1. Introduction

The conical diffuser is used in various technical systems and performs various functions depending on the purpose (flow stabilization, pressure equalization, minimization of energy losses, flow regulation and distribution, reduction in aerodynamic noise, pneumatic transport, etc.) [

1]. Conical diffusers are applicable for increasing the thermodynamic efficiency of gas turbines [

2], suppressing flow instabilities in hydro turbines [

3], improving the performance of wind turbines [

4], smoothing the pressure in the ejector [

5], controlling the movement of solid particles in a biomass gasifier [

6], improving the organic Rankine cycle [

7], optimizing the afterburner of aircraft engines [

8], and wind tunnels [

9]. Therefore, the gas-dynamic perfection of the processes inside a conical diffuser determines the efficiency and performance of the final product. The development of active and passive design methods for controlling the flow structure in diffusers remains a pressing challenge for the intensive advancement of science (applied gas dynamics, thermal physics) and technology (technical devices for various purposes).

Research related to processes in conical diffusers can be roughly divided into two areas: (1) optimization of diffuser design to improve the efficiency of a given technical system and (2) gas-dynamic improvement of the flow structure within the diffuser under various boundary conditions. A brief overview of articles within these areas is presented below.

The refinement of conical diffuser design for wind turbines is a current area of research [

10,

11,

12]. For example, Nile A.T. et al. investigated 6 different flange diffuser designs to improve the efficiency of wind turbines [

10]. Scientists succeeded in reducing drag by 20.7% and increasing extracted power by almost 2 times by fine-tuning the inlet nozzle and diffuser configurations. Naghavi Moghaddam A. et al. used mathematical modeling to optimize the diffuser design for small urban wind turbines [

11]. Scientists were able to increase the kinetic energy in the throat by almost 5.5 times and the kinetic energy at the diffuser outlet by almost 1.5 times. Similar scientific and technical results were also obtained by Gujar S.H. et al. [

12].

Optimization of the conical diffuser design for a specific gas turbine also remains a pressing issue for scientists and engineers [

13,

14,

15,

16]. Thus, Zeng L. et al. refined the design of an exhaust diffuser for a gas turbine using numerical modeling [

13]. The specialists succeeded in increasing the static pressure recovery coefficient for the new diffuser configuration by 8% compared to the baseline design. Dong Y. et al. proposed an original design of an exhaust diffuser with a splitter [

14]. Scientists have proven that the use of a splitter design improves the aerodynamic performance of the exhaust diffuser. Specifically, an optimal splitter design increases the exhaust diffuser’s static pressure recovery coefficient by 7–15%. Yan Y. et al. developed a new design of an aerodynamic diffuser with air bleed for a gas turbine combustor [

15]. The use of this diffuser allowed for an increase in the static pressure recovery up to 20% compared to the basic combustor configuration. Zhu Z. et al. performed a design tuning of the diffuser for the afterburner of an aircraft engine [

16]. The scientists succeeded in significantly reducing hydraulic losses in the system under consideration.

There are also scientific works on optimizing the design of a conical diffuser for high-power liquid machines [

17], heat exchangers with phase transition [

18], and mixing chambers of ejectors for various purposes [

19]. The main results of these studies include the development of a new diffuser configuration tailored to the specific operating conditions of the device. The new diffuser should ensure the required flow distribution, reduce hydraulic losses, and/or increase the pressure recovery coefficient in the system.

The second major scientific field concerns detailed research into the gas-dynamic characteristics of flow in a conical diffuser and the improvement of flow distribution within the diffuser. For example, research into the structure of flow in a diffuser, depending on the parameters of the inlet flow (turbulence level, pulsation, swirl, and delivery method), is particularly noteworthy [

20,

21,

22,

23,

24]. Ilić D. et al. developed a mathematical model for predicting the distribution of the velocity and pressure field in a conical diffuser when a swirling flow is supplied by an axial fan [

20]. The authors proposed a physical and mathematical description of the unsteady and complex motion of the air flow in the diffuser with a detailed analysis of the gas-dynamic characteristics. The calculation results were confirmed by experimental optical methods. Similar studies were also carried out by Čantrak Đ.S. et al. [

21]. The authors investigated the influence of the initial flow swirl on the velocity field distribution in the diffuser using mathematical modeling. Reddy H. and Subramanian B. studied the influence of the initial flow turbulence level on the flow structure in diffusers with different opening angles [

22]. The experts formulated practical recommendations for optimizing the diffuser design to improve the turbulent flow structure inside the diffuser. Plotnikov L. and Ryzhkov A. studied the influence of the transverse profiling of the diffuser feed channels on the flow structure and turbulence intensity based on experimental methods [

23]. Qiu B. et al. studied the relationship between the flow parameters in the last stage turbine and the flow structure in the exhaust diffuser of a gas turbine for different operating modes using numerical simulation [

24]. In the applied aspect, the results of the reviewed articles are useful for predicting the operation of technical devices with diffusers and the gas-dynamic characteristics of the flow in and after the diffuser.

There is a separate group of studies on the investigation of separation phenomena in conical diffusers for steady and pulsating gas flow regimes [

25,

26,

27,

28,

29]. Thus, Budnikova A.O. et al. studied the influence of various aerodynamic factors on the characteristics of separated flow in a subsonic asymmetric diffuser with different opening angles using mathematical modeling [

25,

26]. Teshnizi E.S. and Momeni F. proposed an original prediction method for analyzing the separation point shift in diffusers based on computational and experimental studies [

27]. Skripkin S. et al. used machine learning algorithms to predict the development features of non-stationary vortex phenomena (precessing vortex core) in a conical diffuser [

28]. The results of the reviewed articles provide an opportunity to refine and deepen our understanding of the complex physical processes occurring in conical diffusers. This data is also useful for developing more practical and accurate methods for calculating and designing technical systems with diffusers.

There are also studies on the characteristics of two-phase flow motion in conical diffusers in relation to various technical systems [

30,

31]. Thus, Salem K.M. et al. created a unique mathematical model for predicting and analyzing the characteristics of the behavior of two-phase gas–solid flows in an axisymmetric diffuser [

30]. Boujjat H. et al. studied the specifics of the gas dynamics and structure of a two-phase flow in a conical diffuser in relation to a biomass in-line gasifier [

31]. The results of these studies are of obvious practical interest in the form of recommendations for optimizing and improving the efficiency of heat and mass transfer in such technical devices with diffusers.

