An HACCP-Inspired Post-Evaluation Framework for Highway Preventive Maintenance: Methodology and Case Application

Abstract

1. Introduction

2. Literature Review

2.1. Current Research Status of Preventive Maintenance Technologies

2.2. Current Research Progress on Post-Evaluation of Preventive Maintenance

2.3. Framework Selection and HACCP-Inspired Indicator Development

2.3.1. Comparative Analysis of Multiple Evaluation Methods

2.3.2. Overview of the HACCP Method

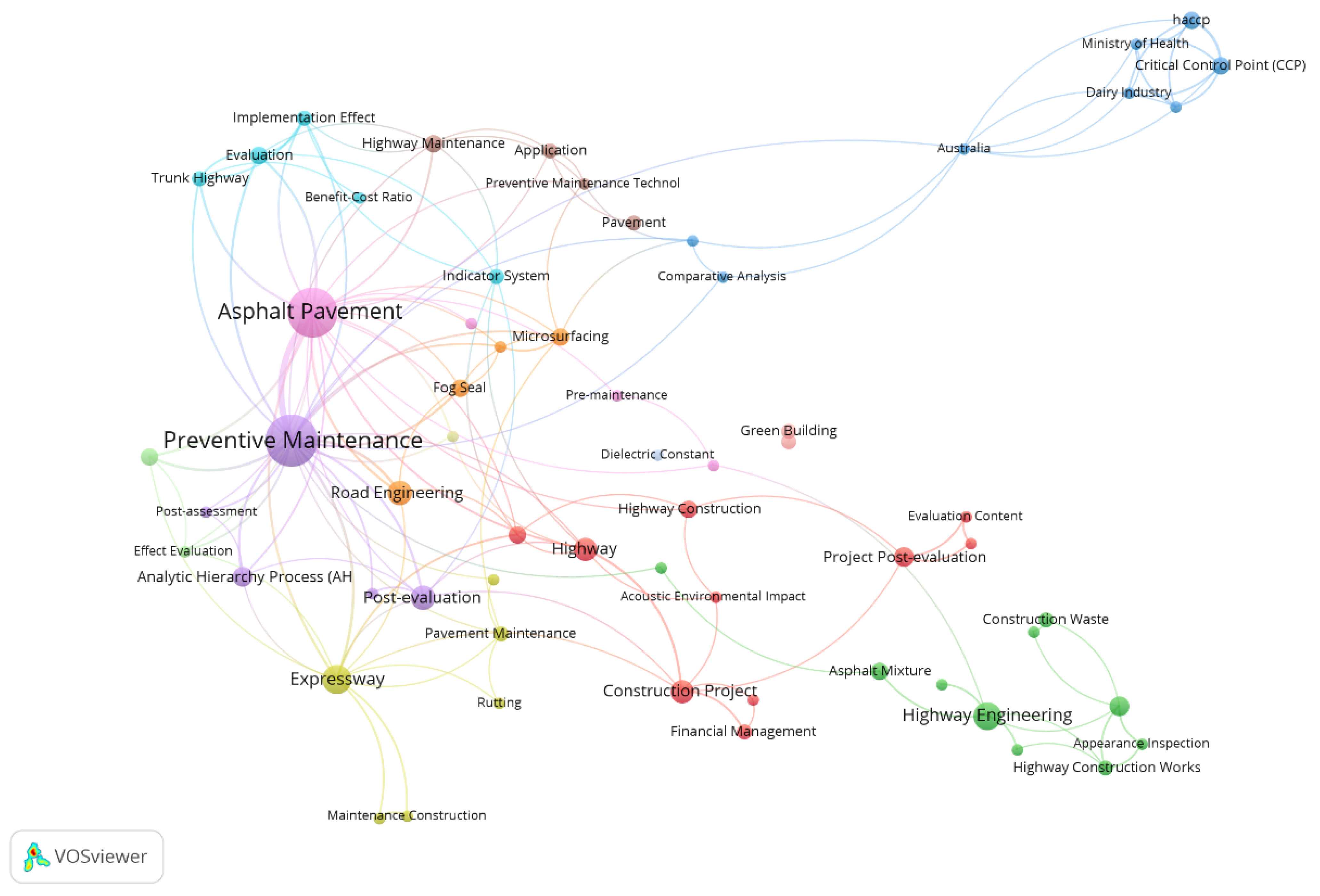

2.4. Scientometric Analysis of Related Literature

2.5. Limitations of Current Post-Evaluation Systems for Highway Preventive Maintenance Projects

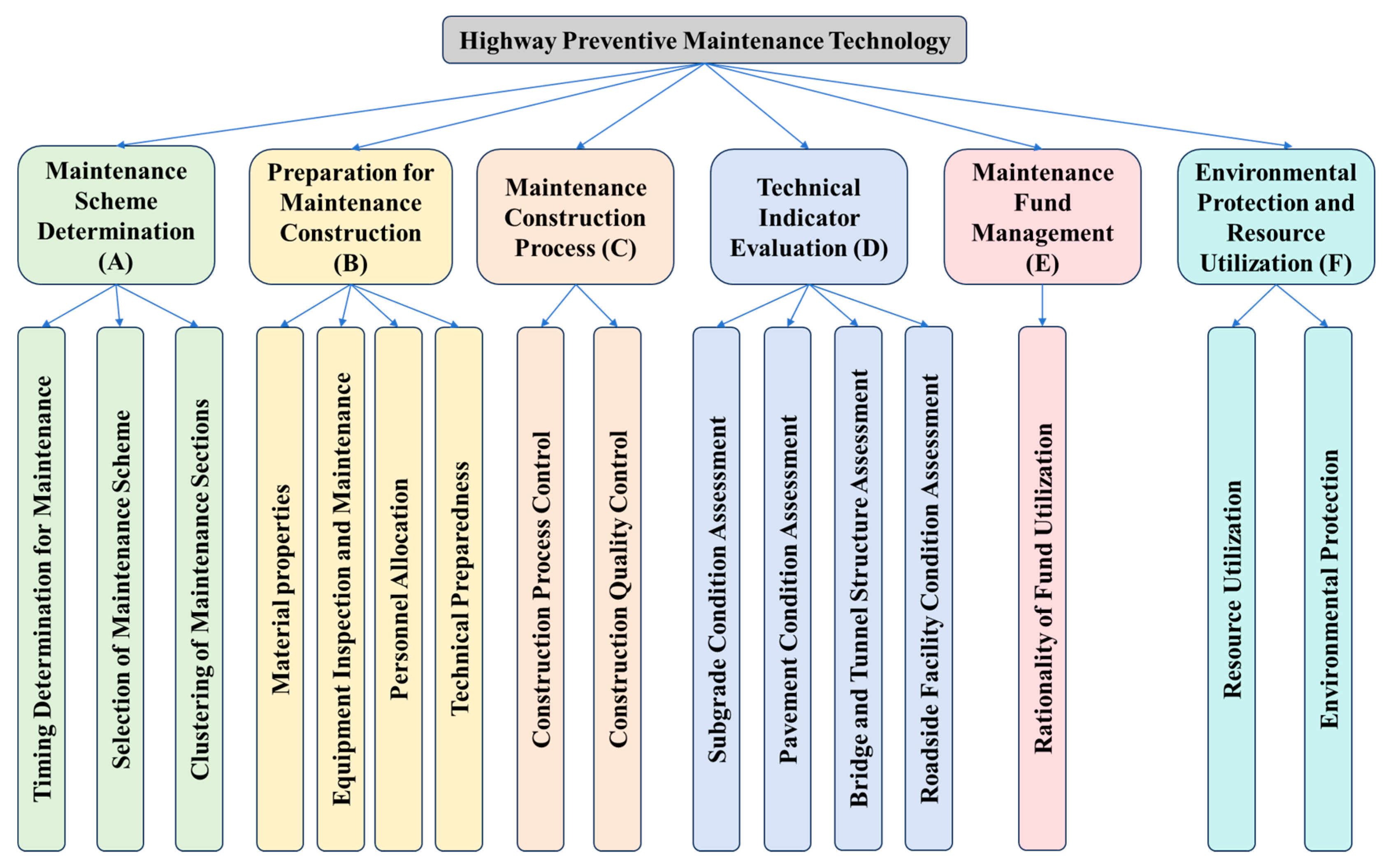

