1. Introduction

Lean engineering and Six Sigma have dissimilar performance initiatives but are favored in supporting organizations that aspire for operational superiority to participate in global competition. They are confirmed techniques with a mutual goal of continuous improvement, but they meet these objectives differently. Lean Six Sigma (LSS) methodology is applied to identify and address the root causes of inefficiency [

1]. It is an appropriate technique that blends efficiency and sustainability. The goal of Lean Six Sigma is to reduce cycle time by combining “Lean”, a manufacturing system that aims to remove seven kinds of waste: transportation, inventory, motion, waiting, overproduction, over-processing, and defects, with the “Six Sigma” technique, which reduces the output inconsistency in the process. Lean Six Sigma applies to all operations, as it is based on a process approach [

2]. The DMAIC cycle, a Six Sigma component, describes the core thinking behind data-centric process improvement. Completing each DMAIC cycle theoretically recognizes project goals while improving performance and preserving project quality [

3]. Antony et al. [

4] stated that implementing Lean without Six Sigma results in the underutilization of tools to achieve full improvement. Conversely, if Six Sigma is applied without considering Lean principles, then an extensive range of tools will be available for improvement projects but with no strategy to advance their application to a system. The Lean Six Sigma approach has an advantage over other quality methodologies. It uses Lean concepts to streamline corporate processes and decrease waste, resulting in more satisfied consumers and addressing variations in organizational processes by applying Six Sigma systems and tools. When combined, Lean and Six Sigma become highly dynamic. They employ Lean manufacturing and Six Sigma techniques and tools. In addition to the Define, Measure, Analyze, Improve, and Control (DMAIC) problem-solving methodology, Six Sigma employs various excellent problem-solving tools. Several potent tools in the Lean concept set aid in eliminating waste, organizing, and simplifying work processes; their application depends on the type of process being researched and the issues encountered [

5,

6,

7]. Although many manufacturing and service organizations have adopted the integrated Lean and Six Sigma methodology, higher education institutions are far behind in introducing and developing this process excellence strategy.

Experimentation and testing form the foundation of modern engineering practices in higher education institutions. Although computer modeling enables extensive research and design to be performed before testing, the requirement for thorough testing and experimentation remains as strong as ever. Laboratory work is essential in improving and creating goods and processes, verifying designs, and determining how materials, parts, components, and systems react under different conditions. As a result, students must be able to function efficiently in such environments. Higher education institutions may also apply continuous improvement concepts such as Lean Engineering and Six Sigma, to improve overall efficiency, reduce waste, and streamline operational processes. These approaches emphasize data-driven decision-making, problem-solving, and the involvement of stakeholders in driving improvements [

6].

The aim of this study is to implement and evaluate the Lean Six Sigma (LSS) methodology, particularly in the DMAIC framework, at an international higher education institution, i.e., university mechanical and industrial engineering technology workshops, to improve productivity, workflow efficiency, and safety standards. The study seeks to demonstrate that applying LSS tools in an educational laboratory setting can result in measurable performance improvements and establish a sustainable framework for ongoing operational excellence.

To achieve the aim, the study addresses the following research questions:

What are the primary inefficiencies and forms of waste affecting the performance of university mechanical engineering workshops?

How does the integration of Lean and Six Sigma tools within the DMAIC framework impact process capability and operational flow?

What quantifiable improvements in workshop efficiency and safety can be achieved through the implementation of LSS tools?

By answering these questions, the study aims to contribute to the limited but growing body of knowledge on Lean Six Sigma application in non-profit, higher education environments, especially in engineering education. Additionally, it aspires to provide practical insights that can be used to adapt these methodologies for similar academic or technical settings.

By adopting these frameworks and methodologies, higher education institutions can systematically identify areas for improvement, implement effective strategies, and monitor progress toward achieving their quality and efficiency goals. Furthermore, a culture of continuous improvement promotes innovation, collaboration, and commitment to excellence across the organization, benefiting students, faculty, staff, and the broader community.

2. Literature Review

Although Lean Six Sigma has been widely used in many manufacturing and service organizations, its application in higher education institutions represents a significant challenge for those involved in its implementation. More academic research is needed on its implementation in the non-profit service industry, especially when it pertains to higher education institutions. This review has been conducted in various research works to establish the connection between increased efficiency, productivity, and Lean Six Sigma implementation in higher education institutions. Waste at higher education institutions was defined by [

8], and proven techniques to reduce waste were detailed based on engineering and technical backgrounds and higher education administrative perspectives. The study highlighted the importance of categorizing and prioritizing waste, because efforts should be directed toward removing waste with the most significant potential to improve the overall system’s efficiency.

In developing an integrated LSS framework, the focus was placed on guaranteeing the concurrent development of Lean and Six Sigma components, with the purpose of helping organizations simultaneously tackle the ‘waste reduction’ and important quality elements of their business. Since then, the theoretical models of Lean and Six Sigma have been around for quite some time. Although the literature on TQM and Lean implementation in higher education is extensive, LSS differs from these and other quality methods because it creates collaborations between Lean and Six Sigma that its predecessors overlooked. A tailored Lean Six Sigma framework and the right and careful selection of tools and procedures suited for integration into the engineering workshop setup are necessary. When considering Lean Six Sigma for higher education institutions, it is crucial to balance the drive for efficiency and process improvement with the unique needs and values of the academic environment. Lean methodology can help LSS reduce waste and accelerate process flow. LSS can benefit from the Six Sigma technique in complex problems with uncertain answers when prior solutions have been ineffective. Several universities globally have begun to employ both Lean and Six Sigma to achieve operational excellence over recent years.

Antony et al. [

9] highlighted that despite the completion of several Lean Six Sigma projects, none focused on improving academic processes like teaching effectiveness. The study highlighted the potential of LSS in the higher education sector, though its adoption is still limited due to the misconception that LSS is only applicable in manufacturing. The research emphasized the need for strategic leadership for successful LSS deployment. It proposed future research areas, including developing an LSS toolkit for higher education institutions and evaluating the role of academic leadership in LSS success. The paper also suggested further exploration of the criteria for successful LSS projects in educational settings. Vijaya and Mahalingam [

10] present numerous benefits of employing Lean Six Sigma in higher education, which are matched to other quality excellence systems. The benefits included efficiently completing accreditation standards, offering a framework for structured problem-solving, promoting total involvement, developing a measuring system, making processes transparent, gathering consumer voices, and assisting in identifying hidden expenses. Monteiro et al. [

11] discussed successful Lean office implementation at a public sector organization. They highlighted the substantial performance improvements achieved by applying Lean principles in office areas, similar to those in traditional manufacturing environments. Despite the perceived intangibility of office operations, the Lean approach led to significant gains in lead times, productivity, and workplace organization. Implementing Lean principles started with process mapping, effectively reducing lead times and improving productivity. Notable lead times were observed in critical office processes: the monthly accounting process was reduced by 44% (from 8 days to 4.5 days), the payroll processing time was reduced by 50% (from 10 days to 5 days), and the time taken for payment to suppliers was reduced by 85% (from 10 days to 1.5 days). The process mapping approach generated results quickly, which increased employee motivation and involvement across the organization. Lean implementation fostered a common culture among teams and improved cooperation between different departments. The LSS methodology with DMAIC was also used in a telecom service company and resulted in significant reductions in various lead times [

12]. This led to improvements in the service capability of the company with an improved order fulfillment process.

