Safety Challenges in Battery Swapping Operations of Electric Underground Mining Trucks

Abstract

1. Introduction

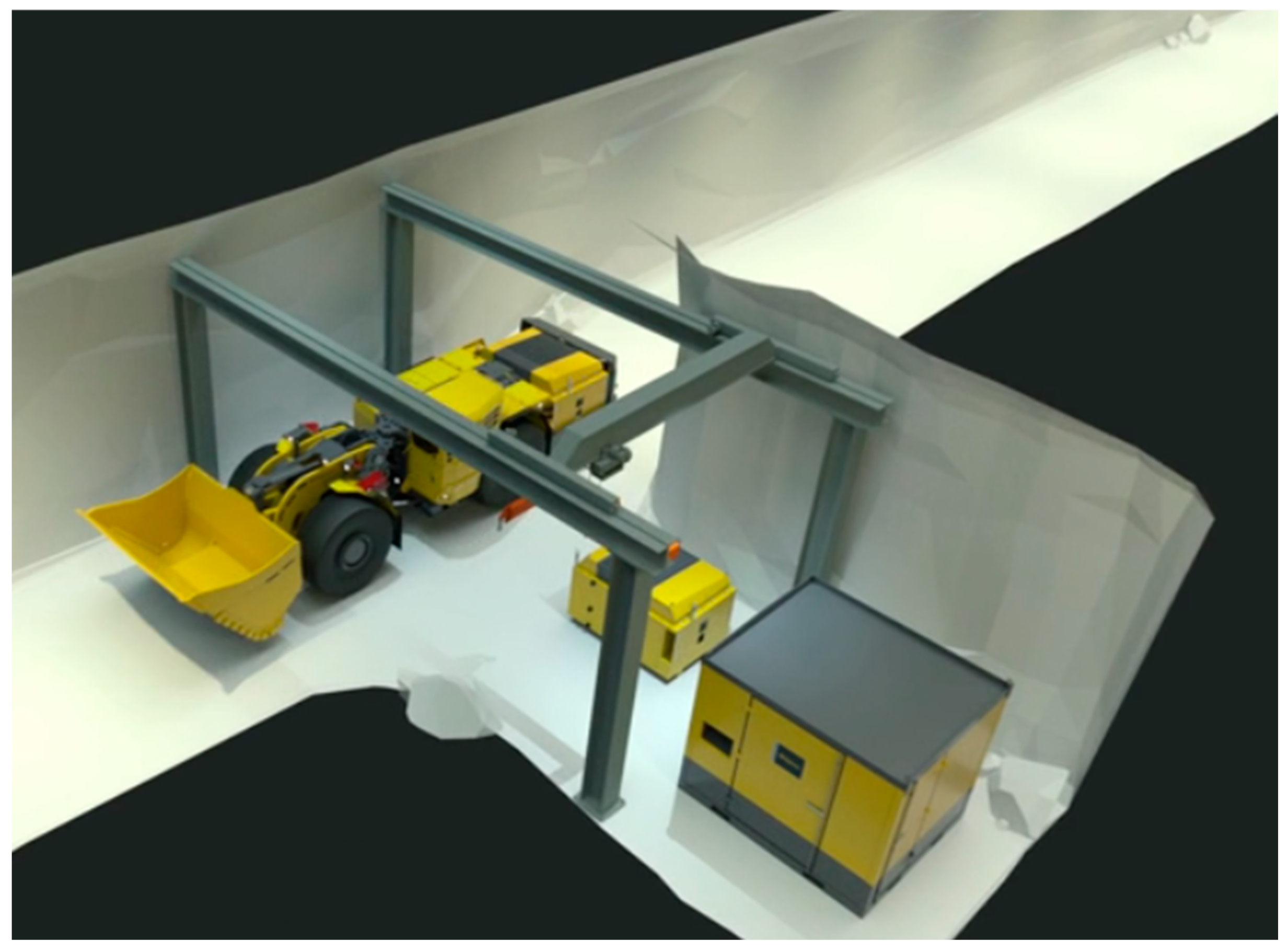

2. Current Battery Swapping Methods for Underground Electric-Powered Trucks

- Parking the machine;

- Disconnecting the charged battery from the charger;

- Disconnecting the battery on the machine;

- Removing the discharged battery from the machine with the crane and laying it down in the chamber;

- Lifting the charged battery and placing it on the machine;

- Connecting the charged battery on the machine;

- Connecting the discharged battery to the charger;

- Driving the machine from the charging station.

