and apply Equation (29) for Gaussian perturbation.

- Step 6: Use Equations (23) and (24) for exploitation updates, with the adaptive weight defined in Equation (28).

- Step 7: If the current iteration count , repeat steps 4 to 6. If the maximum iteration count is reached, terminate the iteration.

- Step 8: Output the best individual position, which represents the weights and biases of the Extreme Learning Machine (ELM). Then, establish the IPOA-ELM slippage prediction model and perform error analysis and evaluation.

4. Discussion

4.1. Test Data Collection

4.2. Comparison Models and Evaluation Metrics

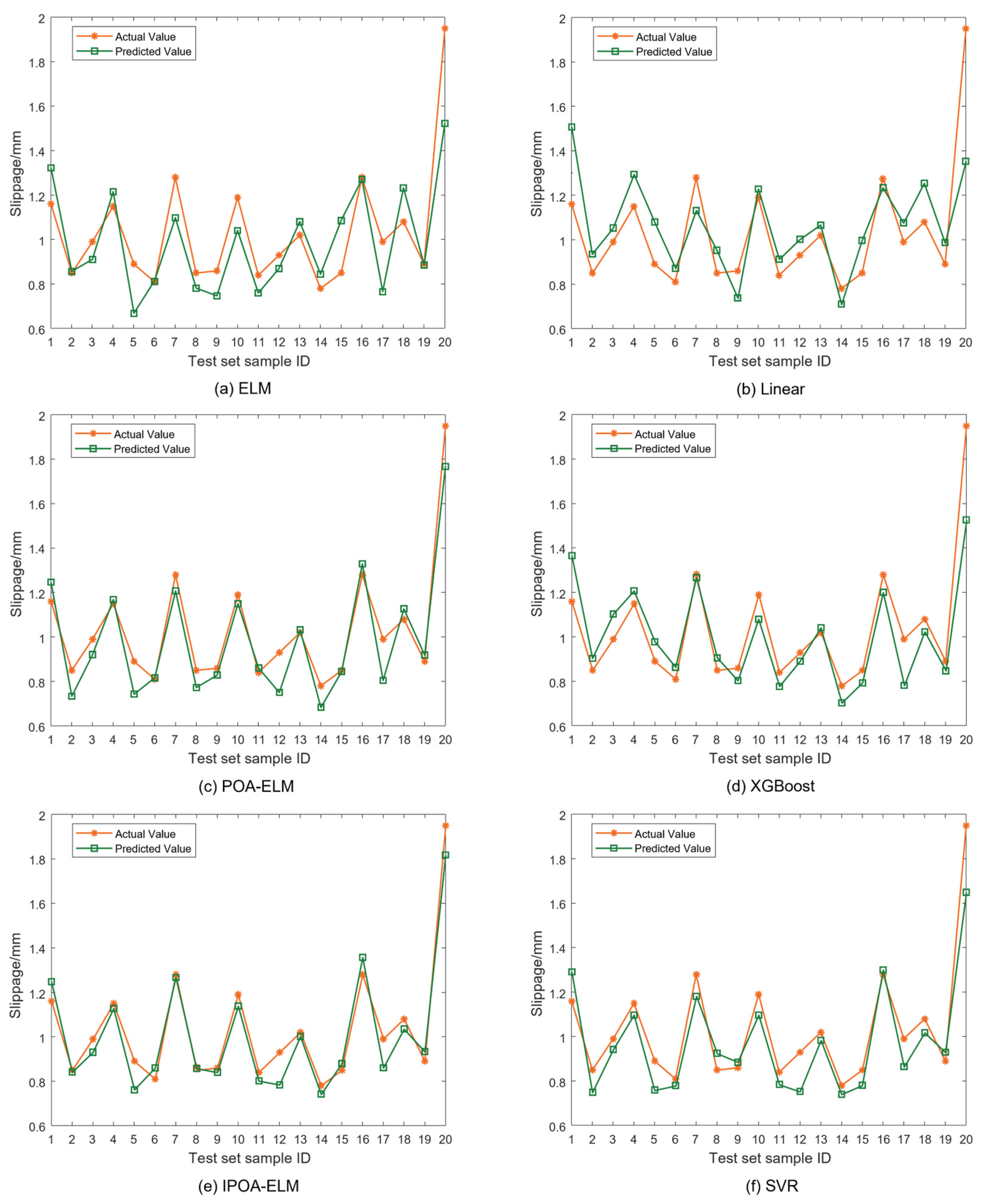

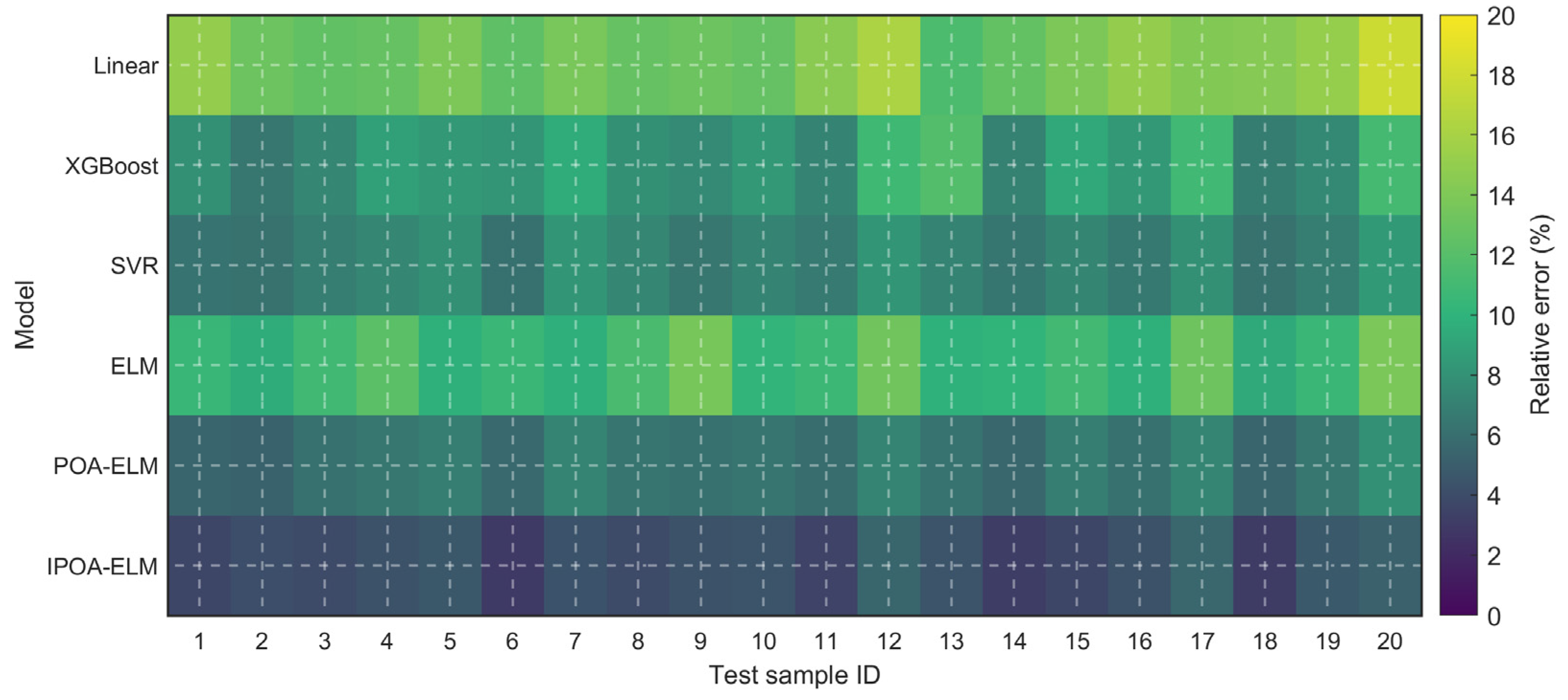

4.3. Prediction Results Analysis

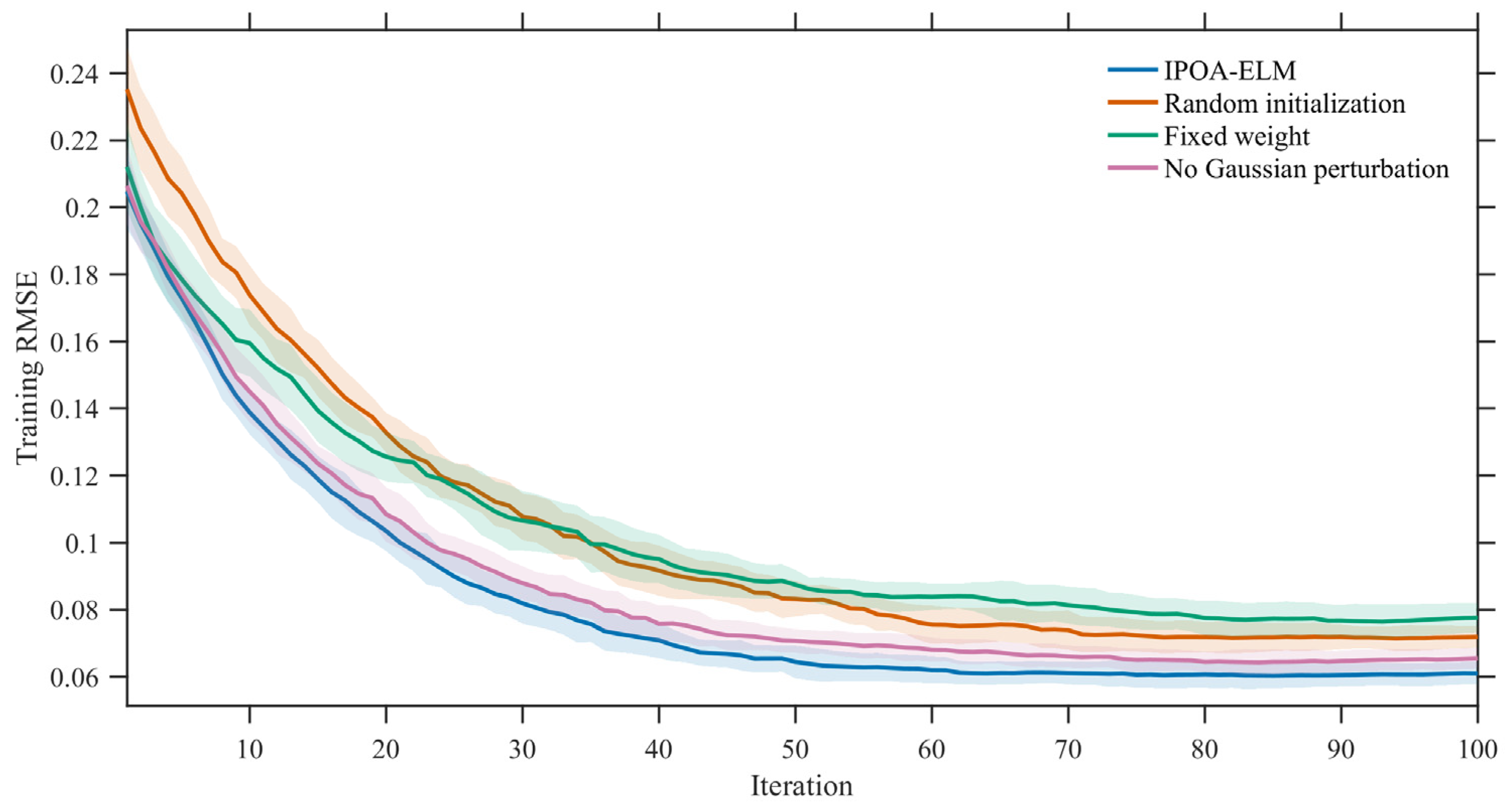

4.4. Ablation Analysis of IPOA-ELM

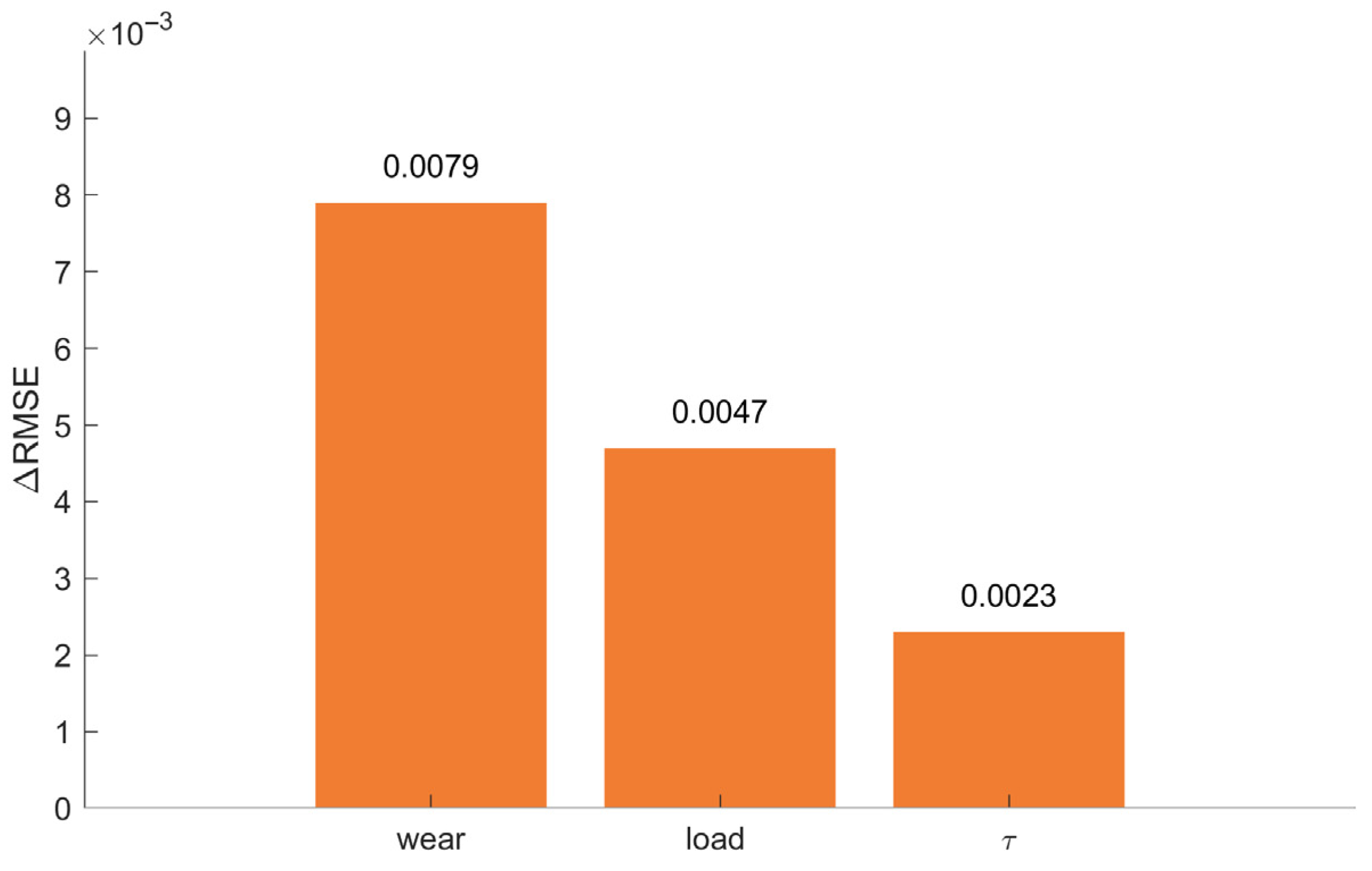

4.5. Robustness and Sensitivity of IPOA-ELM

5. Conclusions

- (1)

- Through the study of the slippage mechanism between the elevator traction sheave and the wire rope, it is found that the equivalent friction coefficient and the rope’s wrap angle on the sheave groove are the key factors determining the traction capacity. For a semicircular groove with a notch, the traction capacity ceases to change once the wear depth reaches a certain level. During constant-speed operation and acceleration/deceleration, the slippage mainly depends on the material properties of the wire rope, the contact length, the load difference, and the wear of the groove. These analyses provide theoretical support for the prediction of elevator slippage. Practically, within the tested operating envelope, wear has the largest marginal impact on slippage. Load is secondary, and the tension ratio is least influential. Accordingly, maintenance should prioritize wear inspection and calibration, followed by load balancing.

