1. Introduction

The wheel is a fundamental component of a vehicle, enabling movement and transportation while providing structural support [

1]. As Genta [

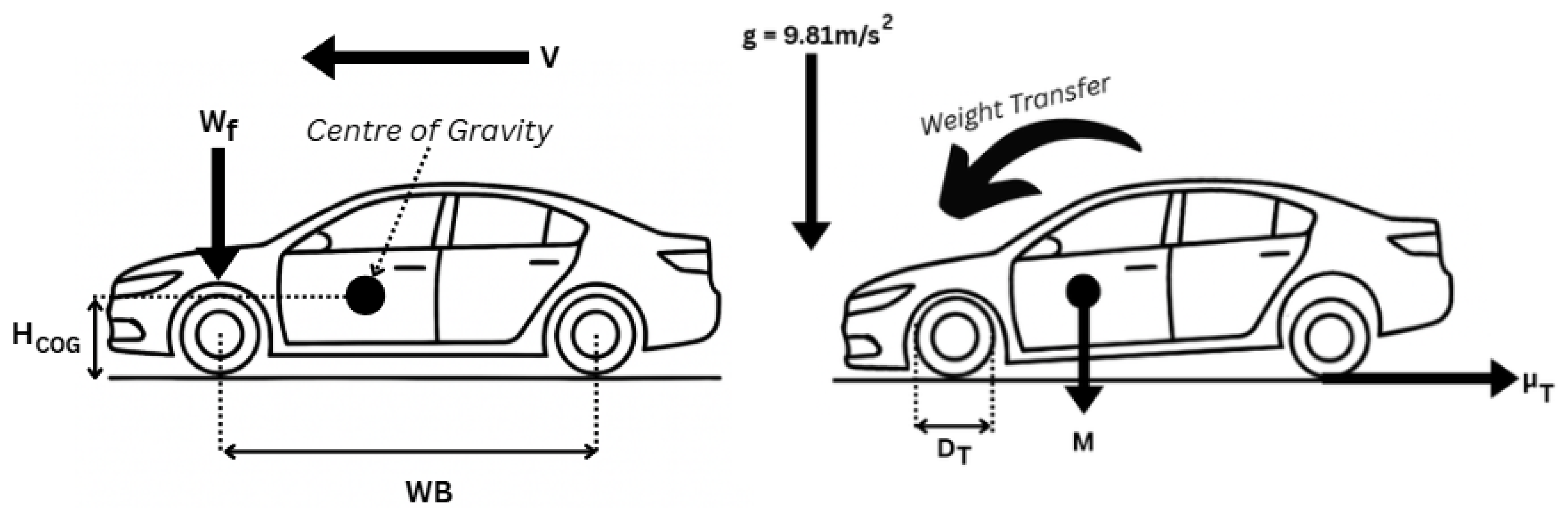

2] suggests, the forces and torques acting on a vehicle’s wheel are some of the most crucial internal forces and torques within chassis design. These forces include tractive, braking, and cornering forces, and consider tyre characteristics, rolling resistance, and weight transfer.

To counter these forces and enhance vehicle safety, high-strength wheel rims can be designed. However, this can compromise vehicle performance due to increased wheel mass and inertia. In contrast, the automotive industry often favours lightweight wheels with minimal material usage, allowing for lower consumer costs. These can, however, be susceptible to fatigue cracking [

1], ultimately leading to premature failure.

