Abstract

The electric power industry, as a High-Reliability Organization (HRO), demands a mature safety culture. However, existing diagnostic tools often lack industry specificity. This study addresses this gap by developing and validating a specialized safety culture diagnostic tool for the Korea Electric Power Corporation (KEPCO). A mixed-methodology was employed, resulting in a 50-item questionnaire tailored to the power industry’s unique risks. The tool assesses four domains: ‘Hierarchical Safety Leadership’, ‘Safety and Health Management System’, ‘Worker Participation’, and ‘Accident and Risk Management’. The survey was administered to 680 personnel (426 KEPCO internal; 254 contractors). The tool’s reliability was validated using Cronbach’s alpha (internal $\alpha$ = 0.991; contractor $\alpha$ = 0.989), and its structural validity was confirmed through confirmatory factor analysis (CFA). The overall safety culture score was favorable, with a mean of 4.25 (out of 5.0). However, the analysis revealed significant perception gaps between organizational groups. Contractors reported the highest score (4.46), whereas the headquarters (HQ) scored the lowest (4.00). Notably, the HQ showed weaknesses in ‘Worker Participation’ (3.93) and ‘Accident and Risk Management’ (3.98). These results suggest that KEPCO’s culture is currently in the ‘Calculative’ stage. It also demonstrates a significant gap between the HQ’s administrative management and the contractors’ on-site execution. This study expanded the scope of safety research by including contractors, who are often overlooked. This validated tool enables KEPCO to quantitatively diagnose these perception gaps. This supports data-driven interventions and the transition toward a ‘Proactive’ safety culture.

1. Introduction

The 1986 Chernobyl and 2011 Fukushima nuclear power plant accidents demonstrate that beyond technical flaws, an inadequate safety culture was a primary contributor to these major disasters [1,2]. Domestically in South Korea, a lack of safety culture was also identified as a key factor in catastrophic events such as the Seongsu Bridge and Sampoong Department Store collapses [3]. The electric power industry is a core sector supporting essential national economic and social infrastructure. It encompasses high-risk facilities such as thermal, nuclear, and renewable power plants, as well as transmission and distribution (T&D) grids. A single incident within this sector can result in large-scale loss of life, prolonged power outages, and immense socioeconomic damage. Moreover, the power grid functions as Critical Infrastructure and is intrinsically linked to the operational safety of all other industries. Its disruption can trigger cascading industrial damage. Moreover, the power grid functions as Critical Infrastructure, intrinsically linked to the operational safety of all other industries; its disruption can trigger cascading industrial damage. As shown in Table 1, the number of fatalities from industrial safety accidents (occupational accidents) at Korea Electric Power Corporation (KEPCO) significantly decreased over the recent five-year period (2020–2024), falling from 11 in 2020 to 3 in 2024. However, 2023 experienced a temporary spike with 9 fatalities. While overall fatalities from industrial accidents are on a steady downward trend due to reduction efforts, further enhancements to safety standards are necessary to achieve the corporate goal of “Zero Serious Accidents” [4].

Table 1.

Occupational Fatalities at Korea Electric Power Corporation (KEPCO) over the Last Five Years.

The 21st administration of South Korea has prioritized the establishment of fundamental countermeasures for industrial accident prevention as a key national agenda, announcing core tasks necessary for this initiative [5]. In response, on September 1, KEPCO held a “Safety Management Innovation Declaration Ceremony” to “Achieve the Foundational Year for Eradicating Serious Accidents.” Through this declaration, KEPCO committed to fostering a culture of safety deeply embedded in both field operations and daily routines. This commitment includes pursuing uncompromising innovation to eliminate serious accidents and establishing a symbiotic safety culture in cooperation with its contractors. To effectively establish this safety culture at KEPCO, a precise diagnosis and evaluation of its current safety culture level is required. This assessment is essential for formulating mid- to long-term development strategies. The goal is to ensure that a robust safety culture becomes fully embedded in both field operations and daily routines.

As a high-risk, high-reliability organization responsible for critical national infrastructure, the safety culture level of the electric power industry is directly linked to public safety. However, traditional safety management approaches have predominantly focused on regulatory compliance and technical countermeasures, revealing limitations in internalizing safety as a core organizational value. Case studies of major domestic and international accidents have repeatedly identified a lack of safety culture as a primary causal factor. This is particularly critical for the power industry, where the scale and ripple effect of an accident are overwhelmingly large, making the establishment and maturation of a robust safety culture an absolute imperative.

While various diagnostic tools exist to assess safety culture levels, they often have limitations. These tools (such as the KSCI, KOSHA-Care, NOSACQ-50, and BV) often reflect the specific national contexts of their development, are centered on the manufacturing sector, or are designed for general-purpose use [6,7,8,9]. Consequently, there is a distinct need to develop a diagnostic tool specifically centered on the electric power industry. KEPCO, as the core institution in the nation’s power industry, performs a critical role in guaranteeing the stability and safety of the national electricity supply. Given these specific responsibilities, the development of a customized safety culture diagnostic tool that reflects KEPCO’s unique organizational characteristics and operational environment is necessary. The current reliance on external consulting for safety culture improvement presents limitations in terms of sustainability and organizational autonomy. Therefore, a systematic approach is required. This will enable the organization to continuously manage and advance its safety culture based on an internal Plan-Do-Check-Act (PDCA) cycle, thereby strengthening its internal safety capabilities. An accurate internal diagnosis of the safety culture level enables the formulation of a development path tailored to the organization’s specific maturity stage. This facilitates the creation of a practical roadmap for the power industry to transition beyond mere regulatory compliance toward an autonomous and progressively improving safety culture. This progression will, in turn, allow the industry to secure public trust and establish a sustainable safety management system.

Against this backdrop, the objectives of this study are threefold:

First, existing safety culture diagnostic tools are primarily focused on the manufacturing, construction, or nuclear industries and thus fail to adequately reflect the unique risk factors and organizational structures inherent to the electric power industry. This study aims to design a diagnostic framework and derive industry-specific indicators based on Hudson’s Ladder of Safety Culture Maturity. This will establish a foundation for objectively and systematically evaluating the safety culture of power industry organizations. Therefore, the primary goal is to establish a safety culture diagnostic system tailored to the characteristics of the electric power industry.

Second, this study develops safety culture diagnostic survey items (a questionnaire) that reflect the specific characteristics of the power industry. It aims to enhance the reliability and validity of the safety culture diagnosis by integrating both qualitative and quantitative approaches.

Third, this research is intended to serve as foundational data for proposing safety culture enhancement strategies specific to the power industry’s unique characteristics. The power industry is characterized by its strong public service mandate, requirement for operational continuity, high complexity, and dependence on regulation. Consequently, strengthening safety culture solely within the internal confines of the organization is insufficient. A broader governance approach is necessary, encompassing regulatory bodies, operators, contractors, and even the local community. This study reflects implications from safety culture research that extend beyond legal and institutional regulations. It aims to propose a cooperative safety culture model between power operators and their contractors. It seeks to provide the foundational data for presenting concrete implementation strategies. These include expanding worker participation, strengthening leadership, and enhancing the safety capabilities of contractors.

