Abstract

This study investigates the long-term mechanical and microstructural behavior of high-performance concrete (HPC), incorporating hybrid mixtures of coal bottom ash (CBA) and waste foundry sand (WFS) as sustainable mineral additives. The experimental program included evaluation of physical parameters (porosity, water absorption, and density), mechanical properties (compressive, splitting tensile, flexural strength, and elastic modulus), ultrasonic pulse velocity (UPV), and microstructural observations by scanning electron microscopy (SEM). The incorporation of CBA and WFS up to 30 wt% modified the pore structure and densified the matrix, leading to improved long-term strength and durability. The BA25FS5 and BA20FS10 mixtures exhibited the most balanced performance, showing compressive strengths up to 86 MPa at 730 days and UPV exceeding 4.5 km/s (measured at 730 days). SEM analysis confirmed a dense C–S–H network and strong ITZ bonding in hybrid concretes. Empirical models, including Ryshkevich, Balshin, and ACI–fib correlations, accurately described the relationships between porosity, density, and mechanical properties, achieving coefficients of determination above 0.9. The results demonstrate that the combined use of CBA and WFS enhances microstructural refinement, stiffness, and long-term performance while promoting sustainable utilization of industrial by-products in high-performance concrete.

1. Introduction

The construction industry is one of the largest consumers of natural resources and contributors to global CO2 emissions. Concrete production alone accounts for more than 50% of raw material extraction worldwide, leading to growing concerns about the depletion of natural aggregates and environmental sustainability [1,2]. The increasing scarcity of high-quality sand and gravel, combined with the environmental impact of mining operations, has driven the search for alternative materials in concrete production. Industrial by-products such as coal bottom ash (CBA, also referred to as coal slag or boiler slag) and waste foundry sand (WFS) have attracted significant attention due to their abundance, favorable chemical composition, and potential to replace natural aggregates [3,4,5,6].

Coal bottom ash is produced as a coarse residue during coal combustion in thermal power plants, typically constituting 10–25% of the total coal ash output [7]. It is characterized by irregular particle shapes, porous texture, and variable carbon content, which may limit its direct use in concrete [8]. Nevertheless, numerous studies have reported that CBA can be used as a partial replacement for fine or coarse aggregate, with varying effects on mechanical strength and durability [9,10,11]. Recent comprehensive reviews confirm that controlled substitution of 10–30% CBA can improve strength, durability, and sustainability of concrete while reducing CO2 emissions and landfill waste [12]. While moderate replacement levels often lead to satisfactory performance, excessive amounts can cause reductions in workability, increased porosity, and decreased elastic modulus [13,14,15].

Waste foundry sand, generated during metal casting processes, represents another major waste stream, with global annual production estimated at 6–10 million tons [16,17]. Foundries reuse sand multiple times in molding cycles. However, after repeated use, it becomes unsuitable for further casting and is disposed of as waste. WFS consists primarily of high-purity silica coated with residual binders such as clays, resins, and carbonaceous materials, which affect its engineering behavior [18]. Research has shown that WFS can successfully replace natural sand in concrete mixtures at levels up to 20–30% without significantly reducing compressive strength or durability [19,20,21,22]. At higher replacement levels, however, mechanical performance and microstructural integrity are often compromised [23,24,25].

Recent studies have highlighted the synergistic benefits of combining multiple waste materials in concrete. In particular, simultaneous use of CBA and WFS has been shown to improve particle packing, reduce porosity, and enhance long-term strength development [26,27,28]. Similar synergistic approaches combining bottom ash with other secondary aggregates such as fly ash or recycled concrete have also demonstrated enhanced mechanical performance and workability in self-compacting concrete [29]. In a recent pilot investigation, Smarzewski [30] reported that an optimal total replacement percentage of waste materials could be established, balancing sustainability benefits with satisfactory mechanical performance. That study demonstrated that moderate levels of combined CBA and WFS resulted in improved compressive strength and denser microstructures compared to the reference mix.

Despite these promising findings, most available studies have focused on early-age properties (28–90 days), with very limited data on the long-term behavior and microstructural evolution of high-performance concretes incorporating both CBA and WFS. In particular, the durability-related indicators such as ultrasonic pulse velocity (UPV) after extended curing, as well as microstructural evidence from scanning electron microscopy (SEM) of the interfacial transition zone (ITZ), remain insufficiently documented.

Therefore, this study extends the author’s previous optimization work [19], which identified the optimal total substitution range of 30% (CBA + WFS) as ensuring a balanced compromise between mechanical performance and workability in high-performance concrete. Building on these findings, the present research investigates the long-term compressive strength, UPV, and microstructural performance of hybrid CBA–WFS mixtures. The experimental program covers compressive strength development up to 730 days, splitting tensile and flexural strengths at 28 and 56 days, static modulus of elasticity at 28 days, and UPV at 730 days. The findings aim to clarify the long-term correlations between strength, density, porosity, and UPV, as well as to verify microstructural coherence at the ITZ level. Overall, the study provides new insights into the feasibility of using combined industrial by-products as sustainable constituents of durable high-performance concrete.

2. Materials and Methods

2.1. Materials

Ordinary Portland cement CEM I 42.5 R (CEMEX, Chełm, Poland) was used as the primary binder. Densified silica fume (SF) was dosed at 5% by mass of cement. Natural river sand (0–2 mm) served as fine aggregate and crushed granite (2–16 mm) as coarse aggregate in the reference mixture. Two industrial by-products replaced part of the natural aggregates: (i) coal bottom ash (CBA) used as a coarse aggregate substitute, and (ii) waste foundry sand (WFS) used as a fine aggregate substitute. A polycarboxylate ether superplasticizer (PCE) was used to achieve target workability. Potable tap water was used for mixing and curing.

The coal bottom ash used in this study originated from a local combined heat and power plant in Lublin, collected from boiler hoppers after bituminous coal combustion. The waste foundry sand was obtained from a local gray cast-iron foundry located in the Lublin region, consisting mainly of silica sand with residual clay and resin films typical of molding sands.

Only the minimum characteristics necessary for mix design are reproduced here. Comprehensive physical/chemical and microstructural data for the CBA (phase assemblage, LOI, radioactivity indices, EDX) and WFS (oxide chemistry, grading) have been reported previously [19,30]. In brief, the CBA was a porous, largely siliceous–aluminous clinker (typical SiO2 ≈ 50%, Al2O3 ≈ 24–27%, LOI ≈ 7–13%), with specific gravity 1.2–1.8 and high open porosity. SEM/EDX and XRD confirmed quartz–mullite–glass matrices and good paste–slag adhesion at suitable replacement levels. The WFS was a silica-rich fine sand with minor clay/coal residues and near-neutral pH, used here as a fine aggregate substitute.

Both materials were oven-dried before batching to remove residual moisture and ensure consistent mass balance. The CBA was sieved to the 2–16 mm range to match the reference coarse aggregate, and the WFS was used in its as-received grading (<2 mm) typical of foundry molding sands. No additional cleaning or crushing procedures were intentionally applied, as the study aimed to assess the performance of readily available industrial by-products under realistic reuse conditions. After preparation, both wastes were stored in sealed containers until mixing.

