Abstract

As port operations rapidly evolve toward intelligent and heavy-duty applications, fault diagnosis for core equipment demands higher levels of real-time performance and robustness. Deep learning, with its powerful autonomous feature learning capabilities, demonstrates significant potential in mechanical fault prediction and health management. This paper first provides a systematic review of deep learning research advances in rotating machinery fault diagnosis over the past eight years, focusing on the technical approaches and application cases of four representative models: Deep Belief Networks (DBNs), Convolutional Neural Networks (CNNs), Auto-encoders (AEs), and Recurrent Neural Networks (RNNs). These models, respectively, embody four core paradigms, unsupervised feature generation, spatial pattern extraction, data reconstruction learning, and temporal dependency modeling, forming the technological foundation of contemporary intelligent diagnostics. Building upon this foundation, this paper delves into the unique challenges encountered when transferring these methods from generic laboratory components to specialized port equipment such as shore cranes and yard cranes—including complex operating conditions, harsh environments, and system coupling. It further explores future research directions, including cross-condition transfer, multi-source information fusion, and lightweight deployment, aiming to provide theoretical references and implementation pathways for the technological advancement of intelligent operation and maintenance in port equipment.

1. Introduction

Port equipment serves as the core hub of modern logistics systems, with its operational status directly impacting the overall efficiency and safety of port operations. Typical large-scale core port equipment, such as quay container cranes (quayside gantry cranes) and tire-mounted/rail-mounted container gantry cranes (yard gantry cranes) [1], exhibits structural complexity characterized by large dimensions, flexibility, and multi-mechanism coordination [2]. Operationally, this equipment exhibits distinct characteristics including heavy loads, frequent starts and stops, and exposure to impact loads. Simultaneously, this equipment endures prolonged operation in highly saline, humid marine environments prone to corrosion [3]. These factors collectively result in more complex and concealed failure modes for critical components such as hoisting mechanisms, traveling mechanisms, wire ropes, and steel structures.

Therefore, fault diagnosis for port equipment faces more stringent demands than general rotating machinery: on one hand, extremely high safety and reliability requirements mean that even minor faults can lead to catastrophic consequences; on the other hand, enormous downtime costs demand diagnostic systems to possess high precision and early warning capabilities to enable predictive maintenance and minimize unplanned downtime. Driven by sustained growth in import-export trasssde, port equipment operates under increasingly intense workloads. Its operational data exhibits multidimensional, heterogeneous, and massive characteristics [4], posing significant challenges for data-driven precision equipment management. Achieving accurate fault diagnosis for port equipment [5] is a core element in ensuring safe operation, protecting personnel safety, and controlling maintenance costs.

To achieve this goal, the industry has progressed through distinct technological phases. Early approaches predominantly relied on traditional methods such as manual inspection and vibration monitoring [6]. Manual inspection heavily depended on technicians’ experience, entailed high on-site operational risks, and lacked consistency; vibration monitoring [7] utilizes techniques like Fourier transforms but faces limitations in accuracy and real-time performance. These methods are costly and struggle to establish precise models for extracting deep features from data.

Therefore, deep learning technology—capable of autonomously learning features from big data—can be introduced as a developmental and breakthrough approach to fault diagnosis in port equipment [8]. Its core advantage is that as a universal function approximator, it can directly learn highly nonlinear mapping relationships from data without relying on complex explicit physical models. This ability not only makes it a breakthrough in the fields of image recognition and natural language processing but also is accelerating its penetration into multiple scenes such as industry, commerce, finance, people’s livelihood and agriculture, showing strong cross-domain adaptability and generalization ability.

In the industrial field, deep learning is widely used in quality inspection and defect recognition. For example, abdulrahim Mohammed et al. [9] systematically reviewed the application of deep learning in automatic welding defect detection and analyzed the ability of single-stage and two-stage models in processing small-size defects, low image contrast and diversified defect geometry. Aman nohwal et al. [10] used a convolutional neural network (CNN) and fully connected network (FCN) to realize automatic discrimination of tungsten inert gas welding (TIG) defects of stainless steel 304 based on visible spectral images. In addition, Junlai Zhao et al. [11] proposed a deep learning method based on 3D point cloud data, which realized the real-time detection of powder bed defects in the process of laser powder bed fusion (LPBF) and further expanded the perception dimension of industrial quality monitoring.

In the direction of business intelligence, deep learning provides a new path for business process optimization and risk prediction. Junyi Xu et al. [12] proposed an improved Bilstm Kan framework, introduced the agent attention mechanism to enhance the modeling ability of long-term dependencies, and used Kan to replace the traditional MLP, which improved the performance of business process prediction and enhanced the interpretability of the model. Nicola Contuzzi et al. [13] built an overall architecture that integrates IOT sensors, LSTM networks and business intelligence systems to achieve collaborative optimization of sales forecasting, raw material procurement and logistics management in the organic food processing industry. Budan Wu et al. [14] proposed a business process activity prediction model based on a transformer and attention mechanism, which quantifies the impact of events and attributes through an attention score and provides highly explanatory prediction results.

In financial analysis, deep learning also shows excellent time series modeling and risk identification ability. Yahui Bai et al. [15] summarized the extensive application of reinforcement learning in the financial field through systematic review and meta-analysis, proposed the “RL premium” index to unify performance evaluation, and discussed key challenges such as interpretability, unstable environment and model robustness. The 4C FinNet framework proposed by SHIMENG Yang et al. [16] converts the financial statement data into a four channel feature map and combines mobilenetv2 and LSTM networks to significantly improve the accuracy and robustness of financial risk prediction.

In addition, in-depth learning also plays an important role in social fields such as people’s livelihood and agriculture. Miia Chabot et al. [17] developed a flood management decision support system (DSS) integrating convlstm, digital twins and economic risk assessment, which improved the accuracy of flood prediction and the ability of risk visualization and provided a new tool for adaptive governance. Pouya Bohlol et al. [18] proposed a non-destructive method based on deep learning and adaptive data enhancement, which realized the intelligent identification of the quality of exported saffron and provided a feasible technical path for the quality control system of agricultural products.

The above cross-domain success jointly confirms the strong potential of deep learning to mine common patterns from complex data. Based on this, it has also made great progress in the specific field of mechanical equipment fault diagnosis. Specifically, in this field, in-depth learning relies on the parallel computing ability of general purpose computing on graphics processing units (GPGPUs) to independently mine potential features from complex data streams such as operating parameters and state parameters of mechanical equipment [19]. This approach significantly enhances diagnostic accuracy and efficiency by performing multi-level, multi-dimensional analysis of sensor signals to extract features reflecting equipment health status. With diverse models designed to address distinct data pattern recognition challenges, this paper focuses on four key architectures: Recurrent Neural Networks (RNNs) [20], CNNs [21], Auto-encoders (AEs) [22], and Deep Belief Networks (DBNs) [23]. This selection is justified not only by their extensive application and relative maturity in fault diagnosis but, more critically, because they fundamentally represent four complementary and core data processing paradigms.

Deep Bayesian Networks (DBNs) embody the paradigm of unsupervised pre-training and deep feature generation, excelling at autonomously learning robust degenerate feature representations from unlabeled mechanical equipment vibration data [24]. Convolutional Neural Networks (CNNs) embody the paradigm of spatial local feature extraction, efficiently capturing fault-related local impact patterns from signals (especially image data after time-frequency transformation), making them suitable for analyzing vibration images or acoustic images of mechanical equipment [25]. AEs embody the paradigm of data compression and reconstruction learning, primarily serving feature dimensionality reduction, data denoising, and anomaly detection [26]. They are highly suitable for establishing baseline models of normal operation for mechanical equipment under unlabeled conditions. Recurrent neural networks and their variants (e.g., LSTM, GRU) embody the paradigm of temporal dynamic modeling. They comprehend temporal dependencies in signals [27], enabling diagnosis and prediction of fault evolution processes. These four paradigms systematically cover the core technological chain in fault diagnosis—from feature learning and spatial pattern recognition to time series analysis—collectively forming the technical foundation for tackling complex diagnostic tasks in mechanical equipment.

In recent years, several outstanding review papers have systematically examined the application of deep learning in fault diagnosis for general mechanical equipment. The review by Neupane et al. [28] not only systematically reviews the application of mainstream deep learning models such as CNNs, RNNs, and auto-encoders in the diagnosis of general components like bearings and gears, but it also places particular emphasis on summarizing cutting-edge paradigms such as reinforcement learning and federated learning. It comprehensively catalogs over 30 publicly available dataset resources, providing researchers with a crucial methodological foundation and experimental benchmarks. Zhao et al. [29] analyzed the application, advantages, and limitations of deep learning, graph embedding, and Transformer-based methods in rolling bearing fault diagnosis. Furthermore, they delve into major challenges in current research—such as complex network structures, insufficient information attention, difficulties in graph data processing, and long-term dependency modeling—and propose future directions focused on designing lightweight models, enhancing computational efficiency and robustness, and deepening the extraction of fault features. Xin et al. [30] provide a detailed summary of traditional data-driven approaches (including expert systems, signal decomposition, and machine learning models), traditional deep learning approaches (including auto-encoders, deep belief networks, convolutional neural networks, and recurrent neural networks), and emerging graph embedding methods and Transformer models. They highlight the advantages of these methods in feature extraction, temporal modeling, and non-Euclidean data processing while also pointing out common issues such as high model complexity, inadequate modeling of long-term dependencies, and sensitivity to data sparsity and noise. Garcia et al. [31] conducted a comprehensive analysis of signal processing, machine learning, deep learning, and hybrid physics-data-driven models in industrial equipment condition monitoring and predictive maintenance through a hybrid systematic literature review combining natural language processing and expert validation. They meticulously categorized mainstream technologies, explored key challenges and proposed solutions while integrating Industry 5.0 concepts to guide future research directions. Covering practical applications across diverse industrial equipment, this work provides essential reference for researchers and practitioners in related fields.

To sum up, deep learning, as a universal approximator, has shown strong modeling ability in many tasks across images, languages, industrial vision, business processes, financial time series, environmental prediction, agricultural quality inspection and even mechanical equipment fault diagnosis. This cross-domain success not only verifies the universality of its methodology but also provides a solid technical endorsement and migration potential for its further application in port equipment fault diagnosis, which is also a complex scenario with high noise, nonlinear and multimodal data characteristics.

For the field of fault diagnosis, the above research work provides a solid theoretical foundation. However, most existing reviews focus primarily on validating the methods themselves on generic components such as bearings and gears. They have not sufficiently addressed the unique challenges that arise when applying these advanced technologies to the specific complex industrial setting of “port equipment.” For instance: How can we address the challenges to model robustness posed by extreme operating conditions in ports? How can effective diagnostics be achieved despite scarce failure data? And how can diagnostic models be engineered for integration with existing port management systems?

Therefore, this paper aims to fill this research gap. Its core contribution lies not merely in listing four models but in constructing a systematic knowledge framework that bridges “general-purpose algorithms” to “port applications.” It not only reviews methodologies but also focuses on exploring their adaptability, challenges, and implementation pathways within port environments. The logical progression of this paper is as follows: First, it is grounded in deep learning models validated on general components and possessing strong transfer potential. Subsequently, it systematically analyzes their applicability, limitations, and future breakthrough directions when addressing the unique diagnostic challenges of port equipment.

Compared with the existing reviews, the main contributions of this paper are as follows:

- A systematic overview framework for port fault diagnosis applications is proposed. This paper goes beyond the traditional “model introduction—application case” paradigm and constructs a progressive discussion structure of “methodological basis—general component verification—port scenario challenge analysis—system deployment path”, which provides a complete guide from theory to practice for the implementation of deep learning technology in port equipment.

- This paper provides a comparative analysis of multidimensional and insightful deep learning models. This paper is not limited to the common accuracy comparison but constructs a qualitative and quantitative comparison framework from the core principles, applicable data types, calculation efficiency, noise resistance and port application potential and other dimensions, providing a profound decision-making basis for model selection under the port scene.

