The Role of Process Parameters in Shaping the Microstructure and Porosity of Metallic Components Manufactured by Additive Technology

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

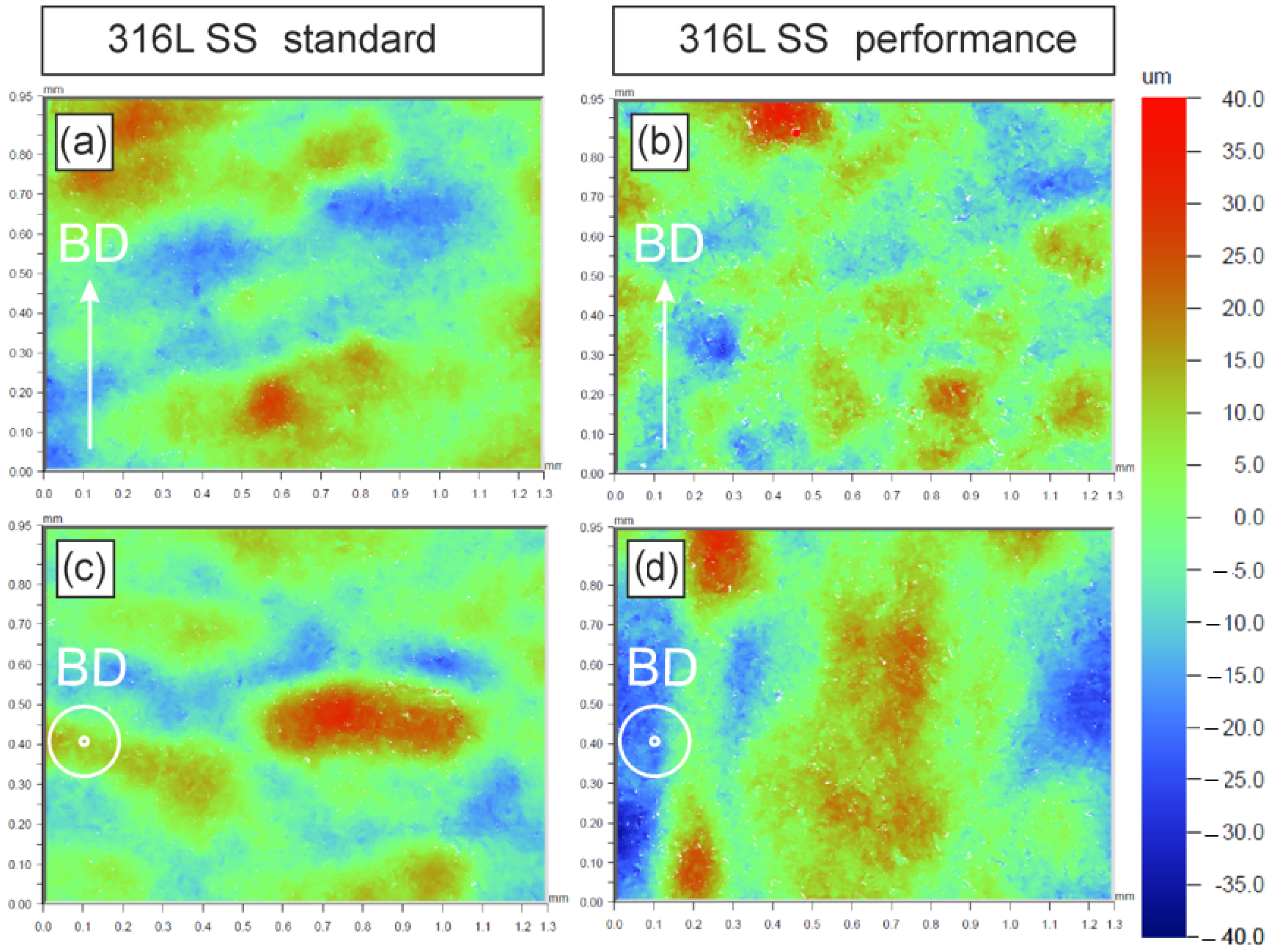

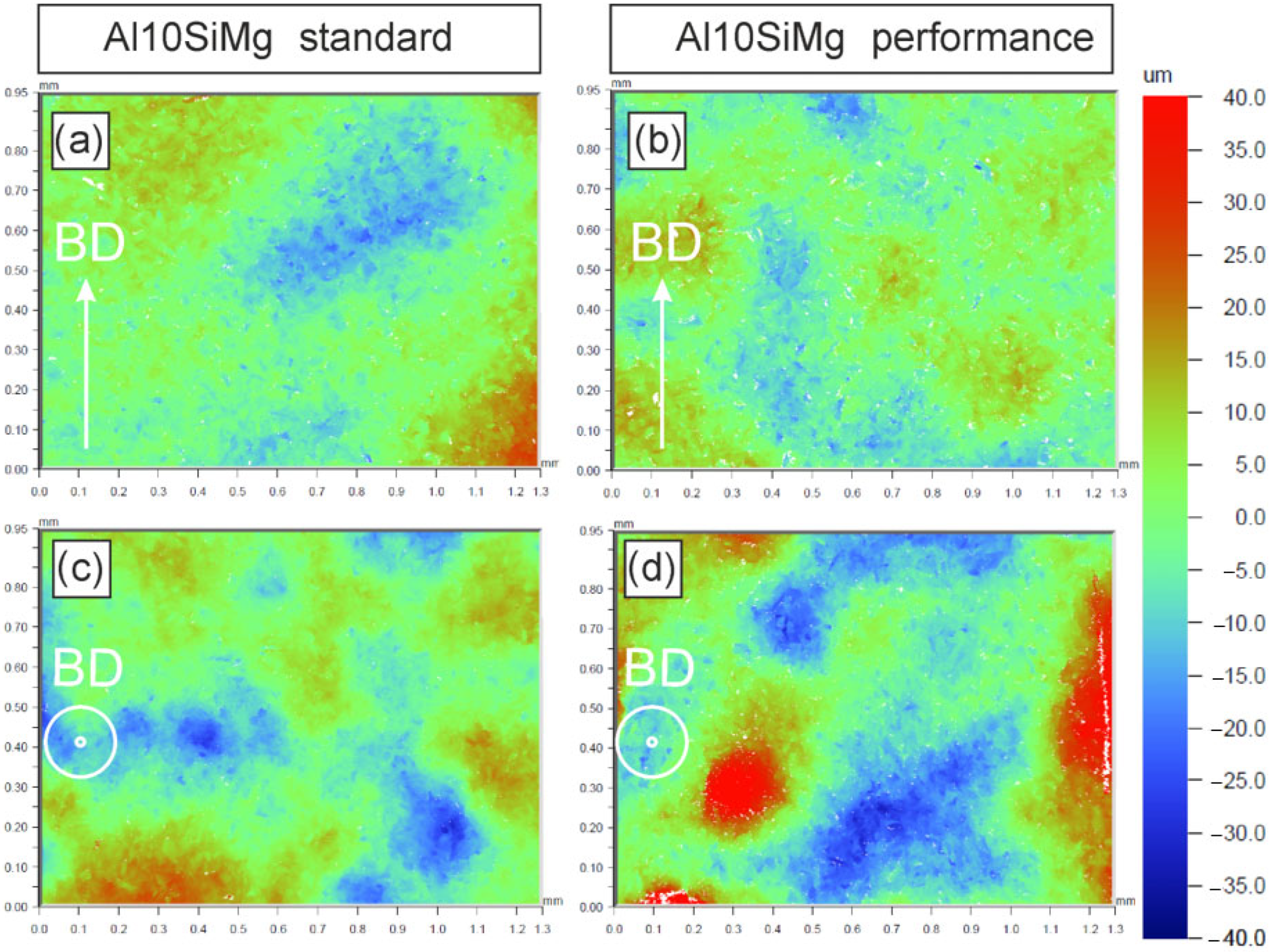

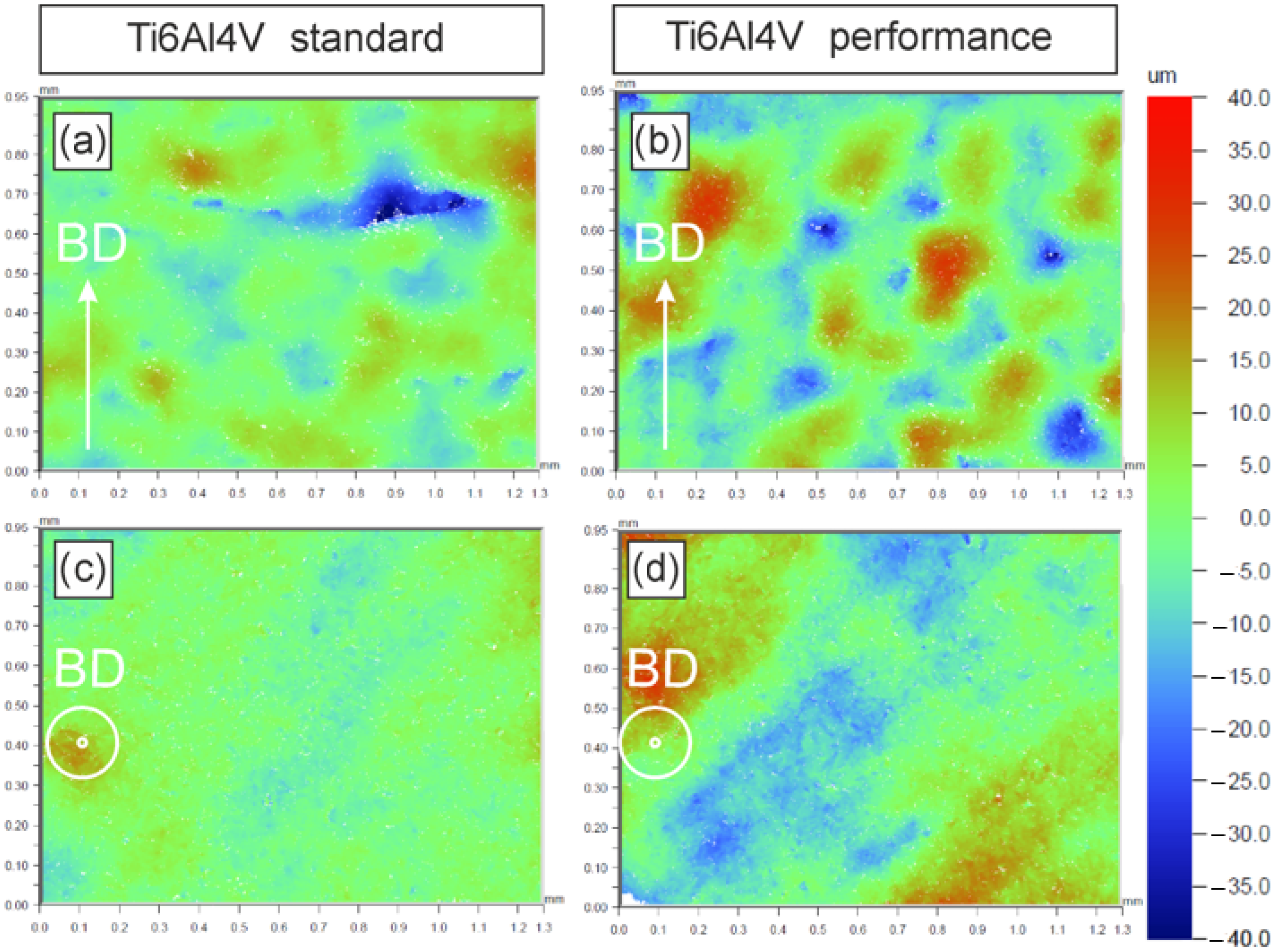

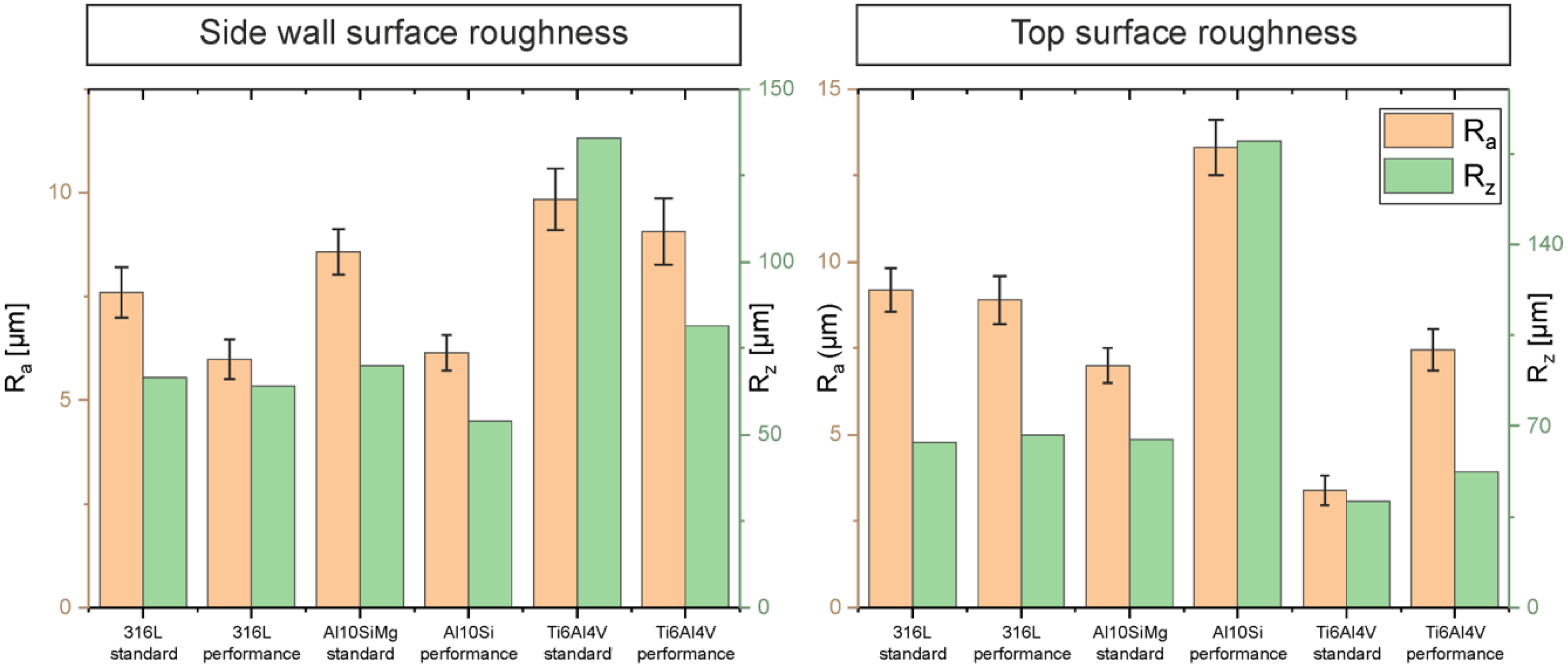

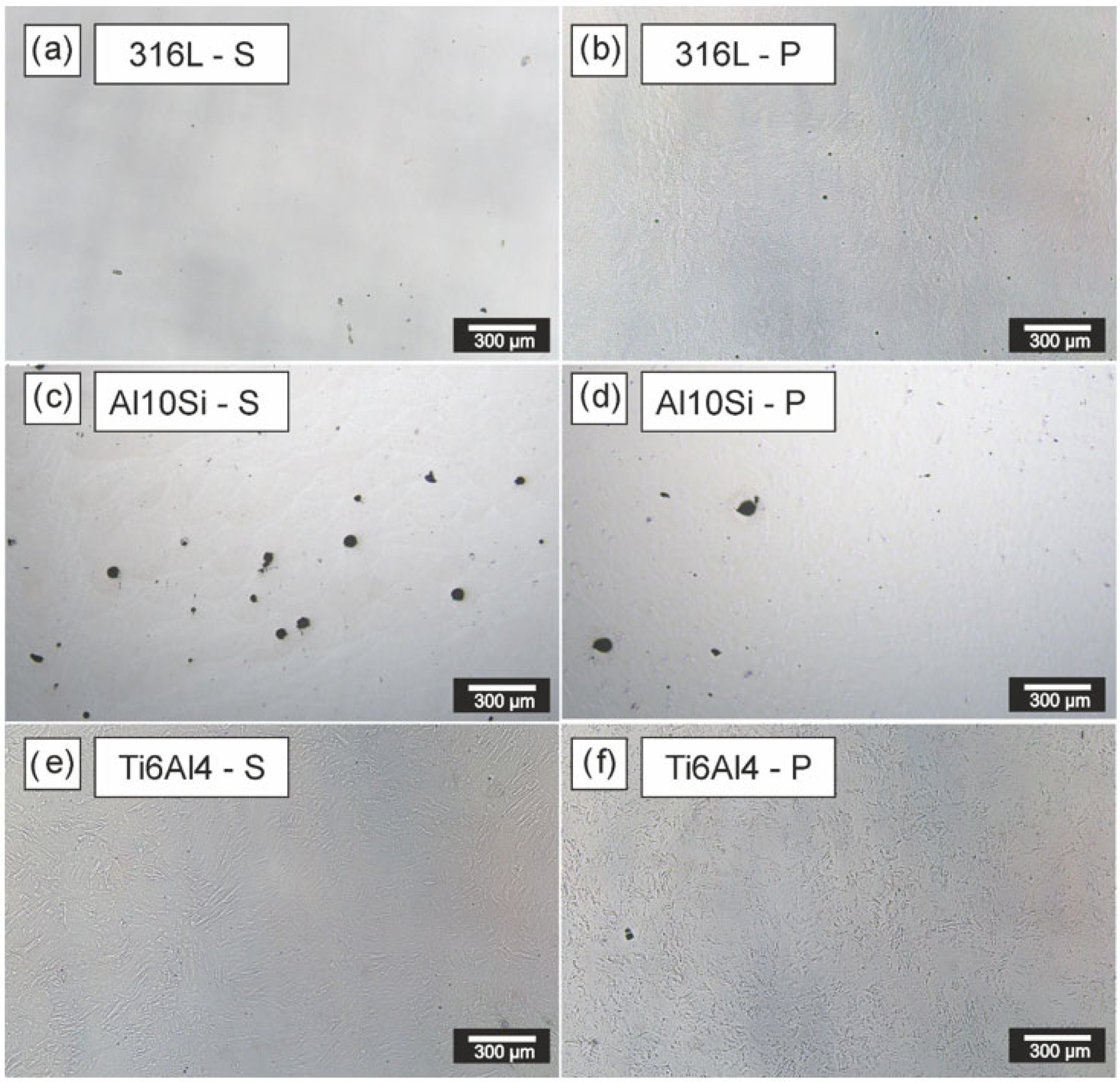

3.1. Surface Roughness