3. Determination of Technical Evaluation Indicators for Highway Preventive Maintenance Projects

3.1. Hazard Analysis of Preventive Maintenance Implementation

3.1.1. Hazard Classification in Maintenance Projects

3.1.2. Hazard Analysis in Maintenance Projects

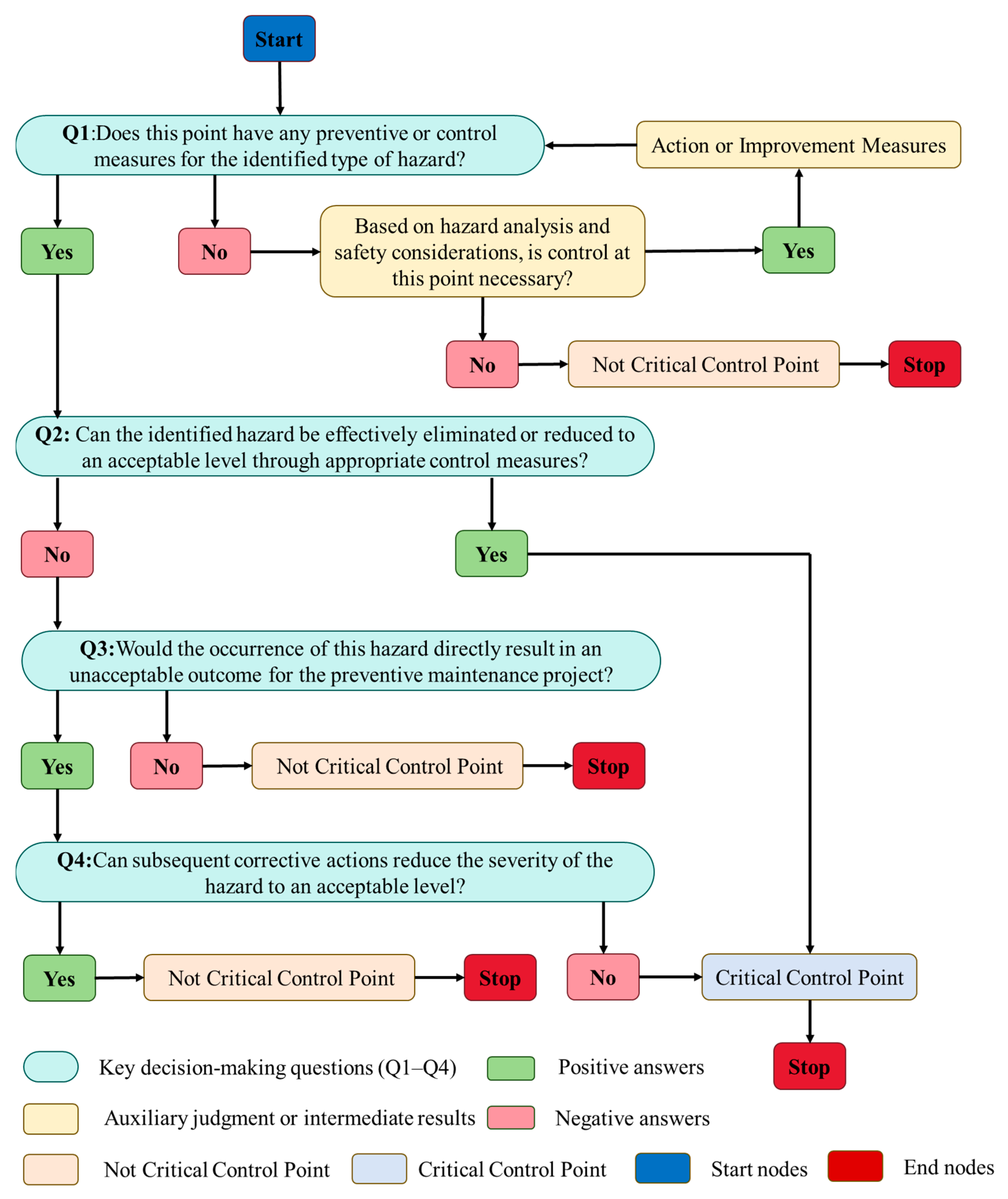

3.2. Identification of Technical Critical Control Points in Preventive Maintenance Projects

3.2.1. Critical Control Points in the Pre-Implementation Phase

3.2.2. Critical Control Points in the Mid-Implementation Phase

3.2.3. Critical Control Points in the Post-Implementation Phase

3.3. Determination of Evaluation Indicators

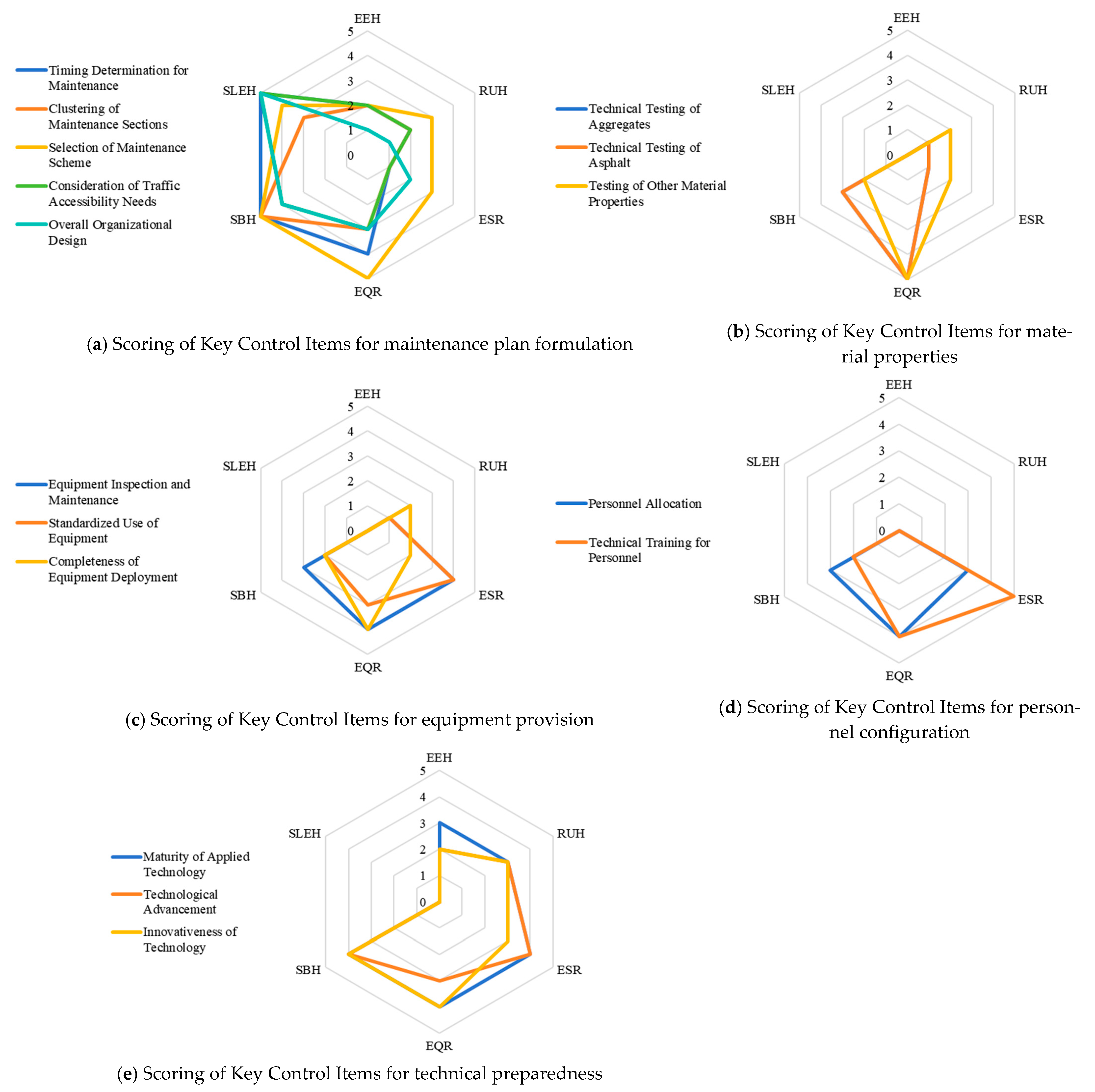

3.3.1. Key Control Items in the Pre-Implementation Phase