Aggregates met the grading requirements for concrete aggregates (sieving per PN-EN 933-1 [31]). Cement conformed to PN-EN 197-1 [32]. Admixture data (density 1.07 g·cm−3 at 20 °C; chloride ≤ 0.1% mass; alkalis ≤ 1.5% mass) were provided by the manufacturer.

2.2. Mixture Proportions

Four concrete series were produced at a constant binder content mb = 372 kg·m−3 (cement 353.4 kg·m−3 + SF 18.6 kg·m−3) and water-to-binder ratio w/b = 0.50 (water 186 L·m−3). The series differed only in aggregate substitutions by mass:

- Series 1 (REF): 0% CBA, 0% WFS (natural sand + granite only)

- Series 2 (BA25FS5): 25% CBA (replacing granite) + 5% WFS (replacing natural sand)

- Series 3 (BA20FS10): 20% CBA + 10% WFS

- Series 4: 15% CBA + 15% WFS.

The total aggregate content was maintained at approximately 1770 kg·m−3 (fine-to-coarse ratio ≈ 1:2.3) to preserve packing density. The target fresh density was approximately 2330 kg·m−3 across all series, following a constant-solids approach. The dosage of polycarboxylate ether (PCE) superplasticizer was fixed at 5.9 L·m−3 for all mixtures, corresponding to 0.9% by binder mass, to ensure consistent workability and comparable slump. The selected replacement ratios (BA25FS5, BA20FS10, and BA15FS15) were derived from the author’s previous optimization study [19], which demonstrated that moderate combined levels of CBA and WFS (totaling around 30%) preserve mechanical performance while improving sustainability. Higher overall substitutions were shown to reduce early-age strength due to increased porosity and weaker interfacial transition zones (ITZs). Accordingly, the present research investigates three representative combinations at constant total replacement (30%) to elucidate the influence of varying BA/WFS ratios on long-term behavior.

2.3. Experimental Program

The test matrix covered mechanical, physical and microstructural properties:

- compressive strength at 28, 56 and 730 days;

- splitting tensile strength and flexural tensile strength at 28 and 56 days;

- static modulus of elasticity at 28 days;

- bulk density, open porosity and water absorption at 28 days;

- ultrasonic pulse velocity (UPV) at 730 days;

- SEM for selected series at 730 days to interpret ITZ and pore features.

The selected testing ages were chosen to represent key stages of mechanical performance development in high-performance concretes containing industrial by-products. The 28-day age corresponds to the conventional reference period for strength classification. The 56-day interval reflects the secondary hydration and strength stabilization phase, when pozzolanic and latent hydraulic reactions of coal bottom ash and foundry sand typically become more pronounced. The 730-day tests (two years) were included to assess the long-term strength evolution under combined curing conditions, where specimens were water-cured up to 56 days and subsequently stored under stable laboratory conditions (20 ± 2 °C, RH ≈ 75%) without additional humidity control, representing natural drying and carbonation exposure typical of real service conditions. This approach enabled the evaluation of intrinsic material stability and delayed pozzolanic effects representative of realistic structural exposure. Microstructural observations were limited to 730 days, providing a qualitative assessment of the mature matrix and interfacial transition zones.

2.4. Specimen Production and Curing

All aggregates were oven-dried before batching to remove free moisture. No pre-saturation was applied. Instead, the total water content was corrected based on aggregate absorption values determined according to ASTM C642 [33] to maintain a consistent effective water-to-binder ratio (w/b = 0.50) across all series.

Dry constituents (sand, granite and/or CBA, cement, SF, WFS) were premixed, followed by addition of ~80% of the mixing water with dissolved PCE. The remainder of water was added progressively to reach target consistency. Mixing continued until a uniform appearance was obtained. The mixture was considered uniform when no visible segregation or dry pockets were present, and the paste fully coated the aggregates with consistent color and texture. All mixes exhibited comparable consistency, with only a slightly stiffer appearance observed in those containing waste materials (CBA and WFS), which did not affect compaction or subsequent strength development.

Specimens were cast as 100 × 100 × 100 mm cubes (compressive, splitting), 50 × 50 × 250 mm prisms (flexural), and Ø150 × 300 mm cylinders (modulus). Fresh specimens were compacted by table vibration, covered to prevent evaporation, demolded at 24 ± 2 h, and water-cured at 20 ± 2 °C to the test ages. The cylinder end faces were ground before modulus testing to ensure planarity.

2.5. Test Methods and Standards

Mechanical and physical tests were performed in accordance with European standards, complemented by widely adopted ASTM procedures.

Compressive strength was tested on 100 mm cubes in a 3000 kN servo-hydraulic testing frame at a constant loading rate of 0.6 MPa·s−1, in accordance with PN-EN 12390-3 [34]. The cube surfaces were loaded directly without capping, as the casting faces ensured sufficient planarity and smoothness.

Splitting tensile strength was determined according to PN-EN 12390-6 [35] on identical cubes using 3 mm thick hardboard strips placed along the loading lines to ensure even stress distribution and prevent local crushing.

Flexural strength was measured on 50 × 50 × 250 mm prisms under a third-point loading configuration, following PN-EN 12390-5 [36]. The span between supports was 150 mm, and the load was applied at a constant rate of 0.05 MPa·s−1 until failure.

Static modulus of elasticity was determined on Ø150 × 300 mm cylinders in accordance with PN-EN 12390-13 [37]. Cylinder ends were ground to ensure planarity prior to testing. Two opposite clip-on extensometers were mounted on a rigid frame (gauge length 210 mm; resolution ± 1 µm) to record axial strain. The hydraulic press executed six controlled loading–unloading cycles between a lower stress of approximately 0.5 MPa and an upper level corresponding to about 0.33 fcm, where fcm denotes the average compressive strength of the series at the test age. The loading rate was 9 kN s−1, with a 60 s hold at the maximum load in each cycle. The tangent modulus Ecm was evaluated from the stabilized cycle within this quasi-elastic range. Symmetry of deformation was checked by comparing opposite extensometers, with deviations limited to ≤10%.

Bulk density of hardened concrete followed PN-EN 12390-7 [38], whereas open porosity and water absorption were assessed by mass change using the immersion/boiling procedure in ASTM C642 [33], with oven-dry and vacuum-saturated conditions defined therein.

Ultrasonic pulse velocity (UPV) was measured by direct transmission across 100 mm cubes in accordance with PN-EN 12504-4 [39]. Instrument calibration, transducer coupling, and path length were verified before each series, and interpretation of velocity ranges referenced established non-destructive testing guidance [40]. UPV was measured only at 730 days to provide an endpoint quality index under a matured microstructure.