- Arrival and parking of the BPM in the charging station;

- Disconnecting the charged battery from the charger;

- Moving the machine to the location for the lowering of the discharged battery;

- Lowering of discharged battery;

- Moving and manoeuvring the BPM to the charged battery;

- Hooking and lifting the battery onto the machine;

- Parking the machine;

- Connecting the discharged battery to the charger;

- Driving the machine from the charging station.

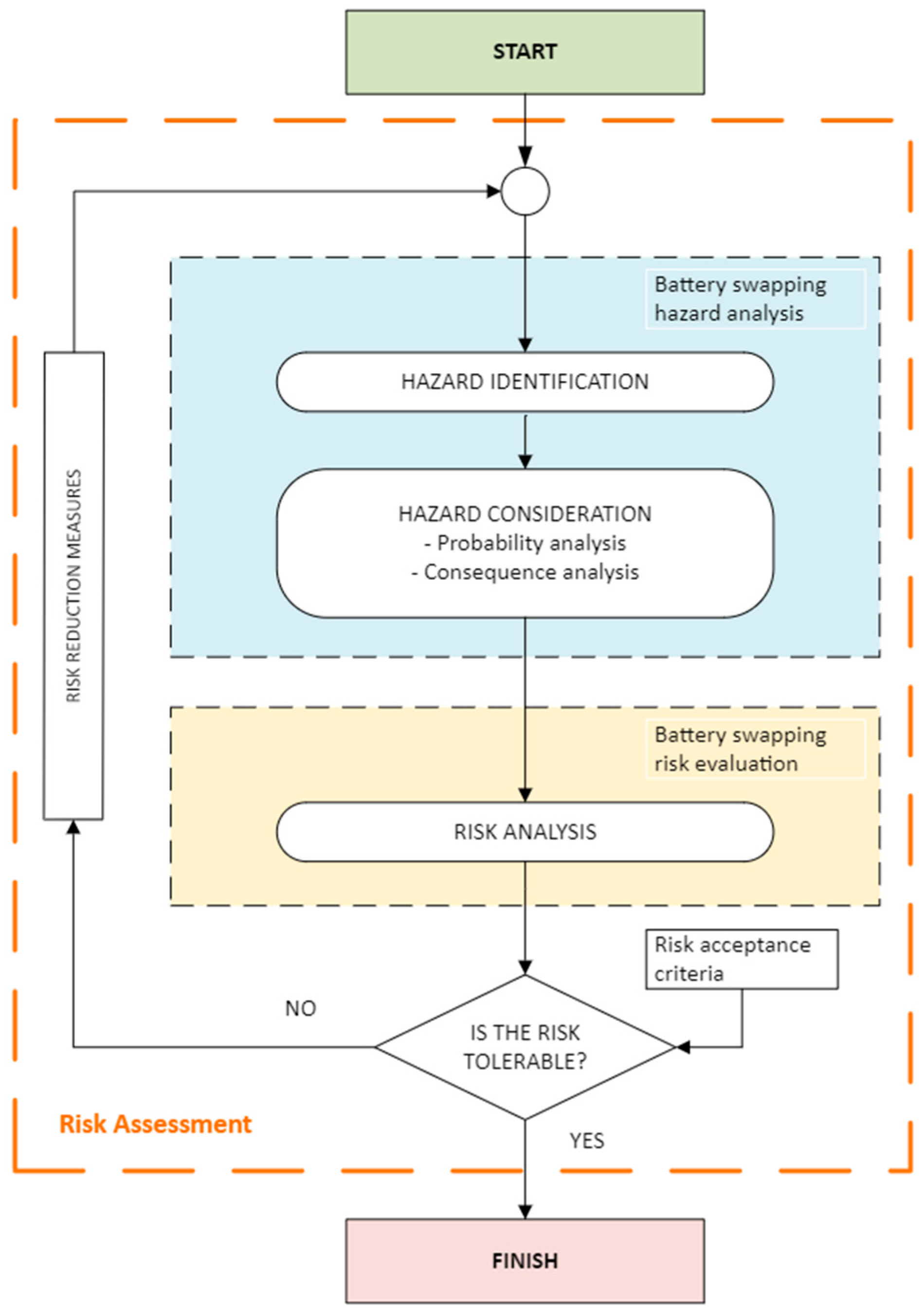

3. Identification of Hazards and Risk Assessment During Battery Swapping

- 1.

