Effectiveness of High-Performance Concrete Jacketing in Improving the Performance of RC Structures

Abstract

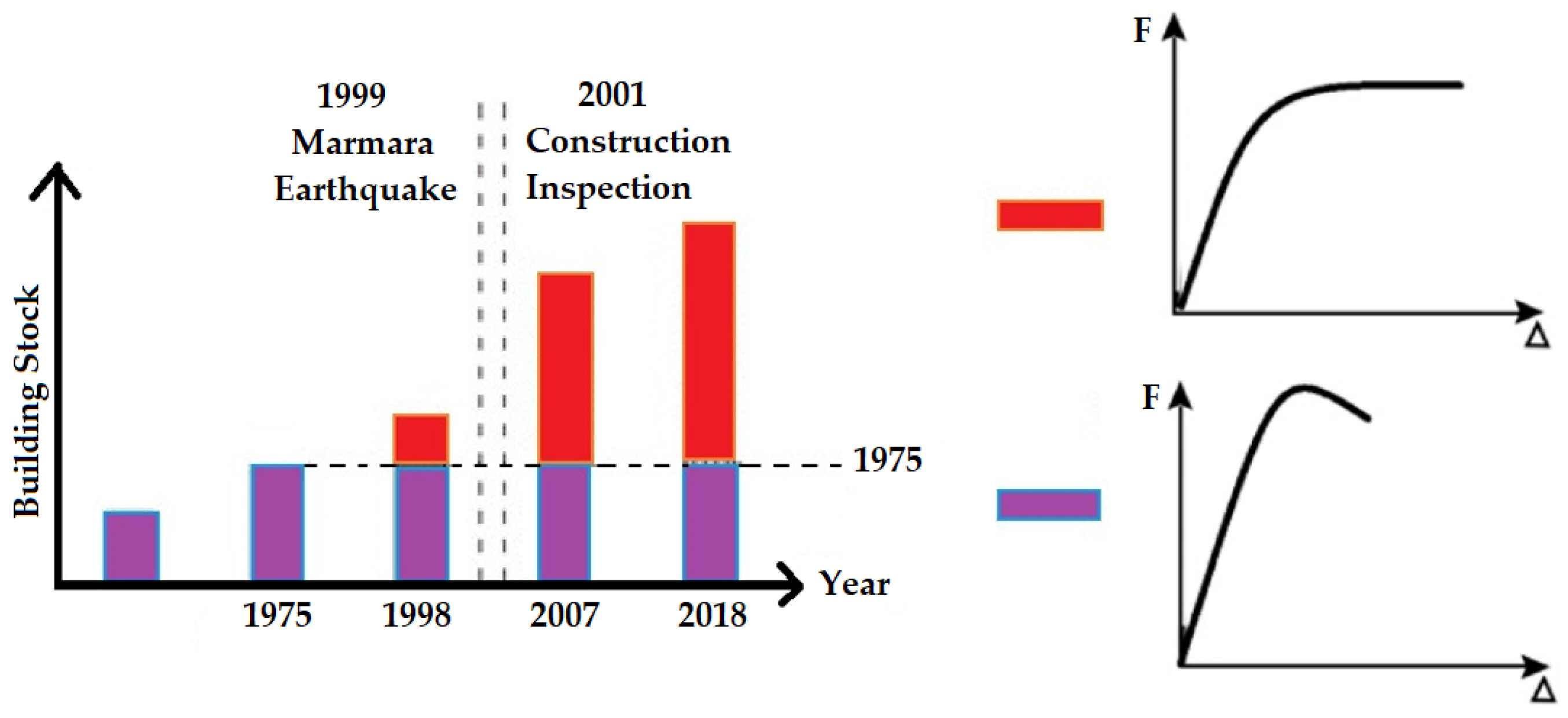

1. Introduction

2. Advances in RC Strengthening and High-Performance Concrete

3. Structural Damages in RC Columns in the Light of the 2023 Kahramanmaraş Earthquakes

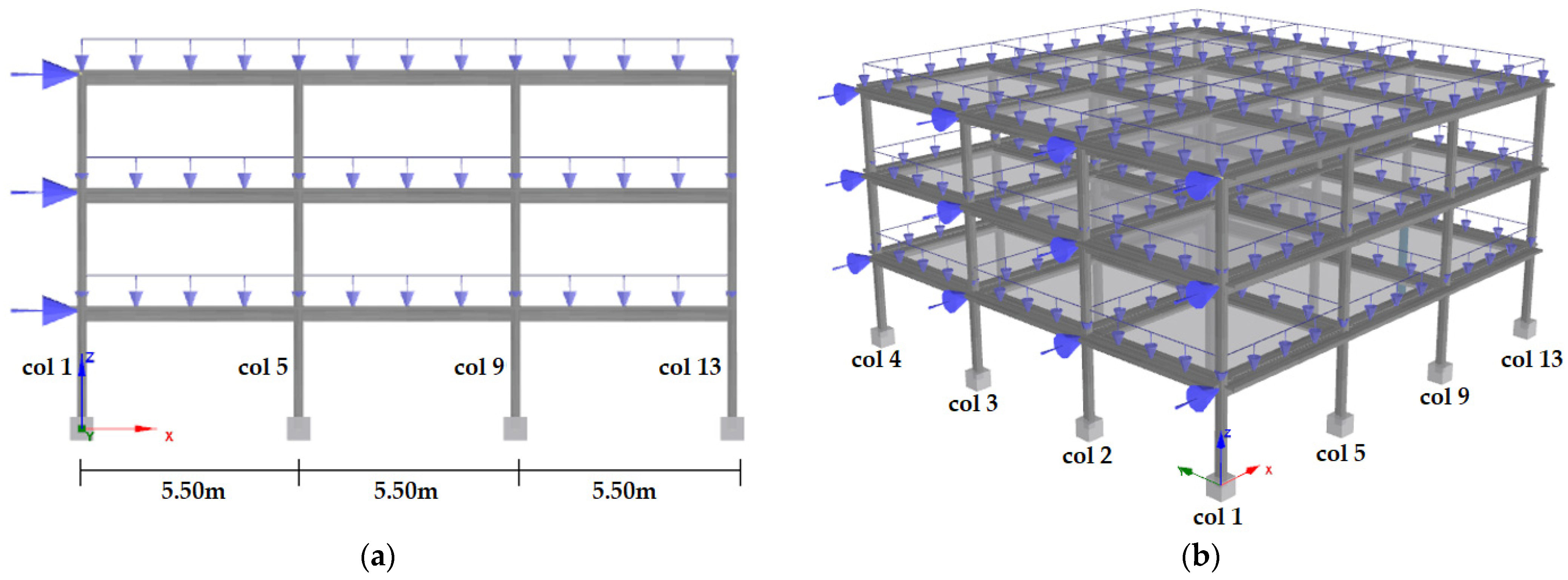

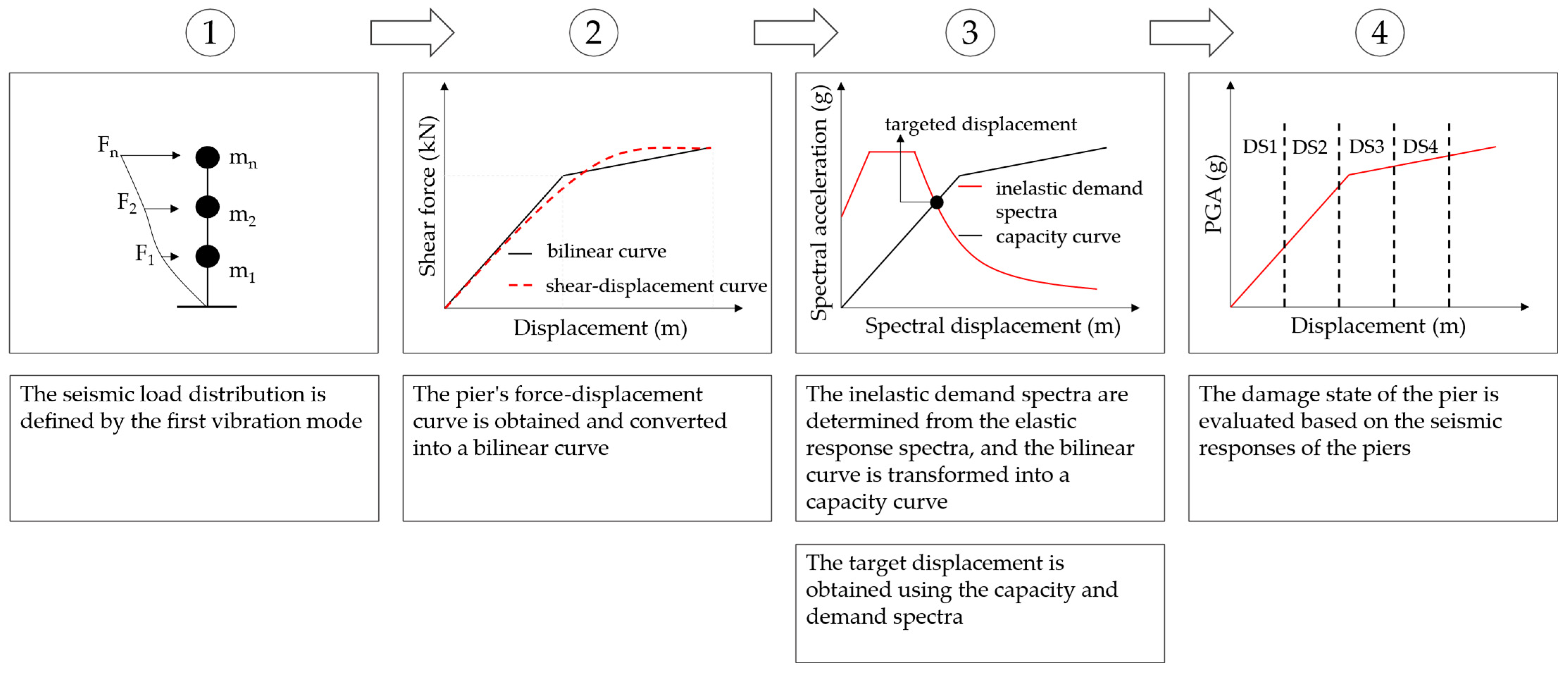

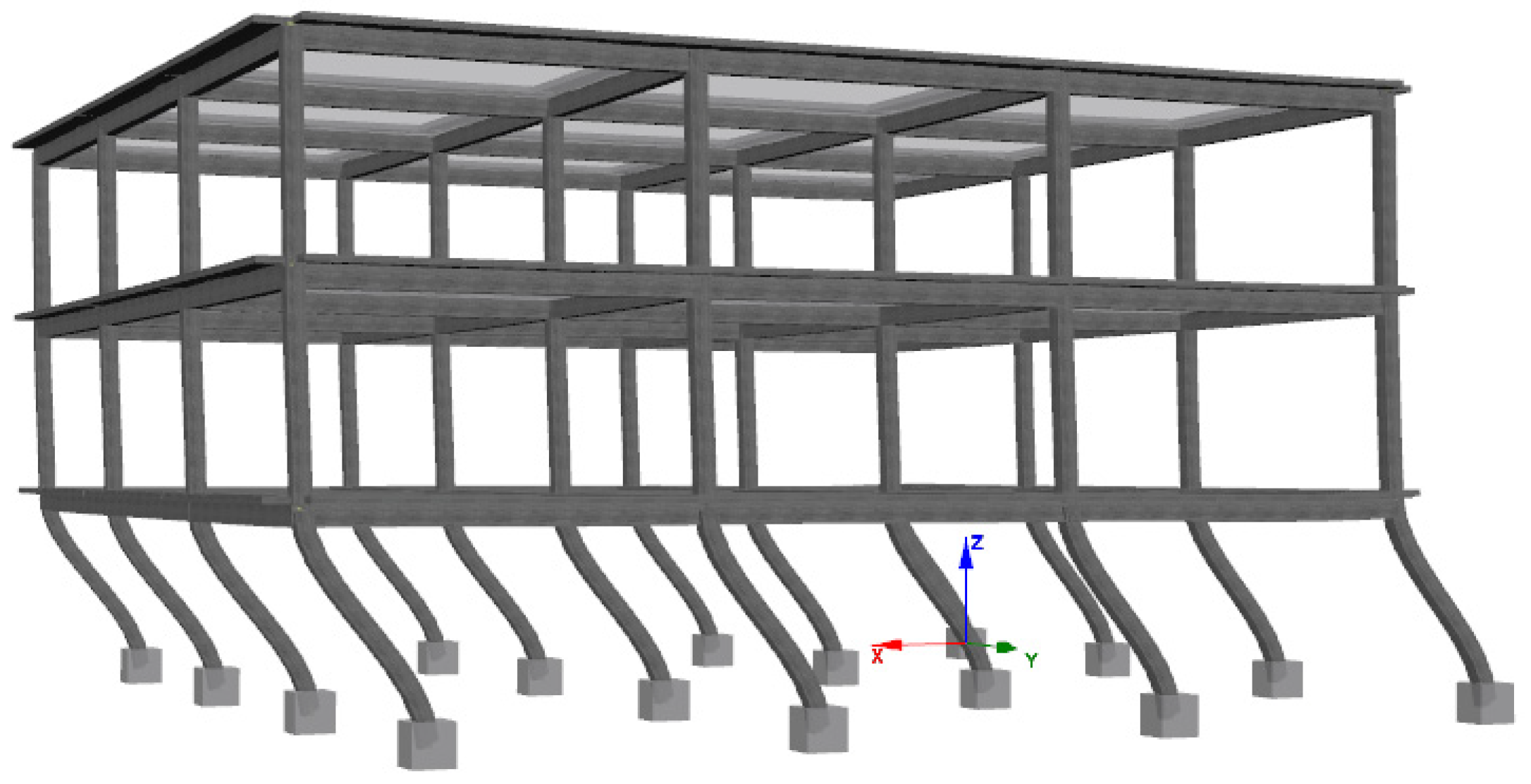

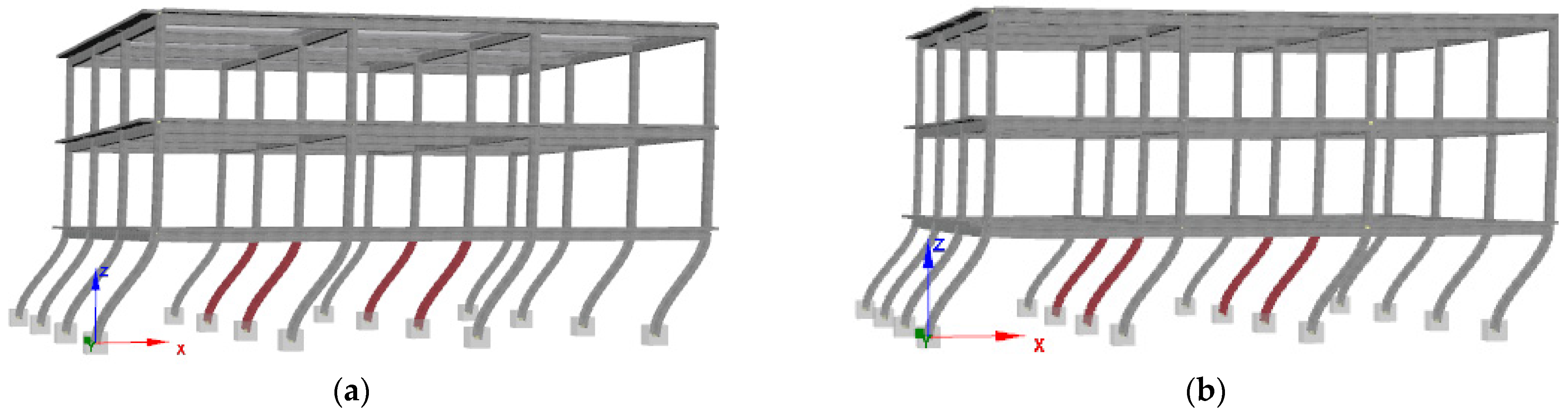

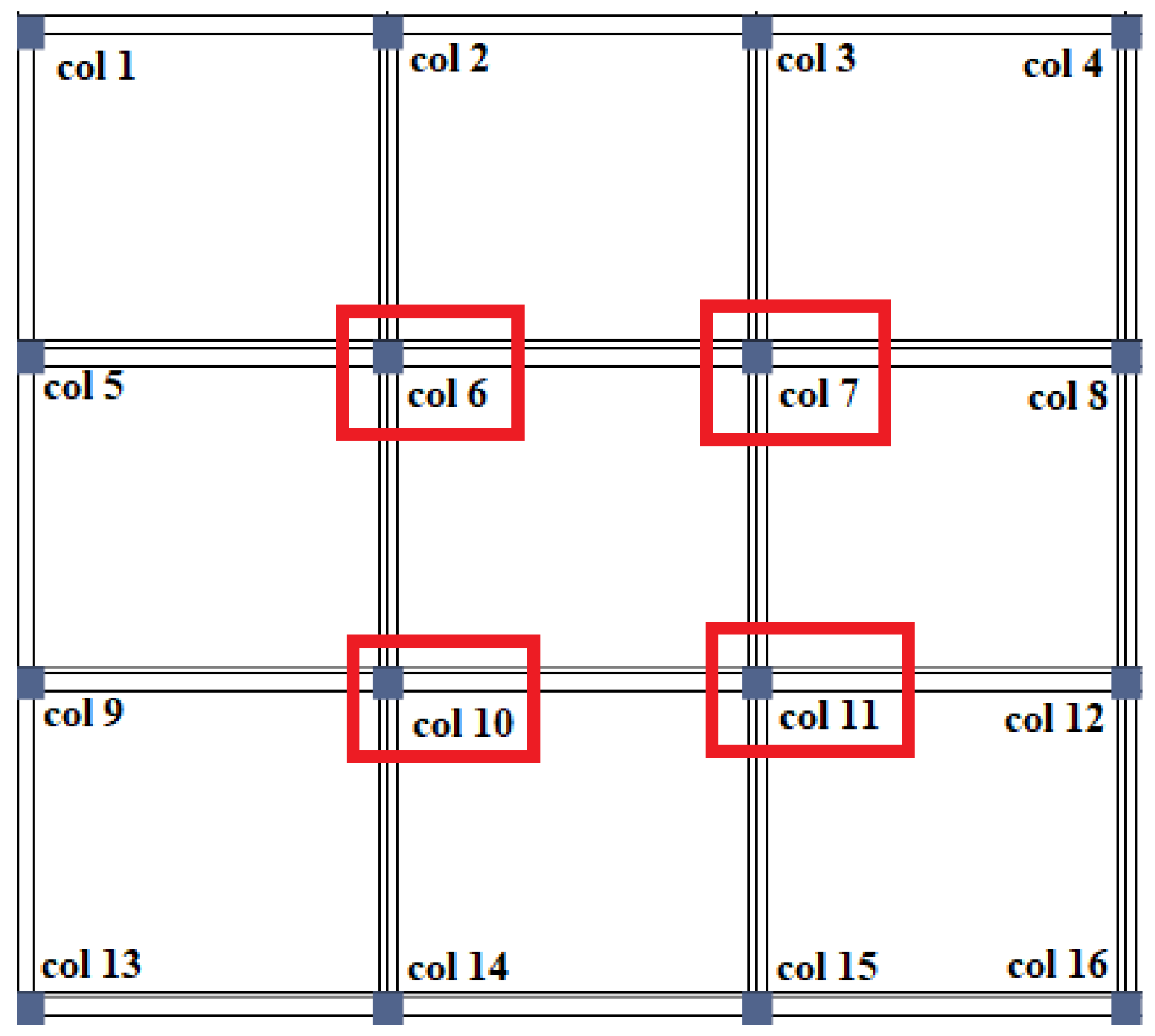

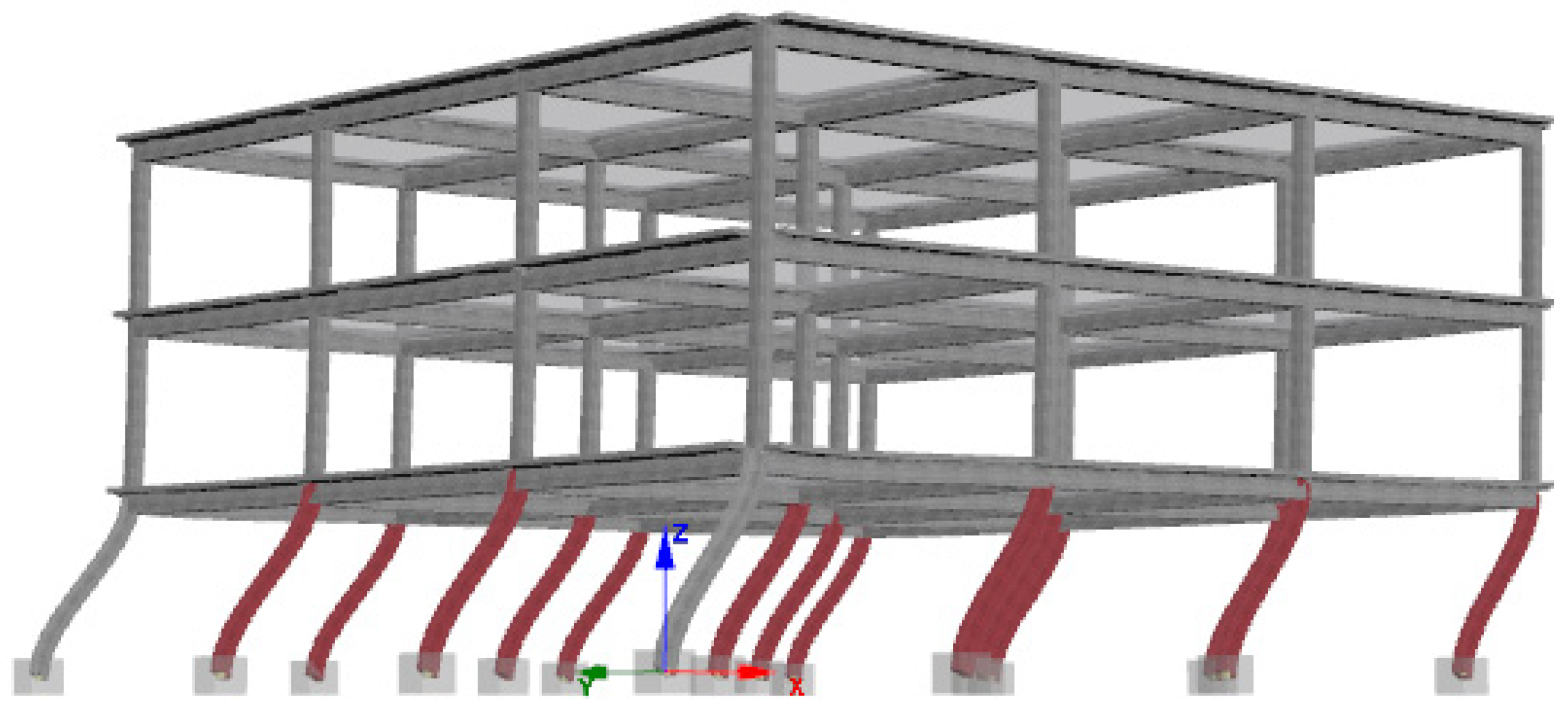

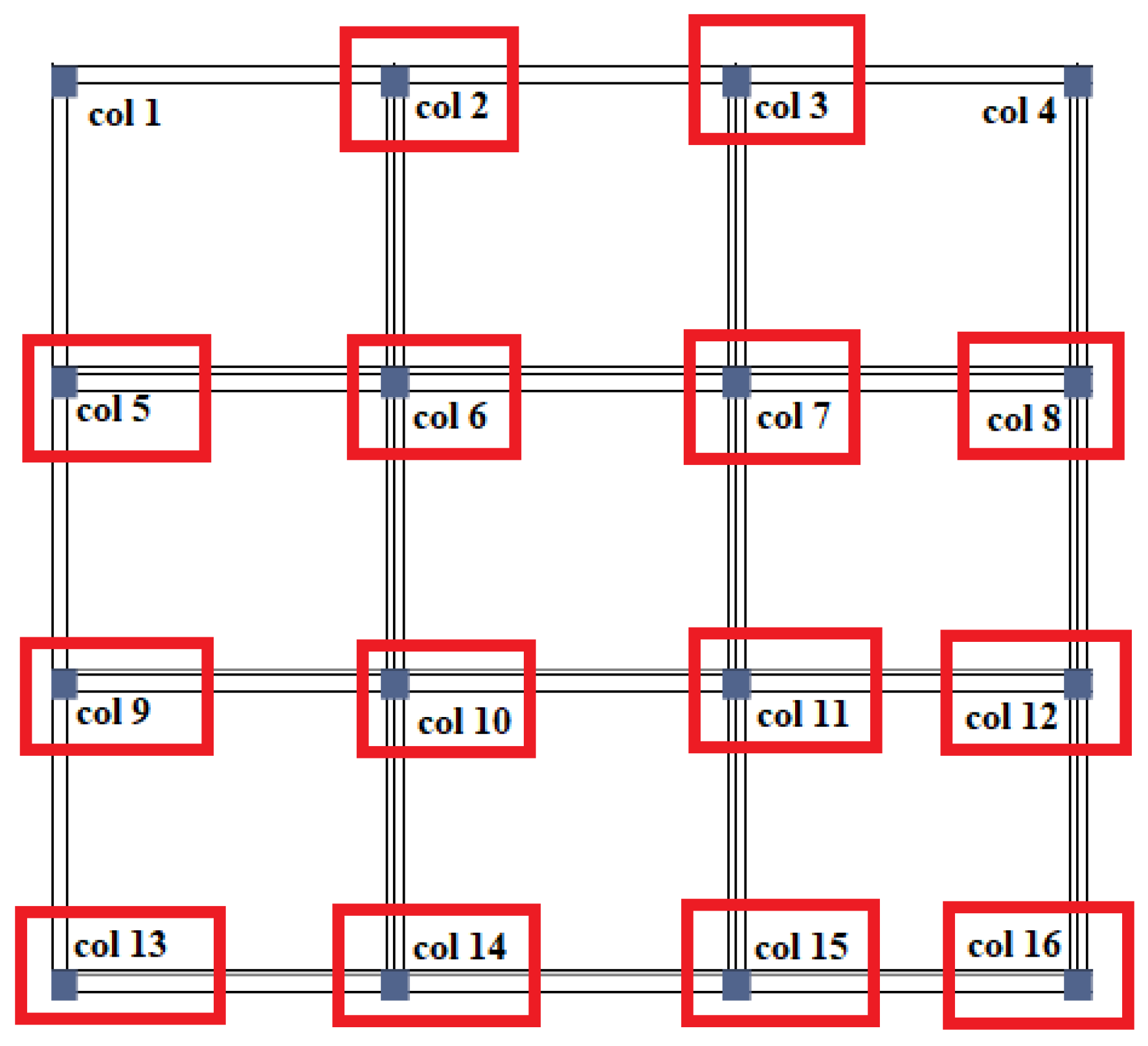

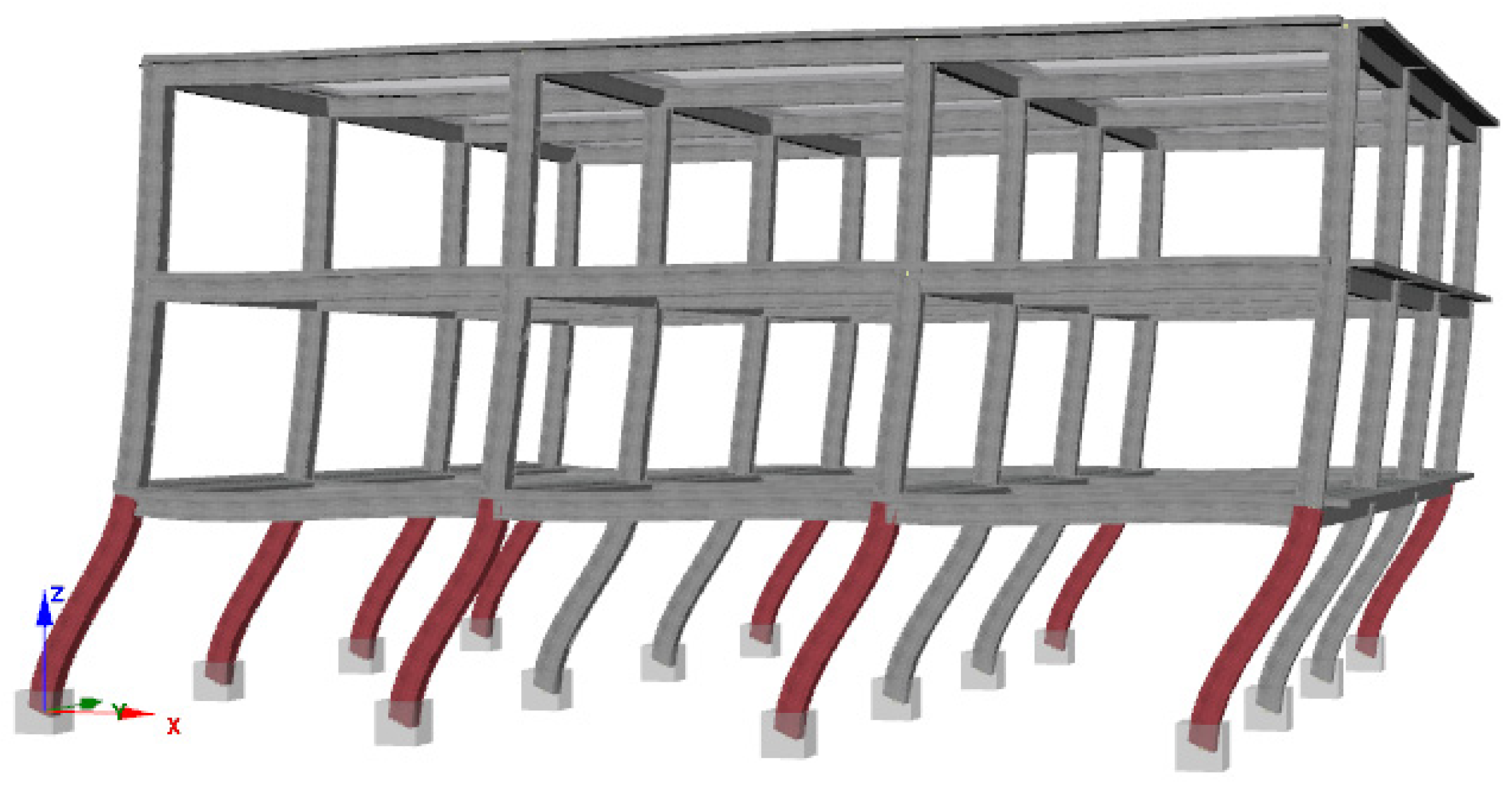