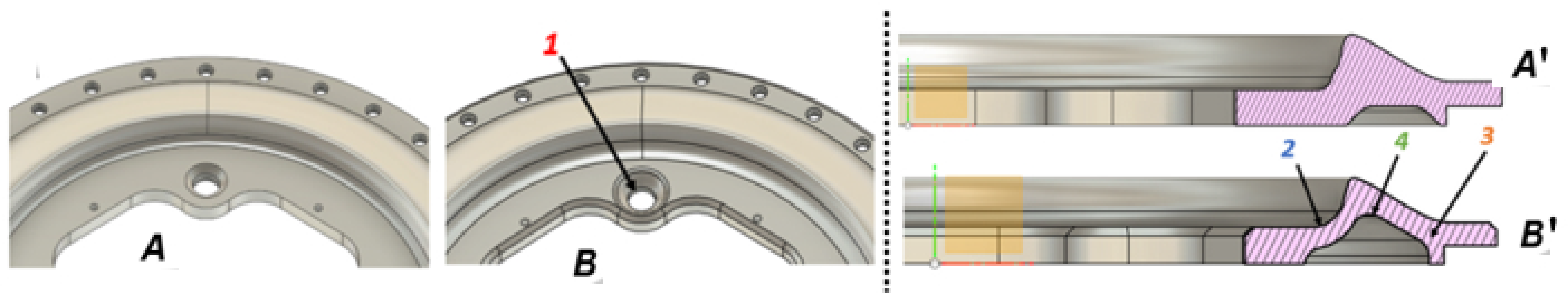

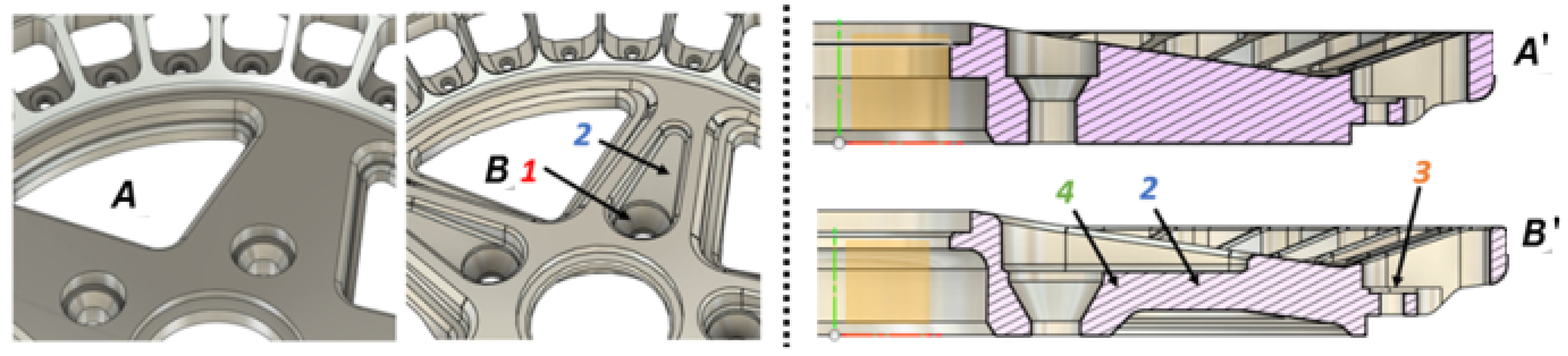

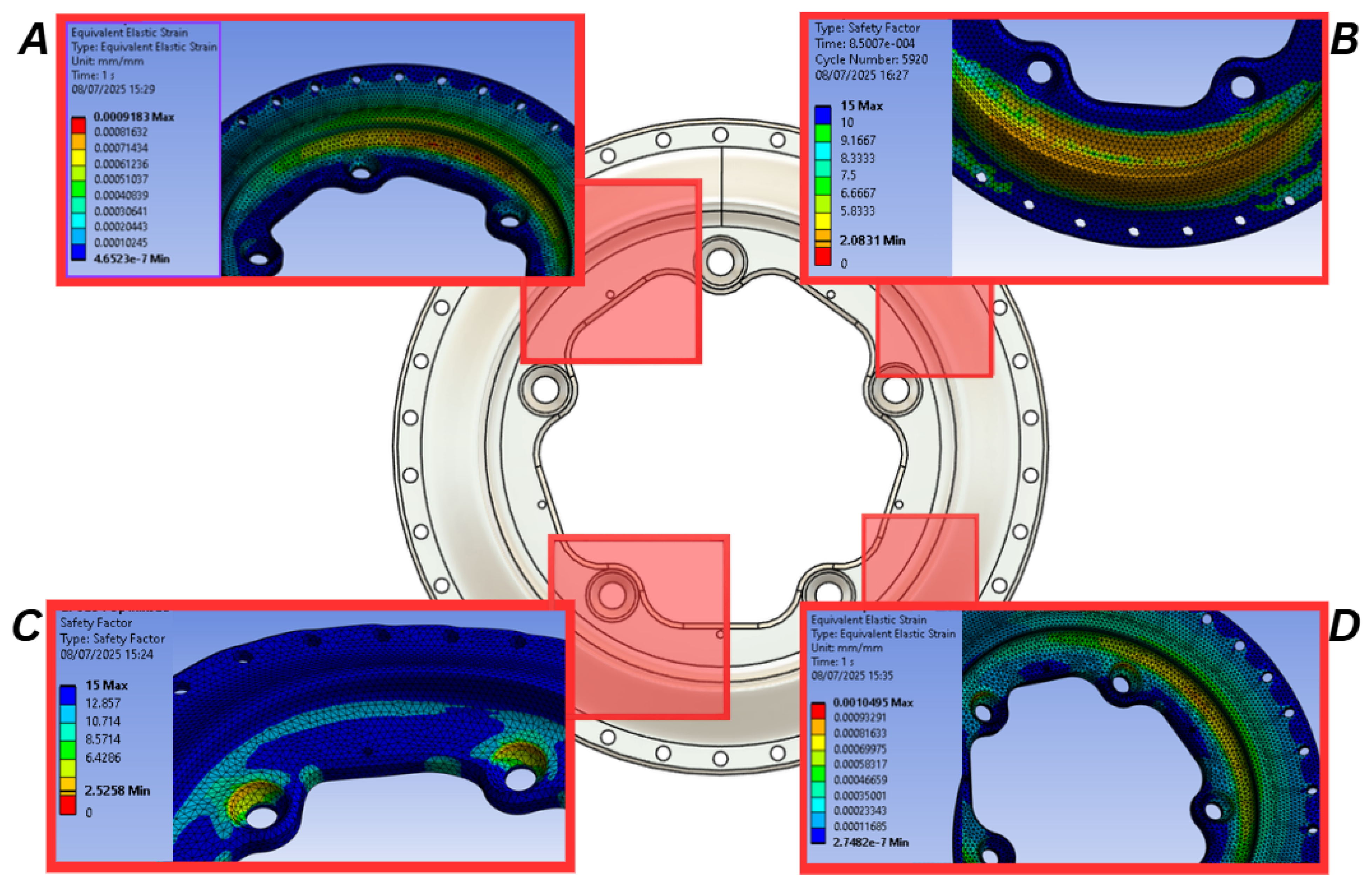

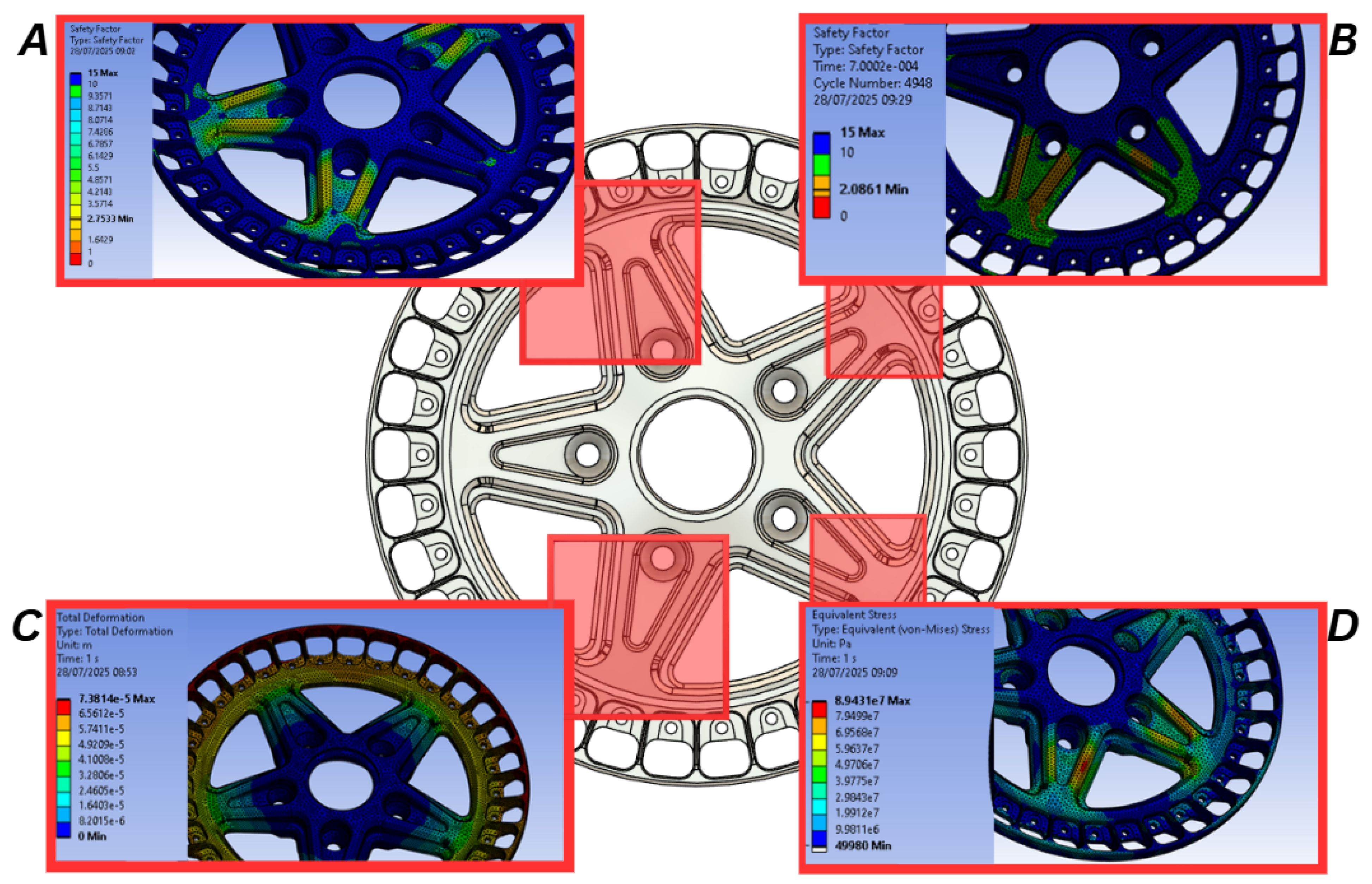

While many companies have developed multiple unique wheel designs (see

Figure 1), a common issue is the lack of dedicated structural testing capabilities, often due to the added expense or inaccessibility of physical testing. As a result, many wheel designs are overengineered, with excessive material usage, increased weight, higher production costs, and bulkier designs. Furthermore, the absence of rigorous design testing can contribute to stress fractures and wheel failures (see

Figure 2).

These challenges are widespread throughout the alloy wheel industry (specific examples provided in the Background Research and Knowledge Gaps Section). However, many mass-produced wheel manufacturers have successfully addressed these risks by incorporating finite element analysis (FEA), allowing for the validation of the structural integrity of designs prior to production

Several studies demonstrate the effectiveness of FEA in the identification and mitigation of wheel failures (covered in detail in the Background Research and Knowledge Gaps Section). Recent research has even extended beyond conventional FEA-based wheel design towards topology optimisation and generative design techniques, enabling faster and more efficient redesigns [

3]. Other studies have also investigated the use of lightweight composite materials to further enhance wheel performance [

4], and artificial intelligence (AI) is becoming increasingly popular to develop frameworks for automotive component testing and geometric optimisation [

5]. However, these methods typically require high computational power, large datasets, and increased costs. Consequently, limited research addresses the application of FEA for small-scale alloy wheel manufacturers, where physical testing or AI approaches may not be financially viable. This has created a knowledge gap in ideal testing practices.

This study therefore addressed the challenges faced by bespoke, limited-production wheel manufacturers who cannot justify the expense of full-scale physical testing. A validated digital testing framework is proposed which adapts physical simulation methods into a computational methodology for bespoke wheel manufacturers to replicate, ultimately leading to lighter, more efficient, and safer wheels, whilst ensuring industry standards are met.

To ensure that this research contributed towards a real-world engineering problem, it was centred around a UK-based engineering company specialising in the design of bespoke, limited-production aftermarket multi-piece alloy wheels. Throughout this report, they are referred to as Company A for confidentiality.