Vijayanand and Vaddi [

13] explored the application of Lean principles in the machine shop of an engineering college, intending to educate aspiring engineers on the use of Lean tools. Lean methodologies such as 5S, standard work, and machine maintenance were employed, with students learning about the challenges and successes of implementing these practices. The findings emphasized eliminating non-value-added activities, or “Muda”, to enhance efficiency. A series of 5S audits supported the improvement of kaizen initiatives and the adherence to Lean principles. The study used a questionnaire with a five-point Likert scale to assess the impact of Lean tools on the machine shop. Notable improvements following the implementation of Lean principles included a 6.6% increase in space utilization, a 95.12% enhancement in safety measures, an 83.3% reduction in machine failure occurrences, and an 80.2% decrease in the time required for tool searches. The study concluded that Lean methodologies in an educational machine shop establish a framework for organizational value and continuous improvement. Muthukumaran et al. [

14] applied the process control strategy of LSS to higher education institutions. Lean Six Sigma is readily applicable in the manufacturing industry, but there is evidence that it may be successfully applied to any process; in the study of Muthukumaran et al. [

14], the LSS was applied as a breakthrough approach to influence faculty aims in academia to boost throughput and income.

Li et al. [

15] highlighted that higher education institutions are complex organizations that manage extensive resources, diverse organizational processes, and multiple stakeholders. According to them, LSS offers a structured approach to achieving the redesigned business processes in higher education by reducing waste, improving quality, and optimizing performance. Sari et al. [

16] discussed the implementation of the 5S methodology in the industrial engineering laboratory of an international university. The laboratory was facing issues related to disorganized equipment, accumulated files from previous years, and wasteful movements due to misplaced items. The study enhanced the efficiency of the laboratory by applying the 5S, with a 50% improvement in overall organization and cleanliness. This improvement led to better use of the laboratory space, reducing the time required to search for tools and materials and enhancing visual control over equipment placement. Nethada and Wan [

17] reported the benefits of implementing LSS to improve students’ learning experience in a material engineering laboratory in a university setting. They discovered that the effectiveness of the LSS operating process saved preparation time, had a high success rate, and provided 100% student satisfaction.

A study by Antony et al. [

4] explored the challenges and critical success factors in implementing Lean Six Sigma (LSS) within a UK higher education institution (HEI). They presented a case study of how LSS was used to improve the efficiency of business processes such as finance, administration, HR, IT, and library services. The study reveals several issues, including a lack of senior management support, insufficient understanding of LSS benefits, and a lack of knowledge about LSS tools. Maazoun et al. [

18] examined the practical application of Lean Manufacturing principles through the DMAIC to enhance production efficiency and minimize waste in a glass transformation company. The study’s primary aim was to validate the effectiveness of implementing Lean manufacturing through the DMAIC framework, focusing on improving production flow and reducing waste in the company’s workshop. This Lean manufacturing approach using DMAIC has proven effective in enhancing production efficiency, improving flow, and achieving significant financial gains for the glass transformation company. In a study, the Six Sigma DMAIC framework changed defective quality control and test assignment processes in clinical biochemistry laboratories and helped to achieve significant cost savings [

19].

The literature review indicated that almost all market sectors showed evidence of successful benefits after implementing Lean Six Sigma. Several higher education institutions have used the Lean management concept to improve the efficiency of scientific activities by eliminating waste and activities that do not add value. Lean is viewed from an education perspective as a methodology that enables universities, schools, and teachers to teach all students effectively and efficiently by removing or minimizing wastes or losses associated with the operations and activities in education institutes. Based on the literature, it can be concluded that adopting Lean and Six Sigma can result in significant benefits in terms of waste reduction, cost reduction, quality improvement, productivity improvement, and customer satisfaction. Lean and Six Sigma can be applied consecutively or concurrently. Several studies have concentrated on process optimization and lowering defects and costs; however, few have focused on quality improvement. It is known that Lean is the concept of boosting an organization’s speed and efficiency by removing waste. On the other hand, Six Sigma is a continuous improvement approach recommended to eliminate variability. Structured problem-solving methods like the PDCA and DMAIC cycles inspired both concepts. The benefits of LSS in both manufacturing and services have been highlighted extensively in the literature. They include ensuring that services are performed, meeting customer needs, removing non-value-adding steps from important business processes, reducing expenses due to poor quality, reducing defective transactions, lowering the cycle time, and delivering the right service at the right time in the correct location. Lean Six Sigma tools offer benefits by improving processes, improving equipment efficiency, and reducing waste. The most commonly used tools and techniques, Value Stream Mapping, 5S, Kanban, and Kaizen, are examples of Lean tools that are generally applicable. The practice of Six Sigma offers a framework for merging quality tools such as statistical process controls and DMAIC procedures with high-level management support. It aims to identify and eliminate sources of variability. Lean Six Sigma uses tools from both toolboxes to exploit the best aspects of the two methodologies, increasing speed and accuracy. Lean, conversely, is the identification and elimination of wastes arising from non-value-added activities and quality improvement. Six Sigma employs many Lean tools and methodologies across all five stages of DMAIC. It primarily evaluates process data using statistical and characterization methods to identify and eradicate the fundamental causes of process waste and other problems. Essential factors of success are the elements required for an organization or project to achieve its mission. Lean Six Sigma is an organizational improvement process that aims to generate shareholder value by improving quality, speed, consumer satisfaction, and costs. It accomplishes this by combining tools and principles from Lean and Six Sigma.

The main aim of the present study was to comprehensively employ the Lean Six Sigma methodology framework in the mechanical and industrial engineering technology workshops of an international higher education institute, i.e., a university, through a case study approach. The professional bachelor qualification in the mechanical engineering program at the university under study requires students to attend various lectures and laboratory courses. Students attend laboratory courses in diverse mechanical engineering disciplines (materials, fluids, thermodynamics), and all laboratory and lecture courses have many laboratories and facilities in common. Students and staff were found to be spending too much time on non-value-adding tasks, such as searching for tools, setting up equipment, and waiting for machine access. In particular, the lack of adherence to the 5S methodology, i.e., Sort, Set in order, Shine, Standardize, and Sustain, resulting in students spending excessive time searching for tools, navigating cluttered spaces, and encountering hazardous conditions. Students using the study’s mechanical workshop frequently cannot complete experimental work within the allotted time, primarily due to a lack of understanding that necessitates significant assistance from technicians. Additionally, workshops and their offices failed to meet safety audit requirements. Issues such as inadequate visual management, poor housekeeping, and limited access to necessary tools were prevalent. These challenges, both directly and indirectly, hindered the overall efficiency of workshop operations, leading to delays, compromised safety standards, and reduced productivity. Addressing these concerns was critical to ensure a safe, efficient, and conducive learning environment while improving operational workflow and resource utilization. These inefficiencies not only hindered the students’ ability to engage in productive learning but also exposed them to increased safety risks, reducing the overall effectiveness of the workshop. Furthermore, the absence of Lean practices in these educational settings prevents students from gaining exposure to industry-relevant methodologies, leaving them underprepared for the Lean-driven environments that they will encounter in their future careers.

The DMAIC technique for variability reduction and Lean manufacturing concepts for waste reduction in processes have been merged to create the Lean Six Sigma approach, which is extensively utilized in top-tier companies for revolutionary performance improvement. The detailed methodology, tools and techniques used, and implementation steps are discussed in the next section.