2. Methodology for Diagnosing the Safety Culture Level of Korea Electric Power Corporation (KEPCO)

2.1. Concept of Safety Culture

Safety culture, defined as shared beliefs, values, attitudes, and behavioral patterns related to safety within an organization, began to receive significant international attention following the 1986 Chernobyl nuclear power plant accident. The International Atomic Energy Agency (IAEA) identified an “inadequate safety culture” as a key contributing factor to the accident, thereby emphasizing that safety culture is not merely a matter of technical management but a fundamental issue pervading the entire organizational culture [10]. Safety culture transcends the simple definition of ‘an accident-free state.’ It is a continuous learning process wherein safety is established as the paramount value in organizational operations, risks are actively perceived, and potential hazards are proactively identified and remediated [11,12,13,14,15,16]. In essence, the core of safety culture lies not in relying solely on technical and physical safeguards, but in achieving safety through the autonomous participation and sense of responsibility of all organizational members. The concept of safety culture is particularly critical in High-Reliability Organizations (HROs), such as the electric power industry. The stable, long-term operation of complex and hazardous facilities requires more than mere regulatory compliance; it demands an internalized culture where members genuinely accept safety as a paramount value. For these reasons, safety culture has become a central pillar of modern safety management and can be considered an essential foundation that must be established for the sustainable development of the power industry.

2.2. Characteristics of Safety Culture in the Power Industry

The electric power industry possesses unique characteristics that clearly distinguish it from general manufacturing or construction, and these traits are directly reflected in the formation of its safety culture. Foremost, the industry exhibits the archetypal attributes of a High-Reliability Organization (HRO). Critical facilities, such as power plants and transmission/distribution (T&D) grids, require long-term, uninterrupted operation. A seemingly minor error can escalate into catastrophic societal damage, including large-scale blackouts, radiological releases, fires, or explosions. Consequently, the safety culture in the power industry must transcend mere regulatory compliance; it must be built upon a prevention-oriented mindset and a learning-oriented attitude that responds with high sensitivity to even minor deviation signals. Furthermore, the power industry is characterized by a complex operational environment involving multi-layered organizational structures and numerous stakeholders. Operations are conducted within an interconnected network comprising KEPCO, its generation subsidiaries, independent power producers (IPPs), and T&D contractors. The safety culture level of one organization directly impacts the safety of others. For instance, if a contractor neglects safety regulations, this negligence can immediately translate into risk for the entire power grid. Accordingly, safety culture in the power industry cannot be confined to a single operator but must be approached from an integrated perspective that encompasses the entire industrial ecosystem. Moreover, the power industry operates in close interaction with regulatory bodies. Multiple agencies, such as the Nuclear Safety and Security Commission (NSSC), the Ministry of Trade, Industry and Energy (MOTIE), and the Ministry of Employment and Labor (MOEL), not only provide the legal and institutional framework but also exert significant influence on the operator’s safety culture. If regulatory oversight is limited to formal compliance, operators may perceive safety as a mere obligation. Conversely, if regulators adopt a cooperative, learning-oriented approach, operators are more likely to embrace safety as a core value. As such, the power industry’s safety culture is continuously reconstructed through the dynamic interaction among regulators, operators, and workers.

Finally, the safety culture of the power industry holds significant meaning in the context of securing public trust and ensuring public service integrity. Electricity is an essential public good, forming the basis of national life and directly linked to national security. Therefore, a safety incident in the power industry transcends an internal corporate issue and becomes a societal disaster. Consequently, the safety culture of the power industry functions as social capital, earning trust from the public and local communities. Through this, it can simultaneously ensure the industry’s long-term sustainability and operational stability.

2.2.1. Organizational and Business Characteristics of KEPCO

KEPCO is composed of 270 sites nationwide, including its headquarters, 19 regional and construction headquarters (15 regional HQs, 4 construction HQs), 233 branches (182 local branches, 45 power branches, 6 construction branches), and 17 special business sites. The Safety Division, operating directly under the headquarters, oversees corporate-wide policy formulation and safety management. At the regional level, the Safety and Disaster Department in each regional headquarters manages local safety and occupational accident prevention. Furthermore, one dedicated safety manager is appointed at each branch. As of 2024, KEPCO maintains a high ratio of safety personnel, with 12,649 of its 23,136 total employees (approximately 54.7%) designated as safety-related staff. The primary responsibilities of this dedicated safety workforce include the planning of safety management policies and systems, inspection of legal requirements, field feedback collection, safety patrols and consulting, and oversight of construction site operations, encompassing all general safety-related duties. KEPCO’s core business involves the new construction and maintenance of power facilities. As of 2024, the company manages 16,035 facilities (comprising 46 major target facilities, 15,871 power facilities, and 118 public-use facilities). In the same year, the total number of construction sites was 245,031, broken down into distribution (242,648), transmission and substation (997), civil engineering (624), and other (762) projects. In accordance with the Electric Work Business Act, KEPCO procures construction services, which are then executed by contractors. Based on approximately 245 business days (weekdays) per year, this equates to an average of over 1000 construction projects being conducted daily.

2.2.2. Safety Management and Safety Activities

KEPCO has achieved significant outcomes, including advancing its safety-first management system, strengthening safety compliance requirements for contractors, building a foundation for field safety implementation, clarifying safety competency and evaluation/compensation systems, and enhancing health management. The company actively promotes various safety activities targeting its business sites and contractors, such as conducting risk assessments, certifying exemplary safe workplaces, and operating a robust Safety and Health Management System. These activities cover workplaces, construction sites, facilities, and research laboratories. Furthermore, KEPCO endeavors to disseminate its safety culture through diverse initiatives, including safety-themed musicals, “Challenge! Safety Golden Bell” quizzes, and safety culture promotional content.

2.2.3. Triangulation Approach to Safety Culture in the Power Industry

The proposed safety culture diagnostic methodology is a multi-faceted approach that triangulates data from document review (a practical approach), safety culture surveys (an analytical approach), and interviews stratified by organizational hierarchy (an academic approach). The significance of this method lies in its departure from merely quantifying respondent perceptions. It aims to cross-validate these perceptions against actual behaviors observed in the field, values embedded in institutional regulations, and the tacit assumptions held by different groups, from management to frontline workers. In the context of the power industry, items for document review would include power plant operating regulations, transmission and distribution (T&D) equipment inspection procedures, and disaster response manuals. Concurrently, field observations must evaluate the implementation of systems such as Tool Box Meetings (TBM), Permit to Work (PTW) systems, and “zero-accident” campaigns.