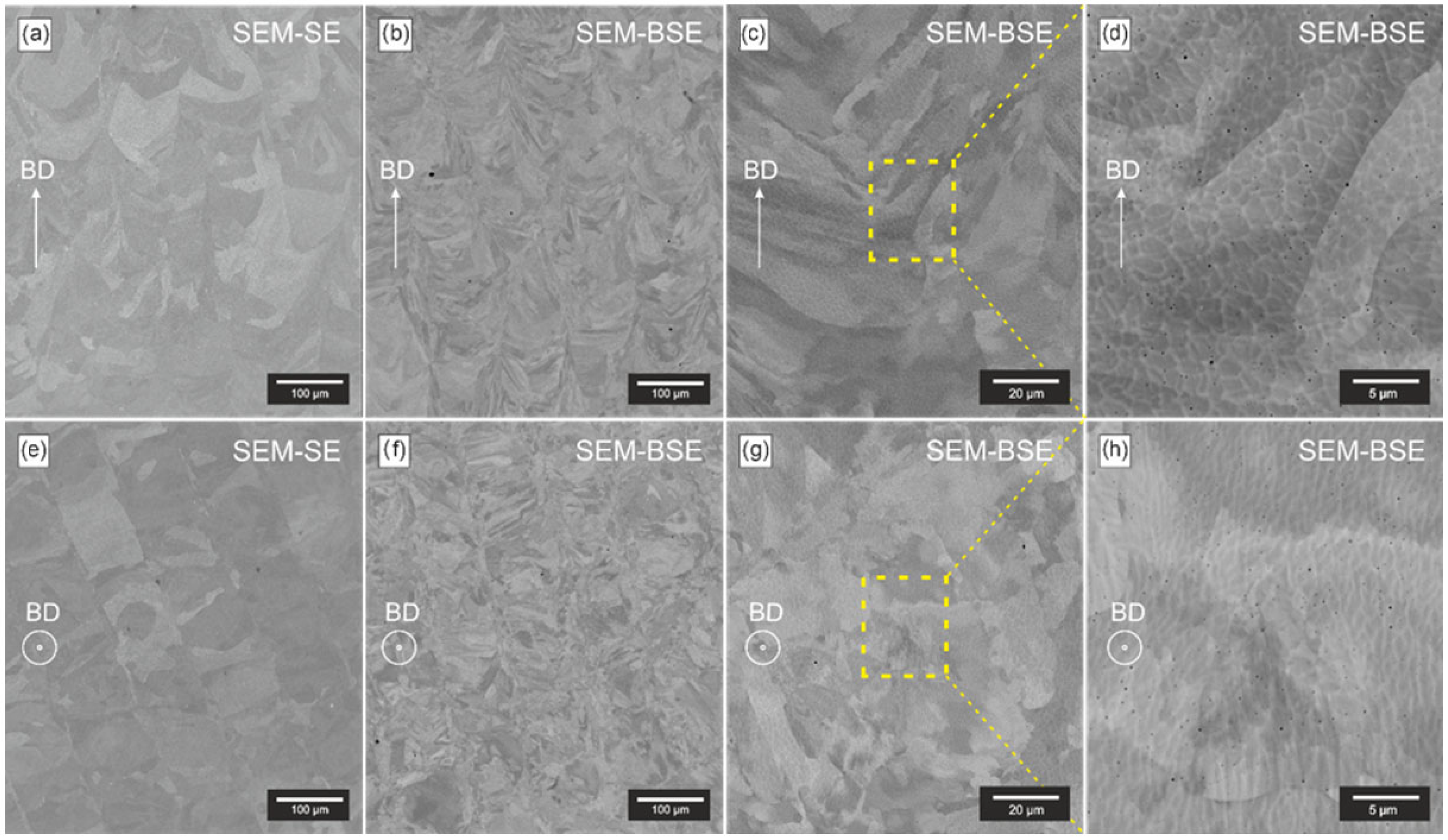

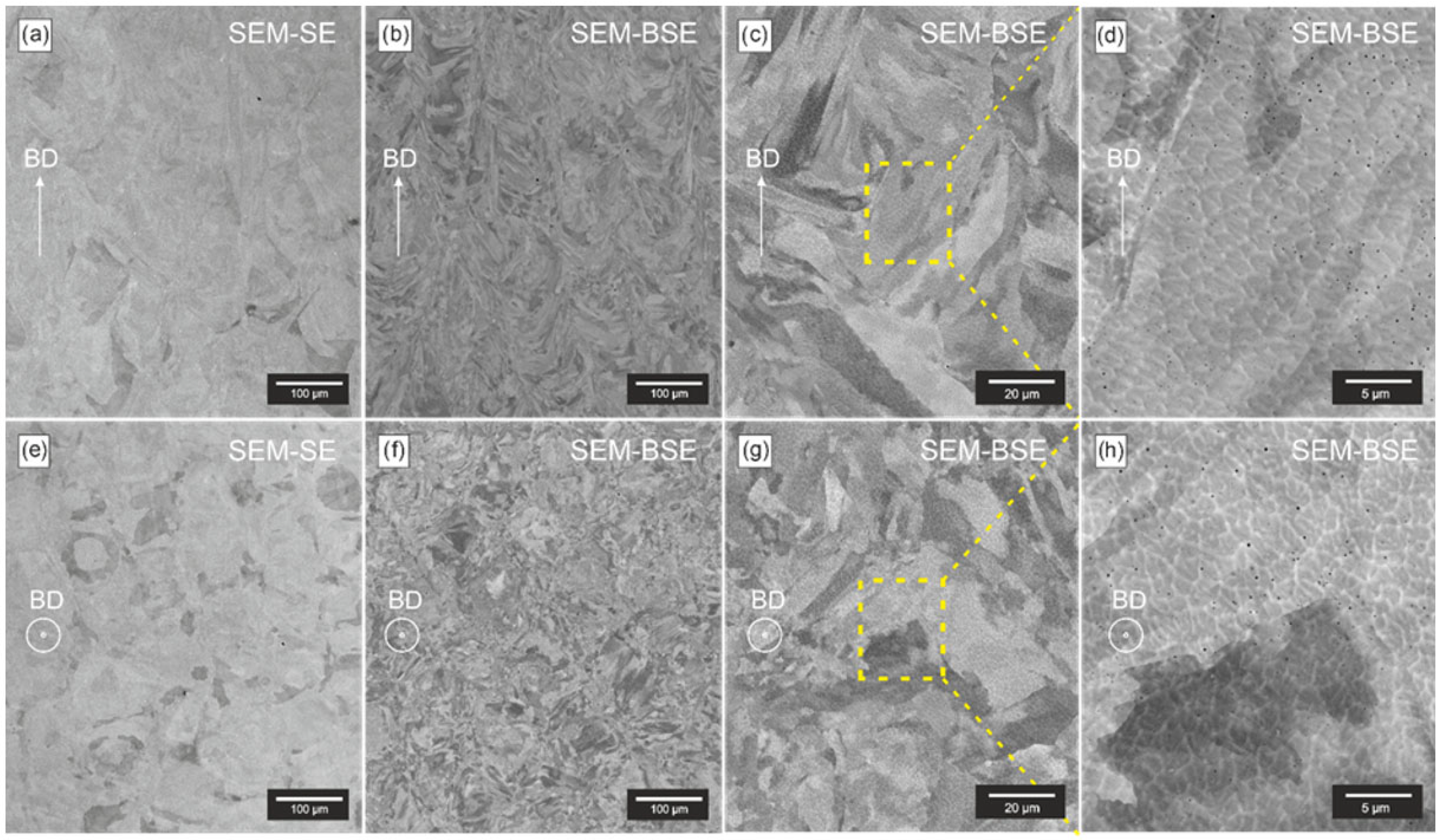

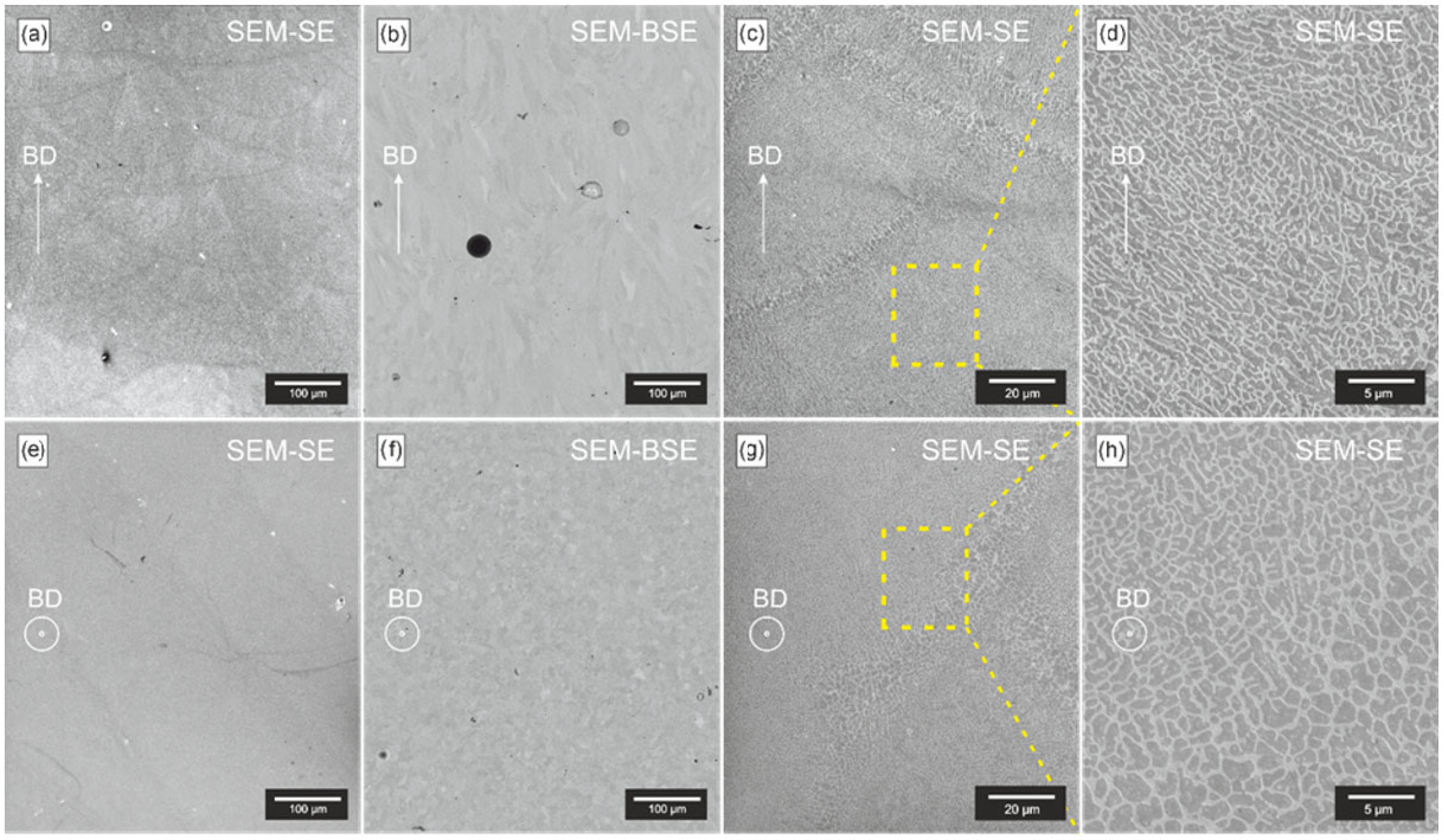

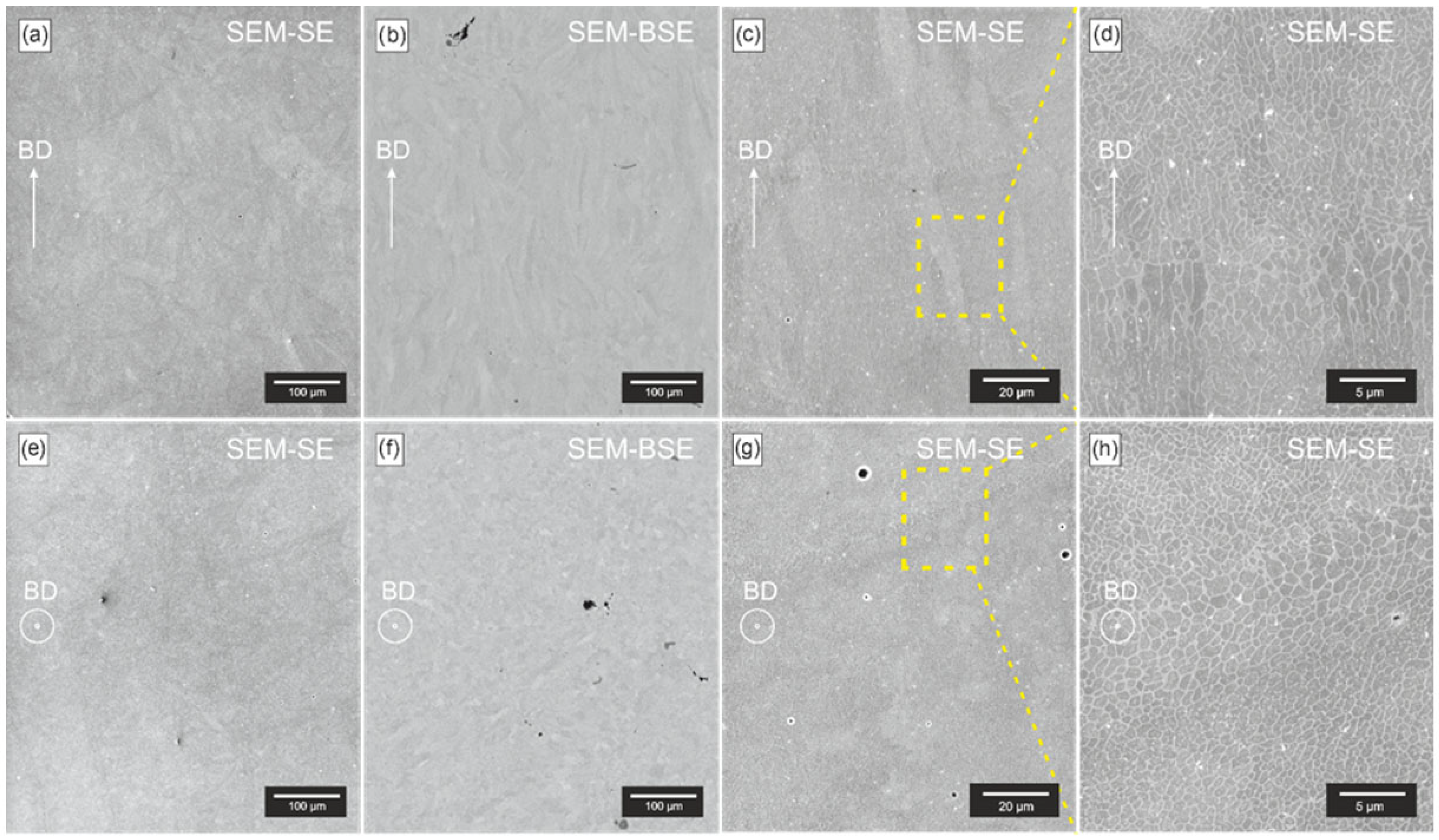

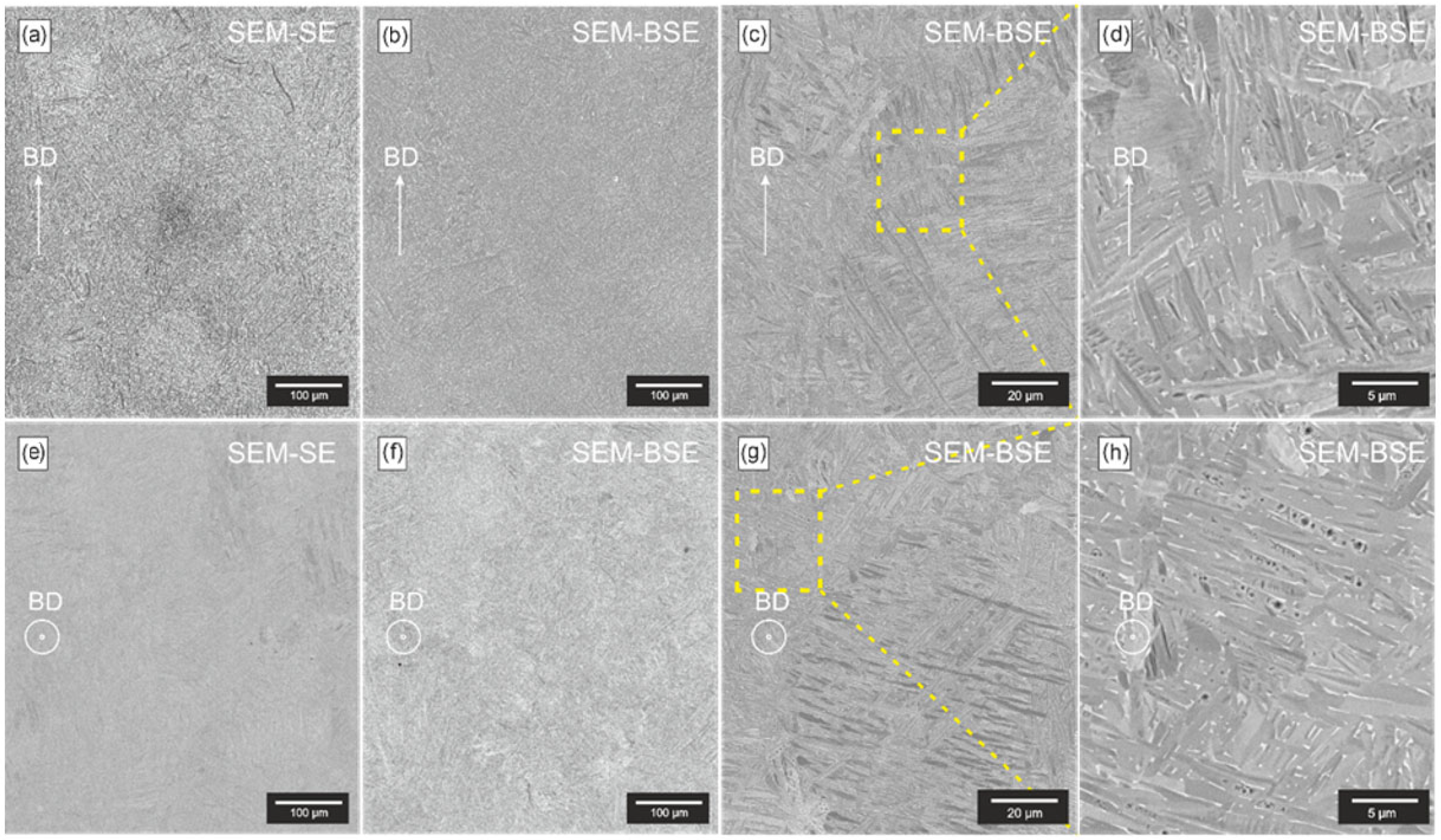

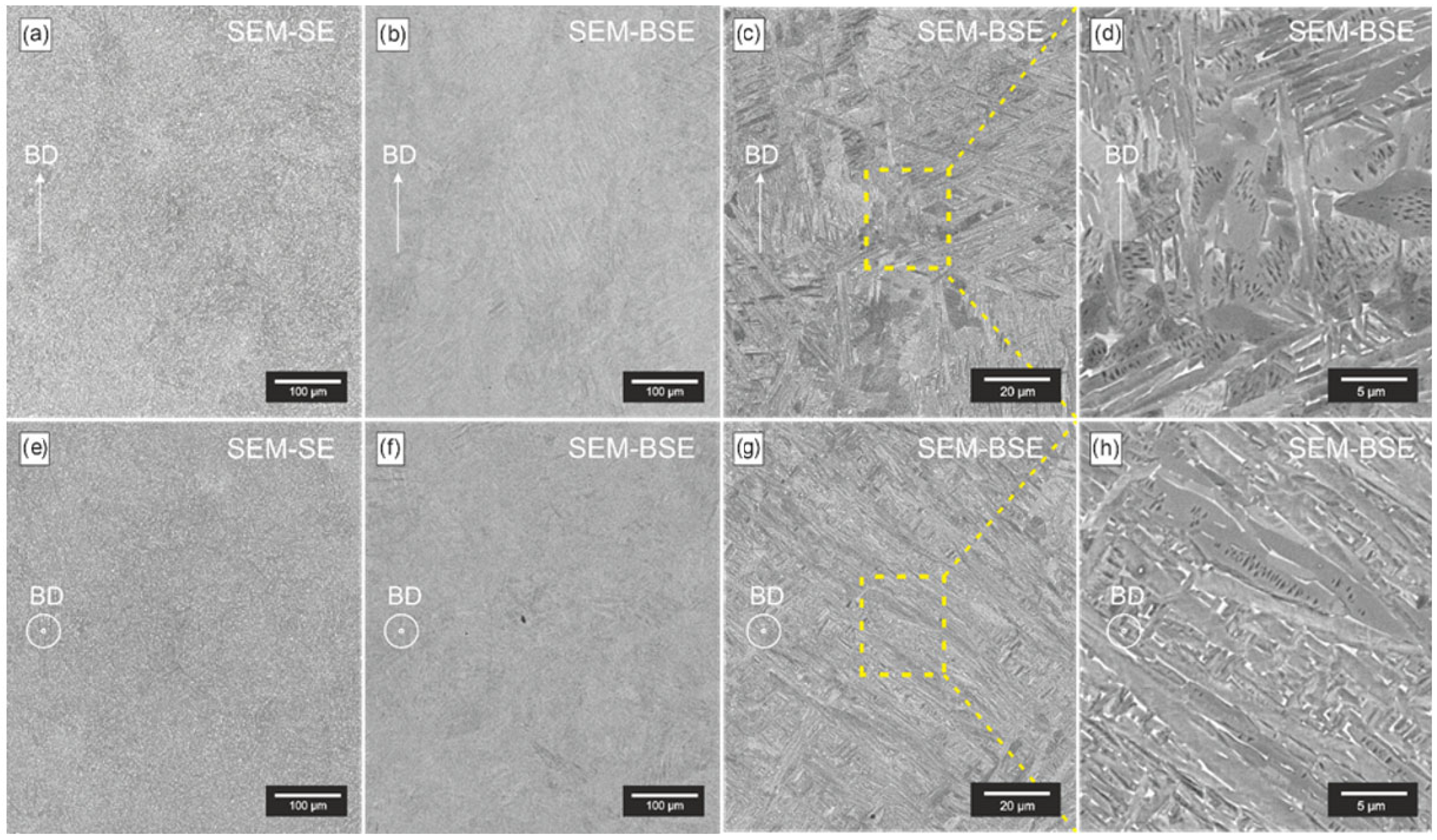

3.2. Microstructure

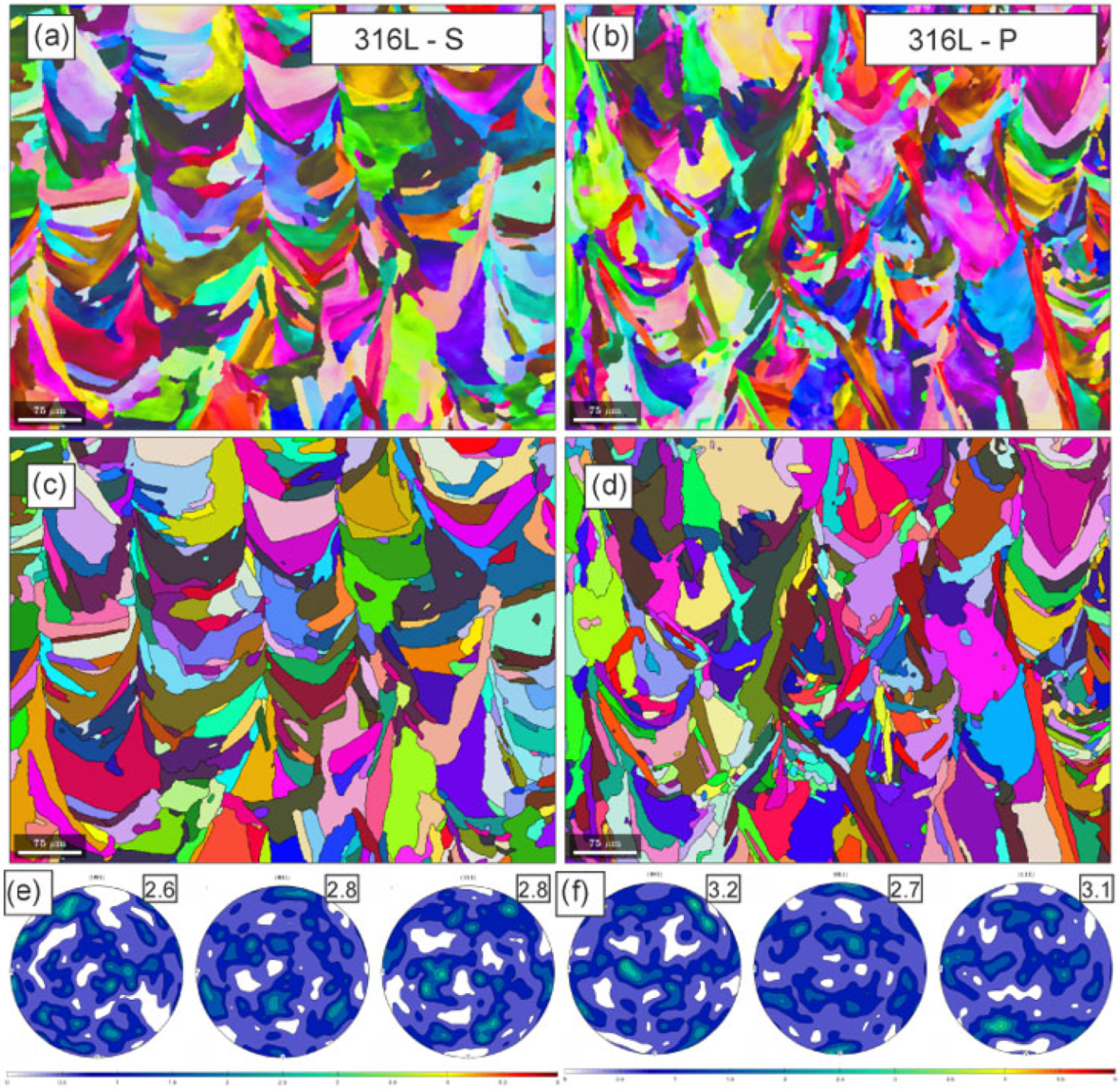

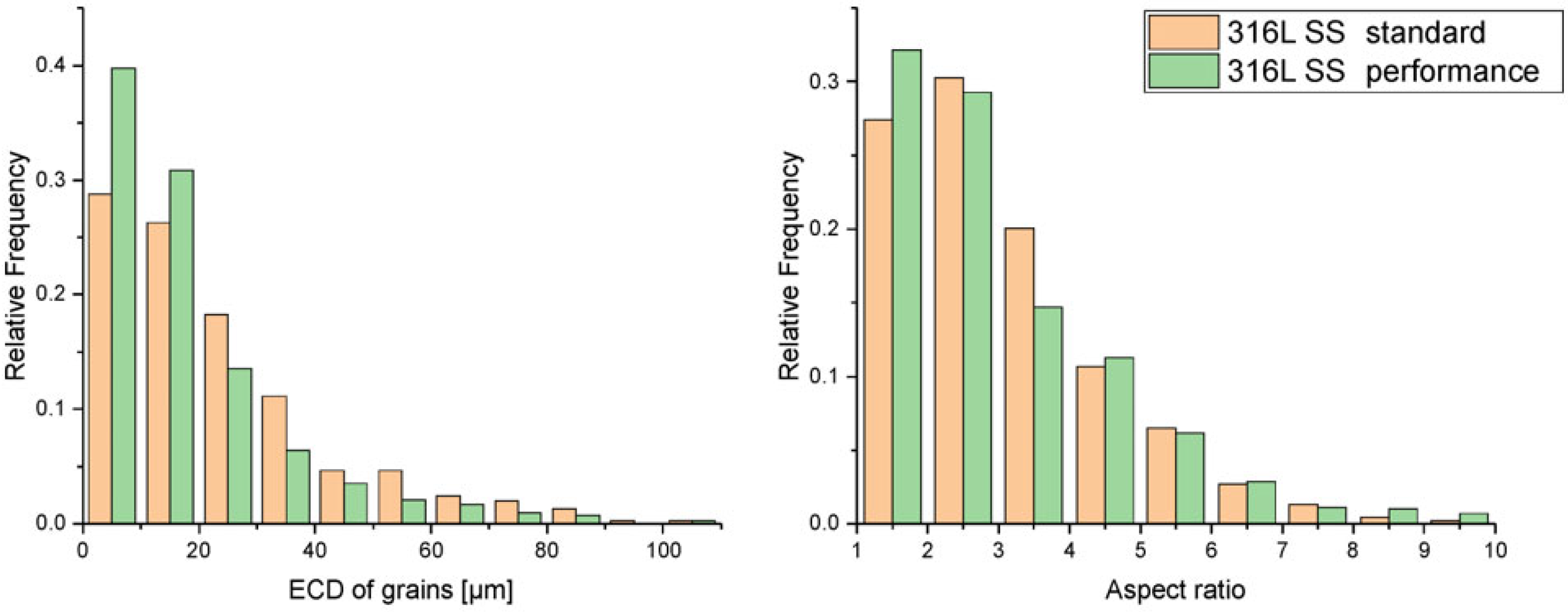

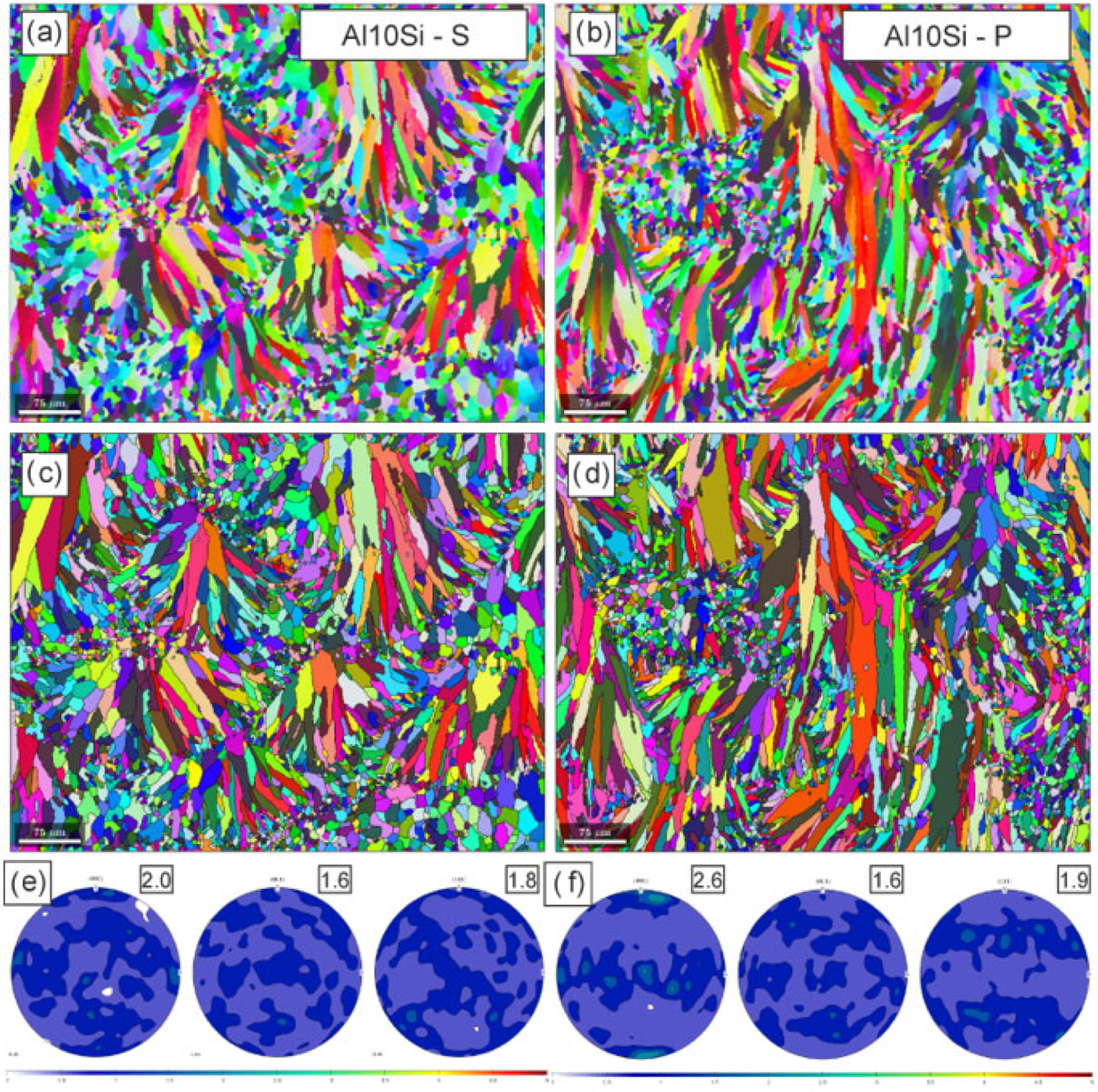

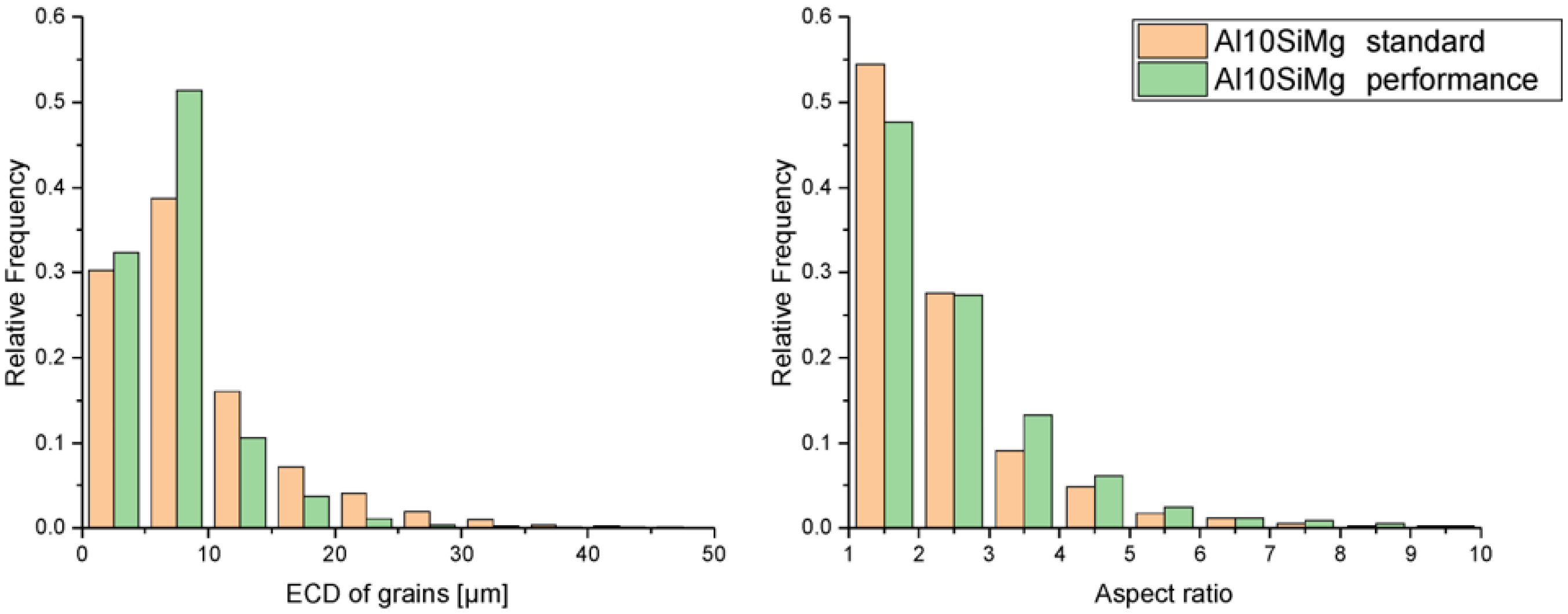

