Ground Pressure Control Measures and Microseismic Verification During the Recovery Process of Residual Ore Bodies

Abstract

1. Introduction

2. Engineering Background

2.1. Mine Overview

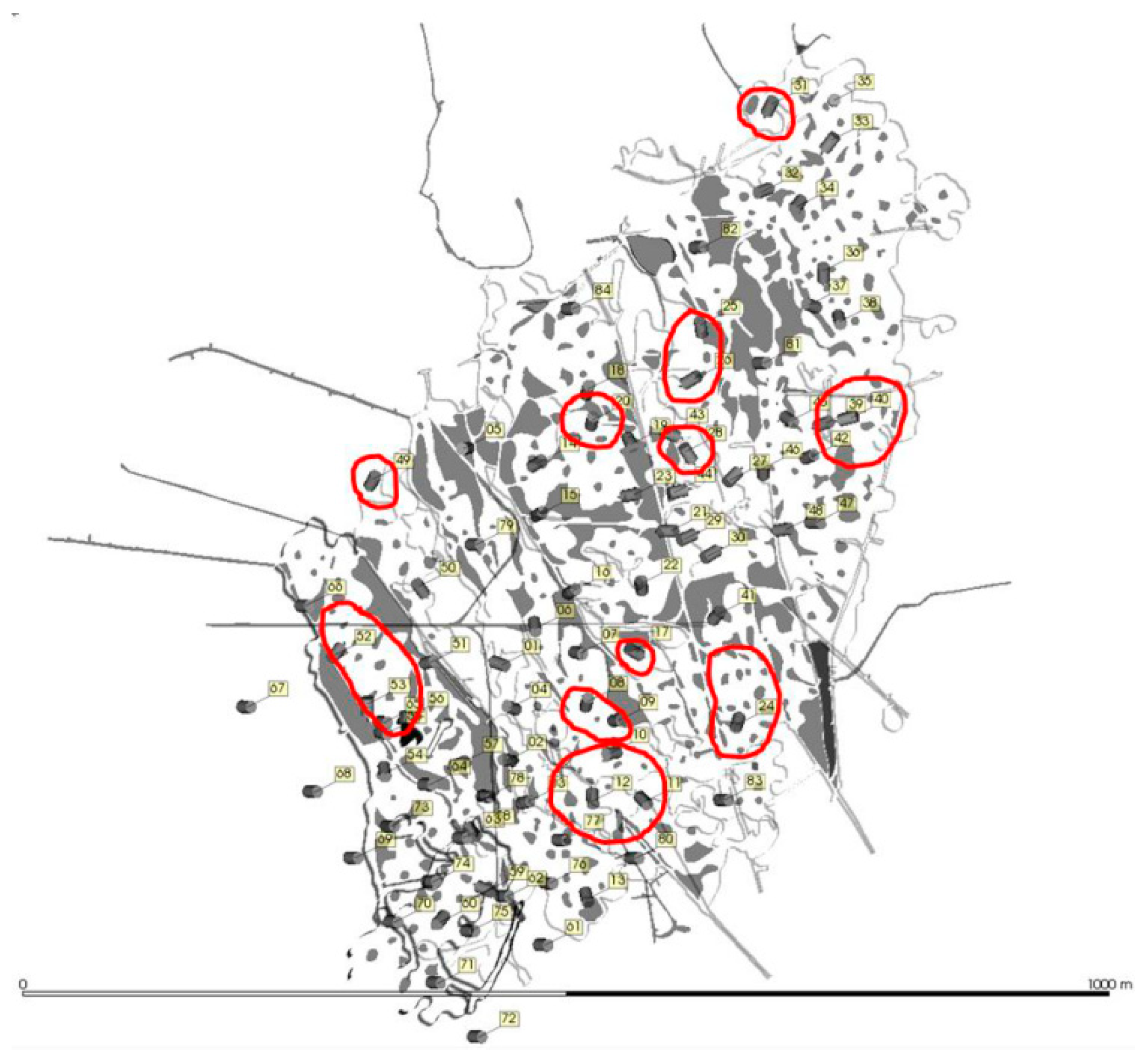

2.2. Residual Mining Situation

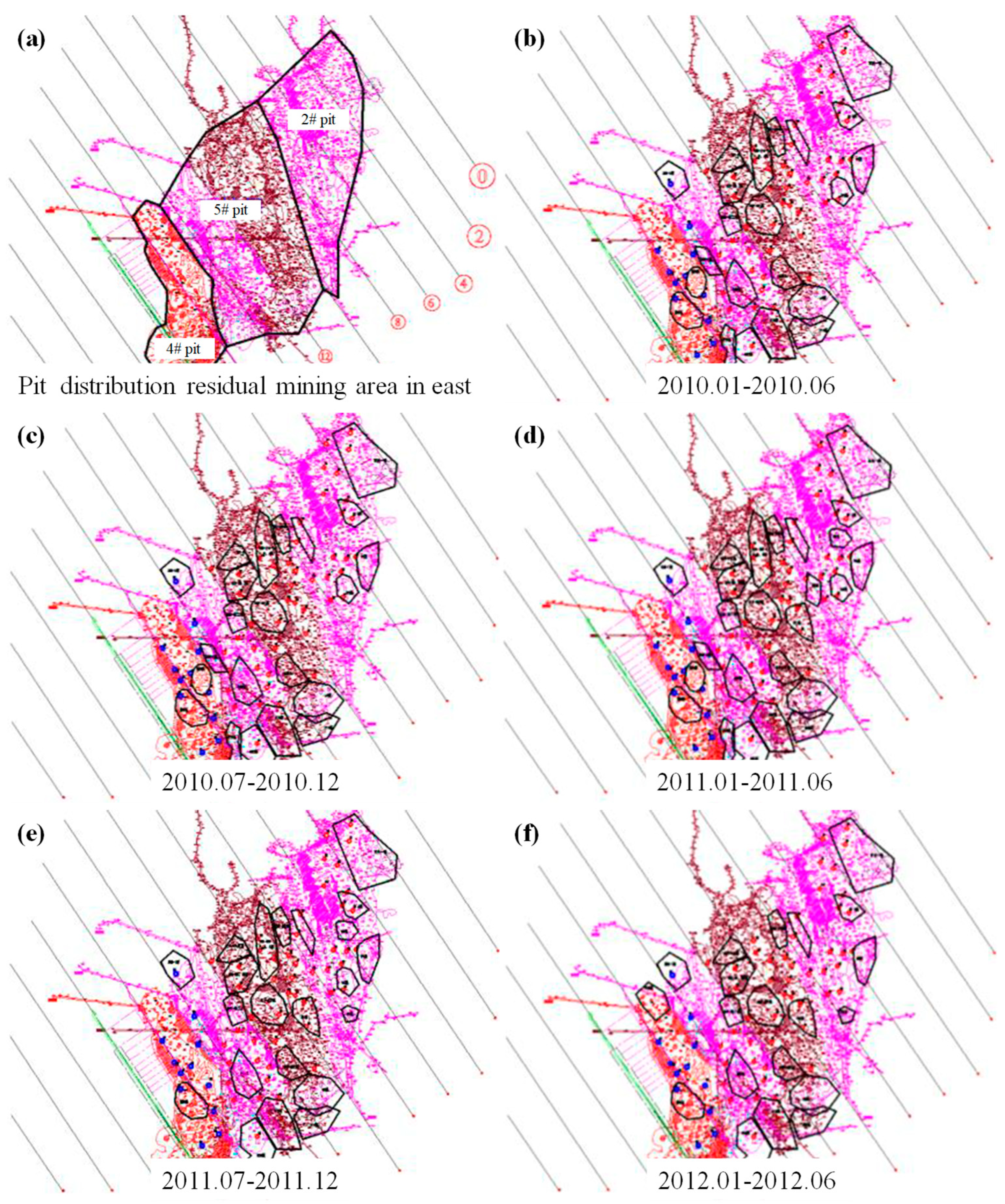

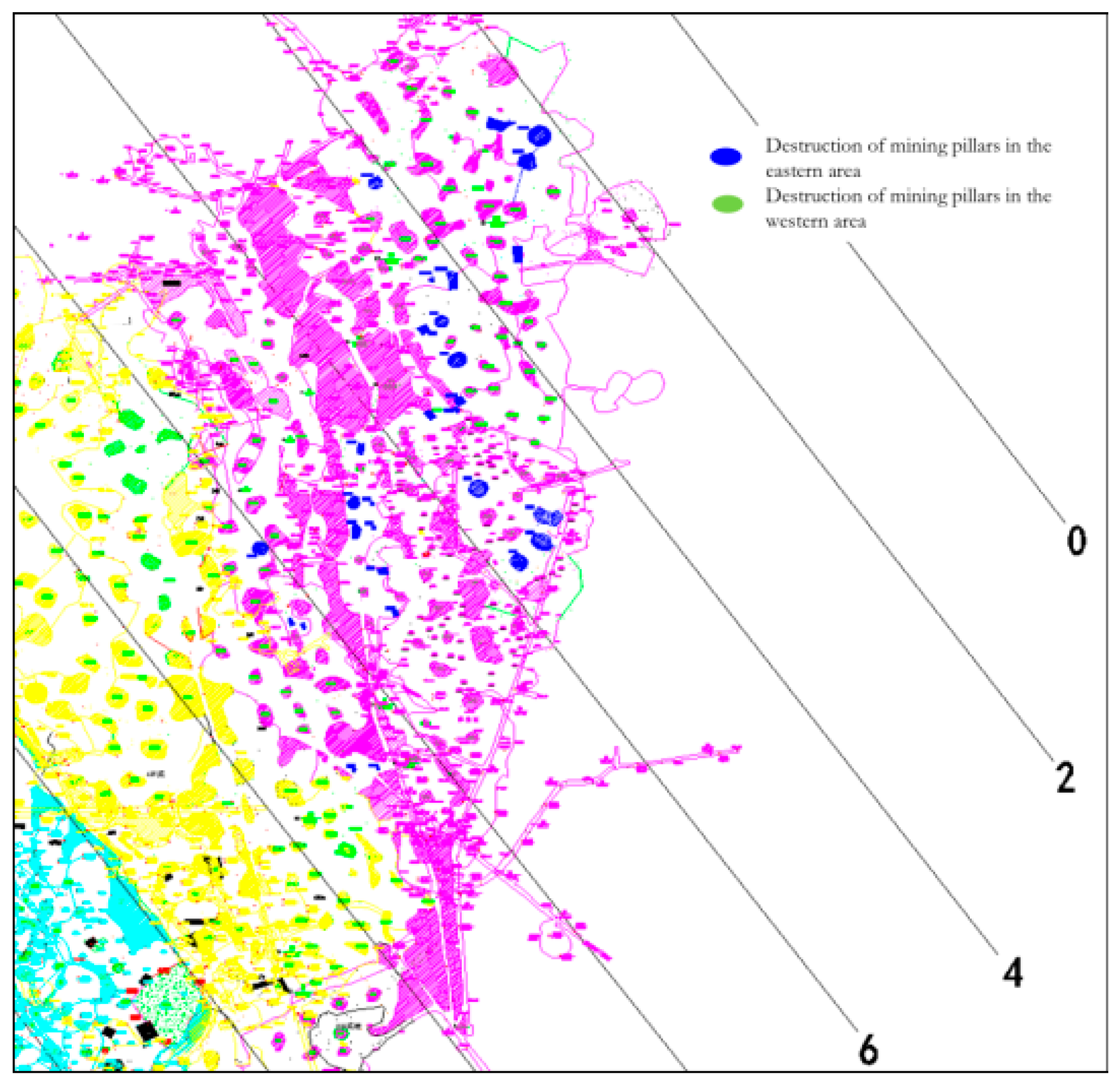

2.2.1. Residual Mining Situation in the Eastern Region

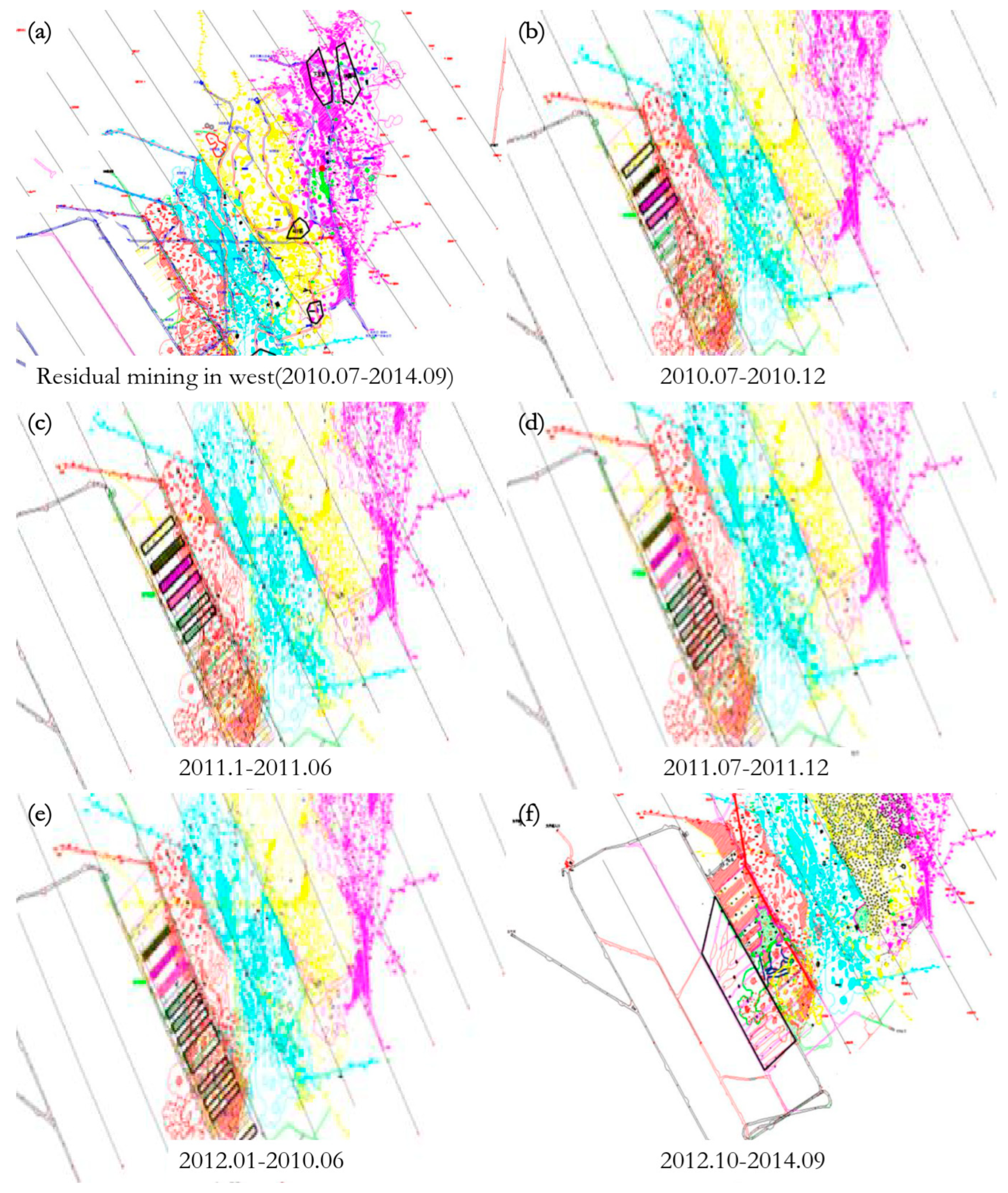

2.2.2. Western Residual Mining Situation

2.2.3. Trend of Changes in Extracted Ore Volume

2.3. Micro-Seismic Monitoring System

2.3.1. System Configuration and Sensor Layout

2.3.2. Data Collection and Processing Parameters

2.3.3. System Operation and Data Validation

3. Governance Techniques for Ground Pressure Disasters

3.1. Preparation Before Filling

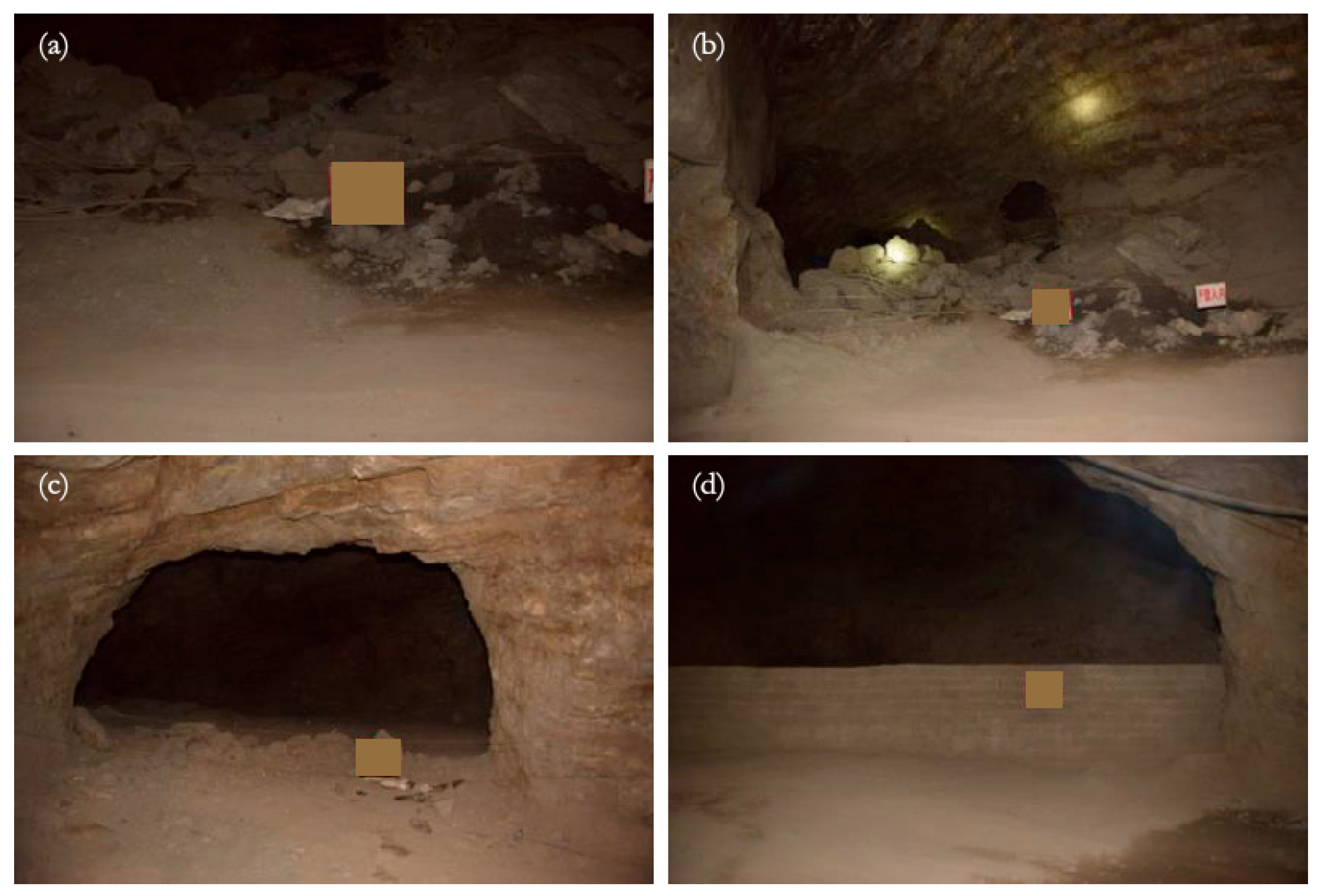

3.1.1. Ground Pressure and Ground Pressure Management Situation

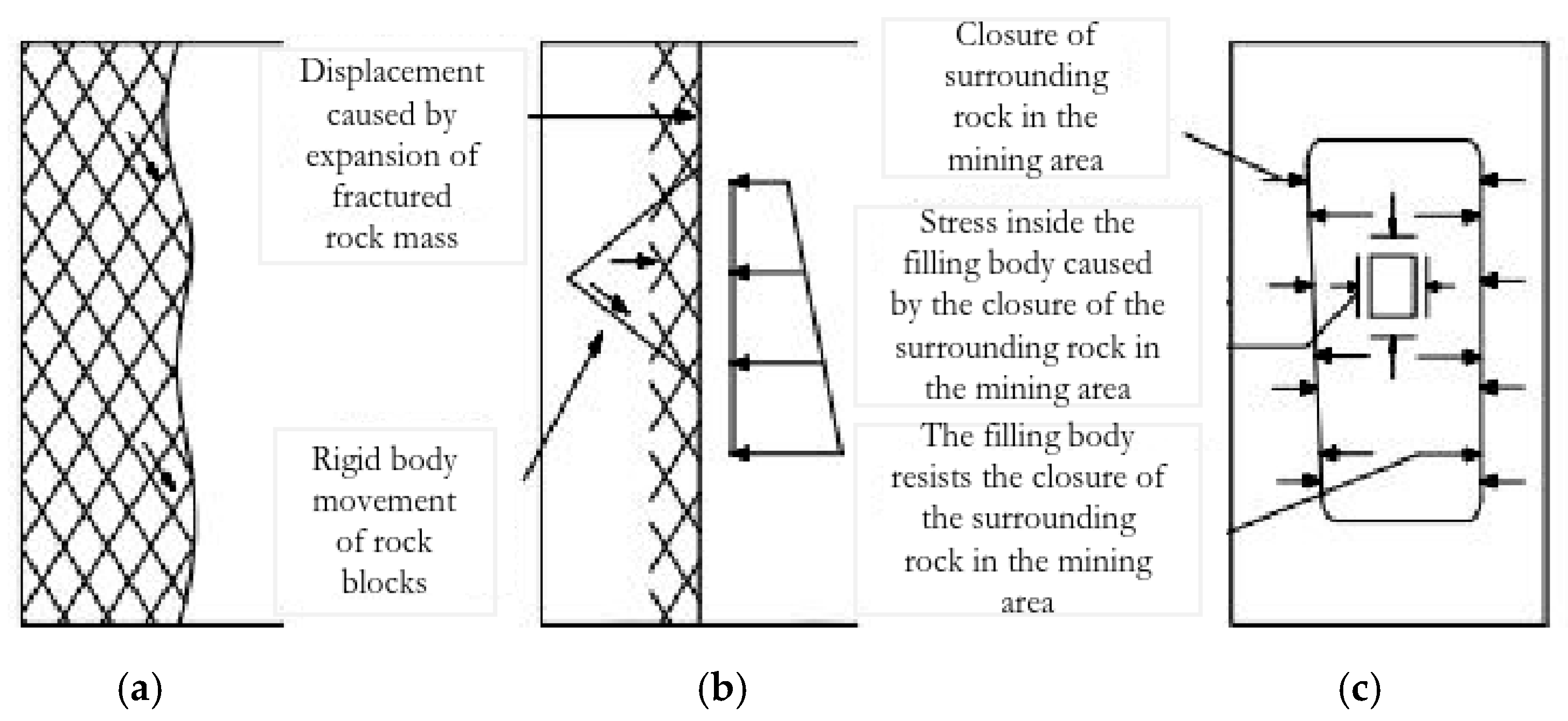

3.1.2. Description of Filling Function and Mechanism