3.3.2. Key Control Items in the Mid-Implementation Phase

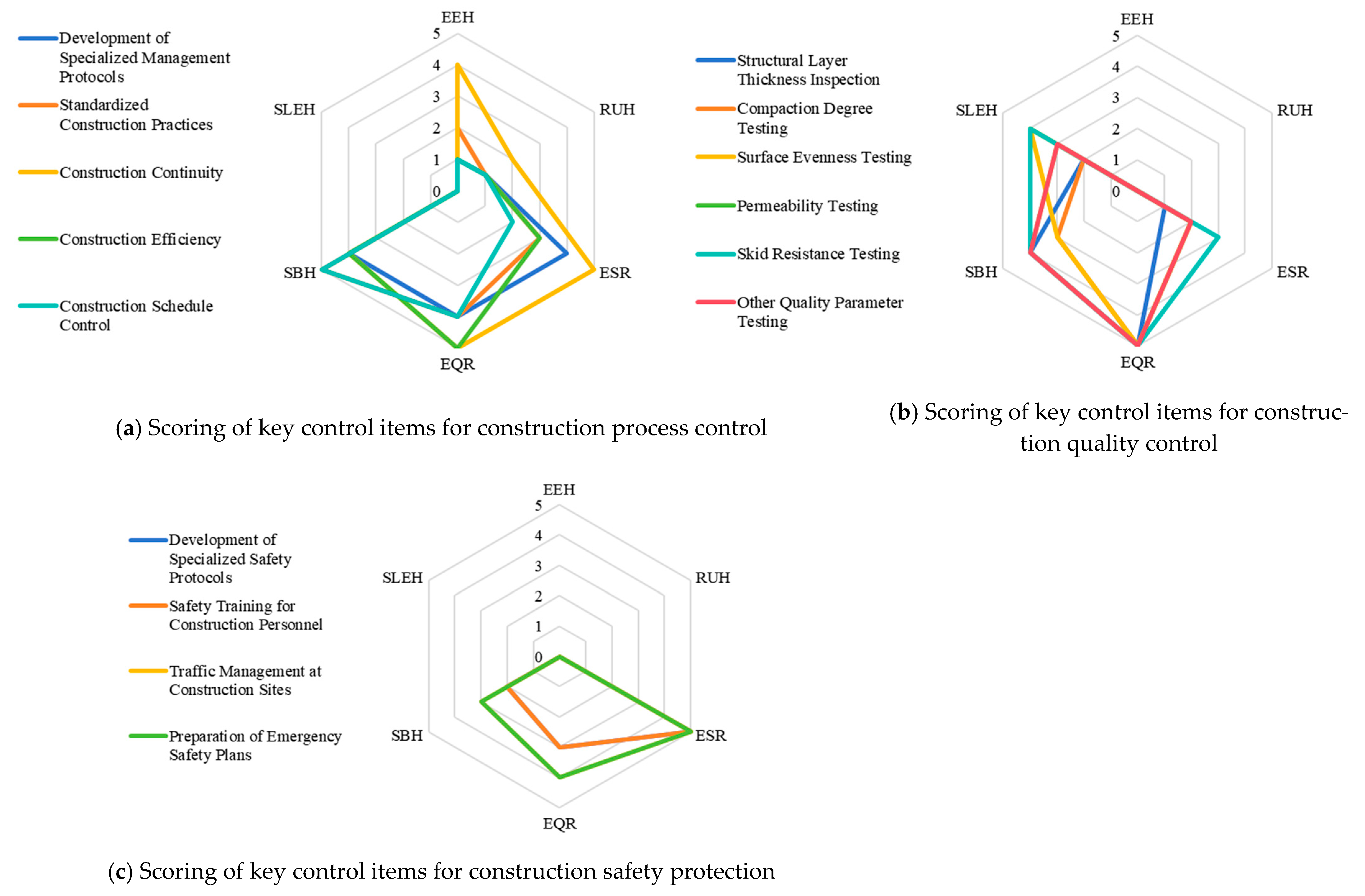

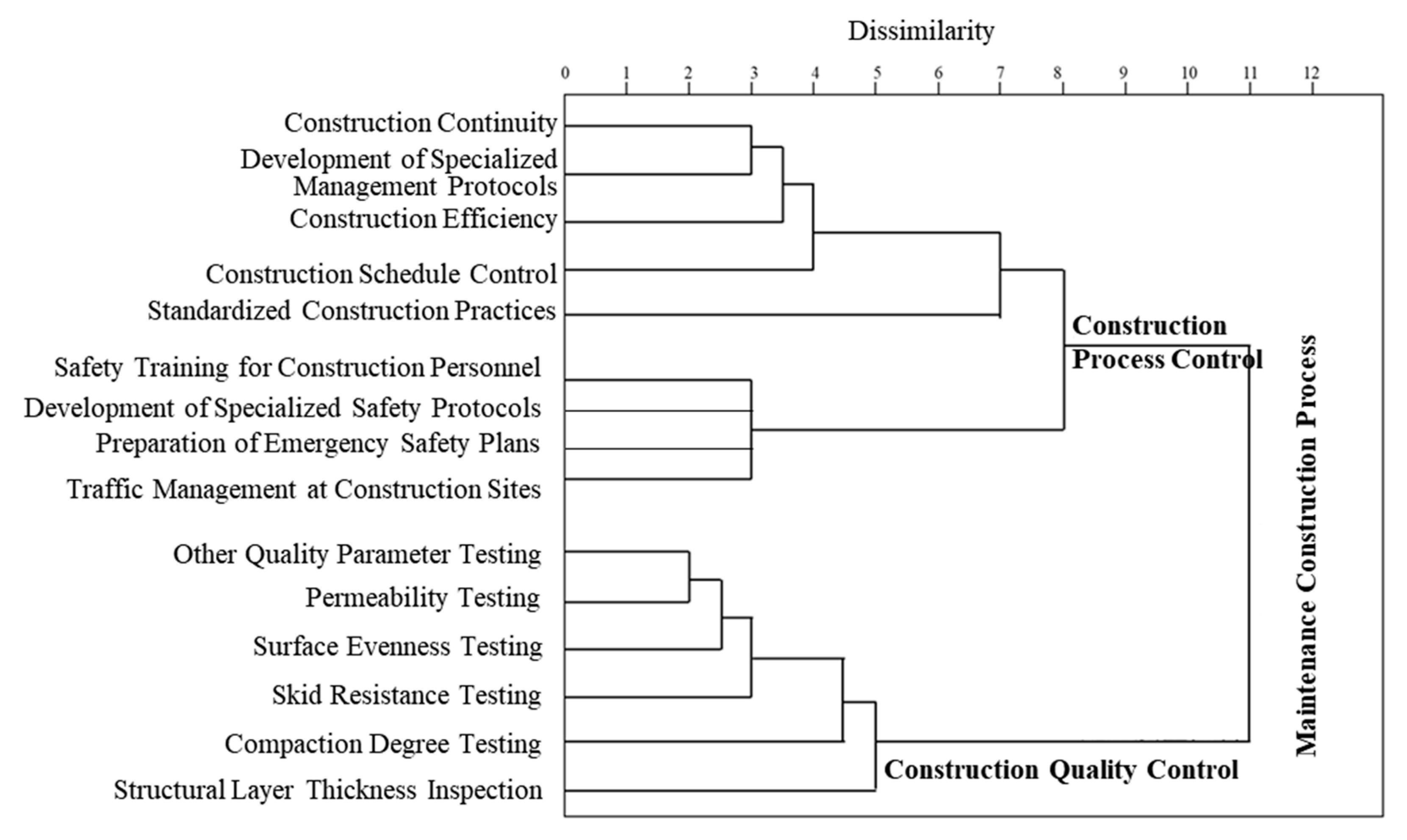

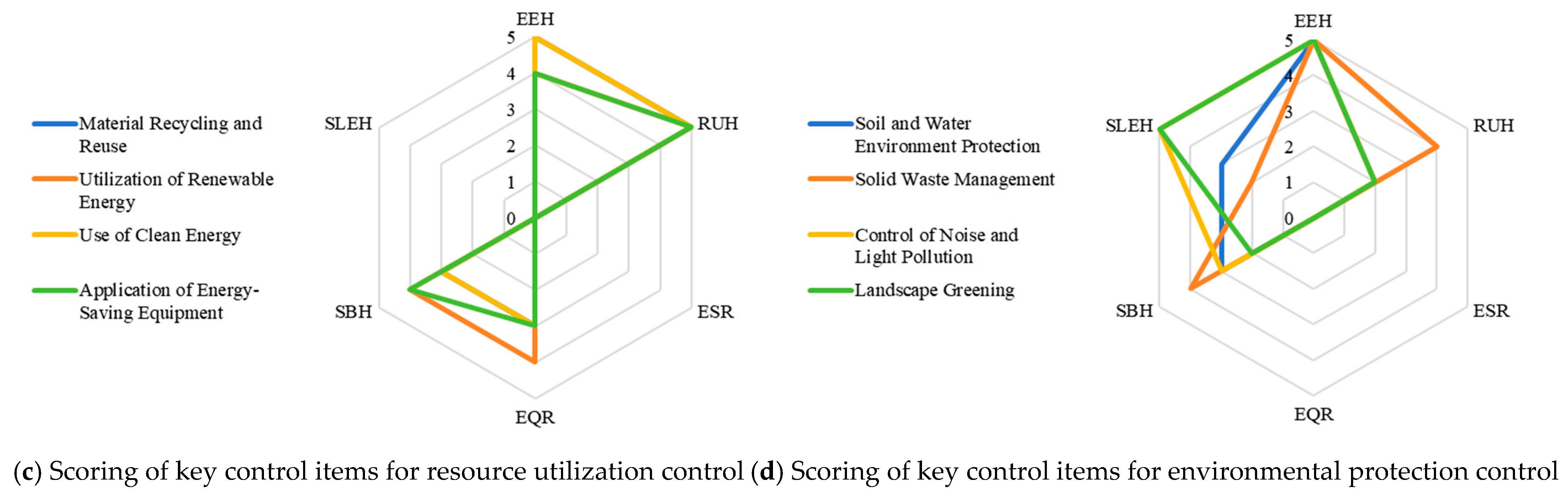

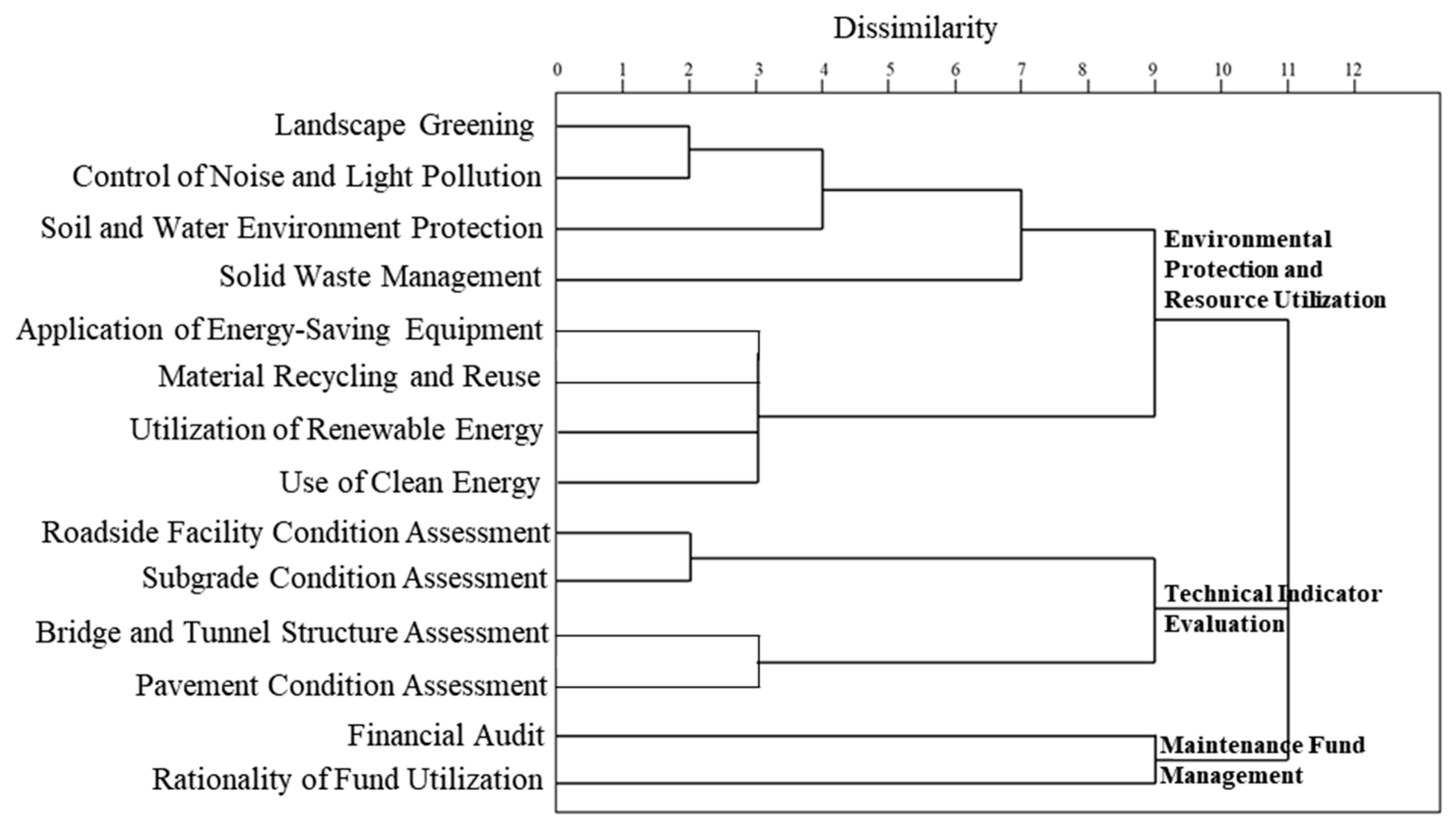

3.3.3. Key Control Items in the Post-Implementation Phase

3.4. Establishment of the Evaluation System

4. Case Study: Engineering Application of the Evaluation System

4.1. Project Overview

4.2. Indicator Scoring Framework

4.3. Case Evaluation and Discussion

5. Discussion

5.1. Methodological Adaptability and Current Limitations

5.2. Future Research Directions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix A.1. Evaluation Criteria for Key Control Items

