Research on Crack Propagation in Hard Rock Coal via Hydraulic Fracturing

Abstract

1. Introduction

2. Materials and Methods

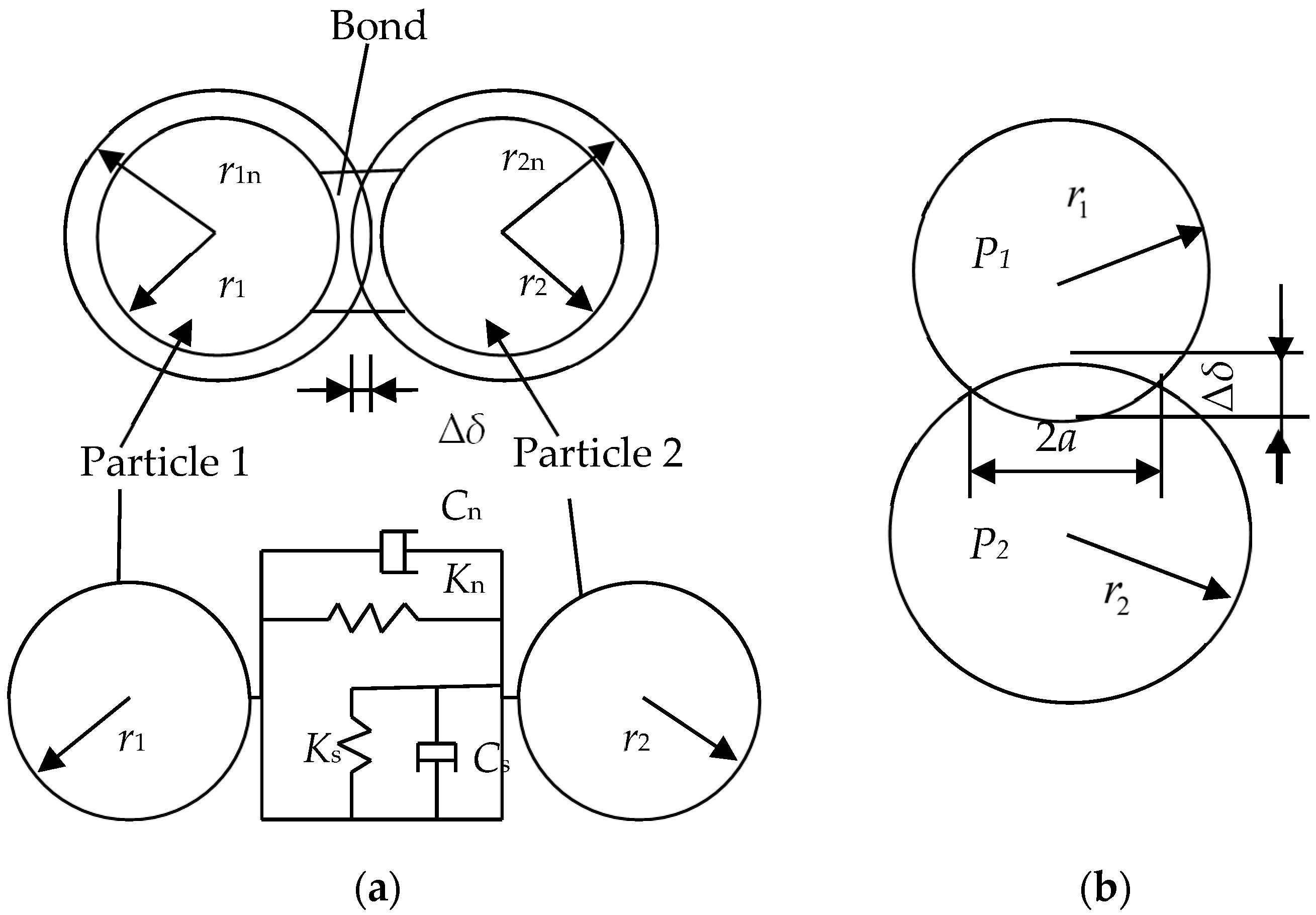

2.1. Discrete Element Method (DEM)