- This paper realizes the deep integration of deep learning and port diagnosis scenarios and systematically analyzes the domain-specific challenges. For the first time, this paper systematically identifies and deeply analyzes the core bottlenecks caused by the “high reliability paradox” of the port, such as data scarcity, model robustness under dynamic adverse conditions, and interpretability requirements under multi-system coupling and safety requirements and sorts out the corresponding adaptive technology path.

- A clear implementation path of system level project is outlined. This paper fills the practical gap from algorithm prototype to industrial system integration and discusses in detail the “cloud edge end” collaborative architecture, the integration scheme with SCADA/ERP and other port management systems, as well as the standardized deployment process, providing a clear road map for the industrial transformation of the research results.

Based on the above contributions, this paper follows a logical framework of “theoretical foundation—methodological review—challenge analysis—practical pathways—future outlook.” The introduction clarifies the background of intelligent operation and maintenance for port equipment and the application value of deep learning. Subsequently, the paper systematically explains the literature search and screening methods to ensure the comprehensiveness and reliability of the review. It then details the fundamental principles of four types of deep learning models and summarizes their application cases in the diagnosis of general mechanical components. Building on this foundation, it critically analyzes data, environmental, and system-level challenges encountered when transferring these methods to specialized port scenarios, proposing corresponding countermeasures. It then explores hardware architecture and integration pathways for system deployment from an engineering perspective. Finally, the paper clarifies its contributions through discussion and outlines future research directions—including lightweight approaches, interpretability, and integration of physical mechanisms—aiming to provide systematic guidance for the technological advancement of intelligent port equipment maintenance.

2. Literature Review Methodology

2.1. Literature Search Strategy

To comprehensively cover relevant domestic and international research, this review systematically searched two major Chinese and English academic databases: Web of Science (WoS) across all collections and China National Knowledge Infrastructure (CNKI). The search timeframe was restricted to January 2018 through October 2025 to focus on the latest achievements during the rapid development phase of deep learning in the field of fault diagnosis.

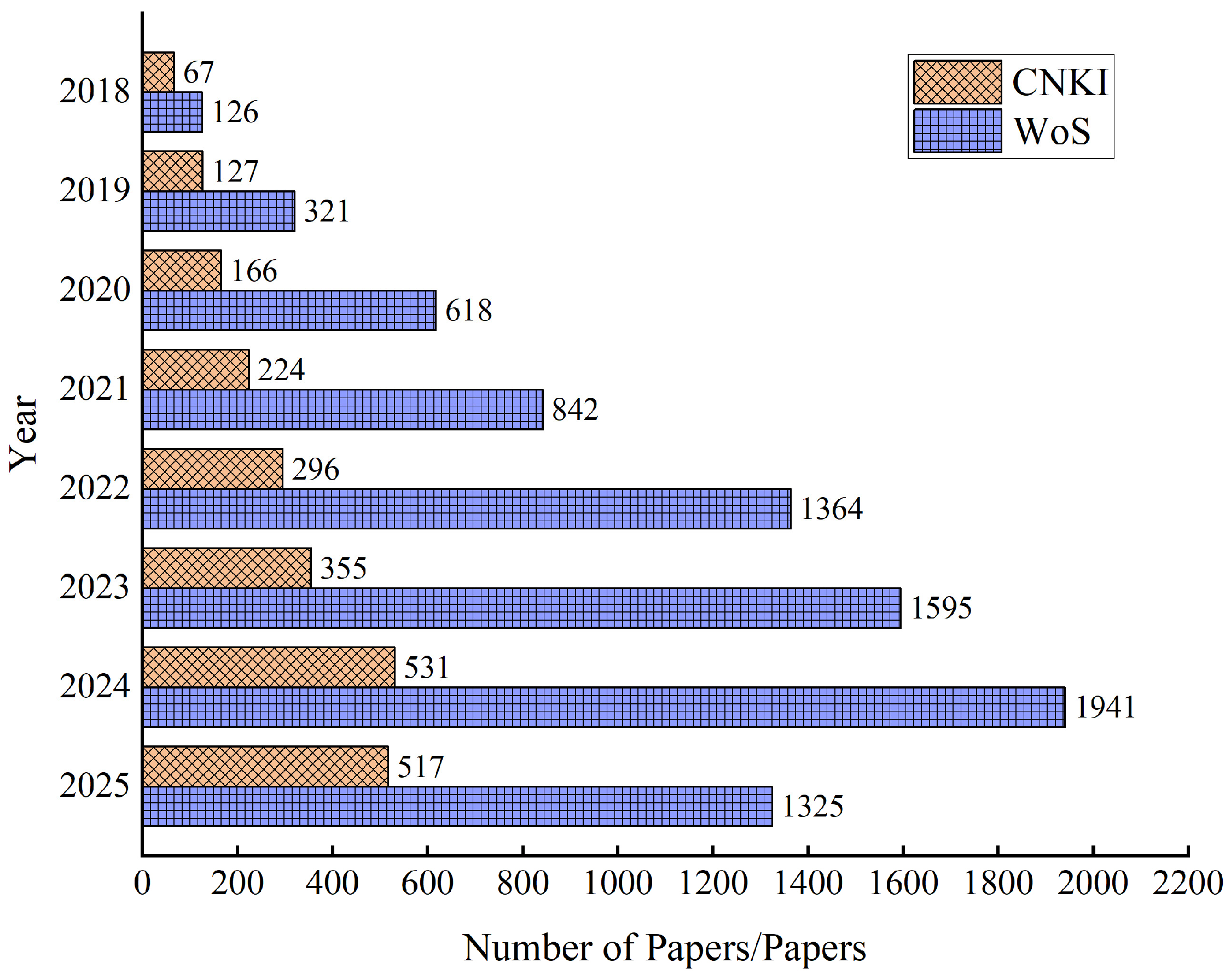

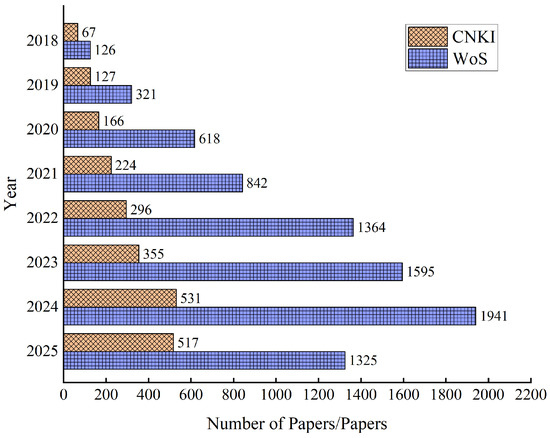

The search employed a combination strategy of “subject terms/keywords.” In the CNKI database, the basic search query used the Chinese term “深度学习” (deep learning) combined with “故障诊断” (fault diagnosis). In the WoS database, the corresponding search used “Deep learning” AND “fault diagnosis.” The preliminary search results indicate that since 2018, research attention in this field has been steadily increasing, with a significant upward trend in annual publication volume, as shown in Figure 1. As of October 2025, approximately 1800 relevant papers have been published this year, with the total expected to surpass the 2024 figure of nearly 2500 by year-end. This confirms the timeliness and significance of this review’s topic selection.

Figure 1.

Number of deep learning-related articles in the field of rotating machinery fault diagnosis.

2.2. Inclusion and Exclusion Criteria for Literature

Based on preliminary searches, explicit inclusion and exclusion criteria were established to precisely identify literature highly relevant to this research topic.

Inclusion Criteria: (1) Research must explicitly address the application of one of four target deep learning models—Deep Belief Networks (DBNs), Convolutional Neural Networks (CNNs), Auto-encoders (AEs), or Recurrent Neural Networks (RNNs) and their variants—in mechanical fault diagnosis. (2) The research subjects must be typical rotating mechanical components or systems, such as bearings, gearboxes, engines, etc. (3) The literature type must be journal articles or review papers.

Exclusion Criteria: (1) Research subjects involving non-rotating mechanical equipment or fields completely unrelated to port equipment operating conditions. (2) Literature where the full text is unavailable, duplicated publications, or works not written in Chinese or English.

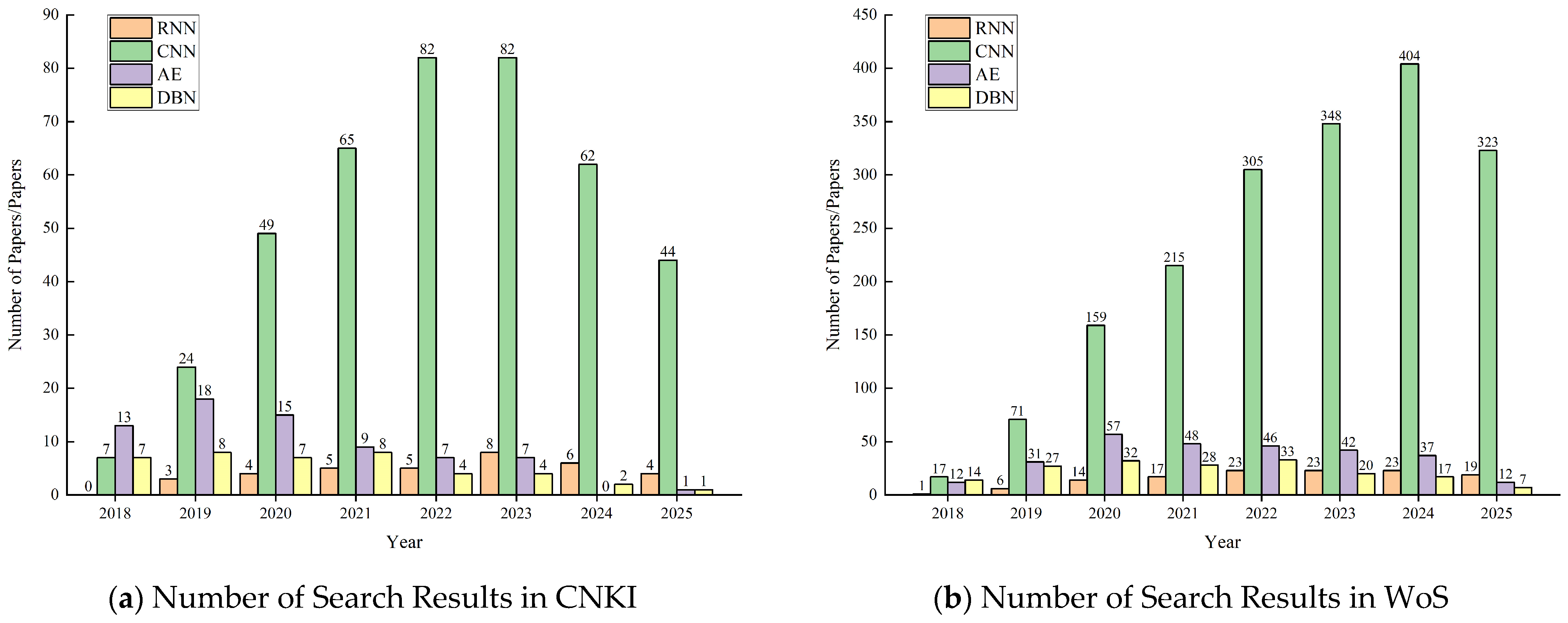

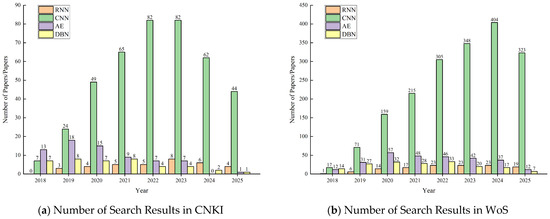

Based on the aforementioned criteria, the search terms were refined and supplemented. Specific search queries were constructed for each of the four model categories, with the results shown in Figure 2. The Chinese search terms included the following: “深度学习 + 故障诊断 + 循环神经网络” (Deep learning + fault diagnosis + recurrent neural network), “深度学习 + 故障诊断 + 卷积神经网络” (Deep learning + fault diagnosis + convolutional neural network), “深度学习 + 故障诊断 + 自编码” (Deep learning + fault diagnosis + auto-encoder), and “深度学习 + 故障诊断 + 深度置信网络” (Deep learning + fault diagnosis + deep belief network). The English search terms include: “Deep learning + fault diagnosis + RNN,” “Deep learning + fault diagnosis + CNN,” “Deep learning + fault diagnosis + Auto Encoder,” and “Deep learning + fault diagnosis + DBN.” Analysis reveals that the Web of Science database contains a larger volume of literature overall compared to CNKI, reflecting the greater activity within the international academic community in this interdisciplinary research field.

