Research on Electrical Energy Parameters in the Distribution System of a Mining Facility

Abstract

1. Introduction

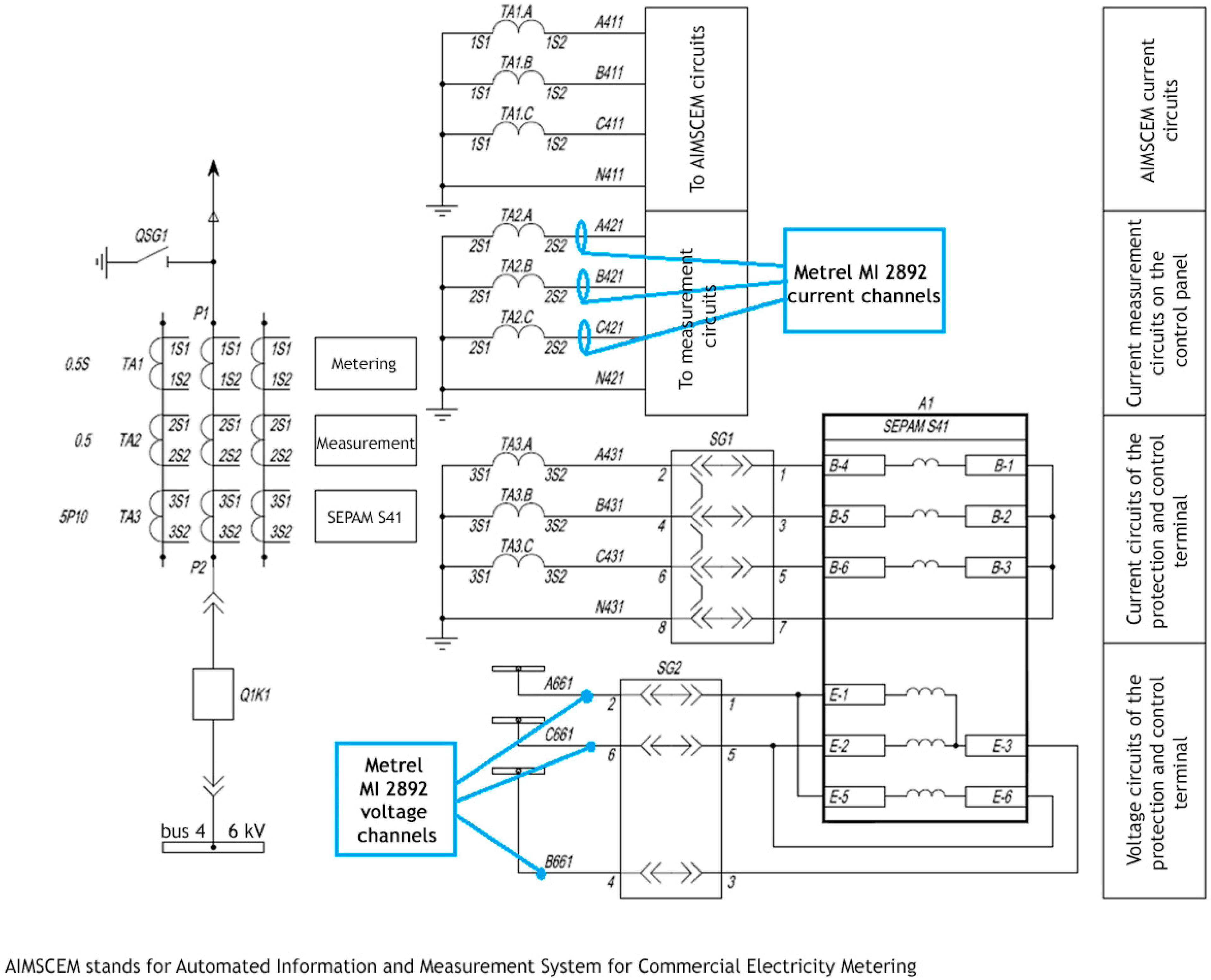

2. Materials and Methods

- The results of Metrel MI2892 protocols are more consistent and clearer than those of Resurs-UF2M.

- Resurs-UF2M protocols are not intended for detailed analysis since these enable only a comparison between the PQI measured and the standard values to be drawn.

- Resurs-UF2M is completely unsuitable for further use in terms of analyzing distortions recorded and identifying their origins. This is due to the following Resurs-UF2M technical abilities. Firstly, to perform PQ analysis, only a final measurement protocol is provided, with the measurement dataset not accessed, which excludes the possibility of verifying protocol values. The 1 min aggregation interval allows PQI measurement to be conducted only in long-term monitoring mode, which does not enable rapid processes such as lightning, switching surges, or other transients to be taken into account. Therefore, the recorder is unsuitable for analyzing and identifying the root causes of emergency conditions.

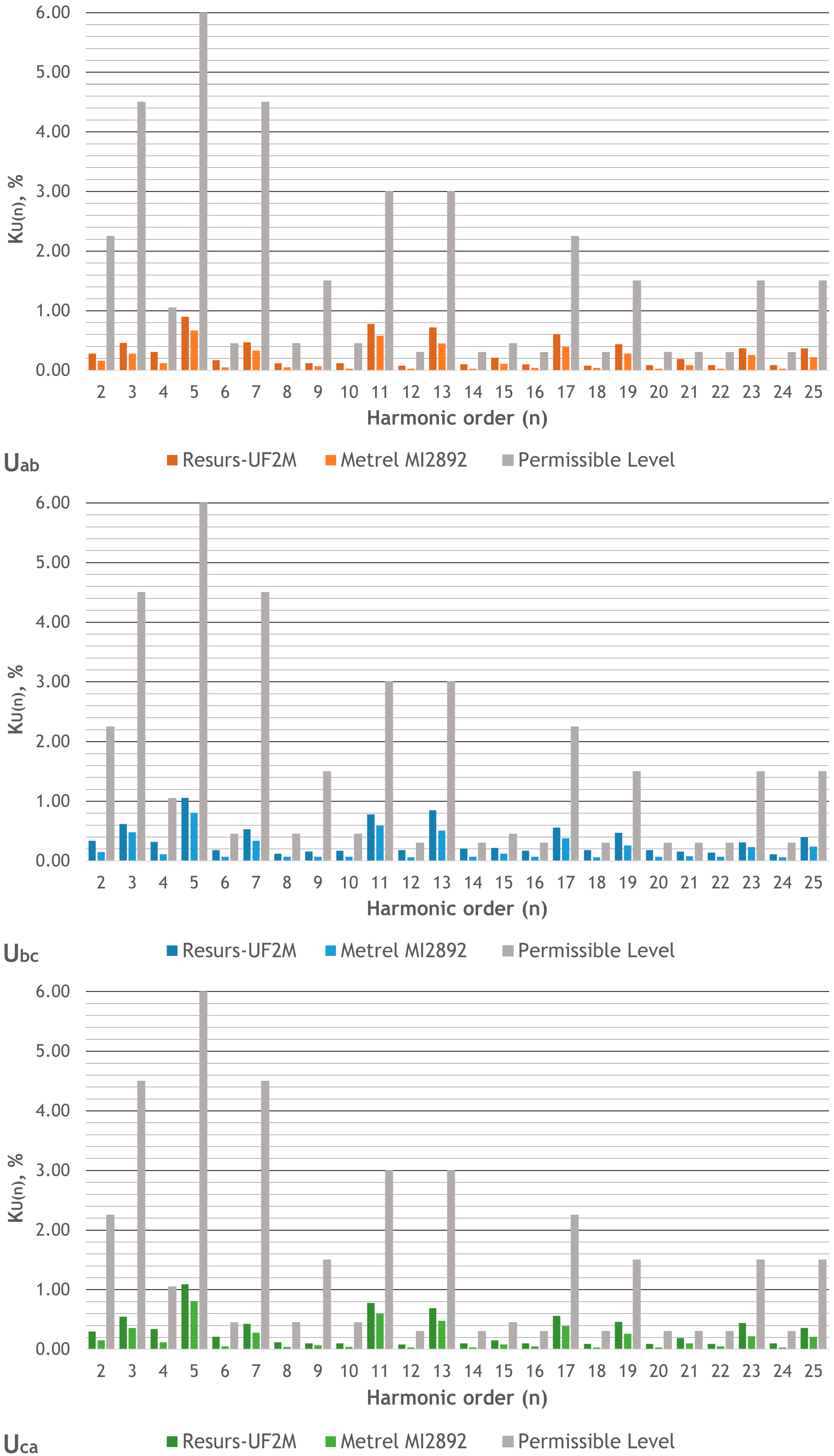

- Resurs-UF2M recorder shows a total number of voltage dips that differs from Metrel MI2892 data and total dip duration (which is uninformative a without description of dip history and consequences being presented). Since both instruments are certified, this can be explained by instrument accuracy, the aggregation time interval used, and analytics performed when forming statistical data for protocols. Significant discrepancies are also noted in the individual harmonic voltages measured (Figure 3).

