Abstract

Work performed in confined and low-height spaces (NSLH) is relatively common across several industries, yet it has not been adequately addressed from an ergonomic perspective. Such activities require workers to adopt awkward postures, most often with the trunk bent and rotated, while handling loads positioned at varying distances from the body. These conditions lead to rapid fatigue, musculoskeletal strain, and, in the long term, may cause serious health disorders. Traditional ergonomic risk assessment methods, such as REBA, RULA, or QEC, were initially applied in these situations; however, the results were unsatisfactory. Their broad applicability and reliance on calculation tables that incorporate factors irrelevant to NSLH tasks prevent them from providing an accurate evaluation of ergonomic risks in these environments. To overcome these limitations, a new assessment method, RALH (Risk Assessment for Narrow Spaces with Low Height), was developed. The method aims to evaluate ergonomic risks in contexts where workers cannot maintain an upright posture, resulting in significant stress on the spinal column, particularly in the lumbar and cervical regions. The RALH methodology incorporates parameters such as trunk inclination, trunk rotation, load weight, distance between the body and the load, exposure duration, and the worker’s physical fitness. A dedicated software tool, ERGO Agent—RALH, was designed to implement this methodology, providing structured data collection, parameter normalization, and ergonomic risk calculation. Case studies, including distribution agents working inside van cargo compartments, demonstrated that the method produces accurate and objective results. Beyond diagnosis, RALH also supports the development of preventive strategies, such as equipment optimization, task allocation, worker training, and physical conditioning. Overall, the RALH method is a practical tool for improving occupational health and efficiency in NSLH environments, where traditional ergonomic approaches are insufficient.

1. Introduction

Ergonomic risk assessment is, without doubt, a particularly important stage when addressing occupational safety and health, as well as worker comfort while performing various tasks. Certain categories of activities are carried out in narrow and low-height spaces (NSLH) [1,2,3,4,5], which expose workers to efforts and postures that may negatively affect them [6,7,8,9,10,11], particularly at the physical level, through rapid fatigue and pain [12,13,14,15]. Over time, these conditions can lead to serious health disorders [16,17,18,19,20,21,22].

In order to provide the most accurate diagnosis of such working situations, we initially attempted to apply established ergonomic risk assessment methods such as REBA [23,24], RULA [25,26], and QEC [27,28,29,30], whose brief descriptions are provided below:

- -

- REBA (Rapid Entire Body Assessment) is a method used to analyze whole-body working postures, particularly in activities where the worker adopts unusual positions, moves frequently, or handles objects. The evaluation is based on the observation of trunk, neck, leg, and arm postures, as well as the application of force. REBA is commonly used for ergonomic assessment in dynamic work environments such as healthcare, construction, or logistics.

- -

- RULA (Rapid Upper Limb Assessment) focuses on the upper body, including the neck, shoulders, arms, elbows, and wrists. It is mainly used in static or office-related tasks where workers maintain prolonged postures or perform repetitive hand movements. RULA is suitable for assessing ergonomic risks in office work, fine assembly, laboratory, or IT activities.

- -

- QEC (Quick Exposure Check) is a quick and interactive method that combines the evaluator’s observation with direct input from the worker. It assesses posture, force, task duration, perceived stress, and environmental factors such as vibration or temperature. QEC is particularly useful for rapid assessments in industrial or repetitive work settings, providing an overall picture of ergonomic risk exposure and actively involving the worker in the evaluation process.

However, the results were not satisfactory, as these methods, being more general in scope, rely on approximations, even through their calculation tables. The tables often include elements that are not relevant in narrow and low-height spaces.

For example, trunk position (especially bending and twisting), the weight of the handled load, and the load’s distance from the body are far more significant than other aspects considered in these methods, such as the position of the arm, elbow, or wrist. To be specific, this means that table B in REBA [31,32] cannot be properly applied for narrow spaces, nor can table C, which leads to the final diagnostic outcome [31,32].

It is particularly important to take into account the specific characteristics of activities carried out in NSLH, namely: the worker is constantly bent forward, with no possibility of straightening the trunk, since the workspace height is lower than the worker’s stature. This represents the defining characteristic of NSLH [4,5].

Additionally, in most cases, the worker cannot sit down while working in NSLH, as there is no available support, the space being both narrow and occupied by various materials. Moreover, the activity is often performed across a relatively wide surface (e.g., the worker must reach with their arms to different areas of a cargo compartment), making seated work impractical.

Given these constraints inherent to NSLH activities, we considered necessary to develop the RALH (Risk Assessment for Narrow Spaces with Low Height) method, designed specifically to evaluate ergonomic risks for workers performing such tasks.

The RALH method has been applied in various real-life NSLH working situations, and the resulting diagnostics have proven highly satisfactory. This method can effectively contribute to the development of efficient preventive measures for workers.

The purpose of this article is to present a methodology for identifying ergonomics-related issues and assessing ergonomic risks in activities carried out in narrow and low-height spaces (NSLH), as well as to highlight the benefits of this method in improving worker comfort.