- (2)

- The IPOA is improved by introducing the Halton sequence, Gaussian perturbation, and a nonlinear inertia weight factor to optimize the initial weights and biases of the ELM. Comparative experiments indicate that, relative to traditional ELM and POA-ELM, as well as SVR, XGBoost, and a physics-informed linear baseline, IPOA-ELM attains a lower MAE, RMSE, and MAPE and a higher , with a faster and smoother convergence; ablation tests attribute the gains to the combined effect of Halton initialization, the bounded sine-based adaptive weight, and Gaussian perturbation, while robustness checks show a small dispersion under repeated runs and a stable performance under moderate hyperparameter changes. Unlike POA variants that mainly target local-extrema handling, this design enlarges early exploration and enforces a controlled late-stage contraction, yielding consistent advantages in accuracy and stability.

- (3)

- The observed relationship between groove wear and slippage provides a basis for real-time failure risk assessment. By accurately predicting abnormal slippage trends, this method enables the timely identification of traction sheave degradation, supporting the development of predictive maintenance schedules. This contributes to a broader engineering objective of preventing structural or operational failures in elevator systems.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ELM | Extreme Learning Machine |

| POA | Pelican Optimization Algorithm |

| IPOA | Improved Pelican Optimization Algorithm |

| SVR | Support Vector Regression |

| XGBoost | Extreme Gradient Boosting |

| RMSE | Root Mean Square Error |

| MAE | Mean Absolute Error |

| R2 | Coefficient of Determination |

| MAPE | Mean Absolute Percentage Error |

| SD | Standard Deviation |

References

- Zhen, Q.; Wu, Y.; Cong, J.; Lyu, S.-K. Mechanism Design and Experimental Verification of Novel Automatic Balance Equipment for a Rope-Type Elevator. Machines 2022, 10, 1180. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, D.; Zhang, D.; Ge, S.; Araújo, J.A. Dynamic Contact and Slip Characteristics of Bent Hoisting Rope in Coal Mine. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 120. [Google Scholar] [CrossRef]

- Nakazawa, D.; Watanabe, S.; Fukui, D.; Fujii, A.; Miyakawa, K. Elevator Rope Tension Analysis with Uneven Groove Wear of Sheave. J. Phys. Conf. Ser. 2018, 1048, 12006. [Google Scholar] [CrossRef]

- Zheng, Q.; Wang, D.; Zhang, K.; Ma, J.; Ding, G.; Zhang, Y.; Yuan, Z. A Parametric Study on the Fatigue Life of Elevator Brake Wheels under Multi-Field Coupling Effects. Eng. Fail. Anal. 2025, 167, 109061. [Google Scholar] [CrossRef]

- Chen, J.; Jing, L.; Hong, T.; Liu, H.; Glowacz, A. Research on a Sliding Detection Method for an Elevator Traction Wheel Based on Machine Vision. Symmetry 2020, 12, 1158. [Google Scholar] [CrossRef]

- Ma, X.; Pan, Y.; Shi, X. Experimental Investigation of Friction and Slip at the Traction Interface of Rope and Sheave. J. Appl. Mech. 2018, 85, 11006. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, D.; Zhang, X.; Wang, D.; Wang, S. A New Transmission Theory of “Global Dynamic Wrap Angle” for Friction Hoist Combining Suspended and Wrapped Wire Rope. Appl. Sci. 2020, 10, 1305. [Google Scholar] [CrossRef]

- Samal, S.; Dash, R. A Hybrid Fruit Fly ELM Framework for Stock Index Price Movement Prediction. In Proceedings of the 2021 International Conference in Advances in Power, Signal, and Information Technology (APSIT), Bhubaneswar, India, 8–10 October 2021; pp. 1–5. [Google Scholar]

- Li, L.; Liu, K.; Wang, L.; Sun, L.; Zhang, Z.; Guo, H. Fault Diagnosis of Balancing Machine Based on ISSA-ELM. Comput. Intell. Neurosci. 2022, 2022, 4981022. [Google Scholar] [CrossRef] [PubMed]

- Shao, H.; Jiang, H.; Li, X.; Wu, S. Intelligent Fault Diagnosis of Rolling Bearing Using Deep Wavelet Auto-Encoder with Extreme Learning Machine. Knowl.-Based Syst. 2018, 140, 1–14. [Google Scholar] [CrossRef]