Appendix A.1.1. Preventive Maintenance Scheme Determination

| Evaluation Grade | Excellent | Good | Fair | Marginal | Poor |

|---|---|---|---|---|---|

| Score Range | ≥90 | 80–89 | 70–79 | 60–69 | <60 |

| Timing Determination | Reasonable | Relatively Reasonable | Moderately Reasonable | Partially Unreasonable | Unreasonable |

| Selection of Maintenance Scheme | Reasonable | Relatively Reasonable | Moderately Reasonable | Partially Unreasonable | Unreasonable |

| Clustering of Maintenance Sections | Reasonable | Relatively Reasonable | Moderately Reasonable | Partially Unreasonable | Unreasonable |

Appendix A.1.2. Preparation for Maintenance Construction

| Evaluation Grade | Excellent | Good | Fair | Marginal | Poor |

|---|---|---|---|---|---|

| Score Range | ≥90 | 80–89 | 70–79 | 60–69 | <60 |

| Material properties (Pass Rate) | ≥90% | 80–89% | 70–79% | 60–69% | <60% |

| Equipment Inspection and Maintenance | Complete | Relatively Complete | Generally Complete | Missing Some Equipment | Poor |

| Personnel Allocation | Complete | Relatively Complete | Generally Complete | Missing Some Staff | Poor |

| Technical Preparedness | Fully Innovative Technology | Derived Innovative Technology | Improved Technology | Mature Technology | Non-Compliant Technology |

Appendix A.1.3. Maintenance Execution Process

| Evaluation Grade | Excellent | Good | Fair | Marginal | Poor |

|---|---|---|---|---|---|

| Score Range | ≥90 | 80–89 | 70–79 | 60–69 | <60 |

| Development of Specialized Safety Protocols | Complete | Relatively Complete | Moderately Complete | Partially Lacking | Poor |

| Construction Schedule Control | Excellent | Good | Average | Below Average | Poor |

| Quality Control (Pass Rate) | ≥90% | 80–89% | 70–79% | 60–69% | <60% |

Appendix A.1.4. Technical Indicator Evaluation

| Evaluation Index | Weight Coefficient | Calculation Formula |

|---|---|---|

| Short-term Performance | 0.3 | (Actual Performance Gain/Expected Gain) × 100 |

| Service Life Index | 0.7 | (Actual Service Life/Expected Service Life) × 100 |

Appendix A.1.5. Maintenance Fund Management

| Evaluation Grade | Excellent | Good | Fair | Marginal | Poor |

|---|---|---|---|---|---|

| Score Range | ≥90 | 80–89 | 70–79 | 60–69 | <60 |

| Rationality of Fund Utilization | Excellent | Good | Moderate | General | Poor |

Appendix A.1.6. Environmental Protection and Resource Utilization

| Evaluation Grade | Excellent | Good | Fair | Marginal | Poor |

|---|---|---|---|---|---|

| Score Range | ≥90 | 80–89 | 70–79 | 60–69 | <60 |

| Utilization of Renewable Energy | High | Relatively High | Moderate | Low | Very Low |

| Recycling of Old Pavement Materials | ≥90% | ≥80%, <90% | ≥70%, <80% | ≥60%, <70% | <60% |

| Environmental Protection | Excellent | Good | Moderate | General | Poor |

Appendix A.2. Determination of Indicator Weights for the Post-Evaluation of Highway Preventive Maintenance Technology Based on the AHP

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| RI | 0 | 0 | 0.58 | 0.9 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 | 1.49 | 1.51 |

| Criteria Level | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| Maintenance Scheme Determination (A) | 1 | 6 | 3 | 0.5 | 2 | 8 |

| Preparation for Maintenance Construction (B) | 0.167 | 1 | 0.5 | 0.125 | 0.25 | 2 |

| Maintenance Construction Process (C) | 0.333 | 2 | 1 | 0.167 | 0.5 | 4 |

| Technical Indicator Evaluation (D) | 2 | 8 | 6 | 1 | 4 | 9 |

| Maintenance Fund Management (E) | 0.5 | 4 | 2 | 0.25 | 1 | 6 |

| Environmental Protection and Resource Utilization (F) | 0.125 | 0.5 | 0.25 | 0.111 | 0.167 | 1 |

| A | A1 | A2 | A3 | Wi |

|---|---|---|---|---|

| A1 | 1 | 0.5 | 2 | 0.286 |

| A2 | 2 | 1 | 4 | 0.571 |

| A3 | 0.5 | 0.25 | 1 | 0.143 |

| λmax = 3, CI = 0, RI = 0.58, CR = 0 < 0.10 | ||||

| B | B1 | B2 | B3 | B4 | Wi |

|---|---|---|---|---|---|

| B1 | 1 | 4 | 6 | 2 | 0.512 |

| B2 | 0.25 | 1 | 2 | 0.5 | 0.138 |

| B3 | 0.167 | 0.5 | 1 | 0.25 | 0.074 |

| B4 | 0.5 | 2 | 4 | 1 | 0.275 |

| λmax = 4.0604, CI = 0, RI = 0.9, CR = 0.0224 < 0.10 | |||||

| C | C1 | C2 | Wi |

|---|---|---|---|

| C1 | 1 | 2 | 0.667 |

| C2 | 0.5 | 1 | 0.333 |

| λmax = 2, CI = 0, RI = 0, CR = 0 < 0.10 | |||

| D | D1 | D2 | D3 | D4 | Wi |

|---|---|---|---|---|---|

| D1 | 1 | 0.5 | 2 | 4 | 0.275 |

| D2 | 2 | 1 | 4 | 6 | 0.512 |

| D3 | 0.5 | 0.25 | 1 | 2 | 0.138 |

| D4 | 0.25 | 0.167 | 0.5 | 1 | 0.074 |

| λmax = 4.01, CI = 0.003, RI = 0.9, CR = 0.004 < 0.10 | |||||

| F | F1 | F2 | Wi |

|---|---|---|---|

| F1 | 1 | 2 | 0.667 |

| F2 | 0.5 | 1 | 0.333 |

| λmax = 2, CI = 0, RI = 0, CR ≤ 0.10 | |||

| Criteria Level | Indicator Level | A | B | C | D | E | F | Combined Weight |

|---|---|---|---|---|---|---|---|---|

| 0.251 | 0.047 | 0.088 | 0.433 | 0.151 | 0.03 | |||

| Maintenance Scheme Determination A | Timing Determination for Maintenance | 0.286 | 0.072 | |||||

| Selection of Maintenance Scheme | 0.571 | 0.144 | ||||||

| Clustering of Maintenance Sections | 0.143 | 0.036 | ||||||

| Preparation for Maintenance Construction B | Material properties | 0.512 | 0.024 | |||||

| Equipment Inspection and Maintenance | 0.138 | 0.006 | ||||||

| Personnel Allocation | 0.074 | 0.003 | ||||||

| Technical Preparedness | 0.275 | 0.013 | ||||||

| Maintenance Construction Process C | Construction Process Control | 0.667 | 0.058 | |||||

| Construction Quality Control | 0.333 | 0.029 | ||||||

| Technical Indicator Evaluation D | Subgrade Condition Assessment | 0.275 | 0.119 | |||||

| Pavement Condition Assessment | 0.512 | 0.222 | ||||||

| Bridge and Tunnel Structure Assessment | 0.138 | 0.06 | ||||||

| Roadside Facility Condition Assessment | 0.074 | 0.032 | ||||||

| Maintenance Fund Management E | Rationality of Fund Utilization | 1 | 0.151 | |||||

| Environmental Protection and Resource Utilization F | Resource Utilization | 0.667 | 0.02 | |||||

| Environmental Protection | 0.333 | 0.01 |

References

- Ge, P. Research on Highway Asphalt Pavement Maintenance Technology. TranspoWorld 2019, 33, 24–25. [Google Scholar]

- Niu, F. Preliminary Discussion on Preventive Maintenance Technology of Asphalt Pavement. Priv. Sci. Technol. 2011, 12, 302. [Google Scholar]

- Lu, C. On the Relationship Between Highway Routine Maintenance and the Design and Construction of Highways. Guangdong Sci. Technol. 2014, 23, 132, 98. [Google Scholar]

- Zhang, L.; Wang, X.; Gao, T. Discussion of Contingency Maintenance for Asphalt Pavement. J. Munic. Technol. 2009, 27, 5–8. [Google Scholar]

- Liu, B.Z. Asphalt Pavement Preventive Maintenance Technology Overview. Appl. Mech. Mater. 2014, 638–640, 1135–1138. [Google Scholar] [CrossRef]

- Zhang, J. Evaluation Research on Preventive Maintenance Measures of Asphalt Pavement. J. Shandong Ind. Technol. 2017, 4, 261, 226. [Google Scholar]