3.1.3. Define Hazardous Areas

3.2. Filling Process

3.2.1. Filling Measures

3.2.2. Filling Results

3.3. Auxiliary Filling Measures

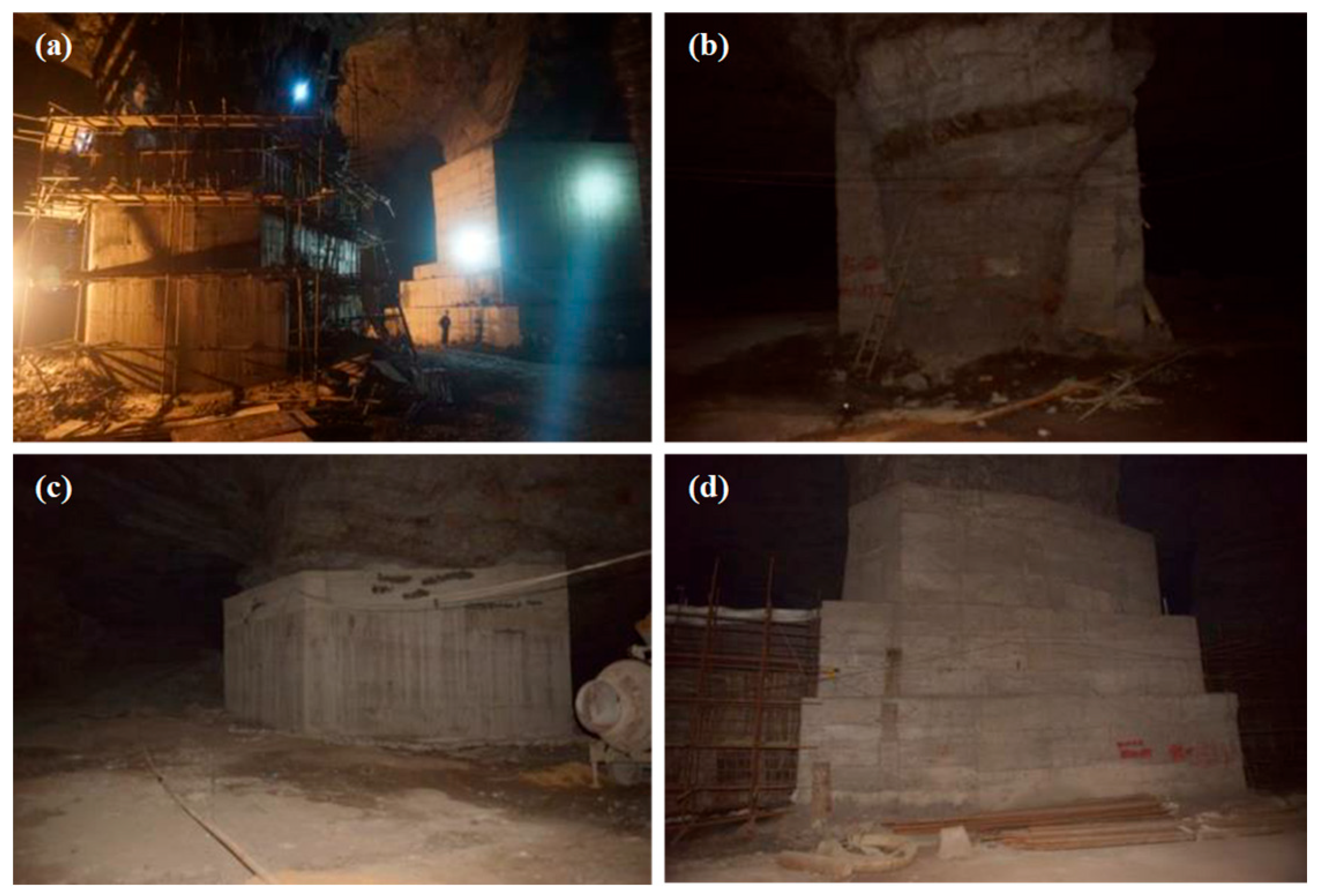

3.3.1. Reinforcement of Mining Pillars

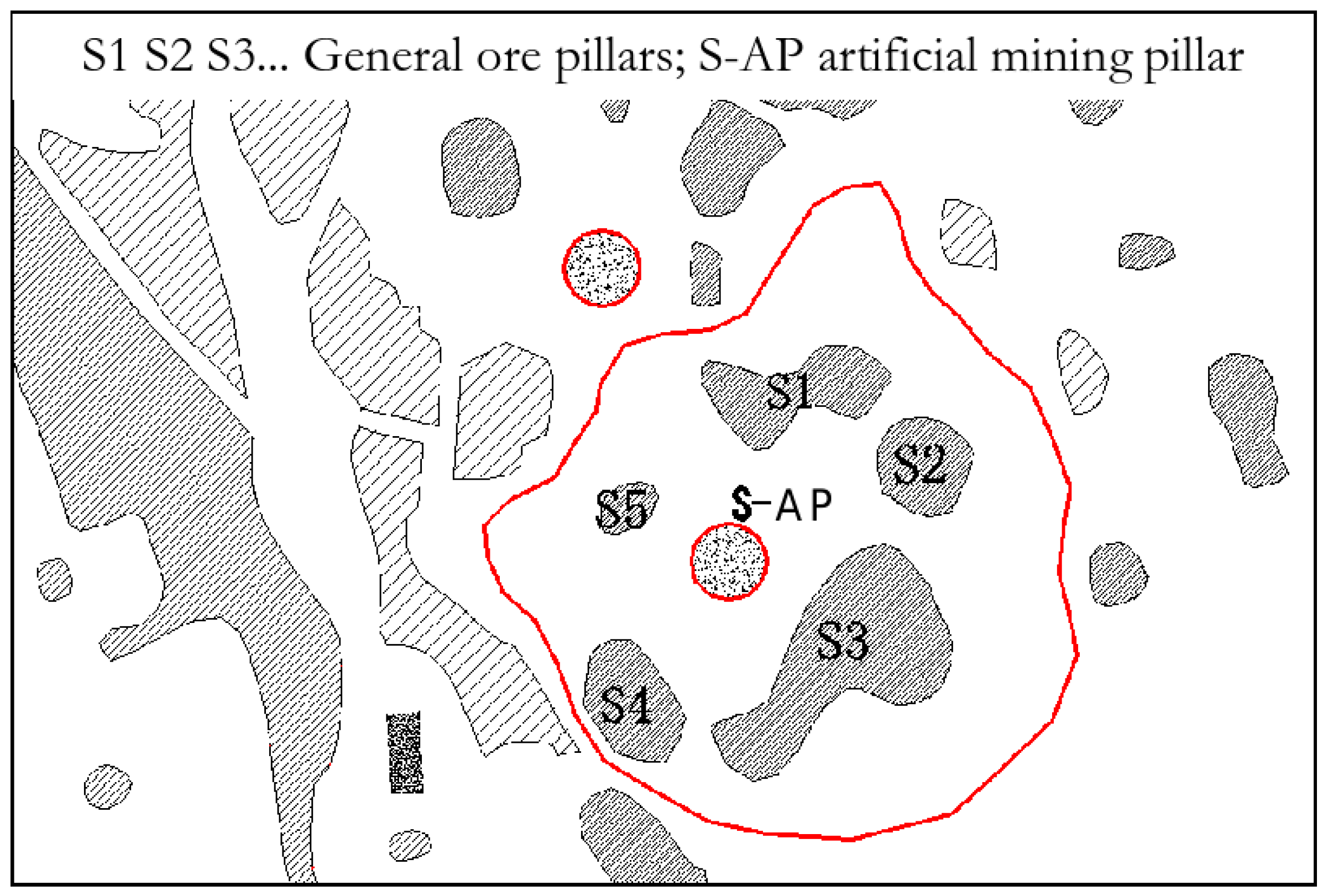

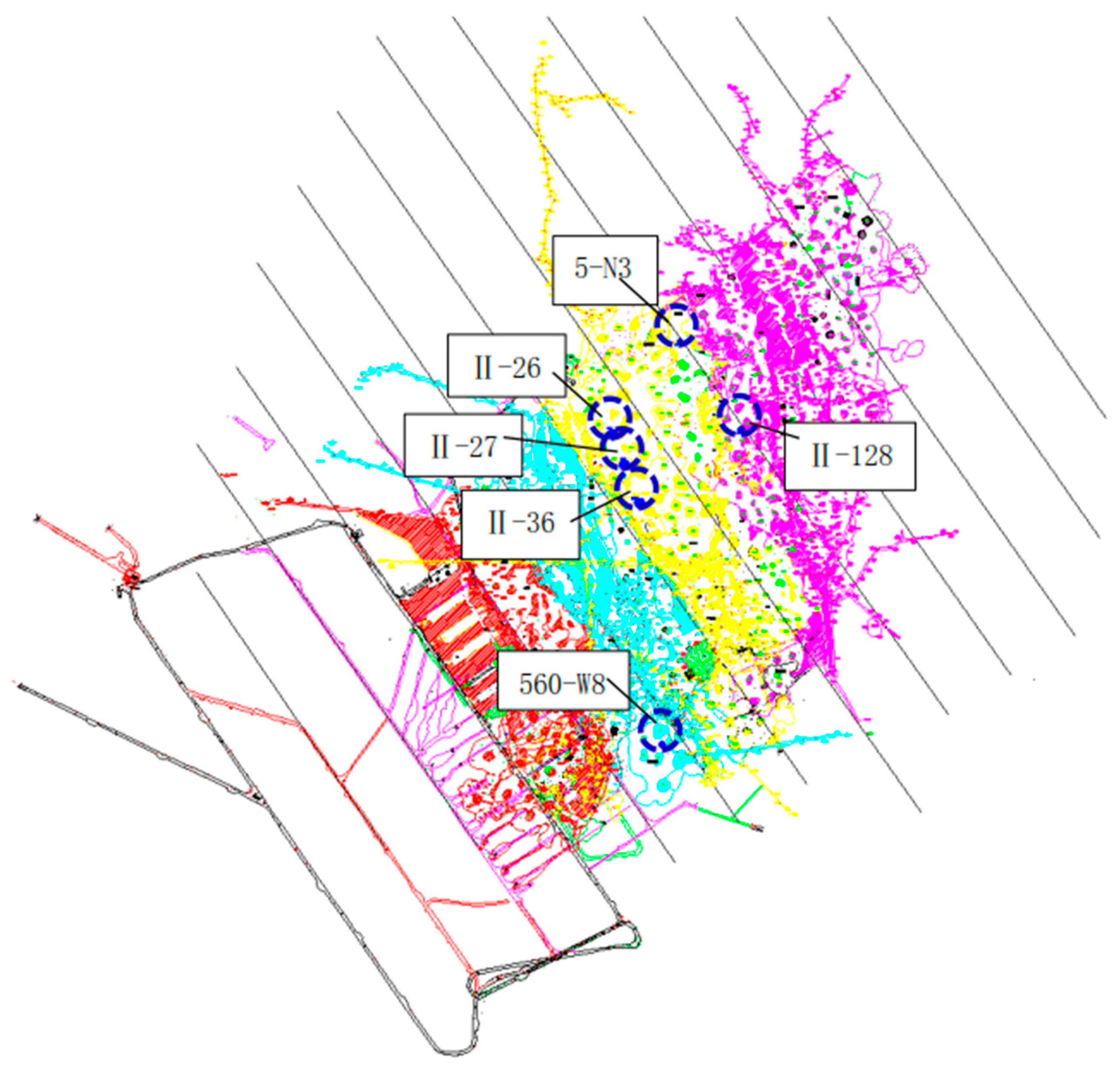

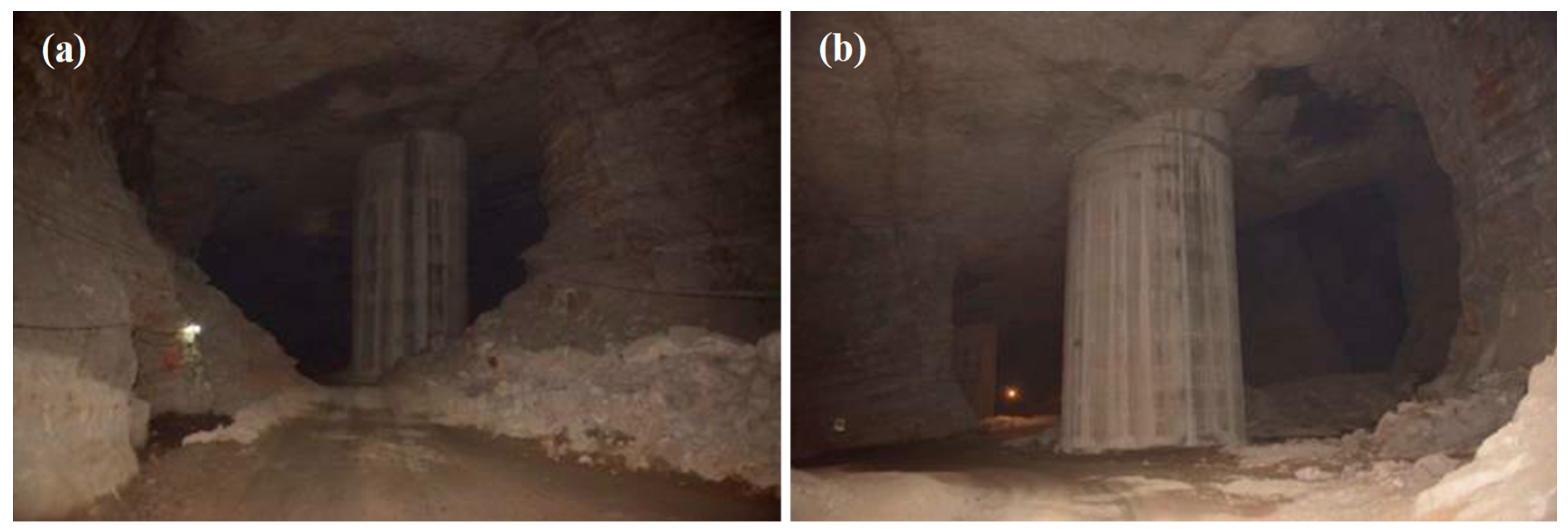

3.3.2. Artificial Pillar

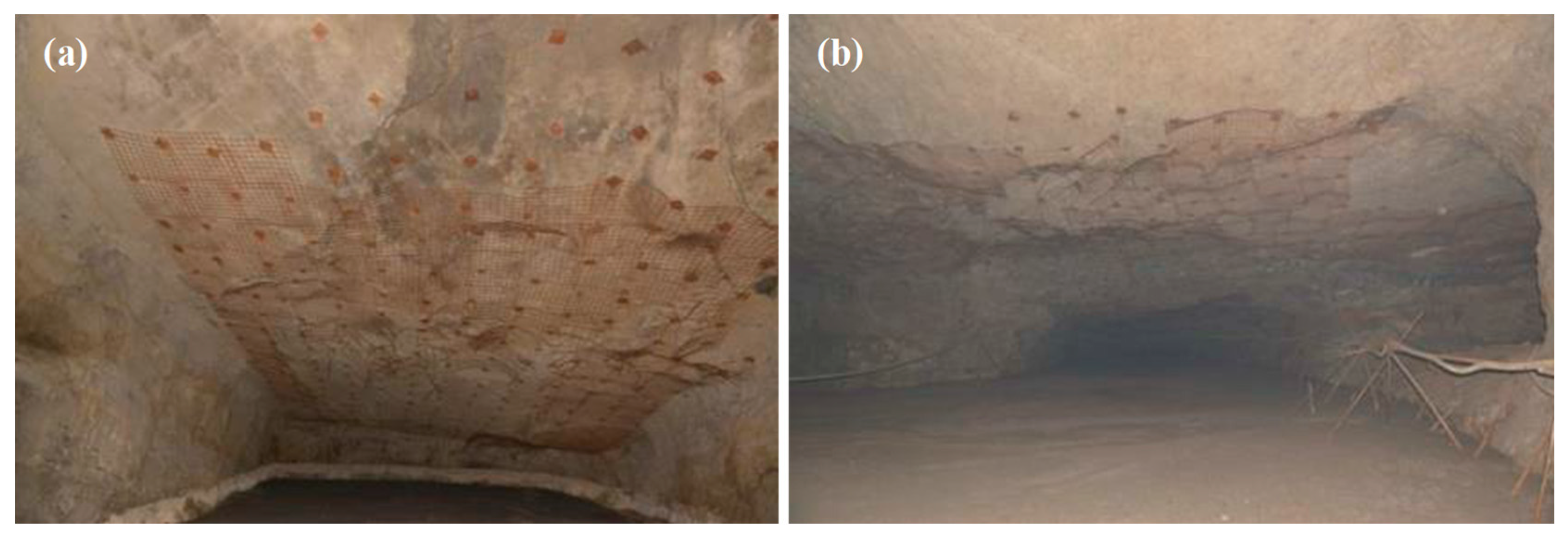

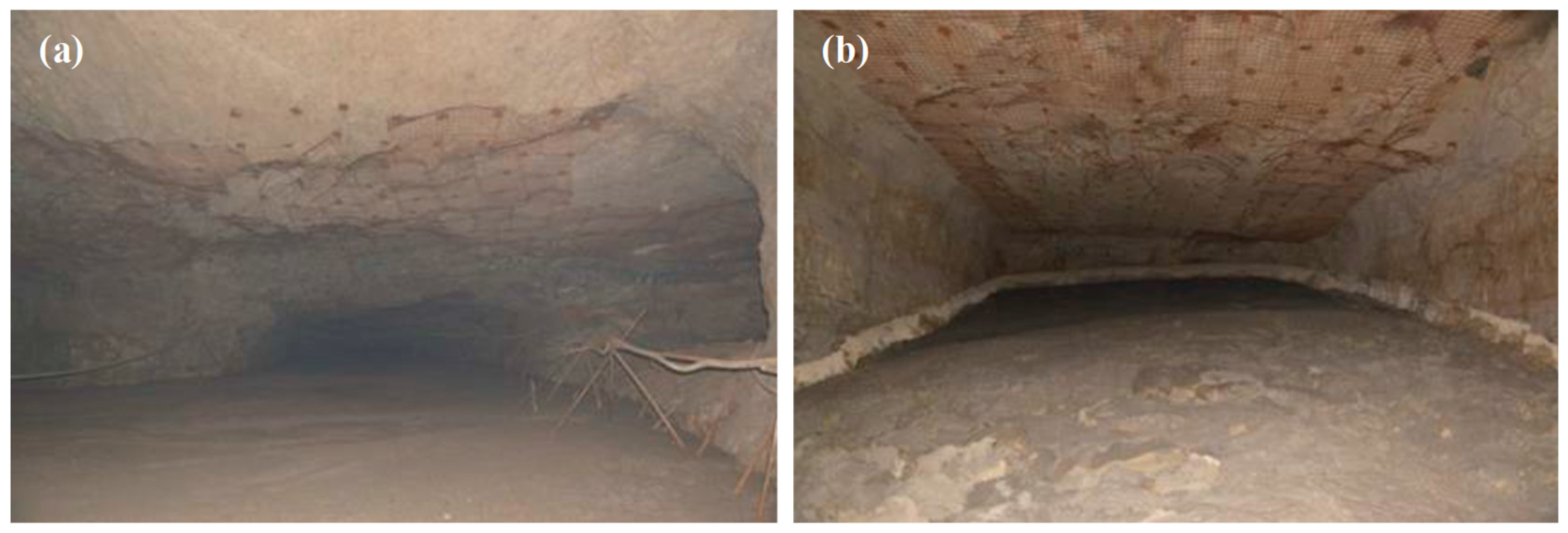

3.3.3. Laying Mesh to Protect the Roof

3.3.4. Capacity Regulation

4. Verification of Microseismic Response/Parameters

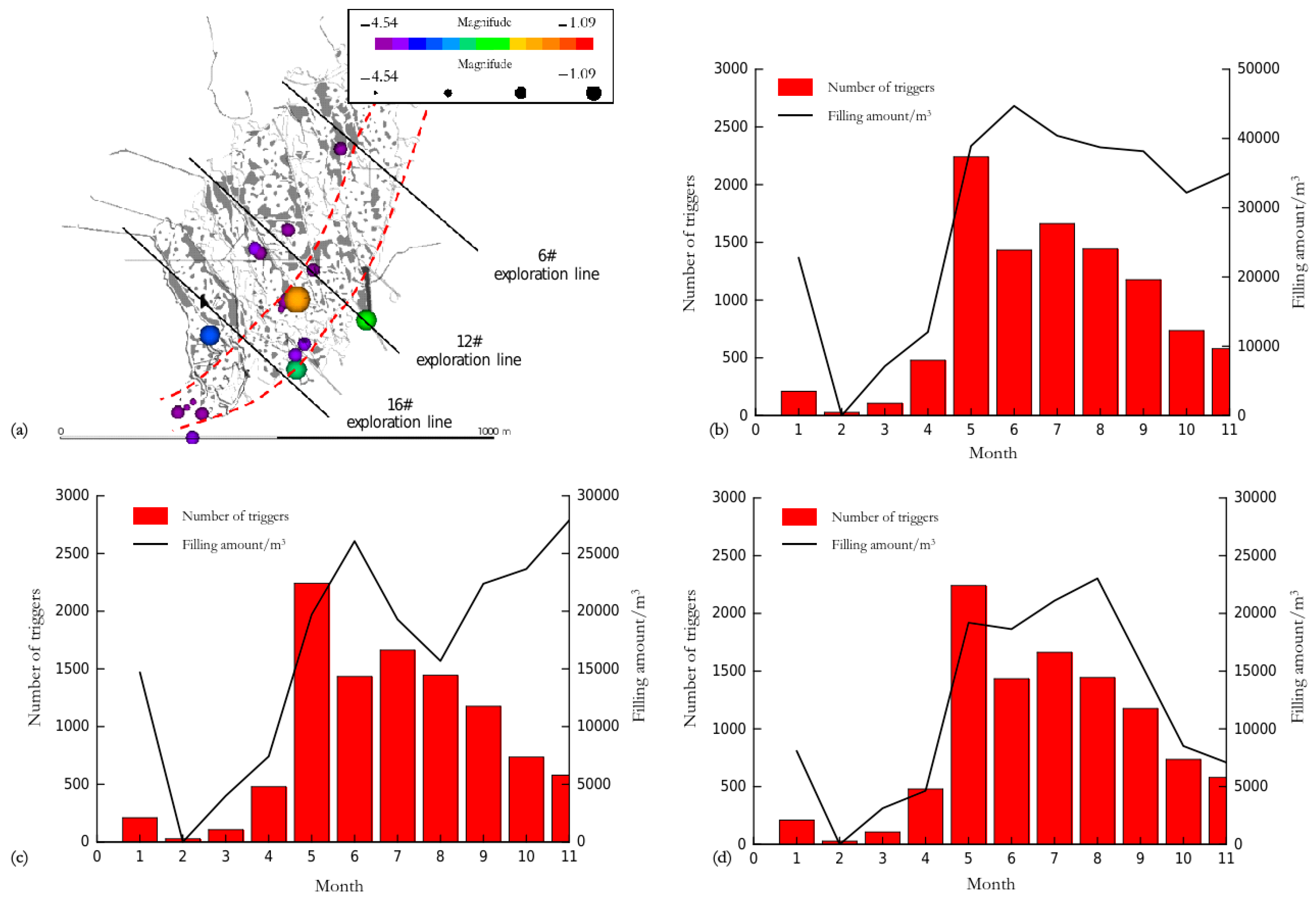

4.1. Relationship Between Microseismic Activity and Filling

4.2. Relationship Between Ground Pressure Manifestation and Filling

4.3. Microseismic Event Parameters and Warning Mechanism

4.4. Filling Volume and Microseismic Control

5. Discussion

6. Conclusions

- (1)