- Crushing/Impact—the risk of injury by crushing the operator by fixed and moving object (battery).

- ○

- This hazard occurs during the battery handling—load lifted with the overhead crane. The estimated probability rank of this hazard is 2, and the consequence rank is 5;

- ○

- The same hazard occurs during machine movement in situations when other people are present in the charging station. The estimated probability rank of this hazard is 3, and the consequence rank is 5;

- 2.

- Moving equipment—risk of equipment damage by moving objects;

- ○

- Hazard similar to the previous one, but in regard to the equipment and assets present at the site. The estimated probability rank of this hazard is 2, and the consequence rank is 3;

- 3.

- Pinch points—the risk of pinching the part of the human body between two objects.

- ○

- Pinching hazard is present during connecting and disconnecting the power supply cables to the battery. The estimated probability rank of this hazard is 2, and the consequence rank is 2;

- ○

- Pinching can occur during the suspended load handling and fitting the slings and ropes to the load (battery). The estimated probability rank of this hazard is 2, and the consequence rank is 3;

- 4.

- Static stability—risk by disrupting the static balance (equilibrium) of forces by adding or removing the weight;

- ○

- Adding and removing the weight (battery) impacts the static stability of a battery-powered machine by moving the machine’s centre of gravity. The estimated probability rank of this hazard is 2, and the consequence rank is 5;

- 5.

- Dynamic stability—the impact of dynamic forces and velocity on the system;

- ○

- Manipulating the battery with an overhead crane generates dynamic forces in lifting ropes/chains (swinging) and the load-bearing structure. The estimated probability rank of this hazard is 3, and the consequence rank is 3;

- 6.

- Mechanical strength—the strength of all load-bearing components;

- ○

- Load-bearing components, such as steel beams of the overhead crane and hooks for lifting/lowering the battery, must have sufficient mechanical strength for expected loads during the battery handling. The estimated probability rank of this hazard is 1, and the consequence rank is 4;

- 7.

- Roll over—risk of tipping;

- ○

- The hazard of battery tipping occurs during battery handling with an overhead crane (lifting and lowering). The estimated probability rank of this hazard is 2, and the consequence rank is 3;

- 8.

- Wearing and Scraping—risk of equipment wearing;

- ○

- Frequent connecting and disconnecting of power supply cables to the battery creates the hazard of the cable’s insulation wear and tear. The estimated probability rank of this hazard is 1, and the consequence rank is 3;

- 9.

- Fall at level—tripping hazard for the operator;

- ○

- A tripping hazard at the level is present during the suspended load handling when the attention of the operator is focused on the suspended battery. Additional obstacles (cables lying on the ground) contribute to the hazard. The estimated probability rank of this hazard is 3, and the consequence rank is 3;

- 10.

- Fall from height—the risk of falling while working on the height;

- ○

- Some activities during battery swap are performed at height (connecting and disconnecting the battery on the machine, crane inspection), and such situations represent the falling from height hazard. The estimated probability rank of this hazard is 3, and the consequence rank is 4;

- 11.

- Falling object—the risk of an object falling from a height;

- ○

- A falling battery suspended on the crane represents a hazard for the operator and other equipment and assets on the site. The estimated probability rank of this hazard is 1, and the consequence rank is 5;

- ○

- Falling of the battery from the lifting and lowering mechanism due to the failure of the mechanism or inappropriate battery hooking. The estimated probability rank of this hazard is 1, and the consequence rank is 5;

- 12.

- Roll away—the risk of uncontrollable machine movement;

- ○

- This hazard occurs when parking the machine on a sloped surface. The estimated probability rank of this hazard is 3, and the consequence rank is 5;

- 13.