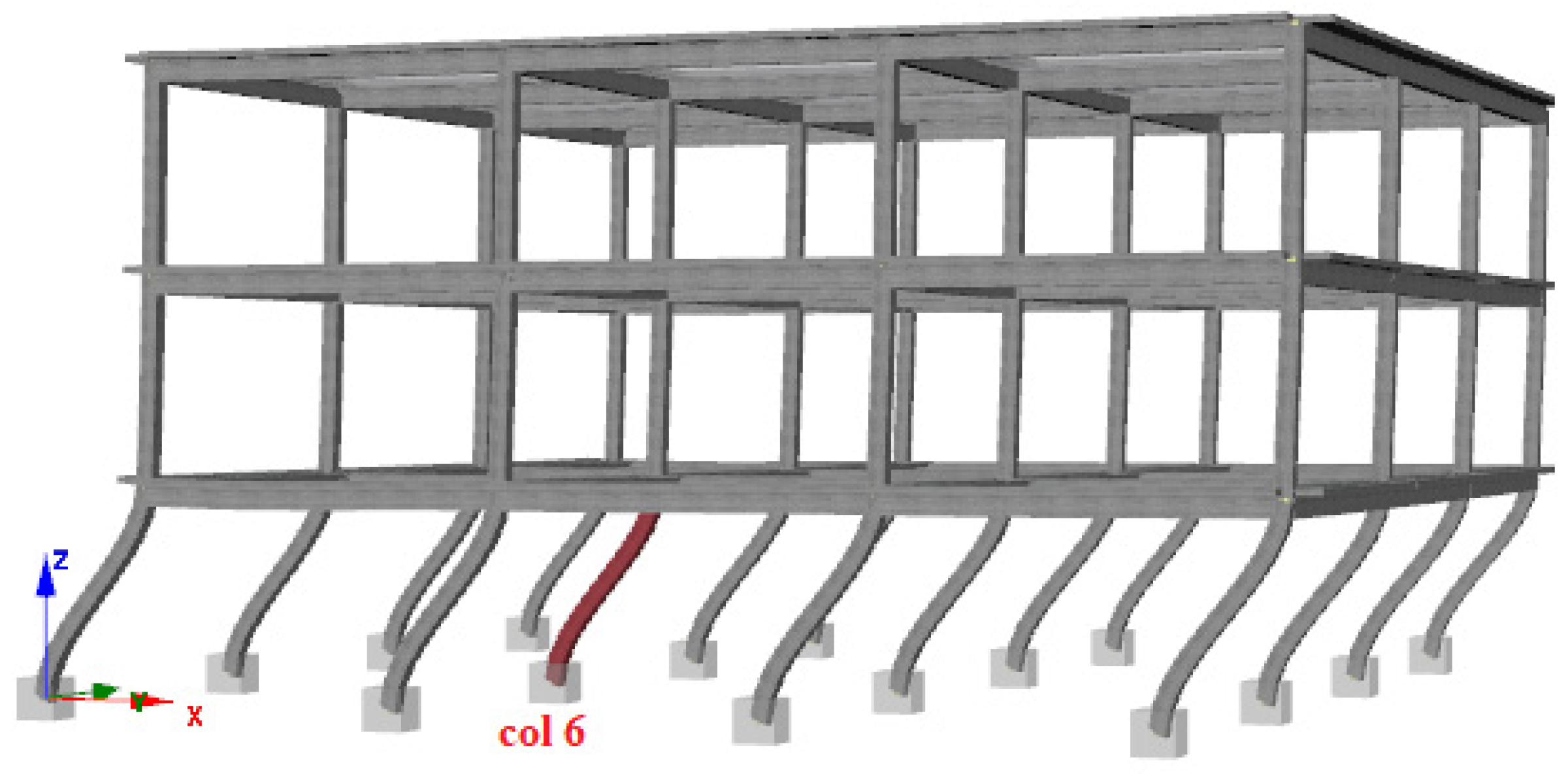

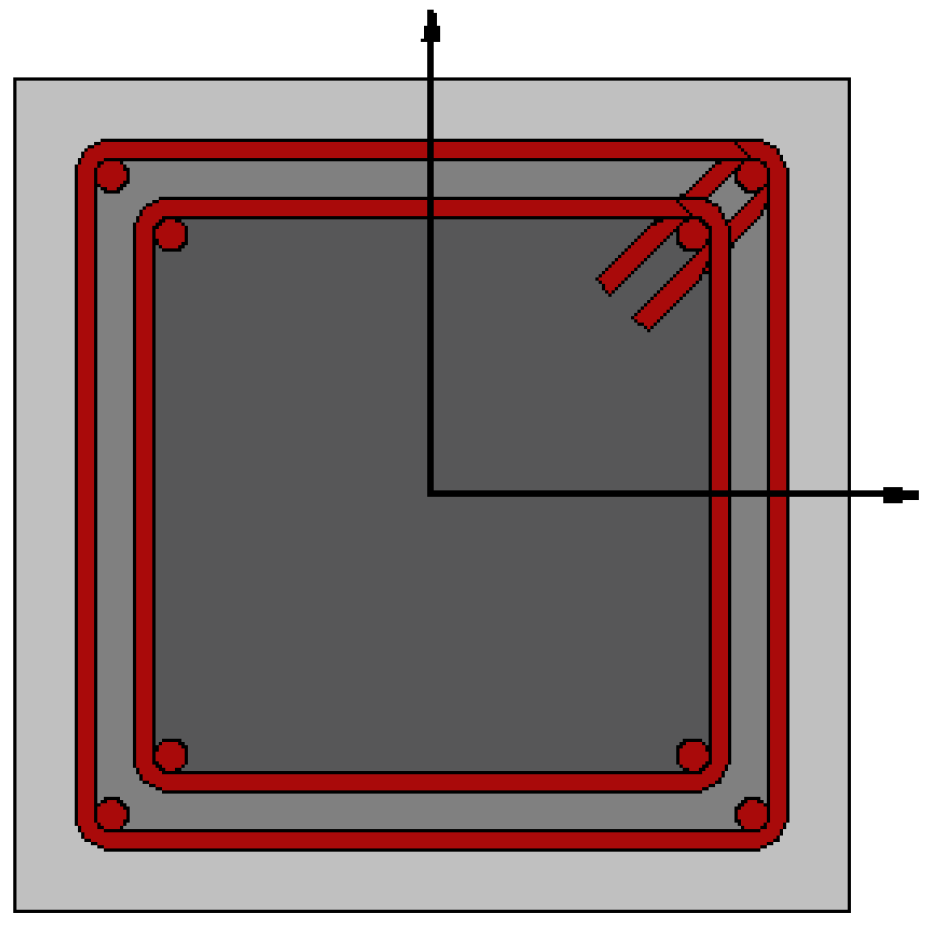

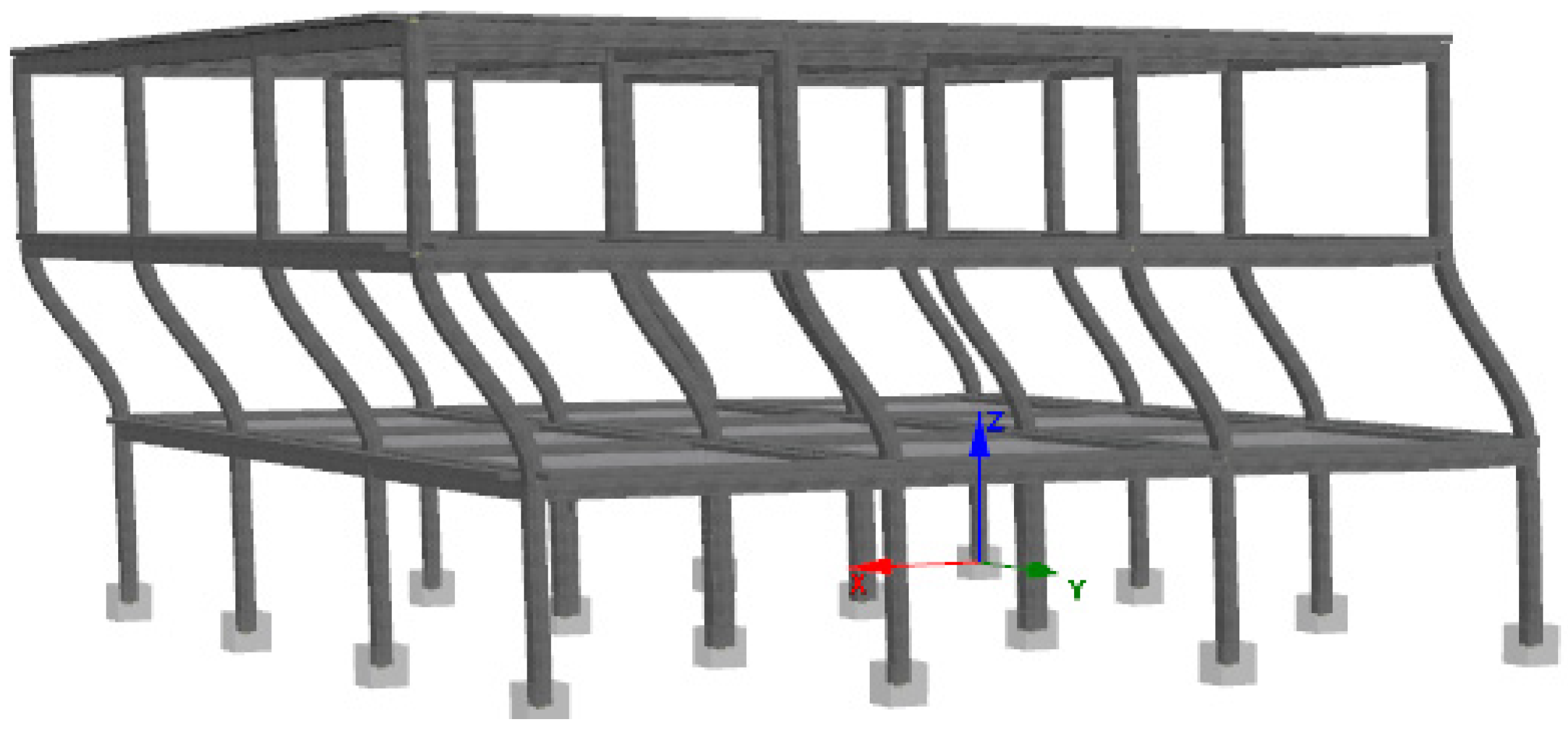

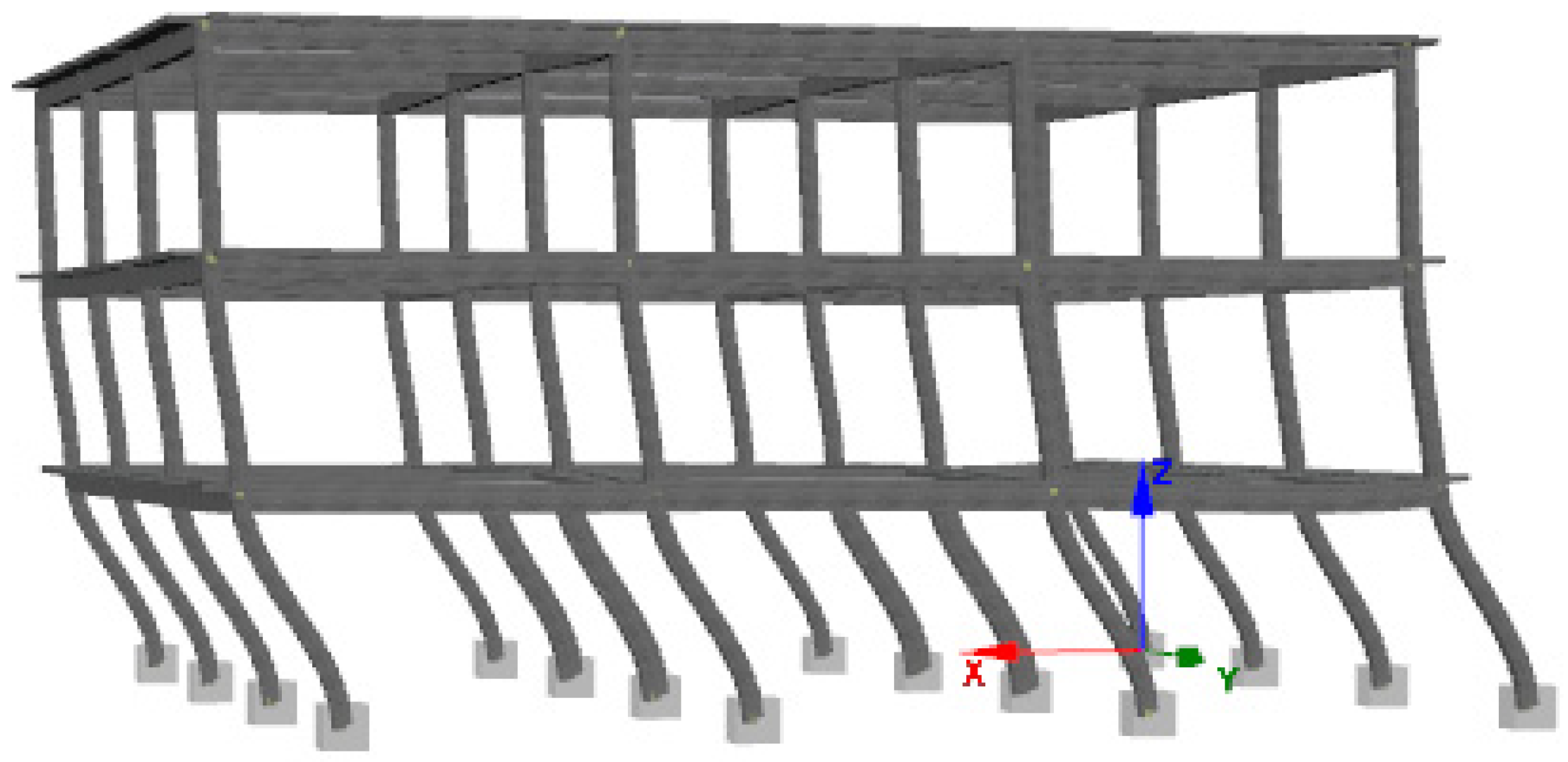

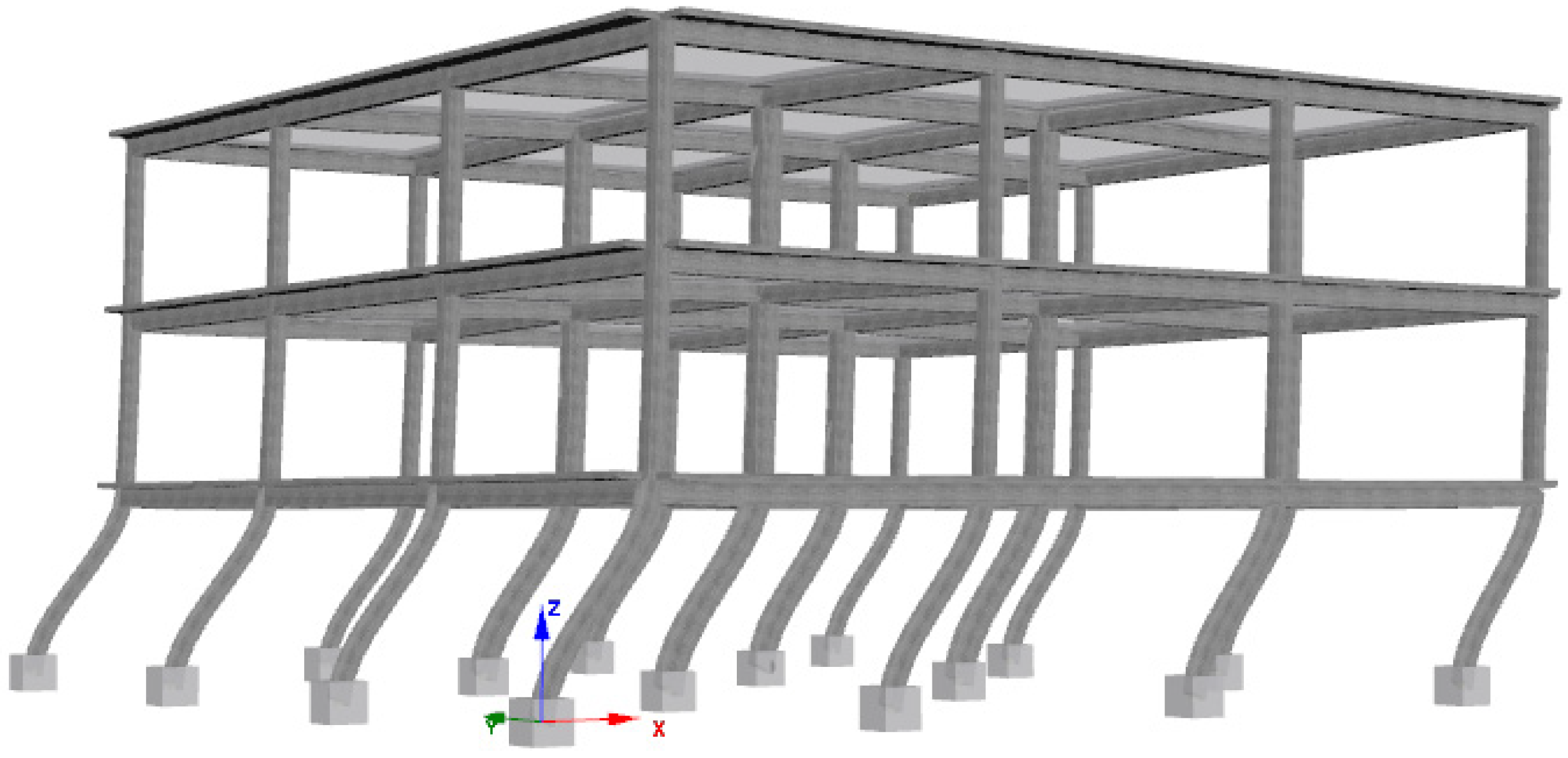

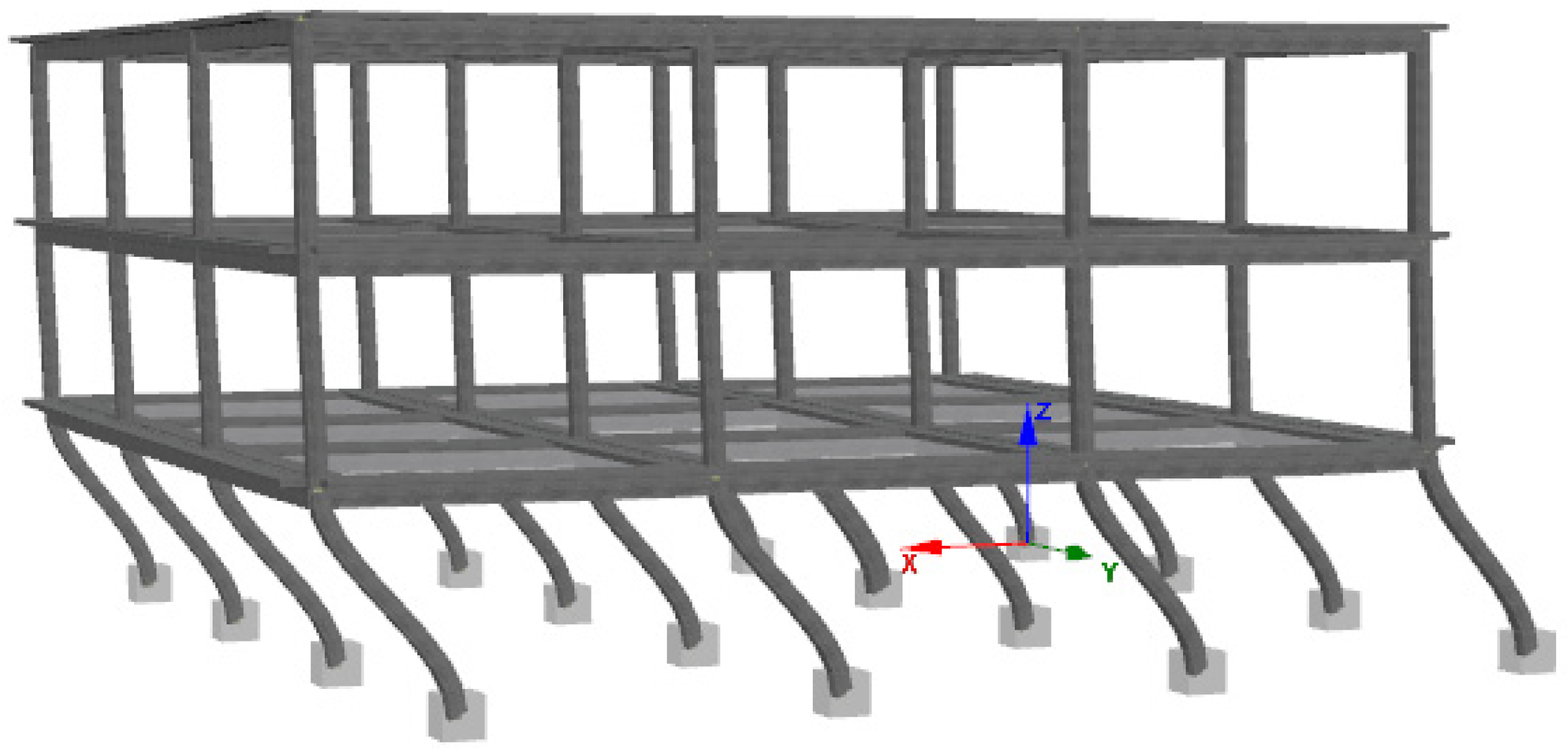

4. Numerical Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Megalooikonomou, K.G.; Beligiannis, G.N. Application of Supervised Neural Networks to Classify Failure Modes in Reinforced Concrete Columns Using Basic Structural Data. Appl. Sci. 2025, 15, 10175. [Google Scholar] [CrossRef]

- Öztürk, M.; Karan, M.A. Impact of Near-Fault Seismic Inputs on Building Performance: A Case Study Informed by the 2023 Maras Earthquakes. Appl. Sci. 2025, 15, 10142. [Google Scholar] [CrossRef]