3. Methodology

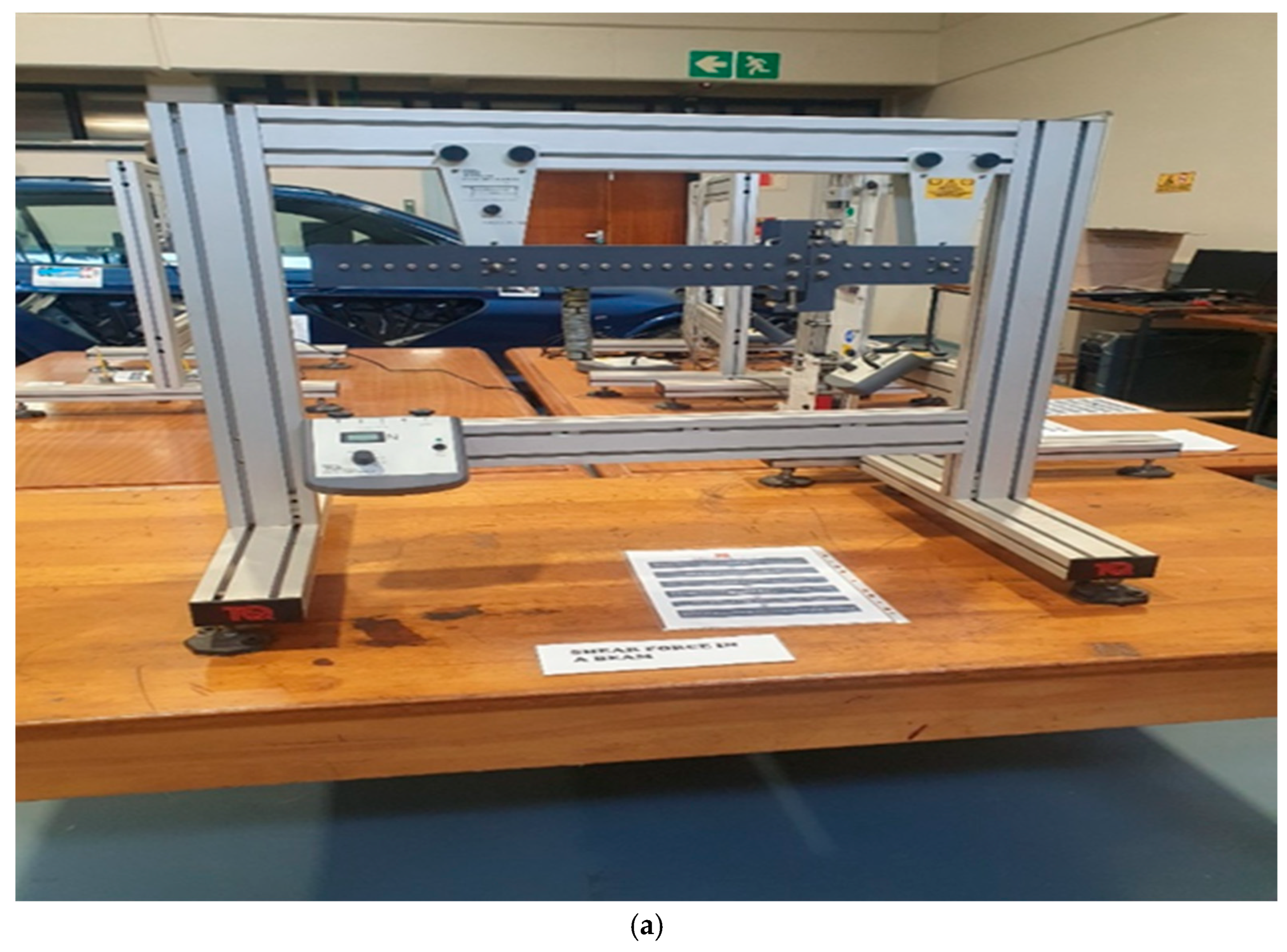

The existing theories of Lean Six Sigma have been explored and researched via a review of past work to understand the implementation procedure of Lean, Six Sigma, and Lean Six Sigma tools in service industries and higher education institutions in South Africa and globally. The primary research framework for this study involves implementing the DMAIC cycle of Six Sigma, which is a five-phase cycle: define phase, measure phase, analyze phase, improve phase, and control phase. The five phases of DMAIC have specific purposes in a project management context [

19]. The DMAIC cycle consistently emphasizes problem-solving by incorporating precise tools into each step of the phases. The project was implemented according to the DMAIC cycle, known from the Six Sigma theory and applicable Lean Tools. The first part mainly consisted of measuring the existing state of the 3 workshops to map the process and frame issues and origins of variation. During the second part of the project, the focus shifted towards Lean thinking while applying chosen Lean and Six Sigma tools. The approach is outlined, and the tools utilized in each phase are discussed. The DMAIC method is favored as it combines Six Sigma and Lean tools and techniques at suitable stages for process improvement [