- Resurs-UF2M protocols are given separately for each day, while Metrel MI2892 provides summarized protocols for the entire measurement period. Therefore, comparing measurement results is problematic. Certified PQ recorders standardize only the recording process and data output format; however, some of them do not take into account initial recording time, calculating statistics exclusively from 0:00 h, which became extremely significant for the instruments employed.

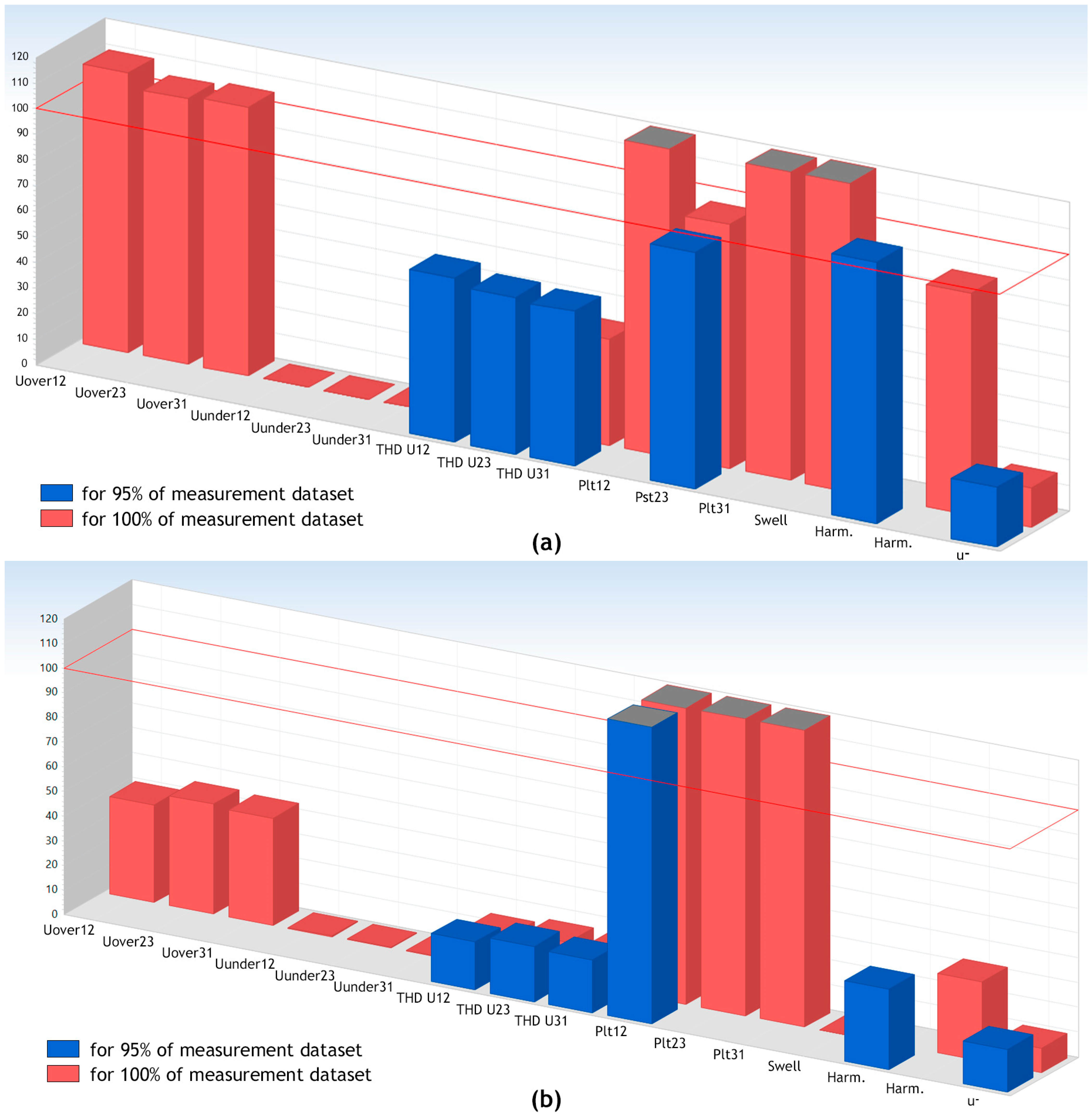

- The values of several PQIs measured by Metrel MI2892 exceed the permissible levels, while all the PQI values measured by Resurs-UF2M do not. Therefore, it should be noted that the Resurs-UF2M recorder is not appropriate for monitoring PQ in high-voltage grids since it does not meet modern requirements for striving towards the Smart Grid concept and fulfilling the full cycle: PQI measurement; PQ analysis—mitigation technique development to modernize problematic areas of the high-voltage network, ensuring uninterrupted and efficient operation of a power system.

- Insufficient time resolution detail. Up-to-date PQ standards limit themselves to specifying only basic requirements for instrument accuracy and minimum measurement cycle duration. For example, EN 50160 requires a minimum time resolution of 1 min, which is insufficient to accurately capture short-term events such as short overvoltages or voltage sags. Such events occur almost instantaneously, often being associated with the switching of high-power loads or commutation processes. The absence of these within a final report creates a false impression of power supply stability.

- Failure to account for the influence of voltage pulse duration. Standard methods assume averaging data over long-time intervals (up to 1 h or more), ignoring the distribution of pulse deviations within each cycle. For example, a sharp increase in the power of asynchronous motors or induction effects in transformers generates peak overloads lasting only a few milliseconds, which the standard is unable to capture.

- Instruments fail to meet up-to-date requirements. Some certified instruments use algorithms for calculating PQI based on outdated signal processing principles. For example, the widely used Resurs-UF2M records integral voltage and current parameters, and the detailed waveform reconstruction cannot be performed. This hampers identification of the distortion causes. Instrumentation systems such as the Metrel MI 2892 PQ analyzer enable the performance of more precise monitoring of parameter dynamics but require significant storage resources and computing power.

- Limited range of frequency recorded. Most instruments used are limited to recording low-order harmonics (usually up to 40th order), although the practice shows the presence of significant higher harmonics (especially under frequency converter and thyristor rectifier operation conditions). Ignoring such components leads to an underestimation of the true distortion pattern and potential flaws in fault diagnosis.

- Calibration and data verification problems. Most instruments measure independently, increasing the risk of interpretation flaws and reducing the credibility of reports. A mechanism for automatic data synchronization and cross-checking of parameter values obtained by using different instruments is needed to ensure uniformity of approaches and eliminate discrepancies.

- Standards and permissible levels are technically outdated. A comparative analysis presented in [28,29] shows that Russian and international standards on PQ have similar approaches to the main PQI, although there are distinctions in PQI permissible levels for different voltage levels. However, these standards adopted decades ago do not reflect the realities of modern industrial production associated with the widespread adoption of digital energy management technologies and sensitive electronic devices.