- Confined space—the risk of performing the tasks in small and enclosed areas;

- ○

- This hazard is somewhat difficult to describe but it is common in underground mining. All tasks to be performed must be planned with limitations generated by this hazard (for example, the charging cables should not be longer than necessary since it would contribute to the risk—tripping, cable wear, generating larger heat loads, and similar). The estimated probability rank of this hazard is 2, and the consequence rank is 1;

- ○

- A specific confined space hazard, which is not directly related to battery swapping, is a completely discharged battery. A battery-powered machine with a completely discharged battery is blocking the roadway for other traffic, thus disrupting the regular operations in the mine. Removing such machines would include options such as towing, mobile chargers and similar. The estimated probability rank of this hazard is 2, and the consequence rank is 1;

- 14.

- Pedestrians—the risk of injury to personnel in case of their presence;

- ○

- This hazard is related to the presence of other personnel at the site, not directly related to the battery swapping. The presence of personnel is increasing the level of hazard due to the increased possibility of risks occurring described in this list. The estimated probability rank of this hazard is 3, and the consequence rank is 4;

- 15.

- Remote activities/Isolation—tasks performed on remote sites and in isolation;

- ○

- As said above, OEMs are suggesting that battery swapping can be performed solely by the operator of BPM. Working in isolation is a relevant hazard, especially in the case of an incident when an injured operator requires medical attention. The estimated probability rank of this hazard is 2, and the consequence rank is 5;

- 16.

- Ambient heat/Heat stress/Radiant heat—heat emitted from the equipment;

- ○

- The battery charging process is closely related to the heat emission. Considering the size of the charging stations, this hazard may become relevant both regarding legally regulated temperatures for the human working environment and the equipment’s operational temperature ranges, which is of high relevance for the lithium-ion batteries. The estimated probability rank of this hazard is 4, and the consequence rank is 2;

- 17.

- Ventilation—the requirement of providing a sufficient amount of fresh air and to create acceptable temperature at the work site;

- ○

- This is closely related to the previous hazard. Supply of fresh air is not seen as a major hazard, since there is no air consumption during the battery charging process. However, ventilation may be influenced by the requirement to secure specific room temperatures inside the charging station due to numerous heat emission sources. In some cases, air conditioning (cooling) may be required to create acceptable working conditions. The estimated probability rank of this hazard is 3, and the consequence rank is 1;

- 18.

- Contact—contact with hot or cold surface;

- ○

- In general, no sizable items with high or low temperatures will be present inside the charging station. However, specific smaller components such as connecting sock pins, components of the charger or components of air-cooling equipment (if used) may be at temperatures which could cause an injury. The estimated probability rank of this hazard is 2, and the consequence rank is 1;

- 19.

- Pushing and pulling—the risk of injury during manual work;

- ○

- This risk is related to handling the battery as a load (fixing the ropes/chains/slings to the battery) and handling the power supply cable for connecting and disconnecting. Both activities require some level of manual work, during which injury can occur. The estimated probability rank of this hazard is 2, and the consequence rank is 1;

- 20.

- Short circuit—the hazard from the unintended current path;

- ○

- This is usually related to the abnormal electrical connection between two or more conductors, where batteries with low internal resistance are capable of generating dangerously high currents in case of short circuits. Short circuits in charging stations can occur due to equipment malfunctions and environmental factors (humidity, dust, debris, etc.). It can result in major to catastrophic consequences to humans and equipment. The estimated probability rank of this hazard is 3, and the consequence rank is 4;

- 21.

- Arcing (arc flash)—the electrical hazard of current flow through the air;

- ○

- Current flow through the air can occur between conductors or from one conductor to a grounded object due to malfunctioning insulation or an accidental short circuit. The consequences of this hazard can be very serious for workers and can also damage the equipment. The estimated probability rank of this hazard is 3, and the consequence rank is 5;

- Rare (1)—highly low probability of hazard, negligible;

- Unlikely (2)—low probability of hazard to occur, not negligible;

- Possible (3)—moderate probability of hazard to occur. Such a hazard is not uncommon, but also is not frequent;

- Likely (4)—a high probability of hazard to occur, occasionally, or repeatedly;

- Almost certain (5)—the highest level of hazard to occur, frequently.

