Electroconductive Thermosensitive Shape Memory Polymers Manufactured by Fused Filament Fabrication: A Critical Review

Abstract

1. Introduction

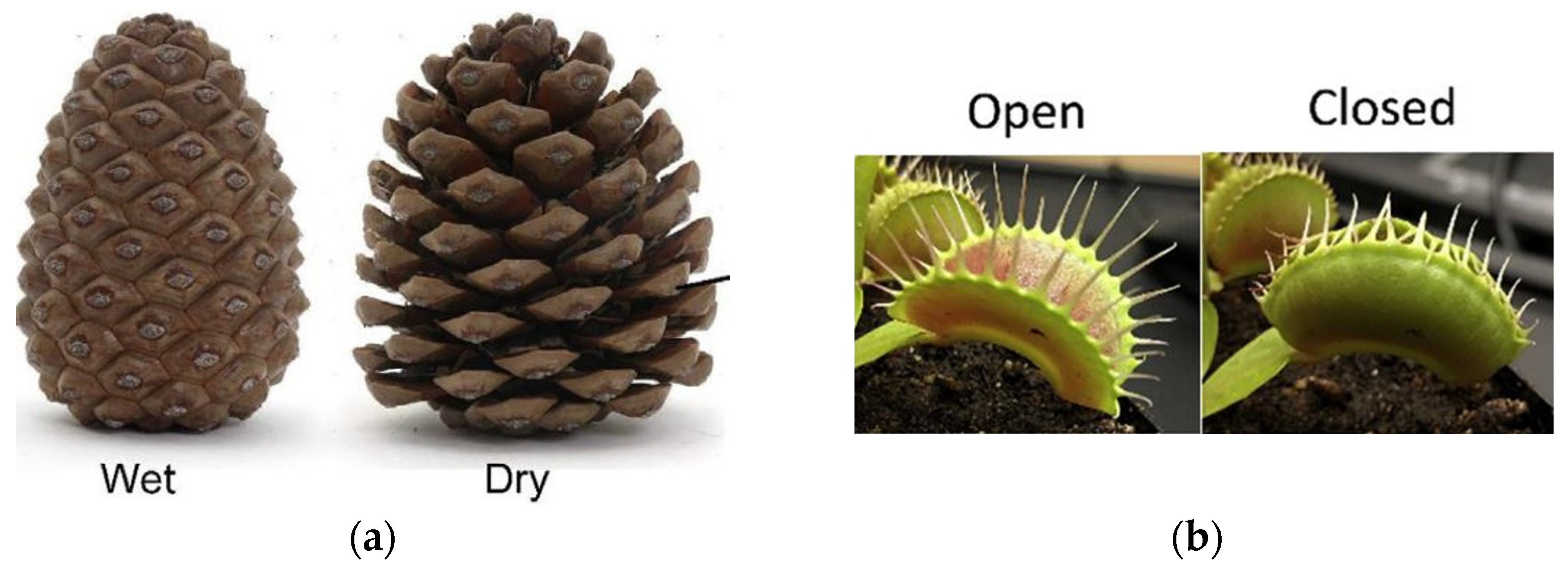

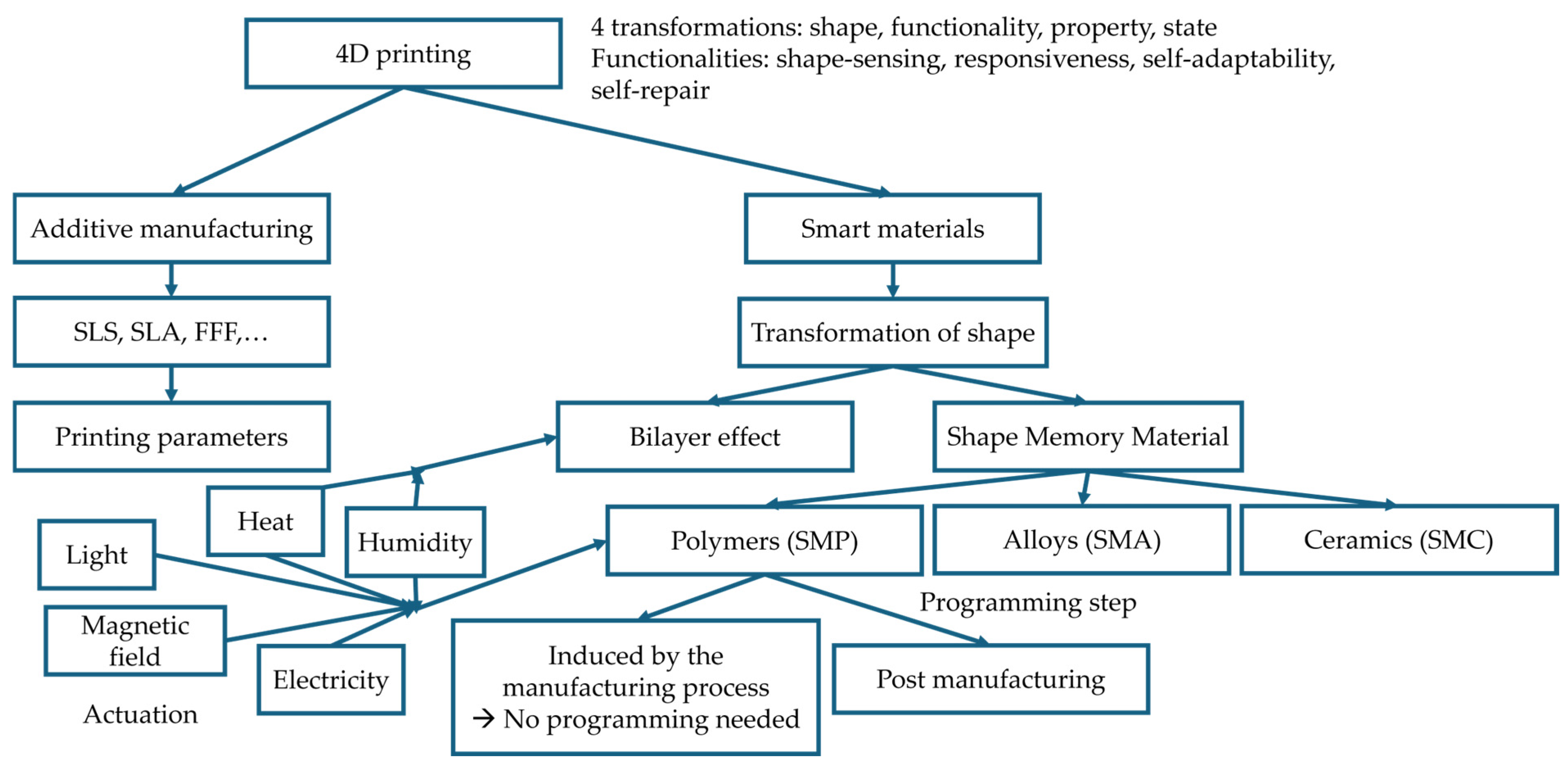

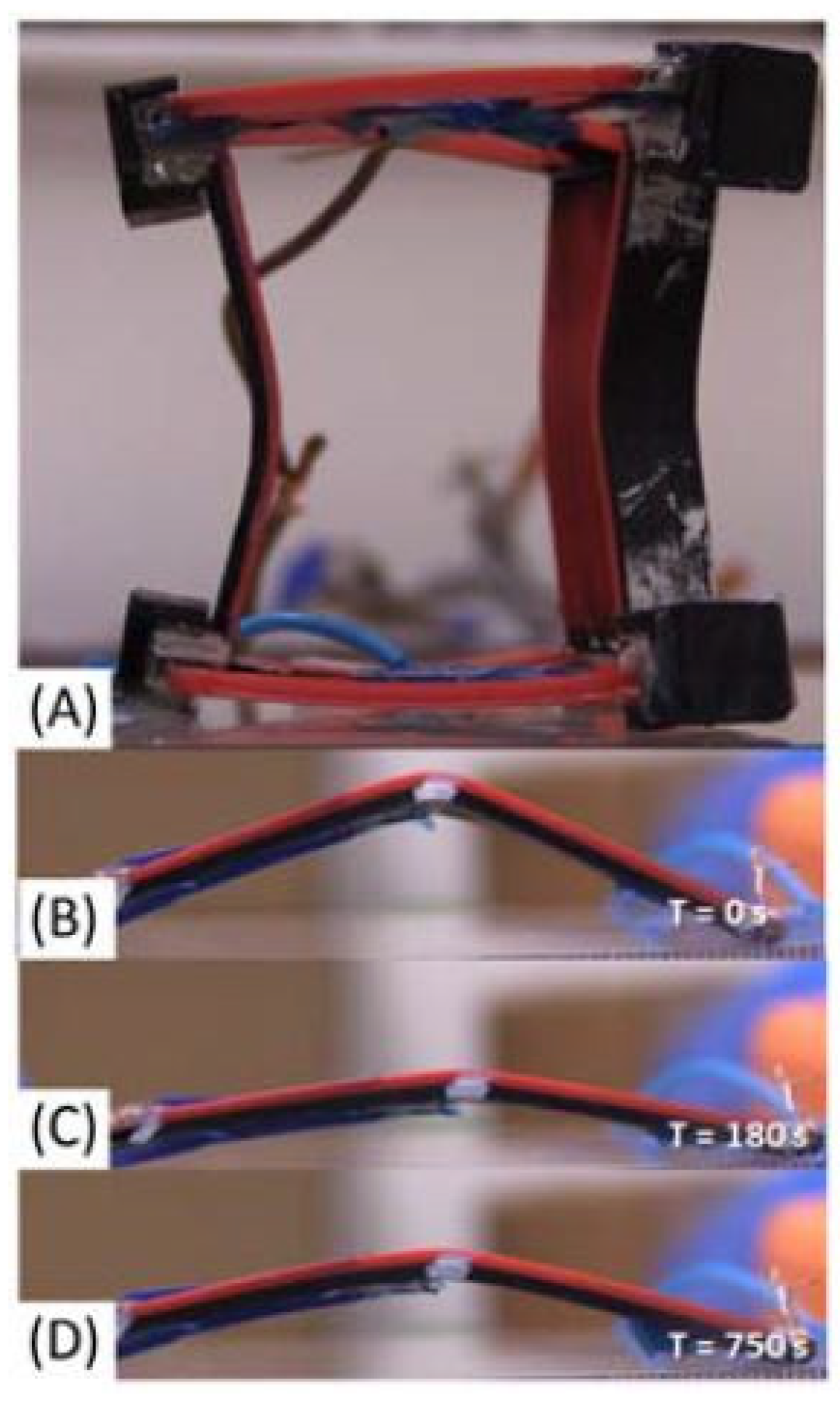

2. Four-Dimensional Printing

2.1. Concept

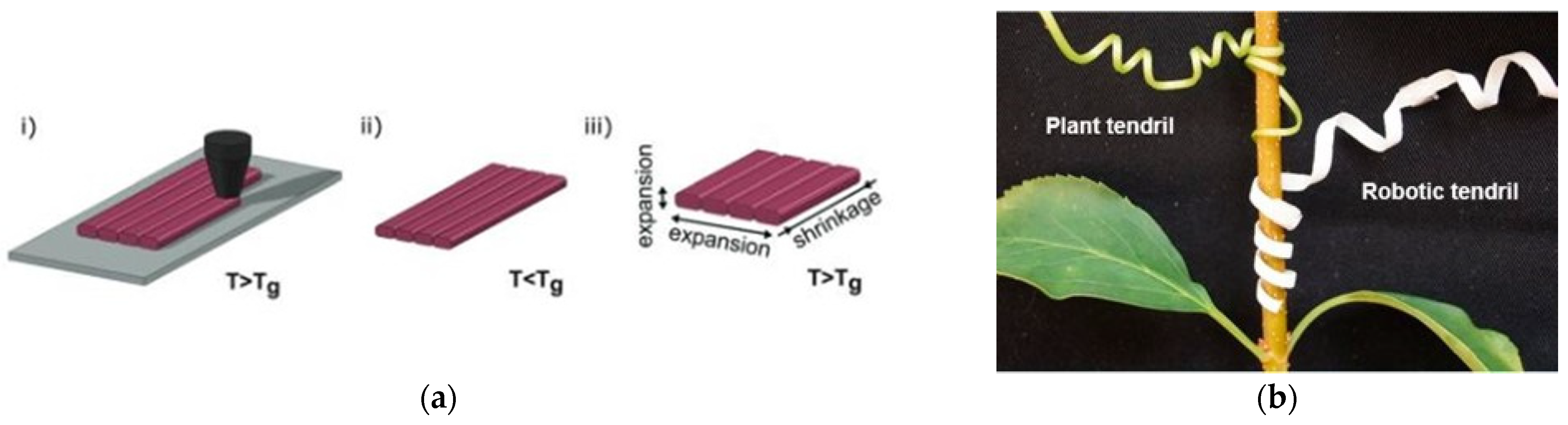

2.2. Applications

