Featured Application

This study explores the application of BIM and AI tools to minimize construction time and enhance project management by streamlining data organization, enabling predictive modeling, and facilitating proactive, data-driven decision-making. By addressing critical challenges such as fragmented records, regulatory compliance, and resource allocation, these technologies pave the way for more efficient workflows and optimized renovation outcomes.

Abstract

Digital transformation powered by Building Information Modeling (BIM) and Artificial Intelligence (AI) is reshaping renovation practices by addressing persistent challenges such as fragmented records, scheduling disruptions, regulatory delays, and inefficiencies in stakeholder coordination. This study explores the integration of these technologies through a case study of a Catholic church renovation (2022–2023) in Hong Kong, supplemented by insights from 10 comparable projects. The research proposes a practical framework for incorporating digital tools into renovation workflows that focuses on diagnosing challenges, defining objectives, selecting appropriate BIM/AI tools, designing an integrated system, and combining implementation, monitoring, and scaling into a cohesive iterative process. Key technologies include centralized BIM repositories, machine learning-based predictive analytics, Internet of Things (IoT) sensors, and robotic process automation (RPA). The findings show that these tools significantly improve data organization, proactive planning, regulatory compliance, stakeholder collaboration, and overall project efficiency. While qualitative in nature, this study offers globally relevant insights and actionable strategies for advancing digital transformation in renovation practices, with a focus on scalability, continuous improvement, and alignment with regulatory frameworks.

1. Introduction

The building maintenance and renovation sector is undergoing a transformative shift driven by the integration of digital technologies. In the context of the Industry 4.0 era, Building Information Modeling (BIM) and Artificial Intelligence (AI) have emerged as pivotal tools to address persistent challenges such as fragmented historical records, regulatory compliance, inefficient resource allocation, and project delays [1,2]. It is submitted that these technologies may provide a centralized platform for data organization, predictive modeling, and proactive decision-making, thereby enhancing project outcomes and promoting sustainable practices for building maintenance [3].

The possible impact of this transformation is particularly significant in dense urban environments like Hong Kong, where aging infrastructure and stringent regulatory requirements necessitate innovative approaches to building management. The Urban Renewal Authority (URA) of Hong Kong has outlined guidelines and templates for maintenance manuals [4], yet the adoption of digital tools remains limited, especially in the private sector. Traditional practices, characterized by manual data handling and fragmented workflows, fail to meet the demands of modern renovation projects, resulting in inefficiencies and increased costs.

Existing research highlights the potential of BIM and AI to revolutionize construction and maintenance practices. BIM serves as a collaborative digital platform, enabling real-time visualization and coordination among stakeholders, while the AI models, such as Machine Learning (ML) and Deep Learning (DL), analyze historical data to optimize scheduling, predict risks, and enhance resource allocation. Despite these advancements, barriers such as high implementation costs, lack of technical expertise, and resistance to change have hindered their widespread adoption, particularly in renovation projects of private buildings in Hong Kong [5].

This study investigates the role of digitalization, BIM, and AI in transforming building maintenance and renovation processes. Through a qualitative approach, including a case study of a Catholic church building with educational and administrative use in Hong Kong extensively renovated between 2022 and 2023, the research examines how these technologies address key industry challenges. The study also explores the integration of predictive modeling and weather forecasting data to enhance proactive planning and mitigate potential delays.

By examining meeting records, maintenance histories, and regulatory frameworks, this paper highlights the synergistic potential of BIM and AI in streamlining workflows, minimizing errors, and enhancing project timelines. The research makes a significant contribution to the evolving discourse on smart building management, providing actionable insights for implementing resilient, cost-effective, and sustainable digital solutions.

While this study focuses on Hong Kong as a representative case, the challenges and opportunities presented by digital transformation in building maintenance are echoed globally. Many urban centers around the world face similar issues: aging infrastructure, complex regulatory environments, and fragmented data management, which hinder efficient building upkeep and renovation. Internationally, the adoption of BIM and AI is gaining momentum as governments and industry stakeholders recognize their capacity to improve transparency, foster collaboration, and optimize lifecycle management. The regulatory frameworks and digitalization efforts observed in Hong Kong closely parallel trends in other major cities, underscoring the global relevance of integrating advanced technologies into building maintenance practices [1,3].

2. Literature Review

BIM and AI have been pivotal in driving the digital transformation of the Architecture, Engineering, and Construction (AEC) industry, enabling more sustainable building practices and advancing smart city development. By combining digital modelling with intelligent analytics, these technologies enhance project quality by improving transparency, fostering collaboration, and increasing efficiency, thereby establishing a foundation for a connected and data-driven built environment [6].

A set of emerging and disruptive technologies, most notably the Internet of Things (IoT), 5G, Virtual/Augmented Reality (VR/AR), and Digital Twins (DT), further expand capabilities in design, construction, and operations. IoT enables real-time data collection and monitoring; VR/AR and DT support immersive visualization, coordination, and operational simulations that improve collaboration and sustainability, including energy optimization, predictive maintenance, and lifecycle assessments. Realizing these benefits at scale requires overcoming persistent issues such as interoperability, high implementation costs, and change resistance among stakeholders [7,8].

Policy environments increasingly influence adoption trajectories. For example, in Hong Kong, BIM has been mandated for public works above specified thresholds since 2018 to drive productivity, safety, and delivery performance [9]. Despite this momentum, private-sector uptake remains constrained by high upfront costs, limited funding, uncertain return on investment (ROI), and market dynamics that favor lowest-bid procurement, shifting near-term burdens to contractors while long-term gains accrue to owners [10,11,12]. Experience from Chinese Mainland suggests that mandates, financial incentives, standardized training, and maturing national standards can accelerate diffusion and capability building. Government-led BIM standards and Common Data Environments, complemented by tax incentives and mandatory training, illustrate coordinated, policy-driven approaches to overcome cost and change barriers and to scale consistent, collaborative practices [13,14,15,16,17,18,19,20].

Technological advances are reshaping workflows of building renovation. BIM structures asset information and streamlines maintenance; AI—especially ML—adds predictive analytics for proactive decisions; DT enables real-time monitoring and lifecycle management; IoT connects systems for fault detection and energy optimization; and Generative Design (GD) algorithmically explores solutions under constraints such as cost and efficiency. Collectively, these tools enable scenario testing, continuous condition sensing, and optimization, thereby improving sustainability outcomes [21,22], planning and execution [23,24,25,26,27,28] in renovation contexts.

However, sector-wide adoption still faces common impediments: high initial investments in software, hardware, and training; shortages of skilled personnel; organizational resistance to change; and interoperability hurdles across heterogeneous systems. Addressing these barriers requires coordinated actions, including public–private partnerships, targeted financial support, capability-building programs, and research into scalable, standards-based frameworks that can be deployed by small- and medium-sized firms as well as large enterprises [29,30,31,32].

These global and regional trends converge on the practical demands of building upkeep in dense, aging urban environments. In Hong Kong, the Building Management Ordinance (BMO, Cap. 344) and the Property Management Services Ordinance (PMSO) establish expectations for preventive maintenance, financial planning, and compliance, promoting transparency and accountability while recognizing administrative constraints among smaller firms [4,33,34,35,36,37]. Digitalization strengthens this governance context: BIM centralizes collaboration and data exchange; predictive analytics anticipates maintenance needs and optimizes resource allocation; and data-aligned workflows improve auditability and compliance. When aligned to BMO/PMSO expectations, these digital tools can directly address fragmented records, coordination inefficiencies, and reactive maintenance practices—moving management regimes toward systematic, transparent, and proactive operation [21,38].