- Wang, H.; Wang, J.; Yin, X.; Liang, X. Quantitative Hazard Assessment of Mining-Induced Seismicity Using Spatiotemporal b-Value Dynamics from Microseismic Monitoring. Appl. Sci. 2025, 15, 10073. [Google Scholar] [CrossRef]

- Dedeoglu, I.O. Evaluating Earthquake-Induced Damage in Hatay Following the 2023 Kahramanmaraş Earthquake Sequence: Tectonic, Geotechnical, and Structural Engineering Insights. Appl. Sci. 2025, 15, 9704. [Google Scholar] [CrossRef]

- Kutanis, M.; Ulutaş, H.; Işik, E. PSHA of Van Province for Performance Assessment Using Spectrally Matched Strong Ground Motion Records. J. Earth Syst. Sci. 2018, 127, 99. [Google Scholar] [CrossRef]

- Kocaman, I.; Gedik, B.; Okuyucu, D. The Effects of the Kahramanmaraş Earthquakes on Historical Masonry Minarets in Hatay, Türkiye. Sādhanā 2025, 50, 155. [Google Scholar] [CrossRef]

- Kontoni, D.-P.N.; Savvides, A.-A.; Zafeiropoulos, P. Data-Driven Analysis of the Tectonic History in Greece (1975–2025) and Neural Network-Based Modeling of Seismic Response Spectra. Med. Geosc. Rev. 2025. [Google Scholar] [CrossRef]

- Adar, K.; Akyildiz, M.H.; Buyuksarac, A. Assessment of Soil Conditions with Rayleigh Ellipticity Analysis and Microtremor Methods at Strong Motion Stations in Diyarbakır (Türkiye). Appl. Sci. 2025, 15, 8973. [Google Scholar] [CrossRef]

- Bilgin, H.; Hadzima-Nyarko, M.; Isik, E.; Ozmen, H.B.; Harirchian, E. A Comparative Study on the Seismic Provisions of Different Codes for RC Buildings. Struct. Eng. Mech. 2022, 83, 195–206. [Google Scholar] [CrossRef]

- Rodrigues, P.Q.; Pantoja, J.C.; Varum, H. SeismicV: A Mobile Tool for Assessing the Seismic Vulnerability of Buildings. Buildings 2025, 15, 2541. [Google Scholar] [CrossRef]

- Usta, G.; Şahinöz, S. Evaluation of Services Provided During Three Major Earthquakes in Türkiye: A Phenomenological Study. J. Contingencies Crisis Manag. 2025, 33, e70078. [Google Scholar] [CrossRef]