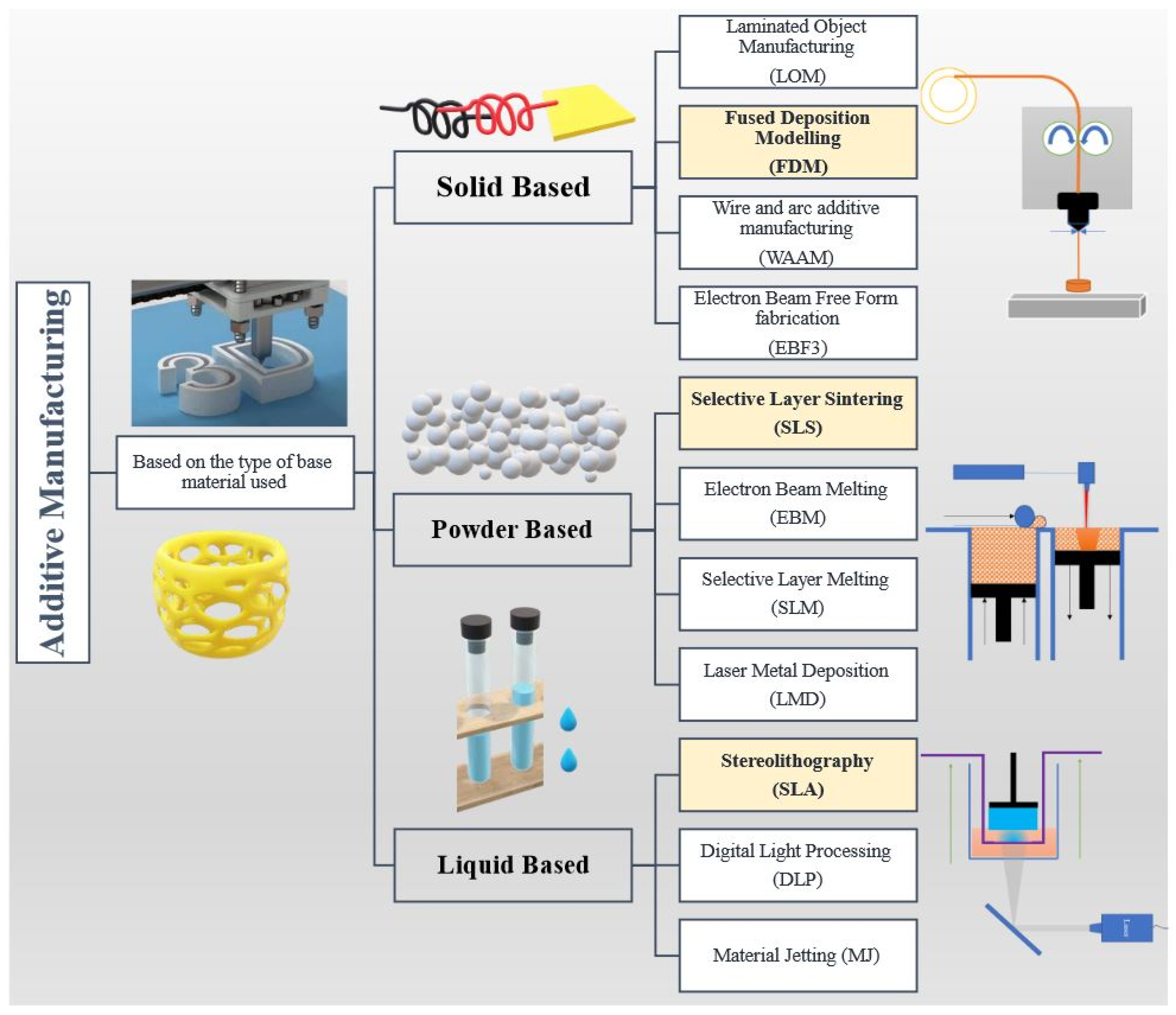

3. Fused Filament Fabrication

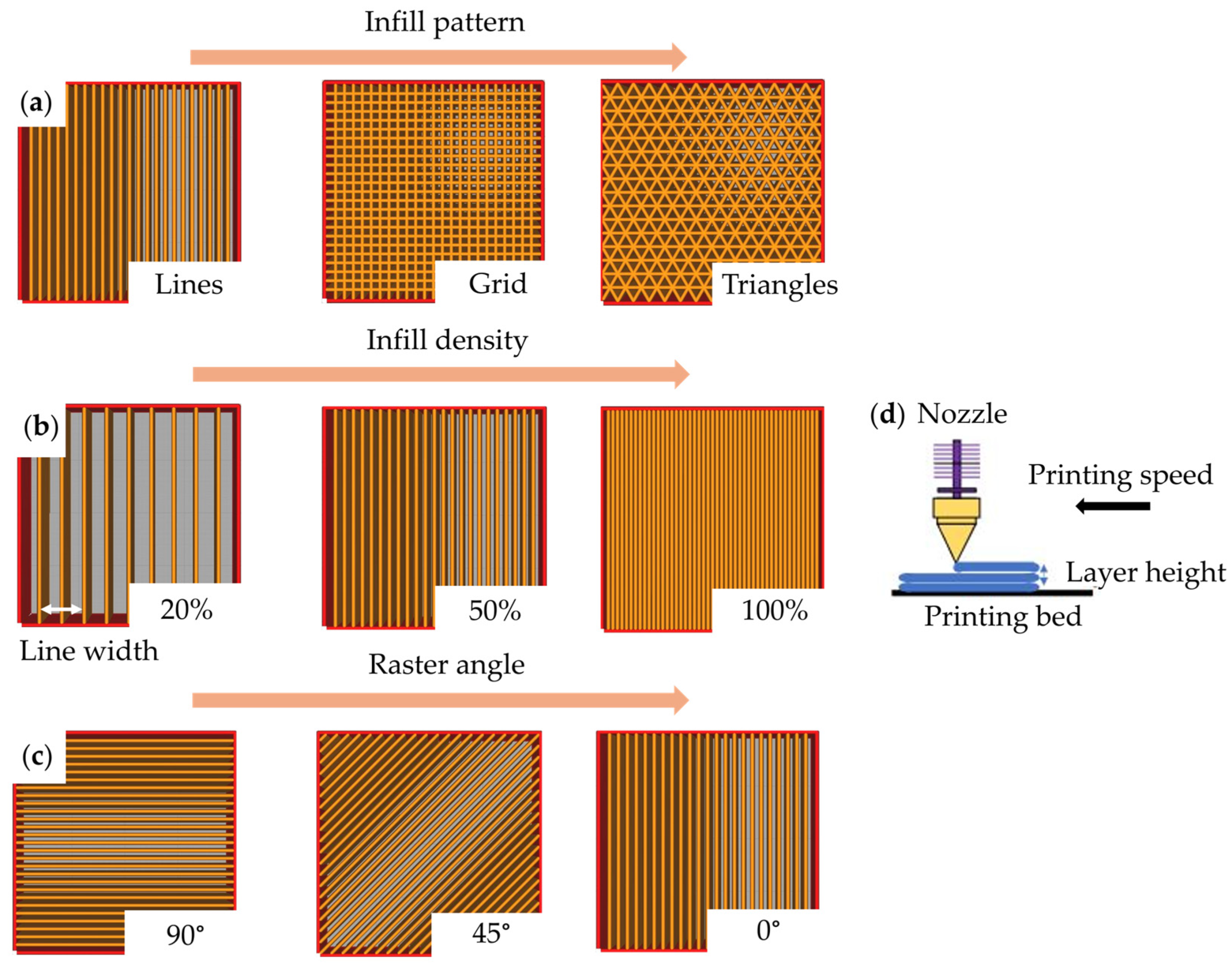

3.1. Processing Parameters

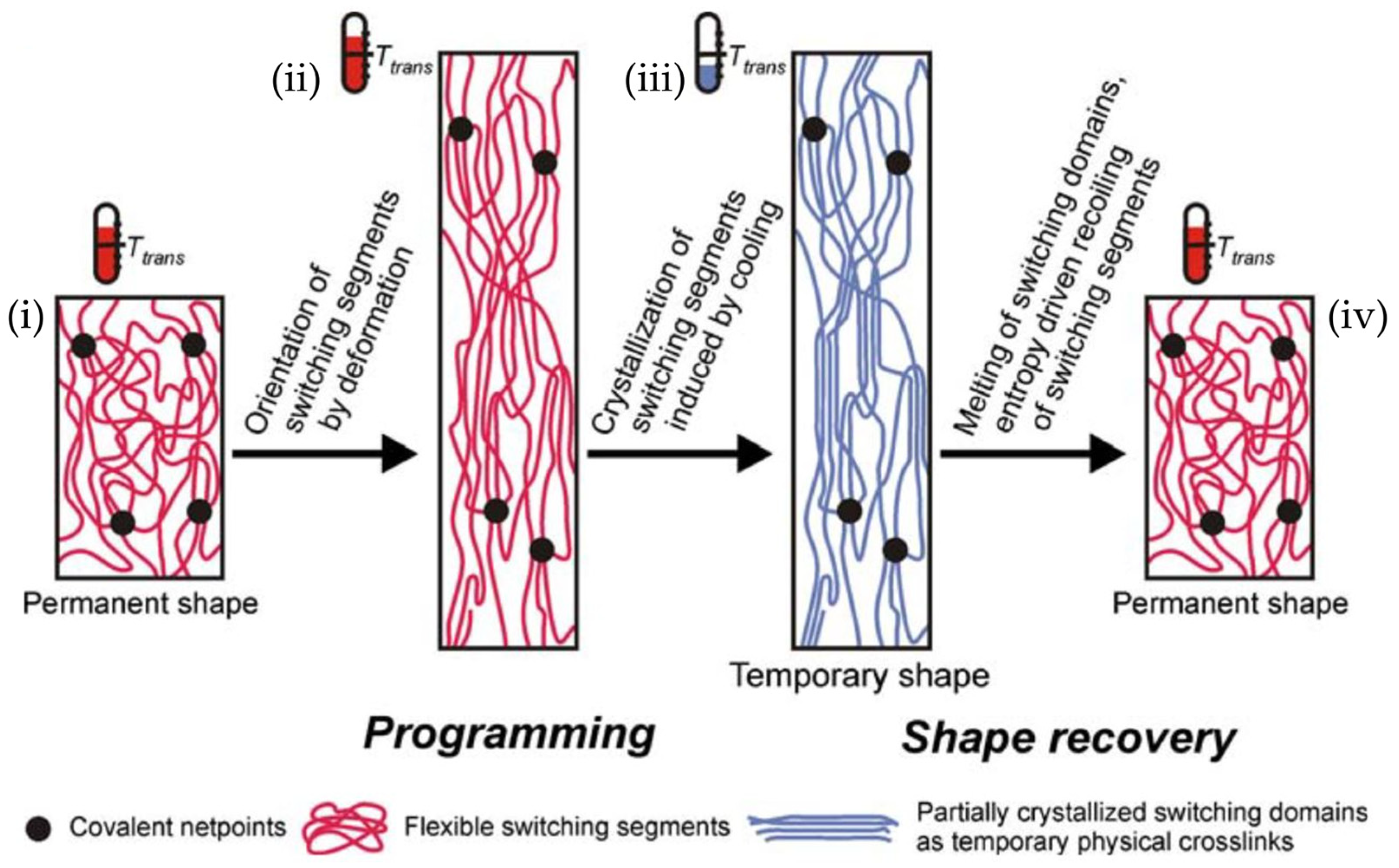

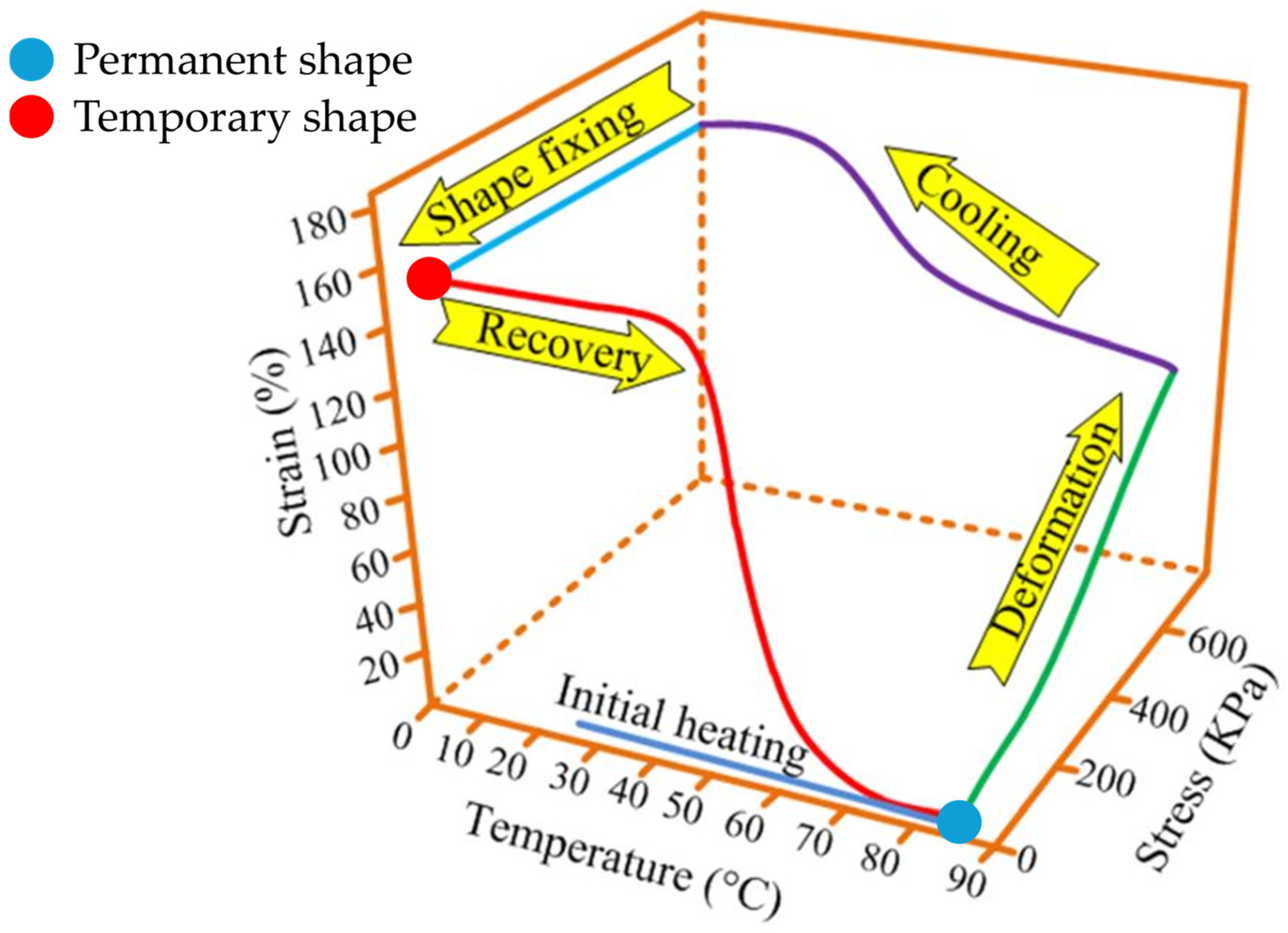

3.2. Four-Dimensional-Printed Thermosensitive Shape Memory Polymers

4. Properties of 4D-Printed Thermosensitive Structures

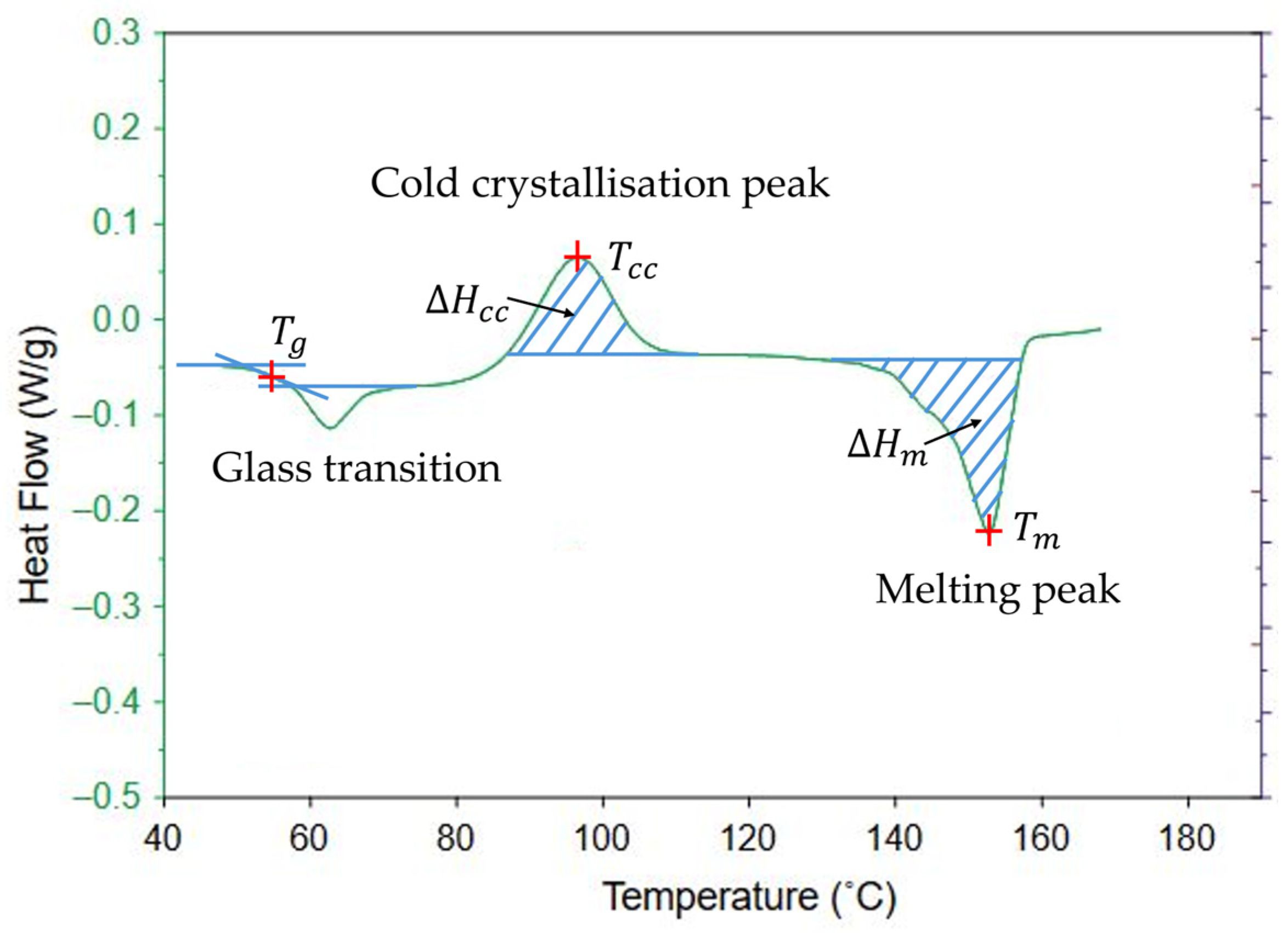