Microstructural examinations were carried out by scanning electron microscopy (SEM). Backscattered electron imaging was used to enhance phase contrast and delineate the interfacial transition zone (ITZ), characterize WFS and CBA inclusions, and paste–aggregate interfaces. Small fragments were taken from the central zone of the cubes after completion of the splitting tensile tests, ensuring that the observed microstructure represented the interior of the specimen and not the exposed surface. The observations were performed using a FEI Quanta 250 FEG scanning electron microscope (FEI, Hillsboro, OR, USA) operated in high-vacuum mode. The samples were embedded in epoxy resin, polished, and gold-coated prior to imaging. Sample preparation and acquisition parameters followed the protocols reported in the prior characterization studies [19,30].

The complete workflow of material preparation, curing, and testing adopted in this study is illustrated in Figure 1.

Figure 1.

Experimental program flow diagram. Arrows indicate the chronological sequence.

2.5.1. Sampling, Numbers and Statistics

For each series and age, n = 3 specimens were tested per property (compressive: 3 per age; splitting/flexural: 3 per age; modulus: 3 cylinders per series at 28 d, duplicated where scatter exceeded 10%). Reported values are arithmetic means. Dispersion is expressed as standard deviation. Any set with coefficient of variation > 10% was repeated. All statistical analyses were performed using one-way ANOVA with Tukey’s Honestly Significant Difference (HSD) post hoc test at a 95% confidence level (α = 0.05). The effect size was quantified by eta-squared (η2) to assess the proportion of total variance explained by the mix composition. Normality and homoscedasticity assumptions were verified prior to testing using the Shapiro–Wilk and Levene tests, respectively.

2.5.2. Rationale for Selected Ages

Short and medium-term (28, 56 d) results capture early densification effects of SF and the influence of WFS/CBA porosity on strength gain. 730 d extends the window to observe long-term microstructural development and the known tendency of slagged mixes to catch up or even surpass reference compressive strength, despite slightly lower stiffness or UPV due to aggregate porosity. This was documented in related long-term campaigns on coal-slag HPC [30] and is leveraged here to benchmark trends.

3. Results

3.1. Physical Properties

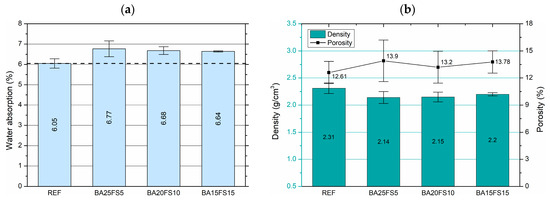

Figure 2a shows that water absorption increased slightly after incorporating CBA and WFS: 6.05% (REF) vs. 6.64–6.77% (CBA/WFS), i.e., a 0.6–0.7 pp absolute rise (10–12% relative). Open porosity also rose modestly from 12.61% (REF) to 13.2–13.9% (Figure 2b), while bulk density decreased from 2.31 g/cm3 to 2.14–2.20 g/cm3. The standard deviations are small and the error bars overlap in several cases (notably BA20FS10 vs. BA15FS15), indicating small effect sizes.

Figure 2.

(a) Water absorption of REF and CBA/WFS concretes (mean ± SD); (b) bulk density (bars, left axis) and open porosity (squares with error bars, right axis). Numerical labels denote mean values.

Mechanistically, these shifts are consistent with the lower specific gravity and higher intrinsic porosity/roughness of CBA particles and with surface coatings/binder residues present in WFS, which increase water demand and can weaken the ITZ, leading to slightly higher accessible pore volume. The trends were repeatedly reported for WFS/CBA systems (e.g., modest density drops and absorption/porosity increases at moderate replacement levels) [20,24,41]. Among tested mixes, BA20FS10 exhibits the lowest porosity (13.2%) within the waste series, whereas BA15FS15 shows the lowest absorption (6.64%) and the highest density (2.20 g/cm3) among CBA/WFS variants. Given the overlapping SDs, the data suggest that moderate total waste contents (25–30% combined CBA + WFS) can maintain physical properties close to REF, aligning with prior evidence that ≤20% WFS (as sand replacement) and moderate CBA levels limit penalties in transport-related parameters [20,24], and with observations for SCC that optimized fines packing can reduce capillary uptake despite waste additions [41].

Two practical implications emerge. First, the density drop (up to 7%) is modest and typical for CBA/WFS concretes. It should be factored into mixture design where density is performance-critical (radiation shielding or mass-related design checks). Second, the slight increases in absorption/porosity are small enough that downstream durability indicators (UPV, chloride penetration) may remain acceptable. Indeed, several studies report that with proper proportioning and curing, long-term compactness and matrix refinement can offset early-age transport penalties [24,30].

3.2. Mechanical Properties

3.2.1. Compressive Strength

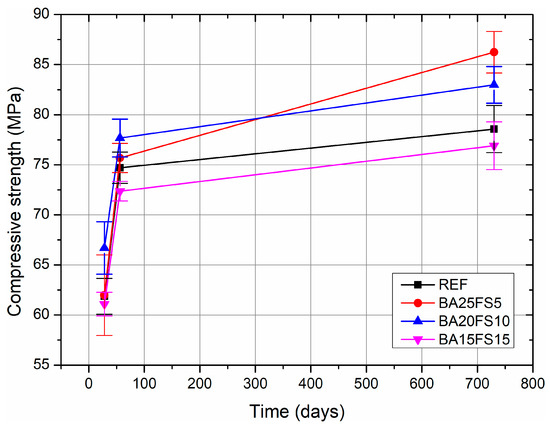

The evolution of compressive strength at 28, 56 and 730 days is plotted in Figure 3 (mean of n = 3, whiskers denote SD). At 28 days, BA20FS10 attains the highest average strength (66.7 MPa), followed by BA25FS5 (62.0 MPa, larger scatter), BA15FS15 (61.1 MPa) and REF (61.9 MPa). Between 28 and 56 days, all mixes show a marked gain (16–22%), while the late-age gain (from 56 to 730 days) differentiates the systems. BA25FS5 exhibits the strongest continued development (14%, 86.2 MPa at 730 d), BA20FS10 shows a moderate increase (6.9%, 83.0 MPa), and BA15FS15 is the lowest (6.3%, 76.9 MPa), close to REF (5.2%, 78.6 MPa). Overall, between 28 and 730 d, growth is 39% (BA25FS5), 24.5% (BA20FS10), and 25.9% (BA15FS15) compared to 26.9% (REF).

Figure 3.

Time evolution of compressive strength for REF and BA/FS concretes at 28, 56, and 730 days (mean ± SD, n = 3).

Two features stand out. First, the BA/FS concretes do not suffer any early-age penalty relative to REF. The 28-day means are comparable or higher (BA20FS10), consistent with improved particle packing from a balanced CBA–WFS blend. Second, the pronounced late-age gain of BA25FS5 indicates sustained matrix densification (continued hydration/latent pozzolanic effects and ITZ refinement), which is frequently reported for waste-modified systems when the total waste content is moderate. In contrast, the higher WFS fraction (BA15FS15) tracks slightly below REF at all ages, in line with literature noting that elevated WFS contents can increase ITZ porosity and capillary connectivity, limiting long-term strength development.