- Arslan, M.H.; Dere, Y.; Ecemiş, A.S.; Doğan, G.; Özturk, M.; Korkmaz, S.Z. Code-Based Damage Assessment of Existing Precast Industrial Buildings Following the February 6th, 2023 Kahramanmaraş earthquakes (Pazarcık Mw 7.7 and Elbistan Mw7.6). J. Build. Eng. 2024, 86, 108811. [Google Scholar] [CrossRef]

- Işık, E.; Avcil, F.; Hadzima-Nyarko, M.; İzol, R.; Büyüksaraç, A.; Arkan, E.; Radu, D.; Özcan, Z. Seismic Performance and Failure Mechanisms of Reinforced Concrete Structures Subject to the Earthquakes in Türkiye. Sustainability 2024, 16, 6473. [Google Scholar] [CrossRef]

- Ozturk, M.; Arslan, M.H.; Korkmaz, H.H. Effect on RC Buildings of 6 February 2023 Turkey Earthquake Doublets and New Doctrines for Seismic Design. Eng. Fail. Anal. 2023, 153, 107521. [Google Scholar] [CrossRef]

- Işık, M.F.; Avcil, F.; Harirchian, E.; Bülbül, M.A.; Hadzima-Nyarko, M.; Işık, E.; İzol, R.; Radu, D. A Hybrid Artificial Neural Network—Particle Swarm Optimization Algorithm Model for the Determination of Target Displacements in Mid-Rise Regular Reinforced-Concrete Buildings. Sustainability 2023, 15, 9715. [Google Scholar] [CrossRef]

- Yilmaz, M.; Dogan, G.; Arslan, M.H.; Ilki, A. Categorization of Post-Earthquake Damages in RC Structural Elements with Deep Learning Approach. J. Earthq. Eng. 2024, 28, 2620–2651. [Google Scholar] [CrossRef]

- Erbaş, Y.; Mercimek, Ö.; Anıl, Ö.; Çelik, A.; Akkaya, S.T.; Kocaman, İ.; Gürbüz, M. Design Deficiencies, Failure Modes and Recommendations for Strengthening in Reinforced Concrete Structures Exposed to the February 6, 2023 Kahramanmaraş Earthquakes (Mw 7.7 and Mw 7.6). Nat. Hazards 2025, 121, 3153–3194. [Google Scholar] [CrossRef]

- Işık, E.; Hadzima-Nyarko, M.; Tayeh, B.A.; Harrat, Z.R.; Avcil, F.; Arkan, E. Comparison of Reinforcement Methods with Advanced Materials for r/c Columns. Adv. Eng. Lett. 2025, 4, 1–13. [Google Scholar] [CrossRef]

- Ilki, A.; Comert, M.; Demir, C.; Orakcal, K.; Ulugtekin, D.; Tapan, M.; Kumbasar, N. Performance Based Rapid Seismic Assessment Method (PERA) for Reinforced Concrete Frame Buildings. Adv. Struct. Eng. 2014, 17, 439–459. [Google Scholar] [CrossRef]

- Işık, E.; Hadzima-Nyarko, M.; Radu, D.; Bulajić, B. Study on Effectiveness of Regional Risk Prioritisation in Reinforced Concrete Structures after Earthquakes. Appl. Sci. 2024, 14, 6992. [Google Scholar] [CrossRef]

- Doğan, T.P.; Kızılkula, T.; Mohammadi, M.; Erkan, İ.H.; Tekeli Kabaş, H.; Arslan, M.H. A Comparative Study on the Rapid Seismic Evaluation Methods of Reinforced Concrete Buildings. Int. J. Disaster Risk Reduct. 2021, 56, 102143. [Google Scholar] [CrossRef]

- Yuzbasi, J. Post-Earthquake Damage Assessment: Field Observations and Recent Developments with Recommendations from the Kahramanmaraş Earthquakes in Türkiye on February 6th, 2023 (Pazarcık M7.8 and Elbistan M7.6). J. Earthq. Eng. 2024, 1–26. [Google Scholar] [CrossRef]

- Uysal, Y.; Ecemiş, A.S.; Aksoylu, C.; Arslan, M.H. Effects of Shear Wall Ratio and Location on Earthquake Performance of Reinforced Concrete Buildings Having Different Ribbed Slab Configurations. J. Build. Eng. 2025, 113, 113958. [Google Scholar] [CrossRef]

- Aras, F. A Failure Mechanism Seen After the February 6th, 2023 Kahramanmaraş Earthquake Sequence, Buckling of Compression Reinforcement in RC Beams. J. Earthq. Tsunami 2025, 19, 2450038. [Google Scholar] [CrossRef]

- Nemutlu, Ö.F.; Sarı, A. Seismic Performance of the Kahramanmaraş Earthquakes: Ground Motion Prediction Models and the Role of Vertical Components. Bitlis Eren Üniversitesi Fen Bilim. Derg. 2025, 14, 610–632. [Google Scholar] [CrossRef]

- Peker, F.Ü.; Yuzbasi, J.; Işık, E.; Büyüksaraç, A.; Avcil, F. Damage Assessment, Regional Ground Motion Record Evaluation, and Seismic Performance Analysis of a High-Rise 14-Story Dual System Building after the 2023 Kahramanmaraş Earthquakes. Structures 2025, 80, 109897. [Google Scholar] [CrossRef]

- Dedeoglu, I.O.; Yetkin, M.; Tunc, G.; Ozbulut, O.E. Evaluating Earthquake-Induced Damage in Dogansehir, Malatya after 2023 Kahramanmaras Earthquake Sequence: Geotechnical and Structural Perspectives. J. Build. Eng. 2025, 104, 112266. [Google Scholar] [CrossRef]

- Kocakaplan Sezgin, S.; Sakcalı, G.B.; Özen, S.; Yıldırım, E.; Avcı, E.; Bayhan, B.; Çağlar, N. Reconnaissance Report on Damage Caused by the February 6, 2023, Kahramanmaraş Earthquakes in Reinforced-Concrete Structures. J. Build. Eng. 2024, 89, 109200. [Google Scholar] [CrossRef]

- Işık, E. A Study on Strengthening RC Structural Elements with Fibers Based Polymers. Bitlis Eren Üniversitesi Fen Bilim. Derg. 2025, 14, 1269–1286. [Google Scholar] [CrossRef]

- Cetin, K.O.; Soylemez, B.; Guzel, H.; Cakir, E. Soil Liquefaction Sites Following the February 6, 2023, Kahramanmaraş-Türkiye Earthquake Sequence. Bull. Earthq. Eng. 2025, 23, 921–944. [Google Scholar] [CrossRef]

- Vuran, E.; Serhatoğlu, C.; Timurağaoğlu, M.Ö.; Smyrou, E.; Bal, İ.E.; Livaoğlu, R. Damage Observations of RC Buildings from 2023 Kahramanmaraş Earthquake Sequence and Discussion on the Seismic Code Regulations. Bull. Earthq. Eng. 2025, 23, 1153–1182. [Google Scholar] [CrossRef]

- Binici, B.; Yakut, A.; Kadas, K.; Demirel, O.; Akpinar, U.; Canbolat, A.; Yurtseven, F.; Oztaskin, O.; Aktas, S.; Canbay, E. Performance of RC buildings after Kahramanmaraş Earthquakes: Lessons toward performance based design. Earthq. Eng. Eng. Vib. 2023, 22, 883–894. [Google Scholar] [CrossRef]

- Işık, E.; Radu, D.; Harirchian, E.; Avcil, F.; Arkan, E.; Büyüksaraç, A.; Hadzima-Nyarko, M. Failures in Reinforced-Concrete Columns and Proposals for Reinforcement Solutions: Insights from the 2023 Kahramanmaraş Earthquakes. Buildings 2025, 15, 1535. [Google Scholar] [CrossRef]

- İnce, O. Structural Damage Assessment of Reinforced Concrete Buildings in Adıyaman after Kahramanmaraş (Türkiye) Earthquakes on 6 February 2023. Eng. Fail. Anal. 2024, 156, 107799. [Google Scholar] [CrossRef]

- Avcil, F.; Bilgin, H.; Arkan, E.; Işık, E. Numerical Analysis of Structural Behavior and Damage Mechanisms in Shear-Deficient Reinforced Concrete Columns Retrofitted with RC Jacketing. Türk Doğa Ve Fen Derg. 2025, 14, 150–161. [Google Scholar] [CrossRef]

- Altunişik, A.C.; Arslan, M.E.; Kahya, V.; Aslan, B.; Sezdirmez, T.; Dok, G.; Kirtel, O.; Öztürk, H.; Sunca, F.; Baltaci, A.; et al. Field Observations and Damage Evaluation in Reinforced Concrete Buildings After the February 6th, 2023, Kahramanmaraş–Türkiye Earthquakes. J. Earthq. Tsunami 2023, 17, 2350024. [Google Scholar] [CrossRef]

- Yön, B.; Dedeoğlu, İ.Ö.; Yetkin, M.; Erkek, H.; Calayır, Y. Evaluation of the Seismic Response of Reinforced Concrete Buildings in the Light of Lessons Learned from the February 6, 2023, Kahramanmaraş, Türkiye Earthquake Sequences. Nat. Hazards 2025, 121, 873–909. [Google Scholar] [CrossRef]

- Çelebi, E.; Kırtel, O. Seismic Performance of Reinforced Concrete Framed Buildings with Ribbed Slabs at the Affected Region by 2023 Kahramanmaraş Earthquakes. Bull. Earthq. Eng. 2025, 23, 3623–3646. [Google Scholar] [CrossRef]

- Demir, A.; Celebi, E.; Ozturk, H.; Ozcan, Z.; Ozocak, A.; Bol, E.; Sert, S.; Sahin, F.Z.; Arslan, E.; Dere Yaman, Z.; et al. Destructive Impact of Successive High Magnitude Earthquakes Occurred in Türkiye’s Kahramanmaraş on February 6, 2023. Bull. Earthq. Eng. 2025, 23, 893–919. [Google Scholar] [CrossRef]

- Doğruyol, M. Characterisation of Acrylic Copolymer Treated Concretes and Concretes of Reinforced Concrete Buildings Collapsed in the 6 February 2023 Mw = 7.8 Kahramanmaraş (Türkiye) Earthquake. Eng. Fail. Anal. 2024, 161, 108249. [Google Scholar] [CrossRef]

- Zeng, J.-J.; Su, T.-H.; Chen, J.-D.; Hu, X.; Ng, C.-T.; Zheng, Y.; Quach, W.-M.; Zhuge, Y. Novel Prefabricated FRP Bar Reinforced UHPC Shells for Column Strengthening: Development and Axial Compression Tests. J. Build. Eng. 2024, 94, 109935. [Google Scholar] [CrossRef]

- Zeng, J.-J.; Chen, S.-P.; Peng, K.-D.; Dai, J.-G. Novel FRP Micro-Bar Reinforced UHPC Permanent Formwork for Circular Columns: Concept and Compressive Behavior. Compos. Struct. 2022, 285, 115268. [Google Scholar] [CrossRef]

- Zeng, J.J.; Lin, G.; Teng, J.G.; Li, L.J. Behavior of Large-Scale FRP-Confined Rectangular RC Columns under Axial Compression. Eng. Struct. 2018, 174, 629–645. [Google Scholar] [CrossRef]