3. Methodology

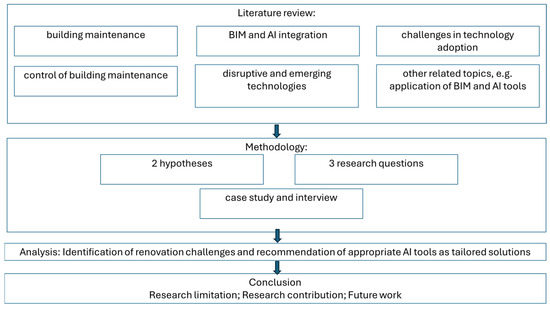

The research methodology adopted in this study employs a qualitative approach to address the research objectives and hypotheses, focusing on the role of digital transformation in building renovation, with specific implications from Hong Kong. The methodology consists of three interconnected components: a literature review, a case study analysis, and validation through interviews and literature synthesis, as illustrated in Figure 1. The case study provides empirical insights into theoretical concepts and principles, offering a practical lens to examine the application of digital transformation strategies. Interviews are used to identify challenges and opportunities in the adoption of digital tools, while also validating findings from literature and case study. This approach ensures a nuanced understanding of the broader implications of digital transformation in building renovation, emphasizing context-specific insights without overgeneralization [1,39].

Figure 1.

Research process.

The data collection process integrates both primary and secondary sources to provide a comprehensive evaluation of the impact of digital transformation in building maintenance [40]. Primary data were gathered through in-depth interviews with a local renovation contractor, who has over 15 years of expertise in building renovation, including maintenance and mandatory building inspection works. While the company has encouraged its staff to participate in training programs related to BIM, these technologies have not yet been fully integrated into their workflows.

The church renovation project served as a focal case study to identify specific operational challenges in building renovation, such as fragmented historical records, weather-related scheduling disruptions, and approval delays. These challenges were validated and expanded upon through semi-structured interviews with contractors and project documentation from 10 additional renovation projects. The church case provided a detailed lens to examine real-world issues, enabling the triangulation of findings across multiple data sources. This integration ensures that the challenges identified are both grounded in specific case data and broadly representative of industry trends.

This study utilized a qualitative approach, incorporating the semi-structured interviews and an extensive document review to explore the challenges and opportunities associated with digital transformation in building renovation projects. The interviews were conducted with two senior directors (D1 and D2) from a focal renovation contractor, each having over 15 years of industry experience. Each interview lasted approximately 60 min and employed open-ended questions. The directors’ commitment to improving project quality and adopting innovative practices provided valuable insights into the practical barriers and opportunities for digital adoption in the renovation sector.

The interview data were supplemented with a comprehensive review of project documentation from ten representative renovation projects, with budgets ranging from USD 0.7 to 1.3 million. This included 24 sets of site meeting minutes, client feedback (both positive and negative), and complaint logs, as well as maintenance histories, non-conformance reports, and procurement records. The triangulation of interview insights with project records ensured consistency and enhanced the credibility of the findings.

Thematic coding of the data identified recurring challenges, including “fragmented records”, “coordination inefficiencies”, and “approval delays”. These themes were cross-referenced with project documentation to validate and deepen the analysis. By focusing on projects with similar scopes, such as mandatory inspection requirements, building typologies, and levels of complexity, the study identified robust cross-case patterns. This analytical approach provided actionable insights into how digital tools, including BIM and AI, could address operational inefficiencies and improve project outcomes.

The interviews offer valuable qualitative insights into the practical challenges, limitations, and opportunities associated with adopting digital technologies within traditional renovation processes. Through thematic analysis of interview notes, we derived first-order codes (e.g., “missing records”, “weather delays”, “approval loops”) and aggregated them into broader themes. These themes were then cross-checked against project documentation—including meeting minutes, non-conformance reports, and client feedback—to validate findings through triangulation. The convergence between interview claims and documented incidents strengthened the reliability of our inferences. Deviant cases (e.g., a project with unusually fast completion) were analyzed to refine theme boundaries rather than excluded, ensuring comprehensive understanding of the phenomena.

Building on these empirical findings and the literature review, we identified specific applications where digital tools could address the observed challenges. For instance, ML algorithms could analyze extensive datasets of building characteristics, similar to the fragmented records identified in our interviews. When combined with cost–benefit analysis models, these digital tools could support strategic planning of building renovations [24,41].

To ensure clarity and support the analysis, the contractor’s background and relevant data are systematically summarized in Table 1.

Table 1.

Profile of the Contractor in the Case Study.

Based on the literature review above, we have proposed two hypotheses and three research questions (as illustrated in Table 2) to attain the research objective:

Table 2.

Alignment of Literature Review Findings with Hypotheses and Research Questions.

To investigate how the integration of BIM and AI can address the challenges of building maintenance and renovation in Hong Kong, with a focus on improving project timelines, optimizing costs, enhancing stakeholder collaboration, and ensuring compliance with regulatory and safety standards, thereby promoting sustainable and resilient renovation practices.

Hypotheses:

- Contractors and property managers in Hong Kong exhibit hesitation in adopting BIM and AI tools for private building renovation due to barriers such as high costs, lack of technical expertise, and resistance to change.

- The integration of BIM and AI in building renovation projects significantly improves project timelines, reduces lifecycle costs, and enhances compliance with safety and regulatory standards.

Research Questions:

- What are the primary challenges in adopting BIM and AI in private building renovation projects in Hong Kong, and how can these barriers be mitigated?

- How do BIM and AI contribute to project management efficiency, cost optimization, and stakeholder collaboration in renovation projects?

- Can a framework be developed to integrate BIM and AI tools into renovation workflows, enhancing project quality?

The case study focuses on the renovation project of the external walls of a building used for education and administration Hong Kong. With a project budget of approximately USD 1 million, the renovation, undertaken between 2022 and 2023, involved extensive repair works, including 5000 m2 of built surface, external wall repairs, lobby renovation, material provision and safety measures. The project duration is 12 months.

The study applies a structured methodology, as outlined in Figure 1, to identify and analyze challenges in building renovation and maintenance projects. This involves thematic analysis of interview responses and content analysis of project documents, enabling the identification of recurring issues such as ‘coordination inefficiencies’, ‘regulatory delays’, and ‘data fragmentation’. Qualitative data from project communications (e.g., meeting minutes, client feedback, and complaint logs) were systematically coded and categorized into key themes. This iterative process, grounded in prior literature and aligned with the study’s research objectives, ensures a comprehensive understanding of operational challenges and the potential for digital interventions. By triangulating findings across multiple data sources, the study establishes a replicable framework for advancing sustainable and efficient practices in building renovation and maintenance. To ensure accuracy and relevance, member checking was conducted by sharing preliminary findings with interview participants, allowing them to review and validate the interpretations of their input. Thematic analysis was conducted through a systematic coding process, where initial first-order codes (e.g., ‘fragmented records’, ‘weather delays’) were iteratively refined and aggregated into broader themes. This iterative approach ensured consistency, credibility, and alignment between the data and the overarching research objectives.