Figure 2.

(a) Number of search results for four models in CNKI; (b) Number of search results for four models in WoS.

2.3. Literature Search Process

Literature screening followed a systematic process. First, relevant literature was identified through preliminary database searches, with duplicate records excluded. Subsequently, initial screening was conducted by reviewing article titles and abstracts against inclusion and exclusion criteria. Full-text articles that passed this screening were downloaded and critically evaluated to assess their relevance to the study topic and depth of content. Ultimately, 130 articles were confirmed for inclusion in this review, undergoing in-depth qualitative analysis and discussion. This process ensured the comprehensiveness and representativeness of the selected literature.

2.4. Literature Quality Assessment

During the intensive reading phase, the 130 papers ultimately included underwent comprehensive evaluation across multiple dimensions, including methodological innovation, soundness of experimental design, representativeness of datasets, and credibility and comparability of results. Particular emphasis was placed on studies that proposed novel model architectures, effectively addressed specific diagnostic challenges, and were thoroughly validated on public datasets or real-world industrial data. This ensured that the technical approaches discussed in this review possess sufficient advancement and reference value.

3. Basic Architecture of Deep Learning Models

3.1. DBN

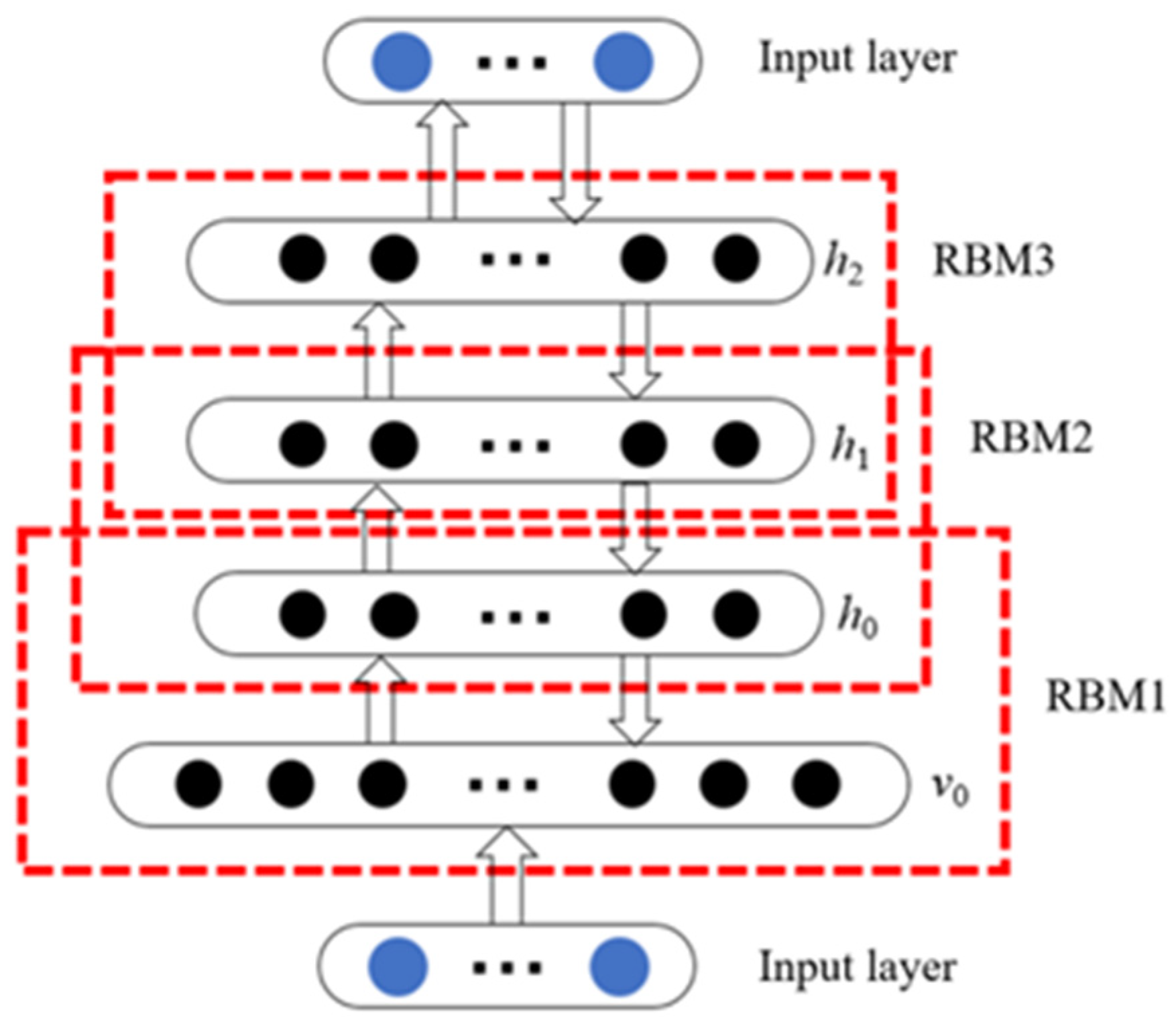

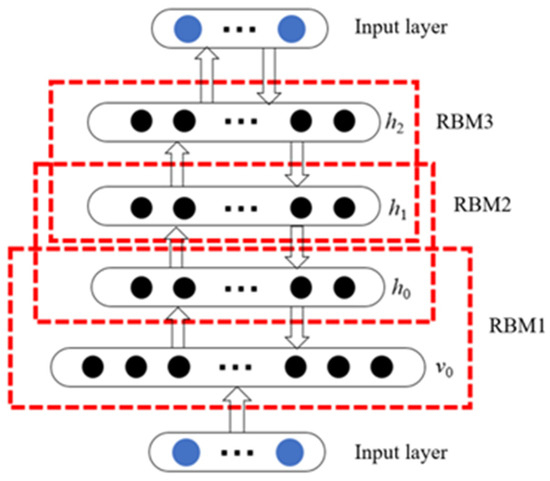

A typical DBN model primarily consists of multiple layers of RBMs and a single layer of Back-Propagation (BP) neural networks. Its core lies in employing a layer-wise greedy learning algorithm to optimize the connection weights between RBM layers [32], with its basic structure shown in Figure 3. In a DBN model, the output of neurons in the preceding layer serves as the input for neurons in the subsequent layer. This process repeats across each layer until the entire neural network completes training. This approach allows for the creation of multiple reasonable hidden and visible layers based on practical requirements, thereby enhancing the model’s breadth and depth. This improvement boosts the model’s learning and computational capabilities [33] and enables the exploration of deep characteristics within the raw data [34].

Figure 3.

Structure of DBNs.

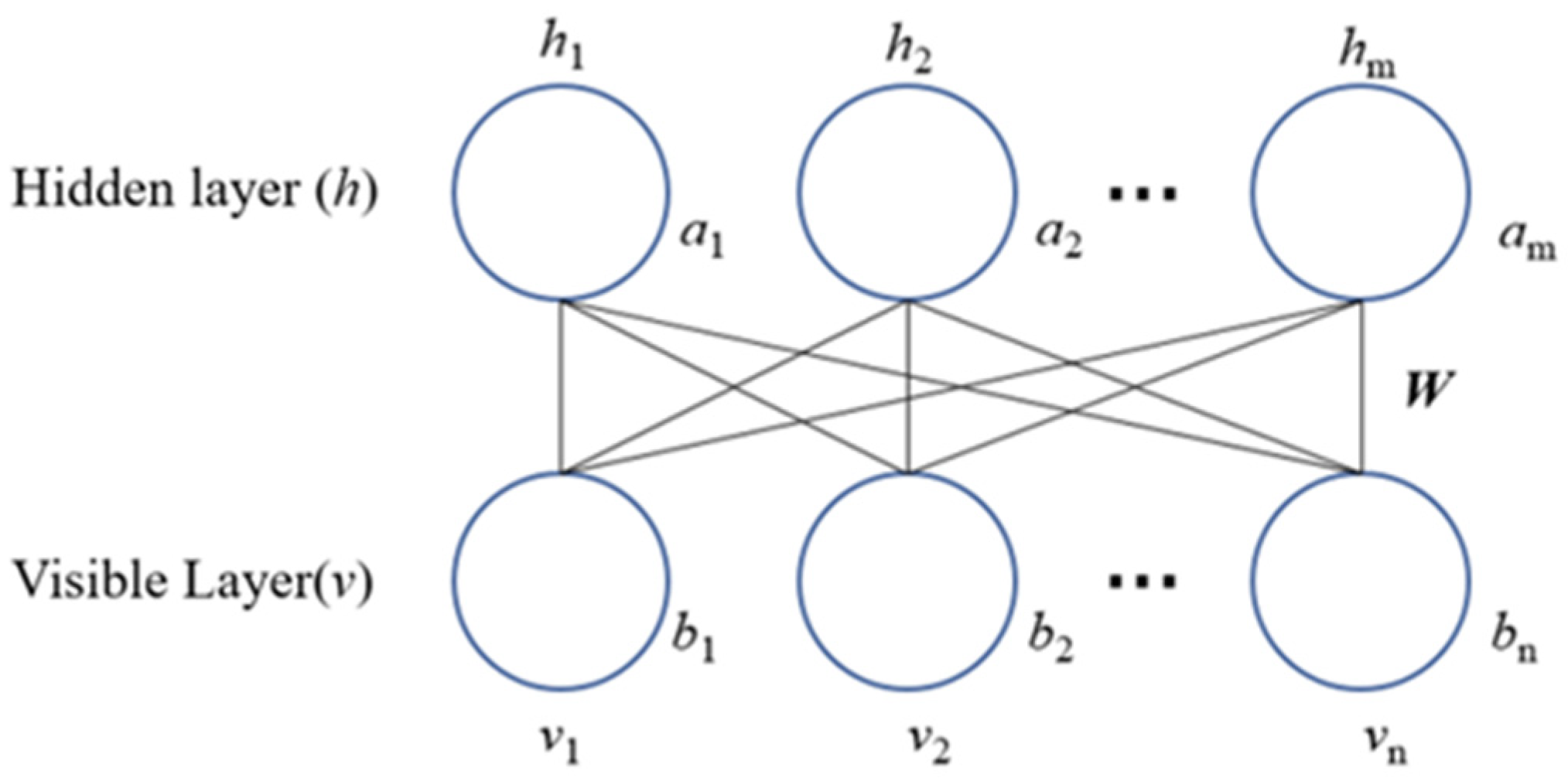

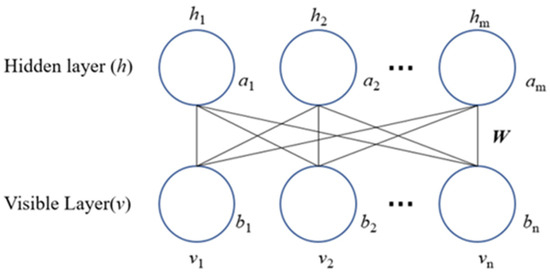

Each RBM consists of bidirectionally connected hidden and visible layers, with connections between neurons at the same layer level removed [35]. The basic structure of an RBM is shown in Figure 4, where and denote the bias vectors of the hidden and visible layers, respectively. W represents the weight matrix between the hidden and visible layers. n and m denote the number of neurons in the hidden and visible layers, respectively. and denote the neuron states of the hidden and visible layers, respectively. denotes the state of the i-th neuron in the hidden layer and the j-th neuron in the visible layer. For states , the energy function of the RBM is defined as:

Figure 4.