Research on the study of flow characteristics in diffusers of uncommon designs stands out: S-shaped diffuser [

32], flat diffuser [

33], and square-section diffuser [

34].

Thus, the review of research has shown that studying gas dynamics in conical diffusers is a pressing issue, and there is a lack of reliable experimental data on the flow structure in conical diffusers for different air delivery methods. Accordingly, obtaining new data and developing original methods for controlling the flow structure in diffusers is an important and promising task for various technical systems.

The main objectives of the study were as follows:

- -

To create an experimental setup, select a methodology for conducting experiments, and develop a method for supplying air to the diffuser through nozzle tubes positioned at different angles;

- -

To compare the flow structure in a vertical conical diffuser (VCD) for air supply through a single duct and for air supply through nozzle tubes (4 pieces);

- -

To evaluate the evolution of the air flow structure in the VCD for different nozzle tube installation angles;

- -

To formulate practical recommendations for the use of nozzle air supply in VCDs for in-line biomass gasifiers (wood chips).

The study’s results are planned to be used to optimize the operation of a single-stage in-line sawdust gasifier being developed in a laboratory at the Ural Federal University. Therefore, all experimental data are analyzed in the context of the operating characteristics and efficient airflow within the gasifier.

2. Description of the Experimental Base and Research Methods

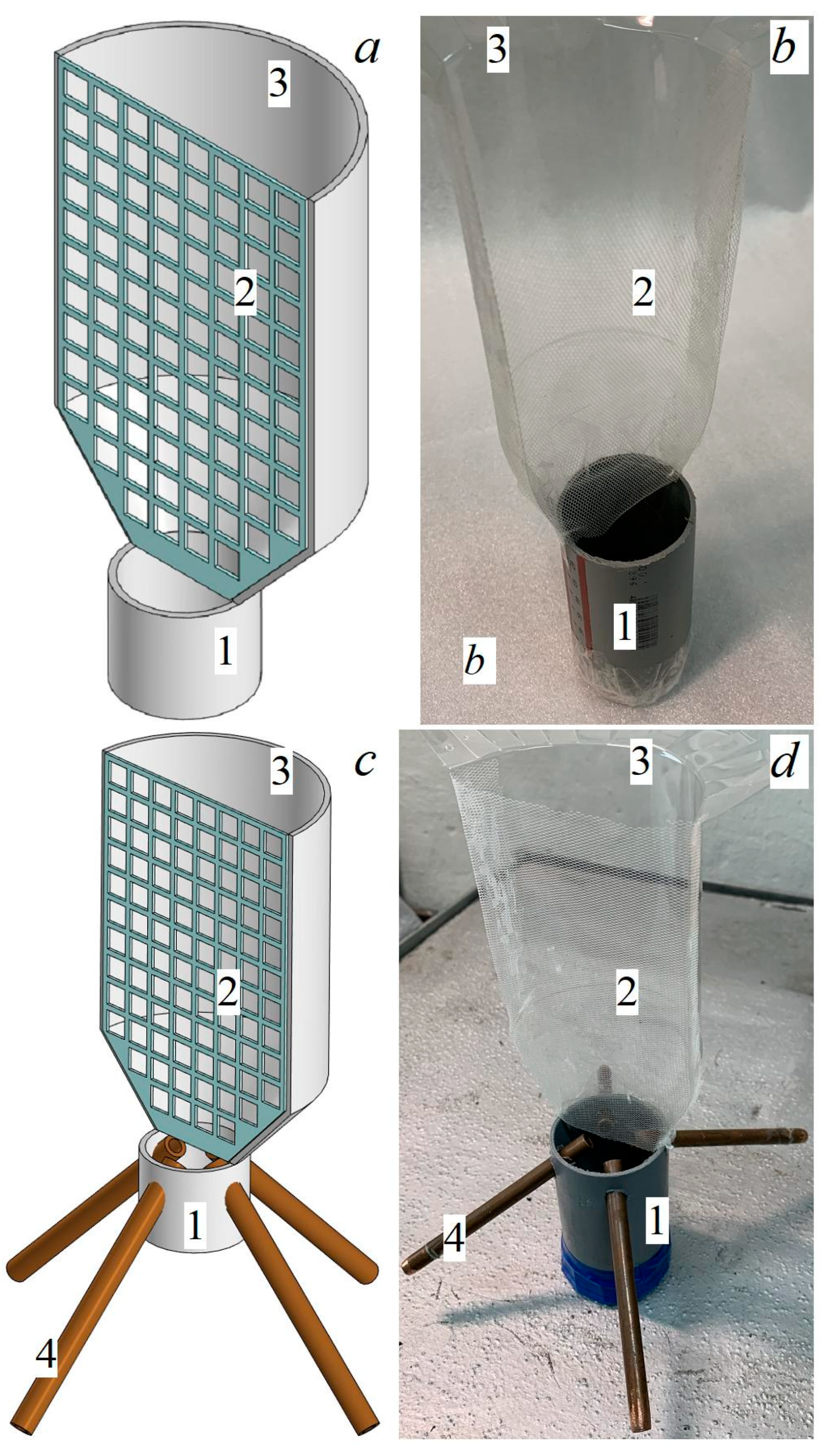

The study of the gas-dynamic structure of the flow in the VCD was carried out on a specially designed experimental setup (

Figure 1).

The main elements of the setup were (1) a supercharger with the ability to control the air consumption; (2) a special heating module with the ability to regulate the power (air heating temperature); (3) a thermal imaging camera for obtaining thermograms; (4) a measuring unit for monitoring the air consumption through the system and the flow temperature; and (5) the vertical conical diffuser under study.

The experimental procedure was as follows:

- -

The compressor was started with a specified air flow rate.

- -

Air was supplied to a receiver with a honeycomb to equalize the flow after the compressor; the receiver had a capacity of 50 L, and a plate honeycomb was installed inside the receiver.

- -

The air was then heated in a flow heating module; this module consisted of two electric heating elements with a capacity of 1.2 kW and 2.0 kW, arranged sequentially along the flow direction; the heating module’s power was regulated by a voltage regulator.

- -

Air consumption was monitored using a constant-temperature hot-wire anemometer; the hot-wire anemometer sensor was installed at the outlet of the heating module.

- -

Intermediate air temperature monitoring was performed using a thermocouple; the thermocouple was installed in the connecting duct downstream of the heating module.

- -

Heated air was supplied to the diffuser through four circular nozzles.