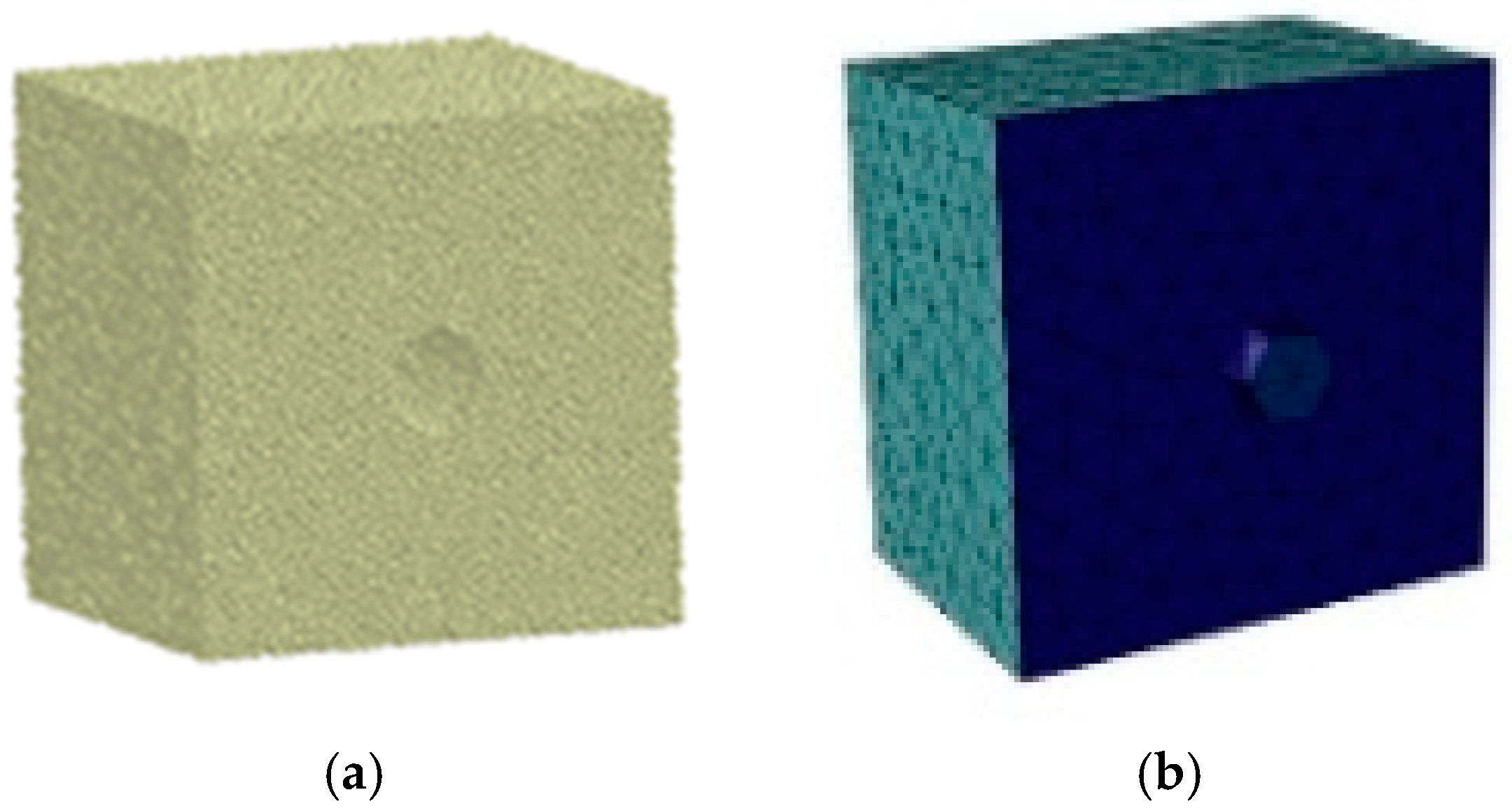

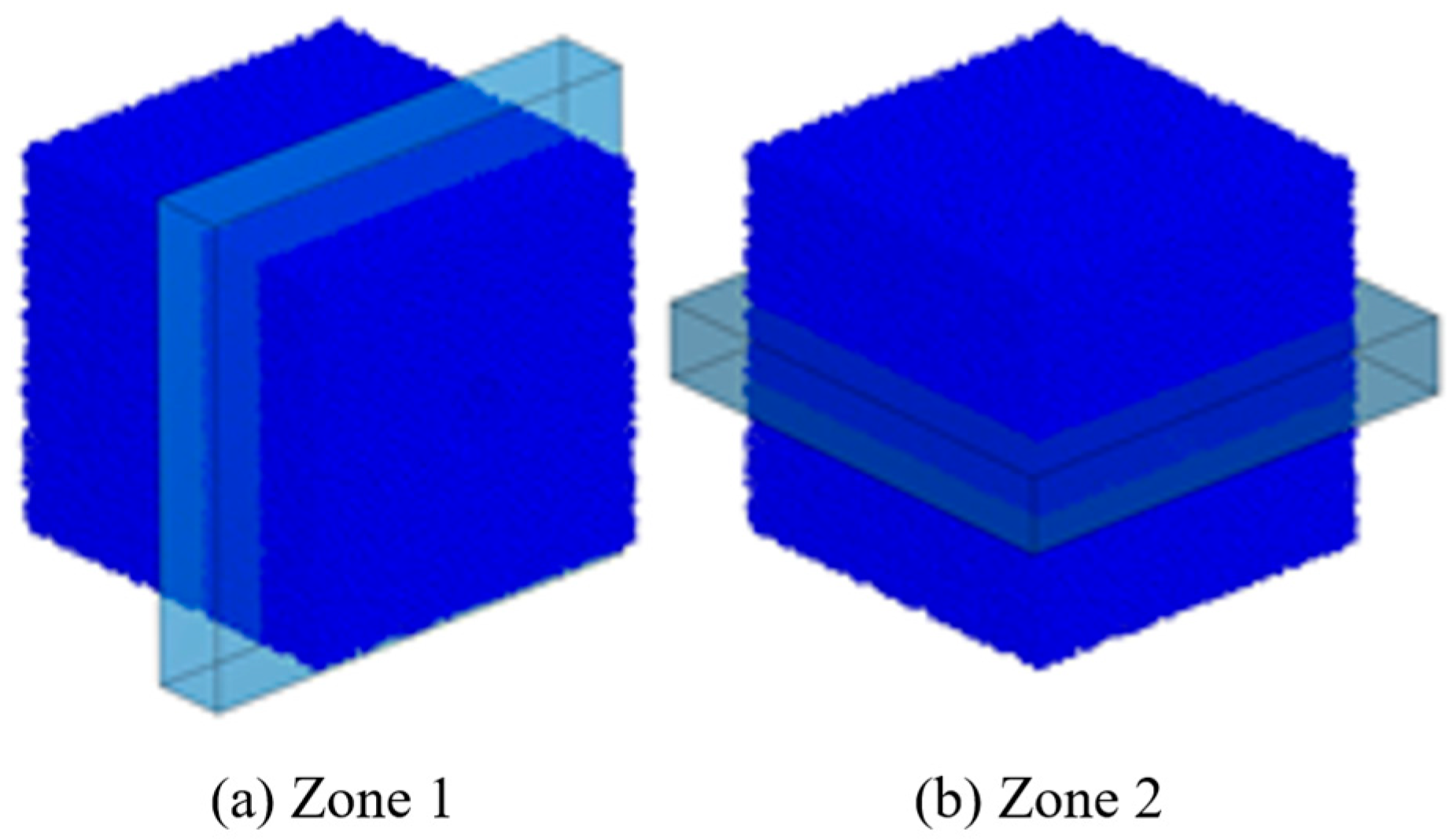

2.2. Coupled Model Establishment

2.3. Simulation Parameters

3. Simulation Results and Analysis

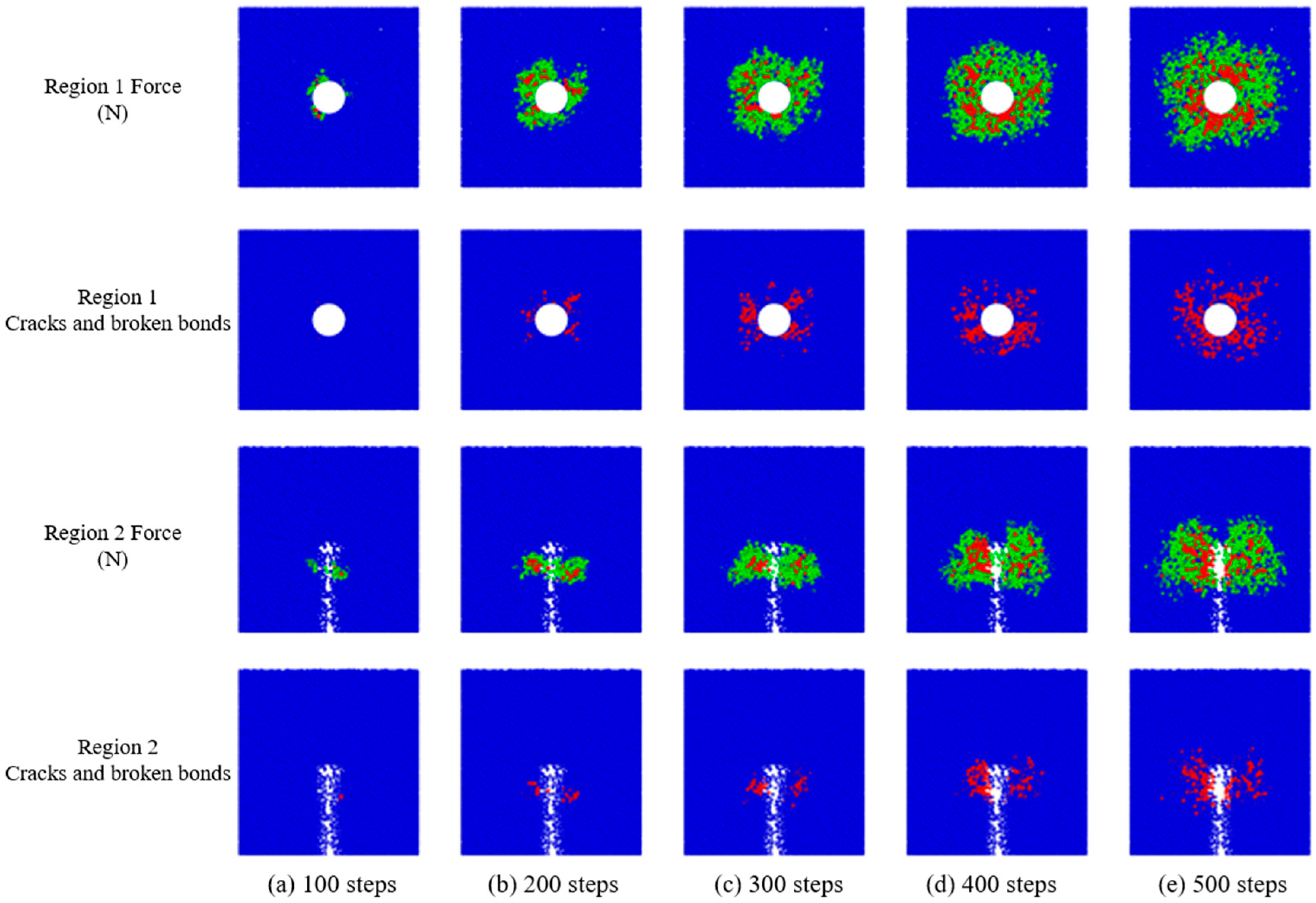