Linking to physical properties (see Section 3.1), BA20FS10 combines the lowest open porosity (13.2%) among waste mixes with a high 730-day strength (83.0 MPa), while BA25FS5 (despite slightly higher porosity than BA20FS10) delivers the top strength at 730 days (86.2 MPa), suggesting that microstructural factors beyond bulk porosity (e.g., ITZ quality and pore size distribution) govern the late-age response. This behavior aligns with prior findings for WFS/CBA concretes that moderate replacement levels can maintain or improve strength by enhancing packing and long-term compactness, whereas higher FS shares tend to dampen the rate of strength gain.

From a practical standpoint, both BA25FS5 and BA20FS10 meet a high-performance threshold at 730 days (=83–86 MPa). The BA25FS5 variant appears optimal for long-term compressive strength, while BA20FS10 offers the best 28-day performance with a robust long-term outcome. Visually, error-bar overlap is most noticeable at 28 days for BA25FS5 (higher scatter), and minimal at 730 days, supporting the above ranking. To quantify between-mix effects at each age, a one-way ANOVA with Tukey’s HSD (α = 0.05) was performed. At 28 days the mix factor was not statistically significant (F(3,8) = 2.83, p = 0.106; η2 = 0.515), confirming that the early-age differences observed in Figure 3 are small relative to within-group scatter. At 56 days the mix effect became significant (F(3,8) = 6.39, p = 0.016; η2 = 0.705), with Tukey’s test indicating BA20FS10 > BA15FS15 (Δ = 5.30 MPa, p = 0.011). All other pairwise contrasts remained non-significant. At 730 days a clear separation emerged (F(3,8) = 11.49, p = 0.0029; η2 = 0.812): BA25FS5 outperformed REF (Δ = 7.68 MPa, p = 0.011), and both BA25FS5 and BA20FS10 were superior to BA15FS15 (Δ = 9.34 MPa, p = 0.003 and Δ = 6.09 MPa, p = 0.036, respectively), while BA25FS5 and BA20FS10 were statistically indistinguishable. These results corroborate the time–strength profiles in Figure 3, highlighting BA25FS5 as the best long-term performer and BA20FS10 as the strongest at 28 days with a robust 730-day outcome.

3.2.2. Splitting Tensile Strength and Flexural Strength

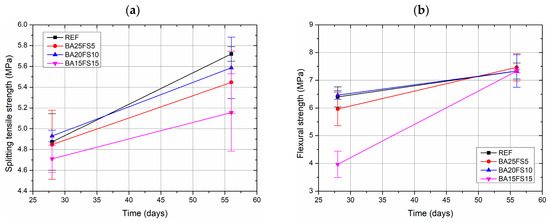

The development of splitting tensile and flexural strengths for the reference and CBA/WFS concretes is presented in Figure 4a and Figure 4b, respectively.

Figure 4.

Splitting tensile strength (a) and flexural strength (b) of REF and CBA/WFS concretes at 28 and 56 days (mean ± SD, n = 3).

At 28 days, the splitting tensile strength of all CBA/WFS mixes remained comparable to the control, ranging between 4.7 and 4.9 MPa. The one-way ANOVA confirmed that the mix factor was not statistically significant (F(3,8) = 0.51, p = 0.687, η2 = 0.16), and no pairwise differences were detected by Tukey’s HSD. At 56 days, all mixtures exhibited a uniform strength gain, reaching 5.2–5.7 MPa, and the ANOVA again showed no significant differences (F(3,8) = 2.18, p = 0.168, η2 = 0.45). These findings indicate that moderate incorporation of CBA and WFS does not compromise tensile behavior, which aligns with prior research demonstrating similar or slightly improved bond integrity and ITZ densification when industrial by-products are used in optimized proportions [5,20,24].

In contrast, the flexural strength at 28 days showed a more distinct differentiation among the mixtures. While REF, BA25FS5, and BA20FS10 achieved comparable average values (6.0–6.5 MPa), the BA15FS15 series exhibited a markedly lower mean of 4.0 MPa. The one-way ANOVA indicated a highly significant effect of the mix factor (F(3,8) = 22.45, p < 0.001, η2 = 0.86). Tukey’s post hoc test revealed that BA15FS15 was significantly lower than BA20FS10 (Δ = 2.50 MPa, p = 0.0005), BA25FS5 (Δ = 2.00 MPa, p = 0.002), and REF (Δ = 2.43 MPa, p = 0.0006). However, by 56 days, all mixtures converged to similar values between 7.0 and 7.8 MPa, and the differences became statistically insignificant (F(3,8) = 0.08, p = 0.97, η2 = 0.03). This time-dependent recovery suggests a progressive densification of the matrix and improvement of the interfacial transition zone (ITZ) due to pozzolanic and filler effects, as reported in Martins et al. [41] and Di Maida et al. [42].

The results collectively imply that the tensile strength of CBA/WFS concretes is less sensitive to the waste replacement level than the flexural response, which is more influenced by the early-stage ITZ quality. In particular, the BA25FS5 and BA20FS10 mixtures demonstrated stable tensile performance and full flexural strength recovery by 56 days, confirming their structural applicability. These outcomes are in agreement with previous findings on long-term mechanical enhancement and microstructural refinement in CBA-based HPC systems [24,30].

3.2.3. Modulus of Elasticity

The 28-day modulus of elasticity (E) shows a clear mix effect (Figure 5). Average values (mean ± SD, n = 3) were REF 38.93 ± 0.82 GPa, BA25FS5 31.72 ± 0.92 GPa, BA20FS10 31.15 ± 1.16 GPa, and BA15FS15 42.56 ± 0.51 GPa. Thus, mixes with higher CBA content (BA25FS5, BA20FS10) exhibit a reduction of 18–20% relative to REF, whereas BA15FS15 yields a 9% increase over REF.

Figure 5.

Static modulus of elasticity of REF and CBA/WFS concretes at 28 days (mean ± SD, n = 3).

A one-way ANOVA confirmed a highly significant effect of the mix factor (F(3,8) = 120.45, p < 0.001; η2 = 0.98). Tukey’s HSD (α = 0.05) showed:

BA15FS15 > REF (Δ = +3.63 GPa, p = 0.004),

REF > BA25FS5 (Δ = +7.21 GPa, p < 0.001) and REF > BA20FS10 (Δ = +7.78 GPa, p < 0.001),

BA15FS15 > BA25FS5 (Δ = +10.84 GPa, p < 0.001) and BA15FS15 > BA20FS10 (Δ = +11.41 GPa, p < 0.001),

BA25FS5 vs. BA20FS10 not significant (p = 0.858).