- -

The flow structure (thermogram) in the VCD was recorded using a thermal imaging camera.

The simplified equations of continuity and momentum balance for an incompressible steady-state Newtonian flow, as applied to the gas-dynamic system under consideration, have the following form:

where

w is the flow velocity, m/s; ρ is the density, kg/m

3;

p is the flow pressure, Pa.

The working environment in the studies was air at a temperature of 65 ± 1 °C (after the heating module). The initial air temperature (before the heating module) was 23 ± 1 °C. The volumetric air consumption

q through the studied system (through the diffuser) ranged from 0.0018 m

3/s to 0.006 m

3/s. The Reynolds number Re for the air flow at the inlet to the VCD ranged from 10,500 to 106,500. The Reynolds number was determined by the following formula [

35]:

where ρ is the density, kg/m

3;

w is the flow velocity, m/s;

d is the diameter of a single duct, m; υ is the kinematic viscosity of the medium, m

2/s. The flow velocity was determined in a single duct before entering the diffuser; the diameter was defined as the internal diameter of a single duct; the density and kinematic viscosity of air were determined for a temperature of 65 °C.

The air flow mode in the diffuser was stationary. Previous studies have shown that the flow regime in the system was turbulent with turbulence intensity TI in the diffuser ranging from 0.15 to 0.35, depending on the air consumption (flow velocity) and the height of the control section [

23,

36]. The TI was determined as the ratio of the rms fluctuating velocity component to the average velocity of the flow [

35]:

where

w′ is the pulsation component of the velocity projections and

w is the average gas flow rate in the channel. Instantaneous flow velocity values and average flow velocity were determined using a constant temperature hot-wire anemometer.

Thus, the boundary conditions in the experiments were as follows:

The velocity profile at the diffuser inlet was parabolic.

The turbulence intensity at the diffuser inlet was approximately 0.1 (TI was determined based on hot-wire anemometer data).

The pressure at the diffuser outlet was fixed (atmospheric) and approximately equal to 0.1 MPa.

The diffuser wall characteristics were as follows: material—ABS plastic; surface roughness 1.6 μm; friction coefficient was between 0.0170 and 0.0234.

The flow structure in the VCD was studied using thermograms obtained using a thermal imaging technique. This technique is based on the analysis of temperature distribution fields in the test area under investigation, which are obtained using a thermal imaging camera and thermal imaging grid [

37,

38,

39]. This grid is made of polymer threads (mesh size 1 mm by 1 mm) and is installed in the flow control section of the test object. The use of a grid of thin threads practically does not distort the flow structure in the VCD, leading to heating (cooling) of the threads and the formation of a temperature field on the grid. This field is identical to the temperature field of the air flow in the diffuser. The intensity of thermal radiation from the threads corresponds to the temperature of the flow, which is recorded by a thermal imager and converted into a visual image in the form of a color field (thermogram). This thermogram is decoded into numerical temperature values at points of the air flow by comparing colors with a color-temperature scale. Thus, a one-time measurement of the temperature field of the air flow takes place at many points in the VCD, the dimensions of which are determined by the dimensions of the grid. The thermal imaging grid threads are made of a material with a thermal conductivity coefficient of 0.95–1.05, which ensures increased accuracy in measuring the air flow temperature field due to the absence of heat flow through the mesh threads and a reduction in the temperature difference between the surface of the grid threads and the air at the boundary between them. This results in the identity of the temperature fields of the air and the grid, which increases the accuracy of measuring the temperature field of the grid using a thermal imager. This method is protected by a Russian patent (patent RU 2230300 C2).

Accordingly, the air was preheated to 65 ± 1 °C using an electric heating module to obtain thermograms. A thermal imaging camera (model Testo 890-2, Testo, Lenzkirch, Germany) was used to obtain thermograms of the flow distribution inside the VCD (measurement error ± 0.2 °C according to the operating manual).

The air consumption

q was determined based on measurements of the average flow velocity in a channel with a known cross-sectional area in front of the VCD using a constant temperature hot-wire anemometer (Dantec Dynamics, Skovlunde, Denmark). The methodology for using thermal anemometry to measure flow velocity, determine air consumption, and calculate turbulence intensity is described in detail in [

40]. The relative uncertainty in recording the air consumption was 5.25%.

Additional air temperature monitoring before the VCD was performed using a chromel-copel thermocouple (model TRID TP101, Teplopribor, Moscow, Russia). The relative uncertainty of the flow temperature recording was 3.0%.

Thus, the measuring system and research methods correspond to the current level of science and allow obtaining reliable data on the flow structure in the VCD for different boundaries and configuration conditions.

In this study, two methods of air supply to the VCD were used: (1) air supply through a single duct (

Figure 2a,b) and (2) air supply through 4 small tubes (nozzles) (

Figure 2c,d).

The single supply ducts had a circular cross-section with diameters of 32 mm (

Figure 2a) and 50 mm (

Figure 2b). Accordingly, the conical section of the VCD had ratios of 1:2.56 (32 mm by 82 mm) and 1:1.64 (50 mm by 82 mm). The area ratio was 6.57 (32 mm by 82 mm) and 2.69 (50 mm by 82 mm). The diffuser opening angle in both cases was 30°. Other main geometric dimensions of the VCD are shown in

Figure 2a,b. The average roughness of the inner surface of a single supply duct was 3.2 μm.

Air was supplied to the diffuser through nozzles for bases with diameters of 32 mm (

Figure 2c) and 50 mm (

Figure 2d). The main geometric dimensions of the air diffuser remained the same as for the single-duct configuration. The nozzles had an internal diameter of 5 mm and a length of 100 mm. Four nozzles were installed in the base, evenly spaced around the circumference (the angle between the nozzles was 90°). The nozzle angles were 45°, 60°, and 70° relative to the base axis (and diffuser). The choice of nozzle angles was determined by the technical and technological capabilities of the existing laboratory gasifier. The nozzle angles used in the experiments corresponded to those of the flow gasifier built in the university laboratory. Other key dimensions of the VCD with nozzle air supply are shown in

Figure 2c,d. The nozzle tube roughness was approximately 3.2 µm.

The boundary conditions and geometric dimensions of the investigated VCD were selected based on the configuration of the model of a single-stage in-line gasifier of wood sawdust, developed in the laboratory “New Energy Technologies” of the Ural Federal University.

The general view and photograph of the VCD configuration with air supply through a single duct are shown in

Figure 3a,b. The 3D model and photograph of the VCD configuration with air supply through nozzles are presented in

Figure 3c,d.