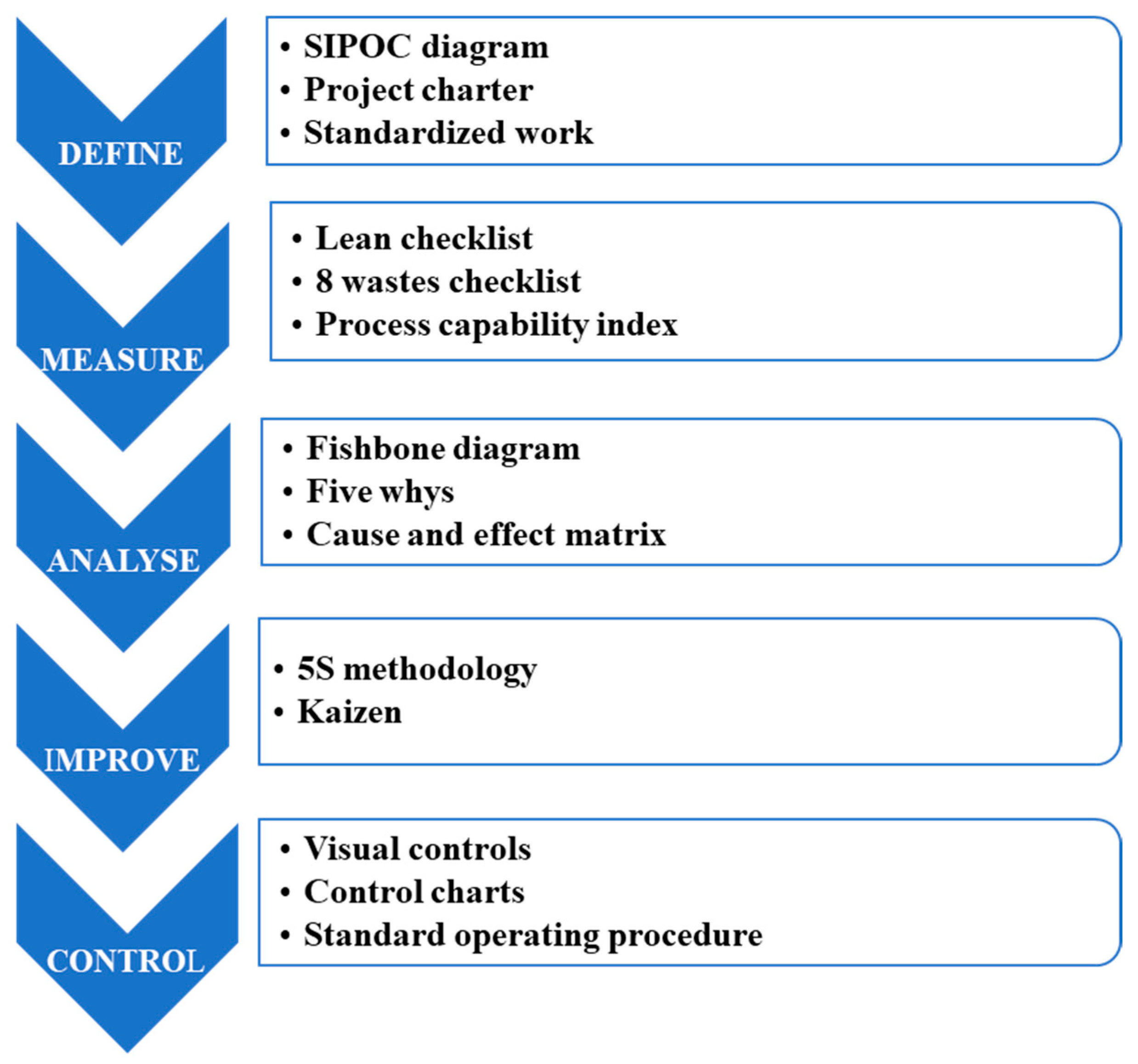

20]. The standard five-stage DMAIC methodology roadmap, which led to the research case in this study, is illustrated in

Figure 1. According to Adeodu et al. [

21], the DMAIC approach is considered the most effective for implementing LSS in an organizational setting for process enhancement. This research used the LSS tools as presented in

Figure 1,

Figure 2 and

Figure 3, suitable for the mechanical engineering workshop setting. Two university mechanical engineering technology workshops in the same faculty were used in this case study. The study sought to eliminate diverse types of waste within the two engineering workshops and accelerate the process flow using Lean and Six Sigma tools. Eliminating these wastes will assist the workshops in allocating resources to maximize productivity, resulting in an increased throughput of graduates where it matters most and throughput improvement.

The Lean Six Sigma framework was implemented over a period of six months within two mechanical engineering technology workshops in the faculty of engineering at an international higher education institution. The DMAIC steps were coordinated and executed by the research team, comprising academic staff from the departments of quality and operations management and mechanical and industrial engineering technology.

The implementation was supported by workshop technicians, laboratory supervisors, and final-year mechanical engineering students who were regular users of the laboratory space. Stakeholders’ involvement during each DMAIC phase was as follows:

Define and Measure: The research team collaborated with technicians and supervisors to conduct SIPOC analysis and apply Lean waste checklists to assess current workflow and bottlenecks.

Analyze: Root causes of inefficiencies were examined using tools like the Fishbone Diagram and 5 Whys technique in consultation with laboratory staff.

Improve: Improvement actions (including 5S, layout redesign, and Kaizen initiatives) were jointly executed by the researchers and workshop personnel, with assistance from students during non-instructional hours.

Control: PDCA boards were installed, and visual control mechanisms were introduced. Technicians received guidance on how to perform ongoing audits and maintain control charts for the sustainability of results.

This participatory approach ensured the buy-in of all stakeholders and enhanced the relevance and feasibility of improvements made in the workshop settings.

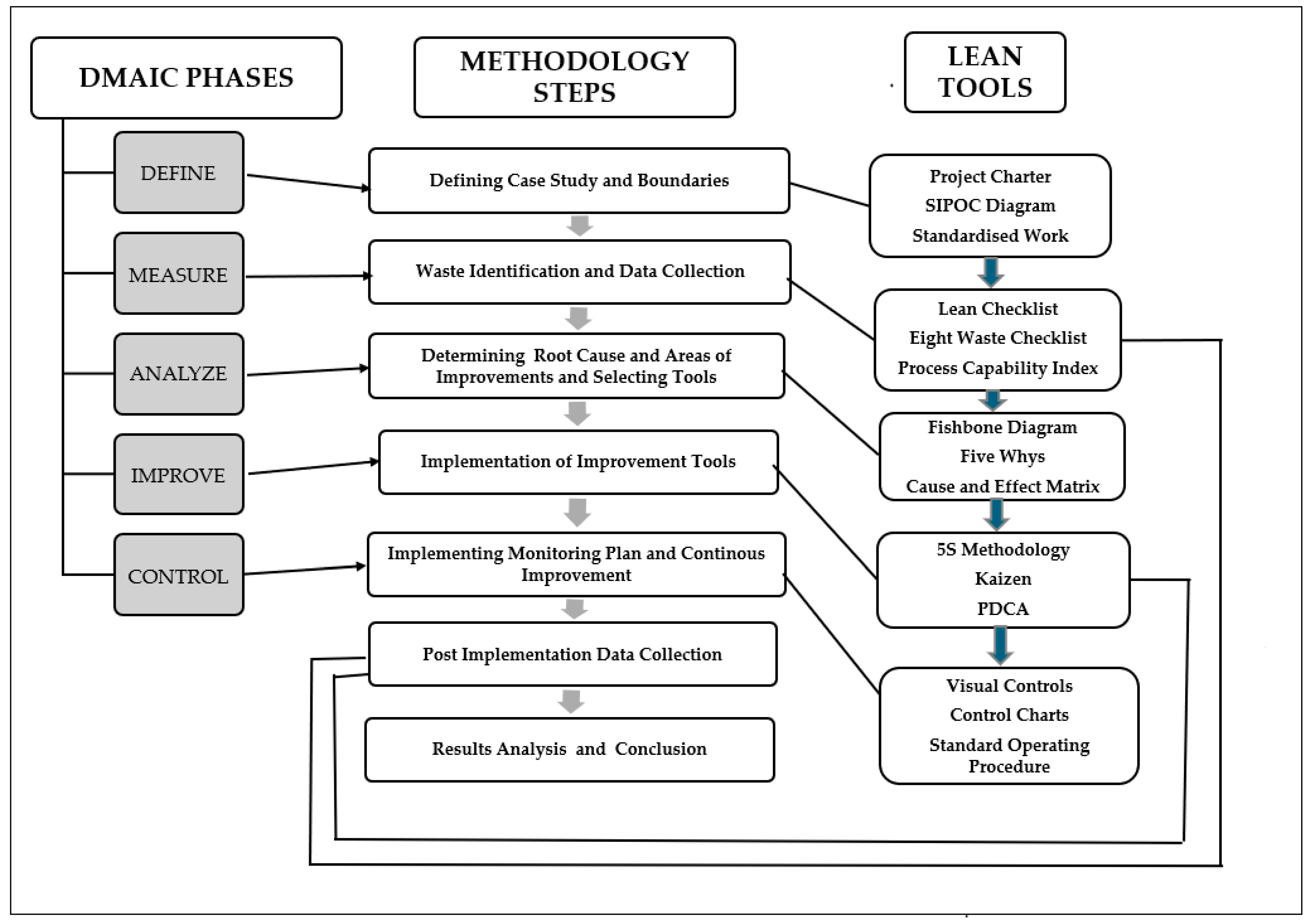

The overall methodology of the study is shown in the flowchart in

Figure 2, displaying the selected tools applied in different stages, and the details are as follows:

Define: The SIPOC (Suppliers, Inputs, Process, Outputs, and Customers) diagram was used to map out and evaluate the input and output of the engineering workshops. The project charter document was used to understand the workshop’s current state while determining the study’s goal.