2. Materials and Methods

The study included 46 workers engaged in activities within NSLH environments. To collect data supporting the development of the RALH method, workers from different fields were interviewed regarding their daily tasks and related ergonomic risks, as follows:

- A total of 29 sales agents arranging goods in van cargo compartments;

- A total of 4 electricians working in technical basements;

- A total of 7 distribution agents handling parts and materials using vans;

- A total of 6 electricians and mechanics working inside wind turbine nacelles.

The interviews were conducted individually, each lasting approximately 10–15 min, and followed a semi-structured interview guide. The guide addressed the following topics:

- Which activity (lifting, placing, bending, twisting) is felt to be the most strenuous?

- On average, how long does an activity inside the cargo compartment last, in order to prepare a delivery for a client?

- What working postures are most frequently adopted (bent, squatting, kneeling, etc.)?

- Which body parts (back, neck, knees, shoulders, etc.) are most strained and where is pain most frequently experienced?

- At what stage of the task do you consider the risk of injury to be highest?

- What improvements would you like to see in order to reduce discomfort or risk?

Some information was already known from prior discussions with the supervisors of distribution agents, following questions such as the average number of clients served by an agent per day or the criteria used to assign clients and to allocate a specific type of vehicle to each agent/worker. Each worker was also able to share additional difficulties or specific characteristics of their work, relevant to the research theme. Informed consent was obtained from all participants prior to conducting the interviews.

The main characteristic of NSLH work, as noted, is that the workspace height is lower than the worker’s height (Equation (1)):

where

Hs < Hw,

- Hs—height of the workspace,

- Hw—height of the worker.

In NSLH, workers face the following ergonomic issues:

- Awkward postures (bent and twisted trunk);

- Load handling depending on the activity sector (boxes with products, tool kits, parts to be assembled/disassembled, adjustments, etc.), often with the load positioned at a considerable distance from the body;

- Static exertion;

- Contact stress, as the narrow space forces contact with various objects or surfaces, which cannot necessarily be used as support.

In many situations, additional factors are also present, such as poor lighting, stale air due to insufficient ventilation and dust, as well as limited range of motion during actions like lifting/moving/placing boxes, tightening/loosening bolts with a wrench, hammering, or securing parts into the correct position. Also, a key factor to consider in all NSLH working conditions is the duration of exposure to these ergonomic risk factors.

2.1. RALH Method: Applying Risk Assessment for Narrow Spaces with Low Height

The RALH method also takes into account a series of worker-related parameters, such as physical fitness, the worker’s perception of task performance, and gender. Ergonomic risk assessment using the RALH methodology involves going through several main stages, as described in Figure 1.

Figure 1.

Steps of the RALH Method.

2.2. RALH Method Parameters

2.2.1. Trunk Inclination

When working in an NSLH, the worker cannot stand in a fully upright position; therefore, the trunk will be inclined. According to human anatomical structure, the trunk begins to incline from approximately half of the person’s height. It was also observed that, in NSLH environments, workers generally stand supported on both legs, with knees almost straight. This fact was confirmed during the ergonomic risk assessment.

As a result, the formula for calculating the minimum trunk inclination relative to the vertical axis, while respecting Equation (1), is expressed in Equation (2):

where

- Bt—bending trunk; minimum trunk inclination, in degrees, relative to the vertical;

- Hs—height of the workspace;

- Hw—height of the worker;

- —mathematical constant, ≈ 3.14, radians = 180 degrees.

Equation (2) expresses the minimum trunk inclination when the worker’s head touches the ceiling of the workspace. In practice, this angle is larger. In order to compare the values obtained for each parameter of the RALH method, it is necessary to normalize these values using Table 1, Table 2, Table 3, Table 4, Table 5 and Table 6. For this specific section, trunk inclination places significant strain on the lumbar region of the spine.

Table 1.

Trunk inclination, Bt.

Table 2.

Trunk rotation, Rt.

Table 3.

Handled load, Gbax.

Table 4.

Distance between the body and the handled load, d.

Table 5.

Time spent in low-height spaces, t.

Table 6.

Ergonomic risk assessment matrix in NSLH.

2.2.2. Trunk Rotation

This parameter represents the angle by which the trunk rotates relative to the neutral position of the spinal column, i.e., the orientation of the trunk laterally (to the left or right) relative to the normal anatomical axis, while the pelvis (hips) remains relatively fixed. The normalized values of this parameter are presented in Table 2. Trunk rotation also places significant strain on the lumbar region of the spine.

2.2.3. Handled Load

2.2.4. Distance Between the Body and the Handled Load

This parameter represents the horizontal distance between the median point of the worker’s trunk (generally in the lumbar region, T12-L1) and the center of gravity of the handled object, measured in the horizontal plane, regardless of the trunk’s inclination angle.

The greater this distance, the higher the torque exerted on the spinal column. Naturally, the more the trunk is inclined and the farther the object is from the body, the greater the strain on the back muscles and the lumbar spine. The normalized values of this parameter (d) are presented in Table 4.

2.2.5. Time Spent in Low-Height Spaces

The value grid presented in Table 5 for the parameter Duration refers only to the time the agent spends inside the van cargo compartment, which complies with the condition expressed in Equation (1).