4.1. Physical Characteristics

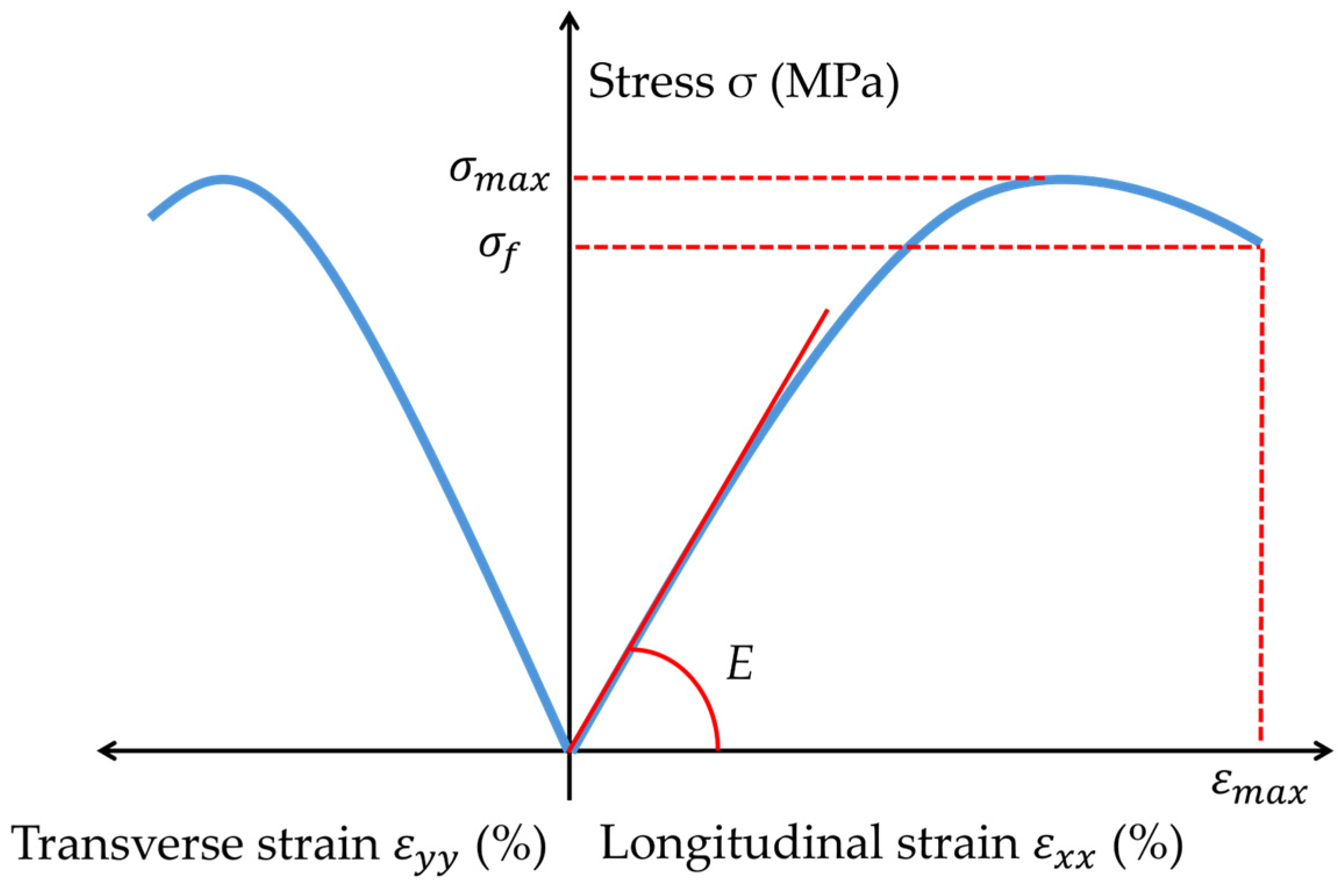

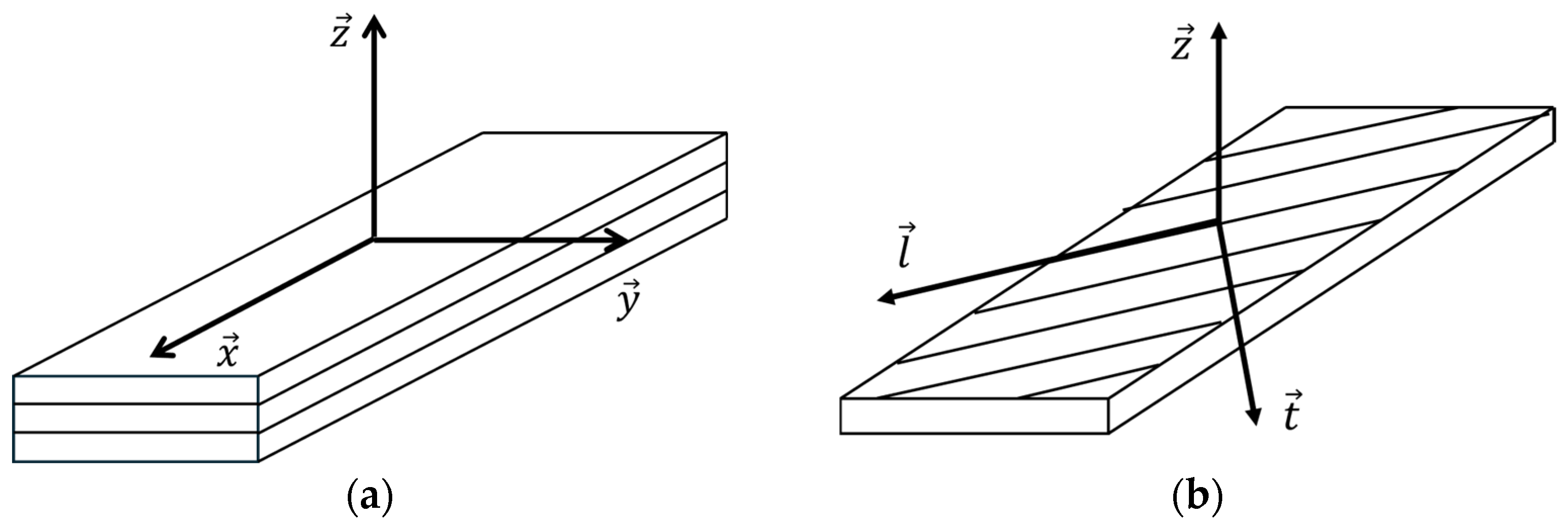

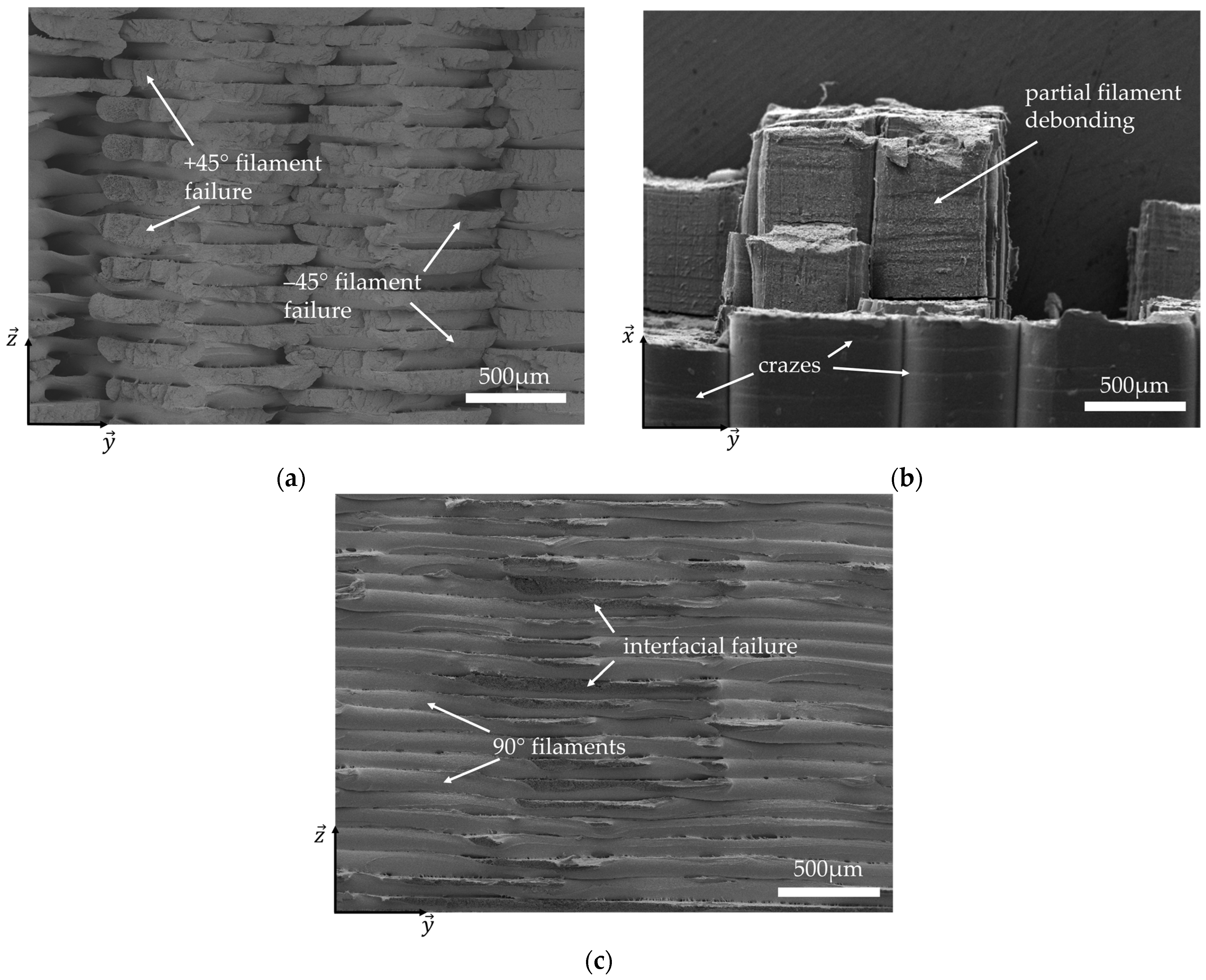

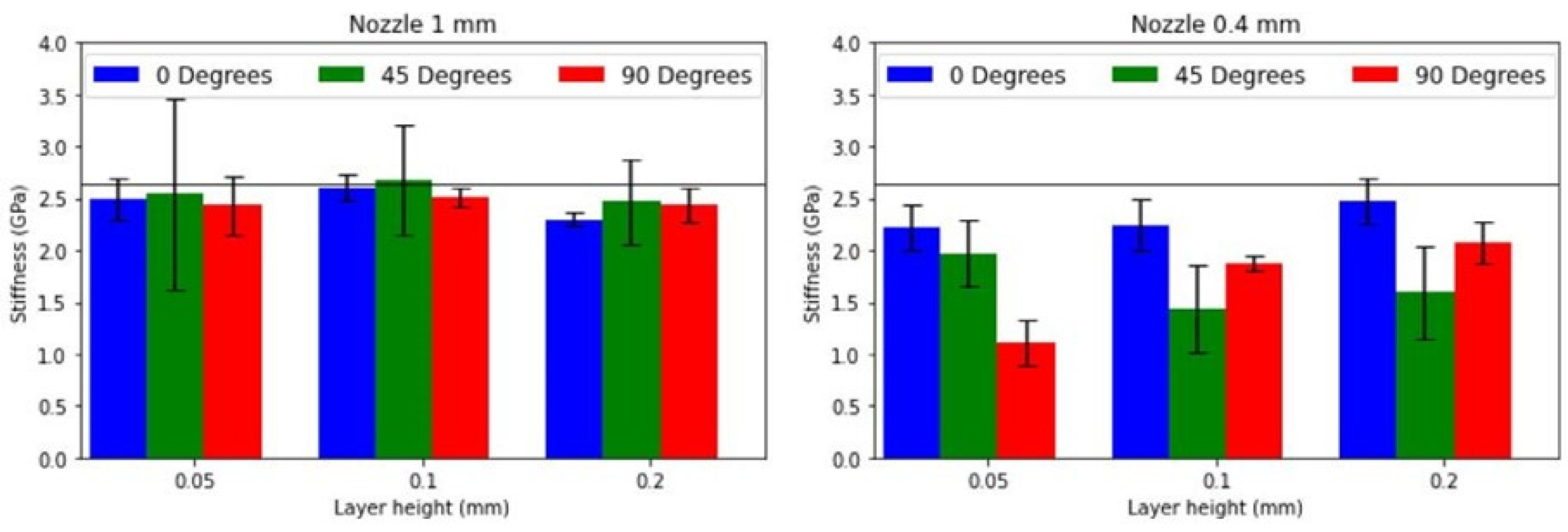

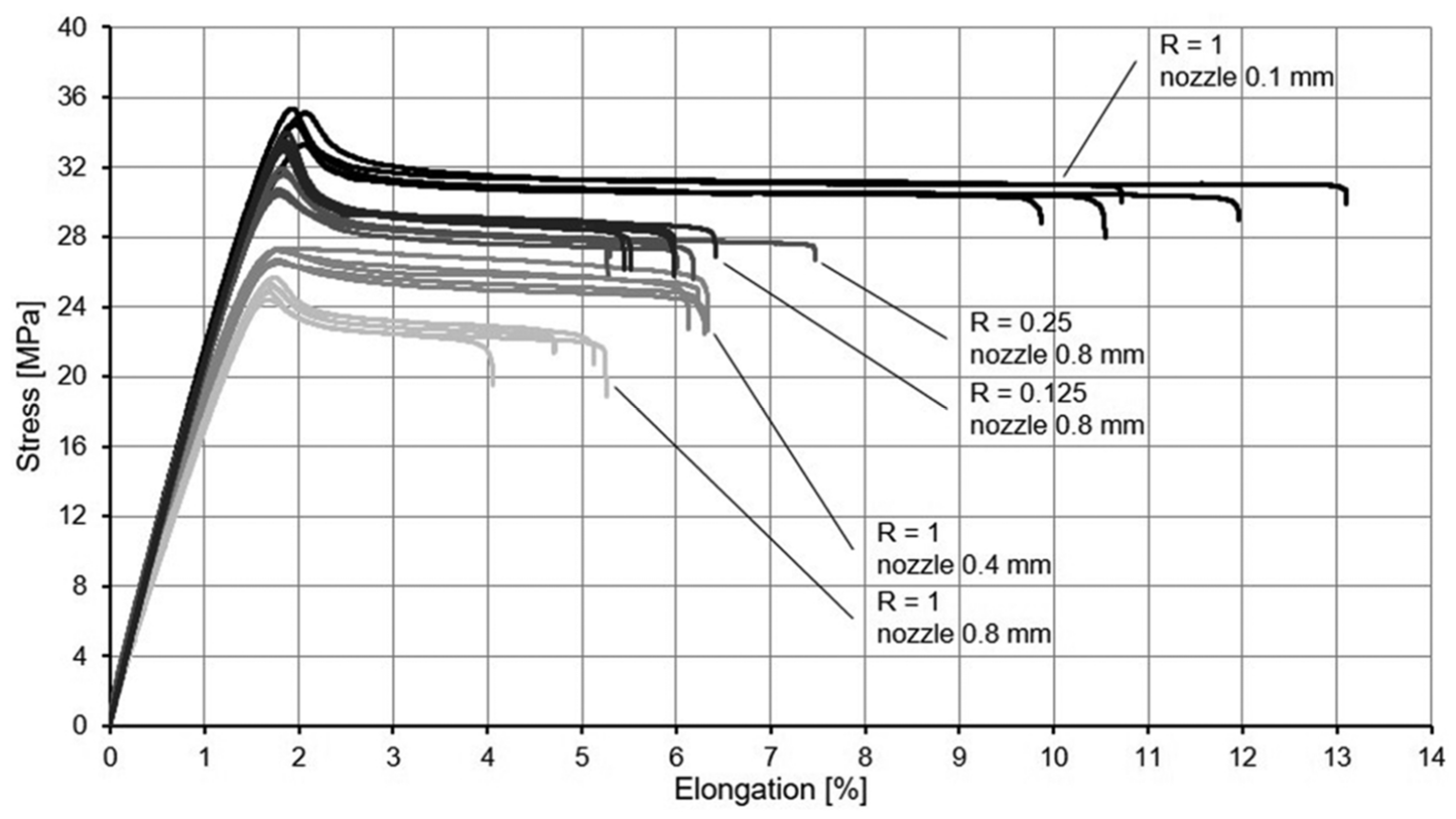

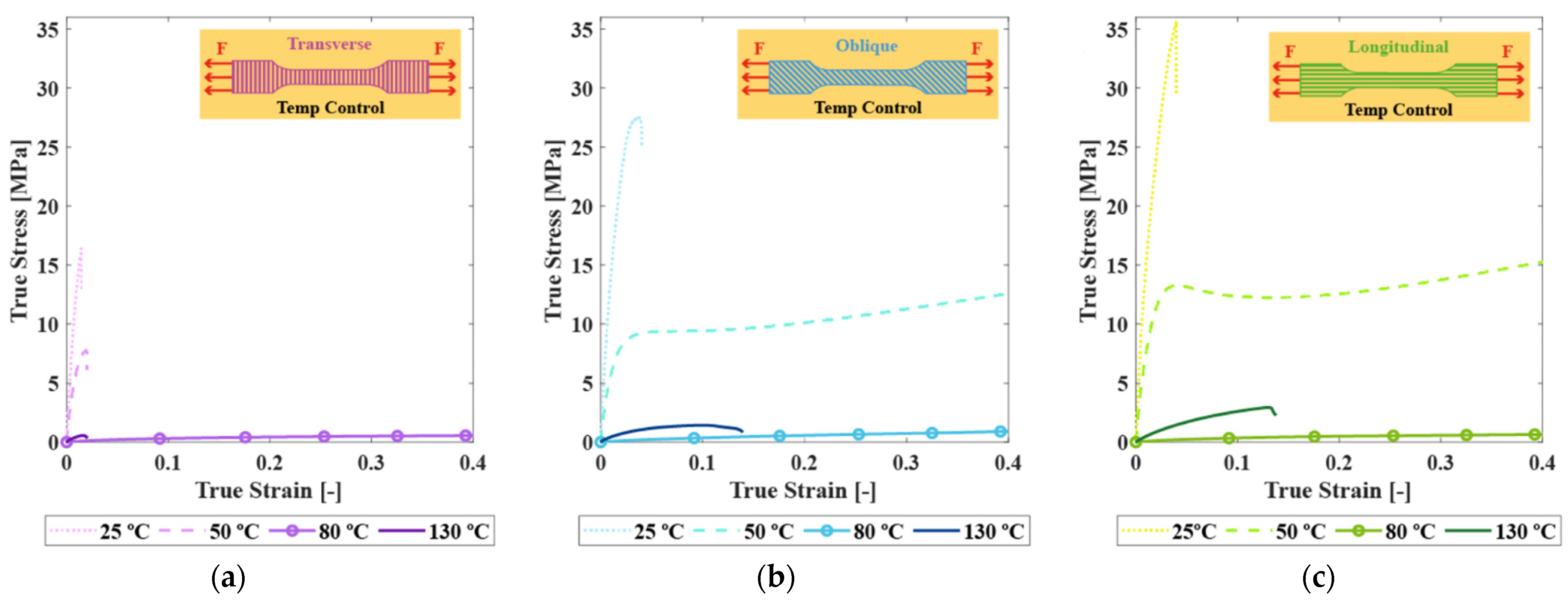

4.2. Mechanical Characteristics

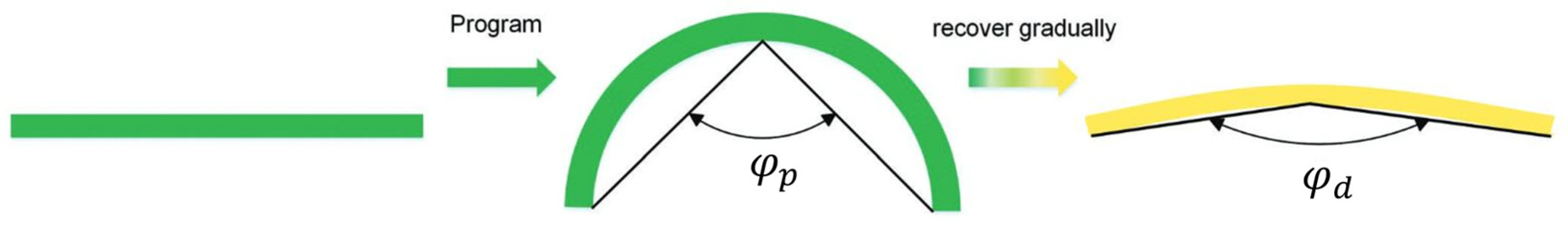