Measure: The Lean Checklist and Eight Waste Checklist were used to identify and categorize the wastes within the workshop. The process capability index was used to determine the capability of the 2 engineering workshops to deliver services to the students and faculty.

Analyze: The fishbone diagram and five whys were used to identify the potential causes of the workshop’s non-productivity, drilling down to discover its root cause.

Improve and Control: The tools in these two phases were implemented for improvement and continuous improvement.

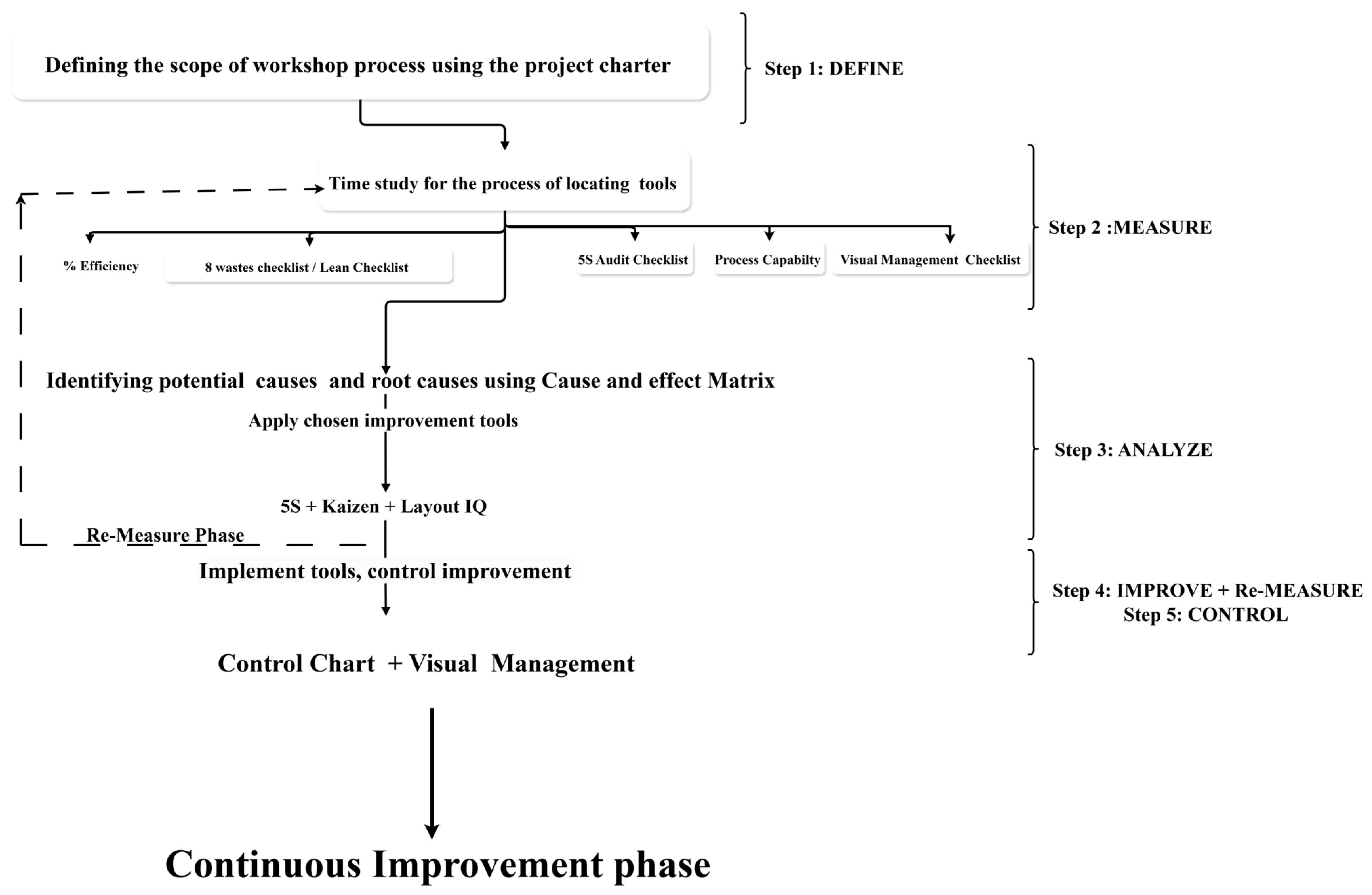

The framework was developed to streamline operations and improve productivity. The diagram in

Figure 3 presents a systematic approach to process improvement in a workshop setting using Lean and DMAIC principles. It highlighted specific tools to define goals, measure performance, identify causes, implement changes, and sustain improvements in each phase. This structured framework aimed to reduce waste, optimize workflow, and maintain high-quality output through ongoing control measures. A case study approach was applied to the proposed framework to validate the framework and improve a mechanical engineering workshop. The framework implementation for a workshop process shows the steps and tools used to streamline operations and improve productivity. A breakdown of each step in the diagram is as follows:

The Define phase established the project scope by utilizing the project charter to outline the goals and objectives of the workshop process.

In the Measure phase, several checklists and metrics were employed to capture the current state:

The 8 Wastes Checklist/Lean Checklist identified types of waste within the process (e.g., unnecessary motion, waiting time) to streamline activities.

The 5S Audit Checklist evaluated the effectiveness of the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) in the workspace.

Process Capability: This assessed how well the current processes met performance standards.

Visual Management Checklist: This ensured that visual aids effectively communicated status and streamlined workflow.

In the Analyze phase, a Cause-and-Effect Matrix was used to identify potential causes and root causes of inefficiencies or issues.

This matrix guided the selection of the most appropriate improvement tools by highlighting areas that required intervention.

The Improve phase involved applying selected improvement tools, such as the following:

The 5S organized and optimized the workspace to eliminate waste and improve productivity.

Kaizen focused on continuous improvement by making incremental changes.

Layout IQ examined and adjusted the workspace layout for optimal flow and efficiency.

After implementing improvements, a Re-Measure step assessed the impact of the changes.

In the Control phase, measures were implemented to maintain the improvements achieved. These include the following:

Control Chart: This monitored process performance over time.

Visual Management: This continuously used visual tools to ensure that processes were followed and issues were visible.

PDCA (Plan–Do–Check–Act) continuous improvement board: This provided a structured approach to sustaining improvements.

4. Results and Discussion

This study introduced an innovative Lean Six Sigma (LSS) framework tailored to university mechanical and industrial engineering workshops, leading to quantifiable efficiency gains. The improvements were validated through process capability indices, visual management audits, and layout optimizations.

4.1. Pre-Implementation Results

4.1.1. Process Capability Index

The Process capability was calculated for the main workshop and the welding laboratory. The process considered was allowing experiments to be carried out by students using the machinery and equipment. The specification limits are LSL for lower specifications and USL for upper specifications. The Cp index gauges the process variability’s capacity to fit within the specification range. Because the index lacks a measure of the process average, it cannot tell whether the process operates within the specification (another measure addresses this, Cpk). As determined by Cpk, process capability is the range of a process concerning the mean value. A process with a Cp of 1.0 barely meets specification constraints (specification range ± 3σ). C should be at least 1.33 because many applications are crucial and because the process average will not stay in the middle of the specified range.

Mean (µ) = 36.4 min; standard deviation (σ) = 8.355; upper limit (USL) = 45 min; lower limit (LSL) = 30 min; Cp = 0.33.

Cp and Cpk are less than 1.33, which means that the process of the main workshop has the potential to be incapable.