2.3. Level of Ergonomic Risk—Level of Ergonomic Risk Assessment (LERA)

The ergonomic risk level (ERL) is determined based on the results obtained in Table 1, Table 2, Table 3, Table 4, Table 5 and Table 6, by substituting these values into Equation (3):

where

- ERL—ergonomic risk level

- Bt—trunk inclination

- Rt—trunk rotation

- Gbax—handled load weight

- d—distance between the body and the load

- t—time spent by the worker in NSLH

In Equation (3), the sum of the trunk inclination and trunk rotation coefficients is weighted by a factor of 2, as these coefficients play a significant role both in the effort required, and in the strain and potential disorders affecting the worker’s spinal column.

ERL is directly proportional to the duration of exposure, and Equation (3) highlights this aspect. The risk assessment matrix is presented in Table 6. After calculating the score for ERL, the obtained values are classified according to the matrix.

Areas where the risk is assessed as High or Very High/Unacceptable must be treated as a priority. The action plan should focus both on implementing technical measures and on addressing the relationship between the worker’s height and the workspace height. The greater the difference between these two dimensions, the higher the likelihood that the worker will be adversely affected.

3. Results

A synthesis of the case study is presented, in which ergonomic risks were evaluated using the RALH method for 4 out of 7 randomly selected distribution agents, who handle goods inside the cargo compartments of vans that they also drive. The vans were of different brands and had varying cargo compartment heights, but all complied with the condition expressed in Equation (1).

The loads handled by the distribution agents in the van compartments, during a single lift, were most frequently between 6 kg and 15 kg, the goods being packed in cardboard boxes. The average duration of a worker’s stay inside the cargo compartment was 5 min. However, depending on the quantity and type of goods being distributed, and the need to transfer products from one box to another, the process could last between 3 min and 15 min in rare cases, for a single delivery. On average, a worker performed approximately 12 deliveries per day.