4.3. Recovery Ratio

5. Response of 4D-Printed Shape Memory Polymers

5.1. Influence of the Printing Parameters

5.2. Interdependencies of the Properties

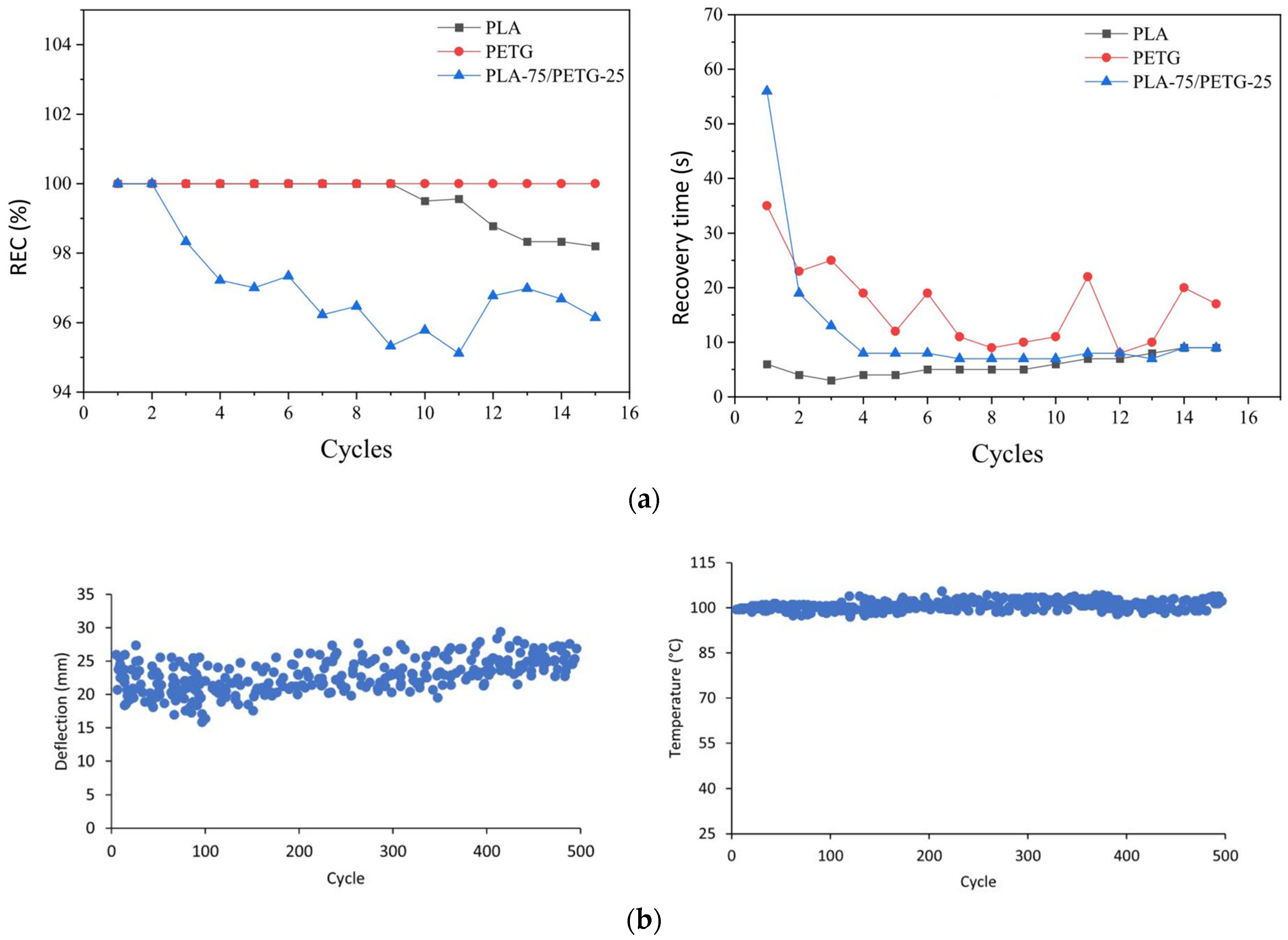

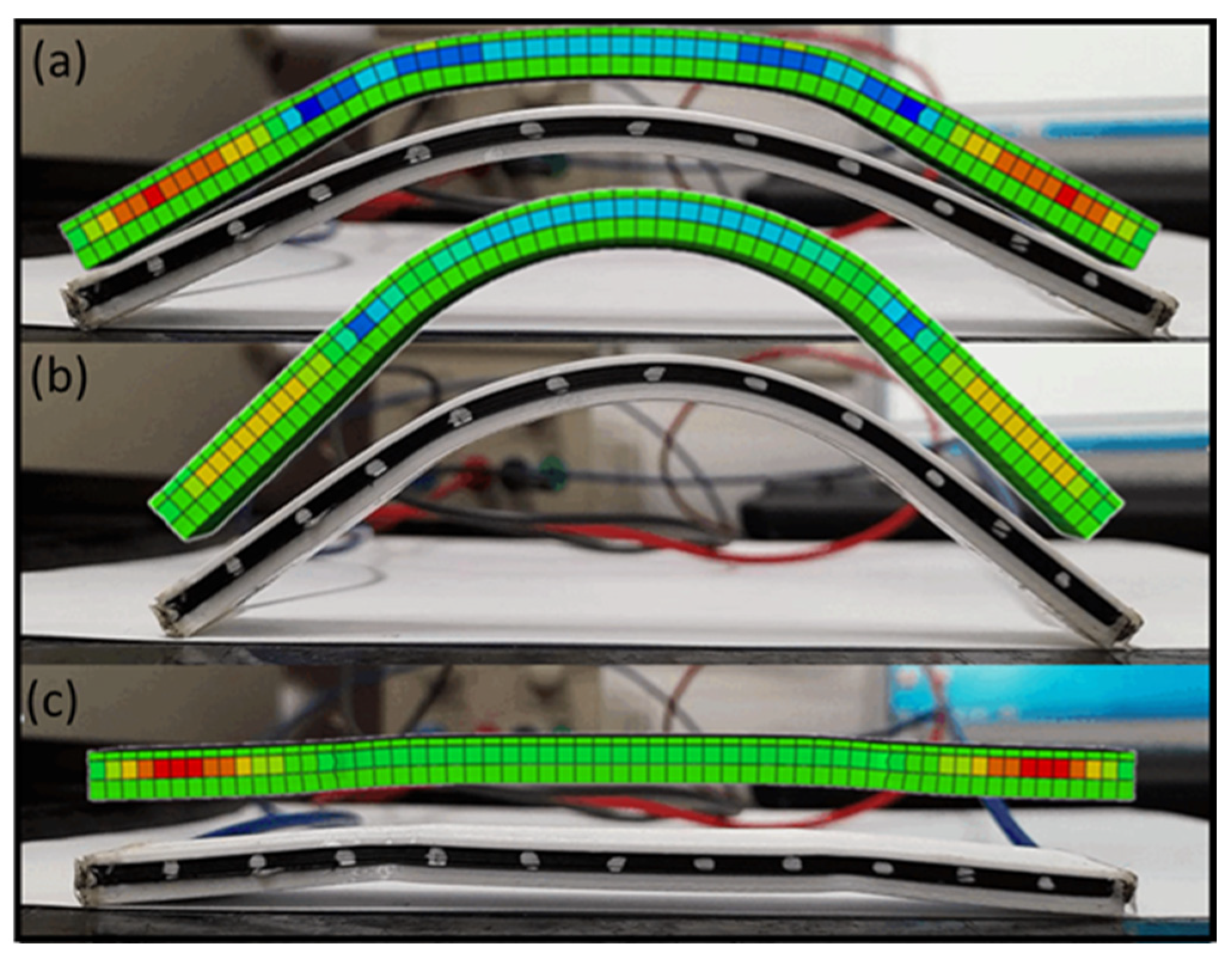

5.3. Durability

5.4. Numerical Modelling

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ryan, K.R.; Down, M.P.; Banks, C.E. Future of additive manufacturing: Overview of 4D and 3D printed smart and advanced materials and their applications. Chem. Eng. J. 2021, 403, 126162. [Google Scholar] [CrossRef]

- Margoy, D.; Gouzman, I.; Grossman, E.; Bolker, A.; Eliaz, N.; Verker, R. Epoxy-based shape memory composite for space applications. Acta Astronaut. 2021, 178, 908–919. [Google Scholar] [CrossRef]