3. Results and Discussion

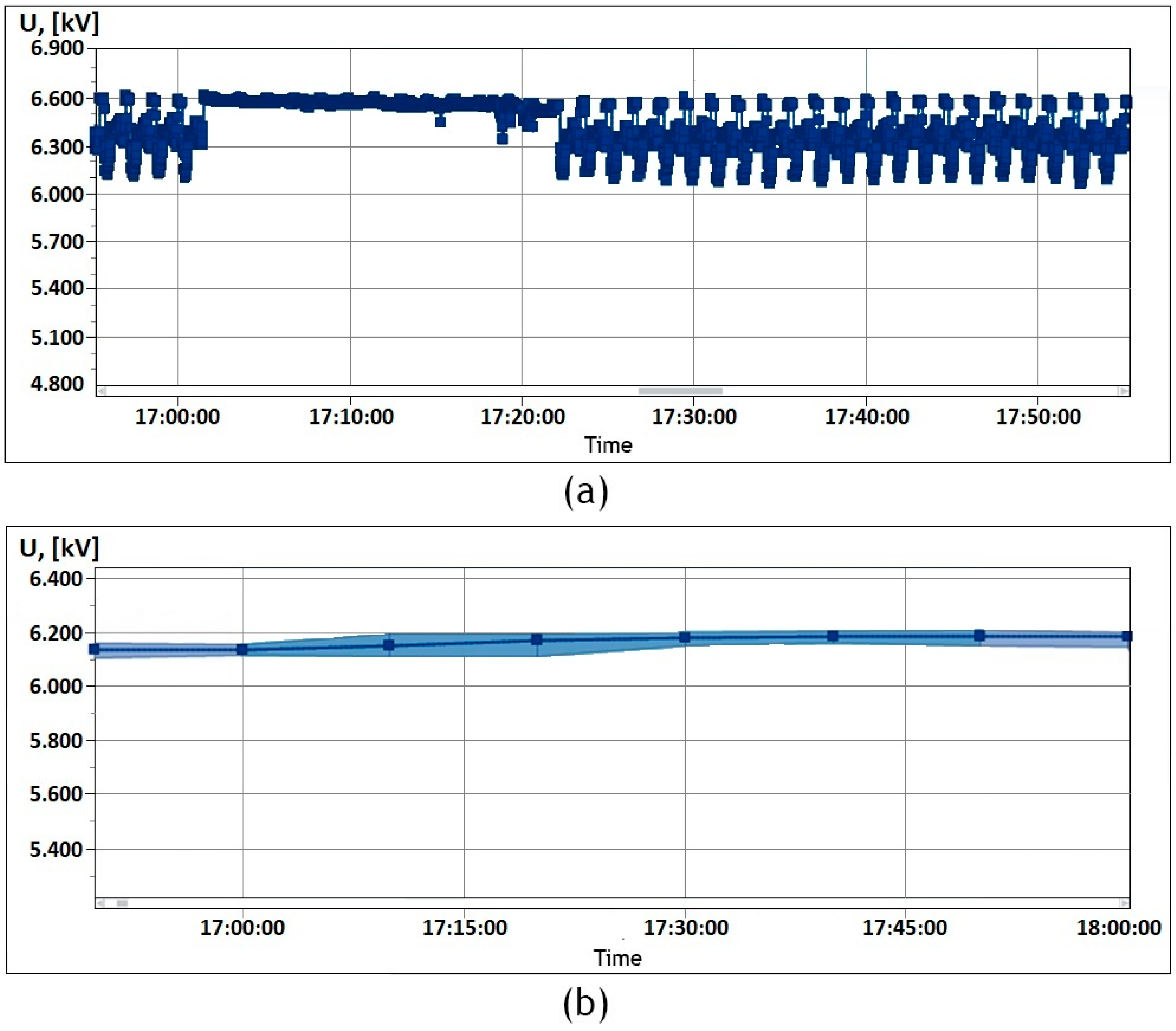

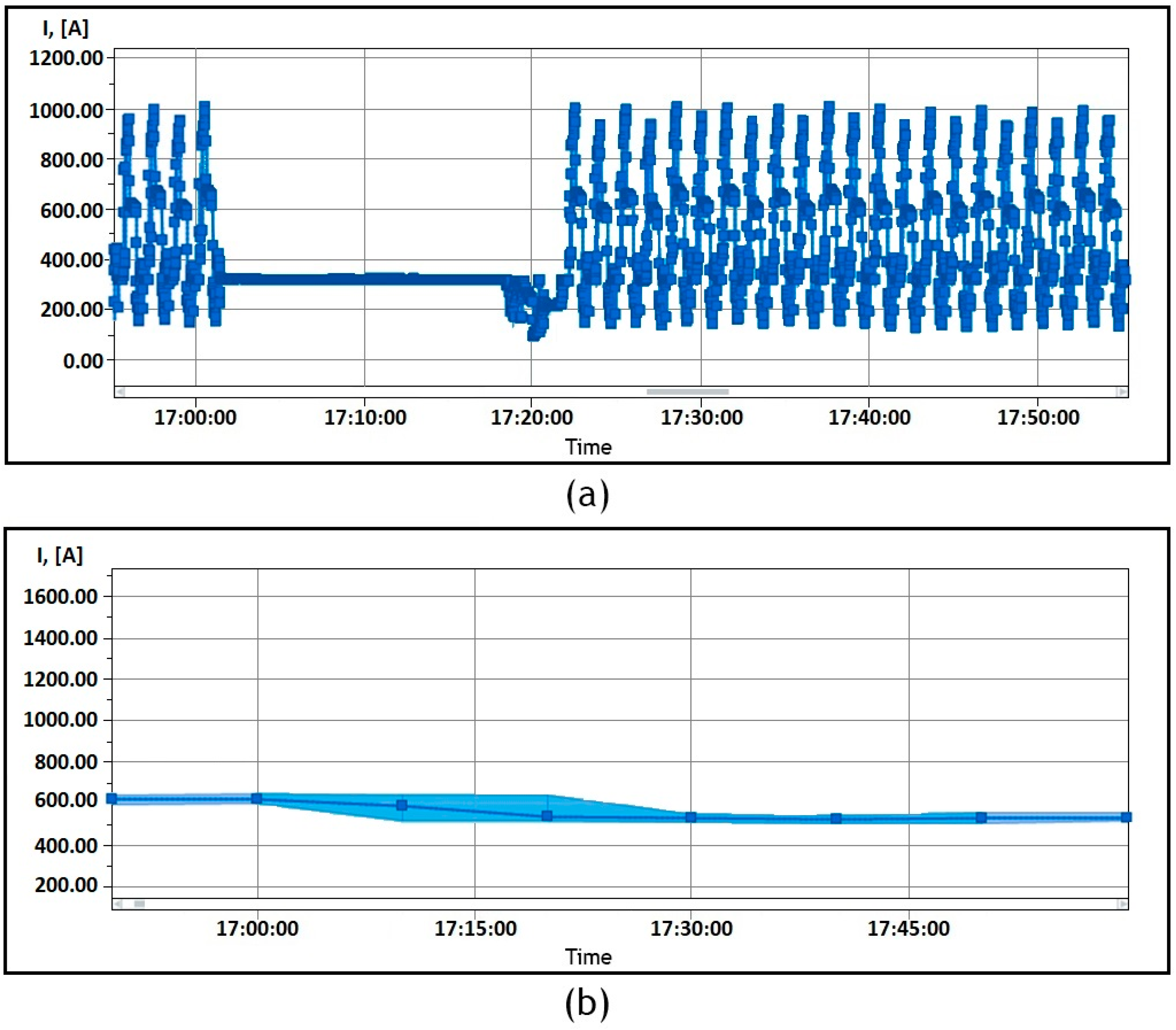

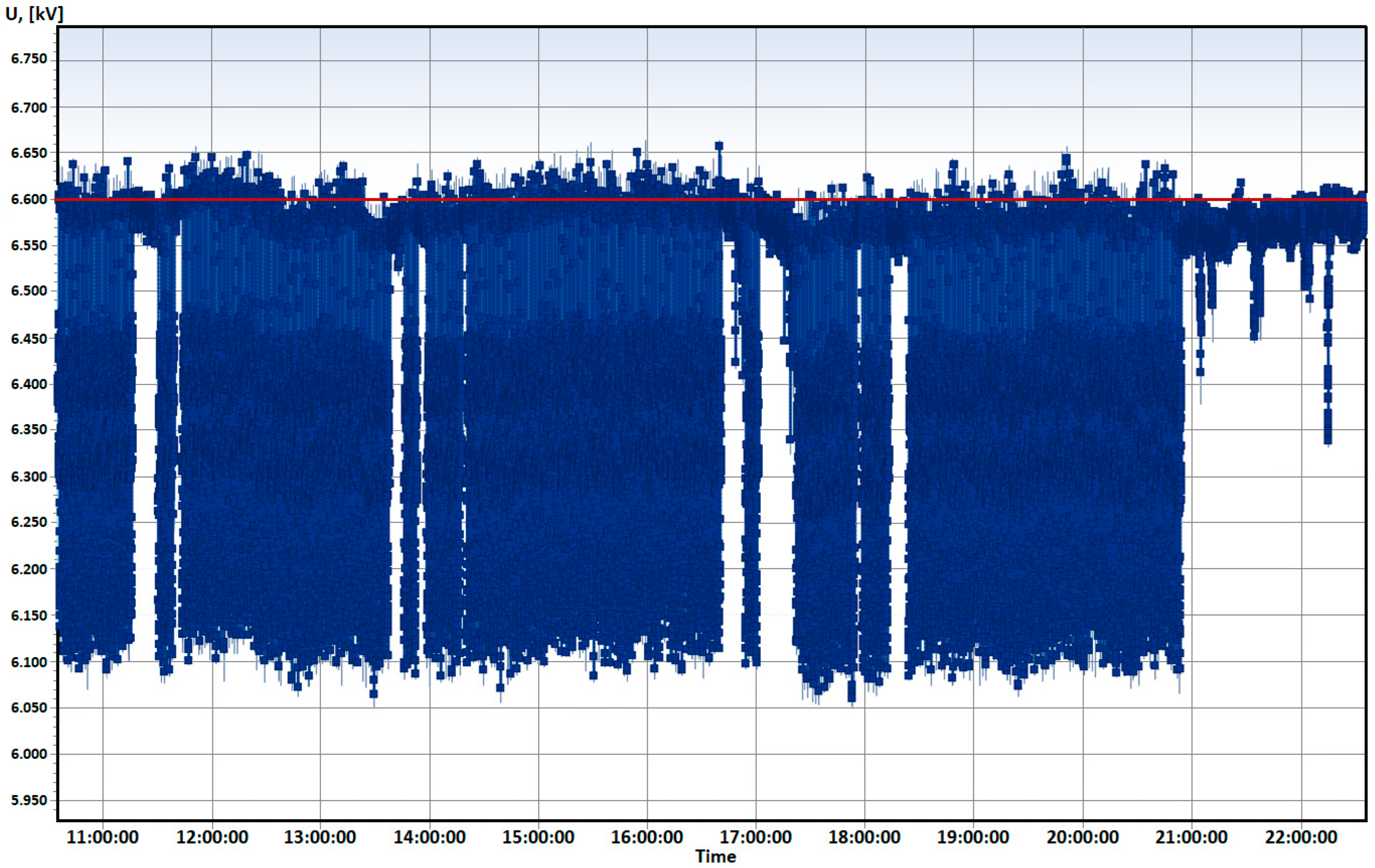

3.1. Influence of Data Aggregation Time Interval on PQ Assessment

3.2. Analysis of the PQ Survey Results

3.2.1. Results Obtained Using 10 min Data Aggregation Method

3.2.2. Results Obtained Using the 1 s Data Aggregation Method

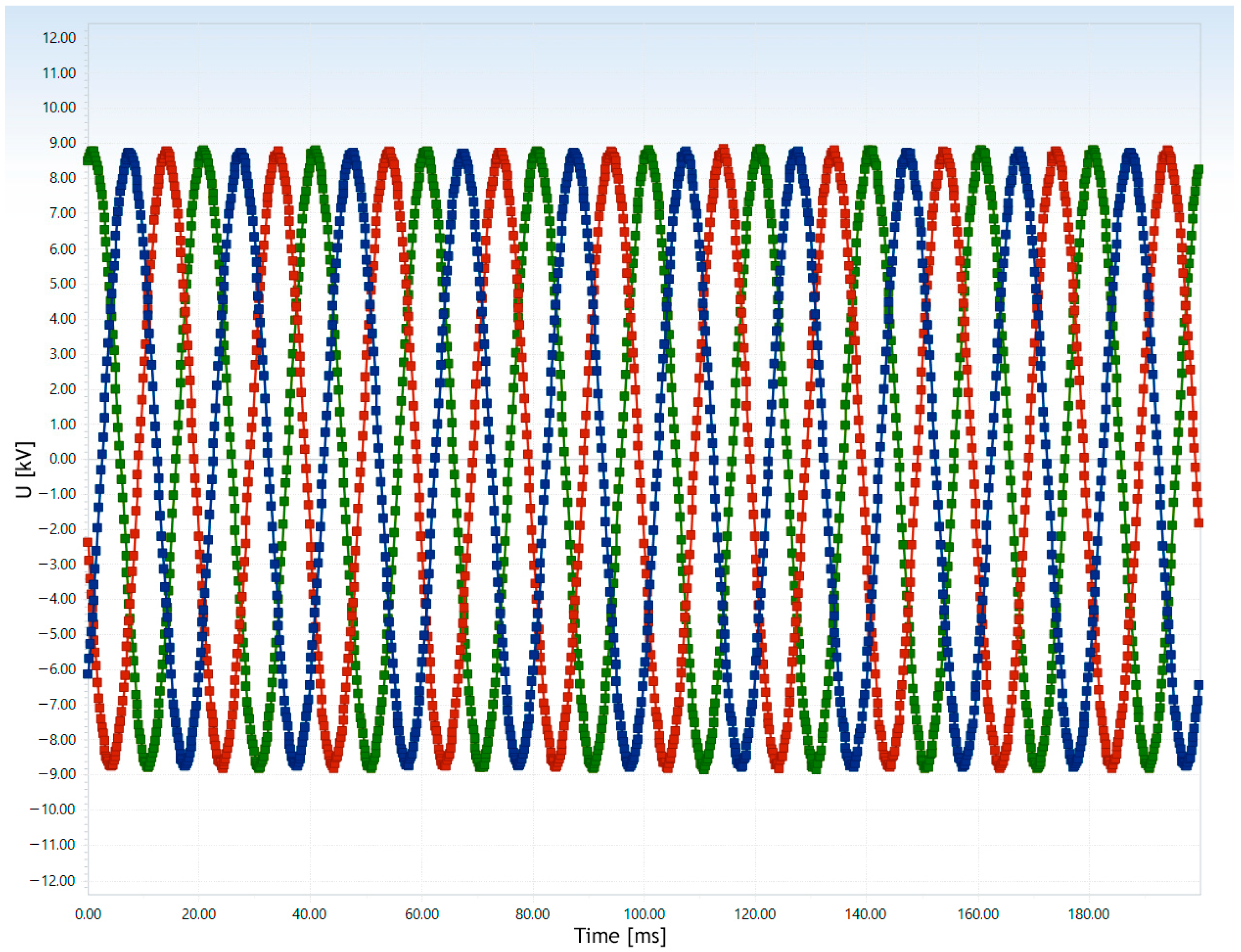

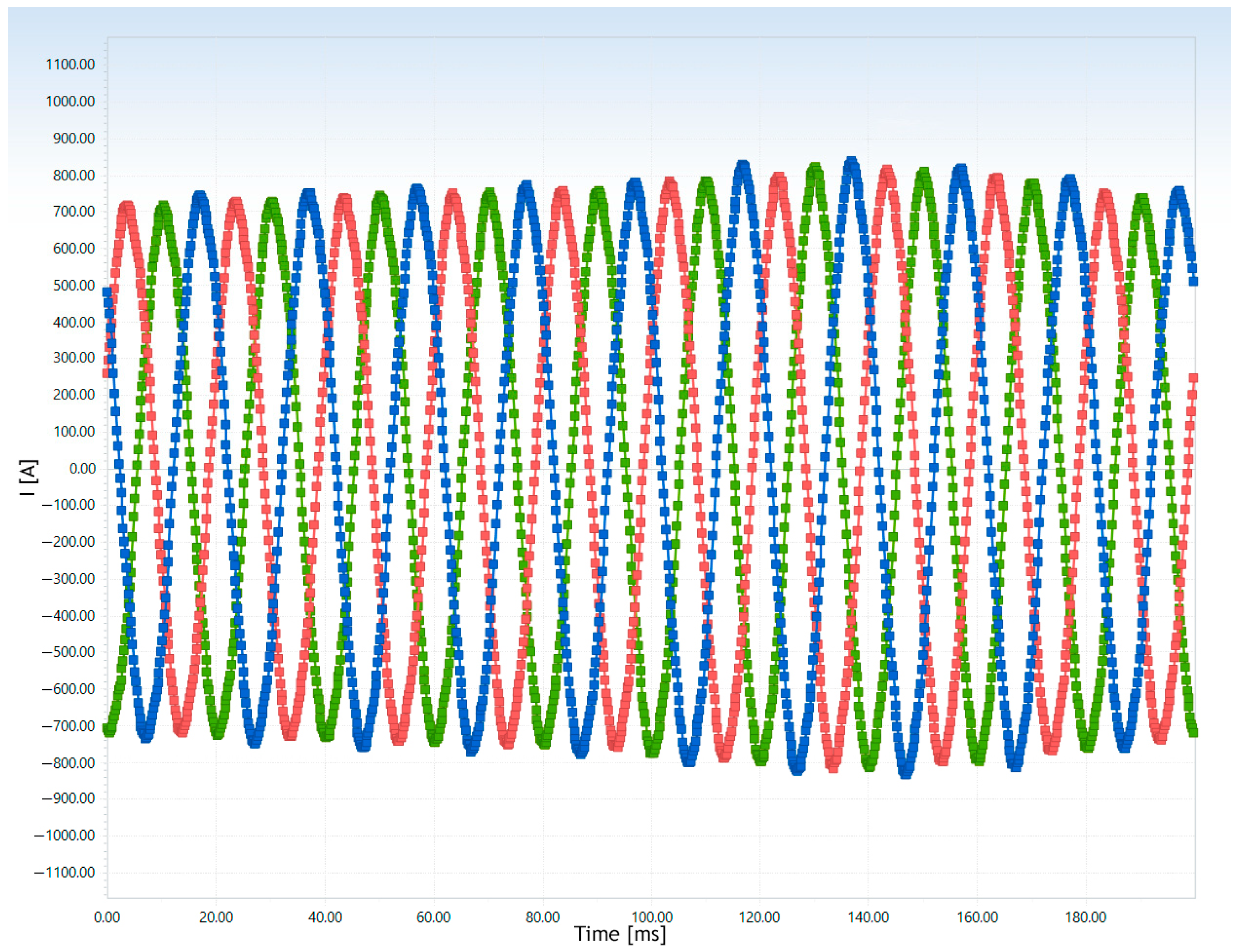

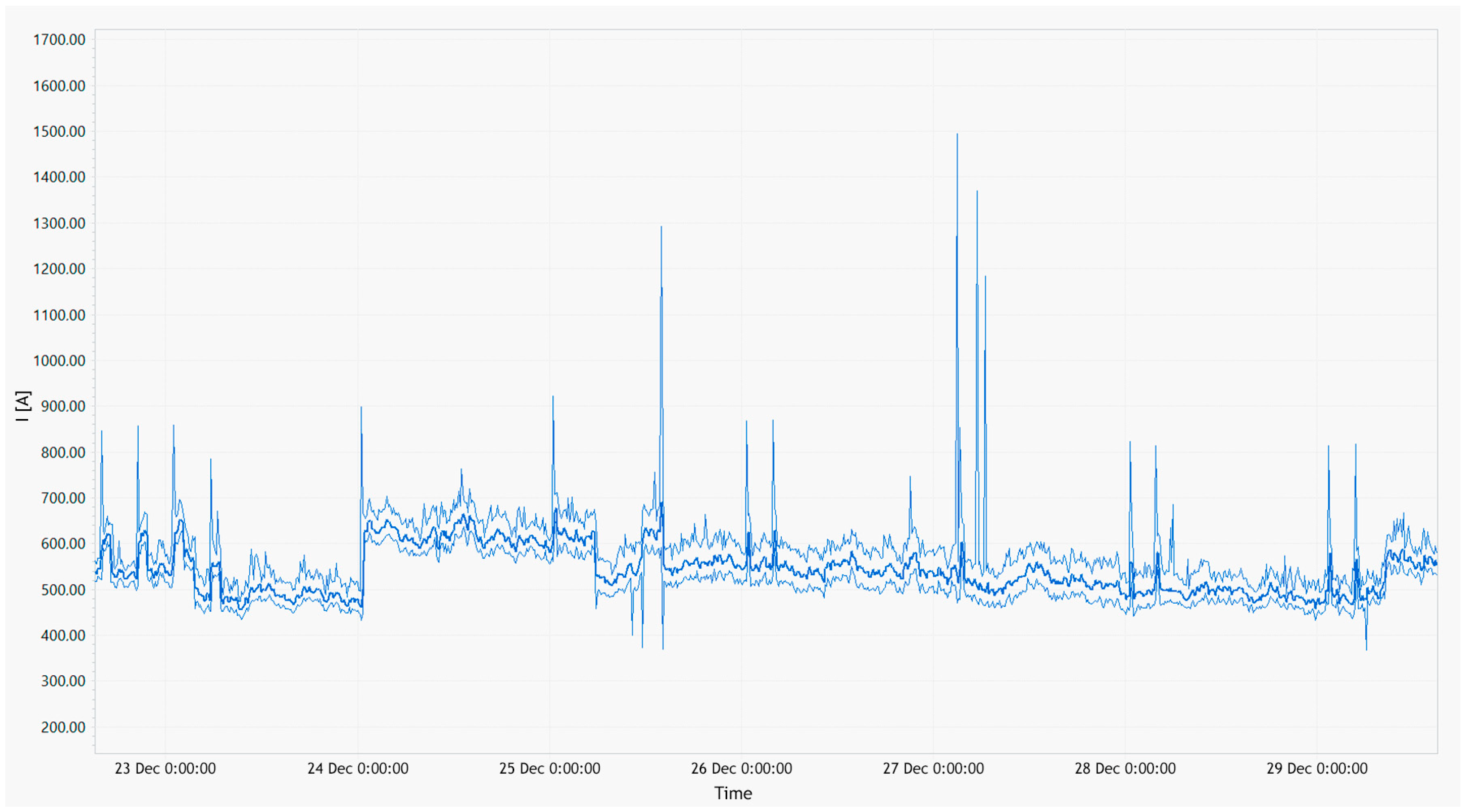

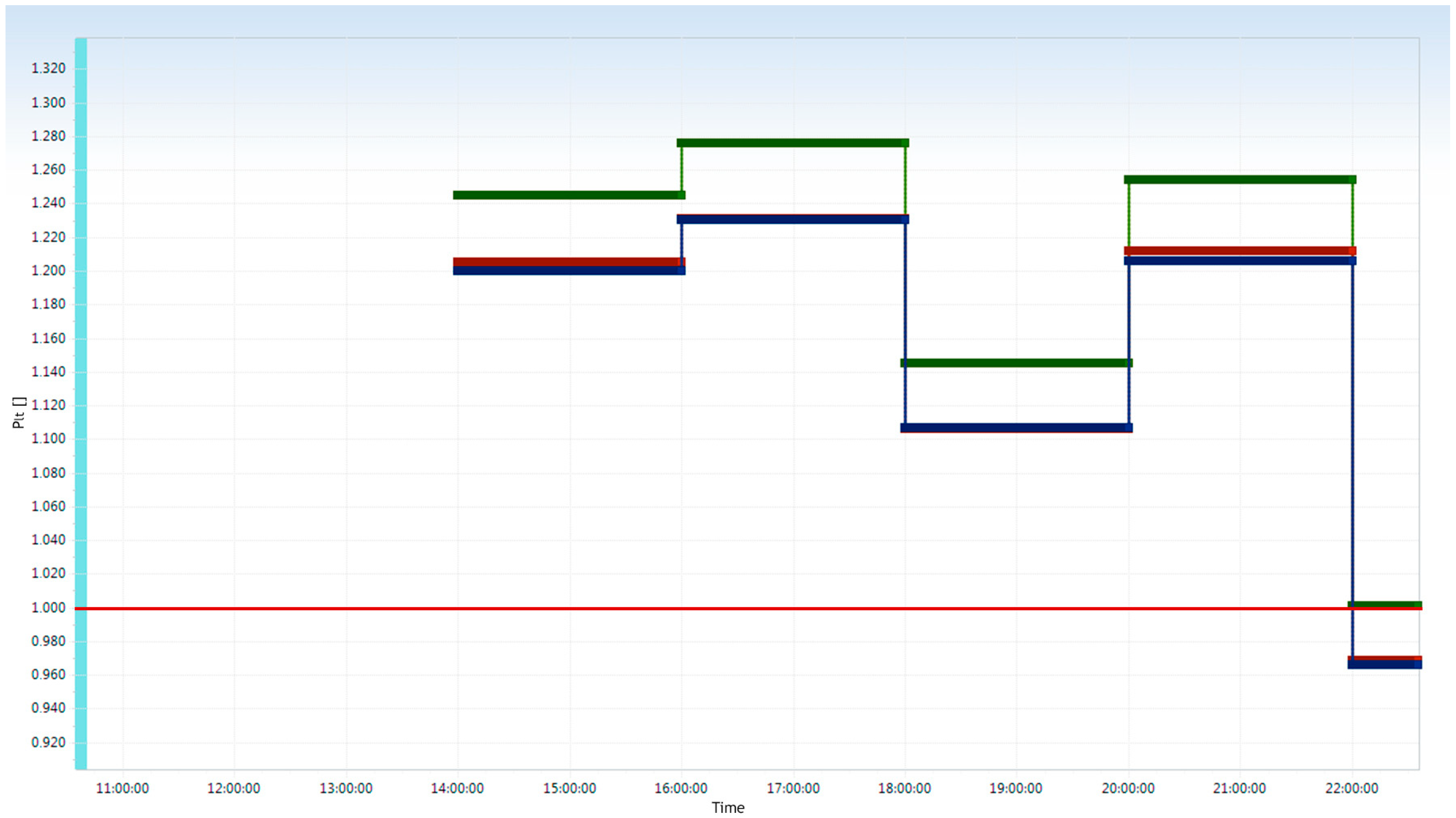

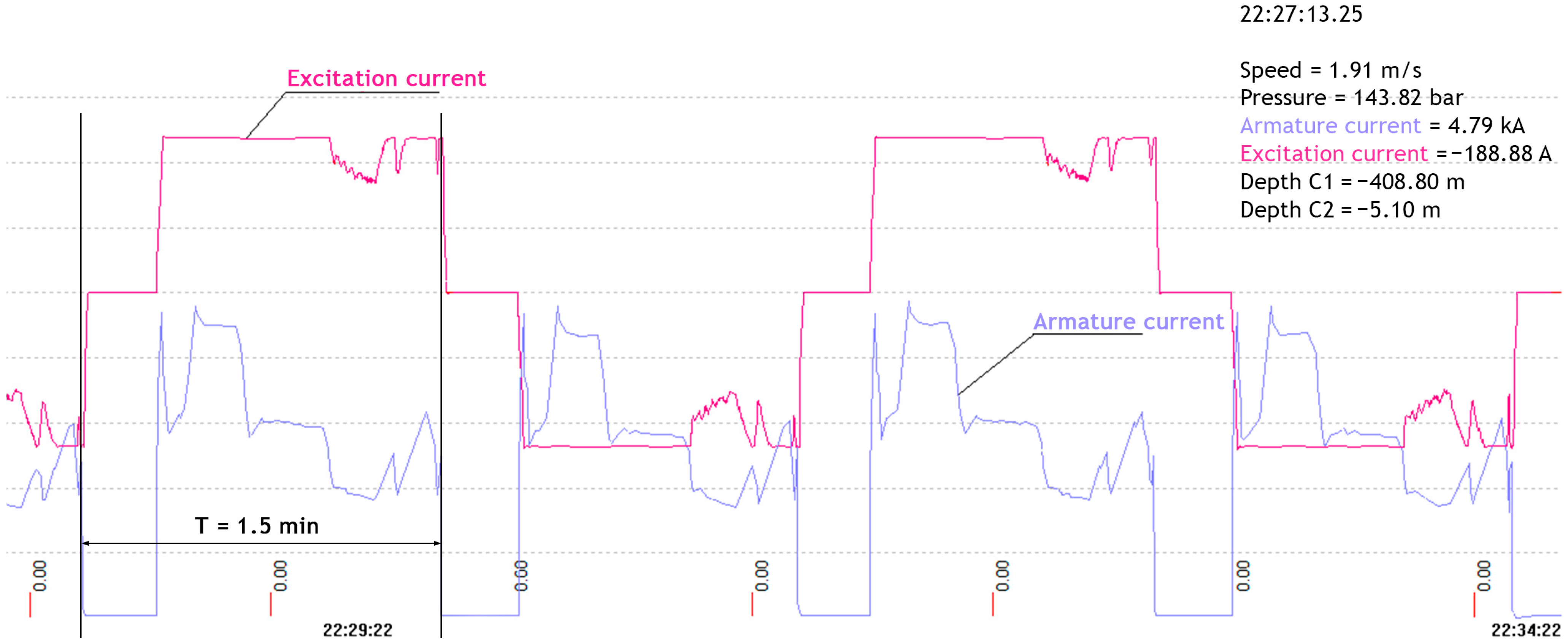

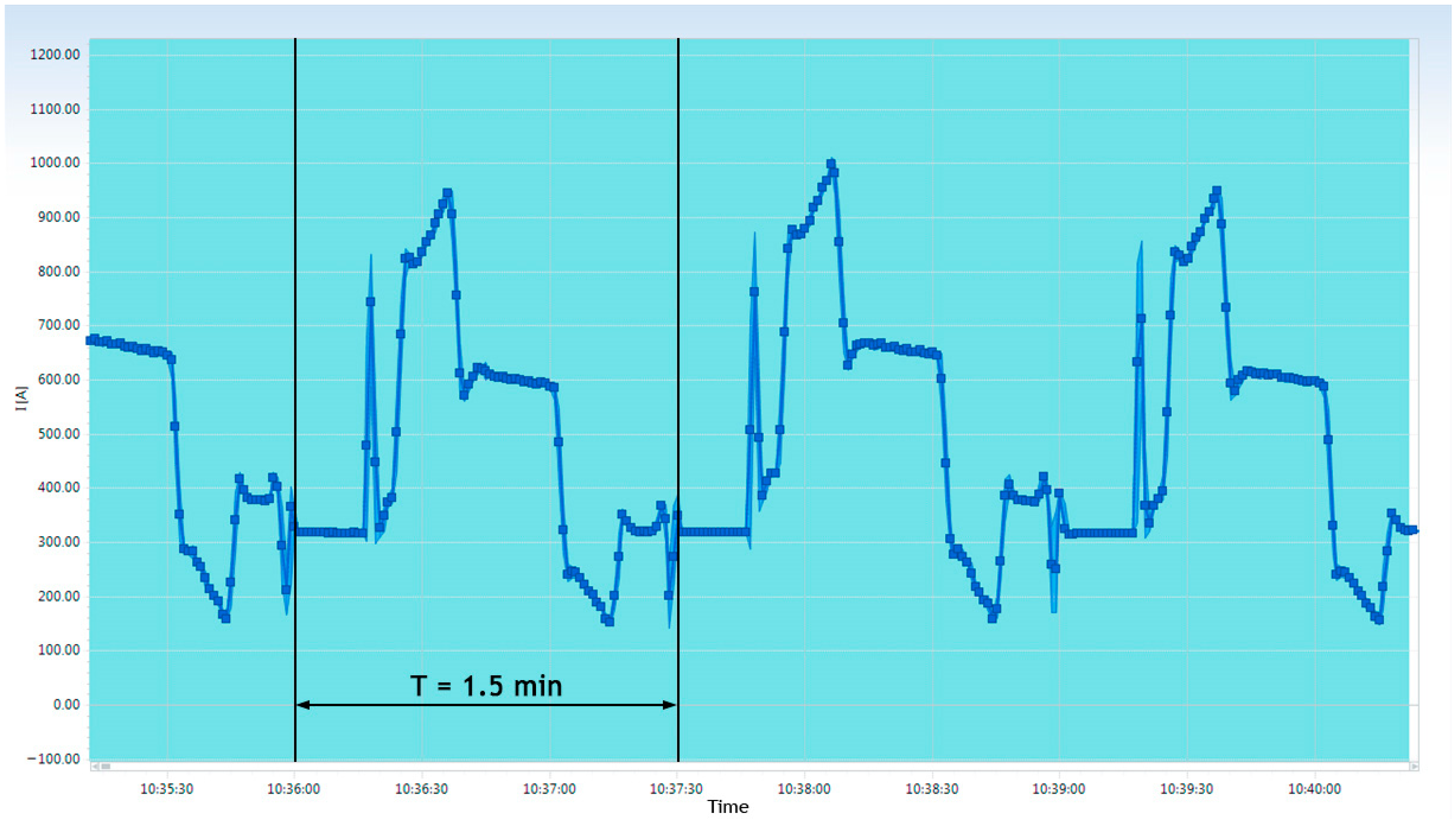

3.2.3. Identification of the PQ Distortion Origin