Mechanistically, the drop in E for CBA-rich mixes is consistent with the lower stiffness and higher intrinsic porosity of bottom-ash particles, which reduces the load-bearing skeleton and increases matrix compliance. Trends widely reported for CBA/WFS concretes at comparable replacement levels [20,24]. By contrast, BA15FS15 combines the lowest CBA share with a higher fraction of silica-rich WFS, yielding a stiffer aggregate skeleton and improved fines packing. Since static modulus is strongly governed by aggregate stiffness and packing (more than by modest changes in accessible porosity), E can rise even when open porosity is similar or slightly higher than REF. The observed decoupling between modulus (which peaks for BA15FS15) and early-age flexural strength (which was initially decreased for BA15FS15) indicates that elastic stiffness is dominated by mineralogical stiffness and packing, whereas flexural strength at early age is more sensitive to ITZ quality and microcracking, consistent with Singh and Siddique [5] on ITZ effects and with time-dependent recovery reported for SCC with WFS [41]. In the context of long-term performance, your 730-day compressive-strength gains for BA25FS5 suggest that continued matrix densification can offset a lower 28-day modulus, a pattern often noted for CBA-modified HPC where late-age hydration refines the pore system [30]. For stiffness-critical applications, BA15FS15 provides the highest 28-day elastic modulus, while BA25FS5/BA20FS10 should be selected where late-age compressive strength and sustainability targets dominate and a moderate reduction in 28-day modulus is acceptable.

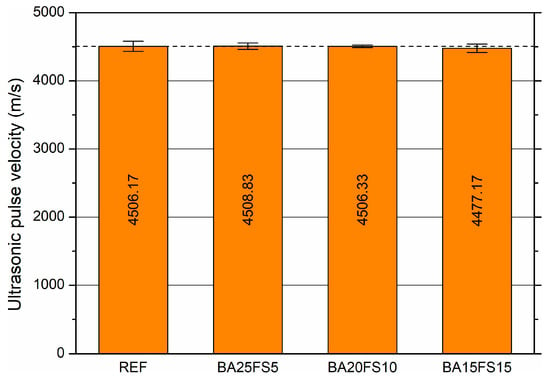

3.2.4. Ultrasonic Pulse Velocity

At 730 days, all concretes exhibit very similar UPV values in the range 4.45–4.51 km/s, with group means (n = 6) of REF 4506 m/s, BA25FS5 4509 m/s, BA20FS10 4506 m/s, and BA15FS15 4477 m/s (Figure 6). The between-mix spread is ≤ 0.7% of the grand mean, and the standard deviations are modest (=50–75 m/s), indicating comparable internal compactness across mixtures. The only visible deviation is the slightly lower mean for BA15FS15, which is consistent with its relatively lower long-term compressive strength (Section 3.2.1) and the literature notion that higher WFS shares can introduce a more porous ITZ and microcracking susceptibility at early ages that may persist locally [5,24].

Figure 6.

Ultrasonic pulse velocity at 730 days for REF and BA/FS concretes (mean ± SD, n = 6).

BA25FS5 shows a marginally higher mean UPV, consistent with its highest 730-day compressive strength; at this single observation age the mixes exhibit comparable internal compactness. An effect repeatedly noted for CBA-modified concretes and SCC with exhaust foundry sand when the total waste level is moderate [20,30,41]. The near-overlap of error bars across groups implies that microstructural quality at 2 years is essentially equivalent, with only small second-order differences driven by ITZ refinement and pore connectivity rather than bulk porosity alone (compare Section 3.1).

From a durability and quality control standpoint, all mixes meet a high UPV benchmark at 730 d, supporting their structural applicability. Mixtures BA25FS5 and BA20FS10 combine high UPV with top long-term compressive strength, which is advantageous for service-life performance predictions using UPV–strength correlations reported for waste-modified HPC [30,41].

3.3. Microstructural Observations

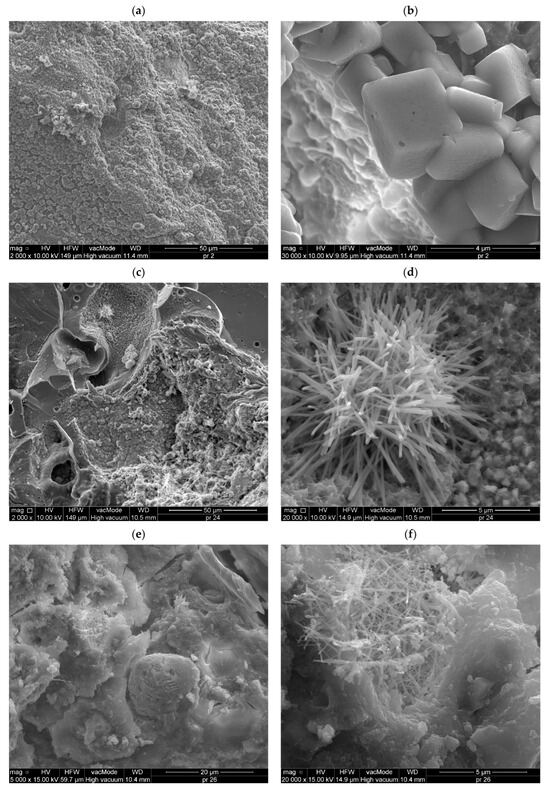

The morphology and microstructure of the raw waste materials (CBA and WFS) were previously characterized in detail by the author [19]. In the present study, SEM observations were limited to the 730-day age to capture the fully developed matrix and interfacial transition zones (ITZ), representative of the mature microstructural state after long-term curing. The SEM images (Figure 7a–f) provide microstructural evidence supporting the physical and mechanical performance trends discussed in the previous sections.

Figure 7.

SEM micrographs of (a,b) REF, (c,d) BA20FS10, and (e,f) BA15FS15 concretes showing typical microstructural features (hydration products, C–S–H gel, and ITZ morphology).

The reference concrete (Figure 7a,b) reveals a relatively dense cement matrix with residual portlandite crystals and partially hydrated C–S–H clusters. The surface is moderately compact, but small capillary voids and localized porosity can still be identified. In contrast, the BA20FS10 mixture (Figure 7c,d) exhibits a notably refined microstructure, where fine coal slag particles act as secondary nucleation sites promoting the formation of well-distributed hydration products. The abundant formation of fibrous and globular C–S–H gels and needle-like ettringite clusters suggests an extended hydration process and improved packing density. This morphology is consistent with earlier SEM observations of waste-based HPCs [19,30], confirming that hybrid CBA–WFS systems sustain long-term hydration and microstructural stability through the coexistence of fibrous and globular C–S–H phases. This agrees with the long-term strength development and stable UPV results (Section 3.2), which both indicate improved matrix densification after 730 days.

In the BA15FS15 composite (Figure 7e,f), the microstructure is even more compact, featuring closely packed grains and cohesive bonding at the ITZ, with fewer disconnected pores. The presence of both plate-like and acicular hydrates (C–S–H and ettringite) indicates a well-developed secondary hydration mechanism. Such morphology correlates with the highest static modulus of elasticity (Section 3.2.3), confirming that increased stiffness originates from the microstructural integrity of the aggregate–matrix interface.