- Khoo, Z.X.; Teoh, J.E.M.; Liu, Y.; Chua, C.K.; Yang, S.; An, J.; Leong, K.F.; Yeong, W.Y. 3D printing of smart materials: A review on recent progresses in 4D printing. Virtual Phys. Prototyp. 2015, 10, 103–122. [Google Scholar] [CrossRef]

- Delbart, R.; Roumy, L.; Harcourt, M.; Robert, C.; Touchard, F.; Truong-Hoang, T.Q.; Martínez-Hergueta, F. 4D-printed composite actuators. In Additive Manufacturing of Polymer-Based Composite Materials; Elsevier: Amsterdam, The Netherlands, 2024; pp. 147–183. [Google Scholar] [CrossRef]

- Ren, L.; Li, B.; Song, Z.; Liu, Q.; Ren, L.; Zhou, X. Bioinspired fiber-regulated composite with tunable permanent shape and shape memory properties via 3d magnetic printing. Compos. Part B Eng. 2019, 164, 458–466. [Google Scholar] [CrossRef]

- Riley, K.S.; Ang, K.J.; Martin, K.A.; Chan, W.K.; Faber, J.A.; Arrieta, A.F. Encoding multiple permanent shapes in 3D printed structures. Mater. Des. 2020, 194, 108888. [Google Scholar] [CrossRef]

- Ge, Q.; Sakhaei, A.H.; Lee, H.; Dunn, C.K.; Fang, N.X.; Dunn, M.L. Multimaterial 4D Printing with Tailorable Shape Memory Polymers. Sci. Rep. 2016, 6, 31110. [Google Scholar] [CrossRef]

- Lendlein, A.; Jiang, H.; Jünger, O.; Langer, R. Light-induced shape-memory polymers. Nature 2005, 434, 879–882. [Google Scholar] [CrossRef]

- Schmidt, A.M. Electromagnetic Activation of Shape Memory Polymer Networks Containing Magnetic Nanoparticles. Macromol. Rapid Commun. 2006, 27, 1168–1172. [Google Scholar] [CrossRef]

- Josselin, M.; Di Cesare, N.; Castro, M.; Colinart, T.; Scarpa, F.; Le Duigou, A. Hygro-thermal coupling on 4D-printed biocomposites as key for meteosensitive shape-changing materials. Virtual Phys. Prototyp. 2024, 19, e2335233. [Google Scholar] [CrossRef]

- Dong, K.; Panahi-Sarmad, M.; Cui, Z.; Huang, X.; Xiao, X. Electro-induced shape memory effect of 4D printed auxetic composite using PLA/TPU/CNT filament embedded synergistically with continuous carbon fiber: A theoretical & experimental analysis. Compos. Part B Eng. 2021, 220, 108994. [Google Scholar] [CrossRef]

- Demoly, F.; Dunn, M.L.; Wood, K.L.; Qi, H.J.; André, J.-C. The status, barriers, challenges, and future in design for 4D printing. Mater. Des. 2021, 212, 110193. [Google Scholar] [CrossRef]

- Orellana, J.; Moreno-Villoslada, I.; Bose, R.K.; Picchioni, F.; Flores, M.E.; Araya-Hermosilla, R. Self-Healing Polymer Nanocomposite Materials by Joule Effect. Polymers 2021, 13, 649. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Z.; Song, Z.; Ren, L.; Liu, Q.; Ren, L. Biomimetic Shape–Color Double-Responsive 4D Printing. Adv. Mater. Technol. 2019, 4, 1900293. [Google Scholar] [CrossRef]

- Dimassi, S.; Demoly, F.; Cruz, C.; Qi, H.J.; Kim, K.-Y.; André, J.-C.; Gomes, S. An ontology-based framework to formalize and represent 4D printing knowledge in design. Comput. Ind. 2021, 126, 103374. [Google Scholar] [CrossRef]

- Wischke, C.; Lendlein, A. Shape-Memory Polymers as Drug Carriers—A Multifunctional System. Pharm. Res. 2010, 27, 527–529. [Google Scholar] [CrossRef]

- Delbart, R.; Robert, C.; Truong Hoang, T.Q.; Martinez-Hergueta, F. Development of an electro-thermo-mechanical 4D printed multi-shape smart actuator: Experiments and simulation. Compos. Part Appl. Sci. Manuf. 2024, 186, 108381. [Google Scholar] [CrossRef]

- De Kergariou, C.; Le Duigou, A.; Perriman, A.; Scarpa, F. Design space and manufacturing of programmable 4D printed continuous flax fibre polylactic acid composite hygromorphs. Mater. Des. 2023, 225, 111472. [Google Scholar] [CrossRef]

- De Kergariou, C.; Demoly, F.; Perriman, A.; Le Duigou, A.; Scarpa, F. The Design of 4D-Printed Hygromorphs: State-of-the-Art and Future Challenges. Adv. Funct. Mater. 2023, 33, 2210353. [Google Scholar] [CrossRef]

- Le Duigou, A.; Chabaud, G.; Scarpa, F.; Castro, M. Bioinspired Electro-Thermo-Hygro Reversible Shape-Changing Materials by 4D Printing. Adv. Funct. Mater. 2019, 29, 1903280. [Google Scholar] [CrossRef]

- Touchard, F.; Sarasini, F. (Eds.) Additive Manufacturing of Polymer-Based Composite Materials; Elsevier: Amsterdam, The Netherlands, 2024. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, X.; Lu, X.; Zhao, Y.; Zhou, Z.; Xu, J.; Yin, J.; Tang, T.; Wang, P.; Yi, S.; et al. 4D Additive–Subtractive Manufacturing of Shape Memory Ceramics. Adv. Mater. 2023, 35, 2302108. [Google Scholar] [CrossRef]

- Milleret, A.; Laitinen, V.; Ullakko, K.; Fenineche, N.; Attallah, M.M. Laser powder bed fusion of (14 M) Ni-Mn-Ga magnetic shape memory alloy lattices. Addit. Manuf. 2022, 60, 103231. [Google Scholar] [CrossRef]

- Holman, H.; Kavarana, M.N.; Rajab, T.K. Smart materials in cardiovascular implants: Shape memory alloys and shape memory polymers. Artif. Organs 2021, 45, 454–463. [Google Scholar] [CrossRef]

- Abdalla, A.; Hamzah, H.H.; Keattch, O.; Covill, D.; Patel, B.A. Augmentation of conductive pathways in carbon black/PLA 3D-printed electrodes achieved through varying printing parameters. Electrochim. Acta 2020, 354, 136618. [Google Scholar] [CrossRef]

- Junpha, J.; Wisitsoraat, A.; Prathumwan, R.; Chaengsawang, W.; Khomungkhun, K.; Subannajui, K. Electronic tongue and cyclic voltammetric sensors based on carbon nanotube/polylactic composites fabricated by fused deposition modelling 3D printing. Mater. Sci. Eng. C 2020, 117, 111319. [Google Scholar] [CrossRef]

- Mitchell, A.; Lafont, U.; Hołyńska, M.; Semprimoschnig, C. Additive manufacturing—A review of 4D printing and future applications. Addit. Manuf. 2018, 24, 606–626. [Google Scholar] [CrossRef]

- Decroly, G.; Toncheva, A.; Blanc, L.; Raquez, J.-M.; Lessinnes, T.; Delchambre, A.; Lambert, P. Programmable Stimuli-Responsive Actuators for Complex Motions in Soft Robotics: Concept, Design and Challenges. Actuators 2020, 9, 131. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Kaynak, A.; Kouzani, A. Closed-loop 4D-printed soft robots. Mater. Des. 2020, 188, 108411. [Google Scholar] [CrossRef]

- Lalegani Dezaki, M.; Bodaghi, M.; Serjouei, A.; Afazov, S.; Zolfagharian, A. Adaptive reversible composite-based shape memory alloy soft actuators. Sens. Actuators Phys. 2022, 345, 113779. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, Y.; Yao, T.; Feng, X. A flexible carbon fibre-based electrothermal film for fast actuation of shape memory alloy sheets. Smart Mater. Struct. 2022, 31, 045019. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Lakhi, M.; Ranjbar, S.; Tadesse, Y.; Bodaghi, M. 3D printing non-assembly compliant joints for soft robotics. Results Eng. 2022, 15, 100558. [Google Scholar] [CrossRef]

- Zhang, Z.; Demir, K.G.; Gu, G.X. Developments in 4D-printing: A review on current smart materials, technologies, and applications. Int. J. Smart Nano Mater. 2019, 10, 205–224. [Google Scholar] [CrossRef]

- Yamamura, S.; Iwase, E. Hybrid hinge structure with elastic hinge on self-folding of 4D printing using a fused deposition modeling 3D printer. Mater. Des. 2021, 203, 109605. [Google Scholar] [CrossRef]

- Barletta, M.; Gisario, A.; Mehrpouya, M. 4D printing of shape memory polylactic acid (PLA) components: Investigating the role of the operational parameters in fused deposition modelling (FDM). J. Manuf. Process. 2021, 61, 473–480. [Google Scholar] [CrossRef]

- Akbari, S.; Sakhaei, A.H.; Kowsari, K.; Yang, B.; Serjouei, A.; Yuanfang, Z.; Ge, Q. Enhanced multimaterial 4D printing with active hinges. Smart Mater. Struct. 2018, 27, 065027. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, W.; Zhang, F.; Leng, J.; Pei, S.; Wang, L.; Jia, X.; Cotton, C.; Sun, B.; Chou, T.-W. Microstructural design for enhanced shape memory behavior of 4D printed composites based on carbon nanotube/polylactic acid filament. Compos. Sci. Technol. 2019, 181, 107692. [Google Scholar] [CrossRef]

- Wang, W.; Li, C.; Cho, M.; Ahn, S.-H. Soft Tendril-Inspired Grippers: Shape Morphing of Programmable Polymer–Paper Bilayer Composites. ACS Appl. Mater. Interfaces 2018, 10, 10419–10427. [Google Scholar] [CrossRef]

- Smirnov, A.; Terekhina, S.; Tarasova, T.; Hattali, L.; Grigoriev, S. From the development of low-cost filament to 3D printing ceramic parts obtained by fused filament fabrication. Int. J. Adv. Manuf. Technol. 2023, 128, 511–529. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Kafle, A.; Luis, E.; Silwal, R.; Pan, H.M.; Shrestha, P.L.; Bastola, A.K. 3D/4D Printing of Polymers: Fused Deposition Modelling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA). Polymers 2021, 13, 3101. [Google Scholar] [CrossRef]

- Auffray, L.; Gouge, P.-A.; Hattali, L. Design of experiment analysis on tensile properties of PLA samples produced by fused filament fabrication. Int. J. Adv. Manuf. Technol. 2022, 118, 4123–4137. [Google Scholar] [CrossRef]

- Beloshenko, V.A.; Varyukhin, V.N.; Voznyak, Y.V. The shape memory effect in polymers. Russ. Chem. Rev. 2005, 74, 265–283. [Google Scholar] [CrossRef]

- Melly, S.K.; Liu, L.; Liu, Y.; Leng, J. Active composites based on shape memory polymers: Overview, fabrication methods, applications, and future prospects. J. Mater. Sci. 2020, 55, 10975–11051. [Google Scholar] [CrossRef]

- Dai, L.; Song, J.; Qu, S.; Xiao, R. Triple-shape memory effect in 3D-printed polymers. Express Polym. Lett. 2020, 14, 1116–1126. [Google Scholar] [CrossRef]

- Wu, Y.; Hu, J.; Zhang, C.; Han, J.; Wang, Y.; Kumar, B. A facile approach to fabricate a UV/heat dual-responsive triple shape memory polymer. J. Mater. Chem. A 2015, 3, 97–100. [Google Scholar] [CrossRef]

- Van Manen, T.; Janbaz, S.; Zadpoor, A.A. Programming 2D/3D shape-shifting with hobbyist 3D printers. Mater. Horiz. 2017, 4, 1064–1069. [Google Scholar] [CrossRef]

- Bodaghi, M.; Noroozi, R.; Zolfagharian, A.; Fotouhi, M.; Norouzi, S. 4D Printing Self-Morphing Structures. Materials 2019, 12, 1353. [Google Scholar] [CrossRef]

- Kačergis, L.; Mitkus, R.; Sinapius, M. Influence of fused deposition modeling process parameters on the transformation of 4D printed morphing structures. Smart Mater. Struct. 2019, 28, 105042. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X. 4D-printed bi-material composite laminate for manufacturing reversible shape-change structures. Compos. Part B Eng. 2021, 219, 108918. [Google Scholar] [CrossRef]