Thus, two VCD configurations with single air supply ducts and six VCD configurations with nozzles positioned at different angles relative to the diffuser’s axis of symmetry were studied. An analysis of the flow structure thermograms for the different VCD designs is presented in the next section.

3. Analysis of the Gas-Dynamic Structure of the Flow in a Vertical Diffuser

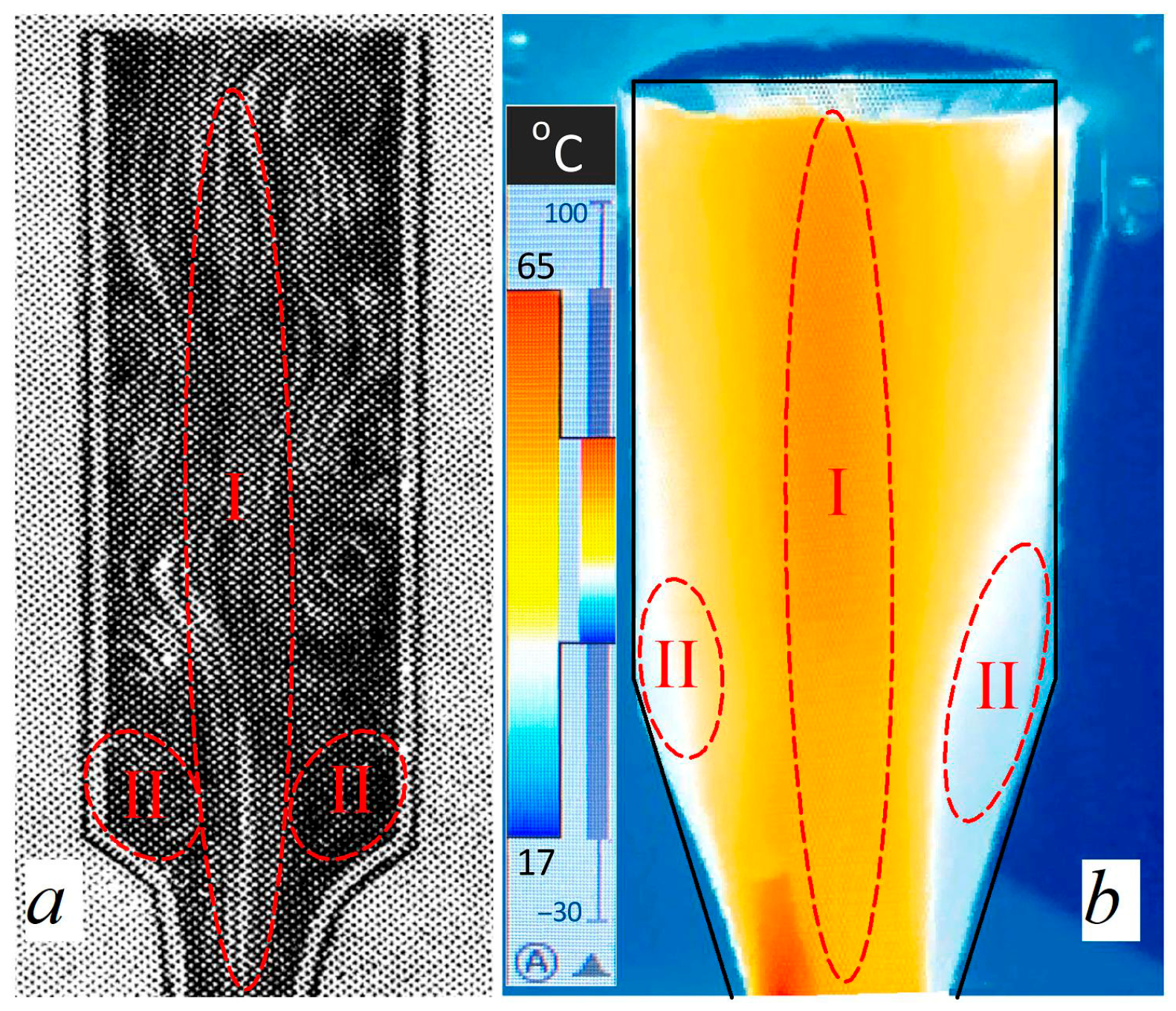

Before conducting the research, a qualitative and quantitative comparison of the thermograms of the flow distribution in the VCD was carried out with the results of other authors (

Figure 4) and data obtained using the PIV (Particle Image Velocimetry) method (

Figure 5).

Experimental data on the flow structure in a VCD from the classic monograph by I.E. Idelchik are presented in

Figure 4a [

41]. The figure shows that there are two distinct sections in the diffuser: I—the main flow (central flow), formed as a result of the pressurized movement of air from the compressor, and II—stagnation zones (zones with near-zero flow velocity) in the corners of the diffuser. Large vortices are also observed along the walls of the straight section of the diffuser.

The thermogram of the flow distribution in the diffuser (based on the thermal imaging method) qualitatively replicates the data of Idelchik I.E. [

41] (

Figure 4b). It is also possible to distinguish two distinct zones on the thermogram: I—the main flow (significant temperature gradient) and II—the stagnation zone, characterized by a near-zero temperature dispersion on the thermogram.

It should be noted that the flow structure was obtained for a practically equal Reynolds number, Re ≈ 20,000, as shown in

Figure 4. Accordingly, the thermogram of the flow structure qualitatively reproduces the air distribution in the VCD obtained by another author.