- Yang, D.; Yang, K. Multi-Step Prediction of Strong Earthquake Ground Motions and Seismic Responses of SDOF Systems Based on EMD-ELM Method. Soil Dyn. Earthq. Eng. 2016, 85, 117–129. [Google Scholar] [CrossRef]

- Yaseen, Z.M.; Deo, R.C.; Hilal, A.; Abd, A.M.; Bueno, L.C.; Salcedo-Sanz, S.; Nehdi, M.L. Predicting Compressive Strength of Lightweight Foamed Concrete Using Extreme Learning Machine Model. Adv. Eng. Softw. 2018, 115, 112–125. [Google Scholar] [CrossRef]

- Kaloop, M.R.; Kumar, D.; Samui, P.; Gabr, A.R.; Hu, J.W.; Jin, X.; Roy, B. Particle Swarm Optimization Algorithm-Extreme Learning Machine (PSO-ELM) Model for Predicting Resilient Modulus of Stabilized Aggregate Bases. Appl. Sci. 2019, 9, 3221. [Google Scholar] [CrossRef]

- Ge, D.; Zhang, Z.; Kong, X.; Wan, Z. Extreme Learning Machine Using Bat Optimization Algorithm for Estimating State of Health of Lithium-Ion Batteries. Appl. Sci. 2022, 12, 1398. [Google Scholar] [CrossRef]

- Xiong, J.; Peng, T.; Tao, Z.; Zhang, C.; Song, S.; Nazir, M.S. A Dual-Scale Deep Learning Model Based on ELM-BiLSTM and Improved Reptile Search Algorithm for Wind Power Prediction. Energy 2023, 266, 126419. [Google Scholar] [CrossRef]

- Huang, G.; Huang, G.-B.; Song, S.; You, K. Trends in Extreme Learning Machines: A Review. Neural Netw. 2015, 61, 32–48. [Google Scholar] [CrossRef] [PubMed]

- Ding, S.; Zhao, H.; Zhang, Y.; Xu, X.; Nie, R. Extreme Learning Machine: Algorithm, Theory and Applications. Artif. Intell. Rev. 2015, 44, 103–115. [Google Scholar] [CrossRef]

- Li, D.; Li, S.; Zhang, S.; Sun, J.; Wang, L.; Wang, K. Aging State Prediction for Supercapacitors Based on Heuristic Kalman Filter Optimization Extreme Learning Machine. Energy 2022, 250, 123773. [Google Scholar] [CrossRef]

- Wang, J.; Lu, S.; Wang, S.-H.; Zhang, Y.-D. A Review on Extreme Learning Machine. Multimed. Tools Appl. 2022, 81, 41611–41660. [Google Scholar] [CrossRef]

- Trojovsky, P.; Dehghani, M. Pelican Optimization Algorithm: A Novel Nature-Inspired Algorithm for Engineering Applications. Sensors 2022, 22, 855. [Google Scholar] [CrossRef]

- Krömer, P.; Platoš, J.; Snášel, V. Differential Evolution for the Optimization of Low-Discrepancy Generalized Halton Sequences. Swarm Evol. Comput. 2020, 54, 100649. [Google Scholar] [CrossRef]

- Qiao, L.; He, N.; Cui, Y.; Zhu, J.; Xiao, K. Reservoir Porosity Prediction Based on BiLSTM-AM Optimized by Improved Pelican Optimization Algorithm. Energies 2024, 17, 1479. [Google Scholar] [CrossRef]