- Xu, Y. The Optimal Timing of Preventive Maintenance of Highway Asphalt Pavements. Master’s Thesis, Chang’an University, Xi’an, China, 2009. [Google Scholar]

- Hu, G.; Li, J.; He, X. Post Evaluation Method for Preventive Maintenance Project of Expressway Asphalt Pavement. Road Mach. Constr. Mech. 2008, 7, 55–57. (In Chinese) [Google Scholar]

- Liu, Z. A Study on Post-Evaluation of Expressway PPP Projects Based on Analytic Hierarchy Process and Success Degree Method. Master’s Thesis, Lanzhou Jiaotong University, Lanzhou, China, 2023. [Google Scholar]

- Cuelho, E.; Mokwa, R.; Akin, M. Preventive Maintenance Treatment of Flexible Pavement: A Synthesis of Highway; The State of Montana Department of Transportation: Helena, MT, USA, 2006; pp. 11–20. [Google Scholar]

- Udelhofen, G. Scrub Cape Seal Provides Cost-Effective Solution. Asph. Contract. 2010, 24, 38, 40–42, 44. [Google Scholar]

- Wu, B. Brief Discussion on New Technology of Pavement Maintenance of American Highway. North. Commun. 2012, 11, 120–121. [Google Scholar]

- Zhang, H. Introduction to Preventive Maintenance Technology in the United States. Maint. Manag. 2017, 1, 46–49. [Google Scholar]

- Yang, R.; Zhang, C.; Zhou, Q.; Wei, Y. Study on Application of Novachip Ultra-Thin Layer. E3S Web Conf. 2021, 283, 01042. [Google Scholar] [CrossRef]

- Wu, Y. Comparative Analysis of Highway Maintenance Strategies at Home and Abroad. Maint. Manag. 2012, 5, 80–95. [Google Scholar]

- Highway Pavement and Bridge Maintenance Methods in France. J. China Foreign Highw. 1983, 2, 57–58.

- Li, F. Construction and Maintenance of French Expressways. Highw. Eng. 1989, 3, 21–24. [Google Scholar]

- Liu, J. Maintenance and Management of German and French Expressways. Shandong Commun. Sci. Technol. 1997, 1, 11–16. [Google Scholar]

- Wu, Y. Review on the Development of Pavement Maintenance Methods of French Expressways. Hunan Commun. Sci. Technol. 2001, 2, 56–58. [Google Scholar]

- Jiang, J. Research of Timing and Strategy of Asphalt Pavement Preventive Maintenance Based on Exponential Smoothing Method. Master’s Thesis, Hebei University of Technology, Tianjin, China, 2010. [Google Scholar]

- JTJ 073-96; Highway Maintenance Technical Specification. Ministry of Transport of the People’s Republic of China: Beijing, China, 1996.

- JTG/T 5142-01-2021; Technical Specifications for Preventive Maintenance of Highway Asphalt Pavement. Ministry of Transport of the People’s Republic of China: Beijing, China, 2021.

- DBJTJ/T-002-2005; Technical Guidelines for Highway Maintenance in Shaanxi Province. Shaanxi Provincial Department of Transportation: Xi’an, China, 2005.

- Fang, K. Study on Preventive Maintenance Decision and Post Evaluation of Asphalt Pavement. Master’s Thesis, Chang’an University, Xi’an, China, 2017. [Google Scholar]

- Yang, J. Evaluation on the Implementation Effect of Preventive Maintenance of Asphalt Pavement of Trunk Highways in Shaanxi Province. Master’s Thesis, Chang’an University, Xi’an, China, 2021. [Google Scholar]

- Henan Gaoyuan Highway Industry Co. Construction of Low-Noise Micro-Surfacing on Dedicated Lanes for Guangzhou Asian Games. TranspoWorld 2010, 11, 76–77. [Google Scholar]

- Li, X. Study on Application of Micro-Surfacing Technology of Asphalt Pavement with Low Noise. Master’s Thesis, Chang’an University, Xi’an, China, 2016. [Google Scholar]

- Wang, Z. Surface Function Analysis of Thus-12 Extremely Thin Overlay on Chengya Overpass in Sichuan. Sichuan Cem. 2020, 5, 160, 241. [Google Scholar]

- Li, J.; Liu, Z.; Zeng, G.; Li, H. Application of Extremely Thin Wearing Course in Preventive Maintenance Engineering of Guangming Expressway. Jiangxi Build. Mater. 2022, 6, 26–27, 31. [Google Scholar]

- Zhang, Y.; Song, X.; Wang, T.; Liu, Z.; Zhu, H. Application Technology of Warm-Mix Asphalt Ultra-Thin Overlay in Road Maintenance. Highway 2011, 1, 223–226. [Google Scholar]

- Yao, G. Study on the Mechanism of Post-Evaluation of Investment Projects; Economic Science Press: Beijing, China, 2002. [Google Scholar]

- The World Bank. Implementation Completion Report: Good Practices, Operational Policies of the World Bank Operational Manual; The World Bank: Washington, DC, USA; London, UK, 1994. [Google Scholar]

- Tang, X. Study on Theory and Application of Road-Bridge Investment Project Ex Post Evaluations. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2005. [Google Scholar]

- Huang, S. Project Post-Evaluation Technical Research of Highway Construction. Master’s Thesis, Hebei University of Technology, Tianjin, China, 2008. [Google Scholar]

- Wang, W. Evaluation of Maintenance Management Decision-Making for Highway Asphalt Pavement. TranspoWorld 2011, 21, 106–107. [Google Scholar]

- Ma, S.; Wang, Y. Research on Evaluation System for Implementation Effect of Highway Maintenance Projects. J. China Foreign Highw. 2011, 31, 283–287. [Google Scholar]

- Wang, C. Discussion on the Construction of Performance Evaluation System for Highway Maintenance Management in Beijing. Highway 2007, 12, 123–128. [Google Scholar]

- Xu, J.; Wang, Z.; Yin, X. Study on the Post-Evaluation of Highway Asphalt Pavement Maintenance Engineering Technology. Highw. Traffic Technol. (Appl. Technol. Ed.) 2020, 16, 73–76. [Google Scholar]

- Wang, S. How to Evaluate the Effect of Preventive Maintenance Projects. Maint. Manag. 2016, 11, 30–36. [Google Scholar]

- Zhang, H. Research on Post-Evaluation Method for Asphalt Pavement Preventive Maintenance. Highw. Traffic Technol. (Appl. Technol. Ed.) 2019, 15, 178–180, 187. [Google Scholar]

- Tang, Y.; Zhou, D.; Zhao, T. Evaluation Model and Application on Preventive Maintenance Effect of Highway Based on SVM. Eng. Constr. 2020, 52, 72–77. [Google Scholar]

- Li, J.; Zheng, D.; Gao, M.; Zhao, Y. Evaluation and Analysis on the Application Effect of Preventive Maintenance Technology of Expressway. Shanxi Archit. 2020, 46, 136–138. [Google Scholar]

- Wang, Z. The Post-Evaluation System Study of Asphalt Pavement Preventive Maintenance. Transp. Energy Conserv. Environ. Prot. 2022, 18, 76–79. [Google Scholar]

- Ghalenoee, M. Environmental Assessment of Buildings through HQE® Method: Case Study of a Three-Story Residential Apartment in the 5th District of Isfahan. J. Environ. Stud. 2011, 37, 123–134. [Google Scholar]

- Guo, X. The Reference Study of French High Quality Environmental Evaluation System to the Development of Green Buildings in China. Master’s Thesis, South China University of Technology, Guangzhou, China, 2022. [Google Scholar]

- Liu, M.; Meng, C.; Zeng, L.; Hu, A.; Wang, X.; Deng, Y.; Dai, R. French High Quality Environment Assessment System and Application Research. Heat. Vent. Air Cond. 2023, 53, 22–27. [Google Scholar]

- Ding, Y.; Li, B. Study on GSAS Green Building Rating System in the Middle East Region. Urban. Archit. 2021, 18, 53–56, 59. [Google Scholar]

- Wang, Y. Green Building Assessment Research Based on Extenics Evaluation. Master’s Thesis, Dalian University of Technology, Dalian, China, 2016. [Google Scholar]

- Zhang, K. The Sustainable Building Assessment System: DGNB of Germany. Eco-City Green Build. 2015, 1, 42–45. [Google Scholar]

- Shang, Z. Introduction of LCA Method in DGNB and Case Study in China. Green Build. 2017, 9, 29–32. [Google Scholar]

- Orova, M.; Reith, A. Multiscalarity in International Sustainable Assessment Systems: A Qualitative Comparison of LEED, CASBEE, BREEAM, DGNB and ESTIDAMA on Building, Neighbourhood and City Scale. IOP Conf. Ser. Earth Environ. Sci. 2019, 290, 012056. [Google Scholar] [CrossRef]

- Zhang, S. Research on the Application of ESG System in China. Financ. Perspect. J. 2017, 11, 80–85. [Google Scholar]

- Huang, J.; Zhang, Y. How to Apply Balanced Scorecard. Logist. Technol. 2005, 12, 37–40. [Google Scholar]

- Liu, S.; Ding, Z.; Sun, Y.; Cui, M. Evaluation System for Modern Construction Industry Cluster Based on NESS Model. Sichuan Cem. 2022, 1, 64–65. [Google Scholar]

- Gao, Z. Review of CIPP Educational Evaluation Model. Teach. Adm. 1998, Z1, 57–59. [Google Scholar]

- ISO 31000:2018; Risk Management—Guidelines. International Organization for Standardization: Geneva, Switzerland, 2018.