4. Analysis and Results

From the case study and ten similar projects, we highlight key operational challenges and their implications for renovation workflows. Ten recurring issues are analyzed alongside potential digital interventions using BIM and AI tools. Each challenge is linked to targeted solutions, emphasizing their role in improving project efficiency and compliance within regulatory framework.

With reference to our literature review, the interviews and records reveal several context-specific challenges and adaptive strategies in Hong Kong’s private renovation market that are not fully captured by prior studies, including:

- (i)

- the operational impact of legacy record fragmentation on statutory submissions and variation claims;

- (ii)

- the role of weather volatility on short-run scheduling of external works;

- (iii)

- approval bottlenecks arising from bespoke material selections in heritage-like settings; and

- (iv)

- pragmatic workarounds (e.g., WhatsApp-based coordination) that partially compensate for the absence of integrated digital environments.

Some excerpts from the interview:

D1: “For a 30-year-old block, old repair records were referred to. They’re usually in boxes with no index. When the client asked, ‘why is this variation of order proposed?’, we struggled to provide supporting documents with evidence”.

D2: “External wall works are weather-sensitive. Two or three unexpected rainy days or typhoon push inspections and paint curing…Clients like special tiles or tailor-made window glass. Getting consultant approval takes time; small changes may require re-submittals and discussion with clients; and delayed deliveries”.

4.1. Key Challenges in the Selected Renovation Projects

While prior research highlights generic barriers to AI adoption, such as high costs, skill shortages, and resistance to change, this study identifies unique operational challenges in building maintenance and renovation. These include fragmented records disrupting workflows, weather-induced scheduling issues, delays in approving bespoke materials, and reliance on unstructured communication channels, all of which digital interventions may be addressed.

We identify ten operational challenges in renovation projects and link them to practical digital solutions, offering actionable recommendations for improvement. Key examples include implementing centralized BIM repositories to address fragmented records, with predictive analytics and AI models to mitigate weather-induced schedule disruptions, using automated workflows to reduce approval delays, and adopting structured communication platforms to enhance traceability and accountability. By addressing these challenges with targeted digital interventions, the study demonstrates how AI and BIM tools can streamline workflows, resolve inefficiencies, and optimize project outcomes.

- (1)

- Fragmented Historical Records

Observed Issue: Incomplete or inconsistent access to maintenance logs and records of past remedial works led to significant uncertainty during project scoping and hindered the ability to substantiate variation claims. Meeting minutes frequently highlighted repeated requests for critical information, such as prior waterproofing techniques, which were poorly documented.

Interview Excerpt (D1): “We discovered a previous patch repair only after opening up the roof. This caused delays and additional work to reassess the situation.

In the church building renovation case, incomplete records of past repair works led to significant delays in scoping and decision-making. For example, prior waterproofing techniques were poorly documented, requiring additional investigations to determine the appropriate remedial measures. This issue is consistent with challenges observed in the 10 comparable projects, where fragmented records frequently disrupted workflows and regulatory submissions”.

Implication: The absence of reliable historical records increases the likelihood of unforeseen issues during construction, resulting in added survey contingencies and a heightened risk of rework. This affects project timelines and undermines confidence in cost estimates and resource planning.

Digital applications:

- BIM as a Living Repository: Centralizes and organizes historical and real-time building data, providing a single source of truth for all stakeholders.

- Deep Learning Optical Character Recognition (DLOCR) and Natural Language Processing (NLP)/ ML: Enables bulk digitalization and classification of legacy records, linking entities such as maintenance activities, materials, and equipment specifications for easier retrieval.

- IoT Integration: Facilitates ongoing asset data capture, automatically updating maintenance logs and equipment performance to ensure records remain current and actionable.

Expected outcome: This approach minimizes uncertainty, strengthens claims substantiation, and supports smoother workflows by ensuring that critical information is readily accessible and systematically managed [45,46].

- (2)

- Inadequate Stakeholder Coordination

Observed issue: Fragmented responsibilities among owner corporations, consultants, and contractors resulted in different instructions, delays in decision-making, and slow resolution of queries. While informal communication channels, such as chat groups, improved response times, they lacked transparency and auditability, creating challenges in tracking decisions and maintaining accountability.

Interview excerpt (D1): “Three messages from three different people gave three different answers. We need a single source of instructions to avoid confusion and delays”.

Digital application:

- BIM Collaboration Hubs with Role-Based Access: Centralize communication and documentation, ensuring that all stakeholders work from a unified platform with permissions tailored to their roles.

- Digital Twin (DT)-Enabled Coordination Spaces: Create virtual environments for real-time collaboration, allowing stakeholders to visualize project progress and track decisions in context.

- IoT-Backed Status Feeds: Provide real-time updates on project milestones, site conditions, and task statuses, ensuring all parties have access to accurate and up-to-date information.

- Decision Logs Aligned with URA Templates and DMC Roles: Standardize and document decisions to ensure alignment with regulatory requirements and clearly delineate stakeholder responsibilities.

Expected Outcome: By integrating these digital tools, projects can reduce miscommunication, improve decision traceability, and enhance collaboration. This fosters greater accountability and enables more efficient project workflows [47].

- (3)

- Limited Predictive Capabilities

Observed Issue: The church building renovation project encountered frequent weather disruptions, including unexpected rainfall and typhoons, which significantly impacted external masonry work and inspections. Scheduling adjustments were managed reactively, leading to missed inspection windows and resource reallocation delays. This challenge highlights the need for predictive capabilities, such as weather forecasting and risk modeling, which could proactively adjust schedules. Similar challenges were observed in the 10 comparable projects, underscoring the importance of AI-driven predictive tools to optimize planning and mitigate disruptions. Project schedules failed to adapt in real time, resulting in missed inspection windows, stalled tasks, and cascading delays across project timelines [48].

Interview Excerpt (D2): “Two typhoon days can set us back an entire week because inspections couldn’t proceed as planned, and the schedule didn’t fully account for such adjustments”.

Digital application:

- ML-Based Schedule Risk Forecasts: Analyze historical weather data and task dependencies to predict potential delays, enabling proactive adjustments to project schedules.

- DT Simulations: Test alternative sequencing strategies and assess the impact of weather-related disruptions in a virtual environment, helping teams identify the most efficient rescheduling options.

- Integration of Short-Term Weather APIs: Provide real-time weather updates to enable micro-adjustments in scheduling and resource allocation, reducing the likelihood of delays.

Expected outcome: Application of predictive and real-time digital tools can mitigate the impacts of weather-induced slippages, allowing for dynamic scheduling and more precise planning. This reduces downtime, increases resource efficiency, and ensures that project timelines better align with on-site realities. Extension of time may be granted easily due to reliable and objective proof [47,48].

- (4)

- Non-Compliance with Regulatory Standards

Observed Issue: Inconsistent documentation of visual checks for hoarding, fire safety, and access routes led to recurring non-conformance issues and rework.

Interview Excerpt (D1): “We had to redo the hoarding signage because the photos weren’t properly tagged”.

Digital application:

- Computer Vision (CV): Automates detection of safety elements (e.g., signage, access clearances) to ensure compliance.