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| EMC | Electromagnetic compatibility |

| PQ | Power quality |

| PQI | Power quality indices |

| RMS | Root mean square |

| THD | Total harmonic distortion |

| TVR | Thyristor voltage regulator |

Appendix A

| Function | Measurement Range | Resolution | Measurement Error |

|---|---|---|---|

| Voltage measurement | 50…1000 V (L-N); 50…1730 V (L-L) | 10 mV in range of 50…1000 V (L-N); 100 mV in the range of 50…1730 V (L-L) | ±0.1% |

| Current measurement | Maximum up to 12 kA (depending on clamps used) | Depends on clamps used | Depends on clamps used |

| Frequency measurement | 42.5…57.5 Hz (when fnom = 50 Hz); 51…69 Hz (when fnom = 60 Hz); 335…465 Hz (when fnom = 400 Hz) | 1 mHz; 10 mHz in range of 335…465 Hz (when fnom = 400 Hz) | ±10 mHz; ±100 mHz in range of 335…465 Hz (when fnom = 400 Hz) |

| Measurement of zero and negative phase sequence components | 0.0…17.0% | 0.10% | ±1% |

| Measurement of voltage sag or voltage swell magnitude | 10…150% Unom | 10 mV | ±0.2% Unom |

| Measurement of residual voltage during interruption | 0…10% Unom | 10 mV | ±0.2% Unom |

| Measurement of power and power factor | Class 1 according to [34] | – | – |

| Energy measurement | Class 1 according to [35] | – | – |

| Measurement of harmonics (up to 50 order) | 0…20% Unom | – | Class 1 according to [36] |

| Measurement of voltage interharmonics | 0…20% Unom | – | Class 1 according to [36] |

| Display | 4.3 in, color TFT (480 × 272) | – | – |

| Data transfer | USB, RS232, Ethernet | – | – |

| General characteristics | |||

| Supply | 220 V/50 Hz or 6 AA batteries | ||

| Overvoltage class | CAT IV/600 V, CAT III/1000 V | ||

| Measurements | 230 × 140 × 80 mm | ||

| Mass | 1.1 kg | ||

| Parameter Measured | Measurement Range | Limits of Permissible Errors: Absolute Error Δ; Relative Error δ, %; Reference Error γ, % | Note |

|---|---|---|---|

| RMS voltage U, V | From 0.01Unom | ±0.1 (γ) | γ relative to Unom Unom = 57,735/100 V |