Basic structure of RBM.

3.2. CNN

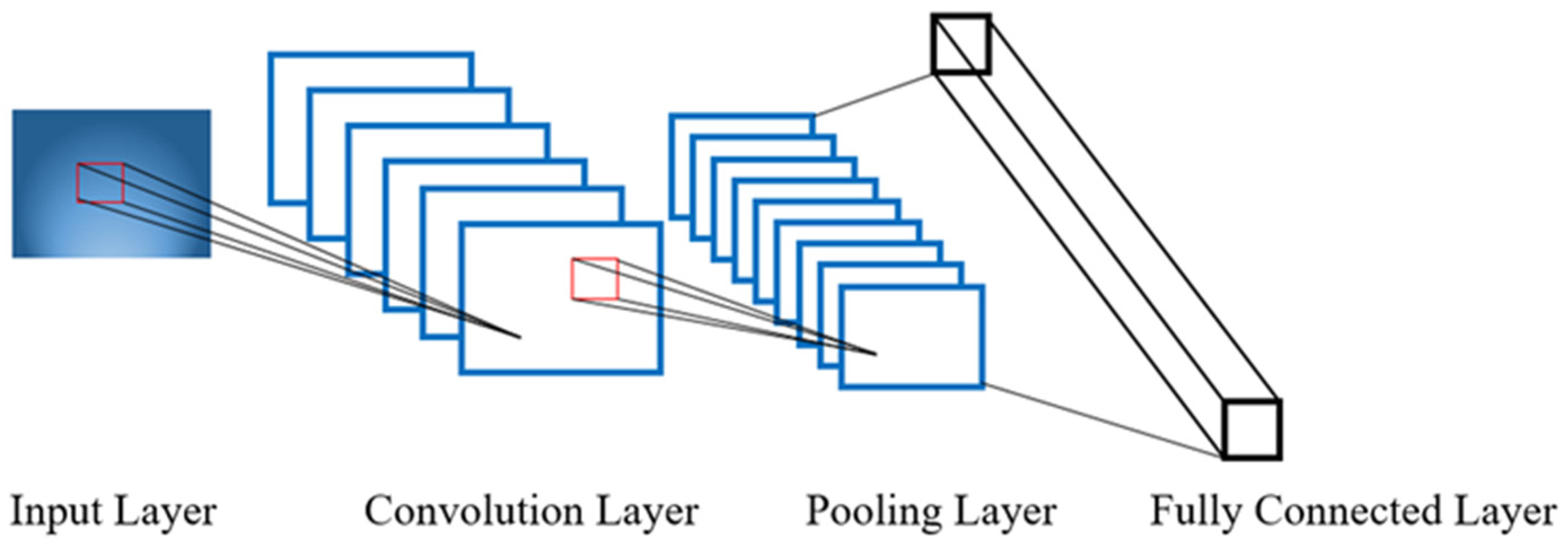

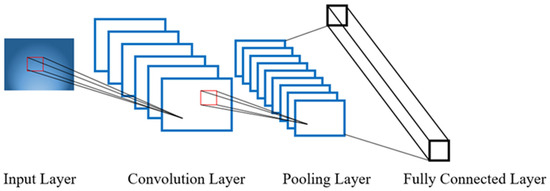

The CNN model [36] is essentially a multilayer perceptron, with its key features being the restricted connections between neurons and shared weights [37]. The basic structure of the CNN is shown in Figure 5, consisting of an input layer, convolutional layers, pooling layers, and fully connected layers. The reduced number of weights facilitates network optimization while lowering the risk of overfitting. Moreover, the ability to directly input multidimensional vibration signals into the network eliminates the need for data rearrangement during feature extraction and classification processes.

Figure 5.

Basic structure of a convolutional neural network.

The essence of a convolutional layer lies in performing convolution calculations by scanning the feature maps of the input layer with a convolution kernel, thereby extracting multidimensional features based on the objective function. The convolution operation is defined as:

In the formula: “” denotes the convolution operation; represents the input feature map combination; k denotes the convolution kernel connecting the i-th input feature map and the j-th output feature map; is the input to the l-th layer of the network; f is the activation function; is the bias term.

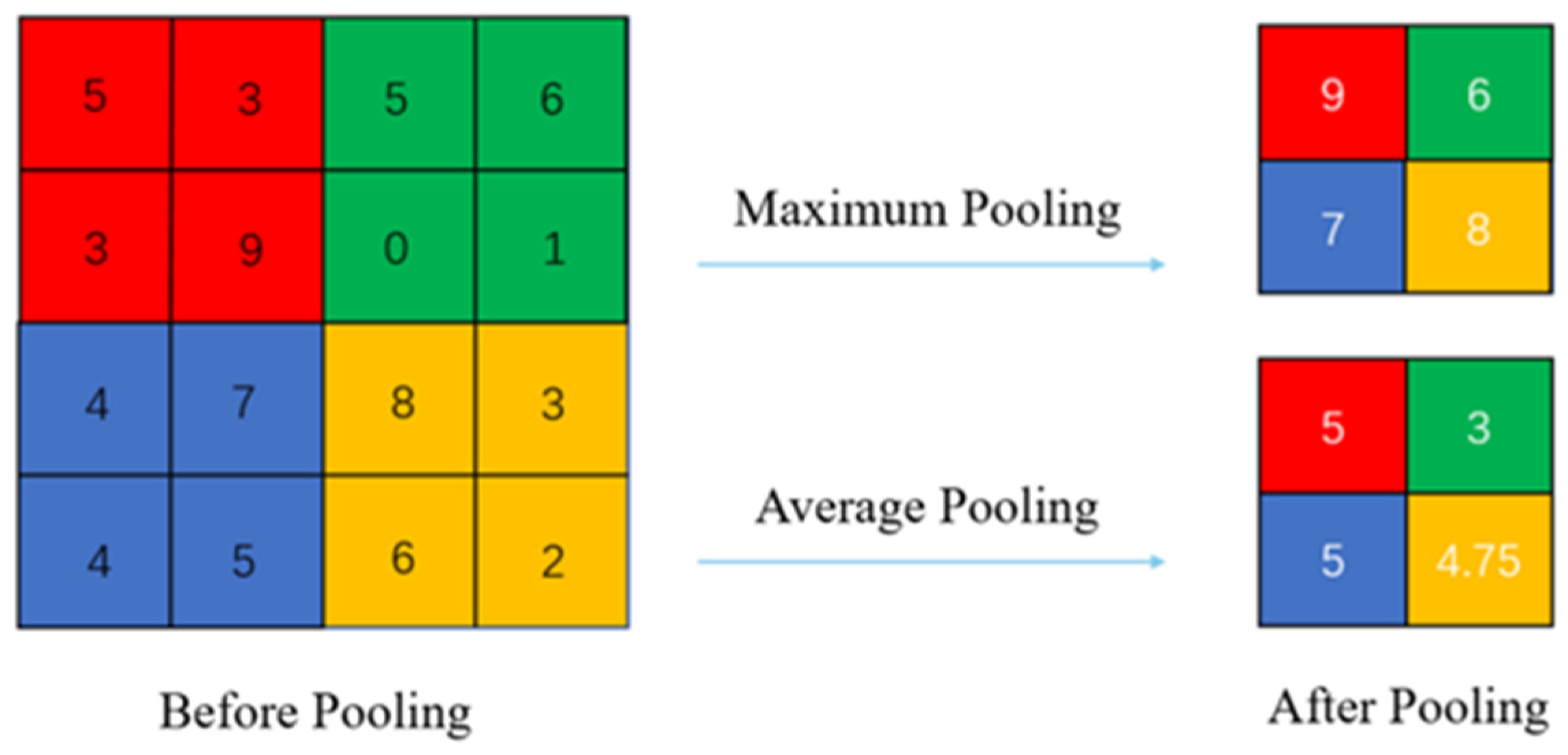

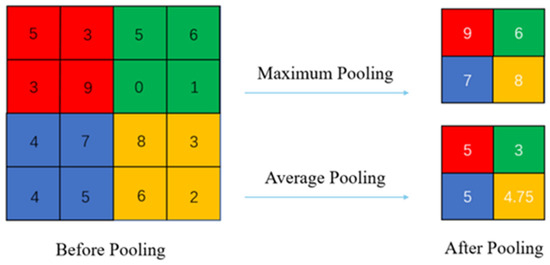

Pooling layers correspond one-to-one with convolutional layers. By performing operations such as averaging, calculating probability values, or finding maximum values on the feature points extracted from convolutional layers, pooling not only reduces feature dimensions but also increases channel capacity while preventing overfitting. The computational principle of pooling is illustrated in Figure 6, with its operation defined as follows:

Figure 6.

The principle of pooling computation.

In the formula: β denotes the network multiplicative bias; down (*) denotes the pooling function.

After undergoing multiple convolutional and pooling layers, the CNN completes feature extraction and compression of the input signal. It then connects to a fully connected layer to obtain global information. The output from the fully connected layer is typically fed into a classifier employing Softmax logistic regression for classification. If the actual classification result deviates from the expected classification result, the error is propagated backward layer by layer to update the parameters of each network layer.