Quantitative safety culture measurement has become a core tool for systematically diagnosing an organization’s safety culture and establishing improvement strategies. Research focused on the power industry, particularly KEPCO, is necessary to develop a specialized quantitative diagnostic tool tailored to the industry’s unique characteristics. Perceptions of safety vary by hierarchy: top management may view safety investment as long-term risk management, whereas field workers are acutely sensitive to immediate hazard control and the availability of Personal Protective Equipment (PPE). Consequently, quantitative measurement should not aim to produce a single, monolithic score. Instead, it must segment, compare, and analyze safety culture levels across different groups (e.g., managers, supervisors, and frontline workers). It is essential to clearly distinguish and analyze the safety perception gaps between hierarchical levels within the power industry. Given that this industry provides services directly linked to public life, it is crucial to develop quantitative management indicators. Metrics such as the achievement of zero-accident goals, TBM participation rates, and safety training completion rates should be quantified, reflected in the performance evaluations of different business sites, and subsequently linked to group and individual reward systems to promote the internalization of safety culture. This approach facilitates the design of an improvement roadmap aimed at reducing perception gaps and fostering shared safety values across the organization. This is valued as a quantitative management strategy that links safety activities to achievement and motivation, rather than treating them as mere compliance burdens.

2.2.4. Reliability Assessment of the Safety Culture Diagnostic Questionnaire

While various metrics exist for evaluating the reliability of a safety culture questionnaire, the most widely used indicator is Cronbach’s alpha (α) coefficient. Cronbach’s (α) summarizes the internal consistency of a scale—that is, how closely related a set of items are as a group—with a value between 0 and 1. A higher value indicates greater internal consistency. Although the practical interpretation of (α) can vary by research context, the following thresholds are commonly accepted: 0.90 (Excellent), 0.80–0.90 (Good), 0.70–0.80 (Moderate), and 0.60–0.70 (Minimally Acceptable). If a low (α) value is obtained, it necessitates an inspection of questionnaire quality issues, such as heterogeneity in item content or asymmetry in the response range. Modifying or removing problematic items may be considered.

2.2.5. Phased Establishment and Internalization of Safety Culture

Ultimately, to embed safety culture into field operations and daily routines, it must be operationalized as a system of quantitative measurement and continuous feedback. This approach transcends a single, short-term diagnosis. It establishes a virtuous cycle (a feedback loop) by tracking annual changes in the safety culture level based on measurement results, and feeding this data back into the refinement of training, institutional policies, and compensation systems. Given the immense societal impact of an accident in the power industry, such a feedback-driven quantitative measurement system becomes the core mechanism for maintaining and advancing safety culture maturity over the long term.

3. Materials and Methods

This study employed a mixed-methodology approach to scientifically and systematically measure and analyze the safety culture level, reflecting the unique characteristics of the electric power industry. The research methodology was broadly structured into three phases: (1) Preliminary Preparation, (2) Design of the Assessment Methodology, and (3) Development of the Safety Culture Diagnostic Questionnaire. Each phase was designed to secure the reliability and validity of the results by concurrently utilizing quantitative investigation and qualitative analysis.

3.1. Preliminary Preparation Phase

In the preliminary preparation phase, domestic and international safety culture policy trends and activity case studies were investigated. KEPCO has the specific characteristic of being responsible for the entire nationwide power supply in Korea, which involves the construction and maintenance of transmission, distribution (T&D), and power facilities [17,18,19,20]. In particular, KEPCO’s existing Safety and Health Management System and safety activity cases were analyzed to identify inherent risks in the power industry, thereby deriving potential safety culture vulnerabilities [4,21,22]. This process established a baseline framework for the safety culture measurement and clearly defined the necessity and scope of the assessment.

3.2. Research Hypotheses

To supply the nationwide power grid, KEPCO conducts hundreds of projects daily related to the construction and maintenance of transmission, distribution (T&D), and power facilities. Despite these safety management efforts, accidents persistently occur every year.

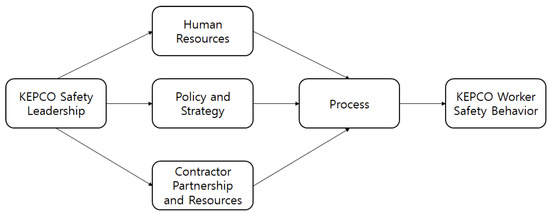

This study aims to investigate the influence of KEPCO’s safety leadership on the safety behaviors of its workers and contractors. To diagnose the safety culture level, a safety culture diagnostic questionnaire was developed. The independent variable, KEPCO Safety Leadership, is hypothesized to influence the implementation drivers: Human Resources, Policy and Strategy, and Contractor Partnership and Resources. These drivers, in turn, are expected to affect the Process, forming a mediating structure that ultimately leads to the dependent variable, KEPCO Worker Safety Behavior. Accordingly, this study designed a research model setting the implementation drivers and the ‘Process’ as mediating variables. KEPCO Worker Safety Behavior is the key outcome indicator determined by the interplay of KEPCO Safety Leadership and these implementation drivers. In other words, this study hypothesizes a structural causal relationship, as shown in Figure 1:

Figure 1.

Research Hypotheses.

KEPCO Safety Leadership → Implementation Drivers (Human Resources, Policy and Strategy, Contractor Partnership and Resources) → Process → KEPCO Worker Safety Behavior. A review of prior literature suggests that KEPCO Safety Leadership does not directly link to Worker Safety Behavior. Instead, it forms a structural process, transmitting its influence through the implementation drivers and the subsequent ‘Process’. Based on this framework, the following hypotheses were established [23,24,25,26].

3.3. Data Analysis Method

In this study, the collected data were analyzed using the R 4.5.1 program according to the following procedures. First, descriptive statistics (frequencies and percentages) were conducted for demographic variables such as gender, age, work type, and work experience to confirm the characteristics and distribution of the sample. Second, the means and standard deviations for the main indicators—KEPCO Safety Leadership, Human Resources, Policy and Strategy, and Contractor Partnership and Resources—were calculated to assess their overall distributional characteristics. Third, Cronbach’s $\alpha$ (alpha) coefficients were calculated for each indicator to verify the internal consistency and reliability of the measurement items. Fourth, a Pearson correlation analysis was conducted to examine the relationships between the main variables.

3.4. Design of Assessment Methodology

For the safety culture diagnosis and assessment methodology, a ‘Triangulation’ method was adopted, combining surveys, interviews, document reviews, and field observations. This approach overcomes the limitations of a single methodology and enhances the reliability of the results through multi-faceted validation. Furthermore, new safety culture assessment indicators suitable for the power industry were developed. These indicators were categorized into four primary domains: (1) Hierarchical Safety Leadership, (2) Safety and Health Management System, (3) Worker Participation, and (4) Accident and Risk Management. Each indicator was meticulously tailored to reflect the power industry’s characteristics, such as operational continuity, public service mandate, and regulatory dependence. As shown in Table 2, these new safety culture indicators were developed based on existing domestic and international indices, including KSCI, KOSHA-Care, BV, and NOSACQ-50, while incorporating the specific attributes of the power industry.

Table 2.