- Rule-Based Checks: Map regulatory requirements (BO/BMO/FSD) for real-time validation.

- Compliance Dashboards: Centralize results linked to URA checklists for streamlined reporting and tracking.

Expected outcome: Automating compliance checks reduces errors, prevents recurring issues, and ensures adherence to safety and regulatory standards [49].

- (5)

- Cost and Time Overruns

Observed Issue: In the church building renovation case, delays caused by approval processes for bespoke materials, such as custom stained glass and heritage tiles, and weather disruptions, including typhoon interruptions, led to escalating preliminary costs. Static cost forecasts failed to reflect real-time changes, limiting proactive decision-making and resource reallocation.

Interview Excerpt (D1): “When approvals are delayed, preliminary costs increase, but our forecasts don’t account for it”.

Digital application:

- ML Regression and Probabilistic Cost–Time Forecasts: Integrate with BIM 4D/5D models to dynamically predict cost and schedule impacts.

- Variance Alerts: Automatically flag deviations in cost and time for timely intervention.

- CIC-Aligned Templates: Standardize input formats to enhance consistency and forecasting accuracy across projects.

Expected outcome: The church case study demonstrates how real-time forecasting and automated alerts could enable more adaptive planning, reducing cost overruns and improving resource allocation efficiency. These solutions could also mitigate similar issues observed in the 10 comparable projects, where approval delays and static forecasting models frequently disrupted project timelines and budgets [50].

- (6)

- Water Leakage Management

Observed Issue: Recurrent water leakage posed significant challenges, including reactive containment measures, unplanned scope additions, and delays in tracing leakage sources. These leaks often went undetected until they caused visible damage, necessitating costly repairs and extensive investigations. For example, moisture may be discovered behind walls previously assessed as “dry”, highlighting the limitations of traditional inspection methods and the lack of real-time monitoring systems. This issue disrupted project timelines and increased the risk of structural damage and mold growth.

Interview Excerpt (D2): “We found active moisture behind supposedly ‘dry’ walls…It is time-consuming to fix with high cost”.

Digital application:

- BIM-Integrated Moisture Maps: Seamlessly integrate IoT sensor data into BIM models to generate visual moisture maps that trace leakage paths across stacks, facilitating precise and targeted interventions.

- Predictive Models: Use TinyML on small, energy-efficient devices to detect water leaks early by training simple models on recorded pipe noise and compressing them for optimized performance on low-power boards, such as the Arduino Nano, enabling fast and localized leak detection without relying on centralized systems [51].

Expected Outcome:

The integration of BIM-linked visualization and edge-based predictive models ensures proactive and accurate detection of water leaks, reducing the time and cost associated with manual tracing and reactive containment. Early identification of potential leaks minimizes structural damage, improves resource allocation, and enhances project efficiency [51].

- (7)

- Scaffolding and General Safety Concerns

Observed Issue: Falling-object risks and dynamic site hazards were frequently observed, with near-miss incidents recorded on two projects.

Interview Excerpt (D2): “Manual top-down safety inspections were conducted but occasionally failed to identify hazards present during the morning work hours”.

Digital application:

- CA for Hazard Detection: Automatically identifies missing safety measures (e.g., toe boards, netting, drop zones) and falling-object risks in real-time.

- AIoT Wearables: Monitors worker proximity to hazardous zones and tracks vital signs to deliver real-time alerts and promote safer working conditions.

- Automated Toolbox Talk Prompts: Provides tailored safety reminders based on detected site risks.

Expected Outcomes:

- Enhanced Hazard Detection: CA detects missing safety measures (e.g., toe boards, netting) and identifies falling-object risks in real-time, reducing the likelihood of accidents [52].

- Improved Worker Safety: Real-time monitoring of worker proximity and health reduces the occurrence of near-miss incidents, fostering a safer work environment.

- (8)

- Unplanned Scope Changes

Observed Issue: Hidden defects discovered post-opening-up triggered variation negotiations and resequencing.

Interview Excerpt (D2): “Spalling was worse than the survey showed; we had to extend the patch area”.

Digital application: ML scenario estimators for variation magnitudes; DT to reflow 4D sequences; BIM change sets with cost–time impact previews.

Expected Outcomes:

- Proactive Scope Management: ML scenario estimators predict the magnitude of hidden defects, enabling better preparation for potential scope changes.

- Optimized Resequencing: DT allow teams to test and reflow 4D construction sequences in response to scope changes, minimizing disruption to project timelines.

- Cost and Time Clarity: BIM change sets preview cost and time impacts of scope variations, facilitating faster decision-making and smoother negotiations [53].

- (9)

- Surveillance and Monitoring Limitations

Observed Issue: Camera outages and blind spots undermined site security and incident reviews.

Interview Excerpt (D1): “A camera was down for days—only noticed after a minor theft”.

Digital application:

- AI-Enabled Video Analytics: Monitors camera functionality, detects intrusions and anomalies in real-time, and provides uptime alerts for continuous surveillance.

- BIM-Linked Camera Coverage Planning: Optimizes camera placement using BIM to eliminate blind spots and simulate coverage with 3D models.

- IoT Perimeter Sensors: Detects unauthorized access or movement using sensors like vibration and motion detectors for added security.

Expected outcome: Comprehensive surveillance is achieved through optimized camera placement, real-time AI monitoring, and IoT perimeter sensors. This enhances site security, minimizes theft and vandalism, and improves incident response efficiency [54].

- (10)

- Material Procurement and Approval Delays

Observed Issue: Specialty finishes, mock-ups, and submittals faced iteration loops, and late approvals caused expedited shipping.

Interview Excerpt (D2): “We approved a sample; however, the batch color did not match, requiring an additional round of submissions”.

Digital application:

- BIM-Integrated Product Data and Visual Checks: Implement a system that integrates Building Information Modeling (BIM) with comprehensive product data to enable visual checks and ensure consistency between approved samples and delivered batches. This includes utilizing BIM to create accurate representations of materials and finishes, allowing for early detection of discrepancies.

- Machine Learning (ML) Demand Forecasting: Employ machine learning algorithms to forecast material demand accurately, minimizing the risk of shortages or delays in procurement. ML can analyze historical project data, market trends, and other relevant factors to predict material needs and optimize the procurement process.

- Robotic Process Automation (RPA) for Submittal Workflows: Automate submittal workflows using RPA to streamline the process, reduce iteration loops, and accelerate approvals. RPA can handle repetitive tasks such as data entry, document routing, and follow-up communications, freeing up project team members to focus on more critical activities.

- Digital Mock-Up Comparisons: Use digital mock-up comparisons to minimize iterations and ensure that the final product aligns with the approved design. This involves creating virtual mock-ups that can be easily reviewed and modified, reducing the need for physical mock-ups and accelerating the approval process.

Expected Outcomes:

- Streamlined Submittal Workflows: RPA automates submittal processes, significantly reducing iteration loops and approval delays. This leads to faster turnaround times and improved project efficiency [55].

- Accurate Visual Checks: BIM-integrated product data and digital mock-up comparisons ensure consistency between approved samples and delivered batches, minimizing rework and reducing the risk of costly errors. This results in higher quality outcomes and improved client satisfaction [55].