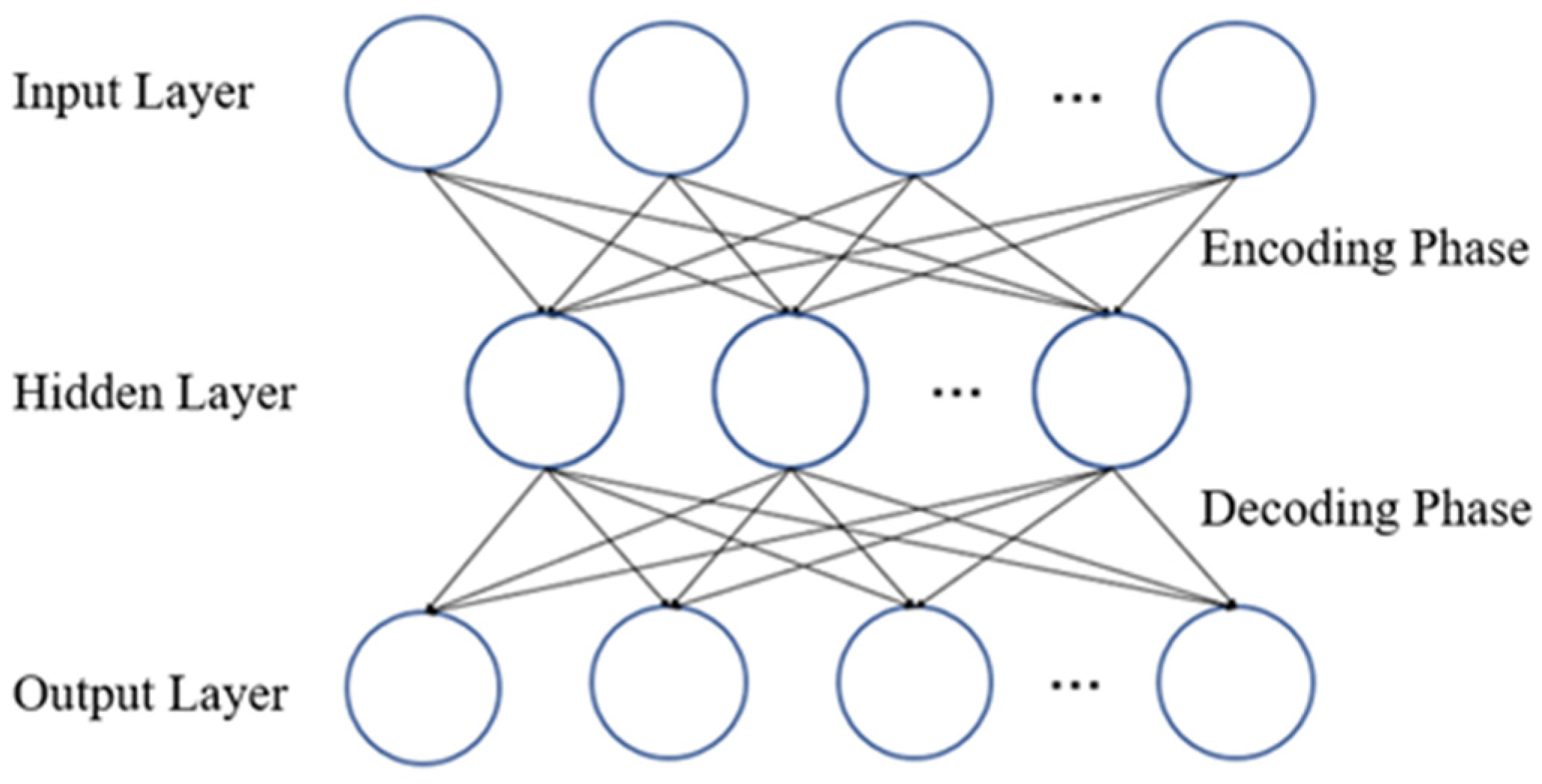

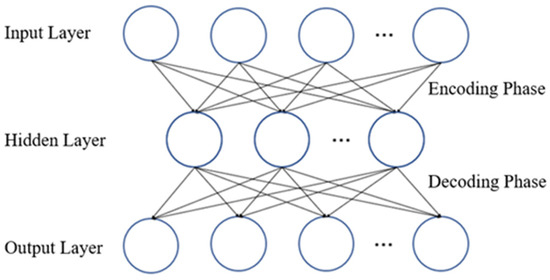

3.3. AE

Auto-encoders are neural networks designed to reconstruct input signals as faithfully as possible, comprising an encoder and a decoder. Their fundamental architecture is illustrated in Figure 7. If the output layer can effectively reconstruct the input layer, the hidden layers can serve as features representing the input signal [38]. The efficient representation of input data is termed encoding, typically with dimensions far smaller than the input data, enabling auto-encoders for dimensionality reduction. More importantly, auto-encoders serve as powerful feature detectors for pre-training deep neural networks.

Figure 7.

AE structural diagram.

The process of data passing from the output layer to the hidden layer is called encoding, and its mathematical expression is:

Here, f is the activation function; is the vector of the hidden layer; is the input vector, with n denoting the number of neurons in the input layer; k denotes the number of neurons in the hidden layer; is the weight matrix connecting the input layer to the hidden layer; is the bias vector of the hidden layer.

The process of data passing from the hidden layer to the output layer is called decoding, and its mathematical expression is:

Among these: is the output vector of the reconstruction layer, where the number of neurons in the output layer is identical to that in the input layer. and are the bias vectors of the output layer.

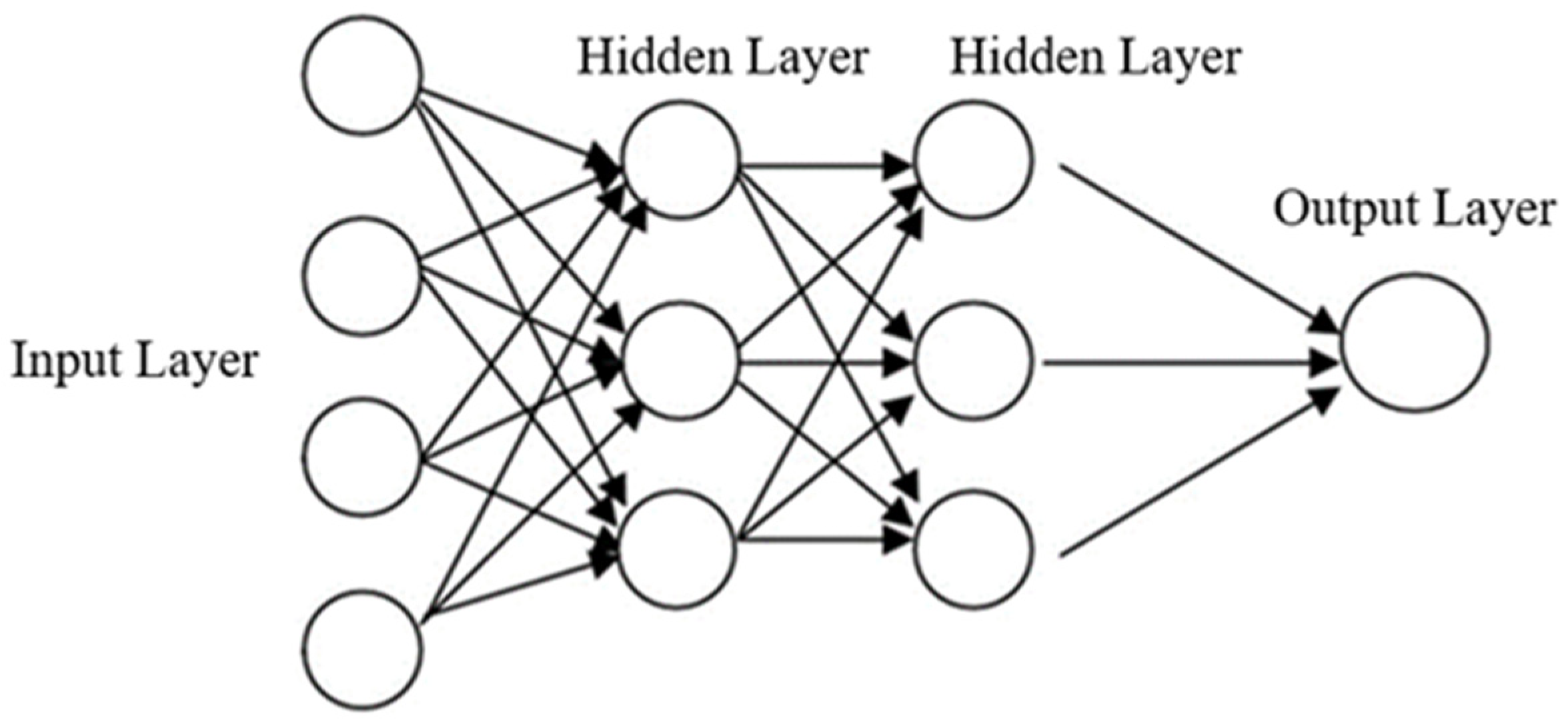

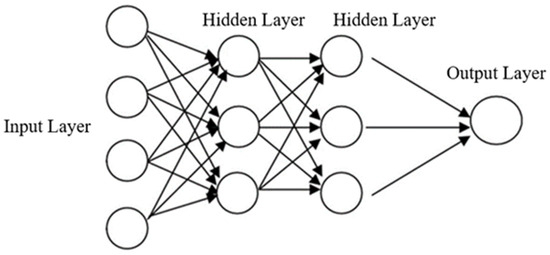

3.4. RNN

Recurrent Neural Networks (RNNs) are a crucial type of neural network model in deep learning, primarily used for processing data with sequential characteristics (e.g., temporal order, logical sequence). Within their network architecture, the outputs of neurons can be fed back into other neurons for computation. This feature also endows RNNs with “memory” capabilities [39]. The basic structure of an RNN is shown in Figure 8, primarily consisting of an input layer, hidden layers, and an output layer. Through connections between nodes in the hidden layers, RNNs store historical information within the network architecture for use in subsequent computations. This mechanism also introduces dependency relationships among the input data.

Figure 8.

RNN architecture diagram.

To address the issue of long-term dependencies in RNNs, Long Short-Term Memory (LSTM) networks [40] and Gated Recurrent Unit (GRU) networks [41] were developed as improvements upon RNNs. LSTM and GRU combine short-term and long-term memory through a “gate structure,” resolving the long-term dependency problem inherent in RNNs [42]. The essence of the “gate structure” is a fully convolutional neural network that performs phase-wise multiplication, utilizing the Sigmoid activation function.

4. Signal Preprocessing and Feature Extraction for Deep Learning

Vibration and acoustic monitoring signals from port equipment are inherently non-stationary, non-Gaussian time-varying signals, whose fault characteristics often manifest as transient impacts or dynamic changes in frequency components. Directly feeding these raw one-dimensional time-series signals into deep learning models is feasible but overlooks temporal dependencies and frequency-domain features within the signals, resulting in limited model performance. Effective signal preprocessing and feature extraction aim to condense and highlight the key fault-related information implicit in the signals, transforming it into a form more suitable for deep learning models to understand and process. This constitutes a critical step in enhancing the diagnostic model’s performance, robustness, and generalization capability.

4.1. Signal Preprocessing Methods

Signal preprocessing first requires data cleaning and quality assessment, which form the foundation for ensuring the reliability of subsequent analysis. The focus of data cleaning lies in addressing outliers and missing data issues. Typically, statistical 3σ criteria or box plots are employed to identify and handle outliers [43], thereby eliminating the impact of sensor failures or transmission interference. For missing values, reasonable filling can be achieved through interpolation methods [44] or deep learning-based approaches to ensure data continuity. Concurrently, signal quality must be assessed using quantitative parameters such as signal-to-noise ratio and kurtosis metrics, providing scientific basis for selecting subsequent processing strategies. This step is particularly crucial for ensuring the reliability of long-term monitoring data for port equipment.

In signal denoising, due to the complex operating environment of port equipment, signals are often subject to intense noise interference, necessitating the adoption of multiple effective denoising methods. Traditional filtering techniques, including low-pass, high-pass, and band-pass filters, are suitable for noise removal within specific frequency bands. Wavelet threshold denoising leverages the multi-resolution properties of wavelet transform (WT) [45] to suppress noise at different scales. Experimental modal decomposition (EMD) [46] achieves signal reconstruction by decomposing and removing noise-dominated intrinsic modal function (IMF) components; deep learning approaches utilize network structures like auto-encoders to learn the mapping relationship between noise and useful signals. The judicious selection of these methods is crucial for extracting faint fault features in highly noisy backgrounds.

Data standardization and augmentation are vital steps for enhancing model training effectiveness and generalization capabilities. Normalization scales data to a specific range (e.g., [0, 1] or [−1, 1]) to eliminate dimensional effects; standardization transforms data into a normal distribution with mean 0 and standard deviation 1, accelerating model convergence. Addressing the scarcity of fault samples in port equipment, data augmentation techniques like noise injection and temporal stretching expand training datasets, effectively enhancing model robustness and generalization capabilities.

4.2. Feature Extraction Technology

Core feature extraction methods include time-domain feature extraction and frequency-domain feature extraction. Time-domain features are extracted directly from signal waveforms, encompassing statistical features (mean, variance, peak, kurtosis, skewness, etc.), dimensionless features (waveform factor, peak factor, pulse factor, etc.), and temporal features (autocorrelation function, cross-correlation function, etc.). These features are computationally straightforward, possess clear physical significance, and effectively reflect signal amplitude characteristics and distribution patterns, making them suitable for rapid assessment of port equipment operational status.

Frequency-domain features involve transforming signals to the frequency domain via Fourier transform for analysis. They extract spectral characteristics (spectral centroid, frequency variance, mean square frequency, etc.), spectral line features (amplitude and phase information of primary frequency components), and envelope spectrum features. These reveal signal periodicity and resonance characteristics, making them particularly suitable for fault diagnosis in rotating components like bearings and gears. They hold significant value in monitoring port equipment transmission systems.