- Sharma, K.D.; Srivastava, S. Failure mode and effect analysis (FMEA) implementation: A literature review. J. Adv. Res. Aeronaut. Space Sci. 2018, 5, 1–17. [Google Scholar]

- Rasool, M.; Franck, T.; Denys, B.; Halidou, N. Methodology and tools for risk evaluation in construction projects using Risk Breakdown Structure. Eur. J. Environ. Civ. Eng. 2012, 16 (Suppl. S1), s78–s98. [Google Scholar] [CrossRef]

- ISO. Risk Management—Principles and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2009. [Google Scholar]

- Liu, W.; Ye, H. Construction of Food Safety Evaluation Index System Based on 4T. Saf. Environ. Eng. 2018, 25, 106–113. [Google Scholar]

- Zhang, Z.; Wang, M. Research and Application Progress of HACCP: A Review. Chin. J. Food Hyg. 1994, 3, 51–55, 62. [Google Scholar]

- Hall, D.C. Managing Fraud in Food Supply Chains: The Case of Honey Laundering. Sustainability 2023, 15, 14374. [Google Scholar] [CrossRef]

- Fan, Y.; Li, T.; Bao, D. Application and Management Status of HACCP at Home and Abroad: A Review. Chin. J. Food Hyg. 2001, 5, 38–42. [Google Scholar]

- Gao, P.; Ma, F.; Yan, Z. Research and Application of HACCP Management in China and Abroad. Chin. J. Public Health 2002, 10, 114–116. [Google Scholar]

- Salgot, M.; Priestley, G.K.; Folch, M. Golf Course Irrigation with Reclaimed Water in the Mediterranean: A Risk Management Matter. Water 2012, 4, 389–429. [Google Scholar] [CrossRef]

- Škerjanec, M.; Steinman, F.; Rak, G. Integrated Flood Management Based on Hazard Analysis Critical Control Point Approach. J. Flood Risk Manag. 2022, 15, e12769. [Google Scholar] [CrossRef]

- Möderl, M.; Sitzenfrei, R.; Lammel, J.; Apperl, M.; Kleidorfer, M.; Rauch, W. Development of an Urban Drainage Safety Plan Concept Based on Spatial Risk Assessment. Struct. Infrastruct. Eng. 2015, 11, 918–928. [Google Scholar] [CrossRef]

- El-Rawy, M.; Fathi, H.; Abdalla, F.; Alshehri, F.; Eldeeb, H. An Integrated Principal Component and Hierarchical Cluster Analysis Approach for Groundwater Quality Assessment in Jazan, Saudi Arabia. Water 2023, 15, 1466. [Google Scholar] [CrossRef]

- Doan, V.T.; Le, C.C.; Le, H.V.T.; Trieu, N.A.; Vo, P.L.; Tran, D.A.; Vu, T.T.H. Comprehensive Statistical Analysis for Characterizing Water Quality Assessment in the Mekong Delta: Trends, Variability, and Key Influencing Factors. Sustainability 2025, 17, 5375. [Google Scholar] [CrossRef]

- JTG 5421-2018; Code for Maintenance Design of Highway Asphalt Pavement. Ministry of Transport of the People’s Republic of China: Beijing, China, 2018.

- JTG 5142-2019; Technical Code for Maintenance of Highway Asphalt Pavement. Ministry of Transport of the People’s Republic of China: Beijing, China, 2019.

- JTG F40-2004; Technical Specifications for Construction of Highway Asphalt Pavement. Ministry of Transport of the People’s Republic of China: Beijing, China, 2004.

- JTG E20-2011; Test Specifications for Asphalt and Asphalt Mixtures in Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- GB/T 23577-2009; State Administration for Market Regulation, Standardization Administration of the People’s Republic of China. Road Construction and Maintenance Machinery and Equipment—Basic Types, Identification and Description. State Administration for Market Regulation (SAMR): Beijing, China, 2009.

- JTG H30-2015; Code for Safety Operations in Highway Maintenance. Ministry of Transport of the People’s Republic of China: Beijing, China, 2015.

- JTG 5110-2023; Technical Standards for Highway Maintenance. Ministry of Transport of the People’s Republic of China: Beijing, China, 2023.

- T/THTS 001-2024; Technical Guide for Post-Evaluation of Highway Asphalt Pavement Maintenance Projects. Tianjin Highway Institute: Tianjin, China, 2024.

- JTG 5220-2020; Standards for Quality Inspection and Evaluation of Highway Maintenance Projects—Volume 1: Civil Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2020.

- JTG 5210-2018; Highway Performance Assessment Standards. Ministry of Transport of the People’s Republic of China: Beijing, China, 2018.

- JTG F71-2006; Technical Specification for Construction of Highway Safety Facilities. Ministry of Transport of the People’s Republic of China: Beijing, China, 2006.

- Wang, Y.L.; Zhang, L.; Zhou, Y.P.; Yin, L.; Wang, X.Y. Assessment of Ecological Environment Sensitivity in Chishui City Based on GIS Technology. Environ. Ecol. 2023, 5, 10–18. [Google Scholar]

- Yan, Z.B.; Li, C.X.; Zhou, M. Study on Quality Evaluation and Improvement Measures of Urban Road Construction. China Constr. 2025, 7, 83–85. [Google Scholar]

- Xu, X.; Wang, S.; Kang, F.; Li, S.; Li, Q.; Wu, T. Multi-Attribute Decision-Making Method in Preventive Maintenance of Asphalt Pavement Based on Optimized Triangular Fuzzy Number. Sustainability 2024, 16, 2787. [Google Scholar] [CrossRef]

- Ruggeri, M.; Zaki, M.G.; Vinci, G. Towards Social Life Cycle Assessment of Food Delivery: Findings from the Italian Case Study. Int. J. Life Cycle Assess. 2024, 29, 1007–1022. [Google Scholar] [CrossRef]

- Hu, G.; Shi, G.; Zhang, R.; Chen, J.; Wang, H.; Wang, J. Assessment of Intelligent Unmanned Maintenance Construction for Asphalt Pavement Based on Fuzzy Comprehensive Evaluation and Analytical Hierarchy Process. Buildings 2024, 14, 1112. [Google Scholar] [CrossRef]

- Li, H.L.; Si, J.Z.; Jia, W.D.; Fu, L.; Li, Q.; Yang, S.; Zhang, S. Multi-Objective Weighted Grey Target Decision-Making for Asphalt Pavement Preventive Maintenance Schemes Based on Three-Level Maintenance Standards. J. Beijing Univ. Technol. 2024, 50, 543–555. [Google Scholar] [CrossRef]

- Hao, J.; Sun, Z.; Xing, Z.; Pei, L.; Feng, X. Dual-Layer Fusion Model Using Bayesian Optimization for Asphalt Pavement Condition Index Prediction. Sensors 2025, 25, 2616. [Google Scholar] [CrossRef]

- Arun, V.; Suresha, S.N. Prediction of Pavement Maintenance Cost for Rural Roads at Network Level. J. Inst. Eng. India Ser. A 2025, 106, 489–509. [Google Scholar] [CrossRef]

- Lu, L.; D’Avigneau, A.M.; Pan, Y.; Sun, Z.; Luo, P.; Brilakis, I. Modeling Heterogeneous Spatiotemporal Pavement Data for Condition Prediction and Preventive Maintenance in Digital Twin-Enabled Highway Management. Autom. Constr. 2025, 174, 106134. [Google Scholar] [CrossRef]

- Zhao, K.; Xu, S.; Loney, J.; Visentin, A.; Li, Z. Road Pavement Health Monitoring System Using Smartphone Sensing with a Two-Stage Machine Learning Model. Autom. Constr. 2024, 167, 105664. [Google Scholar] [CrossRef]

- Jiang, D.; Cao, Z.; Gong, G.; Wang, C.; Gao, Y. VOCs Inhibited Asphalt Mixtures for Green Pavement: Emission Reduction Behavior, Environmental Health Impact and Road Performance. J. Clean. Prod. 2025, 489, 144671. [Google Scholar] [CrossRef]

- Huang, C. Advancements in Sustainable Pavement Materials: A Literature Review. Adv. Eng. Innov. 2025, 16, 175–192. [Google Scholar] [CrossRef]

- Li, P.; Ding, Z. Analysis of Environmental and Ecological Effects on New Techniques for Asphalt Pavement Materials. In Proceedings of the International Symposium on Water Resource and Environmental Protection (ISWREP), Xi’an, China, 20–22 May 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 3532–3536. [Google Scholar] [CrossRef]

- Chen, G.; Zhao, S.; Li, P.; Wang, S.; Zhou, X.; Potekhin, V. The Improved Mountain Gazelle Optimizer for Spatiotemporal Support Vector Regression: A Novel Method for Railway Subgrade Settlement Prediction Integrating Multi-Source Information. Appl. Intell. 2025. Online ahead of print. [Google Scholar] [CrossRef]

- Yang, J. Stability Analysis of Embankment Slope Considering Water Absorption and Softening of Subgrade Expansive Soil. Water 2022, 14, 3528. [Google Scholar] [CrossRef]