These ten challenges offer practice-based evidence of delay mechanisms and their digital touchpoints. While pinpointing where and how BIM and AI tools intersect with regulatory templates, role assignments, and standard practices, digital solutions may streamline workflows, enhance decision-making, and embed predictability into project delivery and governance. Table 3 consolidates these findings, offering a comparative overview of key challenges and digital solutions identified across the studied projects.

Table 3.

Comparative Overview of Key Challenges and Digital Solutions Across Projects.

4.2. Implications for Digital Transformation of Renovation Projects

The adoption of digital technologies may address inefficiencies, improve regulatory compliance, and foster sustainable practices, offering a pathway to overcome long-standing challenges in project management, stakeholder collaboration, and cost optimization. The findings strongly validate the first hypothesis, which posits that renovation contractors in Hong Kong hesitate to adopt BIM and AI due to barriers such as high costs, limited technical expertise, and resistance to change. Interviews with contractors revealed consistent concerns about the high initial costs associated with implementing BIM and AI tools, including software acquisition, training, and the hiring of specialized personnel. The lack of in-house technical capacity further exacerbates this hesitation, particularly for smaller firms that struggle to justify the investment. Additionally, a preference for traditional workflows, combined with skepticism about the tangible benefits of these technologies, contributes to organizational resistance. The highly competitive nature of Hong Kong’s renovation market, where contractors often prioritize cost-cutting measures to secure bids, further hinders the adoption of innovative tools. This observation is consistent with similar research [45,56,57].

The second hypothesis, which asserts that the integration of BIM and AI significantly improves project timelines, reduces lifecycle costs, and enhances regulatory compliance, is also validated. Evidence from case studies and literature demonstrates that these technologies streamline workflows, optimize resource allocation, and improve compliance with Hong Kong’s stringent regulatory requirements. For instance, predictive analytics and centralized data systems have been shown to mitigate delays, enhance decision-making, and achieve substantial cost savings over the lifecycle of renovation projects [58].

The first research question examines the primary challenges in adopting BIM and AI in private building renovation projects and explores potential mitigation strategies. The findings highlight several key challenges, including high upfront costs, a lack of technical expertise, resistance to change, and short-term focus among contractors. The recent economic downturn in the property market has further reinforced these barriers, as firms prioritize immediate cost savings over long-term investments in digital tools. To address these challenges, several strategies are proposed. Government policies with financial incentives, such as subsidies, tax breaks, and low-interest loans, could help offset implementation costs, making BIM and AI more accessible to renovation contractors. Training programs, offered in partnership with institutions like the CIC, could bridge the skills gap by equipping professionals with the technical expertise needed to operate these systems. Additionally, pilot projects that illustrate the tangible benefits of BIM and AI can build stakeholder confidence, while structured change management programs can help overcome resistance by emphasizing the long-term advantages of digital transformation [59].

The second research question investigates how BIM and AI contribute to project management efficiency, cost optimization, and stakeholder collaboration. The integration of these technologies has demonstrated significant improvements in project outcomes. BIM serves as a centralized platform for managing project data, eliminating inefficiencies caused by fragmented records and enabling real-time collaboration among stakeholders [38]. AI-driven tools enhance predictive capabilities, allowing contractors to anticipate risks such as weather-related delays or structural vulnerabilities and plan proactive mitigation strategies [60]. These technologies also optimize resource allocation and improve scheduling, reducing delays and cost overruns. Furthermore, BIM fosters transparent communication, ensuring alignment among property managers, contractors, and regulatory authorities. AI-enabled reporting tools enhance accuracy and build trust among stakeholders, facilitating smoother project execution. For example, the case study of the Catholic church building renovation suggested that BIM and AI were instrumental in complying with URA guidelines, optimizing resource allocation, and achieving cost savings.

The third research question explores practical frameworks for integrating BIM and AI within Hong Kong’s regulatory guidelines to ensure sustainable and resilient renovation practices. A comprehensive framework, which covers regulatory alignment, financial and policy support, capacity building, pilot projects, and digital ecosystem development, is necessary to facilitate the adoption of BIM and AI in the renovation sector. Specifically, BIM and AI tools can be configured to meet the requirements of the BMO and DMC, with automated compliance checks integrated into their workflows. Financial mechanisms, such as government grants and tax incentives, can encourage adoption by alleviating the financial burden on contractors. Training programs and public–private partnerships can address the skills gap [61]. A centralized digital platform integrating BIM, AI, and IoT technologies could further enhance data sharing, real-time monitoring, and decision-making, fostering a more systematic and transparent approach to building maintenance [57].

The implications of digital transformation extend beyond individual renovation projects, contributing to broader goals such as smart city development and sustainable urban renewal [62]. By streamlining workflows, optimizing resource allocation, and enhancing collaboration, BIM and AI can address critical industry challenges while promoting sustainability. However, the adoption of these technologies requires a coordinated effort to overcome barriers such as high costs, skill shortages, and resistance to change. Establishing standardized frameworks for BIM and AI adoption, as seen in Mainland China, can ensure consistency and interoperability across projects [15,16,17,18,19]. Developing scalable digital tools tailored to the needs of small- and medium-sized enterprises can further democratize access to these technologies. Policy support, in the form of financial incentives and regulatory reforms, can accelerate adoption while maintaining flexibility for smaller firms.

The above analysis addresses the hypotheses and provides answers to the research questions. It shows that while renovation contractors in Hong Kong face significant barriers to adopting BIM and AI, these challenges can be mitigated through targeted financial, technical, and policy interventions. Furthermore, the integration of BIM and AI significantly improves project timelines, reduces lifecycle costs, and enhances compliance with regulatory standards. The analysis is summarized in Table 4 with URA tool application. It synthesizes our findings by mapping specific digital solutions to the identified challenges, demonstrating the practical integration of BIM and AI tools and respective regulatory framework.

Table 4.

Digital Solutions Framework: Mapping AI/BIM Tools to Renovation Challenges and Regulatory Context.

Solving the challenges as illustrated in Table 4 requires technologies NLP, IoT sensors and ML predictive analytics. For example, IoT sensors integrated with BIM repositories enable real-time updates to maintenance logs, ensuring compliance and reducing delays caused by incomplete documentation [63]. Similarly, ML-powered tools improve project outcomes by forecasting scheduling risks, identifying cost–time variances, and enabling proactive adjustments to mitigate disruptions from weather or unplanned scope changes [64].

Complementing these solutions, the ranking of BIM and AI tools in Table 5 highlights their practical impact and application evidence. Centralized BIM repositories, ranked as the most impactful tool, address fragmented project documentation while fostering seamless collaboration among stakeholders. Predictive analytics powered by ML and IoT sensors follow closely, demonstrating their ability to optimize resource allocation, minimize risks, and enhance project timelines [65]. Additionally, DT platforms and AI compliance dashboards contribute to improved stakeholder coordination and regulatory adherence through real-time scenario testing and automated safety checks. Together, these findings emphasize the dual role of digital tools in overcoming operational inefficiencies while delivering measurable improvements in timelines, costs, and compliance. By bridging the insights from regulatory-aligned solutions and their ranked impact, these tools provide a roadmap for adopting BIM and AI technologies in renovation projects, ultimately transforming current practices into more sustainable and resilient workflows.

Table 5.