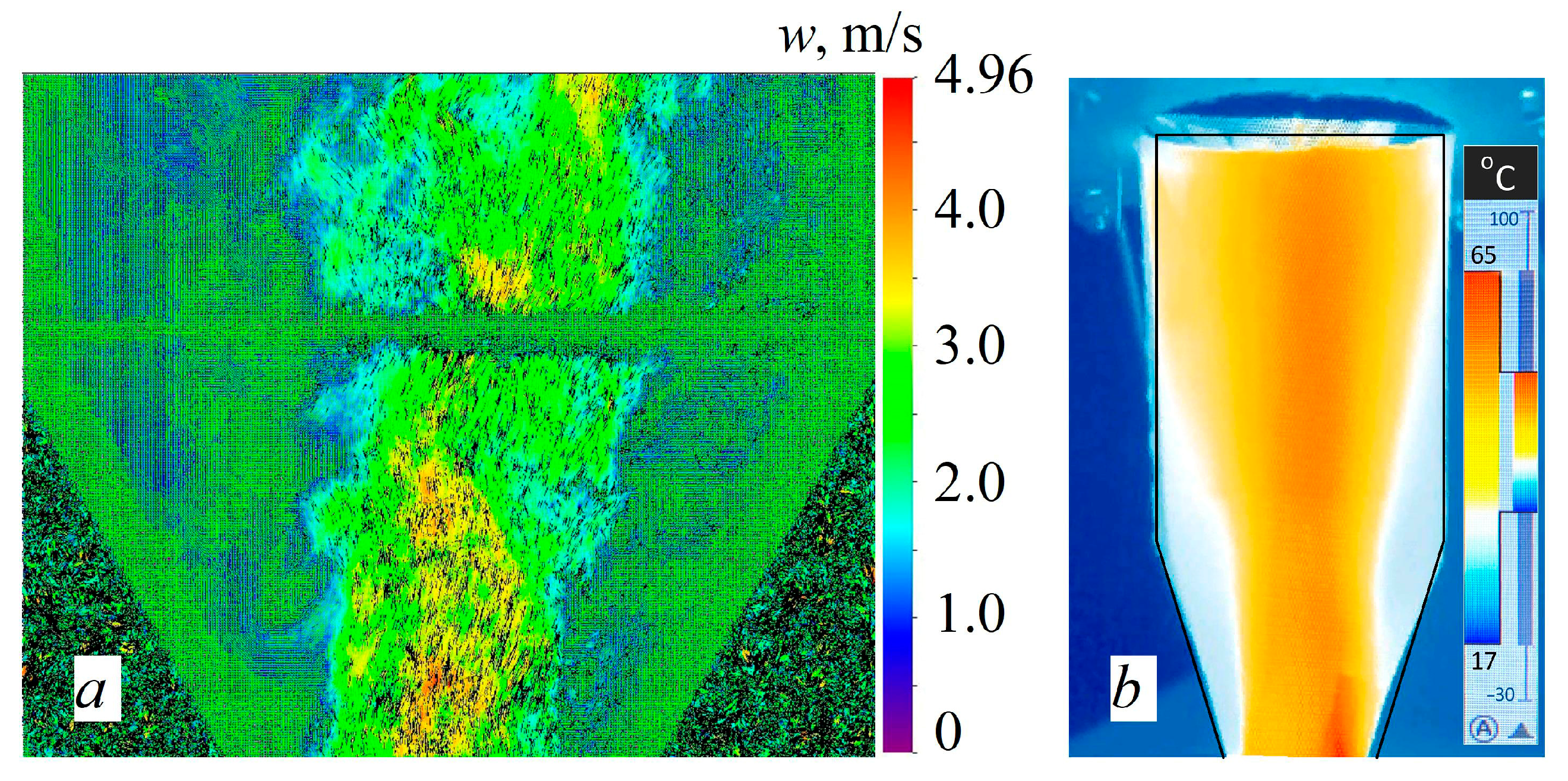

Figure 5 shows a comparison of the flow structure in the VCD for practically identical boundary conditions and diffuser configurations, obtained using the PIV method (

Figure 5a) and the thermal imaging method (

Figure 5b).

The maximum flow velocity reaches almost 5 m/s (

Figure 5a). A pronounced central flow (gradient velocity field in accordance with the dimensional scale) and a lack of air movement in the diffuser corners are observed (

Figure 5a). The air distribution thermogram in the VCD (

Figure 5b) qualitatively reproduces the velocity field in

Figure 5a. There is also a main flow along the VCD axis and virtually no movement in the corners and along the side walls of the diffuser (

Figure 5b).

Thus, it can be stated that thermograms of the thermal imaging method adequately and reliably reproduce the distribution of air in the VCD at a qualitative level and can be used for scientific research.

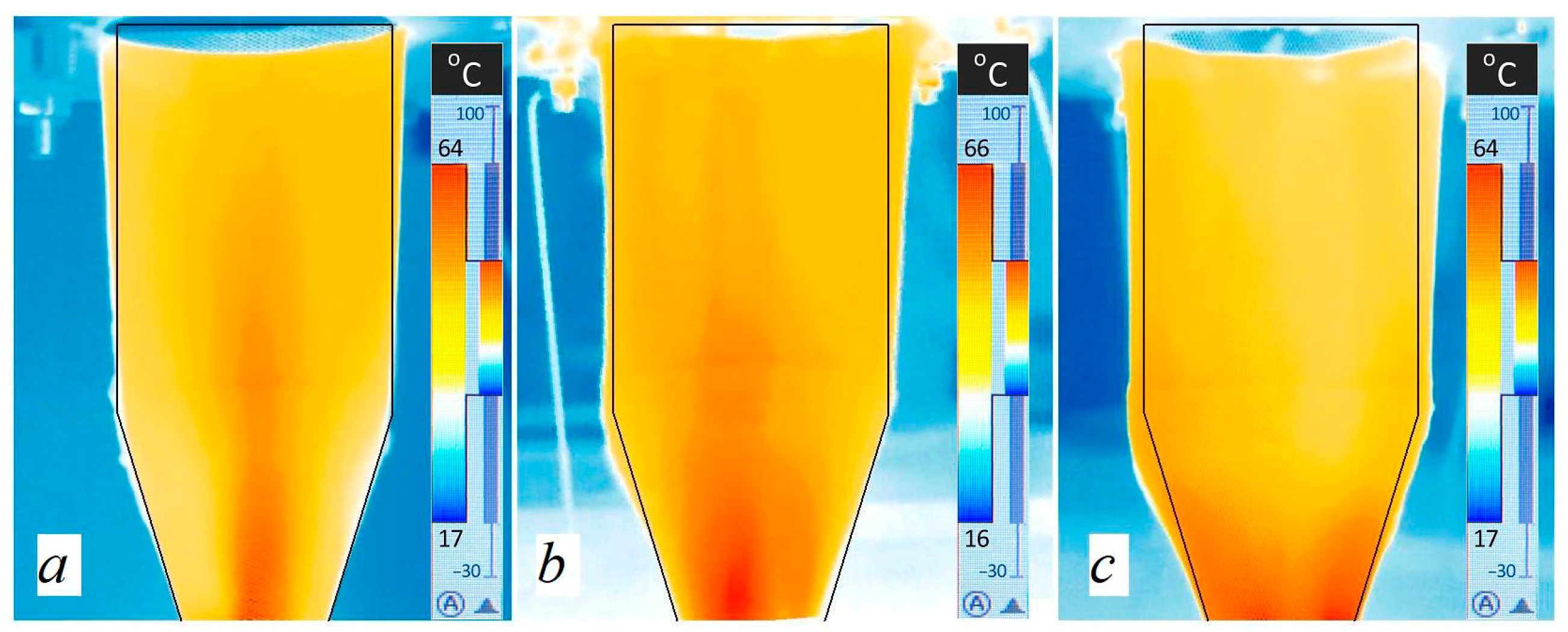

At the first stage of the study, a comparison of the flow structure in the VCD for air supply through a single duct and through 4 nozzles for different flow characteristics was carried out (

Figure 6 and

Figure 7).