- Qiong, X.; Shun, D.; Xu, W. A Study on Seepage Field in Subgrade Slope Subjected to Various Rainfall Patterns. J. Railw. Eng. Soc. 2014, 31, 35–39. [Google Scholar]

| Evaluation Type | References | Indicator Determination Method | Weight Determination Method |

|---|---|---|---|

| Existing post-evaluation systems | Ma et al. [36] | Panorama analysis method | Not addressed |

| Wang et al. [37] | Expert interviews | Expert judgment | |

| Xu et al. [38] | Expert interviews | Expert judgment | |

| Existing preventive maintenance systems | Hu et al. [8] | Expert interviews | Not addressed |

| Wang et al. [39] | Expert interviews | Not addressed | |

| Zhang et al. [40] | Economic-based indicators | Not addressed | |

| Tang et al. [41] | Expert interviews | Decision function | |

| Wang et al. [43] | Expert interviews | Not addressed | |

| This study | HACCP-Inspired | Analytic Hierarchy Process (AHP) | |

| No. | Task Objective | Hazard Types | Potential Hazard Factors | Risk Identification Basis |

|---|---|---|---|---|

| 1 | Maintenance plan formulation | EEH, RUH, ESR, EQR, SBH, SLEH | Incomplete analysis of historical pavement data; poor design safety/economy; inappropriate maintenance timing; poor sectioning; unreasonable measure selection; lack of local traffic demand consideration; disorganized planning leading to cost overruns. | [22,70,71] |

| 2 | Material properties | RUH, ESR, EQR, SBH | Use of unqualified materials; lack of standard inspection; long-distance material transportation. | [72,73] |

| 3 | Equipment provision | RUH, ESR, EQR, SBH | Inadequate communication, power, lighting, and safety facilities; irregular maintenance of machinery; inefficient use; lack of pre-operation checks. | [72,74] |

| 4 | Personnel configuration | ESR, EQR, SBH | Unqualified technical staff; poor skill mastery; lack of motivation and discipline. | [72,75] |

| 5 | Technical preparedness | EEH, RUH, ESR, EQR, SBH | Incomplete technical preparation; insufficient staff training; increased risk of construction safety and quality issues. | [72,76] |

| No. | Task Objective | Hazard Types | Potential Hazard Factors | Risk Identification Basis |

|---|---|---|---|---|

| 1 | Construction process control | EEH, RUH, ESR, EQR, SBH | Improper coordination of labor and equipment; poor organization; inadequate safety training; weak supervision; poor schedule and cost control; increased project costs and reduced social benefits. | [72,76,77] |

| 2 | Quality control | ESR, EQR, SBH, SLEH | Inadequate inspection of contract compliance and material quality; failure in on-site verification and acceptance; surface defects such as unevenness and poor compaction; quality failures impacting public satisfaction; budget overruns. | [72,76,78] |

| 3 | Safety protection | ESR, EQR, SBH | Incomplete safety protocols; lack of emergency plans; traffic management failures; equipment misuse; storage safety issues; fire hazards due to poor prevention measures. | [72,75,76] |

| No. | Task Objective | Hazard Types | Potential Hazard Factors | Risk Identification Basis |

|---|---|---|---|---|

| 1 | Technical indicators | ESR, EQR, SBH, SLEH | Untimely/inaccurate performance testing; poor road condition data; lack of load-bearing capacity monitoring causing structural damage and traffic interruption. | [77,79] |

| 2 | Financial management | ESR, EQR, SBH | Poor fund allocation and disbursement; lack of cost control; excessive overspending; salary arrears; inadequate cost awareness among staff; material waste and inefficient logistics. | [22,70,71,77] |

| 3 | Resource utilization | EEH, RUH, EQR, SBH | Low adoption of energy-saving equipment; use of high-energy temporary facilities. | [22,70,71,77] |

| 4 | Environmental protection | EEH, RUH, SBH, SLEH | Emissions from machinery (e.g., asphalt pavers, chip spreaders); GHG emissions from production; noise pollution; light pollution from nighttime construction; increased traffic emissions and noise affecting local residents’ well-being. | [22,70,71,77] |

| No. | Task Objective | Q1 | Q2 | Q3 | Q4 | Identified as CCP |

|---|---|---|---|---|---|---|

| 1 | Maintenance plan formulation | Yes | Yes | N/A | N/A | Yes |

| 2 | Material performance | Yes | Yes | N/A | N/A | Yes |

| 3 | Equipment provision | Yes | Yes | N/A | N/A | Yes |

| 4 | Personnel configuration | Yes | Yes | N/A | N/A | Yes |

| 5 | Technical preparedness | Yes | Yes | N/A | N/A | Yes |

| No. | Critical Control Point | Control Measures |

|---|---|---|

| 1 | Maintenance plan formulation | Precisely determine the timing of maintenance; accurately cluster maintenance sections to enable targeted interventions; select optimal maintenance measures to ensure defect resolution and quality improvement; fully consider local travel needs; ensure rational overall project design. |

| 2 | Material performance | Conduct standardized technical tests for all materials; select suppliers with reasonable transport distances to ensure logistics efficiency. |

| 3 | Equipment provision | Perform routine checks according to technical specifications; operate machinery strictly as prescribed; conduct pre-operation adjustments and maintenance inspections. |

| 4 | Personnel configuration | Prepare construction personnel in line with technical requirements; enhance training on methods and procedures. |

| 5 | Technical preparedness | Apply proven, innovative, or newly derived technical methods; provide comprehensive training to improve operational proficiency. |

| No. | Task Objective | Q1 | Q2 | Q3 | Q4 | Identified as CCP |

|---|---|---|---|---|---|---|

| 1 | Construction process control | Yes | Yes | N/A | N/A | Yes |

| 2 | Quality control | Yes | Yes | N/A | N/A | Yes |

| 3 | Safety protection | Yes | Yes | N/A | N/A | Yes |

| No. | Critical Control Point | Control Measures |

|---|---|---|

| 1 | Construction process control | Establish special management protocols and training; define construction zones clearly; enhance workflow continuity; optimize work sequences to control project timelines; implement digital construction management to improve efficiency and equipment utilization. |

| 2 | Quality control | Strictly verify construction parameters including layer thickness, smoothness, compaction, permeability, and skid resistance; adjust evaluation indicators as needed based on maintenance techniques; ensure compliance with applicable standards for new technologies. |

| 3 | Safety protection | Develop and enforce dedicated safety protocols; promote safety awareness and training; improve site safety measures and establish robust safety management mechanisms. |

| No. | Task Objective | Q1 | Q2 | Q3 | Q4 | Identified as CCP |

|---|---|---|---|---|---|---|

| 1 | Technical indicators | Yes | Yes | N/A | N/A | Yes |

| 2 | Financial management | Yes | Yes | N/A | N/A | Yes |

| 3 | Resource utilization | Yes | Yes | N/A | N/A | Yes |

| 4 | Environmental protection | Yes | Yes | N/A | N/A | Yes |

| No. | Critical Control Point | Control Measures |

|---|---|---|

| 1 | Technical indicators | Continuously monitor road performance to ensure alignment with design expectations. Key indicators include: Subgrade Condition Index (SCI), Pavement Quality Index (PQI), Pavement Condition Index (PCI), Ride Quality Index (RQI), Rut Depth Index (RDI), Bump Index (PBI), Pavement Wear Index (PWI), Skid Resistance Index (SRI), Pavement Structural Strength Index (PSSI), Bridge Condition Index (BCI), and Traffic Facility Index (TCI). |

| 2 | Financial management | Establish standardized funding management procedures; ensure reasonable allocation, disbursement, and supervision of funds; prevent cost overruns and project violations; enforce cost control mechanisms during construction preparation. |

| 3 | Resource utilization | Promote renewable energy use and material recycling; increase the adoption of clean energy sources such as wind and solar; encourage hybrid renewable energy applications. |

| 4 | Environmental protection | Manage construction wastewater per regulations; centralize and dispose of solid waste promptly; use machinery compliant with emissions standards; implement noise and light pollution controls; enhance roadside greening efforts. |

| No. | Critical Control Point | Key Control Items |

|---|---|---|

| 1 | Maintenance plan formulation | Timing Determination for Maintenance Clustering of Maintenance Sections Selection of Maintenance Scheme Consideration of Traffic Accessibility Needs Overall Organizational Design |

| 2 | Material properties | Technical Testing of Aggregates Technical Testing of Asphalt Testing of Other Material Properties |

| 3 | Equipment provision | Equipment Inspection and Maintenance Standardized Use of Equipment Completeness of Equipment Deployment |

| 4 | Personnel configuration | Personnel Allocation Technical Training for Personnel |

| 5 | Technical preparedness | Maturity of Applied Technology Technological Advancement Innovativeness of Technology |

| No. | Critical Control Point | Key Control Items |

|---|---|---|

| 1 | Construction process control | Development of Specialized Management Protocols Standardized Construction Practices Construction Continuity Construction Efficiency Construction Schedule Control |

| 2 | Quality control | Structural Layer Thickness Inspection Compaction Degree Testing Surface Evenness Testing Permeability Testing Skid Resistance Testing Other Quality Parameter Testing |

| 3 | Safety protection | Development of Specialized Safety Protocols Safety Training for Construction Personnel Traffic Management at Construction Sites Preparation of Emergency Safety Plans |

| No. | Critical Control Point | Key Control Items |

|---|---|---|

| 1 | Technical indicators | Subgrade Condition Assessment Pavement Condition Assessment Bridge and Tunnel Structure Assessment Roadside Facility Condition Assessment |

| 2 | Financial management | Rationality of Fund Utilization Financial Audit |

| 3 | Resource utilization | Material Recycling and Reuse Utilization of Renewable Energy Use of Clean Energy Application of Energy-Saving Equipment |

| 4 | Environmental protection | Soil and Water Environment Protection Solid Waste Management Control of Noise and Light Pollution Landscape Greening |

| Level 1 Indicator | Level 2 Indicator | Level 3 Indicator | Level 4 Indicator |

|---|---|---|---|

| Highway Preventive Maintenance Technology | Maintenance Scheme Determination | Timing Determination for Maintenance | — |

| Selection of Maintenance Scheme | — | ||

| Clustering of Maintenance Sections | — | ||

| Preparation for Maintenance Construction | Material properties | Technical Testing of Aggregates | |

| Technical Testing of Asphalt | |||

| Testing of Other Material Properties | |||

| Equipment Inspection and Maintenance | — | ||

| Personnel Allocation | — | ||

| Technical Preparedness | — | ||

| Maintenance Construction Process | Construction Process Control | Development of Specialized Safety Protocols | |

| Construction Schedule Control | |||

| Construction Quality Control | — | ||

| Technical Indicator Evaluation | Subgrade Condition Assessment | Subgrade Condition Index (SCI) | |

| Pavement Condition Assessment | Pavement Quality Index (PQI) | ||

| Pavement Condition Index (PCI) | |||

| Ride Quality Index (RQI) | |||

| Rutting Depth Index (RDI) | |||

| Bump Index (PBI) | |||

| Pavement Wear Index (PWI) | |||

| Skid Resistance Index (SRI) | |||

| Pavement Structural Strength Index (PSSI) | |||

| Bridge and Tunnel Structure Assessment | Bridge Condition Index (BCI) | ||

| Roadside Facility Condition Assessment | Traffic Facility Condition Index (TCI) | ||