- Fros, D.; Vesely, P. Thermomechanical Assessment of Novel Composites Intended for Fused Deposition Modeling. In Proceedings of the 2022 45th International Spring Seminar on Electronics Technology (ISSE), Vienna, Austria, 11–15 May 2022; pp. 1–8. [Google Scholar] [CrossRef]

- Gong, T.; Li, W.; Chen, H.; Wang, L.; Shao, S.; Zhou, S. Remotely actuated shape memory effect of electrospun composite nanofibers. Acta Biomater. 2012, 8, 1248–1259. [Google Scholar] [CrossRef]

- Zhang, Q.; Yan, D.; Zhang, K.; Hu, G. Pattern Transformation of Heat-Shrinkable Polymer by Three-Dimensional (3D) Printing Technique. Sci. Rep. 2015, 5, 8936. [Google Scholar] [CrossRef]

- Jeong, H.Y.; Woo, B.H.; Kim, N.; Jun, Y.C. Multicolor 4D printing of shape-memory polymers for light-induced selective heating and remote actuation. Sci. Rep. 2020, 10, 6258. [Google Scholar] [CrossRef]

- Guo, Q.; Bishop, C.J.; Meyer, R.A.; Wilson, D.R.; Olasov, L.; Schlesinger, D.E.; Mather, P.T.; Spicer, J.B.; Elisseeff, J.H.; Green, J.J. Entanglement-Based Thermoplastic Shape Memory Polymeric Particles with Photothermal Actuation for Biomedical Applications. ACS Appl. Mater. Interfaces 2018, 10, 13333–13341. [Google Scholar] [CrossRef]

- Mohr, R.; Kratz, K.; Weigel, T.; Lucka-Gabor, M.; Moneke, M.; Lendlein, A. Initiation of shape-memory effect by inductive heating of magnetic nanoparticles in thermoplastic polymers. Proc. Natl. Acad. Sci. USA 2006, 103, 3540–3545. [Google Scholar] [CrossRef]

- Shao, L.-H.; Zhao, B.; Zhang, Q.; Xing, Y.; Zhang, K. 4D printing composite with electrically controlled local deformation. Extrem. Mech. Lett. 2020, 39, 100793. [Google Scholar] [CrossRef]

- Garces, I.T.; Ayranci, C. Active control of 4D prints: Towards 4D printed reliable actuators and sensors. Sens. Actuators Phys. 2020, 301, 111717. [Google Scholar] [CrossRef]

- Jeong, Y.G.; An, J.-E. UV-cured epoxy/graphene nanocomposite films: Preparation, structure and electric heating performance: UV-cured epoxy/graphene composite films. Polym. Int. 2014, 63, 1895–1901. [Google Scholar] [CrossRef]

- Cortés, A.; Cosola, A.; Sangermano, M.; Campo, M.; González Prolongo, S.; Pirri, C.F.; Jiménez-Suárez, A.; Chiappone, A. DLP 4D-Printing of Remotely, Modularly, and Selectively Controllable Shape Memory Polymer Nanocomposites Embedding Carbon Nanotubes. Adv. Funct. Mater. 2021, 31, 2106774. [Google Scholar] [CrossRef]

- Natali, M.; Monti, M.; Puglia, D.; Kenny, J.M.; Torre, L. Ablative properties of carbon black and MWNT/phenolic composites: A comparative study. Compos. Part Appl. Sci. Manuf. 2012, 43, 174–182. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, F.; Leng, J.; Fu, K.; Lu, X.L.; Wang, L.; Cotton, C.; Sun, B.; Gu, B.; Chou, T. Remotely and Sequentially Controlled Actuation of Electroactivated Carbon Nanotube/Shape Memory Polymer Composites. Adv. Mater. Technol. 2019, 4, 1900600. [Google Scholar] [CrossRef]

- Ye, W.; Wu, W.; Hu, X.; Lin, G.; Guo, J.; Qu, H.; Zhao, J. 3D printing of carbon nanotubes reinforced thermoplastic polyimide composites with controllable mechanical and electrical performance. Compos. Sci. Technol. 2019, 182, 107671. [Google Scholar] [CrossRef]

- Khan, F.; Singh, K. An experimental investigation of the effect of strain on the electrical conductivity of a shape memory polymer. Polym. Test. 2016, 49, 82–87. [Google Scholar] [CrossRef]

- Roumy, L.; Touchard, F.; Marchand, D.; Truong Hoang, T.Q.; Martinez-Hergueta, F. Durability of Joule effect of 3D printed carbon black/polylactic acid: Electrical cyclic tests and analytical modelling. Int. J. Fatigue 2023, 173, 107677. [Google Scholar] [CrossRef]

- Li, F.; Scarpa, F.; Lan, X.; Liu, L.; Liu, Y.; Leng, J. Bending shape recovery of unidirectional carbon fiber reinforced epoxy-based shape memory polymer composites. Compos. Part Appl. Sci. Manuf. 2019, 116, 169–179. [Google Scholar] [CrossRef]

- Lupone, F.; Padovano, E.; Venezia, C.; Badini, C. Experimental Characterization and Modeling of 3D Printed Continuous Carbon Fibers Composites with Different Fiber Orientation Produced by FFF Process. Polymers 2022, 14, 426. [Google Scholar] [CrossRef]

- Wu, S.; Shan, Z.; Chen, K.; Wu, X.; Zou, D.; Wang, S.; Xiong, J. Investigation of bending performance of printed continuous carbon fiber reinforced polylactic acid using acoustic emission. Polym. Compos. 2023, 44, 863–872. [Google Scholar] [CrossRef]

- Silva, M.; Gomes, S.; Correia, C.; Peixoto, D.; Vinhas, A.; Rodrigues, M.T.; Gomes, M.E.; Covas, J.A.; Paiva, M.C.; Alves, N.M. Biocompatible 3D-Printed Tendon/Ligament Scaffolds Based on Polylactic Acid/Graphite Nanoplatelet Composites. Nanomaterials 2023, 13, 2518. [Google Scholar] [CrossRef]

- Ouhib, R.; Renault, B.; Mouaziz, H.; Nouvel, C.; Dellacherie, E.; Six, J.-L. Biodegradable amylose-g-PLA glycopolymers from renewable resources. Carbohydr. Polym. 2009, 77, 32–40. [Google Scholar] [CrossRef]

- Yu, L.; Dean, K.; Li, L. Polymer blends and composites from renewable resources. Prog. Polym. Sci. 2006, 31, 576–602. [Google Scholar] [CrossRef]

- Wang, N.; Zhang, X.; Ma, X.; Fang, J. Influence of carbon black on the properties of plasticized poly(lactic acid) composites. Polym. Degrad. Stab. 2008, 93, 1044–1052. [Google Scholar] [CrossRef]

- Solarski, S.; Ferreira, M.; Devaux, E. Characterization of the thermal properties of PLA fibers by modulated differential scanning calorimetry. Polymer 2005, 46, 11187–11192. [Google Scholar] [CrossRef]

- Tirado-Garcia, I.; Garcia-Gonzalez, D.; Garzon-Hernandez, S.; Rusinek, A.; Robles, G.; Martinez-Tarifa, J.M.; Arias, A. Conductive 3D printed PLA composites: On the interplay of mechanical, electrical and thermal behaviours. Compos. Struct. 2021, 265, 113744. [Google Scholar] [CrossRef]

- Delbart, R.; Noble, T.; Roumy, L.; Fernandez Toribio, J.C.; Robert, C.; Truong Hoang, T.Q.; Martinez-Hergueta, F. Multiscale characterisation of the electrical response of 3d printed carbon black polylactic acid. J. Mater. Sci. 2023, 58, 13118–13135. [Google Scholar] [CrossRef]

- Delbart, R.; Papasavvas, A.; Robert, C.; Quynh Truong Hoang, T.; Martinez-Hergueta, F. An experimental and numerical study of the mechanical response of 3D printed PLA/CB polymers. Compos. Struct. 2023, 319, 117156. [Google Scholar] [CrossRef]

- Jeon, J.G.; Hong, G.-W.; Park, H.-G.; Lee, S.K.; Kim, J.-H.; Kang, T.J. Resistance Temperature Detectors Fabricated via Dual Fused Deposition Modeling of Polylactic Acid and Polylactic Acid/Carbon Black Composites. Sensors 2021, 21, 1560. [Google Scholar] [CrossRef]

- Crespo-Miguel, J.; Garcia-Gonzalez, D.; Robles, G.; Hossain, M.; Martinez-Tarifa, J.M.; Arias, A. Thermo-electro-mechanical aging and degradation of conductive 3D printed PLA/CB composite. Compos. Struct. 2023, 316, 116992. [Google Scholar] [CrossRef]

- Crespo-Miguel, J.; Lucarini, S.; Arias, A.; Garcia-Gonzalez, D. Thermo-electro-mechanical microstructural interdependences in conductive thermoplastics. Npj Comput. Mater. 2023, 9, 134. [Google Scholar] [CrossRef]

- Truman, L.; Whitwam, E.; Nelson-Cheeseman, B.B.; Koerner, L.J. Conductive 3D printing: Resistivity dependence upon infill pattern and application to EMI shielding. J. Mater. Sci. Mater. Electron. 2020, 31, 14108–14117. [Google Scholar] [CrossRef]

- Mudhar, R.; Mucolli, A.; Ford, J.; Lira, C.; Yazdani Nezhad, H. Electrical and Magnetic Properties of 3D Printed Integrated Conductive Biodegradable Polymer Nanocomposites for Sustainable Electronics Development. J. Compos. Sci. 2022, 6, 345. [Google Scholar] [CrossRef]

- Guo, J.; Tsou, C.-H.; Yu, Y.; Wu, C.-S.; Zhang, X.; Chen, Z.; Yang, T.; Ge, F.; Liu, P.; Guzman, M.R.D. Conductivity and mechanical properties of carbon black-reinforced poly(lactic acid) (PLA/CB) composites. Iran. Polym. J. 2021, 30, 1251–1262. [Google Scholar] [CrossRef]

- Kumar, A.; Tumu, V.R. Physicochemical properties of the electron beam irradiated bamboo powder and its bio-composites with PLA. Compos. Part B Eng. 2019, 175, 107098. [Google Scholar] [CrossRef]

- Yang, L.; Li, S.; Zhou, X.; Liu, J.; Li, Y.; Yang, M.; Yuan, Q.; Zhang, W. Effects of carbon nanotube on the thermal, mechanical, and electrical properties of PLA/CNT printed parts in the FDM process. Synth. Met. 2019, 253, 122–130. [Google Scholar] [CrossRef]

- Garcia Rosales, C.A.; Garcia Duarte, M.F.; Kim, H.; Chavez, L.; Hodges, D.; Mandal, P.; Lin, Y.; Tseng, T.-L. 3D printing of shape memory polymer (SMP)/carbon black (CB) nanocomposites with electro-responsive toughness enhancement. Mater. Res. Express 2018, 5, 065704. [Google Scholar] [CrossRef]

- Czyżewski, J.; Burzyński, P.; Gaweł, K.; Meisner, J. Rapid prototyping of electrically conductive components using 3D printing technology. J. Mater. Process. Technol. 2009, 209, 5281–5285. [Google Scholar] [CrossRef]

- Mu, Q.; Wang, L.; Dunn, C.K.; Kuang, X.; Duan, F.; Zhang, Z.; Qi, H.J.; Wang, T. Digital light processing 3D printing of conductive complex structures. Addit. Manuf. 2017, 18, 74–83. [Google Scholar] [CrossRef]

- Ibrahim, Y.; Elkholy, A.; Schofield, J.S.; Melenka, G.W.; Kempers, R. Effective thermal conductivity of 3D-printed continuous fiber polymer composites. Adv. Manuf. Polym. Compos. Sci. 2020, 6, 17–28. [Google Scholar] [CrossRef]

- Da Silva, M.M.; Proença, M.P.; Covas, J.A.; Paiva, M.C. Shape-Memory Polymers Based on Carbon Nanotube Composites. Micromachines 2024, 15, 748. [Google Scholar] [CrossRef]

- Wang, L.; Qiu, J.; Sakai, E.; Wei, X. The relationship between microstructure and mechanical properties of carbon nanotubes/polylactic acid nanocomposites prepared by twin-screw extrusion. Compos. Part A Appl. Sci. Manuf. 2016, 89, 18–25. [Google Scholar] [CrossRef]