- Minor (1)—OH&S hazard: Reversible health effects of little concern. Economic hazard: Minimal consequence to the asset (easy to repair) without impact on the operations;

- Medium (2)—OH&S hazard: Reversible health effects of concern that would typically result in medical treatment. Economic hazard: Little damage to the asset, reparable, slight delay in operations;

- Serious (3)—OH&S hazard: Severe, reversible health effects of concern that would typically result in a lost time illness. Economic hazard: Significant damage to the asset, replacement required, delays at the scale of one to two shifts, and some impact on production volumes;

- Major (4)—OH&S hazard: Irreversible health effects or disabling illness. Economic hazard: Major damage to the asset, delays at the scale of days, and impact on production volumes;

- Catastrophic (5)—OH&S hazard: Fatality or serious disabling illness to multiple people. Economic hazard: Asset replacement required with associated delays, impact on production volumes.

- Critical (in red)—Risk which is significantly higher than the acceptance level and requires immediate attention;

- High (in orange)—Risk which is higher than the acceptance level and requires proactive management;

- Medium (in yellow)—Risk on the acceptance level and requires active monitoring. Additional measures can be implemented to further reduce the risk;

- Low (in green)—Risk on the acceptance level.

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Paraszczak, J.; Svedlund, E.; Fytas, K.; Laflamme, M. Electrification of Loaders and Trucks—A Step Towards More Sustainable Underground Mining. Renew. Energy Power Qual. J. (REPQJ) 2014, 12, 81–86. [Google Scholar] [CrossRef]

- Brink, H.G.; Dore, E.; Perlatti, F.; Lattanzi, P. Editorial for the Special Issue “Sustainable Mining as the Key for the Ecological Transition: Current Trends and Future Perspectives”. Minerals 2024, 14, 389. [Google Scholar] [CrossRef]

- Paraszczak, J.; Fytas, K.; Laflamme, M. Feasibility of Using Electric Trucks in Deep Metal Mines. In Mine Planning and Equipment Selection; Drebenstedt, C., Singhal, R., Eds.; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar] [CrossRef]

- Leonida, C. Reloaded: Introducing the Next Generation of Underground Mining Trucks. Eng. Min. J. Jacksonv. 2024, 225, 28–33. [Google Scholar]

- Assimi, H.; Ataabadi, S.N.H.; Islam, S.M.M.; Soong, W.L.; Pourmousavi, S.A. Toward Underground Mobile Fleet Electrification: Three essential steps to make a real change. IEEE Electrif. Mag. 2024, 12, 16–26. [Google Scholar] [CrossRef]

- Loomis, I.M. Considerations of the overall impact on costs in the Battery Electric versus Diesel-powered equipment selection and trade-off. In Proceedings of the 18th north American Mine Ventilation Symposium (NAMVS 2021), Rapid City, SD, USA, 12–17 June 2021; Tukkaraja, P., Ed.; CRC Press: Boca Raton, FL, USA, 2021. ISBN 978-1-032-03679-3. [Google Scholar]

- Balboa-Espinoza, V.; Segura-Salazar, J.; Hunt, C.; Aitken, D.; Campos, L. Comparative life cycle assessment of battery-electric and diesel underground mining trucks. J. Clean. Prod. 2023, 425, 139056. [Google Scholar] [CrossRef]

- Rafi, M.A.H.; RennieR; Larsen, J.; Bauman, J. Investigation of Fast Charging and Battery Swapping Options for Electric Haul Trucks in Underground Mines. In Proceedings of the IEEE Transportation Electrification Conference & Expo (ITEC), Chicago, IL, USA, 23–26 June 2020. [Google Scholar] [CrossRef]

- Grafe, R. Electro-mobility in underground mining. Glückauf-Min. Rep. 2017, 153, 158–164. [Google Scholar]

- Yan, X.; Jin, H.; Kou, Z.; Zhang, L.; Niu, N. Intelligent Scheduling Strategy of Electric Locomotive Robots for Underground Mining. IEEE Access 2021, 9, 161533–161545. [Google Scholar] [CrossRef]