Comparison between the Korean Safety Culture Index (KSCI) and Safety Culture Indicators for the Power Industry.

3.5. Development of Safety Culture Diagnostic Questionnaire Items

The safety culture assessment phase is a core process for identifying the actual level and characteristics of safety culture within the electric power industry field. In this study, quantitative and qualitative methods were used concurrently to enhance the reliability of the assessment and to meticulously reflect hierarchical and organizational characteristics. The most fundamental method employed was an organization-wide survey. This survey was designed to measure perceptions across four primary domains—Hierarchical Safety Leadership, Safety and Health Management System, Worker Participation, and Accident and Risk Management—targeting top management, middle managers, field workers, and contractor employees. The survey was administered concurrently via both online and paper-based formats to secure a sufficient response rate. The questionnaire was designed using a 5-point Likert scale to enable quantification. As shown in Table 3, to secure indicators customized for the power industry, specific items reflecting the industry’s characteristics were included, such as those related to KEPCO’s Key Performance Indicators (KPIs), job types within the headquarters and regional/business sites, and systems for contractor training, communication, and cooperation.

Table 3.

Comparison between the Korean Safety Culture Index (KSCI) and the Power Industry Safety Culture Index.

3.6. Research Subjects and Tools

The survey, based on the contents of Appendix A, was administered over approximately two months from June to August 2025, targeting workers from KEPCO and its contractors within the power industry. As for the specific methodology, the survey was designed for respondents to access it directly on their mobile devices using a QR code. The survey was distributed to contractor employees in coordination with on-site managers. A total of 426 KEPCO employees participated in the survey, categorized into Headquarters (HQ), Business/Regional Sites, and Others. The Business/Regional Sites are responsible for the construction and maintenance of transmission, distribution (T&D), and power facilities in various regions nationwide. The ‘Others’ category includes support and specialized fields such as research and development (R&D), safety education, and safety management. A total of 680 individuals responded to the safety culture diagnosis survey specialized for the electric power industry at KEPCO. This sample comprised 426 respondents from KEPCO’s internal divisions (Headquarters and Business/Regional Sites) and 254 respondents from contractor companies.

3.7. General Characteristics of Respondents

The distribution of respondents according to their general characteristics is presented in Table 4. For the KEPCO internal survey (Headquarters/Business Sites), a total of 426 individuals participated. The sample was composed of 382 males (89.7%) and 44 females (10.3%). By age group, 32 respondents (7.5%) were in their 20s, 158 (37.1%) in their 30s, 104 (24.4%) in their 40s, and 132 (31.0%) were 50 or older. Regarding affiliation, the Business/Regional Sites accounted for the vast majority with 383 respondents (89.9%). In terms of work type, 233 (54.7%) were office workers, 165 (38.7%) were field workers, and 28 (6.6%) were classified as others. For work experience, participants with 20 years or more constituted the largest group, with 184 respondents (43.2%).

Table 4.

Demographic Characteristics of KEPCO Respondents (n = 426).

As shown in Table 5, a total of 254 contractor employees responded. The sample consisted of 236 males (92.9%) and 18 females (7.1%). The age distribution showed that 8 respondents (3.1%) were in their 20s, 37 (14.6%) in their 30s, 39 (15.4%) in their 40s, and 170 (66.9%) were 50 or older, making the 50+ age group the largest. In terms of work type, field workers were the majority with 137 respondents (53.9%), followed by 104 office workers (40.9%) and 13 (5.1%) classified as others. Regarding work experience, participants with 20 years or more constituted the largest proportion, with 132 respondents (52.0%).

Table 5.

Demographic Characteristics of Contractor Respondents (n = 254).

4. Results

4.1. Reliability Analysis of the Safety Culture Diagnostic Questionnairet

The safety culture was assessed using two separate 50-item questionnaires: one for KEPCO internal employees and one for contractor employees. The reliability of these measurement instruments was evaluated by assessing their internal consistency using Cronbach’s (α). The internal consistency results for the overall scale, as well as for each detailed sub-domain, are presented in Table 6.

Table 6.

Cronbach’s (α) Coefficients for the Safety Culture Diagnostic Questionnaire.

The reliability analysis of the 50-item questionnaire for KEPCO internal employees indicated excellent reliability, with a Cronbach’s alpha (α) coefficient of 0.991 for the overall scale. Furthermore, the (α) coefficients for the sub-domains demonstrated stable internal consistency, with a median of 0.931, a minimum of 0.824, and a maximum of 0.978. Similarly, the reliability analysis of the 50-item questionnaire for contractor employees also showed excellent reliability, with an overall scale (α) calculated at 0.989. The sub-domains for this questionnaire also confirmed stable internal consistency, with a median (α) of 0.927, a minimum of 0.825, and a maximum of 0.973.

The results of the Confirmatory Factor Analysis (CFA) indicated that the model fit criteria were satisfied (χ2/df = 2.5, CFI = 0.95, TLI = 0.94, and RMSEA = 0.05). Therefore, the structural validity of this tool was statistically verified. The results of Harman’s single-factor test indicated that the first factor explained 38.5% of the variance, which does not exceed the 50% threshold. Therefore, it was concluded that common method bias (CMB) was not a significant issue.

4.2. Results of the KEPCO Safety Culture Diagnosis Survey

The analysis was conducted based on the mean scores of each item from the safety culture diagnosis survey at KEPCO. Responses were structured on a 5-point Likert scale (ranging from 1 = “Strongly Disagree” to 5 = “Strongly Agree”).

To comprehensively assess the safety perceptions of organizational Personnels, the survey was administered to employees working at KEPCO’s headquarters, business/regional sites, and other affiliated organizations. The sample of 426 respondents was composed of 22 participants from the headquarters, 383 from business/regional sites, and 21 from other organizations, with the proportion of respondents from business/regional sites being the highest. The ‘Other’ organizations category includes special-purpose entities outside the headquarters and main sites, specifically construction branches, the Human Resources Development Institute, the KEPCO Research Institute, and special business sites.

4.2.1. Individual Item Analysis

As shown in Table 7, the analysis of the mean 5-point Likert scale scores for the four safety culture domains revealed an overall mean of 4.25, indicating a favorable level. By domain, the ‘Safety and Health Management System’ recorded the highest score (4.30), followed by ‘Accident and Risk Management’ (4.25), ‘Hierarchical Safety Leadership’ (4.24), and ‘Worker Participation’ (4.22). The finding that all domains scored above 4.2 suggests that a positive safety culture is well-established throughout the organization.

Table 7.

5-Point Likert Scale Results for the Overall Safety Culture Questionnaire and Sub-domains by Respondent Group. (KEPCO Internal vs. Contractors).

An analysis of the 50 individual items revealed an overall mean of 4.32 (out of 5), indicating a very high level of safety culture. Notably, all individual items scored 4.00 or higher. This suggests that a stable safety consciousness is prevalent across the organization, rather than there being severe deficiencies in specific areas. The score range was relatively narrow (0.49 points), from a high of ‘Safety Inspection’ (4.49) to a low of ‘Motivation’ (4.00).