Mean (µ) = 32 min; standard deviation (σ) = 3.753; upper limit (USL) = 45 min; lower limit (LSL) = 30 min; Cp = 0.67.

Cp and Cpk are less than 1.33, which makes the welding laboratory process potentially incapable.

4.1.2. Establishing Causes and Effects

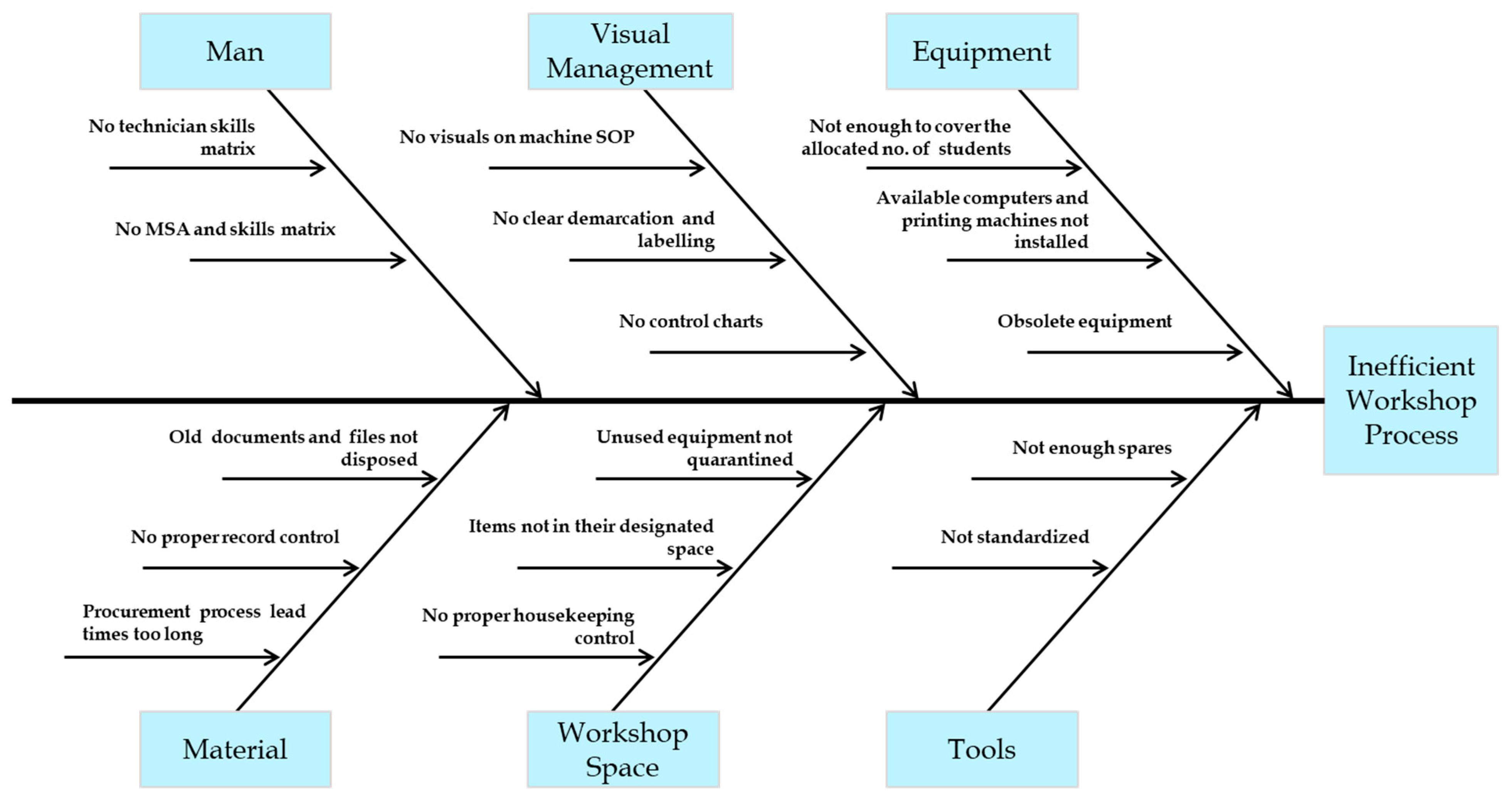

Figure 4 shows a fishbone diagram of the potential causes related to the inefficiency of the mechanical workshop process of serving customers, which included students and the faculty.

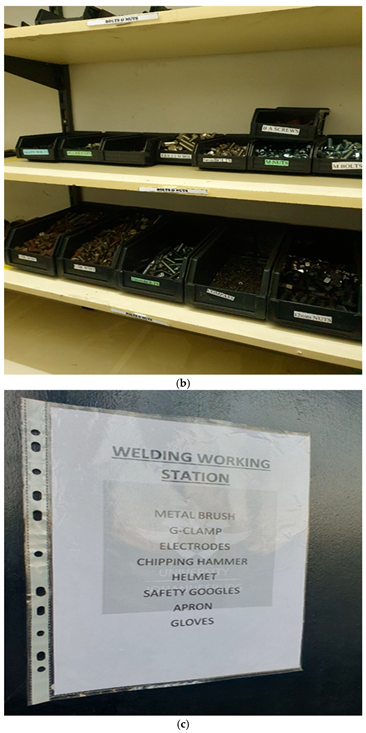

Equipment: There is not enough to cover the allocated number of students; available computers and printing machines are not installed, and the equipment is obsolete.

Tools: There are not enough spares, and they are not standardized.

Visual Management: There is no visual standard operating procedure on the machine; no clear demarcation and labelling; and no control chart.

Workshop Space: Unused equipment is not quarantined; items are not in their designated space, and there is no proper housekeeping control.

Man There is no technician skills matrix and no measurement system analysis.

Material: Old documents and files are not disposed of; there is no proper record control; and there is a lengthy procurement process lead time.