4.3. Time-Frequency Analysis Method

Time-frequency analysis simultaneously reveals the energy distribution of signals across both time and frequency dimensions, making it a powerful tool for processing non-stationary signals. The Short-Time Fourier Transform (STFT) [47] segments a signal using a fixed-length sliding window function, applying a Fourier transform to each segment to reveal how the signal’s frequency components vary over time. The result is a spectrogram. The limitation of STFT lies in its time-frequency resolution, constrained by the Heisenberg Uncertainty Principle, which prevents achieving both high time resolution and high frequency resolution simultaneously.

Wavelet Transform (WT) analyzes signals using scalable, shiftable mother wavelet functions, exhibiting multiresolution analysis characteristics: short time windows achieve high temporal resolution for high-frequency components, while long time windows achieve high frequency resolution for low-frequency components. This makes WT particularly suitable for capturing transient impact components in port equipment vibration signals. Empirical Mode Decomposition (EMD) is an adaptive signal decomposition method that breaks down complex signals into a series of intrinsic mode functions (IMFs). Each IMF component contains information about a specific frequency band within the original signal. This method is entirely data-driven, requiring no predefined basis functions.

Additionally, Variational Modal Decomposition (VMD) [48] achieves adaptive signal decomposition through a variational framework, effectively avoiding modal aliasing issues. The Hilbert-Huang Transform (HHT) [49] combines EMD with the Hilbert transform to provide a high-resolution time-frequency representation.

The aforementioned time-frequency analysis methods each possess distinct characteristics. Their core principles and applicability are summarized in Table 1. Understanding these differences forms the foundation for their subsequent effective integration with deep learning models.

Table 1.

Characteristics comparison of major time-frequency analysis methods.

4.4. A Fusion Paradigm of Time-Frequency Analysis and Deep Learning

Time-frequency analysis methods provide deep learning with rich, high-information-density input features. The effective integration of these two approaches has formed two primary technical paradigms, offering robust technical support for port equipment fault diagnosis.

The feature input paradigm employs time-frequency analysis as a fixed front-end feature extractor. By converting one-dimensional raw vibration signals into two-dimensional time-frequency images, it fully leverages deep learning’s strengths in image processing. Specifically, port equipment monitoring signals are converted into time-frequency images—such as spectrograms or wavelet scale maps—via methods like STFT, CWT, or EMD. These images are then fed into convolutional neural networks for deep feature learning and classification. This “signal → image → diagnosis” technical pathway transforms fault diagnosis into an image recognition problem, yielding significant practical results. It is particularly well-suited for handling impact-induced fault characteristics in port equipment vibration signals, such as typical failure modes like bearing spalling and gear tooth breakage.

The collaborative analysis and decision fusion paradigm emphasizes deeper synergy between time-frequency analysis and deep learning at the feature level. This approach first decomposes signals into multiple components using time-frequency analysis techniques like EMD or VMD. Statistical features are then extracted from each component to form feature vectors, which are fed into deep belief networks or fully connected networks for diagnostic analysis. An alternative implementation path involves establishing separate deep learning models for different components, followed by decision-level fusion. This paradigm offers greater flexibility, leveraging the strengths of time-frequency analysis in signal decomposition and deep learning in modeling nonlinear relationships. It is particularly well-suited for comprehensive multi-source signal analysis and composite fault diagnosis in complex port equipment.

In practical applications, both paradigms offer distinct advantages. The feature input paradigm fully leverages CNNs’ exceptional capability in image feature extraction, offering a straightforward diagnostic workflow and excelling in single fault mode identification. The collaborative analysis and decision fusion paradigm, through multi-level feature extraction and model fusion, demonstrates greater adaptability when handling complex faults and system-level diagnostic challenges. For the uniquely complex operational environments of port equipment, appropriate fusion strategies can be selected based on specific diagnostic requirements to achieve optimal diagnostic outcomes.

4.5. Feature Selection and Dimension Reduction

Feature selection and dimensionality reduction are crucial steps in optimizing model performance. Feature selection aims to identify the most effective subset of features from a large number of extracted features. Filtering methods [50] evaluate feature importance based on statistical metrics such as correlation coefficients and chi-square tests; wrapping methods [51] select optimal feature subsets through model performance feedback, such as recursive feature elimination; embedding methods perform feature selection automatically during model training, such as LASSO regression.

Feature dimensionality reduction maps high-dimensional features to lower-dimensional spaces through mathematical transformations. Principal Component Analysis (PCA) preserves key feature information via linear transformations; Linear Discriminant Analysis (LDA) retains class discriminative information while reducing dimensions [52]; t-SNE, as a nonlinear dimensionality reduction method [53], facilitates visualization analysis of high-dimensional data. When processing multi-sensor fusion data from port equipment, these techniques can effectively eliminate redundant information and enhance diagnostic efficiency.

4.6. Special Considerations for Port Equipment

The unique operating environment of port equipment imposes special demands on signal preprocessing. In terms of environmental adaptability, preprocessing methods must withstand high temperatures, high humidity, and highly corrosive marine conditions. For real-time requirements, online monitoring systems demand preprocessing algorithms with high computational efficiency. Regarding multi-source data fusion, integration of multi-sensor information such as vibration, acoustic, and temperature data is essential. Concerning adaptability to operational variations, preprocessing strategies must accommodate drastic changes in equipment load and speed. These specialized considerations must be integrated throughout the entire preprocessing workflow design to ensure the diagnostic system’s reliability in real industrial environments.

5. Applications of Deep Learning in the Field of Fault Diagnosis

In the field of equipment fault diagnosis, traditional execution processes primarily consist of signal collection, data processing, feature extraction, and feature recognition. Integrating equipment operating parameters and processes with deep learning enables the establishment of feature relationships with deep-level correlated variables. The application approach can be summarized as follows:

- (1)

- After processing signal data, deep learning methods are utilized to reveal the intrinsic features of the data, thereby avoiding errors from manual selection. After feature selection, widely adopted fault diagnosis techniques are applied to partially optimize diagnostic outcomes.

- (2)

- Following signal data processing, deep learning methods are applied separately to data with low and high correlation for feature selection. This approach significantly simplifies the process and reduces computational load.

- (3)

- Collected signals are imported into a predefined model to output desired target results. Through feature selection learning and result classification during the process, the entire workflow is simulated and learned. This approach reduces complexity and minimizes errors, enabling comprehensive optimization across all steps. However, it may increase computational load and potentially impact model generalization.

5.1. Diagnostic Methods and Application Potential of DBNs

5.1.1. Fault Diagnosis Method Based on DBN

Currently, DBN-based fault diagnosis methods are widely applied in fields such as rolling bearings, gearboxes, and hydraulic pipelines.

Given the limitations of traditional rolling bearing fault diagnosis methods (e.g., shallow network structures and reliance solely on time-frequency component features), Guo et al. [54] proposed a novel fault diagnosis approach based on the DBN model, incorporating a multi-domain feature fusion algorithm. The main steps are as follows: First, vibration acceleration data is processed using noise reduction algorithms to extract time-domain, frequency-domain, and IMF energy features. Next, efficient features are selected and subjected to dimensionality reduction and fusion. Finally, the processed features are input into the DBN for fault diagnosis. The statistical results demonstrate that compared to traditional methods, this approach significantly improves accuracy while reducing analysis time, exhibiting good applicability across various fault types.

During the fault diagnosis process of the DBN model, the most time-consuming part is the structural debugging of the network layer. To reduce computation time and improve the accuracy of bearing fault diagnosis, Li Yibing et al. [55] improved the DBN model based on the particle swarm optimization algorithm. To address parameter assignment issues within the model, this algorithm employs adaptive time estimation for minor adjustments. It then extracts low-dimensional fault features from raw vibration acceleration data and utilizes a Softmax classifier to distinguish fault types.

Given the complexity of equipment operating environments, extracting features from vibration acceleration signals presents significant challenges, making accurate feature extraction crucial. Ren Zhaohui et al. [56] employed an unsupervised feature extraction method. Considering the high feature extraction efficiency of the DBN model, they utilized one-dimensional mapping to assign DBN features of modal components to a particle swarm optimization support vector machine, thereby completing bearing fault diagnosis.

To address gearbox fault diagnosis challenges, Zheng Pengfei et al. [57] proposed two fault diagnosis algorithms based on the DBN model, utilizing variational modal decomposition and wavelet denoising techniques, respectively. The results demonstrated that the DBN algorithm, grounded in gearbox big data, not only identifies gearbox faults but also accurately classifies fault types, exhibiting outstanding diagnostic performance.

To address the issues of low accuracy and poor generalization in intelligent fault diagnosis caused by poor training data quality, Tang et al. [58] proposed an improved Bi-DBN method for bearing fault diagnosis. This method introduces a reverse generation component into the standard DBN, reducing imbalance rates and enhancing feature learning efficiency. Additionally, parameters optimized using a quantum genetic algorithm further improved the fitting accuracy of the Bi-DBN model.

To address the “black-box” nature of existing deep neural network (DNN)-based fault diagnosis models for shore-to-ship container crane (STSC) trolley mechanisms—which fail to provide rational explanations for decision-making—Liao et al. [59] proposed a knowledge-based reverse deep belief network (KBRDBN). This approach constructs an efficient neural-symbolic system by extracting two types of relational knowledge: confidence rules and soft rules. Compared to other typical DNNs and neural-symbolic models, the KBRDBN achieves higher accuracy, effectively performing knowledge discovery and uncertainty reasoning, with an average diagnostic accuracy of 98.8%.

To address the performance dependency of DBN fault diagnosis models on the number of hidden layer neurons and the difficulty in determining optimal structures, Sun et al. [60] proposed an IHHO-DBN-ELM-based fault detection method. This approach incorporates the Improved Harris-Hawke Optimization (IHHO) algorithm into the optimization of the DBN and Extreme Learning Machine (ELM). It first employs the Cyclically Recurrent Convolutional Blind Deconvolution (CYCBD) algorithm to denoise bearing vibration signals, followed by IHHO of the DBN structure. The optimized DBN-ELM model achieves a fault classification accuracy of 99.17%, demonstrating significant performance enhancement.

Addressing the limited predictive capability of traditional methods for bearing measurement data with strong dynamic characteristics and nonlinearity, Wang et al. [61] proposed a Continuous Delay Hidden Layer Deep Belief Network (CDHLDBN). They constructed a KPCA-CDHLDBN bearing life prediction model based on Kernel Principal Component Analysis (KPCA) preprocessing. The results demonstrate that this model better predicts nonlinear dynamic time series data, exhibiting superior prediction accuracy and faster prediction speed compared to other deep learning models.

Vibration signals extracted from rolling bearings are often mixed with noise signals, making it difficult to identify fault characteristic parameters using time-domain and frequency-domain methods. Zhao et al. [62] proposed a novel rolling bearing fault diagnosis method based on wavelet packet decomposition (WPD) for feature extraction and the chaotic sparrow search optimization algorithm (CSSOA) for optimizing DBN parameters, establishing the WPD-CSSOA-DBN fault diagnosis model. The results demonstrate that this method exhibits enhanced feature extraction capabilities and outstanding rolling bearing fault diagnosis performance.

To address the scarcity of labeled samples and the homogeneity of monitoring data in rotating machinery fault diagnosis, Han et al. [63] proposed a novel multi-source heterogeneous information fusion (MSHIF) network approach. By designing data-augmented deep belief networks (DEDBN) and data-augmented one-dimensional convolutional neural networks (DE-1DCNN), this method enables more comprehensive and robust identification of rotating machinery health status under limited datasets. The results demonstrate that MSHIF achieves average recognition accuracies of 99.491%, 99.143%, and 99.037% across three distinct case studies.