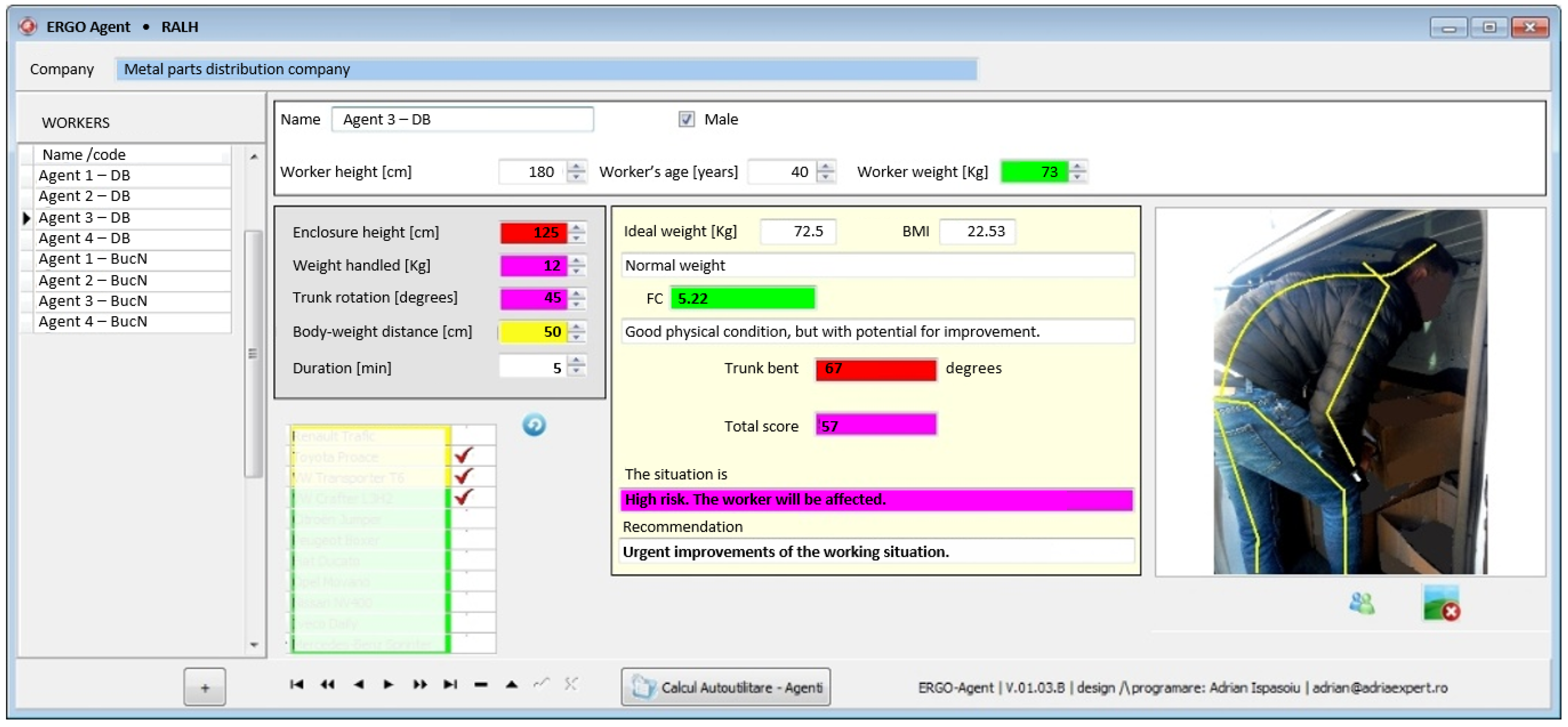

It should be noted that the distance between the worker’s body and the boxes being handled could reach 90 cm, and the boxes could also be located laterally relative to the worker’s position. This forced the worker to bend the trunk and simultaneously rotate it at an angle that could exceed 60°. The cargo compartment space was generally so narrow that it was very difficult for the worker to turn and align their body with the box to be lifted. The average trunk rotation angle was considered to be 45°, while the average distance of a box from the body (from the position of the feet) was 50 cm. In Figure 2, these aspects regarding the forced positions of sales agents when handling goods in the cargo compartment can be observed: the torso is bent forward and often rotated, the spine is curved, and in this posture they lift and place the heavy boxes at different distances from the body. The photographs shown in Figure 2 represent only a snapshot captured at a given moment. These images do not necessarily illustrate the most unfavorable posture of the respective worker. The characteristics of each worker are presented in Table 7.

Figure 2.

Distribution agents sorting goods for delivery.

Table 7.

Characteristics of the evaluated workers.

For the workers evaluated in terms of their exposure to ergonomic risks—through both direct observation during task performance and structured interviews—it was determined that they were generally in good health and possessed an adequate level of physical fitness. Their experience in this type of work ranged from four months to six years.

The most important finding was that all distribution agents interviewed, regardless of age or length of service, reported back pain, particularly in the lumbar and cervical regions.

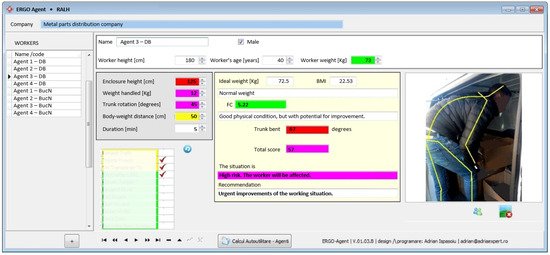

To ensure a clear record of the ergonomic risks faced by these workers, and to facilitate calculations while minimizing errors, the ERGO Agent—RALH software application, V.01.03.B/2024 was developed. This tool implements the RALH methodology and records ergonomic risk data for each individual worker. A screenshot of the application is shown in Figure 3. Some of the results obtained by applying the RALH methodology using the ERGO Agent software application are presented in Table 8.

Figure 3.

Screenshot from the ERGO Agent—RALH Software Tool, Version V.01.03.B/2024.

Table 8.

Results obtained by applying the RALH method.

The results shown in Table 8 represent the most unfavorable situation (with an average duration) observed in the field, individualized for each worker evaluated while performing the respective activity.