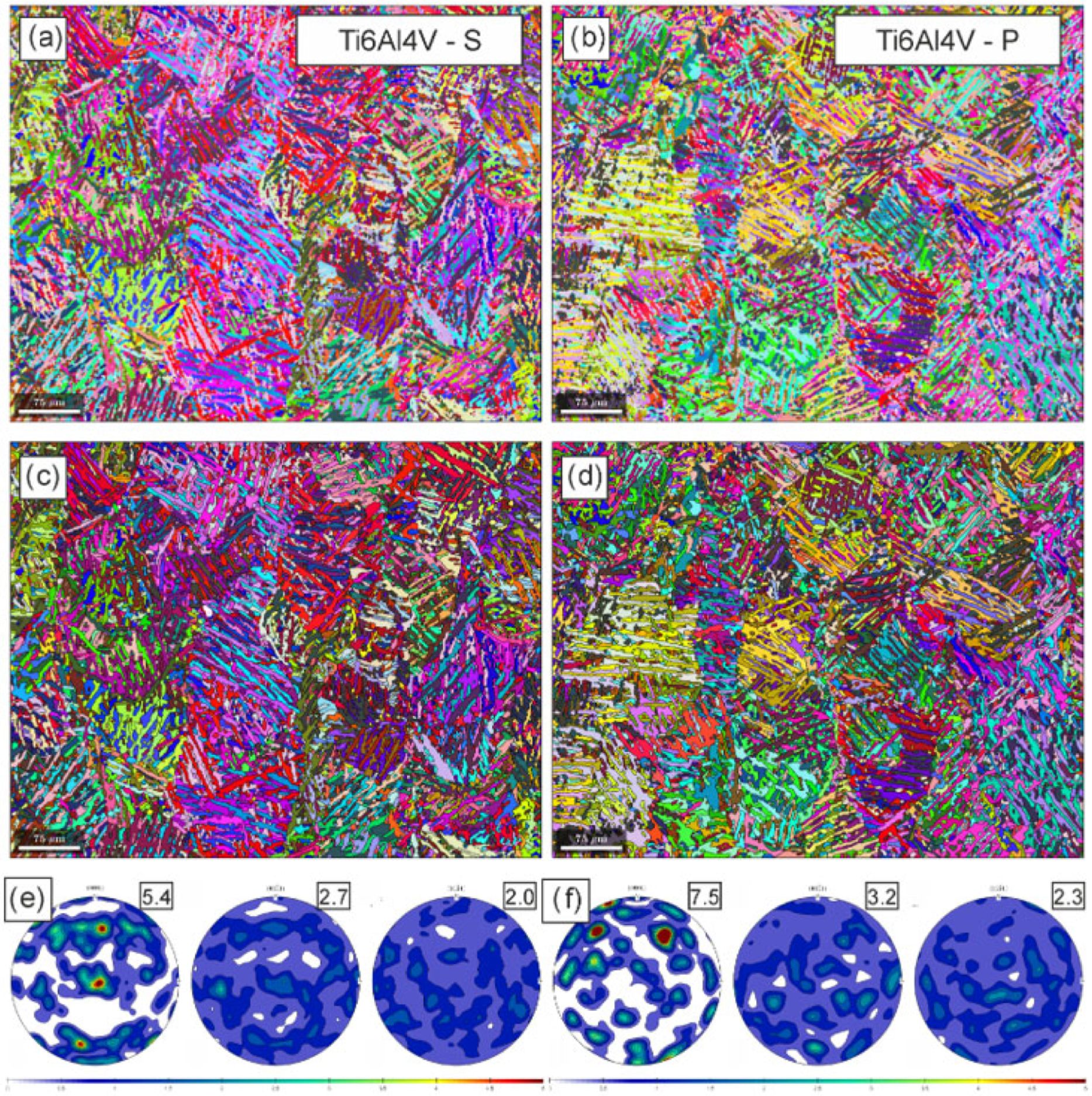

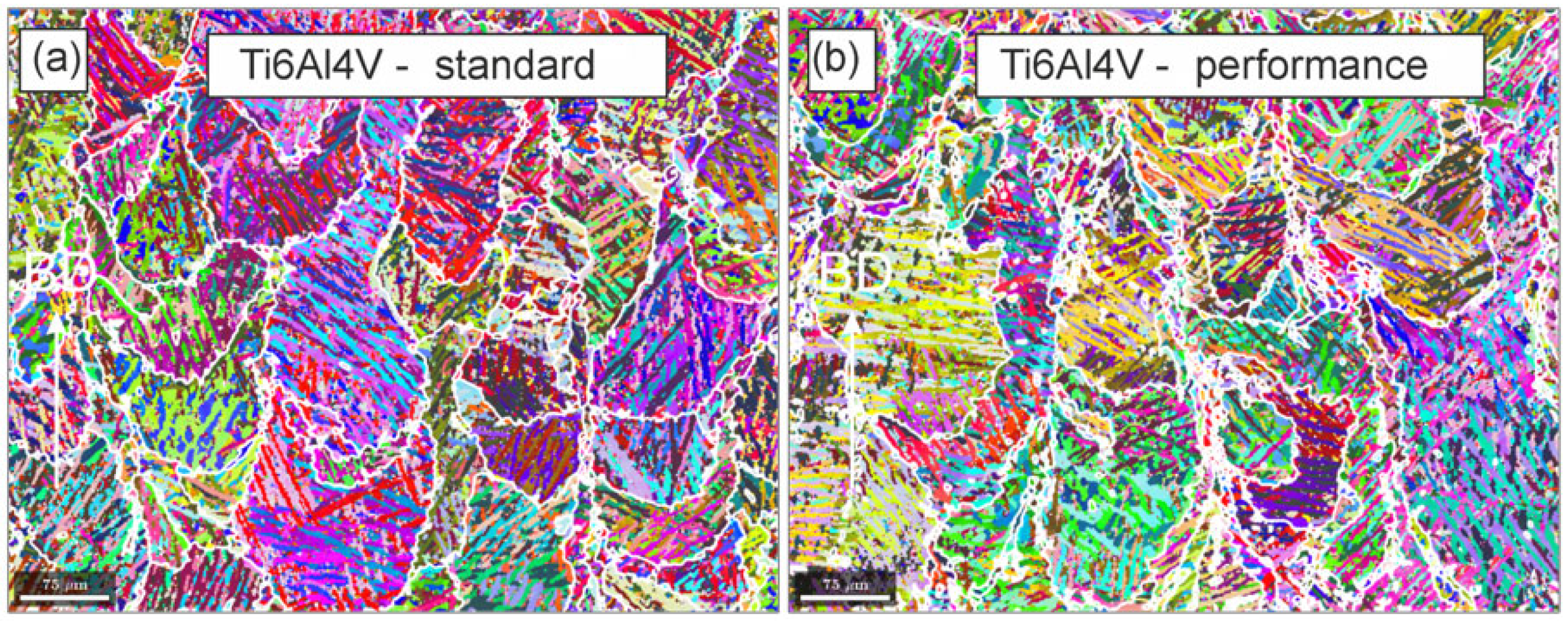

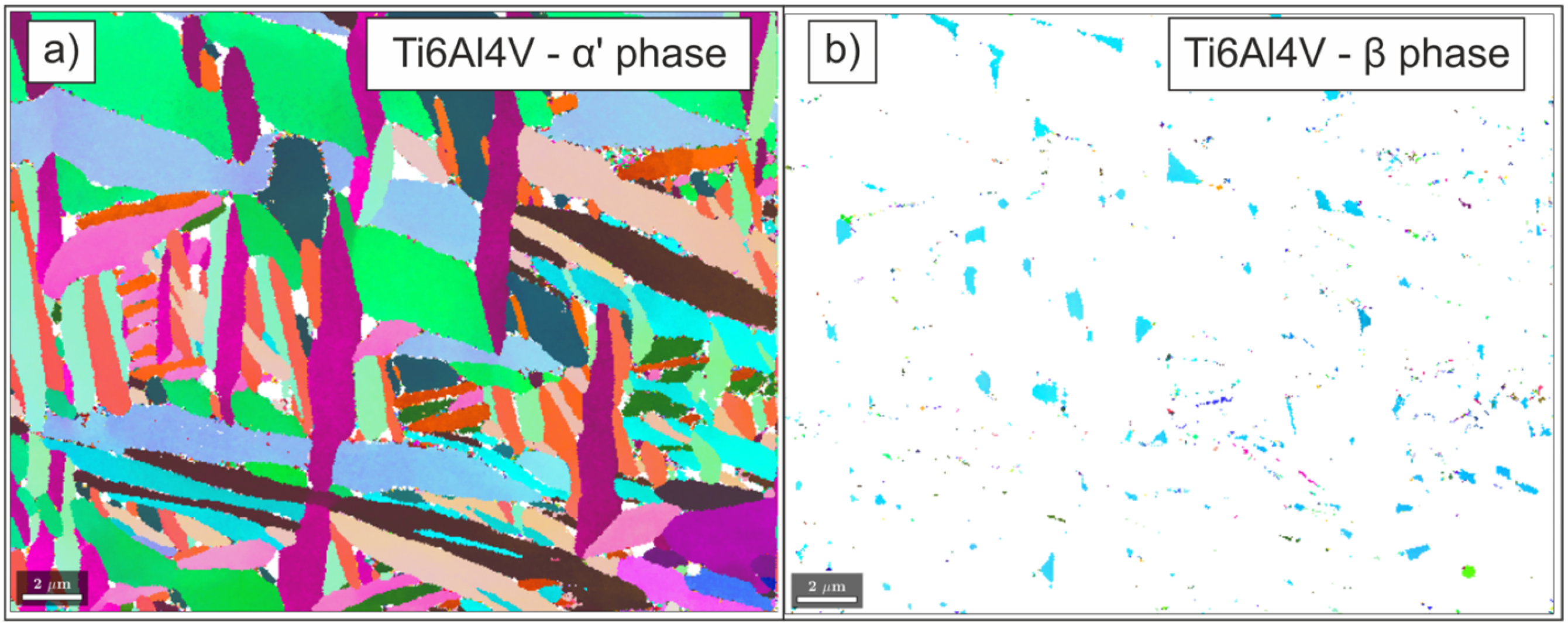

3.3. Grain Size and Orientation

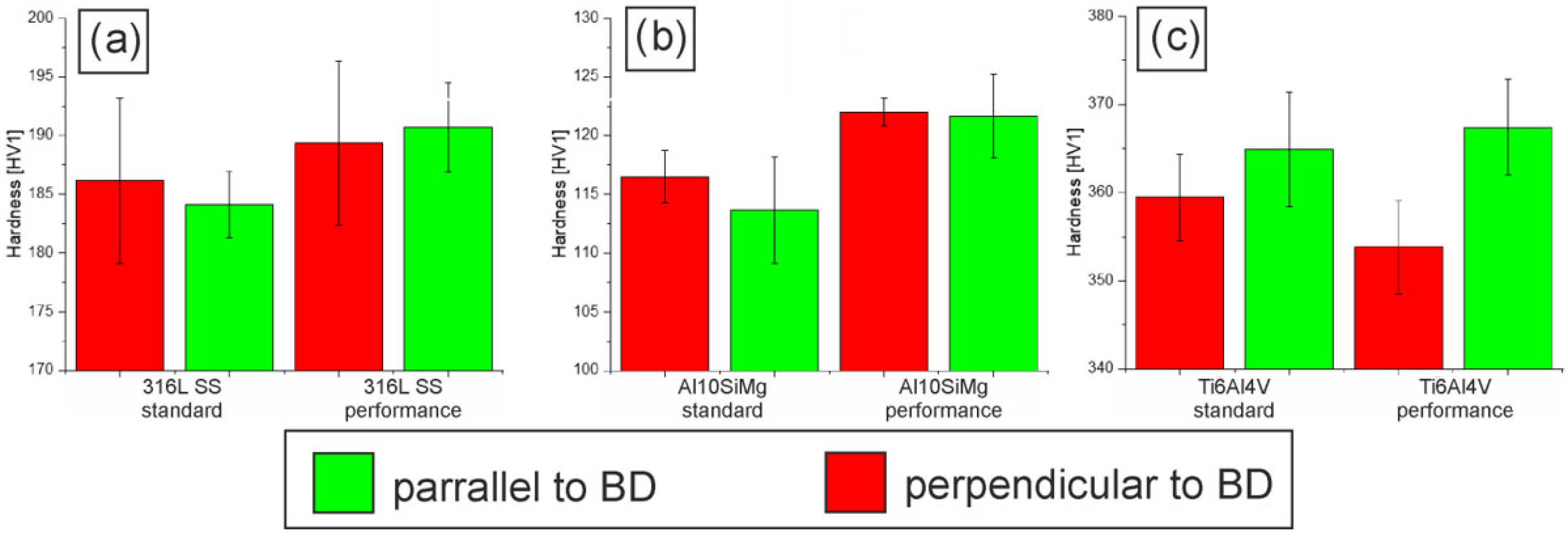

3.4. Hardness

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Caravella, I.; Cortis, D.; Angelo, L.; Orlandi, D. Experimental Data Collection of Surface Quality Analysis of CuCrZr Specimens Manufactured with SLM Technology: Analysis of the Effects