A closer look at the score distribution shows that 32 of the 50 items (64%) were concentrated between 4.20 and 4.39. This reaffirms that most safety activities are managed at a consistently high level without significant deviation. The composition of the top 10 items identified the organization’s clear strengths. ‘Safety Inspection’ (4.49), ‘Safety Environment Management’ (4.48), ‘Safety Goals and Performance Assessment’ (4.48), and ‘Safety Regulations and Procedures’ (4.47) ranked highest.

This implies that the institutional and systemic elements corresponding to the ‘Safety and Health Management System’ domain are very positively perceived in the field. In other words, the formal safety system—establishing procedures, conducting inspections, and managing the environment—is analyzed as functioning successfully.

Conversely, the bottom 10 items clearly highlighted areas for future improvement. ‘Motivation’ (4.00) recorded the lowest score among all items, while ‘Accident Investigation’ (4.13) and ‘Management Safety Investment’ (4.13) were also in the lower tier.

This presents a contrast to the aforementioned strengths (systems, regulations). It suggests that beyond systemic management, the more informal and cultural elements—such as motivating voluntary participation, ensuring visible management safety investment, and conducting substantive root cause analysis after incidents—are perceived as relatively weak.

High Consistency (Low Standard Deviation): Items such as ‘Safety Inspection’ (SD = 0.74), ‘Safety Regulations’ (SD = 0.75), and ‘Manager Safety Instructions’ (SD = 0.76) showed low standard deviations. This indicates that most respondents consistently perceive these items as “performing well,” supporting their status as firm organizational strengths.

Low Consistency (High Standard Deviation): It is highly noteworthy that the lowest-scoring items perfectly aligned with the items showing the highest standard deviation (i.e., the greatest perception variance). ‘Motivation’ (SD = 1.14), ‘Accident Investigation’ (SD = 1.11), and ‘Management Safety Investment’ (SD = 1.07) showed strongly divergent opinions within the organization.

This implies that these items are not just scoring low; they are subject to a “polarization of perception,” where some members rate them positively while a significant number rate them very negatively. Therefore, improvement strategies for these domains must focus not only on raising the mean score but also on reducing the perception gap among members and building a shared consensus.

4.2.2. Analysis of Safety Culture Levels by Organizational Affiliation

The analysis of safety culture levels by affiliation revealed that significant differences exist in the perception and practice of safety culture depending on the organizational type.

Contractors reported the highest assessment (4.46 out of 5), whereas the Headquarters (HQ) recorded the lowest (4.00). These were followed by ‘Others’ (4.30) and ‘Business Sites’ (4.25). A substantial gap of 0.46 points was observed between the highest-scoring group (Contractors) and the lowest (HQ). This finding suggests that the specific characteristics and operational environment of each affiliation significantly impact the perception of safety culture.

Contractors demonstrated the most robust performance across all four assessment domains, recording their highest score (4.51) in ‘Hierarchical Safety Leadership’. This result is interpreted as a consequence of their work environment, in which they are under the direct safety management and supervision of the principal client (KEPCO). This oversight appears to foster a naturally internalized and well-maintained level of safety consciousness and practice.

Conversely, the HQ received the lowest assessment in every domain and exhibited clear vulnerabilities, scoring below the 4.0-point threshold in ‘Worker Participation’ (3.93) and ‘Accident and Risk Management’ (3.98). This is analyzed as stemming from a relative lack of direct field exposure to hazards and an office-centric work environment, which affords fewer opportunities to perceive the tangible importance of safety culture.

The KEPCO HQ, with an overall mean of 3.99, was the only group to score below 4.0, indicating that comprehensive improvement is an urgent task. While ‘Safety and Health Management System’ (4.10) was its highest-rated domain, ‘Worker Participation’ (3.93) was its lowest. The inter-domain variation was relatively small at 0.17 points; however, this is interpreted not as positive balance, but rather as homogenization at an overall low level.

Business Sites (mean = 4.25) performed at the same level as the overall average. ‘Safety and Health Management System’ (4.30) was their primary strength, whereas ‘Worker Participation’ (4.20) emerged as an area needing relative improvement. This group featured the smallest inter-domain variation (0.10 points), characterized by a stable and balanced safety culture level across all four domains.

The ‘Others’ group reported a high mean of 4.30. Their main strength was in the ‘Safety and Health Management System’ (4.36), with a relative weakness in ‘Hierarchical Safety Leadership’ (4.25). The inter-domain variation (0.11 points) was also stable, similar to the Business Sites.

Contractors recorded the highest overall mean (4.46) and can be considered an exemplary case of safety culture. Their greatest strength was in ‘Hierarchical Safety Leadership’ (4.51). Notably, even their lowest-rated domain, ‘Safety and Health Management System’ (4.41), scored higher than the highest domain scores of the other organizations. Their inter-domain variation was minimal (0.10 points), indicating that their greatest strength is the maintenance of a consistently high and balanced level of safety culture across all domains.

5. Discussion and Conclusions

This study developed a safety culture diagnostic tool reflecting the characteristics of the electric power industry, enabling a multi-dimensional diagnosis of the current safety culture status within KEPCO and its contractors, and proposing directions for improvement. In particular, the survey results confirmed differences in the levels of the ‘Safety and Health Management System’ and ‘Worker Participation’ between the headquarters (HQ), business/regional sites, and contractors. This indicates that while a foundation for overall safety management is in place through the establishment and operation of a safety management system, the system itself has not yet fully taken root. KEPCO is assessed to be in the Calculative stage of the Hudson Culture Ladder, necessitating a plan to establish a safety culture that can advance to the Proactive stage. In conclusion, the following implications and future directions can be derived.

Safety culture diagnosis in the power industry has generally centered on nuclear power plants. However, the Korean power industry has a unique characteristic, being separated into generation companies (e.g., nuclear, thermal) and KEPCO, which handles transmission and distribution (T&D). This study developed a diagnostic tool that reflects this industrial specificity, enabling the diagnosis and improvement of the safety culture across the entire power industry.

First, from an academic perspective, this study is significant in that it expanded the scope of existing research. Prior studies predominantly analyzed the effects of safety leadership focusing on internal employees or specific worksites, with analyses including contractor workers being very limited. This study developed questionnaire items to analyze the structural relationship where KEPCO Worker Safety Behavior is mediated by implementation drivers and processes. This is meaningful as it broadens the unit of analysis in safety culture diagnosis from internal client staff to external contractors.

Second, from a practical perspective, this study offers specialized implications for establishing safety management strategies for contractors in the power industry. The Korean power industry involves complex processes where different risks—such as high-voltage electricity, high-altitude work, and traffic/transport—exist simultaneously. As KEPCO is structured to manage project ordering, design, and oversight while contractors handle all on-site construction, contractor workers are multi-dimensionally exposed to severe accident risks like electrocution, falls, and traffic accidents. Consequently, managing complex and overlapping risks, rather than single risks, emerges as a core challenge for safety management in this industry.