- Lv, L.; Zhao, J. The Firefly Algorithm with Gaussian Disturbance and Local Search. J. Signal Process. Syst. 2018, 90, 1123–1131. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Number of floors | 2 | Number of ropes | 5 |

| Floor height | 3.5 m | Acceleration | 0.3 m/s2 |

| Elastic modulus | Number of grooves | 5 | |

| Rated load | 1000 kg | Rated speed | 0.6 m/s |

| Traction ratio | 1:1 | Traction sheave diameter | 400 mm |

| Groove type | Semicircular groove | Wire rope diameter | 10 mm |

| Balance coefficient | 0.45 |

| Wear Amount (mm) | Load Weight (%) | T1 (N) | T2 (N) | Slippage (mm) |

|---|---|---|---|---|

| 0 | 0 | 1483 | 1893 | 0.10 |

| 0 | 100 | 2648 | 1861 | 0.17 |

| 0 | 125 | 2891 | 1911 | 0.32 |

| 0.5 | 0 | 1428 | 1905 | 0.71 |

| 0.5 | 100 | 2618 | 1832 | 0.88 |

| 0.5 | 125 | 2924 | 1921 | 1.13 |

| 1 | 0 | 1479 | 1887 | 0.6 |

| 1 | 100 | 2588 | 1802 | 0.74 |

| 1 | 125 | 2949 | 1911 | 0.99 |

| 2 | 0 | 1449 | 1882 | 0.72 |

| 2 | 100 | 2641 | 1832 | 0.9 |

| 2 | 125 | 2920 | 1920 | 1.22 |

| 4 | 0 | 1452 | 1901 | 0.59 |

| 4 | 100 | 2662 | 1859 | 0.73 |

| 4 | 125 | 3049 | 2018 | 0.94 |

| 5 | 0 | 1459 | 1895 | 0.69 |

| 5 | 100 | 2660 | 1901 | 0.76 |

| 5 | 125 | 2941 | 2020 | 1.31 |

| 6 | 0 | 1488 | 1921 | 0.78 |

| 6 | 100 | 2575 | 1825 | 0.91 |

| 7 | 125 | 1475 | 1903 | 0.74 |

| 7.3 | 0 | 1492 | 1912 | 0.71 |

| Model | MAE | RMSE | MAPE (%) | |

|---|---|---|---|---|

| Linear | 0.1120 | 0.1404 | 0.7101 | 12.0 |

| ELM | 0.1015 | 0.1272 | 0.7619 | 10.9 |

| XGBoost | 0.0734 | 0.0920 | 0.8758 | 7.9 |

| SVR | 0.0698 | 0.0875 | 0.8874 | 7.5 |

| POA-ELM | 0.0669 | 0.0838 | 0.8961 | 7.2 |

| IPOA-ELM | 0.0479 | 0.0603 | 0.9471 | 5.1 |

| Setting | MAE | RMSE | %Improvement | |

|---|---|---|---|---|

| IPOA-ELM | 0.0487 | 0.0610 | 0.9445 | — |

| Random initialization | 0.0574 | 0.0719 | 0.9228 | 15.2% |

| Fixed weight | 0.0619 | 0.0776 | 0.9101 | 21.4% |

| No Gaussian perturbation | 0.0523 | 0.0655 | 0.9360 | 6.9% |

| Setting | L | Activation | Validation RMSE (Mean ± SD) |

|---|---|---|---|

| Baseline | 10 | Sigmoid | 0.057 ± 0.004 |

| Vary L down | 8 | Sigmoid | 0.061 ± 0.005 |

| Vary L up | 12 | Sigmoid | 0.060 ± 0.005 |

| Change activation | 10 | Tanh | 0.059 ± 0.004 |

| Change activation | 10 | ReLU | 0.063 ± 0.006 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Yu, P.; Chen, J.; Wang, Q. Mechanism and IPOA-ELM Predictive Modeling of Slippage in Traction Elevators. Appl. Sci. 2025, 15, 11802. https://doi.org/10.3390/app152111802

Wang Y, Yu P, Chen J, Wang Q. Mechanism and IPOA-ELM Predictive Modeling of Slippage in Traction Elevators. Applied Sciences. 2025; 15(21):11802. https://doi.org/10.3390/app152111802

Chicago/Turabian StyleWang, Yanqi, Ping Yu, Jiayan Chen, and Quan Wang. 2025. "Mechanism and IPOA-ELM Predictive Modeling of Slippage in Traction Elevators" Applied Sciences 15, no. 21: 11802. https://doi.org/10.3390/app152111802

APA StyleWang, Y., Yu, P., Chen, J., & Wang, Q. (2025). Mechanism and IPOA-ELM Predictive Modeling of Slippage in Traction Elevators. Applied Sciences, 15(21), 11802. https://doi.org/10.3390/app152111802