of Process Parameters. Materials 2023, 16, 98. [Google Scholar] [CrossRef]

- Cobbinah, P.V.; Nzeukou, R.A.; Onawle, O.T.; Matizamhuka, W.R. Laser Powder Bed Fusion of Potential Superalloys: A Review. Metals 2021, 11, 58. [Google Scholar] [CrossRef]

- Gupta, A.; Bennett, C.H.J.; Sun, W. High cycle fatigue performance evaluation of a laser powder bed fusion manufactured Ti-6Al-4V bracket for aero-engine applications. Eng. Fail. Anal. 2022, 140, 106494. [Google Scholar] [CrossRef]

- Griffiths, V.; Scanlan, J.P.; Eres, M.H.; Martinez-Sykora, A.; Chinchapatnam, P. Cost-driven build orientation and bin packing of parts in Selective Laser Melting (SLM). Eur. J. Operat. Res. 2019, 273, 334–352. [Google Scholar] [CrossRef]

- NugrahA, A.D.; Supriyanto, E.; Prawara, B.; Martides, E.; Junianto, E.; Wibowo, A.; Sentanuhady, J.; Muflikhun, A.M. First-rate manufacturing process of primary air fan (PAF) coal power plant in Indonesia using laser powder bed fusion (LPBF) technology. J. Mater. Process. Technol. 2022, 18, 4075–4088. [Google Scholar] [CrossRef]

- Fernandes, R.F.; Jesus, J.; Borrego, L.; Ferreira, J.M.; Costa, J.D. Effect of heat treatment on fatigue crack growth performance of AlSi10Mg aluminum alloy submitted to LPBF. Procedia Struct. Integr. 2022, 42, 1054–1060. [Google Scholar] [CrossRef]