Figure 6a shows the distribution of the flow structure in the VCD for air supply through a single duct with a diameter of 32 mm. In this case, there are pronounced stagnant zones (white areas) in the corners of the transition of the cone to the cylindrical section. This indicates a virtual absence of flow movement at the cone’s corners (zero temperature dispersion is observed on the thermogram). Increasing the air consumption slightly reduces the size of the stagnation zone, but does not eliminate it completely. At the same time, intense air movement is observed along the VCD axis, with a slight slope toward the right side of the diffuser. The central air flow extends along the entire length of the VCD (right up to the air outlet from the diffuser). The use of such a VCD configuration will potentially lead to uneven mixing of air and sawdust, as well as accumulation of sawdust in the corners of the diffuser in relation to the in-line gasifier (thus, there is a decrease in the efficiency of gasification).

A fundamentally different flow structure in the VCD is observed for air supply through nozzles located at an angle of 45° at the base with a diameter of 32 mm (

Figure 6b): there is a more uniform distribution of air flow throughout the entire volume of the diffuser compared to supply through a single duct. It is clearly seen that there are no stagnant zones in the corners of the transition of the cone to the cylindrical part of the VCD. There is also a pronounced central flow along the axis of the diffuser. However, this central current does not extend along the entire length of the VCD, but reaches approximately 75% of the total height of the studied apparatus. In other words, the kinetic energy of the flow from the nozzles is dissipated throughout the entire volume of the VCD. The use of this configuration in an in-line gasifier has the potential to increase its efficiency by mixing sawdust and air more evenly compared to a single-duct design.

Figure 7a shows the distribution of the flow structure in the VCD for air supply through a single duct with a diameter of 50 mm. In this case, there are virtually no stagnant zones in the corners of the transition from the cone to the cylindrical section, compared to the air supply through a duct with a diameter of 32 mm (

Figure 6a). This indicates the absence of separation phenomena in the considered VCD configuration. Accordingly, an increase in the diameter of a single duct improves the uniformity of the air flow distribution inside the diffuser. At the same time, no central current is formed in the VCD (

Figure 7a). There is also more intense air movement near the right wall of the VCD (darker yellow color, i.e., more pronounced temperature dispersion in the thermogram). Thus, the use of a single duct with an increased diameter results in a more even flow pattern in the VCD. However, more intense air movement on one side of the diffuser may reduce the efficiency of wood sawdust gasification.

There is a significant change in the flow structure in the VCD for supplying air through nozzles located at an angle of 60° at the base with a diameter of 50 mm (

Figure 7b): local (approximately to the middle of the diffuser), central (along the axis), and active movement of the air flow in the VCD is observed. Meanwhile, uniform air distribution with minimal movement intensity is observed throughout the rest of the diffuser volume (weak temperature dispersion on the thermogram). The use of such a configuration in a wood sawdust gasifier is possible in transient modes, warm-up modes, and/or shutdown modes of the device, i.e., for cases where minor movement of the air flow and sawdust with a minimal yield of synthesis gas is required.

Thus, it has been shown that the flow structure in the VCD undergoes a significant transformation due to a change in the air supply method (single duct or nozzles). Therefore, it is necessary to study in more detail the distribution of the air flow inside the VCD for air supply through nozzles located at different angles.

In the second stage of the study, the evolution of the flow structure in the VCD for air supply through nozzles located at different angles and in bases with different diameters was studied (

Figure 8,

Figure 9,

Figure 10 and

Figure 11).