- The closed-loop ground pressure control system, based on microseismic monitoring, significantly improves the safety of residual ore recovery, and its effectiveness has been verified through a multi-parameter quantitative evaluation. This study constructed a closed-loop ground pressure management system of “monitoring warning control feedback”, which achieved dynamic identification and warning of high-risk areas through key parameters such as microseismic event rate, energy ratio, and event cluster density (event rate ratio ≥ 3, cluster density ≥ 15 events/10,000 cubic meters, energy ratio ≥ 4). Under the condition of a 34% year-on-year increase in ore production in 2019, the number of localized events decreased by 5.9%, and the maximum magnitude decreased from 0.3 to −0.2, systematically demonstrating the quantitative effect of this system in suppressing the intensity of ground pressure activity.

- (2)

- Filling treatment plays a significant role in overall ground pressure control, but its control effect on local roof pressure is limited, and it needs to be combined with collaborative support strategies. Although the cumulative filling volume reached 1.56 million cubic meters (2013–2018) and significantly improved the surrounding rock stress environment, 72.7% of the ground pressure manifestation is still located in the filling area or its adjacent areas, indicating that the bearing capacity of the filling body on the roof and non-filling area pillars is limited. In the future, collaborative measures such as anchor mesh support (with an anchor density of 1 × 1 m) and artificial pillars (with sizes ranging from 2.8 × 2.8 to 7.0 × 7.0 m) should be implemented to enhance the stability of local structures.

- (3)

- Production capacity regulation and regional collaborative governance are key strategies for mitigating the risks associated with dynamic ground pressure. The eastern residual mining area has significantly reduced the frequency of ground pressure activities through capacity regulation (reducing monthly output from 70,000 tons to 40,000 tons) and control of the number of mining points (reducing from 20 or more to 7). The western mining area