- Piller, F.; Poprawe, R.; Schleifenbaum, H.; Schuh, G.; Barg, S.; Dölle, C.; Hinke, C.; Jank, M.-H.; van Bracht, R.; Meiners, W.; et al. Introducing a Holistic Profitability Model for Additive Manufacturing: An Analysis of Laser-powder Bed Fusion. In Proceedings of the 2018 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bangkok, Thailand, 16–19 December 2018; pp. 1730–1735. [Google Scholar] [CrossRef]

- Tenbrock, C.; Fischer, F.; Wissenbach, K.; Schleifenbaum, J.; Wagenblast, P.; Meiners, W.; Wagner, J. Influence of Keyhole and Conduction Mode Melting for Top-Hat Shaped Beam Profiles in Laser Powder Bed Fusion. J. Mater. Process. Technol. 2019, 278, 116514. [Google Scholar] [CrossRef]

- Chowdhury, S.; Yadaiah, N.; Prakash, C.; Ramakrishna, S.; Dixit, S.; Gupta, L.R.; Buddhi, D. Laser powder bed fusion: A state-of-the-art review of the technology, materials, properties & defects, and numerical modelling. J. Mater. Res. Technol. 2022, 20, 2109–2172. [Google Scholar]

- Ghasemi, A.; Fereiduni, E.; Balbaa, M.; Elbestawi, M.; Habibi, S. Unraveling the low thermal conductivity of the LPBF fabricated pure Al, AlSi12, and AlSi10Mg alloys through substrate preheating. Addit. Manuf. 2022, 59, 103148. [Google Scholar] [CrossRef]

- Vaudreuil, S.; Bencaid, S.E.; Vanaei, H.R.; Magri, A.E. Effects of Power and Laser Speed on the Mechanical Properties of AlSi7Mg0.6 Manufactured by Laser Powder Bed Fusion. Materials 2022, 15, 8640. [Google Scholar] [CrossRef]

- Cabrini, M.; Carrozza, A.; Lorenzi, S.; Pastore, T.; Testa, C.; Manfredi, D.; Fino, P.; Scenini, F. Influence of surface finishing and heat treatments on the corrosion resistance of LPBF-produced Ti-6Al-4V alloy for biomedical applications. J. Mater. Process. Technol. 2022, 308, 117730. [Google Scholar] [CrossRef]

- Ghosh, A.; Biswas, S.; Turner, T.; Kietzig, A.M.; Brochu, M. Surface, microstructure, and tensile deformation characterization of LPBF SS316L microstruts micromachined with femtosecond laser. Mater. Des. 2021, 210, 110045. [Google Scholar] [CrossRef]

- Chen, H.; Sun, Y.; Yuan, W.; Pang, S.; Yan, W.; Shi, Y. A Review on Discrete Element Method Simulation in Laser Powder Bed Fusion Additive Manufacturing. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100017. [Google Scholar] [CrossRef]

- Zhao, R.; Shmatok, A.; Fischer, R.; Deng, P.; Belhadi, M.A.; Hamasha, S.; Prorok, B.C. Employing spatial and amplitude discriminators to partition and analyze LPBF surface features. Precis. Eng. 2022, 78, 90–101. [Google Scholar] [CrossRef]

- Polyanska, A.; Savchuk, S.; Dudek, M.; Sala, D.; Pazynich, Y.; Cicho, D. Impact of digital maturity on sustainable development effects in energy sector in the condition of Industry 4.0. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2022, 6, 97–103. [Google Scholar] [CrossRef]

- Riener, K.; Albrecht, N.; Ziegelmeier, S.; Ramakrishnan, R.; Haferkamp, L.; Spierings, A.D.; Leichtfried, G.J. Influence of particle size distribution and morphology on the properties of the powder feedstock as well as of AlSi10Mg parts produced by laser powder bed fusion (LPBF). Addit. Manuf. 2020, 34, 101286. [Google Scholar] [CrossRef]

- Ponticelli, G.S.; Panciroli, R.; Venettacci, S.; Tagliaferri, F.; Guarino, S. Experimental investigation on the fatigue behavior of laser powder bed fused 316L stainless steel. CIRP J. Manuf. Sci. Technol. 2022, 38, 787–800. [Google Scholar] [CrossRef]

- Cacace, S.; Demir, A.G.; Sala, G.; Grande, A.M. Influence of production batch related parameters on static and fatigue resistance of LPBF produced AlSi7Mg0.6. Int. J. Fatigue 2022, 165, 107227. [Google Scholar] [CrossRef]

- Kan, W.H.; Chiu, L.N.S.; Lim, C.V.S.; Zhu, Y.; Tian, Y.; Jiang, D.; Huang, A. A critical review on the effects of process-induced porosity on the mechanical properties of alloys fabricated by laser powder bed fusion. J. Mater. Sci. 2022, 57, 9818–9865. [Google Scholar] [CrossRef]

- Du Plessis, A.; Beretta, S. Killer notches: The effect of as-built surface roughness on fatigue failure in AlSi10Mg produced by laser powder bed fusion. Addit. Manuf. 2020, 35, 101424. [Google Scholar] [CrossRef]

- Dong, Z.; Jia, S.; Shao, C. Filtered kriging for improved interpolation of periodic manufacturing surfaces. J. Manuf. Process. 2024, 131, 1–12. [Google Scholar] [CrossRef]

- Nikolsky, V.; Kuzyayev Tikhaya, L.; Howaniec, N.; Bak, A.; Siudyga, T.; Jura, B.; Cabana, E.; Szymanek, A.; Smoliński, A. A Study of Heat Exchange Processes within the Channels of Disk Pulse Devices. Energies 2020, 13, 3492. [Google Scholar] [CrossRef]

- Weiss, C.H.; Heslenfeld, J.; Saewe, J.K.; Bremen, S.; Häfner, C.L. Investigation on the influence of powder humidity in Laser Powder Bed Fusion (LPBF). Procedia CIRP 2022, 111, 115–120. [Google Scholar] [CrossRef]

- Yeganeh, M.; Shahryari, Z.; Talib Khanjar, A.; Hajizadeh, Z.; Shabani, F. Inclusions and Segregations in the Selective Laser-Melted Alloys: A Review. Coatings 2023, 13, 1295. [Google Scholar] [CrossRef]

- Khaimovich, A.; Erisov, Y.; Smelov, V.; Agapovichev, A.; Petrov, I.; Razhivin, V.; Bobrovskij, I.; Kokareva, V.; Kuzin, A. Interface Quality Indices of Al–10Si–Mg Aluminum Alloy and Cr18–Ni10–Ti Stainless-Steel Bimetal Fabricated via Selective Laser Melting. Metals 2021, 11, 172. [Google Scholar] [CrossRef]

- Calderón, L.A.Á.; Rehmer, B.; Schriever, S.; Ulbricht, A.; Jácome, L.A.; Sommer, K.; Mohr, G.; Skrotzki, B.; Evans, A. Creep and creep damage behavior of stainless steel 316L manufactured by laser powder bed fusion. Mater. Sci. Eng. A 2022, 830, 142223. [Google Scholar] [CrossRef]

- Vaglio, E.; Monte, T.; Lanzutti, A.; Totis, G.; Sortino, M.; Fedrizzi, L. Single tracks data obtained by selective laser melting of Ti6Al4V with a small laser spot diameter. Date Brief 2020, 33, 106443. [Google Scholar] [CrossRef]

- CadExpert AlSi10Mg Data Sheet. EOS GmbH—Electro Optical Systems. Available online: https://cadxpert.pl/wp-content/uploads/2022/02/DMLS-Aluminium-AlSi10Mg.pdf (accessed on 19 March 2023).

- CadExpert 316L Data Sheet. EOS GmbH—Electro Optical Systems. Available online: https://cadxpert.pl/wp-content/uploads/2022/02/DMLS-StainlessSteel-316L.pdf (accessed on 19 March 2023).

- CadExpert Ti64 Data Sheet. EOS GmbH—Electro Optical Systems. Available online: https://cadxpert.pl/wp-content/uploads/2022/02/DMLS-Tytan-Ti64.pdf (accessed on 19 March 2023).

- Bachmann, F.; Hielscher, R.; Schaeben, H. Texture Analysis with MTEX—Free and Open Source Software Toolbox. Solid State Phenom. 2010, 160, 63–68. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, R.; Liu, Y.; Zhang, L. Understanding melt pool characteristics in laser powder bed fusion: An overview of single- and multi-track melt pools for process optimization. Adv. Powder Mater. 2023, 2, 100137. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef]

- La Fé-Perdomo, I.; Ramos-Grez, J.; Mujica, R.; Rivas, M. Surface roughness a prediction in Selective Laser Melting of 316L stainless steel by means of artificial intelligence inference. J. King Saud Univ.—Eng. Sci. 2023, 35, 148–156. [Google Scholar] [CrossRef]

- Teich, H.; Maucher, C.; Möhring, H.-C. Influence of LPBF Parameters and Strategies on Fine Machining of Pre-Built Bores. J. Mach. Eng. 2021, 21, 91–101. [Google Scholar] [CrossRef]

- Deng, P.; Karadge, M.; Rebak, R.B.; Gupta, V.K.; Prorok, B.C.; Lou, X. The origin and formation of oxygen inclusions in austenitic stainless steels manufactured by laser powder bed fusion. Addit. Manuf. 2020, 35, 101334. [Google Scholar] [CrossRef]

- Liu, L.; Ding, Q.; Zhong, Y.; Zou, J.; Wu, J.; Chiu, Y.-L.; Li, J.; Zhang, Z.; Yu, Q.; Shen, Z. Dislocation network in additive manufactured steel breaks strength–ductility trade-off. Mater. Today 2018, 21, 354–361. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.Q.; Wang, W.; Attallah, M.M.; Loretto, M.H. Microstructure and strength of selectively laser melted AlSi10Mg. Acta Mater. 2016, 117, 311–320. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Lorusso, M.; Pakkanen, J.; Aversa, A.; Ambrosio, E.P.; Lombardi, M.; Fino, P.; Manfredi, D. On the Selective Laser Melting (SLM) of the AlSi10Mg Alloy: Process, Microstructure, and Mechanical Properties. Materials 2017, 10, 76. [Google Scholar] [CrossRef]

- Rani, S.U.; Kesavan, D.; Kamaraj, M. Evaluation of influence of microstructural features of LPBF Ti-6Al-4 V on mechanical properties for an optimal strength and ductility. J. Alloys Compd. 2023, 960, 170575. [Google Scholar] [CrossRef]

- Xie, Z.; Dai, Y.; Ou, X.; Ni, S.; Song, M. Effects of selective laser melting build orientations on the microstructure and tensile performance of Ti–6Al–4V alloy. Mater. Sci. Eng. A 2020, 776, 139001. [Google Scholar] [CrossRef]

- Murr, L.E.; Quinones, S.A.; Gaytan, S.M.; Lopez, M.I.; Rodela, A.; Martinez, E.Y.; Hernandez, D.H.; Martinez, E.; Medina, F.; Wicker, R.B. Microstructure and mechanical behavior of Ti–6Al–4V produced by rapid-layer manufacturing, for biomedical applications. J. Mech. Behav. Biomed. Mater. 2009, 2, 20–32. [Google Scholar] [CrossRef]

- Huang, G.; Wei, K.; Deng, J.; Liu, M.; Zeng, X. High-power laser powder bed fusion of 316L stainless steel: Defects, microstructure, and mechanical properties. J. Manuf. Process. 2022, 83, 235–245. [Google Scholar] [CrossRef]

- Dinda, G.P.; Dasgupta, A.K.; Mazumder, J. Texture control during laser deposition of nickel-based superalloy. Scr. Mater. 2012, 67, 503–506. [Google Scholar] [CrossRef]