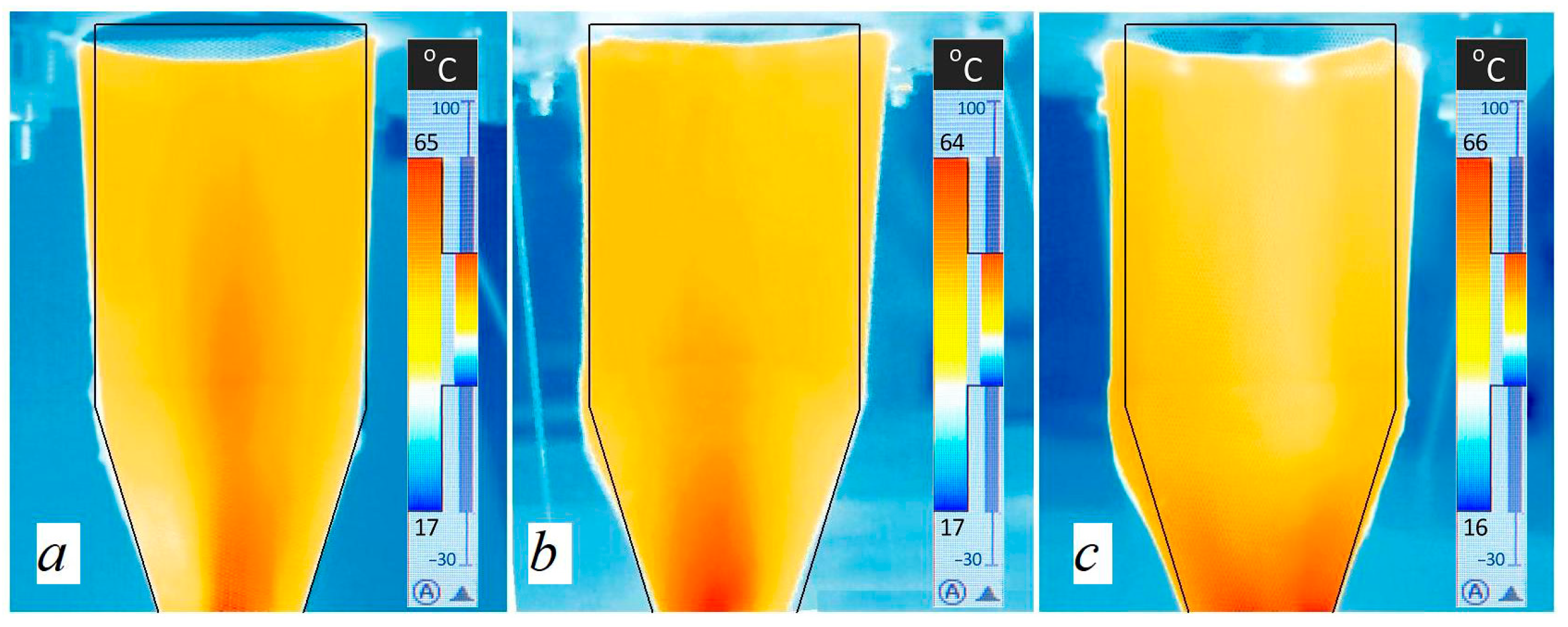

Thermograms of the flow structure in the VCD for a nozzle supply with a base of 32 mm for different air flow rates are shown in

Figure 8 and

Figure 9. First, data for the average air consumption through the system,

q = 0.034 m

3/s, are presented (

Figure 8).

Figure 8a shows that installing the nozzles at a 45° angle results in the formation of a pronounced central flow in the diffuser along the axis at 75% of its height. At the same time, almost imperceptible stagnation zones are observed at the corners of the transition from the conical to the cylindrical section; low-intensity flow occurs in the remaining volume of the diffuser.

An increase in the nozzle installation angle to 60° causes significant changes in the flow structure in the VCD (

Figure 8b). There is also a central flow along the axis to a height of up to 50% of the VCD. In other words, an increase in the nozzle installation angle led to a decrease in the penetration height of the central flow in the diffuser. At the same time, the most intense air movement is formed in the conical part of the VCD. The width of the central stream increases significantly, which is especially typical at the entrance to the VCD. A uniform flow movement up to the exit of the flow from the diffuser takes place in the remaining volume of the VCD. This flow structure is optimal for the gasifier to operate at full capacity with maximum efficiency (active movement of the working fluid in the conical part of the diffuser, central flow to about the middle of the VCD, absence of stagnant zones, uniform flow distribution over most of the VCD).

A further increase in the nozzle installation angle to 70° causes a complete destruction of the central flow in the VCD (

Figure 8c). In this case, there is an active movement of the air flow along the walls of the conical part of the VCD without its penetration into the central part or along the height of the diffuser. At the same time, there are no stagnant zones, and the flow distribution over the volume of the VCD is uniform. This flow structure can be useful in the transient modes of operation of the gasifier (using the working fluid in the conical part without active synthesis gas production).

Thus, it has been preliminarily demonstrated that it is possible to control the flow structure in the VCD by changing the angle of installation of the supply nozzles. This can have a crucial role in improving the sustainability, productivity, and efficiency of in-line biomass gasifiers (e.g., sawdust).

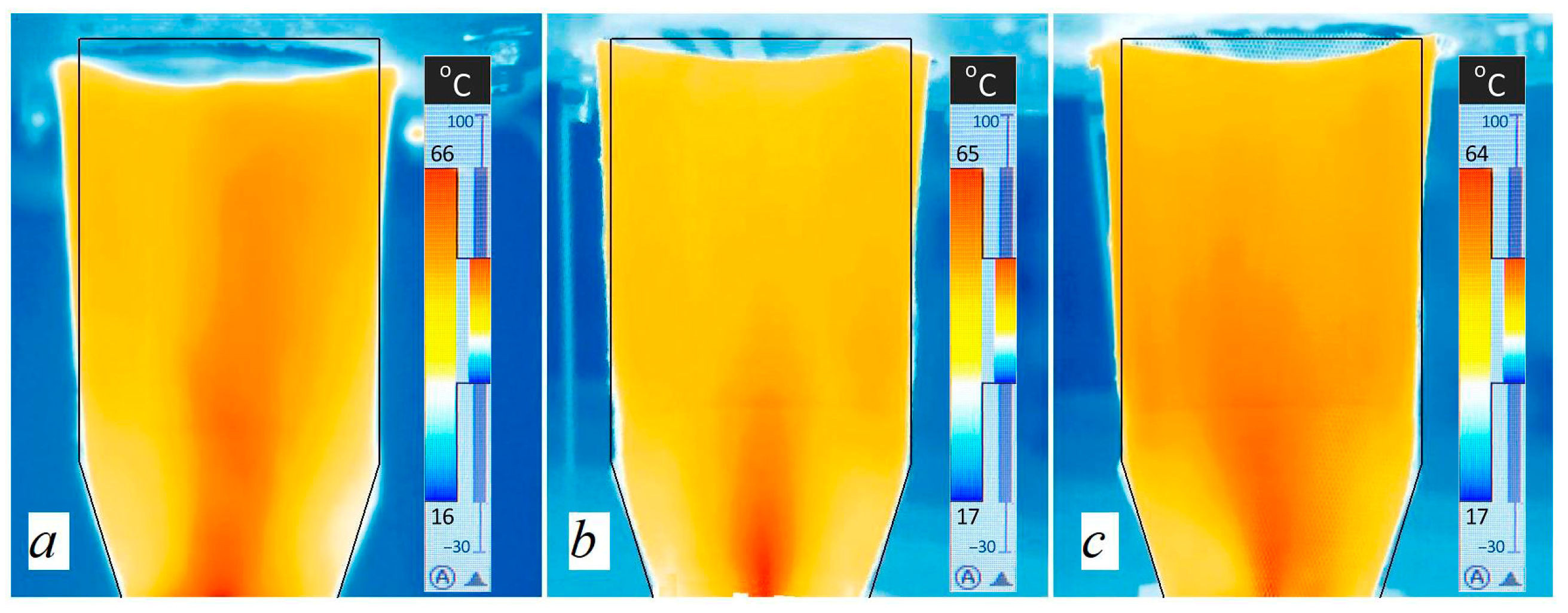

Next, an analysis of the evolution of the flow structure in the VCD for nozzle air supply through a base with a diameter of 32 at an increased air consumption of

q = 0.057 m

3/s through the system was carried out (

Figure 9).