In this context, the study demonstrated that the client’s safety leadership most strongly influences ‘Policy and Strategy’, while ‘Human Resources’ is the key contributing factor at the ‘Process’ stage. This implies that contractor safety management strategies must simultaneously strengthen the two pillars of institutional policy design and on-site human resource management. Therefore, field managers must move beyond simple education and training to implement systematic records management for key field personnel (e.g., signalers, guide workers) and institutionalize a culture of risk experience sharing and feedback. Furthermore, as ‘Process’ was identified as a major mediator leading to safety behavior, it is necessary to design work procedures that minimize mixed-work (simultaneous operations) and to expand technology-based management suitable for power industry sites, such as smart CCTV and mobile surveillance systems.

Crucially, it is important to shift safety leadership activities from ‘administrative management’ to ‘field-oriented support’ as perceived by contractor employees. For example, client-led regular safety communication, providing execution-focused feedback before work, and rapid resource support in hazardous situations are concrete measures that allow contractor workers to feel a tangible change. This suggests that in managing the unique risks of the power industry, safety leadership must not remain at the level of internal system-building but must be converted into an executive power (implementation) that contractor workers can actually experience.

Third, from a policy perspective, this study shows that for legal and institutional mechanisms to operate effectively in the field—especially as the client’s safety responsibility expands under Korea’s Severe Accidents Punishment Act (SAPA) and Occupational Safety and Health Act (OSHA)—KEPCO’s safety leadership must be embodied as specific implementation drivers. The current legal controversy regarding the status of dispatched and subcontracted workers still leaves a gap between institutional frameworks and field execution; this study’s results support that safety leadership is the practical means to bridge this gap. Furthermore, institutional support should be strengthened to allow KEPCO and its contractors practical access to and utilization of safety management systems (based on security protocols), and guidelines clarifying the spheres of responsibility between KEPCO and its contractors are needed. Additionally, policy-level campaigns and data-driven safety management policies should be pursued concurrently so that safety compliance can be established as a social norm, moving beyond mere regulatory adherence.

Business models involving the construction of nationwide infrastructure and the management of new and existing facilities are also found in similar companies, such as those in the railway, telecommunications (wired/wireless), and gas supply sectors. In the future, this safety culture diagnostic tool, specialized for the power industry, can be utilized by companies in similar business sectors by supplementing the questionnaire items to include the specific characteristics of each field.

Author Contributions

Methodology, D.S. and S.J.Y.; Formal analysis, J.L.; Investigation, D.S.; Resources, D.S. and S.J.Y.; Supervision, D.L.; Project administration, S.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by Korea Electric Power Corporation (Grant number: R24XO03-1); This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (2020R1A6A1A03044977).

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki, and approved by the Institutional Review Board (or Ethics Committee) of Soongsil University (protocol code SSU-202508-HR-700-1 and date of approval 11 August 2025).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Power Industry-Specific Safety Culture Diagnostic Questionnaire Items

This study developed safety culture assessment indicators tailored to the specific characteristics of the electric power industry at KEPCO, as presented in Table A1 and Table A2. This framework is designed as a safety culture diagnostic tool that encompasses the entire organization and its contractors through specialized surveys and interviews. It is specifically engineered for practical, field-oriented safety management and cultural improvement within the power industry.

Based on this foundation, the tool can be expanded into a comprehensive safety culture assessment system. This system supports the quantitative and systematic diagnosis of the safety culture level within the organization, thereby enabling the derivation of specific and actionable improvement measures. Furthermore, the methodology focuses on evaluating whether these cultural elements are actually functioning in the field and on enhancing their executive power (implementation capability). The primary objective is to provide a safety culture assessment system that, based on indicators reflecting the power industry’s unique characteristics: (1) quantitatively and systematically diagnoses the organization’s safety culture level; (2) derives improvement measures that possess high field applicability and implementation potential; and (3) supports the strengthening of safety activities that are demonstrably effective in practice.

Table A1.

Safety Culture Diagnostic Questionnaire Items (Internal) Specialized for KEPCO’s Power Industry.

Table A1.

Safety Culture Diagnostic Questionnaire Items (Internal) Specialized for KEPCO’s Power Industry.

| Assessment Domain | No. | Item |

|---|---|---|

| Hierarchical Safety Leadership | 1 | Our company’s management considers safety management (safety-first management) more important than work schedule management. |

| 2 | Our company’s management considers safety the top priority in business operations. | |

| 3 | Our company’s management actively strives to provide the necessary personnel and equipment, secure budgets, and improve systems for safety. | |

| 4 | Our company’s management establishes safety management strategies so that more members can act according to the value of safety-first. | |

| 5 | Managers and senior workers possess expertise, including knowledge and experience, regarding safety. | |

| 6 | Managers take the lead in improving safety issues and strive to prepare improvement plans. | |

| 7 | Managers proactively identify hazardous conditions at the site before work and check unsafe behaviors during work to actively improve them for accident prevention. | |

| 8 | When managers give work instructions, they prioritize safety. | |

| 9 | Managers ensure that workers comply with safety regulations and procedures even under tight work schedules. | |

| 10 | Members stop work immediately when they detect a hazard during work. | |

| 11 | When members are advised of unsafe behaviors or conditions, they listen attentively and improve them immediately. | |

| 12 | Members conduct Tool Box Meetings (TBM) and comply with work standards and safety procedures before work, even when the schedule is tight. | |

| 13 | When a hazardous situation occurs, members actively seek solutions to resolve it. | |

| 14 | Members actively provide opinions to colleagues exhibiting unsafe behaviors to encourage behavioral change. | |

| 15 | Members participate in various safety-related activities through voluntary motivation. | |

| Safety and Health Management System | 1 | Our company manages safety equipment and tools (or work equipment) to enable safe work. |

| 2 | Our company adequately provides Personal Protective Equipment (PPE) and hand tools necessary for work. | |

| 3 | Our company establishes detailed safety inspection plans for the entire workplace, including inspection scope, frequency, and responsible personnel. | |

| 4 | Our company’s safety inspections effectively identify significant hazards and risk factors. | |

| 5 | Our company implements prompt and effective improvement measures for identified hazards and risk factors. | |

| 6 | Our company systematically establishes new safety goals (e.g., priority management, behavior improvement) annually, considering recent safety issues and key safety indicators. | |

| 7 | Our company includes safety performance in personnel evaluation indicators, performance indicators, or Key Performance Indicators (KPIs). | |

| 8 | Our company has established evaluation criteria for achieving safety goals and conducts regular, multi-faceted evaluations. | |

| 9 | Our company establishes a basic safety management plan reflecting trends in safety indicators and major safety issues. | |

| 10 | Our company periodically evaluates and improves the effectiveness of regulations and procedures according to the P-D-C-A (Plan-Do-Check-Act) cycle. | |