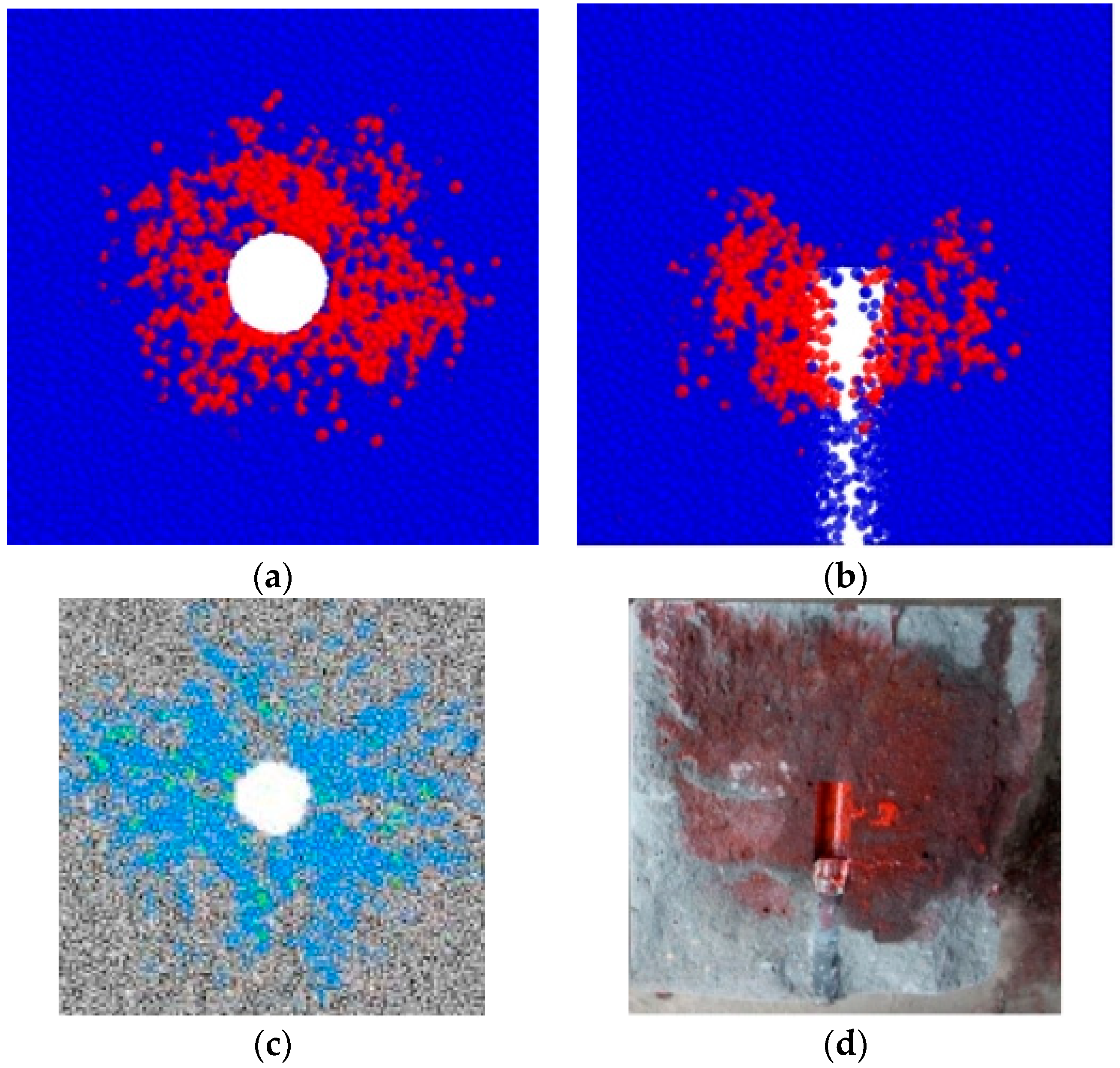

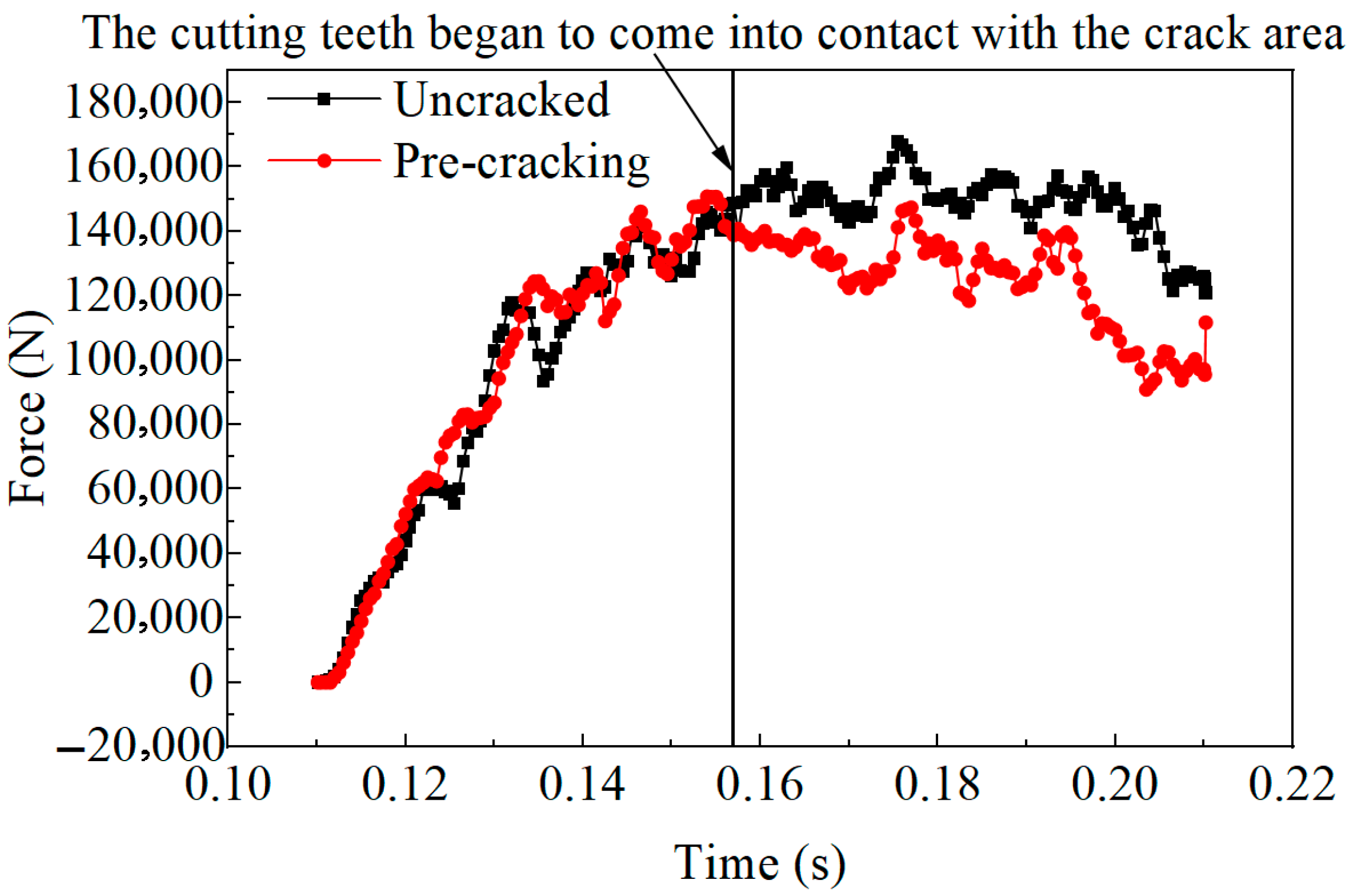

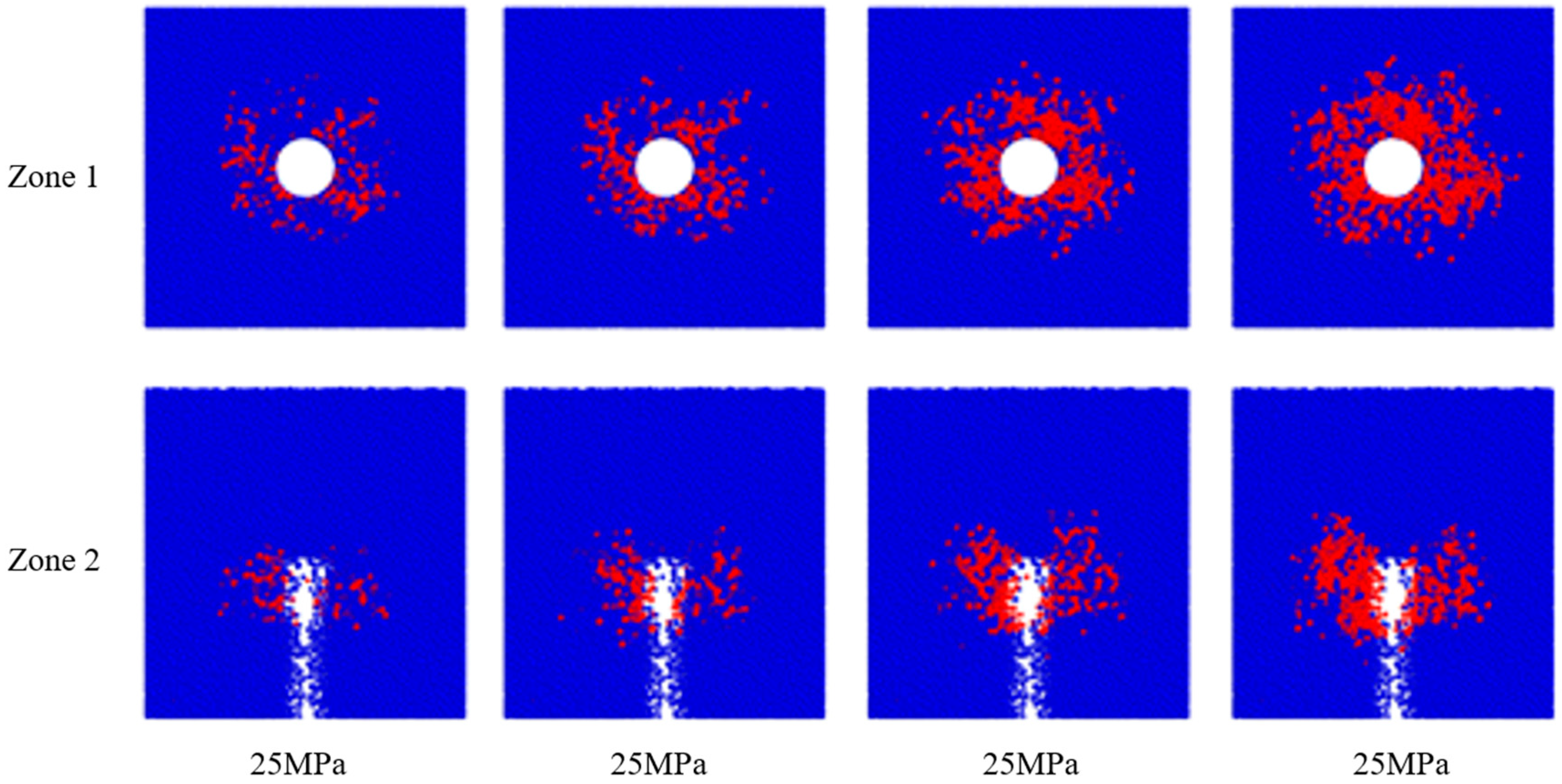

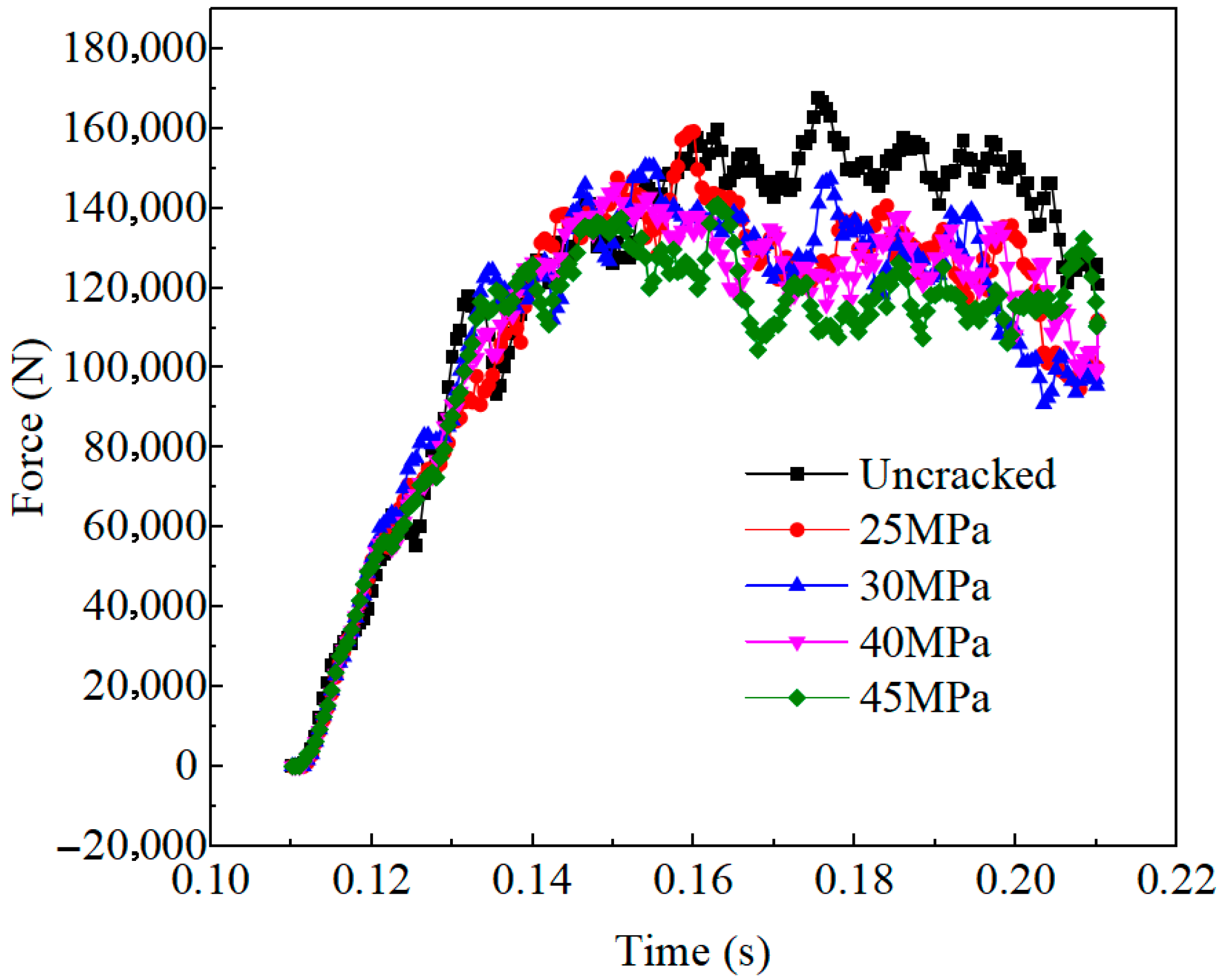

3.1. Crack Propagation Evolution and Cutting Pick Load Study