| Frequency f, Hz | 42.5…57.5 | ±0.01 (Δ) | – |

| Negative phase sequence component of the supply voltage K2U, % | 0…20 | ±0.15 (Δ) | – |

| Zero phase sequence component of the supply voltage K0U, % | 0…20 | ±0.15 (Δ) | – |

| Voltage THD KU, % | 0.5…30 | ±0.05 (Δ) ±5 (δ) | KU < Unom/U(1) KU ≥ Unom/U(1) |

| Individual voltage harmonic coefficient KU(n), % | 0.1…30 | ±0.05 (Δ) ±5 (δ) | KU(n) < Unom/U(1) KU(n) ≥ Unom/U(1) |

| Voltage sag duration Δts, s | 0.01…60 | ±0.02 (Δ) | – |

| Voltage sag depth δUsw, % | 10…100 | ±0.2 (Δ) | – |

| Voltage swell duration Δtsw, s | 0.01…60 | ±0.02 (Δ) | – |

| Voltage swell coefficient KswU | 1.1…2 | ±0.002 (Δ) | – |

| Short-term flicker severity Pst | 0.2…10 | ±5 (δ) | – |

| Phase difference ϕU | −180°…180° | ±0.1° (Δ) | 0.8Unom ≤ U ≤ 1.2Unom |

| RMS current I, A | (0.01…1.2)Inom | ±0.2 (δ) | 0.05Inom ≤ I ≤ 1.2Inom |

| Current THD KI, % | ot 1 дo 100 | ±0.15 (Δ) ±5 (δ) | KI < 3 KI ≥ 3 |

| Individual current harmonic coefficient KI(n), % | ot 0.2 дo 50 | ±0.15 (Δ) ±5 (δ) | KI(n) < 3 KI(n) ≥ 3 |

| Phase angle ϕUI | ±180° | ±0.1° (Δ) | |

| Active power P, W | – | ±0.2 (γ) | γ relative to S |

| Reactive power Q, var | – | ±0.5 (γ) | γ relative to S |

| Apparent power S, VA | – | ±0.5 (δ) | |

| Active energy WP | – | ±0.2 (δ) | |

| Reactive energy WQ | – | ±0.5 (δ) | |

| Time interval (clock movement), s/day | – | ±1 | Without time synchronization device (GPSF receiver) |

| Current time in the national coordinated time scale of the Russian Federation UTC (SU) | – | ±0.02 s | When working with a time synchronization device (GPSF receiver) |

| General characteristics | |||

| Supply | 85…265 V/45…55 Hz | ||

| Measurements | 136 × 294 × 250 mm | ||

| Mass | 3 kg | ||

References

- Zhezhelenko, I.V.; Sayenko, Y.L.; Gorpinich, A.V. Electromagnetic Compatibility in the Industrial Electric Power Supply Systems. In Proceedings of the 10th International Conference on Electrical Power Quality and Utilisation, Lodz, Poland, 15–17 September 2009; IEEE: Piscataway, NJ, USA, 2009. [Google Scholar] [CrossRef]

- Salor, Ö.; Gültekin, B.; Buhan, S.; Boyrazoǧlu, B.; Inan, T.; Atalik, T.; Açik, A.; Terciyanli, A.; Ünsar, Ö.; Altintaş, E.; et al. Electrical Power Quality of Iron and Steel Industry in Turkey. In Proceedings of the IEEE Industry Applications Society 42nd Annual Meeting, New Orleans, LA, USA, 23–27 September 2007; IEEE: Piscataway, NJ, USA, 2007; pp. 404–423. [Google Scholar] [CrossRef]

- Nikolaev, A.A.; Bulanov, M.V.; Antropova, L.I. Ways to Ensure Electromagnetic Compatibility of Powerful Frequency Converters in Internal Power Supply Systems of Industrial Enterprises in the Presence of Resonance Phenomena. In Proceedings of the 2019 International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), Sochi, Russia, 25–29 March 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar] [CrossRef]

- Kuznetsov, V.; Tryputen, N.; Kuznetsova, Y. Evaluating the Effect of Electric Power Quality upon the Efficiency of Electric Power & Consumption. In Proceedings of the IEEE 2nd Ukraine Conference on Electrical and Computer Engineering (UKRCON), Lviv, Ukraine, 2–6 July 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 556–561. [Google Scholar] [CrossRef]

- Dheepanchakkravarthy, A.; Selvan, M.P.; Moorthi, S. Alleviation of Power Quality Issues Caused by Electric Arc Furnace Load in Power Distribution System Using 3-Phase Four-Leg DSTATCOM. J. Inst. Eng. Ser. B 2019, 100, 9–22. [Google Scholar] [CrossRef]

- Sreewirote, B.; Ngaopitakkul, A. Power Quality Analysis on Arc Furnace Capacitor Bank System in Thailand. IOP Conf. Ser. Earth Environ. Sci. 2020, 541, 012010. [Google Scholar] [CrossRef]

- Martinez, R.; Castro, P.; Arroyo, A.; Manana, M.; Galan, N.; Moreno, F.S.; Bustamante, S.; Laso, A. Techniques to Locate the Origin of Power Quality Disturbances in a Power System: A Review. Sustainability 2022, 14, 7428. [Google Scholar] [CrossRef]

- Sukanth, T.; Jayanthu, S.; Jayalaxmi, A. Mitigation of Power Quality Problem in Underground Mine Using Different Control Strategies. In Proceedings of the IEEE Region 10 Humanitarian Technology Conference (R10-HTC), Agra, India, 21–23 December 2016; IEEE: Piscataway, NJ, USA, 2016. [Google Scholar] [CrossRef]

- Yaghoobi, J.; Abdullah, A.; Kumar, D.; Zare, F.; Soltani, H. Power Quality Issues of Distorted and Weak Distribution Networks in Mining Industry: A Review. IEEE Access 2019, 7, 162500–162518. [Google Scholar] [CrossRef]

- Nepsha, F.; Belyaevsky, R.; Efremenko, V.; Varnavskiy, K. Modern Problems of Increasing Coal Mines Power Supply Efficiency. In Proceedings of the IVth International Innovative Mining Symposium, Kemerovo, Russia, 15–16 October 2019; p. 03026. [Google Scholar] [CrossRef]

- Pichuev, A.; Schevyrev, Y.; Zaugolnikova, E. Ensuring Quality of Electricity in Gold Mines and Mills. In Proceedings of the 2020 International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), Sochi, Russia, 18–22 May 2020; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar] [CrossRef]

- Bebikhov, Y.V.; Egorov, A.N.; Semenov, A.S. How Higher Harmonics Affect the Electrical Facilities in Mining Power Systems. In Proceedings of the 2020 International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), Sochi, Russia, 18–22 May 2020; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar] [CrossRef]

- Do, N.Y.; Ngo, X.C.; Nguyen, T.H. Effect of Power Quality on the Performance of Explosion-Proof Transformers in Mining in Vietnam. J. Polish Miner. Eng. Soc. 2023, 2, 65–69. [Google Scholar] [CrossRef]

- Sychev, Y.A.; Zimin, R.Y. Improving the Quality of Electricity in the Power Supply Systems of the Mineral Resource Complex with Hybrid Filter-Compensating Devices. J. Min. Inst. 2021, 247, 132–140. [Google Scholar] [CrossRef]

- Plashchansky, L.A.; Reshetnyak, S.N.; Reshetnyak, M.Y. Improvement of the Electric Energy Quality in Underground Electric Networks in Highly Productive Coal Mines. Min. Sci. Technol. 2022, 7, 66–77. [Google Scholar] [CrossRef]

- Semenov, A.S. Analyzing Impacts of Higher Harmonics on Electricity Quality Parameters at Mining Facilities. In Proceedings of the 2024 International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), Sochi, Russia, 20–24 May 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 321–325. [Google Scholar] [CrossRef]

- Siostrzonek, T.; Wójcik, J.; Dutka, M.; Siostrzonek, W. Impact of Power Quality on the Efficiency of the Mining Process. Energies 2024, 17, 5675. [Google Scholar] [CrossRef]

- Sinchuk, O.; Filipp, Y.; Somochkyn, A.; Strzelecki, R.; Baranovska, M. Methods of Improving Power Indices of Electric Drive Active Rectifiers for Mine Hoists. In Proceedings of the 2nd International Conference on Sustainable Futures: Environmental, Technological, Social and Economic Matters (ICSF 2021), Kryvyi Rih, Ukraine, 19–21 May 2021; p. 05014. [Google Scholar] [CrossRef]

- Hyla, M. Higher Harmonics Filtration in the Power Supply System of Thyristor Hoisting Machine of Shaft Transport in a Mining Plant. Przegląd Elektrotechniczny 2022, 98, 43–48. [Google Scholar] [CrossRef]

- Siostrzonek, T. The Hoisting Machines as Source of Higher Harmonics in Underground Mines. In Power Quality and Harmonics Management in Modern Power Systems; Rawa, M., Ali, Z.M., Abdel Aleem, S.H.E., Eds.; IntechOpen: London, UK, 2024; pp. 1–25. [Google Scholar] [CrossRef]

- Hyla, M.; Latko, A. Advanced Static Var Generator in the Reactive Power Automatic Compensation System of an Underground Mine with a Thyristor Hoisting Machine. Energies 2024, 17, 3628. [Google Scholar] [CrossRef]

- GOST 32144-2013; Electric Energy. Electromagnetic Compatibility of Technical Means. Standards of Power Quality in General-Purpose Power Supply Systems. Standartinform: Moscow, Russia, 2014.