BIM and AI Tools: Practical Impact and Evidence in renovation projects.

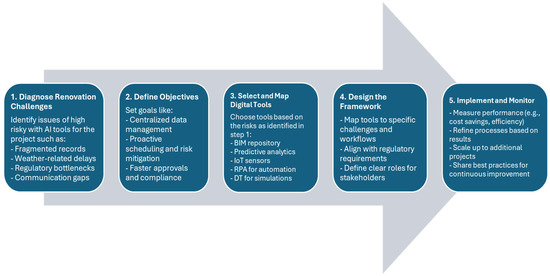

Figure 2 illustrates a practical framework for integrating BIM and AI tools within renovation projects. The framework is structured as a systematic process encompassing five key phases: (1) Diagnosing challenges, (2) Defining project objectives, (3) Selecting appropriate BIM/AI tools, (4) Designing an integrated system, and (5) Implementation, and monitoring. Each phase includes actionable steps tailored to address the identified renovation challenges. By providing a structured approach to integrating digital tools, the figure addresses RQ 3 by demonstrating how BIM and AI technologies can be practically applied to promote resilient renovation practices within a regulatory framework.

Figure 2.

A simplified BIM/AI Framework for renovation projects.

5. Conclusions

This study provides qualitative, practice-based insights into how BIM and AI, augmented by techniques such as ML, DL, CV, IoT, DT, and RPA, can address key challenges in Hong Kong’s private renovation sector. These challenges include fragmented records, coordination gaps, limited predictive capabilities, safety risks, and non-compliance with regulatory standards. Analysis of a focal renovation project and ten comparable cases demonstrates how digital tools streamline data organization, enable proactive planning, and enhance collaboration. The findings align with prior literature, emphasizing the transformative potential of digital technologies in the AEC sector.

Key technologies such as BIM repositories, AI-driven predictive analytics, and IoT sensors emerged as pivotal in improving project timelines, mitigating risks, and optimizing resource allocation. Additionally, DT platforms and AI dashboards supported real-time oversight, automated safety checks, and regulatory compliance, delivering measurable improvements in efficiency, costs, and compliance outcomes while promoting sustainable workflows.

Despite these benefits, adoption barriers, including high upfront costs, limited expertise, interoperability issues, and lowest-bid procurement norms, remain significant. Mitigation strategies include financial incentives, training, demonstrator projects, and standards integrating BIM/AI workflows. The practical framework presented in this study provides a structured approach for piloting and scaling digital transformation initiatives in renovation projects.

The study acknowledges limitations such as qualitative methodology, reliance on a single focal case, and absence of quantitative before-and-after evaluations, which limits attribution of improvements in cost, time, or compliance. Further research should focus on:

- Multi-project quantitative evaluations with standardized benchmarks.

- Exploring interoperability and data governance in common data environments.

- Applying empirical designs to validate causal relationships.

This study contributes by identifying context-specific challenges, aligning BIM and AI workflows with local governance, and proposing actionable pathways for digital transformation in renovation. These insights offer practical guidance for more resilient, sustainable, and efficient urban building practices.

Author Contributions

Conceptualization: P.Y.L.W.; methodology, P.Y.L.W.; formal analysis, P.Y.L.W.; data curation, P.Y.L.W. and H.L.; writing—original draft preparation, P.Y.L.W. and K.C.C.L.; writing—review and editing, P.Y.L.W., J.H.K.L., H.L. and K.C.C.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

We would like to express our gratitude to the anonymous contractor company and its directors for generously providing valuable information and dedicating their time to participate in interviews and share their insights.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AEC | Architecture, Engineering, and Construction |

| AI | Artificial Intelligence |

| AIoT | Artificial Intelligence of Things |

| BD | Buildings Department |

| BIM | Building Information Modeling |

| BMO | Building Management Ordinance |

| BO | Building Ordinance |

| CIC | Construction Industry Council |

| CV | Computer Vision |

| DLOCR | Deep Learning Optical Character Recognition |

| DLBSS | Deep Learning Blind Source Separation |

| DMC | Deed of Mutual Covenant |

| DT | Digital Twin |

| EMSD | Electrical and Mechanical Services Department |

| FSD | Fire Services Department |

| GD | Generative Design |

| IoT | Internet of Things |

| ML | Machine Learning |

| NLP | Natural Language Processing |

| PMSO | Property Management Services Ordinance |

| ROI | Return On Investment |

| RPA | Robotic Process Automation |

| URA | Urban Renewal Authority |

| VR | Virtual Reality |

References

- Newman, C.; Edwards, D.; Martek, I.; Lai, J.; Thwala, W.D.; Rillie, I. Industry 4.0 Deployment in the Construction Industry: A Bibliometric Literature Review and UK-Based Case Study. Smart Sustain. Built Environ. 2021, 10, 557–580. [Google Scholar] [CrossRef]

- Kibwana, Z. Effectiveness of the Completion of Historical Site Renovation Projects in Zanzibar. Ph.D. Thesis, Institute of Accountancy Arusha (IAA), Zanzibar, Tanzania, 2023. [Google Scholar]

- D’Oca, S.; Ferrante, A.; Ferrer, C.; Pernetti, R.; Gralka, A.; Sebastian, R.; Op ‘t Veld, P. Technical, financial, and social barriers and challenges in deep building renovation: Integration of lessons learned from the H2020 cluster projects. Buildings 2018, 8, 174. [Google Scholar] [CrossRef]

- Urban Renewal Authority. Guidelines and Templates for Preparing Maintenance Manual for Residential and Composite Buildings; Urban Renewal Authority: Hong Kong, China, 2024. Available online: https://brplatform.org.hk/f/page/13983/18485/Guidelines%20and%20Templates%20Full%20version%20Eng%20v1.pdf (accessed on 19 August 2025).

- Chan, A.P.; Darko, A.; Ameyaw, E.E.; Owusu-Manu, D.G. Barriers Affecting the Adoption of Green Building Technologies. J. Manag. Eng. 2017, 33, 04016057. [Google Scholar] [CrossRef]

- Rane, N. Integrating Leading-Edge Artificial Intelligence (AI), Internet of Things (IoT), and Big Data Technologies for Smart and Sustainable Architecture, Engineering, and Construction (AEC) Industry: Challenges and Future Directions. Eng. Constr. 2023, 3, 73–95. [Google Scholar] [CrossRef]

- Zhang, Z.; Wen, F.; Sun, Z.; Guo, X.; He, T.; Lee, C. Artificial Intelligence-Enabled Sensing Technologies in the 5G/Internet of Things Era: From Virtual Reality/Augmented Reality to the Digital Twin. Adv. Intell. Syst. 2022, 4, 2100228. [Google Scholar] [CrossRef]

- Logeswaran, K.; Savitha, S.; Suresh, P.; Prasanna Kumar, K.R.; Gunasekar, M.; Rajadevi, R.; Jayasurya, A.S. Unifying Technologies in Industry 4.0: Harnessing the Synergy of Internet of Things, Big Data, Augmented Reality/Virtual Reality, and Blockchain Technologies. In Intelligence Applied to Industry 4.0; Wiley: Hoboken, NJ, USA, 2024; pp. 127–147. [Google Scholar]

- Development Bureau, Hong Kong Government. Technical Circular (Works) No. 1/2025: Adoption of Building Information Modelling for Capital Works Projects in Hong Kong; Development Bureau, Hong Kong Government: Hong Kong, China, 2025. Available online: https://www.devb.gov.hk/filemanager/technicalcirculars/en/upload/1401/1/C-2025-01-01.pdf (accessed on 20 August 2025).