To address the randomness of DBN training parameters, Xu et al. [64] proposed a DBN optimization method based on the Sparrow Search Algorithm (SSA), combined with Wavelet Transform (WT) and Ensemble Empirical Mode Decomposition (EEMD) to extract multidimensional features from vibration signals. This approach significantly enhanced fault diagnosis accuracy and effectiveness, achieving a remarkable 99.17% recognition rate. It outperformed traditional feature sets and mainstream diagnostic methods like PSO-DBN and SSA-SVM, demonstrating high generalization capability and stability.

To address the challenge of effectively utilizing spatial features in time-series signals for bearing fault classification under varying operating conditions, Lin et al. [65] proposed a novel model named SPRout-DBN. This model first encodes vibration signals into two-dimensional images using the Gramian Angular Difference Field (GADF). It then extracts fixed-size time-fused feature vectors through a residual network with spatial pyramid pooling. Finally, a Deep Binary Network (DBN) performs classification and cross-domain learning. The method achieved accuracies of 99.81% and 99.41% on two datasets, demonstrating its robustness and effectiveness across diverse operational environments.

To address the lack of interpretability in bearing fault diagnosis, poor generalization under varying operating conditions and noisy environments, and reliance on large amounts of labeled data, Zhong [66] proposed a multi-source physical information neural network, M-IPISincNet. This approach designs a physical information convolution layer based on an enhanced SincNet architecture. It integrates prior knowledge of fault frequency, employs multi-scale convolutions to extract high- and low-frequency features, and incorporates a Deep Binary Network (DBN) for feature fusion of vibration and current signals. The results demonstrate that the model maintains high accuracy even in zero-signal-to-noise-ratio (SNR) noise environments while featuring fewer parameters and low memory consumption.

To address the insufficient generalization capability of diagnostic models caused by sparse target domain labels, poor pseudo-label quality, and significant inter-domain distribution differences, Wang et al. [67] proposed a semi-supervised domain adaptation method, CSS-DADBN. This approach utilizes RNNs to generate pseudo labels, employs the Chaotic Sparrow Search Algorithm (CSSOA) to optimize confidence and entropy thresholds for selecting high-quality pseudo labels, and leverages a DBN for feature extraction and fusion. It also incorporates MMD loss to mitigate inter-domain distribution differences. The results demonstrate the model’s robust generalization capability and stability in cross-domain tasks.

Currently, most gear fault diagnosis methods cannot distinguish the severity of faults due to the high similarity among monitoring signals. This necessitates enhancing the sensitivity, stability, and accuracy of diagnostic methods, thereby increasing diagnostic complexity. To address this issue, Gai et al. [68] proposed a DBN model based on the Sparrow Search Algorithm and successfully applied it to gear fault severity diagnosis.

Addressing the challenge of diagnosing pipeline faults in hydraulic systems, Huang Xufang et al. [69] extracted time-domain and frequency-domain feature parameters from hydraulic pipeline vibration acceleration data collected over multiple time intervals. They employed a DBN model to identify hydraulic pipeline faults. The results demonstrated that the DBN model not only accurately identified the operational status of hydraulic pipelines but also distinguished between single faults and concurrent faults, achieving an overall accuracy exceeding 99%.

In summary, the general workflow for equipment fault diagnosis using the DBN model is as follows: (1) Collect real-time data from the equipment requiring diagnosis. (2) Screen the data, removing unreasonable entries, and divide it into training and test sets. (3) Establish the DBN diagnostic model, obtain preliminary results using the training set, and adjust the model based on actual data. (4) Validate the trained diagnostic model using the test set.

5.1.2. Diagnostic Potential of DBN in Port Equipment

Based on the above analysis, Deep Belief Networks demonstrate unique application value and development prospects in the field of port equipment fault diagnosis. The DBN’s powerful unsupervised feature learning capability makes it particularly well-suited to address the scarcity of fault samples encountered in port equipment. Large-scale port handling equipment such as gantry cranes and yard cranes exhibit high reliability and low failure rates during operation, resulting in extremely limited fault samples available for training. DBNs can autonomously learn deep feature representations from vast amounts of unlabeled normal operation data, establishing accurate health state baseline models. By monitoring shifts in feature distributions, they enable early fault warning, effectively mitigating the reliance of traditional methods on large fault sample sets.

In handling complex operating conditions, the DBN demonstrates exceptional adaptability through its deep nonlinear network architecture. Port equipment experiences drastic load and speed variations during operation, resulting in highly non-stationary signal characteristics. The DBN learns essential fault features that remain relatively stable despite operational changes. Specifically, an enhanced DBN model combined with intelligent optimization algorithms can adaptively adjust network parameters, maintaining stable diagnostic performance under variable conditions. Furthermore, the DBN’s feature-level fusion capability enables effective integration of multimodal monitoring data such as vibration and current signals, providing technical support for system-level health management of complex port equipment.

Notably, breakthroughs in DBN interpretability open possibilities for its application in safety-critical port environments. Knowledge-based reverse deep belief networks transform “black-box” decision processes into understandable confidence rules by constructing neural-symbolic systems, significantly enhancing the credibility of diagnostic outcomes. This feature is crucial for the safe operation of port equipment, enabling intelligent diagnostics to provide reliable decision support for field engineers. Furthermore, the DBN’s capabilities in processing time-series data lay the foundation for its application in predictive maintenance. By constructing enhanced network architectures, it effectively captures equipment performance degradation trends, supporting the transition from “preventive maintenance” to “predictive maintenance” operational models.

With ongoing advancements in model optimization techniques and the deepening of port intelligentization initiatives, the DBN will demonstrate broader application prospects in addressing critical challenges such as resolving the “high reliability paradox” and achieving precise predictive maintenance. This will provide robust technical support for establishing intelligent operation and maintenance systems for port equipment.

5.2. Diagnostic Methods and Application Potential of CNNs

5.2.1. Fault Diagnosis Method Based on CNN

The original CNN model required two-dimensional input data. Implementation approaches for CNNs in fault diagnosis can be broadly categorized into two types: starting from the input data, converting the data type into two-dimensional format; or starting from the model structure, transforming it into a form that accepts one-dimensional data.

To effectively diagnose rolling bearing faults, Xu et al. [70] proposed a diagnostic model based on the Online Transfer Convolutional Neural Network (OTCNN). The OTCNN first constructs an Offline Convolutional Neural Network (Off-CNN) and an Online Convolutional Neural Network (On-CNN) with identical structures, using multi-channel data fusion and grayscale image conversion as model inputs. Then, source domain features and model parameters in the fully connected layer are obtained from the pre-trained Off-CNN; finally, the parameters of On-CNN are initialized using Off-CNN parameters, achieving domain adaptation through pre-trained source domain features. The results demonstrate that the OTCNN model can reduce training time by half while maintaining accuracy.

For electric motor fault diagnosis, Junior et al. [71] designed a multi-head 1D CNN model based on vibration signals to distinguish six distinct motor faults. Vibration signals measured in two directions were simultaneously input to the multi-head 1D CNN model for training. The results demonstrated the model’s capability to successfully extract features and diagnose motor faults while enabling real-time monitoring of motor operational status.

In the field of hydraulic transmission systems, Tang et al. [72] applied Bayesian Optimization (BO) to adaptive deep learning and employed a CNN model for fault feature extraction and classification in hydraulic piston pumps. First, acoustic signals were converted into time-frequency distributions via continuous wavelet transform. Second, an initial CNN model was established by setting initial parameters to determine the range for each parameter to be optimized. Third, the optimal parameter combination was selected based on BO to construct the CNN-BO model. Finally, the diagnostic efficiency of the CNN-BO model was analyzed using confusion matrices and t-distributed stochastic neighborhood embedding (TSNE). The results demonstrated that the CNN-BO model exhibits higher accuracy and robustness for hydraulic piston pump fault diagnosis.

Regarding rotating machinery fault diagnosis, traditional methods may be constrained by fault features and diagnostic models. Consequently, Li et al. [73] combined Mel-frequency cepstral coefficients (MFCCs) with a Multi-Fusion Convolutional Neural Network (MFCNN) to propose a novel fault diagnosis method based on MFCC feature extraction. This approach not only enhances the quality of obtained fault features but also improves diagnostic performance under varying noise conditions.

To address issues such as the inability to simultaneously extract spatio-temporal features from fault signals, loss of critical feature information, and poor performance in noisy environments, Chen et al. [74] proposed an electric motor bearing fault diagnosis model (ECMCTP). This model utilizes continuous wavelet transform (CWT) to convert one-dimensional vibration signals into two-dimensional time-frequency images, then concurrently extracts spatial and temporal features through parallel CNN and Transformer branches. The results demonstrate that the ECMCTP model achieves 100% fault diagnosis accuracy under noise-free conditions and exhibits superior noise immunity even at low signal-to-noise ratios.

Addressing the challenge of distinguishing and isolating faults with similar frequency characteristics in the frequency domain during composite fault diagnosis of rotating machinery, Wang et al. [75] proposed a composite fault diagnosis method for motor drive systems. This method combines a physically parameterized polar diagram (PPD) enhanced by adaptive filtering with SSA-optimized rotationally invariant convolutional neural networks (SSA-RICNN). The results demonstrate higher diagnostic accuracy for composite faults.

Addressing the challenge of unsatisfactory fault identification results from traditional methods under limited sample sizes and complex environmental noise interference, Yang et al. [76] proposed a fault diagnosis model based on a hybrid framework combining Variational Modal Decomposition (VMD) optimized by an Improved Black Kite Algorithm (IBKA), CNN, and Twin Extreme Learning Machine (TELM). Research indicates that this model maintains robust fault diagnosis capabilities across varying degrees of noise interference.

Addressing challenges in rotary machinery fault diagnosis signals—including complex spectral components, high-energy noise, wide bandwidth, and intricate pattern recognition—Liu et al. [77] proposed a fault diagnosis method based on an improved minimum control recursive averaging-improved spectral subtraction (IMCRA-ISSA) and CNN-TCN model. First, IMCRA-ISSA is applied for signal denoising. Subsequently, the completely integrated empirical mode decomposition with adaptive noise (CEEMDAN) algorithm extracts multi-scale intrinsic mode functions. Finally, the CNN-TCN diagnostic model identifies mechanical fault signals under varying noise levels and operating conditions. This approach effectively reduces noise in mechanical fault signals, addressing the challenge of wideband noise interference in signal processing.

To address the challenges in fault diagnosis for rotating machinery under conditions of strong noise, significant time-varying characteristics, and multi-condition transfer learning scenarios, Pang et al. [78] proposed a WGS-CNN-based model. By integrating WT with a CNN, they improved the initialization strategy for convolutional layers and introduced adaptive Gaussian windows (GW) and quadratic functions to enhance feature extraction capabilities and noise resistance. The results demonstrate that this model consistently achieves over 90% noise resistance on public datasets, significantly outperforming other models.

Addressing fault diagnosis challenges in rotor motors during variable-speed operation—specifically in extracting spatial, temporal, and hierarchical features—Yang et al. [79] proposed a hybrid CNN-BiLSTM-MHSA model. This approach combines the CNN’s spatial pattern recognition capabilities, BiLSTM’s ability to capture long- and short-term temporal dependencies, and MHSA’s key feature enhancement capabilities. Research indicates that its fault diagnosis accuracy reaches 99.33%, outperforming CNN, LSTM, and CNN-LSTM.

To address the issues of extremely low signal-to-noise ratio in early-stage rolling bearing scenarios and the significant impact of input signal length and segmentation strategies on diagnostic accuracy, Zhong et al. [80] proposed an intelligent diagnostic method based on WI-CNN. This approach utilizes Gramian Angular Field theory to construct high-resolution fault features, employs an adaptive stochastic resonance (ASR) strategy driven by particle swarm optimization for denoising preprocessing, performs data segmentation and resampling via waveform cross-correlation coefficients, and finally feeds the data into a CNN for intelligent fault detection. This approach demonstrated high diagnostic accuracy, fast iteration speed, and strong algorithmic robustness in a mixed diagnostic strategy for 10 different fault types on a self-built test platform.