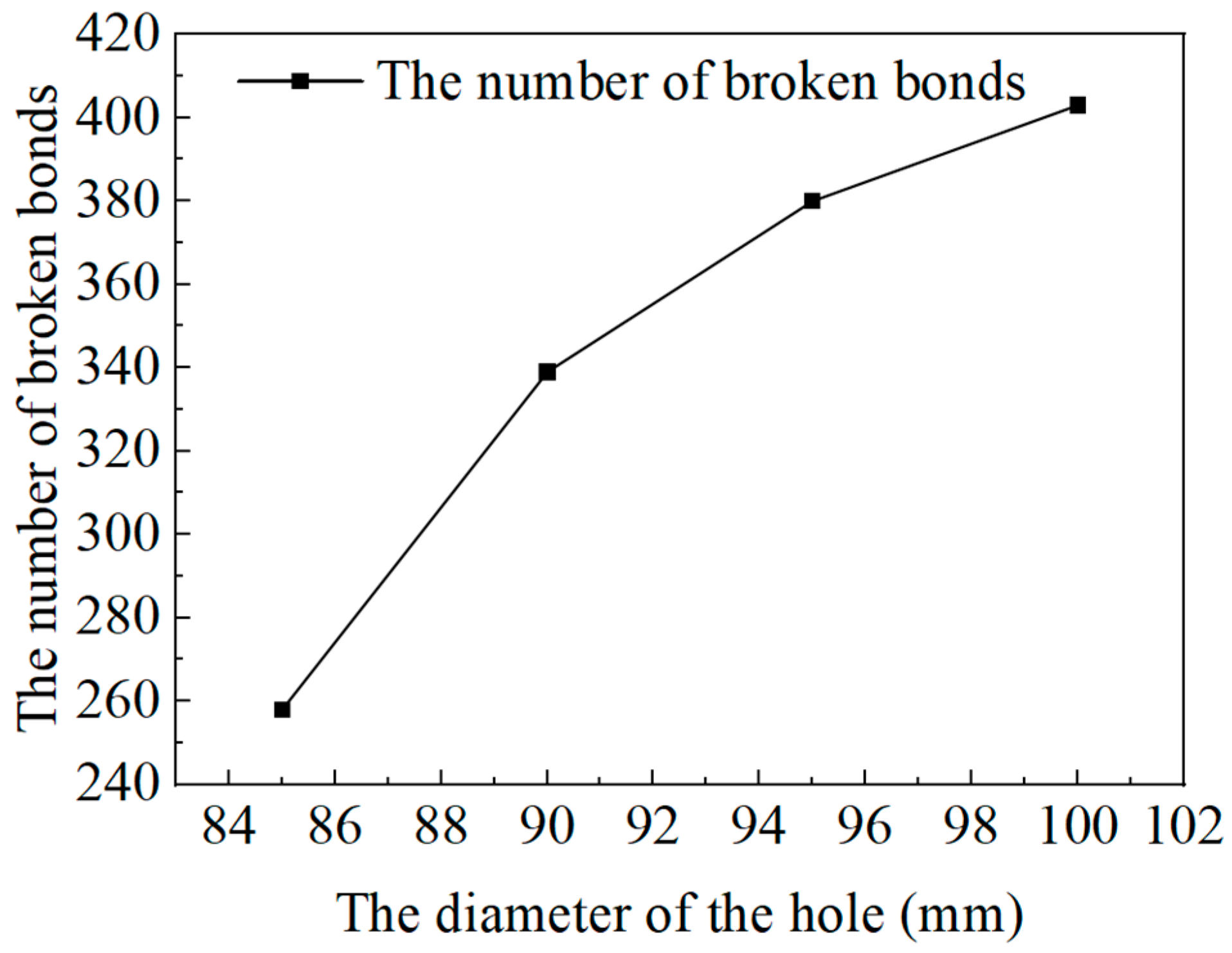

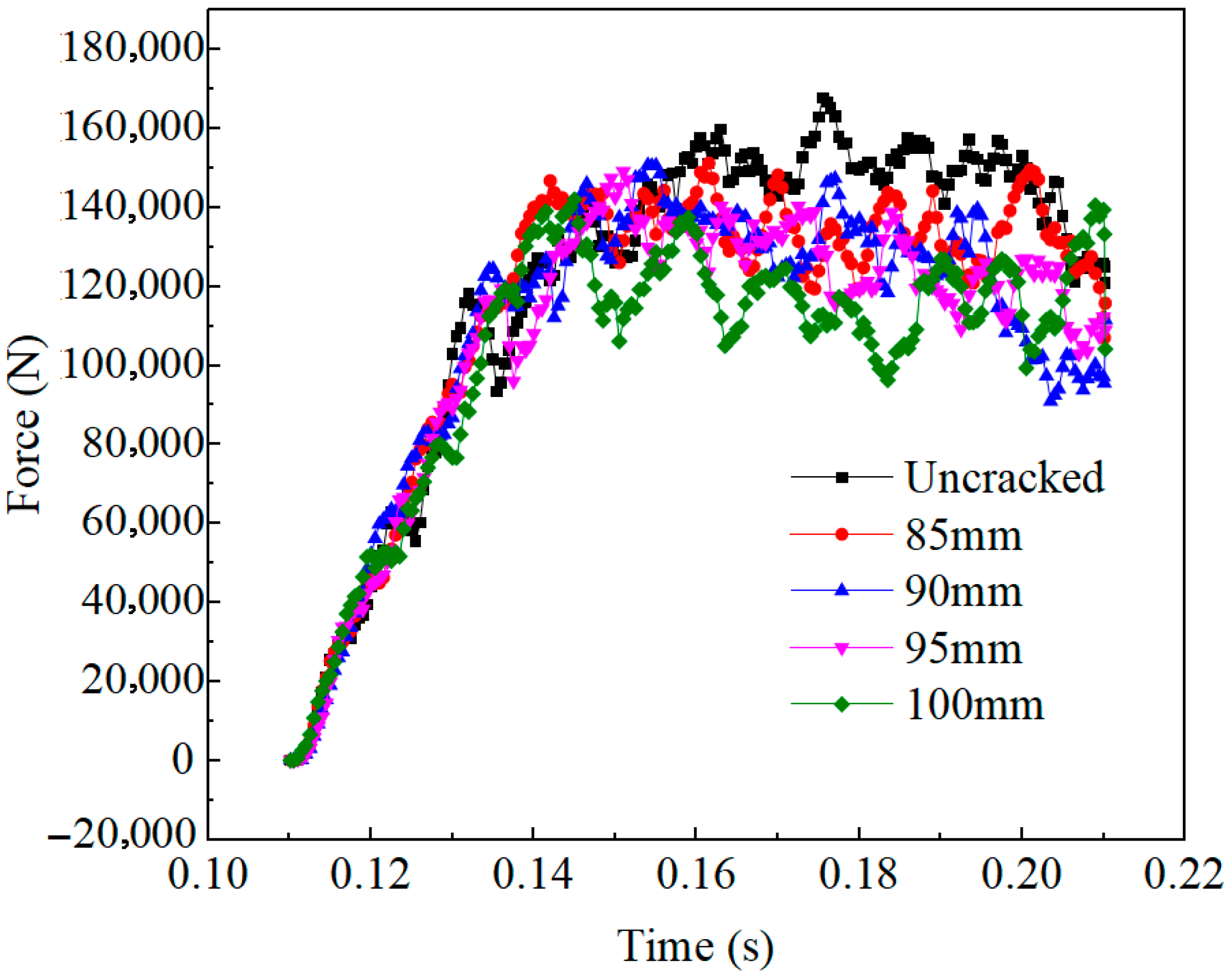

3.2. Influence of Hydraulic Fracturing Borehole Diameter

3.3. Influence of Hydraulic Fracturing Injection Pressure

4. Conclusions

- (1)

- The simulation successfully captured the evolution of cracks during water-injection fracturing, progressing through four distinct phases: (i) initiation of primary cracks, (ii) growth of primary cracks with the concomitant formation of microcracks, (iii) propagation of secondary cracks in conjunction with suppressed primary crack growth, and (iv) the expansive development of secondary crack networks.