- Pan, Y.; Zhang, L. Integrating BIM and AI for Smart Construction Management: Current Status and Future Directions. Arch. Comput. Methods Eng. 2023, 30, 1081–1110. [Google Scholar] [CrossRef]

- Wilkinson, S.J.; Jupp, J.R. Exploring the Value of BIM for Corporate Real Estate. J. Corp. Real Estate 2016, 18, 254–269. [Google Scholar] [CrossRef]

- Oo, B.L.; Tang, O.S. Information Feedback in Construction Contract Bidding: Perceptions of Hong Kong Contractors. Int. J. Constr. Manag. 2023, 23, 1044–1052. [Google Scholar] [CrossRef]

- Salimimoghadam, S.; Ghanbaripour, A.N.; Tumpa, R.J.; Kamel Rahimi, A.; Golmoradi, M.; Rashidian, S.; Skitmore, M. The Rise of Artificial Intelligence in Project Management: A Systematic Literature Review of Current Opportunities, Enablers, and Barriers. Buildings 2025, 15, 1130. [Google Scholar] [CrossRef]

- Morgan McKinley. Skill Shortage Impacts Technology Growth in Hong Kong; Morgan McKinley: Hong Kong, China, 2024; Available online: https://www.morganmckinley.com/hk/article/skill-shortage-impacts-technology-growth-in-hong-kong (accessed on 22 August 2025).

- Construction Industry Council. BIM Adoption Survey; Construction Industry Council: Hong Kong, China, 2020. Available online: https://www.bim.cic.hk/Upload/publication/87/download_2/b55a28ce365e436292cf0e5de923b09e.pdf (accessed on 22 August 2025).

- Xia, X.; Liu, L.; Wang, Z. A Progressive Policy Evaluation Framework for Construction Digitalization in China: Evidence from Wuhan. Buildings 2025, 15, 1925. [Google Scholar] [CrossRef]

- Zhu, X. Smart Compliance Checking Frameworks for BIM Standards. Ph.D. Thesis, Cardiff University, Cardiff, UK, 2024. [Google Scholar]

- GBT 51212-2016; Unified Standard for Application of Building Information Modeling. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2016. Available online: https://www.mohurd.gov.cn/file/old/2017/20170228/GBT%2051212-2016%20%E5%BB%BA%E7%AD%91%E4%BF%A1%E6%81%AF%E6%A8%A1%E5%9E%8B%E5%BA%94%E7%94%A8%E7%BB%9F%E4%B8%80%E6%A0%87%E5%87%86.pdf (accessed on 23 August 2025).

- Zhang, J.; Schmidt, K.; Li, H. BIM and Sustainability Education: Incorporating Instructional Needs into Curriculum Planning in CEM Programs Accredited by ACCE. Sustainability 2016, 8, 525. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, B.; Nie, Y.; Jiang, L.; Zhang, X. Challenge for Chinese BIM Software Extension Comparison with International BIM Development. Buildings 2024, 14, 2239. [Google Scholar] [CrossRef]

- Wong, P.Y.L.; Lo, K.C.C.; Lai, J.H.K.; Wong, T.T.Y. Proactive Regulation for Hydrogen Supply Chains: Enhancing Logistics Frameworks in Australia. Energies 2025, 18, 3056. [Google Scholar] [CrossRef]

- Wong, P.; Lai, J. Energy Transitions in Cities: A Comparative Analysis of Policies and Strategies in Hong Kong, London, and Melbourne. Energies 2025, 18, 37. [Google Scholar] [CrossRef]

- Chanin, R. Innovative and Disruptive Technology in Architecture. Master’s Thesis, University of Cincinnati, Cincinnati, OH, USA, 2022. [Google Scholar]

- Azhar, S.; Khalfan, M.; Maqsood, T. Building Information Modeling (BIM): Now and Beyond. Australas. J. Constr. Econ. Build. 2012, 12, 15–28. [Google Scholar]

- Boje, C.; Menacho, Á.J.H.; Marvuglia, A.; Benetto, E.; Kubicki, S.; Schaubroeck, T.; Gutierrez, T.N. A Framework Using BIM and Digital Twins in Facilitating LCSA for Buildings. J. Build. Eng. 2023, 76, 107232. [Google Scholar] [CrossRef]

- Reddy, Y.B.S.; Kangda, M.Z.; Farsangi, E.N. Integration of Building Information Modeling and Machine Learning for Predictive Maintenance. In Digital Transformation in the Construction Industry; Woodhead Publishing: Cambridge, UK, 2025; pp. 361–378. [Google Scholar]

- Ehab, A.; Mahdi, M.A.; El-Helloty, A. BIM Maintenance System with IoT Integration: Enhancing Building Performance and Facility Management. Civ. Eng. J. 2024, 10, 1953–1973. [Google Scholar] [CrossRef]

- Ozturk, G.B.; Soygazi, F. Generative AI Use in the Construction Industry. In Applications of Generative AI; Springer International Publishing: Cham, Switzerland, 2024; pp. 161–187. [Google Scholar]

- Kuang, S. Public Sector BIM Adoption: Development and Evaluation of Government Policy Interventions: A Systematic Literature Review. In Proceedings of the 30th EG-ICE International Conference on Intelligent Computing in Engineering, London, UK, 4–7 July 2023. [Google Scholar]

- Omrany, H.; Al-Obaidi, K.M.; Husain, A.; Ghaffarianhoseini, A. Digital Twins in the Construction Industry: A Comprehensive Review of Current Implementations, Enabling Technologies, and Future Directions. Sustainability 2023, 15, 10908. [Google Scholar] [CrossRef]

- Akintoye, O.O.; Obaleye, O.; Ajayi, O.V.; Yusuf, S.O. Evaluating the Efficiency of Construction Documents Coordination Among Building Industry Professionals in Abeokuta, Ogun State: Challenges and Opportunities. Int. J. Latest Technol. Eng. Manag. Appl. Sci. 2025, 14, 166–173. [Google Scholar] [CrossRef]

- Bae, C.; Choi, E.; Lee, S. Technologies, Applications, and Challenges of Digital Twin Across Industries: A Systematic Review of the State-of-the-Art Literature. IEEE Access 2025, 13, 152843–152869. [Google Scholar] [CrossRef]

- Lai, J.H.; Yik, F.W.; Chan, K.T.; Lee, W.L.; Chau, C.K. Regulatory controls on building services works in Hong Kong. Constr. Law J. 2011, 27, 459–479. [Google Scholar]

- Lai, J.H.K. Amendments to the Lifts and Escalators (Safety) Ordinance in Hong Kong: Stakeholders’ Views, Implications, and Controls beyond the Statute. Constr. Law J. 2013, 29, 120–137. [Google Scholar]

- Home Affairs Department. A Guide on Building Management Ordinance (Cap. 344); Hong Kong SAR Government: Hong Kong, China, 2018. Available online: https://www.buildingmgt.gov.hk/file_manager/en/documents/bmo_guide/a_guide_on_building_management_ordinance_cap344_en.pdf (accessed on 29 August 2025).