Addressing the issue of diminished feature extraction capability in high-noise environments, Yin et al. [81] proposed an attention-driven hybrid model based on IENEMD and parallel multi-scale CNN. This model utilizes IENEMD to decompose raw vibration signals for noise reduction, while an attention-driven parallel multi-scale CNN adaptively amplifies information-rich components to generate robust fault features. Three case studies and comparative experiments across nine different signal-to-noise ratio (SNR) levels validate the superior performance of this hybrid model.

Addressing the susceptibility of rolling bearings to noise interference under complex operating conditions and the low diagnostic accuracy of traditional methods, Shao et al. [82] proposed a hybrid framework for rolling bearing fault diagnosis based on Variational Modal Decomposition-Discrete Wavelet Transform (VMD-DWT) and a hybrid attention mechanism deep separable convolutional neural network-bidirectional long short-term memory network (HADS-CNN-BiLSTM). This approach achieved a 99.58% fault diagnosis accuracy on the CWRU dataset and 100% accuracy on the Xi’an Jiaotong University (XJTU-SY) dataset.

To address overfitting and poor generalization in rolling bearing fault diagnosis due to sparse fault samples, Bian et al. [83] proposed a Siamese Neural Network (SNN) model based on a wide first-layer kernel deep convolutional neural network (WDCNN) and a bidirectional long short-term memory network (BiLSTM). This model maintains robust diagnostic performance under strong noise interference, effectively resolving overfitting issues in deep learning models under small-sample conditions while enhancing the model’s generalization capability and robustness.

To address challenges such as complex data types and insufficient training samples in mechanical fault diagnosis, Longdengren [84] proposed a fault diagnosis method based on one-dimensional data augmentation and a CNN model. First, a stacked auto-encoder was enhanced using a backpropagation neural network (BPNN) with a softmax classifier to augment one-dimensional vibration signals. Then, the augmented dataset is directly converted into two-dimensional images to train the CNN. This model not only ensures diagnostic efficiency under conditions of numerous fault types and limited training data but also achieves a training accuracy exceeding 98%.

In the field of track monitoring, CNN models can also meet practical application requirements. High false negative rates, high false positive rates, and poor robustness are the primary issues with existing track damage monitoring methods. Han Qiang et al. [85] proposed a multi-level feature fusion-based rail surface damage monitoring method. First, rail images are captured, and damaged areas are annotated. Second, a training strategy is established to increase the quantity and diversity of the training set. Finally, a multi-level feature fusion-based object detection network is trained to automatically detect damaged rail sections. The experimental results demonstrate optimal performance when constructing the damage dataset, meeting practical rail damage detection requirements.

Due to the poor stationarity of planetary gearbox vibration signals, substantial prior knowledge and diagnostic expertise are required to identify and interpret fault characteristics. Hu et al. [86] proposed an intelligent fault diagnosis method based on Empirical Mode Decomposition (EMD) and Deep Convolutional Neural Networks (DCNNs), which accurately and effectively classifies the operating status and fault types of planetary gearboxes. The general procedure involves first performing EMD on the vibration signal to obtain Intrinsic Mode Functions (IMFs). The DCNN then fuses IMF components to extract features, which are finally recognized by a classifier to achieve automatic fault diagnosis. Additionally, Yao Mingjing et al. [87] proposed a gearbox fault diagnosis model based on an improved CNN model and validated it using a gearbox experimental platform. The test results demonstrated that this model can effectively extract gearbox fault vibration signals, distinguish different fault types, and classify them with high accuracy (up to 99.2%).

Of course, the application of the CNN extends beyond the aforementioned domains. For instance, in hydraulic pump fault diagnosis, Du Mingzhe et al. [88] proposed an intelligent fault diagnosis method based on empirical wavelet transform (EWT) and CNN. This approach enables accurate and efficient classification of hydraulic pump operating states and fault types.

5.2.2. Diagnostic Potential of CNN in Port Equipment

Based on a systematic analysis of literature on the application of convolutional neural networks in fault diagnosis, CNN models demonstrate unique and broad application prospects in the field of intelligent operation and maintenance for port equipment. The exceptional spatial feature extraction capability of CNNs provides significant advantages when processing complex monitoring data from port equipment. By converting vibration and acoustic signals into two-dimensional time-frequency images through time-frequency analysis techniques, followed by deep feature learning using CNNs, this “signal → image → diagnosis” technical pathway effectively captures transient impact fault characteristics unique to port equipment. This approach provides a powerful technical means for condition monitoring of critical rotating components such as bearings and gearboxes.

In addressing the challenges of complex port environments, CNNs demonstrate exceptional adaptability. To tackle the harsh conditions of high noise and strong interference at port sites, researchers have developed various enhanced CNN architectures. These include parallel multi-scale CNNs incorporating attention mechanisms and improved models integrating physical prior knowledge. Such innovative structures significantly enhance diagnostic performance under low-signal-to-noise-ratio conditions. Notably, transfer learning-based online transfer CNN models rapidly adapt to the dynamic operating conditions of port equipment through domain adaptation techniques. This approach substantially reduces model training time while maintaining diagnostic accuracy, offering a viable solution for real-time intelligent monitoring of port machinery.

CNNs also excel in multi-source information fusion and specialized component diagnostics. By constructing multi-branch network architectures, CNNs effectively integrate multi-modal monitoring data—including vibration, current, and acoustic signals—enabling more comprehensive equipment condition assessments. In specialized port equipment inspection, CNN-based visual detection technology can be directly applied to intelligent recognition in specific scenarios such as rail surface damage, container lock button status, and wire rope defects, effectively complementing traditional vibration diagnostics. This multi-path fusion application enables CNNs to meet the diverse diagnostic demands of port equipment, ranging from general components to specialized facilities.

With the continuous advancement of deep learning technology, CNNs will see deeper integration into port equipment fault diagnosis. Their unique advantages in interference resistance, cross-operating-condition adaptability, and multi-source data fusion provide robust technical support for resolving diagnostic challenges in port’s unique environments. By integrating with emerging technologies like edge computing and digital twins, CNNs are poised to play a more pivotal role in port equipment predictive maintenance systems, laying a solid technical foundation for building intelligent, precision-driven port equipment operation and maintenance management systems.

5.3. Diagnostic Methods and Application Potential of Auto-Encoders

5.3.1. Fault Diagnosis Method Based on Auto-Encoder

Currently, addressing the data distribution imbalance issue in mechanical system monitoring and diagnostic methods, Zhao et al. [89] designed a bearing-rotor system imbalance fault diagnosis model based on the Normalized Conditional Variational Auto-Encoder with Adaptive Focal Loss (NCVAE-AFL). The NCVAE-AFL model enhances feature learning capabilities and improves the generalization performance of the diagnostic framework.

Intelligent gearbox fault diagnosis often faces the challenge of insufficient typical fault samples. In response, He et al. [90] proposed a novel diagnostic model: the Deep Transfer Multi-Wavelet Auto-Encoder (BTMWAE). First, key features from gearbox vibration signals are extracted and learned using the BTMWAE model. Next, high-quality samples are selected for pre-training. Finally, the obtained parameters are transferred to the target model to perform fault diagnosis. Experiments demonstrate that this method can not only assess the severity of single faults in gearboxes but also identify compound faults.

With the growing demand for intelligent mechanical fault diagnosis, transfer learning techniques have been widely applied in data-driven enhancement. However, the scarcity of labeled data samples remains a challenge. Therefore, Li et al. [91] proposed a deep learning-based method to transfer fault diagnosis information collected from one machine to others. First, an AE model is employed to project feature data from different machines into a common subspace. Second, a cross-machine adaptive algorithm is used for knowledge generalization, mitigating data distribution discrepancies caused by machine variations. Applied to diverse rolling bearing datasets, this approach validates the feasibility of transferring fault diagnosis information across machines, offering a novel and promising method for mechanical equipment fault diagnosis.

In noisy environments, AE-based intelligent fault diagnosis struggles to leverage data collection effectively. To address this, Zhang et al. [92] proposed a novel Ensemble Deep Contractive Auto-Encoder (EDCAE). First, multiple Deep Contractive Auto-encoders (DCAEs) are designed to automatically learn invariant feature representations, effectively handling diverse noisy data. Second, Fisher discriminant analysis is applied to select low-dimensional features, which are then identified and classified using a Softmax classifier. Finally, accurate diagnostic conclusions are obtained by combining the results. The application results of the EDCAE in gearboxes, rolling bearings, and other fields demonstrate the method’s significant advantages.

Bearing condition monitoring and fault diagnosis are crucial for enhancing the safety and reliability of wheels and tracks. Shao et al. [93] proposed a novel Tracking Deep Wavelet Auto-Encoder (TDWAE) method. First, an activation function is employed to design the wavelet auto-encoder (WAE) for enhanced feature quality. Second, a deep wavelet auto-encoder (DWAE) is constructed for advanced feature learning and fault diagnosis. Finally, an adaptive tracking learning algorithm is developed to further improve diagnostic efficiency and performance. When applied to the vibration acceleration signal analysis of locomotive bearings, this method demonstrates superior diagnostic effectiveness compared to traditional diagnostic approaches and standard deep auto-encoders.

In the diagnosis of failures in various rotating machinery, the classification, direction, and severity of rolling bearing failures remain one of the most significant challenges in this field. To address this issue, Shao et al. [94] proposed an Ensemble Deep Auto-encoder (EDAE) method. First, an auto-encoder (AE) is generated using activation functions. Second, the EDAE is constructed for unsupervised feature learning from vibration signals. Finally, a combination strategy is employed to integrate diagnostic data, ensuring both accuracy and stability. Diagnostic analysis of bearing vibration signals validated that this method not only eliminates reliance on manual feature extraction for rolling bearing fault diagnosis but also overcomes limitations inherent in deep learning models.

To address the challenge of abundant non-fault state monitoring data versus scarce fault state data and the difficulty of diagnosing multiple mixed faults, Yang et al. [95] proposed a diagnostic method based on feature reconstruction and sparse auto-encoder (SAE) models. They designed a feature reconstruction algorithm to solve long-sequence feature and weak data feature extraction problems and introduced an improved SAE model to adapt to small-sample data training. Experiments demonstrate that this method achieves high diagnostic accuracies of ≥99.4% and ≥99.7% for multiple mixed faults under data imbalance conditions, applicable to gearboxes and rolling bearings, respectively, showcasing its efficient diagnostic capability and superiority with small training samples.

Addressing the challenges of feature extraction and low diagnostic accuracy in rolling bearing vibration signals under strong noise interference, Ji et al. [96] proposed a joint deep learning model (MDCAE-CACNN) integrating a multi-scale dilated convolutional auto-encoder (MDCAE) and a convolutional neural network with channel attention (CACNN). The MDCAE utilizes convolutional kernels with varying receptive field sizes to capture multi-timescale features and denoise bearing vibration signals, while the CACNN effectively extracts fault features and accurately diagnoses fault types through its channel attention mechanism. The results demonstrate that this model achieves significant improvements in diagnostic accuracy under various noise conditions, exhibiting high precision, strong robustness, and generalization capabilities.

To address the challenge of extracting useful features from bearing signals for fault classification, Li et al. [97] proposed an intelligent fault diagnosis method based on stacked denoising auto-encoders (SDAEs) and adaptive deep hybrid kernel extreme learning machines (ADHKELMs). The SDAE is employed for deep feature extraction, while a novel ADHKELM model is constructed by integrating hybrid kernel extreme learning machines combining polynomial and wavelet kernel functions. Experiments validated that this method outperforms other related approaches in fault classification accuracy, robustness, and generalization capability, with its superiority demonstrated through two sets of experimental data.