- (2)

- A comparative analysis revealed that the average load exerted on the cutter picks during the excavation of pre-fractured rock (111,660 N) was 9.05% lower than that encountered with intact rock (122,278.0 N). Directional decomposition of the forces demonstrated a reduction of 11.46% and 7.2% in the average loads along the Z- and Y-axes, respectively. However, this was accompanied by an increase in load fluctuations. In contrast, the X-axis exhibited a 5.49% increase in average load, coupled with a reduction in fluctuation amplitude.

- (3)

- Parametric investigations quantitatively assessed the influence of hydraulic aperture (ranging from 85–100 mm) and injection pressure (ranging from 25–40 MPa) on the formation of fracture networks and cutting mechanics. The number of fractured bonds exhibited nonlinear growth with both parameters: increasing from 257 to 403 with aperture enlargement and from 245 to 622 with an increase in injection pressure. Correspondingly, the average resultant forces on the cutter picks exhibited a systematic decrease, from 115,784.3 N to 104,187.4 N with aperture variation, and from 111,913.2 N to 105,814.5 N with pressure variation. These forces were consistently 12–15% lower than the baseline resistance of 120,955.2 N observed in non-preconditioned rock. These findings substantiate that the optimization of hydraulic preconditioning parameters can substantially enhance excavation efficiency by fostering the development of controlled fracture networks and reducing the dissipation of mechanical energy.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, S.; Li, H.; Jiang, H.; Zhang, Q.; Cui, Y.; Liu, X. Research progress of coal-rock breaking methods in mines. J. China Coal Soc. 2023, 48, 1047–1069. [Google Scholar] [CrossRef]

- Huang, B.X. Research on theory and application of hydraulic fracture weakening for coal-rock mass. J. China Coal Soc. 2010, 35, 1765–1766. [Google Scholar] [CrossRef]

- Sun, S.; Zhang, S.; Mang, X.; Zou, Y. Study on fractures propagation mechanism in coal hydraulic fracturing based on high-energy CT scanning technique. J. Henan Polytech. Univ. (Nat. Sci.) 2020, 39, 18–25. [Google Scholar] [CrossRef]

- Lu, S.; Wang, S.; Liu, H.; Li, R.; Dong, Q.; Xiao, Y.; Shen, P. Analysis of the influence of natural fracture system on hydraulic fracture propagation morphology in coal reservoir. J. China Coal Soc. 2020, 45, 2590–2601. [Google Scholar] [CrossRef]

- Heider, Y. A review on phase-field modeling of hydraulic fracturing. Eng. Fract. Mech. 2021, 253, 107881. [Google Scholar] [CrossRef]

- Zhang, Y.; Shao, J.; Liu, Z.; Shi, C. An improved hydromechanical model for particle flow simulation of fractures in fluid-saturated rocks. Int. J. Rock Mech. Min. Sci. 2021, 147, 104870. [Google Scholar] [CrossRef]

- Chong, Z.; Yao, Q.; Li, X.; Liu, J. Investigations of seismicity induced by hydraulic fracturing in naturally fractured reservoirs based on moment tensors. J. Nat. Gas Sci. Eng. 2020, 81, 103448. [Google Scholar] [CrossRef]

- Chong, Z.; Yao, Q.; Li, X.; Zhu, L.; Tang, C. Effect of rock brittleness on propagation of hydraulic fractures in shale reservoirs with bedding-planes. Energy Sci. Eng. 2020, 8, 2352–2370. [Google Scholar] [CrossRef]

- Kang, H.; Feng, Y.; Zhang, Z.; Zhao, K.; Wang, P. Hydraulic fracturing technology with directional boreholes for strata control in underground coal mines and its application. Coal Sci. Technol. 2023, 51, 31–44. [Google Scholar] [CrossRef]

- Zhao, K.K.; Zhang, Z.; Li, W.Z.; Wang, X.H.; Yin, K.; Sun, Z.Y. Three-dimensional simulation of hydraulic fracture from a borehole using XSite. Chin. J. Geotech. Eng. 2021, 43, 1483–1491. [Google Scholar] [CrossRef]

- Zhao, K.K. Three-Dimensional Propagation of Hydraulic Fracture from Regional Fracturing in Hard Roof. Ph.D. Thesis, China Coal Research Institute, Beijing, China, 2021. [Google Scholar] [CrossRef]

- Sun, Q.; Song, W. Optimization simulation analysis of hydraulic fracturing parameters of rock roadway machine excavation face. Energy Technol. Manag. 2024, 49, 14–17. [Google Scholar] [CrossRef]

- Liu, J. Research on Breaking Characteristics of Hard Coal with High-Pressure Water Presplitting and Cutting Picks. Ph.D. Thesis, Liaoning Technical University, Fuxin, China, 2022. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assembles. Geotechnique 1978, 29, 47–65. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, Q. PFC numerical analysis on crack initiation mechanism of fracture grouting in top of Ordovician limestone. Coal Geol. Explor. 2023, 51, 72–85. [Google Scholar] [CrossRef]

- Wu, L.; Yu, C.; Liang, Z.; Duan, W.; Cheng, M. Study on Formation Process of Underwater Bench Blasting Pile based on Fluid-structure Coupling Algorithm of Fluent-EDEM. Blasting 2023, 40, 37–43+123. [Google Scholar] [CrossRef]

- Chen, S.; Niu, Y.; Lu, X.; Yang, J.; Dong, Z.; Feng, B. Simulation and experiment of linear wibrating screen for sallop meat and shell eparation based n discreeelement method. J. Chin. Agric. Mech. 2023, 44, 107–114. [Google Scholar] [CrossRef]