- Lai, S.Y.T.; Lai, J.H.K.; Wong, P.Y.L.; Hu, B.X.Y.; Zhang, L.J.; Edwards, D. Comparative Review of Lift Maintenance Regulations in Beijing, Hong Kong, and London. Buildings 2024, 14, 2862. [Google Scholar] [CrossRef]

- Wong, P.; Lai, J. On the Property Management Services Ordinance of Hong Kong: Concerns and Implications. Prop. Manag. 2021, 39, 600–617. [Google Scholar] [CrossRef]

- Wong, P.; Lai, J. Building Information Modelling (BIM): Insights from Collaboration and Legal Perspectives. IOP Conf. Ser. Earth Environ. Sci. 2022, 1101, 052014. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research and Applications, 6th ed.; Sage: Thousand Oaks, CA, USA, 2018. [Google Scholar]

- Bloomberg, L.D.; Volpe, M. Completing Your Qualitative Dissertation: A Roadmap from Beginning to End, 4th ed.; Sage: Thousand Oaks, CA, USA, 2018. [Google Scholar]

- Piras, G.; Muzi, F.; Ziran, Z. A Data-Driven Model for the Energy and Economic Assessment of Building Renovations. Appl. Sci. 2025, 15, 8117. [Google Scholar] [CrossRef]

- ISO 9001:2015; Quality Management Systems—Requirements. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 14001:2015; Environmental Management Systems—Requirements with Guidance for Use. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 45001:2018; Occupational Health and Safety Management Systems—Requirements with Guidance for Use. International Organization for Standardization: Geneva, Switzerland, 2018.

- Regona, M.; Yigitcanlar, T.; Xia, B.; Li, R.Y.M. Opportunities and Adoption Challenges of AI in the Construction Industry: A PRISMA Review. J. Open Innov. Technol. Mark. Complex. 2022, 8, 45. [Google Scholar] [CrossRef]

- Scianna, A.; Gaglio, G.F.; La Guardia, M. HBIM data management in historical and archaeological buildings. Archeol. Calc. 2020, 31, 231. [Google Scholar]

- Gaur, S.; Tawalare, A. Assessment of BIM-Based Stakeholder Management Process. Encyclopedia 2023, 2, 1441. [Google Scholar]

- Schuldt, S.J.; Nicholson, M.R.; Adams, Y.A., II; Delorit, J.D. Weather-Related Construction Delays in a Changing Climate: A Systematic State-of-the-Art Review. Sustainability 2021, 13, 2861. [Google Scholar] [CrossRef]

- Tamoor, M.; Imran, H.M.; Chaudhry, I.G. Revolutionizing Construction Site Safety through Artificial Intelligence. J. Dev. Soc. Sci. 2023, 4, 1099–1104. [Google Scholar]

- Aung, T.; Liana, S.R.; Htet, A.; Bhaumik, A. Using Machine Learning to Predict Cost Overruns in Construction Projects. J. Technol. Innov. Energy 2023, 2, 1–7. [Google Scholar] [CrossRef]

- Atanane, O.; Mourhir, A.; Benamar, N.; Zennaro, M. Smart Buildings: Water Leakage Detection Using TinyML. Sensors 2023, 23, 9210. [Google Scholar] [CrossRef]

- Abbas, M.S.; Hussain, R.; Zaidi, S.F.A.; Lee, D.; Park, C. Computer Vision-Based Safety Monitoring of Mobile Scaffolding Integrating Depth Sensors. Buildings 2025, 15, 2147. [Google Scholar] [CrossRef]

- Narbaev, T.; Hazir, Ö.; Khamitova, B.; Talgat, S. A Machine Learning Study to Improve the Reliability of Project Cost Estimates. Int. J. Prod. Res. 2024, 62, 4372–4388. [Google Scholar] [CrossRef]

- Jeelani, I.; Asadi, K.; Ramshankar, H.; Han, K.; Albert, A. Real-Time Vision-Based Worker Localization & Hazard Detection for Construction. Autom. Constr. 2021, 121, 103448. [Google Scholar]

- Ye, X.; Zeng, N.; Tao, X.; Han, D.; König, M. Smart Contract Generation and Visualization for Construction Business Process Collaboration and Automation: Upgraded Workflow Engine. J. Comput. Civ. Eng. 2024, 38, 04024030. [Google Scholar] [CrossRef]

- Macek, D.; Vitásek, S. Risk Analysis in Building Renovations: Strategies for Investors. Buildings 2024, 14, 2219. [Google Scholar] [CrossRef]

- Loaiza Osorio, L.I. Prioritization of Infrastructure Renovation and Replacement Works. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2024. Available online: https://repository.tudelft.nl/record/uuid:6a21f00c-7c4d-420f-a559-9d0a797a0b21 (accessed on 1 September 2025).

- Ottaviani, F.M.; Zenezini, G.; Saba, F.; De Marco, A.; Gavinelli, L. System-Level Critical Success Factors for BIM Implementation in Construction Management: An AHP Approach. Systems 2025, 13, 94. [Google Scholar] [CrossRef]

- Torres, K.; Sánchez, O.; Castañeda, K.; Noguera, M.; Carrasco-Beltrán, D.; Vidal-Méndez, S.; Lozano-Ramírez, N.E. Exploring the Knowledge Structure of Building Information Modeling (BIM) Adoption in Construction Scheduling: A Bibliometric Analysis from 2008 to 2024. Ain Shams Eng. J. 2025, 16, 103446. [Google Scholar] [CrossRef]

- Abegaz, K. Investigating Security Measures in Common Data Environments: Insights from AEC Industry Case Studies. Master’s Thesis, Jönköping University, Jönköping, Sweden, 2024. Available online: https://www.diva-portal.org/smash/record.jsf?pid=diva2%3A1876696&dswid=-3335 (accessed on 1 September 2025).

- Liu, T.; Mostafa, S.; Mohamed, S.; Nguyen, T.S. Emerging Themes of Public-Private Partnership Application in Developing Smart City Projects: A Conceptual Framework. Built Environ. Proj. Asset Manag. 2021, 11, 138–156. [Google Scholar] [CrossRef]

- Wong, P.Y.L.; Lai, J.H.K.; Lo, K.C.C. Sustainable Transport and Development Partnership: Enhancing Urban Growth in Hobart, Australia Through TOD, PPP and Green Building Practices. Sustainability 2025, 17, 881. [Google Scholar] [CrossRef]

- Volk, R.; Stengel, J.; Schultmann, F. Building Information Modeling (BIM) for existing buildings—Literature review and future needs. Autom. Constr. 2014, 38, 109–127. [Google Scholar] [CrossRef]

- Adebayo, Y.; Udoh, P.; Kamudyariwa, X.B.; Osobajo, O.A. Artificial Intelligence in Construction Project Management: A Structured Literature Review of Its Evolution in Application and Future Trends. Digital 2025, 5, 26. [Google Scholar] [CrossRef]

- Deng, X.; Cheng, J.; Song, M. IoT-Driven Smart Construction: Case Studies and Challenges. J. Constr. Eng. Manag. 2021, 147, 04020123. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).