Background Research and Knowledge Gaps

The wheel is a fundamental circular component of a vehicle that revolves on its axis, enabling movement and transportation of objects while providing structural support [

1]. Modern wheels are commonly manufactured from aluminium alloy. As suggested by Rao, Rajesh, and Babu [

6], aluminium alloy wheels not only enable more aesthetically appealing designs but are also significantly lighter than their steel counterparts. This reduced weight decreases the energy required for rotation, enhancing fuel efficiency, acceleration, and braking performance.

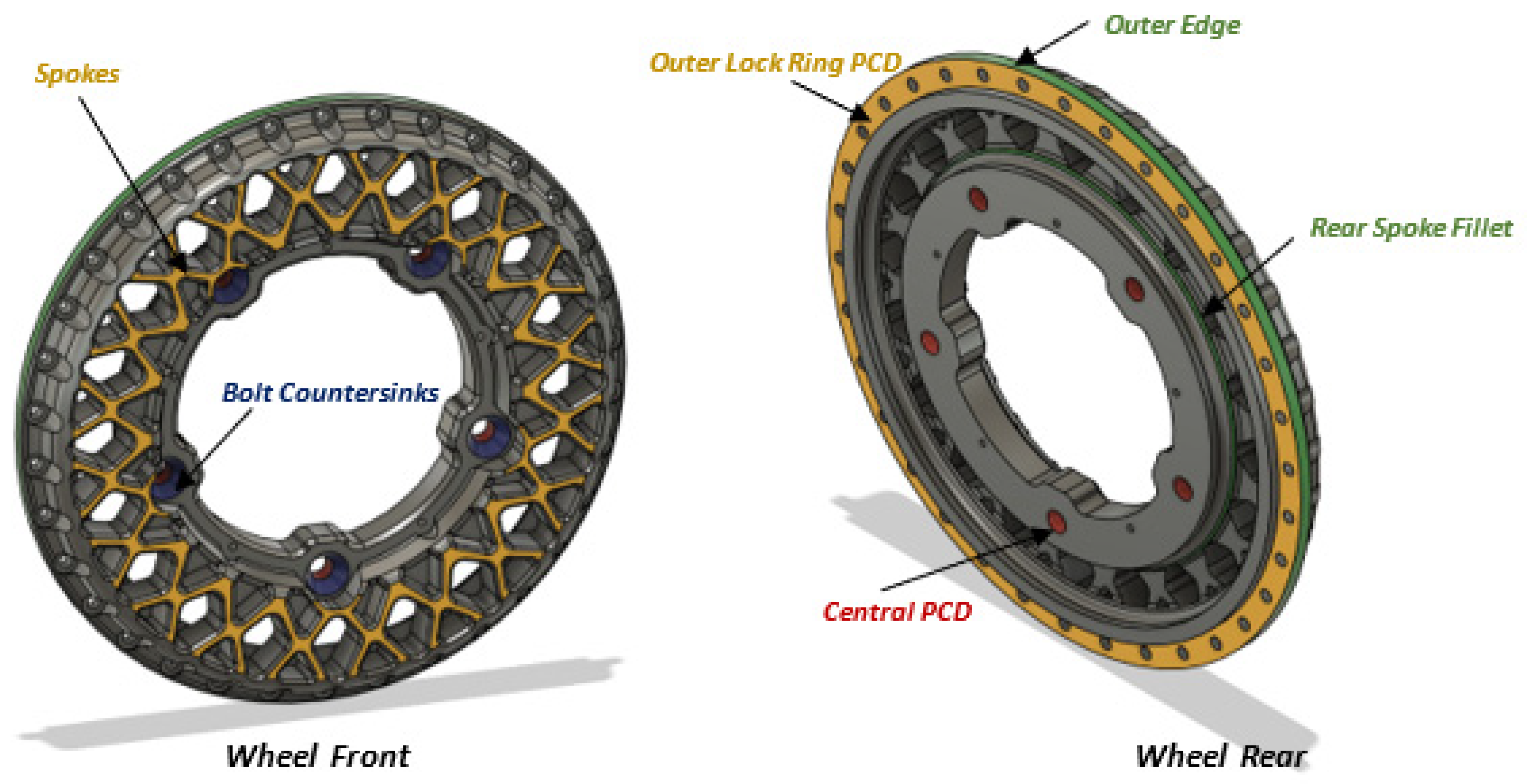

Companies specialising in wheel design often favour multi-piece wheels to meet bespoke customer requirements. ‘Multi-piece wheels are composed of two or three separate components—typically an inner rim, an outer rim, and a wheel centre—that are bolted together’ [

7].

This modular technique allows for ease of customisation, simplified damage repair through individual component replacement, and weight reduction.

Wheels are required to withstand tensile and compressive forces transmitted by the tyre from the road, as well as vehicle load transmitted to the wheel through the hub. These forces can be categorised into the following:

Vertical loads from the tyre contact patch;

Lateral forces occurring during vehicle cornering;

Braking and acceleration torque applied at the wheel hub;

Sudden load variations caused by interactions with the terrain, such as potholes or speedbumps [

8].