- Liao, J.; Yang, K.Y.; Zeng, J.-J.; Quach, W.-M.; Ye, Y.-Y.; Zhang, L. Compressive Behavior of FRP-Confined Ultra-High Performance Concrete (UHPC) in Circular Columns. Eng. Struct. 2021, 249, 113246. [Google Scholar] [CrossRef]

- Zeng, J.-J.; Zeng, W.-B.; Ye, Y.-Y.; Liao, J.; Zhuge, Y.; Fan, T.-H. Flexural Behavior of FRP Grid Reinforced Ultra-High-Performance Concrete Composite Plates with Different Types of Fibers. Eng. Struct. 2022, 272, 115020. [Google Scholar] [CrossRef]

- Mander, J.B.; Priestley, M.J.N.; Park, R. Theoretical Stress-Strain Model for Confined Concrete. J. Struct. Eng. 1988, 114, 1804–1826. [Google Scholar] [CrossRef]

- Beschi, C.; Meda, A.; Riva, P. High Performance Fiber Reinforced Concrete Jacketing in a Seismic Retrofitting Application. In Proceedings of the Improving the Seismic Performance of Existing Buildings and Other Structures; American Society of Civil Engineers: San Francisco, CA, USA, 2009; pp. 224–233. [Google Scholar]

- Ouyang, L.-J.; Gao, W.-Y.; Zhen, B.; Lu, Z.-D. Seismic Retrofit of Square Reinforced Concrete Columns Using Basalt and Carbon Fiber-Reinforced Polymer Sheets: A Comparative Study. Compos. Struct. 2017, 162, 294–307. [Google Scholar] [CrossRef]

- Mohamad, M.E.; Ibrahim, I.S. Interface shear strength of concrete-to-concrete bond with and without projecting steel reinforcement. Sci. Eng. 2015, 75, 169–172. [Google Scholar] [CrossRef]

- Truong, G.T.; Kim, J.-C.; Choi, K.-K. Seismic Performance of Reinforced Concrete Columns Retrofitted by Various Methods. Eng. Struct. 2017, 134, 217–235. [Google Scholar] [CrossRef]

- Ro, K.M.; Kim, M.S.; Lee, Y.H. Improved Shear Strength Equation for Reinforced Concrete Columns Retrofitted with Hybrid Concrete Jackets. Materials 2023, 16, 3734. [Google Scholar] [CrossRef] [PubMed]

- Palanci, Mehmet; Kalkan, Ali; Sene, Sevket Murat Investigation of Shear Effects on the Capacity and Demand Estimation of RC Buildings. Struct. Eng. Mech. 2016, 60, 1021–1038. [CrossRef]

- Mwafy, A.; Elnashai, A. Importance of Shear Assessment of Concrete Structures Detailed to Different Capacity Design Requirements. Eng. Struct. 2008, 30, 1590–1604. [Google Scholar] [CrossRef]

- Jin, L.; Du, X.; Li, D.; Su, X. Seismic Behavior of RC Cantilever Beams under Low Cyclic Loading and Size Effect on Shear Strength: An Experimental Characterization. Eng. Struct. 2016, 122, 93–107. [Google Scholar] [CrossRef]

- Lima, C.; Martinelli, E.; Faella, C. Capacity Models for Shear Strength of Exterior Joints in RC Frames: Experimental Assessment and Recalibration. Bull. Earthq. Eng. 2012, 10, 985–1007. [Google Scholar] [CrossRef]

- Li, Q.; Chen, M.; Li, Y.; Zhang, M. Shear Capacity Calculation Methods for Reinforced Concrete Structure. Adv. Civ. Eng. 2025, 2025, 5088121. [Google Scholar] [CrossRef]

- Ali, S.R.M.; Saeed, J.A. Shear Capacity and Behavior of High-Strength Concrete Beams with Openings. Eng. Struct. 2022, 264, 114431. [Google Scholar] [CrossRef]

- Mansour, M.Y.; Dicleli, M.; Lee, J.Y.; Zhang, J. Predicting the Shear Strength of Reinforced Concrete Beams Using Artificial Neural Networks. Eng. Struct. 2004, 26, 781–799. [Google Scholar] [CrossRef]

- Uddin, M.N.; Yu, K.; Li, L.; Ye, J.; Tafsirojjaman, T.; Alhaddad, W. Developing Machine Learning Model to Estimate the Shear Capacity for RC Beams with Stirrups Using Standard Building Codes. Innov. Infrastruct. Solut. 2022, 7, 227. [Google Scholar] [CrossRef]

- Nguyen, D.-D.; Tran, V.-L.; Ha, D.-H.; Nguyen, V.-Q.; Lee, T.-H. A Machine Learning-Based Formulation for Predicting Shear Capacity of Squat Flanged RC Walls. Structures 2021, 29, 1734–1747. [Google Scholar] [CrossRef]

- Habib, A.; Yildirim, U.; Eren, O. Column Repair and Strengthening Using RC Jacketing: A Brief State-of-the-Art Review. Innov. Infrastruct. Solut. 2020, 5, 75. [Google Scholar] [CrossRef]

- Raza, S.; Khan, M.K.I.; Menegon, S.J.; Tsang, H.-H.; Wilson, J.L. Strengthening and Repair of Reinforced Concrete Columns by Jacketing: State-of-the-Art Review. Sustainability 2019, 11, 3208. [Google Scholar] [CrossRef]

- Karayannis, C.G.; Chalioris, C.E.; Sirkelis, G.M. Local Retrofit of Exterior RC Beam–Column Joints Using Thin RC Jackets—An Experimental Study. Earthq. Eng. Struct. Dyn. 2008, 37, 727–746. [Google Scholar] [CrossRef]

- Vandoros, K.G.; Dritsos, S.E. Concrete Jacket Construction Detail Effectiveness when Strengthening RC Columns. Constr. Build. Mater. 2008, 22, 264–276. [Google Scholar] [CrossRef]

- Tsonos, A.G. Effectiveness of CFRP-Jackets and RC-Jackets in Post-Earthquake and Pre-Earthquake Retrofitting of Beam–Column Subassemblages. Eng. Struct. 2008, 30, 777–793. [Google Scholar] [CrossRef]

- Minafò, G. A practical Approach for the Strength Evaluation of RC Columns Reinforced with RC Jackets. Eng. Struct. 2015, 85, 162–169. [Google Scholar] [CrossRef]

- Ashour, S.A. Effect of Compressive Strength and Tensile Reinforcement Ratio on Flexural Behavior of High-Strength Concrete Beams. Eng. Struct. 2000, 22, 413–423. [Google Scholar] [CrossRef]

- Akbarzadeh, H.; Maghsoudi, A.A. Experimental and Analytical Investigation of Reinforced High Strength Concrete Continuous Beams Strengthened with Fiber Reinforced Polymer. Mater. Des. 2010, 31, 1130–1147. [Google Scholar] [CrossRef]

- Cladera, A.; Marí, A.R. Experimental Study on High-Strength Concrete Beams Failing in Shear. Eng. Struct. 2005, 27, 1519–1527. [Google Scholar] [CrossRef]

- Rashid, M.A.; Mansur, M.A. Reinforced High-Strength Concrete Beams in Flexure. ACI Struct. J. 2005, 102, 462. [Google Scholar] [CrossRef]

- Mohammadhassani, M.; Akib, S.; Shariati, M.; Suhatril, M.; Arabnejad Khanouki, M.M. An Experimental Study on the Failure Modes of High Strength Concrete Beams with Particular References to Variation of the Tensile Reinforcement Ratio. Eng. Fail. Anal. 2014, 41, 73–80. [Google Scholar] [CrossRef]

- Hadi, M.N.S.; Li, J. External Reinforcement of High Strength Concrete Columns. Compos. Struct. 2004, 65, 279–287. [Google Scholar] [CrossRef]

- Akhnoukh, A.K.; Buckhalter, C. Ultra-High-Performance Concrete: Constituents, Mechanical Properties, Applications and Current Challenges. Case Stud. Constr. Mater. 2021, 15, e00559. [Google Scholar] [CrossRef]

- Goldston, M.W.; Remennikov, A.; Sheikh, M.N. Flexural Behaviour of GFRP Reinforced High Strength and Ultra High Strength Concrete Beams. Constr. Build. Mater. 2017, 131, 606–617. [Google Scholar] [CrossRef]

- Thomas, R.J.; Sorensen, A.D. Review of Strain Rate Effects for UHPC in Tension. Constr. Build. Mater. 2017, 153, 846–856. [Google Scholar] [CrossRef]

- Khaksefidi, S.; Ghalehnovi, M.; De Brito, J. Bond Behaviour of High-Strength Steel Rebars in Normal (NSC) and Ultra-High Performance Concrete (UHPC). J. Build. Eng. 2021, 33, 101592. [Google Scholar] [CrossRef]

- Pereira Prado, L.; Carrazedo, R.; Khalil El Debs, M. Interface Strength of High-Strength Concrete to Ultra-High-Performance concrete. Eng. Struct. 2022, 252, 113591. [Google Scholar] [CrossRef]

- Aboukifa, M.; Moustafa, M.A. Experimental Seismic Behavior of Ultra-High Performance Concrete Columns with High Strength Steel Reinforcement. Eng. Struct. 2021, 232, 111885. [Google Scholar] [CrossRef]

- Ramachandra Murthy, A.; Karihaloo, B.L.; Priya, D.S. Flexural Behavior of RC Beams Retrofitted with Ultra-High Strength Concrete. Constr. Build. Mater. 2018, 175, 815–824. [Google Scholar] [CrossRef]

- Lampropoulos, A.P.; Paschalis, S.A.; Tsioulou, O.T.; Dritsos, S.E. Strengthening of Reinforced Concrete Beams Using Ultra High Performance Fibre Reinforced Concrete (UHPFRC). Eng. Struct. 2016, 106, 370–384. [Google Scholar] [CrossRef]

- Kamal, M.M.; Safan, M.A.; Etman, Z.A.; Salama, R.A. Behavior and Strength of Beams Cast with Ultra High Strength Concrete Containing Different Types of Fibers. HBRC J. 2014, 10, 55–63. [Google Scholar] [CrossRef]

- Al-Osta, M.A.; Isa, M.N.; Baluch, M.H.; Rahman, M.K. Flexural Behavior of Reinforced Concrete Beams Strengthened with Ultra-High Performance Fiber Reinforced Concrete. Constr. Build. Mater. 2017, 134, 279–296. [Google Scholar] [CrossRef]

- Said, A.; Elsayed, M.; El-Azim, A.A.; Althoey, F.; Tayeh, B.A. Using Ultra-High Performance Fiber Reinforced Concrete in Improvement Shear Strength of Reinforced Concrete Beams. Case Stud. Constr. Mater. 2022, 16, e01009. [Google Scholar] [CrossRef]

- Mertol, H.C.; Tunç, G.; Akış, T.; Kantekin, Y.; Aydın, İ.C. Investigation of RC Buildings after 6 February 2023, Kahramanmaraş, Türkiye Earthquakes. Buildings 2023, 13, 1789. [Google Scholar] [CrossRef]

- Doğan, T.P.; Kalkan, H.; Aldemir, Ö.; Ayhan, M.; Böcek, M.; Anıl, Ö. Investigation of RC Structure Damages after February 6, 2023, Kahramanmaraş Earthquake in the Hatay Region. Bull. Earthq. Eng. 2024, 22, 5201–5229. [Google Scholar] [CrossRef]