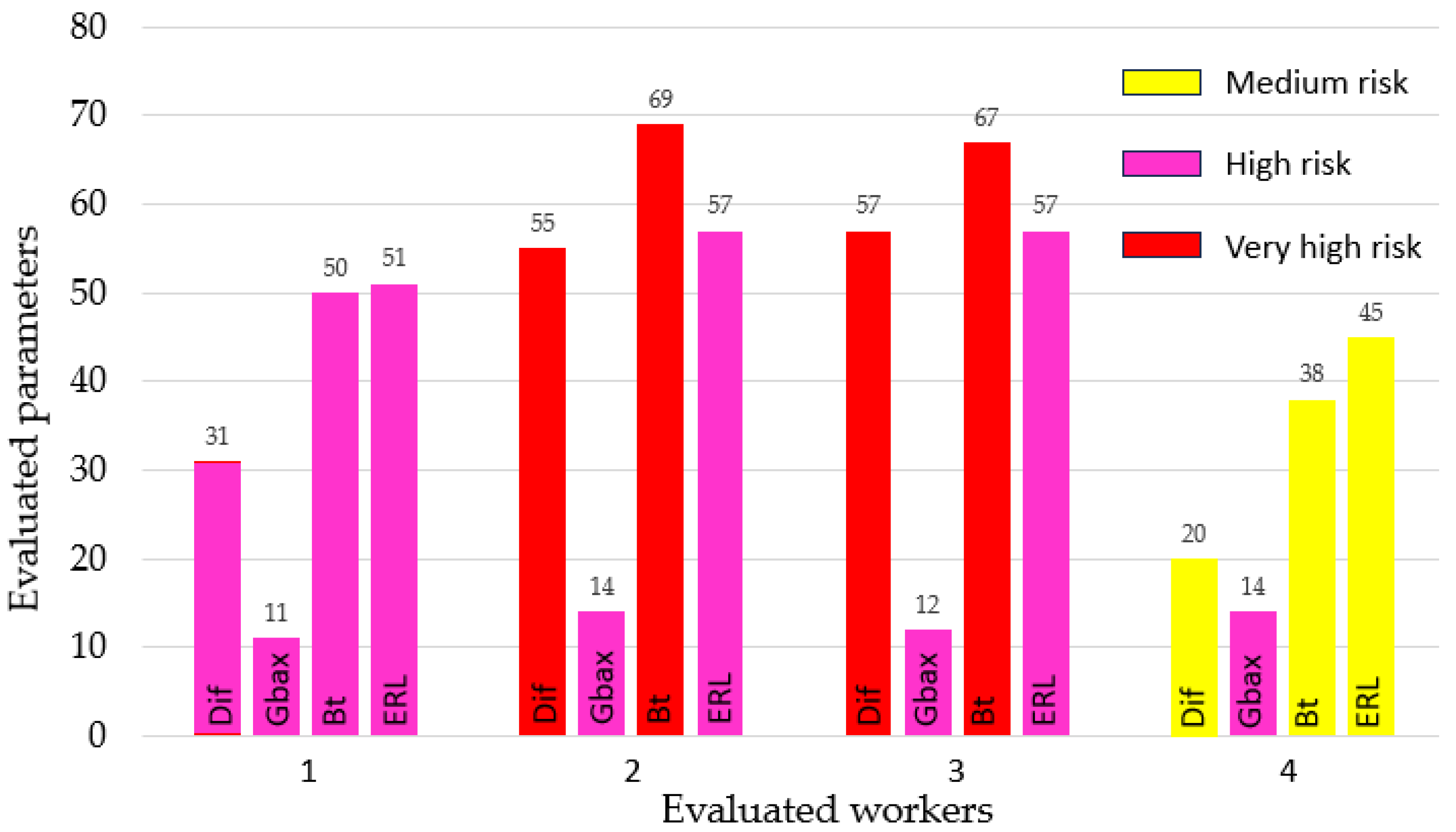

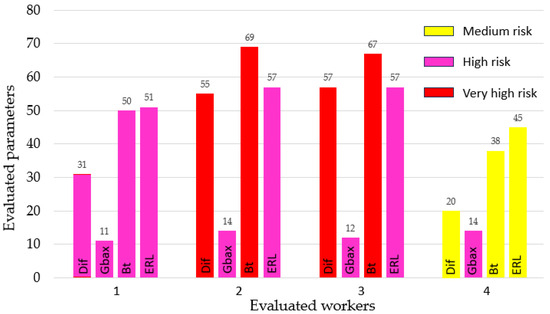

Figure 4 presents the results obtained for the four distribution agents. The difference between the workers’ height and the height of the van cargo compartment in which the agent operates is denoted as Dif. Values of Dif parameter are expressed in centimeters.

Figure 4.

Results analysis for the evaluated distribution agents/workers.

Values for Gbax are expressed in kilograms, those for Bt in degrees, while ERL is dimensionless. Analyzing the results depicted in Figure 4 a direct relationship can be observed between Dif and the worker’s trunk inclination Bt, with a direct impact on the ergonomic risk level ERL. The greater the height difference Dif, the greater the trunk inclination Bt, which results in a higher ergonomic risk level ERL.

4. Discussion

Proactive ergonomics emphasizes the prevention of musculoskeletal disorders (MSDs) by identifying, anticipating, and reducing risk factors during the design stages of work tasks and the selection of work equipment. In the presented case study, involving distribution agents and different types of vans, improvement solutions can be found both in choosing vans with higher cargo compartment heights and in assigning taller workers to vehicles with higher cargo compartments.

In this regard, by applying the formula expressed in Equation (2) and knowing the cargo compartment heights of different types of vans, it is possible to prepare data sheets for each type of vehicle, with corresponding recommended worker heights. A representative example of a data sheet for vans, illustrating the relevant parameters and corresponding details, is presented in Table 9. These have been implemented in the ERGO Agent—RALH software application and can be updated according to the types of vans available on the market at any given time. For freight vehicles, the ratings presented in Table 10 were used.

Table 9.

Example of a data sheet for vans.

Table 10.

Ratings used for freight vehicles.

The ERGO Agent—RALH software application also provides distribution supervisors with the ability to input the height of an agent. Based on the calculation formula from Equation (3), the application can indicate which types of vans can be assigned to that agent, ensuring that the selected vehicles meet the important ergonomic criterion related to cargo compartment height.

The RALH method was an equally effective tool for the assessment of ergonomic risks in NSLH where it was also applied to other types of activities different from those exemplified in this article.

In practice, it has also been observed that, beyond the criteria mentioned above, there are additional parameters that may significantly influence the ergonomics and comfort of distribution agents.

One of these important parameters is the physical fitness condition (FC) of the worker. This parameter can be quantified by a score called the physical fitness score (FS), which is specific to each worker and can decisively influence whether or not the respective activity can be performed under safe and acceptable conditions. The RALH method allows for development based on the FC parameter, and this has been implemented in the ERGO Agent—RALH software application.