- Moreira, I.P.; Sanivada, U.K.; Bessa, J.; Cunha, F.; Fangueiro, R. A Review of Multiple Scale Fibrous and Composite Systems for Heating Applications. Molecules 2021, 26, 3686. [Google Scholar] [CrossRef]

- Hamdi, K.; Aboura, Z.; Harizi, W.; Khellil, K. Structural health monitoring of carbon fiber reinforced matrix by the resistance variation method. J. Compos. Mater. 2020, 54, 3919–3930. [Google Scholar] [CrossRef]

- Daniel, F.; Patoary, N.H.; Moore, A.L.; Weiss, L.; Radadia, A.D. Temperature-dependent electrical resistance of conductive polylactic acid filament for fused deposition modeling. Int. J. Adv. Manuf. Technol. 2018, 99, 1215–1224. [Google Scholar] [CrossRef]

- Ghosh, S.B.; Bandyopadhyay-Ghosh, S.; Sain, M. Composites. In Poly(Lactic Acid); Auras, R., Lim, L., Selke, S.E.M., Tsuji, H., Eds.; Wiley: Hoboken, NJ, USA, 2010; pp. 293–310. [Google Scholar] [CrossRef]

- Choi, J.Y.; Kortschot, M.T. Stiffness prediction of 3D printed fiber-reinforced thermoplastic composites. Rapid Prototyp. J. 2019, 26, 549–555. [Google Scholar] [CrossRef]

- Malagutti, L.; Mazzanti, V.; Mollica, F. Tensile properties of FDM 3D-printed wood flour filled polymers and mathematical modeling through classical lamination theory. Rapid Prototyp. J. 2022, 28, 1834–1842. [Google Scholar] [CrossRef]

- Gay, D. Matériaux Composites; Editions HERMES: Paris, France, 1987. [Google Scholar]

- Nadernezhad, A.; Unal, S.; Khani, N.; Koc, B. Material extrusion-based additive manufacturing of structurally controlled poly(lactic acid)/carbon nanotube nanocomposites. Int. J. Adv. Manuf. Technol. 2019, 102, 2119–2132. [Google Scholar] [CrossRef]

- Miller, A.; Warner, G.; Owolabi, G. Mechanical Performance and Mesostructure Analysis of Proton-Irradiated Fused Filament Fabrication Acrylonitrile Butadiene Styrene Material. J. Mater. Eng. Perform. 2021, 30, 6673–6690. [Google Scholar] [CrossRef]

- Roumy, L.; Truong-Hoang, T.-Q.; Touchard, F.; Robert, C.; Martinez-Hergueta, F. Electro-Mechanical Characterisation and Damage Monitoring by Acoustic Emission of 3D-Printed CB/PLA. Materials 2024, 17, 1047. [Google Scholar] [CrossRef]

- Delbart, R. Development of 4D Printed Actuators with Integrated Temperature-Controlled Triggering System. Ph.D. Thesis, University of Edinburgh, Edinburgh, UK, 2023. [Google Scholar]

- Yu, K.; Li, H.; McClung, A.J.W.; Tandon, G.P.; Baur, J.W.; Qi, H.J. Cyclic behaviors of amorphous shape memory polymers. Soft Matter 2016, 12, 3234–3245. [Google Scholar] [CrossRef]

- Zeng, H.; Leng, J.; Gu, J.; Yin, C.; Sun, H. Modeling the strain rate-, hold time-, and temperature-dependent cyclic behaviors of amorphous shape memory polymers. Smart Mater. Struct. 2018, 27, 075050. [Google Scholar] [CrossRef]

- Bouguermouh, K.; Habibi, M.; Laperrière, L.; Li, Z.; Abdin, Y. 4D-printed PLA-PETG polymer blends: Comprehensive analysis of thermal, mechanical, and shape memory performances. J. Mater. Sci. 2024, 59, 11596–11613. [Google Scholar] [CrossRef]

- Dong, X.; Zhang, F.; Wang, L.; Liu, Y.; Leng, J. 4D printing of electroactive shape-changing composite structures and their programmable behaviors. Compos. Part Appl. Sci. Manuf. 2022, 157, 106925. [Google Scholar] [CrossRef]

- Fischer, D.; Eßbach, C.; Schönherr, R.; Dietrich, D.; Nickel, D. Improving inner structure and properties of additive manufactured amorphous plastic parts: The effects of extrusion nozzle diameter and layer height. Addit. Manuf. 2022, 51, 102596. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Kaynak, A.; Khoo, S.Y.; Kouzani, A. Pattern-driven 4D printing. Sens. Actuators Phys. 2018, 274, 231–243. [Google Scholar] [CrossRef]

- Snyder, A.D.; Phillips, Z.J.; Turicek, J.S.; Diesendruck, C.E.; Nakshatrala, K.B.; Patrick, J.F. Prolonged in situ self-healing in structural composites via thermo-reversible entanglement. Nat. Commun. 2022, 13, 6511. [Google Scholar] [CrossRef]

- Kesentini, Z.; El Mahi, A.; Rebiere, J.L.; El Guerjouma, R.; Beyaoui, M.; Haddar, M. Static and Fatigue Tensile Behavior and Damage Mechanisms Analysis in Aged Flax Fiber/PLA Composite. Int. J. Appl. Mech. 2022, 14, 2250080. [Google Scholar] [CrossRef]

- Ishizawa, J.; Imagawa, K.; Minami, S.; Hayashi, S.; Miwa, N. Research on Application of Shape Memory Polymers to Space Inflatable Systems. In Proceedings of the 7th International Symposium on Artificial Intelligence, Robotics and Automation in Space: I-SAIRAS, Nara, Japan, 19–23 May 2003. [Google Scholar]

- Lamnii, H.; Nait Abdelaziz, M.; Ayoub, G.; Colin, X.; Maschke, U. Experimental investigation and modeling attempt on the effects of ultraviolet aging on the fatigue behavior of an LDPE semi-crystalline polymer. Int. J. Fatigue 2021, 142, 105952. [Google Scholar] [CrossRef]

- Yap, H.K.; Ng, H.Y.; Yeow, C.-H. High-Force Soft Printable Pneumatics for Soft Robotic Applications. Soft Robot. 2016, 3, 144–158. [Google Scholar] [CrossRef]

- Bodaghi, M.; Serjouei, A.; Zolfagharian, A.; Fotouhi, M.; Rahman, H.; Durand, D. Reversible energy absorbing meta-sandwiches by FDM 4D printing. Int. J. Mech. Sci. 2020, 173, 105451. [Google Scholar] [CrossRef]

- Monaldo, E.; Marfia, S. Multiscale technique for the analysis of 3D-printed materials. Int. J. Solids Struct. 2021, 232, 111173. [Google Scholar] [CrossRef]

- Dryzek, M.; Cecot, W.; Tekieli, M. Experimental and multiscale computational static and dynamic study of 3D printed elements with mesostructure. Finite Elem. Anal. Des. 2023, 215, 103876. [Google Scholar] [CrossRef]

- Crespo-Miguel, J.; Lucarini, S.; Garzon-Hernandez, S.; Arias, A.; Martínez-Pañeda, E.; Garcia-Gonzalez, D. In-silico platform for the multifunctional design of 3D printed conductive components. Nat. Commun. 2025, 16, 1359. [Google Scholar] [CrossRef]

- Gonabadi, H.; Chen, Y.; Yadav, A.; Bull, S. Investigation of the effect of raster angle, build orientation, and infill density on the elastic response of 3D printed parts using finite element microstructural modeling and homogenization techniques. Int. J. Adv. Manuf. Technol. 2022, 118, 1485–1510. [Google Scholar] [CrossRef]

- Cattenone, A.; Morganti, S.; Alaimo, G.; Auricchio, F. Finite Element Analysis of Additive Manufacturing Based on Fused Deposition Modeling: Distortions Prediction and Comparison With Experimental Data. J. Manuf. Sci. Eng. 2019, 141, 011010. [Google Scholar] [CrossRef]

- Samy, A.A.; Golbang, A.; Harkin-Jones, E.; Archer, E.; Tormey, D.; McIlhagger, A. Finite element analysis of residual stress and warpage in a 3D printed semi-crystalline polymer: Effect of ambient temperature and nozzle speed. J. Manuf. Process. 2021, 70, 389–399. [Google Scholar] [CrossRef]

| Triggering Method | Filler | Matrix | Lab-Synthesised (LS)/Commercially Available (C) | Ref |

|---|---|---|---|---|

| Magnetic field | MWCNT coated with Fe3O4 nanoparticles | Poly (ε-caprolactone) | LS | [52] |

| Iron(III)oxide with core in silica | Polyetherurethane with a copolymer | LS | [56] | |

| Fe3O4 nanoparticles | Oligo (ε-caprolactone) dimethacrylate/butylacrylate | LS | [9] | |

| Joule heating | Silver nanowires | PLA | LS | [57] |

| Nickel | X | X | [13] | |

| Gold nanoparticles | X | X | [13] | |

| Graphene | PLA | LS | [58] | |

| UV-cured epoxy | LS | [59] | ||

| MWCNT | Hydroxyethylmethacrylate | LS | [60] | |

| PLA + thermoplastic polyurethane | LS | [11] | ||

| Phenolic | LS | [61] | ||

| CNT | PLA | C | [62] | |

| PLA | LS | [37] | ||

| Polyimide | LS | [63] | ||

| CB | Resin | LS | [64] | |

| Phenolic | LS | [61] | ||

| PLA | C | [65] | ||

| Continuous carbon fibres | Epoxy | LS | [66] | |

| Polyamide | C | [67] | ||

| PLA | LS | [68] |

| Matrix | Filler | Properties | |||

|---|---|---|---|---|---|

| Conductivity | Recovery Ratio (%) | Recovery Time (s) | Ref | ||

| PLA | ø | ø | 100 | 3 | [104] |

| PETG | 100 | 5 | |||

| PLA-25/PETG-75 | 90 | 28 | |||

| PLA-50/PETG-50 | 95 | 38 | |||

| PLA-75/PETG-25 | 100 | 56 | |||

| PLA printed at ±45° | ø | ø | 90 | 140 | [37] |

| PLA printed at ±45° | CNT | 81.3 | 140 | ||

| PLA/TPU | CNT + CF | ø | 94 | 25 | [11] |

| PLA/TPU | CNT | 96 | 75 | ||

| PLA | Thermochromic pigments | ø | 92 | 6 | [14] |

| PLA printed at 0° | 8%wt CNT | 35 S/m | 83.3 | 80 | [105] |

| PLA printed at 45° | 98 | 70 | |||

| PLA printed at 90° | 95 | 90 | |||

| PLA + TPU | 21.5%wt CB | 3 S/m | 87.9 | 900 | [17] |

| Pattern and Orientation (°) | Resistivity (Ω·mm) |

|---|---|

| 90 | 228 ± 6 |

| 0 | 119 ± 2 |

| ±45 | 155 ± 2 |

| [06/±455/905]S | 134 ± 12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roumy, L.; Touchard, F.; Truong-Hoang, T.-Q.; Martinez-Hergueta, F. Electroconductive Thermosensitive Shape Memory Polymers Manufactured by Fused Filament Fabrication: A Critical Review. Appl. Sci. 2025, 15, 11641. https://doi.org/10.3390/app152111641

Roumy L, Touchard F, Truong-Hoang T-Q, Martinez-Hergueta F. Electroconductive Thermosensitive Shape Memory Polymers Manufactured by Fused Filament Fabrication: A Critical Review. Applied Sciences. 2025; 15(21):11641. https://doi.org/10.3390/app152111641

Chicago/Turabian StyleRoumy, Laurane, Fabienne Touchard, Thuy-Quynh Truong-Hoang, and Francisca Martinez-Hergueta. 2025. "Electroconductive Thermosensitive Shape Memory Polymers Manufactured by Fused Filament Fabrication: A Critical Review" Applied Sciences 15, no. 21: 11641. https://doi.org/10.3390/app152111641

APA StyleRoumy, L., Touchard, F., Truong-Hoang, T.-Q., & Martinez-Hergueta, F. (2025). Electroconductive Thermosensitive Shape Memory Polymers Manufactured by Fused Filament Fabrication: A Critical Review. Applied Sciences, 15(21), 11641. https://doi.org/10.3390/app152111641