- GOST 33073-2014; Electric Energy. Electromagnetic Compatibility of Technical Equipment. Control and Monitoring of Power Quality in General-Purpose Power Supply Systems. Standartinform: Moscow, Russia, 2015.

- GOST 30804.4.30-2013 (IEC 61000-4-30:2008); Electric Energy. Electromagnetic Compatibility of Technical Equipment. Power Quality Measurement Methods. Standartinform: Moscow, Russia, 2014.

- EN 50160:2010; Voltage Characteristics of Electricity Supplied by Public Electricity Networks. CENELEC: Brussels, Belgium, 2010.

- GOST R 54149-2010; Electric Energy. Electromagnetic Compatibility of Technical Equipment. Power Quality Limits in the Public Power Supply Systems. Standartinform: Moscow, Russia, 2012.

- GOST IEC 61000-4-30-2017; Electromagnetic Compatibility (EMC). Part 4-30. Testing and Measurement Techniques. Power Quality Measurement Methods. Standartinform: Moscow, Russia, 2020.

- Ded, A.V.; Maltsev, V.N.; Sikorski, S.P. Comparative Analysis of the Specifications on the Power Quality of the European Union and the Russian Federation. IOP Conf. Ser. J. Phys. Conf. Ser. 2018, 998, 012007. [Google Scholar] [CrossRef]

- Koptyaev, I.V.; Konareva, A.E. Comparative Analysis of the Standartized Parameters of the Characteristics of the Countries of the EU, the USA and Russia. Mirovaya Nauka 2022, 2, 58–63. [Google Scholar]

- Panfilov, D.I.; Petrov, M.I.; Astashev, M.G. Application of AC Voltage Regulators for Asynchronous Motors Connection to the Power Supply. In Proceedings of the 26th International Workshop on Electric Drives: Improvement in Efficiency of Electric Drives (IWED), Moscow, Russia, 30 January–2 February 2019. [Google Scholar] [CrossRef]

- Sosnina, E.; Sevostyanov, A.; Kryukov, E.; Bedretdinov, R. Thyristor Voltage Regulator Experimental Research. E3S Web Conf. 2020, 209, 07020. [Google Scholar] [CrossRef]

- Kralin, A.A.; Bedretdinov, R.S.; Kryukov, E.V.; Pronina, O.A. Research of Thyristor Voltage Regulator Effect on Power Flows Control in Distribution Electric Networks. IOP Conf. Ser. Mater. Sci. Eng. 2020, 791, 012031. [Google Scholar] [CrossRef]

- Rashitov, P.A.; Astashev, M.G.; Panfilov, D.I.; Rozhkov, A.N.; Petrov, M.I. Thyristor AC Voltage Regulators to Improve the Quality of Electrical Energy in 0.4-KV Distribution Networks. Russ. Electr. Eng. 2022, 93, 458–466. [Google Scholar] [CrossRef]

- GOST IEC 61557-12-2015; Low-Voltage Electrical Distribution Networks with Voltages up to 1000 V AC and 1500 V DC. Electrical Safety. Equipment for Testing, Measuring, or Monitoring Protective Equipment. Part 12. Gosstandart: Minsk, Belarus, 2016.

- GOST 31819.21-2012; Electricity Metering Equipment (a. c). Particular Requirements. Part 21. Static Meters for Active Energy (Classes 1 and 2). Standartinform: Moscow, Russia, 2013.

- GOST 30804.4.7-2013; Electromagnetic Compatibility of Technical Equipment. General Guide on Harmonics and Interharmonics Measurement and Instrumentation for Power Supply Systems and Equipment Connected Thereto. Standartinform: Moscow, Russia, 2014.

| PQI | Instrument | |||

|---|---|---|---|---|

| Resurs-UF2M | Metrel MI2892 | |||

| Basic Interval | Aggregation Interval | Basic Interval | Aggregation Interval | |

| Frequency variations | 200 ms | 20 s | 10 s | Not applicable |

| Voltage variations | 200 ms | 1 min | 200 ms | 10 min |

| Negative and zero phase sequence components of the supply voltage | 200 ms | 3 s | 200 ms | 10 min |

| Total harmonic distortion (THD) | 200 ms | 3 s | 200 ms | 10 min |

| Individual harmonic voltages (for orders up to 40) | 200 ms | 3 s | 200 ms | 10 min |

| Short-term flicker severity | 10 min | Not applicable | 10 min | Not applicable |

| Long-term flicker severity | 10 min | 2 h | 10 min | 2 h |

| PQI | Permissible Level | |

|---|---|---|

| For 95% of Measurement Dataset | For 100% of Measurement Dataset | |

| Frequency variations | ±0.2 Hz 1 ±1.0 Hz 2 | ±0.4 Hz 1 ±5.0 Hz 2 |

| Voltage variations | – | 10% |

| Short-term flicker severity | – | 1.38 pu |

| Long-term flicker severity | – | 1.00 pu |

| Individual harmonic voltages (for orders up to 40) | Table 3 | Table 3 |

| Total harmonic distortion (THD) | 5% 3 | 8% 3 |

| Negative phase sequence component of the supply voltage | 2% | 4% |

| Zero phase sequence component of the supply voltage | 2% | 4% |

| Harmonic Order (n) | KU(n)(95%), % | KU(n)(100%), % | Harmonic Order (n) | KU(n)(95%), % | KU(n)(100%), % |

|---|---|---|---|---|---|

| 2 | 1.50 | 2.25 | 22 | 0.20 | 0.30 |

| 3 | 3.00 | 4.50 | 23 | 1.00 | 1.50 |

| 4 | 0.70 | 1.05 | 24 | 0.20 | 0.30 |

| 5 | 4.00 | 6.00 | 25 | 1.00 | 1.50 |

| 6 | 0.30 | 0.45 | 26 | 0.20 | 0.30 |

| 7 | 3.00 | 4.50 | 27 | 0.20 | 0.30 |

| 8 | 0.30 | 0.45 | 28 | 0.20 | 0.30 |

| 9 | 1.00 | 1.50 | 29 | 1.00 | 1.50 |

| 10 | 0.30 | 0.45 | 30 | 0.20 | 0.30 |

| 11 | 2.00 | 3.00 | 31 | 1.00 | 1.50 |

| 12 | 0.20 | 0.30 | 32 | 0.20 | 0.30 |

| 13 | 2.00 | 3.00 | 33 | 0.20 | 0.30 |

| 14 | 0.20 | 0.30 | 34 | 0.20 | 0.30 |

| 15 | 0.30 | 0.45 | 35 | 1.00 | 1.50 |

| 16 | 0.20 | 0.30 | 36 | 0.20 | 0.30 |

| 17 | 1.50 | 2.25 | 37 | 1.00 | 1.50 |

| 18 | 0.20 | 0.30 | 38 | 0.20 | 0.30 |

| 19 | 1.00 | 1.50 | 39 | 0.20 | 0.30 |

| 20 | 0.20 | 0.30 | 40 | 0.20 | 0.30 |

| 21 | 0.20 | 0.30 | – | – | – |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karpov, A.S.; Yaroshevich, V.V.; Gubskaya, E.I. Research on Electrical Energy Parameters in the Distribution System of a Mining Facility. Appl. Sci. 2025, 15, 11355. https://doi.org/10.3390/app152111355

Karpov AS, Yaroshevich VV, Gubskaya EI. Research on Electrical Energy Parameters in the Distribution System of a Mining Facility. Applied Sciences. 2025; 15(21):11355. https://doi.org/10.3390/app152111355

Chicago/Turabian StyleKarpov, Aleksei S., Vera V. Yaroshevich, and Elizaveta I. Gubskaya. 2025. "Research on Electrical Energy Parameters in the Distribution System of a Mining Facility" Applied Sciences 15, no. 21: 11355. https://doi.org/10.3390/app152111355

APA StyleKarpov, A. S., Yaroshevich, V. V., & Gubskaya, E. I. (2025). Research on Electrical Energy Parameters in the Distribution System of a Mining Facility. Applied Sciences, 15(21), 11355. https://doi.org/10.3390/app152111355