These findings are consistent with the literature on waste-derived concretes incorporating finely divided by-products. Similar densification effects due to pozzolanic and filler contributions of bottom ash and foundry sand were described by Singh and Siddique [5] for ITZ enhancement, by Manoharan et al. [20] for WFS concretes, and by Makul and Sua-Iam [43] for WFS acting as a reactive filler and cement substitute. The observed fibrous hydration morphologies are also comparable to those reported for alkali-activated gangue–slag systems by Ma et al. [44], suggesting similar gel formation pathways dominated by Si–Al–Ca–hydrates. Moreover, the presence of dense C–S–H networks supports the high long-term strength and UPV stability reported in this study and in previous works on HPC with coal-derived residues [30].

In general, SEM evidence confirms that the synergistic combination of coal slag and foundry sand leads to improved hydration continuity, microstructural refinement, and ITZ consolidation, which collectively explain the observed enhancements in mechanical and durability-related properties at later ages.

3.4. Empirical Relationships and Modeling Approach

The interrelation between physical and mechanical characteristics of the studied concretes was examined to identify governing trends and validate empirical models previously reported for high-performance concretes incorporating industrial by-products. The correlations were developed using mean values of compressive strength (fc), open porosity (ϕ), bulk density (ρ), ultrasonic pulse velocity (UPV), modulus of elasticity (Ec), and indirect tensile and flexural strengths. All variables were statistically tested for normality and variance homogeneity (Shapiro–Wilk and Levene tests, p > 0.05), followed by Pearson correlation and nonlinear regression analyses. The models with coefficients of determination R2 > 0.85 were considered significant at the 95% confidence level.

3.4.1. Porosity–Compressive Strength Relationship

The compressive strength exhibited a clear inverse dependence on open porosity, consistent with the classical Ryshkevich [45] and Balshin [46] relationships describing the exponential and power-law degradation of strength with increasing pore volume. The Ryshkevich model (Equation (1)) and the Balshin equation (Equation (2))

where both applied to the experimental data. The exponential model yielded a slightly better fit (R2 = 0.91) across all mixtures, indicating that pore refinement induced by the addition of waste foundry sand (WFS) and coal bottom ash (CBA) has a direct beneficial effect on compressive strength, particularly at longer curing ages. Similar exponential relationships were reported for WFS concretes by Manoharan et al. [20] and Martins et al. [41], and for alkali-activated gangue–slag systems by Ma et al. [44], confirming that waste-derived fines act as micro-fillers improving packing density.

3.4.2. Density–Porosity–Strength Coupling

The combined effect of density and porosity on strength followed a triadic relationship, where strength increased proportionally to the cube of density fc = kρ3, and density decreased linearly with porosity ρ = ρ0 (1−kϕ). These dependencies, consistent with results by Bhardwaj et al. [24] and Smarzewski [30], suggest that the micro-filler action of CBA and WFS improves solid skeleton continuity while maintaining low overall density. The fitted coefficients k = 0.012 and n = 4.8 are typical for HPC containing mineral admixtures and confirm the compactness of the microstructure observed in SEM analysis (Figure 7).

3.4.3. Ultrasonic Pulse Velocity–Compressive Strength Relationship

A strong exponential correlation (R2 = 0.94) was found between UPV and compressive strength, described by:

where V is the ultrasonic pulse velocity (m/s). This relationship aligns with previous studies on high-density HPCs [30,41], demonstrating that UPV effectively reflects the internal continuity and elastic stiffness of the matrix. For the present concretes, the regression model fc = 0.0096V − 13.5 accurately predicted the measured strength values within ±4%. The close proximity of all mixes around V = 4500 m/s indicates minimal microcracking and high compactness, in agreement with the physical test results.

3.4.4. Elastic Modulus–Compressive Strength Correlation

The measured elastic modulus values (31–43 GPa) were compared with the empirical expressions proposed by the ACI 318 [43] and fib Model Code [46]

with k = 3.5–4.3 for dense HPCs. The experimental results agreed well with this prediction (R2 = 0.87), indicating that the stiffness of the CBA–WFS concretes was primarily governed by the strength of the hydrated matrix rather than the type of aggregate. The mixture BA15FS15, exhibiting the highest Ec, also showed reduced porosity and distinct crystalline features in SEM (Figure 7e,f), confirming the structural coherence of the matrix.

3.4.5. Interrelations Between Splitting Tensile, Flexural, and Compressive Strengths

Indirect tensile strength (fsplit) and flexural strength (fflex) correlated well with compressive strength following fib Model Code [46] relations

Both relations were valid across all mixes (R2 = 0.88 and R2 = 0.92, respectively). The tensile-to-compressive strength ratio ranged from 0.065 to 0.075, in accordance with values reported by Di Maida [42] and Martins et al. [41] for concretes with hybrid waste fillers. The increase in tensile and flexural strength between 28 and 56 days was statistically significant (Tukey HSD, p < 0.05), confirming continuous microstructural refinement.

3.4.6. Statistical and Modeling Considerations

All regression analyses were validated through ANOVA and Tukey’s post hoc tests at 95% confidence, ensuring that observed differences among mixtures were statistically significant. Pearson’s correlation coefficients confirmed strong interdependence between physical and mechanical properties (|r| = 0.82–0.95). The empirical models described above provide a consistent framework for predicting mechanical performance of waste-based HPCs and can be further expanded into multi-parametric predictive models using machine learning regression or response surface methodologies in future studies.

4. Discussion Summary and Model Validation

The comprehensive analysis of physical, mechanical, and microstructural parameters confirmed that the hybrid incorporation of CBA and WFS leads to complex but predictable modifications in the performance of HPC. The results demonstrated that a balanced combination of both residues yields a dense, well-hydrated matrix with superior long-term mechanical stability and acceptable durability indices.

At the microstructural level, SEM images revealed the progressive densification of the cementitious matrix and enhanced integrity of the interfacial transition zone (ITZ) for CBA/WFS mixtures compared with the reference concrete. The BA20FS10 and BA15FS15 systems exhibited refined pore morphology and compact C–S–H networks, in agreement with findings by Singh and Siddique [5] and Manoharan et al. [20], who linked fine waste particles to nucleation and ITZ densification effects. The observed morphology also resembles that reported for alkali-activated gangue–slag binders [44], confirming that hybrid waste additives promote continuous hydration and pozzolanic reactions beyond the initial curing period.

The mechanical tests supported these microstructural observations. Moderate waste substitution levels (BA25FS5 and BA20FS10) produced comparable or superior compressive strengths at 730 days, indicating that long-term pozzolanic activity compensates for any early-age strength loss. Flexural and splitting tensile strengths increased significantly between 28 and 56 days, suggesting a microstructural stiffening of the ITZ and improved crack-bridging capacity. The elastic modulus showed a dual trend (slight reduction for CBA-rich mixtures and a notable increase for BA15FS15), highlighting the competing effects of aggregate stiffness, matrix densification, and ITZ quality. These behaviors are consistent with previously reported phenomena in hybrid waste concretes by Martins et al. [41], Di Maida et al. [42], and Smarzewski [30].

The ultrasonic pulse velocity measured at 730 days (~4.5 km/s) validated the internal soundness and compactness of all concretes, confirming the absence of microcracking or internal degradation after two years. The small between-group variance corroborates the microstructural uniformity and the stabilizing role of CBA–WFS mixtures in maintaining high matrix continuity, similar to trends observed by Bhardwaj et al. [24] and Makul and Sua-Iam [43].