employs the “one mining, one filling” orderly mining and step-by-step filling technology, ensuring safe and efficient mining operations. Research has shown that the regional priority filling strategy combined with microseismic feedback can optimize the efficiency of limited filling capacity.

- (4)

- Artificial pillars and comprehensive management systems play a core role in the safe mining of complex goafs. The application of artificial mining pillars increases support strength by 23–40%, and anchor mesh support increases roof stability by 35%. By adhering to the principle of “zone priority and dynamic adjustment” and combining microseismic feedback to optimize the filling sequence, an integrated technical system of “prevention control strong alarm” has been formed, providing quantifiable technical paths and methodological support for similar complex residual mining projects.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, L. Towards sustainability in mineral resources. Ore Geol. Rev. 2023, 160, 105600. [Google Scholar] [CrossRef]

- Nassani, A.A.; Aldakhil, A.M.; Zaman, K. Ecological footprints jeopardy for mineral resource extraction: Efficient use of energy, financial development and insurance services to conserve natural resources. Resour. Policy 2021, 74, 102271. [Google Scholar] [CrossRef]

- Xu, H.; Chen, G.; Sarwar, B.; Shahzad, I. Sustainable development and mineral resource extraction in China: Exploring the role of mineral resources, energy efficiency and renewable energy. Resour. Policy 2024, 90, 104703. [Google Scholar] [CrossRef]

- Zhou, Z.; Huang, Y.; Zhao, C. Microseismic Monitoring and Disaster Warning via Mining and Filling Processes of Residual Hazardous Ore Bodies. Minerals 2024, 14, 948. [Google Scholar] [CrossRef]

- Yin, Y.; Yang, S.; He, Y.; Pan, J.; Guo, Z.; Fan, J.; Wang, Z. Stability assessment of surrounding rock in downward mining route supported by slab-wall backfill structure. Sci. Rep. 2024, 14, 13706. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Fan, K.; Wang, Y.; Wang, W.; Chen, C. Model test research on ground movement law of steeply dipping discontinuities in metal mines. Rock Soil Mech. 2024, 45, 1412–1422. [Google Scholar]

- Li, J.; Bai, J.W.; Feng, G.R.; Wang, S.Y.; Zhao, H.C.; Mi, J.; Pan, R.-K.; Shi, X.-D.; Ma, J.-B. Compressive performance of innovative reinforced pillars in closed/abandoned mines. J. Cent. South Univ. 2024, 31, 2780–2793. [Google Scholar] [CrossRef]

- Yu, Y.; Deng, K.-Z.; Luo, Y.; Chen, S.-E.; Zhuang, H.-F. An improved method for long-term stability evaluation of strip mining and pillar design. Int. J. Rock Mech. Min. Sci. 2018, 107, 25–30. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhao, Y.; Cao, W.; Chen, L.; Zhou, J. Dynamic Response of Pillar Workings Induced by Sudden Pillar Recovery. Rock Mech. Rock Eng. 2018, 51, 3075–3090. [Google Scholar] [CrossRef]

- Zhou, K.P.; Du, X.H. Study on Stability of Residual Ore Recovery Based on Coupling of 3DMINE-MIDAS/GTS-FLAC3D. China Saf. Sci. J. 2011, 21, 17–22. [Google Scholar]