Using Equation (4), the physical fitness score (FS) was calculated, with computations based on data from the literature that correlate indicators such as Body Mass Index (BMI) [33,34], sex [35,36], and age [37] with the general level of physical fitness [38].

where

- Ww—worker’s weight in kilograms

- Hw—worker’s height in meters

- Ww/Hw2—BMI (Body Mass Index)

- Cs—coefficient depending on the worker’s gender (for men, Cs = 1; for women, Cs = 0.85)

- A—worker’s age in years (the age of 35 years is considered optimal from the perspective of an individual’s physical fitness)

- e—base of the natural logarithm, Euler’s number (~2.71828)

The influence of age is represented exponentially, in order to highlight the accelerated decrease in physical capacity with increasing age [37]. The use of logarithmic/exponential functions is a validated practice for attenuating the impact of certain variables [38]. Equation (4) was implemented in an experimental module of the ERGO Agent—RALH software application, taking into account the normalized values of the physical fitness score (FS), as presented in Table 11, which result from the calculations.

Table 11.

Transposed values for physical fitness condition.

Thus, Equation (3) becomes Equation (5):

where

- ERLa—adjusted ergonomic risk level

- Bt—trunk inclination

- Rt—trunk rotation

- FC—normalized value of the physical fitness score

- Gbax—handled load weight

- d—distance between the body and the load

- t—time spent by the worker in NSLH

As can be observed, in Equation (5) the normalized value of the physical fitness score was introduced, weighted by a factor of 2, since physical fitness is a particularly important factor in activities that involve load handling under conditions where the trunk must remain both inclined and rotated. When applying Equation (5), Table 6 is modified by incorporating the FC parameter, as presented in Table 12.

Table 12.

Ergonomic Risk Assessment Matrix in NSLH considering FC.

Future developments of the RALH method will focus both on improvements to the calculation formulas in Equations (4) and (5) including the introduction of a parameter that reflects, as objectively as possible, the worker’s own perception of their physical condition, and on the potential implementation of an artificial intelligence-based system. Such a system could analyze, in real time, when the worker has reached a certain level of physical strain caused by posture and other factors, and provide timely alerts. Furthermore, to substantially reduce evaluation time and enhance process automation, future developments will consider the integration of body-worn sensors together with environmental video monitoring systems. This combined approach will enable both real-time and offline analysis of awkward postures, thereby improving the accuracy and responsiveness of ergonomic risk assessment in NSLH environments [39].

5. Conclusions

The ergonomic risk assessment carried out using the RALH method yielded positive results in diagnosing working situations from an ergonomic perspective in NSLH environments, and it greatly facilitated the identification of solutions to improve worker comfort. In NSLH work situations, it was found that workers are physically affected because their activities are performed in constrained postures caused by the insufficient height of the workspace. The area most affected is the spinal column, particularly the lumbar and cervical regions. In all NSLH scenarios, improving worker comfort is necessary. However, the workspace height cannot always be increased (as might be the case for distribution agents through the acquisition of vans with higher cargo compartments). For example, this is not feasible in tunnels or technical spaces such as those found inside a wind turbine nacelle.

Based on the diagnostics provided by RALH, in situations where technical improvements to the working conditions could not be implemented, measures were taken to restrict access to NSLH areas for workers exceeding a certain height, while also focusing on the physical preparation of workers entering these spaces. This included physical conditioning of the body through warming-up and stretching exercises of approximately 10 min before starting work. Additionally, training workers on correct handling techniques in such spaces proved highly beneficial in preventing occupational disorders and improving task efficiency, thereby reducing exposure time in these types of low-height confined spaces.

The RALH method has therefore proven to be a practical and reliable tool for identifying and assessing ergonomic risks in NSLH environments. Beyond the specific case study, the methodology can be adapted to a wide range of industries and work activities where workers are exposed to constrained postures. Broader application and future research will further validate its effectiveness and support the development of preventive strategies in occupational safety and health.

Author Contributions

Conceptualization, A.I.; methodology, A.I. and I.M.; software, A.I.; validation, I.M., C.G., M.P.-I. and G.O.; writing—original draft preparation, A.I.; writing—review and editing, I.M., C.G., M.P.-I. and G.O.; supervision, I.M., C.G., M.P.-I. and G.O. All authors have read and agreed to the published version of the manuscript.

Funding

The APC was funded by Transilvania University of Brasov, Romania.

Institutional Review Board Statement

All the authors assert that all methods contributing to this work comply with the ethical standards of the national and institutional committees on human rights, with the regulations and rights of the workers, and with the Helsinki Declaration of 1975, as revised in 2008. Registration number of the ethical declaration is AEX2942 from 18 December 2024.

Informed Consent Statement

All participants involved in this study were informed about the aims, procedures, potential risks, and benefits of the research and provided their verbal informed consent prior to participation. Participants were assured that their identities would remain confidential and that any data presented would be anonymized.

Data Availability Statement

The necessary data are presented in this article. Other data and information about certain aspects of interest presented in this article are available upon request from the corresponding author.