As suggested by Padmanabhan [

1] to ensure that a wheel can withstand these forces, spokes are used to connect the wheel hub to the rim. The design and rigidity of spokes is crucial to prevent wheel failure. A study by Zanchini et al., [

4] demonstrates the fatigue cracking of a poorly designed aluminium Ferrari 488 Pista wheel caused by a significant bending moment at a sharp corner of a spoke, causing a stress concentration to occur. Similar failures are seen in studies by Firat et al. [

9] and Raju et al. [

10] where cracks are initiated at various points along the spokes of both alloy and steel wheels during radial fatigue tests.

To minimise the risk of alloy wheel failure through compliance with international wheel design standards, fatigue testing methods are often employed. ‘The main objective in fatigue analysis is to predict the accumulated number of cycles at which a small crack appears at a stress raising geometrical feature’ [

11], where a crack is defined as ‘material separation with a propagation of more than 10 mm occurring during a test’ [

12].

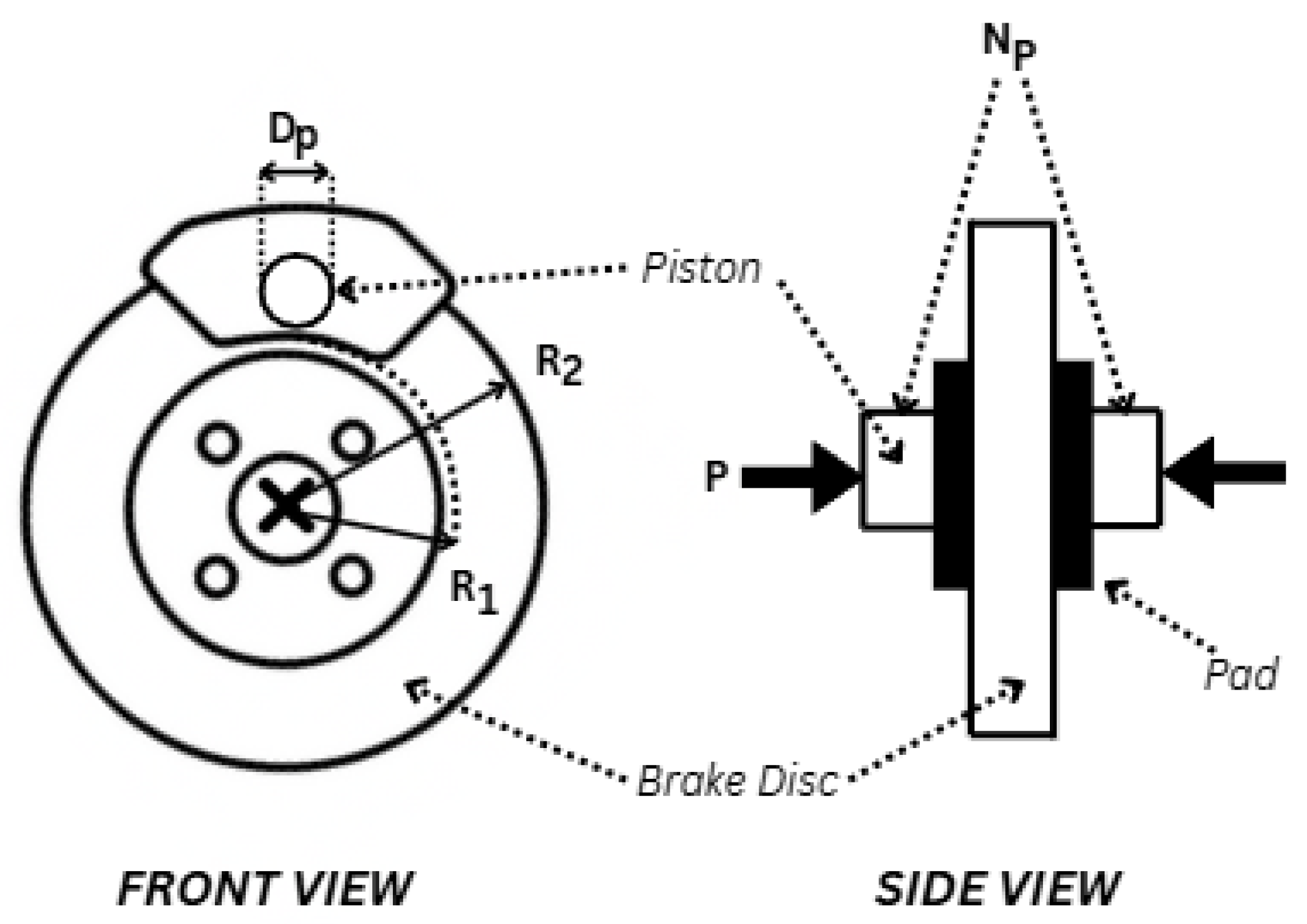

Fatigue tests include cornering, radial, and biaxial tests [

4]. As suggested by Kocabicak and Firat [

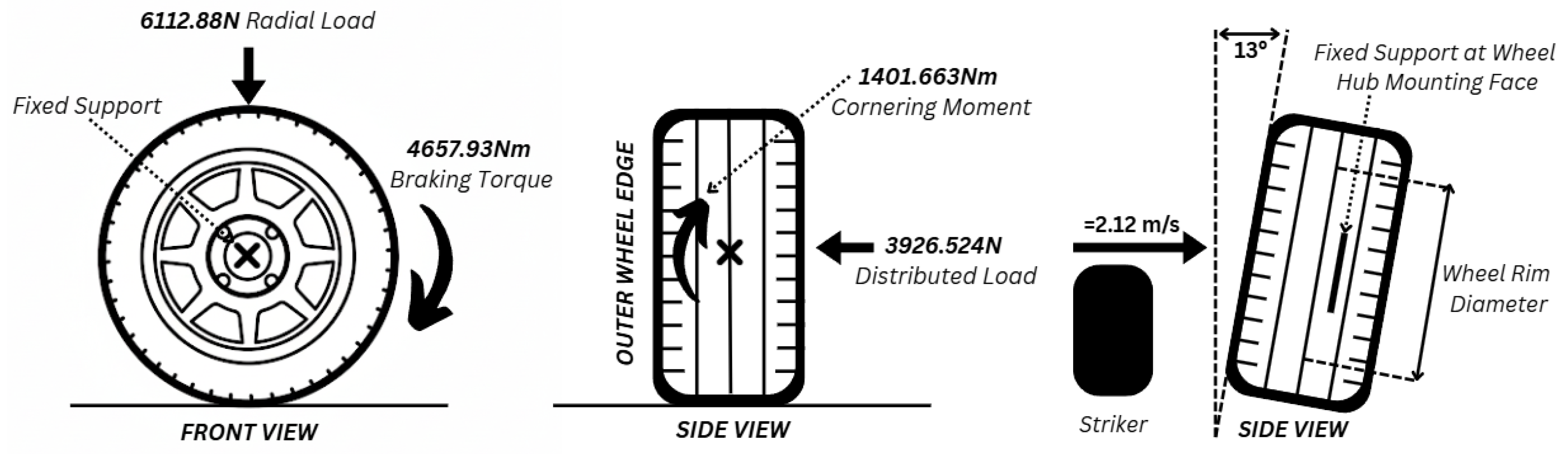

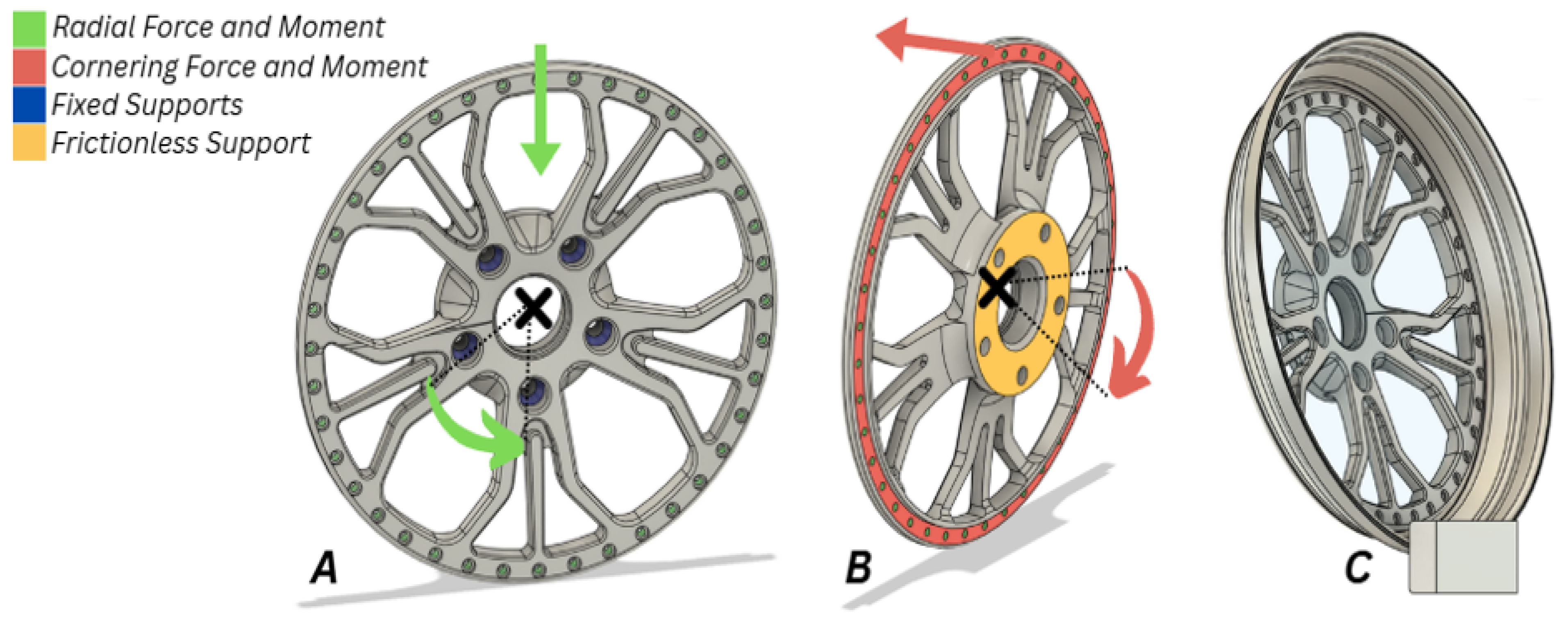

11], the cornering fatigue test is designed to simulate dynamic loading occurring during cornering. This loading includes the vertical and lateral forces which generate a bending moment at the wheel hub.

The radial fatigue test applies a radial load to an alloy wheel in contact with a rotating drum. This test is conducted over several cycles, and eventually, the wheel fails, allowing for the determination of its cycle life [

13].

The biaxial fatigue test combines both radial and cornering tests, emulating real-world driving conditions, such as ‘cornering, straight driving and parking, as well as driving on rough roads’ [

14]. This is achieved through the application of both radial and lateral loads to a wheel situated within a moveable rotating drum representing the ground.