4.1.3. Layout Observations

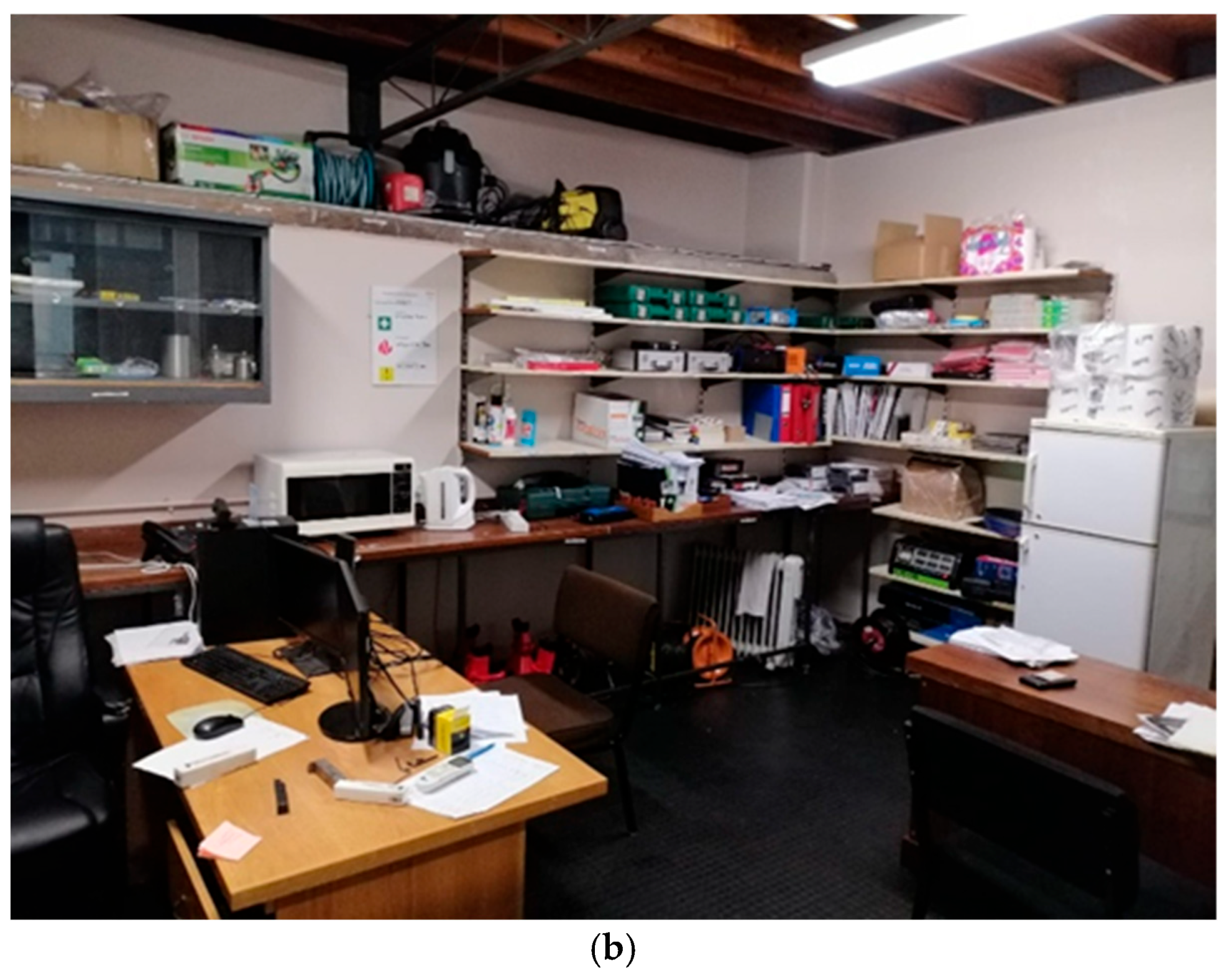

The layout in

Figure 5 features colored lines that illustrate various pathways or workflows within the workshop, indicating movement patterns and resource access points (the actual picture is shown in

Figure 6). Still, some inefficiencies in the design are highlighted. Here is a summary focusing on efficiency:

Red Path (Kettle and Microwave Access): The red line shows access to the kettle and microwave, far from the main entry. This setup requires crossing the area between the door and desks, potentially disrupting people working at the desks. Frequent movement to and from this area may interfere with other activities.

Green Path (Manuals and Tool Shelf): The path to the manuals and tool shelf requires movement from the desks to the far corner on the upper right side. This location is distant from the main workspace, which could slow down workflows, primarily if the shelf is accessed frequently.

Orange Path (First Aid Box): The first aid box is positioned in the far-right corner, meaning that, in case of an emergency, it could be less accessible. Ideally, the first aid box should be centrally located to ensure quick access from multiple points.

Blue Path (Tool Cabinet): The tool cabinet, while relatively central, is positioned near the fridge, which may lead to congestion in that area. Since the tools cabinet may be accessed frequently, placing it next to the fridge could cause interruptions, especially during breaks or mealtimes.

Paths intersect frequently, particularly near the door and between desks, increasing the likelihood of collisions and distractions.

The location of the workshop keys is far from the desks, meaning that workers might have to cross the workspace each time they need access, which could slow down operations.

Placing essential resources (such as the first aid box and manuals) in far corners could add time to retrieval processes and reduce efficiency, particularly in urgent situations.

This layout could benefit from repositioning essential items to reduce travel distances and minimize the intersection of paths, helping to create a more streamlined, efficient workflow.

4.1.4. Visual Management

The visual control management method improves efficiency, safety, and quality through visual cues that quickly convey information. It relies on easily understandable signals like signs, labels, color coding, charts, and other visible markers to organize, monitor, and manage processes. Visual controls ensure that essential information is accessible at a glance, reducing the need for verbal instructions and minimizing errors and inefficiencies. The workshops and offices scored 28.7% in their visual management audit before implementing Lean improvement tools. The visual audit checklist demonstrated a significant lack of visual management and control.

4.2. Post-Implementation Results

4.2.1. Process Capability Index

Increasing process capability in a mechanical workshop means enhancing the workshop’s ability to produce service within specified quality standards, reducing variations, and minimizing defects. Process capability is typically measured by indices such as Cp and Cpk, which indicate how well a process can consistently produce results within set tolerances. The workshop can more reliably meet specifications when the process capability increases, improving the overall quality and efficiency. With Lean tool improvement implemented in the workshop, the process capability has increased for both the main workshop and the welding laboratory; as seen in the below calculations for the main workshop, the Cp has increased from 0.33 to 1.24, and Cpk has increased from 0.26 to 0.99. The Cpk for the main workshop increased; however, it did not reach the value of 1.33 because the computer workstation installation was not completed during the study. The welding laboratory has shown an increase in Cp from 0.67 to 2.13, and Cpk has increased from 0.18 to 1.34. A capable process requires fewer adjustments and less oversight, allowing faster production cycles and smoother workflows. As a result, machines and tools are used more effectively, and experiment times increase for students.

Process Capability for the Main Workshop

Mean (µ) = 39 min; standard deviation (σ) = 2.017; upper limit (USL) = 45 min; lower limit (LSL) = 30 min; Cp = 1.24.

Process Capability for Welding Laboratory

Mean (µ) = 38.15 min; standard deviation (σ) = 0.784; upper limit (USL) = 45 min; lower limit (LSL) = 35 min; Cp = 2.13.

4.2.2. Layout Observations

The layout of the workshop office was improved by implementing the 5S methodology. As seen in

Figure 7, the red lines in the layout represent pathways or workflows between essential items, showing how individuals in this workspace might move to access frequently used tools, resources, or amenities. Actual pictures of the office are shown in

Figure 8a,b.

Analyzing

Figure 7 and

Figure 8 can help assess the efficiency of this setup, as follows:

Multiple red lines connect Desk 1 and Desk 2 to the tool cabinet in the center, suggesting that tools stored here are accessed often by both workstations.

This central location reduces the distance required to retrieve tools, improving efficiency by minimizing walking time, which is beneficial for quick tasks or adjustments.

The tool shelf (below and above the mounted table), manuals and tool shelf, and mounted table are accessible along the top wall. The red lines indicate frequent use of this equipment by both desks.

By positioning these storage areas in a linear arrangement, users can grab tools, manuals, or other necessary items quickly and in one trip, streamlining their workflow.

The fridge, microwave, and kettle cluster are along the top wall near the work areas. The red lines indicate quick access from both desks, allowing users to take breaks efficiently without disrupting the workspace or traveling too far.

This arrangement minimizes the time spent walking to the break area, helping maintain productivity while allowing for convenient breaks.

The layout allows for easy movement between Desk 1 and 2, with no obstacles or long distances between them. The red lines connecting the desks indicate communication or shared tasks, and this clear path enables collaboration and quick interaction.

The red lines leading to the workshop keys and electric main switch on the left side show they are easily accessible, especially from Desk 1. This is useful in cases where these items need to be accessed quickly, such as securing the workshop at the end of the day or responding to electrical issues.