Acknowledgments

We extend our thanks to S.C. ADRIA EXPERT S.R.L. Bucharest, ROMANIA, for their support in conducting this research.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| RALH | Risk Assessment for Narrow Spaces with Low Height |

| NSLH | Narrow Spaces with Low Height |

| Hs | Height of the workspace |

| Hw | Height of the worker |

| Ww | Weight of the worker |

| A | Age |

| Bt | Bending trunk (trunk inclination) |

| Rt | Trunk rotation |

| Gbax | Handled load weight |

| d | Distance between the body and the handled load |

| t | Time spent by the worker in NSLH |

| ERL | Ergonomic risk level |

| ERLa | Adjusted ergonomic risk level |

| FC | Physical Fitness Condition |

| FS | Physical Fitness Score |

References

- Burlet-Vienney, D.; Chinniah, Y.; Bahloul, A.; Roberge, B. Design and application of a 5 step risk assessment tool for confined space entries. Saf. Sci. 2015, 80, 144–155. [Google Scholar] [CrossRef]

- Manwaring, J.C.; Conroy, C. Occupational confined space-related fatalities: Surveillance and prevention. J. Saf. Res. 1990, 21, 157–164. [Google Scholar] [CrossRef]

- Selman, J.; Spickett, J.; Jansz, J.; Mullins, B. An investigation into the rate and mechanism of incident of work-related confined space fatalities. Saf. Sci. 2018, 109, 333–343. [Google Scholar] [CrossRef]

- A Guide To Working in Confined Spaces—What Are the Dangers & Risks? Available online: https://www.tsw.co.uk/blog/health-and-safety/a-guide-to-working-in-small-spaces/ (accessed on 24 April 2025).

- Introduction to Working in Confined Spaces. Available online: https://www.hse.gov.uk/index.htm (accessed on 24 April 2025).

- Naghavi, Z.K.; Mortazavi, S.B.; Asilian, H.M.; Hajizadeh, E. Exploring the Contributory Factors of Confined Space Accidents Using Accident Investigation Reports and Semistructured Interviews. Saf. Health Work. 2019, 10, 305–313. [Google Scholar] [CrossRef] [PubMed]

- Burlet-Vienney, D.; Chinniah, Y.; Bahloul, A.; Roberge, B. Occupational safety during interventions in confined spaces. Saf. Sci. 2015, 79, 19–28. [Google Scholar] [CrossRef]

- Niu, S. Ergonomics and occupational safety and health: An ILO perspective. Appl. Ergon. 2010, 41, 744–753. [Google Scholar] [CrossRef]

- Gerr, F.; Fethke, N.B.; Anton, D.; Merlino, L.; Rosecrance, J.; Marcus, M.; Jones, M.P. A prospective study of musculoskeletal outcomes among manufacturing workers: II. Effects of psychosocial stress and work organization factors. Hum. Factors 2014, 56, 178–190. [Google Scholar] [CrossRef]

- Stefana, E.; Marciano, F.; Rossi, D.; Cocca, P.; Tomasoni, G. Wearable Devices for Ergonomics: A Systematic Literature Review. Sensors 2021, 21, 777. [Google Scholar] [CrossRef]

- Walker-Bone, K.; Reading, I.; Coggon, D.; Cooper, C.; Palmer, K.T. Risk factors for specific upper limb disorders as compared with non-specific upper limb pain: Assessing the utility of a structured examination. Occup. Med. 2006, 56, 243–250. [Google Scholar] [CrossRef]

- Charles, L.E.; Ma, C.C.; Burchfiel, C.M.; Dong, R.G. Vibration and ergonomic exposures associated with musculoskeletal disorders of the shoulder and neck. Saf. Health Work. 2018, 9, 125–132. [Google Scholar] [CrossRef] [PubMed]

- Da Costa, B.R.; Vieira, E.R. Risk factors for work-related musculoskeletal disorders: A systematic review of recent longitudinal studies. Am. J. Ind. Med. 2010, 53, 285–323. [Google Scholar]

- Arvidsson, I.; Dahlqvist, C.; Enquist, H.; Nordander, C. Action Levels for the Prevention of Work-Related Musculoskeletal Disorders in the Neck and Upper Extremities: A Proposal. Ann. Work. Expo. Health. 2021, 65, 741–747. [Google Scholar] [CrossRef]

- Coenen, P.; Douwes, M.; van den Heuvel, S.; Bosch, T. Towards exposure limits for working postures and musculoskeletal symptoms—A prospective cohort study. Ergonomics 2016, 59, 1182–1192. [Google Scholar] [CrossRef]

- Mathiassen, S.E. Diversity and variation in biomechanical exposure: What is it, and why would we like to know? Appl. Ergon. 2006, 37, 419–427. [Google Scholar] [CrossRef]

- Andrasfay, T.; Raymo, N.; Goldman, N.; Pebley, A.R. Physical work conditions and disparities in later life functioning: Potential pathways. SSM-Popul. Health 2021, 16, 100990. [Google Scholar] [CrossRef]

- Chiasson, M.È.; Imbeau, D.; Aubry, K.; Delisle, A. Comparing the results of eight methods used to evaluate risk factors associated with musculoskeletal disorders. Int. J. Ind. Ergon. 2012, 42, 478–488. [Google Scholar] [CrossRef]