Figure 9a (nozzle installation angle 45°) demonstrates that an increase in air consumption through the system leads to a growth in the width of the central flow and the actual elimination of small stagnant zones in the corners of the inlet. At the same time, the height of the central flow remains unchanged (about 75% of the VCD), as for

q = 0.034 m

3/s.

The installation of the supply nozzles at an angle of 60° for increased flow (

q = 0.057 m

3/s) causes a decrease in the area of active air flow in the diffuser conical part (

Figure 9b). In other words, the flow becomes more orderly compared to the case with low air consumption. In this case, there are also no stagnant zones, and the height of the central current does not exceed 50% of the VCD.

An increase in air consumption through a system with nozzles at an angle of 70° does not cause a noticeable change in the flow distribution inside the VCD (

Figure 9c). There is intense movement in the lower part of the diffuser with barely noticeable “gaps” (stagnant zone) in the center of the VCD. There is an assumption that the main flow movement is carried out along the side walls. Additional studies of this effect using more accurate optical methods are needed. Now, this is considered one of the possible directions for further research in the framework of this topic.

Thus, the possibility of controlling the air flow structure in the VCD by changing the inclination angle of the supply nozzles in a wide range of flow characteristics through the system was confirmed.

Thermograms of the flow structure in the VCD for a nozzle supply with a base of 50 mm for different air flow rates are shown in

Figure 10 and

Figure 11. First, the data for the average air consumption through the system with

q = 0.034 m

3/s are presented (

Figure 10).

Figure 10a shows a pronounced central flow along the entire height of the VCD with a deviation toward the right wall to deliver air through nozzles installed at a 45° angle in a 50 mm diameter base. This deviation may be due to the imprecise installation of the VCD during the experiments or the Coanda effect. Additionally, in this case, there are no stagnant zones in the corners of the VCD. The resulting flow structure may cause excessively rapid removal of sawdust from the gasifier’s working area, reducing its performance and efficiency.

An increase in the nozzle installation angle to 60° leads to a significant transformation of the gas dynamic structure in the VCD (

Figure 10b). In this case, there is a local central current, vaguely resembling a “carrot” in appearance. It extends approximately to the middle of the height of the diffuser. There are no stagnant zones in the VCD, and the volume distribution of the air flow is almost uniform. It is necessary to study additionally the presence or absence of a gushing effect in this case. This flow structure is promising for sawdust gasifiers, since it is possible to intensively mix the working fluid and air throughout the entire volume of the VCD without rapidly removing sawdust from the apparatus.

A further increase in the nozzle installation angle to 70° leads to the formation of a new flow structure in the VCD (

Figure 10c). In this case, the beginnings of a central flow are noticeable, which very quickly transforms into multidirectional air movement throughout the entire volume of the diffuser. This multidirectional flow movement extends almost over the entire height of the VCD. There are also no stagnant areas. The question of the formation of large-scale vortices and/or swirling of the flow in the VCD after the rapid decay of the central flow remains open. This issue also requires additional, more accurate studies of gas flow dynamics through mathematical modeling and other optical methods. The resulting flow structure has the potential to be used in in-line biomass gasifiers if it contains large-scale gas dynamic phenomena. These phenomena contribute to the intensive movement and mixing of sawdust and air, which will lead to an increase in the efficiency and productivity of the gasifier.

Thus, it is shown that there is an additional possibility to control the structure of the air flow in the VCD by changing the diameter of the base for installing the supply nozzles.

The analysis of changes in the flow structure in the VCD for nozzle air supply through a base with a diameter of 50 mm for increased air consumption

q = 0.057 m

3/s through the system is presented below (

Figure 11).

Figure 11a illustrates that an increase in air consumption to 0.057 m

3/s through nozzles with an installation angle of 45° at the base with a diameter of 50 mm had virtually no effect on the flow structure in the VCD compared to the average

q value. In this case, there is also a clear central flow with a slope to the right side of the VCD, which extends up to the outlet of the flow from the diffuser. The increase in q in the configuration with nozzles with an installation angle of 60° also had no significant effect on the distribution of air flow inside the VCD (

Figure 11b). In this case, there is a focal, local, intense air movement along the axis of the VCD up to about its middle. The rest of the diffuser has a uniform, stable temperature (velocity) field. The structure of the air flow in the VCD remained almost unchanged with an increase in the air consumption through the nozzles with an installation angle of 70° (

Figure 11c). In this case, the rudiment of a central flow is also observed, which quickly collapses with the formation of a multidirectional flow movement throughout the entire volume of the VCD until the air exits the diffuser. Accordingly, it can be stated that the change in flow characteristics has little effect on the configuration under study (air supply through nozzles with a base of 50 mm).

Thus, it has been demonstrated that the airflow structure in a VCD can be controlled by varying the nozzle angle, the diffuser base diameter, and the airflow consumption through the system. The results obtained can be used to develop methods for organizing air distribution in VCD for various technical systems, refine (verify) mathematical models, and deepen the knowledge base in the field of applied gas dynamics.

4. Conclusions

The main findings of the study are as follows:

1. An experimental setup for studying airflow distribution in the VCD for various operating and configuration factors was created, a thermal imaging method was adapted to the research objectives, and thermograms of the flow structure inside the EVA for various boundary conditions were obtained.

2. The flow structure in the VCD significantly depends on the air supply method (single duct or nozzles), the nozzle installation angle (study range from 45° to 70°), the nozzle base diameter (32 mm or 50 mm), and the initial flow conditions.

3. Nozzle air supply results in a more uniform airflow distribution throughout the VCD volume, with almost complete elimination of separated flows and stagnation zones in the diffuser corners compared to supply through a single duct.

4. Installing nozzles at different angles leads to the transformation of the thermograms of the flow structure in the VCD for a wide range of flow characteristics. It is possible to obtain four characteristic patterns of air flow distribution in the VCD: (1) central flow through the entire VCD with a flow deviation to the right side; (2) local (from 30 to 75% of the VCD height), central flow; (3) intensive air movement in the lower part of the cone with subsequent flow along the side walls; and (4) multidirectional flow movement throughout the entire volume of the VCD.

5. The relationships between the flow structure and the operating characteristics of an in-line gasifier in different operating modes are analyzed. The influence of flow structure on the efficiency and performance of the gasifier needs to be further investigated during its actual operation.

The obtained results can be used to expand the knowledge base in applied gas dynamics; verify or tune mathematical models; develop methods for controlling the flow structure in in-line gasifiers; design new conical diffuser designs; and improve the efficiency, stability, and performance of in-line gasifiers.