- Ji, C.; Guan, Y.; Zheng, H.; Zhang, M. Effect of Particle Size on Performance of Slurry Pump in Deep Sea Mining. Min. Metall. Eng. 2021, 41, 1–6. [Google Scholar] [CrossRef]

- Zhang, W.; Bu, T. Mesoscopic Simulation of Failure and Crack Development of Coal-rock Combination Under Different Confining Pressure. Saf. Coal Mines 2017, 48, 45–48+52. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Y. Analysis of Coal-rock Damage Evolution and Acoustic Emission Characteristics Based on Particle Discrete Element Model. Saf. Coal Mines 2017, 48, 213–216. [Google Scholar] [CrossRef]

- Zhou, T.; Yang, X.; Han, X. Numerical inversion simulation of coal rock under uniaxial compression failure in, P.F.C.2.D. J. Min. Sci. Technol. 2017, 2, 260–266. [Google Scholar] [CrossRef]

- Cheng, J.; Cao, Y.; Dou, Y.; Li, Z. Erosion of water-based fracturing fluid containing particles in a sudden contraction of horizontal pipe. J. Phys. Conf. Ser. 2017, 916, 12–27. [Google Scholar] [CrossRef]

- Li, X.; Niu, Z.; Yao, Q.; Wang, W.; Yu, L. Particle flow analysis of crack propagation characteristics of hole-type trident cracks sandstone. J. China Coal Soc. 2020, 45, 3735–3747. [Google Scholar] [CrossRef]

- Zhang, Q. Experimental and Numerical Research on Rock Cutting by Roadheader Picks. Ph.D. Thesis, Taiyuan University of Technology, Taiyuan, China, 2016. Available online: https://kns.cnki.net/kcms2/article/abstract?v=F0lYaGTXfx_a0xVNQNuEBX74REvOXS23qJzS4fQlOZLGuhNZM3__by4RCJCmQQ23QFyfpIqDm6OsN8V7gjLSDuJl-3uSYM_rExJ8-b4jl8Q4TMsQGK_5bzMv-34o2ktX7mPnI4tHDHLlNuFLFXB7x49xS6wFvGKyTKbP5JoUpy_4bb1hbrE8zQ==&uniplatform=NZKPT (accessed on 1 January 2025).

- Wang, Y. Study on Self-Adaptive Cutting Control of Shearer Based on CPS. Ph.D. Thesis, Liaoning Technical University, Fuxin, China, 2022. [Google Scholar] [CrossRef]

- Sun, S.; Li, W.; Zhang, J.; Chen, D.; Zhao, J.; Zheng, K.; Long, W.; Wang, C.; Jia, B.; Du, T.; et al. Research progress and development trend of staged hydraulic fracturing technology in long-borehole underground coal mine. Coal Geol. Explor. 2022, 50, 1–15. [Google Scholar] [CrossRef]

- Xu, D. Separation Mechanism and Application of Microchannels in Particle Beds Based on CFD-DEM. Master’s Thesis, Chongqing University of Technology, Chongqing, China, 2025. [Google Scholar] [CrossRef]

- Zhang, Y. Research on Technology and Craft of Hard Rock Roadway Fast Excavation Based on Breaking Rock Assisted by Hydraulic Fracturing. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2022. [Google Scholar] [CrossRef]

- Li, Q.; Deng, Y.; Hu, Q.; Zhang, Y.; Song, M.; Liu, J.; Shi, J. Mesoscopic law of stress and fracture evolution of coal seams hydraulic fracturing. Coal Geol. Explor. 2022, 50, 32–40. [Google Scholar] [CrossRef]

- Zhao, L.; Yang, S.; Zhang, H.; Han, L. Fatigue life prediction of shearer rocker shell based on DEM-MFBD bidirectional coupling technology. Coal Sci. Technol. 2023, 51, 252–258. [Google Scholar] [CrossRef]

- Liu, Z. Study on Hard Rock Hydraulic Fracturing Pretreatment Technology in 51207 Head of Chamber Guojiawan Coal Mine. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2022. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Density (kg/m3) | 2600 |

| Compressive Strength (MPa) | 71 |

| Elastic Modulus (MPa) | 21,500 |

| Poisson’s Ratio | 0.19 |

| Protodyakonov Strength Coefficient (f-value) | 8.4 |

| Coefficient of Restitution | 0.45 |

| Static Friction Coefficient | 0.48 |

| Kinetic Friction Coefficient | 0.109 |

| Parallel Bond Normal Stiffness (N/m3) | 2.2017 × 109 |

| Parallel Bond Tangential Stiffness (N/m3) | 1.8775 × 109 |

| Parallel Bond Normal Maximum Stress (MPa) | 28.936 |

| Parallel Bond Tangential Maximum Stress (MPa) | 12.174 |

| Contact Parameters Between Cutting Teeth and Rock Walls | Cutting Head Cutting Tooth Motion Parameters | Cutting Material Parameters | ||||||

|---|---|---|---|---|---|---|---|---|

| Coefficient of Restitution | Static Friction Coefficient | Vibrational Friction Coefficient | Rotational Speed (r·min−1) | Traverse Speed (m·min−1) | Density (kg·m−3) | Shear Modulus (GPa) | Poisson’s Ratio | |

| Value | 0.2 | 0.7 | 0.1 | 45 | 1.4 | 7800 | 70 | 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, Q.; Li, C.; Liu, H.; Liu, Q.; Xu, Y. Research on Crack Propagation in Hard Rock Coal via Hydraulic Fracturing. Appl. Sci. 2025, 15, 11696. https://doi.org/10.3390/app152111696

Dong Q, Li C, Liu H, Liu Q, Xu Y. Research on Crack Propagation in Hard Rock Coal via Hydraulic Fracturing. Applied Sciences. 2025; 15(21):11696. https://doi.org/10.3390/app152111696

Chicago/Turabian StyleDong, Qingguo, Caixia Li, Hongmei Liu, Qingwei Liu, and Yi Xu. 2025. "Research on Crack Propagation in Hard Rock Coal via Hydraulic Fracturing" Applied Sciences 15, no. 21: 11696. https://doi.org/10.3390/app152111696

APA StyleDong, Q., Li, C., Liu, H., Liu, Q., & Xu, Y. (2025). Research on Crack Propagation in Hard Rock Coal via Hydraulic Fracturing. Applied Sciences, 15(21), 11696. https://doi.org/10.3390/app152111696