- Qiu, X.Y.; Chen, J.Y.; Shi, X.Z.; Zhang, S.; Zhou, J.; Chen, X. Deformation prediction and analysis of underground mining during stacking of dry gangue in open-pit based on response surface methodology. J. Cent. South Univ. 2018, 25, 406–417. [Google Scholar] [CrossRef]

- Li, J.; Zhang, H.; Zhang, B.; Zhai, Y. 3-D simulation analysis for the pillar and pressure relief effects in the empty field sharp-inclining mining structure. J. Saf. Environ. 2018, 18, 101–106. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Dong, Q.; Li, Z.; Chi, A.; Feng, X.; Liu, B. Research and Practice on the Flotation Process for Dealing with Deeper Oxidative Low-grade Residual Ore from Downhole Upper Middle of Linglong Gold Mine. Gold Sci. Technol. 2013, 21, 87–90. [Google Scholar]

- Yao, H.; Cai, L.; Liu, W.; Qin, W.Q.; Jiao, F.; Yang, C.R. Current status and development of comprehensive utilization of waste rock in metal mines in China. Chin. J. Nonferr. Met. 2021, 31, 1649–1660. [Google Scholar]

- Yu, C.; Li, H.; Jia, X.; Li, Q. Improving resource utilization efficiency in China’s mineral resource-based cities: A case study of Chengde, Hebei province. Resour. Conserv. Recycl. 2015, 94, 1–10. [Google Scholar] [CrossRef]

- Jiang, L.C.; Jiao, H.Z.; Wang, Y.D.; Wang, G.G. Comprehensive safety factor of roof in goaf underdeep high stress. J. Cent. South Univ. 2021, 28, 595–603. [Google Scholar] [CrossRef]

- Liu, Q.; Lin, B.; Zhou, Y.; Li, Y. Porosity model of the goaf based on overlying strata movement and deformation. Environ. Earth Sci. 2022, 81, 214. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, W.; Yang, S.; Tang, Y.; Liu, P. Asymmetrical distribution of roof microseismicity and its application to roof control of a deep longwall panel. J. Appl. Geophys. 2023, 215, 105142. [Google Scholar] [CrossRef]

- Yang, K.; Chen, C.; Xia, K.; Wang, T.; Sun, Y. Stability analysis and failure mechanism of the hanging wall in a sublevel caving mine based on microseismic monitoring. Bull. Eng. Geol. Environ. 2024, 83, 259. [Google Scholar] [CrossRef]

- Gu, W.; Yang, B.; Pan, H.; Song, T. Research and engineering practice on space characteristics of gangue slurry filling. Sci. Rep. 2023, 13, 22006. [Google Scholar] [CrossRef]

- Yang, G.; Yang, X.; Zhang, J.; He, M.; Hao, Z.; Yang, F.; Shao, J. Effect of Roof Cutting Technology on Broken Roof Rock Bulking and Abutment Stress Distribution: A Physical Model Test. Rock Mech. Rock Eng. 2024, 57, 3767–3785. [Google Scholar] [CrossRef]

- Salmi, E.F.; Sellers, E.J. A Rock Engineering System Based Abandoned Mine Instability Assessment Index with Case Studies for Waihi Gold Mine. Eng. Geol. 2022, 310, 106869. [Google Scholar] [CrossRef]

- Zhang, T.; Yang, Y.-L. Occurrence characteristics and treatment technologies of mine goaf in China: A comprehensive review. Environ. Earth Sci. 2024, 83, 441. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, S.; Cai, X.; Huang, Y.; Zhao, C. Control for rock dynamic disasters induced by blasting mining disturbance under heterogeneous condition in deep metal mines. Chin. J. Nonferr. Met. 2025, 35, 306–322. [Google Scholar]

- Feng, X.-T.; Liu, J.; Chen, B.; Xiao, Y.; Feng, G.; Zhang, F. Monitoring, Warning, and Control of Rockburst in Deep Metal Mines. Engineering 2017, 3, 538–545. [Google Scholar] [CrossRef]

- Liu, J.P.; Si, Y.T.; Wei, D.C.; Shi, H.X.; Wang, R. Developments and prospects of microseismic monitoring technology in underground metal mines in China. J. Cent. South Univ. 2021, 28, 3074–3098. [Google Scholar] [CrossRef]

- Zhou, Z.; Huang, Y.; Zhao, C. Distribution Law of Mine Ground Pressure via a Microseismic Sensor System. Minerals 2023, 13, 649. [Google Scholar] [CrossRef]

- Wei, X.; Su, W.; Du, C. Evaluation of relationship between nonmetallic mineral resources production and sustainable development. Resour. Policy 2024, 88, 104428. [Google Scholar] [CrossRef]

- Pang, L.; Liu, W.; Zheng, Q.; Du, Y.; Meng, X.; Li, X. Evaluation and analysis of metal mine filling based on numerical simulation and actual measurement. Environ. Earth Sci. 2021, 80, 505. [Google Scholar] [CrossRef]

- Liu, C.; Jiang, Q.; Xin, J.; Wu, S.; Liu, J.; Gong, F. Shearing Damage Evolution of Natural Rock Joints with Different Wall Strengths. Rock. Mech. Rock. Eng. 2022, 55, 1599–1617. [Google Scholar] [CrossRef]

- Peng, S.S.; Cheng, J.; Du, F.; Xue, Y. Underground ground control monitoring and interpretation, and numerical modeling, and shield capacity design. Int. J. Min. Sci. Technol. 2019, 29, 79–85. [Google Scholar] [CrossRef]

- Ma, K.; Xie, H.; Ren, F.; Chang, Y. Rockburst early-warning method based on time series prediction of multiple acoustic emission parameters. Tunn. Undergr. Space Technol. 2024, 153, 106060. [Google Scholar] [CrossRef]

| Year | Pillar Number | Location | Pillar Size (m) | Pillar Height (m) |

|---|---|---|---|---|

| 2013 | II-26 | 2# pit mouth | 6.8 × 6.8 | 11 |

| II-27 | 2# pit mouth | 7.0 × 7.0 | 12 | |

| II-36 | 2# pit mouth | 6.2 × 6.2 | 14 | |

| 2014 | II-128 | 2# pit mouth | 2.9 × 2.9 | 23 |

| 5-N3 | 5# pit mouth | 6.4 × 6.4 | 16 | |

| 560-W8 | 4# pit mouth | 2.8 × 2.8 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Zhao, C.; Huang, Y.; Lyu, G. Ground Pressure Control Measures and Microseismic Verification During the Recovery Process of Residual Ore Bodies. Appl. Sci. 2025, 15, 11467. https://doi.org/10.3390/app152111467

Liu C, Zhao C, Huang Y, Lyu G. Ground Pressure Control Measures and Microseismic Verification During the Recovery Process of Residual Ore Bodies. Applied Sciences. 2025; 15(21):11467. https://doi.org/10.3390/app152111467

Chicago/Turabian StyleLiu, Chang, Congcong Zhao, Yinghua Huang, and Guanying Lyu. 2025. "Ground Pressure Control Measures and Microseismic Verification During the Recovery Process of Residual Ore Bodies" Applied Sciences 15, no. 21: 11467. https://doi.org/10.3390/app152111467

APA StyleLiu, C., Zhao, C., Huang, Y., & Lyu, G. (2025). Ground Pressure Control Measures and Microseismic Verification During the Recovery Process of Residual Ore Bodies. Applied Sciences, 15(21), 11467. https://doi.org/10.3390/app152111467