- Vijayakumar, R.; Choi, J.-H. Emerging Trends of Ergonomic Risk Assessment in Construction Safety Management: A Scientometric Visualization Analysis. Int. J. Environ. Res. Public Health 2022, 19, 16120. [Google Scholar] [CrossRef] [PubMed]

- Tavakkol, R.; Kavi, E.; Hassanipour, S.; Rabiei, H.; Malakoutikhah, M. The global prevalence of musculoskeletal disorders among operating room personnel: A systematic review and meta-analysis. Clin. Epidemiol. Glob. Health. 2020, 8, 1053–1061. [Google Scholar]

- Enez, K.; Nalbantoğlu, S.S. Comparison of ergonomic risk assessment outputs from OWAS and REBA in forestry timber harvesting. Int. J. Ind. Ergon. 2019, 70, 51–57. [Google Scholar] [CrossRef]

- Park, J.; Kim, Y.; Han, B. Work sectors with high risk for work-related musculoskeletal disorders in Korean men and women. Saf. Health Work 2018, 9, 75–78. [Google Scholar]

- Hignett, S.; Mcatamney, L. Rapid entire body assessment (REBA). Appl. Ergon. 2000, 31, 201–205. [Google Scholar] [CrossRef] [PubMed]

- Madani, D.; Dababneh, A. Rapid Entire Body Assessment: A Literature Review. Am. J. Eng. Appl. Sci. 2016, 9, 107–118. [Google Scholar] [CrossRef]

- McAtamney, L.; Corlett, E.N. RULA: A survey method for the investigation of work-related upper limb disorders. Appl. Ergon. 1993, 24, 91–99. [Google Scholar] [CrossRef]

- Singh, J.; Lal, H.; Kocher, G. Musculoskeletal Disorder Risk Assessment in small scale forging Industry by using RULA Method. Int. J. Eng. Adv. Technol. 2012, 1, 513–517. [Google Scholar]

- David, G.; Woods, V.; Li, G.; Buckle, P. The development of the Quick Exposure Check (QEC) for assessing exposure to risk factors for work-related musculoskeletal disorders. Appl. Ergon. 2008, 39, 57–69. [Google Scholar] [CrossRef] [PubMed]

- Brown, R.; Li, G. The development of action levels for the “Quick Exposure Check” (QEC) system. Contemp. Ergon. 2003, 1, 38–43. [Google Scholar]

- Oliv, S.; Gustafsson, E.; Baloch, A.N.; Hagberg, M.; Sandén, H. The Quick Exposure Check (QEC)—Inter-rater reliability in total score and individual items. Appl. Ergon. 2019, 76, 32–37. [Google Scholar] [CrossRef]

- Bulduk, E.Ö.; Bulduk, S.; Süren, T.; Ovalı, F. Assessing exposure to risk factors for work-related musculoskeletal disorders using Quick Exposure Check (QEC) in taxi drivers. Int. J. Ind. Ergon. 2014, 44, 817–820. [Google Scholar] [CrossRef]

- REBA: A Step-by-Step Guide. Available online: https://ergo-plus.com/wp-content/uploads/REBA-A-Step-by-Step-Guide.pdf (accessed on 24 April 2025).

- REBA Employee Assessment Worksheet. Available online: https://ergo-plus.com/wp-content/uploads/REBA-Worksheet-v-2.0.pdf?x55548 (accessed on 24 April 2025).

- BMI (Body Mass Index) Frequently Asked Questions. Available online: https://www.cdc.gov/bmi/faq/?CDC_AAref_Val=https://www.cdc.gov/healthyweight/assessing/bmi/adult_bmi/index.html (accessed on 24 April 2025).

- Body Mass Index (BMI). Available online: https://www.medicalnewstoday.com/articles/323446#body-mass-index-bmi (accessed on 24 April 2025).

- Gallagher, D.; Heymsfield, S.B.; Heo, M.; Jebb, S.A.; Murgatroyd, P.R.; Sakamoto, Y. Healthy percentage body fat ranges: An approach for developing guidelines based on body mass index. Am. J. Clin. Nutr. 2000, 72, 694–701. [Google Scholar] [CrossRef]

- Nordander, C.; Ohlsson, K.; Åkesson, I.; Arvidsson, I.; Balogh, I.; Hansson, G.-Å.; Strömberg, U.; Rittner, R.; Skerfving, S. Risk of Musculoskeletal Disorders among Females and Males in Repetitive/Constrained Work. Ergonomics 2009, 52, 1226–1239. [Google Scholar] [CrossRef]

- Tanaka, H.; Seals, D.R. Endurance exercise performance in Masters athletes: Age-associated changes and underlying physiological mechanisms. J. Physiol. 2008, 586, 55–63. [Google Scholar] [CrossRef] [PubMed]

- Obesity: Preventing and Managing the Global Epidemic: Report of a WHO Consultation. Available online: https://iris.who.int/handle/10665/42330 (accessed on 24 April 2025).

- Manghisi, V.M.; Uva, A.E.; Fiorentino, M.; Bevilacqua, V.; Trotta, G.F.; Monno, G. Real time RULA assessment using Kinect v2 sensor. Appl. Ergon. 2017, 65, 481–491. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).