- Saeidi, N.; Allen, C. A discussion on underground mine ventilation design considerations for diesel vs. battery electric mobile equipment. CIM J. 2022, 14, 48–55. [Google Scholar] [CrossRef]

- Halim, A. Field Trials and Fire Safety of Battery Electric Vehicles in Underground Mines: A current snapshot of the advantages and challenges of the use of battery electric vehicles in underground mines. IEEE Electrif. Mag. 2024, 12, 56–65. [Google Scholar] [CrossRef]

- Lajunen, A.; Suomela, J.; Pippuri, J.; Tammi, K.; Lehmuspelto, T.; Sainio, P. Electric and Hybrid Electric Non-Road Mobile Machinery—Present Situation and Future Trends. World Electr. Veh. J. 2016, 8, 172–183. [Google Scholar] [CrossRef]

- Roquet, P.; Raush, G.; Berne, L.J.; Gamez-Montero, P.J.; Codina, E. Energy Key Performance Indicators for Mobile Machinery. Energies 2022, 15, 1364. [Google Scholar] [CrossRef]

- Paraszczak, J. Understanding and assessment of mining equipment effectiveness, Mining Technology. Trans. Inst. Min. Metall. A 2005, 114, 147–151. [Google Scholar] [CrossRef]

- Global Mining Guidelines Group (GMG). Recommended Practices for Battery Electric Vehicles In Underground Mining. 2022. Version 3, Global Mining Guidelines Group (GMG). Available online: https://gmggroup.org/wp-content/uploads/2023/12/2022-06-23_Recommended-Practices-for-Battery-Electric-Vehicles-in-Underground-Mining.pdf (accessed on 15 December 2024).

- Park, S.; Choi, Y. Performance Evaluation of Truck Haulage Operations in an Underground Mine using GMG’s Time Usage Model and Key Performance Indicators. Tunn. Undergr. Space 2022, 32, 254–271. [Google Scholar] [CrossRef]

- Lewis, M.W.; Steinberg, L. Maintenance of mobile mine equipment in the information age. J. Qual. Maint. Eng. 2001, 7, 264–274. [Google Scholar] [CrossRef]

- Hooli, J.; Halim, A. Battery electric vehicles in underground mines: Insights from industry. Renew. Sustain. Energy Rev. 2025, 208, 115024. [Google Scholar] [CrossRef]

- Nåbo, A.; Abrahamsson, M.; Bhatti, H.J.; Björklund, M.; Daniels, D.; Danilovic, M.; Haugland, P.; Huddén, P.; Portinson Hylander, J.; Käck, S.; et al. Battery-Swapping for Heavy Duty Vehicles. A Feasibility Study on Up-Scaling in Sweden, Swedish National Road and Transport Research Institute (VTI), VTI Rapport 1199A. 2024. Available online: http://vti.diva-portal.org/smash/record.jsf?pid=diva2%3A1826965&dswid=-8693 (accessed on 2 June 2025).

- Konz, S.; Johnson, S. Work Design: Occupational Ergonomics; CRC Press: Boca Raton, FL, USA; Taylor & Francis: Abingdon, UK, 2008; ISBN 978-1-890871-79-6. [Google Scholar]

- Mark RLehto, M.R.; Buck, J.R. Introduction to Human Factors and Ergonomics for Engineers. Taylor & Francis Group: Abingdon, UK, 2008; ISBN 978-0-8058-5308-7. [Google Scholar]

- Helander, M. A Guide to Human Factors And Ergonomics, 2nd ed.; Nanyang Technological University: Singapore; CRC: Boca Raton, FL, USA; Taylor and Francis: Abingdon, UK, 2006; ISBN 0-203-64285-6. [Google Scholar]

- Fish, R.M.; Geddes, L.A. Conduction of electrical current to and through the human body: A review. Eplasty 2009, 9, e44. [Google Scholar] [PubMed] [PubMed Central]

- ISO 31010:2019; Risk Management—Risk Assessment Techniques. International Organization for Standardization: Vernier, Switzerland, 2019.