Empirical modeling further substantiated these findings. The Ryshkevich and Balshin equations accurately described the strength–porosity dependence (R2 > 0.9), indicating that pore refinement is the dominant mechanism governing compressive strength. The exponential UPV–strength relationship (R2 = 0.94) confirmed that elastic wave velocity serves as a reliable durability proxy, while ACI and fib-based relations for Ec–fc and fflex, fsplit–fc matched experimental data with minor deviations. The internal consistency of these models with SEM evidence validates the physical soundness of the empirical approach. Structural stiffness and strength evolution are directly coupled to microstructural densification.

Overall, the results confirm that combined use of CBA and WFS up to 30 wt% produces HPC with balanced stiffness, strength, and microstructural quality while maintaining sustainability advantages. The derived empirical correlations (especially those linking porosity, density, and mechanical performance) provide a robust predictive framework for future optimization. The models remain physically consistent with the observed morphology and statistically validated (ANOVA, Tukey HSD, p < 0.05). Future work may refine these relationships using larger datasets or machine-learning regression to generalize the predictive capability for hybrid waste-based concretes.

The present study is limited by the relatively small specimen population per age (n = 3) and the absence of direct durability testing such as chloride penetration, carbonation depth, or leaching resistance. In addition, UPV was measured only at a single age (730 days), restricting temporal interpretation of the microstructural densification process. Although the 730-day curing regime ensured stable temperature and humidity, the results represent intrinsic material behavior rather than full environmental exposure. Future work will therefore include extended ultrasonic and electrical resistivity monitoring to capture the temporal evolution of transport properties.

5. Conclusions

This study investigated the physical, mechanical, and microstructural performance of high-performance concrete incorporating hybrid mixtures of coal bottom ash (CBA) and waste foundry sand (WFS). Based on the experimental and analytical findings, the following conclusions can be drawn.

- 1

- Synergistic interaction of CBA and WFS resulted in refined pore structure, enhanced hydration, and improved long-term stability. Moderate hybridization levels (BA25FS5 and BA20FS10) provided an optimal balance between compactness and workability.

- 2

- Mechanical behavior demonstrated that moderate CBA–WFS substitution maintained or slightly improved compressive strength over time, while the BA15FS15 mixture achieved the highest elastic modulus due to enhanced matrix continuity and ITZ integrity.

- 3

- Microstructural observations confirmed that hybrid mixes developed denser C–S–H networks, fewer microvoids, and stronger interfacial bonding compared with the reference concrete, indicating a direct link between pore refinement and mechanical performance.

- 4

- Durability evaluation based on ultrasonic pulse velocity and porosity confirmed high internal compactness and negligible microcracking after two years of curing, consistent with the high long-term strength and elastic response.

- 5

- Empirical model validation showed strong correlations between compressive strength, porosity, density, and ultrasonic velocity, as well as consistency with classical modulus–strength relationships. The derived models accurately describe the mechanical response of CBA–WFS concretes within experimental uncertainty.

- 6

- Practical implications highlight that replacing up to 30% of natural fine aggregates with combined CBA and WFS can achieve high-performance concretes with sustainable characteristics and long-term mechanical reliability.

Considering the high mechanical performance and radiological safety of the investigated mixtures, the developed concretes can be recommended for non-reinforced or fiber-reinforced HPC applications such as façade panels, architectural and protective precast elements, and high-durability pavements. Due to the carbonaceous residues in coal bottom ash, use in conventionally reinforced concrete is not advised, as steel corrosion risk may increase under humid exposure.

Author Contributions

Conceptualization, P.S.; Methodology, P.S. and P.M.; Software, P.S. and P.M.; Validation, P.S. and P.M.; Formal analysis, P.S. and P.M.; Investigation, P.S.; Resources, P.S.; Data curation, P.S.; Writing—original draft, P.S.; Writing—review & editing, P.S. and P.M.; Visualization, P.S.; Supervision, P.S.; Project administration, P.S.; Funding acquisition, P.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Acknowledgments

The authors would like to thank CEMEX, Chełm, Poland, for donating the materials for this investigation. The careful review and constructive suggestions of the reviewers are gratefully acknowledged.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials; McGraw-Hill: New York, NY, USA, 2014. [Google Scholar]

- Scrivener, K.; John, V.M.; Gartner, E. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Ibrahim, M.H.W.; Abidin, N.E.Z.; Jamaluddin, N.; Kamaruddin, K.; Hamzah, A.F. Bottom ash—Potential use in self-compacting concrete as fine aggregate. ARPN J. Eng. Appl. Sci. 2016, 11, 2570–2577. [Google Scholar]

- Rafieizonooz, M.; Mirza, J.; Salim, M.R.; Hussin, M.W.; Khankhaje, E. Investigation of coal bottom ash and fly ash in concrete as replacement for sand and cement. Constr. Build. Mater. 2016, 116, 15–24. [Google Scholar] [CrossRef]

- Singh, M.; Siddique, R. Effect of coal bottom ash as partial replacement of sand on properties of concrete. Resour. Conserv. Recycl. 2013, 72, 20–32. [Google Scholar] [CrossRef]

- Smarzewski, P.; Barnat-Hunek, D.; Jezierski, W. The possibility of using boiler slag as coarse aggregate in high strength concrete. KSCE J. Civ. Eng. 2017, 21, 2432–2444. [Google Scholar] [CrossRef]

- American Coal Ash Association (ACAA). Production and Use Survey Report; ACAA: Washington, DC, USA, 2020. [Google Scholar]

- Smarzewski, P.; Barnat-Hunek, D. Mechanical and durability related properties of high-performance concrete made with coal cinder and waste foundry sand. Constr. Build. Mater. 2016, 121, 9–17. [Google Scholar] [CrossRef]

- Kim, H.K. Utilization of sieved and ground coal bottom ash powders as a coarse binder in high-strength mortar to improve workability. Constr. Build. Mater. 2015, 91, 57–64. [Google Scholar] [CrossRef]

- Kim, H.K.; Lee, H.K. Coal Bottom Ash in Field of Civil Engineering: A Review of Advanced Applications and Environmental Considerations. KSCE J. Civ. Eng. 2015, 19, 1802–1818. [Google Scholar] [CrossRef]

- Kumar, S.; Kapoor, K.; Singh, S.P.; Singh, P.; Sharma, V. A Review on the Properties of Natural and Recycled Coarse Aggregates Concrete Made with Different Coal Ashes. Clean. Mater. 2022, 5, 100109. [Google Scholar] [CrossRef]

- Aygun, B.F.; Bilir, T.; Uysal, M. Coal bottom ash and its applications in cement and concrete technologies: A review. Discov. Civ. Eng. 2024, 1, 86. [Google Scholar] [CrossRef]

- Singh, M.; Siddique, R. Effect of coal bottom ash as partial replacement of sand on workability and strength properties of concrete. J. Clean. Prod. 2016, 112, 620–630. [Google Scholar] [CrossRef]

- U.S. Federal Highway Administration (FHWA). Foundry Sand Facts for Civil Engineers; FHWA-IF-04-004; FHWA: Washington, DC, USA, 2004.