The full procedures of each fatigue test are documented in detail in ISO 3006:2015 [

12]. Any defects which should be checked for are further described in ISO 14400:2021 Section 6 [

15], where it is noted that wheel rims with any fracture, crack, corrosion, deformation, or other non-conformity should be removed from the vehicle and disposed of [

16].

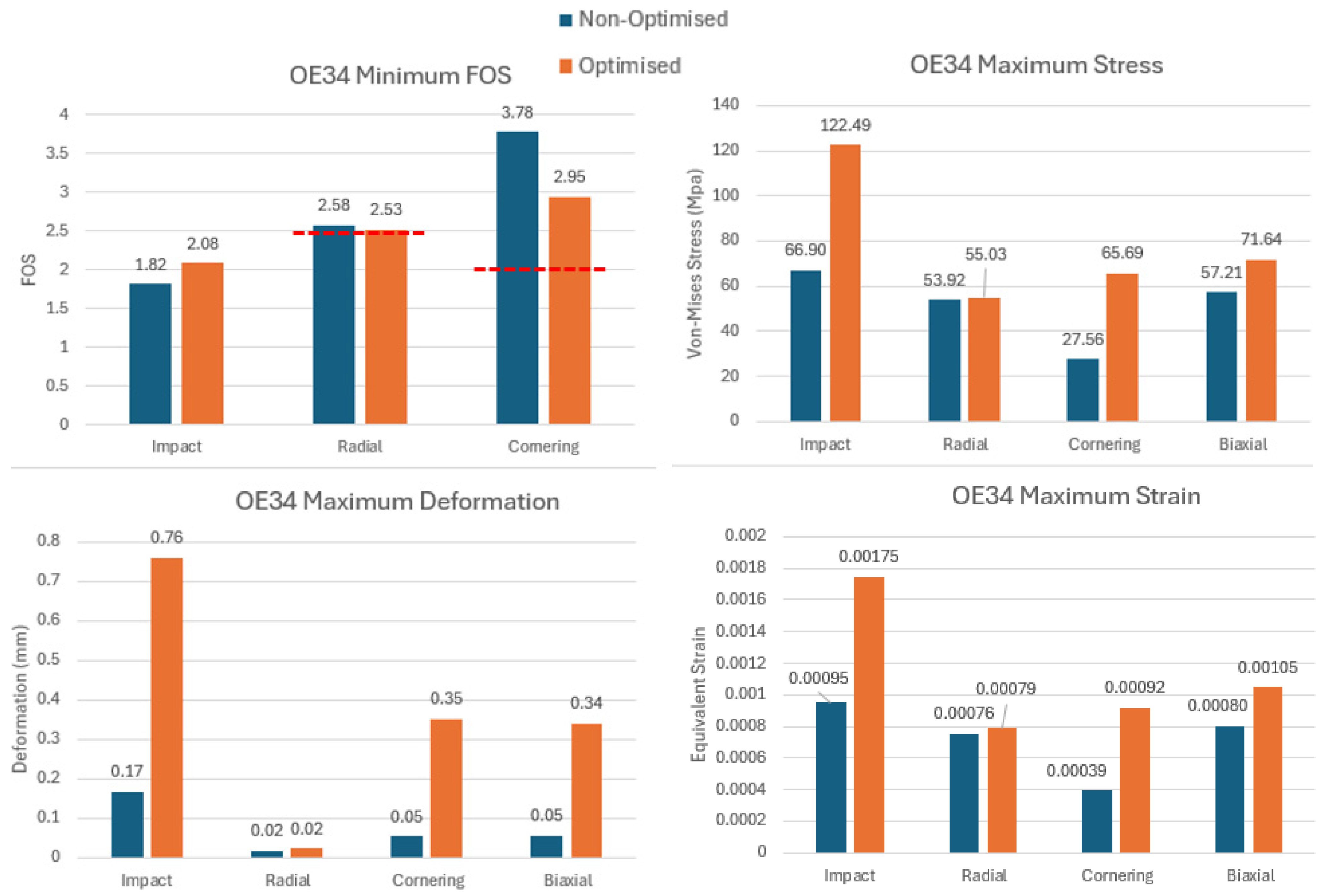

SAE J328:202107 Section 2.2.3 [

16] states that the minimum cycle life for aluminium wheel cornering and radial fatigue tests is 50,000 and 600,000, respectively. The required FOS for wheels are also specified as 2.0 for cornering, and 2.5 for radial tests.

During driving, alloy wheels can also experience severe impact loads, such as striking a curb during parking or colliding with road debris. To address this, regulations specify a standardised impact test. According to SAE J175:200309 Section 4.3 [

17], the procedure involves dropping a mass calculated by Equation (1):

where

W represents the maximum static wheel load in kilograms [

17]. The

Mass is dropped onto the wheel rim at an angle of 13 degrees, after which the wheel is inspected for cracks and other forms of damage.