| 11 | Our company listens to members’ opinions in the process of enacting/revising safety regulations and procedures. | |

| 12 | Our company motivates safety behavior through methods such as praise, rewards, performance bonuses, and promotions. | |

| 13 | Our company provides immediate feedback and coaching when members or workers exhibit unsafe behaviors. | |

| 14 | Our company’s safety management personnel are adequate in number (scale) to find and solve problems and support field operations. | |

| 15 | Our company’s safety management personnel possess the appropriate expertise to find and solve problems and support field operations. | |

| Worker Participation | 1 | Our company’s safety training is practically helpful for accident prevention and is conducted regularly. |

| 2 | Our company’s safety training content is improved based on member needs and effectiveness evaluations. | |

| 3 | Members actively participate and learn during safety training sessions. | |

| 4 | Members strive to apply what they learned in safety training (e.g., safety knowledge, skills) to their actual work. | |

| 5 | Members acquire the competencies necessary to perform their work safely through safety training. | |

| 6 | Members freely exchange opinions on safety, regardless of rank or age. | |

| 7 | Members understand how to use online/offline channels for safety communication and actively utilize them. | |

| 8 | Members seek to achieve safety goals together through communication and cooperation. | |

| 9 | Our company members can easily and accurately check management’s safety messages, safety work recommendations, and accident propagation details anytime, anywhere. | |

| 10 | Our company provides specific feedback and discloses improvement measures for safety suggestions to its members. | |

| Accident and Risk Management | 1 | Members share cases of minor near-misses (e.g., tripping over a protrusion at the worksite without injury). |

| 2 | Members participate in analyzing the causes of accidents and establishing countermeasures with relevant departments. | |

| 3 | When an accident occurs, our company strives to find the direct and root causes rather than blaming the individuals involved. | |

| 4 | Our company’s recurrence prevention measures are practically helpful in improving problems at the site. | |

| 5 | Our company establishes recurrence prevention measures based on accident investigation results and actively utilizes them for prevention. | |

| 6 | Our company conducts risk assessments according to established procedures and reflects them in safety manuals. | |

| 7 | Our company has detailed response procedures for emergency situations and conducts regular drills. | |

| 8 | Our company applies the same safety standards to contractor workers and ensures they can work safely. | |

| 9 | Our company supports safety education and training for contractor workers. | |

| 10 | Our company continuously communicates with contractors regarding safety. |

Table A2.

Safety Culture Diagnostic Questionnaire Items (Contractors) Specialized for KEPCO’s Power Industry.

Table A2.

Safety Culture Diagnostic Questionnaire Items (Contractors) Specialized for KEPCO’s Power Industry.

| Assessment Domain | No. | Item |

|---|---|---|

| Hierarchical Safety Leadership | 1 | KEPCO’s management considers safety management (safety-first management) more important than work schedule management. |

| 2 | KEPCO’s management considers safety the top priority in business operations. | |

| 3 | KEPCO’s management actively strives to provide the necessary personnel and equipment, secure budgets, and improve systems for safety. | |

| 4 | KEPCO’s management establishes safety management strategies so that more members can act according to the value of safety-first. | |

| 5 | Field managers and senior workers possess expertise, including knowledge and experience, regarding safety. | |

| 6 | Field managers take the lead in improving safety issues and strive to prepare improvement plans. | |

| 7 | Field managers proactively identify hazardous conditions at the site before work and check unsafe behaviors during work to actively improve them for accident prevention. | |

| 8 | When field managers give work instructions, they prioritize safety. | |

| 9 | Field managers ensure that contractor workers comply with safety regulations and procedures even under tight work schedules. | |

| 10 | Contractor workers, including myself, stop work immediately when they detect a hazard during work. | |

| 11 | Contractor workers, including myself, listen attentively and improve immediately when advised of unsafe behaviors or conditions. | |

| 12 | Contractor workers, including myself, conduct Tool Box Meetings (TBM) and comply with work standards and safety procedures before work, even when the schedule is tight. | |

| 13 | Contractor workers, including myself, actively seek solutions to resolve hazardous situations when they occur. | |

| 14 | Contractor workers, including myself, actively provide opinions to colleagues exhibiting unsafe behaviors to encourage behavioral change. | |

| 15 | Contractor workers, including myself, participate in various safety-related activities through voluntary motivation. | |

| Safety and Health Management System | 1 | KEPCO manages safety equipment and tools (or work equipment) to enable safe work. |

| 2 | KEPCO adequately provides Personal Protective Equipment (PPE) and hand tools necessary for work. | |

| 3 | KEPCO establishes detailed safety inspection plans for the entire workplace, including inspection scope, frequency, and responsible personnel. | |

| 4 | KEPCO’s safety inspections effectively identify significant hazards and risk factors. | |

| 5 | KEPCO implements prompt and effective improvement measures for identified hazards and risk factors. | |

| 6 | KEPCO systematically establishes new safety goals (e.g., priority management, behavior improvement) annually, considering recent safety issues and key safety indicators, and presents them clearly. | |

| 7 | KEPCO reflects safety performance in personnel evaluations or performance indicators, and these standards are shared with or influence contractors. | |

| 8 | KEPCO regularly evaluates the achievement of safety goals and shares or reflects the results with contractors. | |

| 9 | KEPCO establishes a basic safety management plan reflecting trends in safety indicators and major safety issues. | |

| 10 | KEPCO periodically evaluates and improves the effectiveness of regulations and procedures according to the P-D-C-A (Plan-Do-Check-Act) cycle. | |

| 11 | KEPCO listens to contractor members’ opinions in the process of enacting/revising safety regulations and procedures. | |

| 12 | KEPCO motivates safety behavior through methods such as praise, rewards, and performance bonuses. | |

| 13 | KEPCO provides immediate feedback and coaching when contractor workers exhibit unsafe behaviors. | |

| 14 | KEPCO’s safety management personnel are adequate in number (scale) to find and solve problems and support field operations. | |

| 15 | KEPCO’s safety management personnel possess the appropriate expertise to find and solve problems and support field operations. | |

| Worker Participation | 1 | KEPCO’s safety training is practically helpful for accident prevention and is conducted regularly. |

| 2 | KEPCO’s safety training content is improved based on member needs and effectiveness evaluations. | |

| 3 | Contractor workers, including myself, actively participate and learn during safety training sessions. | |

| 4 | Contractor workers, including myself, strive to apply what they learned in safety training (e.g., safety knowledge, skills) to their actual work. | |

| 5 | Contractor workers, including myself, acquire the competencies necessary to perform their work safely through safety training. | |

| 6 | Contractor workers, including myself, freely exchange opinions on safety, regardless of rank or age. | |

| 7 | Contractor workers, including myself, understand how to use online/offline channels for safety communication and actively utilize them. | |

| 8 | Contractor workers, including myself, seek to achieve safety goals together through communication and cooperation. | |

| 9 | Contractor workers, including myself, can easily and accurately check management’s safety messages, safety work recommendations, and accident propagation details anytime, anywhere. | |