- Bhardwaj, B.; Kumar, P. Waste foundry sand in concrete: A review. Constr. Build. Mater. 2017, 156, 661–674. [Google Scholar] [CrossRef]

- Basar, H.M.; Deveci Aksoy, N. The effect of waste foundry sand (WFS) as partial replacement of sand on the mechanical, leaching and micro-structural characteristics of ready-mixed concrete. Constr. Build. Mater. 2012, 35, 508–515. [Google Scholar] [CrossRef]

- Guney, Y.; Sari, Y.D.; Yalcin, M.; Tuncan, M.; Donmez, S. Re-usage of waste foundry sand in high-strength concrete. Waste Manag. 2010, 30, 1705–1713. [Google Scholar] [CrossRef] [PubMed]

- Siddique, R.; Singh, G. Utilization of waste foundry sand (WFS) in concrete manufacturing. Resour. Conserv. Recycl. 2011, 55, 885–892. [Google Scholar] [CrossRef]

- Smarzewski, P. Microstructure and Mechanical Properties of Sustainable Concrete Incorporating Used Foundry Sand and Coal Bottom Ash. Sustainability 2025, 17, 5983. [Google Scholar] [CrossRef]

- Manoharan, T.; Laksmanan, D.; Mylsamy, K.; Sivakumar, P.; Sircar, A. Engineering properties of concrete with partial utilization of used foundry sand. Waste Manag. 2018, 71, 454–460. [Google Scholar] [CrossRef]

- de Matos, P.R.; Marcon, M.F.; Schankoski, R.A.; Prudêncio, L.R. Novel applications of waste foundry sand in conventional and dry-mix concretes. J. Environ. Manag. 2019, 244, 294–303. [Google Scholar] [CrossRef]

- Smarzewski, P. Mechanical Properties of Ultra-High Performance Concrete with Partial Utilization of Waste Foundry Sand. Buildings 2020, 10, 11. [Google Scholar] [CrossRef]

- García, G.; Cabrera, R.; Rolón, J.; Pichardo, R.; Thomas, C. Systematic review on the use of waste foundry sand as a partial replacement of natural sand in concrete. Constr. Build. Mater. 2024, 430, 136460. [Google Scholar] [CrossRef]

- Bhardwaj, A.; Kumar, P.; Siddique, S.; Shukla, A. Comprehensive review on utilization of waste foundry sand in concrete. Eur. J. Environ. Civ. Eng. 2023, 27, 1056–1087. [Google Scholar] [CrossRef]

- Jamaluddin, N.; Hamzah, A.F.; Wan Ibrahim, M.H.; Jaya, R.P.; Arshad, M.F.; Zainal Abidin, N.E.; Dahalan, N.H. Fresh Properties and Flexural Strength of Self-Compacting Concrete Integrating Coal Bottom Ash. MATEC Web Conf. 2016, 47, 01010. [Google Scholar] [CrossRef]

- Torres, A.; Aguayo, F.; Allena, S.; Ellis, M. Mechanical properties of ultra-high performance fiber reinforced concrete made with foundry sand. J. Civ. Eng. Constr. 2019, 8, 157–167. [Google Scholar] [CrossRef]

- Ahmad, J.; Aslam, F.; Zaid, O.; Alyousef, R.; Alabduljabbar, H. Mechanical and durability characteristics of sustainable concrete modified with partial substitution of waste foundry sand. Struct. Concr. 2021, 22, 2775–2790. [Google Scholar] [CrossRef]

- Siddique, R.; de Schutter, G.; Noumowe, A. Effect of used-foundry sand on the mechanical properties of concrete. Constr. Build. Mater. 2009, 23, 976–980. [Google Scholar] [CrossRef]

- Meena, A.; Singh, N.; Singh, S. Sustainable development of high-volume fly ash self-compacting concrete incorporating bottom ash and recycled concrete aggregates. J. Mater. Eng. Struct. 2023, 10, 615–630. [Google Scholar]

- Smarzewski, P. Long-Term Behavior and Microstructure of High-Performance Concrete with Coal Slag. Materials 2025, 18, 2585. [Google Scholar] [CrossRef]

- PN-EN 933-1:2012; Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method. PKN: Warsaw, Poland, 2012.

- PN-EN 197-1:2012; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. Polish Committee for Standardization: Warsaw, Poland, 2012.

- ASTM C642-21; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2021.

- PN-EN 12390-3:2019; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. PKN: Warsaw, Poland, 2019.

- PN-EN 12390-6:2019; Testing Hardened Concrete—Part 6: Tensile Splitting Strength of Test Specimens. PKN: Warsaw, Poland, 2019.

- PN-EN 12390-5:2019; Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens. PKN: Warsaw, Poland, 2019.

- PN-EN 12390-13:2021; Testing Hardened Concrete—Part 13: Determination of Secant Modulus of Elasticity in Compression. PKN: Warsaw, Poland, 2021.

- PN-EN 12390-7:2020; Testing Hardened Concrete—Part 7: Density of Hardened Concrete. PKN: Warsaw, Poland, 2020.

- PN-EN 12504-4:2021; Testing Concrete—Part 4: Determination of Ultrasonic Pulse Velocity. PKN: Warsaw, Poland, 2021.

- Malhotra, V.M.; Carino, N.J. (Eds.) Handbook on Nondestructive Testing of Concrete, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Martins, M.A.B.; Silva, L.R.R.; Kuffner, B.H.B.; Barros, R.M.; Melo, M.L.N.M. Behavior of High-Strength Self-Compacting Concrete with Marble/Granite Processing Waste and Waste Foundry Exhaust Sand, Subjected to Chemical Attacks. Constr. Build. Mater. 2022, 323, 126492. [Google Scholar] [CrossRef]

- Di Maida, P.; Sciancalepore, C.; Radi, E.; Lanzoni, L.; Milanese, D. Recycling Foundry Sands in Concrete: A Comparative Study on the Use of Green Sand and Chemically Bonded Sand as Partial Replacements for Natural Sand. Materials 2025, 18, 4245. [Google Scholar] [CrossRef]

- Makul, N.; Sua-Iam, G. Innovative utilization of foundry sand waste obtained from the manufacture of automobile engine parts as a cement replacement material in concrete production. J. Clean. Prod. 2018, 199, 305–320. [Google Scholar] [CrossRef]

- Ma, H.; Zhu, H.; Wu, C.; Chen, H.; Sun, J.; Liu, J. Study on compressive strength and durability of alkali-activated coal gangue-slag concrete and its mechanism. Powder Technol. 2020, 368, 112–124. [Google Scholar] [CrossRef]

- ACI Committee 318. Building Code Requirements for Structural Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2019. [Google Scholar]

- fib Model Code. CEB-FIP Model Code for Concrete Structures; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).