Having these critical items on the periphery but still easily reachable is an efficient choice, as it keeps them out of the way but within quick reach.

The first aid box is located conveniently for both desks and close to the tool area, where injuries might be more likely.

The red lines show that it is reachable without significant movement across the room, ensuring a fast emergency response, which is critical for efficiency and safety.

Overall, the red lines illustrate a well-thought-out layout emphasizing minimized movement, easy access to frequently used items, and clear pathways, enhancing the workspace’s overall productivity and efficiency.

4.2.3. Visual Management

Visual controls align well with Lean management and 5S principles by organizing spaces in a way that is intuitive and reduces waste (time, resources, and space), ensuring that items are where they should be and that standards are easy to see and maintain. The workshop and office scores for the visual management audit improved to 91.7%. By standardizing instructions and visual cues, visual controls ensure that processes are consistent across shifts and teams, reducing the risk of deviation from established procedures. The tools and equipment storage in the workshops have been standardized, and lists have been created and displayed on the continuous improvement board. The chart shown in

Figure 9 compares the results of an audit before and after the implementation of visual management practices in the workshop. Before implementation, the workshop scored approximately 30%, and after implementation, the score significantly increased to around 90%. This shows a substantial improvement in the workshop’s visual management system after implementing visual controls, contributing to better organization, easier navigation, and overall process productivity. The visual tools as shown in

Figure 10 helped to maintain a more structured and standardized work environment.

4.3. Discussion

This study aimed to assess the application of Lean Six Sigma (LSS) through the DMAIC framework to improve efficiency and productivity in university mechanical and industrial engineering technology workshops. In alignment with the research questions, the study sought to identify key inefficiencies, apply structured tools for improvement, and assess the quantifiable outcomes of LSS interventions.

The improvement in process capability indices, particularly the rise in Cp from 0.33 to 1.24 for the main workshop and from 0.67 to 2.13 for the welding laboratory, confirms that structured LSS implementation can significantly enhance process reliability and reduce variation in academic technical environments. The welding laboratory’s greater performance gain can be attributed to several factors such as a simpler workflow and smaller-scale work requirement, the faster adoption of visual management, and fewer dependencies on incomplete infrastructure. In detail, it can be said that the welding laboratory had fewer machines and processes, allowing Lean and Six Sigma tools (e.g., 5S, Kaizen, layout adjustments) to be applied more rapidly and thoroughly. Moreover, the welding laboratory had better baseline engagement from staff, resulting in more immediate compliance with visual standards and 5S rules. Lastly, unlike the main workshop, the welding laboratory did not rely on computer workstation installations, which delayed full Lean implementation in the main workshop.

These results reinforce the value of applying industrial quality tools in non-industrial settings, echoing the findings of Antony et al. [

4] and Muthukumaran et al. [

14], who noted the benefits of LSS in educational service processes.

Despite the improvements, the main workshop’s Cpk of 0.99 fell short of the target of 1.33. While the delay in computer workstation installation was a primary factor, other contributors included the more complex layout and higher student and technician traffic and initial resistance or slower adaptation to visual management tools due to the workshop size and diversity of operations.

The 5S and visual management tools were found crucial in reducing the tool retrieval time by 99.62%. The workshops moved from a visual management score of 28.7% pre-implementation to 91.7% post-implementation, demonstrating enhanced organization and clarity in workspaces. In other words, the improved scores supported the hypothesis that improved organization, standardization, and visual controls not only enhance efficiency but also promote safety and reduce the time lost to non-value-adding activities. The centralization of tools and first aid resources in the revised layout further contributed to time savings and improved safety. Streamlining access paths, centralizing tool storage, and minimizing unnecessary movement were pivotal in reducing wasted motion. The new design with layout changes reduced workflow interruptions and made emergency resources (e.g., first aid boxes) more accessible. PDCA and Kaizen supported continuous engagement and iterative improvements, particularly in the welding laboratory, where smaller teams enabled quicker feedback cycles and adoption of changes.

These outcomes align with the 5S implementation benefits reported in the engineering laboratory study by Sari et al. [

16] and support the principle that Lean tools can be directly translated into improved educational laboratory environments.

Moreover, the improved workflow layout and the implementation of PDCA and Kaizen fostered a culture of continuous improvement, an aspect highlighted by Vijayanand and Vaddi [

13] in their work with engineering students. The involvement of technicians and students in the improvement process enabled the contextual adaptation of tools and contributed to sustained engagement, consistent with the participatory improvement models advocated by Li et al. [

15] and Hayden and Peters [

8]. Importantly, the results provide new evidence that LSS is not only viable but also impactful in the higher education sector, countering lingering perceptions that such frameworks are too manufacturing-centric for academic environments. This contributes to bridging a gap in the literature, particularly in the South African context, where such applications are limited. However, the results also suggest the partial fulfillment of the workshops’ improvement goals. The main workshop, for instance, did not meet the Cpk benchmark of 1.33, primarily due to incomplete infrastructure (e.g., workstation installation). This underscores the importance of full infrastructure readiness for successful LSS implementation and offers direction for future enhancement. Overall, the study confirms the potential of DMAIC-guided Lean Six Sigma as a replicable approach to driving operational excellence in academic engineering facilities. It builds on previous findings, extends the application of LSS in higher education, and provides a foundation for further multidisciplinary integration including digital tools and ergonomic studies.

5. Conclusions

The key observation from the study is the confirmation of Lean and Six Sigma applicability in higher education institutions for improving operational activities. In this work, Lean was focused on improving flow and eliminating waste at a broad and strategic level. At the same time, Six Sigma offered a more granular, systematic approach to identifying and reducing process variability and defects. LSS implementation revealed several benefits in the workshops during each DMAIC phase. The workshop process was clearly defined and mapped to understand the critical inputs and outputs. Visual controls were also successfully used in this study to align well with Lean management and housekeeping by organizing spaces in a way that was intuitive and reduced waste (time, resources, and space). By standardizing instructions and visual cues, visual controls ensured that processes were consistent across shifts and teams, reducing the risk of deviation from established procedures. A control chart was implemented to track performance and identify areas for ongoing improvement to ensure sustained efficiency over time. By consistently monitoring process output, the mechanical workshop can identify and reduce sources of variability, improving the overall process capability. This leads to fewer defects, higher quality, and more reliable production outcomes in future operations, as well. To encourage incremental enhancements in workshop processes and student performance, continuous improvement initiatives like Kaizen were also implemented. The process capability for the main workshop increased from 0.33 to 1.24, and that for the welding laboratory increased from 0.67 to 2.13. The process capability index for the main workshop increased from 0.26 to 0.99, and that for the welding laboratory increased from 0.18 to 1.34. Increasing the process capability laid a solid foundation for continuous improvement, as it will be easier to optimize predictable processes.

6. Limitations and Future Research

The current study was focused on workshops and the determination of some of the factors to evaluate productivity, process capability, and control. Further work can include the implementation of Lean engineering and Six Sigma in combination with ergonomics, artificial intelligence, and sustainability to other laboratories and facilities, incorporating time study, work study, waste management, and safety. Also, this study focused on engineering workshops of a higher education institution, but future research could explore broader applications in other technical disciplines. While short-term improvements are quantified in this study, further work should track long-term effectiveness and institutional adoption. Most importantly, this study primarily relied on manual Lean applications; however, digital tools such as IoT-based monitoring or AI-driven workflow optimization could enhance efficiency further.