| Maintenance Fund Management | Rationality of Fund Utilization | — | |

| Environmental Protection and Resource Utilization | Resource Utilization | Utilization of Renewable Energy | |

| Recycling of Old Pavement Materials | |||

| Environmental Protection | — |

| Level 1 Indicator | Level 2 Indicator | Weight | Score | Level 3 Indicator | Weight | Score | Level 4 Indicator | Weight | Score |

|---|---|---|---|---|---|---|---|---|---|

| Highway Preventive Maintenance Technology | Maintenance Scheme Determination | 0.251 | 25 | Timing Determination for Maintenance | 0.072 | 7 | — | — | — |

| Selection of Maintenance Scheme | 0.144 | 14.5 | — | — | — | ||||

| Clustering of Maintenance Sections | 0.036 | 3.5 | — | — | — | ||||

| Preparation for Maintenance Construction | 0.047 | 5 | Material properties | 0.024 | 2.5 | Technical Testing of Aggregates | 0.008 | 0.5 | |

| Technical Testing of Asphalt | 0.008 | 0.5 | |||||||

| Testing of Other Material Properties | 0.008 | 1.5 | |||||||

| Equipment Inspection and Maintenance | 0.006 | 0.5 | — | — | — | ||||

| Personnel Allocation | 0.003 | 0.5 | — | — | — | ||||

| Technical Preparedness | 0.013 | 1.5 | — | — | — | ||||

| Maintenance Construction Process | 0.088 | 9 | Construction Process Control | 0.058 | 6 | Development of Specialized Safety Protocols | 0.029 | 3 | |

| Construction Schedule Control | 0.029 | 3 | |||||||

| Construction Quality Control | 0.029 | 3 | — | — | — | ||||

| Technical Indicator Evaluation | 0.433 | 43 | Subgrade Condition Assessment | 0.119 | 12 | Subgrade Condition Index (SCI) | — | — | |

| Pavement Condition Assessment | 0.222 | 22 | Pavement Quality Index (PQI) | 0.02775 | 3 | ||||

| Pavement Condition Index (PCI) | 0.02775 | 3 | |||||||

| Ride Quality Index (RQI) | 0.02775 | 2.5 | |||||||

| Rutting Depth Index (RDI) | 0.02775 | 3 | |||||||

| Bump Index (PBI) | 0.02775 | 2.5 | |||||||

| Pavement Wear Index (PWI) | 0.02775 | 2.5 | |||||||

| Skid Resistance Index (SRI) | 0.02775 | 2.5 | |||||||

| Pavement Structural Strength Index (PSSI) | 0.02775 | 3 | |||||||

| Bridge and Tunnel Structure Assessment | 0.06 | 6 | Bridge Condition Index (BCI) | — | — | ||||

| Roadside Facility Condition Assessment | 0.032 | 3 | Traffic Facility Condition Index (TCI) | — | — | ||||

| Maintenance Fund Management | 0.151 | 15 | Rationality of Fund Utilization | 0.151 | 15 | — | — | — | |

| Environmental Protection and Resource Utilization | 0.03 | 3 | Resource Utilization | 0.02 | 2 | Utilization of Renewable Energy | 0.01 | 1 | |

| Recycling of Old Pavement Materials | 0.01 | 1 | |||||||

| Environmental Protection | 0.01 | 1 | — | — | — |

| Level 2 Indicator | Level 3 Indicator | Maintenance Description | Score |

|---|---|---|---|

| Maintenance Scheme Determination (25 pts) | Timing Determination for Maintenance (7 pts) | Pavement condition data show a PQI score of 88 and a PCI score of 77. The surface damage level is Fair. If maintenance is not conducted in time, further deterioration may occur, resulting in increased costs and significant impacts on road functionality. Based on standards, PQI = 88 meets the timing requirement; PCI = 77 is slightly below the requirement. Overall assessment: Good. Score: 7 × 85% = 6. | 6 |

| Selection of Maintenance Scheme (14.5 pts) | According to the Specifications for Maintenance Design of Highway Asphalt Pavement (JTG 5421-2018), functional maintenance is recommended for this project. In practice, milling and resurfacing was adopted for the surface layer, while patch repairs (either surface or base layer) were implemented at specific damaged locations. The overall strategy complies with the standard, though localized patching decisions were insufficiently justified. Overall assessment: Excellent. Score: 14.5 × 90% = 13. | 13 | |

| Clustering of Maintenance Sections (3.5 pts) | According to the Specifications for Maintenance Design of Highway Asphalt Pavement (JTG 5421-2018), it suggests dividing road sections by kilometers, with finer segmentation for special sections. In this project, sections were generally divided by kilometers, meeting the requirement, but some special segments were not subdivided in detail. Overall assessment: Good. Score: 3.5 × 85% = 3. | 3 |

| Level 2 Indicator | Level 3 Indicator | Maintenance Description | Score |

|---|---|---|---|

| Preparation for Maintenance Construction (5 pts) | Material properties (2.5 pts) | The technical specifications of raw materials used in the pavement structure must comply with the Technical Specifications for Construction of Highway Asphalt Pavements (JTG F40-2004 [72]), and all materials delivered to the site must undergo quality testing. Approval based solely on supplier reports or inspection certificates is not permitted. This project met all requirements. Full score awarded. | 2.5 |

| Equipment Inspection and Maintenance (0.5 pts) | Adequate provision of water, electricity, construction equipment, materials, and essential living supplies must be ensured. This project met all relevant requirements. Full score awarded. | 0.5 | |

| Personnel Allocation (0.5 pts) | This content was not included in the project documentation. No score assigned. | — | |

| Technical Preparedness (1.5 pts) | The project adopted mature and conventional technologies. According to the evaluation standard, this item is rated as “Fair.” Score: 1.5 × 65% = 1. | 1 |

| Level 2 Indicator | Level 3 Indicator | Maintenance Description | Score |

|---|---|---|---|

| Maintenance Construction Process (9 pts) | Construction Process Control (6 pts) | For construction safety, prior to commencement of the Jinghuan Expressway maintenance project, the supervising engineer, technical personnel, and project leader conducted technical briefings, quality briefings, and safety education for all workers. Personnel responsibilities were clearly defined. The entire construction process strictly followed relevant provisions in the Technical Specifications for Construction of Highway Safety Facilities (JTG F71-2006 [80]). The project was completed within the scheduled timeline. Full score awarded. | 6 |

| Construction Quality Control (3 pts) | The construction quality of this project was not adequately controlled, lacking temperature monitoring, asphalt content tests, and total gradation inspections of aggregates. According to the evaluation standard, this item is rated as “Fair.” Score: 3 × 65% = 2. | 2 |

| Level 2 Indicator | Level 3 Indicator | Level 4 Indicator | Score Description | Score |

|---|---|---|---|---|

| Technical Indicator Evaluation (43 pts) | Subgrade Condition Assessment (12 pts) | — | — | — |

| Pavement Condition Assessment (22 pts) | PQI (3 pts) | Based on pavement condition survey, rated as “Fair”; score = 3 × 65% = 2. | 2 | |

| PCI (3 pts) | Based on pavement condition survey, rated as “Fair”; score = 3 × 65% = 2. | 2 | ||

| RQI (2.5 pts) | Based on pavement condition survey, rated as “Fair”; score = 3 × 65% = 2. | 1 | ||

| RDI (3 pts) | Based on pavement condition survey, rated as “Fair”; score = 3 × 65% = 2. | 3 | ||

| PBI (2.5 pts) | Based on pavement condition survey, this item received full score. | 2.5 | ||

| PWI (2.5 pts) | Based on pavement condition survey, this item received full score. | 2.5 | ||

| SRI (2.5 pts) | Based on pavement condition survey, this item received full score. | 2 | ||

| PSSI (3 pts) | — | — | ||

| Bridge and Tunnel Structure Assessment (6 pts) | — | — | — | |

| Roadside Facility Condition Assessment (3 pts) | — | — | — |

| Level 2 Indicator | Level 3 Indicator | Maintenance Description | Score |

|---|---|---|---|

| Maintenance Fund Management (15 pts) | Rationality of Fund Utilization (15 pts) | The project complied with official fund allocation procedures. Detailed audit reports were provided. The project met all regulatory requirements. Therefore, this item received a full score. | 15 |

| Level 2 Indicator | Level 3 Indicator | Level 4 Indicator | Maintenance Description | Score |

|---|---|---|---|---|

| Environmental Protection and Resource Utilization (3 pts) | Resource Utilization (2 pts) | Utilization of Renewable Energy (1 pt) | No clean energy was used in this project. Therefore, this item received a score of 0. | 0 |

| Recycling of Old Pavement Materials (1 pt) | All milled old pavement materials were fully recovered, achieving a 100% recycling rate. This item received a full score. | 1 | ||

| Environmental Protection (1 pt) | — | Measures were implemented for noise control, air quality protection, water environment protection, solid waste management, and ecological conservation. The project complied with relevant regulations and thus received a full score. | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, N.; Wang, C.; Chang, H. An HACCP-Inspired Post-Evaluation Framework for Highway Preventive Maintenance: Methodology and Case Application. Appl. Sci. 2025, 15, 11377. https://doi.org/10.3390/app152111377

Fang N, Wang C, Chang H. An HACCP-Inspired Post-Evaluation Framework for Highway Preventive Maintenance: Methodology and Case Application. Applied Sciences. 2025; 15(21):11377. https://doi.org/10.3390/app152111377

Chicago/Turabian StyleFang, Naren, Chen Wang, and Huanyu Chang. 2025. "An HACCP-Inspired Post-Evaluation Framework for Highway Preventive Maintenance: Methodology and Case Application" Applied Sciences 15, no. 21: 11377. https://doi.org/10.3390/app152111377

APA StyleFang, N., Wang, C., & Chang, H. (2025). An HACCP-Inspired Post-Evaluation Framework for Highway Preventive Maintenance: Methodology and Case Application. Applied Sciences, 15(21), 11377. https://doi.org/10.3390/app152111377