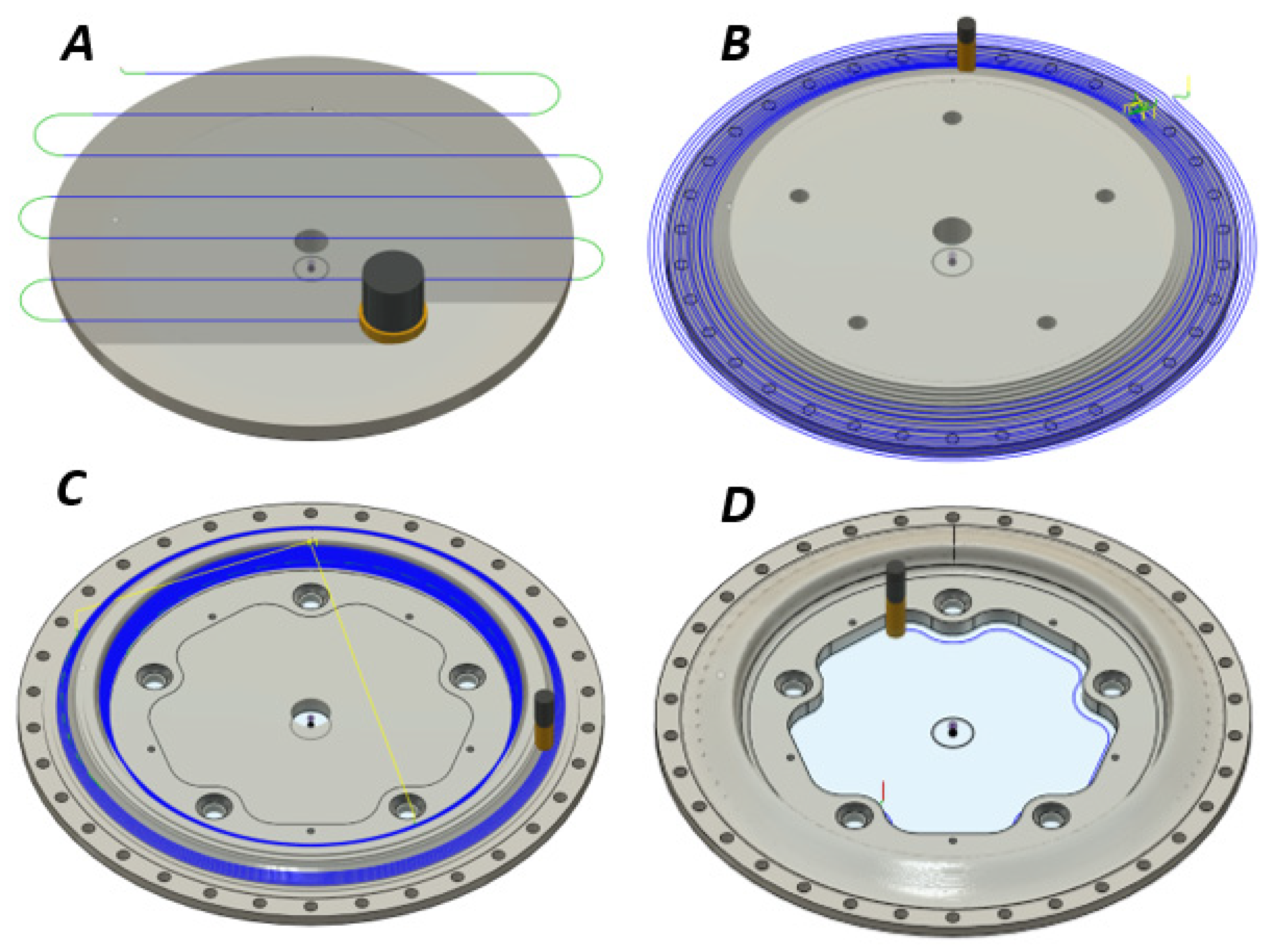

The above tests are usually carried out through physical testing; however, similar scenarios can be simulated through finite element analysis (FEA), which ‘has been established as one of the major techniques to evaluate structural behaviour during product development’ [

18]. Wheel manufacturers often use finite element analysis (FEA) tools to minimise material usage and costs, while ensuring that designs comply with international standards. FEA software (ANSYS Workbench 2024 R2) computationally applies complex sets of equations ‘to validate and test designs safely, quickly, and economically by creating virtual models of real-world assets’ [

19]. This allows manufacturers to identify potential failure points in their wheels prior to production.

The FEA process typically involves three main stages: pre-processing, solving, and post-processing. According to Boart, Anderson, and Elfström [

18]. Pre-processing includes several critical steps. First, the geometry is defined by importing a 3D CAD model. Next, a mesh is generated over the model using elements of varying shapes and sizes. As suggested by Chang and Yang [

20], tetrahedral meshes are commonly used for wheels due to their irregular geometry where uniform meshes are difficult to generate. Finally, the solver inputs are defined by applying boundary conditions such as supports, forces, and moments. The factors to be solved for are also selected, such as stress, strain, or deformation.

In the solving stage, software solves partial differential equations across all mesh elements. While increasing the number of mesh elements improves solution accuracy, it also significantly raises the computational cost. To ensure reliability, a mesh independence study is often conducted to determine the point at which the results no longer vary with further mesh refinement. The final stage, post-processing, enables the user to interpret and analyse the simulation results, providing valuable insight into the structural performance of the model.

Korkut et al. [

21] used FEA to redesign alloy wheel spokes. The analysis identified areas of stress concentration and moderate deflection, enabling targeted design modifications to be made by adding or removing material as necessary. In this case, minimal stress and deflection were observed on the outer spoke edge, while small stress concentrations appeared within pockets near to the wheel hub. To address this, the design was adjusted by reducing the pocket size and removing excess material from the outer spoke, ultimately decreasing the wheel’s weight while improving the design strength.

Additionally, Zanchini et al. [

4] analysed a sports car wheel through FEA, revealing that the fatigue life of the spokes was insufficient. This finding directly correlates with the crack propagation observed when physically testing the wheel, proving the validity of FEA in preparing wheels for manufacture.

The insights gained from the above research directly informed the methodology of this work.