- Sofinowski, K.A.; Raman, S.; Wang, X.; Gaskey, B.; Seita, M. Layer-wise engineering of grain orientation (LEGO) in laser powder bed fusion of stainless steel 316L. Addit. Manuf. 2021, 38, 101809. [Google Scholar] [CrossRef]

- Liu, M.; Wei, K.; Zeng, X. High power laser powder bed fusion of AlSi10Mg alloy: Effect of layer thickness on defect, microstructure and mechanical property. Mater. Sci. Eng. A 2022, 842, 143107. [Google Scholar] [CrossRef]

- Ma, R.; Peng, C.; Cai, Z.; Wang, R.; Zhou, Z.; Li, X.; Cao, X. Effect of bimodal microstructure on the tensile properties of selective laser melt Al-Mg-Sc-Zr alloy. J. Alloys Compd. 2020, 815, 152422. [Google Scholar] [CrossRef]

- Li, C.-L.; Woo, S.C.; Oh, J.M.; Hong, J.; Yeom, J.-T.; Kang, J.-H.; Mei, Q.-S.; Park, C.H. Bimodal grain structures and tensile properties of a biomedical Co–20Cr–15W–10Ni alloy with different pre-strains. Rare Met. 2021, 40, 20–30. [Google Scholar] [CrossRef]

- Flipon, B.; Keller, C.; Garcia de la Cruz, L.; Hug, E.; Barbe, F. Tensile properties of spark plasma sintered AISI 316L stainless steel with unimodal and bimodal grain size distributions. Mater. Sci. Eng. A 2018, 729, 249–256. [Google Scholar] [CrossRef]

- Cepeda-Jiménez, C.M.; Potenza, F.; Magalini, E.; Luchin, V.; Molinari, A. Pérez-Prado M.T., Effect of energy density on the microstructure and texture evolution of Ti-6Al-4V manufactured by laser powder bed fusion. Mater. Charact. 2020, 163, 110238. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, L.; Zhang, H.; Maldar, A.; Zhu, G.; Chen, W.; Park, J.-S.; Wang, J.; Zeng, X. Effect of heat treatment on the tensile behavior of selective laser melted Ti-6Al-4V by in situ X-ray characterization. Acta Mater. 2020, 189, 93–104. [Google Scholar] [CrossRef]

- Cao, S.; Zou, T.; Lim, C.V.S.; Wu, X. Review of laser powder bed fusion (LPBF) fabricated Ti-6Al-4V: Process, post-process treatment, microstructure, and property. Adv. Manuf. 2021, 20, 313–332. [Google Scholar] [CrossRef]

- Smith, T.R.; Sugar, J.D.; Marchi, C.S.; Schoenung, J.M. Strengthening mechanisms in directed energy deposited austenitic stainless steel. Acta Mater. 2019, 164, 728–740. [Google Scholar] [CrossRef]

- Cheng, H.; Lin, Y.C.; He, D.-G.; Qiu, D.-G.; Zhu, J.C.; Chen, M.-S. Influences of stress-aging on the precipitation behavior of δ phase (Ni3Nb) in a nickel-based superalloy. Mater. Des. 2021, 197, 109256. [Google Scholar] [CrossRef]

- Pyzalski, M.; Bialoskórski, J.; Walasek, E. Reaction between Carbon Fibres and Molten Silicon: Heat Determination Using DTA. J. Therm. Anal. 1986, 31, 1247–1254. [Google Scholar] [CrossRef]

- Tucho, W.M.; Lysne, V.H.; Austbø, H.; Sjolyst-Kverneland, A.; Hansen, V. Investigation of effects of process parameters on microstructure and hardness of SLM manufactured SS316L. J. Alloys Compd. 2018, 740, 910–925. [Google Scholar] [CrossRef]

- Serjouei, A.; Libura, T.; Brodecki, A.; Radziejewska, J.; Broniszewska, P.; Pawłowski, P.; Szymczak, T.; Bodaghi, M.; Kowalewski, Z.L. Strength-hardness relationship for AlSi10Mg alloy produced by laser powder bed fusion: An experimental study. Mater. Sci. Eng. A 2022, 861, 144345. [Google Scholar] [CrossRef]

- Ferraris, S. Porous Titanium by Additive Manufacturing: A Focus on Surface Modification for Bone-Contact Applications. Metals 2021, 11, 1343. [Google Scholar] [CrossRef]

- Seex, K.A.; Finlayson, K.; Davies, R.; Mobbs, R.J. Clinical Outcomes of 3D-Printed Titanium Patient-Specific Interbody Cages: A Prospective Case Series of 30 Patients. J. Pers. Med. 2025, 15, 320. [Google Scholar] [CrossRef]

- Hijazi, K.M.; Alnaser, A.A.; Rasheed, R.A. Titanium Alloy Implants with Lattice Structures for Mandibular Reconstruction: A Review. Materials 2023, 17, 140. [Google Scholar] [CrossRef]

- Hudák, R.; Živčák, J.; Rendošová, J.; Harničárová, M.; Dovica, M.; Varga, J.; Kováčiková, L. Additive Manufacturing of Porous Ti6Al4V Alloy for Biomedical Applications. Appl. Sci. 2021, 11, 2611. [Google Scholar] [CrossRef]

- Koju, N.; Niraula, S. Additively Manufactured Porous Ti6Al4V for Bone Implants: A Review. Metals 2022, 12, 687. [Google Scholar] [CrossRef]

- Olmos, L.; González-Pedraza, A.S.; Vergara-Hernández, H.J.; Bouvard, D.; López-Cornejo, M.S.; Servín-Castañeda, R. Development of Tailored Porous Ti6Al4V Materials by Extrusion 3D Printing. Materials 2025, 18, 389. [Google Scholar] [CrossRef]

- Joshua, R.J.N.; Vignesh, V.; Sundar, R.S.; Suresh, S.; Narmatha, M.; Arunkumar, S. Powder Bed Fusion 3D Printing in Precision Manufacturing: A Comprehensive Review. Materials 2024, 17, 769. [Google Scholar] [CrossRef]

- Wehmöller, M.; Weihe, S.; Rasche, C.; Scherer, P.; Eufinger, H. CAD/CAM-Prefabricated Titanium Implants for Large Skull Defects—Clinical Experience with 166 Patients from 1994 to 2000. Int. Congr. Ser. 2004, 1268, 667–672. [Google Scholar] [CrossRef]

- Li, J.; Chen, M.; Fan, X.; Zhou, H. Porous Titanium Scaffolds Fabricated by Additive Manufacturing: A Review. Mater. Sci. Eng. C 2015, 48, 592–605. [Google Scholar] [CrossRef]

- Zadpoor, A.A. Mechanical Performance of Additively Manufactured Meta-Biomaterials. Acta Biomater. 2019, 85, 41–59. [Google Scholar] [CrossRef] [PubMed]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive Manufacturing of Metals. Prog. Mater. Sci. 2016, 92, 112–224. [Google Scholar] [CrossRef]

- Li, P.; Lu, L.; Meng, Q.; Wang, L.; Ma, Q.; Yang, L. Comparison of Lattice Structures Fabricated by L-PBF and E-PBF for Cranial Implant Applications. Mater. Des. 2022, 217, 110653. [Google Scholar] [CrossRef]

- US Food and Drug Administration. Technical Considerations for Additive Manufactured Medical Devices. In Guidance for Industry and Food and Drug Administration Staff; FDA: Silver Spring, MD, USA, 2017. Available online: https://www.fda.gov/media/97633/download (accessed on 8 September 2025).

- Bobyn, J.D.; Pilliar, R.M.; Cameron, H.U.; Weatherly, G.C. The Optimum Pore Size for the Fixation of Porous-Surfaced Metal Implants by the Ingrowth of Bone. Clin. Orthop. Relat. Res. 1980, 150, 263–270. [Google Scholar] [CrossRef]

| 316L—S | 316L—P | Al10SiMg—S | Al10SiMg—P | Ti6Al4V—S | Ti6Al4V—P | |

|---|---|---|---|---|---|---|

| VR [mm3/s] | 2.0 | 1.6 | 7.2 | 6.4 | 5 | 3.3 |

| VED [J/mm3] | ~65 | ~80 | ~55 | ~62 | ~80 | ~120 |

| Layer thickness [µm] | 20 | 20 | 40 | 40 | 40 | 40 |

| Chemical Composition | Al (Balance) [wt-%] |

|---|---|

| Si | 9.0–11.0 |

| Fe | ≤0.55 |

| Cu | ≤0.05 |

| Mn | ≤0.45 |

| Mg | 0.2–0.45 |

| Ni | ≤0.05 |

| Zn | ≤0.10 |

| Pb | ≤0.05 |

| Sn | ≤0.05 |

| Ti | ≤0.15 |

| Chemical Composition | Fe (Balance) [wt-%] |

|---|---|

| Cr | 17.00–19.00 |

| Ni | 13.00–15.00 |

| Mo | 2.25–3.00 |

| C | ≤0.03 |

| Mn | ≤2.00 |

| Cu | ≤0.50 |

| P | ≤0.025 |

| S | ≤0.010 |

| Si | ≤0.75 |

| N | ≤0.10 |

| Chemical Composition | Ti (Balance) [wt-%] |

|---|---|

| Al | 5.50–6.50 |

| V | 3.50–4.50 |

| O | ≤0.150 |

| N | ≤0.040 |

| C | ≤0.080 |

| H | ≤0.012 |

| Fe | ≤0.250 |

| Y | ≤0.005 |

| Other, each | ≤0.10 |

| Other, total | ≤0.40 |

| 316L—S | 316L—P | Al10SiMg—S | Al10SiMg—P | Ti6Al4V—S | Ti6Al4V—P | ||

|---|---|---|---|---|---|---|---|

| Mean ECD [µm] | 23.5 ± 19 | 18 ± 16 | 9.3 ± 6.8 | 8.7 ± 6.6 | α’ Lath Width [µm] | 1.0 ± 0.4 | 1.4 ± 0.5 |

| ECD Primary β-phase [µm] | 63 ± 47 | 66 ± 63 | |||||

| SF | 3.1 ± 1.6 | 3.1 ± 1.8 | 2.3 ± 1.3 | 1.5 ± 0.9 | SF Primary β-phase | 2.1 ± 0.8 | 2.2 ± 1.0 |

| Maximum texture coefficient | 2.8 | 3.2 | 2.0 | 2.6 | 5.4 | 7.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sala, D.; Ledwig, P.; Pasiowiec, H.; Cichocki, K.; Jasiołek, M.; Libura, M.; Pyzalski, M. The Role of Process Parameters in Shaping the Microstructure and Porosity of Metallic Components Manufactured by Additive Technology. Appl. Sci. 2025, 15, 11624. https://doi.org/10.3390/app152111624

Sala D, Ledwig P, Pasiowiec H, Cichocki K, Jasiołek M, Libura M, Pyzalski M. The Role of Process Parameters in Shaping the Microstructure and Porosity of Metallic Components Manufactured by Additive Technology. Applied Sciences. 2025; 15(21):11624. https://doi.org/10.3390/app152111624

Chicago/Turabian StyleSala, Dariusz, Piotr Ledwig, Hubert Pasiowiec, Kamil Cichocki, Magdalena Jasiołek, Marek Libura, and Michał Pyzalski. 2025. "The Role of Process Parameters in Shaping the Microstructure and Porosity of Metallic Components Manufactured by Additive Technology" Applied Sciences 15, no. 21: 11624. https://doi.org/10.3390/app152111624

APA StyleSala, D., Ledwig, P., Pasiowiec, H., Cichocki, K., Jasiołek, M., Libura, M., & Pyzalski, M. (2025). The Role of Process Parameters in Shaping the Microstructure and Porosity of Metallic Components Manufactured by Additive Technology. Applied Sciences, 15(21), 11624. https://doi.org/10.3390/app152111624