- Duijm, N.J. Recommendations on the use and design of risk matrices. Saf. Sci. 2015, 76, 21–31. [Google Scholar] [CrossRef]

- Johansen, I.L.; Rausand, M. Foundations and choice of risk metrics. Saf. Sci. 2014, 62, 386–399. [Google Scholar] [CrossRef]

| Probability | ||||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| Consequence | 5 | Medium | High | Critical | Critical | Critical |

| 4 | Medium | High | High | Critical | Critical | |

| 3 | Low | Medium | High | Critical | Critical | |

| 2 | Low | Low | Medium | High | Critical | |

| 1 | Low | Low | Medium | High | High | |

| Hazard Number | Probability | Consequence | Risk (Priority Rating) | Measure |

|---|---|---|---|---|

| 1b | 3 | 5 | Critical | Restrict access to the site. |

| 4 | 2 | 5 | Critical | Prevent unexpected movement of the machine (parking brake, wheel blocks, etc.). |

| 12 | 3 | 5 | Critical | Prevent unexpected movement of the machine (parking brake, wheel blocks, etc.). Proper training. |

| 20 | 3 | 4 | Critical | Proper training. Adhering procedures. |

| 21 | 3 | 5 | Critical | Regular inspection of installation and insulation. Proper training. |

| 1a | 2 | 5 | High | Training for lifting loads in confined space. Clear instructions. |

| 9 | 3 | 3 | High | Clear instructions. Rested workers, enough breaks during shifts. |

| 10 | 3 | 4 | High | Training for works on heights. Use of personal protective equipment. |

| 14 | 3 | 4 | High | Restrict access to the site. |

| 15 | 2 | 5 | High | Including distress caller and underground locator as mandatory personal protective equipment. Video monitoring site. |

| 16 | 4 | 2 | High | Sufficient ventilation of the site. Protective equipment that reduces heat. |

| 2 | 2 | 3 | Medium | Active monitoring. When necessary additional planning and training |

| 3b | 2 | 3 | Medium | Active monitoring. Training for lifting loads in confined space. Clear instructions. |

| 5 | 3 | 3 | Medium | Active monitoring. Training for lifting loads in confined space. Clear instructions. Regular inspection of steel structure. |

| 6 | 1 | 4 | Medium | Regular inspection of steel structure. |

| 7 | 2 | 3 | Medium | Regular crane inspection. Active monitoring of battery movement. |

| 11a | 1 | 5 | Medium | Active monitoring. Regular crane inspection. |

| 11b | 1 | 5 | Medium | Proper training. High concentration. Enough breaks during shift. |

| 17 | 3 | 1 | Medium | Ensuring technical ventilation is adequate. Periodical ventilation measurements. |

| 3a | 2 | 2 | Low | - |

| 8 | 1 | 3 | Low | - |

| 13a | 2 | 1 | Low | - |

| 13b | 2 | 1 | Low | - |

| 18 | 2 | 1 | Low | - |

| 19 | 2 | 1 | Low | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martinetti, A.; Popović, O.; Demichela, M.; Oreste, P.P.; Cvjetić, A.; Milisavljević, V. Safety Challenges in Battery Swapping Operations of Electric Underground Mining Trucks. Appl. Sci. 2025, 15, 6763. https://doi.org/10.3390/app15126763

Martinetti A, Popović O, Demichela M, Oreste PP, Cvjetić A, Milisavljević V. Safety Challenges in Battery Swapping Operations of Electric Underground Mining Trucks. Applied Sciences. 2025; 15(12):6763. https://doi.org/10.3390/app15126763

Chicago/Turabian StyleMartinetti, Alberto, Ognjen Popović, Micaela Demichela, Pier Paolo Oreste, Aleksandar Cvjetić, and Vladimir Milisavljević. 2025. "Safety Challenges in Battery Swapping Operations of Electric Underground Mining Trucks" Applied Sciences 15, no. 12: 6763. https://doi.org/10.3390/app15126763

APA StyleMartinetti, A., Popović, O., Demichela, M., Oreste, P. P., Cvjetić, A., & Milisavljević, V. (2025). Safety Challenges in Battery Swapping Operations of Electric Underground Mining Trucks. Applied Sciences, 15(12), 6763. https://doi.org/10.3390/app15126763