| 10 | KEPCO provides specific feedback and discloses improvement measures for safety suggestions to its members. | |

| Accident and Risk Management | 1 | Contractor workers, including myself, share cases of minor near-misses (e.g., tripping over a protrusion at the worksite without injury). |

| 2 | Contractor workers, including myself, participate in analyzing the causes of accidents and establishing countermeasures with relevant departments. | |

| 3 | When an accident occurs, KEPCO strives to find the direct and root causes rather than blaming the individuals involved. | |

| 4 | KEPCO’s recurrence prevention measures are practically helpful in improving problems at the site. | |

| 5 | KEPCO establishes recurrence prevention measures based on accident investigation results and actively utilizes them for prevention. | |

| 6 | KEPCO conducts risk assessments according to established procedures and reflects them in safety manuals. | |

| 7 | KEPCO has detailed response procedures for emergency situations and conducts regular drills. | |

| 8 | KEPCO applies the same safety standards to contractor workers and ensures they can work safely. | |

| 9 | KEPCO supports safety education and training for contractor workers. | |

| 10 | KEPCO continuously communicates with contractors regarding safety. |

References

- Lee, S.H.; Lee, J.; Kim, J.E. A Guide to Safety Culture I; Korea Occupational Safety and Health Agency (KOSHA): Ulsan, Republic of Korea, 2021; pp. 1–110. [Google Scholar]

- Fleming, M.; Horvath, K.; Barry, K.C. Development and testing of a nuclear regulator safety culture perception survey. Saf. Sci. 2022, 153, 105820. [Google Scholar] [CrossRef]

- Lee, M.N. Exploration of Organizational Characteristic Variables Affecting Safety Culture. Master’s Thesis, Pusan National University, Busan, Republic of Korea, 2025; pp. 1–10. [Google Scholar]

- Korea Electric Power Corporation (KEPCO). 2024 Safety Management Responsibility Report; KEPCO: Naju, Republic of Korea, 2025; pp. 5–69. [Google Scholar]

- DR & AJU LLC. Public Strategy Group Issue Report—Legislative Tasks and Policy Prospects of the Lee Jae-Myung Administration; DR & AJU LLC: Seoul, Republic of Korea, 2025; pp. 2–3. [Google Scholar]

- Jin, S.S.; Lee, Y.S.; Moon, G.S.; Kim, D.M. Validation and Advancement of the Korean Safety Culture Index (KSCI); Korea Occupational Safety and Health Agency (KOSHA): Ulsan, Republic of Korea, 2024; pp. 50–53. [Google Scholar]

- Na, M.O.; Choi, Y.S.; Choi, W.C. Application methods of workplace safety consciousness enhancement programs for improving workplace safety culture. J. Korean Soc. Saf. Cult. 2024, 33, 65–83. [Google Scholar]

- Parker, D.; Lawrie, M.; Hudson, P. A framework for understanding the development of organisational safety culture. Saf. Sci. 2006, 44, 551–562. [Google Scholar] [CrossRef]

- Oltedal, H.A.; Engen, O.A. Local management and its impact on safety culture and safety within Norwegian shipping. In Safety, Reliability and Risk Analysis: Theory, Methods and Applications; Martorell, S., Guedes Soares, C., Barnett, J., Eds.; CRC Press: London, UK, 2009; pp. 1423–1430. [Google Scholar]

- International Atomic Energy Agency (IAEA). Safety Culture in Nuclear Installations: Guidance for Use in the Enhancement of Safety Culture; IAEA-TECDOC-1329; IAEA: Vienna, Austria, 2002; pp. 3–15. [Google Scholar]

- Reason, J. Achieving a safe culture: Theory and practice. Work Stress 1998, 12, 293–306. [Google Scholar] [CrossRef]

- Guldenmund, F.W. Understanding and Exploring Safety Culture. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2010; pp. 156–189. [Google Scholar]

- Schein, E.H. Culture: The missing concept in organization studies. Adm. Sci. Q. 1996, 41, 229–240. [Google Scholar] [CrossRef]

- Hudson, P. Safety culture: The ultimate goal. Flight Saf. Aust. 2001, 5, 29–31. [Google Scholar]

- Lawrie, M.; Parker, D.; Hudson, P. Investigating employee perceptions of a framework of safety culture maturity. Saf. Sci. 2006, 44, 259–276. [Google Scholar] [CrossRef]

- Kines, P.; Lappalainen, J.; Mikkelsen, K.L.; Olsen, E.; Pousette, A.; Tørrud, J.; Tómasson, K.; Törner, M. Nordic Safety Climate Questionnaire (NOSACQ-50): A new tool for diagnosing occupational safety climate. Int. J. Ind. Ergon. 2011, 41, 634–646. [Google Scholar] [CrossRef]

- Moon, Y.J. A study on the validation of the safety culture scale for social welfare organizations: Focusing on community welfare centers, senior welfare centers, and welfare centers for the disabled. J. Korean Soc. Saf. Cult. 2024, 26, 27–40. [Google Scholar]

- Choi, Y.S.; Chae, H.S. The effect of corporate safety culture on safety behavior: Focusing on the moderating effect of supervisor safety competency. J. Korean Soc. Saf. Cult. 2025, 39, 83–97. [Google Scholar]

- Fleming, M. Safety Culture Maturity Model; Offshore Technology Report 2000/049; Health and Safety Executive (HSE): Sudbury, UK, 2000; pp. 4–77. [Google Scholar]

- Hudson, P. Implementing a safety culture in a major multi-national. Saf. Sci. 2007, 45, 697–722. [Google Scholar] [CrossRef]

- Korea Electric Power Corporation (KEPCO). 2022 Safety Management Responsibility Report; KEPCO: Naju, Republic of Korea, 2023; pp. 4–77. [Google Scholar]

- Korea Electric Power Corporation (KEPCO). 2023 Safety Management Responsibility Report; KEPCO: Naju, Republic of Korea, 2024; pp. 4–69. [Google Scholar]

- Wu, C.; Fang, D.; Li, N. Roles of owners’ leadership in construction safety: The case of high-speed railway construction projects in China. Int. J. Proj. Manag. 2015, 33, 1665–1679. [Google Scholar] [CrossRef]

- Wu, C.; Song, X.; Wang, T.; Fang, D. Core dimensions of the construction safety climate for a standardized safety-climate measurement. J. Constr. Eng. Manag. 2015, 141, 04015018. [Google Scholar] [CrossRef]

- Wu, C.; Wang, F.; Zou, P.X.; Fang, D. How safety leadership works among owners, contractors and subcontractors in construction projects. Int. J. Proj. Manag. 2016, 34, 789–805. [Google Scholar] [CrossRef]

- Clarke, S. Safety leadership: A meta-analytic review of transformational and transactional leadership styles as antecedents of safety behaviours. J. Occup. Organ. Psychol. 2013, 86, 22–49. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).