- Avcil, F. Investigation of Precast Reinforced Concrete Structures during the 6 February 2023 Türkiye Earthquakes. Sustainability 2023, 15, 14846. [Google Scholar] [CrossRef]

- Aydın, M.C.; Işık, E.; Büyüksaraç, A.; Ulu, A.E.; Avcil, F. Technical and Socio-Economic Perspective on the Disaster of the Century (6 February 2023 Earthquake) in Türkiye on the Second Anniversary. Geol. J. 2025. [Google Scholar] [CrossRef]

- Tan, M.T.; Binici, B.; Kale, O.; Ozcebe, G. The Successful Performance of a Reinforced Concrete Building with FRP Strengthened Infill Walls and Externally Installed Shear Walls Subjected to Kahramanmaras and Hatay 2023 Earthquakes. Bull. Earthq. Eng. 2025, 23, 1183–1202. [Google Scholar] [CrossRef]

- Işık, E.; Avcil, F.; İzol, R.; Büyüksaraç, A.; Bilgin, H.; Harirchian, E.; Arkan, E. Field Reconnaissance and Earthquake Vulnerability of the RC Buildings in Adıyaman during 2023 Türkiye Earthquakes. Appl. Sci. 2024, 14, 2860. [Google Scholar] [CrossRef]

- Demir, A.; Sezen, H. Seismic Performance of Industrial Buildings During the 2023 Kahramanmaras, Turkey Earthquakes. J. Earthq. Eng. 2024, 1–15. [Google Scholar] [CrossRef]

- Ivanov, M.L.; Chow, W.-K. Structural Damage Observed in Reinforced Concrete Buildings in Adiyaman during the 2023 Turkiye Kahramanmaras Earthquakes. Structures 2023, 58, 105578. [Google Scholar] [CrossRef]

- Tapan, M.; Comert, M.; Demir, C.; Sayan, Y.; Orakcal, K.; Ilki, A. Failures of Structures during the October 23, 2011 Tabanlı (Van) and November 9, 2011 Edremit (Van) earthquakes in Turkey. Eng. Fail. Anal. 2013, 34, 606–628. [Google Scholar] [CrossRef]

- Arslan, M.H.; Korkmaz, H.H. What is to be Learned from Damage and Failure of Reinforced Concrete Structures during Recent Earthquakes in Turkey? Eng. Fail. Anal. 2007, 14, 1–22. [Google Scholar] [CrossRef]

- Tanvir Wasti, S.; Sucuoğlu, H.; Utku, M. Structural Rehabilitation of Damaged RC Buildings After the 1 October 1995 Dİnar Earthquake. J. Earthq. Eng. 2001, 5, 131–151. [Google Scholar] [CrossRef]

- Arslan, M.H.; Korkmaz, H.H.; Gulay, F.G. Damage and Failure Pattern of Prefabricated Structures after Major Earthquakes in Turkey and Shortfalls of the Turkish Earthquake Code. Eng. Fail. Anal. 2006, 13, 537–557. [Google Scholar] [CrossRef]

- Elnashai, A.S. Analysis of the Damage Potential of the Kocaeli (Turkey) Earthquake of 17 August 1999. Eng. Struct. 2000, 22, 746–754. [Google Scholar] [CrossRef]

- Kaplan, H.; Yilmaz, S.; Binici, H.; Yazar, E.; Çetinkaya, N. May 1, 2003 Turkey—Bingöl Earthquake: Damage in Reinforced Concrete Structures. Eng. Fail. Anal. 2004, 11, 279–291. [Google Scholar] [CrossRef]

- Sayın, E.; Yön, B.; Onat, O.; Gör, M.; Öncü, M.E.; Tuğrul Tunç, E.; Bakır, D.; Karaton, M.; Calayır, Y. 24 January 2020 Sivrice-Elazığ, Turkey Earthquake: Geotechnical Evaluation and Performance of Structures. Bull. Earthq. Eng. 2021, 19, 657–684. [Google Scholar] [CrossRef]

- Yakut, A.; Sucuoğlu, H.; Binici, B.; Canbay, E.; Donmez, C.; İlki, A.; Caner, A.; Celik, O.C.; Ay, B.Ö. Performance of Structures in İzmir after the Samos island Earthquake. Bull. Earthq. Eng. 2022, 20, 7793–7818. [Google Scholar] [CrossRef]

- Aksoylu, C.; Mobark, A.; Hakan Arslan, M.; Hakkı Erkan, İ. A comparative Study on ASCE 7-16, TBEC-2018 and TEC-2007 for Reinforced Concrete Buildings. Rev. Constr. 2020, 19, 282–305. [Google Scholar] [CrossRef]

- Işık, E. A Comparative Study on the Structural Performance of an RC Building Based on Updated Seismic Design Codes: Case of Turkey. CJSMEC 2021, 7, 123. [Google Scholar] [CrossRef]

- Büyüksaraç, A.; Işık, E.; Bektaş, Ö. A Comparative Evaluation of Earthquake Code Change on Seismic Parameter and Structural Analysis; A Case of Turkey. Arab. J. Sci. Eng. 2022, 47, 12301–12321. [Google Scholar] [CrossRef]

- Alpyürür, M.; Ulutaş, H. Comparison of Performance Analysis Results with Developed Site-Specific Response Spectra and Turkish Seismic Design Code: A Case Study from the SW Türkiye Region. Buildings 2024, 14, 1233. [Google Scholar] [CrossRef]

- Aras, F.; Doğan, T.P.; Öztürk, M.; Tün, M.; Işık, E.; Arslan, M.H. Assessment of the Damage Caused by the 6 February 2023 Earthquakes on Old and New Dated Reinforced Concrete Buildings in Elbistan, Turkey. Adv. Struct. Eng. 2025, 13694332251375194. [Google Scholar] [CrossRef]

- Specification for Structures to Be Built in Disaster Areas; ABYYHY: Ankara, Turkey, 1975.

- TBEC. Turkish Building Earthquake Code; T.C. Resmi Gazete; TBEC: Ankara, Turkey, 2018. [Google Scholar]

- Seismosoft. SeismoStruct 2024—A Computer Program for Static and Dynamic Nonlinear Analysis of Framed Structures; Seismosoft: Pavia, Italy, 2024. [Google Scholar]

- Işık, E.; Özdemir, M. Performance Based Assessment of Steel Frame Structures by Different Material Models. Int. J. Steel Struct. 2017, 17, 1021–1031. [Google Scholar] [CrossRef]

- Menegotto, M.; Pinto, P.E. Method of Analysis for Cyclically Loaded R.C. Plane Frames Including Changes in Geometry and Non-Elastic Behaviour of Elements under Combined Normal Force and Bending. In Symposium on the Resistance and Ultimate Deformability of Structures Acted on by Well-defined Repeated Loads; International Association for Bridge and Structural Engineering: Zurich, Switzerland, 1973; pp. 15–22. [Google Scholar] [CrossRef]

- Antoniou, S.; Pinho, R. SeismoStruct–Seismic Analysis Program by Seismosoft; Technical Manual and User Manual; SeismoStruct: Pavia, Italy, 2003. [Google Scholar]

- Krawinkler, H.; Seneviratna, G. Pros and Cons of a Pushover Analysis of Seismic Performance Evaluation. Eng. Struct. 1998, 20, 452–464. [Google Scholar] [CrossRef]

- Elnashai, A.S. Advanced Inelastic Static (Pushover) Analysis for Earthquake Applications. Struct. Eng. Mech. 2001, 12, 51–69. [Google Scholar] [CrossRef]

- Borzi, B.; Pinho, R.; Crowley, H. Simplified Pushover-Based Vulnerability Analysis for Large-Scale Assessment of RC Buildings. Eng. Struct. 2008, 30, 804–820. [Google Scholar] [CrossRef]

- Chopra, A.K.; Goel, R.K. A Modal Pushover Analysis Procedure for Estimating Seismic Demands for Buildings. Earthq. Eng. Struct. Dyn. 2002, 31, 561–582. [Google Scholar] [CrossRef]

- Guo, W.; Hu, Y.; Liu, H.; Bu, D. Seismic Performance Evaluation of Typical Piers of China’s High-Speed Railway Bridge Line Using Pushover Analysis. Math. Probl. Eng. 2019, 2019, 9514769. [Google Scholar] [CrossRef]

| Parameter | 1975 |

|---|---|

| Concrete Grade | C14 |

| Reinforcement Grade | S220 |

| Columns Dimensions (mm) | 250 × 250 |

| Beams Dimensions (mm) | 200 × 300 |

| Beam Lower Reinforcement | 2 ϕ 12 |

| Beam Upper Reinforcement | 2 ϕ 12 |

| Longitudinal Reinforcement (column) | 4 ϕ 14 |

| Transversal reinforcement (mm) | ϕ8 |

| Concrete cover (mm) | 25 |

| Spacing of Transversal reinforcement (mm) | 200 |

| Model No. | Description |

|---|---|

| Model I | Insufficient Transverse Reinforcement: Transverse reinforcement spacing in columns has been increased to 400 mm. (ϕ8/400) |

| Model II | Low-Strength Concrete: Concrete that is below the intended strength (C8/10) |

| Model III | Insufficient Transverse Reinforcement (ϕ8/400) + Low-Strength Concrete (C8/10) |

| Model IV | Inadequate Concrete Cover (0.10 cm) |

| Section Material (s) | Section Dimensions | ||

|---|---|---|---|

| External Longitudinal/transverse reinforcement | S420 | External height | 350 mm |

| Internal Longitudinal/transverse reinforcement | S220 | Internal height | 250 mm |

| External longitudinal reinforcement | 4 ϕ 14 | External width | 350 mm |

| Concrete Jacketing | C60 | Internal width | 250 mm |

| Concrete core | C14 | Cover thickness | 25 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hadzima-Nyarko, M.; Işık, E.; Radu, D.; Bulajić, B.; Lozančić, S.; Radić, J.; Ereš, A. Effectiveness of High-Performance Concrete Jacketing in Improving the Performance of RC Structures. Appl. Sci. 2025, 15, 11421. https://doi.org/10.3390/app152111421

Hadzima-Nyarko M, Işık E, Radu D, Bulajić B, Lozančić S, Radić J, Ereš A. Effectiveness of High-Performance Concrete Jacketing in Improving the Performance of RC Structures. Applied Sciences. 2025; 15(21):11421. https://doi.org/10.3390/app152111421

Chicago/Turabian StyleHadzima-Nyarko, Marijana, Ercan Işık, Dorin Radu, Borko Bulajić, Silva Lozančić, Josip Radić, and Antonija Ereš. 2025. "Effectiveness of High-Performance Concrete Jacketing in Improving the Performance of RC Structures" Applied Sciences 15, no. 21: 11421. https://doi.org/10.3390/app152111421

APA StyleHadzima-Nyarko, M., Işık, E., Radu, D., Bulajić, B., Lozančić, S., Radić, J., & Ereš, A. (2025). Effectiveness of High-Performance Concrete Jacketing in Improving the Performance of RC Structures. Applied Sciences, 15(21), 11421. https://doi.org/10.3390/app152111421